Page 1

User Manual Druck DPI620 Genii

GE Measurement & Control

Druck DPI 620 Genii

Advanced Modular Calibrator

K0541

© 2014 General Electric Company. All Rights Reserved. Specifications are

subject to change without notice. GE is a registered trademark of General

Electric Company. Other company or product names mentioned in this

document may be trademarks or registered trademarks of their respective

companies, which are not affiliated with GE

Page 2

User Manual Druck DPI620 Genii

Contents

1 Overview ................................................................................................................... 9

1.1 Equipment in the Box ........................................................................................ 9

1.2 Optional Items ................................................................................................ 10

1.3 Observance of the User Manual .................................................................... 10

1.4 General Safety Precautions ............................................................................. 11

1.5 General Warnings ........................................................................................... 12

1.6 Electrical warnings .......................................................................................... 13

1.7 Pressure Warnings .......................................................................................... 16

1.8 Preparing the Instrument ............................................................................... 17

1.9 Install the Battery ............................................................................................ 17

1.10 Charge the Battery .......................................................................................... 19

Battery Charging Times ........................................................................... 19 1.10.1

1.11 Basic Modes .................................................................................................... 20

Power On ................................................................................................ 20 1.11.1

Power Off ................................................................................................ 20 1.11.2

Power up from Standby Mode ................................................................ 21 1.11.3

1.12 Druck DPI 620 Genii, Modes ........................................................................... 22

Dashboard navigation ............................................................................. 23 1.12.1

Set Date, Time and Language ................................................................. 24 1.12.2

Themes .................................................................................................... 24 1.12.3

Druck DPI 620 Genii Manual ................................................................... 24 1.12.4

Alarm Status ............................................................................................ 24 1.12.5

................................................................................................................................ 24

28 April 2014 K0541 issue 2 Page 2 of 200

Page 3

User Manual Druck DPI620 Genii

To View Alarms select: ................................................................................................ 25

1.13 Software and Firmware Upgrades .................................................................. 26

Viewing Software Revision ...................................................................... 26 1.13.1

Upgrading the Software .......................................................................... 26 1.13.2

1.14 Maintenance ................................................................................................... 31

Cleaning ................................................................................................... 31 1.14.1

1.15 Instrument Return .......................................................................................... 32

Returned Material Procedure for USA .................................................... 32 1.15.1

Returned Goods Procedure for Europe .................................................. 33 1.15.2

Instrument Disposal in the European Union ........................................... 34 1.15.3

1.16 Packaging for Storage or Transportation ........................................................ 35

Environment............................................................................................ 35 1.16.1

1.17 Marks and Symbols ......................................................................................... 35

2

Electrical

Operations

............................................................................................... 36

2.1 Basic Calibrator Operation .............................................................................. 36

Saving Tasks ............................................................................................ 37 2.1.1

Electrical Tasks ........................................................................................ 38 2.1.2

Favourites ................................................................................................ 40 2.1.3

Custom Task ............................................................................................ 41 2.1.4

2.2 Set the Function Utility Options ...................................................................... 44

Max/Min ................................................................................................. 44 2.2.1

Switch Test .............................................................................................. 45 2.2.2

Relief Valve.............................................................................................. 46 2.2.3

2.3 Measurement Display Options ....................................................................... 48

2.4 Example Procedure: Measure or Source Current ........................................... 50

2.5 Example Procedure: Measure DC Voltage ...................................................... 51

28 April 2014 K0541 issue 2 Page 3 of 200

Page 4

User Manual Druck DPI620 Genii

2.6 Example Procedure: Measure AC Voltage (CH1), 0 to 20 Vrms Only ............. 52

2.7 Example Procedure: Measure AC Voltage (CH1) with the AC Probe .............. 53

2.8 Example Procedure: Source DC Voltage (CH1) ............................................... 54

2.9 Example Procedure: Measure or Source Current with 24V Loop ................... 55

2.10

Example Procedure:

Measure or Source Frequency

Signals

........................... 57

2.11 Example Procedure: Measure/Simulate a Resistance Temperature Detector

(RTD) 59

2.12 Example Procedure: Measure or Simulate a Thermocouple (TC) ................... 61

2.13 Example Procedure: Switch Test ..................................................................... 63

2.14 Measure Pressure: IDOS Option ..................................................................... 66

IDOS Option Assembly Instructions ........................................................ 67 2.14.1

IDOS Function Procedures ...................................................................... 68 2.14.2

2.15 Error Indications .............................................................................................. 69

3 Pressure Indicator Operation (MC620) ................................................................... 70

3.1 Parts and Assembly ......................................................................................... 71

Assembly Instructions ............................................................................. 73 3.1.1

3.2 Pressure Connections ..................................................................................... 74

Procedure (Attaching External Equipment) ............................................ 74 3.2.1

3.3 Procedure Overview ....................................................................................... 76

3.4 Set up a Leak Test ........................................................................................... 79

3.5 Set the Pressure Module to Zero .................................................................... 81

3.6 Error Indications .............................................................................................. 82

4 Data Logging Operation .......................................................................................... 83

4.1

Set-up

.............................................................................................................. 85

4.2 Operation ........................................................................................................ 87

4.3 File Review ...................................................................................................... 87

28 April 2014 K0541 issue 2 Page 4 of 200

Page 5

User Manual Druck DPI620 Genii

4.4 Chart View ....................................................................................................... 88

4.5 File Management ............................................................................................ 89

Transfer ................................................................................................... 89 4.5.1

Erase ........................................................................................................ 90 4.5.2

Memory Status ........................................................................................ 90 4.5.3

4.6 Data

Format .................................................................................................... 91

5 Documentation ....................................................................................................... 92

5.1 Analysis ........................................................................................................... 92

5.2

Set-up

.............................................................................................................. 94

Define the Reference Channel ................................................................ 95 5.2.1

Define each Input Channel ...................................................................... 96 5.2.2

5.3 Analysis Function ............................................................................................ 98

5.4 Run Procedure ................................................................................................ 99

Sequence to Upload and Download File ............................................... 100 5.4.1

6 HART® Operations ................................................................................................. 101

6.1 HART® Menu Operations .............................................................................. 101

6.2 Start-up ......................................................................................................... 102

6.3 HART® Connections....................................................................................... 103

6.4 Power Supply from the Calibrator ................................................................ 103

6.5 External Loop Power ..................................................................................... 104

6.6 Communicator Attached to a Network ......................................................... 105

6.7 Use of Test Connections ............................................................................... 105

6.8 Viewing Primary Variables ............................................................................ 106

Device Polling ........................................................................................ 106 6.8.1

Viewing HART® Configuration ............................................................... 107 6.8.2

6.9 Start HART® SDC Application ........................................................................ 107

28 April 2014 K0541 issue 2 Page 5 of 200

Page 6

User Manual Druck DPI620 Genii

6.10 HART® Toolbar .............................................................................................. 110

6.11 Data Display .................................................................................................. 111

6.12 Editing Values ................................................................................................ 112

6.13 Executing Methods ....................................................................................... 114

Method Example - Self-test .................................................................. 115 6.13.1

Method Example - Analog Trim ............................................................ 116 6.13.2

6.14 Preferences ................................................................................................... 118

6.15 Failed to find Device ..................................................................................... 119

7 HART® Offline ........................................................................................................ 120

7.1 Introduction .................................................................................................. 120

7.2 Start-up ......................................................................................................... 120

7.3 Start HART® Offline ....................................................................................... 121

7.4 Create an Offline Configuration .................................................................... 122

Connected Configuration ...................................................................... 123 7.4.1

Disconnected Configuration ................................................................. 124 7.4.2

7.5 Edit an Offline Configuration ........................................................................ 125

7.6 Saving the Configuration ............................................................................... 127

7.7 Uploading the Configuration ........................................................................ 128

7.8 Working with Saved Configurations ............................................................. 128

Open HART Config ................................................................................. 128 7.8.1

Upload Config to Device ....................................................................... 128 7.8.2

Copy HART Config to USB ..................................................................... 128 7.8.3

Delete HART Config ............................................................................... 129 7.8.4

7.9 Further Operations ....................................................................................... 129

Delete All Configuration Files ................................................................ 129 7.9.1

Import Configuration Files from USB Memory stick ............................. 129

.2

28 April 2014 K0541 issue 2 Page 6 of 200

7.9

Page 7

User Manual Druck DPI620 Genii

8 Foundation™ Fieldbus ........................................................................................... 130

8.1 Introduction .................................................................................................. 130

8.2 Start up .......................................................................................................... 130

8.3 FOUNDATION™ Fieldbus Toolbar ................................................................. 133

8.4 Scanning For Devices .................................................................................... 135

Context Sensitive Menu ........................................................................ 137 8.4.1

Troubleshooting .................................................................................... 139 8.4.2

8.5 Device Focus View ......................................................................................... 140

8.6 The Navigation Menu Tree ........................................................................... 142

7.6.1 Block Header bar .......................................................................... 143 8.6.1

8.7 Functional Group View ................................................................................. 144

Displaying Parameter Help.................................................................... 146 8.7.1

