Page 1

roduced,

communicated in any way to third parties, nor stored in any data processing system, without the express written authority of

CERTIFICATE RELATED DRAWING

NOT TO BE MODIFIED WITHOUT

T

HE APPROVAL OF THE CERTIFICATION ENGINEER

APPROVED: M T CONCANNON

RTIFICATES: Baseefa10ATEX0010X

CE

Pressure measurement

for research & industry

Druck Limited

Fir Tree Lane

Groby

Leicester LE6 0FH

England

Tel: 0116 231 7100

Baseefa10ATEX0012X

IECEx BAS 10.0002X

IECEx BAS 10.0004X

DPI 620-IS

Advanced Modular Calibrator

User Manual

K0460

Druck Limited 2010

This document is the property of Druck Limited and may not, either in part or whole, be copied or otherwise rep

Druck Limited.

Page 1 of 98 K0460 Issue 1

Page 2

G DOCHERTY

M CONCANNON

Amendment Record

Iss No Date C/N No Originator Typed Workflow

N

1 21/07/10 N/A Robert Lee Robert Lee 149146 New document

Amendments

o.

Approvals

Engineering

Marketing

M SHELTON

Engineering (Certification)

Technical Communications

R LEE

Page 2 of 98 K0460 Issue 1

Page 3

Print Instructions: K0460

•

Finished Size: A5 Portrait (148 x 210 mm)

• Print in colour throughout (covers + text), saddle stitched.

• Cover to 285 gsm, content to 100 gsm.

THIS HARDCOPY IS NOT TO BE USED AS CAMERA COPY.

Page 3 of 98 K0460 Issue 1

Page 4

Page 4 of 98 K0460 Issue 1

Page 5

GE

Measurement & Control Systems

Druck DPI 620-IS

advanced modular calibrator

user manual - K0460

Page 6

Issue 1

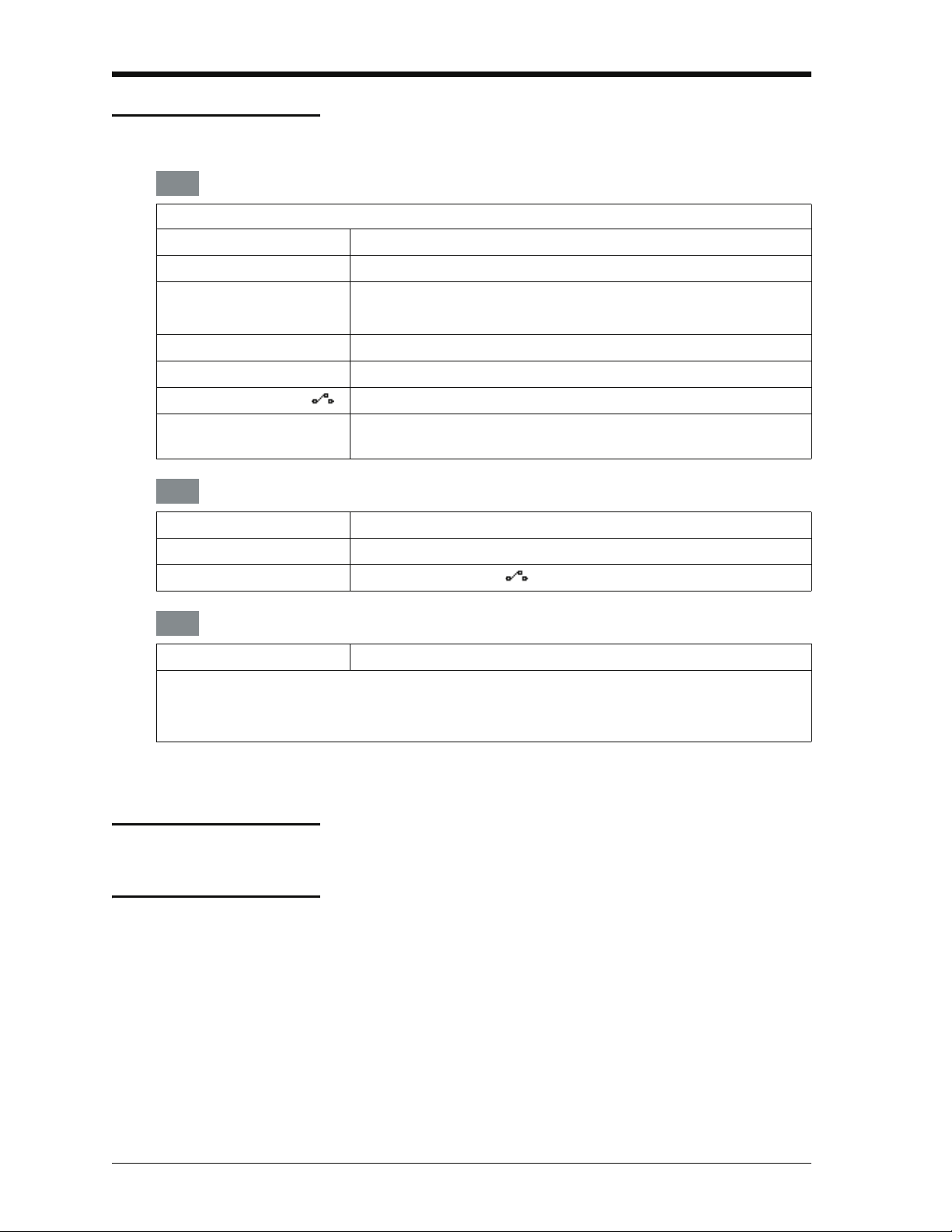

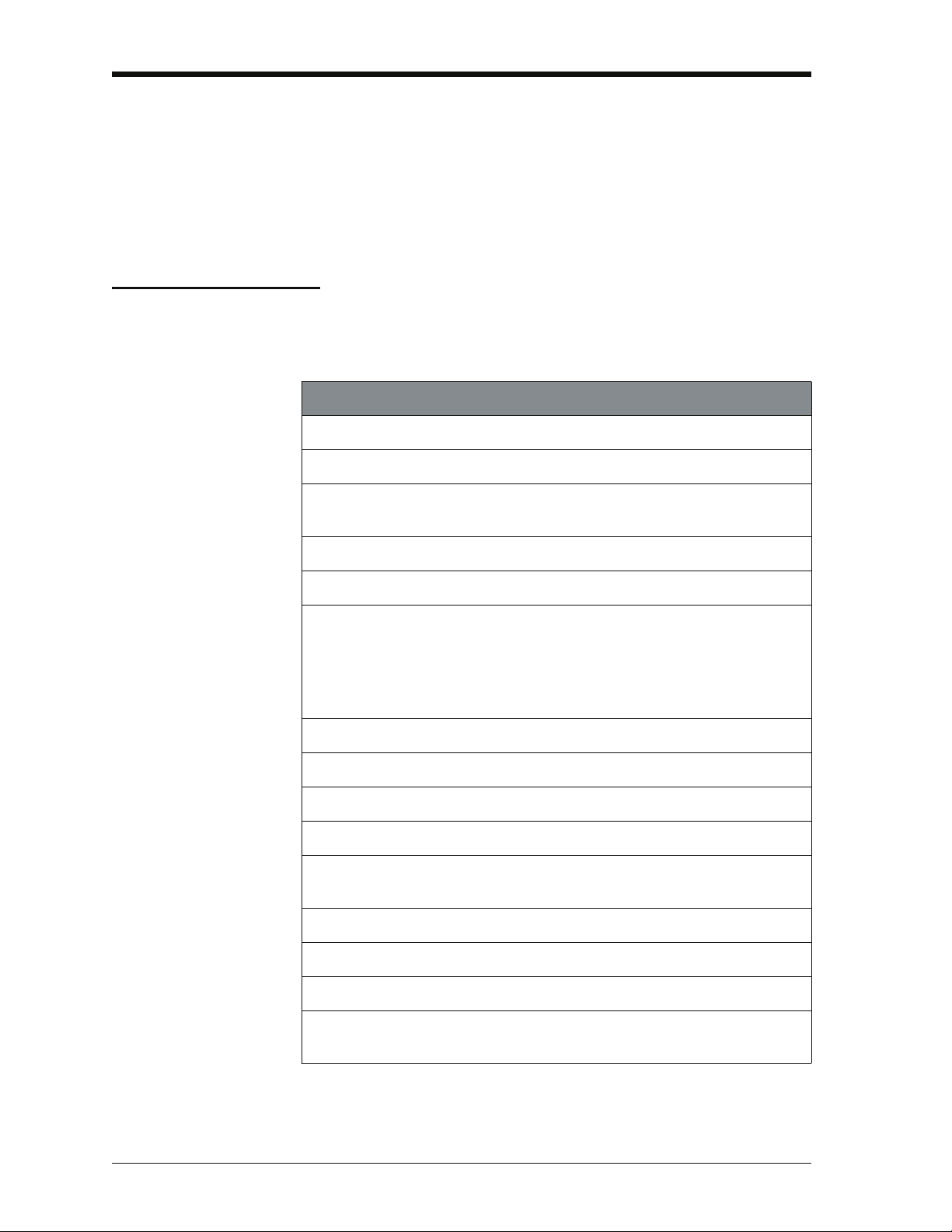

Quick reference data

A1.1

DPI 620-IS: Channel 1 (CH1)

Measure (M) / Source (S) / Power (P)

±30 V (M) ±55 mA (M)

0 to 12 V (S) 0 to 24 mA (S)

±2000 mV (M) 8 RTDs (M/S): Pt1000, Pt500, Pt200, Pt100(385),

0 to 2000 mV (S) Pt50, D 100, Ni 100, Ni 120

0 to 4000 Ω (M/S) 12 Thermocouples (M/S): K, J, T, B, R, S, E, N, L, U, C, D

0 to 5 kHz (M/S)

Switch (M)

Pulse counting and

sourcing up to 5k.

A1.2

DPI 620-IS: Channel 2 (CH2)

±30 V (M) 0 to 20 mA (S)

±2000 mV (M) 24 V nominal; maximum: 20 mA

±55 mA (M) Switch (M)

A1.3

DPI 620-IS + MC 620-IS + PM 620-IS

Pressure* (M)

Gauge: 25 mbar to 200 bar (0.36 to 3000 psi).

Absolute: 350 mbar to 1000 bar (5 to 15000 psi).

Note: Maximum pneumatic pressure: 500 bar (7250 psi).

*Caution: To prevent damage to the PM 620-IS module, only use it within the specified

pressure limit on the label.

Copyright © 2010 General Electric Company. All rights reserved.

Trademarks Microsoft and Windows are either registered trademarks or

trademarks of Microsoft Corporation in the United States and/or

other countries.

®

HART

Communications Foundation.

is a registered trademark of the HART

All product names are trademarks of their respect ive

companies.

ii

Page 7

Issue 1

Safety

General warnings

Electrical warnings

Before using the instrument, read and understand all the

related data. This includes: the applicable local safety

procedures, this publication, and the instructions for any

accessories/options/equipment.

WARNING

• It is dangerous to ignore the specified limits for the

instrument or its related accessories. Do not use the

instrument or accessory if it is not in its normal

condition. Use the applicable protection and obey all

safety precautions.

• To prevent electrical shocks or damage to the

instrument, do not connect more than 30V between the

terminals, or between the terminals and the ground

(earth).

• This instrument uses a Ni-MH battery pack. To prevent

an explosion or fire, do not short circuit, do not

disassemble, keep it safe from damage. For operating

conditions, see Table 11-1.

Pressure warnings

• To prevent battery leakage or heat generation, only use

the battery charger and power supply in the

temperature range 0 to 40°C (32 to 104°F). For

operating conditions, see Table 11-1.

• To make sure the display shows the correct data,

disconnect the test leads before setting the power to on

or change to another measure or source function.

When using a pressure option with the DPI 620-IS calibrator,

these warnings are also applicable:

• Some liquid and gas mixtures are dangerous. This

includes mixtures that occur because of contamination.

Make sure that the equipment is safe to use with the

necessary media.

• Pressurized gases and fluids are dangerous. Before

connecting or disconnecting pressure equipment,

safely release all the pressure.

• To prevent a dangerous release of pressure, make sure

that all the related pipes, hoses and equipment have the

correct pressure rating, are safe to use and are

correctly attached.

[EN] English - K0460 Safety iii

Page 8

Issue 1

• It is dangerous to attach an external source of pressure

to a PM 620-IS series pressure station. Use only the

specified mechanisms to set and control the pressure

in the pressure station.

