Page 1

GE

D25

994-0081

Version 3.00 Revision 21

Grid Solutions

TM

Substation Controller

User's Manual

GE Information

Page 2

D25

User's Manual

GE Grid Solutions

2

are trademarks and service marks

Important

COPYRIGHT NOTICE

© 2003-2017, General Electric Company. All rights reserved.

The information contained in this online publication is the exclusive property of General Electric Company, except as otherwise

indicated. You may view, copy and print documents and graphics incorporated in this online publication (the “Documents”) subject

to the following: (1) the Documents may be used solely for personal, informational, non-commercial purposes; (2) the Documents

may not be modified or altered in any way; and (3) General Electric Company withholds permission for making the Documents or

any portion thereof accessible via the internet. Except as expressly provided herein, you may not use, copy, print, display,

reproduce, publish, license, post, transmit or distribute the Documents in whole or in part without the prior written permission of

General Electric Company.

The information contained in this online publication is subject to change without notice. The software described in this online

publication is supplied under license and may be used or copied only in accordance with the terms of such license.

TRADEMARK NOTICES

GE and

* Trademarks of General Electric Company.

IEC is a registered trademark of Commission Electrotechnique Internationale. Microsoft and Windows are registered trademarks of

Microsoft Corporation. Panasonic is a registered trademark of Matsushita Electric Industrial Co., Ltd. Tadiran is a registered

trademark of Tadiran Israel Electronics Industries Ltd.

Other company or product names mentioned in this document may be trademarks or registered trademarks of their respective

companies.

of General Electric Company.

The circuit boards in the D25 contain many electrostatically sensitive

electronic components.

To prevent damage when handling these products use approved static

control procedures.

994-0081-3.00-21 GE Information

Page 3

GE Grid Solutions

D25

User's Manual

3

Contents

About This Document ................................................................................................................................. 6

Product Support 9

GE Grid Solutions Web Site ............................................................................................... 9

GE Grid Solutions Technical Support Library ................................................................... 9

GE Grid Solutions Technical Support ................................................................................ 9

Product Returns ................................................................................................................. 10

Chapter 1: Before You Start ............................................................................................................. 11

Product Safety ................................................................................................................... 11

Product Overview ............................................................................................................. 14

Restriction of Hazardous Substances (RoHS) .................................................................. 15

Chapter 2: Installing the D25 ............................................................................................................ 18

Installation Tools List ....................................................................................................... 18

Installation Steps ............................................................................................................... 18

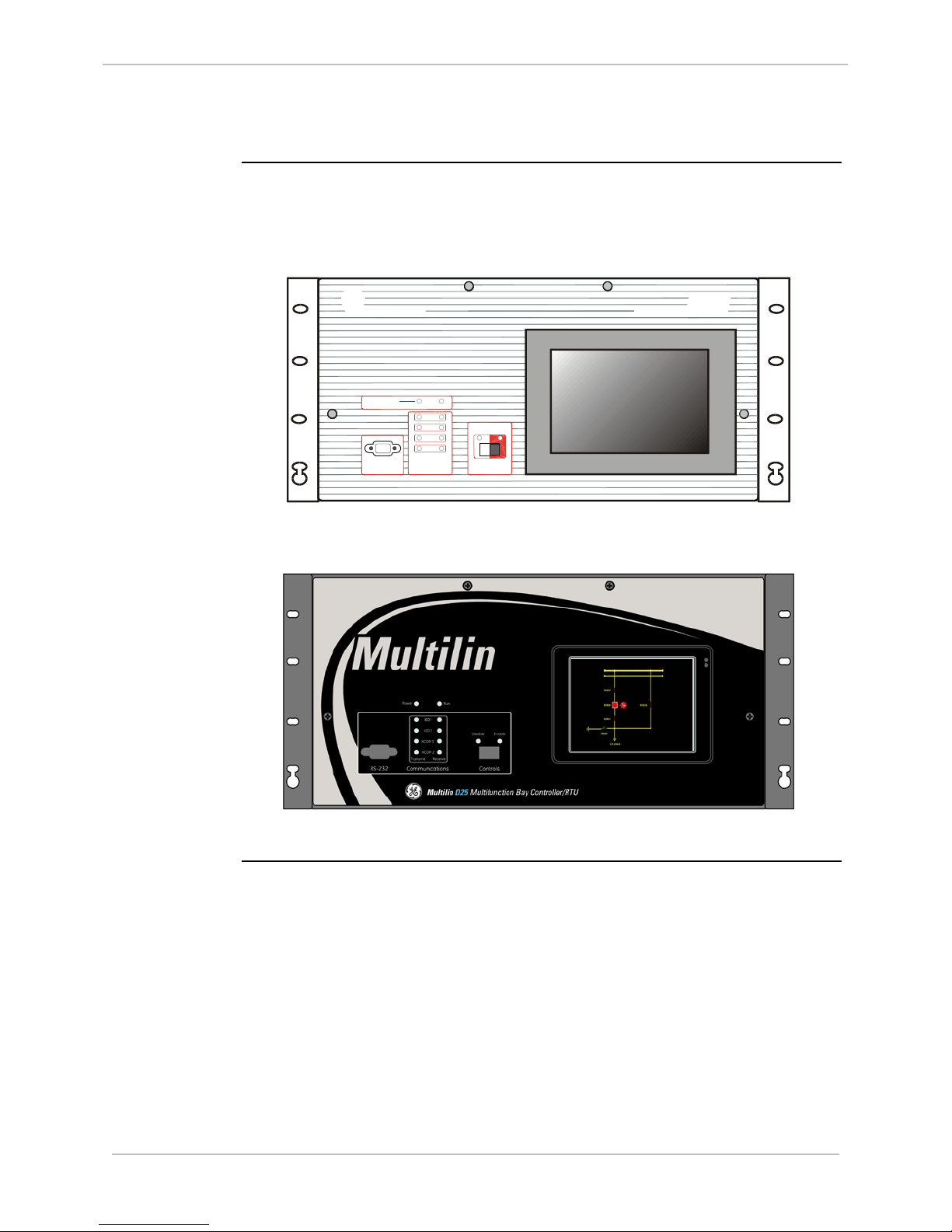

First Look at the D25 ........................................................................................................ 19

Physical Mounting ............................................................................................................ 21

LCD Panel Overview ........................................................................................................ 22

Graphic Display Panel (GDP) and Color GDP (CGDP) Overview .................................. 24

Configuration of a GDP .................................................................................................... 27

Set Up of a Color GDP (CGDP) ....................................................................................... 28

Connecting Field Wiring .................................................................................................. 33

Power Supply .................................................................................................................... 33

Digital Inputs .................................................................................................................... 34

Control Outputs ................................................................................................................. 41

DC Analog Inputs ............................................................................................................. 65

AC Analog Inputs ............................................................................................................. 67

Communications Ports ...................................................................................................... 68

Configuring the D25 to work with a DNP3 I/O Module .................................................. 78

Chapter 3: Powering-up and Testing ............................................................................................... 80

Testing Utilities ................................................................................................................. 80

Boot Up ............................................................................................................................. 82

Using WESMAINT .......................................................................................................... 83

Testing Hardware I/O Points ............................................................................................ 85

Chapter 4: Configuring the D25 Software ....................................................................................... 93

D25 Software .................................................................................................................... 93

GE Information 994-0081-3.00-21

Page 4

D25

User's Manual

GE Grid Solutions

4

Downloading a Configuration........................................................................................... 96

Chapter 5: Operating the D25 ......................................................................................................... 105

LED Indicators ................................................................................................................ 105

Controls Switch ............................................................................................................... 106

Using Current-Monitored Digital Outputs ...................................................................... 108

Chapter 6: Servicing the D25 .......................................................................................................... 110

Fuse Replacement ........................................................................................................... 111

Battery Replacement ....................................................................................................... 113

Chapter 7: Upgrading and Replacing D25 Modules ..................................................................... 116

Module Replacement ...................................................................................................... 116

Main Board ..................................................................................................................... 118

DDSP Modules ............................................................................................................... 122

Memory Expansion Board .............................................................................................. 123

Shelf Plate ....................................................................................................................... 123

Configuring Radio Keying Option.................................................................................. 126

D25 Ethernet Card 100Base (10/100Base-T and 100Base-FX) ..................................... 127

Power Supply Card ......................................................................................................... 129

Digital Input Cards .......................................................................................................... 131

Digital Output Card ........................................................................................................ 132

DC Analog Input Card .................................................................................................... 133

CT/PT Modules ............................................................................................................... 134

Reconnecting Power ....................................................................................................... 143

Chapter 8: Troubleshooting ............................................................................................................ 144

Run-time and Startup Problems ...................................................................................... 144

Initialization Errors ......................................................................................................... 146

LAN-Based Problems ..................................................................................................... 147

Reporting Problems ........................................................................................................ 148

Appendix A: Product Specifications .................................................................................................. 152

Electrical Specifications.................................................................................................. 152

Testing and Certification................................................................................................. 156

Approvals ........................................................................................................................ 156

Physical Specifications ................................................................................................... 157

Storage and Battery ......................................................................................................... 158

Appendix B: Engineering Value Calculations .................................................................................. 159

Conversion Formulas ...................................................................................................... 159

994-0081-3.00-21 GE Information

Page 5

GE Grid Solutions

D25

User's Manual

5

Appendix C: Ordering Information ................................................................................................... 161

Appendix D: Installing and Connecting DNP3 I/O Modules .............................................................. 162

Overall Procedure to Install and Connect DNP3 I/O Modules ....................................... 162

Installing DNP3 I/O Modules in a Rack ......................................................................... 163

Connecting DNP3 I/O Modules (Low Voltage) ............................................................. 165

GE Information 994-0081-3.00-21

Page 6

D25

User's Manual

6

About This Document

Purpose

Intended

Audience

Additional

Documents

The purpose of this document is to provide users with information on how to

install and commission a D25* IED. This guide also provides details on the

operation and maintenance of D25 IEDs.

This document is intended for readers who are installing or maintaining a D25

IED. Readers are assumed to have background knowledge of substation

automation equipment and practices.

For further information about the D25 IED, refer to the following documents:

• D25 Plant I/O Subsystem Configuration Guide (P097-0CG)

• 68K Monitor User’s Guide (SWM0023)

GE Grid Solutions

• SGConfig* Online Help

• WESMAINT II+ User’s Guide (B014-1UG)

• All related Product Bulletins

994-0081-3.00-21 GE Information

Page 7

GE Grid Solutions

D25

User's Manual

7

FX

Document

Scope

The following part numbers are not covered by this document. For

information on these parts, please refer to the D25 Multifunction IED

Installation and Maintenance Guide (994-0023).

For upgrading information and understanding the compatibility between the

new parts and obsolete parts, refer to Product Bulletin PRBT-0233 D25 Parts

Compatibility and Upgrade Guide.

Main Boards

504-0005 D25 WESDAC Type II

504-0010 D25 WESDAC Type II, 2MB Flash

Power Supplies

521-0118 D25 HV Power Supply, 140 - 300 VDC / 240 VAC, 24V Wetting

521-0119 D25 Power Supply, 20 - 60 VDC, 48V Wetting

521-0124 D25 Power Supply, 70 - 150 VDC, 24V Wetting

521-0135 D25 Power Supply, 60-150 VDC / 120 VAC, 24V Wetting

521-0136 D25 HV Power Supply, 250 VDC / 220 VAC, 24V Wetting

521-0138 D25 HV Power Supply, 250 VDC / 220 VAC, 48V Wetting

521-0139 D25 Power Supply, 60-150 VDC / 120 VAC, 48V Wetting

DC Analog Card

517-0397 D25 DC Analog I/P 8 Channel ± 5V

517-0404 D25 DC Analog I/P 8 Channel ± 1mA

517-0405 D25 DC Analog I/P 8 Channel ± 5mA

517-0406 D25 DC Analog I/P 8 Channel ± 10mA

517-0407 D25 DC Analog I/P 8 Channel ± 20mA

517-0408 D25 DC Analog I/P 16 Channel ± 1mA

517-0409 D25 DC Analog I/P 16 Channel ± 5mA

Ethernet Card

580-0993 D25 10BASE-FL XCOM Card

580-0994

This card is obsolete and is replaced by 504-0305LF. A 100BASEswitch or converter is required when upgrading from 580-0993 to 5040305LF, since 10BASE-FL is incompatible with 100BASE-FX

580-0994: D25 10BASE-T XCOM CARD

Replaced by 504-0305LF.

GE Information 994-0081-3.00-21

Page 8

D25

User's Manual

GE Grid Solutions

8

Document Scope (continued)

Analog Input Cards

Status Cards

0009 is the Gen 3 Plant I/O DSP Card and

517-0410 D25 DC Analog I/P 16 Channel ± 10mA

517-0411 D25 DC Analog I/P 16 Channel ± 20mA

517-0413 D25 DC Analog I/P 16 Channel ± 5V

517-0416 D25 DC Analog I/P 8 Channel Scalable Adapter

517-0417 D25 DC Analog I/P 16 Channel Scalable Adapter

517-0402 D25 Status Card, 32 Channel, 24V, 5mA

517-0403 D25 Status Card, 32 Channel, 48V, 5mA

517-0425 D25 Status Card, 32 Channel, 12V, 10mA

517-0426 D25 Status Card, 32 Channel, 120V, 0.75mA

517-0427 D25 Status Card, 32 Channel, 12V, 5mA

517-0428 D25 Status Card, 32 Channel, 250V, 0.75mA

517-0431 D25 Status Card, 16 Channel, 48V, 5mA

517-0432 D25 Status Card, 16 Channel, 24V, 5mA

517-0433 D25 Status Card, 16 Channel, 12V, 5mA

517-0434 D25 Status Card, 16 Channel, 120V, 0.75mA

517-0435 D25 Status Card, 16 Channel, 250V, 0.75mA

AC Input

504-0008 D25 Analog Interface Card (Gen 1)

504-0009

D25 Analog Interface Card (Gen 2 and Gen 3).

