Page 1

g

GE Consumer Home Services Training

TECHNICAL SERVICE GUIDE

Wizard

Super Capacity Dryer

TM

7.0 Cubic Foot

MODEL SERIES:

DPSE592EA0

DPSE592GA0

DNCD450EA0

DNCD450GA0

PUB # 31-9059 08/00

Page 2

!

IMPORTANT SAFETY NOTICE

The information in this service guide is intended for use by

individuals possessing adequate backgrounds of electrical,

electronic, and mechanical experience. Any attempt to repair a

major appliance may result in personal injury and property

damage. The manufacturer or seller cannot be responsible for the

interpretation of this information, nor can it assume any liability in

connection with its use.

WARNING

If the information in this manual is not followed exactly, a fire or

explosion may result causing proper ty damage, personal injury or

death. If you smell gas:

- Do not try to light any appliance.

- Do not touch any electrical switch; do not use any phone in

the building.

- Immediately call the gas supplier from a neighbor’s phone.

Follow the gas supplier’s instructions.

- If you cannot reach the gas supplier , call the fire department.

WARNING

To avoid personal injury, disconnect power before servicing this

product. If electrical power is required for diagnosis or test

purposes, disconnect the power immediately after performing the

necessary checks.

RECONNECT ALL GROUNDING DEVICES

If grounding wires, screws, straps, clips, nuts, or washers used

to complete a path to ground are removed for service, they must

be returned to their original position and properly fastened.

GE Consumer Home Services Training

Technical Service Guide

Copyright © 2000

All rights reserved. This ser vice guide may not be reproduced in whole or in part

in any form without written permission from the General Electric Company.

Page 3

Table of Contents

Dryer Nomenclature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Warranty Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Installation Highlights. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Operating Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Electronic Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Control Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Removal and Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Schematics and Strip Circuits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Troubleshooting Flowcharts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Illustrated Parts Breakdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

- 1 -

Page 4

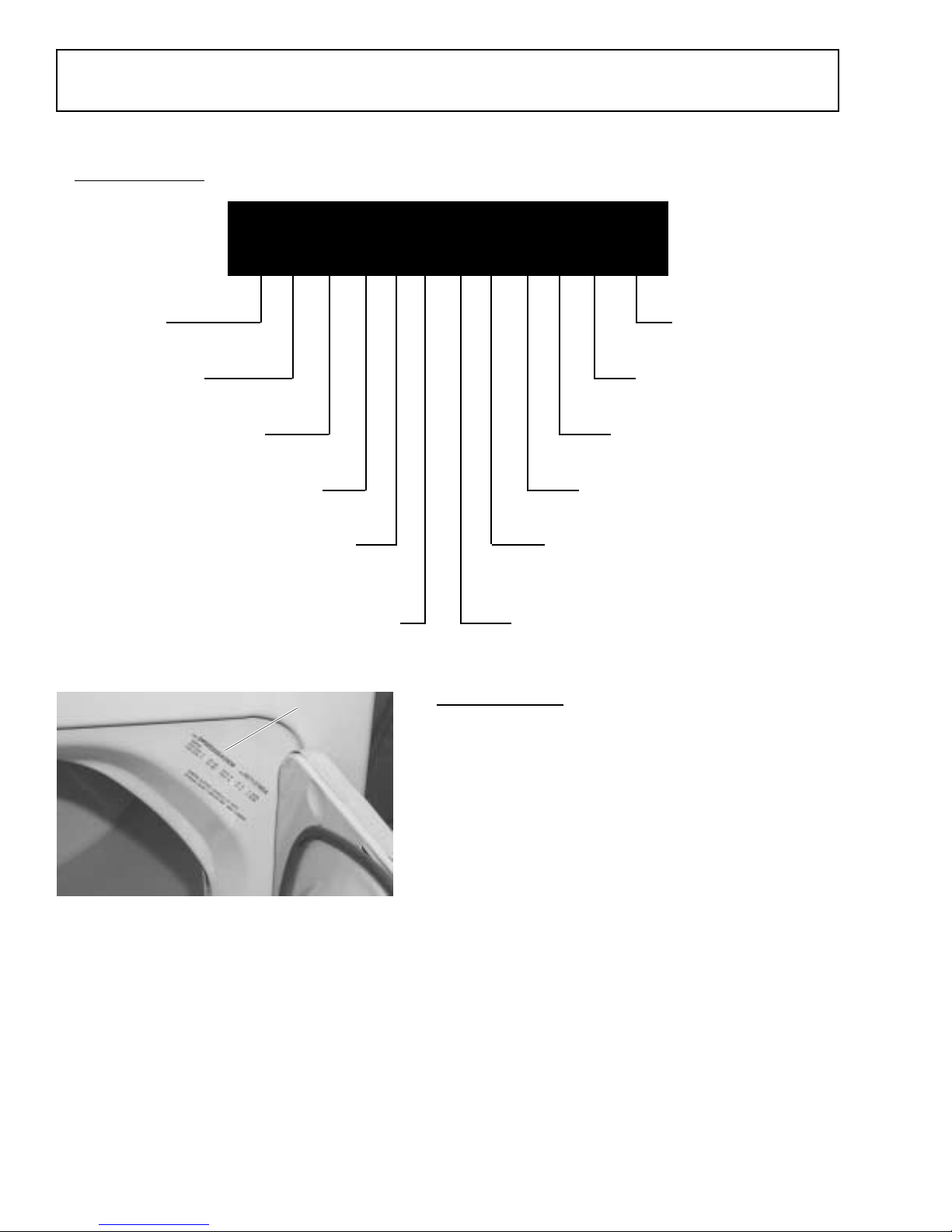

Model Number

Nomenclature

Dryer Nomenclature

D P S E 5 9 2 E A 0 W W

Product

D = Dryer

Features

P = Profile

Capacity

S = Super

Product T ype

E = Electronic

Number of Heat Select

5 = 5 Settings

Number of Cycles

9 = 9 Cycles

Nomenclature

Nomenclature

Key Attribute Color

W = White

Body Color

W = White

Engineering Revision

0 = None

Model Y ear

A = 2000

Fuel/Voltage

E = Electric

G = Gas

Dryer Control

2 = Electronic

Serial Number

The first two numbers of the serial number

identify the month and year of manufacture.

Example: AZ123456S = January, 2000

GEA00519

A - JAN 2005 - H

D - FEB 2004 - G

F - MAR 2003 - F

G - APR 2002 - D

H - MAY 2001 - A

L - JUN 2000 - Z

M - JUL 1999 - V

R - AUG 1998 - T

S - SEP 1997 - S

T - OCT 1996 - R

V - NOV 1995 - M

Z - DEC 1994 - L

Note: The technical sheet is located under the

control panel.

– 2 –

The letter designating the

year repeats every 12

years.

Example:

T - 1974

T - 1986

T - 1998

Page 5

Warranty Information

(For customers in the United States)

All warranty service is provided by our Factory

Service Centers or an authorized Customer Care

technician. For service, call 800-GE-CARES.

:fOdoirePehTroF :ecalpeRlliWEG

raeYenO

trapynA

ehtfoetadehtmorF

esahcruplanigiro

,egrahcfoeerf

.trap

sraeYeviF

ehtfoetadehtmorF

esahcruplanigiro

,ytnarrawdetimil

.stsocecivres

:revoCtoNlliWEGtahW

This warranty is valid only in the United States .

®

Warranty may vary in Canada. See your

approved Profile dealer for details.

sihtgniruD.pihsnamkrow

,ytnarrawraey-enolluf

murdreyrdyticapacrepusroegralartxeynA

sihtgniruD.pihsnamkrowroslairetamnitcefed

roslairetamnitcefedaoteudsliafhcihwreyrdehtfo

,edivorposlalliwEG

evitcefedehtecalperotecivresemoh-nidnaroballla

aoteudsliafhcihw

raey-ruoflanoitidda

emoh-nirorobalynarofelbisnopsereblliwuoy

• Service trips to your home to teach you

how to use the product.

• Improper installation.

• Failure of the product if it is abused, misused, or used for other than the intended

purpose or used commercially.

• Replacement of house fuses or resetting of

circuit breakers.

• Damage to the product caused by accident,

fire, floods or acts of God.

• Incidental or consequential damage to

personal property caused by possible

defects with this appliance.

Note: Some models may hav e an e xtended w arranty be y ond 5 y ears . Those models ha ve a special warranty sheet

enclosed when delivered to the customer . Unless that additional warranty sheet is attached, all other warranty

conditions shown abov e apply.

This warranty is extended to the original purchaser and any succeeding o wner for products purchased for home

use within the USA. In Alaska, the w arranty excludes the cost of shipping or service calls to your home.

Some states do not allow the exclusion or limitation of incidental or consequential damages. This w arranty giv es

you specific legal rights, and you ma y also ha v e other rights which vary from state to state. To kno w what y our legal

rights are, consult your local or state consumer affairs office or your state’s Attorney General.

Warrantor: General Electric Company, Louisville, KY 40225

– 3 –

Page 6

Installation Highlights

Exhaust Information

WARNING: Use only metal 4-in. duct. Do not use

duct longer than specified in the Exhaust Length

table.

Exhaust longer than specified will:

• Increase the drying times and the energy cost.

• Reduce the dryer’s life.

• Accumulate lint, creating a potential fire hazard.

The correct exhaust installation is your responsibility. Problems due to incorrect installation are not covered by the warranty.

