Page 1

GE

Appliances

GE Window Type Air Conditioner

AEE07KP, AED07KP,AEE09KP, AED09KP,AEE12KP,

AED12KP,AEE18KP,

Service Manual

AEE24KP,

Page 2

Service Manual

Table of Contents

Summary and Features ....................................................... 1

1. Safety Precautions .......................................................... 2

2. Specications .................................................................. 3

3. Construction Views ....................................................... 13

4. Refrigerant System Diagram ........................................ 15

5. Schematic Diagram ....................................................... 16

5.1 Electrical Data .......................................................................................................... 16

5.2 Electrical Wiring ........................................................................................................ 16

5.3 Printed Circuit Board ................................................................................................ 18

6. Function and Control .................................................... 19

6.1 Remote Control Operations ...................................................................................... 19

6.2 Description of Each Control Operation ..................................................................... 31

7. Installation Instructions ................................................ 35

8. Exploded Views and Parts List .................................... 37

9. Troubleshooting ............................................................ 58

10. Removal Procedure ..................................................... 62

Appendix: ........................................................................... 68

Appendix 1: Reference Sheet of Celsius and Fahrenheit ............................................... 68

Appendix 2: List of Resistance for Temperature Sensor ................................................ 69

Table of Contents

Page 3

Service Manual

Summary and Features

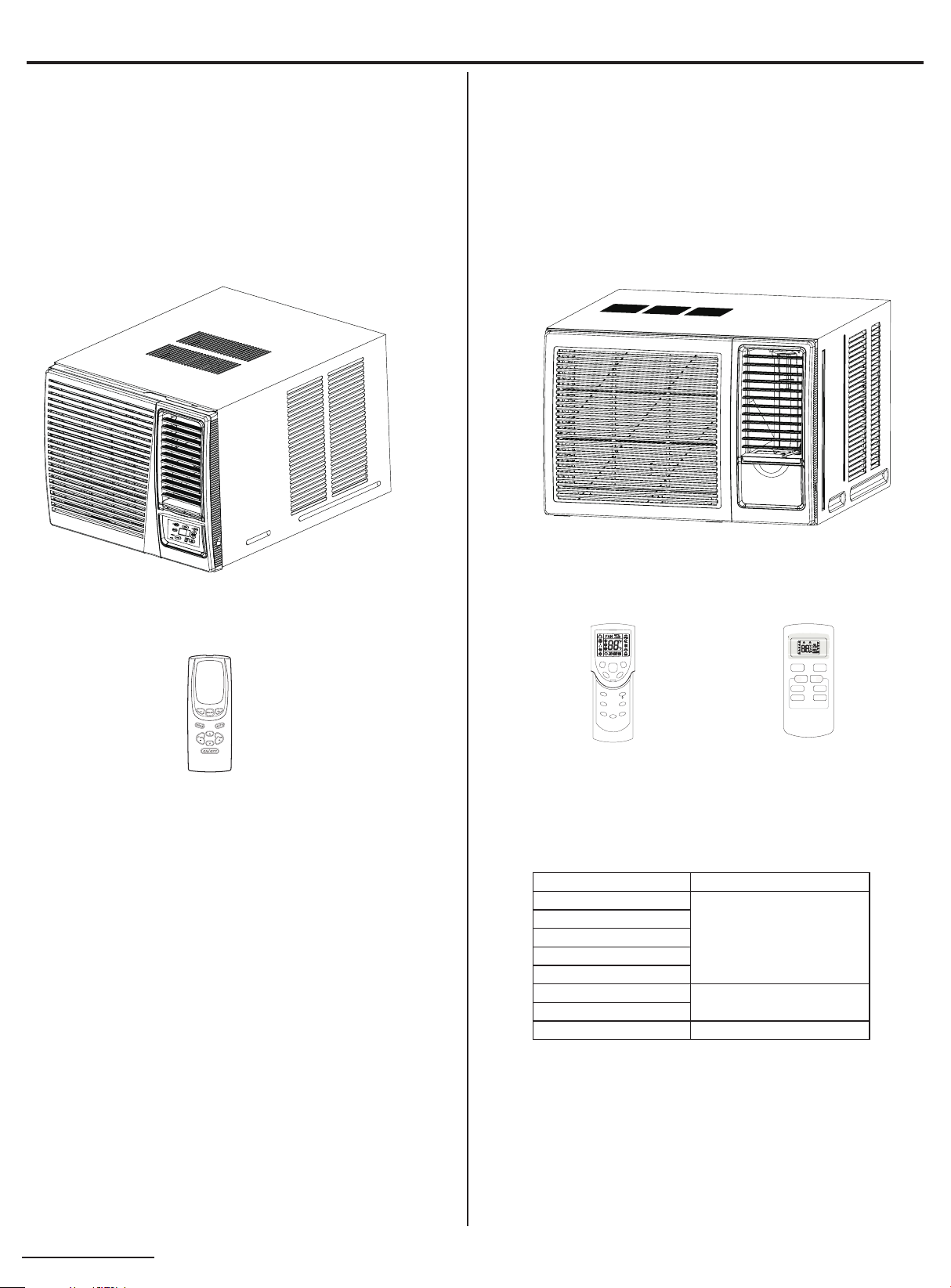

AEE07KP AEE09KP AEE12KP

AEE18KP AEE24KP

YK4EB

AED07KP

AED09KP

AED12KP

YS1FA YX1F

MODE

FAN

ON/OFF

-

+

CLOCK

TIMER OFF

TIMER ON

LIGHT

ENERGY

SAVER

SLEEP

T-ON T-OFF

AUTO

COOL

DRY

FAN

HEAT

ON/OFF

_

FAN SWING

SLEEP

SWING

SLEEP

LOCK

SPEED

MODE

+

TIMER

Technical Information

Model Remote control

AEE07KP

AEE09KP

AEE12KP

YK4EB(MC)

AEE18KP

AEE24KP

AED07KP

AED09KP

YS1FA

AED12KP YX1F

1

Page 4

1. Safety Precautions

Installing, starting up, and servicing air conditioner can be

A

according to local regulations and the instructions given in

this manual.

electric shock, explosion or injury.

.

A large enough opening for the air conditioner. Installation

Service Manual

hazardous due to system pressure, electrical components,

and equipment location, etc.

Only trained, qualified installers and service personnel are

allowed to install, start-up, and service this equipment.

Untrained personnel can perform basic maintenance functions such as cleaning coils. All other operations should

be performed by trained service personnel.

When handling the equipment, observe precautions in the

manual and on tags, stickers, and labels attached to the

equipment. Follow all safety codes. Wear safety glasses

andwork gloves. Keep quenching cloth and fire extinguisher

nearby when brazing.

Read the instructions thoroughly and follow all warnings or

cautions in literature and attached to the unit. Consult local

building codes and current editions of national as well as

local electrical codes.

Recognize the following safety information:

Warning

Caution

Incorrect handling could result in

personal injury or death.

Incorrect handling may result in

minor injury,or damage to product

or property.

parts are supplied for double-hung windows.

Make sure the ceiling/wall is strong enough to bear the

weight of the unit.

Adequate wall support for weight of air conditioner.

Follow all the installation instructions to minimize the risk

of damage from earthquakes, typhoons or strong winds.

Avoid contact between refrigerant and fire as it generates

poisonous gas.

Apply specified refrigerant only. Never have it mixed with

any other refrigerant. Never have air remain in the

refrigerant line as it may lead to rupture and other hazards

Make sure no refrigerant gas is leaking out when installation is completed.

Should there be refrigerant leakage, the density of refrigerant in the air shall in no way exceed its limited value,

or it may lead to explosion.

Keep your fingers and clothing away from any moving

parts.

Clear the site after installation. Make sure no foreign objects are left in the unit.

Always ensure effective grounding for the unit.

Warning

ll electric work must be performed by a licensed technician

Before installing, modifying, or servicing system, main

electrical disconnect switch must be in the OFF position.

There may be more than 1 disconnect switch. Lock out

and tag switch with a suitable warning label.

Never supply power to the unit unless all wiring and tubing are completed, reconnected and checked.

This system adopts highly dangerous electrical voltage.

Incorrect connection or inadequate grounding can cause

personal injury or death. Stick to the wiring diagram and

all the instructions when wiring.

Have the unit adequately grounded in accordance with

local electrical codes.

Have all wiring connected tightly. Loose connection may

lead to overheating and a possible fire hazard.

All installation or repair work shall be performed by your dealer or a specialized subcontractor as there is the risk of fire,

Caution

Never install the unit in a place where a combustible gas

might leak, or it may lead to fire or explosion.

Make a proper provision against noise when the unit is

installed at a telecommunication center or hospital.

Provide an electric leak breaker when it is installed in a

watery place.

Never wash the unit with water.

Handle unit transportation with care. The unit should not

be carried by only one person if it is more than 20kg.

Never touch the heat exchanger fins with bare hands.

Never touch the compressor or refrigerant piping without

wearing glove.

Do not have the unit operate without air filter.

Should any emergency occur, stop the unit and disconnect the power immediately.

Properly insulate any tubing running inside the room to

prevent the water from damaging the wall.

