Page 1

GE Consumer Products

TECHNICAL SERVICE GUIDE

Profile Gas and

Electric Dryers

A

C

B

K

M

O

E

H

C

Y

C

Y

L

M

E

L

P

H

E

A

R

T

S

T

O

T

P

S

W

E

O

R

P

MODEL SERIES:

DPGT750EC/GC

PUB # 31-9104 07/03

Page 2

IMPORTANT SAFETY NOTICE

The information in this service guide is intended for use by

individuals possessing adequate backgrounds of electrical,

electronic, and mechanical experience. Any attempt to rep air a

major appliance may result in personal injury and property

damage. The manufacturer or seller cannot be responsible for the

interpretation of this information, nor can it assume any liability in

connection with its use.

WARNING

If the information in this manual is not followed exactly , fire or explosion

may result causing property damage, personal injury or death. If you smell

gas:

– Do not try to light any appliance.

– Do not touch any electrical switch; do not use any phone in the

building.

– Immediately call the gas supplier from a neighbor’s phone. Follow

the gas supplier’s instructions.

– If you cannot reach the gas supplier, call the fire dep artment.

WARNING

To avoid personal injury, disconnect power before servicing this product. If

electrical power is required for diagnosis or test purposes, disconnect the

power immediately after performing the necessary checks.

RECONNECT ALL GROUNDING DEVICES

If grounding wires, screws, straps, clips, nuts, or washers used to

complete a path to ground are removed for service, they must be returned

to their original position and properly fastened.

GE Consumer Products

Technical Service Guide

Copyright © 2003

All rights reserved. This service guide may not be reproduced in whole or in part in any

form without written permission from the General Electric Company .

– 2 –

Page 3

Table of Contents

Airflow Diagram (Gas and Electric Models)....................................................................................15

Backsplash ...................................................................................................................................20

Belt Switch....................................................................................................................................26

Blower Motor .................................................................................................................................27

Component Locator Views.............................................................................................................16

Consumer Help Screens................................................................................................................13

Control Features............................................................................................................................. 7

Control Quick Reference Chart ......................................................................................................38

Control System .............................................................................................................................20

Door Switch...................................................................................................................................25

Drive Belt.......................................................................................................................................26

Drive Motor ....................................................................................................................................27

Drum .............................................................................................................................................24

Drum Light ....................................................................................................................................26

Drum Rollers .................................................................................................................................25

Dry Cycles ..................................................................................................................................... 9

Dryer Components ........................................................................................................................20

Dryer Control Panel ........................................................................................................................ 7

Dryer T emperature Settings (Gas and Electric)..............................................................................15

Error Charts............................................................................................................................... ....43

Factory T est Mode ........................................................................................................................36

Field Service Mode........................................................................................................................35

Front Panel ...................................................................................................................................23

Gas V alve......................................................................................................................................32

Heater Assembly (Electric Models) ...............................................................................................29

Hi-Limit Thermostat .......................................................................................................................32

Ignitor ............................................................................................................................................33

Ignitor and Flame Detector ............................................................................................................34

Inlet Safety Thermostat .................................................................................................................30

Inlet Thermistor .............................................................................................................................30

Inverter ..........................................................................................................................................21

Inverter and Main Board Pin Connectors ........................................................................................18

Main Control Board and T ouch Screen LCD...................................................................................20

Membrane Keypanel .....................................................................................................................21

Moisture Sensor............................................................................................................................34

My Cycles.....................................................................................................................................12

Nomenclature ................................................................................................................................. 4

Operation Overview ........................................................................................................................15

Outlet Thermistor ..........................................................................................................................31

Outlet Thermostat .........................................................................................................................31

Overview ......................................................................................................................................... 6

Parts ............................................................................................................................................. 48

Quick Start..................................................................................................................................... 8

Reversing the Door Swing..............................................................................................................58

Sales Demo Mode.........................................................................................................................14

Schematics...................................................................................................................................46

Signal (Beeper) .............................................................................................................................22

Summary Screen ..........................................................................................................................10

Switching the Washer and Dryer Backsplashes ............................................................................60

T op Cover ......................................................................................................................................23

Troubleshooting .............................................................................................................................39

Troubleshooting Charts..................................................................................................................40

Warranty ........................................................................................................................................ 5

– 3 –

Page 4

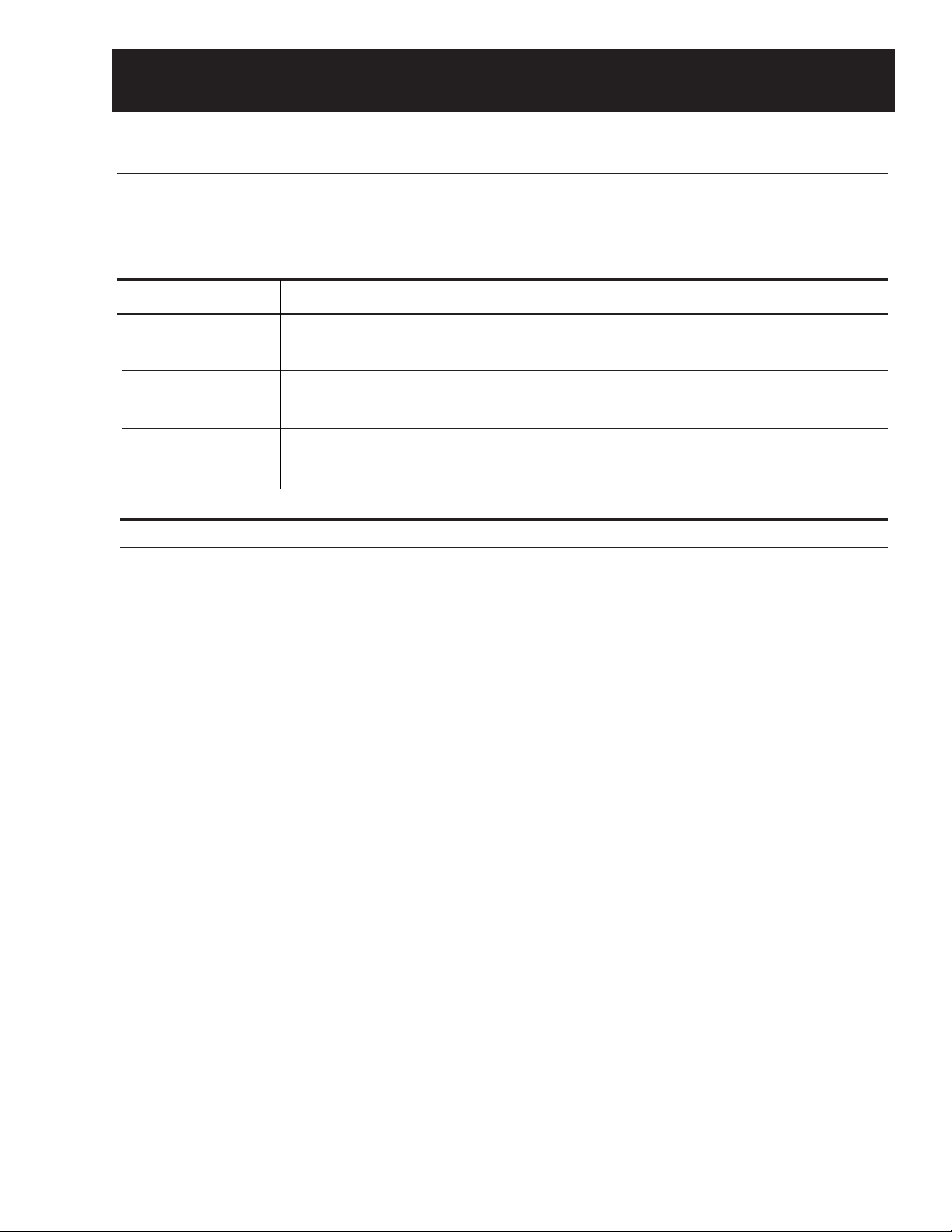

Nomenclature

D P G T 7 5 0 E C 0 W W

GE Dryer

Feature Pack

Common Brand Features

Exceptions:

H = Energy Star

P = Profile™

K, N = Special

S = Spacemaker®

Capacity/Configuration

L = Large S = Super

X = Extra-Large K = Compact

G = Giant

Control Platform

B = Buttons (Touch Pad) T = Touch Screen

Q = QuickClean S = Stationary

R = Rotary F = Fabric Care

P = Portable H = Horizontal Axis

Drying Machine

Backsplash

Color

Body Color

Model Year

Designator

Engineering

Revision

Fuel/Voltage

E = Electric

G = Gas

Dryer Control

Number of Cycles

Heat Selections

Model & Serial Numbers

Note: Model number and serial number are

located on the front panel inside the door .

• The technical sheet is located behind

the control panel.

Serial Number

The first two characters of the serial number

identify the month and year of manufacture.

Example: RF123456S = August 2003

A - JA N 2005 - H

D - FEB 2004 - G

F - MAR 2003 - F

G - APR 2002 - D

The letter

designating the

year repeats every

12 years.

H - MA Y 2001 - A

L - JUN 2000 - Z

M - JUL 1999 - V

R - AUG 1998 - T

S - SEP 1997 - S

Example:

T - 1974

T - 1986

T - 1998

T - OCT 1996 - R

V - NOV 1995 - M

Z - DEC 1994 - L

– 4 –

Page 5

For The Period Of: We Will Replace:

One Year Any part of the dryer which fails due to a defect in materials or workmanship. During this

From the date of the full one-year warranty, GE will also provide, free of charge, all labor and related service costs to

original purchase replace the defective part.

Second Year Any part of the dryer which fails due to a defect in materials or workmanship. During this

From the date of the additional one-year limited warranty, you will be responsible for any labor or related service costs.

original purchase

Third through Fifth Year The extra-large or super-capacity dryer drum and main electronic control board if any of these parts should

From the date of the fail due to a defect in materials or workmanship. During this additional three-year limited warranty,

original purchase you will be responsible for any labor or related service costs.

A

ll warranty service provided by our Factory Service Centers or

an authorized Customer Care

®

technician. To schedule service

on-line, 24 hours a day, visit us at www.GEAppliances.com or

call 800.GE.CARES (800.432.2737).

■ Service trips to your home to teach you how to use

the product.

■ Improper installation, delivery or maintenance.

■ Failure of the product if it is abused, misused, or

used for other than the intended purpose or used

commercially.

■ Replacement of the light bulb after its expected

useful life.

■ Replacement of house fuses or resetting of circuit

breakers.

■ Damage to the product caused by accident, fire, floods

or acts of God.

■ Incidental or consequential damage caused by possible

defects with this appliance.

■ Damage caused after delivery.

What Is Not Covered:

This warranty is extended to the original purchaser and any succeeding owner for products purchased for home use within the

USA. In Alaska, the warranty excludes the cost of shipping or service calls to your home. Proof of the original purchase date is

needed to obtain service under the warranty.

Some states do not allow the exclusion or limitation of incidental or consequential damages. This warranty gives you specific

legal rights, and you may also have other rights which vary from state to state. To know what your legal rights are, consult

your local or state consumer affairs office or your state’s Attorney General.

Warrantor: General Electric Company. Louisville, KY 40225

Warranty

Note: The LCD screen is part of the main electronic board and under the 5 year part warranty. The

inverter board is covered by a 2 year part warranty.

– 5 –

Page 6

Overview

General

The GE Profile Harmony Dryer is part of the GE Profile

Harmony Clothes Care System utilizing the latest

developments in dryer technology .

Most conventional drying systems have a single motor

that powers both the blower and the drum. Therefore,

the blower fan and dryer drum are powered at the same

rate of speed. If air flow is impeded by lint buildup or

lengthy venting, the dryer cannot increase the fan

speed without increasing the drum speed. The

Harmony Dryer System utilizes dual motors and

strategically placed sensors. This enables the dryer to

respond quickly to temperature changes and ensure

proper air flow to optimize drying effectiveness.

Other features include:

A

C

B

K

E

L

P

H

M

O

E

H

C

Y

C

Y

L

M

E

A

R

T

S

T

O

T

P

S

W

E

O

R

P

Communication Link to the Washer- The dryer uses a

serial cable to automatically receive information from

the washer about the nature of the wash load,

essentially presetting the dryer controls so the user

doesn’t have to.

Dual Motors - The dryer is equipped with dual motors one dedicated to the drum, the other to the blower fan.

The addition of a dedicated blower motor enables the dryer to alter fan speed whenever necessary to

optimize air flow. This capability greatly increases drying performance and efficiency. (See

and Blower Motor).

Drive Motor

V ariable Heater - The dryer's heater is capable of variable heat output. It s voltage regulation feature

allows the system to be rated at 6000 watts.

Dual Thermistors - Thermistors are much more sensitive to temperature changes and can relay the

information faster than thermostats. The dryer uses dual thermistors to monitor incoming air

temperature as well as the air temperature leaving the drum. The sensors work together with the

variable heater and blower to provide consistent even heat. (See

Inlet Thermistor.)

Moisture Sensor - The moisture sensor allows the control to monitor the fabric for moisture content and

end the cycle at the desired moisture level. (See

Moisture Sensor.)

Plastic Top & Backsplash - The dryer top and backsplash have UV stabilizers to prevent yellowing when

exposed to sunlight.