Refreshing Data ..................................................................................... 147 8.7.2

Editing Values ........................................................................................ 148 8.7.3

Methods ................................................................................................ 149 8.7.4

8.8 Function Finder ............................................................................................. 150

8.9 Exporting Data to Main Genii Application .................................................... 152

Viewing Exported Variables in Channel Window .................................. 154 8.9.1

8.10 My Block ........................................................................................................ 155

8.11 Application Settings ...................................................................................... 157

Device Library ........................................................................................ 157 8.11.1

Options .................................................................................................. 158 8.11.2

Advanced .............................................................................................. 159 8.11.3

9 Calibration Procedures ......................................................................................... 160

9.1 Before Starting .............................................................................................. 160

9.2 Procedures (CH1/CH2): Current (measure) .................................................. 163

28 April 2014 K0541 issue 2 Page 7 of 200

Page 8

User Manual Druck DPI620 Genii

9.3 Procedures (CH1/CH2): Current (source) ..................................................... 166

9.4 Procedures (CH1/CH2): DC mV/Volts (measure) .......................................... 168

9.5 Procedures (CH1): DC mV/Volts (source) ..................................................... 170

9.6 Procedures (CH1): Frequency (measure/source) ......................................... 172

9.7 Procedures (CH1): Frequency Amplitude (source) ....................................... 178

9.8 Procedures (CH1): Resistance measure) ....................................................... 180

9.9 Procedures (CH1): True Ohms (measure) ..................................................... 182

9.10 Procedures (CH1): Resistance (source) ......................................................... 183

9.11 Procedures (CH1): TC mV (measure or source) ............................................ 185

9.12 Procedures (CH1): Cold Junction (TC method) and CJ (measure) ................. 187

9.13 Procedures (CH1): AC mV/Volts (measure) .................................................. 190

9.14 Procedures: Pressure Indicator Modules (PM 620) ...................................... 192

9.15 Procedures: IDOS UPM ................................................................................. 195

10 General Specification ........................................................................................ 196

10.1 Introduction .................................................................................................. 196

11 Manufacturer .................................................................................................... 199

12 Display Icons ..................................................................................................... 200

28 April 2014 K0541 issue 2 Page 8 of 200

Page 9

User Manual Druck DPI620 Genii

1 Overview

The Druck DPI620 Genii is a battery-powered instrument

for electrical measure and source operations and HART®

communications. The Druck DPI620 Genii also supplies the

power and user interface functions for all optional items.

The touch-screen displays up to six different parameters.

This version of the manual is applicable to software

revisions DK420 v2.01 and above.

1.1 Equipment in the Box

The following items are supplied with the Druck DPI 620

Genii:

• DC power supply

• Li-polymer battery

• Set of six test leads

• AC Probe

• Quick Start Guide

• Stylus

28 April 2014 K0541 issue 2 Page 9 of 200

Page 10

User Manual Druck DPI620 Genii

1.2 Optional Items

The items that follow are optional items which can be used

with the Druck DPI 620 Genii:

• Pressure Module Carrier, MC 620, this attaches directly

to the Druck DPI 620 Genii to make a fully integrated

pressure instrument.

• Pressure Module, PM 620, this attaches to the pressure

module carrier (MC 620) or a Pressure Station (PV 62X) to

enhance the pressure measurement functionality.

• Pressure Stations, PV 62X, if the Druck DPI 620 Genii is

installed in a Pressure Station, it becomes a fully

integrated pressure calibrator.

1.3 Observance of the User Manual

This manual contains safety and battery installation

information for the Druck DPI 620 Genii. It is the

responsibility of the customer, to make sure that all

personnel operating and maintaining the equipment are

correctly trained and qualified. Before operating or using the

equipment read and obey all sections, including all

WARNINGS and CAUTIONS given in the Quick Start Guide.

28 April 2014 K0541 issue 2 Page 10 of 200

Page 11

User Manual Druck DPI620 Genii

1.4 General Safety Precautions

Read and obey all the operator's local Health and Safety

regulations and Safe Working Procedures or Practices.

When doing a procedure or task:

• Use only the approved tools, consumable materials

and spares to operate and maintain the equipment.

• Read and obey all applicable WARNING signs.

• Make sure that:

All work areas are clean and clear of

unwanted tools, equipment and materials.

All unwanted consumable materials are

discarded in accordance with local health

and safety and environmental regulations.

28 April 2014 K0541 issue 2 Page 11 of 200

Page 12

User Manual Druck DPI620 Genii

1.5 General Warnings

• It is dangerous to ignore the specified limits for the

instrument or its related accessories. This can

cause injuries.

• If the equipment is used in a manner not specified

by the manufacturer, the protection provided by

the equipment may be impaired.

• Do not use the instrument in locations with explosive gas,

vapour or dust. There is a risk of an explosion.

• Make sure all equipment is serviceable.

• Use equipment only for the purpose for which it is

provided.

• Wear all applicable Personal Protective Equipment (PPE).

• Do not use sharp objects on the touch-screen.

28 April 2014 K0541 issue 2 Page 12 of 200

Page 13

User Manual Druck DPI620 Genii

1.6 Electrical warnings

• To prevent electrical shocks or damage to the instrument,

do not connect more than 30V CAT I between the

terminals, or between the terminals and the ground

(earth).

• External circuits should have appropriate insulation to

the mains.

• To prevent electrical shocks, use only the GE specified

AC probe (Part: IO620-AC) to measure AC voltages

that are more than 20 Vrms. Do not connect more

than 300V CAT II between the IO620-AC leads, or

between the leads and the ground (earth). Attach it to

the specified connections only.

• This instrument uses a Lithium-Polymer (Li-Polymer)

battery pack. To prevent an explosion or fire, do not

short circuit, do not disassemble, and keep it safe

from damage.

• To prevent an explosion or fire, use only the GE

specified battery (Part: 191-356), power supply (Part:

191-339) and battery charger (Part: IO620-CHARGER).

• To prevent battery leakage or heat generation, only

use the battery charger and power supply in the

temperature range 0°C to 40°C (32°C to 104°F).

• The power supply input range is 100 – 240Vac, 50 to 60Hz,

250mA, installation category CAT II.

• Position the power supply so not to obstruct the supply

disconnecting device.

28 April 2014 K0541 issue 2 Page 13 of 200

Page 14

User Manual Druck DPI620 Genii

• Note that the operating and storage temperature range

of the mains PSU does not match that of the DPI620.

Mains PSU operating temperature range 0°C to +40°C,

storage temperature range -40°C to +70°C.

• The DC input to the DPI620 Genii is rated at 5V (+/-5%).

Maximum current 2 Amps.

• To make sure the display shows correct data,

disconnect the test leads before power is set to on or

changing to another measure or source function.

• Make sure the power is OFF before connecting or

disconnecting the probe.

.

• Keep the probe and leads free from all contaminants

28 April 2014 K0541 issue 2 Page 14 of 200

Page 15

User Manual Druck DPI620 Genii

Overvoltage

Description

Overvoltage category I has the least severe

Overvoltage category II describes an electrical

The following summary of installation and measurement

overvoltage categories are derived from IEC61010-1.

The overvoltage categories indicate the severity of

overvoltage transients

Category

overvoltage transients. Generally CAT I

CAT I

equipment is not designed to be directly

connected to the mains supply. Examples of CAT I

equipment are process loop powered devices

installation where typically single phase

CAT II

equipment is connected. Examples of such

equipment are appliances and portable tools

28 April 2014 K0541 issue 2 Page 15 of 200

Page 16

User Manual Druck DPI620 Genii

1.7 Pressure Warnings

• Some liquid and gas mixtures are dangerous. This

includes mixtures that occur because of

contamination. Make sure that the equipment is safe

to use with the necessary media.

• To prevent a dangerous release of pressure, isolate

and bleed the system before disconnecting a

pressure connection.

• To prevent a dangerous release of pressure, make

sure that all the related pipes, hoses and equipment

have the correct pressure rating, are safe to use and

are correctly attached.

• To prevent damage to the Druck DPI 620 Genii, only

use it within the specified pressure limits.

• Do not exceed the maximum pressures stated in the

appropriate component manual for the unit under test.

• Reduce pressure at a controlled rate when venting to

atmosphere.

• Carefully de-pressurize all pipes to atmospheric

pressure before disconnecting and connecting to the

unit under test.

• Observe cleanliness when using the instrument.

• Severe damage can be caused if equipment

connected to this instrument is contaminated.

• Connect only clean equipment to the instrument. To

avoid any contamination, an external filter is

recommended.

28 April 2014 K0541 issue 2 Page 16 of 200

Page 17

User Manual Druck DPI620 Genii

1.8 Preparing the Instrument

On receipt of the instrument check the contents in the

box, listed in section 1.1. It is recommended to retain the

box and packaging for future use.