2

Technical Information

Page 5

Service Manual

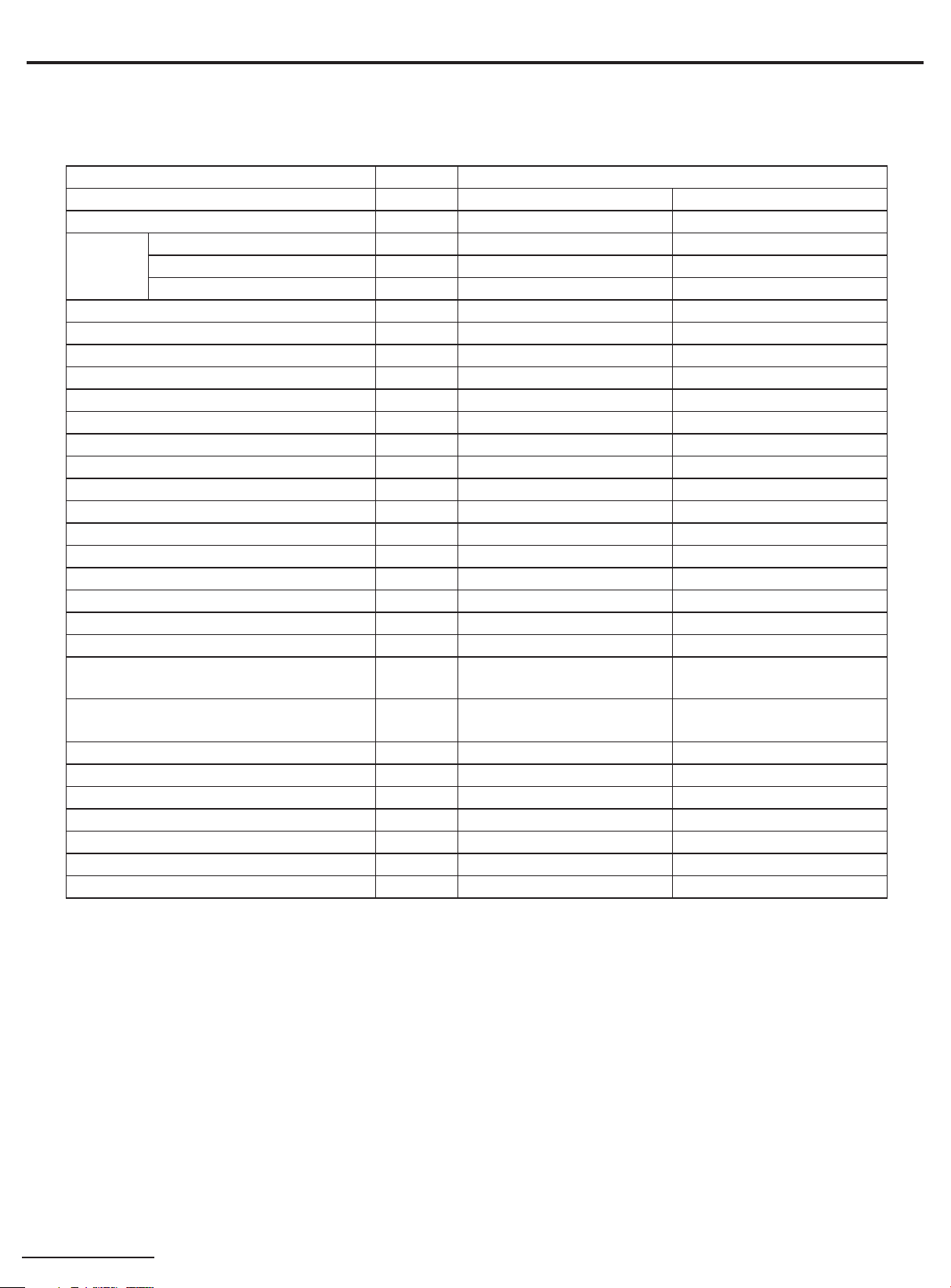

2. Specications

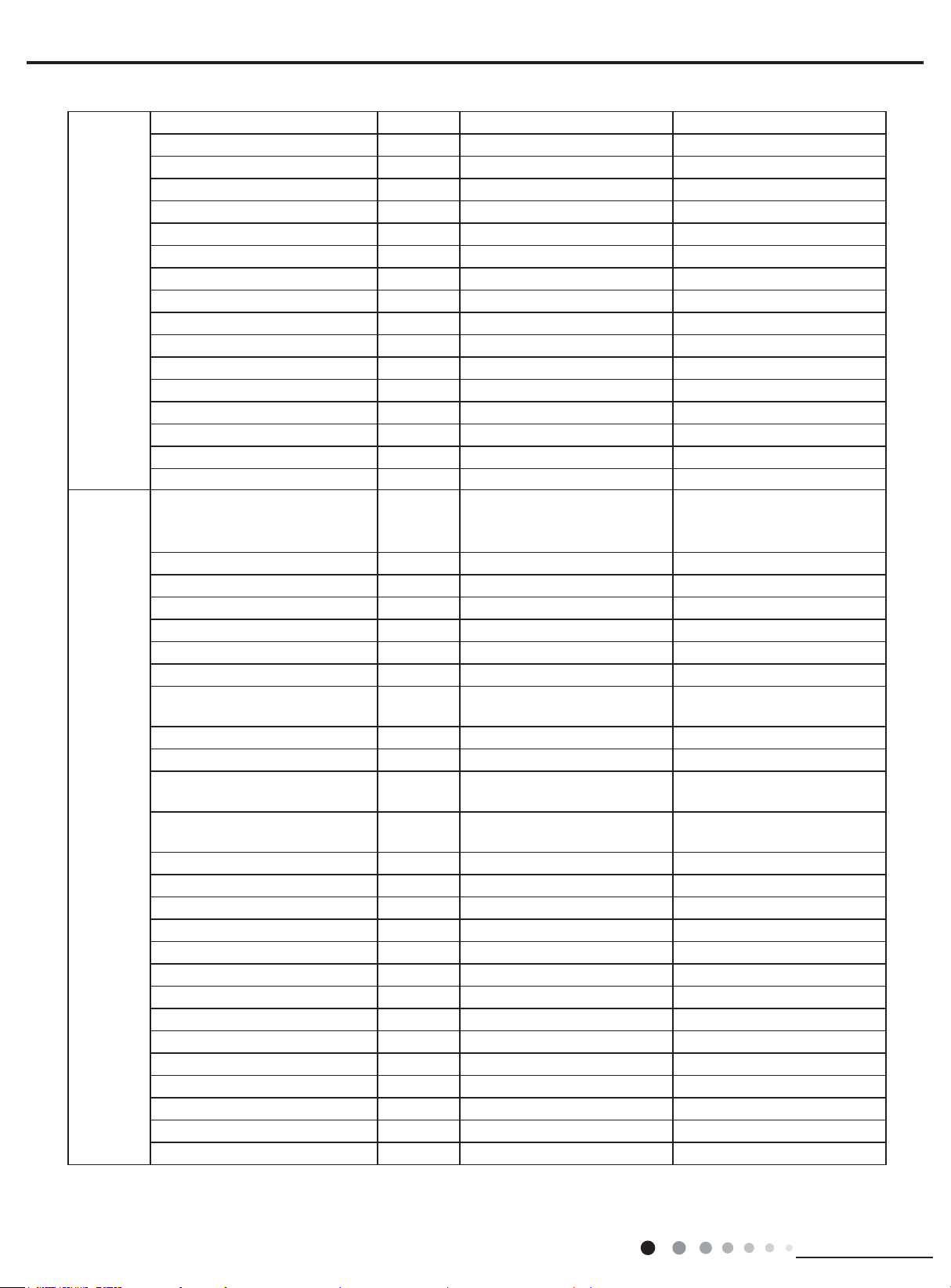

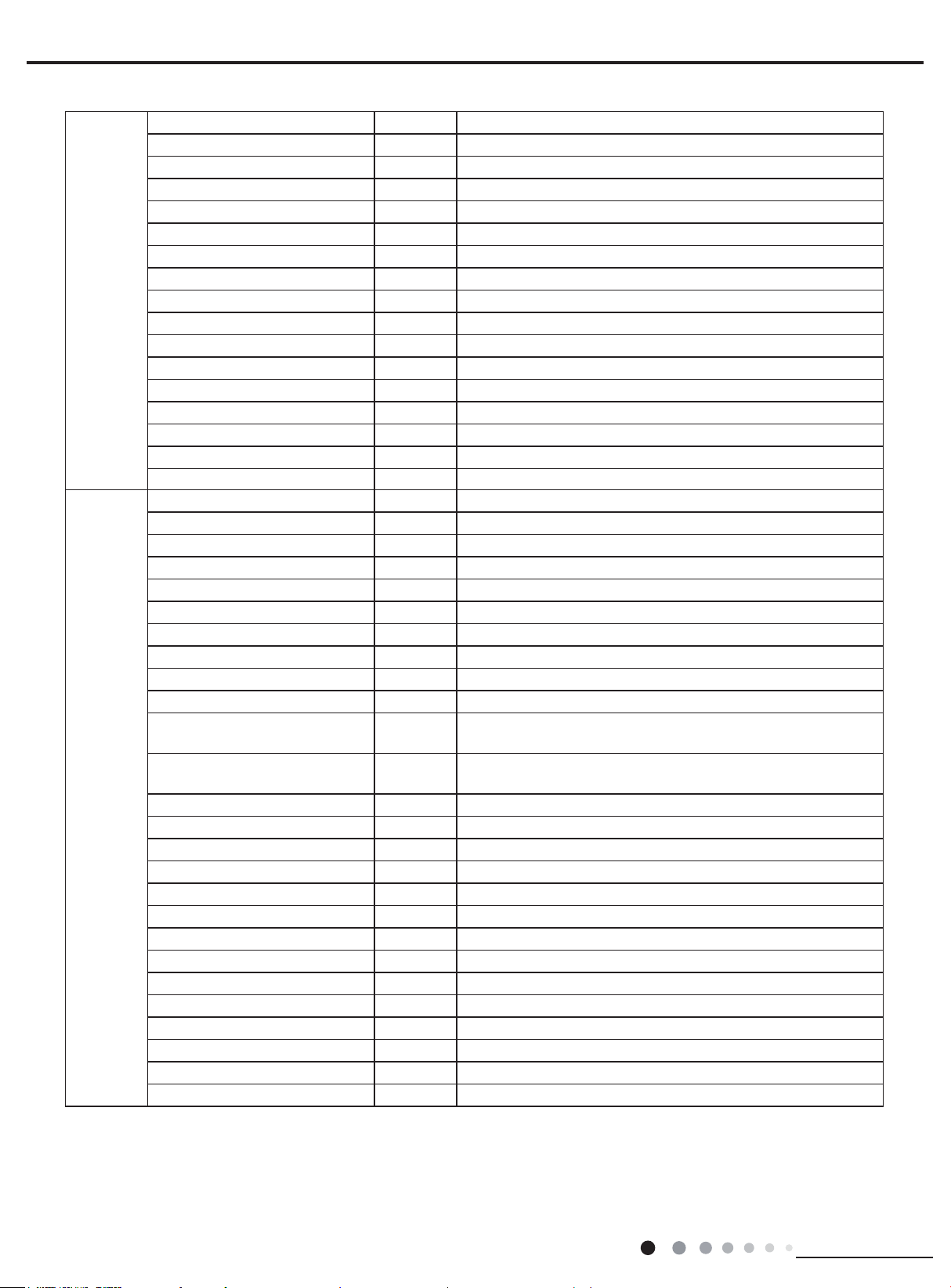

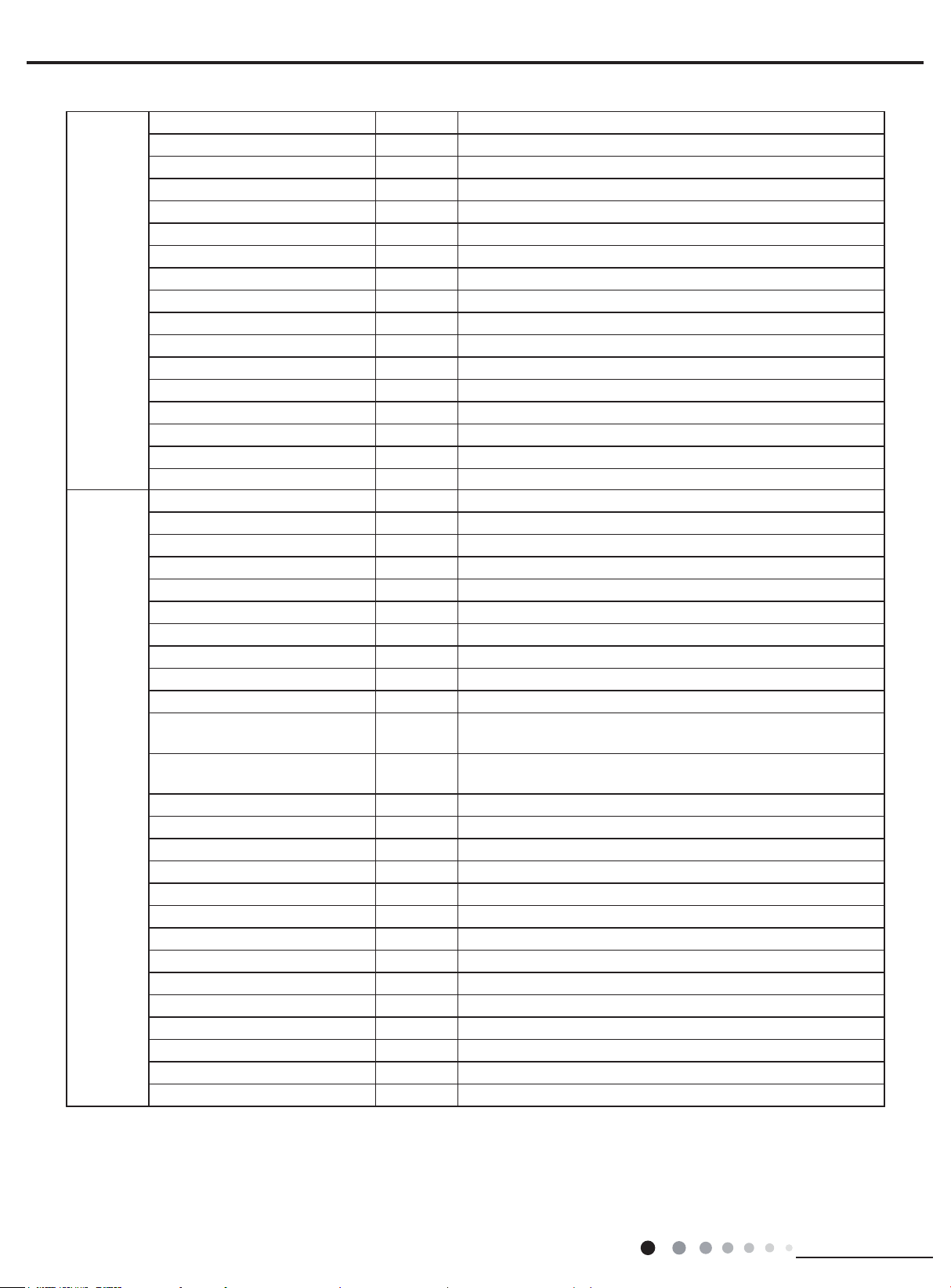

Parameter Unit Value

Model AEE07KP AEE09KP

Product Code CC052005800_K93320 CC052005900_K93320

Power

Supply

Cooling Capacity W 1950 2640

Heating Capacity W / /

Cooling Power Input W 680 920

Heating Power Input W / /

Cooling Power Current A 3.2 4.3

Heating Power Current A / /

Rated Input W 900 1100

Rated Current A 4.86 5.95

Air Flow Volume (H/M/L) m3/h 350/300/250 480/430/380

Dehumidifying Volume L/h 0.6 1

EER W/W 2.86 2.86

COP W/W / /

Application Area m

Climate Type T1 T1

Isolation I I

Moisture Protection IP24 IP24

Permissible Excessive Operating Pressure for

the Discharge Side

Permissible Excessive Operating Pressure for

the Suction Side

Dimension (WXHXD) mm 450X350X580 560X375X618

Dimension of Carton Box (LXWXH) mm 668X518X359 727X661X463

Dimension of Package (LXWXH) mm 671X521X374 730X664X478

Net Weight kg 31 42

Gross Weight kg 34 46

Refrigerant R22 R22

Refrigerant Charge kg 0.55 0.48

Rated Voltage V~ 220 220

Rated Frequency Hz 60 60

Phases 1 1

2

MPa 3 3

MPa 1.5 1.5

7-12 12-18

Technical Information

3

Page 6

Indoor

Side

Outdoor

Side

Service Manual

Fan Type Centrifugal Centrifugal

Fan Diameter Length (DXL) mm Φ180X85 Φ205.5X111

Cooling Speed (H/M/L) r/min 1110/1010/820 920/820/720

Heating Speed (H/M/L) r/min / /

Fan Motor Power Output W 45 88

Fan Motor RLA A 0.4 0.4

Fan Motor Capacitor μF 3.5 4

Electric Heating Power Input W / /