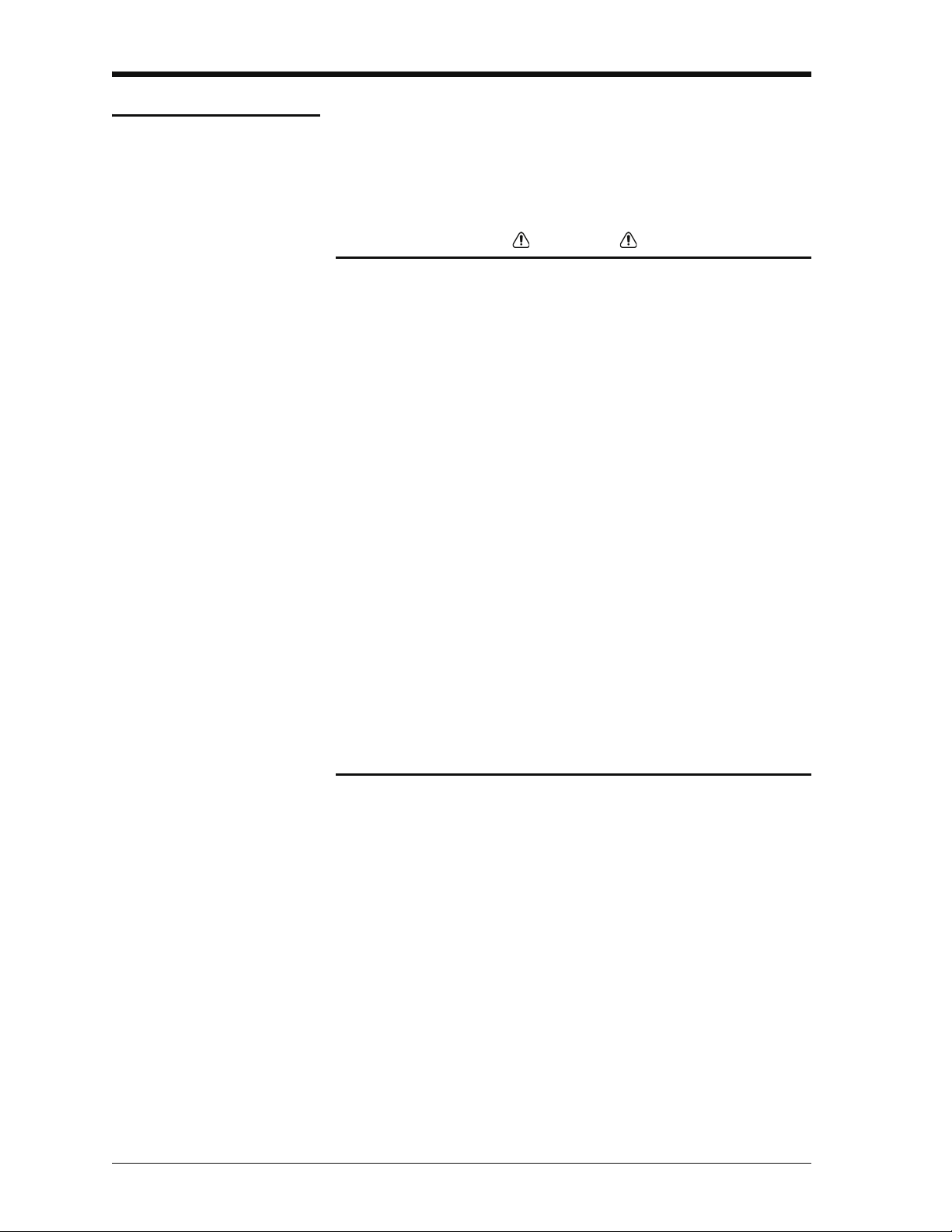

Cautions

Marks and symbols

on the instrument

To prevent damage to the display, do not use sharp

objects on the touch-screen.

To prevent damage to the PM 620-IS module, only use it

within the specified pressure limit on the label.

Before starting an operation or procedure in this publication,

the user must have the necessary skills (if necessary, with

qualifications from an approved training establishment). Follow

good engineering practice at all times.

Complies with European

Union directives

Read the manual USB port: Mini type B

Ground (Earth)

Do not dispose of this product as household waste. Refer to

Chapter 9 (Maintenance procedures).

More marks and symbols are specified in this manual: electrical marks,

display symbols (Chapter 1); pressure related marks and symbols

(Chapter 4).

Warning - refer to the

manual

connector

ON/OFF

iv Safety K0460 - [EN] English

Page 9

Issue 1

DPI 620-IS

MC 620-IS

PM 620-IS

Pressure calibrator

Overview

The intrinsically safe, advanced modular calibrator (AMC) is

part of a set of hand-held modules that can be quickly put

together to include a wide range of calibrator functions.

Advanced modular calibrator, DPI 620-IS (this user

manual): This is a battery-powered instrument for electrical

measure and source operations and HART® communications;

see Table A1 (front cover). It also supplies the power and user

interface functions for all the add-on modules. Use the

touch-screen to display up to six different parameters.

Pressure module carrier, MC 620-IS (this user manual):

This attaches to the DPI 620-IS calibrator to make a fully

integrated pressure indicator instrument. To measure and

display pneumatic or hydraulic pressures, up to two

interchangeable pressure modules can be used at a time.

When not in use fit blanking device (part number 191-369).

Pressure modules, PM 620-IS (this user manual):

Optional item. These modules attach to the pressure module

carrier (MC 620-IS) or to a pressure station (PV 62x-IS) to give

the DPI 620-IS calibrator the necessary pressure measurement

functionality. They are fully interchangeable “plug and play”

modules with no initial set-up or user calibration.

Pressure stations, PV 62x-IS (user manual - K0462:

Optional item. To make a fully integrated pressure calibrator,

attach the DPI 620-IS calibrator to one of the three pressure

stations:

• two pneumatic pressure stations gives an accurate and

controlled pressure and vacuum conditions:

PV 621-IS: -950 mbar to 20 bar (-13.5 to 300 psi) version

PV 622-IS: -950 mbar to 100 bar (-13.5 to 1500 psi) version

• one hydraulic pressure station gives an accurate and

controlled hydraulic pressure conditions:

PV 623-IS: 0 to 1000 bar (15000 psi)

The advanced modular calibrator (AMC-IS) and the pressure

module (PM 620-IS) are part of a set of hand-held modules that

can be quickly put together to include a wide range of calibrator

functions.

To give the attached equipment overpressure protection, there

are pressure relief valves (PRV) available for all the pressure

stations.

[EN] English - K0460 Overview v

Page 10

Issue 1

Software (this user manual): The DPI 620-IS calibrator

includes the following software:

• documenting software • HART® communications software

Other accessories and options: For part numbers (P/N),

refer to Section 1.4 (Accessories).

Summary of

functions

This table gives a summary of the available functions with the

DPI 620-IS calibrator.

DPI 620-IS - Calibrator functions

Function

Easy to read, Active Matrix Organic Light Emitting Diode Display in colour.

No keys: the touch-screen has large buttons for finger operation.

Rechargeable NiMH battery with enhanced power control for prolonged

battery life.

*

Measure current (mA), voltage (Volts/mV), frequency (Hz/pulse count).

* Supply current (mA), voltage (Volts/mV), frequency (Hz/pulse count).

* Measure/simulate:

- a Resistance Temperature Detector (RTD): Ω or °C/°F

- a thermocouple (TC): mV or °C/°F

- a resistor (Ω)

Cold Junction (CJ) compensation: Automatic/Manual.

Step/Ramp functions: Automatic/Manual.

Switch test and condition indicator (open/closed).

Language selection (see Section 2.8 (Menu sequence)).

Universal Serial Bus (USB) communications ports: For computer

communications, external modules.

®

† Windows

** Measure pressure/Leak test: See pressure accessories.

Documenting software to give an analysis of a device calibration.

Set-up function to save and recall personal settings, instrument calibration

settings and other standard instrument operations.

vi Summary of functions K0460 - [EN] English

CE operating system.

Page 11

* Refer to the datasheet

Example

buttons:

** Optional item

† Factory configured

Issue 1

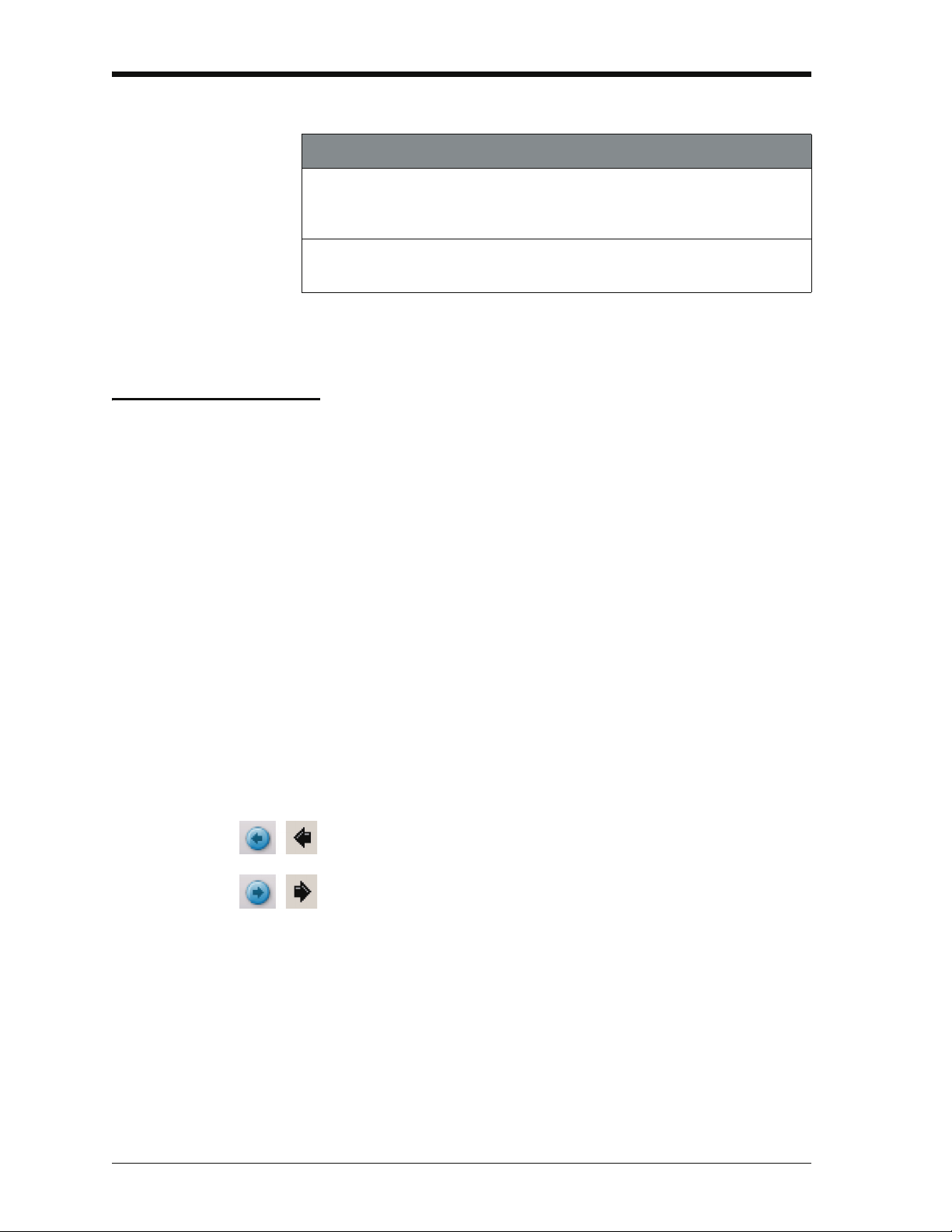

DPI 620-IS - Calibrator functions (Continued)

Function

HART® (Highway Addressable Remote Transducer) communications

software to set up and calibrate devices that use the HART field

communications protocol.

Other functions: Hold, maximum/minimum/average, filter, tare, adjustable

backlight, alarm indication (on the display), automatic power off.

About this manual

This user manual is set up for use on a computer or similar

device that has the necessary software to read a Portable

Document Format (PDF) file.

It is supplied as a PDF on a compact disc (CD) but can be

copied or saved onto a computer or similar device that has the

necessary PDF software.

To navigate between related items of information, the user

manual includes cross references and links (shown in blue); for

example:

• text cross references: ... Figure 1-1; Table 11-1; Chapter 1;

Section 1.4 (Accessories)

Note: Moving the PDF software cursor over an item that has a

link, the cursor symbol normally changes.

Click on a link, and the PDF software shows the applicable

page. To help navigate through the links use, the PDF software

which usually includes these buttons:

Previous view: To go back to a previous page selection.

Next view: In a sequence of page selections, this moves

forward to the next page.

Note: Different software versions have different buttons. In

some versions, it is also necessary to set up the “View” to

include these “Tools” in the “Page Navigation Toolbar”; refer to

the PDF software documentation.

[EN] English - K0460 About this manual vii

Page 12

Issue 1

viii About this manual K0460 - [EN] English

Page 13

Issue 1

Table of Contents

Quick reference data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ii

Trademarks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .ii

Safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iii

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .v

Summary of functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vi

About this manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .vii

Table of Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ix

Chapter 1: Instrument parts, accessories and options

1.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.2 The instrument. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.3 The display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1.4 Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Chapter 2: Prepare the instrument

2.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.2 Initial checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.3 Initial procedures. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.4 Power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.5 The battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

2.5.1 Battery condition. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

2.5.2 Install the battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

2.5.3 Charge the battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

2.5.4 Charge times . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

2.5.5 Operating time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

2.6 Power on or off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

2.7 Display operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

2.7.1 Change items in a list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

2.7.2 Change numeric values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

2.7.3 Enter text . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

2.7.4 Maximise/minimise a window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

2.8 Menu sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

2.8.1 Procedure to set the basic operations: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

2.8.2 Procedure to see the instrument status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

2.8.3 Procedures to make Task selections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

2.8.4 Set a function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

2.8.5 Set the units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

2.8.6 Set up a utility:Maximum/Minimum/Average example . . . . . . . . . . . . . . . . . 2-12

[EN] English - K0460 Table of Contents ix

Page 14

Issue 1

2.9 Measure and source operations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

2.9.1 Set the Process options (measure) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

2.9.2 Set the Automation options (source) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

2.9.3 Set the Observed settings (source) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-17

2.10 The Advanced menu options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-18

2.10.1 Advanced: Calibration options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-18

2.10.2 Advanced Setup options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-19

2.11 The Help menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-20

Chapter 3: Electrical and IDOS operations

3.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.2 Measure and source operations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.2.1 Procedure overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.2.2 Example procedure: Measure or source current . . . . . . . . . . . . . . . . . . . . . . 3-2

3.2.3 Example procedure: Measure DC voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

3.2.4 Example procedure: Source DC voltage (CH1) . . . . . . . . . . . . . . . . . . . . . . . 3-3

3.2.5 Example procedure: Measure or source frequency signals . . . . . . . . . . . . . . 3-4

3.2.6 Example procedure: Measure or simulate an RTD (or Resistance) . . . . . . . . 3-5

3.2.7 Example procedure: Measure or simulate a thermocouple (or TC mV) . . . . . 3-6

3.2.8 Example procedure: Switch test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

3.3 Error indications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

Chapter 4: Pressure indicator operation (MC 620-IS)