The maximum allowable length of the exhaust

system depends upon the type of duct, the number of

turns, the type of exhaust hood (wall cap), and all

conditions noted in this section. Both, rigid and

flexible metal ducts are shown in the following table.

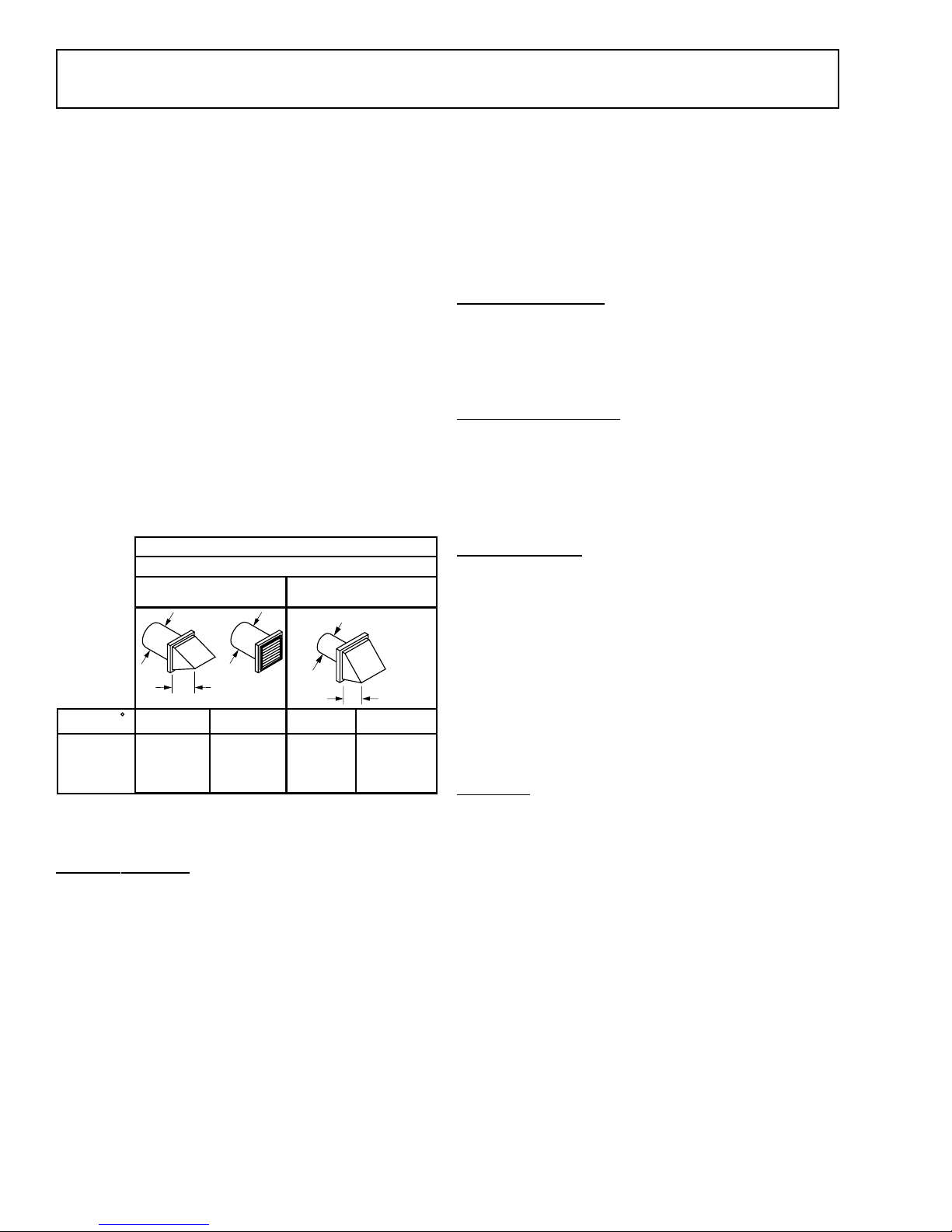

EXHAUST LENGTH

RECOMMENDED MAXIMUM LENGTH

Exhaust Hood Types

Use only for short

run installations

4" DIA.

2-1/2"

Rigid

Metal

30 Feet

20 Feet

10 Feet

Flexible

Metal

15 Feet

10 Feet

GEA00565

No. of 90

Elbows

0

1

2

3

Recommended

4" DIA.

4"

Rigid

Metal

45 Feet

35 Feet

25 Feet

15 Feet

4" DIA.

Flexible

Metal

30 Feet

20 Feet

10 Feet

Exhaust System Checklist

Hood or Wall Cap

Note: To check airflow restrictions on the electric

dryer model, check amperage from the black wire

to pin #8. If 22.2 amps are shown and the relay

does not trip within 10 minutes, the airflow is OK.

If the relay trips the inlet thermostat withinin the

first 5 minutes and reads 11.1 amps, then airflow

is restricted.

Separation of Turns

For best perfor mance, separate all tur ns by at

least 4 ft of straight duct, including the distance

between the last turn and the dampened wall cap.

Turns Other Than 90°

• One turn of 45° or less may be ignored.

• Two 45° tur ns should be treated as one 90° turn.

• Each turn over 45° should be treated as one 90°

turn.

Sealing of Joints

• All joints should be tight to avoid leaks. The male

end of each section of duct must point away

from the dryer.

• Do not assemble the ductwork with fasteners

that extend into the duct: they will serve as a

collection point for lint.

• Duct joints can be made airtight and moisturetight by wrapping the overlapped joints with duct

tape.

Insulation

Duct work that runs through an unheated area or

is near air conditioning should be insulated to

reduce condensation and lint buildup.

• Terminate in a manner to prevent back drafts or

entry of birds or other wildlife.

• Termination should present minimal resistance

to the exhaust airflow and should require little or

no maintenance to prevent clogging.

• Never install a screen over the exhaust duct.

• Wall caps must be installed with opening

pointed down at least 12 in. above ground level

or any other obstruction.

• If roof vents or louvered plenums are used, they

must be equivalent to a 4-in. dampened wall

cap in regard to resistance to airflow, prevention

of back drafts, and maintenance required to

prevent clogging.

Exhaust Connection

WARNING: To reduce the risk of fire or personal

injury:

• This dryer must be exhausted to the outdoors.

• Use only metal duct.

• Do not terminate exhaust in a chimney, any gas

vent, under an enclosed floor (crawl space), or

into an attic: the accumulated lint could create a

fire hazard.

• Provide access for inspection and cleaning of

the exhaust system, especially at turns. Inspect

and clean at least once a year.

