Page 1

Pressure measurement

for research & industry

Druck Limited

Fir Tree Lane

Groby

Leicester LE6 0FH

England

Tel: 0116 231 7100

DPI 610/615 IS

Portable Pressure Calibrator/Indicator

User Manual

K249

©

Druck Limited 2005

This document is the property of Druck Limited and may not, either in part or whole, be copied or otherwise

reproduced, communicated in any way to third parties, nor stored in any data processing system, without the

express written authority of Druck Limited.

Page 1 of 68 K

249 Issue No. 4

Do Not Print This Page

Page 2

Page 2 of 68 K249 Issue No. 4

Do Not Print This Page

Amendment Record

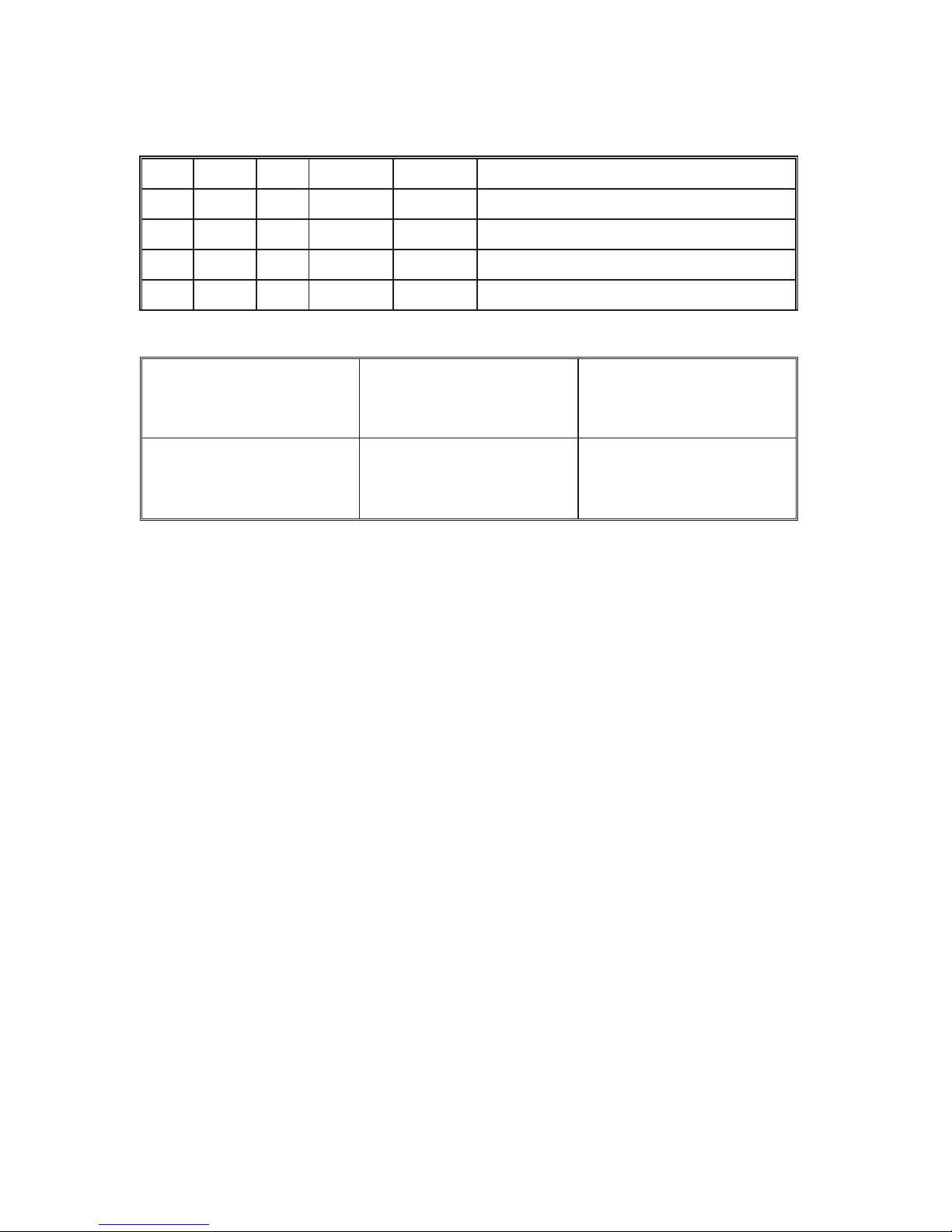

Iss No Date C/N No Originator Typed Amendments

1 17/01/00 - CER - New specification

2 13/09/01 12016 CER - No details recorded on amendment sheet

3 01/11/01 12946 CER - No details recorded on amendment sheet

4 05/07/04 15727 Bob Lee - Add copy of the Certificate of Conformity

Approvals

Engineering

Stephen Walls

Date:

Marketing

Mike Shelton

Date:

Publications

Paul Stephens

Date:

Engineering

Harbi Mankia

Date:

Page 3

Page 3 of 68 K249 Issue No. 4

Do Not Print This Page

Print Instructions

P

rint black on white, double sided as supplied on disk.