4.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.2 Parts and assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.2.1 Assembly instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

4.3 Pressure connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

4.3.1 Procedure (to attach external equipment) . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

4.4 Measure pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

4.4.1 Procedure overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

4.4.2 Set-up a Leak Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

4.4.3 Set the pressure module to zero. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

4.4.4 Example procedure: Measure pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

4.5 Error indications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Chapter 5: Instrument communications

5.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5.2 Connect to a computer (USB). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

x Table of Contents K0460 - [EN] English

Page 15

Issue 1

Chapter 6: Datalog operation

6.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

6.2 Set-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

6.3 Data Logging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

6.4 Data handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

Chapter 7: Documenting functions

7.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

7.2 Analysis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

7.3 Run a procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

Chapter 8: HART® device operations

8.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

8.2 About HART . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

8.3 HART Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-7

8.3.1 Power supply from the calibrator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-7

8.3.2 External loop power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-8

8.3.3 Communicator attached to a network. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-9

8.3.4 Failed to find device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-10

Chapter 9: Maintenance procedures

9.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

9.2 Clean the unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

9.3 Replace the batteries. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

Chapter 10: Calibration procedures

10.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-1

10.2 Before starting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-1

10.3 Selection sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-2

10.4 Procedures (CH1/CH2): Current (measure). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-3

10.5 Procedures (CH1/CH2): Current (source) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-3

10.6 Procedures (CH1/CH2): DC mV/Volts (measure). . . . . . . . . . . . . . . . . . . . . . . . . . 10-5

10.7 Procedures (CH1 mV (measure)/Volts (source) . . . . . . . . . . . . . . . . . . . . . . . . . . 10-6

10.8 Procedures (CH1): Frequency (measure/source) . . . . . . . . . . . . . . . . . . . . . . . . . 10-7

10.9 Procedures (CH1): Frequency amplitude (source). . . . . . . . . . . . . . . . . . . . . . . . 10-9

10.10 Procedures (CH1): Resistance (measure) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-10

10.11 Procedures (CH1): Resistance (source) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-11

10.12 Procedures (CH1): TC mV (measure or source) . . . . . . . . . . . . . . . . . . . . . . . . 10-12

10.13 Procedures (CH1): CJ (measure) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-13

10.14 Procedures (CH1): Pressure indicator modules (PM 620-IS). . . . . . . . . . . . . . 10-14

[EN] English - K0460 Table of Contents xi

Page 16

Issue 1

Chapter 11: General specification

11.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-1

Customer service. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Back cover

xii Table of Contents K0460 - [EN] English

Page 17

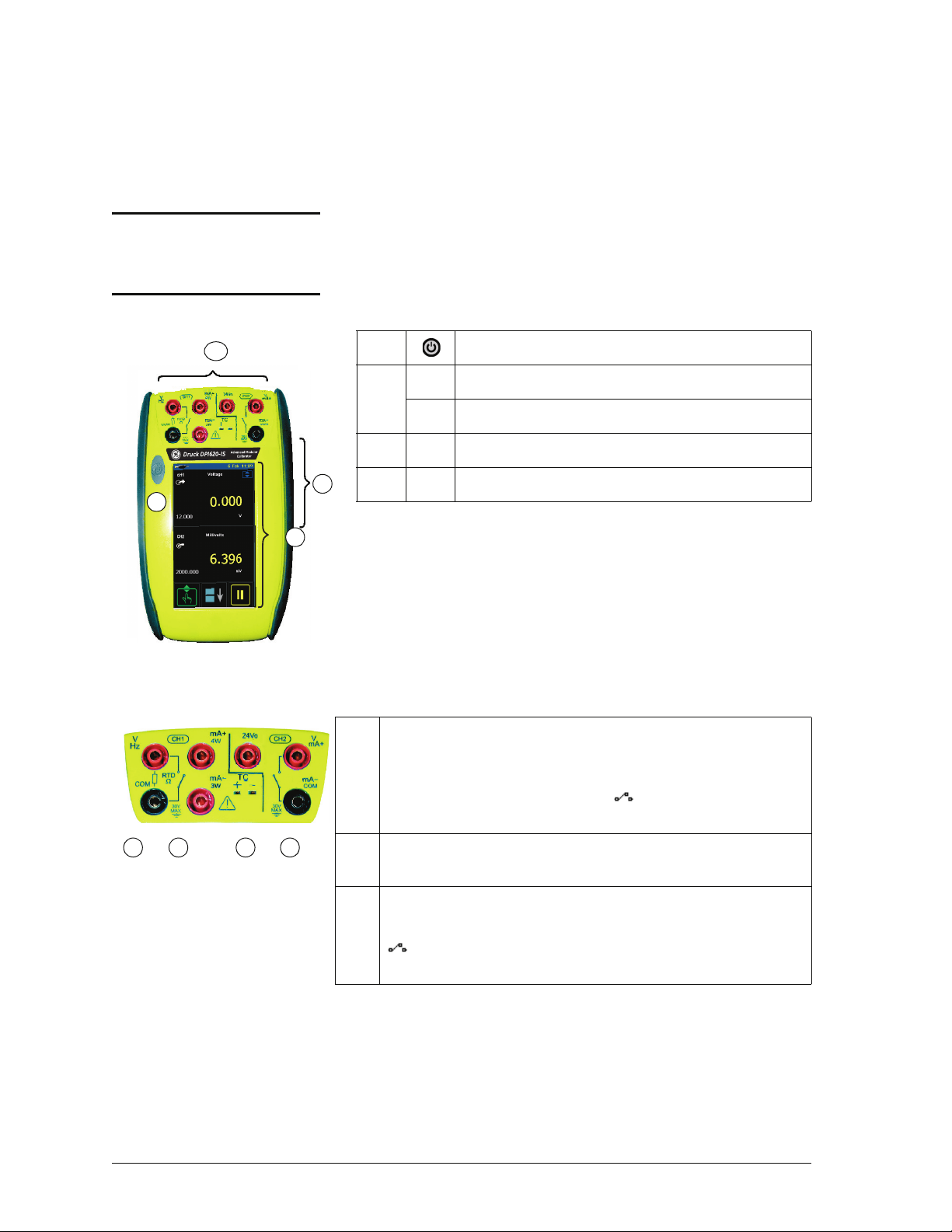

Chapter 1: Instrument parts,

1

2

4

Figure 1-1: General view of

the instrument

3

Figure 1-2: CH1/CH2

connections

2 b ca

accessories and options

1.1 Introduction

1.2 The instrument

This chapter gives a description of the different parts of the

instrument and the accessories/options available.

1. On or off button. Refer to “Quick Reference”.

2. CH1 Connectors for Channel 1

CH2 Connectors channel 2

3. USB Connector.

4. Display screen.

2a Channel 1 (CH1) connectors for:

V: volts/mV DC; Hz: frequency and counts/min, counts/hour

(cpm/cph);

resistance temperature detectors; : switch operation; mA+,

mA-: current. Refer to Chapter 3 (Electrical operations).

2b Channel 1 (CH1) connectors for thermocouples (TC). Refer to

[EN] English - K0460 Instrument parts, accessories and options 1-1

Chapter 3.

2c Isolated channel 2 (CH2) connectors for:

V: volts/mV DC; mA+, mA-: current; 24Vo: 24V loop power supply;

refer to Chapter 8.

Ω: resistance; RTD: 2-wire, 3-wire (3W), 4-wire (4W)

: switch operation; refer to Chapter 3. For HART connections,

Page 18

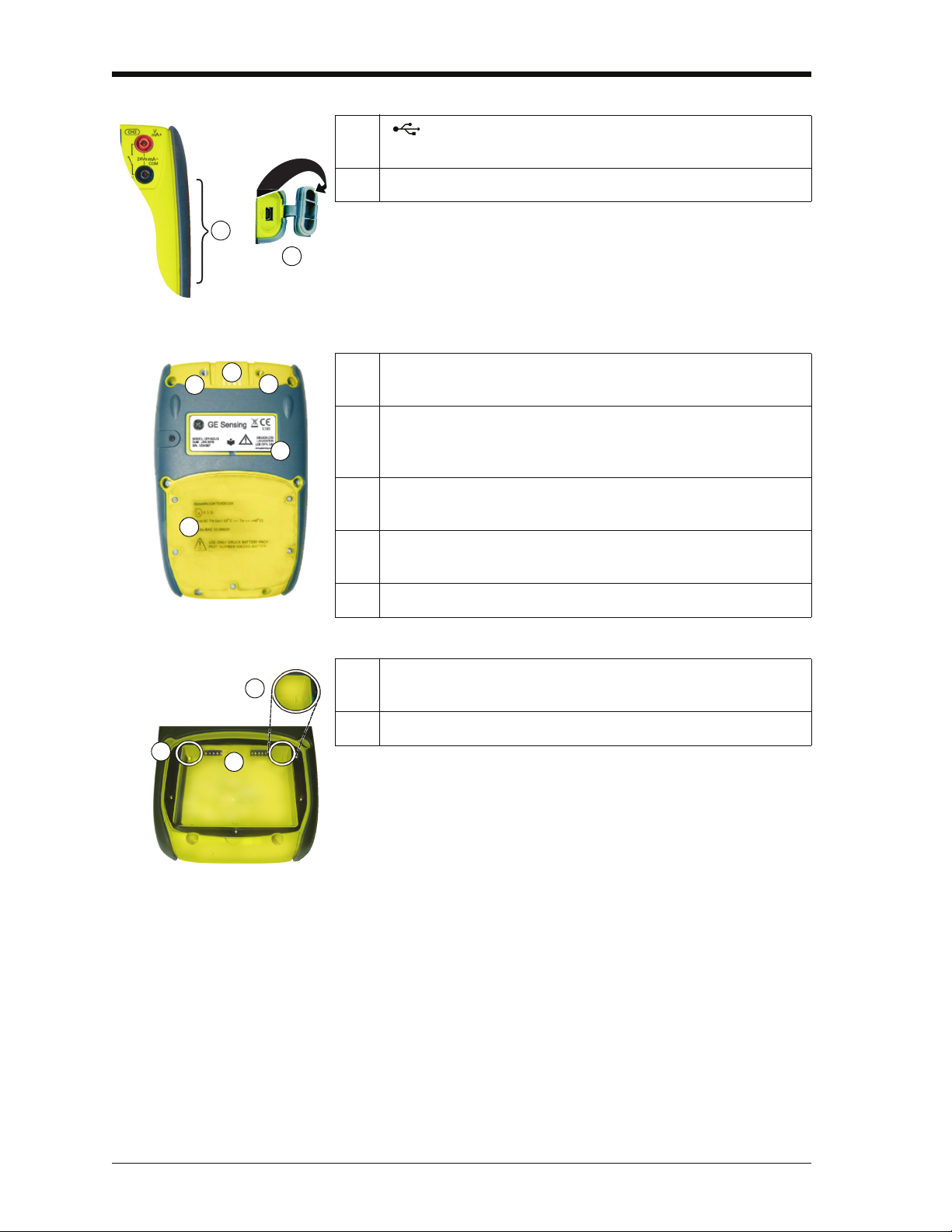

Issue 1

Figure 1-3:

The USB connector

3

5

Figure 1-4: Bottom view

(cover attached)

8

7

6

9

6

Figure 1-5: Bottom view

(cover/battery removed)

11

10

10

3. : USB mini Type B connector for communication with a

computer.

5. Cover for the USB connector (Figure 1-3). For IP65, press it fully

into the recess over the connectors.

6. Two connection points to attach the pressure module carrier

(MC 620-IS); refer to Chapter 4 (Pressure indicator operation

(MC 620-IS)).

7. Electrical connections for the pressure module carrier

(MC 620-IS) or a pressure station (PV 62x-IS).

8. Label: model, date of manufacture (DoM: month/year), serial

number (S/N); manufacturer: name, address, website

9. Compartment cover for the battery.

10. Two position guides for the battery. Refer to Section 2.5.2 (Install

the battery).