This card is obsolete. 504does not work with the Gen 4 Plant I/O (P097-0 v4xx or 5xx). In

addition, the 504-0015LF does not work with the Gen 3 Plant I/O

(P097-0 v3xx).

994-0081-3.00-21 GE Information

Page 9

GE Grid Solutions

D25

User's Manual

9

Product Support

If you need help with any aspect of your GE Grid Solutions product, you can:

• Access the GE Grid Solutions Web site

• Search the GE Grid Solutions Technical Support library

• Contact GE Grid Solutions Technical Support

GE Grid Solutions Web Site

The GE Grid Solutions Web site provides fast access to technical information, such as

manuals, release notes and knowledge base topics.

Visit us on the Web at: http://www.gegridsolutions.com

GE Grid Solutions Technical Support Library

This site serves as a document repository for post-sales requests. To get access to the

Technical Support Web site, go to: http://sc.ge.com/*SASTechSupport

GE Grid Solutions Technical Support

GE Grid Solutions Technical Support is open 24 hours a day, seven days a week for you

to talk directly to a GE representative.

In the U.S. and Canada, call toll-free: 1 800 547 8629.

International customers call: +1 905 927 7070

Or send an e-mail to: multilin.tech@ge.com

GE Information 994-0081-3.00-21

Page 10

D25

User's Manual

10

Product Returns

A Return Merchandise Authorization (RMA) number must accompany all

equipment being returned for repair, servicing, or for any other reason. Before

you return a product, please contact GE Grid Solutions to obtain a Return

Merchandise Authorization number and complete instructions for return

shipments.

Have the following information ready to give to GE Grid Solutions Technical

Support:

• Ship to address (the address that the product is to be returned to)

• Bill to address (the address that the invoice is to be sent to)

• Contact name

• Contact phone number

• Contact fax number

• Contact e-mail address

GE Grid Solutions

• Product number / serial number

• Description of problem

Technical Support will provide you with a case number for your reference.

This case number is NOT the RMA number. You will be sent the RMA

number and RMA documents via fax or e-mail. Once you receive the RMA

documents, attach them to the outside of the box that your product is

packaged in and send the product to GE.

Note: Product returns will not be accepted unless accompanied by the Return

Merchandise Authorization number.

994-0081-3.00-21 GE Information

Page 11

GE Grid Solutions

D25

User's Manual

11

Chapter 1: Before You Start

Product Safety

Resolving

Problems

Safety

Precautions

If you attempt to resolve problems with your GE product using methods not

recommended by GE Grid Solutions, this might result in damage or injury to

persons and property.

Follow all safety precautions and instructions in this manual:

• Only qualified personnel should work on the D25. Maintenance personnel

should be familiar with hazards associated with electrical equipment.

• All AC voltage and current terminals are protected from accidental contact by

mechanical safety shields. The D25 is designed so that field wiring does not

have to be touched or disconnected when removing printed circuit boards

(PCBs).

• Always use the puller that is provided to remove Modules that hold potentially

hazardous voltages. This is located inside the D25 front cover on the edge of the

Indicator Switch Card.

• The CONTROLS switch on the front panel of the D25 has a mechanical

protector to prevent accidental operation of the switch. The switch can be locked

in the Local or Remote position.

• All components within the D25 are susceptible to damage from electrostatic

discharge. Observe standard ESD precautions.

GE Information 994-0081-3.00-21

Page 12

D25

User's Manual

12

MAY BE PROTECTED BY ONE OR MORE OF

Product Safety, Continued

GE Grid Solutions

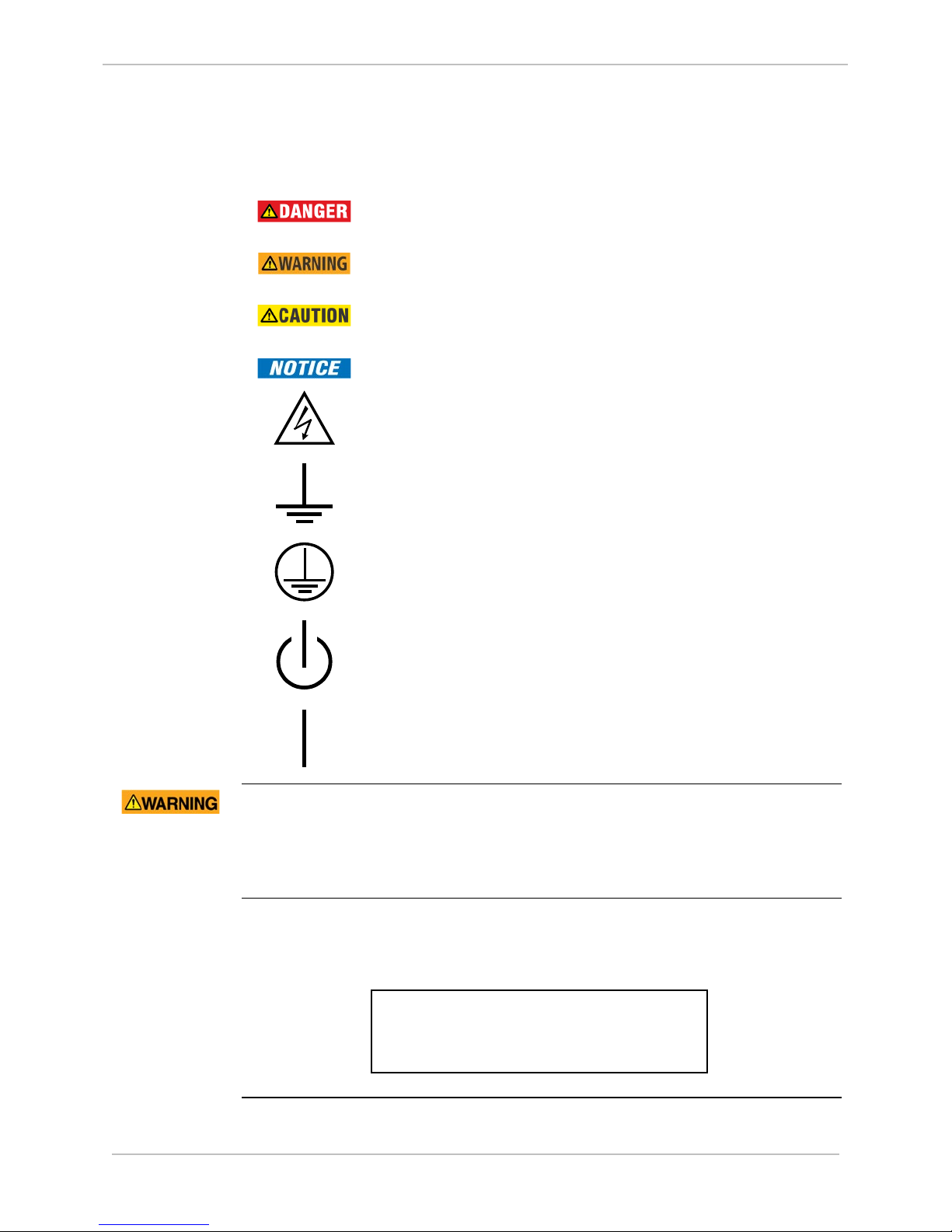

Warning

Symbols on

Enclosure Back

Panel

Indicates a hazardous situation which, if not avoided,

will result in death or serious injury.

Indicates a hazardous situation which, if not avoided,

could result in death or serious injury.

Indicates a hazardous situation which, if not avoided,

could result in minor or moderate injury.

Indicates practices that are not related to personal injury.

Caution Risk of electric shock

Earth Ground Terminal

Protective Ground Terminal

Power Supply Off (Stand-by Mode)

Hazardous

Voltages

Patent

Protection

Label

Power Supply On

Hazardous Voltages can cause shock, burns or death.

• Disconnect and lockout all power sources before servicing and removing

components.

• Short all current transformer primaries before servicing.

A label similar to the one shown below on the rear panel of the D25

enclosure. It is a formal notification of the US patents that protect the product

and the technology developed by GE Grid Solutions.

THE FOLLOWING US PATENTS:

5237511, 5303112, 5513061, 5701226

994-0081-3.00-21 GE Information

Page 13

GE Grid Solutions

D25

User's Manual

13

• The D25’s enclosure is intended for indoor use primarily to provide

!

Product Safety, Continued

Operating

Environment

Operation in

Residential

Areas

Protection

During

Maintenance

protection against accidental contact with the enclosed modules and

voltages.

− Do not place the product in environments where unusual conditions

exist (windblown dust and dirt, liquids, etc.) without a secondary

protective enclosure.

• Never operate the D25 in the field with front panel open.

− Operating the unit with the front panel open may alter product

performance specifications, and result in component damage from

debris.

The D25 generates radio frequency energy. If it is not operated and used in

accordance with the instructions provided in this guide, it may cause harmful

interference to radio communications in a residential area. Users are required

to correct interference at their own expense.

Ensure that the D25 is protected from falling debris during maintenance.

Small metallic particles (such as wire clippings) can fall through the

ventilation holes on the top of the unit, possibly damaging or interfering

with the safe and reliable operation of the D25.

If you cover the unit for maintenance, remove the cover before operating

to provide adequate cooling airflow.

Make sure that the metal case is grounded at the protective ground stud

Grounding

located at the top-left corner of the rear of the enclosure.

Connection must be provided with separate green/yellow wire connected

between the D25 and the protective earth system of the facility.

Use of this equipment in a manner not recommended or specified by GE Grid

Solutions may impair the protection provided by the equipment.

The high voltage area of the D25 High Current KE Digital Output Module is

in close proximity to the D25 chassis. Ensure that relay contacts are deenergized before removing the D25 HCKE DO Module.

