Page 1

GE

D20/D200

PRPI-019

Version 3.00 Revision 10

GE Information

Grid Solutions

Technical Overview

Page 2

D20/D200 Technical Overview

GE Grid Solutions

ii

are trademarks and service marks of General E

COPYRIGHT NOTICE

© 2007-2017, General Electric Canada. All rights reserved.

The information contained in this document is subject to change without notice. The software described in this document is supplied

under license and may be used or copied only in accordance with the terms of such license.

The information contained in this document is the exclusive property of General Electric Company except as otherwise indicated, and

shall not be disclosed or reproduced in whole or in part without prior written consent from General Electric Company.

The contents of this manual are the property of General Electric Canada. No part of this work may be reproduced or transmitted in

any form or by any means, except as permitted in written license agreement with General Electric Canada. The information contai ned

in this document is subject to change without notice.

Any attached hardware schematics and technical descriptions, or software listings that disclose source code, are for information

purposes only. Reproduction in whole or in part to create working hardware or software for other than General Electric Canada

products is strictly prohibited, except as permitted by written license agreement with General Electric Canada.

TRADEMARK NOTICES

GE and

ABB® is a registered trademark of ABB Asea Brown Boveri Ltd.; Amtrak™ is a trademark of National Railroad Passenger

Corporation; Allen-Bradley® is a registered trademark of Allen-Bradley Company Inc.; Belden® is a registered trademark of Belden

Wire and Cable Company; Boeing™ is a trademark of The Boeing Company; CDC® is a registered trademark of Control Data

Corporation; Cegelec® is a registered trademark of Cegelec Societe Anonyme France; ESCA® is a registered trademark of ESCA

Corporation; Ferranti® is a registered trademark of Ferranti International PLC; Fluke® is a registered trademark of Fluke

Corporation; Freescale™ is a trademark of Freescale Semiconductor, Inc.; GETAC® is a registered trademark of GETAC

Corporation; Harris® is a registered trademark of Harris Corporation; IEC® is a registered trademark of Commission

Electrotechnique Internationale; IEEE® is a registered trademark of The Institute of Electrical and Electronics Engineers, Inc;

Modbus® is a registered trademark of Gould Inc.; Motorola® is a registered trademark of Motorola Inc.; NEMA® is a registered

trademark of the National Manufacturer’s Association; PG&E® is a registered trademark of Pacific Gas and Electric Company;

pSOS® is a registered trademark of Wind River Inc.; Sangamo® is a registered trademark of Schlumberger Industries, Inc.; SES®

is a registered trademark of Scientific and Engineering Software, Inc.; Siemens® is a registered trademark of Siemens

Aktiengesellschaft; Sinaut® is a registered trademark of Siemens Aktiengesellschaft; Telegyr® is a registered trademark of LGZ

Landis; Telenetics® is a registered trademark of Telenetics Corporation; UCA™ is a trademark of Electric Power Research Institute,

Inc.; Valmet® is a registered trademark of Valmet Oy; and Westinghouse® is a registered trademark of Westinghouse Electric

Corporation.

Other company or product names mentioned in this document may be trademarks or registered trademarks of their respective

companies.

lectric Company.

PRPI-019-3.00-10 GE Information

Page 3

GE Grid Solutions

D20/D200 Technical Overview

iii

Contents

About this Document .....................................................................................................................1

Purpose ........................................................................................................................................ 1

Who Should Use this Document? ............................................................................................... 2

Additional Documentation .......................................................................................................... 2

Product Support .............................................................................................................................3

GE Grid Solutions Web Site ....................................................................................................... 3

GE Technical Support Library .................................................................................................... 3

Contact Technical Support .......................................................................................................... 3

What’s New.....................................................................................................................................4

D20ME II Main Processor .......................................................................................................... 4

D20EME (Ethernet/Memory Expansion) ................................................................................... 5

New D20/D200 I/O Peripherals .................................................................................................. 5

D20AC, AC Analog Input Peripheral ..................................................................................... 5

D20 High-Voltage Peripherals ................................................................................................ 6

D20K4Z Termination Module ................................................................................................ 6

New Power Supplies ................................................................................................................... 6

Multiple Language Support ........................................................................................................ 7

1. System Overview ........................................................................................................................8

1.1 System Architecture ............................................................................................................ 9

1.2 Hardware Design ................................................................................................................ 9

1.3 D20/D200 Product Comparison ........................................................................................ 10

1.4 D20 RTU Platform ............................................................................................................ 10

1.5 D200 Substation Automation Platform ............................................................................. 13

1.5.1 D200 Features .............................................................................................................. 13

1.6 D20/D200 RTU Hardware ................................................................................................ 16

1.6.1 Chassis ......................................................................................................................... 16

1.6.2 Main Processor ............................................................................................................. 17

1.6.3 Ethernet/Memory Expansion (EME) Kit ..................................................................... 19

1.6.4 Power Supplies ............................................................................................................. 19

1.6.5 Modems ........................................................................................................................ 20

1.7 I/O Peripherals .................................................................................................................. 20

1.8 Auxiliary Equipment ......................................................................................................... 21

1.9 Communications ............................................................................................................... 21

1.10 Firmware ........................................................................................................................... 22

1.11 Configuration and Maintenance Software ........................................................................ 22

GE Information PRPI-019-3.00-10

Page 4

D20/D200 Technical Overview

GE Grid Solutions

iv

1.12 System Documentation ..................................................................................................... 22

2. Detailed Technical Description ...............................................................................................25

2.1 Mechanical Design and Packaging ................................................................................... 25

2.1.1 General ......................................................................................................................... 25

2.1.2 Enclosure ...................................................................................................................... 26

2.1.3 Chassis ......................................................................................................................... 26

2.1.4 Peripheral I/O Module Assembly ................................................................................ 28

2.1.5 Environmental .............................................................................................................. 29

2.2 Main Processor.................................................................................................................. 30

2.2.1 Hardware ...................................................................................................................... 30

2.2.2 D20/D200 Main Processor Specifications ................................................................... 31

2.2.3 Firmware ...................................................................................................................... 32

2.2.4 Time Synchronization .................................................................................................. 34

2.3 Ethernet/Memory Expansion (EME) Kit .......................................................................... 36

2.4 I/O Peripheral Modules ..................................................................................................... 37

2.4.1 Types of I/O Peripherals .............................................................................................. 37

2.4.2 Termination Types ....................................................................................................... 38

2.4.3 Hardware ...................................................................................................................... 40

2.4.4 Firmware ...................................................................................................................... 41

2.4.5 I/O Processing .............................................................................................................. 43

2.4.6 D20S Digital Input Peripheral ..................................................................................... 44

2.4.7 D20A Analog Input Peripheral .................................................................................... 48

2.4.8 D20K Control Output Peripheral ................................................................................. 53

2.4.9 Interposing Relay Panel ............................................................................................... 57

2.4.10 D20C Combination I/O Peripheral ............................................................................ 59

2.4.11 D20AC, AC Analog Input Peripheral ........................................................................ 62

2.5 D20/D200 Power Supplies and Chargers ......................................................................... 64

2.5.1 D20 Power Supply Specifications ............................................................................... 65

2.5.2 D20 Battery Chargers .................................................................................................. 66

2.6 D20 Modems ..................................................................................................................... 67

2.6.1 WESDAC 202/V.23 Modem Specifications ................................................................ 68

2.7 Communications ............................................................................................................... 69

2.8 D.20 Link .......................................................................................................................... 70

2.8.1 Designing a Distributed D20 Network......................................................................... 71

2.8.2 D.20 Communication Interface .................................................................................... 72

2.8.3 Adapter Modules .......................................................................................................... 73

2.8.4 D.20 Fiber Optic Splitter .............................................................................................. 73

2.8.5 Communication Cables ................................................................................................ 74

2.8.6 Power Requirements .................................................................................................... 75

2.9 Redundancy....................................................................................................................... 75

2.9.1 D20/D200 Redundancy ................................................................................................ 76

2.9.2 D.20 Link Redundancy ................................................................................................ 77

2.10 Auxiliary Equipment ......................................................................................................... 78

2.10.1 Universal Protocol Converter .................................................................................... 78

2.10.2 Data Display Panel ..................................................................................................... 79

PRPI-019-3.00-10 GE Information

Page 5

GE Grid Solutions

D20/D200 Technical Overview

v

2.10.3 Fiber Optic Interfaces................................................................................................. 79

3. Configuration and Maintenance Software ............................................................................80

3.1 SGConfig .......................................................................................................................... 80

3.2 LogicLinx .......................................................................................................................... 80

3.3 WESMAINT ..................................................................................................................... 80

3.4 PROMAINT ...................................................................................................................... 81

3.5 68K Monitor...................................................................................................................... 81

4. Application Software ...............................................................................................................82

4.1 User Programmable Logic ................................................................................................ 82

4.2 Generation, Transmission, and Feeder Bay Automation Applications............................. 82

4.3 Distribution Automation Applications .............................................................................. 82

4.4 Communication Services Applications ............................................................................. 83

4.5 Data Logging / Storage Applications ................................................................................ 83

4.6 Data Reduction and Summarizing Applications ............................................................... 83

4.7 Data Conversion Applications .......................................................................................... 84

4.8 Other DTAs ....................................................................................................................... 84

5. Frequently Asked Questions ...................................................................................................85

5.1 What is the performance of the D20 and D200?............................................................... 85

5.2 What is the difference between the D20 and the D200? ................................................... 85

5.3 Will VME cards work with my non-VME systems? ........................................................ 85

5.4 What is the I/O capacity of a D20 system? ....................................................................... 86

5.5 What is the I/O capacity of a D200 system? ..................................................................... 86

5.6 What are the added features of the ME II Main Processor over the ME Main Processor?

86

A. Specifications and Supported Standards ..............................................................................87

B. Supported Host Protocols .......................................................................................................90

C. Supported IED Protocols........................................................................................................91

D. Power Consumption – D20 Modules .....................................................................................92

E. D20/D200 Main Processor Compatibility .............................................................................93

F. D.20 Link Installation .............................................................................................................94

GE Information PRPI-019-3.00-10

Page 6

D20/D200 Technical Overview

GE Grid Solutions

vi

Figures

Figure 1 D20ME II Main Processor.............................................................................................. 4

Figure 2 D20EME (Ethernet/Memory Expansion) ....................................................................... 5

Figure 3 GE Integrated Substation Control System ...................................................................... 8

Figure 4 D20 System Architecture ............................................................................................. 11

Figure 5 Example D20 Rack Layout .......................................................................................... 12

Figure 6 D200 Substation Automation Platform ........................................................................ 13

Figure 7 D200 System Architecture ........................................................................................... 14

Figure 8 Example D200 Rack Layout ........................................................................................ 15

Figure 9 D20 Perspective Drawing ............................................................................................. 16

Figure 10 D200 Perspective Drawing ......................................................................................... 17

Figure 11 D20ME II Main Processor.......................................................................................... 18

Figure 12 D20EME (Ethernet/Memory Expansion) ................................................................... 19

