GE DPGT750GC2WW, DPGT750GC2PL, DPGT750GC1PL, DPGT750GC1WW Owner’s Manual

0

Q.

GEAppliances.com

Safety Instructions ........... 2-5

Operating Instructions

Controls .............................. 6

Cycle Options ........................ 8

Dryer Features ...................... 15

Help ............................. 13, 14

Loading and Using

the Dryer ........................ 16, 17

"My Cycles" . .................... 11, 12

Quick Start Guide .................... 7

Summary Screen ................ 9, 10

Troubleshooter ..................... 13

Installation Instructions

Before You Begin ............... 18-20

Connecting a Gas Dryer ........ 21-24

Connecting an

Electric Dryer ................... 25-27

Exhausting the Dryer ........... 28-32

Final Setup ...................... 33, 34

Reversing the Door Swing ...... 35, 36

Switching the Washer and

Dryer Backsplashes ............ 37-40

DPGT750

Troubleshooting Tips ........ 4_

Consumer Support

Consumer Support ................. 4/4

Warranty .......................... 43

Write the model end seriol

numbers here:

Model #

Seriol #

They are on the label on the front

of the dryer behind the door.

Printed in Korea 175D1807P641 49-90379 04-09 JR

IMPORTANT SAFETY INSTRUCTIONS

READ ALL INSTRUCTIONS BEFORE USING.

Ak WARNING! For your safety, the information in this manual must be followed to

minimize the risk offire or explosion, electric shock, or to prevent

property damage, personal injury, or loss of life.

*Do not store or use gasoline or other

flammable vapors and liquids in the vicinity

of this or any other appliance.

*Installation and service must be performed by

a qualified installe,; service agency or the gas

supplier.

WHAT TO D 0 IF YOU SMt_2LLGAS:

O Do not try to light a match, or cigarette,

or turn on any gas or electrical appliance.

Do not tot_ch an}_electrical switch; do not

use any phone in your building.

O ;lea, the room, building, or area of all

occupan ts.

Cali}rnia Safe Drinking Water and Toxic El_rcement Act

This act requires the governor of Calif_rnia to publish a list of substances known to the state to

cause cancer, birth defects or other reproductive harm and requires businesses to warn customers

of potential exposure to such substances.

Gas appliances can cause minor exposure to f_ur of these substances, namely benzene, carbon

monoxide, f_rmaldehyde and soot, caused primarily by the incomplete combustion of naulral gas

or LP fi_els.

Properly adjusted dryers will minimize incomplete combustion. Exposure to these substances can

be minimized further by properly venting the d_)_er to the outdoors.

Immediately call your gas supplier

O

from a neighbor's phone. Follow the

gas supplier's instructions carefillly.

If you cannot reach your gas supplie_,

O

call the fire department.

IMPORTANT SAFETY INSTRUCTIONS

READ ALL INSTRUCTIONS BEFORE USING.

WAP NING ! For your safety, the information in this manual must be followed to minimize the risk offire

or explosion, electric shock, or to prevent proper_ damage, personal injury, or loss of life.

PROPER INS TALLA 770N

This du(<r m_Lstbe [Jro[._<rlyinstalled arid located ir_accordance with the lnstallatior_ Instructions b@_v it

is _sed. lnstallatior_ lns#_uctions a_v ir_cluded ir_the back c_this marmal.

Properly ground dryer to conform with all

governing codes and ordinances. Follow derails

in Installation Instructions.

Install or store where it will not be exposed

to temperatures below fleezing or exposed to

the weather

Connect to a properly rated, protected and

sized power supply circuit to avoid electrical

overload.

Remove all sharp packing items and dispose

of all shipping materials properly.

Exhaust/Ducting:

[7] Gas dryers MUST be exhausted to the

outside.

Exhausting electric dryers to the outside is

strongly recommended to prevent large

amounts of moisture and lint flom being

blown into the room.

Use only rigid metal 4" diameter duct_,vork

inside the dryer cabinet. USE OF PLASTIC

OR OTHER COMBUSTIBLE DUCTWORK

CAN CAUSE A FIRE. PUNCTURED

DUCTWORK CAN CAUSE A FIRE IF ff

COLLAPSES OR BECOMES OTHERWISE

RESTRICTED IN USE OR DURING

INSTAI_J_ATION.

YOUR LA UNDR Y A! 2A

Keep the area tmderneadl and arotmd your

appliances flee of combustible materials

(lint, paper; rags, etc.), gasoline, chemicNs

and other flammable vapors and liquids.

Keep the floor around your appliances clean

and d W to reduce the possibility of slipping.

Close supervision is necessm T if dfis appliance

is used by or near children. Do not allow

chiktren to play on, with or inskte this or

any other appliance.

For complete derails, fbllow the Installation

Instructions.

*Keep the area around the exhaust opening

and adjacent surrounding areas flee flom the

accumulation of lint, dust, and dirt.

*Keep aH laund W aids (such as demrgents

and bleaches) out of file reach of children,

preferably in a locked cabinet. Obsexwe all

warnings on container labels to avoid i_0m>

*Never climb on or stand on the dwer top.

IMPORTANT SAFETY INSTRUCTIONS

READ ALL INSTRUCTIONS BEFORE USING.

WARNING! For your safety, the information in this manual must be followed to minimize the risk of fire

or explosion, electric shock, or to prevent property damage, personal injury, or loss of life.

WHEN USINGeY0 UR DR YER

Never reach into file d,Ter while die drum is

moving. Befbre loading, unloading, or adding

clothes, wait until the drum has complemly

stopped.

*Clean die lint filter before each load to prevent

lint accumulation inside the dryer or in the

room. DO NOT OPERATE THE DRYER

WITHOUT THE LINT FILTER IN PLACE.

*Do not wash or d,Tarticles flint have been

cleaned in, washed in, soaked in or spotted

with combustible or explosive substances

(such _kswax, oil, paint, gasoline, degreasers,

dry-cleaning sokents, kerosene). These

substances give off vapo,_ that mW igmim or

explode. Do not add these substances to the

wash water Do not use or place these

substances around your washer or dryer

during operation.

Do not place items exposed to cooking oils in

your dryer Imms conmminamd with cooking

oils may conuibum to a chemicN reaction that

couM cause a clothes load to catch fire.

*Any article on which you have used a cleaning

solvent or that contains flammable mamria/s

(such _kscleaning cloths, mops, towels used

in beaut T salons, restaurants or barber shops)

must not be placed in or near the dryer until

sokents or flammable materials have been

removed. There are ma_W highly flammable

imms used in homes such as acetone,

denatured alcohol, gasoline, kerosene,

soiile household cleaners, some spot reIllove_3,

t/iYpentines, w_txes, wax ieinovei3 and

products containing penoleum disfillams.

*The laund_T process can reduce file flame

remrdancy of rid)tics. To avoid such a result,

careflflly fbllow the gamlent manufimmrer's

care instructions.

*Do not dW ardcles containing rubbe_; pkLsfic,

foam or similar materials such as padded bras,

galoshes, bath mats, rugs, bibs, baby pants,

plasdc bags and pillows, that m W melt or burn°

Some rubber materials, when heated, can

under certain circmnsmnces produce fire by

spontaneo tlS coIIlbtlstion.

*Do not store pkkstic, paper or clodflng flint

may burn or melt on top of the dryer during

operation.

* Garments labeled Dry Away from Heat or

Do Not Tumble Dry (such as life jackets

containing kapok) must not be put in

your dryer

*Do not dIT fiberglass articles in yore dryer

Skin irritation could result flom file remaining

particles that may be picked up by clothing

during subsequent dwer uses.

*To minimize die possibility of electric shock,

unplug this appliance flom the power supply

or disconnect the dryer at the building's

distribution panel by removing the fhse or

switching off the circuit breaker before

attempting any mainmnance or cleaning

(except the removal and cleaning of the lint

filter). NOTE: Pressing STOP or POWER

does NOT disconnect the appliance flom

the power suppl>

IMPORTANT SAFETY INSTRUCTIONS

READ ALL INSTRUCTIONS BEFORE USING.

WARNING ! For your safety, the information in this manual must be followed to minimize the risk of fire

or explosion, electric shock, or to prevent property damage, personal injury, or loss of life.

WHEN USING

YOUR DR YER (cont.)

e

Never attempt to operate dlis appliance if

it is dmnaged, ma/fhncdoning, partially

disassembled, or has missing or broken parts,

including a dmnaged cord or plug.

The interior of die machine and die exhaust

duct connection inside the diTer should be

cleaned at least once a year by a qualified

mchnician. See the Loading and Using the

Dryer section.

e If yours is a gas &yet; it is equipped widl an

automatic electric ignition and does not have

a pilot light. DO NOT ATTEMPT TO LIGHT

WITH A MATCH. Burns m W result flom

having your hand in tlle vicinity of tlle burner

when the autonmdc ignition turns on.

WHEN NO T USING YOUR DR YER

(;rasp the plug firmly when disconnecting this

appliance to avoid damage to the cord while

pulling. Place the cord away flom mfffic areas

so it will not be stopped on, tripped (wer or

subjected to damage.

Do not attempt to repair or replace any part

of dfls appliance or attempt any sexwicing

unless specifically recommended in this

Owner's Manual or in published user-repair

instructions that you understand and have

the skills to carry out.

*You may _,visllto soften your laundered fhbrics

or reduce the smdc electricity in them by using

a drye>applied rid)tic softener or an andsmfic

conditioner We reconmlend you use either

a fabric softener in tlle wash cycle, according

to the mamffhcmrer's instructions for those

products, or try a dryer-added product for

which the mamffhcmrer gives written assurance

on the package that their product can be safely

used in your dryer Service or perfbmmnce

problems caused by use of these products are

the responsibility of the manufacturers of

those products and are not covered under

the warranty of this appliance.

* gefbre discarding a dryer; or removing it flom

sela'ice, remove the dwer door to prevent

children flom hiding inside.

* Do not romper with controls.

P__AD AND FOLLOW THIS SAFETY

INFOP_fATION CAREFULLY.

SAVE THESE INS TR UC TIONS.

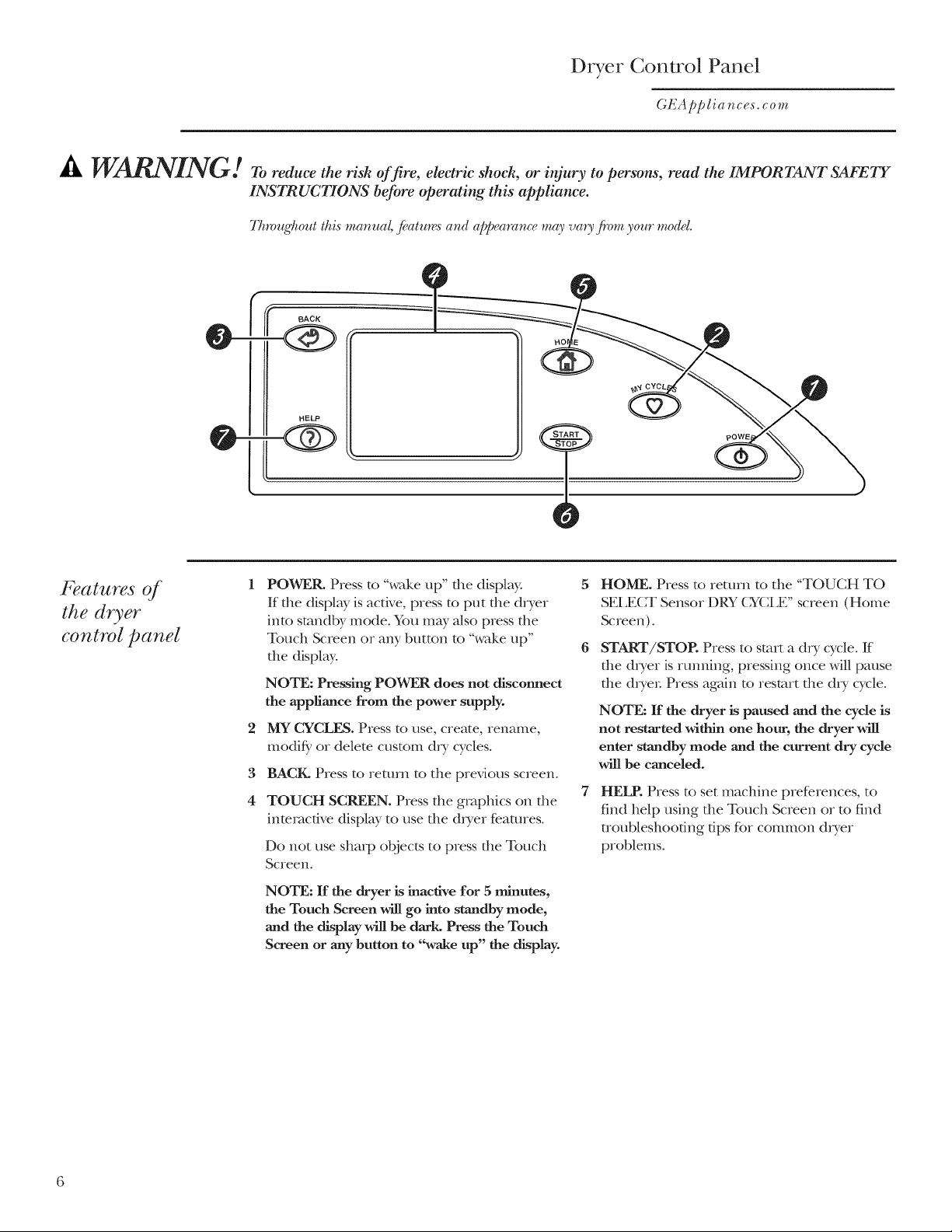

Dryer Control Panel

GEA /_/_Iiar_ces. corn

it WARNING!