GE Information 994-0081-3.00-21

Page 14

D25

User's Manual

14

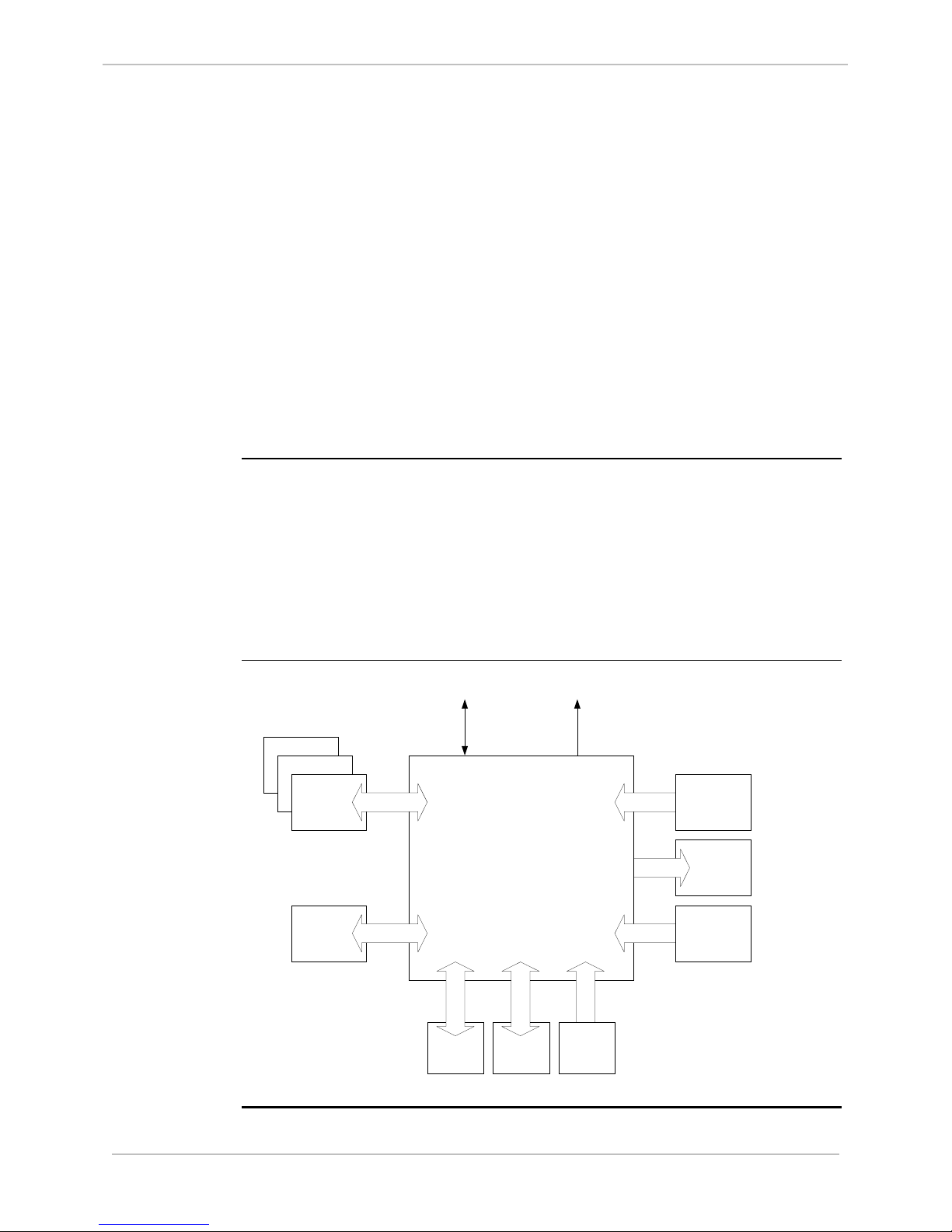

Digital

Outputs

Analog

Processor

.....Future

Ethernet LAN

RS-232/485

Metering

Power Quality

LogicLinx

Digital Fault Recording

Substation Monitoring &

Diagnostics

Digital Inputs

AC/DC Analog

Inputs

IED 2

IED 1

UTC

WESMAINT

Auxiliary

Outputs

Communications

Options

Inpu/Output

Options

Direct CT

and PT

Trip/Close

Raise/Lower

COS

SOE

ACC

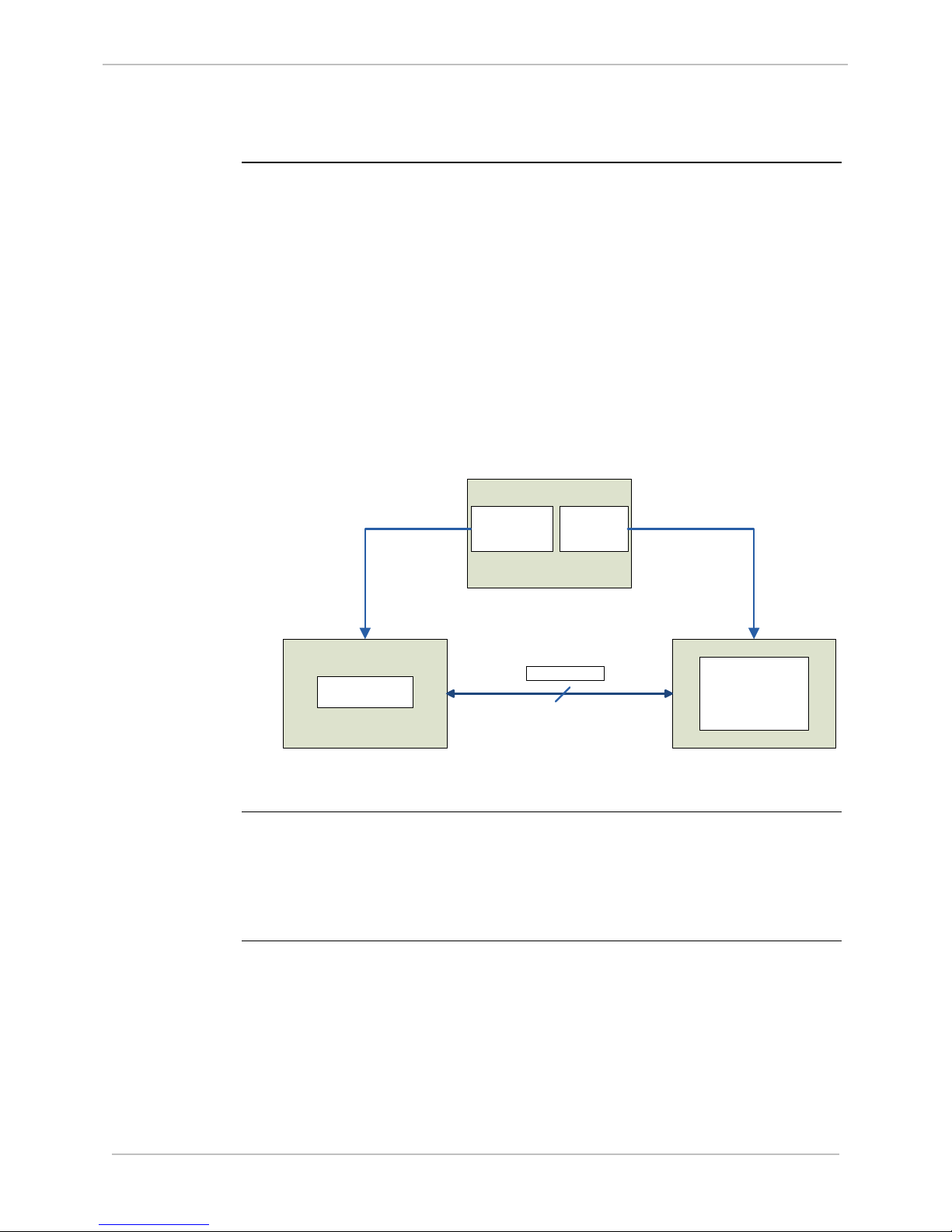

Product Overview

GE Grid Solutions

What is the

D25?

Main Features

and Options

Functional

Overview

The D25 is a standalone intelligent electronic device that can operate as:

• Programmable logic controller (PLC)

• Substation LAN node

• IED gateway

• Bay level controller

• Power quality monitor

• Fault/event (waveform) recorder

It is suitable for various power system applications, including:

• Substation monitoring

• Control

• Automation applications

The multi-processor design allows many functional options:

• Expansion cards

• Configurable digital inputs, digital outputs, AC and DC analog inputs

• LCD and Graphics Display front panels

Communication plug-in options:

• LAN: connection to iSCS Ethernet LAN with fiber optic, twisted pair or coaxial

• Serial: user selectable from RS-232 or RS-485

994-0081-3.00-21 GE Information

Page 15

GE Grid Solutions

D25

User's Manual

15

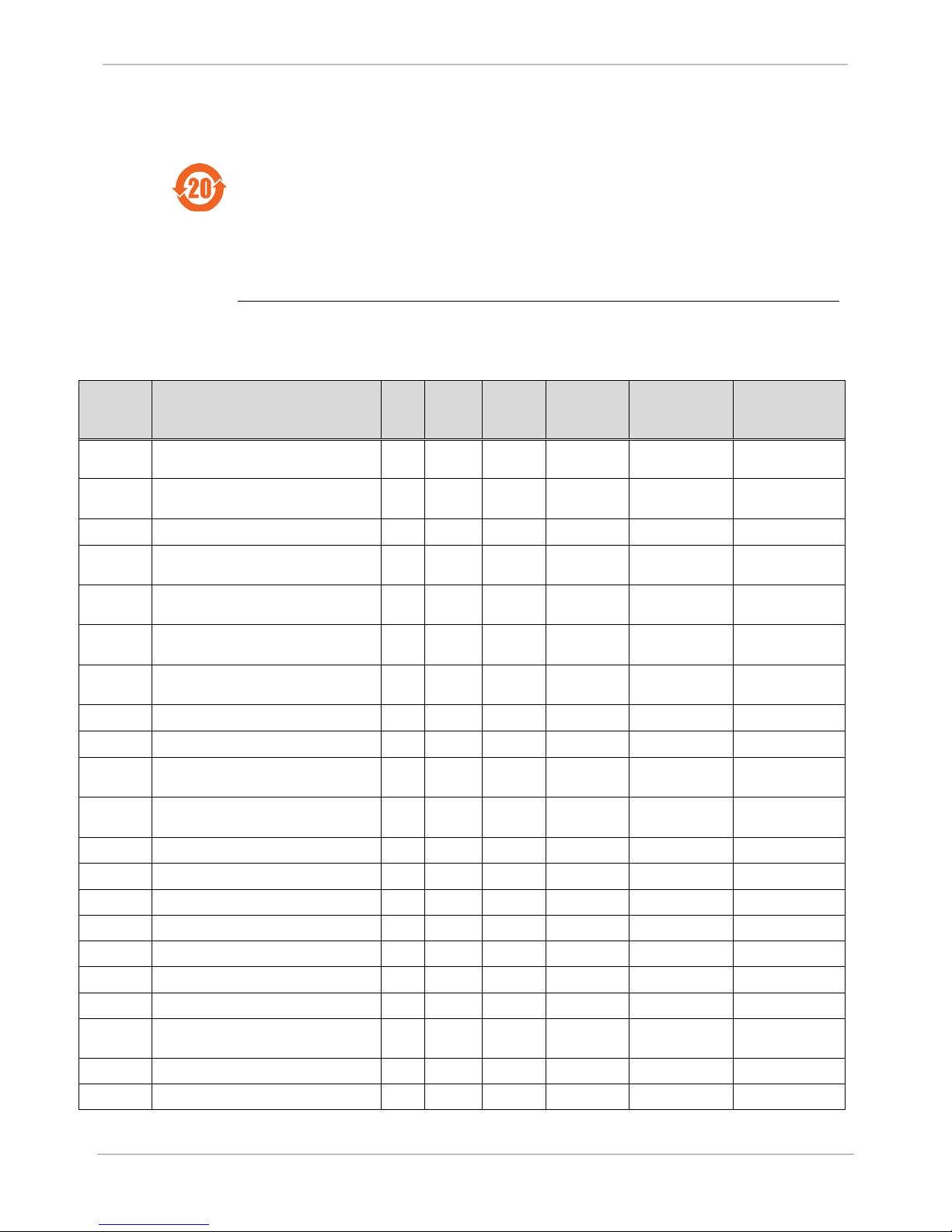

The environmental protection use period (EPUP), as defined in PRC

RoHS Material Declaration Data Content by PCB Assembly

GE Part

Description

Lead

Mercury

Cadmium

Hexavalent

Polybrominated

Polybrominated

450-0083

Transformer, 63.5V Nom 158.75V Max

X

450-0084

Transformer, 120V Nom, 300V Max Panel

X

O O O O O

450-0085

Transformer, 69.3V Nom, 173.25 Max

Panel

X

O O O O O

450-0088

Transformer, 5A Nom, 10A Max Panel

X

O O O O O

450-0090

Transformer, 220V Nom. 550V Max Panel

X

O O O O O

450-0105

XRFM, 1A Nom 2A Max, 400R, Panel

X

O O O O O

504-0009

D25 AIF/DSP-II Card

X

O O O O O

504-0013

D25 Main Bus Termination Card

X

O O O O O

504-0014LF

D25 MEMX 20M Card Lead Free

O O O O O

O

504-0015

D25 Dual DSP-50 2MB RAM Card

X O O O O

O

504-0306LF

D25 TYPE IV WESDAC Module, CE Mark

O O O O O

O

517-0401

D25 PT Module

X O O O O

O

Restriction of Hazardous Substances (RoHS)

SJ/T11363-2006, for the D25 hardware assemblies listed in the table below is

in excess of 20 years.

The following table shows the RoHS Material Declaration Data Content by

PCB Assembly

Table: RoHS

Compliance

Number

160-0081 512KX8 OTP EPROM 120NS PLCC IND

TEMP

Panel

450-0086 Transformer, 110V Nom, 146.67V FS.

Panel

450-0087 Transformer, 5A Nom, 10A Max Panel

Short

Long

450-0107 Transformer 1A Nom, 42A Max, 100R

Burden, CE Mark

450-0108 Transformer 5A NOM, 210A Max, 100R

Burden, CE Mark

(Pb)

(Hg)

O

O O O O O

O O O O O

X

O O O O O

X

O O O O O

X

O O O O O

X

O O O O O

(Cd)

Chromium

(Cr6)

biphenyls (PBB)

diphenyl ethers

(PBDE)