– 4 –

Page 7

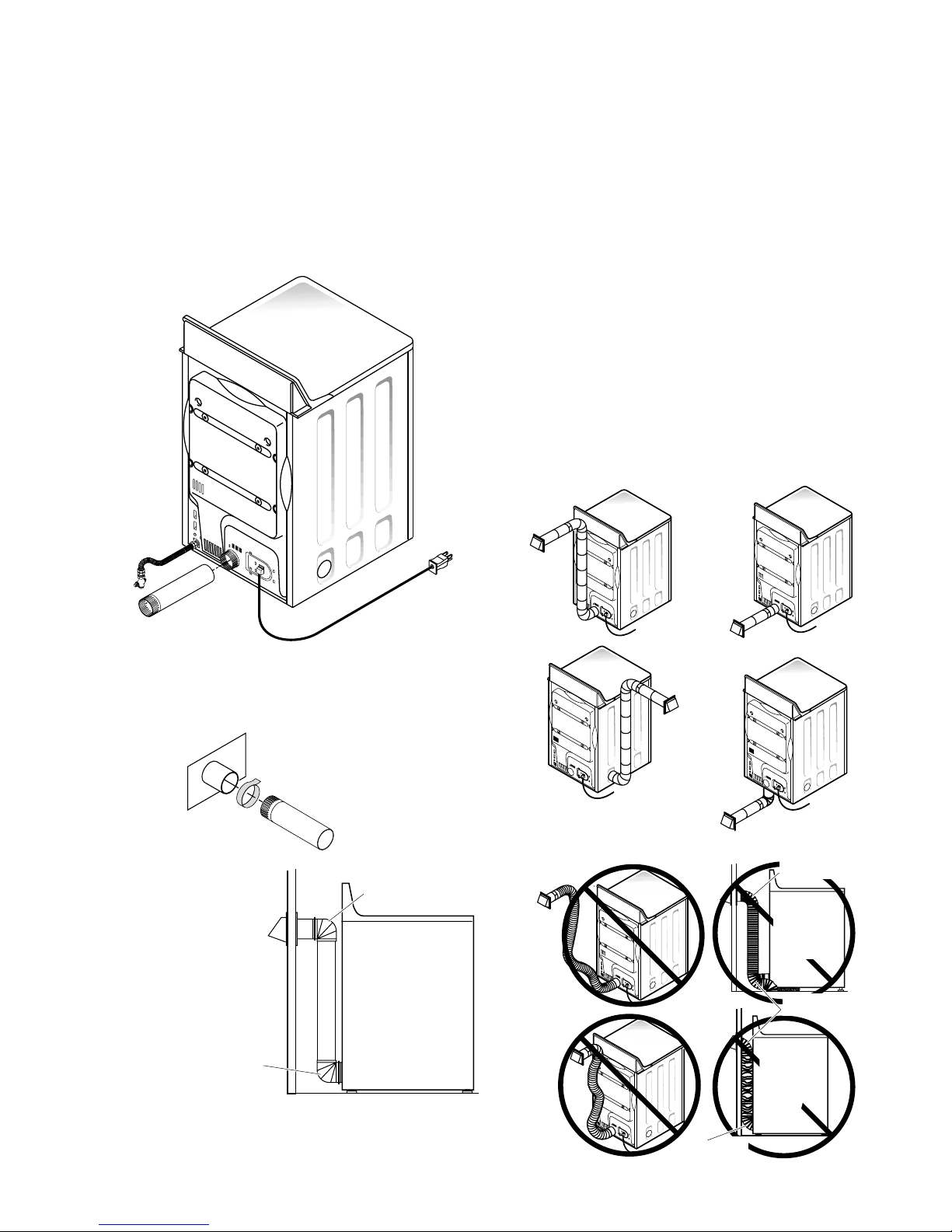

• Never terminate the exhaust into a common duct

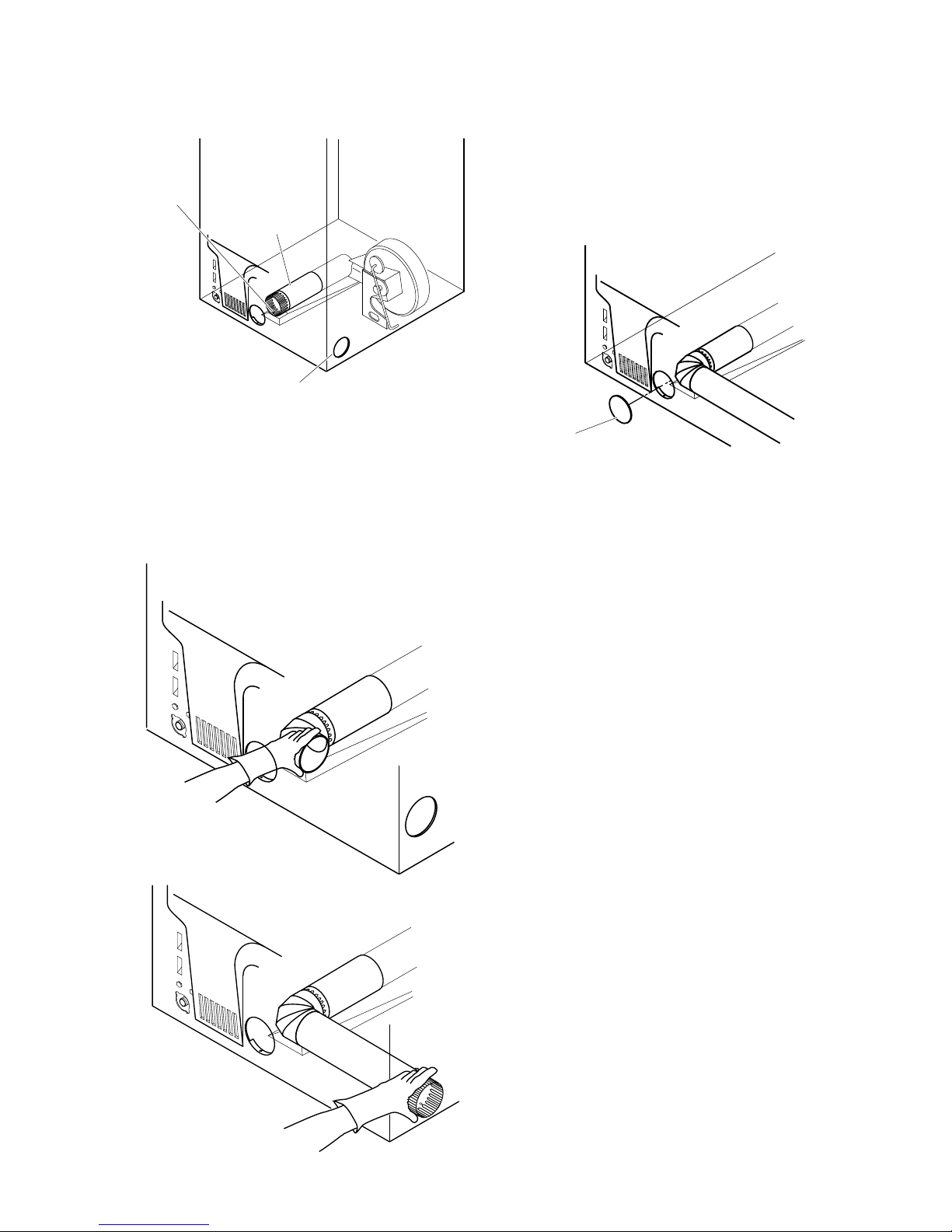

GEA00556

Elbow Highly

Recommended

Do Not

Sit Dryer

On Flexible

Exhaust

Elbows Highly

Recommended

Do Not

Crush

Flexible

Exhaust

Against

Wall.

Elbow Highly

Recommended

GEA00557

with a kitchen exhaust: a combination of lint and

grease could create a fire hazard.

• Do not obstruct incoming or exhausted air.

This dryer comes ready for rear exhausting. If

space is limited, use the “Dryer Exhaust to Left or

Bottom of Cabinet” instructions to exhaust directly

from the left side or bottom of the cabinet.

STANDARD REAR EXHAUST

Using Flexible Metal Ducts

If rigid all-metal duct cannot be used, then flexible

all-metal venting can be used, but it will reduce the

maximum recommended duct length. In special

installations when it is impossible to make connection with the above recommendations, UL-listed

clothes dryer transition duct may be used as

transition venting between the dryer and wall

connection only. The use of this ducting will affect

dry time.

If flexible transition duct is necessary, you must

adhere to the following directions:

• Use the shortest duct length possible.

• Stretch the duct to its maximum length.

• Do not crush or collapse the duct.

• Never use transition duct inside the wall or

inside the dryer.

• Avoid resting the duct on sharp objects.

• Venting must conform to local building codes.

Cut The Standard Exhaust

Duct To Proper Length.

Avoid Bunching Of The Duct

Behind The Dryer.

For Straight

Line Installation,

Connect The

Dryer Exhaust

To The Wall Using

Duct Tape

Elbow Highly

Recommended

Note: Elbows will prev ent duct kinking and col-

lapsing.

GEA00554

Elbow Highly

Recommended

Recommended

Configuration

To Minimize

Exhaust

Blockage

GEA00555

– 5 –

Page 8

Alcove or Closet Installation

• If your dryer is approved for installation in an

alcove or closet, it will be stated on a label on

the dryer back.

• The dryer must be vented to the outdoors. See

the “Exhaust Information” section.

• Minimum clearance between the dryer cabinet

and adjacent walls or other surfaces is:

0 in. either side

3 in. front and rear

• Minimum vertical space from the floor to the

overhead cabinets, ceiling, etc. is 52 in.

• Closet doors must be louvered or otherwise

ventilated and must contain a minimum of

60 sq. in. of equally distributed open area. If the

closet contains both a washer and a dryer, the

doors must contain a minimum of 120 sq. in. of

equally distributed open area.

For Gas Dryers:

• The closet should be vented to the outdoors to

prevent gas pocketing in case of a gas leak in

the supply line.

• No other fuel-burning appliance shall be installed in the closet with the dryer.

tening devices which extend into the inter ior of

the exhaust vent.

• Provide an opening with a free area of at least

25 sq. in. to introduce outside air into the dryer

room.