Print on paper to 110 gsm, Silverblade matt art, wiro bind in 270 gsm covers.

Size A5.

THIS PUBLICATION IS PRINTED EXTERNALLY, THIS HARDCOPY IS NOT TO BE USED AS

CAMERA COPY.

Page 4

Page 4 of 68 K249 Issue No. 4

Do Not Print This Page

Page 5

Druck DPI 610/615 IS

Portable Pressure Calibrator

User manual - K249

GE Infrastructure

Sensing

Page 6

Page 7

i

K249 Issue No. 4

English

DPI 610/615 IS

PORTABLE PRESSURE CALIBRATOR/INDICATOR

USER GUIDE

K249

DPI 610/615 IS Portable Pressure Calibrator

Calibrator Version Indicator Version

Hydraulic Actuator Version

Page 8

ii

K249 Issue No. 4

WARNING

B

efore operating this instrument, read the safety instructions!

© General Electric Company. All rights reserved.

Page 9

iii

K249 Issue No. 4

EnglishEnglish

Page 10

iv

K249 Issue No. 4

Safety

The manufacturer has designed this equipment to be s

afe when operated using

the procedures detailed in this manual. Do not use this equipment for any other

purpose than that stated.

This publication contains operating and safety instructions that must be followed

to ensure safe operation and to maintain the equipment in a safe condition. The

safety instructions are either warnings or cautions issued to protect the user and

the equipment from injury or damage.

Use suitably qual ified * technicians and good engineering practice for all

procedures in this publication.

Pressure

Do not apply pressures greater than the safe working

pressure to the equipment.

Toxic Materials

There are no known toxic materials used in construction of this equipment .

Maintenance

The equipment must be maintained using the procedures in this publication.

Further manufacturers procedures should be carried out by authorized service

agents or the manufacturers service departments.

Approved Service Agents

www.gesensing.com

Technical Advice

For technical advice contact the manufacturer.

*

A qualif ied technician must have the necessary technical knowledge,

documentation, special test equipment and tools to carry out the required

work on this equipment .

This equipment meets the requirements of all relevant European

safety directives. The equipment carries the CE mark.

This symbol, on the instrument, indicates that the user should refer

to the user manual. This symbol, in this manual, indicates a

hazardous operation.

Page 11

v

K249 Issue No. 4

English

Specification

Pressure Ranges (Internal Transducers)

Safe working pressure

20 bar range 1.75 x full-scale

350 bar range 1.2 x full-scale

400 bar range 1.5 x full-scale

All other ranges 2 x full-scale

Accuracy

Combined non-linearity, hysteresis and repeatability

±

70 mbar range 0.05% F.S.

up to ±150 mbar 0.05% span

200 mbar to 20 bar (Calibrator): 0.025% F.S.

35 bar to 700 bar (Indicator): 0.025% F.S.

70 bar to 400 bar (Hydraulic) 0.025% F.S.

Temperature Effects

±0.004% of reading/°C (averaged over -10° to -40°C w.r.t. 20°C)

Electrical Parameters

Voltage Inputs

Range: ±30V

Accuracy ±0.05% rdg, ±0.004% F.S.

Resolution 100µV max

Current Inputs

Range: ±55mA

Accuracy ±0.05% rdg, ±0.004% F.S.

Resolution 1µA max

Current sink

Range: 24mA

A

ccuracy ±0.05% rdg, ±0.01% F.S.

Display

Size: 60 x 60 mm LCD Graphics

Reading ±99999, update rate 2 readings/sec

Environmental

Operating Temp.: -10°C to 50°C (Calibrated -10°C to 40°C)