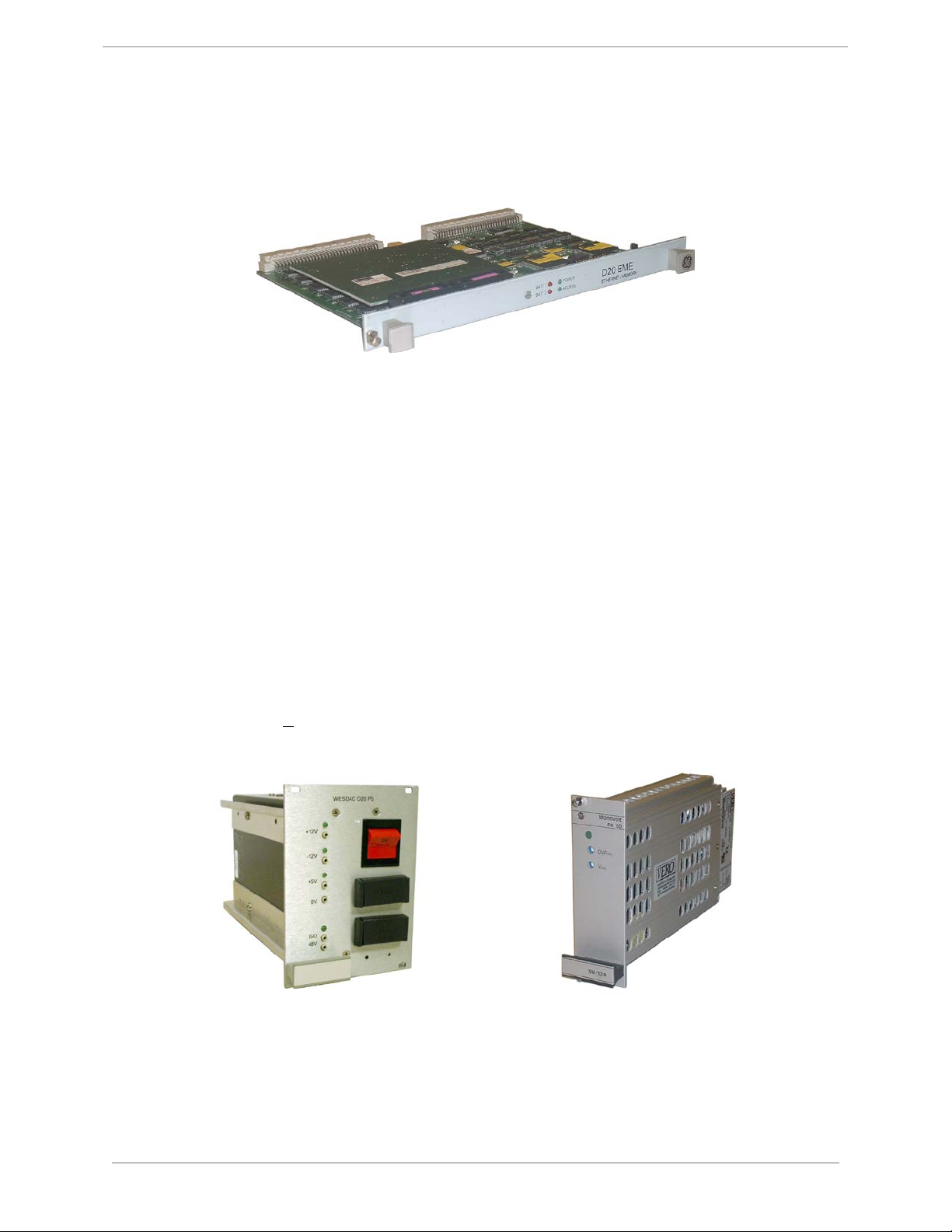

Figure 13 D20/D200 Chassis Mounted Power Supplies............................................................. 19

Figure 14 D20A I/O Peripheral................................................................................................... 20

Figure 15 D20 Chassis (non-VME version) ............................................................................... 27

Figure 16 D20 Chassis (VME version) ....................................................................................... 27

Figure 17 D200 Chassis .............................................................................................................. 28

Figure 18 D20 Peripheral I/O Module ........................................................................................ 29

Figure 19 D20ME Block Diagram .............................................................................................. 30

Figure 20 D20/D200 Time Synchronization............................................................................... 35

Figure 21 Demodulated IRIG B Signal ...................................................................................... 35

Figure 22 D20EME (Ethernet/Memory Expansion) ................................................................... 36

Figure 23 D20 I/O Peripheral - Compression Termination ........................................................ 38

Figure 24 D20 I/O Peripheral – DB25 Termination ................................................................... 38

Figure 25 D20 I/O Peripheral – Disconnect Termination ........................................................... 39

Figure 26 D20 I/O Peripheral – Barrier Termination ................................................................. 39

Figure 27 D20 Peripheral I/O Block Diagram ............................................................................ 40

Figure 28 D20S Digital Input Peripheral .................................................................................... 44

PRPI-019-3.00-10 GE Information

Page 7

GE Grid Solutions

D20/D200 Technical Overview

vii

Figure 29 D20S Digital Input Peripheral Block Diagram .......................................................... 45

Figure 30 D20A Analog Input Peripheral ................................................................................... 48

Figure 31 D20A Analog Input Peripheral Block Diagram ......................................................... 49

Figure 32 Analog Conversion Process ........................................................................................ 49

Figure 33 Three-point Linearity Correction ............................................................................... 51

Figure 34 D20K Control Output Peripheral................................................................................ 53

Figure 35 Interposing Relays ...................................................................................................... 58

Figure 36 D20 Power Supply ...................................................................................................... 64

Figure 37 D200 Power Supplies ................................................................................................. 65

Figure 38 D.20 Link Example Configuration ............................................................................. 71

Figure 39 D.20 Communications Interface ................................................................................. 72

Figure 40 D.20 Communication Interface .................................................................................. 72

Figure 41 DCI Modes of Operation ............................................................................................ 73

Figure 42 D.20 Fiber Optic Splitter ............................................................................................ 73

Figure 43 D.20 Fiber Optic Splitter ............................................................................................ 74

Figure 44 D200 Redundancy ...................................................................................................... 76

Figure 45 Single D20/D200 with Loop Redundancy ................................................................. 77

Figure 46 Single D20/D200 with Redundant LAN .................................................................... 78

Figure 47 Data Display Panel ..................................................................................................... 79

GE Information PRPI-019-3.00-10

Page 8

D20/D200 Technical Overview

GE Grid Solutions

viii

Tables

Table 1 D20/D200 Power Supply Replacements.......................................................................... 6

Table 2 D20/D200 Product Comparison...................................................................................... 10

Table 3 D20/D200 Power Supplies............................................................................................. 20

Table 4 D20/D200 Main Processor Specifications ..................................................................... 31

Table 5 D20/D200 Ethernet Media Types .................................................................................. 36

Table 6 D20/D200 I/O Peripherals ............................................................................................. 37

Table 7 I/O Processing ................................................................................................................. 43

Table 8 D20S Specifications ....................................................................................................... 47

Table 9 D20S Options ................................................................................................................. 47

Table 10 D20A Specifications .................................................................................................... 52

Table 11 D20A Options .............................................................................................................. 53

Table 12 D20K Specifications .................................................................................................... 56

Table 13 D20K Options .............................................................................................................. 57

Table 14 D20KI Options ............................................................................................................. 58

Table 15 D20C Daughter Boards ................................................................................................ 59

Table 16 D20C Specifications .................................................................................................... 60

Table 17 D20C Options .............................................................................................................. 61

Table 18 D20AC Features and Specifications ............................................................................ 62

Table 19 D20AC Options ........................................................................................................... 63

Table 20 D20/D200 Power Supplies........................................................................................... 65

Table 21 D20/D200 Battery Chargers ........................................................................................ 66

Table 22 D20/D200 Modems...................................................................................................... 67

Table 23 WESDAC 202/V.23 Modem Specifications ............................................................... 68

Table 24 D20/D200 Communications Links .............................................................................. 69

Table 25 D20/D200 Fiber Optic Links ....................................................................................... 79

PRPI-019-3.00-10 GE Information

Page 9

GE Grid Solutions

D20/D200 Technical Overview

GE Information

PRPI-019-3.00-10

1

About this Document

Purpose

This document provides a technical overview of the D20/D200 Remote Terminal Unit (RTU).

The document is organized as follows:

• What’s New: This section highlights recent additions and enhancements that have been

made to the D20/D200 product line.

• 1. System Overview: This section provides an overview of the D20/D200 system hardware

and software.

• 2. Detailed Technical Description: This section provides a detailed description of the

D20/D200 hardware, software and operation.

• 3. Configuration and Maintenance Software: This section describes utilities and

applications that are available to help you configure, manage and maintain your D20/D200

system.

• 4. Application Software: This section describes some of the substation automation and

SCADA applications that are available for the D20/D200.

• 5. Frequently Asked Questions: This appendix presents answers to frequently asked

questions about the D20/D200.

• A. Specifications and Supported Standards: This appendix lists key industry

specifications with which the D20/D200 complies.

• B. Supported Host Protocols: This appendix lists SCADA host protocols supported by the

D20/D200.

• C. Supported IED Protocols: This appendix lists IED protocols supported by the

D20/D200.

• D. Power Consumption – D20 Modules This appendix lists nominal power consumption

for D20 components, for use in power calculations.

• E. D20/D200 Main Processor Compatibility: This appendix shows the compatibility of

D20 processors with the D20/D200 chassis.

• F. D.20 Link Installation: This appendix provides guidelines on planning and installing a

D.20 Link.

Page 10

D20/D200 Technical Overview

GE Grid Solutions

2

Who Should Use this Document?

This document is a helpful resource for utility customers or GE partners who are purchasing or

evaluating a remote terminal unit or substation control system. It is intended for readers who

have knowledge of substation automation equipment and applications.

Additional Documentation

For further information about the D20/D200 product family, refer to the following documents:

• D20/D200 Installation and Operation Guide (994-0078)

• D20, D25, iBOX Automation Applications (PRPI-048)

PRPI-019-3.00-10 GE Information

Page 11

GE Grid Solutions

D20/D200 Technical Overview

3

Product Support

If you need help with any aspect of your GE Grid Solutions product, you can:

• Access the GE Grid Solutions Web site

• Search the GE Grid Solutions Technical Support library

• Contact GE Grid Solutions Technical Support

GE Grid Solutions Web Site

The GE Grid Solutions Web site provides fast access to technical information, such as manuals, release

notes and knowledge base topics.

Visit us on the Web at: http://www.gegridsolutions.com

GE Technical Support Library

This site serves as a document repository for post-sales requests. To get access to the Technical Support

Web site, go to:

http://sc.ge.com/*SASTechSupport

Contact Technical Support

The GE Grid Solutions Technical Support is open 24 hours a day, seven days a week for you to

talk directly to a GE representative.

In the U.S. and Canada, call toll-free: 1 800 547 8629

International customers, please call: +1 905 927 7070

or email to multilin.tech@ge.com

Have the following information ready to give to Customer Service:

• Ship to address (the address that the product is to be returned to)

• Bill to address (the address that the invoice is to be sent to)

The Technical Support centre will provide you with a case number for your reference.