1.9 Install the Battery

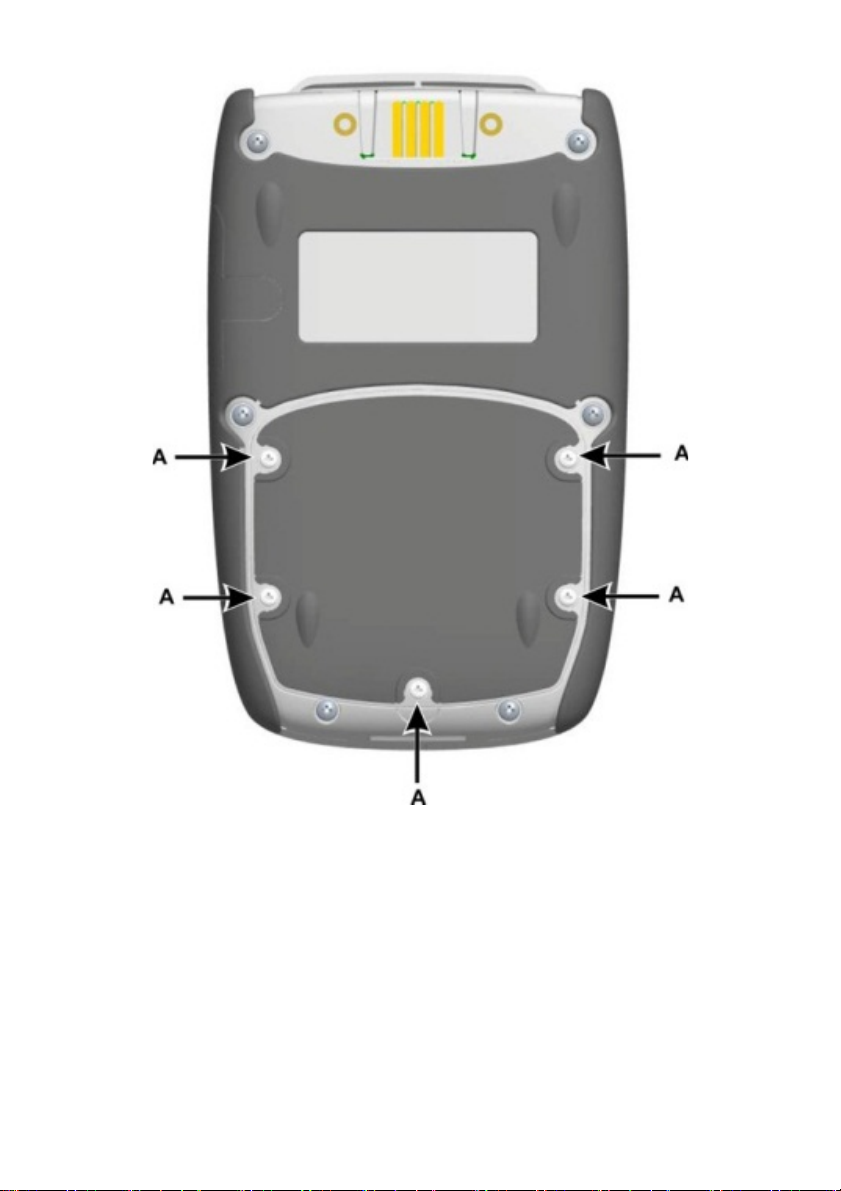

1. Remove the five Pozidriv screws (A) (Ref: Figure 1-1).

2. Remove the battery cover.

3. Check the connections on the battery line up with the

connections in the battery compartment.

4. Place the battery in the battery compartment.

5. Replace the battery cover.

6. Secure the cover with the five Pozidriv screws.

28 April 2014 K0541 issue 2 Page 17 of 200

Page 18

User Manual Druck DPI620 Genii

Figure 1-1

28 April 2014 K0541 issue 2 Page 18 of 200

Page 19

User Manual Druck DPI620 Genii

1.10 Charge the Battery

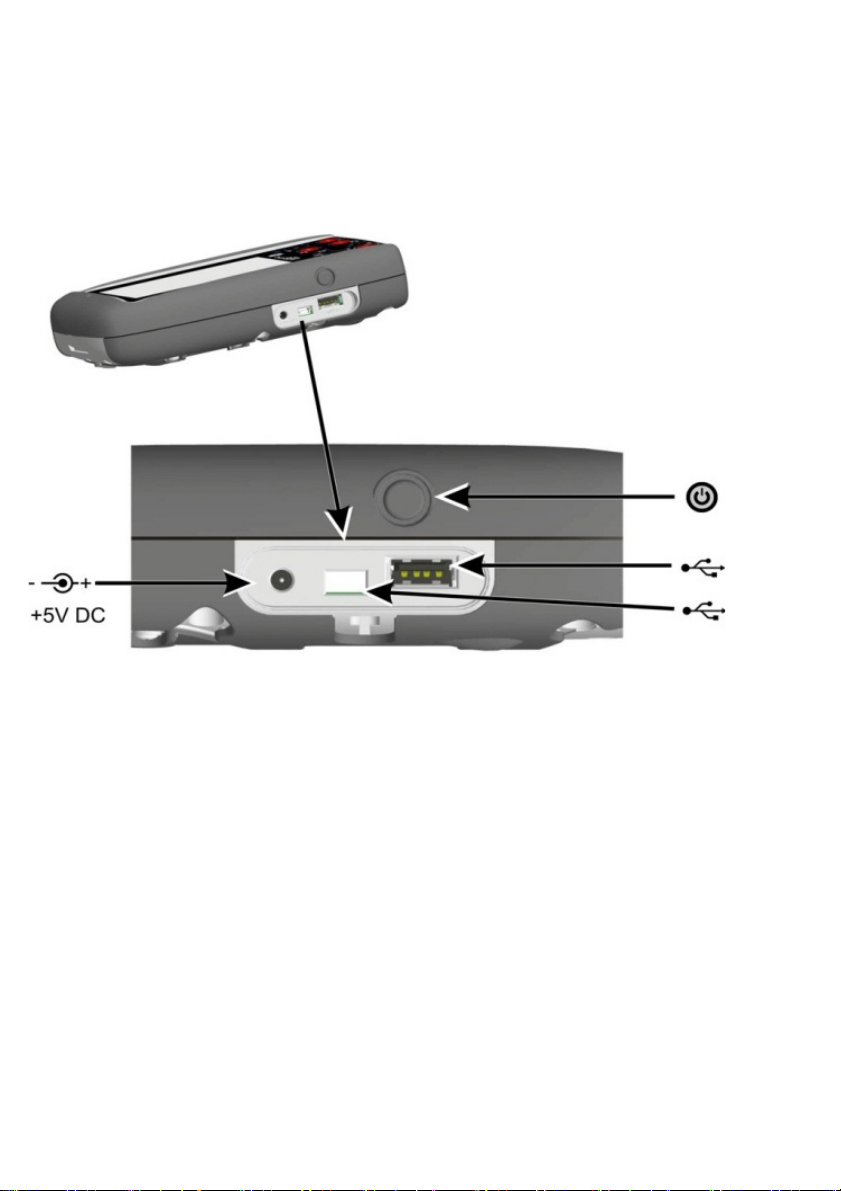

1. Connect the DC power supply into the +5V DC

connection on the side of the unit (Ref: Figure 1-3).

2. The battery can also be charged using the USB

connections (Ref: Figure 1-3).

3. The unit can be On or Off when charging. Charging

times may be longer if charging when the unit is

switched on.

Battery Charging Times 1.10.1

Charging Connection Charge Time

DC Power Supply 6.5 hours

External Battery Charger 6.5 Hours

28 April 2014 K0541 issue 2 Page 19 of 200

Page 20

User Manual Druck DPI620 Genii

1.11 Basic Modes Power On 1.11.1

From OFF – momentarily press the power button until the

display flashes (Ref: Figure 1-3) .

Power Off 1.11.2

Press and Release the Power Button:

The POWERDOWN OPTIONS window will be displayed

Figure 1-2 Powerdown Options

SWITCH OFF – Full power down of Druck DPI 620 Genii –

recommended if unit is not going to be used for several

hours (Requires full reboot on next power up)

STANDBY – DPI620G placed in standby mode – reduced

power consumption from operating mode – recommended

if unit is to be inactive for short periods. (Druck DPI 620 Genii

has fast turn on from STANDBY mode).

Note: SWITCH OFF can also be achieved by pressing and

holding the power button until the screen is blank.

28 April 2014 K0541 issue 2 Page 20 of 200

Page 21

User Manual Druck DPI620 Genii

Power up from Standby Mode 1.11.3

When powered-up from standby mode the instrument

always opens the last screen shown before going into

standby mode.

Figure 1-3

28 April 2014 K0541 issue 2 Page 21 of 200

Page 22

User Manual Druck DPI620 Genii

1.12 Druck DPI 620 Genii, Modes

The Druck DPI 620 Genii can be used as follows:

• Calibrator (with independent functions on each of six

channels).

- Data logging capabilities

- Documenting capabilities

• HART® Communicator.

• Foundation Field-bus Communicator.

28 April 2014 K0541 issue 2 Page 22 of 200

Page 23

User Manual Druck DPI620 Genii

Dashboard navigation 1.12.1

The Dashboard is navigated by swiping a finger from top

to bottom while touching the screen. Functions screens

are navigated by swiping a finger from right to left while

touching the screen.