11. Electrical connections for the battery.

1-2 Instrument parts, accessories and options K0460 - [EN] English

Page 19

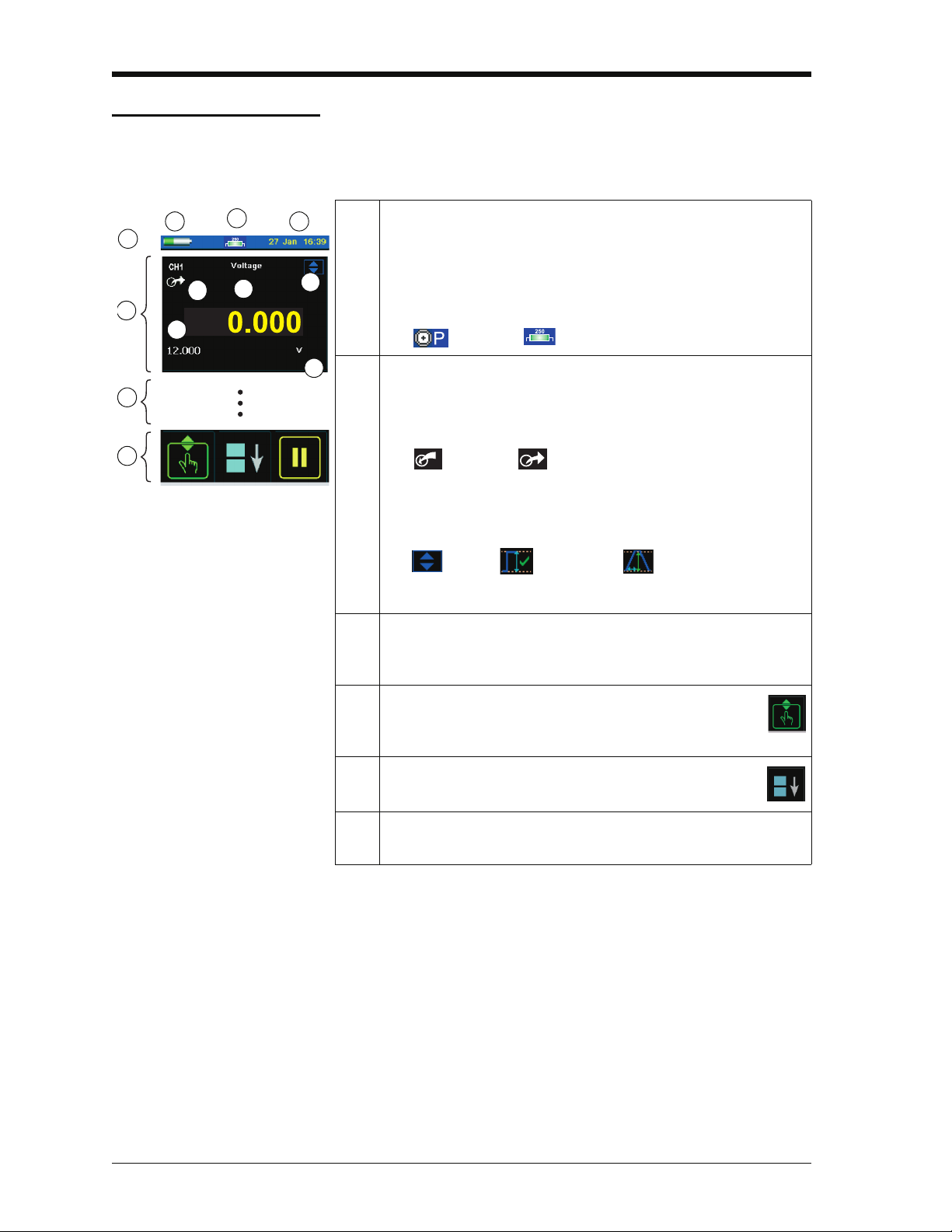

Issue 1

Figure 1-6: Example display

h

b

1

2

4

3

g

a

d

c

e

f

1.3 The display

This is a OLED with a colour display with a touch-screen. To

make a selection, lightly tap on the applicable display area with

a finger; see Section 2.7 (Display operation).

1. Status bar: This includes:

a. Battery indicator b. Date and time

c. Indicators for a Pressure connection, a HART protocol

resistor, Datalog and wireless operation; for example:

: Pressure; : HART

2. CH1: Window for the channel 1 settings and values; see

Section 2.8.1.

d. Measure or source indication:

: Measure; : Source

e. Function (voltage, current, pressure ...)

f. Source process indicator; for example:

: Nudge; : Span check; : Ramp

g. Full scale (FS) range h. Function units

3. Other windows: The number of windows seen on the display is

set by the number of task selections and external modules you

are working with (maximum: 6); see Section 2.7.

4. Tap this button to set up the Task, set up the instrument

(Configure) and to access Help (?). see Section 2.8 (Menu

sequence).

5. Tap this button to maximise each of the available

windows in sequence; see Section 2.7.4

6. Pause (II) or Play (X): Tap (II) to hold (freeze) all the data on the

display. To release the display and continue, tap (X).

[EN] English - K0460 Instrument parts, accessories and options 1-3

Page 20

Issue 1

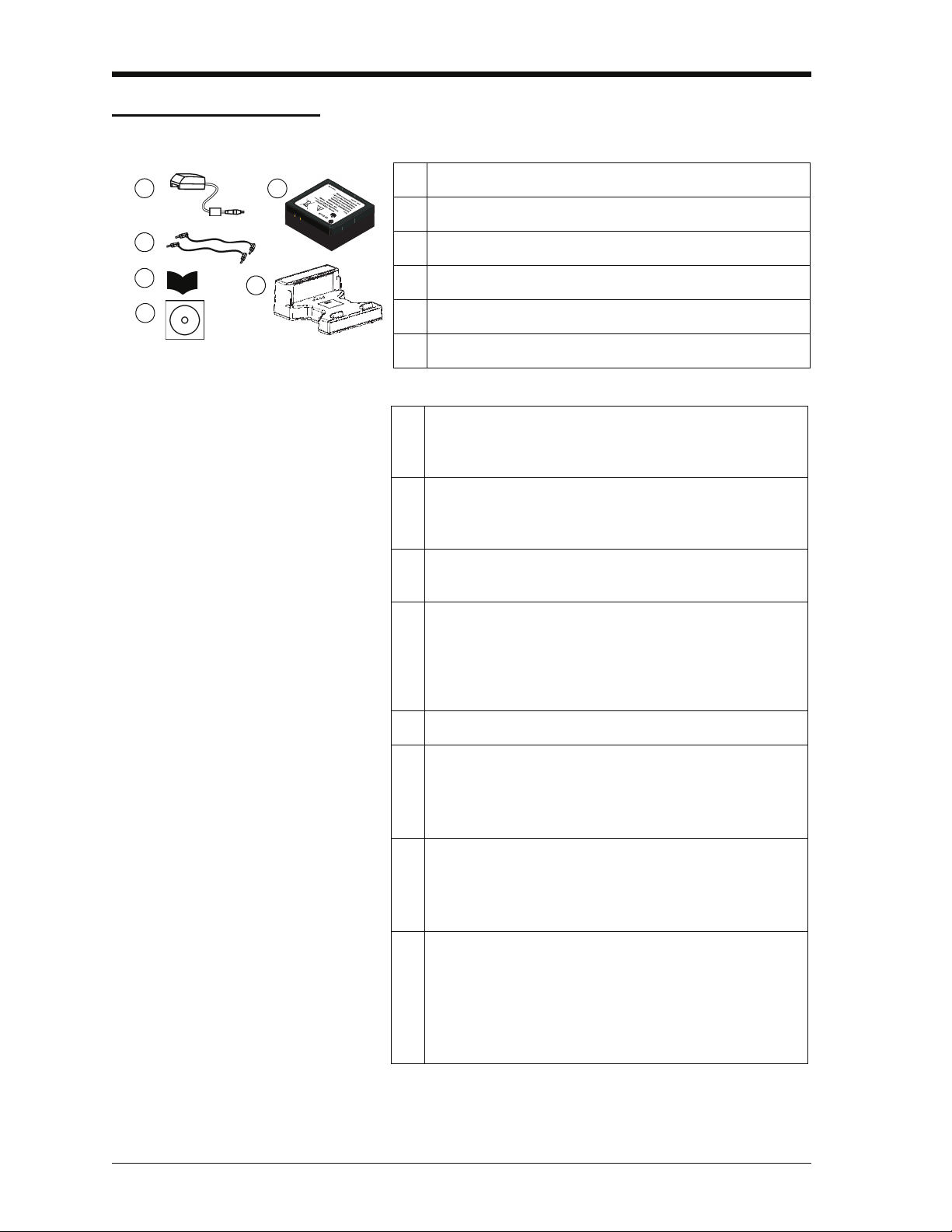

Figure 1-7: Accessories included

1

4

5

2

3

6

1. IO620IS-CHARGER

2. IO620-IS BATTERY. Ni-MH battery

3. 209-539. Set of six electrical test leads

4. K0461. Safety and quick reference guide

5. UD-0004. CD with the user manual

6. IO620IS CRADLE

7. IO620-CASE-1. Fabric carry case with a belt loop,

shoulder strap and a large pocket for accessories. It can

hold one DPI 620-IS calibrator.

8. IO620-CASE-2. Fabric carry case. It can hold a set of

units: one DPI 620-IS calibrator; one MC 620-IS module

carrier; PM 620-IS modules and related accessories.

9. IO620-USB-PC. USB mini Type B cable to connect the

DPI 620-IS calibrator to a computer.

10. IO620-FIELD-CAL. Intecal field calibration manager. Use

the documenting functions in the calibrator with

elements of the Intecal database; set-up new device

records and procedures; upload Intecal data to your

computer database.

11. Pressure modules (PM 620-IS); refer to the datasheet .

12. Pneumatic hose kit rated to 400 bar (5800 psi) with “Quick

fit” connectors for the test port .

IO620-HOSE-P1-IS: 1 metre (≈ 39”)

IO620-HOSE-P2-IS: 2 metre (≈ 78”)

13. Hydraulic hose kit rated to 1000 bar (15000 psi) with

“Quick fit” connectors for the test port .

IO620-HOSE-H1-IS: 1 metre (≈ 39”)

IO620-HOSE-H2-IS: 2 metre (≈ 78”)

14. Pressure adaptor sets designed for the MC 620-IS,

PV 62x-IS and the hose kits:

IO620-BSP: G1/8, G1/4 male; G1/4, G3/8 and G½ female

IO620-NPT: 1/8NPT, ¼NPT male, ¼NPT, 3/8NPT, and

½NPT female

IO620-MET: M14 x 1.5 and M20 x 1.5 female

1.4 Accessories

1-4 Instrument parts, accessories and options K0460 - [EN] English

Page 21

Issue 1

[EN] English - K0460 Instrument parts, accessories and options 1-5

Page 22

Issue 1

1-6 Instrument parts, accessories and options K0460 - [EN] English

Page 23

Chapter 2: Prepare the instrument

2.1 Introduction

2.2 Initial checks

This chapter gives a description of these items:

• the initial checks and procedures

• the available power options

• the battery and related procedures (install and charge)

• the start-up procedures

• the menu structure and options

• the Process and Automation options available for the

measure and source ( )functions

Before using the instrument for the first time:

• Make sure that there is no damage to the instrument, and

that there are no parts missing; see Figure 1-7.

• Remove the plastic film that protects the display. Use the

tag (◗ ) in the top right-hand corner.

2.3 Initial procedures

2.4 Power supply

Before using the instrument for the first time, complete these

procedures:

• Charge the battery (Section 2.5.3).

• Install the fully-charged battery (Section 2.5.2). Then refit

the cover.

• To make sure that the calibration schedule works correctly,

set the date and time; see Section 2.8 (Menu sequence).

This instrument is battery powered:

Ni-MH battery (Section 2.5): All the instrument functions are

available with a fully-charged battery.

[EN] English - K0460 Prepare the instrument 2-1

Page 24

Issue 1

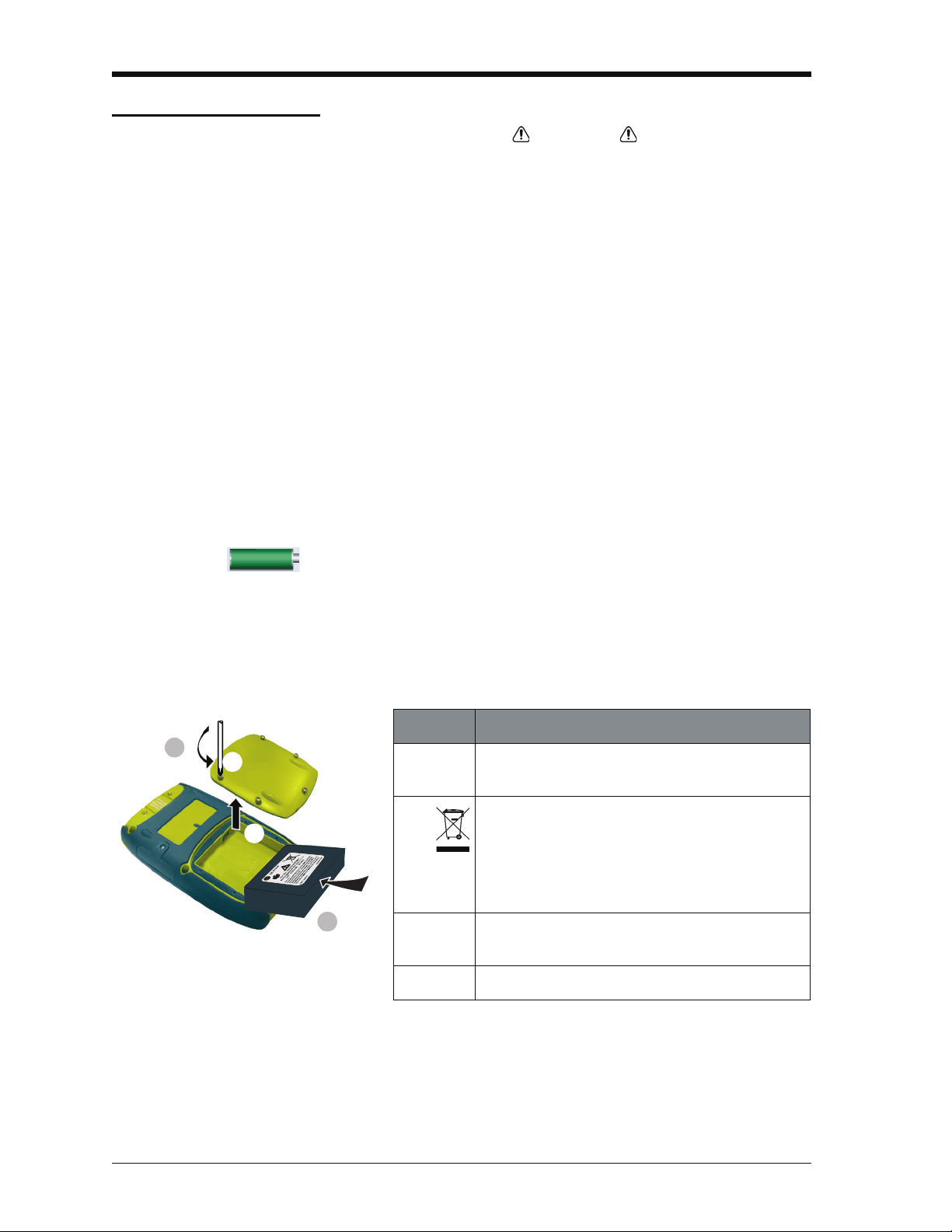

b

2

a

1

Step Procedure

1. When the power is off, loosen the five screws (a)

and remove the cover (b).

If necessary, turn the instrument over and collect

the discharged battery.

If the battery does not hold a charge, discard it

safely. Obey all the local health and safety

procedures.