Evaporator Form Aluminum Fin-copper Tube Aluminum Fin-copper Tube

Evaporator Pipe Diameter mm Φ7 Φ7

Evaporator Row-n Gap mm 3-1.3 3-1.5

Evaporator Coil Length (LXDXW) mm 285.7X38.1X246 330X38.1X323.9

Swing Motor Model MP24VA MP24VA

Swing Motor Power Output W 2.5 2.5

Fuse Current A 3.15 3.15

Sound Pressure Level (H/M/L) dB (A) 50/48/46 50/48/46

Sound Power Level (H/M/L)

Compressor Manufacturer

dB (A)

60/58/56

Air Conditioning Compressor

Divison(Tianjin) LG Electronics

Inc.

60/58/56

PANASONIC WANBAO

COMPRESSOR (GUANG ZHOU)

CO.LTD,

Compressor Model QA102KAD 2P14S236A1G

Compressor Oil RB68EP/FVC68D ATMOS NM56M

Compressor Type Rotary Rotary

Compressor LRA A 16 26

Compressor RLA A 3 3.8

Compressor Power Input W 662 845

Compressor Overload Protector

MRA12060-12026 or B128-150-

241E

MRA99027-9201

Throttling Method Capillary Capillary

Set Temperature Range

Cooling Operation Ambient

Temperature Range

Heating Operation Ambient

Temperature Range

O

C 16~30 16~30

O

C 18~45 18~45

O

C / /

Condenser Form Aluminum Fin-copper Tube Aluminum Fin-copper Tube

Condenser Pipe Diameter mm Φ7 Φ7

Condenser Rows-n Gap mm 3-1.6 2-1.3

Condenser Coil Length (LXDXW) mm 364X38.1X331 472X25.4X343

Fan Motor Speed (H/M/L) rpm 1110/1010/820 920/820/720

Fan Motor Power Output W 45 88

Fan Motor RLA A 0.4 0.4

Fan Motor Capacitor μF 3.5 4

Outdoor Unit Air Flow Volume m3/h 600 850

Fan Type Axial-ow Axial-ow

Fan Diameter mm Φ310 Φ353

Sound Pressure Level (H/M/L) dB (A) 58/56/54 58/56/54

Sound Power Level (H/M/L) dB (A) 68/66/64 68/66/64

Defrosting Method / /

The above data is subject to change without notice. Please refer to the nameplate of the unit.