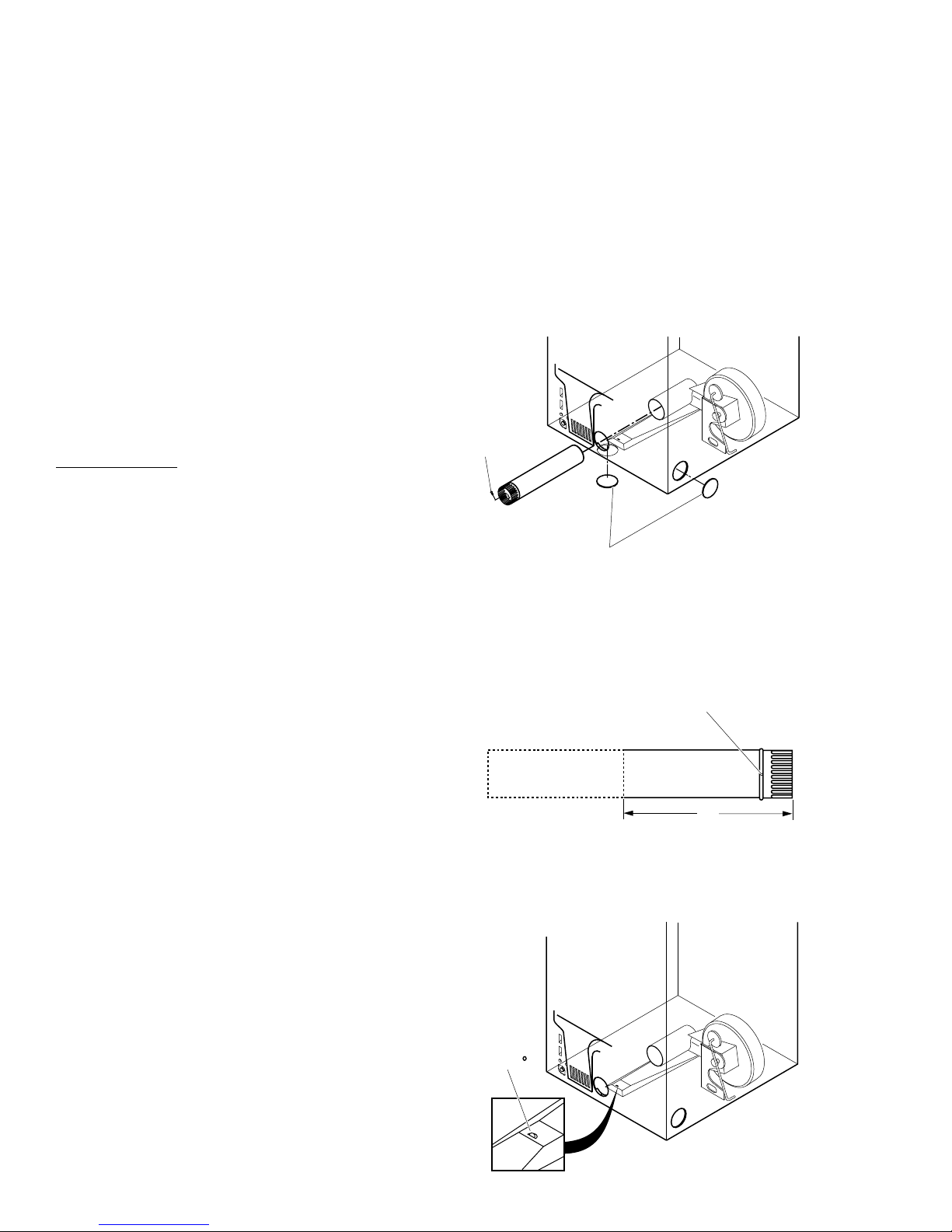

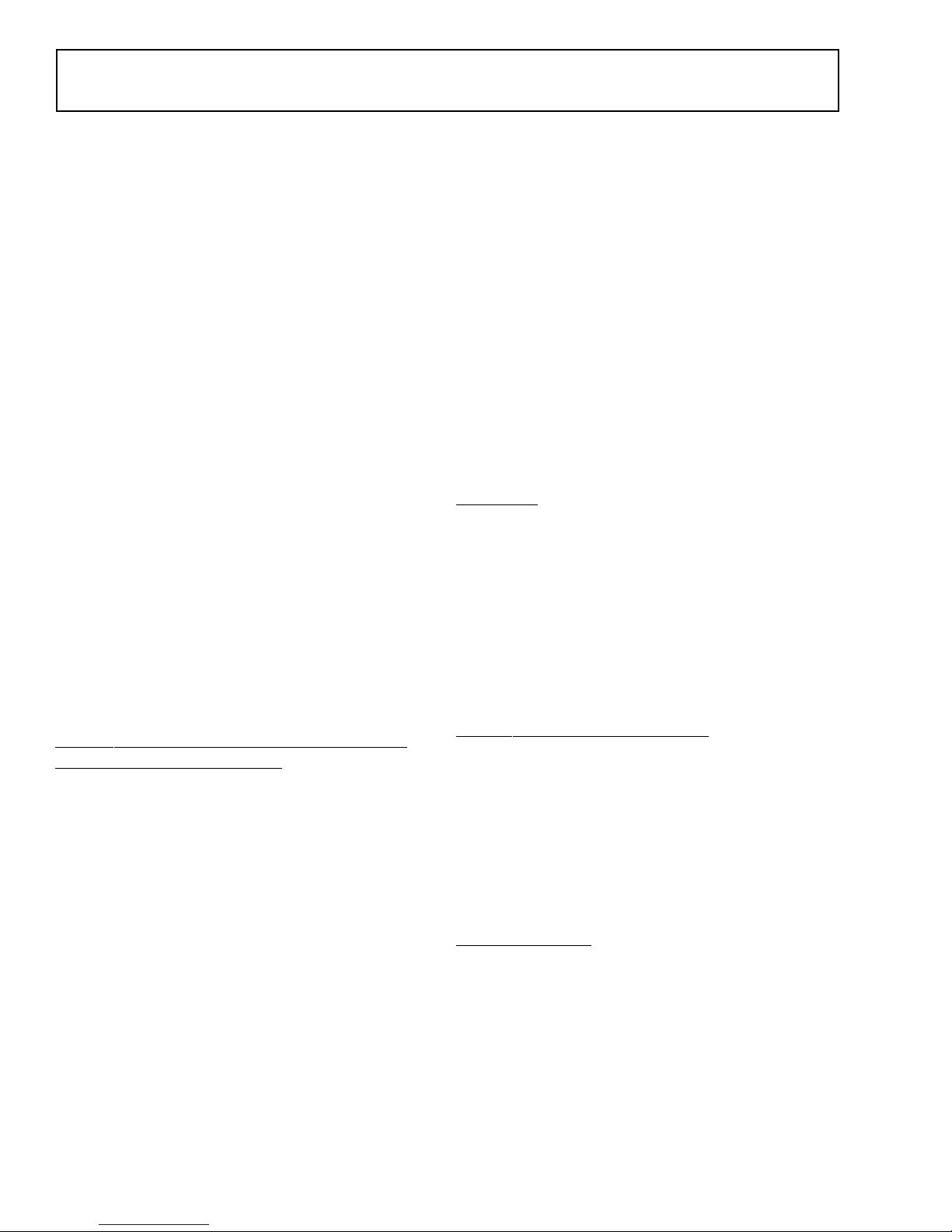

Dryer Exhaust to Left or Bottom of Cabinet

WARNING: Protect your hands and arms from

sharp edges when working inside the cabinet.

1. Detach and remove the bottom or left-side

knockout as desired.

Remove

Screw

And Save

Remove Desired

Knockout (One Only)

GEA00558

Bathroom or Bedroom Installation

• The dryer must be vented to the outdoors. See

the “Exhaust Information” section.

• The installation must conform with local codes

or, in the absence of local codes, with the

National Fuel Gas Code, ANSI Z223.

Mobile or Manufactured Home Installation

• Installation must conform to the Manufactured

Home Construction & Safety Standard, Title 24,

Part 32-80 or, when such standard is not applicable, with the American National Standard for

Mobile Home, ANSI/NFPA No. 501B.

• The dryer must be vented to the outdoors with

the termination securely fastened to the mobile

home’s structure. See the “Exhaust Information”

section.

• The vent must not be terminated beneath a

mobile or manufactured home.

• The vent duct material must be metal.

• Kit 14-D3A6-33 must be used to attach the

dryer securely to the structure.

• The vent must not be connected to any other

duct, vent, or chimney.

• Do not use sheet metal screws or other refas-

2. Remove and save the screw inside the dryer

exhaust duct. Pull the duct out of the dryer.

3. Cut the duct as shown and keep portion A.

Fixing Hole

AB

9"

GEA00559

4. Through the rear opening, locate the tab in the

middle of the appliance base. Lift the tab to

approximately 45° using a flat-blade screwdriver.

Bend

Tab 45

GEA00560

– 6 –

Page 9

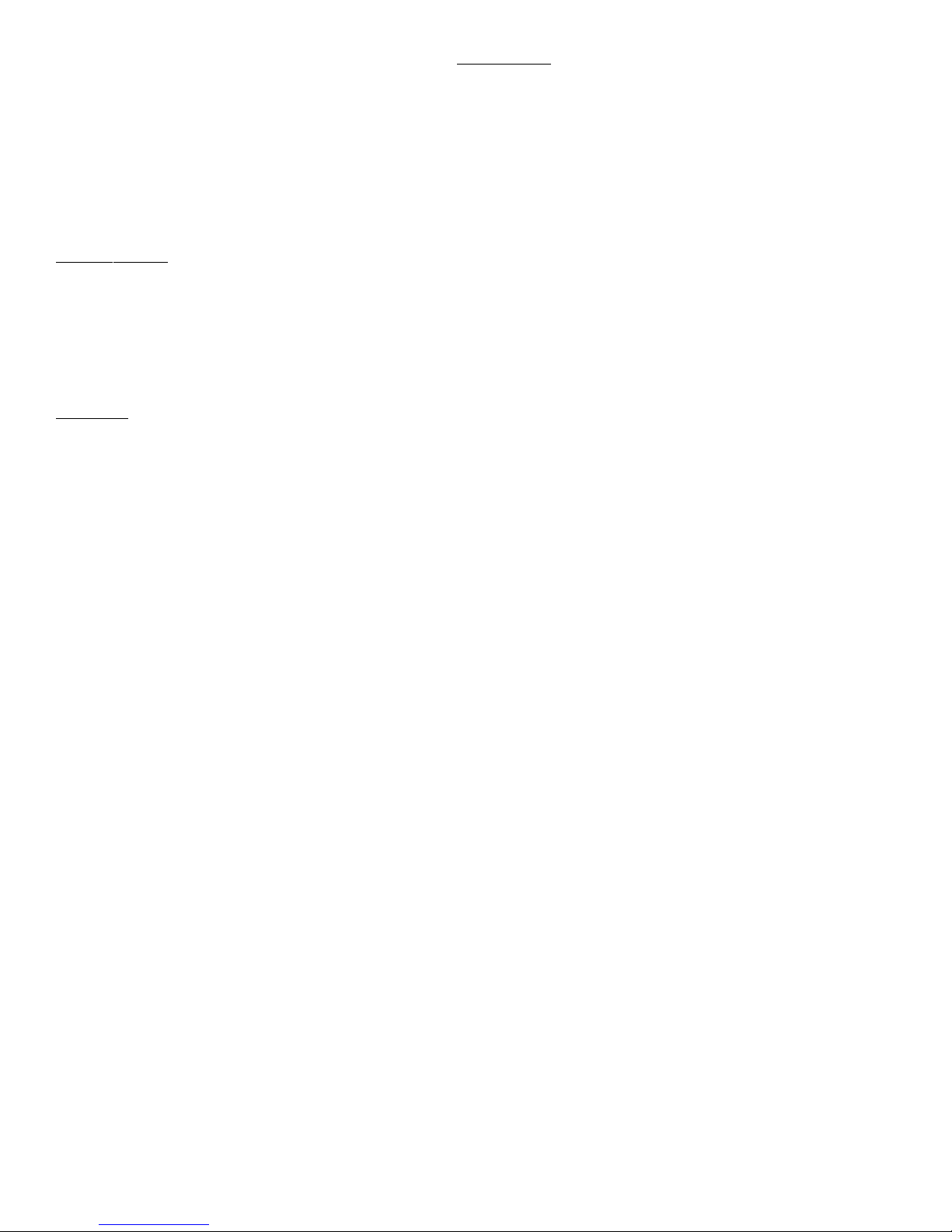

5. Reconnect the cut portion (A) of the duct to

the blower housing. Ensure the fixing hole is

aligned with the tab in the base.