2. Install the new fully-charged battery in the

compartment .

3. Refit the cover.

2.5 The battery

2.5.1 Battery condition

Charge indications After switching on, the battery symbol at the top of the display

WARNING

• This instrument uses the GE specified, Ni-MH battery

pack. To prevent an explosion or fire, do not short

circuit, do not disassemble, keep it safe from damage.

For operating conditions, see Table 11-1.

• Charge the GE specified battery in a safe area, using the

GE supplied charger and cradle.

• To prevent battery leakage or heat generation, only use

the battery charger and cradle in the temperature range

0 to 40°C (32 to 104°F). For operating conditions, see

Table 11-1.

For a full battery specification, refer to Table 11-1.

On receipt of a new DPI 620-IS calibrator, the battery will be

partly-charged. We recommend that it is fully-charged

(Section 2.5.3).

shows the charge condition in 10% increments.

To get an accurate indication (1% increments), use the

Configuration menu; see Section 2.8.2 (Procedure to see the

instrument status).

2.5.2 Install the battery

2-2 Prepare the instrument K0460 - [EN] English

Page 25

Issue 1

[a]

[b]

[c]

[d]

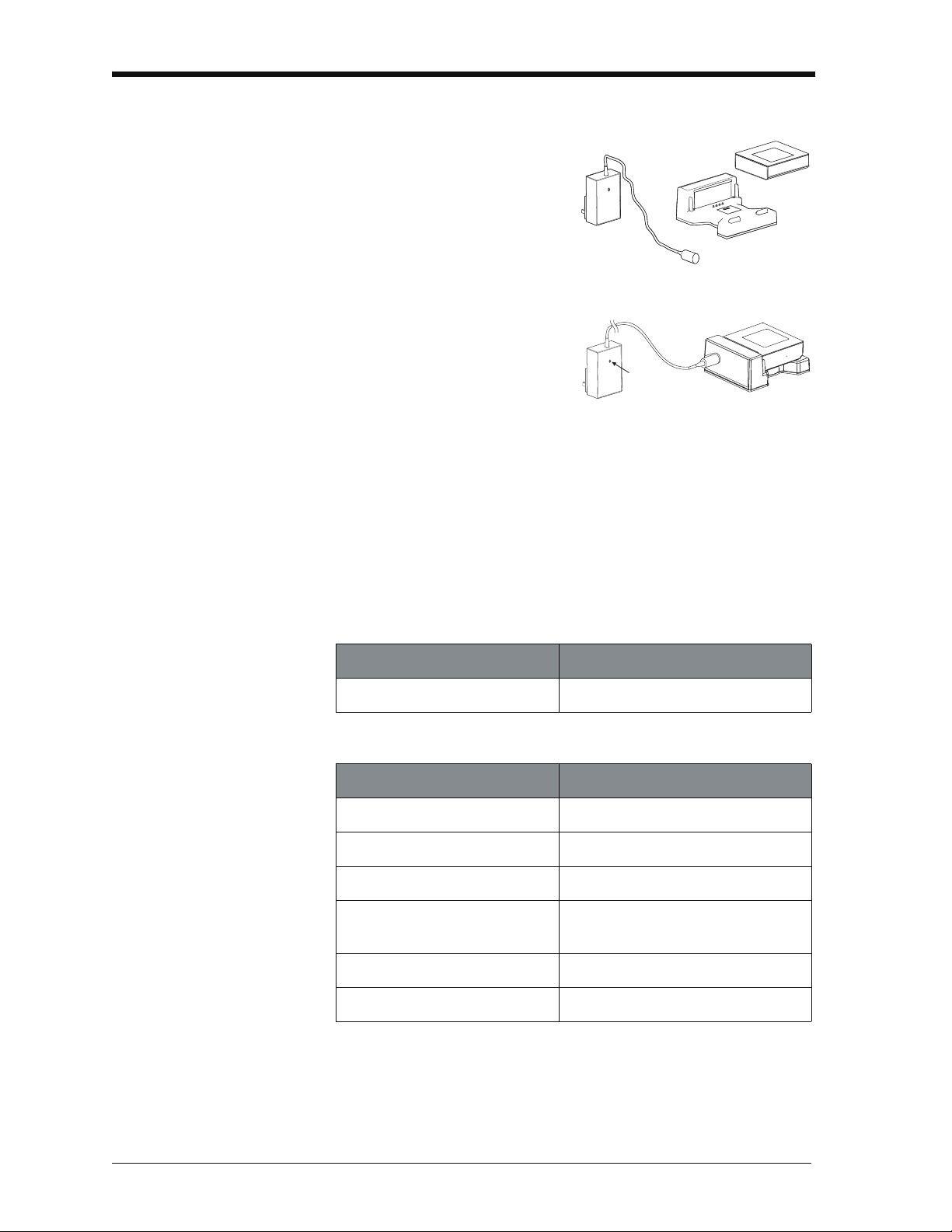

2.5.3 Charge the battery

Fully-charge the battery, using

the charger and cradle, in a

safe area.

• The battery pack [a] (part

number: IO620IS – Battery)

will be partly-charged, it is

recommended to fully

charge the battery pack

before using the instrument:

• Connect the charger [b]

(part number:

IO620IS-Charger) to a

power supply.

• Connect the charger to the cradle [c] (part number:

IO620IS-Cradle).

• Correctly insert the battery into the cradle (making sure the

battery pack label faces upwards).

• The battery charger LED [d] indicates the different charge

states. When the LED shows green the battery pack is

fully-charged and ready to use. The battery pack takes

approximately 8 hours to fully charge.

2.5.4 Charge times

Charge method Charge time (to full capacity)

External battery charger

≈ 6.5 hours

During the charge cycle the charger LED indicator changes

colour:

LED Indicator Mode

Yellow Battery not connected

Yellow Battery initialisation and analysis

Orange Fast charge

Green with intermittent yellow

flash

Green Trickle charge

Alternating orange - green Error

Top-off charge

[EN] English - K0460 Prepare the instrument 2-3

Page 26

Issue 1

TAP

2.5.5 Operating time

Operation Battery duration

Continuous operation (measure) > 10 hours

Continuous operation (measure and

source with loop power on)

These are typical operating times for a new, fully-charged

Ni-MH battery pack with these settings:

> 6 hours

• Backlight Intensity set to 80% (Default: 80%).

• Backlight Timeout set to 2 hours (Default: 2 minutes).

Power save options To get the best battery duration, set a low value for the

Backlight Intensity (40%) and a short Timeout; see

Section 2.8.1 (Procedure to set the basic operations:).

2.6 Power on or off

To set the instrument power on, press and hold this button

down until the display comes on (≈ 2 seconds). During the

power on sequence, the instrument shows a timer and then

shows the applicable data.

To set the instrument power off, press and hold this button.

When the power is off, the last set of configuration options

stays in memory.

2.7 Display operation

This instrument has a touch-screen. To make a selection,

lightly tap on the applicable display area (window, button,

option) with a finger.

Caution: To prevent damage to the display, do not use

sharp objects on the touch-screen.

The number of windows shown on the display is set by the

number of task selections and external modules enabled

(maximum: 6); see Section 2.8.3 (Procedures to make Task

selections).

2-4 Prepare the instrument K0460 - [EN] English

Page 27

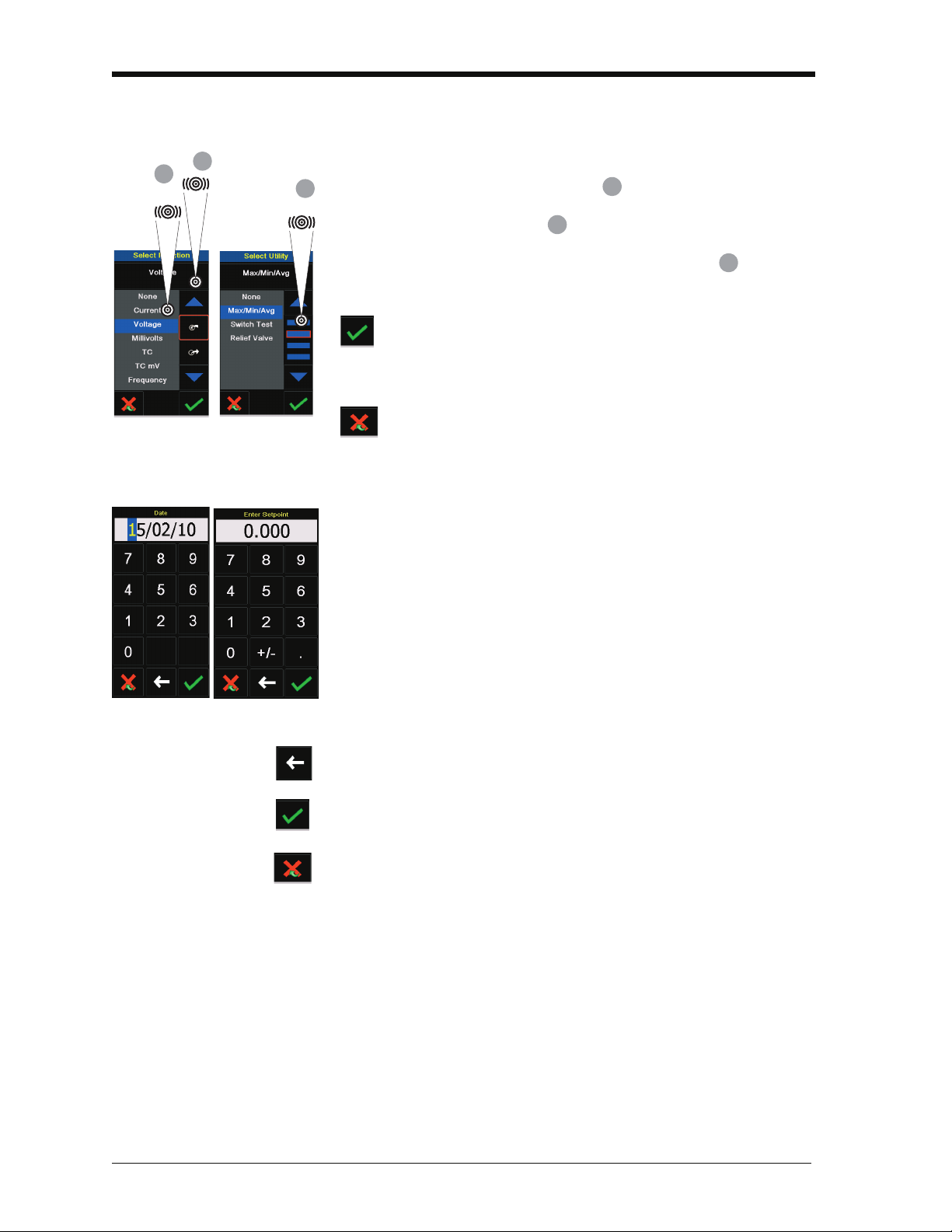

2.7.1 Change items in a list

A

B

C

ABC

2.7.2 Change numeric values

Issue 1

To change an item in a list, you have these options:

• tap on the item you want to use .

• tap on the ▲ or ▼ button .

• tap on one of the horizontal bars beside the list

(if applicable).

Accept: To accept the selection and go back to the

previous display, tap this button. If necessary, tap this

button on all subsequent displays until you get back to

the start.

Cancel: To cancel the selection and go back to the

previous display, tap this button

There are numeric key-pad displays for these items:

• dates and times

• set-point values

• source Automation processes (Nudge, Span Check, ... )

• calibration and other processes

Tap in the necessary value on the key-pad. If applicable, the

key-pad includes the buttons for +/- and decimal point.

Backspace: To go back one character, tap this button. If it is

not a date or time, it deletes the character.

Accept: To accept the specified value and go back to the

previous display, tap this button.

Cancel: To cancel the specified value and go back to the

previous display, tap this button.

[EN] English - K0460 Prepare the instrument 2-5

Page 28

Issue 1

1

2

TAP

Maximise Minimise

*

*

* Alternative options for step ➀

2

1

1

Processes (measure operations )

Automation (source operations )

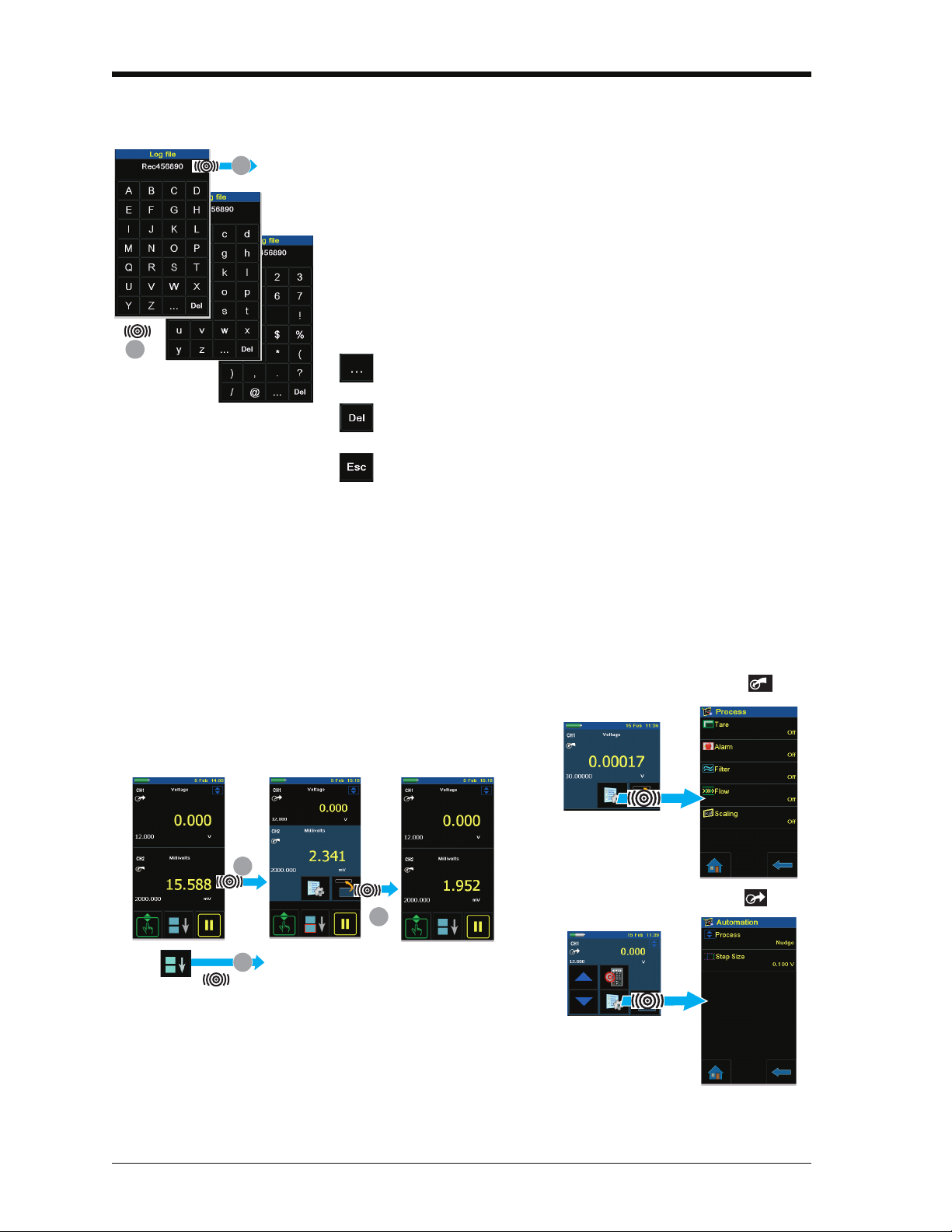

2.7.3 Enter text

There are alphanumeric key-pad displays for these items:

• Captions; see Section 2.8.4 (maximum: 15 characters; all

characters permitted)

• Filenames (maximum: 10 characters; no special characters)

1. Tap in the applicable characters.

2. To accept the data and go back to the previous display, tap

on the completed text in the data entry box.

Next key-pad: To use characters on the next key-pad

(upper case > lower case > numeric), tap this button.

Delete: To delete the last character in the data entry box,

tap this button.

Escape: If there are no characters in the data entry box,

the Esc button replaces the Del button. To leave the

key-pad and go back to the previous display, tap on the

Esc button.

2.7.4 Maximise/minimise a window

There can be up to 6 functions on the display. To set a Process

(measure operations), an Automation option (source

operations), or other Settings maximise the applicable function:

2-6 Prepare the instrument K0460 - [EN] English

Page 29

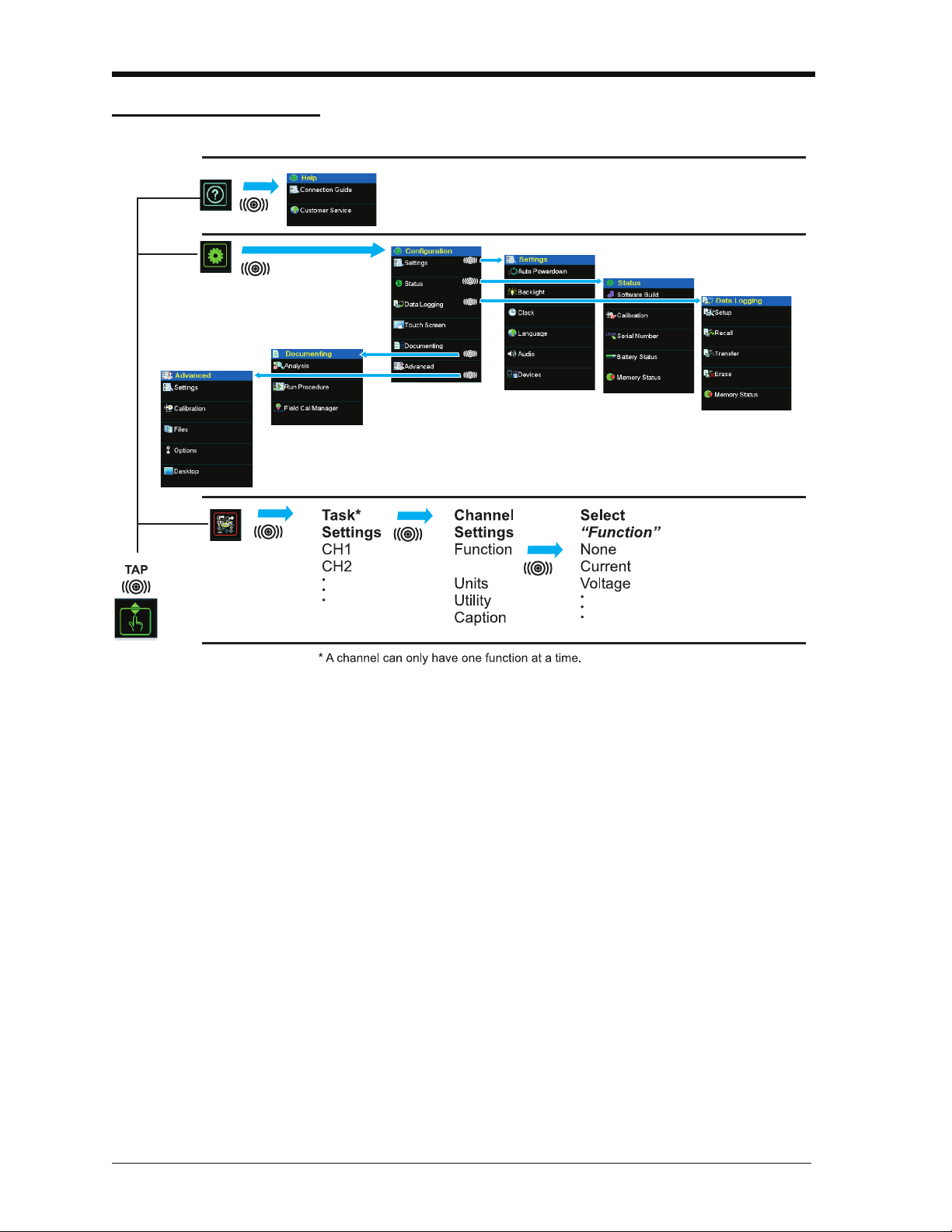

2.8 Menu sequence

Section 2.8.2

Chapter 6

Chapter 7

Section 2.8.1

Section 2.10

†

†

Normally, this is only necessary for versions with the Windows CE operating

system, Touch Screen enables the screen to be calibrated and re-centred.

Issue 1

[EN] English - K0460 Prepare the instrument 2-7

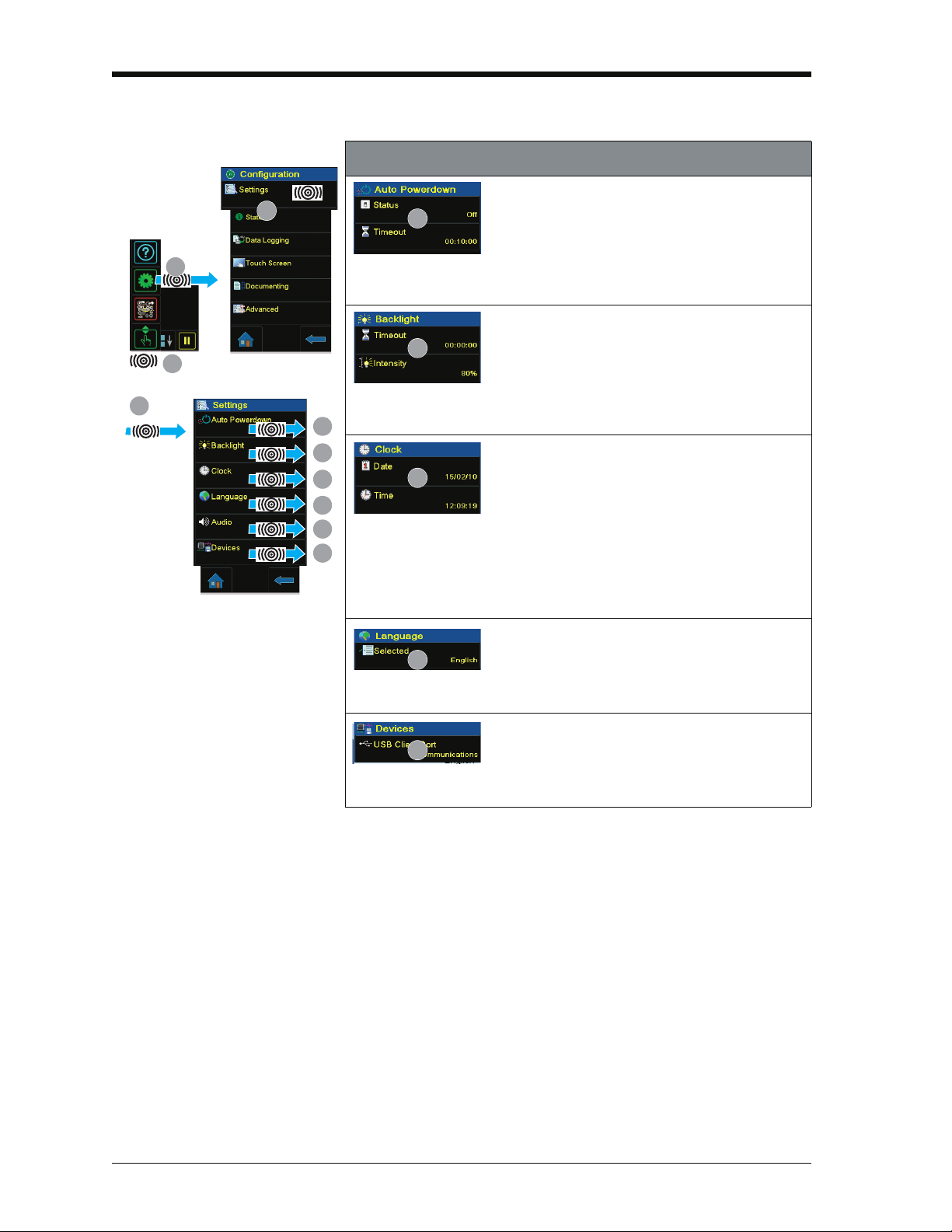

Page 30

Issue 1

TAP

Configuration

2

1

3

Settings

3

B

C

D

E

A

F

A

B

C

D

F

2.8.1 Procedure to set the basic operations:

Description

Status: On or Off

Timeout: 00:02:00 to 01:00:00 hours:minutes:seconds (hh:mm:ss)

Timeout: 00:02:00 to 02:00:00 hours:minutes:seconds (hh:mm:ss)

Intensity: 20, 40, 60, 80, 100%

Sets the power off automatically after the

specified Timeout period. To save the battery

power, set this to On.

Sets the backlight. Low values save battery

power; see Section 2.5.5 (Operating time).

Sets the date and time. The calibration function

uses this to give calibration messages.

Date: day/month/year (dd/mm/yy) OR month/day/year (mm/dd/yy).

The format is factory configured.

Time: 24 hour;

hours:minutes:seconds (hh:mm:ss)

Sets the language.

Selected: English (Other languages to be released).

Sets the communications using the USB port.

Communications: Storage device, communications, active sync.

2-8 Prepare the instrument K0460 - [EN] English

Page 31

2.8.2 Procedure to see the instrument status

TAP

Configuration

2

1

3

Status

The amount of memory available (in MB and as a

% of the total on the device): SD Card (internal).

Charging or battery-powered, and the amount of

charge in 1% increments.

The date of the next calibration.

CH1:

source

CH2:

measure

TAP

2

1

C

B

A

A

2.8.3 Procedures to make Task selections

When first using the calibrator, there are default measure

and source functions on the display:

• CH1 settings: RTD source, RTD type is PT100, scale is °C;

Automation is Nudge; see Chapter 3.

Issue 1

• CH2 settings: Current measure, see Chapter 3.

Procedure Overview Use the Tas k menu to complete these procedures:

• Set the calibrator functions on the display: item ; see

Section 2.8.4.

a. CH1: Channel 1 electrical function: Choose one option:

None Resistance

Current RTD

Voltage CJ

Millivolts Observed*

TC (°C/°F)

TC (mV)

Frequency

b. CH2: Channel 2 electrical function: Choose one option:

None Voltage

Current Millivolts

Current (24V) Observed*

[EN] English - K0460 Prepare the instrument 2-9

Page 32

Issue 1

Note: * Observed (Only

available as a source

option). Use this option to

make a manual record of

the readings on another

instrument; see

Section 2.9.3.

B

Continued

C

c. * Pressure function (P1): for the PV 62x-IS pressure

stations, refer to user manual - K0462; for the MC 620-IS

module carrier, see Chapter 4.

d. * Pressure function (P2): the MC 620-IS module carrier

can use P1 and/or P2; see Chapter 4.

e. HART function: HART device communications; see

Chapter 8.

• If applicable, change the Units for the function: item ;

see Section 2.8.5.

• If applicable, set a Utility for the function: item

a. Max/Min/Avg; see Section 2.8.6.

b. Switch Test: CH1, P1, P2 and IDOS functions use the

CH2 switch connections; CH2 functions use the CH1

switch connections. See Chapter 3.

c. Leak Test (Pressure options only); see Chapter 4.

Note: Making the connections for a switch on CH1 or CH2

means another function cannot be set on that channel.

2-10 Prepare the instrument K0460 - [EN] English

Page 33

2.8.4 Set a function

TAP

Select the function list

(Measure or Source)

Task Settings

Task Se t t i n g sSelect Function Channel Settings

1

2

3

4

97 8

5

Channel Settings

Source

Measure

6

Section 2.8.5

(Units)

Section 2.8.6

(Utility)

Section 2.7.3

(Caption text)

Issue 1

This example shows the sequence to set the Channel 1 (CH1)

function. It is a similar procedure for other functions.