– 6 –

Page 7

P

O

W

E

R

M

Y

C

Y

C

L

E

S

B

A

C

K

H

E

L

P

S

TART

S

TOP

H

O

M

E

Features of

the dryer

control

panel

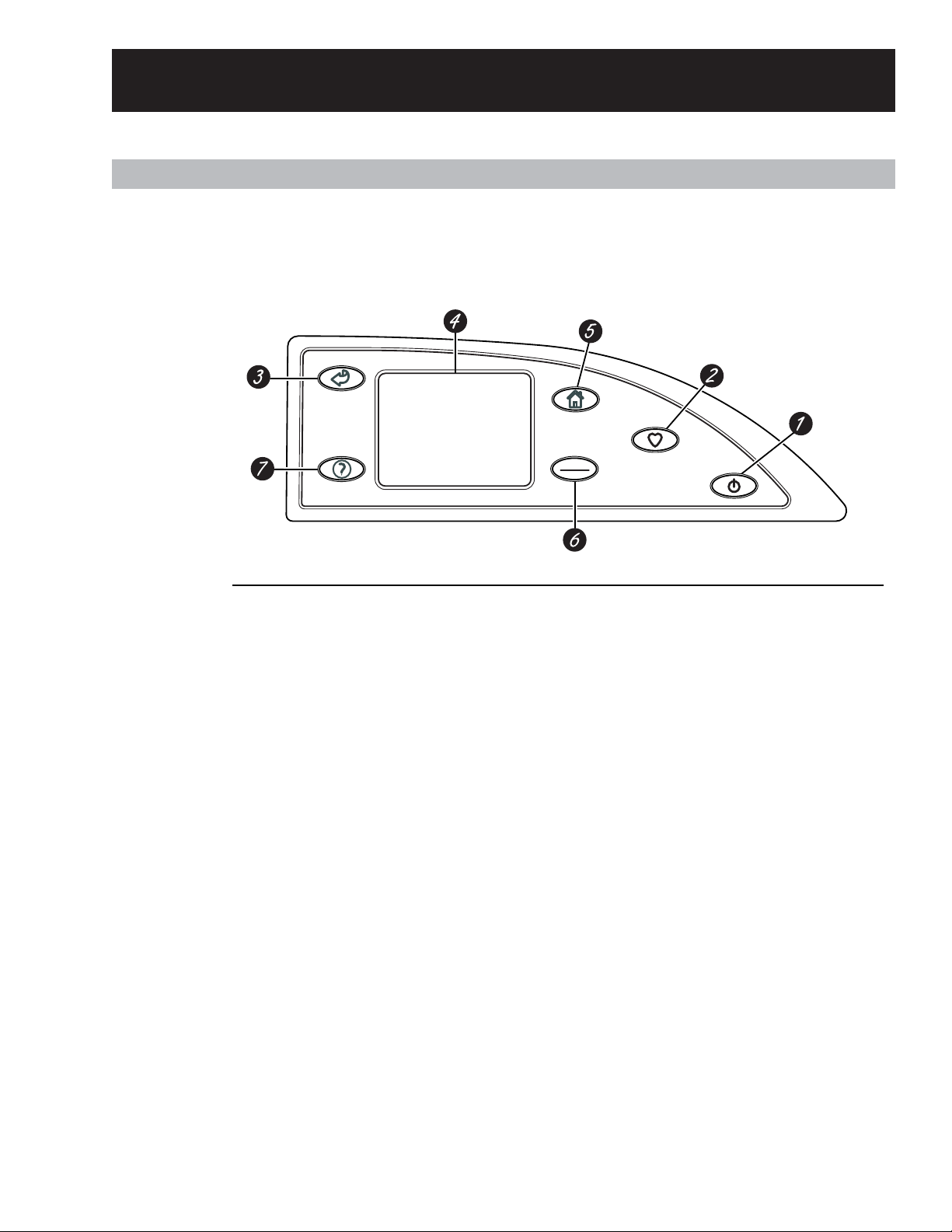

1 POWER. Press to “wake up” the display. If

the display is active, press to put the dryer

into standby mode. You may also press the

Touch Screen or any button to “wake up”

the display.

NOTE: Pressing POWER does not

disconnect the appliance from the power

supply.

2 MY CYCLES. Press to use, create, rename,

modify or delete custom dry cycles.

3 BACK. Press to return to the previous

screen.

4 TOUCH SCREEN. Press the graphics

on the interactive display to use the dryer

features.

Do not use sharp objects to press the Touch

Screen.

NOTE: If the dryer is inactive for 5

minutes, the Touch Screen will go into

standby mode, and the display will be dark.

Press the Touch Screen or any button to

“wake up” the display.

5 HOME. Press to return to the “TOUCH TO

SELECT Sensor DRY CYCLE” screen (Home

Screen).

6 START/STOP. Press to start a dry cycle.

If the dryer is running, pressing once will

pause the dryer. Press again to restart the

dry cycle.

NOTE: If the dryer is paused and the cycle

is not restarted within five minutes, the

dryer will enter standby mode and the

current dry cycle will be canceled.

7 HELP. Press to set machine preferences, to

find help using the Touch Screen or to find

troubleshooting tips for common dryer

problems.

Throughout this manual, features and appearance may vary from your model.

Control Features

Dryer Control Panel

– 7 –

Page 8

Quick Start

Getting

Started

If the Touch

Screen is

dark, press

POWER or

the Touch

Screen to

access the

dry cycles

menu.

Clean the lint filter.

IMPORTANT: Clean the lint filter each time

you use the dryer.

Add clothes. Do not overload. This wastes

energy and promotes wrinkling.

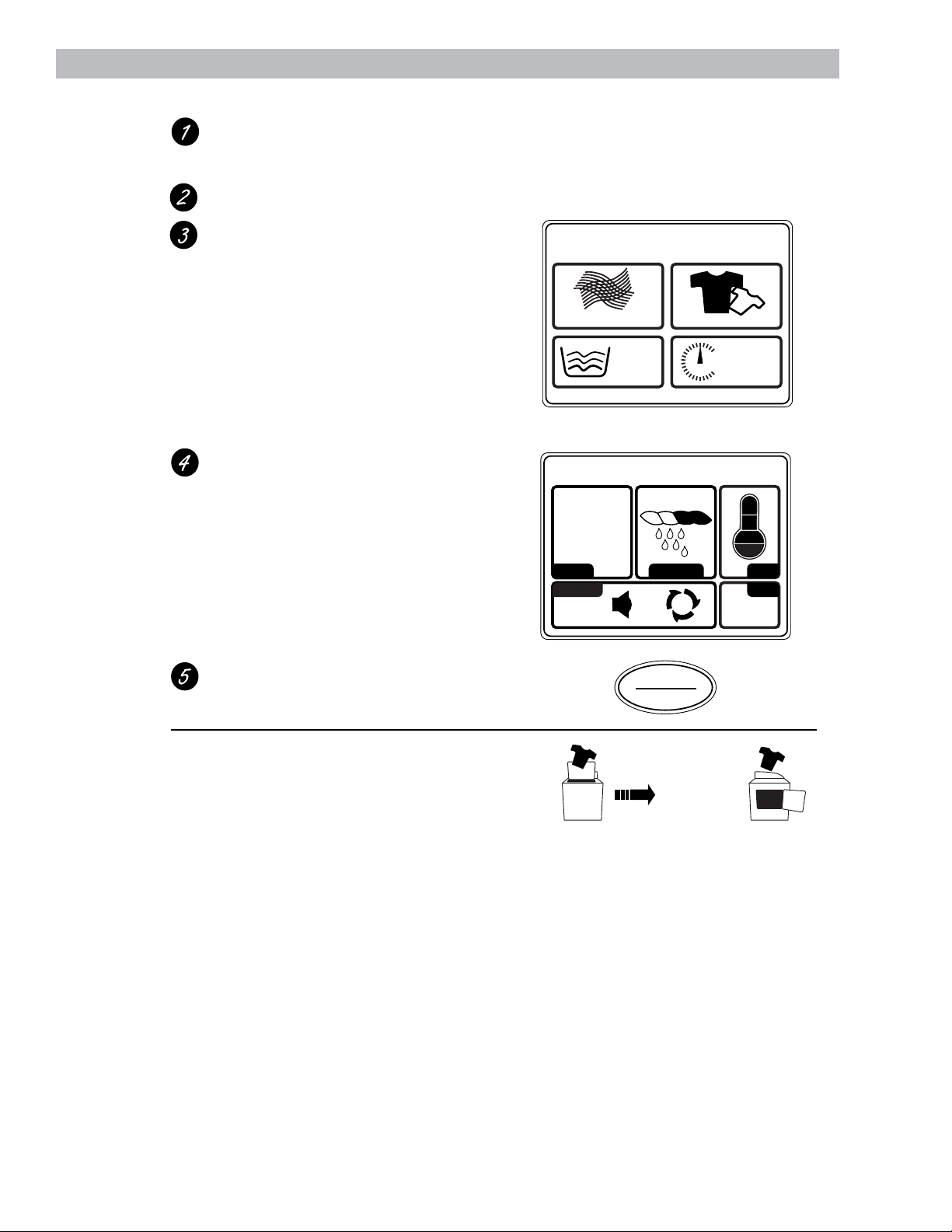

Select one of the four drying methods from the

Home Screen:

• Press BY FABRIC to dry according to fabric

type.

• Press BY GARMENT to dry according to

clothing type.

• Press SPECIAL CYCLES to dry nongarment

items, to dry without heat or to dry using the

drying rack.

• Press TIMED DRY to specify a drying time

and temperature.

Change any of the automatic settings, if

desired, by pressing the Touch Screen and

following the on-screen instructions.

By changing the settings you can:

• Change the level of dryness

• Change the drying temperature

• Set a Delay Start or Extended Tumble, or

change the End-of-Cycle Signal volume

• Adjust time settings

TOUCH TO SELECT

Sensor

BY

FABRIC

SUMMARY SCREEN

COTTONS MORE DRY

SPECIAL

CYCLES

Home Screen

DRY CYCLE

BY

GARMENT

TIMED DRY

0:36

TEMPDRYNESSCYCLE

TIMEOPTIONS

Washer

Communicated

Cycles

Close the door and press START.

The dryer will not operate unless the door is

closed.

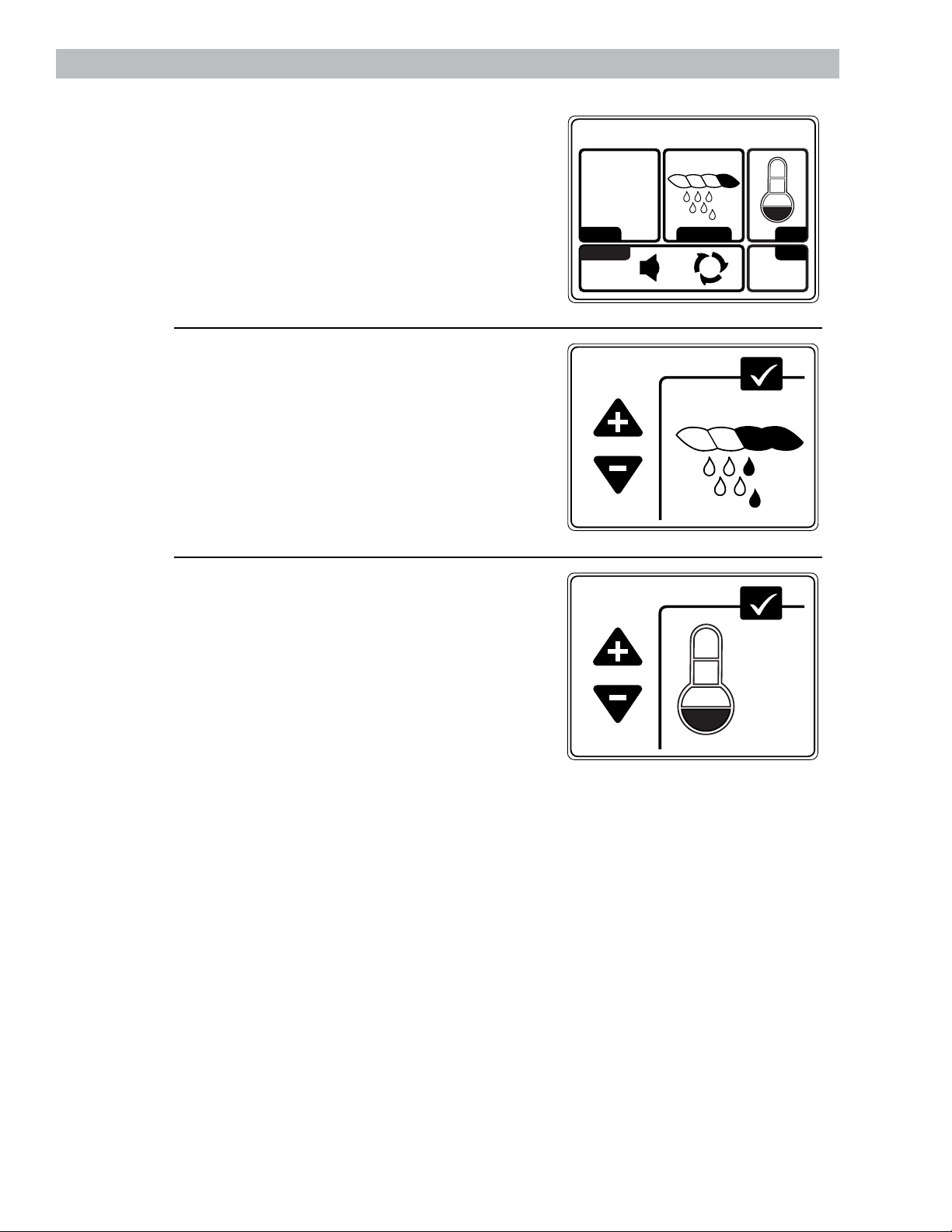

If the Washer/Dryer Communication features

of your washer and dryer are turned ON, your

dryer will receive cycle information from your

washer to create a dry cycle that matches your

wash load.