Storage Temp: -20°C to 60°C

Calibration Temp: 21°C ±2°C

Sealing

Sealed to IP54

Physical

Size: 300 x 170 x 140 mm

Weight: 3 kg

Page 12

vi

K249 Issue No. 4

Introduction

G

eneral

Description of Procedures 1

Using the Guide 2

Summary of Functions

OPERATOR CONTROLS 3

DISPLAY 3

HARD KEY FUNCTIONS 4

SOFT KEYS 5

CURSOR KEYS 5

ELECTRICAL CONNECTIONS 6

Getting Started

Fitting Batteries 7

Switching On 7

Change Pressure Units 8

Voltage and Current Measurements 8

Typical Calibration Set-up (Pressure to Voltage) 9

Zero Display Reading 9

Task Selection

Task Key 10

Using TASK Functions 10

Set Units 10

Cal Mode 11

Basic Mode (Task Basic) 11

Taking Measurements

Pressure Transmitter (P-I) Task 12

Voltage Output Pressure Transmitter (P-V) Task 12

Pressure Converter (P-P) Task 13

Current to Pressure Converter (I-P) Task 14

Pressure Switch Test (P-Switch) Task 14

Pressure to Display (P-Display) Task 15

Leak Tests (Leak Test) Task 16

Transmitter Simulator (TX SIM) Task 17

Relief Valve Test (REL VALVE) Task 18

CONTENTS

C

ontd./

Page 13

vii

K249 Issue No. 4

English

Advanced Task

General 19

Select Input 19

Ambient Temperature Measurement 19

Process Functions 20

Tare Process Function 21

Min/Max Process Function 22

Filter Process Function 22

Flow Function 23

% Span 23

Select Output 24

Electrical Outputs (Loop Power) 24

mA Step 25

mA Ramp 26

mA Value 27

Task Set-up/Removal 28

Define New Task 28

Clear Task 28

Memory Operations

Saving Display (Snapshot) or Datalog 29

Store Operations (Screen Snapshots) 29

Recalling Stored Data (Screen Snapshots) 29

Datalog Operations 30

Auto Log (T imer) 30

Manual Logging 30

Recall Datalog Files 31

Uploading Datalog Files 32

Delete Datalog and Procedure Files 32

Downloading Procedure Files 33

Running Procedure Files 34

Recalling Data Files 35

CONTENTS (contd.)

Contd./

Page 14

vii i

K249 Issue No. 4

Using Set-up

G

eneral 36

Store Mode 36

Contrast 36

Settings - Select Set-up Option 36

Units 37

Def ine Special Units 37

Language 37

RS232 38

Powerdown 38

Calibration 38

Date and T ime (Real Time Clock) 39

Date Format 39

Set Date 39

Set T ime 39

Calibration

General 40

Calibration Check 40

Calibration Adjustment 40

General Procedures 41

Using The Calibration Menu 41

Temperature 42

Change PIN number 42

Add External Sensor 42

Hydraulic Calibrator Version

Introduction 45

Safety Instructions 46

Preparation for Use 46

Bleeding the System 47

Operation 48

Draining the Hydraulic Fluid 48

Flushing, Replenishing or Changing the Hydraulic Fluid 49

Appendix 1 - Datalog File Example

Typical Uploaded Datalog File (DPI 610 IS) 53

Typical Uploaded Datalog File (DPI 615 IS) 54

Appendix 2 - Baseefa Certificate of Conformity

EC-Type Examination Certificate AP2-1

CONTENTS (contd.)

Page 15

1

K249 Issue No. 4

English

General

The DPI 610 IS and DPI 615 IS intrinsically safe instruments measure and display

pneumatic and hydraulic pressure applied to the test port . Pressure

measurement can be absolute, gauge and sealed gauge and in ranges from 2.5

mbar to 700 bar.

Calibrator versions of this instrument contain pneumatic or hydraulic pressure

generation components to produce pneumatic pressure ranges between -1 to 20

bar and hydraulic pressure ranges up to 400 bar.

Using external electrical connections, the DPI 610 IS and DPI 615 IS intrinsically

safe instruments measure ±30 volts d.c. and ±55 mA. An integral sensor provides

measurement of ambient temperature. Additional sensors (option B1) connect to

an external connector and extend the pressure measurement range and include

differential pressure measurement. The DPI 615 instrument has an RS 232

connector to enable downloading of test data to a compatible documenting

system. Six alkaline C size batteries, IEC Type LR14, power the instrument .

Important Notice

Zinc-carbon and zinc-chloride cells must NOT be used in this instrument.

Use only the battery types as shown in the Table on page 7.

Description of Procedures

In the procedures outlined in this User Guide, hard

(fixed function) and soft

(variable function) key operations are shown in bold type (e.g.) TASK and F1. These

statements mean press the TASK key and press the F1 key. Soft key operations

can be allocated to both the F1 and F2 keys. Where a specific soft function is

referred to it is written in bold italics (e.g.) PROCESS.

This instrument has a number of operating modes which are described in

simplif ied form in the following sections. Diagrams accompanying the procedures

give typical selection sequences and shaded controls indicate that this control key

should be pressed in the appropriate sequence. Diagrams should be read from left

to right, top to bottom where appropriate. A shaded display soft box indicates

that the function key immediately below that soft box should be pressed (either F1

for the left hand soft box or F2 for the right).

In the above diagram the following key sequence is indicated.

(a) Press the F2 key (the key immediately below the UNITS soft box).

(b) Use the Up and Down cursor keys (only) to select the required

option. (If all keys shaded, use all these keys to select or enter data).

(c) Press the ENTER key.

INTRODUCTION Summary of Functions

Page 16

2

K249 Issue No. 4

INTRODUCTION Summary of Functions

Using This Guide

The following key symbols are used in the procedure diagrams which follow

Shaded cursor keys indicate that a combination of these

four keys, Up, Down, Left and Right should be used to (e.g.)

enter an alpha numeric value or to select a function.

Indicates the ENTER key. Used to confirm an operation or a

selection. Shading indicates key operation.

Exit key, used to clear current menu selection and return to

next menu level above current level. Used as an escape key

from current operation. Shading indicates key operation.