Figure 1-4 Dashboard

Note: Fieldbus is not installed on all units

28 April 2014 K0541 issue 2 Page 23 of 200

Page 24

User Manual Druck DPI620 Genii

Set Date, Time and Language 1.12.2

To access Date, Time and Language menus select:

DASHBOARD >> SETTINGS >> DATE

>> TIME

>> LANGUAGE

Themes 1.12.3

Two themes are available: Dark and Light; select the correct

theme for the light level. Select:

DASHBOARD >> SETTINGS >> THEME

Druck DPI 620 Genii Manual 1.12.4

Select the Help icon on the Dashboard to access the

manual. All the information required to operate the Druck

DPI 620 Genii, is in the Help section of the Dashboard

which is accessed by selecting:

DASHBOARD >> HELP

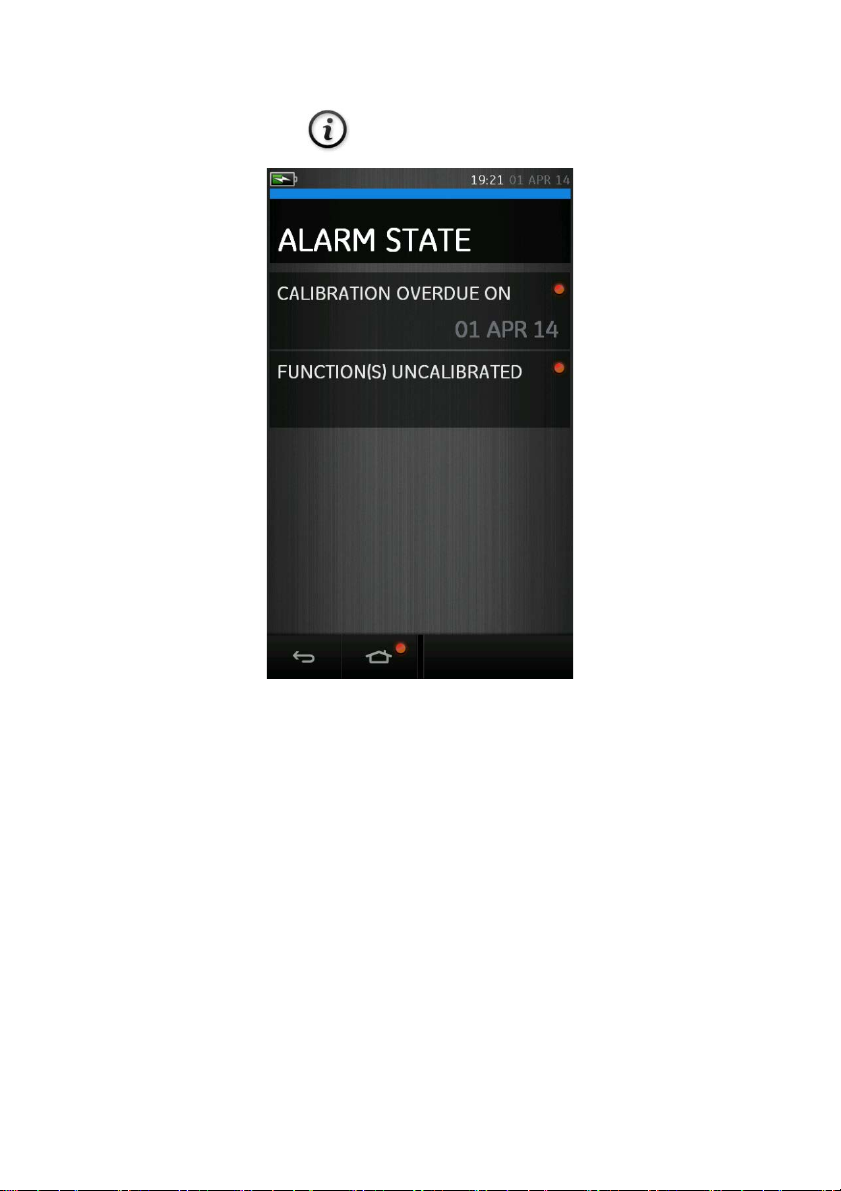

Alarm Status 1.12.5

An Alarm Status is indicated on the DASHBOARD with a Red

LED on the Status button and on the Home button on other

screens.

28 April 2014 K0541 issue 2 Page 24 of 200

Page 25

User Manual Druck DPI620 Genii

To View Alarms select:

DASHBOARD >> STATUS >> ALARM STATE

Figure 1-6 Alarm State

Selecting the Alarm will clear the indication until the next

power down.

28 April 2014 K0541 issue 2 Page 25 of 200

Page 26

User Manual Druck DPI620 Genii

1.13 Software and Firmware Upgrades Viewing Software Revision 1.13.1

The software revisions running on the Druck DPI 620 Genii

can be viewed by selecting:

DASHBOARD >> STATUS >> SOFTWARE BUILD

Note: If the software revision number is highlighted red then

an upgrade is available.

Upgrading the Software 1.13.2

Follow the website instructions to download the files onto

a USB flash memory device.

www.ge-mcs.com

1. Select:

DASHBOARD >> ADVANCED

2. Enter the calibration PIN: 5487

3. Select the button.

4. Select:

UPGRADE

5. Continue with one of these operations:

28 April 2014 K0541 issue 2 Page 26 of 200

Page 27

User Manual Druck DPI620 Genii

• Upgrade the Application software and SDC625

Application.

1. Copy the ‘AMC’ application folder into the root of

a USB flash memory device.

2. Put the USB flash memory device in the USB

type A connector.

3. Select:

APPLICATION

4. Follow the on-screen instructions.

Note: The SDC625 HART® Application can only be

upgraded as part of an application upgrade.

• Upgrade the Operating System and Bootloader

software.

1. Create a folder named ‘OS’ in the root of a USB

flash memory device.

2. Copy the files ‘DK418.nb0’ and ‘DK419.nb0’ into

the ‘OS’ folder.

3. Put the USB flash memory device in the USB

type A connector.

4. Select:

OPERATING SYSTEM

5. Follow the on-screen instructions.

Note: The bootloader can only be upgraded as part of

an operating system upgrade.

28 April 2014 K0541 issue 2 Page 27 of 200

Page 28

User Manual Druck DPI620 Genii

• Upgrade the HART processor Application and Boot

Loader

1. Create a folder named ‘HART’ in the root of a

USB flash memory device.

2. Copy the files ‘DK416.s19’ and ‘DK417.s19’ into

the ‘HART’ folder.

3. Put the USB flash memory device in the USB

type A connector.

4. Select:

HART APPLICATION

5. Follow the on-screen instructions.

Note: The HART bootloader can only be upgraded as

part of an HART application upgrade.

• Upgrade the CH1 FPGA

1. Create a folder named ‘FPGA’ in the root of a

USB flash memory device.

2. Copy the files ‘DK413.bin’’ into the ‘FPGA’ folder.

3. Put the USB flash memory device in the USB

type A connector.

4. Select:

CH1 FPGA

5. Follow the on-screen instructions.

Note: The CH2 cannot be remotely upgraded .

28 April 2014 K0541 issue 2 Page 28 of 200

Page 29

User Manual Druck DPI620 Genii

• Upgrade the HART Device Library

By default the HART device library is stored on the

micro SD Card.

1. Set the DPI620 Genii USB client port to Storage

Device mode by selecting:

DASHBOARD >> DEVICES >> USB CLIENT PORT

2. Locate the self-extracting file

‘DPI620_DD_library_20**_*.exe’

3. Connect DPI620 Genii Client USB port to PC

USB port. Device will connect to PC as a

Removable Disk.

4. Run ‘DPI620_DD_library_20**_*.exe’ and

extract files to the Removable Disk (this will

take several minutes due to the large file size).

**_* indicates the DD release version from the

HART foundation.

The required directory structure on the micro SD

card is shown in Figure 1-7 Hart DD Directory

Structure.

28 April 2014 K0541 issue 2 Page 29 of 200

Page 30

User Manual Druck DPI620 Genii

Figure 1-7 Hart DD Directory Structure

Note:

• If a mistake is made during upgrade and there are

no files to upload, follow the on-screen instructions

and complete the procedure.

• When an upgrade completes normally, the initial

operation of the touch screen may be slower (a

period of approximately 30 seconds).

• To make sure the upgrade completed correctly,

use the Status menu.

28 April 2014 K0541 issue 2 Page 30 of 200

Page 31

User Manual Druck DPI620 Genii

1.14 Maintenance

The DPI620 Genii instrument contains no user serviceable

parts and should be returned to a GE service center for

repair.

Cleaning 1.14.1

CAUTION

Do not use solvents or abrasive materials.

Clean the case and display with a lint free cloth and a weak

detergent solution.

28 April 2014 K0541 issue 2 Page 31 of 200

Page 32

User Manual Druck DPI620 Genii

1.15 Instrument Return Returned Material Procedure for USA 1.15.1

If the instrument is unserviceable and requires a repair,

return to a GE Service Centre or Approved Service Agent.