After the wash cycle is complete,

communication begins once either the washer

or dryer Touch Screen is activated.

Once the information is received, your dryer

can then create the optimal dry cycle for your

load. You can then change any of the

automatic cycles, as desired.

NOTE: For some communicated wash cycles,

your dryer will prompt you to select a FABRIC

TYPE.

See “Final Setup” in the Installation

Instructions for attaching the serial cable for

Washer/Dryer Communication.

S

TART

S

TOP

SENDING INFO TO DRYER... RECEIVING...

Washer Display Dryer Display

– 8 –

Page 9

Dry Cycles

Drying by

Fabric Type

If the Touch Screen is dark, press POWER or the Touch Screen to access the dry cycles menu.

The default cycle settings are based on standard load types. Always follow the fabric manufacturer’s

care label when laundering.

• Blends

• Cottons

• Delicates

• Knits

• Polyester

• Silks (Washable)

BY

FABRIC

Drying by

Garment

Type

• Athletic Wear

• Blouses

• Delicates

• Dress Shirts

• Easy Care

• Everyday

Wear/Casual

• Jackets/Coats

• Jeans

• Khakis

• Knits

• Lingerie

• Mixed Garments

• Play Clothes

• Silks (Washable)

• Sweaters

• Swimwear

• Underwear

BY

GARMENT

Select By FABRIC to dry loads sorted by fabric type.

FABRIC CYCLES include:

Select By Garment to dry loads sorted by garment type.

GARMENT CYCLES include:

Drying

Using

Timed Dry

1 Press TIMED DRY.

2 Use the arrows to set more or less time; then press OK.

3 Use the arrows to set the temperature; then press OK.

4 Press START.

TIMED DRY

Select TIMED DRY to set your own drying time.

Timed Dry is also recommended for small loads.

Drying

Using the

Special

Cycles

• Air Dry

• Blankets (Cotton)

• Blankets (Other)

• Comforter

• Dewrinkle

• Dryel

™

• Pet Bedding

(Washable)

• Pillows (Washable)

• Rack Dry

• Sheets

• Sneakers

• Throw Rugs

(Washable)

• Towels

• Warm Up

SPECIAL

CYCLES

Select SPECIAL CYCLES to dry loads of nongarment items, use the

drying rack or to tumble using low or no heat.

SPECIAL CYCLES include:

– 9 –

Page 10

Summary Screen

About the

Summary

Screen

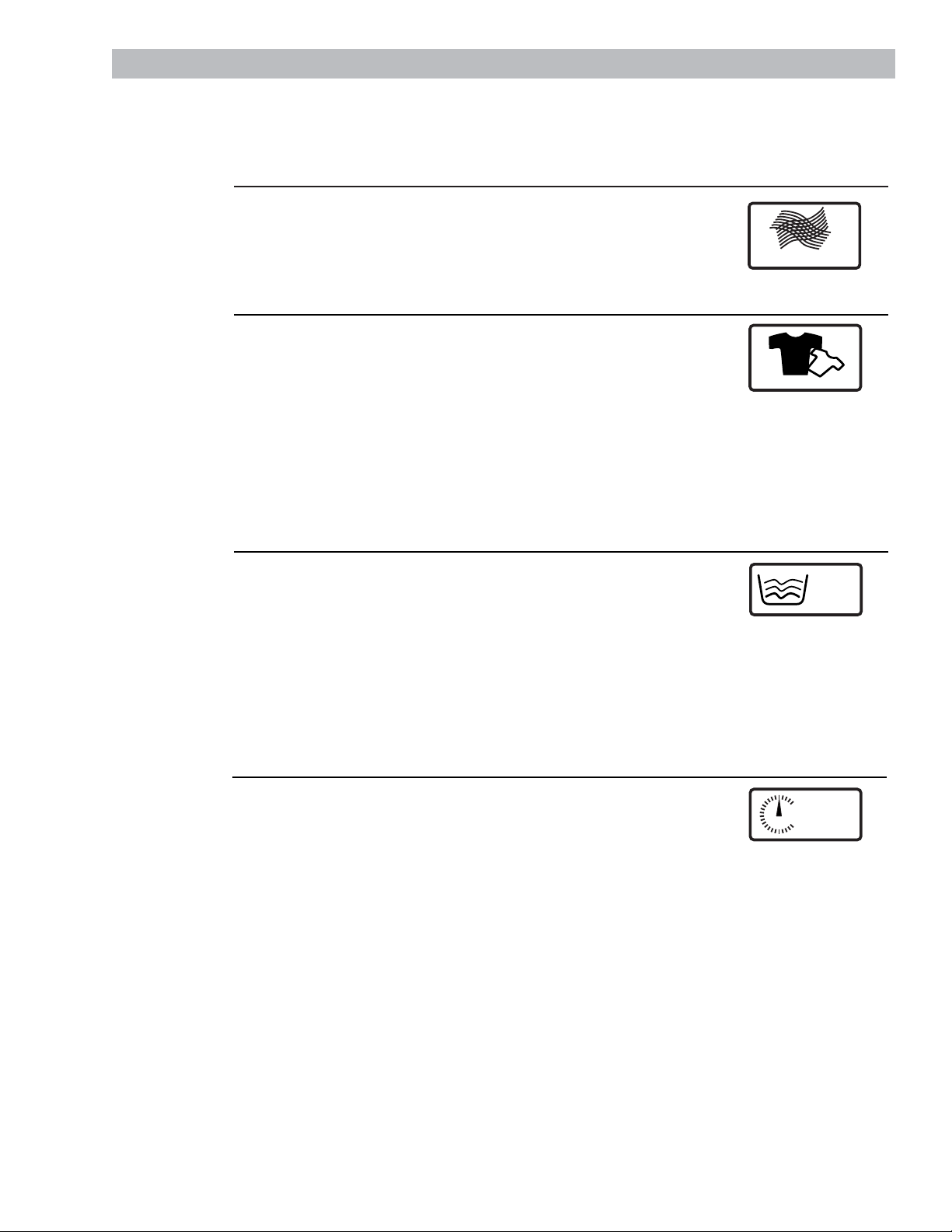

After selecting a dry cycle, the Summary Screen

displays the automatic settings for the cycle you

have chosen. You can adjust these by touching

the screen location for any of the settings

shown.

If you change any of the automatic settings,

you can save the new settings as a custom

“My Cycle” by pressing the MY CYCLES button

while on the Summary Screen and choosing

SAVE CURRENT SETTINGS.

Changing

the Dryness

Level

To change the dryness level, touch the

DRYNESS pad on the Touch Screen; then use

the arrows to select the level of dryness. Press

OK when you have reached the desired setting.

MORE DRY – Use for heavy-duty fabrics.

DRY – Use for a normal dryness level suitable

for most loads. This is the preferred cycle for

energy saving.

LESS DRY – Use for lighter fabrics.

DAMP – Use to leave items partially damp.

Changing

the Drying

Temperature

To change the drying temperature, touch

the TEMP pad on the Touch Screen; then

use the arrows to select higher or lower

temperature. Press OK when you have

reached the desired setting.

HIGH – For regular to heavy cottons.

MEDIUM – For synthetics, blends and items

labeled permanent press.

LOW – For delicates, synthetics and items

labeled Tumble Dry Low.

EXTRA LOW – For delicates, lingerie and

special-care fabrics.

AIR DRY – For tumbling items without heat.

SUMMARY SCREEN

COTTONS MORE DRY

TEMPDRYNESSCYCLE

TIMEOPTIONS

0:36

DRYNESS

MORE DRY

LESS DRY

TEMPERATURE

HIGHER

LOWER

OK

DRY

OK

EXTRA

LOW

– 10 –

Page 11

Summary Screen

About

the Drying

Options

Adjusting

the Time

Settings

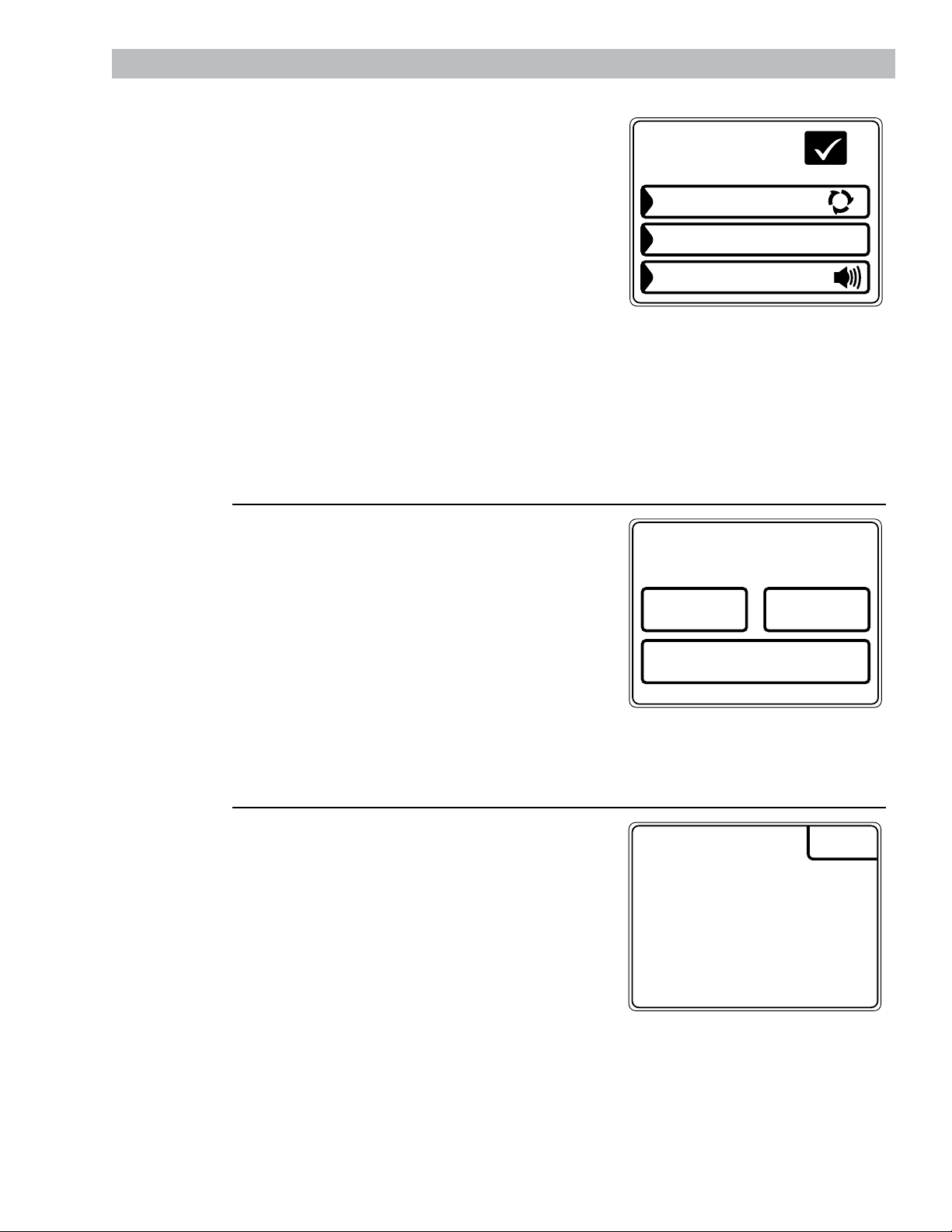

Touch the OPTIONS pad on the Touch Screen to

select drying options. After selecting any drying

options, press OK to save your setting.

Delay Start

Touch the DELAY START pad repeatedly to set a

delay time of up to 12 hours. The countdown time

will be shown in the display.

Extended Tumble

Minimizes wrinkles by adding approximately 20

minutes of no-heat tumbling after clothes are dry.

Touch EXTENDED TUMBLE to turn the feature

on or off. If set, the Extended Tumble time will

not be included in the cycle time shown in the

display. The dryer will signal for the first 6 minutes

during Extended Tumble.

End-of-Cycle Signal

Alerts you that the cycle is complete. The clothes

should be removed when the beeper goes off so

wrinkles won’t set in. Touch END OF CYCLE

SIGNAL to select the volume or to turn the

beeper off. The new volume will be saved as

the default setting.

You can adjust the time setting for the dry cycle,

delay start and extended tumble times. Touch the

TIME pad on the Summary Screen; then choose

the time you wish to adjust.

To change the dry cycle time, select CYCLE TIME;

then use the arrows to select more or less drying

time. If the Cycle Time is changed, the dryness

sensor will be turned off.