Features of

the dryer

control panel

To reduce the risk of fire, electric shock, or injury to persons, read the IMPORTANT SAFETY

INSTRUCTIONS before operating this appliance.

BELP

POWER. Press to "wake up" file display. 5

If die display isactive, press to put die dryer

into standby mode. You mW a/so press the

Touch Screen or any button to "wake up" 6

the display.

NOTE: Pressing POWER does not disconnect

the appliance from the power supply.

MY CYCLES. Press to use, create, rename,

modif_ or delete custom dry cycles.

3

BACK. Press to return to the previous screen.

4

TOUCH SCREEN. Press the graphics on the

interactive display to use the dryer fe.amres.

Do not use shmp objects to press the Touch

Screen.

HOME. Press to return to the "TOUCH TO

SELECT Sensor DRY (XCLE" screen (Home

Screen).

START/STOP. Press to start a chT cycle. If

the &Ter is running, pressing once will pause

the dryer Press again to restart the dry cycle.

NOTE: If the dryer is paused and the cycle is

not restarted within one hour, the dryer will

enter standby mode and the current dry cycle

will be canceled.

HELP. Press to set machine preferences, to

find help using the Touch Screen or to find

troubleshooting tips for common dryer

problems.

NOTE: If the dryer is inactive for 5 minutes,

the Touch Screen will go into standby mode,

and the display will be dark. Press the Touch

ScTeen or any button to "wake up" the display.

Quick Start

Gb2Applia r_ces, corn

Getting

Started

If the 7buch

Sc_ven is dark,

p_v,s_POWER

or the 7buch

Screen to access

the dry cycles

'}Tlg Tl _ .

Clean the lint filteL

0

IMPORTANT: Clean the lint filter each time

youuse the (hTe_:

A&t clothes. Do not overload. This ,xvtsms

energ0,and promoms _rinkling.

Select one ofthe fi_v(h).ing methods fiom the

Home Screen:

*Press BYFABRIC to (h?' according to fabric

type.

*Press BYGARMENT to &?'according to

clodfing type.

*Press SPECIAL CYCLESto (hy nongarment

items, todr) without heat or to (hy using the

(h?ing tack.

*Press TIMED DRYto specif_.'a (hying time

and tempecature.

* Press WASHER RECOMMENDED CYCLE

to tcansfer the infbmmtion that was input

into the washer to the &),'e_:

Change an} of the automatic settings, if

@

desired, by pressing the Touch Screen and

fbllowing the on-screen instructions.

Bychanging the settingsyou can:

*Change the levelof(hyness

*Change the (h).ing tempecature

*Seta Delay Start or Extended Tumble, or

change the End<)fCycle Signalvolume

*Adjust time settings

TOUCH TO SELECT DRY CYCLE

1T,MEOORY

">%m"

SPECIAL CYCLE

BY FABRIC CYCLES

HomeScreen

SUMMARY SCREEN

COTTONS MORE DRY

BY GARMENT

WASHER

RECOMMENDED

%

0:36

Washer

Communicated

Cyc#s

Close the door and press START.

0

The &).'er willnot opecate unless the door is

closed.

If the _¢\;tsher/D,yerCommunication features of your

,_asherand (hTerare turned ON, your (h}>r will

recei_ cycleinfbmmfion fiom your _tsher to cream

a (hy cyclethat matches your ,_vtshload.

Mter the washQcle is complete, conmmnication

begins once either the washer or (h).'er Touch Screen

isactivated.

Once the infbmmdon isrecei;ed, your &?w can

then cream the optimal (tU cyclefor )_)urload. _bu

can then change any of the automatic cycles,as

desired.

NOTE: For some conmmnicated wash cycles your

&?'erwill prompt you to selecta FABRICTYPE.

See "Final Setup" in the Installation Instructions fbr

attaching the serial cable fbr _tsher/Duer

Conmmnication.

SENDING INFO TO DRYER...

WasherDisplay

lP

RECEIVING...

DryerDisplay

Dryer Cycles

GEAppgia noes. corn

If the Touch Screen is dark, press POWER or the Touch Screen to access the dry cycles menu.

The default cycle settings are based on standard load types. Always follow the fabric

manufacturer's care label when laundering.

Drying by

l_)_bric Type

Drying by

Garment

Type

Drying

Using the

@ecial

@des

Select By FABRIC to dry loads sorted by fabric type.

FABRIC CYCI,ES include:

* Blends (on some

models)

* Cottons * F_fits

<"Delicates

Select By Garment to dry loads sorted by garment type.

GARMENT (_CLES include:

*Athletic Wear *Jackets/Coats * Play Clothes

. Blouses *Jeans . Silks (Washable)

* Delicates * Khakis * Sweaters

* Dress Shirts * F_fits * Swimwear

* Easy Care * Lingerie * Underwear

* Everyday * Mixed Garments

Wear/Casual

Select SPECIAL CYCLES to dry loads of nongarment items, use the

drying rack or to tumble using low or no heat.

SPECIAL (NCLES include:

* Air Dry * Pet Bedding * Throw Rugs

* Blankets (Cotton) (Washable) (Washable)

* Blankets (Other)

<"Comfbrter

* Dewrinkle

* Dryelr' * Washable Wools

* Easy Care (on

some models)

* Pillows (Washable) * Towels

* Rack Dry * WarIn Up

* Sheets * Hosiew/Bra

* Sneakers (mesh bag)

<"Polyester

* Silks (Washable)

BY FABRIC

Drying Using

Timed D U

Select TIMED DRY to set your own drying time.

Timed Dry is also recomInended if>rsmall loads.

1 Press TIMED DRY.

2 Use the arrows to set more or less time; then press OK.

3 Use the arrows to set the temperature; then press OK.

4 Press START.

._ i TIMED DRY

[ "" % ]

Summary Screen

GEApplia r_ces,corn

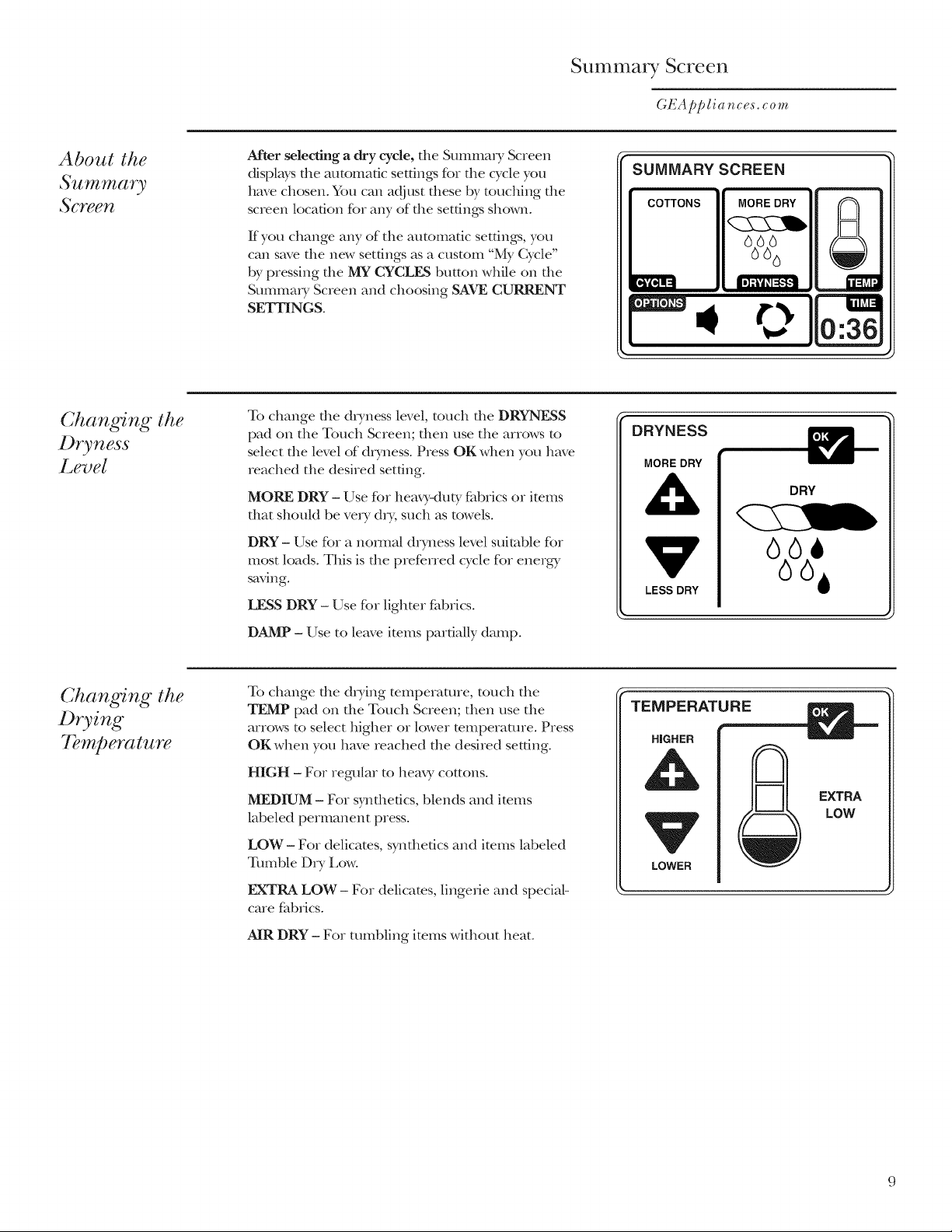

About the

Summa U

Screen

Changing the

Dryness

Level

After selecting a dry cycle, the Summary Screen

displays the automatic settings for the cycle you

have chosen. You can adj ust these by touching the

screen location for any of the settings shown.

ff you change any of the automatic settings, you

can save the new settings as a custom "My, Cycle"

by pressing the MY CYCLES button while on the

Sumtnm y Screen and choosing SAVE CURRENT

SETTINGS.

To change file dxyness level, touch file DRYNESS

pad on the Touch Screen; then use the arrows to

select the level of dryness. Press OK when you have

reached the desired setting.

MORE DRY - Use for heaxT<tuty fabrics or items

that should be ve_T dry, such as towels.

DRY- Use for a nomml dryness level suitable for

most loads. This is the preferred cycle for energy

saving.

LESS DRY - Use for lighter fabrics.

DAMP - Use to leave items partially damp.

SUMMARY SCREEN

COTTONS MORE DRY

%

llihV_l=

0:36

DRYNESS

MORE DRY

DRY

LESS DRY

Changing the

Drying

7?mpera ture

To change die &ying temperature, touch the

TEMP pad on the Touch Screen; then use the

arrows to select higher or lower temperature. Press

OK when you have reached the desired setting.

HIGH - For regular to hem T cottons.

MEDIUM - For synthetics, blends and items

labeled permanent press.

LOW - For delicates, synthetics and items labeled

Tumble D_T Low.

EXTRA LOW - For delicates, linge,ie and special-

care fabrics.

AIR DRY - For tumbling items without heat.

TEMPERATURE

HIGHER

EXTRA

LOW

LOWER

Summary Screen

GEApplia r_ces,corn

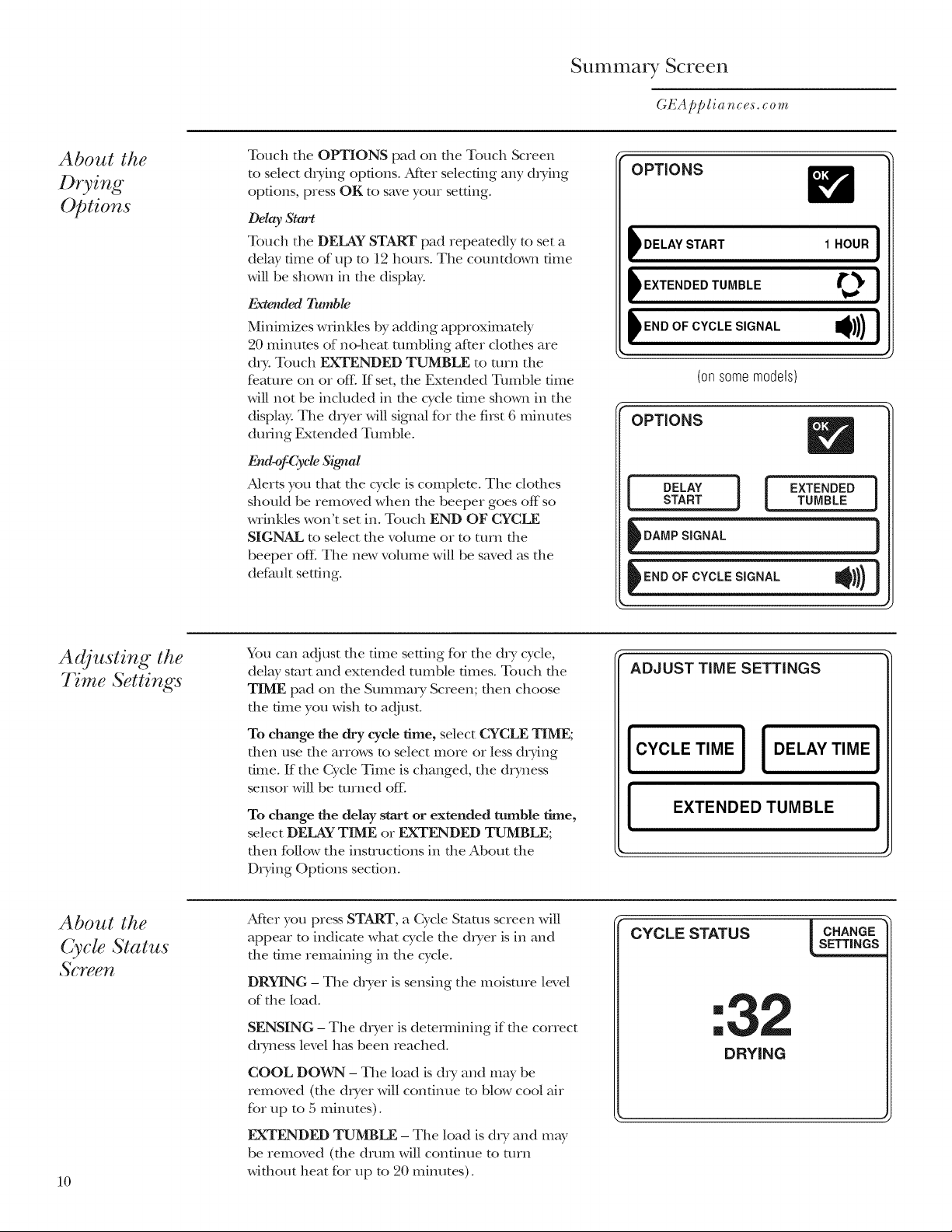

About the

Drying

Options

Touch the OPTIONS pad on the Touch Screen

to select drying options. After selecting any drying

options, press OK to save your setting.