Hardkey (total 7). Legend beside key symbol indicates

function. Shading indicates key operation.

Maximum Instrument Ratings

The following table shows the maximum measurement input ratings of the

instrument which should not be exceeded.

PRESSURE 120% FULL SCALE

VOLTAGE 30 V d.c.

CURRENT 55 mA d.c.

Note 1: The display flashes if the input pressure, voltage or current overrange.

Note 2: Max applied voltage for external loop supply = 30V dc (see Page 8).

Page 17

3

K249 Issue No. 4

English

Figure 1 - DPI 610/615 Key-pad

DISPLAY

The display section of the instrument basically divides into four distinct sections.

The two main sections of the display are used to display a Measurand (input

parameter) and a Source (output paramet er). The remaining sections are used as a

status display area and to def ine soft key functions. A typical display is shown

below (e.g.),

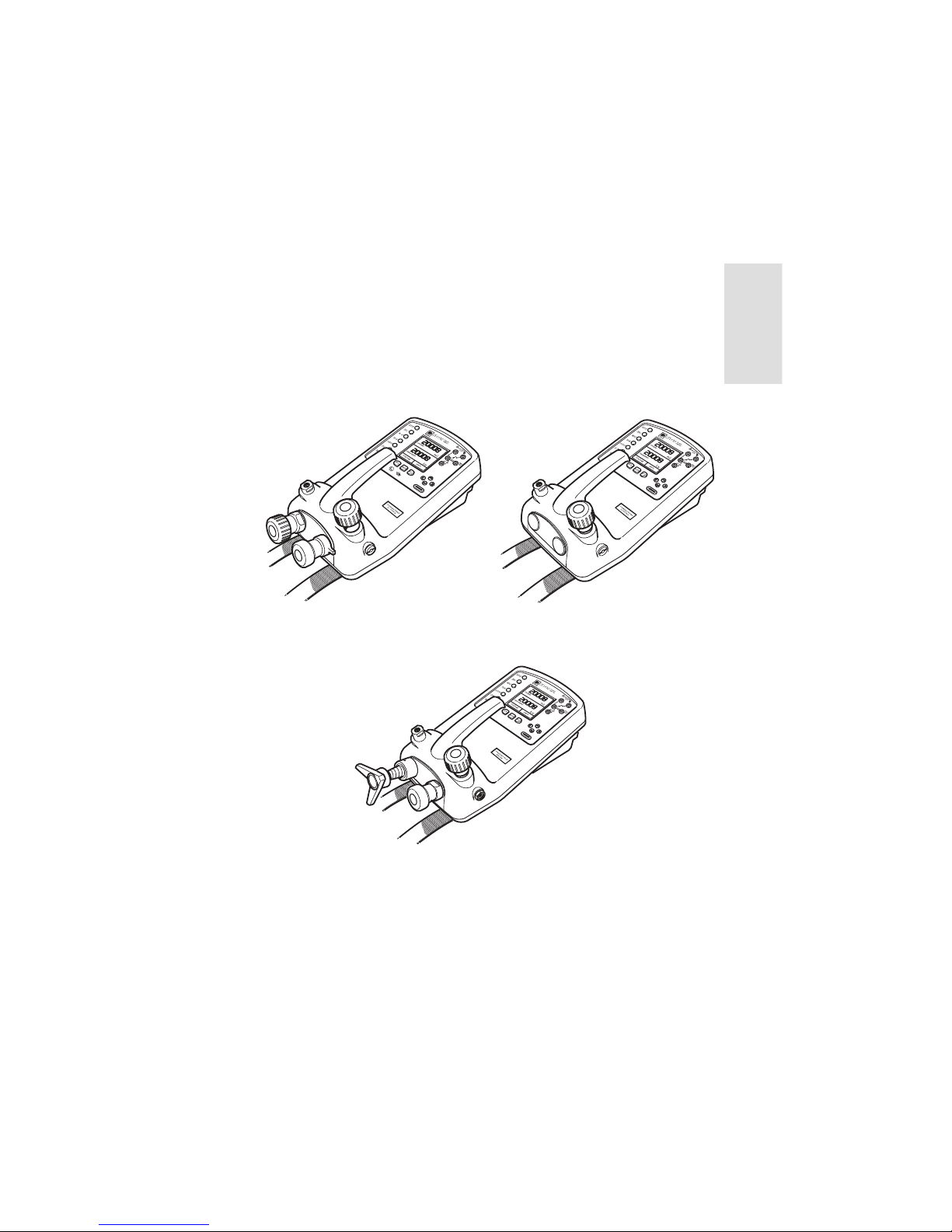

OPERATOR CONTROLS (Figure 1)

These divide into two groups, the operator/display c

ontrols (shown in Figure 1) and

the pressure/vacuum generation components (shown in Figure 2). The operator

controls and a typical display, common to all instrument versions, is shown below.