To change the delay start or extended tumble time,

select DELAY START or EXTENDED TUMBLE;

then follow the instructions in the About the

Drying Options section.

NOTE: After the dry cycle begins, you will not be

able to change the Cycle Time or Delay Time. The

dryer will beep twice if you try to change the times

after the cycle begins.

OPTIONS

DELAY START

EXTENDED TUMBLE

END OF CYCLE SIGNAL

ADJUST TIME SETTINGS

OK

20

MIN

CYCLE TIME DELAY TIME

EXTENDED TUMBLE

About the

Cycle Status

Screen

After you press START, a Cycle Status screen will

appear to indicate what cycle the dryer is in and

the time remaining in the cycle.

DRYING – The dryer is sensing the moisture level

of the load.

SENSING – The dryer is determining if the correct

dryness level has been reached.

:00 COOL DOWN – The load is dry and may be

removed (the dryer will continue to blow cool air

for up to 5 minutes).

:00 EXTENDED TUMBLE – The load is dry and

may be removed (the drum will continue to turn

without heat for up to 20 minutes).

– 11 –

CYCLE STATUS

:32

DRYING

CHANGE

SETTINGS

Page 12

Modifying,

Renaming

or Deleting

a “My Cycle”

To modify the settings of a “My Cycle” from the

Home Screen:

1 Press the MY CYCLES button.

2 Select MODIFY from the Touch Screen

menu.

3 Select the cycle name from the Touch Screen

menu.

4 Change any of the automatic settings and

select any options.

5 Press SAVE on the Touch Screen.

To delete a “My Cycle” from the Home Screen:

1 Press the MY CYCLES button.

2 Select DELETE from the Touch Screen

menu.

3 Select the cycle name from the Touch Screen

menu.

4 Choose YES to delete the cycle or CANCEL

to return to the list of “My Cycles.”

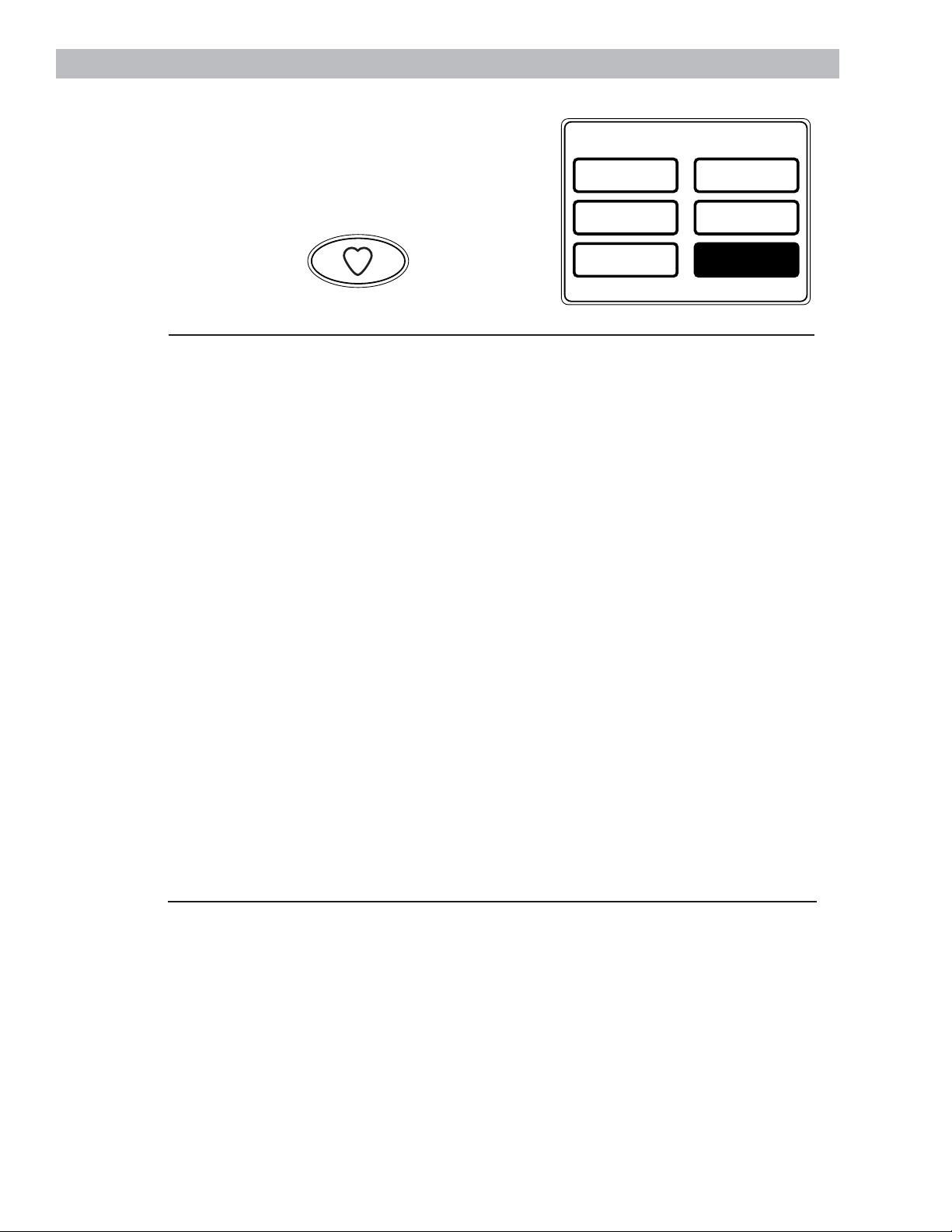

My Cycles

About the “My

Cycles” Feature

The “My Cycles” feature allows you to create,

store and reuse up to 6 custom cycles. Create

your own cycles from scratch or adjust the

settings of a predefined dry cycle; then save for

one-touch recall.

Creating

and Using a

“My Cycle”

You can create “My Cycles” two ways, by either

modifying a predefined dry cycle or creating a

cycle from your own combination of settings

and options.

To build your own “My Cycle” from the Home

Screen:

1 Press the MY CYCLES button.

2 Select CREATE from the Touch Screen

menu.

3 Choose whether you want to modify a

predefined cycle or create a new cycle.

4 If you are modifying a predefined cycle,

select the dry cycle you wish to modify.

5 Change any of the automatic settings and

select any options.

6 Touch SAVE on the Touch Screen.

7 Using the keypad on the Touch Screen, type

the name of your “My Cycle” and press OK.

To begin using your new “My Cycle” right away,

select it from the Touch Screen menu and press

START.

To save a current cycle as a “My Cycle” from the

Summary Screen:

1 After setting a dry cycle, or after a dry cycle

has just completed, press the MY CYCLES

button.

2 Select SAVE CURRENT SETTINGS from the

Touch Screen menu.

3 Using the keypad on the Touch Screen, type

the name of your “My Cycle” and press OK.

To begin using your new “My Cycle” right away,

select it from the Touch Screen menu and press

START.

To use a “My Cycle” from the Home Screen:

1 Press the MY CYCLES button.

2 Select USE from the Touch Screen menu.

3 Select the cycle name from the Touch Screen

menu.

4 Change any of the automatic settings and

select any options.

5 Press START.

MY CYCLES

USE MODIFY

C

Y

L

C

Y

M

E

S

CREATE RENAME

DELETE

SAVE CURRENT

SETTINGS

– 12 –

Page 13

About

the Help

Feature

Pressing the HELP button from the Home

Screen allows you to locate troubleshooting tips

for common dryer problems, to find help with

using the Home Screen or to set machine

preferences.

Pressing the HELP button while on any other

screen allows you to find additional information

on features found on that screen. Press HELP;

then touch any pad on the Touch Screen for an

explanation of that feature. To exit the feature,

press HELP once to return to the previous

screen or twice to exit Help.

Using the

Troubleshooter

To locate Troubleshooting Tips for common

dryer problems:

1 Press the HELP button.

2 On the Touch Screen, select TROUBLE

SHOOTER.

3 On the Touch Screen, select the problem

description from the list. You can use the

arrows at the right of the screen to scroll up

and down through the list of additional

problems.

4 On the Touch Screen, select a possible cause

for the problem and follow the on-screen

instructions to find a solution.

Finding Help

Using the

Home Screen

Pressing the HELP button then selecting

HOME SCREEN HELP allows you to find

additional information on features found on

the Home Screen. Touch any pad on the Touch

Screen for an explanation of that feature. To

exit the feature, press the BACK button.

My Cycles

To rename a “My Cycle” from the Home Screen:

1 Press the MY CYCLES button.

2 Select RENAME from the Touch Screen

menu.

3 Select the cycle name from the Touch Screen

menu.

4 Using the keypad on the Touch Screen, type

the name of your “My Cycle” and press OK.

Consumer Help Screens

– 13 –

MACHINE

PREFERENCES

TROUBLE SHOOTER

TROUBLE SHOOTER

PRESS DESCRIPTION FOR POSSIBLE CAUSES

LONG DRY TIME

NOT HEATING OR NO HEAT

TOO MUCH HEAT

COLLARS OR WAISTBANDS WET

SQUEAKING DURING STARTUP

HOME SCREEN

HELP

Page 14

Consumer Help Screens

The machine settings on the Help feature

allow you to control the volume of the button

beep and end-of-cycle signal, and turn the

washer/dryer communication feature on

or off.

Press the HELP button, then select from the

on-screen options.

Button Beep

The button beep controls the volume of the

beep that is made when you press any of the

buttons on the control panel or Touch Screen.

To change the volume of the button beep:

1 From the Home Screen, press the HELP

button.

2 Select MACHINE PREFERENCES from the

Touch Screen.

3 Select BUTTON BEEP from the Touch

Screen.

4 Use the arrows to make the volume louder

or softer, or to turn the beep off.

5 Select OK from the Touch Screen.

The new volume is now saved as the default

setting.

Washer/Dryer Communication

Washer/Dryer communication allows your

dryer to receive cycle information from your

washer to create a dry cycle that matches your

wash load.

After the wash cycle is complete,

communication begins once either the washer

or dryer Touch Screen is activated.

Once the information is sent, your dryer can

then create the optimal dry cycle for your load.

To turn the Washer/Dryer Communication

feature on or off:

1 From the Home Screen, press the HELP

button.

2 Select MACHINE PREFERENCES from the

Touch Screen.

3 Select WASHER/DRYER

COMMUNICATION from the Touch

Screen.

4 Touch the pad at the bottom of the Touch

Screen to select ON or OFF.

5 Select OK from the Touch Screen.

End-of-Cycle Signal

The End-of-Cycle signal alerts you when the

cycle is complete.

To change the volume of the end-of-cycle

signal:

1 From the Home Screen, press the HELP

button.

2 Select MACHINE PREFERENCES from the

Touch Screen.

3 Select END OF CYCLE SIGNAL from the

Touch Screen.

4 Use the arrows to make the volume louder

or softer, or to turn the signal off.

5 Select OK from the Touch Screen.

The new volume is now saved as the default

setting.

Setting the

Machine

Preferences

MACHINE PREFERENCES

Sales Demo Mode

Pressing HOME and MY CYCLES simultaneously

for three seconds will enter into the sales

demonstration mode. This mode allows the user

to view a dryer cycle. To exit, press HOME and

MY CYCLES simultaneously for three seconds or

disconnect the power to the machine.