Delay Start

Touch the DELAYSTART pad repeatedly to set a

del W time of up to 12 hours. The countdown time

will be shown in the display.

Extended Tumble

Minimizes wrinldes by adding approximately

20 minums of no-heat rambling after clothes are

din Touch EXTENDED TUMBLE to mrn the

fe.ature on or off: If set, the Extended Tumble time

will not be included in the cycle time shown in the

display. The d,yer will signal for the fi_t 6 minums

during Extended Tumble.

Alerts you that the cycle is complete. The clothes

should be removed when the beeper goes off so

wrinkles won't set in. Touch END OF CYCLE

SIGNAL to select the volume or to mrn the

beeper ore The new volume will be saved as the

defiuflt setting.

OPTIONS

) DELAY START IHOUR l

) EXTENDED TUMBLE _,_ ]

)END OF CYCLE SIGNAL I_1))) ]

(onsomemodels)

OPTIONS

[ DELAY ] [ EXTENDED ]

START TUMBLE

_DAMP SIGNAL I

_END OF CYCLE S,GNAL _}))i

Adjusting the

7Vme Settings

About the

Cycle Status

Screen

10

You can adjust file time setting for the &Y cycle,

delay start and extended ramble times. Touch the

TIME pad on the Summa_ T Screen; then choose

the time you wish to adjust.

To change the dry cycle time, select CYCLE TIME;

dlen use file arrows to select more or less drying

time. If the Cycle Time is changed, the dryness

sensor will be turned ore

To change the delay start or extended tumble time,

select DELAY TIME or EXTENDED TUMBLE;

then follow the instructions in the About the

Drying Options section.

After you press START, a Cycle Smms screen will

appear to indicate what cycle the &Ter is in and

the time remaining in the cycle.

DRYING - The &Ter is sensing the moisture level

of the load.

SENSING - The &Ter is detemdning if the correct

&Tness level h_s been reached.

COOL DOWN - The load is chT and may be

removed (the dcyer will continue to blow cool air

for up to 5 minutes).

EXTENDED TUMBLE - The load is dry and may

be removed (the drum will continue to mrn

without heat for up to 20 minutes).

ADJUST TIME SETTINGS

[C C'E""EI[OE'AY""E!

EXTENDED TUMBLE ]

CYCLE STATUS

m

m

DRYING

CHANGESETTINGS

"My'_' 1 "_yC es

GEA /)/)lia n ces. corn

About the

"My Cycles"

P)ature

Creating

and Using a

"My Cycle"

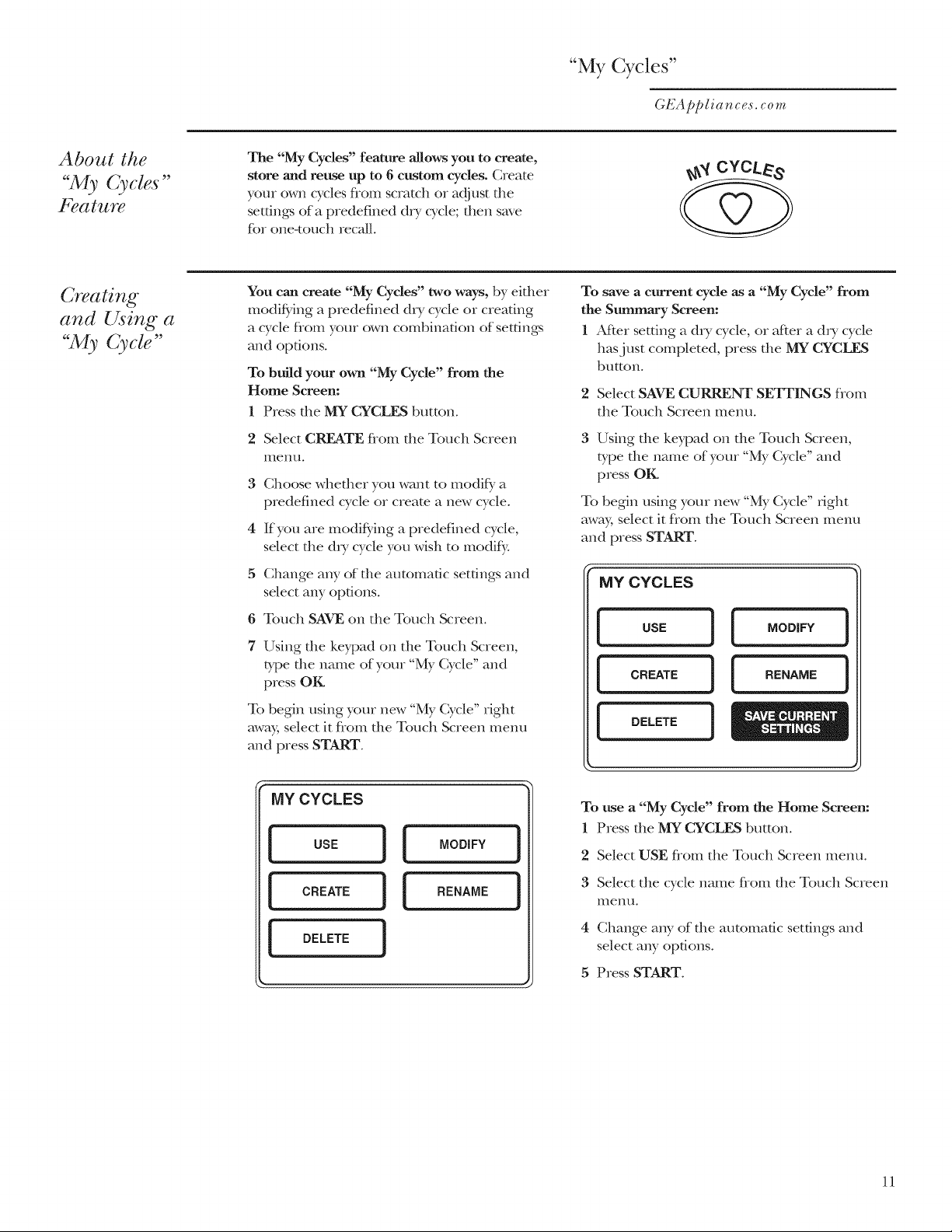

The "My Cycles" feature allows you to create,

store and reuse up to 6 custom cycles. Create

your o_,_ cycles flom scratch oradj ust tile

settings of a predefined dry cyde; then save

fbr one-touch recN1.

You can create "My Cycles" two ways, by eidler

modif_,ing a predefined dxy cycle or creating

a cycle flom your own combination of settings

and options.

To build your own "My Cycle" from the

Home Screen:

1 Press the MY CYCLES button.

2 Select CREATE flom tile Touch Screen

Illen/lo

Choose whether you want to modif_ a

predefined cycle or create a new cycle.

If you are modif_dng a predefined cycle,

select tile d_T cycle you wish to modif_,o

Change any of the automatic settings and

select any options.

6 Touch SAVE on the Touch Screen.

7 Using tlle keypad on tlle Touch Screen,

type tile name of your "My Cycle" and

press OK

To save a current cycle as a "My Cycle" from

the Summary Screen:

1 After setting a dry cycle, or after a d_y cycle

has just completed, press the MY CYCLES

button.

2 Select SAVE CURRENT SETTINGS flom

the Touch Screen metal

3 Using tlle keypad on tlle Touch Screen,

type tile name of your "My Cycle" and

press OK.

To begin using your new "My Cycle" fight

away, select it flom tile Touch Screen menu

and press START.

MY CYCLES

{

{

To begin using your new "My Cycle" right

away, select it flom tile Touch Screen menu

and press START.

MY CYCLES

[ i{

[DELETE]

MODIFY

RENAME

]

1

DELETE

{

To use a "My Cycle" from the Home Screen:

1 Press die MY CYCLES button.

2 Select USE flom tile Touch Screen menu.

3 Select the cycle name flom the Touch Screen

IllenIl.

4 Change any of die automatic setdngs and

select any options.

5 Press START.

11

"My'_-' 1 "_yC eS

GEA /)/)lia n ces. corn

Modifying,

Renaming

or Deleting

a "My Cycle"

To modify the settings of a "My Cycle" from

the Home Screen:

1 Press the MY CYCLES button.

2 Select MODIFY flom tile Touch Screen

Illen!lo

3 Select tile cycle name flom file Touch Screen

Illen!l.

4 Change any of die automatic settings and

select any options.

5 Press SAVE on the Touch Screen°

To rename a "My Cycle" from the

Home ScTeen:

1 Press die MY CYCLES button.

2 Select RENAME flom the Touch Screen

Illenu.

3 Select tile cycle name flom file Touch Screen

IllenI1.

4 Using die l<eypad on die Touch Screen,

type file name of your "My Cycle" and

press OK

To delete a "My Cycle" from the Home ScTeen:

1 Press die MY CYCLES button.

2 Select DELETE fiom tile Touch Screen

IIlen/1.

3 Select tile cycle name flom file Touch Screen

IllenIl.

4 Choose YES to delete die cycle or CANCEL

to return to die list of "My, Cycles."

12

Help

GEAppliances. corn

About the

Help l_ature

Usin K the

7Youbleshooter

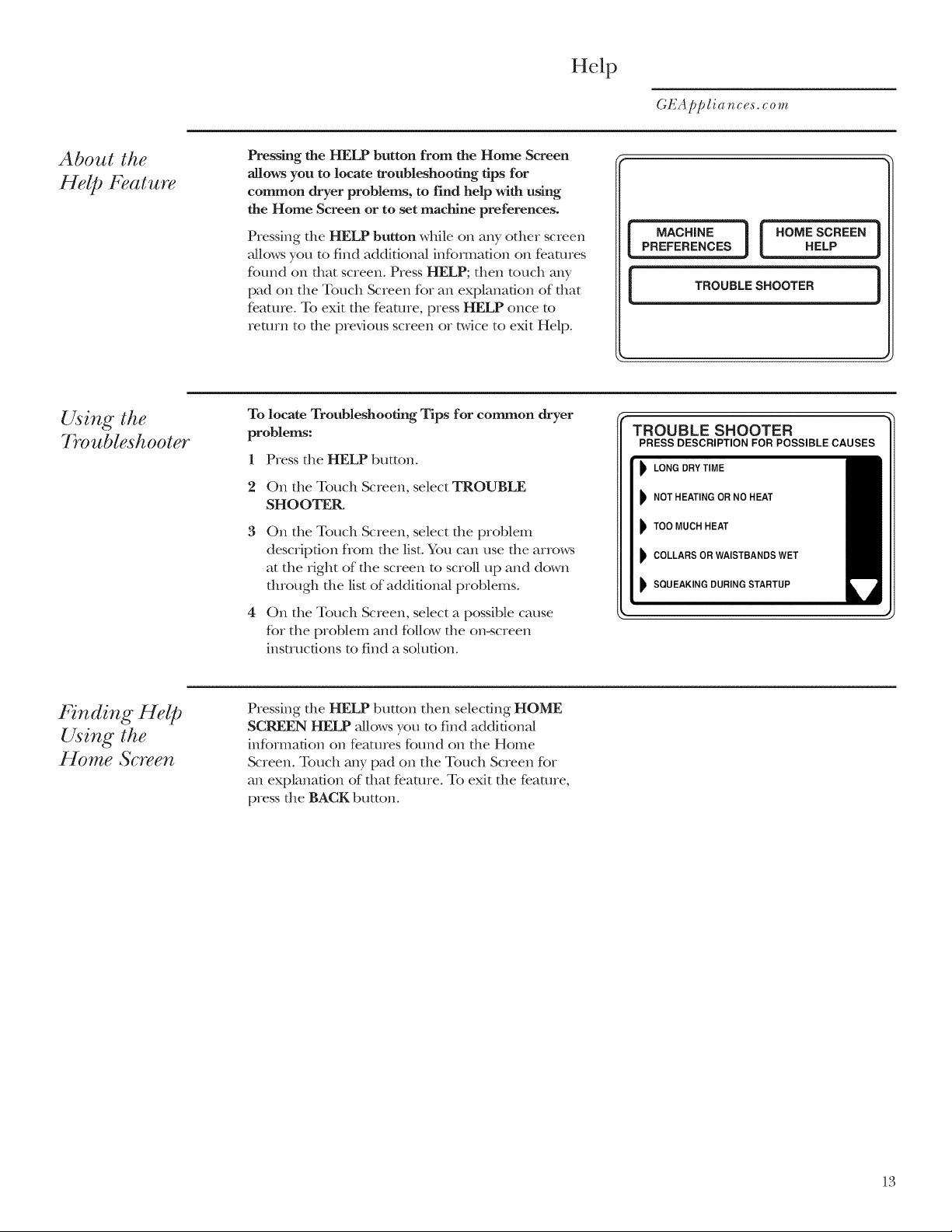

Pressing the HELP button from the Home Screen

allows you to locate troubleshooting tips for

common dryer problems, to find help with using

the Home Screen or to set machine preferences.