• Contact name

• Contact phone number

• Contact fax number

• Contact e-mail address

• Product number / serial number

• Description of problem

GE Information PRPI-019-3.00-10

Page 12

D20/D200 Technical Overview

GE Grid Solutions

4

What’s New

GE Grid Solutions is pleased to announce the following additions to the D20/D200 product

family:

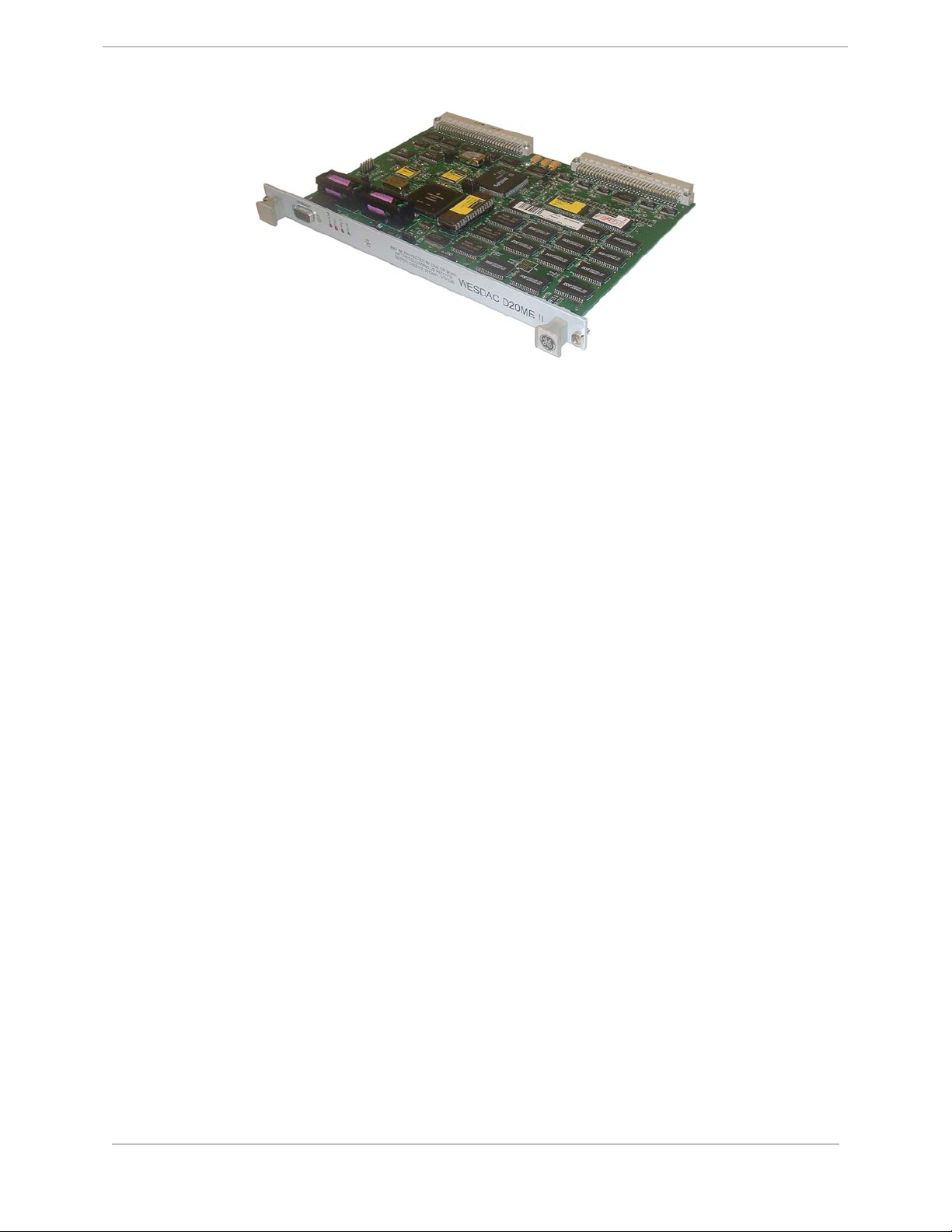

D20ME II Main Processor

The D20ME II, the fifth generation of D20/D200 processors, builds on the increased memory,

performance and communication port speed introduced with the D20ME. Where the D20ME

supports up to eight RS-232 serial ports (one of which is reserved for the maintenance port), the

D20ME II supports:

• Seven serial ports, each of which can be configured as either RS-485 or RS-232, and

• One RS-232 maintenance port.

Each D20ME II RS-485 port can communicate with up to 32 devices and operate over distances up

to 4000 feet, without the use of repeaters (see note below). The D20ME II is backwards compatible

with VME and non-VME versions of the D20 chassis, and with the D200 chassis. For more

information, see section 2.2, Main Processor.

Note: The RS-485 port on the D20ME II provides no isolation and offers limited built-in

transient suppression. If you are using the D20ME II in an environment where longer cable runs

with larger transients are expected, installation of an external transient suppression device is

recommended to protect the RTU. In addition, GE recommends the installation of an external

transient suppression device when the RS-485 communication cable must be run to devices

located outside of the RTU cabinet containing the D20ME II. Contact Customer Service for

additional information.

Figure 1 D20ME II Main Processor

PRPI-019-3.00-10 GE Information

Page 13

GE Grid Solutions

D20/D200 Technical Overview

5

D20EME (Ethernet/Memory Expansion)

The D20EME is a VME-based module that combines Ethernet support and global memory

expansion.

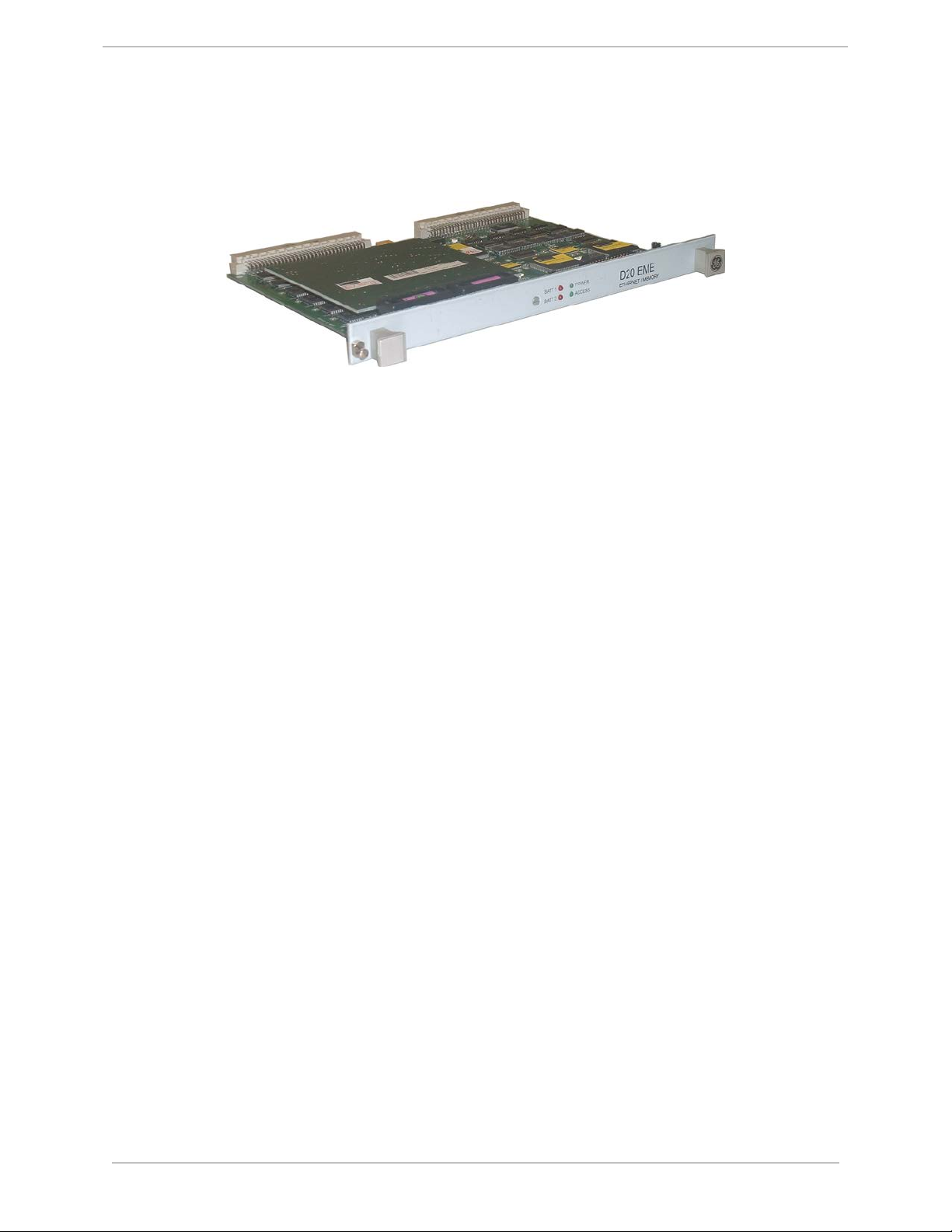

Figure 2 D20EME (Ethernet/Memory Expansion)

The D20EME allows VME-based D20 and D200 systems to be connected directly to any 10 MB

Ethernet-based network. Available configurations of the D20EME module include:

• Ethernet only

• Memory only

• Ethernet and Memory

For more information, see section 2.3, Ethernet/Memory Expansion (EME) Kit.

New D20/D200 I/O Peripherals

Several new I/O peripherals have been added to the D20/D200 product family.

D20AC, AC Analog Input Peri phe ra l

The D20AC, AC analog input peripheral provides AC analog computing and monitoring. It has

the following features:

• Up to 132 analog values and 18 accumulator values

• Direct AC analog inputs from current and voltage transformers for up to three 3-phase

circuits, eliminating the need for transducers and/or metering IEDs

• Integrated key substation functions such as metering, analog processing and power quality

measurement

• 3-element and 1-element (balanced system) metering

• Meter calculations include kW, kVArs, kVA, power factor, frequency, kWh, kVARh, kVAh

and symmetrical components.

• Power quality data: %THD (total harmonic distortion), 21st harmonic

For more information, see section 2.4.11 , D20AC, AC Analog Input Peripheral.

GE Information PRPI-019-3.00-10

Page 14

D20/D200 Technical Overview

GE Grid Solutions

6

D20 High-Voltage Peripherals

D20 high-voltage peripherals provide an extra level of protection for your system. They are

packaged similar to the standard D20 I/O peripherals, but the input and output circuits are

conditioned to handle higher voltages. For instance, the high-voltage version of the D20S, the

D20 SZ, supports ON thresholds of up to 220 VDC. For more information, see section 2.4, I/O

Peripheral.

D20K4Z Termination Module

The WESTERM D20K4Z is the termination panel for the D20K4Z high-voltage control output

module. As well as providing outputs that can withstand higher voltages, all of the control relays

on the D20K4Z termination module are 4-pole, momentary contact, so that both sides of an

interposer coil can be switched for additional control security. For more information, see section

2.4, I/O Peripheral.

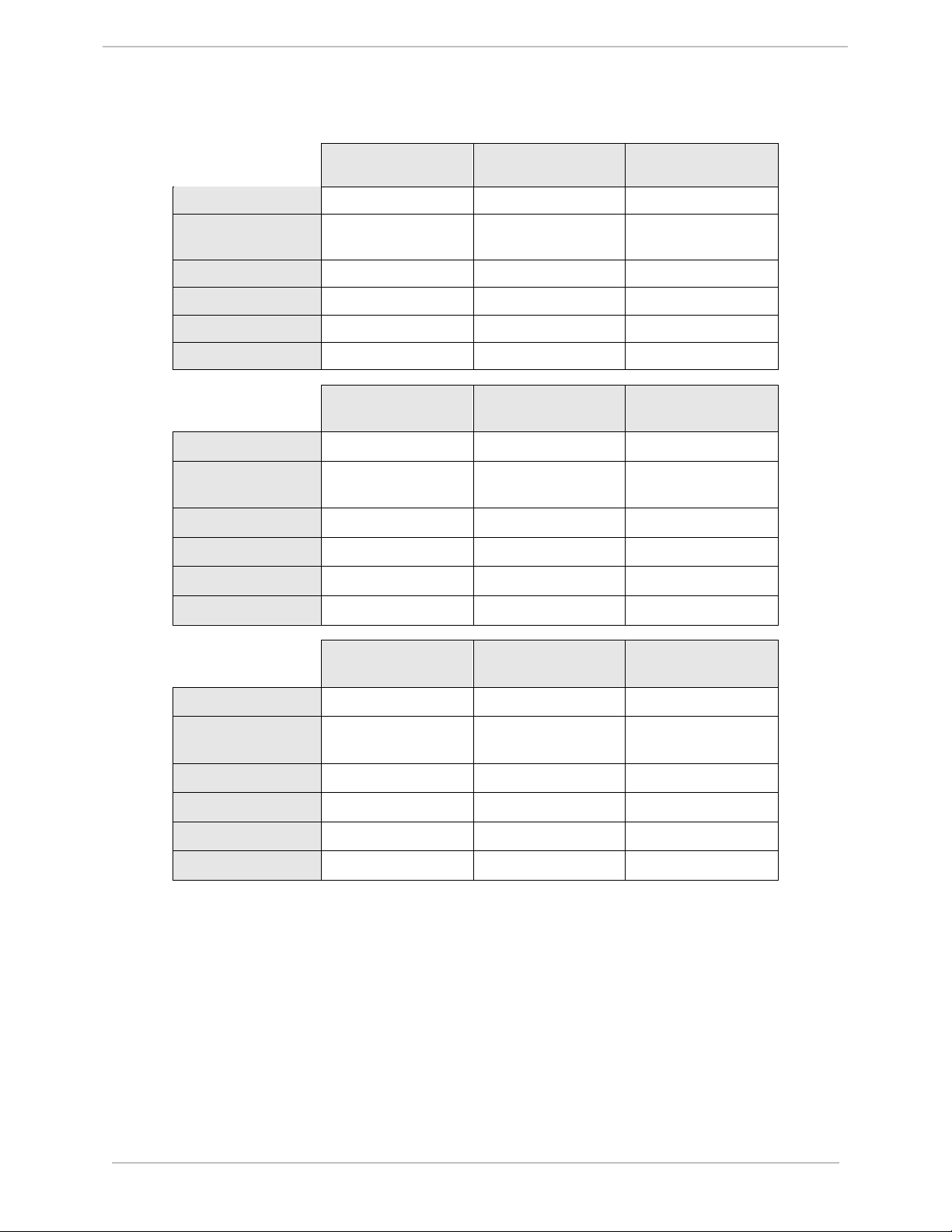

New Power Supplies

GE Grid Solutions has introduced several new D20/D200 power supplies that provide additional