END OF CYCLE

SIGNAL

Harmony Clothes

The Washer Talks, The Dryer Listens

The Result is Better Clothes Care

LEARN

MORE

CONTROLS

– 14 –

BUTTON BEEP

WASHER/DRYER

COMMUNICATION

Care System

TRY THE

Page 15

Operation Overview

Airflow Diagram (Gas and Electric Models)

LINT

FILTER

EXHAUST AIR

INLET

AIR

AREA

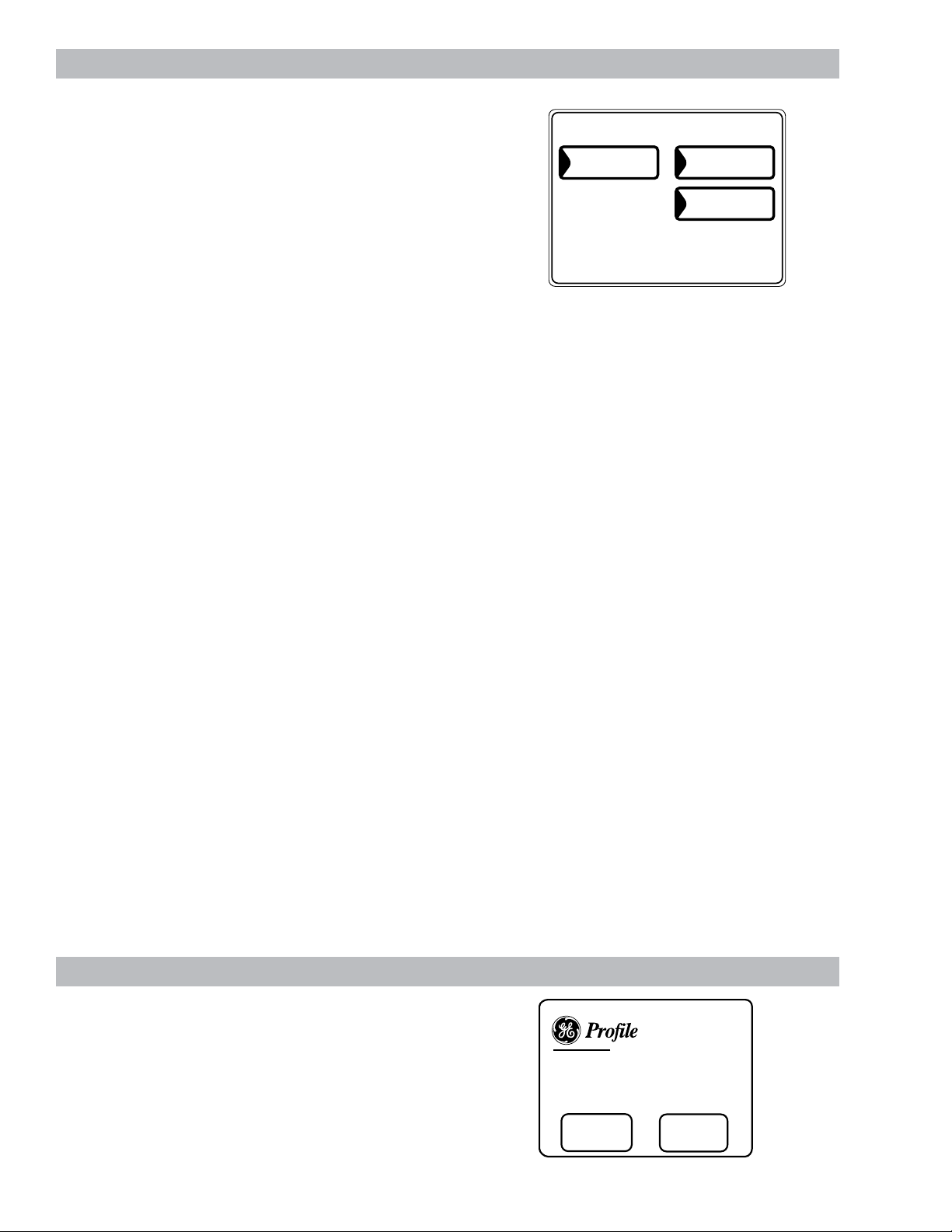

Dryer T emperature Settings (Gas and Electric Models)

DRYER TEMPERAT URE

SETTING

EXTRA LOW 10.5 AM PS 115F - 125F 2500 W 15000 BTU

LOW 16 AM PS 130F - 140F 4000 W 18000 BTU

ME DIUM 19 AM PS 145F - 155F 5000 W 22000 BTU

HIGH 24 AM PS 160F - 175F 6000 W 25000 BTU

APP RO XI M AT E CURRENT

DRAW (L1)

Note: Above measurements are at 70°F ambient temperature with no clothes load and vent

disconnected.

APPROXI MATE T EMPERATUR E

AT LINT FILTER

ELE CTR IC MO D EL

GAS MODEL

– 15 –

Page 16

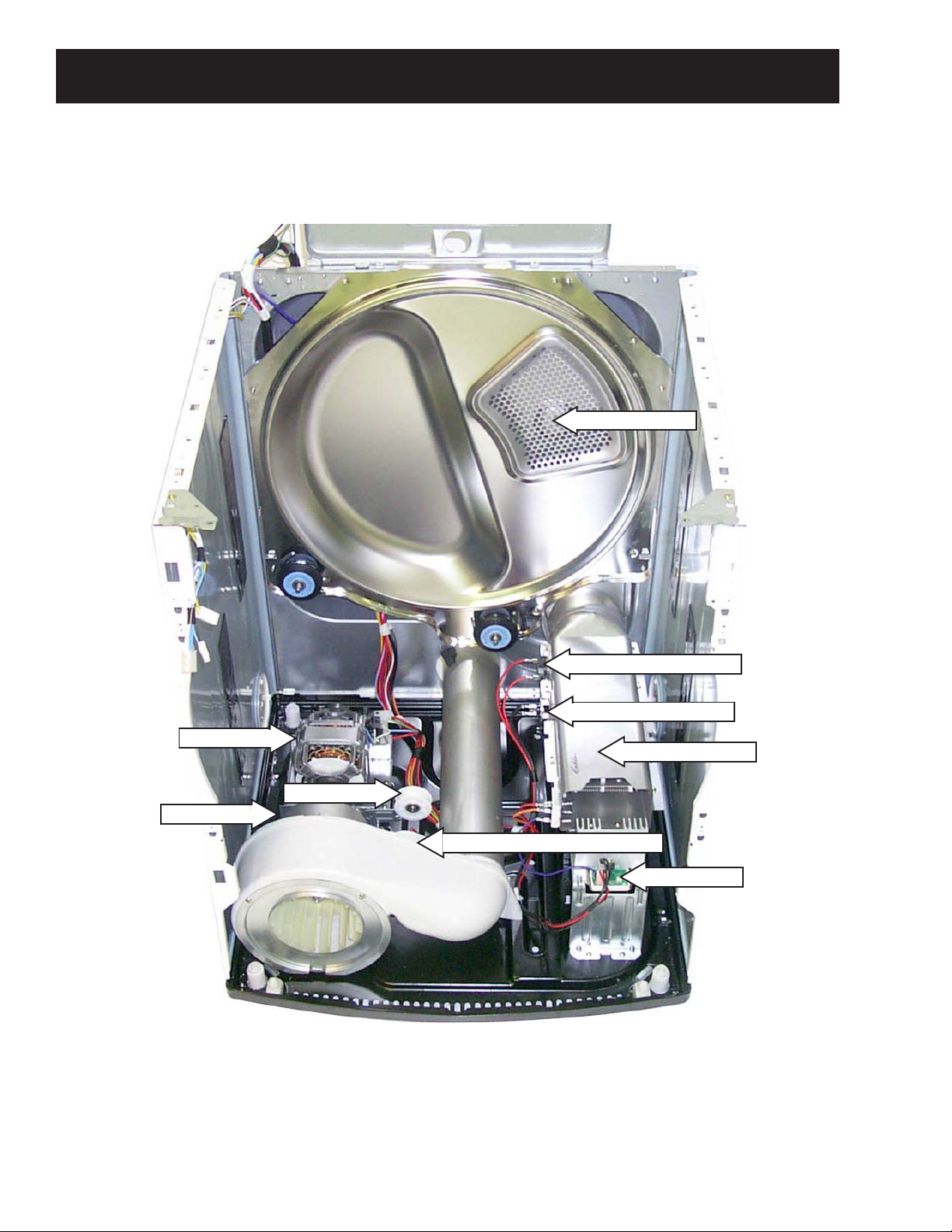

Electric Model

Component Locator Views

Inlet Thermistor

Drive Motor

Blower Motor

Inlet Hi-Limit Thermostat

Inlet Safety Thermostat

Heater Housing

Idler Pulley

Outlet Thermistor & Thermostat

TRIAC Board

– 16 –

Page 17

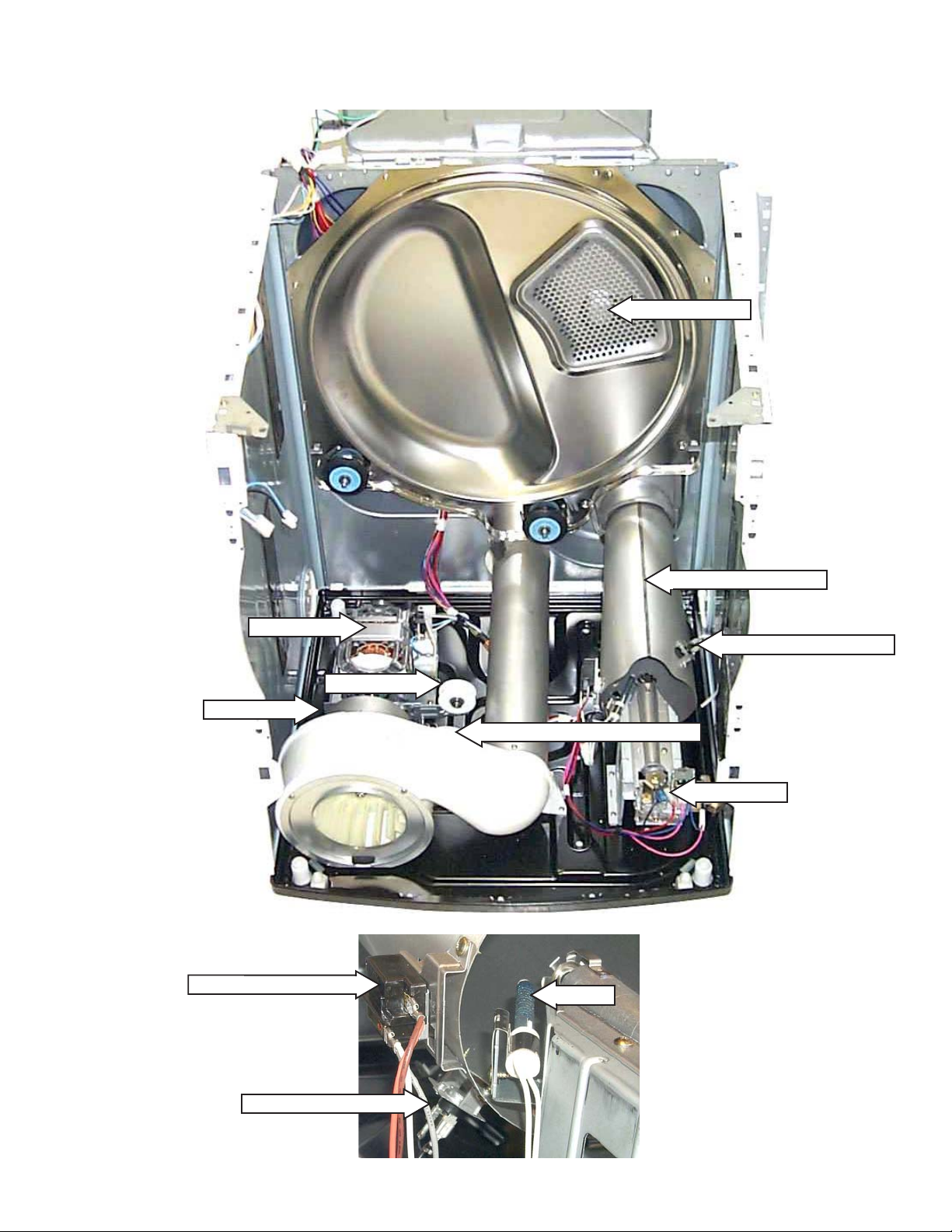

Gas Model

Inlet Thermistor

Drive Motor

Idler Pulley

Blower Motor

Flame Sensor (Detector)

Combustion Chamber

Inlet Hi-Limit Thermostat

Outlet Thermistor & Thermostat

Gas V alve

Ignitor

Inlet Safety Thermostat

– 17 –

Page 18

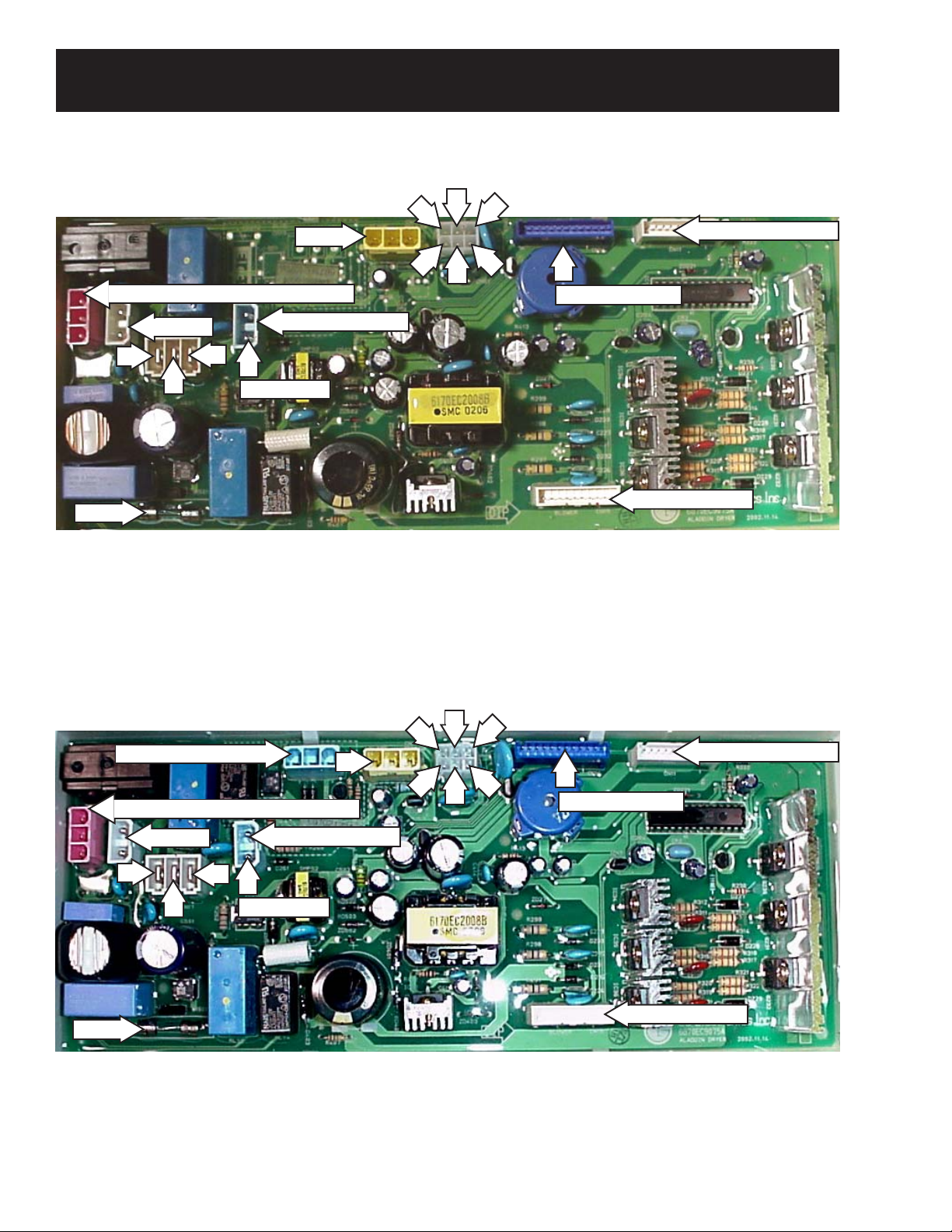

Inverter and Main Board Pin Connectors

Inverter Board (Electric Model)