504-0207 D25 Type III WESDAC Module, CE Mark X O O O O O

504-0305LF D25 100FX and 10/100TX XCOM Card O O O O O O

580-0939 RAYMAR/Telenetic Standalone Digital Fast

Poll Modem

517-0400 D25 CT Module X O O O O O

X O O O O O

GE Information 994-0081-3.00-21

Page 16

D25

User's Manual

GE Grid Solutions

16

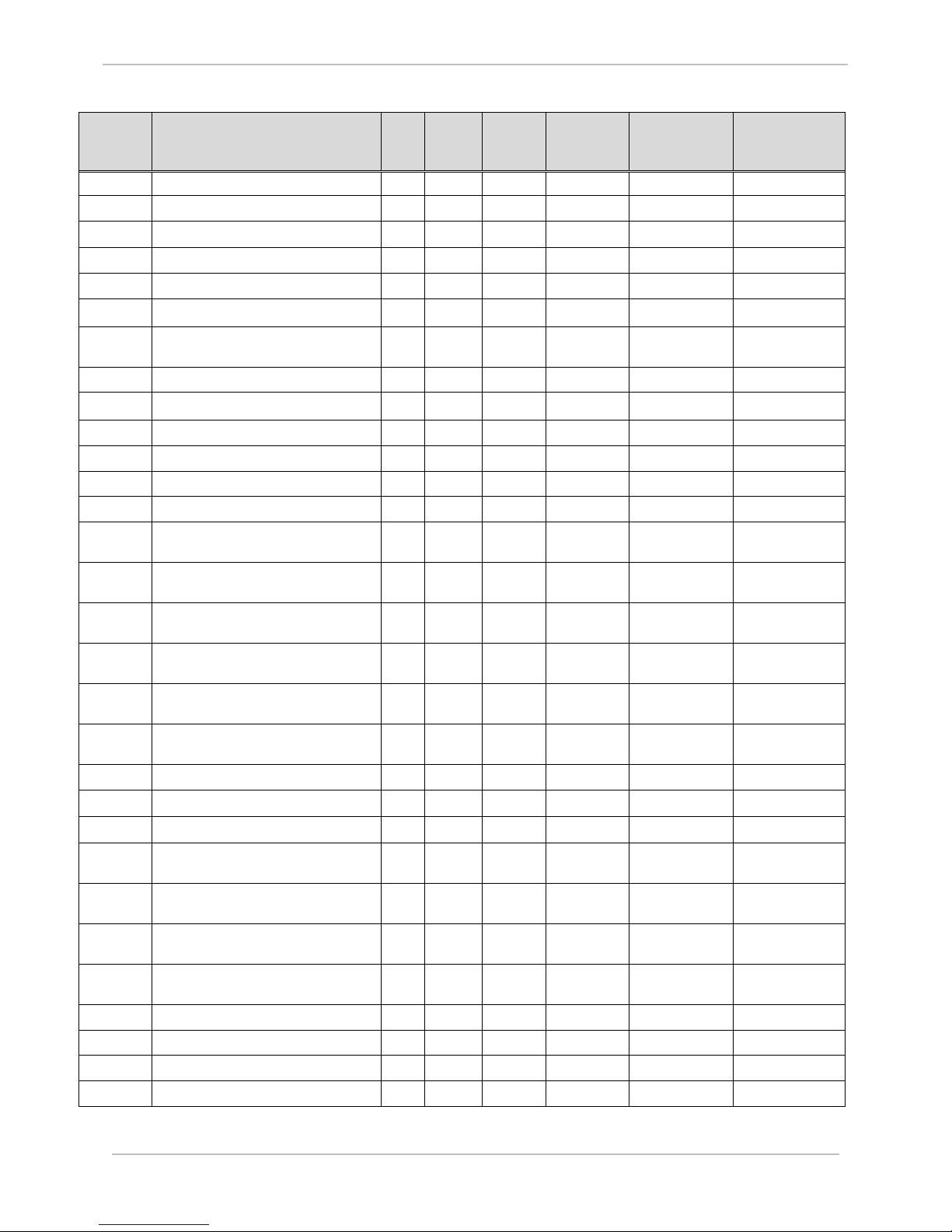

GE Part

Description

Lead

Mercury

Cadmium

Hexavalent

Polybrominated

Polybrominated

517-0401

D25 PT Module

X O O O O

O

517-0441

D25 CT Module - 400 Ohms Burden

X O O O O

O

517-0443

D25KE Control Module FACE 40

X O O O O

O

517-0449

D25 KE Control Module, DB25, 16 Channel

X O O O O

O

517-0452

D25 KE Control Module, FACE40, 16

X O O O O

O

517-0469

D25, 16ADC 5V Input Card SMT

X O O O O

O

517-0470

D25, 16ADC 1MA Input Card SMT

X O O O O O 517-0474

D25, 16 ADC 10MA Input Card SMT

X

517-0478

D25, 16 ADC Socketed Input Card SMT

X O O O O

O

517-0485

D25 32CH Status Input Module, 12V

X O O O O O 517-0486

D25 32CH Status Input Module, 24V

X O O O O O 517-0487

D25 32CH Status Input Module, 48V

X O O O O O 517-0488

D25 32CH Status Input Module, 120V

X O O O O O 517-0489

D25 32CH Status Input Module, 250V

X O O O O O 517-0490

D25 32CH Status Input Module, 10mA, 24V

X O O O O

O

517-0492

D25 HC KE 32 Control w 8 SEAL-IN

X O O O O

O

521-0131

D25 PSA Card

X O O O O

O

521-0143

D25 120VAC/60-150VDC Power Supply,

X O O O O O 521-0144

D25 120VAC/60-150VDC Power Supply,

X O O O O

O

521-0146

D25 220VAC/250VDC Power Supply, 48V

X O O O O

O

530-0003

Analog Adaptor, Input 20MA/1V

X O O O O O 530-0004

Analog Adaptor, Input Voltage

X O O O O

O

530-0025

1.2MA/1V Input Analog Adaptor

X O O O O

O

Number

(Pb)

(Hg)

(Cd)

Chromium

biphenyls (PBB)

(Cr6)

517-0429 D25 High Accuracy CT Module X O O O O O

517-0447 D25KE Control Module DB25 X O O O O O

Channel

517-0456 D25 X42 CT X O O O O O

517-0476 D25, 16 ADC 20MA Input Card SMT X O O O O O

Wetting, CE Mark

diphenyl ethers

(PBDE)

Wetting, CE Mark

Wetting, CE Mark

Wetting, CE Mark

Wetting, CE Mark

Wetting, CE Mark

521-0119 D25 20-60VDC/48 Wetting Power Supply X O O O O O

24V Wetting, CE Mark

48V Wetting, CE Mark

521-0145 D25 220VAC/250VDC Power Supply, 24V

Wetting, CE Mark

Wetting, CE Mark

X O O O O O

530-0005 Analog Adaptor, Input 1MA/1V X O O O O O

994-0081-3.00-21 GE Information

Page 17

GE Grid Solutions

D25

User's Manual

17

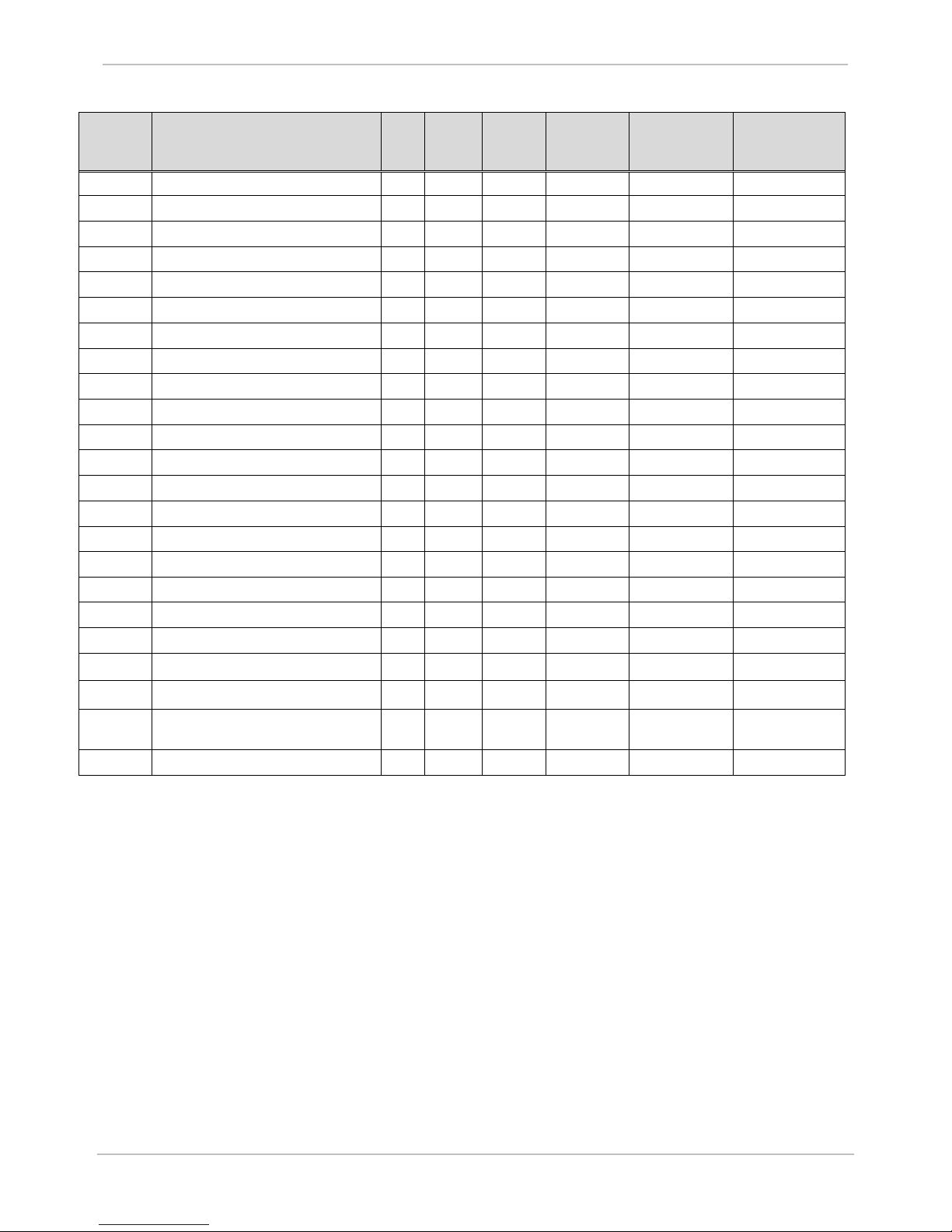

GE Part

Description

Lead

Mercury

Cadmium

Hexavalent

Polybrominated

Polybrominated

530-0030

1.5MA/1V Input Analog Adaptor

X O O O O

O

530-0073

5MA/1V Input Analog Adaptor

X O O O O

O

530-0090

Analog Adaptor, I/P 1MA/5V

X O O O O O 530-0091

1.1MA/5V Input Analog Adaptor

X O O O O

O

530-0095

Analog Adaptor, Input 1.5MA/5V

X O O O O O 530-0108

Analog Adaptor, 2MA/5V I/P .01%

X O O O O

O

530-0141

Analog Adaptor, Input 10V

X O O O O

O

540-0248

Graphics LCD Assembly

X O O O O

O

540-0412

D25 IND Switch Card

X O O O O O 580-0894

D25 IEDRTC Card

X O O O O

O

580-0993

D25 10BASE-FL XCOM Card

X O O O O

O

580-3429

Multii-language touch screen LCD 512KB

X O O O O

O

580-3570

Graphic Display, Color, 5.7 inch, 640 x 480

X O O O O

O

580-3500

GDP OP-7100 600 Series Firmware with

X O O O O

O

955-9017

D25 Enclosure Type II

O O O O O

O

Number

(Pb)

(Hg)

(Cd)

Chromium

biphenyls (PBB)

(Cr6)

530-0045 Analog Adaptor, Input 2MA/1V X O O O O O

530-0052 Analog Adaptor, Input 20MA/5V X O O O O O

530-0073 5MA/1V I/P Analog Adaptor X O O O O O

530-0094 Analog Adaptor, Input 1.25MA/5V X O O O O O

530-0131 Analog Adaptor 12.8MA/5V X O O O O O

540-0256 D25 Data Display Assembly X O O O O O

diphenyl ethers

(PBDE)

580-0991 D25 SERIAL XCOM Card STD X O O O O O

580-0994 D25 10BASE-T XCOM Card X O O O O O

DNP Protocol (version 6.03)

O Indicates that this toxic or hazardous substance contained in all of the homogeneous materials for this item

is below the limit required in PRC SJ/T11363-2006 and EU Directive 2002/95/EC (RoHS)

X: Indicates that this toxic or hazardous substance contained in at least one of the homogeneous materials

used for this item is above the limit requirement in PRC SJ/T11363-2006 and EU Directive 2002/95/EC (RoHS)

The maximum concentration limits (MCV's) apply.

Lead (Pb) 0.1% by weight = 1000 mg/kg = 1000 ppm

Mercury (Hg) 0.1% by weight = 1000 mg/kg = 1000 ppm

Cadmium (Cd) 0.01% by weight = 100 mg/kg = 100 ppm

Chromium VI (Cr6) 0.1% by weight = 1000 mg/kg = 1000 ppm

PBB, PBDE 0.1% by weight = 1000 mg/kg = 1000 ppm

GE Information 994-0081-3.00-21

Page 18

D25

User's Manual

18

Multi-meter (for testing points)

Procedure

Follow these steps to install the D25:

Step

Action

1

Unpack the D25.

2

Using the First Look at the D25 section of this guide, inspect the D25

Product Safety for contact details.

3

Loosen the D25 front panel and remove the battery “PULL” tabs (one

place to insulate the battery during shipment.

4

Install the D25. Follow the procedure set out in section: Connecting

5

Carry out all field wiring connections and jumper settings

Input and output pinouts

6

Power-up the D25 and check for normal operation. See section:

the self-diagnostics and ascertain what is malfunctioning.

Chapter 2: Installing the D25

Installation Tools List

GE Grid Solutions

Installation

Tools List

Before you begin the install of the D25, gather the following:

• A Flat Screwdriver with 0.6x3.5 mm blade (for terminal block wiring)

• A #2 Phillips Screwdriver (for rack mounting the unit)

• Wire Cutters

• Wire Strippers

• Wire Crimping Tool

• Tie-wraps (for gathering extra wire)

•

Installation Steps

for damage.

Note: Report any damage immediately to GE Grid Solutions. See:

for the Mainboard battery, and one for the optional Memory

Expansion card battery). The D25 is delivered with these tabs in

Field Wiring.

configuration as set out in section: Configuring the D25 to work with

a DNP3 I/O Module:

• Power

• Serial and Ethernet communication

•

Configuring the D25 to work with a DNP3 I/O Module. Some testing

requires that code and configuration files have been downloaded to

the D25.