capacity and improved standards compliance. The new power supplies are designed to be drop-in

replacements for the existing D20 power supplies. As shown in the following tables, each of the

existing power supplies has two possible replacements, one with a 24 V isolated output, and one

with a 48 V isolated output. For more information, see section 2.5, D20/D200 Power Supplies

and Chargers.

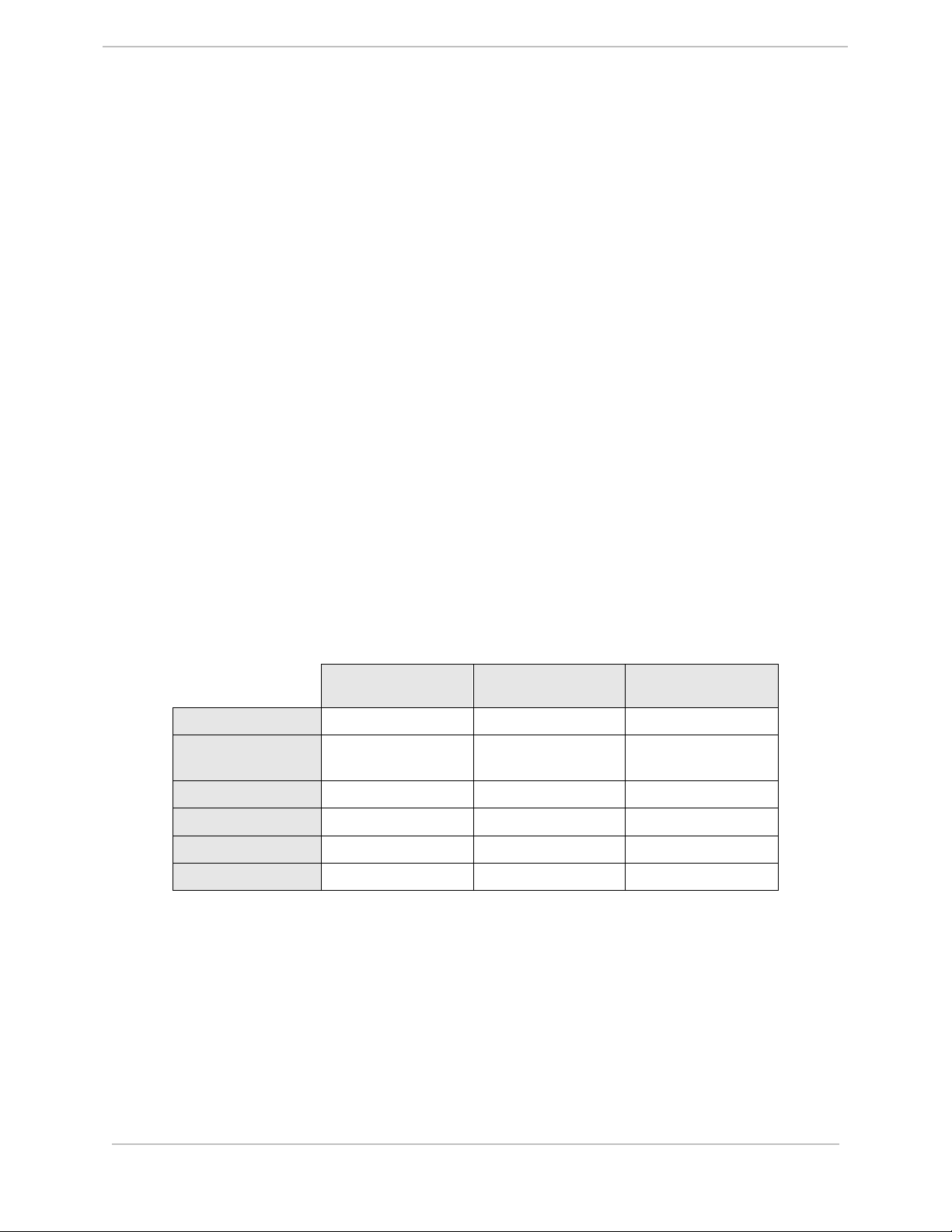

Part Number

Input Voltage Range

+5 V Current

+12 V Current

-12 V Current

ISO V/I

Table 1 D20/D200 Power Supply Replacements

Supply Phased Out Drop In Replacement

580-0240 580-2006 580-2007

90-135 VAC

5 A 7 A 7 A

1 A 2 A 2 A

½ A 1 A 1 A

24 V/3 A 24 V/3 A 48 V/1½ A

100-300 VDC or

85-264 VAC

Alternative

Replacement

100-300 VDC or

85-264 VAC

PRPI-019-3.00-10 GE Information

Page 15

GE Grid Solutions

D20/D200 Technical Overview

7

Part Number

Input Voltage Range

+5 V Current

+12 V Current

-12 V Current

ISO V/I

Part Number

Input Voltage

Range

+5 V Current

+12 V Current

-12 V Current

Supply Phased Out Drop In Replacement

580-0241 580-2006 580-2007

100-150 VDC

5 A 7 A 7 A

1 A 2 A 2 A

½ A 1 A 1 A

24 V/½ A 24 V/3 A 48 V/1½ A

Supply Phased Out

100-300 VDC or

85-264 VAC

Drop In

Replacement

580-0296 580-2004 580-2005

20-60 VDC 20-60 VDC 20-60 VDC

5 A 7 A 7 A

1 A 2 A 2 A

½ A 1 A 1 A

Alternative

Replacement

100-300 VDC or

85-264 VAC

Alternative

Replacement

ISO V/I

Part Number

Input Voltage

Range

+5 V Current

+12 V Current

-12 V Current

ISO V/I

24 V/½ A 24 V/3 A 48 V/1½ A

Supply Phased Out

Drop In

Replacement

Replacement

580-0297 580-2007 580-2006

100–300 VDC or

90–265 VAC

100-300 VDC or

85-264 VAC

100-300 VDC or

5 A 7 A 7 A

1 A 2 A 2 A

½ A 1 A 1 A

48 V/1½ A 48 V/1½ A 24 V/3 A

Alternative

85-264 VAC

Multiple Language Support

To meet the needs of our international customers, GE Grid Solutions has added multiple

language support to many of our software products that complement the D20/D200, including

PowerLink, SGConfig and WESMAINT. These products can be supplied in other languages by

request so that end users, such as system operators, can work efficiently in their native language.

Contact GE Grid Solutions for details.

GE Information PRPI-019-3.00-10

Page 16

D20/D200 Technical Overview

GE Grid Solutions

8

1. System Overview

This section provides an overview of the D20/D200 system hardware and software. More

detailed technical information can be found in 2. Detailed Technical Description.

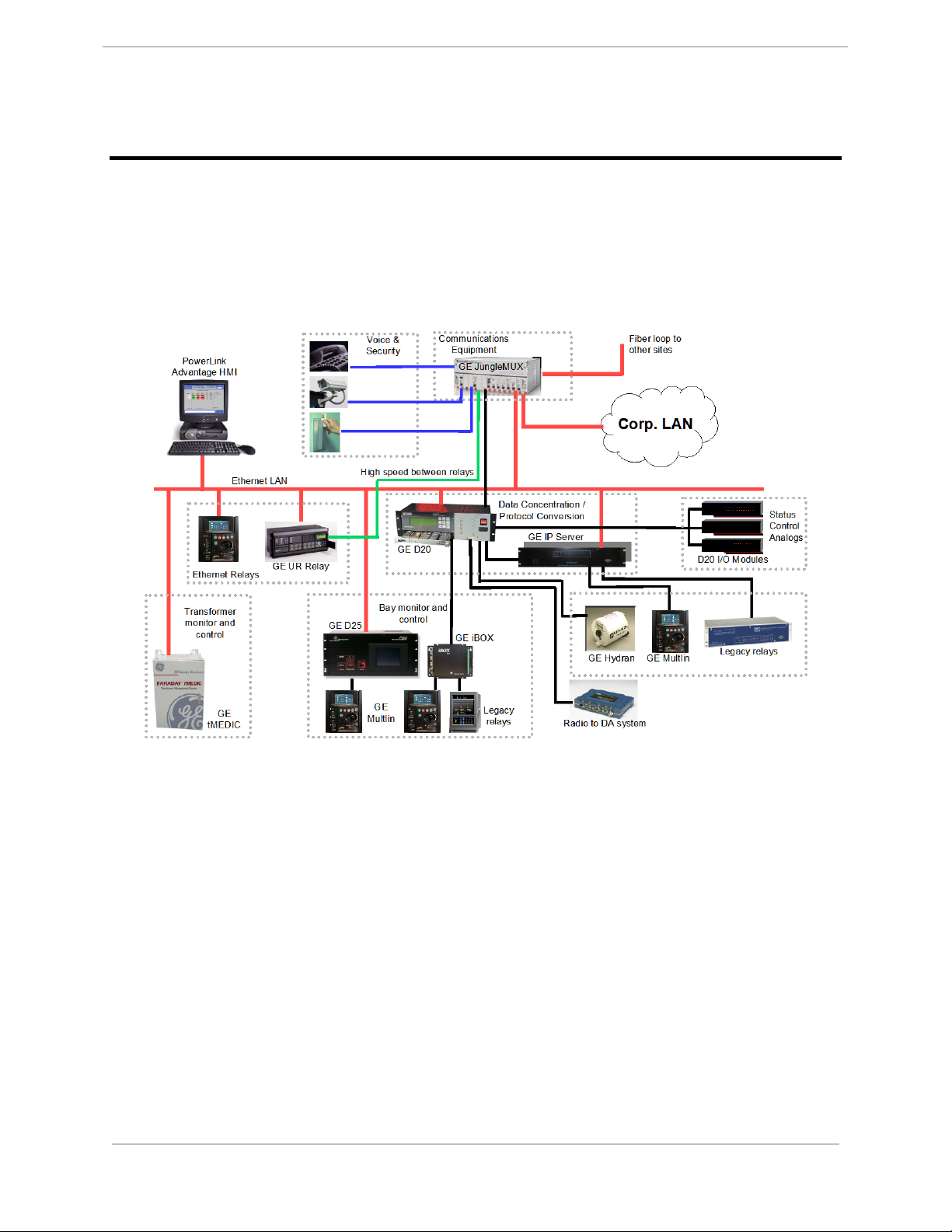

The D20/D200 is the heart of GE Grid Solutions’s iSCS (Integrated Substation Control System),

as illustrated in Figure 3.