Triac

120 VAC Input From RF Choke CN10

5

4

3

1

Main Board CN11

1

2

Main Board CN14

Ground

6

Fuse

1-Moisture Sensor

2-Inlet Thermistor

7

7

Door Switch

3-Inlet/Outlet Thermistor

4-Ground

Inverter Board (Gas Model)

Gas Valve ON/OFF

120 VAC Input From RF Choke CN10

Safety Thermostat

8

Blower Motor

5-Inlet Thermistor

7-Drum Motor

6-Heating Coil

5

4

3

1

Main Board CN11

1

2

Main Board CN14

Ground

6

7

Fuse

1-Moisture Sensor

2-Inlet Thermistor

Safety Thermostat

7

Door Switch

3-Inlet/Outlet Thermistor

4-Ground

– 18 –

5-Inlet Thermistor

6-Linear Gas V alve

Blower Motor

7-Drum Motor

8-Flame Sensor

Page 19

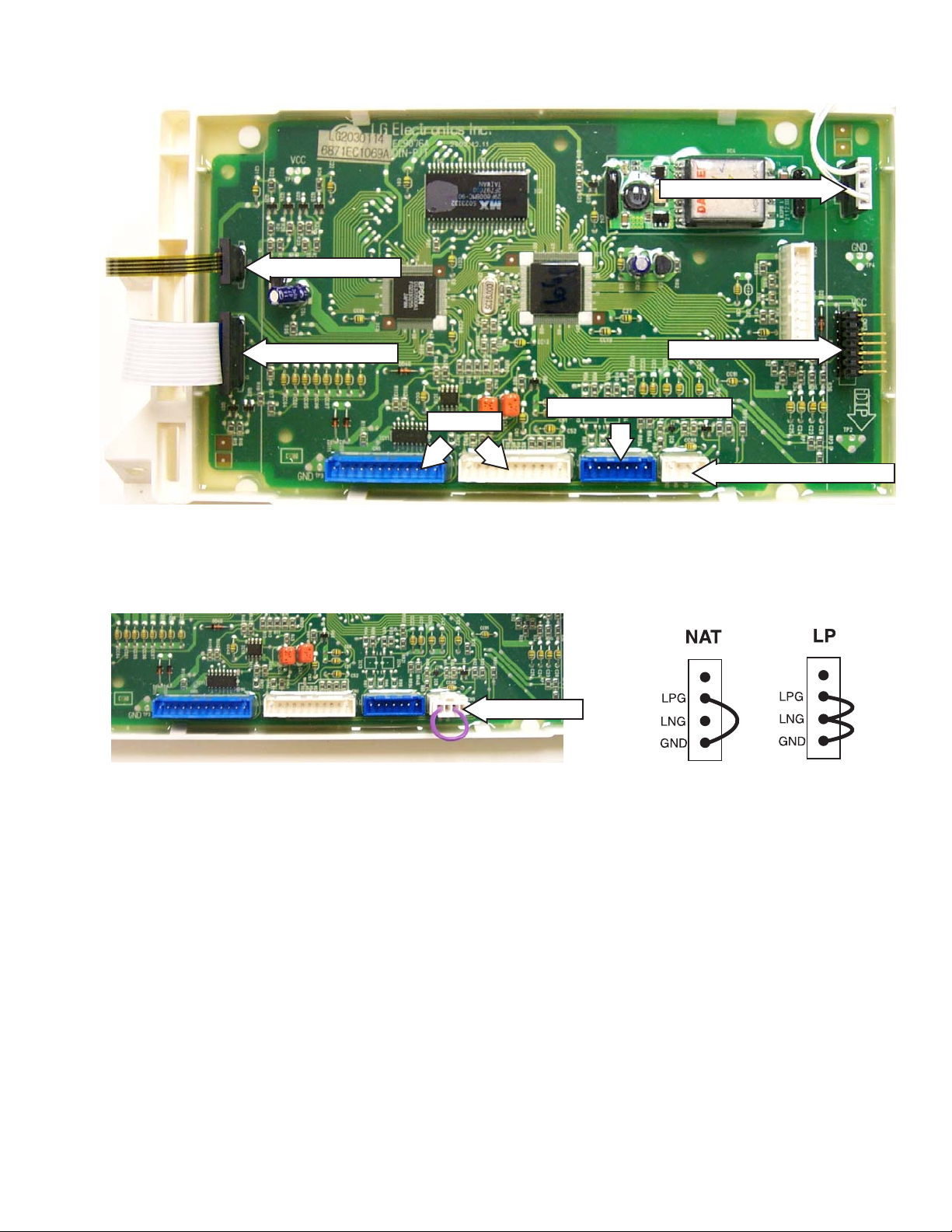

Main Board

LCD Backlight (>800 VDC)

Touch Screen

LCD Display

Serial Communication Link

Inverter

Keypanel Membrane

Model Selector Connector

WARNING: THE CONNECTOR AT THE LCD BACKLIGHT IS OVER 800 VDC. USE APPROPRIATE

TYPE VOLTMETER OR DAMAGE COULD RESULT.

Jumper Configurations

Jumper Plug

Note: The gas dryer main board differs from the electric dryer main board by the addition of a jumper

plug on the model selector connector (the electric model has no jumper plug). Depending on how the

pins have been jumped will determine what type of gas (natural or LP) the dryer is using.

The LP conversion kit is part number WE25X10014 and consists of the LP model selector and an LP

orifice for the gas valve.

The dryer control performs three checks to determine whether the dryer is an electric, LP gas or natural

gas.

• Initially , the control looks for a flame sensor. If the flame sensor is detected, the control then looks for

a model selector set for natural or LP gas.

• If both conditions are satisfied, the dryer will start.

• The dryer control then monitors temperature based on specific software parameters for each type of

gas. If the temperature is outside of that range, an error is displayed on the LCD display and the

dryer will shut down. (See

Error Chart Gas Setup Failed).

– 19 –

Page 20

Dryer Components

Backsplash

The backsplash must be removed to access the

control system components.

To remove the backsplash:

1. Remove the 4 Phillips head screws that hold

the backsplash in place.

Backsplash

2. Place a towel over the lid of the dryer to

prevent scratches to the surface. Gently lift

each corner of the backsplash; then roll it

forward so it rests on top of the dryer .

Main Control Board and Touch Screen

LCD

The main control board and touch screen LCD

are attached to the backsplash as one unit. The

touch screen LCD and main control board are

only available as a complete assembly .

To remove the main control board and LCD

touch screen assembly:

1. Remove the

2. Disconnect the ribbon at the right of the main

control board.

Note: Do not disconnect any other ribbons from

the main control board.

Backsplash.

3. Disconnect the wiring to the control board.

Remove the backsplash.

Control System

The dryer control system consists of three main

components:

• Main control board and touch screen LCD

• Membrane keypanel

• Inverter

Caution: To prevent electrostatic discharge from

damaging any electronic components, use an

ESD wristband or touch a grounded metal

surface before servicing.

Disconnect Ribbon

3. Remove the 4 Phillips head screws (2 on

each side) that hold the main control board

and LCD touch screen assembly in place.

Remove the assembly.

– 20 –

Page 21

Membrane Keypanel

Inverter

The membrane keypanel is attached to the

backsplash and is available only as a complete

assembly.

• When ordering a replacement backsplash, the

part must be ordered as left or right,

depending upon installation.

• The membrane keypanel is connected to the

control board by a ribbon cable.

Membrane Keypanel Test

To test the membrane keypanel, press the

appropriate pad and check for continuity (0 Ω)

between the following pins:

Pad Pins

Power 1 and 3

My Cycles 1 and 4

Back 2 and 3

Help 2 and 4

Home 1 and 7

Start/Stop 1 and 5

The inverter board is enclosed in a protective box

mounted on the top panel under the backsplash.

To access and remove the inverter board:

1. Remove the

2. Remove the 2 Phillips head screws that hold

the inverter box in place.

3. Slide the inverter box toward the rear of the

dryer and lift out.

Backsplash.

7

5

4

3

2

1

Note: The number 1 molded on the membrane

connecter is not a pin reference number.

1

MEMBRANE

RIBBON

4. Lift the inverter box up. Press the tabs on the

side and gently pry it open

5. Disconnect the wiring from the inverter board.

Remove the inverter.

– 21 –

Page 22

T esting the Inverter

r

Signal (Beeper)

CN14

120 VAC Input From RF Choke CN10

Fuse

CN11

• The inverter receives 120 V AC at the red 3-pin

connector CN10. The voltage first passes

through an RF choke. The RF choke filters the

line voltage and is replaced as an assembly. If

120 V AC is not present, check the wall outlet,

power cord, and RF choke.

• When 120 V AC is present at CN10, there

should be 5 VDC between pin 3 (white wire)

and pin 7 (blue wire) on the white connector

CN1 1. (This voltage is used to keep the

membrane and LCD display in standby,

waiting for a key-press.)

The beeper is mounted on the inverter, but

controlled by the main control board.

• The beeper uses the same 12 VDC supply as

the LCD backlight.

• To check the 12 VDC circuit, measure

between pin 3 (white wire) on white connector

CN1 1 and pin 8 (pink wire) on the blue

connector CN14. (See

Pin Connectors.

12 11

109876

1110987654321

)

Inverter and Main board

CN14

54321

CN11

• Upon activating a membrane pad or touching

the LCD screen, the control "wakes up" and a

second transformer is energized. When this

condition is present, 12 VDC and 20 VDC can

be measured on the board.

• 12 VDC should be between pin 3 (white wire)

on white connector CN1 1 and pin 8 (pink wire)

on the blue connector CN14.

• 20 VDC should be between pin 3 (white wire)

on white connector CN1 1 and pin 12 (brown

wire) on the blue connector CN14.

Voltage CON Pin

120 VAC CN10 1 BLK CN10 3 WHT

5 VD C CN11 3 WHT CN11 7 BLU

12 VDC C N11 3 WHT CN14 8 PNK

20 V DC CN11 3 WHT CN1 4 1 2 B RN

Wire

Color

CON Pin

Wire

Colo

– 22 –

Page 23

Top Cover

Front Panel

The top cover is held in place by 2 Phillips head

screws, located on the back of the washer,

and two front tabs.

To remove the top cover:

1. Remove the Backsplash.

2. Remove the 2 screws that hold the

box in place.

3. Place the inverter box off to the side of the

dryer.

4. Slide the wiring harness guard out.

Disconnect the wires to the RF choke/surge

protector.

Inverter

WARNING: Sharp edges may be exposed when

the inner top cover is removed. Use caution to

avoid injury when servicing dryer . Wear Kevlar

gloves or equivalent protection.

To remove the front panel:

1. To access the 2 top Phillips head screws

securing the front panel, remove the

backsplash and top cover .

2. Open the door and remove the 4 Phillips

screws from the front panel.

5. Remove the 2 rear Phillips head screws that

hold the top cover in place.

6. Lift the top cover and slide it forward to clear

the front tabs.

3. Remove the 2 Phillips screws that hold the

front panel to the inner top cover .

4. Lift and tilt the front panel forward slightly to

disconnect wiring to the door switch.

Door Switch

5. Remove the front panel .

– 23 –

Page 24

Drum

WARNING: Sharp edges may be exposed.

Wear Kevlar gloves or equivalent protection.

The dryer drum is made of 304 stainless steel

and has three replaceable drum baffles attached

to the inside. The drum rotates clockwise at 47 to

50 rpm.

4. Remove the 4 screws that hold the front drum

support to the sides of the dryer.

To remove the drum:

1. Remove the

Top Cover and the Front Panel.

2. The heat shield is held in place by 4 Phillips

head screws (2 on each side) and 2 plastic

rails (1 on each side). Remove the screws

that hold the plastic rails in place. Slide the

rails forward and out.

Tech Tip: The drum can be removed without

removing the heat shield if desired. However,

installation and removal of the dum can be difficult

due to the limited space around the drum if the

heat shield is left in place.