If the front panel Power and Run LEDs do not show normal

operation, then use WESMAINT to inspect the error messages from

994-0081-3.00-21 GE Information

Page 19

GE Grid Solutions

D25

User's Manual

19

WESMAINT

STATUS

CONTROLS

SWITCH

KEYPAD

LCD or Touch

Screen Graphical

Installation Steps, Continued

7 If the FLASH memory has been deleted or corrupted, then you

need to download the code and configuration files. See Chapter 4:

Configuring the D25 Software.

8 If you have to download code and configuration files, then go back

to step 5 and verify that the D25 is now operating correctly.

Note

If you are replacing a component that is already installed on the D25 or

upgrading a specific component, then see Chapter 7: Upgrading and

Replacing D25 Modules.

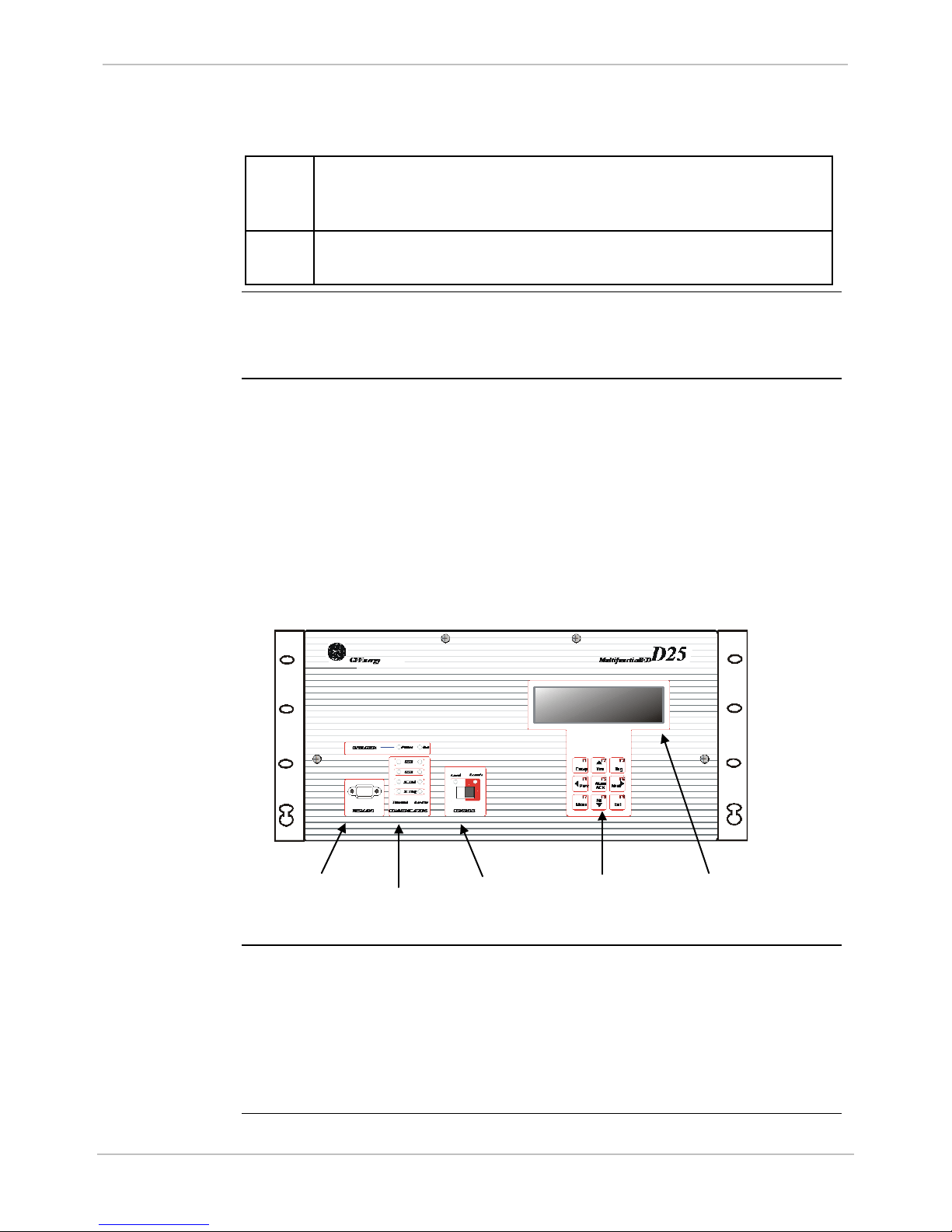

First Look at the D25

Front Panel

Back Panel

• WESMAINT II+ connector for connecting a maintenance terminal or PC

• LEDs for information on status, operation and traffic on communication ports

• CONTROLS switch for setting Local or Remote operational state of the digital

output module

• Optional LCD Display to display selected data stored in the D25 database

• Keypad for using the menus shown on the LCD Display. Only present if LCD

option is included

CONNECTOR

INDICATOR

DISPLAY

The D25 back panel is modular with removable sections. The types and

number of connectors are specified when the unit is ordered but can be

changed in the field.

There are two back panel options for the D25KE control board:

• Termination with six DB-25 connectors

• Termination with two FACE40 connectors

GE Information 994-0081-3.00-21

Page 20

D25

User's Manual

20

With six DB-25 connectors:

ON

OFF

POWER

A

D25 MAINT

IED 1

IED 2

UTC

C

E

B

D

F

DC

INPUTS

GND

XCOM 1

XCOM 2

J1 J2 J3

P1 P3 P5 P7 P9

P2 P4 P6 P8

1 3 5 7 9 11 13 15 17 19 21 23 25 27 29 31 33 35 37 39

2 4 6 8 10 12 14 16 18 20 22 24 26 28 30 32 34 36 38 40

2 1 2 1 2 1

FAIL AUX KEY

SYS RADIO

1 3 5 7 9 11 13 15 17 19 21 23 25 27 29 31 33 35 37 39

2 4 6 8 10 12 14 16 18 20 22 24 26 28 30 32 34 36 38 40

1 3 5 7 9 11 13 15 17 19 21 23 25 27 29 31 33 35 37 39

2 4 6 8 10 12 14 16 18 20 22 24 26 28 30 32 34 36 38 40

STATUS 1

FUSE - F3

STATUS 2 –

FUSE - F4

STATUS 3: -

FUSE - F5

FIELD

OUTPUT

FUSE – F1

PS FUSE

F2

AUXILIARY CONTROLS

B

D

F

H

DC ANALOG

INPUTS

P1 P3 P5 P7 P9

P2 P4 P6 P8

2 4 6 8 10 12 14 16 18 20 22 24 26 28 30 32 34 36 38 40

1 3 5 7 9 11 13 15 17 19 21 23 25 27 29 31 33 35 37 39

2 4 6 8 10 12 14 16 18 20 22 24 26 28 30 32 34 36 38 40

1 3 5 7 9 11 13 15 17 19 21 23 25 27 29 31 33 35 37 39

2 4 6 8 10 12 14 16 18 20 22 24 26 28 30 32 34 36 38 40

G

CONTROL

OUTPUTS

2 4 6 8 10 12 14 16 18 20 22 24 26 28 30 32 34 36 38 40

AC ANALOG

INPUTS

DC ANALOG

INPUTS

CONTROL

OUTPUTS

DIGITAL

INPUTS

COMMUNICATION

PORTS

XCOM 1 XCOM 2TB 31

CTRL PWR

FUSE – F6

ON

OFF

POWER

D25 MAINT

IED 1

IED 2

UTC

2 1 2 1 2 1

FAIL AUX KEY

SYS RADIO

FIELD

OUTPUT

FUSE – F1

PS FUSE

F2

A

GND

STATUS 1

FUSE - F3

POWER

A

D25 MAINT

IED / HOST 1

IED / HOST 2

UTC

C

B

D

DC ANALOG

INPUTS

GND

XCOM 1

XCOM 2

SYS

FAIL AUX KEY

6 5 4 3 2 1

RADIO

1 3 5 7 9 11 13 15 17 19 21 23 25 27 29 31 33 35 37 39

2 4 6 8 10 12 14 16 18 20 22 24 26 28 30 32 34 36 38 40

1 3 5 7 9 11 13 15 17 19 21 23 25 27 29 31 33 35 37 39

2 4 6 8 10 12 14 16 18 20 22 24 26 28 30 32 34 36 38 40

1 3 5 7 9 11 13 15 17 19 21 23 25 27 29 31 33 35 37 39

2 4 6 8 10 12 14 16 18 20 22 24 26 28 30 32 34 36 38 40

H

E F

G2

G1

GROUND STUD

POWER

CONNECTIONS

POWER SWITCH

DIGITAL INPUTS

COMMUNICATION

AC ANALOG

CONTROL

AUXILIARY CONTROLS

First Look at the D25, Continued

Back Panel

Diagrams

GE Grid Solutions

PORTS

OUTPUTS

With two FACE-40 connectors:

Legacy System Back Panel:

INPUTS

Part Number

The part number label on the rear of the enclosure identifies the D25 options

at the time of delivery (See Appendix C: Ordering Information):

• Each digit in the part number indicates the options included in the D25

• If the D25 is modified after delivery, the part number may no longer represent

• Update the part number label to match any option changes made after delivery

the options accurately

994-0081-3.00-21 GE Information

Page 21

GE Grid Solutions

D25

User's Manual

21

!

Physical Mounting

19” Rack

Physical

Mounting

Rack Spacing

Required

Clearances

Wiring Rod

Installation

To mount the D25 in a rack:

1. Align the D25 in the desired position in a 19-inch mounting rack.

2. Holding the D25 firmly in place in the rails of the mounting rack, install and

tighten the four rack screws.

You are now ready to connect all power and field wiring to the back of the D25, see

0 Connecting Field Wiring.

When mounting multiple D25s in a rack (or if mounting a D25 in a rack with other

equipment) verify that there is at least one rack unit (RU) space above and below the

D25 to allow for cooling airflow.

1 RU = 1.75 inches (44.5mm)

The exterior dimensions of the standard D25 enclosure are:

• 19” length x 9” deep x 8.75” high (483mm x 227mm x 222mm)

Clearance:

• Allow approximately 14 inches (356 mm) of total cabinet depth to provide

clearance for hardware on the front panel, and interface cables on the rear.

The optional D25 Wiring Rod assembly supports field wiring and prevents undue

stress on the connectors on the rear of the D25.

You require:

• Wire Rod Assembly, Part Number: 953-4029

• 2 - 6-32 - ½ inch LG Screws (screws removed from enclosure may be re-used, if

they are ½ inch long)

Mount the Wiring Rod on the back of the unit at a height where it will support cables

attached to the DB-25 or FACE-40 connectors.

GE Information 994-0081-3.00-21

Page 22

D25

User's Manual

22

M ultifunct ion IED

D25

COMM UN ICA TION S

WES MA IN T

Tra ns mit Receiv e

XCOM

2

XCOM

1

IED 2

IED 1

Power

Run

OPERATI ON

Local

Remot e

CONTROL S

F1 F2

Escape YesF3To g

F4 F5 F6

F7 F8 F9

Pre v

ACK

Alarm

Next

Menu

No

Ent

GE Energy Services

F

+

+ +

+

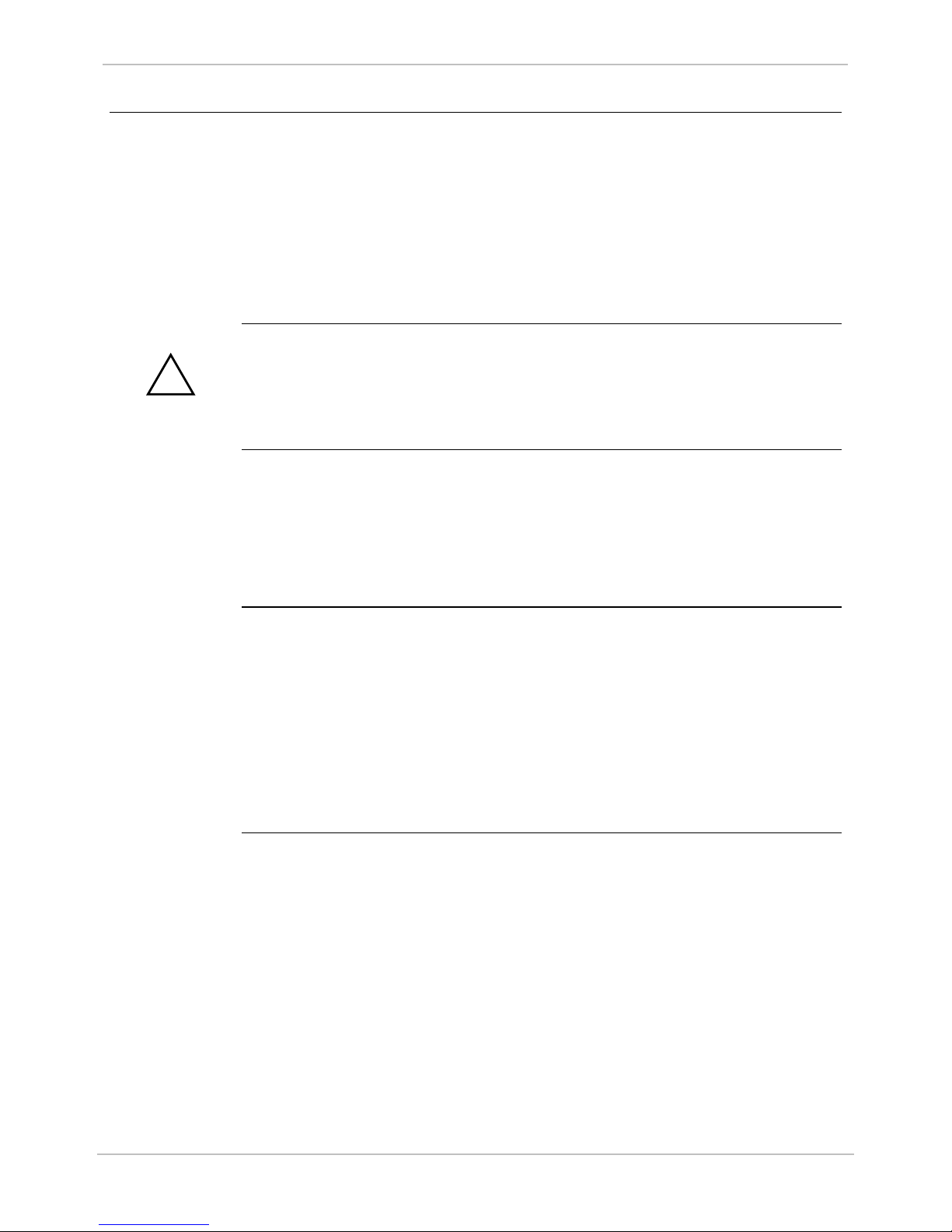

LCD Panel Overview

LCD Panel

Diagram

A Liquid Crystal Display Panel (LCD) option has been made available for

applications where alphanumeric front-panel display of analog and digital

system input points is desired.