Fixing

Hole

Portion "A"

8. Connect standard metal elbows and ducts to

complete the exhaust system.

Caution: Never leave the rear opening uncovered.

Install a cover plate.

9. Cover back opening with a plate (Kit

WE1M454) that is available from your local

service provider.

Left Side

Exhaust

GEA00561

6. Use the previously saved screw to secure the

duct in place through the tab on the the appliance base.

7. For exhaust to the side of the cabinet, insert

the elbow and the duct.

Insert 4" Elbow

Through Rear Opening

Plate

(Kit WE1M454)

10. Place the dryer in its final location.

GEA00564

Insert 4" Exhaust

Through Side Opening

GEA00562

GEA00563

– 7 –

Page 10

Operating Characteristics

Note: Not all models have the same features. Your

model may vary from those discussed in this

manual.

Basic Dryer Operation

The L3 Dryer contains both sensor dry and timed

dry options.

• The six

desired dryness level as measured by the rod

voltage signal. Each cycle’s settings control the

heated dry time and specific cooldown time. At

the end of cooldown, the machine stops the

drying operation and signals the end of the

cycle.

• During

dries the load for the specified time, including

extended tumble time (if selected). At the end of

the selected time, the dryer ceases to tumble

and heat the clothes, and signals the end of the

cycle.

Note: Only one sensor or timed dry cycle can be

selected at any time. A new cycle selection will

override the previous one.

SENSOR DRY cycles

TIMED DRY cycles

, the dryer tumble-

dry clothes to a

voltage signal.

• When the load reaches the Damp threshhold,

the dryer calculates the required remaining time

to dry the load to the specified dryness level.

The estimated remaining time appears in the

display, the countdown resumes, and the Sens-

ing LED turns OFF. The countdown continues until

the end of the cycle, including cooldown time.

• At the end of the cycle, the unit stops drying, the

Sensor Dry LED turns OFF, the display reads

“00,” and the Clean Lint Filter LED turns ON.

• The display and Clean Lint Filter LED turn OFF

when the user 1) opens the door, 2) presses

Stop/Cancel, or 3) starts another cycle selection.

Speed Dry

When the Speed Dry button is pushed, the letters

“SP” appear in the digital display. When the user

presses Start/Pause, the display enters Variable

Speed Racetrack mode until the Damp threshhold

is calculated, then it shows “SP” for the entire

cycle.

One Touch Sensor Dry Cycles

Cottons, Mixed Loads, Easy Care/Perm Press,

Knits/Sweaters, and Delicates

These buttons use predetermined dryness levels

(either Dry or Less Dr y) and temperatures (Extra

Low to High/[Regular]) to dry clothes. The Sensor

Dry LED is ON until the end of the cooldown

period.

The cycles proceed as follows:

• Pressing a cycle button will cause the display to

show the default numbers for that cycle.

• Once the user presses the Start/Pause button,

the display begins the normal countdown, and

the Sensor Dry LED turns ON.

• When the default minimum time for the selected

cycle is reached, the display enters Variable

Speed Racetrack mode and the Sensing LED

begins to flash. Four speed levels are available;

the speed will be determined by the sensor rod

One T ouch Timed Dry Cycles

DRYEL™, De wrinkle, and Air Dry

These buttons use Medium or (for Air Dry) no heat

and a specified time period to tumble and dry loads.

The

DRYEL™

runs for 20 minutes, and Air Dry runs for 10 minutes.

The Timed Dry LED turns ON until the end of the

cycle (including cooldown), then the Clean Lint

Filter LED turns ON as described earlier.

DRYEL™ System

DRYEL™ helps “dry clean only” clothes look and

smell clean and fresh. While not a complete dry

cleaning system, DRYEL™ uses a perfumed pad

and nylon bag to eliminate odors (such as smoke

and perspiration) and wrinkles from clothes. The

DRYEL™ kit, available in retail stores, also includes a spot remover for removing small stains.

Caution: Using any other bag with the DR YEL™

system may damage the clothes or the L3 Dryer.

cycle runs for 30 minutes, Dewrinkle

– 8 –

Page 11

Due to the DRYEL™ pad, clothes may be damp

when the dryer cycle is completed; this is normal.

Note: DRYEL™ is not a replacement for

professional dry cleaning. Fabrics with large or

heavy stains may not come clean using this

system. Also, this system will not press clothes.

Custom Cycles

Custom Cycle buttons allow the consumer to

create two additional One Touch Dry Cycles.

These cycles can be either

, and can include any dryness level, time

Dry

Sensor Dry

or

Timed

period, heat setting, or option desired.

updated. However, heater settings do not change;

default heater settings will be performed.

Start/Pause

When this button is pushed either for the first time

or after the Stop/Cancel button is pushed, the

display defaults to the last cycle run and the Start/

Pause button’s LED light flashes 0.5 seconds ON

and 0.5 seconds OFF, indicating “Action Needed

to Start.”

If the button is pushed after a cycle is selected,

the machine starts per the selected cycle and

options unless the door is open. If the door is

open, the button flashes and no action occurs.

Dryness Levels

Note: Dryness Level buttons are locked out for

One Touch Timed Dry Cycles.

Four dryness levels, including More Dry, Dr y, Less

Dry, and Damp, are available. When a Dryness

Level button is pushed, no other button is affected

with one exception. When a Dryness Level button

is pushed after a One Touch Timed Dry Cycle

button or the Antibacterial button has been

selected, the new dryness setting appears in the

display, and the time matr ix is updated. However,

the heater setting does not change; default heater

settings will be performed.

Timed Dry Only

When any Timed Dry Only button is pushed, the

cycle defaults to a Medium heat setting and no

specific Dryness Level.

The Timed Dry LED turns ON until the end of the

cycle (including cooldown), then the Clean Lint

Filter LED turns ON as described earlier.

Heat Setting

(High/[Regular], Medium, Low, and Extra Low)

Note: Heat Setting buttons are locked out for the

Air Dry cycle.

When any Heat Setting button is pushed, that

option will be selected. No other button will be

affected with one exception. When a Heat Setting

button is pushed after the Knits/Sweaters,

Delicates, Dryel, Dewrinkle, or Antibacterial cycle

has been selected, the new temperature setting

appears in the display and the time matrix is

On initial power-up, either from the factor y or after

a power outage, pressing the Start/Pause button

displays the default settings for the Cotton Sensor

Dry cycle.

If the button is pushed in midcycle, the unit enters

Pause mode. Drying operation stops and the

Start/Pause button’s LED flashes. Pressing the

button again resumes drying operations.

Stop/Cancel

Pushing this button deactivates all selections, and

all LEDs turn OFF. If the machine is running when

this button is pushed, the machine turns OFF.

Idle Mode

The idle mode has no LEDs or relays lit; the

control is waiting for the consumer to touch a

keypad or switch.

Power Outage

In the event of a power outage, and the dryer is in

idle mode, press any key except Stop/Cancel to

set the dryer in the Cotton Sensor Dry cycle.

Change options as needed.

Options

Beeper

Activating this option allows the beeper to sound

(two short tones followed by a long tone) at the

end of a cycle. The beeper signals every 2 minutes up to four times unless the door is opened,

– 9 –

Page 12

the beeper is deactivated, or the Stop/Cancel

button is pressed.

When the Beeper button is pushed during a

deactivated state, the beeper turns ON at high

volume, the LED on the Beeper button turns ON,

and the beeper sounds. Pushing the Beeper

button again deactivates the option and turns OFF

the LED light.

Extend Tumble

Pushing the Extend T umble button activates the

option; pushing the button a second time deactivates the option. The Extended T umble LED is

ON during the extended tumble care portion of the

cycle.

Add Time

Pushing the Add Time button once adds 10

minutes to the current cycle’s drying time. If the

button is pushed after the Stop/Cancel button, a

default 10-minute dry cycle activates at Medium

heat.

Antibacterial

Note: Use this option only with the Cottons or

Mixed Loads cycles. Do not use this cycle for

delicate fabrics.

Pushing the Antibacterial button adds high heat

to a portion of the current drying cycle. The Timed

Dry LED remains ON until the end of the cycle, at

which time the Clean Lint Filter LED turns ON.

Commercial Dryer

The commercial dryer uses the keypad model

control design. It has fewer keypad options and is

designed for apartment or commercial noncoin

applications.