Front Drum Support

5. Grasp the top outside edges of the front drum

support and unsnap the 4 corners from the

from the sides of the dryer. Remove the front

drum support.

6. Remove the

Drive Belt from the motor.

7. Using the belt as a handle, pull the drum

forward and guide it out of the dryer cabinet.

Rail

Rail

3. Disconnect wiring to the drum light and

sensor rods.

Disconnect Drum Light

Disconnect Sensor Rods

– 24 –

Page 25

Drum Rollers

Door Switch

The 304 stainless steel drum rotates on four drum

rollers. Two on the front drum support and two on

the rear drum support.

The drum roller comes as a complete assembly.

To remove the drum rollers:

1. Remove the

2. Remove the front drum support to access the

front drum rollers. Remove the

access the rear drum rollers.

Top Cover and Front Panel.

Drum to

The door switch is fastened to the front panel by

two locking tabs and is common to all dryer

functions.

• When the dryer door is closed, the switch will

complete the motor circuit, allowing dryer

operation.

• Immediately upon detection of a door opening,

the drum motor and blower motor shut off and

all heat is disabled.

• If the door is open at the start of a cycle or

while a cycle is running, the SUMMARY

SCREEN is displayed on the LCD screen.

• Once the door is closed, the dryer pauses and

the SUMMARY SCREEN is displayed showing

cycle parameters and the current estimated

cycle time remaining.

• The dry cycle can be resumed by pressing the

START/STOP pad.

• Opening the dryer door closes the drum light

circuit, allowing the drum light to be energized.

3. Each drum roller is held in place by a plastic

triangular clip.

4. Remove the plastic triangular clip with a small

flat-blade screwdriver and remove the drum

roller.

5. To remove the drum roller shaft from the front

drum support, remove the 14 mm hex nut that

holds the shaft in place.

6. To remove the drum roller shaft from the rear

drum support:

a. Remove the Heater Assembly.

b. Remove the seven screws from the back

of the dryer that hold the rear drum

support in place.

c. Remove the 14 mm hex nut that holds the

drum roller shaft in place.

• The door switch circuit can be checked in the

factory test mode.

– 25 –

Page 26

Drum Light

To install the drive belt:

The drum light has a screw-in 15-watt, 120-VAC

bulb located in the top of the front panel. It is

switched on the neutral side by the door switch.

• Replace only with a bulb of the same size and

type. (The bulb can be found at most local

stores).

• Remove the screw in the bulb lens to access

the bulb.

Screw

1. Place the belt in position around the front of

the drum.

2. Reach under the left side of the drum and

place the belt in position around the motor

pulley . Push the idler pulley to the left and

place the belt onto the idler pulley .

3. Release the idler pulley and guide the belt into

position.

4. Install the

Drum support.

Note: Lift the drum slightly to line up the drum

with the drum support.

5. Check to make sure the belt is in place and

not twisted before installing the top and front

panels.

Belt Switch

The belt switch is fastened to the motor bracket

by 2 Phillips head screws.

Drive Belt

The drive belt extends from the motor pulley , p ast

the idler pulley , and around the perimeter of the

dryer drum. Part # WE12X1001 1.

To remove the drive belt:

1. Remove the

2. Reach under the left side of the drum, push

the idler pulley to the left to take tension off the

belt.

3. Remove the belt from the motor pulley and

idler pulley . Pull the belt through the front of the

dryer.

Top Cover and Front Panel.

Idler Pulley

Belt

• The belt switch is activated by the idler pulley .

• If the drive belt breaks, the belt switch opens

the drive motor circuit, interrupting all dryer

functions except the drum lamp.

Idler Pulley

Belt Switch

To remove the belt switch:

1. Remove the

Top Cover, Front Panel, and Drum.

2. Disconnect the wiring to the belt switch.

3. Remove the 2 Phillips head screws that hold

the belt switch to the motor bracket.

Motor Pulley

– 26 –

Page 27

Drive Motor

Blower Motor

The drive-motor is a single-speed AC, 1/3-hp

motor with an automatic reset overload protector.

• The overload protector is an internal

component of the motor and cannot be

replaced separately .

• The motor contains a centrifugal switch that

serves three purposes:

1. Disengages the motor start winding.

2. Engages the motor run winding.

3. Closes the circuit contacts for the heat

source.

• The switch is an internal component of the

motor and cannot be replaced separately.

The drive motor has an approximate resistance

value of:

•3 Ω between the blue and white wires

•7 Ω between the brown and blue wires.

• 10 Ω between the brown and white wires.

To remove the drive motor:

1. Disconnect power to the unit.

2. Remove the

Top Cover , Front Panel, and Drum.

3. Disconnect the motor wiring.

4. With a flat blade screwdriver, compress the

open end of the spring strap (one strap on

each end of the drive motor) until it releases.

The blower motor is a DC, variable speed motor

capable of operating at different speeds in

response to changing air temperature and venting

impedances. Below 1000 rpm, the dryer control

turns the heater off.

Resistance of the motor windings can be

measured at the 10-pin connector on the inverter

board or at the motor. (See

Board Pin Connectors

).

Inverter and Main

The blower motor has an approximate resistance

value of 14 Ω between the following wires:

• Y ellow to Yellow

• Red to Red

• Blue to Blue

The remaining wires are a ground and feedback

through the control for determining motor speed.

To remove the blower motor:

The blower housing must be removed to access

the blower motor .

1. Disconnect power to the unit.

2. Remove the

Top Cover , Front Panel, and Drum.

3. Disconnect the outlet thermistor and outlet

thermostat wiring located on the back side of

the blower housing.

4. Disconnect the motor wiring.

Disconnect

Spring Strap

5. Remove the spring straps. Remove the drive

motor from its cradle.

Outlet Thermostat Wiring

Outlet Thermistor Wiring

Motor Wiring

(Continued next page)

– 27 –

Page 28

5. Remove the 2 Phillips head screws that hold

the blower guard in place. Remove the blower

guard.

6. Remove the 13 mm center nut. (Turn

clockwise to remove.) Remove the blower

wheel.

8. Remove the remaining 2 Phillips head screws

from the dryer base and exhaust duct.

Top View

Note: The motor shaft has a snap ring, which

prevents the blower wheel from rubbing the back

of the blower housing.

7. Remove the 3 Phillips head screws from the

center of the blower housing. Remove the

front screw from the dryer base.

Snap Ring

9. Remove the blower housing.

10. With a flat blade screwdriver compress the

open end of the spring strap (one strap on

each end of the drive motor) until it releases.

Spring Strap

11. Remove the spring straps. Remove the drive

motor from the motor bracket.

Note: The motor bracket is notched, be sure to

align the motor correctly in the bracket when

installing.

– 28 –

Page 29

Heater Assembly (Electric Models)

The electric dryer has two heating elements. One

is fixed at 3000 watts and cycles on and off. The

other is variable, controlled by a Triac that varies

the wattage from 0 to 3000 watts.

• The total wattage of the dryer will vary from

3000 to 6000 watts.

• The open end in the back of the housing

allows air to be drawn over the heating coils

and into the drum.

• Each row of coils should have a resistance

value of 17 Ω.

Heater Assembly

3. Remove the 2 Phillips head screws that hold

the heater assembly in place.

4. Remove the heater assembly.

To remove the heater assembly:

1. Remove the

Top Cover, the Front Panel, and

the Drum.

2. Note the wire locations and disconnect all

wiring to the heater assembly .

– 29 –

Page 30

Inlet Thermistor

Inlet Safety Thermostat

The inlet thermistor is located on the inside of the

inlet air duct on both electric and gas models.

Inlet Thermistor

• The inlet thermistor measures the incoming

air temperature and responds to temperature

changes.

• The inlet thermistor provides temperature

change information to the electronic control

board.

The inlet safety thermostat is located on the left

side of the heater housing on electric models and

on the lower, left side of the combustion chamber

on gas models.

Electric Model Location

Manual Reset

• The electronic control board makes heating

and blower decisions based on this

information.

• At room temperature the inlet thermistor has a

resistance value of 2.27 K Ω +/- 5%.

To remove the thermistor:

1. Remove the inlet thermistor access cover

located on the back of the dryer.

2. Disconnect the thermistor wiring.

Screw

Disconnect

Gas Model Location

Manual Reset

3. Remove the screw that holds the thermistor in

place. Remove the thermistor.

– 30 –

Page 31

• The inlet safety thermostat monitors incoming

air temperature.

• If the thermostat reaches a temperature

beyond its maximum temperature rating, it will

trip and disable all dryer functions except the

drum lamp.

• The outlet thermistor measures outgoing air

temperature and responds to temperature

changes.

• The outlet thermistor provides temperature

change information to the electronic control

board.

• The inlet safety thermostat must be reset

manually by pressing the reset button on the

back of the thermostat (see photos).

• The inlet safety thermostat on the electric

models has a trip temperature of 212°F

(100°C).

• The inlet safety thermostat on the gas models

has a trip temperature of 266°F (130°C).

To remove the safety thermostat:

1. Remove the

Top Cover, Front Panel, and Drum.

2. Disconnect the safety thermostat wiring.

3. Remove the 2 screws that hold the safety

thermostat in place. Remove the safety

thermostat.

Outlet Thermistor

The outlet thermistor is located on the blower

housing on both the gas and electric models.

• The electronic control board makes heating

decisions based on this information.

• At room temperature the outlet thermistor has

a resistance value of 10 K Ω +/- 3%.

To remove the outlet thermistor:

1. Remove the

Top Cover, Front Panel, and Drum.

2. Disconnect the thermistor wiring.

3. Remove the screw that holds the thermistor in

place. Remove the thermistor.

Outlet Thermostat

The outlet thermostat is located on the blower

housing on both the gas and electric models (see

photos.)

• The outlet thermostat monitors outgoing air

temperature.

• If the outlet thermostat reaches a temperature

beyond its maximum temperature rating, it will

trip and disable the heating function only .

Outlet Thermostat

Outlet Thermostat

Outlet Thermistor

Outlet Thermistor

• The heating function will be restored when the

outlet thermostat cools and resets.

• The outlet thermostat on the electric model

has a trip temperature of 189°F (87°C) and a

reset temperature of 153°F (67°C).

• The outlet thermostat on the gas model has a

trip temperature of 185°F (85°C) and a reset

temperature of 149°F (65°C).

To remove the outlet thermostat:

1. Remove the

Top Cover, Front Panel, and Drum.

2. Disconnect the thermostat wiring.

3. Remove 2 Phillips head screws that hold the

outlet thermostat to the blower housing.

Remove the outlet thermostat.

– 31 –

Page 32

Hi-Limit Thermostat

To remove the hi-limit thermostat:

The hi-limit thermostat is located on the left side

of the heater housing on electric models. It is

located on the right, upper side of the combustion

chamber on gas models.

Electric Model Location

Gas Model Location

1. Remove the

the

Drum.

Top Cover, the Front Panel, and

2. Disconnect the lead wires to the hi-limit

thermostat.

3. Remove the 2 screws that hold the hi-limit

thermostat to the housing. Remove the hi-limit

thermostat.

Gas Valve

The gas valve assembly is located in the bottom,

right, front corner of the dryer cabinet.

Gas Valve

• The hi-limit thermostat monitors incoming air

temperature.

• If the hi-limit thermostat reaches a

temperature beyond its maximum

temperature rating, it will trip and disable the

heating function only .

• Heating functions will be restored when the hilimit thermostat cools and resets.

• The hi-limit thermostat on the electric models

has a trip temperature of 230°F (110°C) and a

reset temperature of 194°F (90°C).

• The hi-limit thermostat on the gas models has

a trip temperature of 194°F (90°C) and a reset

temperature of 158°F (70°C).

• The gas valve consists of 3 valves operated

by 12 VDC solenoid coils.

• Two of the valves are either in an open or

closed state, depending on whether the coils

are energized by the control.

• The resistance value of these coils is

approximately 1900 Ω.

• The third valve is a linear valve. The valve

opening varies depending on the amount of

voltage it receives from the electronic control.

The resistance of the coil on the linear valve is

approximately 65 Ω.

– 32 –

Page 33

• The control operates the gas valves by

supplying voltage based on varying duty

cycles.

• It is difficult to determine specific voltages at

the valve due to software algorithms based on

clothes load and temperature settings. The

most accurate diagnostic check is to measure

resistance of the solenoid coils.

Ignitor

The ignitor is located at the end of the gas valve

assembly in the combustion chamber opening.

Resistance across the ignitor is approximately

300 to 500 Ω.

Combustion Chamber

To remove the gas valve:

1. Shut off the gas and electricity to the dryer .

2. Remove the

Top Cover, and Front Panel.

3. Disconnect all wiring to the gas valve and

ignitor.

4. Remove the 2 Phillips head screws that hold

the gas valve to the elbow coupling.

5. Remove the 2 Phillips screws that hold the

gas valve assembly to the dryer base.

Elbow Coupling

Dryer Floor

Ignitor

Gas Valve Assembly

To remove the ignitor:

1. Shut off the gas and electricity to the dryer .

2. Remove the

Top Cover, Front Panel, and Drum.

3. Using a short Phillips screwdriver, remove the

screw that holds the ignitor to the assembly.

Remove the ignitor.