INTRODUCTION Summary of Functions

Page 18

4

K249 Issue No. 4

HARD KEY FUNCTIONS (Fig. 1)

INTRODUCTION Summary of Functions

yeK noitcnuF egaPfeR

O/I

.FFOdnaNOtnemurtsniehtnrutotdesusiyeksihT

7

*PUTES

ehT PUTES noitarugifnoclarenegs’tnemurtsniehtotsseccasedivorpyek

.yrevilednosretemaraptluafedniatrecotputeserahcihwsretemarap

63

OREZ

ehT OREZ

rodnarusaemdetcelesehtrehtieorezotdesuebnacyek

otstpmettA.orezfo%5nihtiwsignidaeryalpsidehtfi,yalpsidecruos

,egassemrorrenanitlusertesfforegralaorez

,egralootoreZ

9

*TUPNI

ehT TUPNI .deyalpsidsidnarusaemhcihwtcelesotdesusiyek 91,81

KSAT

ehT KSAT tnemurtsniehtgnirugifnocyld

iparfosnaemasadesusiyek

eraerehT.noitarbilacecivedlanretxefosepyttnereffidforebmunarof

demmargorp-erperahcihwfonevele,elbaliavasnoitarugifnocksatytnewt

.elbanifedresueraenindna

01

*TUPTUO

ehT TUPTUO ecruoss’tne

murtsniehtfohcihwtcelesotdesusiyek

.deyalpsidsistuptuo

72-42

*EROTS

s’tnemurtsniehtwohnopugnidnepeD EROTS siyeksiht,putessiedom

ni(sneercsyalpsid02otpuerotsotrehtiedesu TOHSPANS otro,)edom

nineercsagolyllaunam GOLATAD .edom

63,92

*LLACER

.yalpsidehtotneercsderotsylsuoiverpallacerotdesusiyeksihT

ehtnognidnepeD EROTS sllaceryeksihtfonoitarepo,pu-tesedom

nI.elifgolatadroneercsderotsylsuoiverpafotohspansehtrehtoe

EROTS ehtgnisuyB.derotsneercstsalehtsyalpsidnoitceles,edom

hguorhtkcabrodrawrofrehtiellorcsnacrotarepoeht,syekrosruc

.snoitacolyromem

53,13,82

RETNE

ehT RETNE ni,ro,)atadderetnetpecca(atadretneotrehtiedesusiyek

.noitcelesnevigatpeccaot,syektfosehthtiwnoitcnujnoc

2

TIXE

ehT TIXE tfosdnadrahrehtoehtllahtiwnoitcnujnocnisetarepoyek

yletaidemmilevelehtot,levelunemroneercstnerrucehtmorftixeotsyek

sserp,levelunemynamorfyletelpmoctiuqoT.tignidecerp TIXE ehtlitnu

ECRUOS/ERUSAEM .deyalpsidsineercs

2

* These key functions are not available in BASIC mode

Page 19

5

K249 Issue No. 4

English

SOFT KEYS (Fig. 1)

Three soft keys, designated F1, EXIT and F2, are situated immediately below the

display as shown below. These keys have their function allocated by the

instrument software which is indicated in the bottom of the display (Voltage for F1

and Units for F2 in this example). They are used to select menu (program) options

and are fully described under the appropriate section headings.

CURSOR KEYS (Fig. 1)

The cursor keys consist of a block of four keys, arr

anged as shown in Figure 1.

They are designated Up , Down , Left and Right . In programs where

options need to be selected from a list , (e.g.) the TASK selection program, the Up

and Down cursor keys are used to highlight one of the options, from which it can

be selected by the ENTER key. In TASK mode, where more than one page of

options are provided, the Left and Right cursor keys will switch between

pages.

INTRODUCTION Summary of Functions

F

igure 2 - DPI 610/615 IS Calibrator Controls

Release Valve.

Releases system

pressure through vent

port. Use to gradually,

or completely reduce

pressure.

Vent Port

Select positive or

negative pressure

Cursor Keys

Soft Keys

F1, EXIT, F2

Electrical Inputs,

V,I, Switch

and mA sink

External Interfaces under flap

Power, RS232, External Transducer

Pump, pressurises

test port and

internal sensor.

Use to approximately

set output pressure.

Fine pressure adjustment.

Start with control screwed

out half-way to allow

fine adjustment

up or down.

Test port.

Connect to unit under test.

G1/8" coupling.

Use a sealing washer.

Hard keys

5

Page 20

6

K249 Issue No. 4

ELECTRICAL CONNECTIONS

Figure 3 - Electrical System Connections

Measurement

inputs and Source Outputs are made via the control panel sockets as

shown below.

Figure 4 - Electrical Measurement Inputs/Source Outp

uts

INTRODUCTION Summary of Functions

PRESSURE INT

bar

VOLTAGE V

F2F1

Electrical

Measurement

Input Sockets

CURRENT

UNITS

INPUTS

OUTPUTS

Output Window

Input Window

PRESSURE

max 30V

CATII

TASK:BASIC

DPI 615 IS

Page 21

7

K249 Issue No. 4

English

The first time that the instrument is powered up, it will power-up in BASIC mode

with the main screen displaying voltage in the measurand display area and

pressure in the source display area. To switch to Current as measurand, press F1

as shown. Similarly, F1 to return to Voltage.