The D20/D200 provides substation server functionality in a mission-critical, substation-hardened

package. The D20/D200 has a distributed architecture for gathering data from, and controlling,

substation equipment.

The D20/D200 is available with a broad range of:

• SCADA host protocols (see C. Supported Host Protocols)

• IED protocols (see D. Supported IED Protocols)

• Communication options (see section 2.7, Communications)

• Input/output (I/O) peripheral modules (see section 2.4, I/O Peripheral)

• Operation and maintenance utilities (see 3. Configuration and Maintenance Software)

• Substation automation applications (see 4. Application Software)

Figure 3 GE Integrated Substation Control System

PRPI-019-3.00-10 GE Information

Page 17

GE Grid Solutions

D20/D200 Technical Overview

9

1.1 System Architectur e

The D20/D200 is based on a distributed processing architecture that consists of one or more

main processors, peripheral I/O modules, termination panels, power supplies and

communications equipment.

The main components of a D20/D200 system are:

• D20/D200 main chassis, equipped with processor(s), power supply, RS-232/485 ports

• Input/output peripheral modules

• Auxiliary equipment

• Communications interfaces

• Application firmware

• Configuration and maintenance software

• User manuals

The main processor communicates with I/O peripherals over proprietary high-speed D.20

communications links. General-purpose RS-232 and RS-485 serial ports provide

communications with a variety of external devices, including substation equipment (IEDs, for

example), local printers, operator terminals, and SCADA computers.

Field data acquired by the D20/D200 is maintained in the system database, where it can be

accessed and processed by different application programs.

1.2 Hardware Design

The D20 and D200 hardware designs are based on:

• Distributed processing architecture which permits the sharing of I/O data processing between

the main processor and I/O peripheral processors

• CMOS logic devices for low power consumption, noise immunity and high reliability

• Advanced 32-bit Freescale™ 68030 (D20ME and ME II) and 68HC11 (D20 I/O peripherals)

single-chip microcontrollers

• Programmable logic devices (PLD) to provide flexibility and reliability, and to reduce the

physical space taken up by logic circuits

• 9600-baud maintenance port

• D.20 HDLC link over a shielded cable or a glass/plastic fiber optic cable

The modular design of the D20/D200 allows for easy expansion when you need additional

processing power or communication ports.

GE Information PRPI-019-3.00-10

Page 18

D20/D200 Technical Overview

GE Grid Solutions

10

1.3 D20/D200 Product Comparison

Table 2 summarizes the key differences between the D20 and the D200.

Table 2 D20/D200 Product Comparison

Maximum Processor

Boards

Maximum I/O Boards

VME Backplane

Maximum Serial Ports

Base Software

Applications Software

Typical Number of

Applications *

1 - non-VME chassis

3 - VME chassis

31 (without repeaters)

120 (with repeaters)

Optional Standard

7 + 1 Maintenance Port – Non-VME chassis

21 + 3 Maintenance Port – VME chassis

Standard D20 Base, CCU Base CCU Base

Full suite of GE Grid Solutions automation

application software and protocols

5 - 7 * 5 - 7 per node *

D20 D200

7

124 (without repeaters)

480 (with repeaters)

49 + 7 maintenance ports

Full suite of GE Grid Solutions

automation application

software and protocols

* Each D20/D200 application has specific memory and processing requirements. The number

of applications that can be supported is therefore system-specific, and this will be

determined during system engineering. If the applications you require are particularly

processor or memory-intensive, the number that can be supported may be less than that

shown in Table 2. Likewise, if the applications are not particularly processor or memoryintensive, the number that can be supported may be higher than that shown. Contact GE

Grid Solutions for further information.

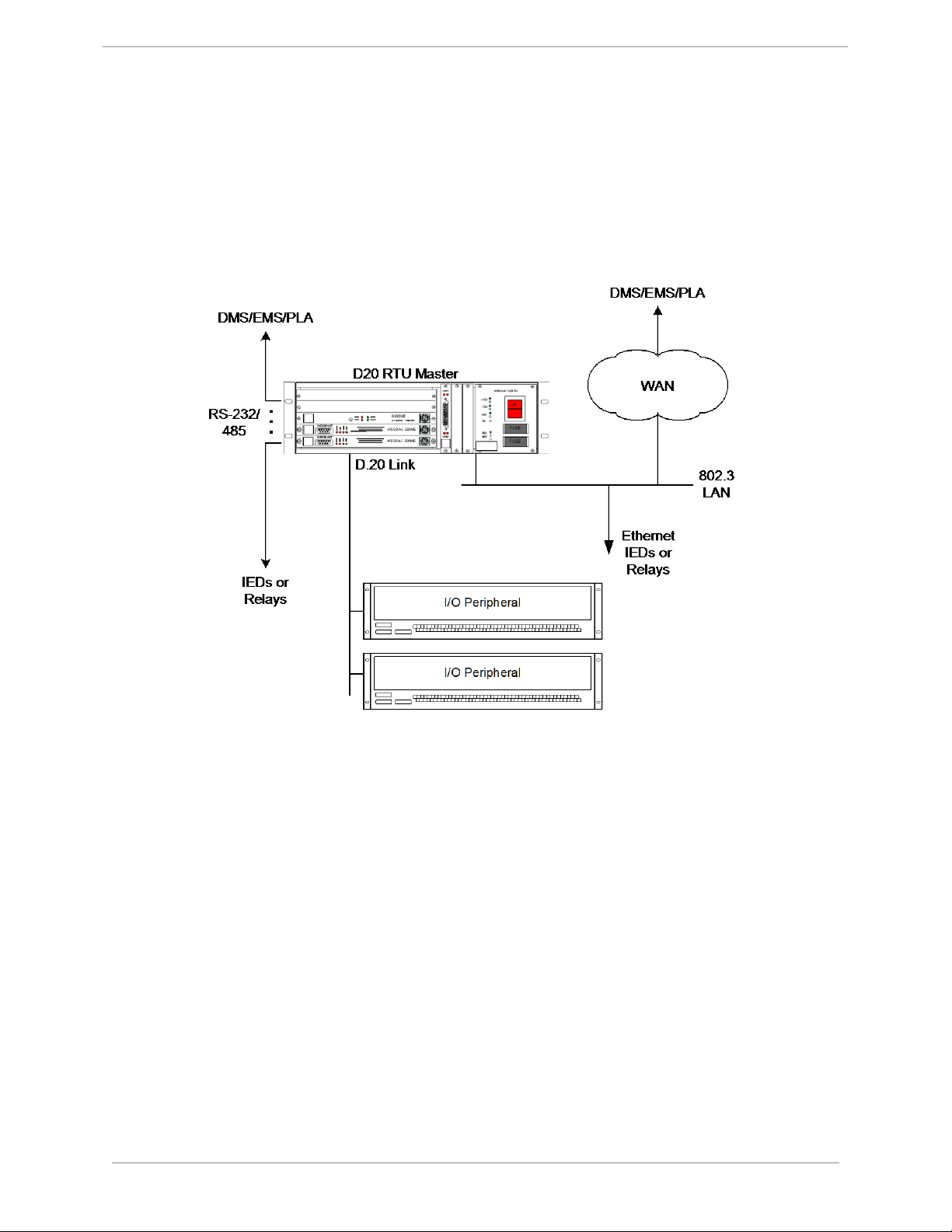

1.4 D20 RTU Platform

There are two types of D20 RTU masters:

• Single-slot (or non-VME) – One processor

• Five-slot VME – Up to three processors plus Ethernet

The D20 hardware consists of a rack-mountable chassis containing one or more processor

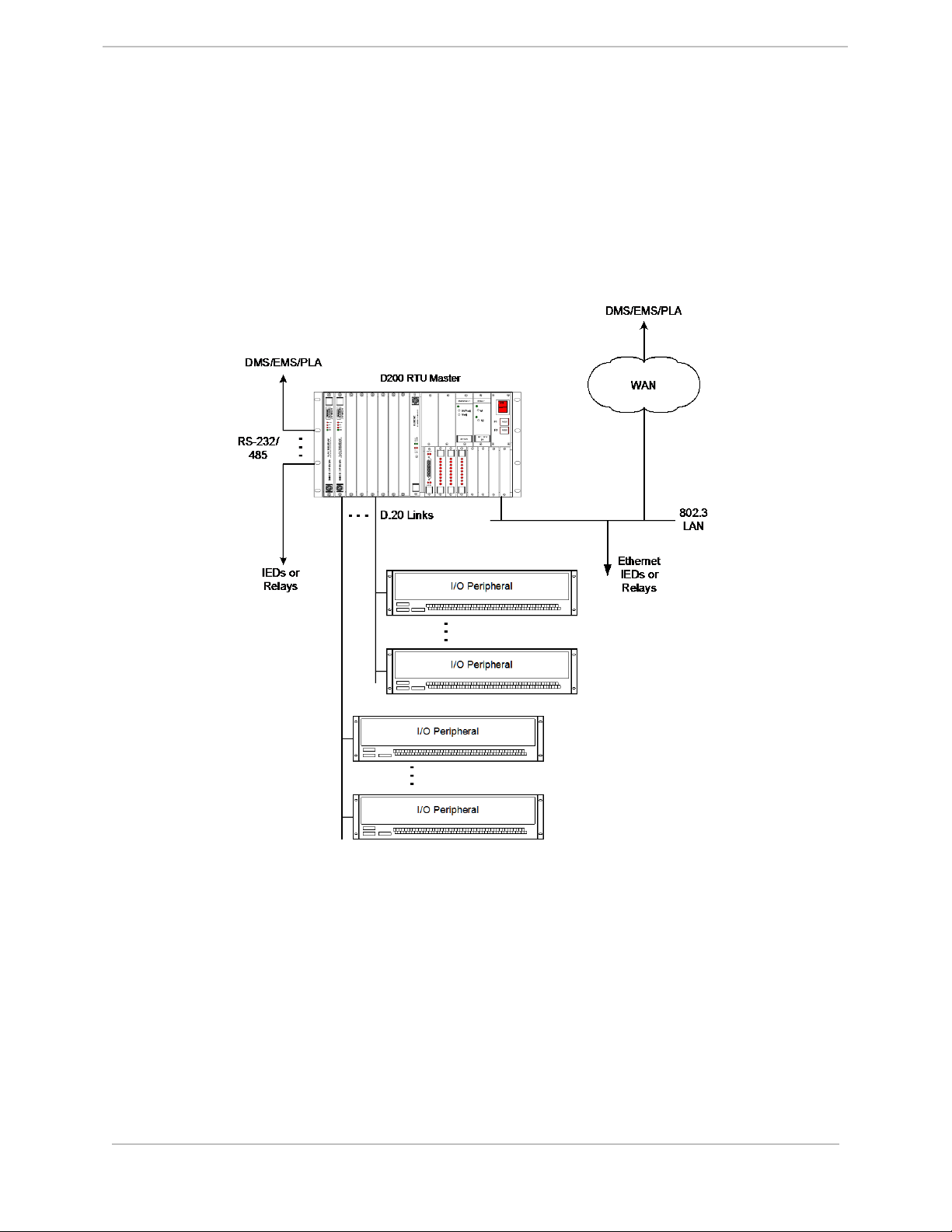

boards, power supplies and modems. As shown in Figure 4, the D20 interfaces with substation

equipment either through peripheral I/O modules, or directly through RS-232, RS-485, or

Ethernet links.