4

Technical Information

Page 7

Service Manual

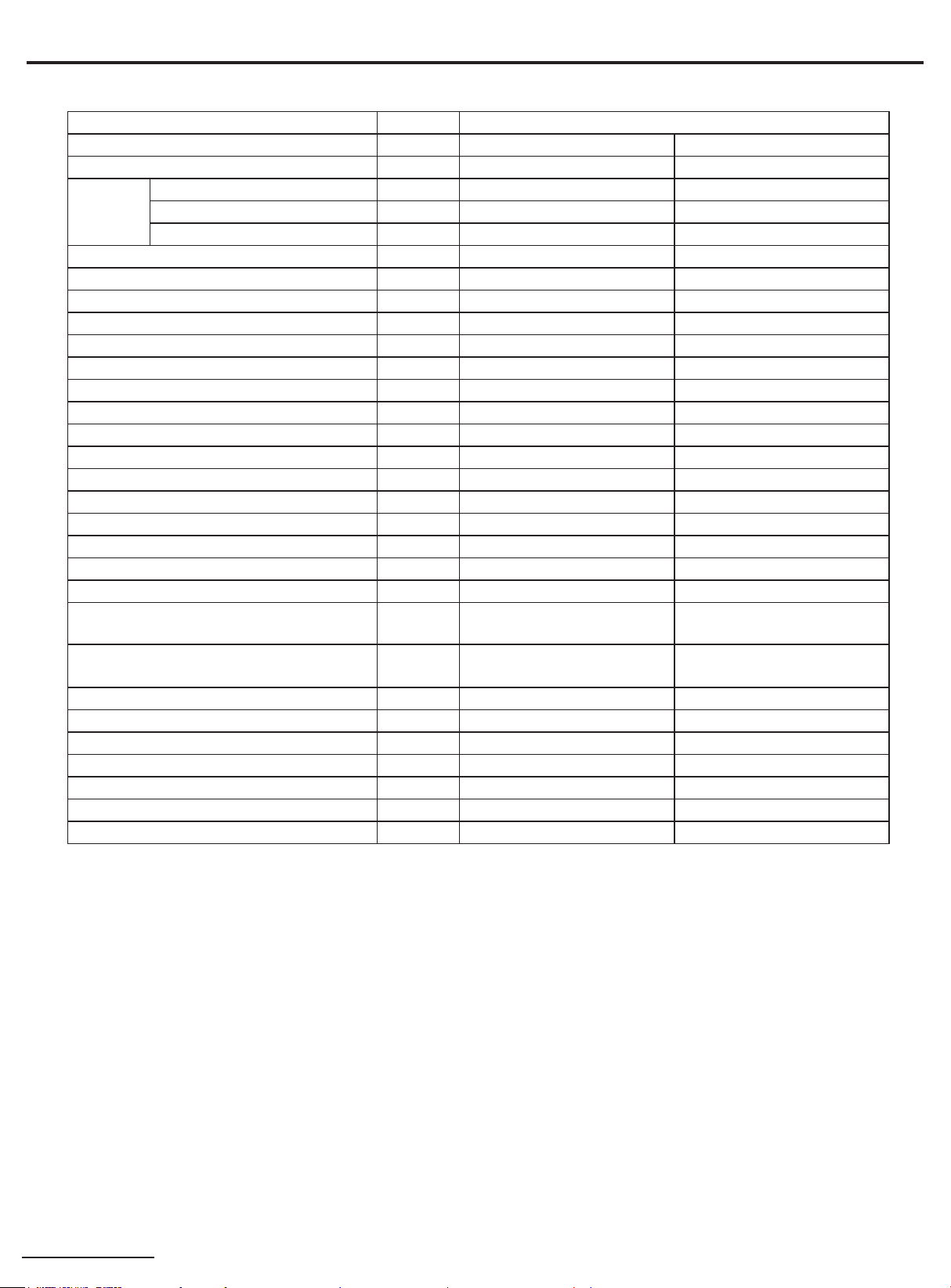

Parameter Unit Value

Model AEE12KP AEE18KP

Product Code CC052006000_K93320 CC052006100_K93320

Power

Supply

Rated Voltage V~ 220 220

Rated Frequency Hz 60 60

Phases 1 1

Cooling Capacity W 3420 5000

Heating Capacity W / /

Cooling Power Input W 1230 1800

Heating Power Input W / /

Cooling Power Current A 5.7 8.4

Heating Power Current A / /

Rated Input W 1600 2300

Rated Current A 8.65 12.43

Air Flow Volume (H/M/L) m3/h 560/510/460 940/890/840

Dehumidifying Volume L/h 1.3 2.2

EER W/W 2.78 2.78

COP W/W / /

Application Area m

2

16-24 23-34

Climate Type T1 T1

Isolation I I

Moisture Protection IP24 IP24

Permissible Excessive Operating Pressure for

the Discharge Side

Permissible Excessive Operating Pressure for

the Suction Side

Dimension (WXHXD)

MPa 3 3

MPa 1.5 1.5

mm 560X375X618 660X428X770

Dimension of Carton Box (LXWXH) mm 727X661X463 736X860X500

Dimension of Package (LXWXH) mm 730X664X478 739X863X515

Net Weight kg 49 59

Gross Weight kg 53 64

Refrigerant R22 R22

Refrigerant Charge kg 0.7 0.91

Technical Information

5

Page 8

Indoor

Side

Outdoor

Side

Service Manual

Fan Type Centrifugal Centrifugal

Fan Diameter Length (DXL) mm Φ205.5X111 Φ224X109.5

Cooling Speed (H/M/L) r/min 1100/960/820 1000/900/800

Heating Speed (H/M/L) r/min / /

Fan Motor Power Output W 100 155

Fan Motor RLA A 0.4 0.8

Fan Motor Capacitor μF 4 7

Electric Heating Power Input W / /

Evaporator Form Aluminum Fin-copper Tube Aluminum Fin-copper Tube

Evaporator Pipe Diameter mm Φ7 Φ7

Evaporator Row-n Gap mm 3-1.5 2-1.3

Evaporator Coil Length (LXDXW) mm 330X38.1X323.9 392X25.4X381

Swing Motor Model MP24VA MP28ED

Swing Motor Power Output W 2.5 2

Fuse Current A 3.15 3.15

Sound Pressure Level (H/M/L) dB (A) 54/52/50 57/55/53

Sound Power Level (H/M/L) dB (A) 64/62/60 67/65/63

Compressor Manufacturer

Air Conditioning Compressor

Divison(Tianjin) LG Electronics

Inc.

Air Conditioning Compressor

Divison(Tianjin) LG Electronics

Inc.

Compressor Model QK173KAB QJ250KBF

Compressor Oil NM56M NM56M

Compressor Type Rotary Rotary

Compressor LRA A 29 42

Compressor RLA A 5.6 7.5

Compressor Power Input W 1141 1606

Compressor Overload Protector

MRA98996-12026/B195-140-

241E/KA-122-LLBN17B

MRA12107-12027/B273-150-

141E

Throttling Method Capillary Capillary

Set Temperature Range

Cooling Operation Ambient

Temperature Range

Heating Operation Ambient

Temperature Range

O

C 16~30 16~30

O

C 18~45 18~45

O

C / /

Condenser Form Aluminum Fin-copper Tube Aluminum Fin-copper Tube

Condenser Pipe Diameter mm Φ7 Φ7

Condenser Rows-n Gap mm 3-1.4 2-1.3

Condenser Coil Length (LXDXW) mm 472X38.1X343 885X25.4X400

Fan Motor Speed (H/M/L) rpm 1100/960/820 1000/900/800

Fan Motor Power Output W 100 155

Fan Motor RLA A 0.4 0.8

Fan Motor Capacitor μF 4 7

Outdoor Unit Air Flow Volume m3/h 880 1670

Fan Type Axial-ow Axial-ow

Fan Diameter mm Φ353 Φ396

Sound Pressure Level (H/M/L) dB (A) 61/59/57 62/60/58

Sound Power Level (H/M/L) dB (A) 71/69/67 72/70/68

Defrosting Method / /

The above data is subject to change without notice. Please refer to the nameplate of the unit.

6

Technical Information

Page 9

Service Manual

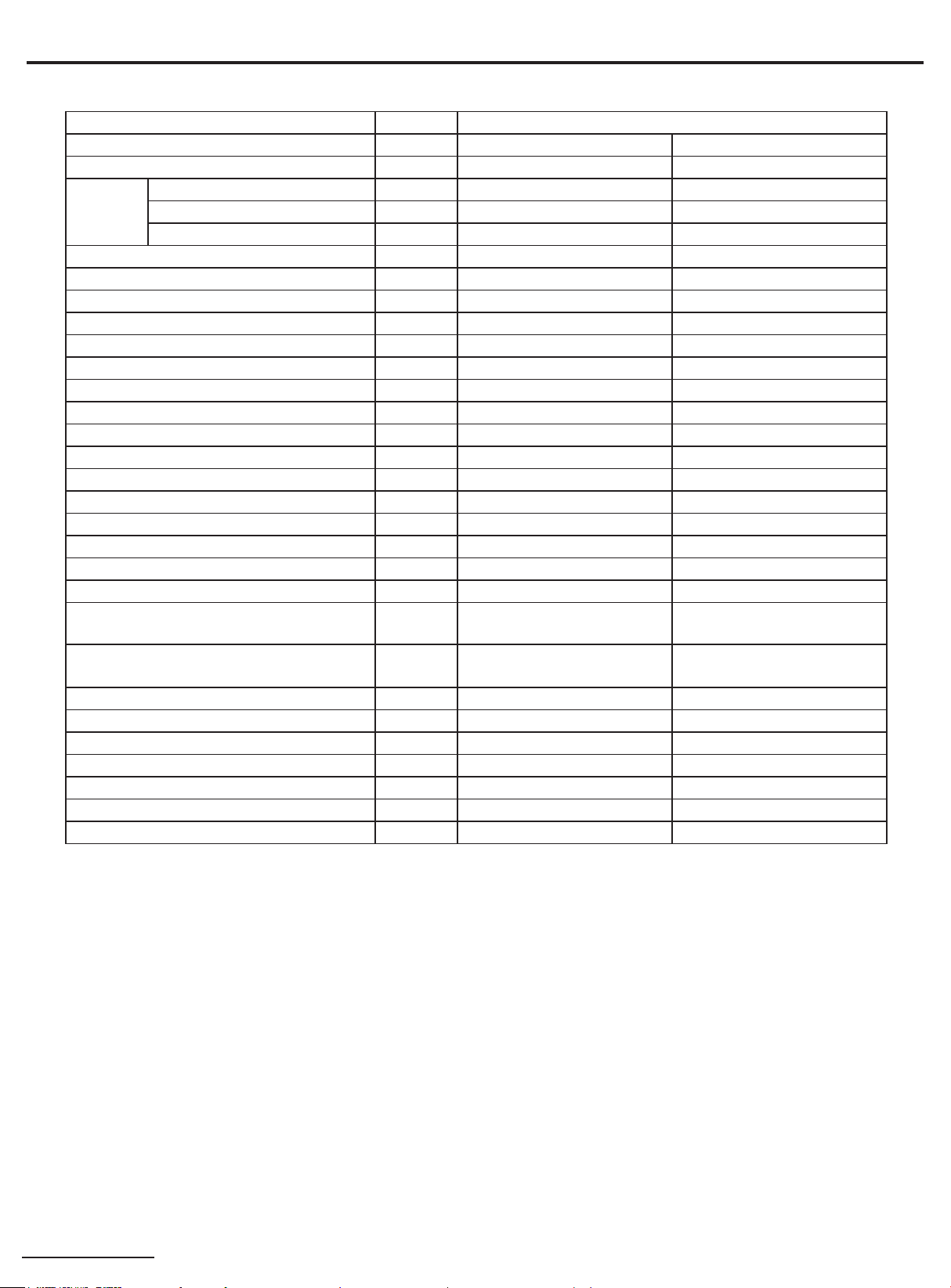

Parameter Unit Value

Model AEE24KP

Product Code CC052006200_K93320

Power

Supply

Rated Voltage V~ 220

Rated Frequency Hz 60

Phases 1

Cooling Capacity W 6530

Heating Capacity W /

Cooling Power Input W 2350

Heating Power Input W /

Cooling Power Current A 10.8

Heating Power Current A /

Rated Input W 2700

Rated Current A 14.59

Air Flow Volume (H/M/L) m3/h 940/890/840

Dehumidifying Volume L/h 2.8

EER W/W 2.78

COP W/W /

Application Area m

2

27-42

Climate Type T1

Isolation I

Moisture Protection IP24

Permissible Excessive Operating Pressure for

the Discharge Side

Permissible Excessive Operating Pressure for

the Suction Side

Dimension (WXHXD)

MPa 3

MPa 1.5

mm 660X428X770

Dimension of Carton Box (LXWXH) mm 736X860X500

Dimension of Package (LXWXH) mm 739X863X515

Net Weight kg 68

Gross Weight kg 73

Refrigerant R22

Refrigerant Charge kg 1.4

Technical Information

7

Page 10

Indoor

Side

Outdoor

Side

Fan Type Centrifugal

Fan Diameter Length (DXL) mm Φ224X109.5

Cooling Speed (H/M/L) r/min 1060/970/820

Heating Speed (H/M/L) r/min /

Fan Motor Power Output W 200

Fan Motor RLA A 0.8

Fan Motor Capacitor μF 7

Electric Heating Power Input W /

Evaporator Form Aluminum Fin-copper Tube

Evaporator Pipe Diameter mm Φ7

Evaporator Row-n Gap mm 3-1.6

Evaporator Coil Length (LXDXW) mm 392X38.1X381

Swing Motor Model MP28ED

Swing Motor Power Output W 2

Fuse Current A 3.15

Sound Pressure Level (H/M/L) dB (A) 57/55/53

Sound Power Level (H/M/L)

dB (A)

67/65/63

Compressor Manufacturer ZHUHAI LANDA COMPRESSOR CO., LTD

Compressor Model QX-F325rF090

Compressor Oil ATMOS NM56EP

Compressor Type Rotary

Compressor LRA A 59

Compressor RLA A 10.5

Compressor Power Input W 2200

Compressor Overload Protector UP14QE5345-M

Throttling Method Capillary

Set Temperature Range

Cooling Operation Ambient

Temperature Range

Heating Operation Ambient

Temperature Range

O

C 16~30

O

C 18~45

O

C /

Condenser Form Aluminum Fin-copper Tube

Condenser Pipe Diameter mm Φ7

Condenser Rows-n Gap mm 3-1.6

Condenser Coil Length (LXDXW) mm 885X38.1X400

Fan Motor Speed (H/M/L) rpm 1060/970/820

Fan Motor Power Output W 200

Fan Motor RLA A 0.8

Fan Motor Capacitor μF 7

Outdoor Unit Air Flow Volume m3/h 1670

Fan Type Axial-ow

Fan Diameter mm Φ396

Sound Pressure Level (H/M/L) dB (A) 62/60/58

Sound Power Level (H/M/L) dB (A) 72/70/68

Defrosting Method /

Service Manual

The above data is subject to change without notice. Please refer to the nameplate of the unit.