Note: There is a cutout on the edge of the

combustion chamber to allow access to the

screw.

6. Slide the gas valve assembly out through the

front of the dryer cavity .

7. Remove the 3 Phillips head screws that

secure the gas valve to the mounting

assembly. Remove the gas valve.

Screw

– 33 –

Page 34

Ignitor and Flame Detector

Moisture Sensor

• When the electronic control calls for heat,

120 V AC is supplied to the ignitor .

• The flame detector, which is in series with the

ignitor, is closed.

• When the ignitor reaches a high enough

temperature, the flame detector opens.

• The electronic control senses the opening of

the detector and energizes the gas valves.

Testing the Ignitor and Flame Detector Circuit

1. Place the dryer in Factory Test Mode:

a. Press HOME, then HELP.

b. Press and hold the HELP and START/

STOP pads simultaneously for 3 seconds.

2. Press START/STOP to begin the test.

• The FLAME SENSOR test will display

whether the detector is open or closed.

The moisture-sensing circuit consists of two

sensor rods mounted in the drum front beneath

the lint filter opening.

• The sensor rods are connected to the main

control board. The rods are spaced about

½ in. apart, which creates an open circuit to

the control.

• The control board utilizes a low-voltage

capacitor that charges to approximately 5

VDC when the circuit is open and discharges

to less than 1 VDC when the circuit is shorted.

• When wet clothes tumble across the two

rods, the clothes create a very low resistance

between the rods, which discharges the

capacitor.

• As the clothes become dry, their resistance

value increases and the charge across the

capacitor builds to approximately 5 VDC.

• In the OFF position, the flame detector is

closed (room temperature/low heat).

ON position, the flame detector is open

(hot).

In the

Sensor Rods

Note: Proper leveling of the dryer is vital for

accurate sensor drying. Excessive rearward

adjustment will cause clothes to tumble toward

the rear of the drum, preventing contact with the

senor rods, thus producing a false dryness

reading.

Testing the Moisture Sensor Circuit

1. Place the dryer in Factory Test Mode:

a. Press HOME, then HELP.

b. Press and hold the HELP and START/

STOP pads simultaneously for 3 seconds.

A dry sensor rod circuit should display a voltage of

4.75 V AC or higher under MOISTURE(S) test.

2. Wet a cloth and place it across the sensor

rods. The display voltage should drop to

1.0 VAC or less if the circuit is working

correctly.

– 34 –

Page 35

Field Service Mode

Overview

The dryer control has a field service mode that

can be accessed by the service technician in

order to give critical information on the status of

various components of the dryer. This mode will

aid the service technician in quickly identifying

failed or improper operation of components and

systems.

The service mode does not use error codes to

identify problems. Instead, the LCD screen

displays a list of components or systems to be

checked if a problem is detected.

To enter the service mode:

Note: Once the service mode is entered all

membrane keypanel buttons are disabled.

1. Press the POWER key to turn the dryer on.

a. If the dryer is on and the home screen is

displayed, proceed to step 2. If the home

screen is not displayed, press HOME on

the keypanel.

TOUCH TO SELECT

Sensor

DRY CYCLE

3. Press and hold MY CYCLES and BACK

simultaneously for 3 seconds:

• The control will display any recorded

errors. If no errors have been recorded,

press EXIT to return to the HOME screen.

SERVICE MODE DIA GNOSTICS

THERE ARE NO SERVICE PROBLEMS

DETECTED WITH THIS UNIT.

EXIT

4. If errors have been recorded, use the error

chart in the

Troubleshooting for proper

diagnostic procedures.

SERVICE MODE DIAGNOSTICS

THERE IS A PROBLEM WITH THE HEATER BOX.

PLEASE CHECK AND REPLACE IF NECESSARY.

REMEMBER T O ALWAYS UNPLUG UNIT

PRIOR T O ANY SER VICING

MAIN : MV1.00

INV . : V01.01

EXIT

BY

FABRIC

SPECIAL

CYCLES

BY

GARMENT

TIMED DRY

2. Press HELP. The main help screen is

displayed.

MACHINE

PREFERENCES

TROUBLE SHOOTER

HOME SCREEN

HELP

– 35 –

• A MORE icon will be displayed on the LCD

screen if additional problems have been

recorded. Press MORE to list additional

errors.

SERVICE MODE DIAGNOSTICS

THERE IS A PROBLEM WITH

THE INLET THERMIST OR.

PLEASE CHECK AND REPLACE IF NECESSARY.

REMEMBER T O ALWAYS UNPLUG UNIT

PRIOR T O ANY SER VICING

MAIN : MV1.00

INV . : V01.01

EXIT

MORE

• Use the BACK pad on the keypanel

membrane to scroll back through the list. If

MORE is not displayed, then there are no

additional errors.

(Continued next page)

Page 36

YOUR DRYER IS NOW

READY FOR YOUR USE.

PLEASE READ YOUR

USER'S MANUAL PRIOR

TO OPERATION.

OK

5. If errors have been recorded, the following

steps MUST be performed.

a. Make a note of the listed errors. Press

EXIT; the screen prompts you to unplug

the dryer before servicing.

SERVICE MODE DIAGNOSTICS

ATTENTION

IN ORDER TO EXIT THE SERVICE MODE

THE UNIT MUST BE UNPLUGGED AND

SERVICED. THE UNIT WILL

AUTOMATICALLY RUN A SETUP POUTINE

AND SELF-DIAGNOSTICS UPON BEING

PLUGGED BACK IN.

Note: Pressing EXIT clears all error messages

and activates the setup mode program.

b. Disconnect power and make necessary

repairs.

c. After the problem has been identified in

service mode and repairs have been

made, the unit prompts the service

technician to run a setup/self diagnostic

check. The self diagnostic check consists

of a series of system tests to ensure the

dryer is operating correctly . Follow the onscreen instructions.

IMPORT ANT: Always disconnect power ,

reconnect power and run the setup/self

diagnostic mode prior to leaving the house. If

this process is not completed and a power

outage should occur, the setup/self

diagnostic mode screen will be displayed for

the customer. This may generate a second

service call when no problem exists.

d. When all errors have been corrected and

the setup/self diagnostic mode has been

completed, the dryer displays the following

screen.

e. Press OK to return the dryer to normal

operation.

CONGRATULATIONS ON THE

PURCHASE OF YOUR NEW GE

PROFILE DRYER!

A BRIEF SELF DIAGNOSTIC

WILL NOW BE RUN ON YOUR

DRYER. THIS MAY TAKE UP

TO 5 MINUTES

OK

List of self diagnostic checks:

• Door

• Touch screen

• Beeper

• Keypanel Buttons

• Sensors

• Heating System

• Motors

• Serial Communication Link

Factory Test Mode

The factory test mode allows the service

technician to view critical tests on dryer

components. The tests are automatic and start as

soon as the test screen is displayed.

• If an error is detected, NG appears on the

LCD screen.

• If no errors are detected, OK appears on the

LCD screen.

1. Press the POWER pad to turn the dryer on.

Press the HOME pad to ensure the home

screen is displayed.

TOUCH TO SELECT

Sensor

DRY CYCLE

BY

FABRIC

SPECIAL

CYCLES

BY

GARMENT

TIMED DRY

– 36 –

Page 37

2. Press the HELP pad. The main help screen is

displayed.

MACHINE

PREFERENCES

TROUBLESHOOTER

HOME SCREEN

HELP

3. Press and hold the HELP and START/STOP

pads simultaneously for 3 seconds. One of

the following screens will be displayed.

2230 rpm

153F

130F

4. 90V

58

CONTRAST

180

OK

OK

OK

OK

OK

00 02 58

ELECTRIC LQC TEST

DOOR :

BLOWER :

HEATING :

INLET THD :

OUTLET THD :

MOISTURE(S):

INPUT(V):

MEMORY :

COMM DATA :

LQC START TIME :

CLOSE

OK

OK

• BLOWER - Displays blower RPM. Speed

ramps up until minimum rpm is reached, at

which time OK is displayed on LCD. Normal

blower speed will vary (1 100 - 2700 rpm)

depending on installation and venting

conditions.

• HEA TING - Control senses an increase in

temperature using the inlet thermistor.

Displays OK once the required temperature is

met (approximately 2 minutes after starting

test).

• INLET THD - Displays inlet thermistor

temperature in °F.

Note: Control is not capable of displaying

temperature below 152°F. (Room temperature

will display as 152°F)

• OUTLET THD - Displays outlet thermistor

temperature in °F.

• MOISTURE - Displays sensor signal

monitored by control. The higher the moisture

content, the lower the voltage. V oltage will vary

from less than 1 volt to approximately 5 volts.

2230 rpm

153F

130F

4. 90V

58

CONTRAST

180

OK

OK

OK

OK

OK

00 02 58

GAS LNG LQC TEST

DOOR :

BLOWER :

HEATING :

INLET THD :

OUTLET THD :

MOISTURE(S):

INPUT(V):

MEMORY :

COMM DATA :

FLAME SENSOR : OFF

LQC START TIME :

CLOSE

OK

OK

4. To exit the factory test mode, press POWER

or unplug the dryer.

Factory Test Information

• CONTRAST 90/180 - Displays current

screen resolution of 90 or 180. This can be

changed by pressing the CONTRAST box on

the LCD screen.

180 - High Contrast (dark)

90 - Low Contrast (light)

• INPUT - Factory test only , no value as a

service test.

• MEMORY - Self-test for control.

• COM TEST - Part of a serial communication

test between the washer and dryer. This test

runs a self diagnostic of the internal

communications within the main board.

• FLAME SENSOR - Displays ON or OFF,

depending on sensor temperature.

OFF - sensor closed - no heat

ON - sensor open - hot

• DOOR - The control senses the door position

through the door switch. LCD displays OPEN

or CLOSED depending on door position.

– 37 –

Page 38

Control Quick Reference Chart

t)

Demo

Mode

Home, Back, My Cycles, or

Help Buttons

Help

Mode

No Power

Power Up

(unit plugged in)

Home & My Cycles

Buttons (3 secs)

Help Button

(other than Home Screen)

User

Interface

Mode

(from Home Screen)

Back

Button

Cycle Started

Cycle Complete

Help Button

Dry Cycle

Mode

Or Paused

Power & Start/Stop

Buttons (3 secs)

Complete

Setup Mode

Exit Button

(no error codes set)

Setup

Mode

Exit Button

Power Cycled

(error codes se

Any Mode

Home Screen Help

Start/Stop & My Cycles

Test

Mode

Button

Buttons (3 secs)

Power

Button

Help Options

Screen

Back

Troubleshooting

Button

Troubleshooting

Mode

Standby

Mode

Button

My Cycles & Back

Buttons (3 secs)

Start/Stop & Help

Buttons (3 secs)

User Activity

Timeout

(5 min normally

or 1Hr when

Cycle Paused)

Field Service

Mode

Factory Test

Mode

Any Mode

(except Dry Cycle

Mode)

– 38 –

Page 39

Troubleshooting

Problem

Possible Cause and Repair

LCD backlight does not come on. The backlight connection on the main board may

not be secure. Check the connection to make

sure it is secure.

Vertical lines on the LCD display when the dryer is

turned on.

Re-seat LCD ribbon cable at connector CN6 on

the main board. If necessary, a piece of scotch

tape may be added to the back of the ribbon. This

TOUCH T O SELECT

BY

Sensor

FABRIC

SPECIAL

CYCLES

DRY CYCLE

BY

GARMENT

TIMED DRY

LCD screen too dark or too light as compared to

LCD washer screen.

additional thickness will provide better contact for

the ribbon terminals.

LCD refresh rate can be changed in

Mode. (See Contrast setting.)

Factory Test

Replacement LCD screen too dark or too light.

LCD refresh rate is matched to inverter output at

the manufacturer.

Touch screen pad activates an adjacent function

incorrectly, i.e. pressing one pad activates a

function of another pad.

Can occur when LCD screen is replaced. New

LCD screen must also be set to inverter output.

Adjust the refresh rate through the Factory Test

Mode. (See contrast setting.)

The LCD display ribbon connection on the main

board may not be secure. Check the connection

to make sure it is secure.

Checkerboard pattern in MY CYCLES screen. Electrostatic discharge on main board. Enter MY

CYCLES and press DELETE on the touch screen

LCD; this will clear the checkerboard pattern.

Scuff marks on the plastic backspash or cover

(Platinum models).

Can be removed by appliance polish, part no.

WR97X216, or a high quality of automotive paste

wax.

– 39 –

Page 40

Troubleshooting Charts

PROBLEM POTENTIAL CAUSE DIAGNOSTIC PROCEDURE ACTION

Long Dry Time

Dryer Heating

Long Dry Time

Dryer Not

Heating

Restricted ducting

Lint filter/trap not cleaned Check filter and lint trap Clean accumulated lint.

Washer not spinning out normally See washer troubleshooting Washer service guide 31-9103

Washer additional

capacity/overloading

Dryer operating at half-heat See Long Dry Time/Dryer Not Heating

Heater error (electric) Check service mode for heater error.

Check blower speed in Factory Test Mode

with no clothes load. If blower speed is

higher an 2700 rpm - ducting is

abnormally restricted and will cause longer

dry times

Inquire about consumer’s laundry habits.

Harmony washer has about 30% more

capacity than other washers with agitators.