PRPI-019-3.00-10 GE Information

Page 19

GE Grid Solutions

D20/D200 Technical Overview

11

The D20 can support up to:

• Two D.20 ports, each supporting up to 31 I/O peripherals, without repeaters, and 120 I/O

peripherals, with repeaters

• 21 RS-232 or RS-485 ports (7 per processor board)

• Two Ethernet channels

Figure 4 D20 System Architecture

GE Information PRPI-019-3.00-10

Page 20

D20/D200 Technical Overview

GE Grid Solutions

12

1

10

20

30

42

40

Optional second 7 COM port

panel

UPC

WESDAC D20A

WESTERM D20A

DUCT PANEL

WESDAC D20S

WESTERM D20S

DUCT PANEL

WESDAC D20K

WESTERM D20K

DUCT PANEL

D20 CHASSIS

(with 7 COM ports)

An example of a D20 rack layout is shown in Figure 5.

Figure 5 Example D20 Rack Layout

PRPI-019-3.00-10 GE Information

Page 21

GE Grid Solutions

D20/D200 Technical Overview

13

1.5 D200 Substation Automation Platform

The D200 has the computing power and expandability needed to provide substation automation

in larger substations. This is achieved through an innovative design that employs multiple D20

processors, communicating over a VME bus.

Figure 6 D200 Substation Automation Platform

The D200 has the processing power to monitor and control thousands of I/O points. It can run

sophisticated automation applications, such as our LogicLinx* programmable logic control,

without compromising performance.

GE Grid Solutions has installed D200 systems with point counts exceeding 80,000. Contact GE

Grid Solutions for further information on engineering large systems.

1.5.1 D200 Features

• RS-232/RS-485 ports support large numbers of host systems and IEDs

• VME bus architecture provides high scalability and performance for adding serial ports,

LAN options, and memory

• Data is integrated and coordinated, so different applications access a single, real-time

database

• Optional redundant configuration for high reliability at critical sites (see section 2.9,

Redundancy)

• Hardened to perform critical control functions in the substation environment, in accordance

with applicable IEEE® and IEC® standards

GE Information PRPI-019-3.00-10

Page 22

D20/D200 Technical Overview

GE Grid Solutions

14

D200 hardware is similar in design to the D20 hardware, but it has significantly more physical

capacity. Based on a 9-slot VME chassis, the D200, illustrated in Figure 7, can support up to:

• 4 D.20 ports, each supporting up to 31 I/O peripherals, without repeaters, and 120 I/O

peripherals, with repeaters

• 49 RS-232 or RS-485 ports (seven per D20ME or D20ME II Main Processor)

• Two Ethernet channels

Figure 7 D200 System Architecture

PRPI-019-3.00-10 GE Information

Page 23

GE Grid Solutions

D20/D200 Technical Overview

15

FAILOVER SUPPLY

L/R SWITCH PANEL

DUCT PANEL

FAILOVER SUPPLY

D200 CCU CHASSIS

UPC

DUCT PANEL

DUAL MODEM PANEL

POWER BAR

1

10

20

30

42

40

POWER BAR

DUCT PANEL

WESDAC D20K

WESTERM D20K

DUCT PANEL

WESDAC D20K

WESTERM D20K

DUCT PANEL

WESDAC D20S

WESTERM D20S

DUCT PANEL

WESDAC D20S

WESTERM D20S

DUCT PANEL

WESDAC D20A

WESTERM D20A

DUCT PANEL

WESDAC D20A

WESTERM D20A

DUCT PANEL

BLANK PANEL

BLANK PANEL

D.20 DC INTERFACE

An example of a D200 rack layout is shown in Figure 8.

Figure 8 Example D200 Rack Layout

GE Information PRPI-019-3.00-10

Page 24

D20/D200 Technical Overview

GE Grid Solutions

16

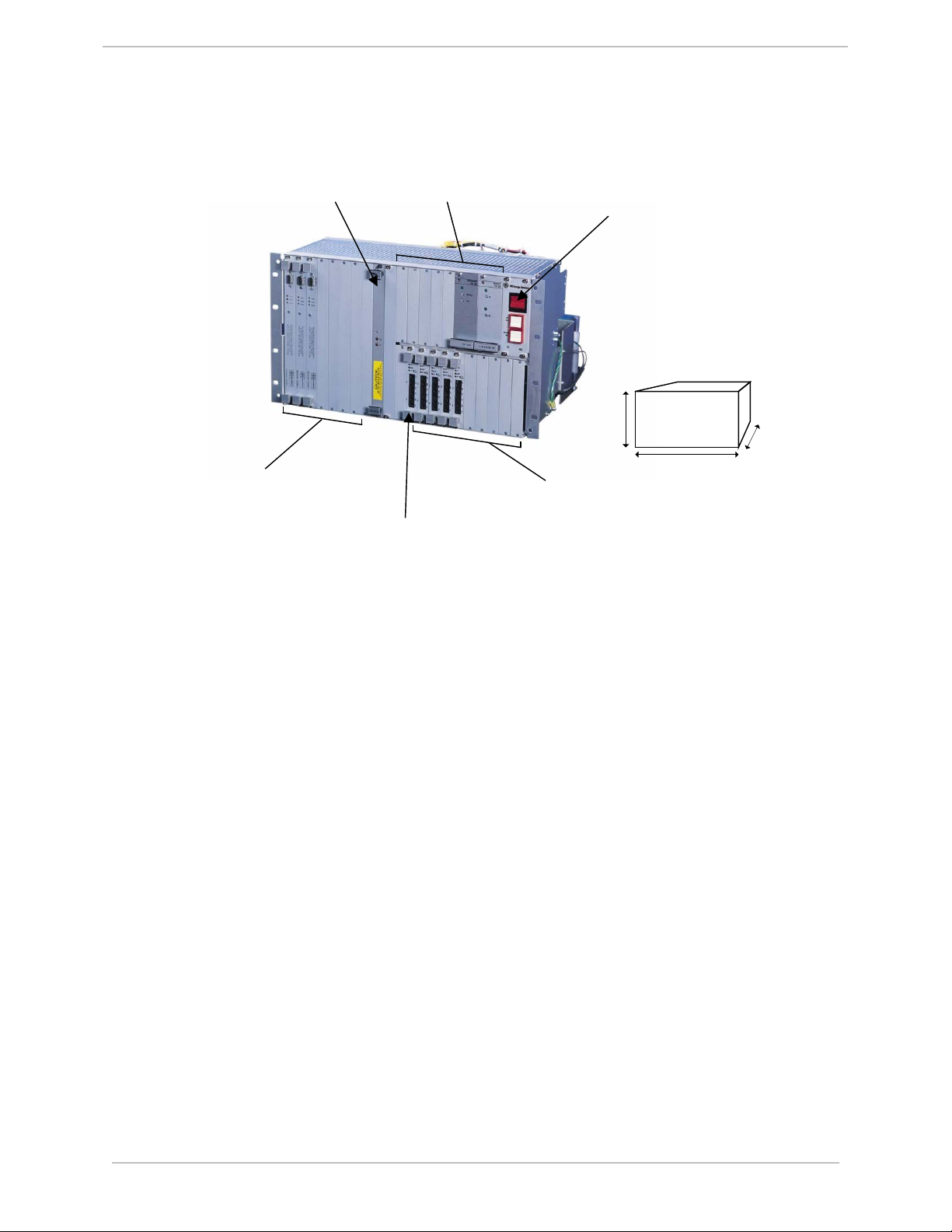

D20ME or D20ME II

Main Processor (up to 2)

D20EME Ethernet

Memory Expansion

Module

Power Supply

Media Interface

Cards

Modem

5.25

in

8.5 in

19.0 in

1.6 D20/D200 RTU Hardware

1.6.1 Chassis

The D20 and D200 chassis feature a VME/Eurocard design for mounting plug-in D20 modules:

• Main Processor

• Power Supplies

• Modems

• Ethernet/Memory Expansion Module

• Media Interface Card

For convenience, maintenance ports, test points, indicators and power switches are brought out to

the front of the chassis. With VME versions of the D20 and D200 chassis, external connections

are provided through rear-mounted termination panels.

1.6.1.1 D20 Chassis

The D20 chassis is available in a single-slot Eurocard version, or a five-slot VME version. The

single-slot chassis provides one horizontal double-size Eurocard slot for mounting the D20

processor card. It is equipped with an integral D20 termination board for customer power and

field connection, and for serial-port access.

The VME chassis is equipped with five horizontal expansion slots for use with VME compatible

printed circuit boards. A separate termination board is required with the full VME chassis. The

VME D20 chassis can support up to:

• Three D20 processor cards

• Two D.20 ports, each supporting up to 31 peripherals without repeaters or 120 I/O

peripherals with repeaters

• Twenty-one RS232 or RS-485 ports (seven per main processor)

• Two Ethernet ports

Figure 9 D20 Perspective Drawing

PRPI-019-3.00-10 GE Information

Page 25

GE Grid Solutions

D20/D200 Technical Overview

17

Power Switch / Fuse Panel

D20EME Ethernet Memory

Expansion Module

Media Interface Card

(MIC)

Modem Slots (seven if M IC

installed, eight otherwis e)

D20ME or D20ME II

Main Processors

(up to seven)

Up to four Power Supplies

10.5 in

19 in.

14 in.

1.6.1.2 D200 Chassis

The D200 chassis is a nine-slot VME chassis that can support up to:

• Seven D20 processor cards

• Four D.20 ports supporting up to 124 peripherals without repeaters and 480 I/O peripherals

with repeaters

• 49 RS-232 or RS-485 ports (seven per main processor)

• Two Ethernet ports

1.6.2 Main Processor

The design of the D20 main processor has evolved with improvements in processor performance

and electronic packaging technology. Previous versions of the D20 main processor (D20M,

D20M+ and D20M++), although no longer available, are still operating at many locations. The

current versions of the D20 main processor (D20ME and D20ME II) are described below. For a

detailed description of the main processors, see section 2.2, Main Processor.

Compatibility of the different versions of the D20/D200 main processors and chassis is listed in

E. D20/D200 Main Processor Compatibility.

Figure 10 D200 Perspective Drawing

GE Information PRPI-019-3.00-10

Page 26

D20/D200 Technical Overview

GE Grid Solutions

18

Figure 11 D20ME II Main Processor

1.6.2.1 D20ME

The D20ME Main Processor:

• Concentrates data from substation equipment, then processes and forwards this data to the

SCADA Master

• Receives control actions from the SCADA Master and forwards these actions to substation

equipment

• Depending on the application software supported on the unit, initiates control actions based

on the status of the substation equipment

• Processes maintenance commands received through the WESMAINT port.

The D20ME interfaces with substation equipment through:

• D20 I/O Peripherals

• RS-232 ports (eight RS-232 ports per D20ME, one of which is the maintenance port)

• Ethernet ports (two per D20/D200)

1.6.2.2 D20ME II

In addition to the D20ME functionality described above, the D20ME II main processor can be

configured to support RS-485 communications on any of seven serial ports (the eighth is

reserved for the RS-232 WESMAINT port). Through each of the RS-485 serial ports, the

D20/D200 can communicate point-to-multipoint with large numbers of end devices, out to a

distance of 4000 feet.

PRPI-019-3.00-10 GE Information

Page 27

GE Grid Solutions

D20/D200 Technical Overview

19

1.6.3 Ethernet/Memory Expansion (EME) Kit

The D20EME is a VME-based module that combines Ethernet support and global memory

expansion.

Figure 12 D20EME (Ethernet/Memory Expansion)

The D20EME allows VME-based D20 and D200 systems to be connected directly to any

10 Mbps Ethernet-based network. Available configurations of the D20EME module include:

• Ethernet only

• Memory only

• Ethernet and Memory

For more information, see section 2.3, Ethernet/Memory Expansion (EME) Kit.

1.6.4 Power Supplies

The D20 switch-mode power supply, installed in the D20 chassis, provides power to the units

that are installed in the chassis, and up to five D20 I/O peripherals depending on the hardware

configuration. For larger systems with more than five I/O peripherals, an external power supply

is always required. D200 power supplies provide power to multiple processors and are

configured as separate +12 and 5 V supplies.