Pressing file HELP button while on any other screen

allows you to find additional infbmmfion on features

f_)und on flint screen. Press HELP; then touch any

pad on the Touch Screen for an explanation of flint

feature. To exit the feature, press HELP once to

return to the previous screen or twice to exit Help.

To locate Troubleshooting Tips for common dryer

problems:

1 Press flxe HELP button.

2 On the Touch Screen, select TROUBLE

SHOOTER.

On the Touch Screen, select flxe problem

description f)rom the list. You can use the arrows

at the right of the screen to scroll up and down

through the list of additional problems.

On the Touch Screen, select a possible cause

for the problem and follow the on-screen

instructions to find a solution.

i MACHINE i I HOME SCREEN i

TROUBLESHOOTER ]

TROUBLE SHOOTER

PRESS DESCRIPTION FOR POSSIBLE CAUSES

LONG DRY TIME

NOT HEATING OR NO HEAT

) TOO MUCH HEAT

COLLARS OR WAISTBANDS WET

_) SQUEAKING DURING STARTUP

k_

Finding Help

Usin K the

Home Screen

Pressing flxe HELP button then selecting HOME

SCREEN HELP allows you to find additional

information on features found on the Home

Screen. Touch any pad on the Touch Screen for

an explanation of that feature. To exit the fe.amre,

press the BACK button.

13

Help

GEAppliar_ces. corn

Setting the

Machine

Pr(erences

14

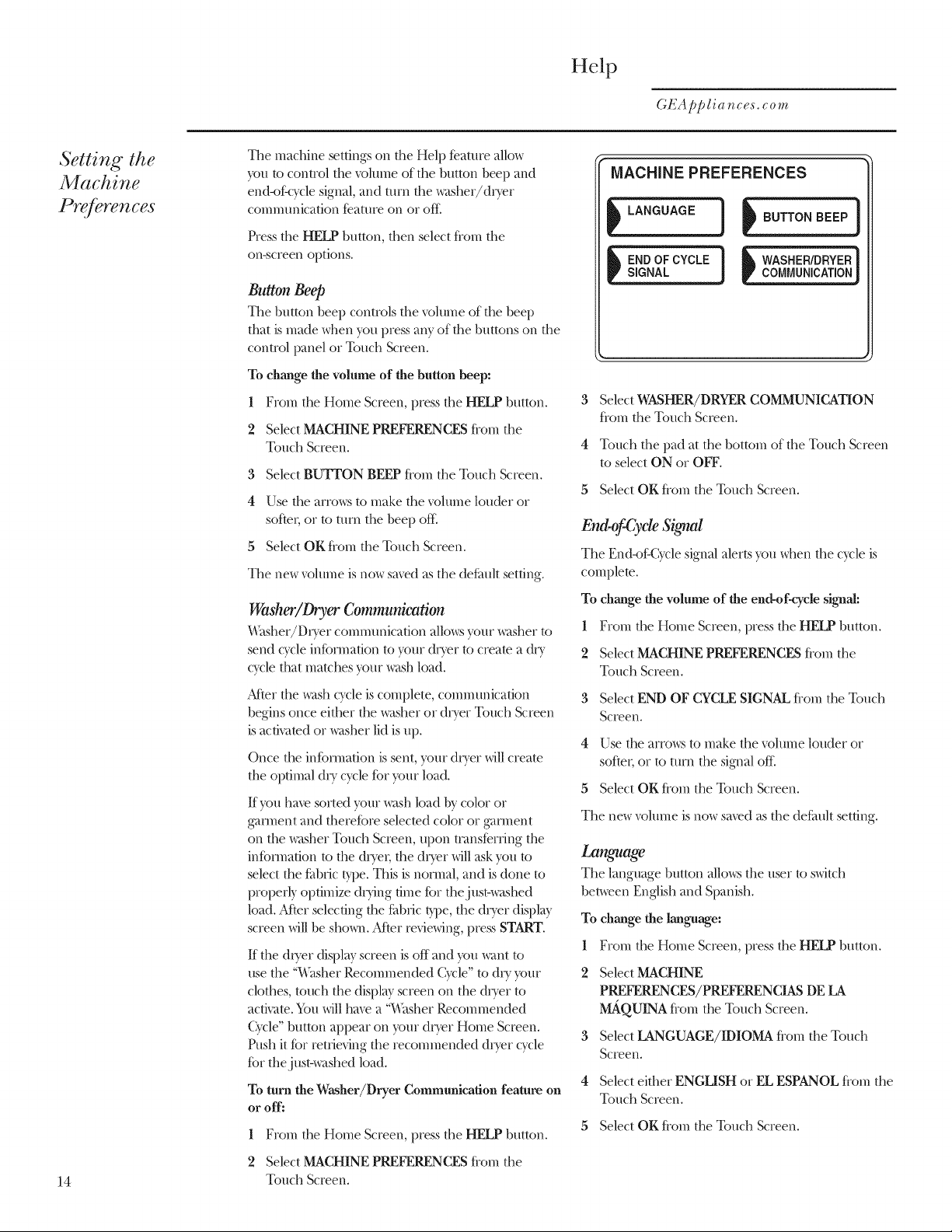

The machine settings on the Hel I) feature allow

you to control the volume of the button bee I) and

end<)fkycle signal, and n/rn the _asher/d_Ter

communication feature on or ofl_

Press the HELP button, then select flom the

on-screen options.

Button Be@

The button beep controls the _lume of the beep

that ismade when you press any of the buttons on the

control panel or Touch Screen.

To change the volume of the button beep:

1 From tl/e Home Screen, press tl/e HELP button.

2 Select MACHINE PREFERENCEShom the

Touch Screen.

3 Select BUTTON BEEP flom the Touch Screen.

4 Use the arro,vsto make the volume louder or

sofleLor to turn the beep off_

5 Select OKhom the Touch Screen.

The new volume is now sa\_d as the defimlt setting.

Washer/Dryer Communication

_hsher/D_yer communication alkm:syour _asher to

send cycleinffmnation toyour duet to cream a &).'

cyclethat matches your ,_tsh load.

After the _xash cycle is complete, communication

begins once either the _xvtsheror (hTer Touch Screen

is activamd or _xvtsherlid is up.

Once the in%rotation is sent, your &Ter will create

the optimal (hT cycle fbr your load.

If you haxe sorted your ,_vtshload hycolor or

,g,mnent and therefore selecmd color or g,mnent

on the _asher Touch Screen, upon tcansferring the

inffmnation to the &Te_;the dryer willask}sinto

select the fabric/ype. This is nomml, and is done to

properly optimize d,)_ng time for thejus/-_avtshed

load. After selecting the fabric bpe, the (hyer display

screen willbe sh(m_. Afterreviewing, press START.

If the (hyer display' screen is off and you ,xm_tto

use the "Washer Recommended Cycle" to &).' your

clothes, touch the display' screen on the (hTer to

activam. Ym will haw a "_¢\;tsher Recommended

Cycle" button appear on your dr}w Home Screen.

Push it for retrieving the recommended (hTer cycle

fbr thejus/-_avtshed load.

To turn the Washer/Dryer Communication feature on

or off:

1 From the Home Screen, press the HELP button.

2 Select MACHINE PREFERENCEShom the

Touch Screen.

MACHINE PREFERENCES

_ LANGUAGE

END OF CYCLE

SIGNAL

Select WASHER/DRYER COMMUNICATION

flom the Touch Screen.

Touch the pad at the botton_ of the Touch Screen

to select ON or OFF.

5 Select OK flom the Touch Screen.

End-of-CycleSignal

The End<if:Cyclesignalalerts you when the cycleis

complete.

To change tim volume of tim end-of-cyclesignal:

1 From the Home Screen, press the HELP button.

2 Select MACHINE PREFERENCEShom the

Touch Screen.

3 Select END OF CYCLESIGNALhom the Touch

Screen.

4 Use the arro,vs/o make the volume louder or

sofle,; or to turn the signaloff_

5 Select OK hom the Touch Screen.

The new volume is nowsa\ed asthe defiuflt setting.

Language

The language button allo,vsthe user to switch

bemeen English and Spanish.

To change tim language:

1 From the Home Screen, press the HELP button.

2 Select MACHINE

PREFERENCES/PREFERENCIAS DE LA

MAQUINAhom the Touch Screen.

3 Select LANGUAGE/IDIOMA fromthe Touch

Screen.

4 Select either ENGLISH or EL ESPANOL hom the

Touch Screen.

5 Select OK hom the Touch Screen.

Dryer Features

GEApplia rices, corn

Changing the

Drum Lamp

Using the

Drying Rack

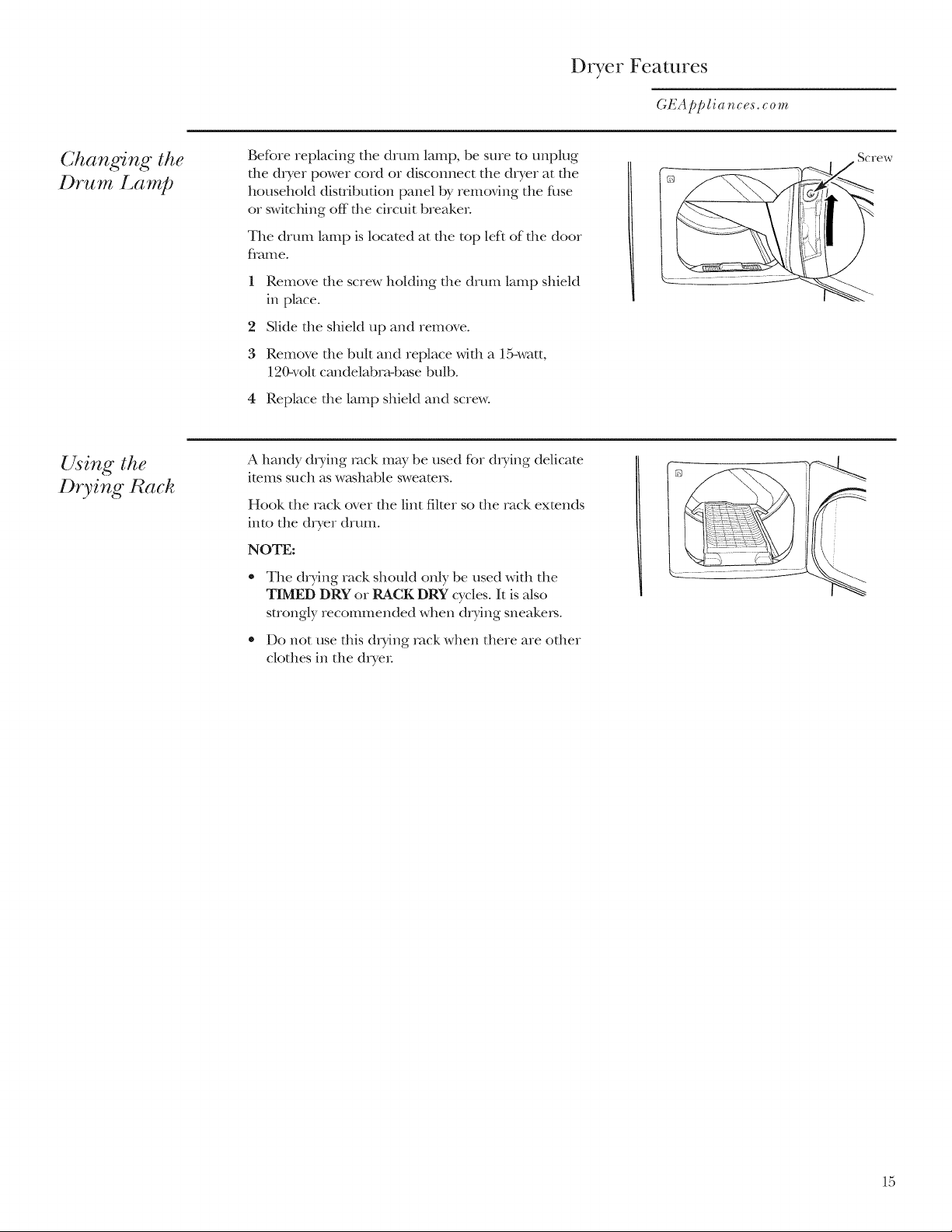

Before replacing the drum lamp, be sure to unplug

the &Ter power cord or disconnect the dxTer at the

household disuibufion panel by removing the fuse

or switching off:the circuit breaker

The drum lamp is located at the top lefZ of the door

flame.