Note: No other keys are active in this mode and the instrument can only be

reconf igured by pressing the TASK key and selecting another mode.

Fitting Batteries

G

etting Started

WARNING: BATTERIES MUST ONLY BE FITTED IN A SAFE AREA.

USE ONLY THE BATTERIES SPECIFIED IN THE TABLE.

Caution: Old batteries can leak and cause corrosion. Never leave

discharged batteries in the instrument. Old batteries should be treated

as hazardous waste and disposed of accordingly.

Switching On

Press the I

/O switch on the front panel and proceed as follows.

rerutcafunaM .oNepyT

rezigrenE 39NEepyTlairtsudnI

rezigrenE 2MA.C.41RL.39E

llecaruD 41RL-0041NM

atraV

epyT4104.oN

2MA.C.41RL

llecorP 41RL-0041NM

Page 22

8

K249 Issue No. 4

Change Pressure Units

To change the pressure units proceed as follows. If

the four units displayed are

not the units required, press TASK and select any task, other than BASIC, press

SETUP and proceed as detailed on page 36. To return to BASIC mode, press TASK

and select BASIC.

In BASIC mode, the unit is configured to carry out basic Pressure to Voltage (P to V)

or Pressure to Current (P to I) tests, a typical test procedure follows.

Voltage and Current Measurements

Connect the electrical input sockets as follows for

voltage and current

measurements. Use the test leads provided and DO NOT push bare wires into the

sockets.

Note: Maximum applied voltage = 30V dc,. Maximum input current = 55mA dc

Getting Started

Note: Maximum applied voltage for external loop supply = 30V dc

Page 23

9

K249 Issue No. 4

English

PRESSURE INT

bar

VOLTAGE

F2F1

V

P

V

-+

CURRENT

PRESSURE

UNITS

Ext Press. Source

(Indicator Only)

Pressure

Regulator

Max30V

CATII

-

+

+

-

BARRIER

SAFE

SAFE

EXT

SUPPL

Y

TASK:BASIC

DPI 615 IS

Typical Calibration Setup (Pressure to Voltage)

Connect a device under test to the instrument as shown below.

General Procedure

Use the hand-pump to pressurise the system to the re

quired level as

indicated on the display. Allow the display to settle and screw the volume

adjuster in or out as a fine adjustment to the required pressure. Record the

measurand (e.g.) Voltage, reading at each applied pressure.

Zero Display Reading

Both the input and output windows can be set to zero by operation of the ZERO

key, providing that the displayed reading is already within 5% of zero. To zero

either the INPUT (Measurand) or OUTPUT (Source) windows, proceed as follows

(e.g.),

Getting Started

Page 24

10

K249 Issue No. 4

Task Selection

Task Key

The TASK key is used to set up the instrument for a

number of specif ic types of

test . There are two modes BASIC and ADVANCED and nine other specif ic types of

test which automatically configure the instrument on selection from the TASK

menu. The tasks available under the TASK menu are held on three pages shown

below. To select a task from the menu, press the TASK key, position the cursor over

the desired task and press the ENTER key as shown below. Use the right/left cursor

keys to switch between pages.

Using TASK Functions

Specific tasks are selected as shown above. The following diagrams show how to

connect the unit under test (UUT) for each task selectable under the TASK menu.

Input and Output units, where applicable can be selected by pressing either the

INPUT or OUTPUT keys as shown below.

Set Units

Note: I

f the four units displayed are not the units required, press SETUP, select

SETTINGS and refer to Page 36.

Page 25

11

K249 Issue No. 4

English

Cal Mode (DPI 615 versions only)

Cal mode, which is available in tasks P-I, P-P, P-V, P-P, P-DISPLAY and P-SWITCH,

provides a method of setting up test parameters manually. Downloaded test

procedures can also automatically set up and turn on the Cal Mode function. The

method of turning on and setting up Cal Mode is shown below for a P-I task. The

method is similar for all the other tasks to which Cal Mode applies.

Pressing the F1 key (TURN ON CAL MODE), provides the set-up screen for the CAL

mode. Initially, the cursor is placed in the UUT SPAN field to allow the required

span range to be entered. The corresponding values for the UUT output

parameter (current) are then set, followed by the maximum error value and error

type (%rdg or %Span). When all test parameters have been set-up, the screen

changes to display the input and output and the test results. The test result can

only be displayed to within a range of ±9.99%. If the test result is outside this

range, either the left pointing (-ve error) or right pointing (+ve error) chevrons are

displayed. W ithin this error band, the actual tolerance value is displayed. Test

results can either be stored as snapshots or logged as datalog f iles, depending

upon how the instrument has been set-up.