GE Grid Solutions

Detailed

Description

Components of

an LCD Panel

System

This diagram shows a D25 front panel with the LCD option installed.

The touch-sensitive keypad below the LCD display can be used to navigate

through the display to show a set of select analog and digital input points.

The Data Display panel option is also available in a rack-mounted version

that can be linked, using the RS-485 multidrop technique.

A D25 must have these components to support an LCD system:

Hardware: Part #

− D25 Front Panel 953-3135

− LCD Text Display 540-0248

− LCD Circuit Board Assembly. 540-0256

− Ribbon Cable Assembly 976-0125

Continued on next page

994-0081-3.00-21 GE Information

Page 23

GE Grid Solutions

D25

User's Manual

23

LCD Panel Overview, Continued

Configuring

The Software

LCD Hardware

Connections

A D25 fitted with an LCD panel must be equipped with the Data Display

DTA (B062) application software to communicate with the panel.

Using SGConfig, specific D25 database input points are mapped into this

software.

A flat ribbon cable (Part # 976-0125) connects from the LCD card (Part #

540-0256) to the Indicator Switch card (Part # 540-0412) which is also

mounted on the inside of the front door of the D25 enclosure.

This cable is both the data and power connection to the LCD card.

GE Information 994-0081-3.00-21

Page 24

D25

User's Manual

GE Grid Solutions

24

M ultifunct ion IED

D25

COMM UN ICA TION SWES MA IN T

Tra ns mit Receive

XCOM 2

XCOM 1

IED 2

IED 1

Power

Run

OPERATI ON

Disabl e

Enable

CONTROL S

GE Energy Services

F

+

++

+

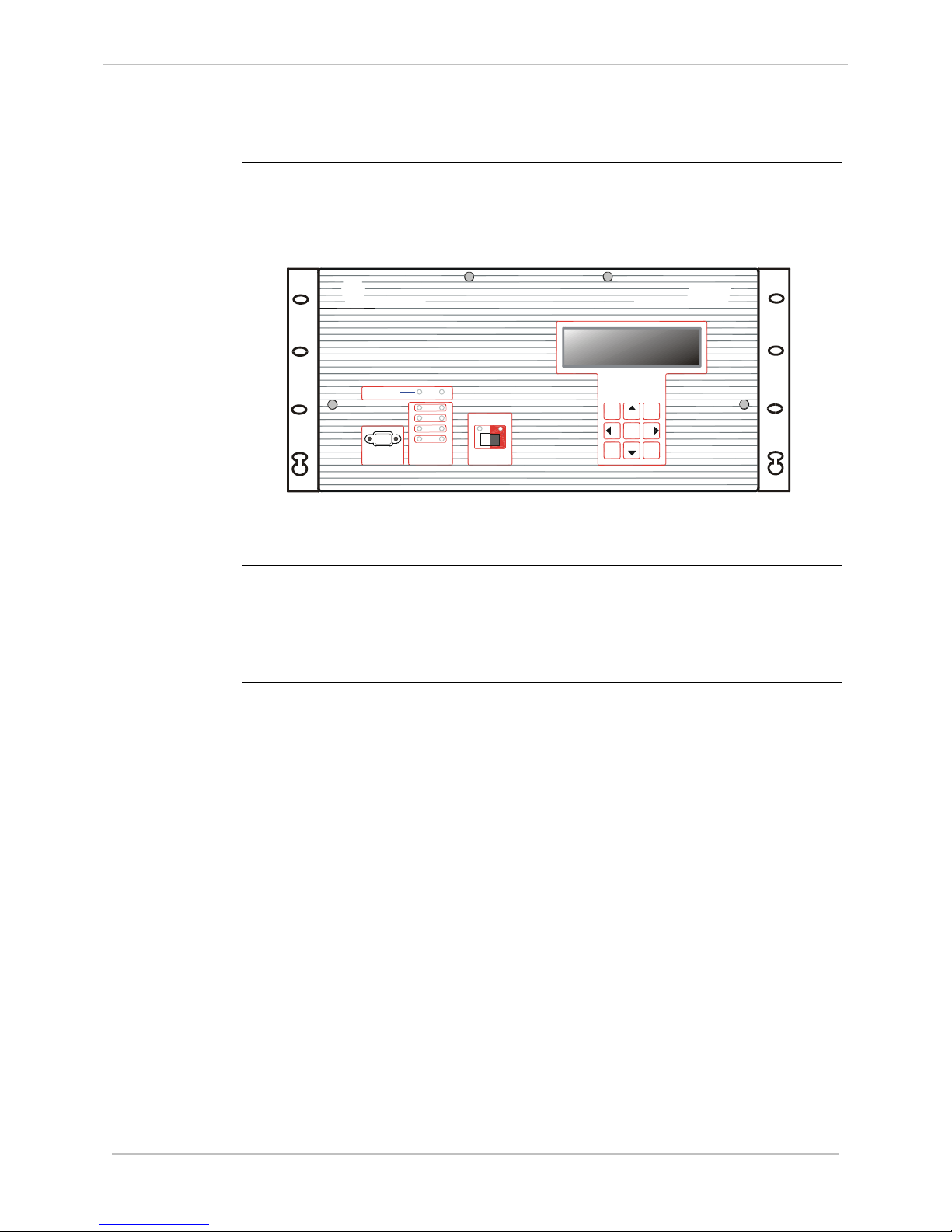

Graphic Display Panel (GDP) and Color GDP (CGDP) Overview

GDP/CGDP

Diagrams

A Graphic Display Panel (GDP) or a Color Graphic Display Panel (CGDP)

option has been made available for applications where graphic front-panel

display and control of system inputs and outputs is desired.

This diagram shows a D25 front panel with the GDP option installed.

This diagram shows a D25 front panel with the CGDP option installed.

Detailed

Description

The touch-sensitive GDP/CGDP can display a selection of customized

graphic displays, each representing a set of analog and digital input and

output points.

Using the touch-sensitive screen, an operator can select various displays,

select points to monitor and issue control commands

994-0081-3.00-21 GE Information

Page 25

GE Grid Solutions

D25

User's Manual

25

Graphic Display Panel (GDP) and Color GDP (CGDP) Overview,

Continued

Components of

a GDP/CGDP

A D25 must have these components to support a GDP system:

Hardware: Part #

− D25 Front Panel 953-3136

− GDP module 580-1186

− Ribbon Cable Assembly 976-0126

− Ribbon Cable Assembly 976-0127

− PSA module 521-0131

A D25 must have these components to support a CGDP system:

Hardware: Part #

− D25 Front Panel 504-0308LF

− CGDP module 580-3570

− Color GDP Cable Assembly 977-0548

GE Information 994-0081-3.00-21

Page 26

D25

User's Manual

GE Grid Solutions

26

!

Graphic Display Panel (GDP) and Color GDP (CGDP) Overview,

Continued

What Can a

GDP/CGDP be

Used For?

The GDP/CGDP can eliminate the need for discrete substation devices.

For example, the GDP/CGDP can be used in place of the following devices:

• circuit breaker control switch and semaphore

• disconnector / earth switch and semaphore

• ammeter, and ammeter selector switch

• voltmeter, and voltmeter selector switch

• MW meter

• power factor meter

• alarm annunciator panel

• mimic diagram.

There are jumper settings at the back of the GDP/CGDP unit that are set at

the factory. These settings shall not be changed and any modification to them

may cause damage to the GDP/CGDP or other modules of the D25.

IMPORTANT

A D25 equipped with a GDP/CGDP has these limitations:

• Only external status wetting can be used when the GDP/CGDP is installed.

− the D25’s power supply field O/P is used exclusively to power the

GDP/CGDP.

− connecting another external load to the field O/P will affect isolation, and

possibly overload the power supply.

• The GDP/CGDP reduces the normal -20° to +70°C operational temperature

rating of the D25 to 0° to +50°C.

• The 20-60 V

D25 power supply is not available with the GDP/CGDP.

DC

994-0081-3.00-21 GE Information

Page 27

GE Grid Solutions

D25

User's Manual

27

Configuration of a GDP

Configuring a

GDP’s

Software

GDP Hardware

Connections

A D25 fitted with a GDP must be equipped with the DNP 3.0 DPA

application software and will use the COM1 (D25 MAINT port) to

communicate with the GDP. Using SGConfig, some or all of the D25’s

database points are mapped into this communication software.

Inside the GDP, these points are then mapped into the GDP graphic objects.

For detailed information about configuring the DNP 3.0 DPA, refer to the

B021-0CG Configuration Guide.

For detailed information about setting up and configuring the GDP, refer to

the “IGPM 16200 Operation and Configuration Manual” (document number

16200-MOC-09-08-E).

To access the GDP manual:

1. Go to GE Grid Solutions Technical Support at:

http://www.gegridsolutions.com/TDSASSupport

2. Log in to the Technical Support Library.

3. Navigate to Substation Automation Products > D25 > GDP –

Monochrome > FW 603 Upgrade > Substation Bay Config Tool Ver

5.01.

4. Download and extract the file; the manual is located in the Manual

folder.

Please contact GE Grid Solutions to learn more about the configuration tools

and settings available for the GDP.

When installed, the PSA module (part # 521-0131) is mounted over the righthand side of the D25’s DAC board, where it plugs onto the three sets of

digital input wetting jumpers (see Low-Voltage Digital Input Card Wetting on

p. 120 for more detail on these jumpers). The PSA taps into the main D25

power supply’s field output through these jumpers.

A flat ribbon cable (Part # 976-0126) connects from the PSA card to the

Indicator Switch card (Part # 540-0412) mounted on the inside the front door

of the D25 enclosure. This cable is the data connection to the GDP.

Another cable (Part # 976-0127) links the PSA card to the GDP. This cable is

both the DC power connections from the PSA to the GDP, as well as the RS485 data interface.

GE Information 994-0081-3.00-21

Page 28

D25

User's Manual

28

PC

SGConfig

SBC Tool

300

D25 CGDP

RS-485

D25 Configuration

SB Viewer 300

(DNP DCA)

DNP PACKETs

SB Viewer 300 Configuration

DNP DPA

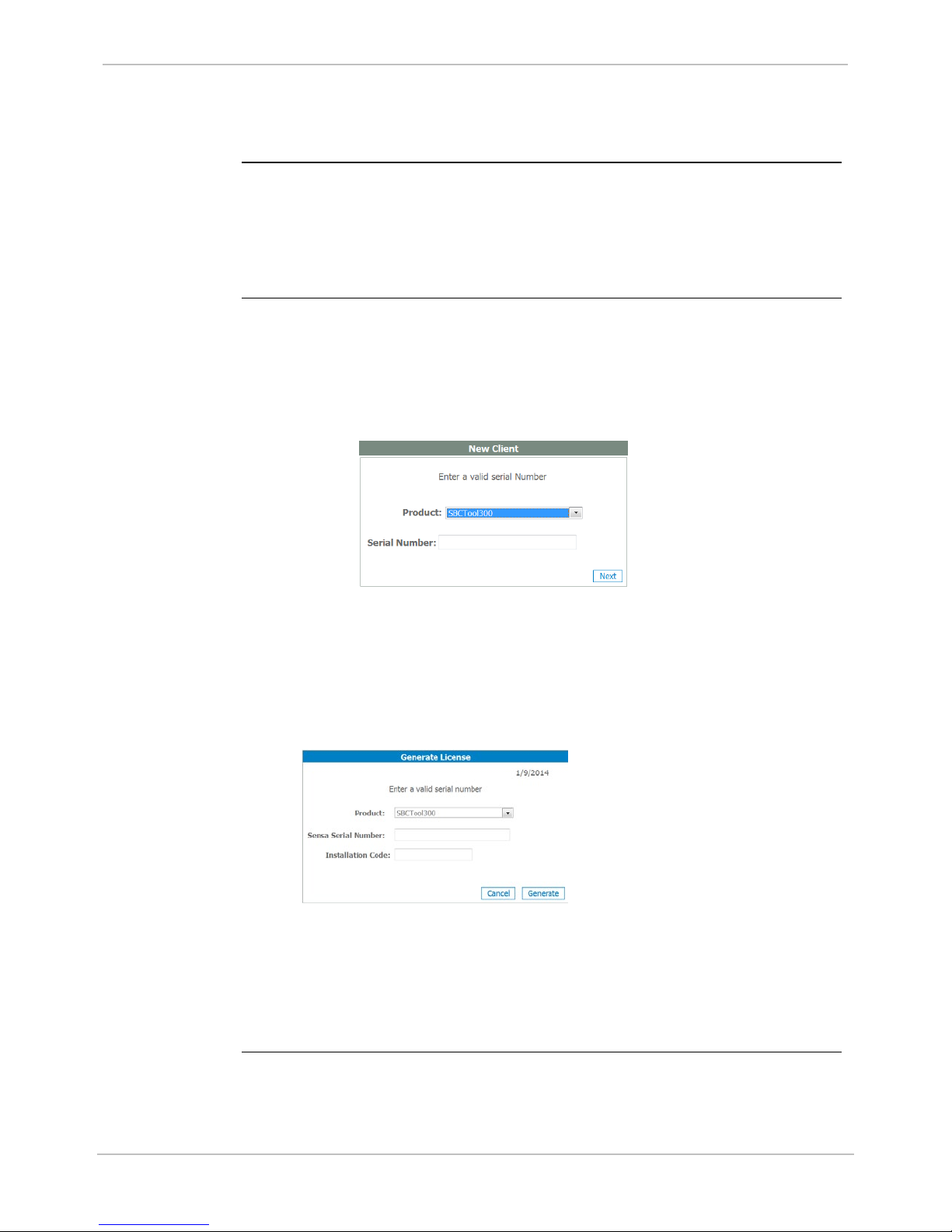

Set Up of a Color GDP (CGDP)