Web site: www.ge-mcs.com

Contact the GE Service Centre, either by 'phone, fax or e-mail

to obtain a Returned Material Authorization (RMA) number,

providing the following information:

Product (i.e. Druck DPI 620 Genii)

Serial number

Details of defect/work to be undertaken

Operating conditions

Safety Precautions

Provide information if the product has been in contact

with any hazardous or toxic substances and the

relevant MSDS references and precautions to be taken

when handling.

Important notice

Do not use unauthorized sources to service this

equipment as this will affect the warranty and may

not guarantee future performance.

28 April 2014 K0541 issue 2 Page 32 of 200

Page 33

User Manual Druck DPI620 Genii

Returned Goods Procedure for Europe 1.15.2

If the instrument is unserviceable and requires a repair,

return to a GE Service Centre or Approved Service Agent.

Web site: www.ge-mcs.com

Contact the GE Service Centre, either by 'phone, fax or e-mail

to obtain a Returned Material Authorization (RMA) number,

providing the following information:

Product (i.e. Druck DPI 620 Genii)

Serial number

Details of defect/work to be undertaken

Operating conditions

Safety Precautions

Provide information if the product has been in contact

with any hazardous or toxic substances and the

relevant COSHH references and precautions to be taken

when handling.

Important Notice

Do not use unauthorized sources to service this

equipment as this will affect the warranty and may

not guarantee future performance. When discarding

used equipment and batteries, obey all the local

health and safety procedures.

28 April 2014 K0541 issue 2 Page 33 of 200

Page 34

User Manual Druck DPI620 Genii

Instrument Disposal in the European Union 1.15.3

Do not dispose of this product or its battery as

household waste.

Use an approved organization that collects and/or

recycles the applicable item.

For more information contact

• GE Sensing customer service department:

(www.ge-mcs.com)

• Local government office.

28 April 2014 K0541 issue 2 Page 34 of 200

Page 35

User Manual Druck DPI620 Genii

DC adaptor polarity: the centre of the plug

1.16 Packaging for Storage or Transportation

To store the unit or to return the unit for calibration or

repair carry out the following procedures:

1. Pack the Instrument.

2. To return the instrument for calibration or repair,

complete the return goods procedure (Ref: 1.14).

3. Return the instrument to the manufacturer or an

approved service agent for all repairs.

Environment 1.16.1

The following conditions apply for both shipping and

storage:

Temperature Range -20° to +70°C (-40° to +158°F)

Altitude Up to 15,000 feet (4,570 metres)

1.17 Marks and Symbols

Complies with FCC directives

Complies with European Union directives

USB ports: Type A; Mini Type B connector

Ground (Earth)

is negative

28 April 2014 K0541 issue 2 Page 35 of 200

Page 36

User Manual Druck DPI620 Genii

Figure 2-1 Task Menu

2

Electrical

Operations

2.1 Basic Calibrator Operation

1. Select:

DASHBOARD >> CALIBRATOR

2. Select the channel by performing the following tasks:

• Swipe to the TASK MENU by swiping the display

from right to left.

28 April 2014 K0541 issue 2 Page 36 of 200

Page 37

User Manual Druck DPI620 Genii

Saving Tasks 2.1.1

At any point within the TASK MENU the currently active tasks

can be saved to FAVOURITES (refer to section 2.1.3) by

selecting Save Task.

Note: Saved Function is what is currently active in the

calibrator window. It is NOT a selected Task – refer to COPY

TASK in Section 2.1.2.

28 April 2014 K0541 issue 2 Page 37 of 200

Page 38

User Manual Druck DPI620 Genii

Electrical Tasks 2.1.2

1. Select ELECTRICAL TASKS from the TASK MENU.

• This will allow the user to select from commonly

used combinations of electrical functions

Figure 2-2 Electrical Tasks

2. Select the required function by selecting on either the

appropriate text or diagram. The DPI620G will set the

functions and return to the CALIBRATOR screen.

28 April 2014 K0541 issue 2 Page 38 of 200

Page 39

User Manual Druck DPI620 Genii

3. Functions can be copied to FAVOURITES (refer to

section 2.1.3) by selecting as shown in Figure 2-3 and

selecting Copy Task.

Figure 2-3 Selected Task

If the required task is not available as a Default, a new task

should be created using CUSTOM TASK. Refer to Section

2.1.3.

28 April 2014 K0541 issue 2 Page 39 of 200

Page 40

User Manual Druck DPI620 Genii

Favourites 2.1.3

1. Selecting FAVOURITES from the TASK MENU allows

selection of all SAVED and COPIED tasks.

Figure 2-4 Favourites

2. Select the required function by selecting on either the

appropriate text or diagram. The DPI620G will set the

functions and return to the CALIBRATOR screen.

3. Tasks can be deleted by selected as shown in Figure

2-3 and selecting DELETE.

28 April 2014 K0541 issue 2 Page 40 of 200

Page 41

User Manual Druck DPI620 Genii

Custom Task 2.1.4

1. Select CUSTOM TASK from the TASK MENU.

• This will allow the user to set up Channels 1 & 2 in

addition to the Pressure Channels, USB (IDOS) and

Communications (HART or Foundation Fieldbus).

Figure 2-5 Task Settings Menu

3. Select CH1 or CH2 to enter the CHANNEL SETTINGS

menu.

P1 and P2 are used for pressure

measurements. (Refer to Section 3).

IDOS is used for external IDOS sensors. (Refer

to Section 2.14)

28 April 2014 K0541 issue 2 Page 41 of 200

Page 42

User Manual Druck DPI620 Genii

Figure 2-6 Channel Settings Menu

is used for Hart® and FOUNDATION™ Fieldbus.

(Refer to sections 6, 7 and 8).

28 April 2014 K0541 issue 2 Page 42 of 200

Page 43

User Manual Druck DPI620 Genii

4. Setup a channel for measurement.

• DIRECTION selects source or measure for

the selected function

• FUNCTION selects the function required (eg Current

or Voltage). For more options scroll down the menu

by swiping the display from bottom to top.

• UNITS selects the type of unit required, (eg Hz, kHz),

please note that there may only be 1 type of unit

available in particular Functions.

• UTILITY selects the required utility (Refer to section

2.2 for details).

• CAPTION allows the user to change the caption, if

required.

5. Once all settings have been selected, press the

button at the bottom of the screen to return to the

TASK SETTINGS screen.

Please note for the settings to be set the user must

also press the

button in the TASK SETTINGS menu.

6. Repeat the above if another channel is required.

28 April 2014 K0541 issue 2 Page 43 of 200

Page 44

User Manual Druck DPI620 Genii

2.2 Set the Function Utility Options

For each function only one utility may be active. Not all

source and measure functions have associated utilities.

For all options the button resets the additional

readings.

Max/Min 2.2.1

This utility is only available with measure functions.

The additional values displayed show the minimum,

maximum, and average values of the input signal.

Figure 2-7 Max/Min Example

28 April 2014 K0541 issue 2 Page 44 of 200

Page 45

User Manual Druck DPI620 Genii

Switch Test 2.2.2

This utility is available with measure or source

functions.

The additional values displayed show signal values

(measure or source) when the instrument detects a switch

opening and closing. The difference between the two values

is displayed as hysteresis value for the switch. This utility

can be used with Ramp Automation, where the rising signal

causes the switch to change state and the falling signal

causes the switch to resume its’ original state.

Figure 2-8 Switch Test Example

28 April 2014 K0541 issue 2 Page 45 of 200

Page 46

User Manual Druck DPI620 Genii

Relief Valve 2.2.3

This utility is only available with measure functions.

This utility tests circuits or mechanisms that have a cut-out

response when an input reaches a defined threshold value.

The utility allows the user to select a mode of operation

which can be rising or falling. The utility displays additional

values that represent the maximum and minimum values

achieved by the input signal.

Figure 2-9 Relief Value Example

28 April 2014 K0541 issue 2 Page 46 of 200

Page 47

User Manual Druck DPI620 Genii

Falling

Rising

Max

Min

Min

Max

Figure 2-10 Relief Value Utility

28 April 2014 K0541 issue 2 Page 47 of 200

Page 48

User Manual Druck DPI620 Genii

Figure 2-11 Calibrator Window – Reduced View

-

2.3 Measurement Display Options

There are 2 display views in the CALIBRATOR screen when

multiple channels are in use:

• Figure 2-11 displays a reduced view of all the

selected channels.

28 April 2014 K0541 issue 2 Page 48 of 200

Page 49

User Manual Druck DPI620 Genii

Figure 2-12 Calibrator Window - Expanded View

• Figure 2-12 displays an expanded view of the

selected channel and minimizes the remaining

channels.

The displays options can be changed by pressing the

channel the user wants to display in expanded view.

Selecting displays all channels in the reduced view

28 April 2014 K0541 issue 2 Page 49 of 200

Page 50

User Manual Druck DPI620 Genii

Figure 2-13 Measure current on CH1. Range ± 55 mA

2.4 Example Procedure: Measure or Source Current

Figure 2-13 shows CH1 set-up to measure or source a

current with external loop power.