8

Technical Information

Page 11

Service Manual

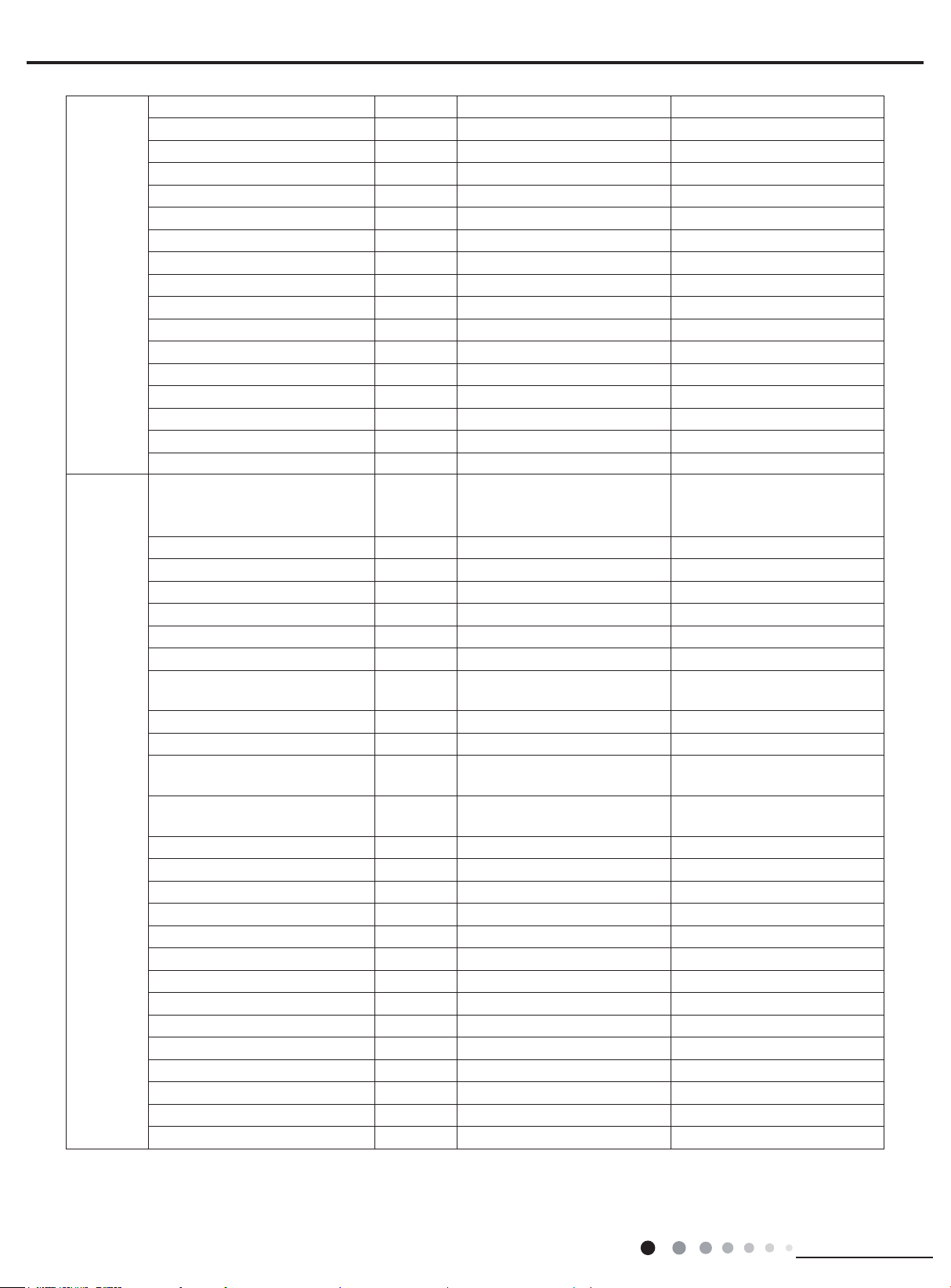

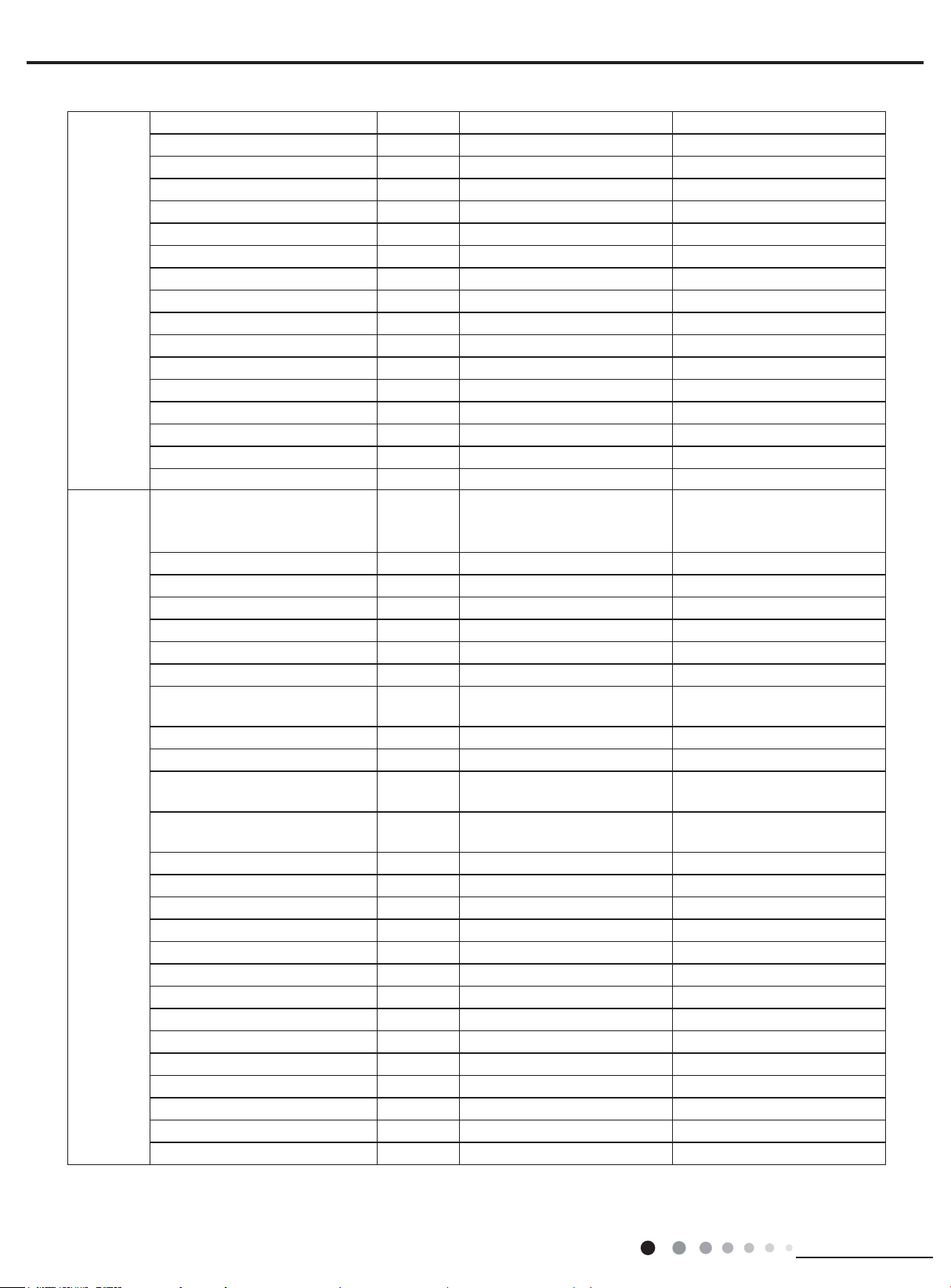

Parameter Unit Value

Model AED07KP AED09KP

Product Code CC052024200_K93412 CC052024300_K93412

Power

Supply

Rated Voltage V~ 220 220

Rated Frequency Hz 60 60

Phases 1 1

Cooling Capacity W 2110 2720

Heating Capacity W / /

Cooling Power Input W 650 840

Heating Power Input W / /

Cooling Power Current A 3 3.9

Heating Power Current A / /

Rated Input W 900 1000

Rated Current A 4.86 5.41

Air Flow Volume (H/M/L) m3/h 480/430/380 480/430/380

Dehumidifying Volume L/h 0.6 1

EER W/W 3.22 3.22

COP W/W / /

Application Area m

2

7-12 12-18

Climate Type T1 T1

Isolation I I

Moisture Protection IP24 IP24

Permissible Excessive Operating Pressure for

the Discharge Side

Permissible Excessive Operating Pressure for

the Suction Side

Dimension (WXHXD)

MPa 3 3

MPa 1.5 1.5

mm 560X375X668 560X375X668

Dimension of Carton Box (LXWXH) mm 763X620X410 763X620X410

Dimension of Package (LXWXH) mm 766X623X425 766X623X425

Net Weight kg 39 45

Gross Weight kg 43 49

Refrigerant R22 R22

Refrigerant Charge kg 0.5 0.7

Technical Information

9

Page 12

Indoor

Side

Outdoor

Side

Service Manual

Fan Type Centrifugal Centrifugal

Fan Diameter Length (DXL) mm Φ205.5X111 Φ205.5X111

Cooling Speed (H/M/L) r/min 950/880/780 950/880/780

Heating Speed (H/M/L) r/min / /

Fan Motor Power Output W 60 60

Fan Motor RLA A 0.5 0.5

Fan Motor Capacitor μF 4 4

Electric Heating Power Input W / /

Evaporator Form Alumium Tube Alumium Tube

Evaporator Pipe Diameter mm Φ7 Φ7

Evaporator Row-n Gap mm 2-1.3 3-1.5

Evaporator Coil Length (LXDXW) mm 330X25.4X323.9 330X38.1X323.9

Swing Motor Model MP24VA MP24VA

Swing Motor Power Output W 1.5 1.5

Fuse Current A 3.15 3.15

Sound Pressure Level (H/M/L) dB (A) 50/48/46 50/48/46

Sound Power Level (H/M/L)

Compressor Manufacturer

dB (A)

60/58/56

Air Conditioning Compressor

Divison(Tianjin) LG Electronics

Inc.