1 Remove file screw holding file drum lamp shield

in place.

2 Slkte the shieM up and remove.

3 Remove the bult and replace with a 15-watt,

120-volt candelabra-b_se bulb.

4 Replace the lamp shieM and screw.

A handy drying rack may be used fin drying delicate

items such as w_kshablesweate,_.

Hook the rack over the lint filter so the rack extends

into the &Ter drum.

NOTE:

The drying rack shouM only be used with the

TIMED DRY or RACK DRY cycles. It is also

strongly recommended when drying sneake_.

ScFew

Do not use this (hTing rack when there are other

clothes in the &Ter

15

Loading and Using the Dryer

Always follow fabric manufadurer's care label when laundering.

gEkpp/ia noes. corn

Sorting and

Loading

Hints

Fabric Care

Labels

As a gene_H rule, if clothes are sorted properly

for the washe_, they are sorted properly for the

dryer %Y also to sort items according to size.

For example, do not dW a sheet with socks or

other small imms.

Do not add fabic softener sheets once the

load has become wamL They mW cause rid)tic

softener stains. Bounce _ Fabic Conditioner

DiTer Sheets have been approved for use in

all GE DxTerswhen used in accordance with

the manufi_cturer's instructions.

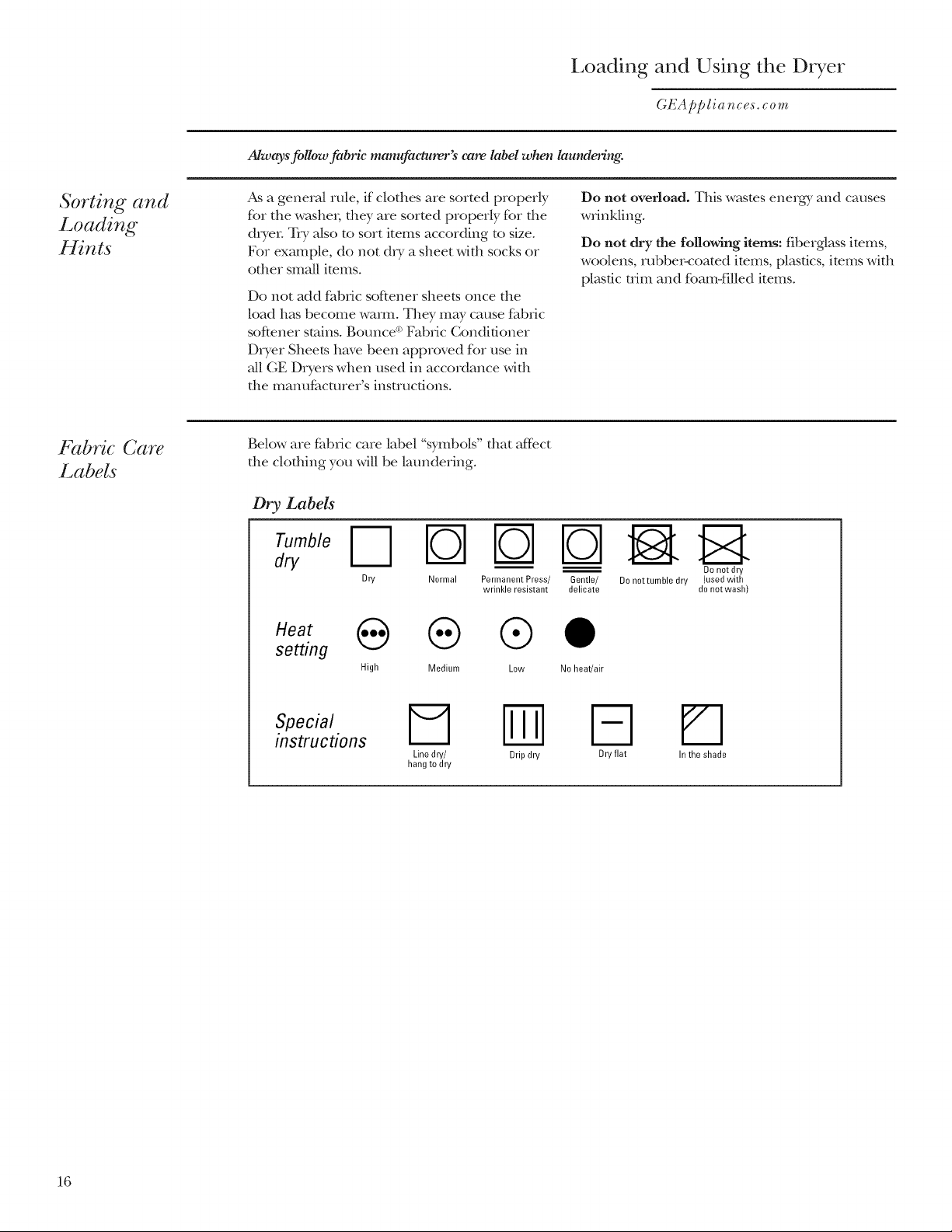

Below are fid)ic care label's) mbols" that affe.ct

the clothing you will be laundering.

Dry Labels

dry

DW Nermal Permanent Press/

wrinkle resistant

setting

High Medium Low

Do not overload. This wastes energ_ and causes

wrinkling.

Do not dry the following items: fiberglass items,

woolens, rubber-coated items, plastics, items with

plastic trim and foam-filled items.

D I2

Gentle/ Do net tumble dry (used with

delicate de not wash)

0

Ne heat/air

Do not dry

16

instructions

m r:l Fq

Line dry/ Drip dry Dry flat In the shade

hang to dry

Loading and Using the Dryer

(;EAppgiances. corn

CglYe and

Cleaning of

the Dryer

Dryer Interior and Duct: The interior of file

appliance and exhaust duct should be cleaned

once a year by qualified service pe,_onnel.

The Exterior: Wipe or dust any spills or washing

compounds wkh a damp cloth. D_yer conuol

panel and finishes may be damaged by some

laundI T pretreatment soil and stain remover

products. Apply these products away f]om the

dryer The fabric may then be washed and dried

nomm/ly: Damage to your dryer caused by these

products is not covered by your warranty:

Do not touch the surface or the Touch Screen

with sharp objects.

The Lint F'flter: Clean file lint filter before each

use. Remove by pulling smdght up. Run your

finget_ across the filter. A waxy buildup may

form on the lint filter fiom using dryer-added

fhb*Jc softener sheets. To remove this buildup,

wash the lint screen in warm, soapy water DtT

thoroughly and replace. Do not operam the

dryer without the lint filmr in place.

\4_cuum the lint flom file dryer lint filter area

if you notice a change in dryer performance.

Stainless Steel: To clean stainless steel surfaces,

use a damp cloth with a mild, nonabrasive

cleaner suitable for stainless smel surfaces.

Remove the cleaner residue, and then &T with

a clean cloth.

The stainless steel used to make file dryer drum

provides the highest reliability available in a GE

dryer If the dryer drum should be scratched

or dented during normal use, the drum will not

rust or corrode. These surface blemishes will not

affect the flmcfion or durability of the drum.

The Exhaust Hood: Check widl a mirror dmt

the inside flaps of the hood move f]eely when

operating. Make sure that there is no wildlife.

(birds, insects, etc.) nesting inside the duct

or hood.

17

sta ati

Drye

structi

i Questions? Carl 800.GE.CARES (800.432.2737) or visit our Web site at: GEAppliances.com i

BEFORE YOU BEGIN

Read these instructions completely and carefully.

FOR YOUR SAFETY:

-&WARNING - RiskofFire

DPGT750

• iMPORTANT- Savetheseinstructionsfor

local electrical inspector's use.

• IMPORTANT- Observea,governing

codes and ordinances,

,, Install the clothes dryer according to the

manufacturer's instructions and local codes.

• Note to installer - Be sure to leave these

instructions with the Consumer.

• Note to Consumer - Keep these instructions for

future reference.

• Clothes dryer installation must be performed by a

qualified installer.

,, This dryer must be exhausted to the outdoors.

• Before the old dryer is removed from service or

discarded, remove the dryer door.

• Service information and the wiring diagram are

located in the control console.

• Do not allow children on or in the appliance.

Close supervision of children is necessary when

the appliance is used near children.

• Proper installation is the responsibility of the

installer.

• Product failure due to improper installation is not

covered under the Warranty.

• Install the dryer where the temperature is above

50°F for satisfactory operation of the dryer

control system.

,, Remove and discard existing plastic or metal foil

duct and replace with UL-listed duct.

,, To reduce the risk of severe injury or death,

follow all installation instructions.

• Clothes dryer installation must be performed

by a qualified installer.

• Install the clothes dryer according to these

instructions and in accordance with local

codes.

,, This dryer must be exhausted to the outdoors.

,, Use only 4" rigid metal ducting for exhausting

the clothes dryer to the outdoors.

,, DO NOT install a clothes dryer with flexible

plastic ducting materials. If flexible metal

(semi-rigid or foil-type) duct is installed, it

must be UL-listed and installed in accordance

with the instructions found in "Connecting the

Dryer to House Vent" on page 29 of this

manual. Flexible ducting materials are known

to collapse, be easily crushed and trap lint.

These conditions will obstruct dryer airflow

and increase the risk of fire.

,, Do not install or store this appliance in any

location where it could be exposed to water

and/or weather.

,, The National Fuel Gas Code restricts

installations of gas appliances in garages.

They must be 18 inches off the ground and

protected by a barrier from vehicles.

,, Save these instructions. (Installers: Be sure to

leave these instructions with the customer.)

CALiFORNiA SAFE DRiNKiNG WATER

AND TOXIC ENFORCEMENT ACT

This act requires the governor of California to

publish a list of substances known to the state to

cause cancer, birth defects or other reproductive

harm and requires businesses to warn customers

of potential exposure to such substances. Gas

appliances can cause minor exposure to four of

these substances, namely benzene, carbon

monoxide, formaldehyde and soot, caused

primarily by the incomplete combustion of natural

gas or LP fuels. Properly adjusted dryers will

minimize incomplete combustion. Exposure to

these substances can be minimized further by

properly venting the dryer to the outdoors.

FOR GAS MODELS ONLY:

NOTE: Installation and service of this dryer

must be performed by a qualified installer,

service agency or the gas supplier.

in the Commonwealth of Massachusetts:

, This product must be installed by a licensed

plumber or gas fitter.

, When using ball-type gas shut-off valves,

they shall be T-handle-type.

, A flexible gas connector, when used, must

not exceed 3 feet.

18

Installation instructions

UNPACKING YOUR DRYER

Tilt the dryer sideways and remove the foam

shipping pads by pulling at the sides and

breaking them away from the dryer legs.

Be sure to remove all of the foam pieces

around the legs.

Remove the bag containing the drying rack,

literature and serial cable.

4,.".=

LOCATION OF YOUR DRYER

IMPORTANT: Gas dryers are not approved

for mobile home installation,

SWITCH WASHER AND DRYER

BACKSPLASHES (optional)

If necessary, switch the backsplashes for the

washer and dryer before making exhaust or

utility connections (see "Switching the

Washer and Dryer Backsplashes").