Note: When using the CH2 connectors, set CH 2 to measure

or source these ranges with internal or external loop power.

Set the appropriate function by selecting mA or mA +24V.

Loop power has three possible settings:

1) OFF 2) 24V 3) 28V

1. Set the applicable software option.

2. Complete the electrical connections and

continue with the measure or source operation.

3. Source only (Automation). Set the applicable

output value.

28 April 2014 K0541 issue 2 Page 50 of 200

Page 51

User Manual Druck DPI620 Genii

Figure 2-14 Measure DC Volts or DC mV on CH1. Range ±30 V

2.5 Example Procedure: Measure DC Voltage

Figure 2-14 shows CH1 set-up to measure a DC

voltage (0 to 30 V) or DC mV (0 to 2000 mV)

Note: When using the CH2 connectors, set-up CH2

to measure these range.

1. Set the applicable software options

2. Complete the electrical connections and continue

with the measure operation

28 April 2014 K0541 issue 2 Page 51 of 200

Page 52

User Manual Druck DPI620 Genii

20 Vrms Max

Figure 2-15 Measure AC Volts or AC mV on CH1. Range ±20 Vrms

2.6 Example Procedure: Measure AC Voltage (CH1), 0 to 20

Vrms Only

WARNING

To prevent electrical shocks, use only the GE specified

AC probe (Part: IO620-AC) to measure AC voltages that

are more than 20 Vrms (maximum: 300 Vrms). Refer to

Section 2.7.

Figure 2-15 shows CH1 set-up to measure an AC voltage (0

to 20 Vrms) or AC mV (0 to 2000 mVrms).

1. Set the applicable software options.

2. Complete the electrical connections and continue with

the measure operation.

28 April 2014 K0541 issue 2 Page 52 of 200

Page 53

User Manual Druck DPI620 Genii

Figure 2-16 Measure AC Volts with AC Probe. Range 300 Vrms

2.7 Example Procedure: Measure AC Voltage (CH1) with the

AC Probe

WARNING

To prevent electrical shocks, use only the GE specified

AC probe (Part: IO620-AC) to measure AC voltages that

are more than 20 Vrms (maximum: 300 Vrms). Attach it

to the specified connections only.

Figure 2-16 shows CH1 set-up to measure an AC voltage

with the AC probe Maximum: 300 V rms.

1. Set the applicable software options for the AC Probe.

2. Complete the electrical connections Red - V/Hz

connector, Black - COM connector. Then continue with

the measure operation.

28 April 2014 K0541 issue 2 Page 53 of 200

Page 54

User Manual Druck DPI620 Genii

Figure 2-17 Source Voltage on CH1. Range 0 to 20V.

2.8 Example Procedure: Source DC Voltage (CH1)

Figure 2-17 shows CH1 Set-up to source a DC voltage on

CH1 (0 to 20V).

.

1. Set the applicable software options.

2. Complete the electrical connections.

3. To continue, set the applicable output value.

28 April 2014 K0541 issue 2 Page 54 of 200

Page 55

User Manual Druck DPI620 Genii

Figure 2-19 Measure current on CH2 with internal loop

power (Range: ±55mA)

Figure 2-18 Source current on CH2 with internal

loop power. (Range: 0 to 24 mA)

2.9 Example Procedure: Measure or Source Current with 24V

Loop

Figure 2-19 and Figure 2-18 show CH2 set-up to measure

(±55mA) or source (0 to 24mA) a current with internal loop

power (Selectable to 24 V or 28V).

28 April 2014 K0541 issue 2 Page 55 of 200

Page 56

User Manual Druck DPI620 Genii

Set the applicable software options.

1. Complete the electrical connections and continue

with the measure or source operation.

2. Source only (Automation): Set the applicable output

value.

Note: The current limit of the Loop power is 30mA.

28 April 2014 K0541 issue 2 Page 56 of 200

Page 57

User Manual Druck DPI620 Genii

Figure 2-20 Example A - Measure Frequency on

CH1 (Range 0 to 50 kHz)

Figure 2-21 Example B - Source Frequency CH1

(Range 0 to 50 kHz)

2.10

Example Procedure:

Measure or Source Frequency

Signals

Figure 2-20 and Figure 2-21 show CH1 set-up to measure

or source a frequency. The units could be Hz, kHz or counts

(cpm or cph).

28 April 2014 K0541 issue 2 Page 57 of 200

Page 58

User Manual Druck DPI620 Genii

Example A

Measure frequency on

CH1

Range: 0 to 50 kHz

Trigger level: 2.5V

1. Set the applicable

software options

2. Complete the electrical

connections

3. If necessary, change the

Trigger Setup

SETTINGS >>

Example B

Source frequency on CH1

Range: 0 to 50 kHz

Waveform: Square

Amplitude:5.0 V

1. Set the applicable software

options

2. Complete the electrical

connections

3. If necessary, change the

Waveform Setup:

SETTINGS

AUTO TRIGGER

4. Set the values that follow:

4. Set the values that

follow:

WAVEFORM

Square

AUTO TRIGGER

(Enabled / Disabled)

MANUAL LEVEL

Trigger Level for

Manual Trigger only

Triangle

Sine

AMPLITUDE

Peak to Peak Amplitude

OFFSET

Only Applies to Sine and

Triangle

28 April 2014 K0541 issue 2 Page 58 of 200

Page 59

User Manual Druck DPI620 Genii

Figure 2-22 PT100 RTD Measure CH1 4-Wire

Figure 2-23 PT100 RTD Source CH1 4-Wire

(Range

2.11 Example Procedure: Measure/Simulate a Resistance

Temperature Detector (RTD)

Figure 2-22 and Figure 2-23 show CH1 set-up to measure

or simulate an RTD. A 4-wire configuration gives the best

accuracy; a 2-wire configuration has the lowest accuracy

(4- wire RTD shown).

(Range -200 to 850 °C)

28 April 2014 K0541 issue 2 Page 59 of 200

-200 to 850 °C)

Page 60

User Manual Druck DPI620 Genii

Note: To measure or simulate resistance Ω, select the

Resistance function (Range 0 to 4000 Ω).

1. Set the applicable software options.

2. Complete the electrical connections.

3. If necessary change the RTD Type.

SETTINGS >> RTD TYPE

28 April 2014 K0541 issue 2 Page 60 of 200

Page 61

User Manual Druck DPI620 Genii

Figure 2-24 K-Type Thermocouple Measure CH1

Figure 2-25 K-Type Thermocouple Source CH1 (Range 270 to 1372 °C)

2.12 Example Procedure: Measure or Simulate a Thermocouple

(TC)

Figure 2-24 and Figure 2-25 show CH1 set-up to measure or

simulate a TC temperature.

To measure or simulate TC millivolts, set the TC mV function.

(Range -270 to 1372 °C)

28 April 2014 K0541 issue 2 Page 61 of 200

Page 62

User Manual Druck DPI620 Genii

Note: To measure or simulate TC millivolts, set the TC mV

function

1. Set the applicable software options.

2. Complete the electrical connections.

3. If necessary change the thermocouple type.

SETTINGS >> TC TYPE

4. Set CJ Compensation mode.

SETTINGS >> MANUAL CJ COMPENSATION

If Manual CJ compensation is not selected, the

internal cold junction is used to calculate the

thermocouple value.

If using an external cold junction, select check box

on MANUAL CJ COMPENSATION and enter value for

cold junction temperature.

28 April 2014 K0541 issue 2 Page 62 of 200

Page 63

User Manual Druck DPI620 Genii

2.13 Example Procedure: Switch Test

CH1, P1, P2 and IDOS functions use the CH2 switch

connections. CH2 functions use the CH1 switch

connections.

Switch operation

When setting the Switch Test utility on one channel, the

software automatically sets-up the other channel for the

switch connections.

Note: If there is a measure or source function on the

switch connection channel it is automatically disabled.

The display will show a screen message:

28 April 2014 K0541 issue 2 Page 63 of 200

Page 64

User Manual Druck DPI620 Genii

Figure 2-26 CH1 Thermocouple Source CH2 Switch Test

Figure 2-26 shows a thermocouple switch test.

1. Set the applicable software options:

• The TC is set to source a temperature

• The UTILITY is set to SWITCH TEST. The AUTOMATION is

set to RAMP

2. Complete the electrical connections.

3. It is a CH1 function, the switch connections must be on

CH2.

4. For the Ramp process, set START and STOP values that

are applicable to the switch value.

5. To get an accurate switch value, set a long TRAVEL

period.

28 April 2014 K0541 issue 2 Page 64 of 200

Page 65

User Manual Druck DPI620 Genii

6. Use to start the “Ramp” cycle.

7. Use to stop the “Ramp” cycle.

8. If necessary, supply the output values in the opposite

direction until the switch changes condition again.