60/58/56

PANASONIC WANBAO

COMPRESSOR (GUANG ZHOU)

CO.LTD,

Compressor Model QA102KAD 2P14S236A1G

Compressor Oil RB68EP/FVC68D ATMOS NM56M

Compressor Type Rotary Rotary

Compressor LRA A 16 26

Compressor RLA A 3 3.8

Compressor Power Input W 662 845

Compressor Overload Protector

MRA12060-12026 or B128-150-

241E

MRA99027-9201

Throttling Method Capillary Capillary

Set Temperature Range

Cooling Operation Ambient

Temperature Range

Heating Operation Ambient

Temperature Range

O

C 16~30 16~30

O

C 18~43 18~43

O

C / /

Condenser Form Aluminum Fin-copper Tube Aluminum Fin-copper Tube

Condenser Pipe Diameter mm Φ7 Φ7

Condenser Rows-n Gap mm 2-1.4 2-1.4

Condenser Coil Length (LXDXW) mm 597X25.4X342.9 597X25.4X342.9

Fan Motor Speed (H/M/L) rpm 950/880/780 950/880/780

Fan Motor Power Output W 60 60

Fan Motor RLA A 0.5 0.5

Fan Motor Capacitor μF 4 4

Outdoor Unit Air Flow Volume m3/h 850 850

Fan Type Axial-ow Axial-ow

Fan Diameter mm Φ353 Φ353

Sound Pressure Level (H/M/L) dB (A) 58/56/54 58/56/54

Sound Power Level (H/M/L) dB (A) 68/66/64 68/66/64

Defrosting Method / /

The above data is subject to change without notice. Please refer to the nameplate of the unit.

10

Technical Information

Page 13

Service Manual

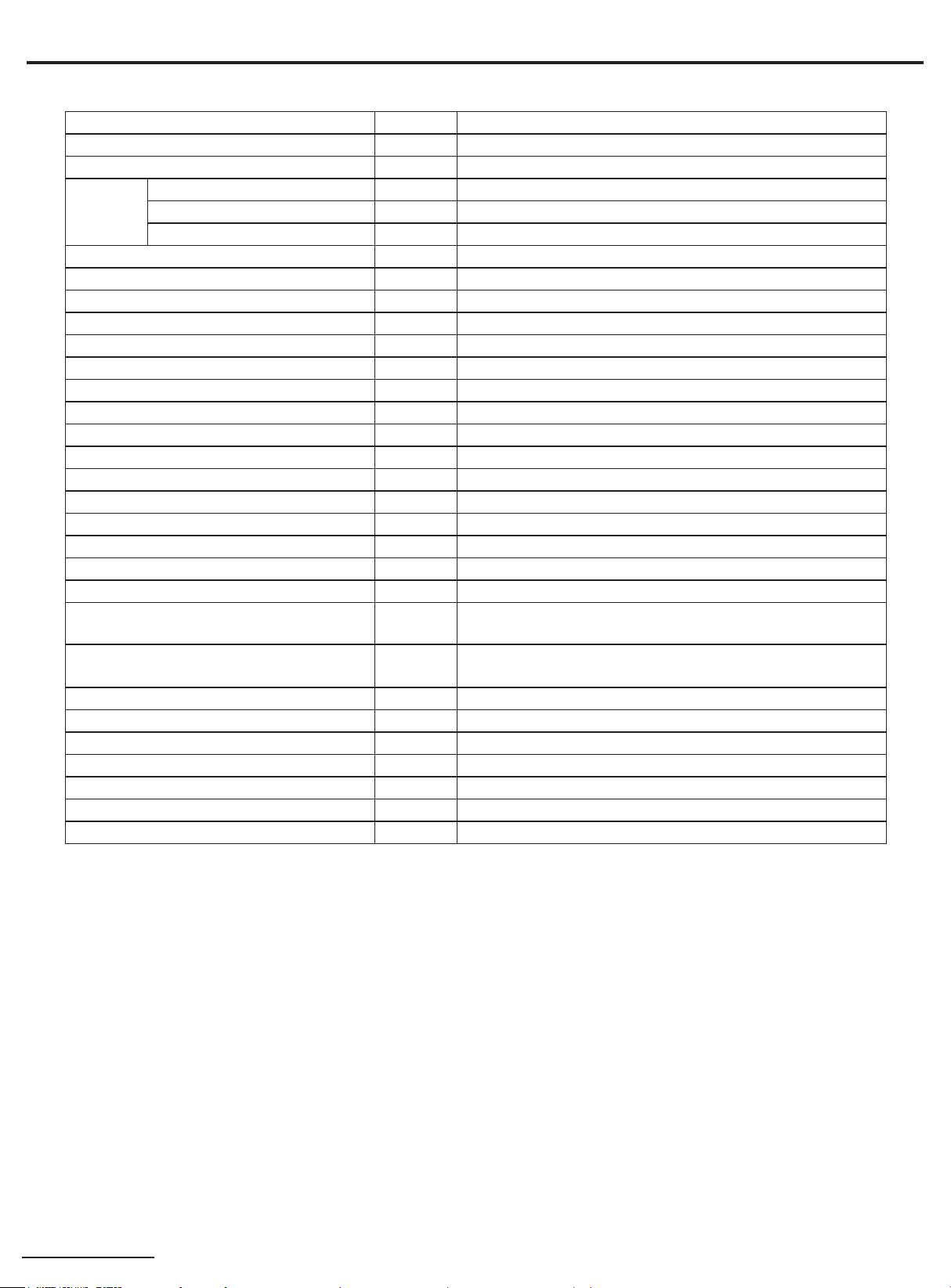

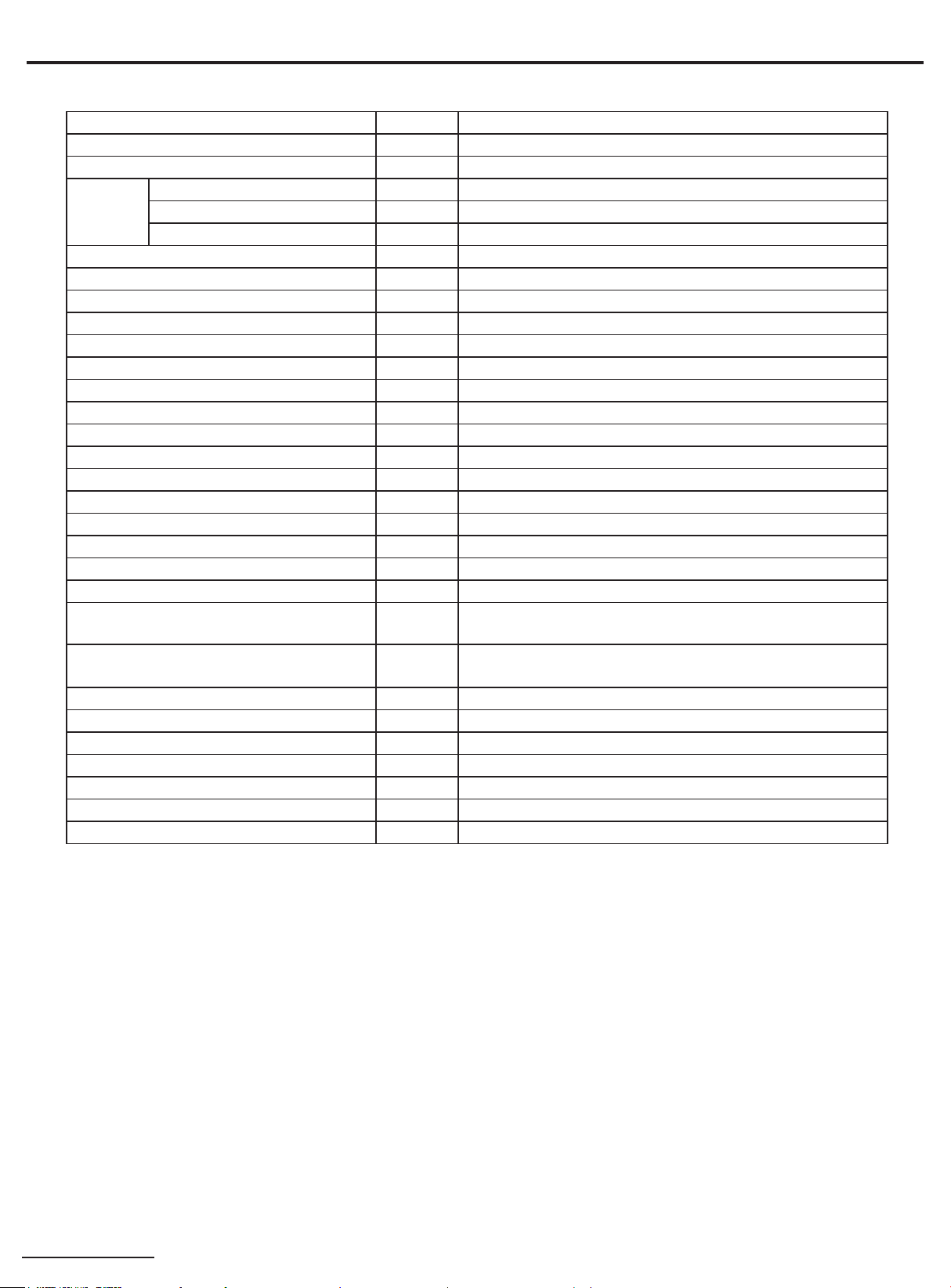

Parameter Unit Value

Model AED12KP

Product Code CC052024400_K93412

Power

Supply

Rated Voltage V~ 220

Rated Frequency Hz 60

Phases 1

Cooling Capacity W 3480

Heating Capacity W /

Cooling Power Input W 1090

Heating Power Input W /

Cooling Power Current A 5

Heating Power Current A /

Rated Input W 1400

Rated Current A 7.57

Air Flow Volume (H/M/L) m3/h 760/710/660

Dehumidifying Volume L/h 1.3

EER W/W 3.19266055

COP W/W /

Application Area m

2

Climate Type T1

Isolation I

Moisture Protection IP24

Permissible Excessive Operating Pressure for

the Discharge Side

Permissible Excessive Operating Pressure for

the Suction Side

Dimension (WXHXD)