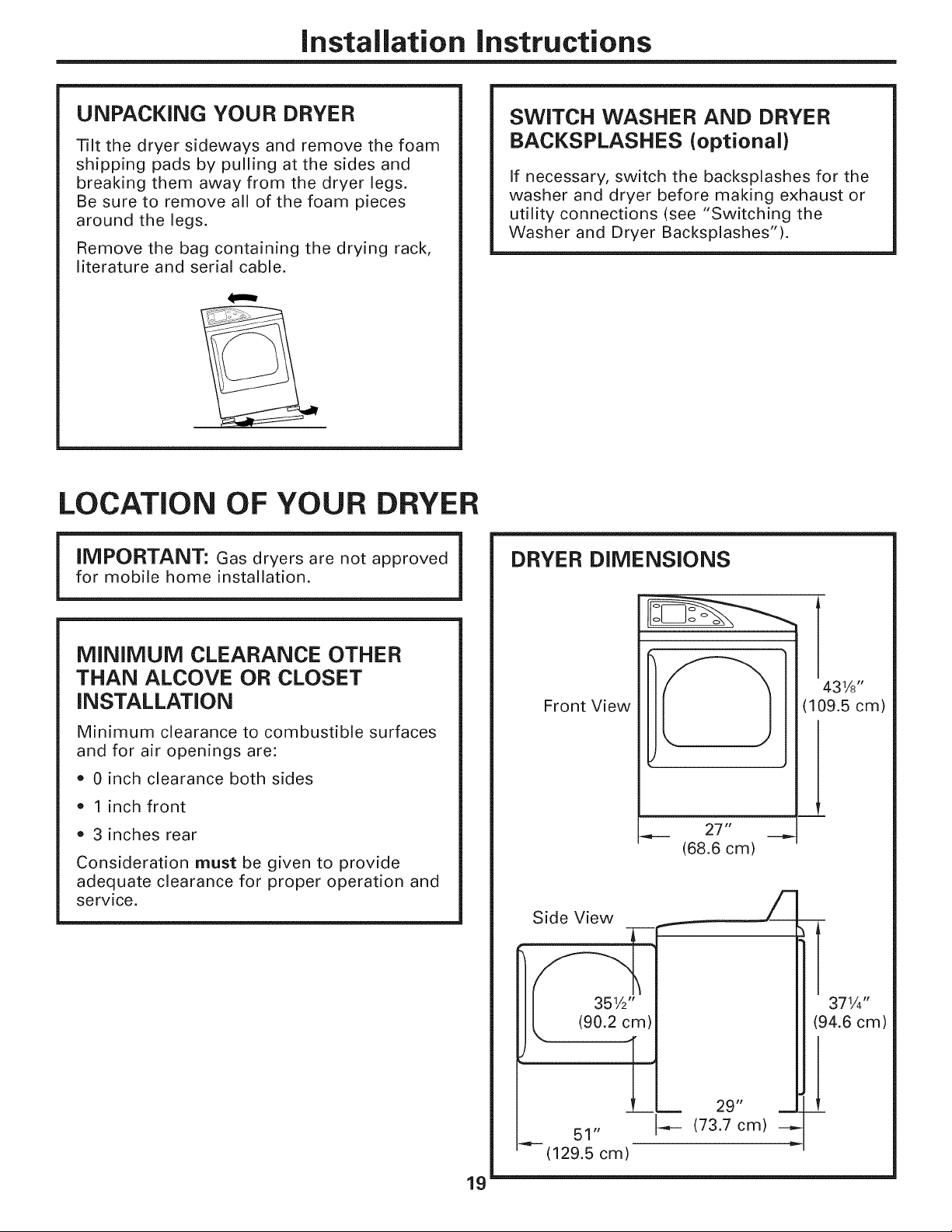

DRYER DIMENSIONS

MINIMUM CLEARANCE OTHER

THAN ALCOVE OR CLOSET

INSTALLATION

Minimum clearance to combustible surfaces

and for air openings are:

,, 0 inch clearance both sides

,, 1 inch front

,, 3 inches rear

Consideration must be given to provide

adequate clearance for proper operation and

service.

Front View

Side View

L (90.2 cm)

o oo

1

431/8"

(109.5 cm)

27"

(68.6 cm)

371/4"

(94.6 cm)

19

51 "

(129.5 cm)

!

m 29" m

(73.7 cm)

Installation instructions

LOCATION OF YOUR DRYER (cont.)

REQUIREMENTS FOR ALCOVE OR

CLOSET iNSTALLATiON

,, Your dryer is approved for installation in

an alcove or closet, as stated on a label on

the dryer back.

,, The dryer MUST be vented to the outdoors.

See the EXHAUST INFORMATION section.

,, Minimum clearance between dryer cabinet

and adjacent walls or other surfaces is:

0" either side

3" front and rear

,, Minimum vertical space from floor to

overhead shelves, cabinets, ceilings, etc.,

is 52".

,, Closet doors must be Iouvered or otherwise

ventilated and have at least 60 square

inches of open area equally distributed.

If the closet contains both a washer and

a dryer, doors must contain a minimum

of 120 square inches of open area equally

distributed.

,, No other fuel-burning appliance shall be

installed in the same closet with the dryer

(gas models only).

BATHROOM OR BEDROOM

INSTALLATION

,, The dryer MUST be vented to the outdoors.

See EXHAUST INFORMATION.

,, The installation must conform with local

codes or, in the absence of local codes,

with the NATIONAL ELECTRICAL CODE,

ANSI/NFPA NO. 70 (for electric dryers) or

NATIONAL FUEL GAS CODE, ANSI Z223

(for gas dryers).

20

Installation instructions

CONNECTING A GAS DRYER (skip for electric dryers)

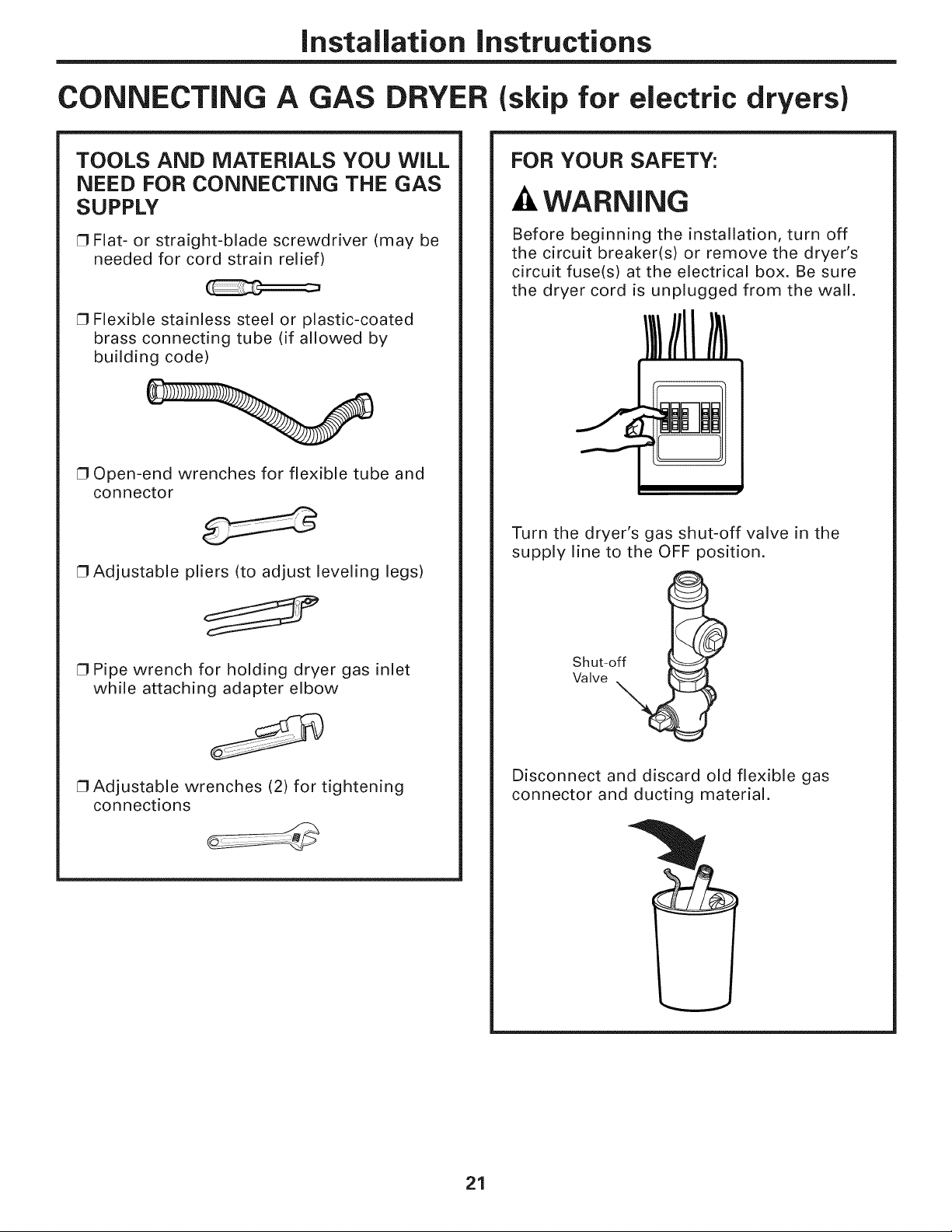

TOOLS AND MATERIALS YOU WiLL

NEED FOR CONNECTING THE GAS

SUPPLY

[] Flat- or straight-blade screwdriver (may be

needed for cord strain relief)

[] Flexible stainless steel or plastic-coated

brass connecting tube (if allowed by

building code)

[]Open-end wrenches for flexible tube and

connector

[] Adjustable pliers (to adjust leveling legs)

FOR YOUR SAFETY:

_4,WARNING

Before beginning the installation, turn off

the circuit breaker(s) or remove the dryer's

circuit fuse(s) at the electrical box. Be sure

the dryer cord is unplugged from the wall.

Turn the dryer's gas shut-off valve in the

supply line to the OFF position.

[] Pipe wrench for holding dryer gas inlet

while attaching adapter elbow

[] Adjustable wrenches (2) for tightening

connections

Shut-off

Valve

Disconnect and discard old flexible gas

connector and ducting material.

21

Installation instructions

CONNECTING A GAS DRYER (cont.)

GAS REQUIREMENTS

-&WARNING

,, Installation must conform to local codes

and ordinances, or in their absence, the

NATIONAL FUEL GAS CODE, ANSI Z223.

,, This gas dryer is equipped with a Valve and

Burner Assembly for use only with natural

gas. Using conversion kit WE25X10014,

your local service organization can convert

this dryer for use with propane (LP) gas.

ALL CONVERSIONS MUST BE MADE

BY PROPERLY TRAINED AND QUALIFIED

PERSONNEL AND IN ACCORDANCE

WITH LOCAL CODES AND ORDINANCE

REQUIREMENTS.

,, The dryer must be disconnected from

the gas supply piping system during any

pressure testing of that system at a test

pressure in excess of 0.5 PSI (3.4 KPa).

,, The dryer must be isolated from the

gas supply piping system by closing the

equipment shut-off valve during any

pressure testing of the gas supply piping

of test pressure equal to or less than

0.5 PSI (3.4KPa).

GAS SUPPLY

,, A 1/8" National Pipe Taper thread plugged

tapping, accessible for test gauge

connection, must be installed immediately

upstream of the gas supply connection to

the dryer. Contact your local gas utility

should you have questions on the

installation of the plugged tapping.

,, Supply line is to be 1/2" rigid pipe and

equipped with an accessible shut-off within

6 feet of, and in the same room with, the

dryer.

,, Use pipe compound appropriate for natural

or LP gas or use Teflon ® tape.

,, Connect flexible metal connector to dryer

and gas supply.

IN THE COMMONWEALTH

OF MASSACHUSETTS

,, This product must be installed by a licensed

plumber or gas fitter.

,, When using ball-type gas shut-off valves,

they shall be the T-handle type.

,, A flexible gas connector, when used, must

not exceed 3 feet.

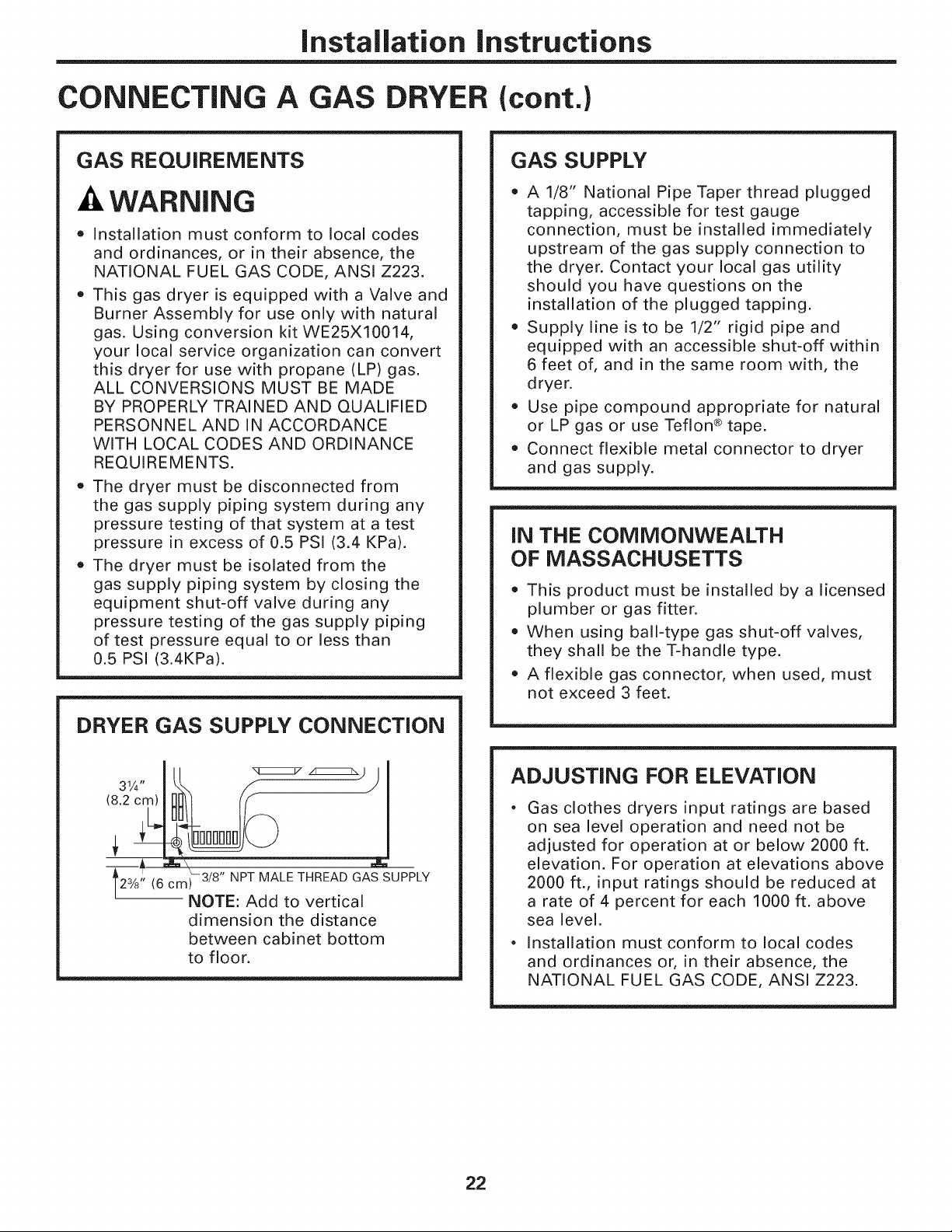

DRYER GAS SUPPLY CONNECTION

I

31/4" _ .,r_, j I

(8.2 cm)

1

(6 cm)

', 3/8" NPT MALE THREAD GAS SUPPLY

NOTE: Add to vertical

dimension the distance

between cabinet bottom

to floor.