Basic Mode (Task BASIC)

This instrument will power-up in this mode the first

time that it is used. To select BASIC

from any other task, press the TASK key and select BASIC and press the ENTER key.

BASIC mode is fully described in the Getting Started, section (see page 7).

Task Selection

Page 26

12

K249 Issue No. 4

Pressure Transmitter (P-I) Task

Select the P-I task from the task menu and connect t

he Unit Under Test (UUT) to

the calibrator as shown below.

Taking Measurements

If required, select the output units as described o

n page 10.

If applicable, turn on Cal Mode and set-up test parameters as detailed on

page 11.

Voltage Output Pressure Transmitter (P-V) Task

Select the P-V task from the task menu and connect the Unit Under Test (UUT) to

the calibrator as shown below.

P

I

Ext Press. Source

(Indicator Only)

Pressure

Regulator

PRESSUREINT bar

CURRENT mA

F2F1

+

+

-

BARRIER

SAFE

SAFE

EXT

SUPPLY

max30V

TASK: P-I

SNAPSHOTMODE

DPI 615 IS

If required, select the output units as described on page 10.

If applicable, turn on Cal Mode and set-up test parameters as detailed on

page 11.

PRESSURE INT

bar

VOLTAGE

F2F1

V

P

V

-+

CURRENT

PRESSURE

UNITS

Ext Press. Source

(Indicator Only)

Pressure

Regulator

Max30V

CATII

-

+

+

-

BARRIER

SAFE

SAFE

EXT

SUPPLY

TASK:BASIC

DPI 615 IS

Page 27

13

K249 Issue No. 4

English

Taking Measurements

Pressure Converter (Pressure to Pressure) Task

Select the P-P task from the task menu and connect the Unit Under Test (UUT) to

the calibrator as shown below. Testing a converter requires one pressure to be

applied to the unit under test (UUT) and another (converter output) to be

measured. The additional measurement is provided by the external transducer

option.

Method

Connect the UUT to the calibrator as shown below an

d plug the external

transducer into the calibrator as shown below.

USERS2 32

INSAFE

AREAONLY

Press the TASK key and select the P-P task. Providing the external

transducer has been calibrated and its parameters stored in the

instrument , the display will show External pressure in the input window

and calibrator Output pressure in the output window. If an error message

NO SENSOR OR CAL INVALID is displayed, this indicates that the external

transducer has not been entered and/or calibrated with the instrument.

Refer to Page 42 for details of adding an external transducer. If an external

transducer change is made, switch the calibrator off and then on to load

new transducer data.

If required, select the input and output units as described on page 10.

If applicable, turn on Cal Mode and set-up test parameters as detailed on

page 11.

Page 28

14

K249 Issue No. 4

P

I

-

PRESSUREINT

bar

F2F1

External

Pressure

Supply

OUTPUT

NEW VALUE

CURRENT mA

OK

+

+

-

-

BARRIER

SAFE

SAFE

EXT

SUPPLY

max30V

TASK: I-P

SNAPSHOTMODE

DPI 615 IS

Current to Pressure Converter (I-P) Task

Taking Measurements

Use the U

p and Down cursor keys to adjust the loop current to the

required value. Alternatively, press ENTER and use cursor keys to enter a

finite value. Cursor keys can then be used to nudge the output either up or

down.

If required, change pressure units with INPUT key. A flashing CHECK LOOP

message indicates either an open circuit supply loop (or no external

supply).

Pressure Switch Test (P-SWITCH) Task

Contact state will be shown on display. When conta

cts close, buzzer sounds.

To run switch test, close vent valve and press the RUN (F1) key.

Using the handpump, increase the appl ied pressure to just below the

switch operating point. Screw the volume adjuster in until the switch

operates (the operating pressure of the switch is then written to the

display).

Reduce pressure until the switch releases (indicated by the switch symbol).

The release pressure is then written to the display and the hysteresis

displayed.

PRESSUREINT

bar

F2F1

External Pressure Source

(Indicator Only)

Pressure

Regulator

RUN

CONTACTSTATE

max30V

TASK: P-SWITCH

SNAPSHOTMODE

DPI 615 IS

Page 29

15

K249 Issue No. 4

English

External Pressure Source

(Indicator Only)

Pressure

Regulator

TEST UNIT

(Dial Gauge)

PRESSURE INT bar

F2F1

DISPLAY

CHANGE

VALUE

TASK: P-DISPLAY

SNAPSHOT MODE

max30V

DPI 615 IS

Taking Measurements

Pressure to Display (P-DISPLAY) Task

P-Display is a special application of Datalog. To use this mode, select Datalog

from the Store Mode menu as detailed on Page 36. Connect the device under test

to the instrument as shown below and, if required, turn on and set-up Cal Mode

(see page 11).

After logging final test point, terminate as follows (e.g.),

Press TASK and select P-DISPLAY. If required, use OUTPUT key to change

pressure units.

Set-up a datalog file as detailed on Page 30.