– 10 –

Page 13

Notes

– 11 –

Page 14

Electronic Controls

The L3 dryer offers the convenience of starting your wash loads with easy one touch cycles. One

simple selection automatically sets your Dryness Level and Heat Setting. Then just press Start.

Model Type 592

O

NE TOUCH

Sensor Dry Cycles

COTTONS

M

IXED

L

OADS

E

ASY CARE

PERM PRESS

KNITS

SWEATERS

D

ELICATES

SPEED

DRY

Commercial Model Type 450

D

W

C

SENSOR DRY

E

RINKLE

USTOM

PRESS 3 SEC TO STORE

1

C

A

IR

D

USTOM

RY

2

D

RYNESS

L

EVEL

M

ORE

D

D

L

ESS

D

D

AMP

SENSOR DRY

C

H

EAT

MIN

MIN

MIN

MIN

40

30

20

10

SETTING

(REGULAR)

M

CLEAN LINT FILTER

T

IMED DRY ONLY

80

RY

RY

RY

MIN

70

MIN

60

MIN

50

MIN

EXTENDED TUMBLE SENSING

YCLE STATUS

H

EDIUM

L

E

XTRA

L

OW

IGH

OW

O

PTIONS

B

E

XTEND

T

UMBLE

T

B

ACTERIAL

EEPER

A

DD

IME

A

NTI

S

TART

PAUSE

S

TOP

CANCEL

E

ST. TIME REMAINING

GEA00567

Description

A keypad electronic dryer control has replaced the

electronic/rotary selection control to improve ease

of use and serviceability.

The L3 electronic control consists of a printed

circuit board, a transformer, and housing.

GEA00566

Estimated Time Remaining

When a cycle is chosen, the Dual Seven Segment

Display (DSSD) displays an estimated time for the

drying cycle.

The default numbers initially displayed for Sensor

Dry cycles will change based on the previous

cycle run. The display will show the selected time

for the Timed Dry cycle; 30 minutes for the Dryel

cycle; 20 minutes for the Dewrinkle cycle; and 10

minutes for the Air Dry cycle.

– 12 –

Page 15

Field Service Mode

To enter the Field Service Mode, disconnect then

reconnect the electrical power at the wall outlet.

Within 30 seconds, simultaneously press and hold

the Cottons and Start/Pause buttons for 3 seconds. The unit will start and run, but continue to

hold the buttons until the diagnostics mode is

entered. As soon as the test cycle is entered, the

Dual Seven Segment Display (DSSD) displays, in

sequence, the letters Fd (Field Service Diagnostics), EL or GA (for electric or gas dryer type), and

the EEPROM version number. Wait for the DSSD

to turn OFF before proceeding with testing.

To index to the next test position, press the Mixed

Loads button. To return to the previous test

position, press the Easy Care/Perm Press button.

The following tables give the functions for the

subsequent positions.

Sensor Rods Check: S0 displays if sensor rods

are open circuit. If a problem exists, E2 displays.

Touch sensor rod with your hand for 20 seconds.

SS displays if capacitor is discharging properly.

Motor Check: Motor switches ON and DSSD

displays Sn.

Heater 1 Check: Tur ns ON heater 1 and displays

H1.

Heater 2 Check: Tur ns ON heater 2 and displays

H2.

Door Status Check: Displays d0 for door open or

dC for door closed.

Test Sequence , Gas Dryer

noitisoP

DSSD

tuptuO

noitcnuF

Test Sequence , Electric Dryer

noitisoP

DSSD

tuptuO

laitinI-0dFedoMcitsongaiDdleiF

laitinI-0LEcirtcelE

laitinI-0# rebmuNnoisreVMORPEE

10ErorrEoN,rotsimrehT

11ErotsimrehTdraoBrororrE

20SlamroN,*tiucriCnepO,sdoR

22EdetrohS,*melborPtiucriC,sdoR

3nSrotoMNOsehctiwS

41HretuO,NOsnruT1retaeH

52HrennI,)FFO1(NOsnruT2retaeH

laitinI-0dFedoMcitsongaiDdleiF

laitinI-0AGsaG

noitcnuF

laitinI-0# rebmuNnoisreVMORPEE

20SlamroN,*tiucriCnepO,sdoR

22EdetrohS,*melborPtiucriC,sdoR

3nSrotoMNOsehctiwS

4n1NOsnruTretingI

5n2NOsnruTyaleReraCartlU

60d)desolCrooD=Cd(nepOrooD

* See Rods Table

Sensor Rods Check: S0 displays if sensor rods

are open circuit. If a problem exists, E2 displays.

Touch sensor rod with your hand for 20 seconds.

SS displays if capacitor is discharging properly.

60d)desolCrooD=Cd(nepOrooD

* See Rods Table

Thermistor Check: E0 displays if no error is in

thermistor circuit. If an error exists, E1 displays. To

verify thermistor, a resistance range of 100K ohms

+/- 10% @ 77 °F should be found between pins 5

and 6 of female connector CN4 at the right side of

the transformer.

Motor Check: Motor switches ON and DSSD

displays Sn.

Igniter Check: Tur ns ON igniter and displays 1n.

Ultra Care Check: Turns ON Ultra Care relay and

displays 2n.

Door Status Check: Displays d0 for door open or

dC for door closed.

– 13 –

Page 16

Sensor Rod Circuit Description

Sensor Rods Table

The moisture-sensing rods are part of a circuit

that is designed to utilize a low-voltage capacitor

that charges to 5 V when the circuit is open, and

discharges to 1 V when the circuit is shorted. The

gap in the circuit is the space between the rods.

When the wet clothes touch the two rods, they

create a short, which discharges the capacitor.

When the clothes become dry, they cannot short

the circuit and the charge across the capacitor

builds to 5 V. A voltage of 1 V across the capacitor

read by the PCB indicates wet clothes. As the

clothes are dried, the voltage increases, and

finally 5 V across the capacitor indicate completely

dry clothes.

In the diagnostics mode, a code of S0 indicates a

normally open circuit (the capacitor is charged

properly). The code E2 indicates a shorted capaci-

tor or some other problem on the board. To check

the discharging of the capacitor, touch the rods

with your hands, shorting the two rods for at least

5 seconds. The S0 will change to SS, indicating

that the capacitor discharged properly. No change

from S0 indicates that either the rods are not

connected to the board or there is some other

problem on the board.

Note: If you want to repeat the test, wait for at

least 45 seconds to fully charge the capacitor.

tuptuODSSD

SSotOS)KOsdoR(tluaFoN

SSot2EskaeLroticapaC

2Eot2EtiucriCotdetcennoCtoN

sisongaiD

The Field Service Mode can be exited in three

ways:

1. Press the Stop/Cancel keypad.

2. Unplug the unit.

3. Control automatically exits test mode after 30

minutes.

Checking Power to the PCB

To check the presence of 240 V at the board, put

the dryer in Air Dry cycle (the motor will run with

no heat).

• If the

outer heating element is OK, there will be

240 V between tap 16 (L2 through coil) and tap

8 (L1).

• If the

inner heating element is OK, there will be

240 V between tap 10 (L2 through coil) and tap

8 (L1).

To Enter Field Service

Diagnostic Mode

Begin

Press and hold

Start/Pause and

Cottons buttons.

Release Start/Pause

button and Cottons

button.

Field Service

Mode

Press Stop/

Cancel button.

To Exit Field Service

Diagnostic Mode

Field Service

Mode

-

30 Min.

Timeout

from Start

of Mode

Idle

Loss of

Power to

Control

GEA00535

– 14 –

Page 17

Dryer control panel.

You can locate your model number on the label on the front of the dryer, behind the door.

Model Type 592

Model Type 591

O

NETOUCH

Quick Start Guide

• Clean lint filter

• Add clothes

• Select dry cycle

• Check dryness level

• Check heat setting

• Close door

• Push

START

Your new dryer offers the convenience of starting your dryer loads with our easy

ONET

OUCH

cycles. Make one simple

selection, and your

DRYNESS LEVEL

and

HEAT SETTING

are automatically set. Then all you have to do is press

START

.

Easy ONET

OUCH

Cycles.

Control Settings

Model Type 592

O

NE TOUCH

Sensor Dry Cycles

COTTONS

M

IXED

L

OADS

EASY CARE

PERM PRESS

K

S

WEATERS

DELICATES

Commercial Model Type 450

NITS

SPEED

DRY

SENSOR DRY

D

E

A

IR

W

RINKLE

D

RY

C

USTOM

C

USTOM

1

PRESS 3 SEC TO STORE

D

RYNESS

L

EVEL

M

D

D

L

D

D

2

SENSOR DRY

C

TIMED DRY ONLY

ORE

ESS

AMP

RY

RY

RY

80

MIN

70

MIN

60

MIN

50

MIN

EXTENDED TUMBLE SENSING

YCLE STATUS

40

MIN

30

MIN

20

MIN

10

MIN

HEAT

SETTING

(REGULAR)

M

CLEAN LINT FILTER

H

EDIUM

L

E

XTRA

L

OW

OPTIONS

B

IGH

E

T

OW

B

EEPER

XTEND

UMBLE

A

DD

T

IME

A

NTI

ACTERIAL

S

TART

PAUSE

S

TOP

CANCEL

E

ST. TIME REMAINING

GEA00567

GEA00566

– 15 –

Page 18

ONET

OUCH

selections.

PRESS... AUTOMATICALLY SELECTS... THEN PRESS...

Changing the automatic settings.