[EN] English - K0460 Prepare the instrument 2-11

Page 34

Issue 1

Channel Settings Task Settings

7 8

TAP

Task Settings

1

2

4

5

6

3

Channel Settings

Channel Settings Task Settings

7

8

TAP

Task Settings

1

2

3

4

Channel Settings

5

6

Press the “reset” button to get a

new set of values.

2.8.5 Set the units

If a function has alternative units, another unit can be set. If

there are no alternatives, the area is shown grey.

2.8.6 Set up a utility: Maximum/Minimum/Average example

This example shows the sequence to set the Max/Min/Avg

utility. Use the same procedure for these options:

• Switch Test; see Chapter 3.

• Leak Test (pressure options only); see Chapter 4.

2-12 Prepare the instrument K0460 - [EN] English

Page 35

Issue 1

1

A

TAP

A

1

B

TAP

B

1

C

C

D

2

1

D

2.9 Measure and source operations

After setting the measure and source functions required on the

display (see Section 2.8.3), these procedures can be set:

• If necessary, change the Process for the CH1 and/or CH2

measure functions (item ) including:

Tar e, Alarm, Filter, Flow, Scaling; see Section 2.9.1.

For more optional Settings for the TC, Frequency, and RTD

functions; see Chapter 3.

• If necessary, change the Automation options for the CH1

and/or CH2 source functions (item ) including:

Nudge, Span Check, Percent Step, Defined Step, Ramp;

see Section 2.9.2.

For more optional Source Settings for the TC, Frequency,

and RTD functions; see Chapter 3.

For other Settings for Observed functions; see

Section 2.9.3.

• If necessary, change the Settings for the pressure function

(item ):

a. Process (Tare, Alarm, Filter, Flow, Scaling); see

Section 2.9.1.

b. Leak Test (Only when the function is set-up with this

Utility - Section 2.8.6); for operation, see Chapter 4.

c. Zero; see Chapter 4.

• If necessary, change the Configuration (item ) including:

Data Logging (Chapter 6), Documenting (Chapter 7), and

Advanced options (Section 2.10).

• When all the software selections are complete, make the

applicable connections (electrical and/or pressure).

Examples:

a. Electrical operations (Chapter 3).

b. Pressure operations with the MC 620-IS module carrier

(Chapter 4).

c. Pressure operations with a PV 62x-IS pressure station

(refer to the user manual - K0462).

[EN] English - K0460 Prepare the instrument 2-13

Page 36

Issue 1

Set the tare to the reading on the display.

Set On or Off.

Shows the stored tare value.

Tap it to set another value.

Previous: Back one display.

Home: Back to start.

1

2

3

TAP

*Set the low alarm value.

Set On or Off.

*Set the high alarm value.

*Default (low/high) = Range limits.

Previous: Back one display.

Home: Back to start

Alarm state

1

2

3

2.9.1 Set the Process options (measure )

Note: Section 2.7 (Display operation) shows how to set and

change the values on the display.

Tar e Use Tare to set a temporary value for zero. This makes an

adjustment to all subsequent readings on the display.

Alarm: When the alarm activates and displays the reading in red.

2-14 Prepare the instrument K0460 - [EN] English

Page 37

Filter: Set the Band and the Time Constant for the low pass filter:

Set the band (%FS). See Definitions.

Set On or Off.

Set the time constant. See Definitions.

Previous: Back one display.

Home: Back to start.

1

2

3

TAP

Set On or Off.

Previous: Back one display.

Home: Back to start.

1

2

3

TAP

Definitions

Band: The filter compares each new value with the

previous value. If the new value is outside the

band, it is not filtered.

Issue 1

Time

Constant:

This sets the cut-off frequency for the filter.

Higher value (in seconds) = more filtering.

Flow: (Square root function)

[EN] English - K0460 Prepare the instrument 2-15

Page 38

Issue 1

Set a scale for

Point 1 and Point 2.

Set On or Off

Set a label name.

Previous: Back one display.

Home: Back to start.

1

2

3

1

TAP

1

TAP

Scaling:

2.9.2 Set the Automation options (source )

Note: Section 2.7 (Display operation) shows how to set and

change the values on the display.

Nudge

Span Check

Description

Process: Nudge; Values to set: Step Size.

Use these buttons to increase or decrease the output

value. Increments = Step size.

Use this button (set-point) to set the output value.

Description

Process: Span Check; Values to set: Low, High, Dwell

Use these buttons to change the value manually from

High to Low.

Use the start and stop buttons to change the value

automatically from High to Low.

Dwell sets the period between each change. The cycle

repeats automatically.

2-16 Prepare the instrument K0460 - [EN] English

Page 39

Percent Step

1

TAP

1

TAP

1

TAP

Defined Step

Issue 1

Description

Process: Percent Step;

Values to set: Low, High, Step Size (%FS), Dwell, Auto Repeat (On/Off).

Use these buttons to change the value manually by the

specified Step Size.

Use the start and stop buttons to change the value

automatically by the specified Step Size.

Dwell sets the period between each change.

Description

Process: Defined Step;

Values to set: Low, High, Step Size, Dwell, Auto Repeat (On/Off).

Use these buttons to change the value manually by the

specified Step Size.

Use the start and stop buttons to change the value

automatically by the specified Step Size.

Dwell sets the period between each change.

Ramp

Description

Process: Ramp;

Values to set: Low, High, Travel, Dwell, Auto Repeat (On/Off).

Use the start and stop buttons for this process. Travel

sets the duration of the Ramp.

Dwell sets the period between each change in direction.

2.9.3 Set the Observed settings (source )

The Observed function is available as a Source on the task

selections: CH1, CH2, P1, P2. To set the Observed function,

see Section 2.8.4.

[EN] English - K0460 Prepare the instrument 2-17

Page 40

Issue 1

2

1

See Section 2.10.1.

Hart On or Off; see Chapter 8. Standards sets

IPTS 68 or ITS 90; see Chapter 3

Lists options installed.

See Section 2.10.2.

3

TAP

Goes back to Windows desktop.

1

TAP

2

2.10 The Advanced menu options

The Advanced menu provides settings and use of options:

• Settings • Calibration

• Files • Options

2.10.1 Advanced: Calibration options

There are two calibration menus that can be used:

Menu to calibrate the

DPI 620-IS

1. Enter the calibration PIN: 4321.

2. Tap the “Accept” button and continue with these operations:

• Calibrate the different measure and source channels on the

DPI 620-IS calibrator.

Contact us at: www.gesensinginspection.com

• Change the calibration PIN and then enable it, confirm the

new PIN.

• Set the next calibration date and/or set the Notification

option. If Notification is On and calibration is overdue, the

display shows “Calibration due ... ” message at the end of

the power on sequence.

2-18 Prepare the instrument K0460 - [EN] English

Page 41

Issue 1

1

TAP

2

Menu to upgrade the

DPI 620-IS software and

To use the most up-to-date software and firmware on the

DPI 620-IS calibrator, visit the GE website:

firmware

Follow the website instructions, use this menu to upgrade:

• Connect the instrument to be upgraded to a PC. Copy the

Note: Make sure the battery is fully-charged before starting the

upgrade process.

2.10.2 Advanced Setup options

FILES

Use this menu to save and recall personal settings, instrument

calibration settings and other standard instrument operations.

Save: After setting up the functions needed on the display

(Section 2.8.3) and all the measure and source operations

(Section 2.9), save the settings to a file.

www.gesensinginspection.com

files to the instrument’s storage memory (make sure the

instrument is in storage mode).

2.11 The Help menu

Recall: To use the specified settings again, select the

applicable filename from the list.

Erase One File: This deletes one file from the list. Confirm the

file to delete.

Clear User Settings: This clears user settings, they are

replaced by default (factory) settings.

Memory Status: The amount of memory available (in MB and

as a % of the total on the device): internal memory; SD card.

The Help menu includes electrical connection diagrams to help

set-up and use the electrical functions on channel 1 (CH1),

channel 2 (CH2).

[EN] English - K0460 Prepare the instrument 2-19

Page 42

Issue 1

2-20 Prepare the instrument K0460 - [EN] English

Page 43

Issue 1

TAP

2

1

A

B

C

Chapter 3: Electrical operations

3.1 Introduction

3.2 Measure and source operations

3.2.1 Procedure overview

This section gives examples of how to connect and use the

instrument for these operations:

• To measure and source electrical values.

Before starting:

• Read and understand the “Safety” section.

• Do not use a damaged instrument.

Note: Use only original parts supplied by the manufacturer.

When using the calibrator for the first time, there are default

measure and source functions on the display; see

Section 2.8.3.

To use the calibrator, complete these procedures:

• Set the required calibrator functions on the display: item

; see Section 2.8.3. This includes:

a. CH1: Channel 1 electrical function (measure or source).

b. CH2: Channel 2 electrical function (measure or source).

c. Pressure function (P1 and/or P2): for the MC 620-IS

module carrier, see Chapter 4; for the PV 62x-IS

pressure stations (P1 only), refer to user manual - K0462.

d. Other functions (maximum: 6 functions).

• If necessary, change the Units for the function: item ;

see Section 2.8.5

• If necessary, set a Utility for the function: item ; see

Section 2.8.6

a. Max/Min/Avg

b. Switch Test

c. Leak Test (pressure options only)

[EN] English - K0460 Electrical operations 3-1

Page 44

Issue 1

1

D

TAP

1

E

TAP

D

E

2

Maximum: 30V

Source current on

channel 1 (CH1)

Range: 0 to 24 mA

Automation: Nudge

(Section 2.9.2)

2

Maximum: 30V

1

B

3

Measure current on

channel 1 (CH1)

Range: ±55 mA

A

1

• If necessary, change the Process for the CH1 and/or CH2

measure functions: item

This includes: Tar e, Alarm, Filter, Flow, Scaling; see

Section 2.9.1.

There are more optional Settings for the TC, Frequency, and

RTD functions.

• If necessary, change the Automation options for the CH1

and/or CH2 source functions: item

This includes: Nudge, Span Check, Percent Step,

Defined Step, Ramp; see Section 2.9.2.

There are more optional Source Settings for the TC,

Frequency, and RTD functions.

There are other Settings for Observed functions; see

Section 2.9.3.

• When all the software selections are complete, make the

applicable electrical connections.

3.2.2 Example procedure: Measure or source current

These examples (A and B) show Channel 1 (CH1) set-up to

measure or source a current with external loop power.

Note: Using Channel 2 (CH2) connectors, use Channel 2 to

measure or source these ranges with internal or external loop

power (internal loop power = 24 V).

3-2 Electrical operations K0460 - [EN] English

Page 45

1. Set the applicable software options; see Section 3.2.1

2

Measure DC millivolts on

channel 1 (CH1)

Range: ±2000 mV (DC)

1

B

Measure DC volts on

channel 1 (CH1)

Range: ±30 V (DC)

A

1

21

3

Source DC volts on

channel 1 (CH1)

Range: 0 to 12 V (DC)

Automation: Nudge

(Section 2.9.2)

A

(Procedure overview).

2. Complete the electrical connections and continue with the

measure or source operation.

3. Source only (Automation): Set the applicable output value;

see Section 2.9.2.

3.2.3 Example procedure: Measure DC voltage

These examples (A and B) show Channel 1 (CH1) set-up to

measure a DC voltage.

Note: Using Channel 2 (CH2) connectors, use Channel 2 to

measure these ranges.

Issue 1

3.2.4 Example procedure: Source DC voltage (CH1)

[EN] English - K0460 Electrical operations 3-3

1. Set the applicable software options; see Section 3.2.1

(Procedure overview).

2. Complete the electrical connections and continue with the

measure operation.

These examples (A and B) show Channel 1 (CH1) set-up to

source a DC voltage.

Page 46

Issue 1

Source DC millivolts on

channel 1 (CH1)

Range: 0 to 2000 mV (DC)

Automation: Nudge

(Section 2.9.2)

B 1

3

2

21

Measure frequency on

channel 1 (CH1)

Range: 0 to 5 kHz

Trigger level: 2.5 V

A

3

Source frequency on

channel 1 (CH1)

Range: 0 to 5 kHz

Waveform: Triangle

Amplitude: 5.0 V

Automation: Nudge

(Section 2.9.2)

2B

4

1

3

A

1. Set the applicable software options; see Section 3.2.1

(Procedure overview).

2. Complete the electrical connections.

3. To continue, set the applicable output value; see

Section 2.9.2.

3.2.5 Example procedure: Measure or source frequency signals

These examples (A and B) show Channel 1 (CH1) set up to

measure or source a frequency. This includes Hz, kHz and

counts (cpm or cph).

The selection of units sets the available range, for example:

Hz = 0 to 1000 Hz kHz = 0 to 5 kHz

3-4 Electrical operations K0460 - [EN] English

Example 1. Set the applicable software options; see Section 3.2.1

(Procedure overview).

2. Complete the electrical connections.

Page 47

3. If necessary, change the Trigger Level (Settings) and

3

B

21

Measure current on

channel 2 (CH2) with

24V loop power

Range: ±55 mA

A

Maximum: 24 mA

Source current on

channel 2 (CH2) with

24V loop power

Range: 0 to 24 mA

Automation: Nudge

(Section 2.11.2)

2B

3

1

continue with the measure operation.

Values to set:

Mode (Automatic/Manual);

Manual Level (trigger level value)

Example 1. Set the applicable software options; see Section 3.2.1

(Procedure overview).

2. Complete the electrical connections.

3. If necessary change the Source Settings and continue with

source operation.

Values to set:

Waveform (Square, Triangle, Sine);

Amplitude (Amplitude value)

4. Automation: Set the applicable output value; see

Section 2.9.2.

Issue 1

3.2.6 Example procedure: Measure or source current (24V loop power)

These examples (A and B) show Channel 2 (CH2) set up to

measure or source a current with 24V loop power.

1. Set the applicable software options; see Section 3.2.1

(Procedure overview).