Note: TRIGGER f ield, automatically set to KEYPRESS, cannot be changed.

Apply a series of test pressures to the device under test. Enter displayed

reading at each pressure and log each point (e.g.),

Page 30

16

K249 Issue No. 4

Leak Test (LEAK TEST) Task

Taking Measurements

Close the vent valve and pressurise the external system to the required

LEAK TEST pressure.

Press the RUN (F2) key to start the leak test. When completed, the bleeper

sounds and the leak test results are written to the display.

If required, use the INPUT key to change pressure units.

Set-up the leak test WAIT and DURATION times to the required values as

shown below. A minimum wait period of 3 minutes is recommended.

External Pressure Source

(Indicator Only)

Pressure

Regulator

EXTERNAL

SYSTEM

PRESSURE INT bar

F2F1

RUN

CHANGE

VALUE

WAIT

DURATION

STARTPRESS

STOP PRESS

PRESS CHANGE

LEAK RATE

secs

secs

bar

bar

bar

bar/m

60

60

max30V

TASK: LEAK TEST

SNAPSHOT MODE

DPI 615 IS

Page 31

17

K249 Issue No. 4

English

On completion of Tx SIM set-up, the display is configured as follows (e.g.).

Connect an external power source to the output loop as detailed on Page 24.

To subsequently change any of the Tx SIM scaling parameters, press CHANGE

VALUE key (F1) to obtain the TX Simulation set-up display.

To change the pressure units, press INPUT and select the required scale units. If

the required scale units are not listed, press SETUP, select SET TINGS and proceed

as detailed on Page 37.

Taking Measurements

T

ransmitter Simulator (TX SIM) Task

When used with an external voltage source (see Page 24), provides a current

output proportional to the calibrators measured output pressure (indicated

pressure on indicator only version). Select task TX SIM. Press EXIT to skip set-up

screen if parameters are correct.

Page 32

18

K249 Issue No. 4

To change the pressure units, if required, press I

NPUT and select the

required units using the cursor keys.

Close the vent valve and, using the hand-pump or external pressure

supply, apply pressure to the relief valve under test .

When the relief valve operates, the maximum recorded pressure indicates

the operating point of the valve.

Record the test results.

Note: The STORE key can be used for this purpose. Use right cursor key

initially, followed by up/down keys to enter Snapshot text.

Open vent valve to release test pressure.

Note: If using external pressure supply, isolate supply before opening the

vent valve.

Taking Measurements

R

elief Valve Test (REL VALVE) Task

To carry out a relief valve test , press TASK and select REL VALVE. Connect the

output pressure port of the instrument to an external system as shown below.

PRESSURE INT

bar

bar

RESET

MAXIMUM

MINIMUM

MAX/MIN

F2F1

External Pressure Source

(Indicator Only)

Pressure

Regulator

PRESSURE INT

max30V

TASK: RELVALVE

SNAPSHOT MODE

DPI 615 IS

Page 33

19

K249 Issue No. 4

English

General

Advanced task allows the user to configure the instrument to monitor one of a

number of different input measurands (Inputs) and outputs (Sources).

Additionally, five process functions, Tare, Max/Min, Filter, Flow and % Span can

be applied to the input functions.

Select Input

To select an input channel for display, select A

DVANCED Task from the task menu

and proceed as follows. If, in addition to process functions, a range of units is

available for the selected channel, a UNITS soft box (actioned by the F2 function

key), will be written to the display.

The following procedure shows the method of input channel selection and the

method of changing units (e.g.),

Note: Left/right arrow keys function as page up/down keys .

Refer to pages 20 to 23 for details of process functions.

Ambient Temperature Measurement

To set-up the instrument to read ambient temperature

, proceed as follows (e.g.),

Note: Ensure that the temperature reading has stabilised.

Advanced Task S

elect Input

Page 34

20

K249 Issue No. 4

Process Functions

If required, the following process functions are available on the Measurand (INPUT)

display but only in ADVANCED task. If the instrument is in any other mode i.e.

BASIC or any other task mode, the input and output displays must first be

configured in ADVANCED task.

Note: PROCESS functions are not available to the output (SOURCE) channel.

A summary of the process functions follows.

Tare Allows either the current display value or a manually

entered value to be tared off display parameter

reading.

Max/Min Displays running Max/Min and Present display values

simultaneously. Resettable via F1 key.

Filter Applies low pass f ilter function to displayed

parameter. Filter characteristics (Settling time and

Band) are user programmable.

Flow Applies square root function to displayed parameter.

% Span Converts displayed parameter reading to a

percentage of span. Span definable via the F1 key.

Following selection of ADVANCED from the task menu, press the INPUT key. Use

the Up

or Down cursor keys to select the required input. Press the PROCESS

(F1) key and use the Left or Right cursor keys to enable the process on/off

(e.g.),

Press ENTER to switch the process ON with existing settings or F1 to change

process settings (where applicable).

Advanced Task Process Functions

Loading...

Loading...