MPa 3

MPa 1.5

mm 660X428X700

Dimension of Carton Box (LXWXH) mm 790X736X500

Dimension of Package (LXWXH) mm 793X739X515

Net Weight kg 52

Gross Weight kg 57

Refrigerant R22

Refrigerant Charge kg 0.68

16-24

Technical Information

11

Page 14

Indoor

Side

Outdoor

Side

Service Manual

Fan Type Centrifugal

Fan Diameter Length (DXL) mm Φ201.5X109.5

Cooling Speed (H/M/L) r/min 900/780/730

Heating Speed (H/M/L) r/min /

Fan Motor Power Output W 100

Fan Motor RLA A 0.8

Fan Motor Capacitor μF 7

Electric Heating Power Input W /

Evaporator Form Alumium Tube

Evaporator Pipe Diameter mm Φ7

Evaporator Row-n Gap mm 3-1.6

Evaporator Coil Length (LXDXW) mm 392X38.1X381

Swing Motor Model MP28ED

Swing Motor Power Output W 2

Fuse Current A 3.15

Sound Pressure Level (H/M/L) dB (A) 57/55/53

Sound Power Level (H/M/L)

dB (A)

67/65/63

Compressor Manufacturer Air Conditioning Compressor Divison(Tianjin) LG Electronics Inc.

Compressor Model QK164KBD

Compressor Oil SUNISO 4GSI

Compressor Type Rotary

Compressor LRA A 24

Compressor RLA A 5.07

Compressor Power Input W 1060

Compressor Overload Protector MRA12124-12026

Throttling Method Capillary

Set Temperature Range

Cooling Operation Ambient

Temperature Range

Heating Operation Ambient

Temperature Range

O

C 16~30

O

C 18~43

O

C /

Condenser Form Aluminum Fin-copper Tube

Condenser Pipe Diameter mm Φ7

Condenser Rows-n Gap mm 3-1.4

Condenser Coil Length (LXDXW) mm 665X38.1X400

Fan Motor Speed (H/M/L) rpm 900/780/730

Fan Motor Power Output W 100

Fan Motor RLA A 0.8

Fan Motor Capacitor μF 7

Outdoor Unit Air Flow Volume m3/h 1300

Fan Type Axial-ow

Fan Diameter mm Φ396

Sound Pressure Level (H/M/L) dB (A) 62/60/58

Sound Power Level (H/M/L) dB (A) 72/70/68

Defrosting Method /

The above data is subject to change without notice. Please refer to the nameplate of the unit.