Overview

This section describes how to set up the Color Graphical Display Panel

(CGDP) on your D25*. The CGDP uses a licensed software package named

the GDP 300 from Quasar Controls, which you must register as part of the

setup procedure. The CGDP software includes system firmware named the

Substation Bay Viewer™ 300 (SB Viewer 300) that runs on the D25 CGDP

and a Windows-based editor named the Substation Bay Config Tool™ 300

(SBC Tool 300) that runs on a PC.

The diagram below shows the relationship between the PC, D25 and CGDP

(SB Viewer 3 00). The SB Viewer 300 and D25 communicate with each

other using the DNP protocol over RS-485. The SB Viewer 300 is configured

using the SBC Tool 300 running on the PC. The D25 is configured using

SGConfig which also run on the PC.

GE Grid Solutions

Prerequisites

Install the:

• Compact Flash Card (GE part number 160-0125) which includes

Windows Embedded CE and SB Viewer 300

• SBC Tool 300 in Windows 7 or Windows Server 2008

994-0081-3.00-21 GE Information

Page 29

GE Grid Solutions

D25

User's Manual

29

1. Go to the Quasar Controls website at:

Set Up of a Color GDP (CGDP), Continued

Set Up

Procedure

To Register the

SBC Tool 300

online:

Setting up the CGDP requires the following tasks:

1. Register the SBC Tool 300.

2. Create the configuration file using the SBC Tool 300.

3. Load the configuration file onto the CGDP.

http://200.23.18.184/LicenseReg/AllUsers/Login.aspx?ReturnUrl=%2fLicen

seReg%2fClientes%2fGenerarClave.aspx.

2. If you are a new client, you need to register.

a. Click Register.

Result: The New Client entry fields appear.

3. Sign in to the client account.

4. Click Generate Licenses.

Result: The Generate License window appears.

5. Input your valid Serial Number and Installation Code.

6. Click the Generate button.

Result: The license information appears. Also, Quasar Controls sends an

email to your client email address containing the license information.

Note: The SBC Tool 300 includes a 30-day trial license. You must register the

software with Quasar Controls within 30 days, or the license is de-activated.

b. Type in valid Serial Number for the SBC Tool 300.

c. Follow the web page instructions to complete the registration.

Result: After completing the registration or you have a new client

account.

GE Information 994-0081-3.00-21

Page 30

D25

User's Manual

30

When using the SBC Tool 300, refer to Section 4 of the “GDP 300 Operation

Set Up of a Color GDP (CGDP), Continued

To create the

configuration

file using the

SBC Tool 300:

and Configuration Manual” (document number 16300-MOC-13-4).

To access this manual:

1. Go to GE Grid Solutions Technical Support at:

http://www.gegridsolutions.com/TDSASSupport

2. Log in to the Technical Support Library.

3. Navigate to Substation Automation Products > D25 > GDP 300 –

Color > GDP 300 Operation and Configuration Manual.pdf.

A D25 fitted with the CGDP must be running DNP 3.0 DPA application

software and will use COM1 (D25 MAINT port) to communicate with the

CGDP (refer to the DNP V3.00 DPA Configuration Guide (B021-0CG)).

Using SGConfig, some or all of the D25’s database points are mapped into

this communication software. Inside the CGDP, these points are then mapped

into the CGDP graphic objects.

GE Grid Solutions

For DNP communications between the CGDP and the D25, both units must

use a matching serial port baud rate and DNP addresses.

Please contact GE Technical Support to learn more about the configuration

tools and settings available for CGDP.

994-0081-3.00-21 GE Information

Page 31

GE Grid Solutions

D25

User's Manual

31

1. On your PC, open your project in the SBC Tool 300.

Set Up of a Color GDP (CGDP), Continued

To load a

configuration

file onto the

CGDP from a

USB flash

drive:

2. From the SBC Tool 300 menu, click Transfer > Send configuration.

Result: The Send Configuration window appears.

3. Select the USB option.

4. Connect a USB flash drive to your computer.

5. Click the Refresh button in the Send configuration window.

Result: The connected drives are listed.

6. Select the location to which the configuration file is to be downloaded from

the USB drive. If you:

• Single-click the drive designation, the project is downloaded to the

root directory of the drive, creating a folder with the project name.

• Double-click, the system prompts you to select the exact path to

which the configuration file is to be downloaded from the USB flash

drive and creates a folder with the project name.

7. Click the Ok button.

Result: When the configuration file has been downloaded, an

acknowledgement window appears.

8. Click OK.

9. Power down the D25 and open the front panel.

10. Insert the USB flash drive into the CGDP.

11. Power on the D25 and copy the project folder from the USB flash drive to

the CGDP’s path.

12. Power down the D25, unplug the USB flash drive, and close the D25 front

panel.

13. Power on the D25 and select the configuration you just downloaded from the

CGDP screen.

Note: Alternatively, the configuration can be loaded through Ethernet. For details,

refer to the Section 4.5 in the “GDP 300 Operation and Configuration Manual”

(Digital document number 16300-MOC-13-4).

GE Information 994-0081-3.00-21

Page 32

D25

User's Manual

32

The CGDP software package makes the following software components available for

If you need help with any aspect of the GDP 300 firmware or configuration tool,

Set Up of a Color GDP (CGDP), Continued

Additional

Documentation

Software

License

Information

• GDP 300 Operation and Configuration Manual (document number

16300-MOC-13-4)

• DNP V3.00 DPA Configuration Guide (GE document number B021-

0CG).

use:

Software Component Description License Requirements

GE Grid Solutions

Quasar Controls

Product Support

Substation Bay Config

Tool 300 (SBC Tool

300)

Substation Bay Viewer

300 (SB Viewer 300)

contact:

Quasar Controls, S.A de C.V

Av. Morelos Oriente 2216,

Col. Centro Torreon,

Coahuila, Mexico C.P. 27000

Sales: +52 (871) 718-60-90

Customer Service: +52 (871) 718-60-90

Web Site: http://www.caname.org.mx/index.php/quasar-controls-s-a-de-c-v

PC-based tool to

create and download

a configuration file to

the CGDP.

Firmware program

that runs on the CGDP.

30-day trial license. Register within

30 days to obtain a licensed version.

See procedure, “To Register the SBC

Tool 300 online”.

License has already been applied.

994-0081-3.00-21 GE Information

Page 33

GE Grid Solutions

D25

User's Manual

33

-- Wetting

+ Wetting

+/L

-- /N

Aux.

Ground

• Positive if using DC power supply

• Negative if DC power supply

!

Connecting Field Wiring

This Section

Use this section to:

• Make all field wiring connections

• Set external jumper configurations

• Configure Serial and Ethernet ports

Power Supply

Power Supply

+ Wetting

Supply Output

- Wetting

Supply Output

+/L Input

-/N Input

Grounding

External

Overcurrent

Protection

A label on the back panel outlines the actual power connection points for the

Power Supply option installed.

Term # 1 2 3 4 5

Either +24V or +48V according to the power supply option specified.

Either -24V or -48V according to the power supply option specified.

• Line if AC power supply

• Neutral if AC power supply

Connect the protective ground stud before operating the D25. Tighten the

ground stud to a torque value between 4.2 to 5.0 in-lb [0.475 to 0.565 Nm]

Use the ground stud for shielding.

The D25 power supply input must be externally protected:

• AC mains supplies shall be fused at no more than 15A, or

• DC mains supplies shall be fused at no more than 10A

GE Information 994-0081-3.00-21

Page 34

D25

User's Manual

34

• An IEC® 60947 compliant main disconnect switch (or other equivalent device

Power Supply, Continued

Power Supply

Source

complying with IEC 60947-1/60947-3) must be as electrically close as practical

to the D25 power supply.

• For the switching power supply to operate correctly, the input voltage must be

within specified limits prior to turning on the power switch.

• DC power supply modules draw an inrush current upon start-up.

− Ensure the field source can supply this start-up current without overloading.

• Use the field supply outputs only when external supplies are not available.

− Use of an external supply improves immunity to EMI and increases power

supply efficiency.

Digital Inputs

Digital Input

Module

Note: The inputs of all variants of the S Cards are not polarity sensitive: they

are bipolar, and are isolated from the D25’s internal power supply.

GE Grid Solutions

Digital Inputs

Wetting Types

The D25 can have up to 96 digital inputs in three banks of 32:

• Digital Inputs 1 to 32 are on connectors A and B

• Digital Inputs 33 to 64 are on connectors C and D

• Digital Inputs 65 to 96 are on connectors E and F

All digital inputs require an input voltage signal large enough to turn on an

optical switch. The input levels required for each D25 digital input card type

are shown in the table below.

• Low Voltage Digital Input cards can each be set to use:

− Externally routed PSU supplied wetting (Supplied Wetting)

− External wetting

− Externally applied input voltage (Voltage Detect)

• High Voltage Digital Input cards can each be set to use:

− External wetting

− Externally applied input voltage (Voltage Detect)

994-0081-3.00-21 GE Information

Page 35

GE Grid Solutions

D25

User's Manual

35

Low Voltage Digital Input Cards

Digital Inputs, Continued

Digital Input

Thresholds

The table shows the on and off state thresholds for each of the listed D25

digital input card options. Before connecting field wiring, refer to the table to

determine the suitability of the installed option.

Verify that inputs do not exceed the maximum overload voltage, or damage to

the card may result.

Card Type 32 Input

Part #s

12V / 5 mA 517-0485 >8 V <4 V 16.8 V 130 mW

24V / 5 mA 517-0486 >18 V <10 V 33.6 V 210 mW

24V / 10 mA 517-0490 >18 V <10 V 33.6 V 530 mW

48V / 5 mA 517-0487 >35 V <16 V 67.2 V 470 mW

120V / 1.6 mA 517-0488 >80 V <40 V 144 V 290 mW

250V / 1.2 mA 517-0489 >160 V <80 V 300 V 450 mW

Note

The inputs of all variants of the D25 digital input cards are not polarity

On Threshold Off Threshold Overload

Voltage

High Voltage Digital Input Cards

Max. Power

Dissipation/

Input

sensitive: they are bipolar, and are isolated from the D25’s internal power

supply.

Fuse

Monitoring

D25 digital input modules include circuitry that detects the presence of

wetting voltage after it has passed through the fuse F1.

Software in the D25 Plant I/O Subsystem (P097 V2.30 or greater) responds to

the signals from each of the three D25 digital input modules and creates

pseudo digital inputs that can be seen in the D25 System Point Database.

If fuse F1 opens or the wetting voltage is removed from the digital input

module for any reason, the pseudo DI for that module will change state and

set an alarm. If a D25 digital input module is not present, the pseudo DI point

will remain in the Off state.

Note: Fuse monitoring can only detect a wetting voltage if the D25 digital

input module is configured for supplied or external wetting.

If the module is configured for voltage detect the fuse monitoring

circuitry will not sense any wetting voltage, and remains in the Off

state

GE Information 994-0081-3.00-21

Page 36

D25

User's Manual

36

!

DI Connector A

1 2 3 4 39 40

Input #1

Contacts

Power Supply Term. Block

1 2 3 4 5

+ Wetting

- Wetting

Digital Inputs, Continued

Digital Input

Field

Connections

Digital Input

Wetting

Selection

External Power

Sources

Digital Inputs

Supplied

Wetting

(Externally

routed)

Field wiring for all variations of Digital Input modules are made through two

FACE-40 connectors for each module on the backplane of the D25 enclosure.

These connectors are provided only if a digital input module is installed in the

D25.

Wetting supply source must be provided externally and independently for

each digital input card.