ADJUSTING FOR ELEVATION

• Gas clothes dryers input ratings are based

on sea level operation and need not be

adjusted for operation at or below 2000 ft.

elevation. For operation at elevations above

2000 ft., input ratings should be reduced at

a rate of 4 percent for each 1000 ft. above

sea level.

• Installation must conform to local codes

and ordinances or, in their absence, the

NATIONAL FUEL GAS CODE, ANSI Z223.

22

Installation instructions

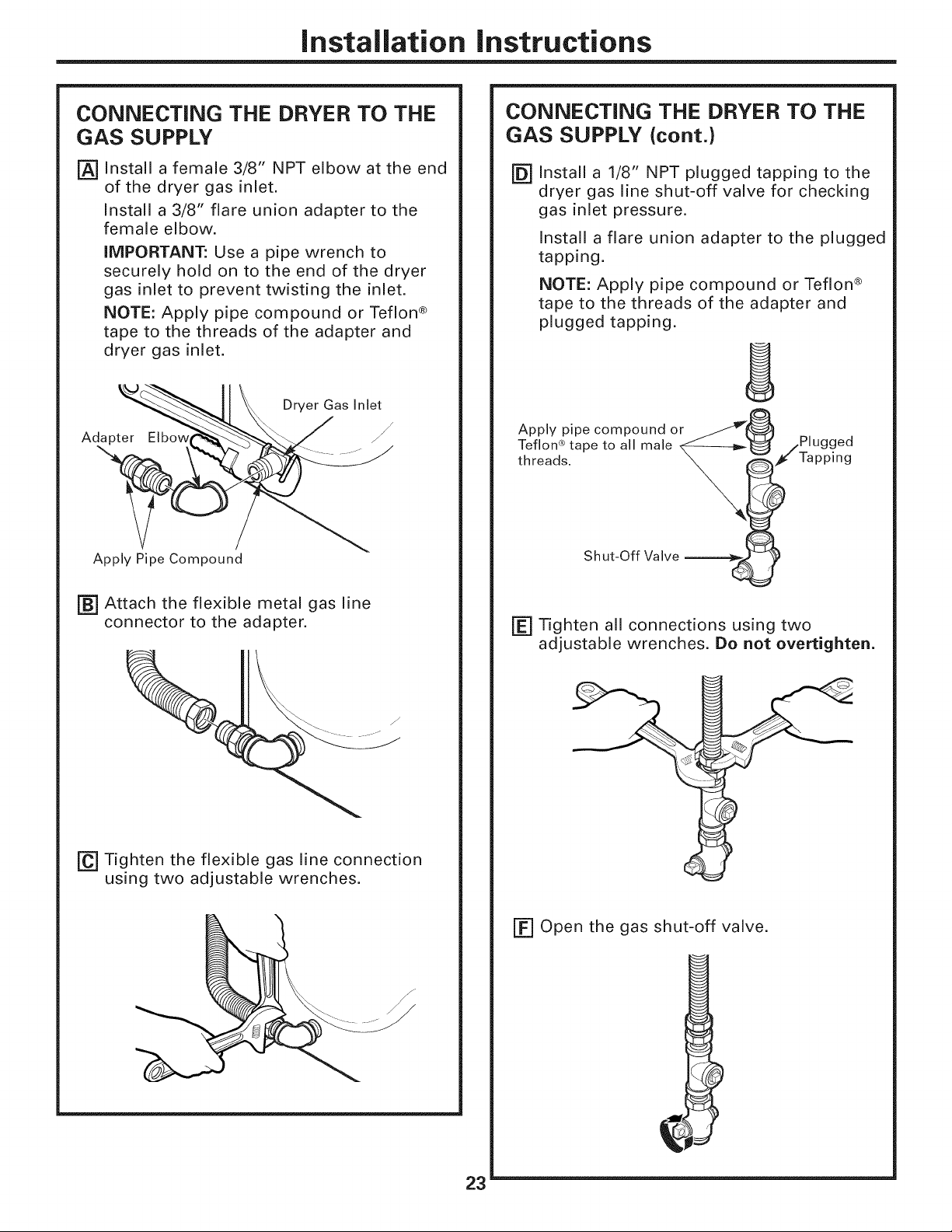

CONNECTING THE DRYER TO THE

GAS SUPPLY

r_ Install a female 3/8" NPT elbow at the end

of the dryer gas inlet.

Install a 3/8" flare union adapter to the

female elbow,

IMPORTANT: Use a pipe wrench to

securely hold on to the end of the dryer

gas inlet to prevent twisting the inlet.

NOTE: Apply pipe compound or Teflon ®

tape to the threads of the adapter and

dryer gas inlet,

Adap_ _ Dryer Gas Inlet

Apply Pipe Compound

CONNECTING THE DRYER TO THE

GAS SUPPLY (cont.)

['D-]Install a 1/8" NPT plugged tapping to the

dryer gas line shut-off valve for checking

gas inlet pressure,

Install a flare union adapter to the plugged

tapping.

NOTE: Apply pipe compound or Teflon ®

tape to the threads of the adapter and

plugged tapping,

Apply pipe compound or __

tTherfle:_l:!ape to all male _-----_/Plapg?:d

Sh ut-Off Valve _ !

F_ Attach the flexible metal gas line

connector to the adapter.

FC--]Tighten the flexible gas line connection

using two adjustable wrenches.

F_ Tighten all connections using two

adjustable wrenches. Do not overtighten.

J

F_ Open the gas shut-off valve.

23

Installation instructions

CONNECTING A GAS DRYER (cont.)

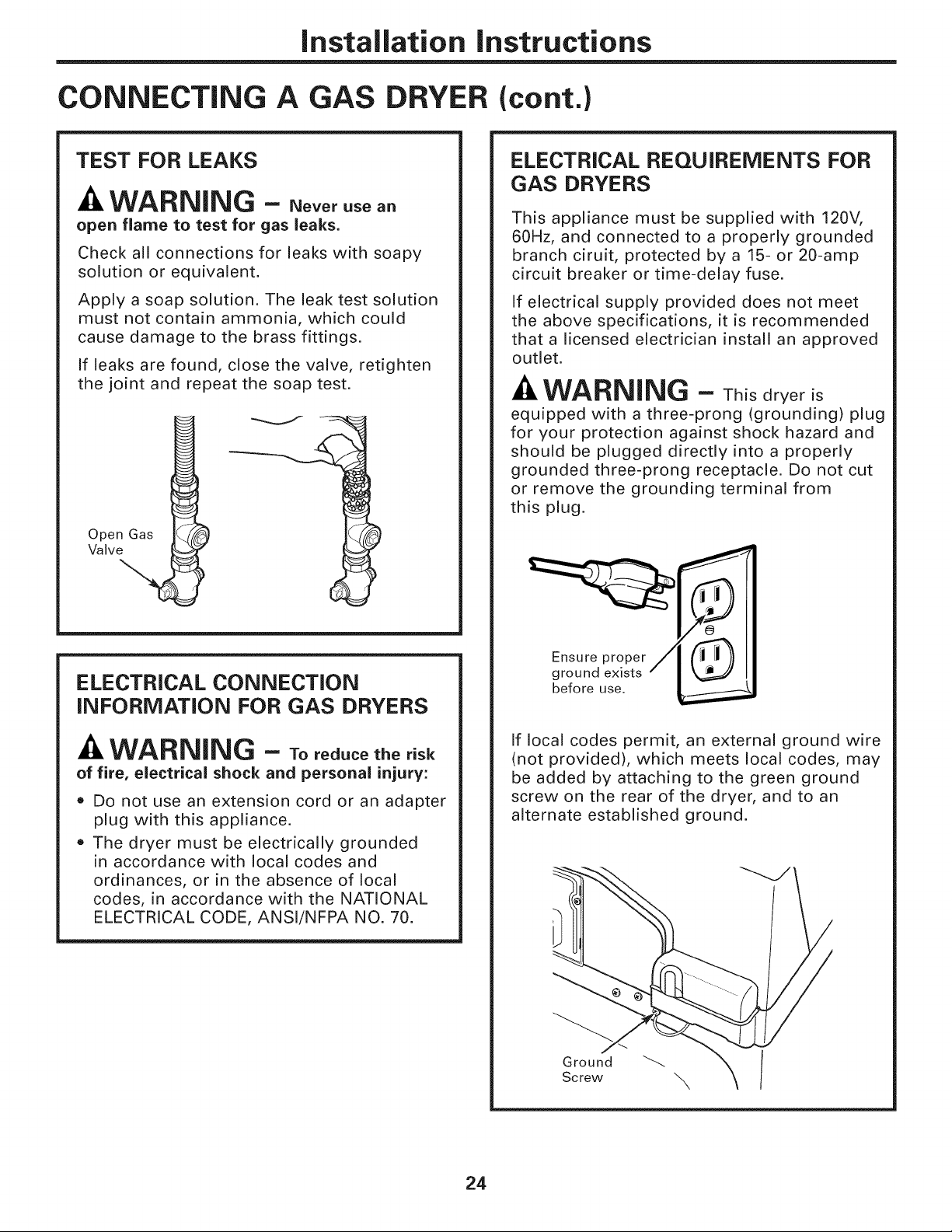

TEST FOR LEAKS

-&WARNING - Neverusean

open flame to test for gas leaks.

Check all connections for leaks with soapy

solution or equivalent.

Apply a soap solution. The leak test solution

must not contain ammonia, which could

cause damage to the brass fittings.

If leaks are found, close the valve, retighten

the joint and repeat the soap test.

Open Gas

Valve

ELECTRICAL REQUIREMENTS FOR

GAS DRYERS

This appliance must be supplied with 120V,

60Hz, and connected to a properly grounded

branch ciruit, protected by a 15- or 20-amp

circuit breaker or time-delay fuse.

If electrical supply provided does not meet

the above specifications, it is recommended

that a licensed electrician install an approved

outlet.

_kWARNING - Thisdryer is

equipped with a three-prong (grounding) plug

for your protection against shock hazard and

should be plugged directly into a properly

grounded three-prong receptacle. Do not cut

or remove the grounding terminal from

this plug.

ELECTRICAL CONNECTION

INFORMATION FOR GAS DRYERS

-&WARNING - Toreducetherisk

of fire, electrical shock and personal injury:

,, Do not use an extension cord or an adapter

plug with this appliance.

,, The dryer must be electrically grounded

in accordance with local codes and

ordinances, or in the absence of local

codes, in accordance with the NATIONAL

ELECTRICAL CODE, ANSI/NFPA NO. 70.

Ensure proper

ground exists

before use.

If local codes permit, an external ground wire

(not provided), which meets local codes, may

be added by attaching to the green ground

screw on the rear of the dryer, and to an

alternate established ground.