For cottons and most linens.

For loads consisting of

cottons and poly-blends.

For wrinkle-free and

permanent press items.

For knits and sweaters with fabric care

labels that say “Machine Dry”.

For lingerie and special care fabrics.

For small loads that are needed in a hurry,

such as sport or school uniforms. Can also

be used if the previous cycle left some

items damp, such as collars or waistbands.

O

NE

T

OUCH

cycles use the

Sensor Dry

feature, which continuously monitors the amount of moisture

in the load and stops the dryer when the clothes are dry.

NOTE: During SPEED DRY

you will see:

Y ou can change any of the automatic settings by simply pressing the desired pads.

– 16 –

Page 19

About drying cycles.

DRYEL™(on some models)

This feature is designed for use with the DRYEL™“dry clean only” fabric care system.

See product package for directions.

For questions or issues related to the use and performance of DRYEL

™

, call

1-800-214-8913, or visit the DRYEL

™

website at www.dryel.com.

Automatic DRYEL™settings:

DEWRINKLE

Use this feature to remove wrinkles from items that are dry or slightly damp.

Automatic DEWRINKLE settings:

AIR DRY

Use this feature to tumble items without heat.

CUSTOM 1 and CUSTOM 2 (on some models)

Set up your favorite combination of settings and save them here for one-touch recall.

These custom settings can be set while a cycle is in progress.

To store a custom combination of settings:

1. Select a

ONE TOUCH

setting.

2. Change

DRYNESS LEVEL

and

HEAT SETTING

to fit your needs.

3. Select any drying

OPTIONS

you want.

4. Press and hold the

CUSTOM 1

or

CUSTOM 2

pad for three seconds to store

your selection. A beep will sound and the pad will light up.

To recall your stored combination:

Press the

CUSTOM 1

or

CUSTOM 2

pad, then press

START/PAUSE

.

To reprogram the CUSTOM settings:

Repeat steps 1-4 above.

Automatic AIR DRY settings:

– 17 –

Page 20

About dryness levels.

MORE DRY

Use for heavy-duty fabrics.

DRY

Use for a normal dryness level suitable for most loads. This is the preferred cycle for

energy saving.

LESS DRY

Use for lighter fabrics.

DAMP

For leaving items partially damp.

HIGH (Regular)

For regular to heavy cottons.

MEDIUM

For synthetics, blends and items labeled permanent press.

LOW

For delicates, synthetics and items labeled

Tumble Dry Low

.

EXTRA LOW

For lingerie and special-care fabrics.

About heat settings.

To use TIMED DRY ONLY:

1. Select the drying time.

2. Select the

HEAT SETTING

.

3. Select any

OPTIONS

. (

NOTE:

The

ANTI BACTERIAL

option is not available with

TIMED DRY ONLY

cycles.)

4. Close door.

5. Push

START

.

About timed dry only cycles.

– 18 –

Page 21

About controls features.

START/PAUSE

■

Press twice to select the last cycle you used and start the dryer.

■

If you have selected a new cycle, press once to start the cycle.

■

If the dryer is running, press once to interrupt the cycle; press again to continue

the cycle.

STOP/CANCEL

■

This pad should

not

be used to interrupt or pause a cycle.

■

Pressing this pad will cancel the current settings and the settings will be lost.

Estimated Time Remaining

Each time the dryer is used, it “learns” what types of loads you dry most often.

It takes this data and determines the approximate time it will take the load to dry.

As the cycle begins, you will see the approximate total cycle time in the display.

Then “racetrack lights” will flash in the display, in a clockwise direction, and the

SENSING

light will flash. This means the dryer is continuously monitoring the amount

of moisture in the load. The racetrack lights will continue until the dryer senses a low

level of moisture in the load. At that point, the dryer will calculate and display the

approximate time remaining.

“Racetrack lights”

– 19 –

Page 22

About cycle options.

BEEPER

Alerts you that the cycle is complete. The beeper will continue to sound every two

minutes for the next 6 minutes, until the clothes are removed. The clothes should

be removed when the beeper goes off so wrinkles won’t set in.

EXTEND TUMBLE

Minimizes wrinkles by adding approximately 20 minutes of no-heat tumbling after

clothes are dry. The beeper will sound every 90 seconds to remind you to remove

the clothes. The

EST. TIME REMAINING

display will show 00.

ADD TIME

This option can be used to extend drying time at the end of any cycle. 10 minutes is

added each time the pad is pressed.

ANTI BACTERIAL (on some models)

This option can only be used with the

COTTONS

or

MIXED LOADS

cycles.

This option reduces certain types of bacteria by 99.9%, including: Staphylococcus

aureus, Pseudomonas aeruginosa, and Klebsiella pneumoniae*. The anti-bacterial process

occurs when high heat is used during a portion of the drying cycle.

NOTE:

Do not use this cycle on

delicate

fabrics.

* The Anti-Bacterial Cycle is Certified by NSF International (formerly National Sanitation

Foundation) to NSF Protocol

P9 Sanitization Performance of Residential Clothes Dryers.

NSF

®

NSF Protocol P9

Sanitization Performance of

Residential Clothes Dryers

– 20 –

Page 23

TIMED DRY

This light comes on when

AIR DRY, DEWRINKLE, DRYEL (on some models)orTIMED DRY

ONLY

is selected.

About cycle status.

These cycle status indicator lights display what part of the cycle the dryer is in and remind you to clean the lint filter.

SENSOR DRY

This light comes on when a

ONET

OUCH

Sensor Dry Cycle

is selected.

SENSING

Sensor Dry Cycles provide greater drying accuracy than standard machines,

resulting in shorter dry times and better clothes care. The

SENSING

light will

flash and “racetrack lights” will flash in the display while the dryer is monitoring

the amount of moisture remaining in the clothes. When the

SENSING

light goes

out, the dryer will calculate and display the approximate time remaining.

EXTENDED TUMBLE

This light comes on when the

EXTEND TUMBLE

option is selected.

CLEAN LINT FILTER

This light is a reminder to clean the lint filter. It comes on at the end of a cycle and

goes off when the door is opened.

“Racetrack lights”

– 21 –

Page 24

Removal and Replacement

Remove Electronic Control Board

1. Remove 4 screws from the top of the

backsplash and rotate the top forward.

2. Tag and remove 11 electrical connections.

Note: Remove and retain the model selector

harness plug for reassembly.

3. Remove 2 screws (1/4-in.) from the control

board.

Caution: To prevent electrostatic discharge,

ground yourself to the dryer cabinet, or use an

ESD wristband.

4. Remove the electronic control board.

Note: When reassemb ling, align the LEDs with

the appropriate control panel indicators.

5. Reverse the above procedure to reinstall.

Remove 4 Screws

GEA00545

Electrical

Electrical

Connections

Connections

Screws

Screws

Model

Model

Selector

Selector

Harness

Harness

GEA00544

– 22 –

Page 25

Notes

– 23 –

Page 26

Schematics

WARNING

POWER MUST BE DISCONNECTED BEFORE SERVICING THE APPLIANCE.

Terminal Layout on PCB, Electric Model DPSE592EA0

BROWN/WHITE

6 1

BROWN

Note: The numbers in the drawing of the PCB

above correspond to the numbers on the

schematic on page 25.

BROWN

BLUE

8

7

GRAY

YELLOW

TERMINAL LAYOUT ON PCB, ELECTRIC DRYER

BROWN

BLACK

2A

9

10

N

PURPLE

16

BLACK

J

L1

ORANGE

ORANGE

MODELS WIRE COLOR

DPSE592 WHITE 1-6

DPSE591 YELLOW, RED 1-3, 4-5

DNCD450 BLACK, YELLOW 1-2-3, 4-5

BLUE

BLUE

GRAY PINK

MODEL SELECTOR CONNECTOR MATRIX CHART

6543 1

WHITE

MODEL SELECTOR

TERMINAL POSITION

GEA00573

Terminal Layout on PCB, Gas Model DPSE592GA0

BROWN/WHITE

6 1

BROWN

BLUE

PURPLE

YELLOW

Note: The numbers in the drawing of the PCB

above correspond to the numbers on the

schematic on page 26.

2A

8

10

7

ORANGE

YELLOW/BLACK

TERMINAL LAYOUT ON PCB, GAS DRYER

BLACK

BLACK

N

169

J

YELLOW/BLACK

L1

BLACK

GRAY PINK

MODEL SELECTOR CONNECTOR MATRIX CHART

MODELS WIRE COLOR TERMINAL POSITION

DPSE592 ORANGE, WHITE 1-3, 5-6

DPSE591 YELLOW, WHITE 1-4, 5-6

DNCD450 GRAY, BLACK 1-2, 4-5-6

43 1

WHITE

MODEL SELECTOR

GEA00572

Refer to microfiche for specific model information.

– 24 –

Page 27

L3 Dryer - Electric Model

L1

Caution: Label all wires prior to disconnection when

servicing the controls. Wiring errors can cause

improper and dangerous operation. Verify proper

operation after servicing.