To use external or supplied wetting:

• Connect external wetting supply to pins 1 and 2 on FACE-40 Connector A, C

and/or E.

To use the voltage detect input:

• Connect (jumper) pins 1 and 2 on Connector A, C and/or E for each module(s).

Note: Internal wetting voltage to Digital Cards is no longer available. Please

refer to Product Bulletin PRBT-213.

While all of the 32 inputs are bipolar and not polarity sensitive, the “B” sides

of all inputs are linked together.

• Use care when connecting multiple external power sources.

For external wetting, the three digital input modules can have independent

wetting configurations and wetting voltage sources.

Supplied Wetting is when the voltage applied to the inputs originates from the

power supply internal to the D25, routed externally to the DI Cards. The

digital input is “turned on” simply by closing a contact across the two input

termination points.

Connections for digital input point number 1.

GE Grid Solutions

Notes

This option is available for 24 and 48V low-voltage DI cards, only. Supplied

Wetting option is not available if the Graphics Display panel is installed

because it reduces the isolation, increasing the D25 unit’s susceptibility to

EMI and transient interference.

994-0081-3.00-21 GE Information

Page 37

GE Grid Solutions

D25

User's Manual

37

DC

Connector

A

Pin # 1 2 3 4 39 40

Input #1

Contacts

External Wetting

Power Supply

Digital Inputs, Continued

Digital Inputs

External

Wetting

Voltage Detect

With External Wetting, operation of the digital inputs is essentially the same

as for Supplied Wetting, except that the voltage that is switched at the input

terminals is supplied by an external (non-D25) source. The external power

source is connected to pins 1 and 2 of Connector(s) A, C or E, for each of the

three Digital Input cards respectively.

Connections for digital input point number 1:

In this type of input, the D25 does not provide the wetting power source, from

either its own power supply, or from an external battery.

Note: Pins 1 and 2 of Connector(s) A, C or E are jumpered for each board

using this configuration.

If using more than one external power source, they must share a common

return, and it must be connected to the “B” input termination for each input

point.

Connections for digital input point number 1:

GE Information 994-0081-3.00-21

Page 38

D25

User's Manual

38

1

Wetting Voltage

Reserved

2

Wetting Voltage

Reserved

3

DI 1A

DI 17A

4

DI 1B

DI 17B

5

DI 2A

DI 18A

6

DI 2B

DI 18B

7

DI 3A

DI 19A

8

DI 3B

DI 19B

9

DI 4A

DI 20A

10

DI 4B

DI 20B

11

DI 5A

DI 21A

12

DI 5B

DI 21B

13

DI 6A

DI 22A

14

DI 6B

DI 22B

15

DI 7A

DI 23A

16

DI 7B

DI 23B

17

DI 8A

DI 24A

18

DI 8B

DI 24B

19

Reserved

Reserved

20

Reserved

Reserved

21

Reserved

Reserved

22

Reserved

Reserved

23

Reserved

Reserved

24

Reserved

Reserved

25

DI 9A

DI 25A

26

DI 9B

DI 25B

27

DI 10A

DI 26A

28

DI 10B

DI 26B

29

DI 11A

DI 27A

30

DI 11B

DI 27B

31

DI 12A

DI 28A

32

DI 12B

DI 28B

33

DI 13A

DI 29A

34

DI 13B

DI 29B

35

DI 14A

DI 30A

36

DI 14B

DI 30B

37

DI 15A

DI 31A

38

DI 15B

DI 31B

39

DI 16A

DI 32A

40

DI 16B

DI 32B

Digital Inputs, Continued

GE Grid Solutions

Table: Digital

Inputs Pinouts

1-32

Pinouts for Digital Inputs 1 through 32:

Pin Connector A Connector B

994-0081-3.00-21 GE Information

Page 39

GE Grid Solutions

D25

User's Manual

39

1

Wetting Voltage

Reserved

2

Wetting Voltage

Reserved

3

DI 33A

DI 49A

4

DI 33B

DI 49B

5

DI 34A

DI 50A

6

DI 34B

DI 50B

7

DI 35A

DI 51A

8

DI 35B

DI 51B

9

DI 36A

DI 52A

10

DI 36B

DI 52B

11

DI 37A

DI 53A

12

DI 37B

DI 53B

13

DI 38A

DI 54A

14

DI 38B

DI 54B

15

DI 39A

DI 55A

16

DI 39B

DI 55B

17

DI 40A

DI 56A

18

DI 40B

DI 56B

19

Reserved

Reserved

20

Reserved

Reserved

21

Reserved

Reserved

22

Reserved

Reserved

23

Reserved

Reserved

24

Reserved

Reserved

25

DI 41A

DI 57A

26

DI 41B

DI 57B

27

DI 42A

DI 58A

28

DI 42B

DI 58B

29

DI 43A

DI 59A

30

DI 43B

DI 59B

31

DI 44A

DI 60A

32

DI 44B

DI 60B

33

DI 45A

DI 61A

34

DI 45B

DI 61B

35

DI 46A

DI 62A

36

DI 46B

DI 62B

37

DI 47A

DI 63A

38

DI 47B

DI 63B

39

DI 48A

DI 64A

40

DI 48B

DI 64B

Digital Inputs, Continued

Table: Digital

Inputs Pinouts

33-64

Pinouts for Digital Inputs 33 through 64:

Pin Connector C Connector D

GE Information 994-0081-3.00-21

Page 40

D25

User's Manual

40

1

Wetting Voltage

Reserved

2

Wetting Voltage

Reserved

3

DI 65A

DI 81A

4

DI 65B

DI 81B

5

DI 66A

DI 82A

6

DI 66B

DI 82B

7

DI 67A

DI 83A

8

DI 67B

DI 83B

9

DI 68A

DI 84A

10

DI 68B

DI 84B

11

DI 69A

DI 85A

12

DI 69B

DI 85B

13

DI 70A

DI 86A

14

DI 70B

DI 86B

15

DI 71A

DI 87A

16

DI 71B

DI 87B

17

DI 72A

DI 88A

18

DI 72B

DI 88B

19

Reserved

Reserved

20

Reserved

Reserved

21

Reserved

Reserved

22

Reserved

Reserved

23

Reserved

Reserved

24

Reserved

Reserved

25

DI 73A

DI 89A

26

DI 73B

DI 89B

27

DI 74A

DI 90A

28

DI 74B

DI 90B

29

DI 75A

DI 91A

30

DI 75B

DI 91B

31

DI 76A

DI 92A

32

DI 76B

DI 92B

33

DI 77A

DI 93A

34

DI 77B

DI 93B

35

DI 78A

DI 94A

36

DI 78B

DI 94B

37

DI 79A

DI 95A

38

DI 79B

DI 95B

39

DI 80A

DI 96A

40

DI 80B

DI 96B

Digital Inputs, Continued

GE Grid Solutions

Table: Digital

Inputs Pinouts

65-96

Pinouts for Digital Inputs 65 through 96.

Pin Connector E Connector F

994-0081-3.00-21 GE Information

Page 41

GE Grid Solutions

D25

User's Manual

41

!

Caution

Control Outputs

Control Module

T/C or DO

(R/L) Sensing

Fuse

Monitoring

The control module can be configured for two basic modes of operation:

• Trip/Close (T/C) – excluding D25 High Current KE Control Card

• Digital Output (DO)

Any other type of operation, such as Raise/Lower, uses the Digital Output

hardware configuration.

D25 software detects what type of digital output command has been received,

and uses the Master Trip and Master Close relays when appropriate.

External jumpering is provided to route the external Control Voltage through

the correct relays for each mode of operation.

The control module includes circuitry that detects the presence of control

voltage on the load side of the fuses. Software in the D25 Plant I/O

Subsystem (P097 V2.30 or greater) responds to the signal from the control

module and creates a pseudo digital input that can be seen in the D25 System

Point Database.

If a fuse opens, or the control voltage is removed from the digital output

module for any reason, the pseudo digital input (DI) for that module will

change state and set an alarm.

Note

If the control module is not present, the pseudo DI point will remain in the Off

state.

Note 1: The fuse monitoring circuitry can only detect a control voltage above

approximately 10 Vdc. If the control voltage is less than this level,

the fuse monitoring circuitry will not sense any voltage, and the

pseudo DI point will remain in the Off state.

Note 2: Fuse monitoring works with positive or negative grounded systems.

Note 3: For D25s with Plant I/O Version 2.30, the fuse-monitoring feature

will only work with DC control voltages. Versions greater than 2.30

support AC control voltage monitoring.

Note 4: The D25 High Current Control Card does not have a fuse and a fuse

monitoring circuit.

The fuse monitoring circuitry has been engineered to detect control voltages

up to the supported maximum specifications of the module. Do not exceed

this level of control voltage. Damage to the module may result.

The D25 KE control module does not require hardware configuration to use

the fuse-monitoring feature.

GE Information 994-0081-3.00-21

Page 42

D25

User's Manual

42

• Insert wire jumpers in the rear 8-pin compression type connector P1 to configure

Control Outputs, Continued

GE Grid Solutions

D25KE Module

External

Connections

D25KE

Variations

About D25 KE

Rear Panels

Output Options

External

Jumper

Configuration

The D25KE Control Module contains (up to) 32 digital output relays, either:

• divided into (up to) 4 groups of 8 relays

− each group is separately configurable as trip/close (T/C) pairs, or raise/lower

(R/L) pairs via field selectable jumpers

• divided into (1 or) 2 groups of 8 pairs of relays (D25KE-4Z Card)

− each group is separately configurable as T/C or R/L

The D25KE control modules are available in two variations:

• with 6 DB-25 connectors for field wiring and one 8-pin compression terminal

block for optioning

• with up to 2 FACE-40 connectors for field wiring and optioning

All DB-25 type D25KE modules are installed in a D25 enclosure that has six

DB-25 connectors on the backplane, regardless of how many channels the KE

board has.

• a 16 channel DB-25 KE module will have two DB-25 connectors that will not be

used.

A D25 KE module installed in an enclosure with FACE-40 connectors will

only have the connectors necessary to support the number of channels in use.

• 32 channel D25 KE module will have two FACE-40 connectors, 16 channel

module will have only one FACE-40 connector installed.

The 32 D25KE digital outputs are divided into up to four groups of eight

relays.

• Each of the four groups is independently configurable as Trip/Close pairs or

Raise/Lower Digital Outputs.

the D25KE DB-25 module.

Note: Use GE Grid Solutions quad-wire jumper, part # 970-0264, or make

an equivalent jumper, as desired.

• Jumper the two FACE-40 connectors G1 and G2 to configure the D25KE FACE-

40 module.

994-0081-3.00-21 GE Information

Page 43

GE Grid Solutions

D25

User's Manual

43

Control Outputs, Continued

Table: D25KE

DB-25

Connector

Pinouts J1 to J3

The DB-25 connector pinouts for D25KE outputs 1 through 16.

Note: TRPx = Trip output point x

CLSx = Close output point x

NC = Not Connected

J1 DB-

25 Pin

1 TRP1 1 TRP9 1 TRP1

2 CLS1 2 CLS9 2 TRP2

3 TRP2 3 TRP10 3 TRP3

4 CLS2 4 CLS10 4 TRP4

5 TRP3 5 TRP11 5 TRP5

6 CLS3 6 CLS11 6 TRP6

7 TRP4 7 TRP12 7 TRP7

8 CLS4 8 CLS12 8 TRP8

9 TRP5 9 TRP13 9 TRP9

10 CLS5 10 CLS13 10 TRP10

11 TRP6 11 TRP14 11 TRP11

12 CLS6 12 CLS14 12 TRP12

13 TRP7 13 TRP15 13 TRP13

14 CLS7 14 CLS15 14 TRP14

15 TRP8 15 TRP16 15 TRP15

16 CLS8 16 CLS16 16 TRP16

17 NC 17 NC 17-25 NC

18-25 COIL_SUP_RTN 18-25 COIL_SUP_RTN

Signal J2 DB-

25 Pin

Signal J3 DB-

25 Pin

Signal

GE Information 994-0081-3.00-21

Page 44

D25

User's Manual

44

Control Outputs, Continued

GE Grid Solutions

Table: D25KE

DB-25

Connector

Pinouts J4 to J6

The DB-25 connector pinouts for D25KE outputs 17 through 32.

J4 DB-

25 Pin

1 TRP17 1 TRP25 1 TRP17

2 CLS17 2 CLS25 2 TRP18

3 TRP18 3 TRP26 3 TRP19

4 CLS18 4 CLS26 4 TRP20

5 TRP19 5 TRP27 5 TRP21

6 CLS19 6 CLS27 6 TRP22

7 TRP20 7 TRP28 7 TRP23

8 CLS20 8 CLS28 8 TRP24

9 TRP21 9 TRP29 9 TRP25

10 CLS21 10 CLS29 10 TRP26

11 TRP22 11 TRP30 11 TRP27

12 CLS22 12 CLS30 12 TRP28

13 TRP23 13 TRP31 13 TRP29

14 CLS23 14 CLS31 14 TRP30

15 TRP24 15 TRP32 15 TRP31

16 CLS24 16 CLS32 16 TRP32

17 NC 17 NC 17-25 NC

18-25 COIL_SUP_RTN 18-25 COIL_SUP_RTN

Signal J5 DB-

25 Pin

Signal J6 DB-

25 Pin

Signal

994-0081-3.00-21 GE Information