Figure 13 D20/D200 Chassis Mounted Power Supplies

GE Information PRPI-019-3.00-10

Page 28

D20/D200 Technical Overview

GE Grid Solutions

20

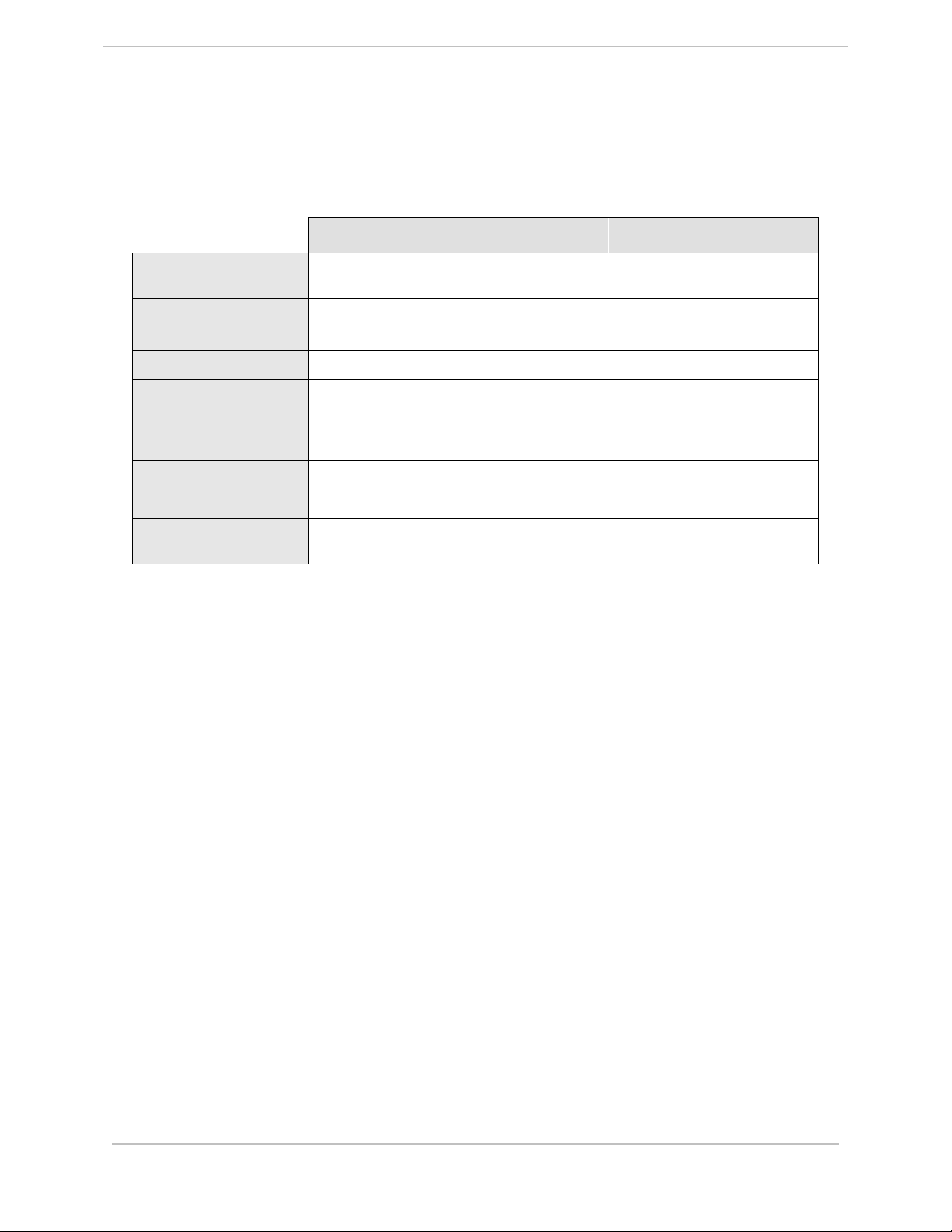

Several types of power supplies are available for D20/D200 systems:

Table 3 D20/D200 Power Supplies

Power Supply Type Features

Standard chassismounted

External Required for large numbers of I/O peripherals or modems.

Redundant Provides fail-over protection and delivers continuous power to the D20 modules and

• Chassis-mounted

• Switch-mode converters

• Provides power for all modules in the chassis, including the main processor, VME

cards, modems.

peripherals.

For a listing of available power supplies, refer to section 2.5, D20/D200 Power Supplies and

Chargers.

1.6.5 Modems

GE Grid Solutions offers a wide range of D20/D200 modems to provide communication between

the D20/D200 and SCADA host computers or remote devices, including proprietary WESDAC

modems and third-party modems from vendors such as Telenetics® and Westermo. For more

information, see section 2.6, D20 Modems.

1.7 I/O Peripherals

A range of I/O peripherals is available to provide expandable input/output functionality for the

D20/D200.

The following types of I/O peripherals meet various input/output requirements.

• D20A – 32-channel DC analog input module

• D20K – 32 control relay module

• D20KI – 8 interposer relay module (up to four D20KIs per D20K)

• D20S – 64-channel digital input module

• D20C – Combination of 16 digital inputs and 8 digital outputs. Optional 16 analog inputs, or

8 analog inputs and 8 analog outputs.

Figure 14 D20A I/O Peripheral

PRPI-019-3.00-10 GE Information

Page 29

GE Grid Solutions

D20/D200 Technical Overview

21

• D20AC – Up to 15 direct AC inputs and 1 DC analog input

For a detailed description, see section 2.4, I/O Peripheral.

D20 I/O peripherals are available in standard and high-voltage versions. The high-voltage

versions of the peripherals are electrically more robust than the standard versions, and meet a

broader range of industry standards. These standards, which include IEC standards for

electrostatic discharge, RFI susceptibility, electrical stress, and vibration, are described in A.

Specifications and Supported Standards.

1.8 Auxiliary Equipment

GE Grid Solutions offers a selection of auxiliary equipment to support specific substation

applications, including:

• Interposing relay panels for applications requiring heavy-duty control ratings

• Universal protocol converter to interface with devices that use synchronous protocols

• Data display panel to view any data point on a built in LCD screen

• Fiber optic interfaces

For more information, see section 2.10, Auxiliary Equipment.

1.9 Communications

The D20/D200 interfaces with peripherals and external devices over several types of

communications facilities:

• RS-232

• RS-485

• D.20 Link

• Ethernet

For a detailed description, see section 2.7, Communications.

GE Information PRPI-019-3.00-10

Page 30

D20/D200 Technical Overview

GE Grid Solutions

22

1.10 Firmware

The D20/D200 software is based on a core set of software modules, collectively referred to as

the base system. The base system is programmed into the D20/D200 on-board flash memory as

firmware. Processing and data acquisition functionality is distributed between the I/O peripheral

processors, which have similar but smaller base systems, and the D20 main processor. The base

system for the D200 is commonly referred to as the CCU base system. For a detailed description,

see section 2.2.3 , Firmware.

D20/D200 base systems have the following features:

• System calls are available for user-generated software

• D20 peripheral firmware and processes

• Support of libraries and processes for a wide range of I/O devices

• Database manager facility (WESDAC Interface Node)

• Background system diagnostics

• Comprehensive diagnostic and maintenance facility support (WESMAINT)

1.11 Configuration and Maintenance Software

The D20/D200 is equipped with a range of maintenance utilities to assist the user in configuring,

testing and monitoring the system:

• SGConfig, a PC-based tool for configuring D20/D200 hardware and software remotely over

a network or locally through the maintenance port.

• LogicLinx, an IEC 61131-3 compliant soft logic automation tool comprising a executor

running in the D20/D200 firmware and PC-based editor for creating PLC-like programs.

• WESMAINT is a maintenance facility that resides on the D20 and D200 accessed through a

simple terminal to view collected data and system status and, for some applications, make

changes to the configuration.

• 68K Monitor, an on-board advanced diagnostic tool accessed thorough a terminal interface

and used for troubleshooting, including memory examination, dumping and editing, setting

break points, and CPU usage and process profiling.

For a detailed description, see 3. Configuration and Maintenance Software.

1.12 S ystem Doc um entation

A full suite of D20/D200 user documentation is provided with each system:

• Hardware Manual, consisting of:

− Hardware installation, operation and maintenance guides

• Software Manual, consisting of:

PRPI-019-3.00-10 GE Information

Page 31

GE Grid Solutions

D20/D200 Technical Overview

23

− Software configuration guides

− Maintenance utility user guides

• Site-Specific Manual, consisting of:

− Bills of Material

− Rack layouts

− Configuration tables

− Termination lists

− Cabling schematics

− Module layout drawings (complete with wiring and jumper configuration instructions).

GE Information PRPI-019-3.00-10

Page 32

Page 33

GE Grid Solutions

D20/D200 Technical Overview

25

2. Detailed Techni cal Description

This section describes the D20/D200 hardware and software design & operation in more detail.

2.1 Mechanical Design and Packaging

2.1.1 General

The design of the D20/D200 packaging was driven by the following electric utility requirements:

• Environmental standards required by the power utility and resource industries

• Compliance with worldwide industry standards

• Maintainability – Minimize the requirement for, and simplify, routine maintenance

• Reliability – Maximize the Mean Time Between Failure and minimize Mean Time To

Restore

• Packaging efficiency

• Safety

To achieve these requirements, D20/D200 packaging is based on:

• Compact modules designed for industry-standard 19" (483 mm) rack mounting.

• VME/Eurocard architecture

• Front access provided on peripheral I/O modules for easy access to field terminations,

displays and auxiliary hardware

• Electronics and logic circuits are easily removed from fixed I/O termination panels, without

powering down the equipment or disconnecting field termination

• High-quality metal panels for all chassis, mountings, panels and terminations

• Corrosion-resistant finishes and anodized parts, for resistance to rust, oxidization and

scratching

• Gold-plated connectors and sockets where necessary, tin or nickel-palladium plated

connectors and sockets otherwise

• Connectors, integrated circuit sockets and terminations providing secure positive connections

• Separate termination boards for customer connections and serial I/O access

• Standard screw compression-type terminal blocks, capable of terminating a single #12 AWG

• Industry-standard FR-4 epoxy glass printed circuit boards, coated with solder mask

[2.05mm] wire supplied for field I/O terminations. Optional DB25 connectors, removable

terminals or customer-specified terminal blocks provide flexible termination schemes.

GE Information PRPI-019-3.00-10

Page 34

D20/D200 Technical Overview

GE Grid Solutions

26

• Intermodule wiring mechanically protected and separated from field cabling

2.1.2 Enclosure

To meet specific customer requirements, GE offers a wide range of equipment enclosures,

including NEMA® 1, 4, 4X and 12 standard wall-mount, freestanding or swing frame cabinets.

The standard cabinet color is beige. Custom colors (e.g. ASAG/gray) are available by request. As

well, a complete line of accessories, such as lighting, AC outlets, and door locks, are available as

options.

2.1.3 Chassis

D20/D200 chassis assemblies are 19” rack-mountable and based on Eurocard/VME

(VersaModular Eurocard) standards. The chassis provides mounting and interconnection for the

following D20 modules:

• Main processors

• Power supplies

• Modems

• Ethernet/Memory expansion

• Media interface cards

Power switches, test points and indicators are mounted on the front of the D20 modules. Rearmounted back planes are used to interconnect the VME bus positions and to provide cable and

wire-harness interfaces.

Depending on your application, the following types of chassis are available:

• D20 Chassis (non-VME)

• D20 Chassis (VME)

• D200 Chassis (VME)

2.1.3.1 D20 Chassis (non-VME)

The D20 chassis is a 3U horizontal slot chassis. Non-VME versions of the D20 provide a single

horizontal Eurocard slot, into which the D20ME board is installed:

PRPI-019-3.00-10 GE Information

Page 35

GE Grid Solutions

D20/D200 Technical Overview

27

Figure 15 D20 Chassis (non-VME version)

The non-VME version of the D20 chassis is equipped with a rear-mounted termination board that

provides power connection and serial port access to the D20 system.