[EN] English - K0460 Electrical operations 3-5

2. Complete the electrical connections and continue with the

measure or source operation.

3. Source only (Automation): Set the applicable output value;

see Section 2.11.2.

Page 48

Issue 1

21

Measure an RTD on

channel 1 (CH1)

Range: 850 °C

RTD Type: PT100

Connection: 4 wire

A

3

Simulate an RTD on

channel 1 (CH1)

Range: 850 °C

RTD Type: PT100

Connection: 4 wire

Automation: Nudge

(Section 2.9.2)

2B

4

1

3

3.2.7 Example procedure: Measure or simulate an RTD (or Resistance)

These examples (A and B) show Channel 1 (CH1) set-up to

measure or simulate an RTD. A 4-Wire configuration gives the

best accuracy; a 2-Wire configuration has the lowest accuracy

(4-Wire RTD shown).

Note: To measure or simulate resistance (

Resistance function.

Ω), set the

3-6 Electrical operations K0460 - [EN] English

Example A 1. Set the applicable software options; see Section 3.2.1

(Procedure overview).

2. Complete the electrical connections.

3. If necessary change the Settings and continue with the

measure operation.

Values to set:

RTD Type (Set the applicable RTD); see Tabl e A 1 (front

cover) for the available options.

Example B 1. Set the applicable software options; see Section 3.2.1

(Procedure overview).

2. Complete the electrical connections.

Page 49

3. If necessary change the Source Settings and continue with

21

Measure a TC temperature

on channel 1 (CH1)

Range: 1372 °C

TC Type: K Type

Cold Junction: 27.43

A

3

Simulate a TC temperature

on channel 1 (CH1)

Range: 1372 °C

TC Type: K Type

Cold Junction: 38.2

Automation: Nudge

(Section 2.9.2)

2B

4

1

3

source operation.

Automation: Set the applicable output value; see

Section 2.9.2.

Values to set:

RTD Type (Set the applicable RTD); see Tabl e A 1 (front

cover) for the available options.

3.2.8 Example procedure: Measure or simulate a thermocouple (or TC mV)

These examples (A and B) show Channel 1 (CH1) set-up to

measure or simulate a thermocouple temperature.

To measure or simulate TC millivolts, set the TC mV function.

Issue 1

[EN] English - K0460 Electrical operations 3-7

Example A 1. Set the applicable software options; see Section 3.2.1

(Procedure overview).

2. Complete the electrical connections.

Page 50

Issue 1

3. If necessary change the Settings and continue with the

measure operation.

Values to set:

TC Type (Set the applicable TC).

CJ compensation (Mode: Automatic/Manual). Automatic

uses the internal cold junction. Use Manual mode for an

external cold junction.

CJ Value. For Manual mode, set an applicable value. The

value is not used in Automatic mode.

Example B 1. Set the applicable software options; see Section 3.2.1

(Procedure overview).

2. Complete the electrical connections.

3. If necessary, change the Source Settings and continue with

source operation.

Values to set:

TC Type (Set the applicable TC).

CJ compensation (Mode: Automatic/Manual). Automatic

mode uses the internal cold junction. Manual mode uses an

external cold junction.

CJ Value. For Manual mode, set an applicable value. The

value is not used in Automatic mode.

4. Automation: Set the applicable output value; see

Section 2.9.2.

3.2.9 Example procedure: Switch test

CH1, P1, P2 functions use the CH2 switch connections; CH2

functions use the CH1 switch connections.

Switch operation When setting the Switch Test utility on one channel, the

software automatically sets-up the other channel for the switch

connections.

Note: If there is a measure or source function on the switch

connection channel, it is automatically disabled with the screen

message “... Function Disabled”.

An attempt to set a measure or source function on the switch

connection channel, causes a screen message “... Function not

set”.

Example This example shows a thermocouple switch:

3-8 Electrical operations K0460 - [EN] English

Page 51

Issue 1

1

3

2

4

Start/Stop

Closed

Open

Reset

1. Set the applicable software options; see Section 3.2.1

(Procedure overview). This example shows one function:

• Thermocouple (TC) is set to source a temperature. The

Utility is set to Switch Test. The Automation is set to Ramp;

see Section 2.9.2.

2. Complete the electrical connections. Because it is a

Channel 1 function (TC), Channel 2 (CH2) must have the

switch connections.

3. For the Ramp process, set “High” and “Low” values that are

applicable to the switch value. Then, to get an accurate

switch value, set a long “Travel” period.

Use Start/Stop to start and stop the “Ramp” cycle. If

necessary, supply the output values in the opposite direction

until the switch changes condition again.

4. The display shows:

• the values to open and close the switch

• the hysteresis value

5. To do the test again, use the reset button.

[EN] English - K0460 Electrical operations 3-9

Page 52

Issue 1

3.3 Error indications

<<<<< Under range: The display shows this symbol for this condition:

>>>>> Over range: The display shows this symbol for this condition:

If the display shows <<<< (under range) or >>>> (over range):

• Make sure that the range is correct.

• Make sure that all the related equipment and connections

are serviceable.

Reading < Negative FS - (10% of negative FS).

Reading > Positive FS + (10% of positive FS).

3-10 Electrical operations K0460 - [EN] English

Page 53

Chapter 4: Pressure indicator

Caution: To prevent damage to the PM 620-IS, use

within the specified pressure limit on the label.

1

2

3

4

1

2

3

b)

a) MC 620-IS

5

a

1. Pressure connection (G1/8 or 1/8NPT) to attach

external pressure equipment.

2. Pressure and electrical connections for a pressure

module (PM 620-IS). These are self-sealing

pressure connections.

3. Two screws to attach the calibrator (DPI 620-IS).

4. Electrical connections for the calibrator

(DPI 620-IS).

5. Pressure module (PM 620-IS) with a pressure

connection, reference port (a) and a label. The

label includes:

Pressure range. Example: 20 bar g (g: gauge;

a: absolute); serial number (S/N); manufacturer:

name, address, website.

operation (MC 620-IS)

4.1 Introduction

4.2 Parts and assembly

This section gives examples of how to connect and use the

instrument to measure pressure with the module carrier

(MC 620-IS) and the applicable pressure modules (PM 620-IS).

To measure pressure with the IDOS UPM, refer to Chapter 3.

To make a fully integrated pressure calibrator instrument with

one of the three pressure stations, refer to the user manual for

the PV 62x-IS series of pressure stations - K0462

Before starting:

• Read and understand the “Safety” section.

• Do not use a damaged instrument.

Note: Use only original parts supplied by the manufacturer.

This figure shows the parts of the module carrier (MC 620-IS)

and pressure module (PM 620-IS).

[EN] English - K0460 Pressure indicator operation (MC 620-IS) 4-1

After attaching these items to the DPI 620-IS calibrator, a fully

integrated pressure indicator is formed that can measure

pneumatic or hydraulic pressure.

Page 54

Issue 1

a

b

4

3

2

1

Step Procedure

1. Align the two slots (a) on the calibrator with the two

posts (b) on the module carrier.

2. When the posts are fully engaged in the slots,

tighten the two screws until they are hand-tight.

3. Attach one or two PM 620-IS modules with the

correct range and type.

4. Tighten each one until it is hand tight only.

When this symbol flashes at the top of the display, it

shows there is communication between the module

and the calibrator.

1

2

NPT

a.

c.

(G) / BSPP

P ≤ 100 bar

b.

(G) / BSPP

3

4.2.1 Assembly instructions

4.3 Pressure connections

4.3.1 Procedure (to attach external equipment)

4-2 Pressure indicator operation (MC 620-IS) K0460 - [EN] English

WARNING: Pressurized gases and fluids are dangerous.

Before attaching or disconnecting pressure equipment,

safely release all the pressure.

The pressure ports for external equipment use “Quick fit”

pressure adaptors; see

Section 1.4 (Accessories). These are

easy to remove, change and install.

Step Procedure

1. Remove the adaptor from the pressure port.

2. Use an applicable seal for the pressure connection:

a. NPT type: Use an applicable sealant on the thread.

b. BSP (parallel) type: A bonded seal at the bottom is

recommended.

c. BSP (parallel) type, 100 bar (1500 psi) or less: a

bonded seal at the top is permitted.

3. Attach the adaptor to the external equipment; if

necessary use one of the alternative adaptors in

Section 1.4 (Accessories), then tighten to the applicable

torque.

Continued

Page 55

Step Procedure

4

TAP

2

1

3

A

3

C

B

A

B

C

1

D

D

4. Re-attach the adaptor to the MC 620-IS carrier and

tighten it until it is hand tight only.

Issue 1

4.4 Measure pressure

4.4.1 Procedure overview

When the pressure indicator assembly is complete

(Section 4.2.1), use the menus to set-up the necessary

operations.

To use the pressure indicator, complete these procedures:

• Set the calibrator functions to use on the display; see

Section 2.8.3. This includes:

a. Pressure function (P1 and/or P2): item .

b. CH1: Channel 1 electrical function (measure or source).

c. CH2: Channel 2 electrical function (measure or source).

d. Other functions (maximum: 6 functions).

• If necessary, change the Units for the function: item ;

see Section 2.8.5.

• If necessary, set a Utility for the function: item ; see

Section 2.8.6.

a. Max/Min/Avg

b. Switch Test

c. Leak Test; see Section 4.4.2.

• If necessary, change the Settings for the pressure function:

item .

a. Process (Tare, Alarm, Filter, Flow, Scaling);

see Section 2.9.1.

b. Leak Test (Only when the Utility is set); see

Section 4.4.2.

c. Zero Recommend - zero a gauge sensor before use; see

[EN] English - K0460 Pressure indicator operation (MC 620-IS) 4-3

Section 4.4.3.

d. Display If necessary, change the number of digits in the

display reading.

Page 56

Issue 1

1

3

4

Select Leak Test Select Test Time

Steps 5 and 6: Set the Test Time

+ Set the Wait Time.

TAP the window

(Maximise)

Select Settings

5

6

7

Start the test and let it

complete.

Go back to the Home window. Start the test

when the pressure system is set-up.

Stop the test (with no results)

2

4.4.2 Set-up a Leak Test

1) Set the Utility Set the Utility to Leak Test (Section 2.8.6).

• When all the software selections are complete, make the

applicable pressure and electrical connections. Examples:

Measure pressure (Section 4.4.4).

2) Set the Leak Test

options

When setting the Utility to Leak Test, set these options:

Wait Time: The time before the test starts in

hours:minutes:seconds (hh:mm:ss).

Test Time: The period of the leak test in

hours:minutes:seconds (hh:mm:ss).

Note: To set the Leak Test options, have a pressure module

correctly installed (Section 4.2.1).

4-4 Pressure indicator operation (MC 620-IS) K0460 - [EN] English

Page 57

4.4.3 Set the pressure module to zero

1

3

4

Select Zero

TAP the window

(Maximise)

Select Settings

5

Accept the adjustment value

Go back to the Home window.

2

See the new reading

p1

p2

p1

p2

P2

P1

31 2

Use this option to write a new zero pressure value to the

pressure module.

The sensor adjustment is permitted if it obeys this condition:

Adjustment ≤ 10% FS positive pressure value

Note: To make a temporary adjustment for zero, use the Tare

function; see Section 2.9.1.

Issue 1

(for the Sensor)

4.4.4 Example procedure: Measure pressure

[EN] English - K0460 Pressure indicator operation (MC 620-IS) 4-5

Page 58

Issue 1

1. Assemble the pressure indicator with the correct PM 620-IS

modules; see Section 4.2.1.

2. Set the applicable software options; see Section 4.4.1

(Procedure overview). This example shows two pressure

functions:

• Pressure functions P1 and P2 are set-up.

3. To attach the external equipment, see Section 4.3.1.

4.5 Error indications

<<<<< Under range: The display shows this symbol for this condition:

>>>>> Over range: The display shows this symbol for this condition:

If the display shows <<<< (under range) or >>>> (over range):

• Make sure that the range is correct.

• Make sure that all the related equipment and connections

are serviceable.

Reading < Negative FS - (10% of negative full-scale).

Reading > Positive FS + (10% of positive full-scale).

4-6 Pressure indicator operation (MC 620-IS) K0460 - [EN] English

Page 59

Chapter 5: Instrument

1

2

4

3

Step Procedure

1. Start the computer.

2. On the right-hand side of the instrument

(Figure 1-3), use the rubber recess to pull down

the cover for the connections.

3. Push the mini Type B end of the USB cable into

the USB socket on the instrument.

4. Set the instrument power on.

communications

5.1 Introduction

5.2 Connect to a computer (USB)

This chapter gives a description of these items:

• the procedures to connect the instrument to a computer with

the optional USB mini Type B cable.

For a full list of optional accessories, refer to Section 1.4.

A USB mini Type B connector connected between the

instrument and a computer can be used to download or upload

data to the SD card, see Chapter 6 (Datalog operation).

Note: If the power supply fails, the data will not transmit

correctly.

When the connections are complete, files can be moved

between the computer and the DPI 620-IS calibrator using

normal file manager software (for example, Windows Explorer).

[EN] English - K0460 Instrument communications 5-1

Note: The computer can get access to the internal memory of

the DPI 620-IS calibrator by using Active Sync.

Page 60

Issue 1

5-2 Instrument communications K0460 - [EN] English

Page 61

Chapter 6: Datalog operation

6.1 Introduction

6.2 Set-up

This section gives examples of how to log measurements with

time and date over a set time period or on a key press. Logged

data is stored in a user defined file. The instrument logs all the

tasks currently enabled.

Stores this data internally but can be downloaded (transferred)

through the mini Type B USB serial port. The data transfer to

the PC uses Active Sync.

To enter data logging select configuration menu and press data

logging.

To set the data logging process:

Selection Action

Filename Enter name using three-page screen alpha/numeric

key-pad.

Trigger Set to Key Press to activate on pressing of bottom

right key or Periodic set to activate on time set in

period.

Period Sets the time period of data recording using numeric

keys and HH:MM:SS format.