9. The display will show the following:

• Values for switch Open and switch Close Points

• Hysteresis value

10. To do the test again press the button.

28 April 2014 K0541 issue 2 Page 65 of 200

Page 66

User Manual Druck DPI620 Genii

2.14 Measure Pressure: IDOS Option

Optional item. An IDOS Universal Pressure Module (UPM)

uses Intelligent Digital Output Sensor (IDOS) technology to

measure the applied pressure and supply the data to an

IDOS instrument. Before using an IDOS module, (Ref: User

Manual: K0378, Druck IDOS UPM).

Note: To attach an IDOS module to the Druck DPI 620 Genii

calibrator use an IO620-IDOS-USB adaptor.

28 April 2014 K0541 issue 2 Page 66 of 200

Page 67

User Manual Druck DPI620 Genii

Step

Procedure

IDOS Option Assembly Instructions 2.14.1

1.

Attach one end of the adaptor IO620IDOS-USB to the IDOS module

2.

Push the Type A end of USB Cable into

the USB socket on the instrument and

the type B end into the adaptor (IO620IDOS-USB)

3.

Set the instrument power on

When this symbol flashes at the top

of the display, it shows there is

communication between the IDOS

module and the calibrator

28 April 2014 K0541 issue 2 Page 67 of 200

Page 68

User Manual Druck DPI620 Genii

IDOS Function Procedures 2.14.2

Set the calibrator functions for use on the display.

This includes:

• IDOS function (to measure the pressure)

• If necessary, change the Units for the function

• If necessary, set a Utility for the function:

i Max/Min/Avg

ii Switch Test

iii Leak Test . The procedure is the same for an

IDOS module or for a MC 620/PM 620

assembly.

• If necessary, change the Settings for the IDOS function:

• Process (Tare, Alarm, Filter, Flow, Scaling)

i Leak Test (Only when the Utility is set). The

procedure is the same for an IDOS module or for

a MC 620/PM 620 assembly.

ii Zero. The procedure is the same for an IDOS

module or for a PM 620 module. Zero the

gauge sensor before use.

• Continue with the pressure operation.

28 April 2014 K0541 issue 2 Page 68 of 200

Page 69

User Manual Druck DPI620 Genii

2.15 Error Indications

Under range:

The display shows this symbol for this condition:

<<<<<

Reading < 102% Negative Full Scale

Over range:

The display shows this symbol for this condition:

>>>>>

Reading > 102% Positive Full Scale

If the display shows <<<< (under range) or >>>> (over range):

• Make sure that the range is correct.

• Make sure that all the related equipment and connections

are serviceable.

28 April 2014 K0541 issue 2 Page 69 of 200

Page 70

User Manual Druck DPI620 Genii

Figure 3-1 MC620G

3 Pressure Indicator Operation (MC620)

This section gives examples of how to connect and use the

instrument to measure pressure with the module carrier (MC

620) and the applicable pressure modules (PM 620).

To make a fully integrated pressure calibrator instrument

with one of the three Pressure Stations, refer to the User

Manual for the PV62x Series of Pressure Stations, K0457.

28 April 2014 K0541 issue 2 Page 70 of 200

Page 71

User Manual Druck DPI620 Genii

Manufacturer

3.1 Parts and Assembly

This section shows the parts of the module carrier (MC620G)

and pressure module (PM620). (Refer to Figure 3-2).

Part

Reference

1

2

3

4

5

Description

Pressure connection (G1/8 or 1/8 NPT) to

attach external pressure equipment.

Pressure and electrical connections for a

pressure module (PM 620). These are

self- sealing pressure connections.

Two screws to attach the calibrator

(Druck DPI 620 Genii).

Electrical connections for the calibrator

(Druck DPI 620 Genii).

Pressure module (PM 620) with a

pressure connection.

The PM620 Label identifies:

Type: g: gauge

a: absolute

Pressure Range

Serial Number

28 April 2014 K0541 issue 2 Page 71 of 200

Page 72

User Manual Druck DPI620 Genii

Figure 3-2 MC620G and PM620G Part Identification

CAUTION

To prevent damage to the PM620 module, only use it within

the specified pressure limit on the label.

When the items are attached to the Druck DPI 620 Genii it is

a fully integrated pressure indicator, measuring pneumatic

or hydraulic pressure.

28 April 2014 K0541 issue 2 Page 72 of 200

Page 73

User Manual Druck DPI620 Genii

and the calibrator.

Assembly Instructions 3.1.1

Step Procedure

1 Align the two slots (a) on the calibrator with the two

posts (b) on the module carrier.

2

When the posts are fully engaged in the slots, tighten

the two screws (2) hand-tight.

3 Attach one or two PM 620 modules (4) with the

correct range and type.

4 Tighten each PM 620 module (4) hand-tight only.

5

When the symbol flashes at the top of the

display, there is communication between the module

Figure 3-3 MC620 Assembly Procedure

28 April 2014 K0541 issue 2 Page 73 of 200

Page 74

User Manual Druck DPI620 Genii

3.2 Pressure Connections

WARNING

Pressurized gases and fluids are dangerous. Before

attaching or disconnecting pressure equipment, safely

release all the pressure.

The pressure ports for external equipment use “Quick fit”

pressure adaptors. (Refer to Figure 3-4).

Figure 3-4 Quick Fit Pressure Adaptor

Procedure (Attaching External Equipment) 3.2.1

Figure 3-5 Pressure Connections

28 April 2014 K0541 issue 2 Page 74 of 200

Page 75

User Manual Druck DPI620 Genii

less: a bonded seal at the top is permitted.

Step Procedure (refer to Figure 3-5)

1

2

3

4

5

Remove the adaptor from the pressure port.

Use an applicable seal for the pressure connection:

a. NPT type: Use an applicable sealant on the

thread.

b. BSP (parallel) type: Use the applicable

bonded seal at the bottom.

c. BSP (parallel) type, 100 bar (1500 psi) or

Attach the adaptor to the external equipment. If

necessary use an alternative adaptor.

Tighten to the applicable torque.

Attach the adaptor to the MC 620 carrier and handtighten.

When the pressure indicator assembly is complete use the

menus to set-up the necessary operations. (refer to Section

3.3).

28 April 2014 K0541 issue 2 Page 75 of 200

Page 76

User Manual Druck DPI620 Genii

3.3 Procedure Overview

Figure 3-6 Task Menu

When PM620 Pressure modules are fitted, PRESSURE TASKS,

are available in the TASK MENU. Refer to Section 2.1 Basic

Calibrator Operation for details.

28 April 2014 K0541 issue 2 Page 76 of 200

Page 77

User Manual Druck DPI620 Genii

Figure 3-7 Pressure Tasks

Select the required function by selecting on either the

appropriate text or diagram. The DPI620G will set the

functions and return to the CALIBRATOR screen.

Pressure Functions can also be selected through the

CUSTOM TASK function. Refer to Section 2.1.4 for details.

Tasks can be SAVED or COPIED into the FAVOURITES. Refer to

Section 2.1.1 for details.

28 April 2014 K0541 issue 2 Page 77 of 200

Page 78

User Manual Druck DPI620 Genii

If required, change the Units or the function. If necessary,

set a Utility for the function:

• Max/Min/Avg

• Switch Test

• Relief valve

• Leak Test

Figure 3-8 Channel Settings

Note: UNITS and UTLILITIES are accessed through selecting

the function through CUSTOM TASK.

28 April 2014 K0541 issue 2 Page 78 of 200

Page 79

User Manual Druck DPI620 Genii

3.4 Set up a Leak Test

This utility is only available in Pressure Measurement

modes.

This utility provides a test to calculate the leak of a system.

Figure 3-9 Leak Test Example

28 April 2014 K0541 issue 2 Page 79 of 200

Page 80

User Manual Druck DPI620 Genii

To configure leak test:

1. Set the Utility to Leak Test.

2. Select:

SETTINGS >> LEAK TEST

3. Set the following periods

WAIT TIME:

The time before the test starts in

hours:minutes:seconds (hh:mm:ss).

TEST TIME:

The period of the leak test in

hours:minutes:seconds (hh:mm:ss)

4. Use to start the Leak Test

5. Use to stop the “Ramp” cycle

Note: To set the Leak Test options, a pressure module must

be correctly installed.

28 April 2014 K0541 issue 2 Page 80 of 200

Page 81

User Manual Druck DPI620 Genii

3.5 Set the Pressure Module to Zero

SETTINGS >> ZERO >> ZERO

Use this option to write a new zero pressure value to the

pressure module in use. The sensor adjustment is permitted

if it obeys the condition that follows:

• Adjustment ≤10% FS positive pressure value (for the

Sensor).

Note: To make a temporary adjustment for zero, use the

Tare function.

28 April 2014 K0541 issue 2 Page 81 of 200

Page 82

User Manual Druck DPI620 Genii

3.6 Error Indications

Under range:

The display shows this symbol for this condition:

<<<<<

Reading < 110% Negative Full Scale

Over range:

The display shows this symbol for this condition:

>>>>>

Reading > 100% Positive Full Scale

If the display shows <<<< (under range) or >>>> (over range):

• Make sure that the range is correct.

• Make sure that all the related equipment and connections

are serviceable.

28 April 2014 K0541 issue 2 Page 82 of 200

Page 83

User Manual Druck DPI620 Genii

4 Data Logging Operation

Select the DATA LOGGING option on the Dashboard.