2.1.3.2 D20 Chassis (VME)

The VME version of the D20 chassis is equipped with five horizontal expansion slots for VMEcompatible modules:

Figure 16 D20 Chassis (VME version)

The VME version of the D20 chassis is equipped with a rear-mounted termination board for

power connections and serial ports for one processor board. An optional rack-mounted serial port

panel is available to support the seven serial ports on a second processor board.

GE Information PRPI-019-3.00-10

Page 36

D20/D200 Technical Overview

GE Grid Solutions

28

2.1.3.3 D200 Chassis

The D200 is a vertical-slot VME chassis, as shown in Figure 17.

Figure 17 D200 Chassis

The D200 chassis is equipped with a rear-mounted termination board for power connections and

serial-port access.

2.1.4 Peripheral I/O Module Assembly

D20 peripheral I/O modules consist of two separate assemblies - a logic panel and a field

termination panel. See Figure 18.

The logic panel contains all of the logic circuitry and active components in the peripheral I/O

module. The termination panel provides terminations for all field I/O, power, and maintenance

connections, as well as connection to the upstream and downstream D.20 links. The termination

panel is designed for flat mounting or 19” rack mounting.

PRPI-019-3.00-10 GE Information

Page 37

GE Grid Solutions

D20/D200 Technical Overview

29

Acrylic Display

Cover

Terminal Blocks

WESTERM Termination Panel

WESDAC Logic Panel

Metal Mounting

Plate

Figure 18 D20 Peripheral I/O Module

The logic panel is housed in a metal enclosure, which plugs directly into the termination panel.

The logic panel enclosure is faced with a semi-transparent acrylic cover, which allows the user to

monitor LED displays for various peripheral functions and field I/O points.

If a unit fails, the operator unplugs the failed logic panel and replaces it with a working unit

while the power remains on. Once the new unit is installed, the D20/D200 automatically

downloads the appropriate operating software and database parameters to the module to make it

operational.

2.1.5 Environmental

Typical operating temperature range of -10°C to +55°C and a relative humidity range of 0 to

95%, non-condensing.

Note: At higher extremes of the temperature and humidity operating ranges (i.e., when

temperature and humidity are both high), occasional errors may be observed on RS485/D.20 links; however, packets with errors are detected and retransmitted by the data

communications protocol. The net result is error-free communications.

Storage conditions, with equipment de-energised: temperature range of -40°C to +80°C (0°C to

+70°C for Graphics Display) and relative humidity less than 95%, non-condensing.

GE Information PRPI-019-3.00-10

Page 38

D20/D200 Technical Overview

GE Grid Solutions

30

CPU/CONTROL

SERIAL

I/O

INTERRUPT

CONTROL

MEMORY

VME BUS

INTERFACE

Data Address and

Control Buses

2 D.20 HDLC Ports

7 RS-232 Ports

Wesmai nt Port

VME Interrupts

Local Interrupts

VME Bus

2.2 Main Processor

D20ME and D20ME II, which are the main processors for the D20/D200, act as master

controllers over D20 peripheral I/O modules, which serve as slaves. The main processors

function as data concentrators and central processors of field data. The D20 I/O peripheral

modules perform the primary processing of data, which increases the speed and efficiency of the

D20, by reducing the workload on the main processor.

Note: In the following sections, references to the D20ME apply also to the D20ME II,

unless explicitly stated.

2.2.1 Hardware

The D20ME is an advanced, single board, VME-bus-compatible central processing unit. It uses a

real-time multi-tasking operating system that supports all standard SCADA/EMS related

functions and advanced custom applications. It features high-speed CMOS logic devices that

ensure low power consumption, noise immunity and reliability.

Figure 19 D20ME Block Diagram

PRPI-019-3.00-10 GE Information

Page 39

GE Grid Solutions

D20/D200 Technical Overview

31

The D20ME consists of five distinct interacting circuit blocks, as shown in Figure 19.

• CPU/Control performs data processing, device addressing and system control. The D20ME

uses an MC68030 32-bit microprocessor, which is capable of addressing up to four

megabytes of on-board memory or four gigabytes when used in conjunction with external

memory accessible via the VME bus interface. Also included in this block are address

decoding, clock and control signal generation, asynchronous control, power

monitor/watchdog timer/reset, status output port and diagnostic/debug facilities.

• Memory consists of memory components and circuits. The D20ME uses boot EPROM and

three banks of four sets of memory devices (static RAM, non-volatile RAM, and flash)

providing up to 1.5 MB, 0.5 MB, and 2 MB respectively of on-board memory.

• Interrupt Control consists of an interrupt handler designed specifically for the VME bus. It

operates in conjunction with a VME bus controller, and determines the importance of, and

controls, interrupts from the serial ports, the D.20 Link HDLC chip, and the real-time clock.

• Serial I/O is the communications center of the D20ME. It consists of two D.20 HDLC

communications ports, one RS-232 9600 baud maintenance port and seven byte-oriented

asynchronous RS-232 communication ports. The seven serial ports, all of which are

programmable, are used for communication with SCADA/EMS master stations and/or other

serial devices, such as printers and IEDs. The HDLC port handles a bit-oriented D.20

protocol structure for communicating with the D20 I/O peripheral.

• VME Bus Interface. The D20ME operates as the VME bus master to allow it to interface to,

control and arbitrate the VME bus.

2.2.2 D20/D200 Main Processor Specifications

Table 4 D20/D200 Main Processor Specifications

Item Description

CPU/Memory

Self Diagnostics

• 32-bit Freescale 68030 microprocessor

• 40 MHz MPU clock

• Real-time clock, 1.0 ms res olution accurate to ±2.0 ppm

• On-board memory

− 2 MB Flash memory

− 2 MB SRAM (incl. 512 K battery back up)

− 512 KB BootROM

• Program memory checksums

• RAM test

• Configuration verification

• Interrupt controller verification

• Serial port test

• Watchdog and power monitor

• Peripheral communication che cks

• Error logger

GE Information PRPI-019-3.00-10

Page 40

D20/D200 Technical Overview

GE Grid Solutions

32

Item Description

Communications

Power Requirements

Physical

• Two HDLC ports for link to peripheral modules

• The D20ME has seven programmable RS-232 serial ports for communications to SCADA

master, satellite RTUs and IEDs. The D20ME II has seven programma ble serial ports,

any combination of RS-232 an d RS-485.

• 38,400 kbps on all 7 ports, all running half duplex & 100% utilization (D20ME and D20ME

II)

• 9600 baud, RS-232 maintenance port (D20ME and D20ME II)

• Support leased/dial-up telephone lines, modems, 900 MHz radio, trunked radio, spread

spectrum radio, microwave, and fiber optic communications.

• Power consumption: 3.5 W typical, 5 W max.

• LED indications: Run/Halt and System Fail

2.2.3 Firmware

The D20ME contains two types of firmware: BootROM and flash applications. BootROM

contains the software needed to start up a D20 and diagnostic applications. Application software

consists of a base system that includes the operating system, hardware-dependent software, and

applications that are modular and hardware-independent so they can run on multiple platforms

(D20, D25 and iBOX, for example).

2.2.3.1 BootROM

BootROM firmware is stored on an EPROM chip. The following types of programs are stored as

BootROM firmware:

• Operating system

• Boot-up (reset) code

• Device drivers

• IRQ controller initialization

• Interrupt service procedures

• Monitor functions

• Root process

• Watchdog task

Operating System

The D20ME operating system is pSOS®. pSOS is a real-time, multi-tasking operating system

kernel, with the following features:

• Integrated, multi-tasking with a structured efficient supervisory layer

• Priority scheduling of processes in coordination with other tasks. User applications are

partitioned into sets of processes

PRPI-019-3.00-10 GE Information

Page 41

GE Grid Solutions

D20/D200 Technical Overview

33

• Inter-task communication and synchronization controlled from an efficient dedicated

functional group

• Dynamic memory allocation and reclamation, using an enhanced, highly efficient, first-fit

algorithm

• Real-time clock control managed via a service call from an external time base. The real-time

clock:

− Maintains calendar time

− Performs time slicing, which allows processes to pause

− Supplies a time-out option to other service calls

• Direct memory access support is not required

• Efficient real-time responsiveness

Boot-Up Code

The D20 system initializes from the BootROM. It checks and verifies the contents of the

BootROM, then initializes the system hardware and various I/O devices. If it finds any errors or

defects in the memory, the system either shuts down to a minimum running state or, in the event

of serious defects, shuts down completely.

After the initial diagnostic routines are run, the boot-up code downloads the operating system

code into RAM so that it can be accessed more quickly. From this point on, all resident firmware

and supplied custom applications run from either 32-bit wide RAM or 32-bit wide flash. The

system and application databases are stored in NVRAM.

Device Drivers

The D20 uses two communication device drivers:

• Octart serial I/O chip, which manages input and output through eight serial ports.

• HDLC controller chip (dual-port), which forms part of the high-speed D.20 Link between

the D20ME and the D20 I/O peripherals.

68K Monitor Functions

Monitor functions include debugging tools that users can access via a PC, VT100 terminal with a

keyboard, or remotely via telnet. Monitor functions include memory examination, dumping and

editing, setting break points, single-step modes, communication port loop-back tests, mark and

space modem adjustments, and CPU usage and process profiling.

Watchdog Task

Watchdog is a simple, low-priority task that is designed to send a reset signal to the

watchdog timer circuit. As long as this circuit is reset every second, the system will not be

rebooted. The D20 performs standard self-checks on initial start-up, periodically during

operation, and as manually requested through WESMAINT.

GE Information PRPI-019-3.00-10

Page 42

D20/D200 Technical Overview

GE Grid Solutions

34

2.2.3.2 Base Applications

The D20 base system includes the following applications:

• WESDAC Interface Node (WIN)

• WESMAINT

• System library resources

Base applications, which are stored in flash memory, can be classified as one of the following:

• Data Collection Applications (DCAs), which poll devices to collect data.

• Data Processing Applications (DPAs), which request and process data required by a

host/master computer.

• Data Translation Applications (DTAs), which manipulate data inside the RTU to generate

new information, translate data to different formats, or take action when certain events occur.

WESDAC Interface Node

The WESDAC Interface Node (WIN) is the central database for the D20/D200. WIN manages

the transfer, storage and manipulation of data between DCAs, DPAs, and DTAs. WIN sends

requests for data to, and receives new data from, DCAs, then stores the new data in the system

database. WIN also receives requests for data from, and sends data to, DPAs, and routes data

output operation requests from DPAs to DCAs.

WESMAINT

WESMAINT is a maintenance facility that resides on the D20 and D200. For a more detailed

description, see section 3.3, WESMAINT

System Library Resources

The system library resources are collections of commonly used functions that assist programmers

in the development of new code. There are several libraries available for the D20.

D.20 Link Subsystem

The D.20 Link subsystem is a DCA that polls data from the D20 I/O peripheral modules, and

then routes that data to WIN. It also asks the peripherals to perform any output operation

requests that it receives from WIN. These communication transactions properly package the data

and send or receive it over the D.20 Link.

The D.20 Link subsystem, which is known as the peripheral scan process, works with the D.20

Link driver to communicate with peripheral modules. The D.20 process formats the data

according to the requirements of the D.20 protocol then calls the HDLC driver, which provides

the actual hardware interface between the D20ME and the I/O peripherals.

2.2.4 Time Synchronization

The D20ME/ME II can be used as an accurate timeserver for synchronizing the clocks of

substation equipment connected to the D20 Ethernet or serial ports.

PRPI-019-3.00-10 GE Information

Page 43