N

L2

RED

ORANGE

SAFETY

THERMO LEFT

TRANSFORMER

L1

ORANGE

THERMO

HI-LIMIT

ELECTRONIC DRYER

POWER BOARD

INLET

BIAS

RELAY

K3-no

DRUM

OUTLET

BLUE

(ULTRACARE)

OUTER COIL

RELAY (15A)

K4-no

BLACK

PURPLE

OUTLET

BIAS RELAY

POWER/START

K2-no

RELAY

K1-no

G5S

G8P

1 6 8 7 J 16 9 10 2A

BROWN BROWN

RIGHT

BROWN/WHITE

ORANGE

INNER COIL

RELAY (15A)

K5-no

G8PG8PG5S

BLACK

YELLOW

GRAY

BLUE

YELLOW

PURPLE

N

WHITE

1

PINK

3

GRAY

4

BLUE

5

BLUE

6

THERMISTOR ASSEMBLY

IDLER SWITCH

CONTROL

9K9K

INLET

YELLOW

PINK

GRAY

LOWER ROD MOV

UPPER ROD MOV

DRUM/BLOWER MOTOR

M6

RED

YELLOW

GRAY

WHITE

DOOR

SWITCH

NC

WHITE BLACK BLACK/RED

COM

NO

GREEN

BROWN/YELLOW

START

RUNM5

BLUE

SOLDER TRACES ON PC BOARD

GANGED SWITCH

COMMERCIAL OMITTED

LEGEND

OVERLOAD

PROTECTOR

M4

BLACK

DRUM LAMP

M1

M2

INNER COIL 19.2

PURPLE

HEATER HOUSING

OUTER COIL 19.2

GEA00552

Note: See schematic for proper switch connections.

1. Heater coil resistance is shown on the wir ing schematic. Check for infinite resistance between

any heater terminal and dryer cabinet. Heater failure could result from low airflow caused by

improper sealing, kinked or excessive ducting, or excessive line voltage.

2. Other factors contributing to long dr y times or clothes conditions include load size, number of

large or bulky items, ambient temperature, room size (if not exhausted outdoors), wetness of

clothes, and washer rinse temperature.

3. Small loads (less than 3 lb) may develop static, causing clothes to cling to the drum surface

(no tumble) and resulting in wrinkles, shrinkage, or melting. Use a fabric softener in the

washer or dryer, or add two large bath towels to act as a buffer when drying.

– 25 –

Page 28

L3 Dryer - Gas Model

L1

Caution: Label all wires prior to disconnection when

servicing the controls. Wiring errors can cause

improper and dangerous operation. Verify proper

operation after servicing.

N

BLACK

TRANSFORMER

BLACK

BLACK

OUTLET/ULTRACARE

BIAS RELAY

POWER/START

LEGEND

SOLDER TRACES ON PC BOARD

GANGED SWITCH

COMMERCIAL OMITTED

K2-no

RELAY

K1-no

G8P

BLACK

BROWN/WHITE BLACK

ELECTRONIC DRYER

POWER BOARD

BIAS

RELAY

K3-no

YELLOW/BLACK

TRIMMER

YELLOW YELLOW/BLACK

GAS VALVE

RELAY

K4-no

9K

DRUM

OUTLET

ULTRACARE RELAY

(GENTAL HEAT)

K5-no

G8PG8PG5SG5S

ORANGE

BROWN/WHITE

BLACK

BLACK WHITE

N

1

3

4

5

9K

CONTROL

INLET

BLACK

9K

6

IDLER SWITCH

PURPLE

ORANGEORANGE

2AL1 1016 97861J

BROWN

PURPLE

BLUE

BLUE

PINK

GRAY

WHITE

DRUM LAMP

YELLOW

PINK

GRAY

SAFETYULTRACARE

LOWER ROD MOV

UPPER ROD MOV

RED

BOOSTER

YELLOW

SAFETY

DOOR SWITCH

GREEN

DRUM/BLOWER MOTOR

M6

START

M5 M4

RUN

OVERLOAD

PROTECTOR

PURPLE

IGNITOR DETECT

COIL

COIL

MAIN

COIL

NC

COM

NO

BROWN/YELLOW

GAS VALVE

WHITE

BROWN/YELLOW

YELLOWBLACK

M1

M2

GEA00550

Note: See schematic for proper switch connections.

1. Other factors contributing to long dry times or clothes conditions include load size, number of

large or bulky items, ambient temperature, room size (if not exhausted outdoors), wetness of

clothes, and washer rinse temperature.

2. Small loads (less than 3 lb) may develop static, causing clothes to cling to the drum surface

(no tumble) and resulting in wrinkles, shrinkage, or melting. Use a fabric softener in the

washer or dryer, or add two large bath towels to act as a buffer when drying.

– 26 –

Page 29

Notes

– 27 –

Page 30

Troubleshooting Flowchar ts

L3 Dryer - Electric Model

Dryer

Proper voltage to

Dryer.

Yes

Enter field service

mode (disconnect/

reconnect power, then

press and hold

and

Cotton

Unit will start

and run. Continue to

hold buttons until

diagnostics mode is

Start

buttons).

entered.

No

Test

Mode.

House fuse, breaker,

wall outlet problem.

DSSD output displays

Fd, EL

, and EEPROM

version number.

Check error codes.

Press

Mixed Loads

button - DSSD output

displays error codes for

existing errors.

Press

Stop

to exit field

service mode.

E0

Thermistor, No Error.

Thermistor Error or

E1

Sensor Rods, Open

S0

Circuit, Normal

Sensor Rods, Circuit

E2

Problem, Shorted

Sn

Motor Switches ON

Heater 1 Turns

H1

Heater 2 Turns ON

H2

(1 OFF), Inner

Board.

ON, Outer

Touch rods

with hand for

20 seconds.

Touch rods

with hand for

20 seconds.

No Fault, Rods OK.

SS

Capacitor Leaks -

SS

Replace capacitor.

Not Connected to

E2

Circuit - Check

connection.

dO

dC

Door Open

Door Closed

– 28 –

Page 31

L3 Dryer - Gas Model

Dryer

Proper voltage to

Dryer.

Yes

Enter field service

mode (disconnect/

reconnect power, then

press and hold

and

Cotton

Unit will start

and run. Continue to

hold buttons until

diagnostics mode is

Start

buttons).

entered.

No

Test

Mode.

House fuse, breaker,

wall outlet problem.

DSSD output displays

Fd, GA

, and EEPROM

version number.

Check error codes.

Press

Mixed Loads

button - DSSD output

displays error codes for

existing errors.

Press

Stop

to exit field

service mode.

Sensor Rods, Open

S0

Circuit, Normal

Sensor Rods, Circuit

E2

Problem, Shorted

Sn

Motor Switches ON

1n

Igniter Turns ON

Ultra Care Relay

2n

dO

Turns ON

Door Open

Touch rods

with hand for

20 seconds.

Touch rods

with hand for

20 seconds.

No Fault, Rods OK.

SS

Capacitor Leaks -

SS

Replace capacitor.

Not Connected to

Circuit - Check

E2

connection.

dC

Door Closed

– 29 –

Page 32

Illustrated Parts Breakdown

Exploded parts views and list for Model DPSE592EA0.

Refer to microfiche for specific model information.

– 30 –

Page 33

Exploded parts views and list for Model DPSE592EA0.

Refer to microfiche for specific model information.

– 31 –

Page 34

Exploded parts views and list for Model DPSE592EA0.

Refer to microfiche for specific model information.

– 32 –

Page 35

Exploded parts views and list for Model DPSE592EA0.

Refer to microfiche for specific model information.

– 33 –

Page 36

Exploded parts views and list for Model DPSE592EA0.

Refer to microfiche for specific model information.

– 34 –

Page 37

Exploded parts views and list for Model DPSE592EA0.

Refer to microfiche for specific model information.

– 35 –

Page 38

Exploded parts views and list for Model DPSE592EA0.

Refer to microfiche for specific model information.

– 36 –

Page 39

Quiz

1. How do you get into the Field Service Mode for

the Wizard Dryer?

a) Press & hold “Start/Pause” button for 3

seconds

b) Press & hold “DeWrinkle/Air Dry” buttons for

3 seconds

c) Press & hold “Mixed Loads” & “Start/Pause”

buttons together for 3 seconds

d) Press & hold “Start/Pause” button, then

press & hold “Cottons” button for 3 seconds

within 30 seconds of power on

e) None of the above

2. What function does Step 3 indicate in the Field

Service Mode for the Wizard Dryer?

a) Thermistor check

b) Sensor rods check

c) Motor check

d) Heater 1 check

e) Heater 2 check

3. The “Dryel” feature of the Wizard Dryer allows

customers to actually dry clean their garments.

T or F

6. To check the rod sensors, you can place your

fingers across the rods and you should measure 5 VDC at the control board 6-pin plug #5

& #6. T or F

7. The thermistor should read approximately

100K ohms at room temperature. T or F

8. During a medium heat cycle, which bias contacts are activated?

a) Outlet bias

b) Inlet bias

c) Outlet & inlet bias

d) None of the above

9. What voltage is applied to the bias heater when

active?

a) 12 VDC

b) 14 VDC

c) 120 VAC

d) 0 VAC

e) 0 VDC

4. An “E1” code for the Wizard Dryer signifies that

the thermistor is either open or shorted. T or F

5.) There is no “Model Selection Plug” for the

Wizard Dryer. T or F

Exploded parts views and list for Model DPSE592EA0.

Refer to microfiche for specific model information.

10. Which components are activated during the

Field Service Mode for the Wizard Electric

Dryer?

a) Thermistor, motor, heater 1, and heater 2

b) Motor, heater 1, heater 2, and drum light

c) Motor, heater 1, and heater 2

d) Motor, igniter, and ultra-care relay

– 37 –

Page 40

Exploded parts views and list for Model DPSE592EA0.

Refer to microfiche for specific model information.

– 38 –

Loading...

Loading...