The Data Logging function records instrument readings so

they can be reviewed or analysed.

Figure 4-1 Data Logging

The data file can be reviewed by using the following:

• Recall

The data file can be processed externally by using the

following:

• Transferred to a USB Flash Memory Device

• Transferred to a computer

28 April 2014 K0541 issue 2 Page 83 of 200

Page 84

User Manual Druck DPI620 Genii

This chapter describes how to use the Data Logging function

to log data to a file.

In Data Logging mode the display data from all active

channels is stored at each data point. The data can be

stored:

• Periodically

• Key press

The data is stored in the internal memory or on an SD

card until the Data Logging is stopped. When Data

Logging has stopped, data can be automatically

transferred to a USB Flash Memory Device.

28 April 2014 K0541 issue 2 Page 84 of 200

Page 85

User Manual Druck DPI620 Genii

4.1

Set-up

Before starting, set all channels to the correct functions.

(Refer to section 2.1). To access the Data logging function

do the following:

DASHBOARD >> DATA LOGGING >> SETUP

Figure 4-2 Datalogging Setup

28 April 2014 K0541 issue 2 Page 85 of 200

Page 86

User Manual Druck DPI620 Genii

• STORAGE AREA

Used to set Internal or SD card storage. Only the

SD card can be read when connected to a PC.

• FILENAME

Enter the filename (10 characters maximum)

• TRIGGER

Select one of the following:

Key Press (logs one data point each time

the button is pressed)

Periodic (logs one data point at a set time

interval)

• PERIOD

Used to set the time interval for periodic data

logging

• TRANSFER WHEN COMPLETE

Used to transfer data to a Flash Drive

To start Data Logging Mode:

1. Select appropriate options and enter filename for

Data Log file.

2. Select the button.

28 April 2014 K0541 issue 2 Page 86 of 200

Page 87

User Manual Druck DPI620 Genii

4.2 Operation

In periodic mode, to begin data logging tap ‘Start logging’

button.

In Key press mode, a data point is taken every time the user

taps the log button.

To stop Data Logging select .

The data logging indicator flashes to indicate whenever

a reading is logged.

4.3 File Review

DASHBOARD >> DATA LOGGING >> RECALL

To view a data file point by point do the following:

1. Tap the Filename button to display the list of data files.

2. Select the file to be displayed.

3. Tap to see the data display.

4. To step the display one data point, tap the Next Log

button.

Note: The data point number sequence is displayed in the top

right-hand corner (e.g. 4 of 100).

5. To go back one data point, press the Previous Log

button.

6. Exit the screen.

28 April 2014 K0541 issue 2 Page 87 of 200

Page 88

User Manual Druck DPI620 Genii

4.4 Chart View

DASHBOARD >> DATA LOGGING >> RECALL

To view a data file on a chart do the following:

1. Tap the Filename button to display the list of data files.

2. Select the file to be displayed.

3. Select VIEW CHART

Figure 4-3 Datalog Chart

Selecting Individual Points will highlight selected

value.

28 April 2014 K0541 issue 2 Page 88 of 200

Page 89

User Manual Druck DPI620 Genii

4.5 File Management

The data log file management options are as follows:

• TRANSFER : Upload data log files to another

computer.

• ERASE: Delete data log files.

• MEMORY STATUS: Displays amount of free

memory.

Transfer 4.5.1

Data may be transferred as follows:

• USB Flash Memory Device: Selected files are written in

the root folder of the USB Flash memory Device.

• SD card: Data logged in an internal storage area can be

transferred to the SD card storage area.

• USB Serial Port: Transfers data as a text file to a

computer. A communications program can be used to

receive the data (e.g. Microsoft® Hyper Terminal). The

serial set-up is as follows:

Baud rate - 19,200 bits/sec

Data bits – 8

Parity - none

Stop bits -1

28 April 2014 K0541 issue 2 Page 89 of 200

Page 90

User Manual Druck DPI620 Genii

Erase 4.5.2

The Erase options are as follows:

• ERASE ONE FILE: Select file and tap tick bottom right

on the screen to erase.

• CLEAR INTERNAL: Clears all internal files.

Memory Status 4.5.3

The MEMORY STATUS button will show the amount of available memory in the areas that follow:

• Internal

• USB Flash Memory Device (if fitted)

• SD card

28 April 2014 K0541 issue 2 Page 90 of 200

Page 91

User Manual Druck DPI620 Genii

4.6 Data

Format

The data files are produced in a Comma Separated

Variable (csv) format (refer to Figure 4-4).. This allows the

data to be imported into a spreadsheet (e.g. Microsoft®

Excel). The first section of the data file contains the

following:

FILENAME - The data file name

COLUMNS - Information for internal use

START - Datalog start time

VERSION - Data format version

CHANNEL - The function setting of each active channel

The second section of the data file contains the following:

Individual headings

Data point data

Figure 4-4 Example .csv Datalog File

28 April 2014 K0541 issue 2 Page 91 of 200

Page 92

User Manual Druck DPI620 Genii

5 Documentation

This chapter describes the Documenting functions

available with the Druck DPI 620 Genii calibrator and are as

follows:

• ANALYSIS

• RUN PROCEDURE

5.1 Analysis

The Analysis function takes readings from two or more DPI

620 channels to calibrate the transfer characteristic of the

device being tested. One channel is the Reference channel

and is used as follows:

• Provides a measure of the input signal to the device.

• If calibrating a temperature transmitter the Reference

channel could be CH1 in either RTD or TC source

mode.

• If the device is a pressure transmitter the Reference

channel would be P1 or P2 measuring the input

pressure to the device.

The other channel is the Input channel and is used as

follows:

• Measures the output signal from the device

• If calibrating a process transmitter it could be CH2 in

Current Measure mode.

28 April 2014 K0541 issue 2 Page 92 of 200

Page 93

User Manual Druck DPI620 Genii

A second input channel can also be used, to calculate the

transfer characteristic between three points in the signal

path and may be calibrated at the same time, as in the

example that follows.

• When calibrating a process transmitter that is

HART® enabled the second input channel could

be the HART® channel. The HART® channel reads

the Primary Variable (PV) value from the sensor in

the process transmitter this would allow the

pressure sensor to be calibrated at the same time

as the current loop output.

Any active channel that is not defined as Reference is Input

by default.

There must be one Reference channel and at least one Input

channel defined for the Analysis function set-up to be

correct.

At each value the Analysis function calculates the difference

of each Input channel to the ideal transfer characteristic and

compares this to a tolerance limit.

• The deviation is shown in %Span or %Rdg

• The tolerance test result is shown a Pass

or Fail icon.

28 April 2014 K0541 issue 2 Page 93 of 200

Page 94

User Manual Druck DPI620 Genii

5.2

Set-up

1. Set the Druck DPI 620 Genii channels in the Calibrator

function. (Refer to section 2.1).

2. Connect the calibrator to the device under test.

3. Enter the Documenting function.

DASHBOARD >> DOCUMENTING

4. Tap the ANALYSIS button.

28 April 2014 K0541 issue 2 Page 94 of 200

Page 95

User Manual Druck DPI620 Genii

Define the Reference Channel 5.2.1

1. Tap the channel button that is to be used as the

Reference channel for the analysis.

Figure 5-1 Select Reference Channel

2. Set the channel type to Reference.

3. All other channel settings for that channel are

cancelled. All other active channels are set to Input.

28 April 2014 K0541 issue 2 Page 95 of 200

Page 96

User Manual Druck DPI620 Genii

Define each Input Channel 5.2.2

Tap each Input channel button to set the Input options.

Figure 5-2 Select Input Options

• SCALING - The scaling values are four set values:

The maximum and minimum Reference

signal values (Reference High and

Reference Low).

The Input signal values (Input High and

Input Low).

The Input signals should relate to the

Reference signal values with a linear or

square root transfer characteristic.

28 April 2014 K0541 issue 2 Page 96 of 200

Page 97

User Manual Druck DPI620 Genii

• ERROR TYPE – The deviation from which the

transfer characteristic is to be

calculated. This can be one of the

following:

% Span - a percentage of the Input signal span.

% Rdg - a percentage of the Input signal reading.

• LINEARITY - The transfer characteristic from

Reference to Input signal. This can be

one of the following:

Linear - a proportional response.

Square Root - often found in flow sensors.

• TOLERANCE – The test limits for the deviation from the

transfer characteristic.

28 April 2014 K0541 issue 2 Page 97 of 200

Page 98

User Manual Druck DPI620 Genii

5.3 Analysis Function

Set Input channel parameters (refer to section 5.2), and

return to CHANNEL SETUP screen.

Select the Start button

The Analysis window displays the following:

• The deviation of each Input channel from the ideal

transfer characteristic.

• A tolerance limit test icon

Pass (within tolerance test limit)

Fail (outside tolerance test limit)

To check the full range of the device do the following:

1. Step the Reference signal value through its range.

2. Check the Analysis window at each step.

3. If the Reference is sourced from the calibrator, move to

the channel window to change the Reference value.

4. Return to the Analysis window.