_<

Ground

Screw

24

Installation instructions

CONNECTING AN ELECTRIC DRYER (skip for gas dryers)

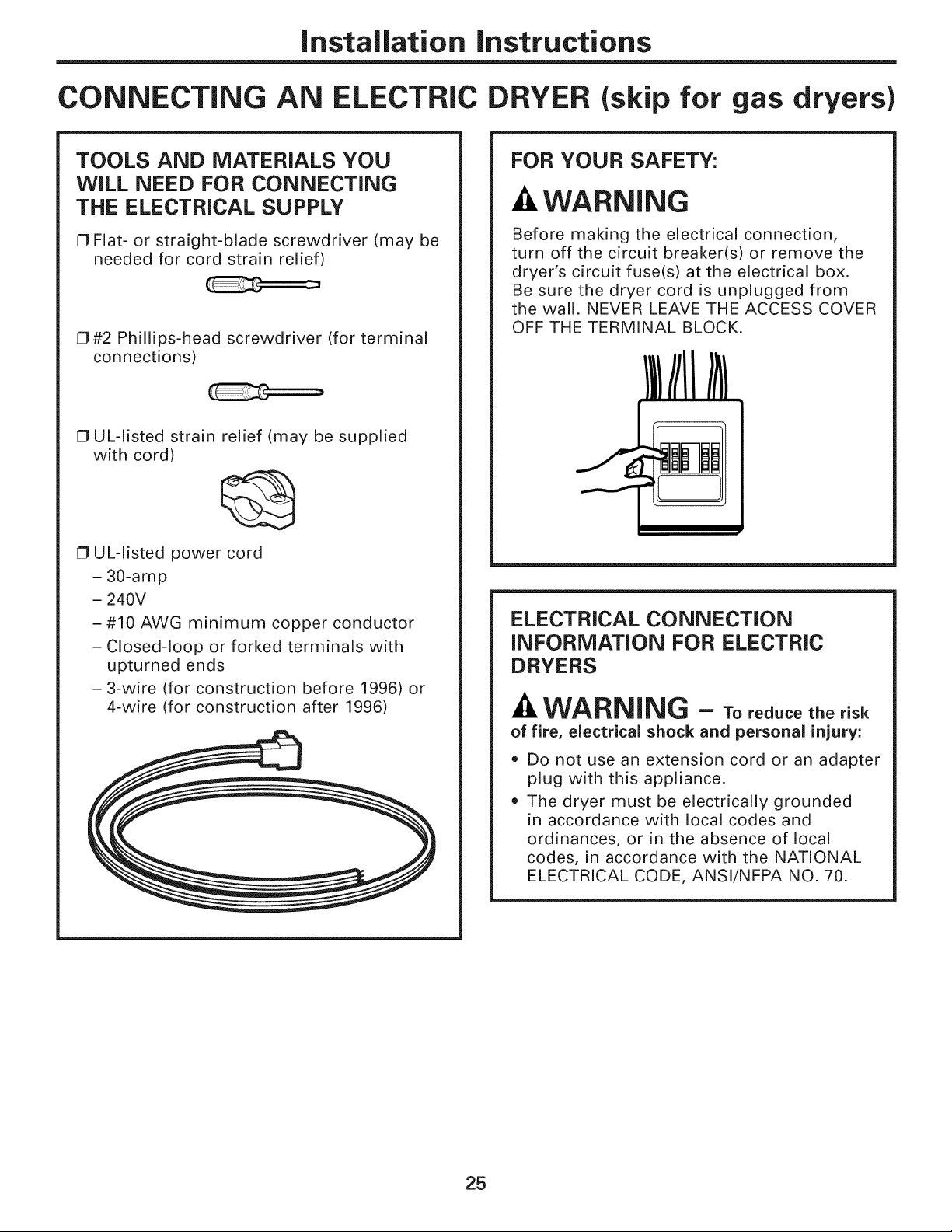

TOOLS AND MATERIALS YOU

WiLL NEED FOR CONNECTING

THE ELECTRICAL SUPPLY

[] Flat- or straight-blade screwdriver (may be

needed for cord strain relief)

[]#2 Phillips-head screwdriver (for terminal

connections)

[] UL-listed strain relief (may be supplied

with cord)

[] UL-listed power cord

- 3O-amp

- 240V

- #10 AWG minimum copper conductor

- Closed-loop or forked terminals with

upturned ends

- 3-wire (for construction before 1996) or

4-wire (for construction after 1996)

FOR YOUR SAFETY:

WARNING

Before making the electrical connection,

turn off the circuit breaker(s) or remove the

dryer's circuit fuse(s) at the electrical box.

Be sure the dryer cord is unplugged from

the wall. NEVER LEAVE THE ACCESS COVER

OFF THE TERMINAL BLOCK.

ELECTRICAL CONNECTION

INFORMATION FOR ELECTRIC

DRYERS

WARNING - Toreducetherisk

of fire, electrical shock and personal injury:

,, Do not use an extension cord or an adapter

plug with this appliance.

,, The dryer must be electrically grounded

in accordance with local codes and

ordinances, or in the absence of local

codes, in accordance with the NATIONAL

ELECTRICAL CODE, ANSI/NFPA NO. 70.

25

Installation instructions

CONNECTING AN ELECTRIC DRYER (cont.)

ELECTRICAL REQUIREMENTS FOR

ELECTRIC DRYERS

This dryer must be connected to an

individual branch circuit, protected by the

required time-delay fuses or circuit breakers.

A three- or four-wire, single phase, 120/240V

or 120/208V, 60Hz, 30-amp circuit is required.

If the electric supply does not meet the above

specifications, then call a licensed electrician.

GROUNDING iNSTRUCTiONS

This dryer must be connected to a grounded

metal, permanent wiring system, or an

equipment-grounding conductor must be

run with the circuit conductors and connected

to the equipment grounding terminal on the

appliance.

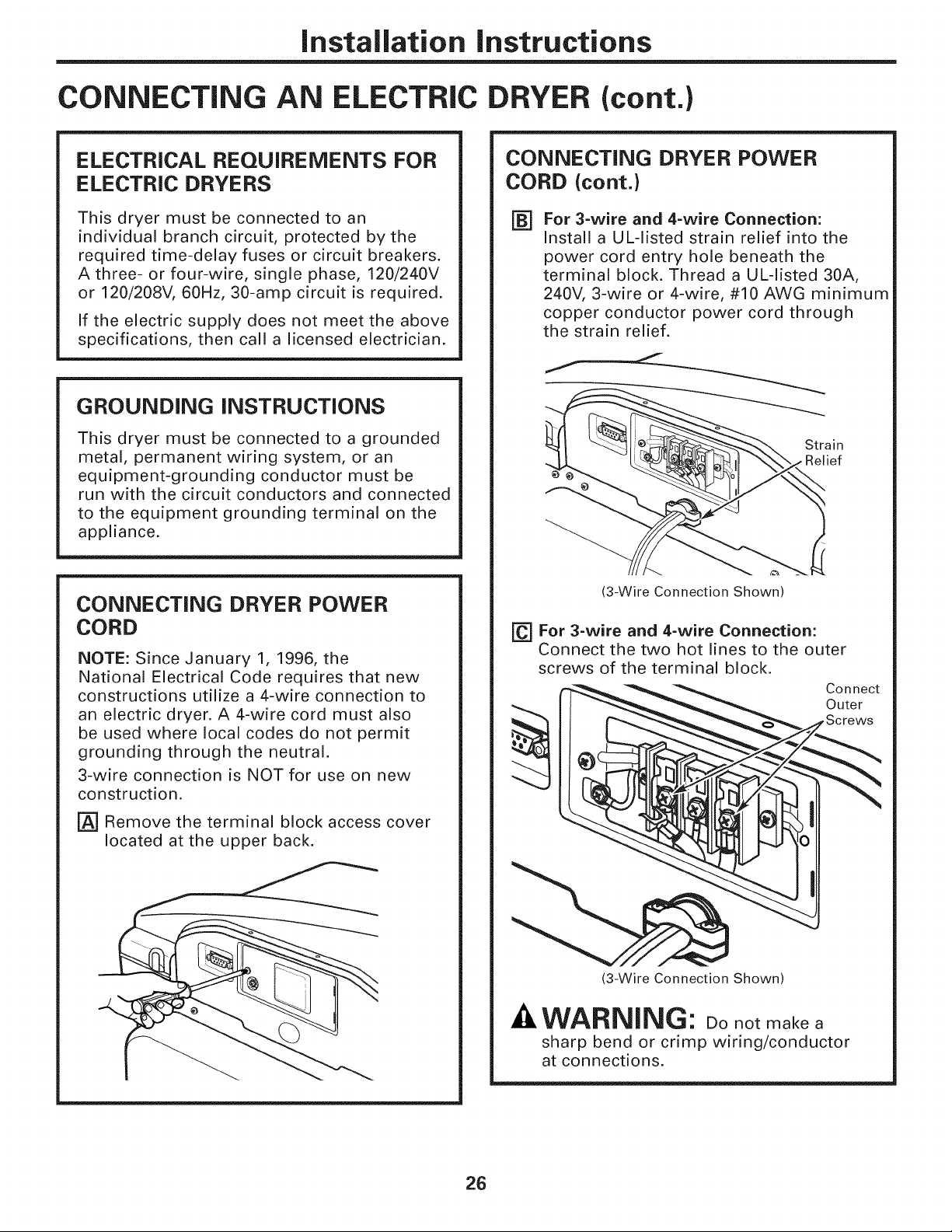

CONNECTING DRYER POWER

CORD

NOTE: Since January 1, 1996, the

National Electrical Code requires that new

constructions utilize a 4-wire connection to

an electric dryer. A 4-wire cord must also

be used where local codes do not permit

grounding through the neutral.

3-wire connection is NOT for use on new

construction.

CONNECTING DRYER POWER

CORD (cont.}

For 3-wire and 4-wire Connection:

Install a UL-listed strain relief into the

power cord entry hole beneath the

terminal block. Thread a UL-listed 30A,

240V, 3-wire or 4-wire, #10 AWG minimum

copper conductor power cord through

the strain relief.

Strain

. Relief

(3-Wire Connection Shown)

[C-] For 3-wire and 4-wire Connection:

Connect the two hot lines to the outer

screws of the terminal block.

Connect

Outer

[_ Remove the terminal block access cover

located at the upper back.

(3-Wire Connection Shown)

WARNING: Donot makea

sharp bend or crimp wiring/conductor

at connections.

26

Installation instructions

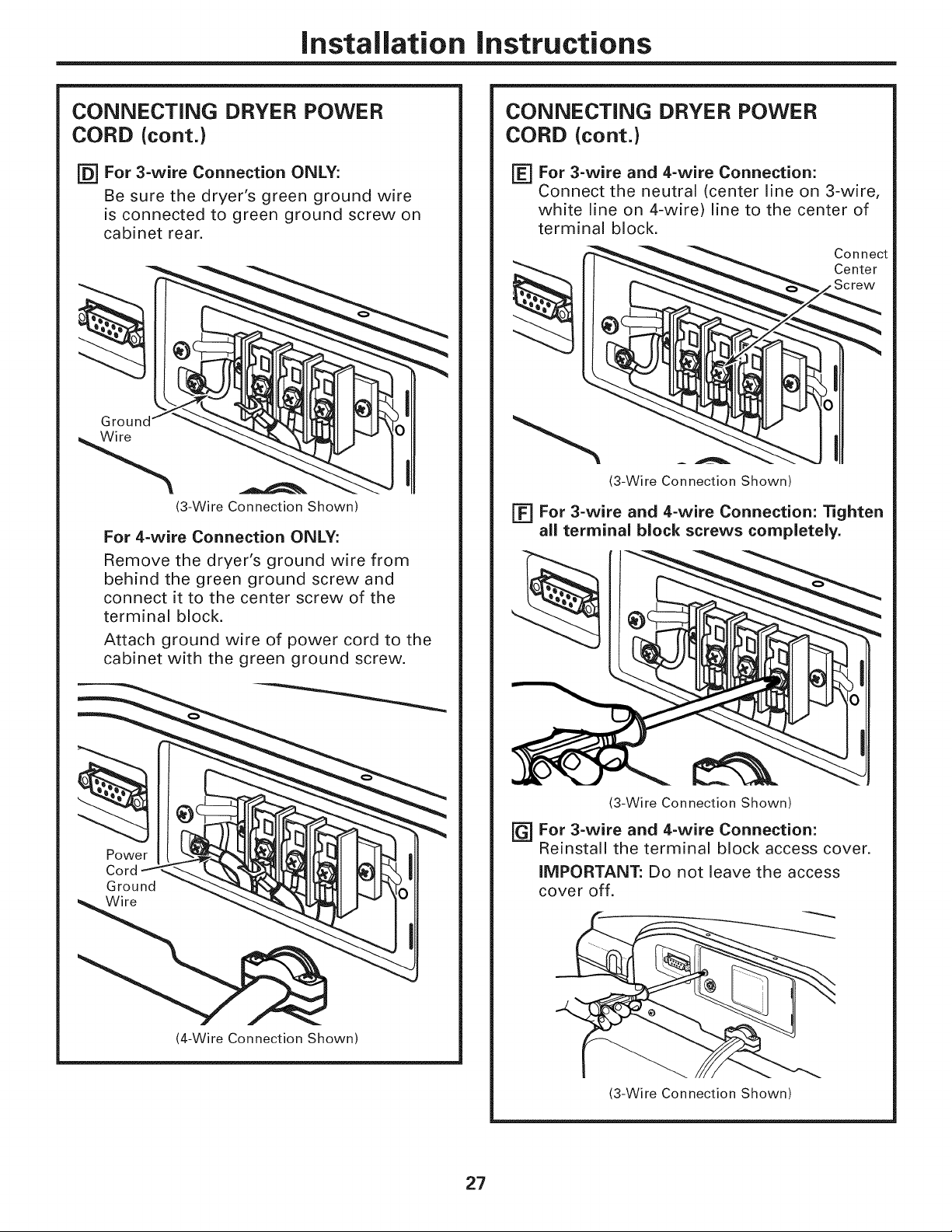

CONNECTING DRYER POWER

CORD (cont.)

['D--]For 3-wire Connection ONLY:

Be sure the dryer's green ground wire

is connected to green ground screw on

cabinet rear.

Ground I

_e

(3-Wire Connection Shown)

For 4-wire Connection ONLY:

Remove the dryer's ground wire from

behind the green ground screw and

connect it to the center screw of the

terminal block.

Attach ground wire of power cord to the

cabinet with the green ground screw.

CONNECTING DRYER POWER

CORD (cont.)

[_ For 3-wire and 4-wire Connection:

Connect the neutral (center line on 3-wire,

white line on 4-wire) line to the center of

terminal block.

Connect

Center

,, Screw

A A

(3-Wire Connection Shown)

[_] For 3-wire and 4-wire Connection: _ghten

all terminal block screws completely.

Power

Cord

Ground

Wire

(3-Wire Connection Shown)

rG-]For 3-wire and 4-wire Connection:

Reinstall the terminal block access cover.

IMPORTANT: Do not leave the access

cover off.

(4-Wire Connection Shown)

(3-Wire Connection Shown)

27

Loading...

Loading...