12

Technical Information

Page 15

Service Manual

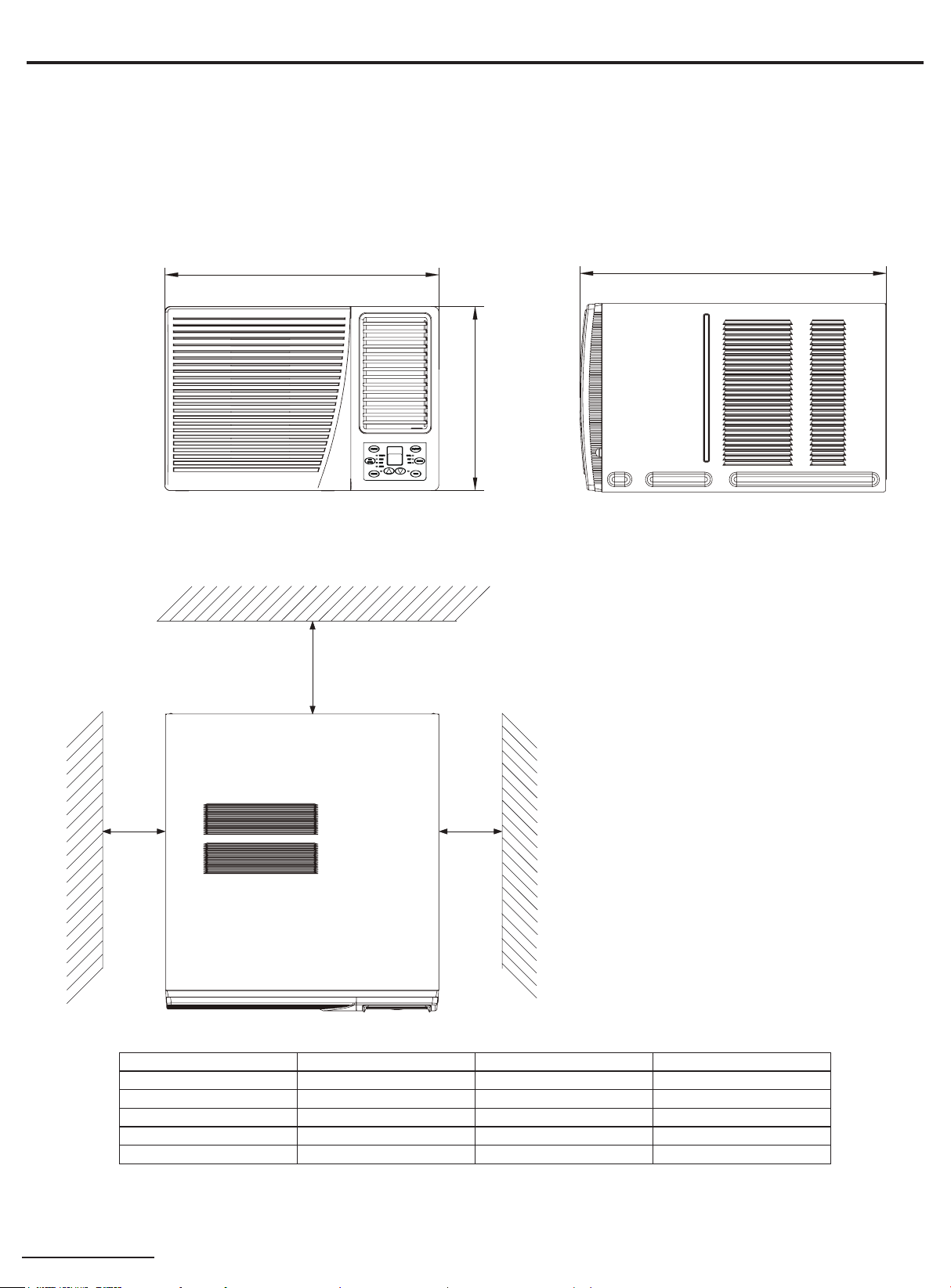

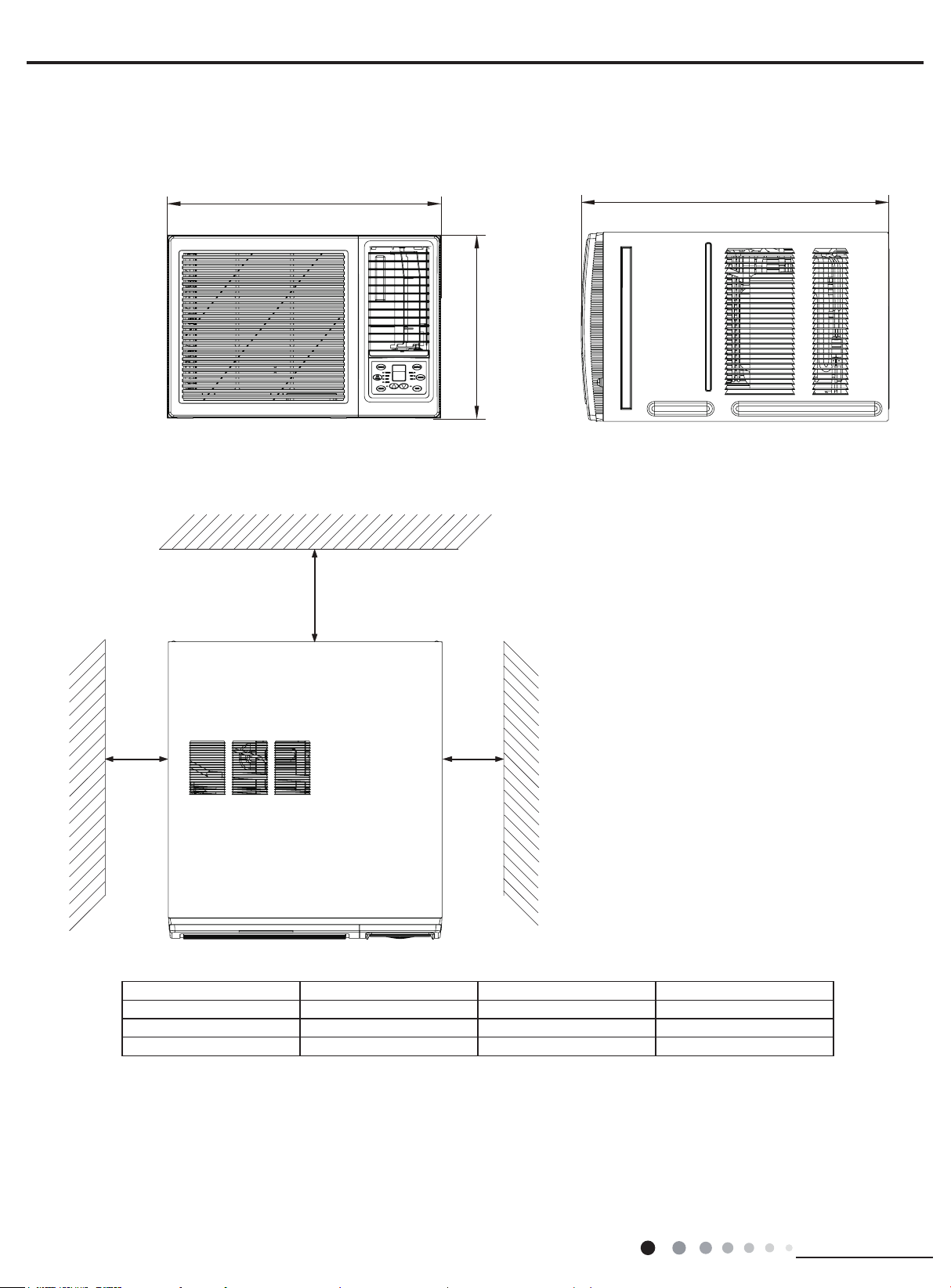

3. Construction Views

(1)Models:AEE07KP,AEE09KP,AEE12KP,AEE18KP,AEE24KP

W D

H

Over

150

Over 500

Over

150

Unit:mm

Model W H D

AEE07KP 450 350 580

AEE09KP 560 375 618

AEE12KP 560 375 618

AEE18KP 660 428 770

AEE24KP 660 428 770

Technical Information

13

Page 16

(2)Models:AED07KP,AED09KP,AED12KP

W D

Service Manual

H

Over

150

Over 500

Over

150

Unit:mm

Model W H D

AED07KP 560 375 668

AED09KP 560 375 668

AED12KP 660 428 700

14

Technical Information

Page 17

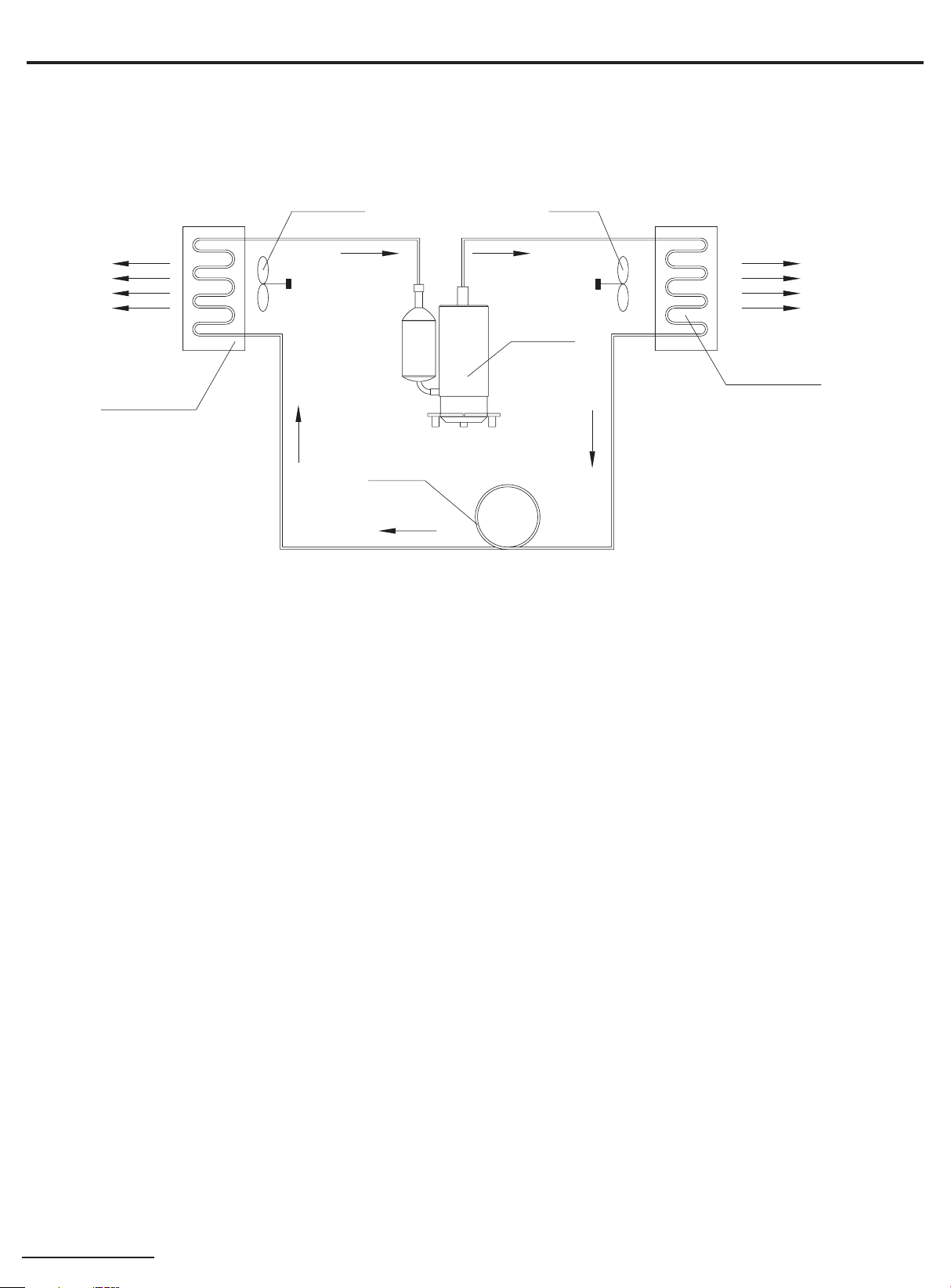

Service Manual

R

REFRIGERANT FLOW DIRECTION

CENTRIFUGAL

4. Refrigerant System Diagram

COOLED AIR

INDOOR COILS

OR CROSS FAN

AXIAL FAN

HOT DISCHARGED AI

COMPRESSOR

OUTDOOR COILS

CAPILLARY

Technical Information

15

Page 18

5. Schematic Diagram

BN(BK)

TRANSFORMER

FAN MOTOR

DISPLAY BOARD

TUBE TEMP.TEMP.ROOM

W4

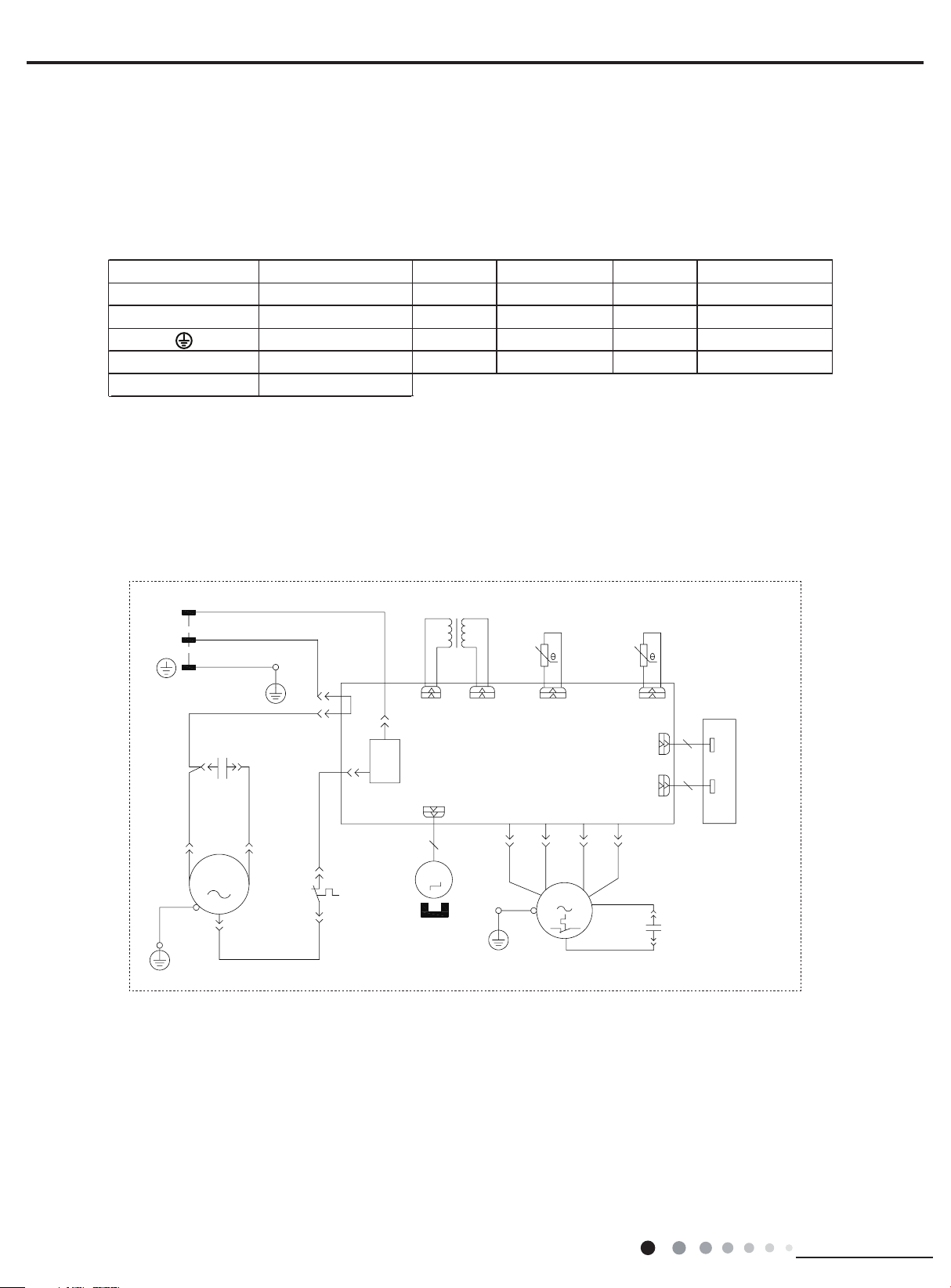

5.1 Electrical Data

Meaning of marks

Symbol Parts name Symbol Color symbol Symbol Color symbol

SAT

COMP

C1

C2

5.2 Electrical Wiring

OVERLOAD

COMPRESSOR

PROTECTIVE EARTH

CBB65

CBB61

BU

YE

RD

YEGN

BLUE

YELLOW

RED

YELLOW GR EEN

VT

OG

BK

BN

Service Manual

VIOL ET

ORAN GE

BLACK

BROWN

(1)Models:AEE07KP, AEE09KP, AEE12KP, AED07KP,

AED09KP,AED12KP

L

BU

BU

COMP

C

PE

BU(WH)

YEGN(GN)

PE

CAP.

C1

YEW2

COMP.

W1

BK

(RD)

S

SAT

N1

TR-INTR-OUT

L

PRINTEDCIRCUIT BOARD

COMP

OVERLOAD

CN2

5

M2

SWING

PROTECTOR

MOTOR

N

POWER

W3

R(M)

YEGN

TC

BU

YEGN

AP1

FL

PE

SENSOR

TUBE

FM

YE

M1

BK

FH

WH

RD

RT2RT1

N2

SENSOR

ROOM

CN1

CN3

BN

C2

10

CAP.

7

DISPLAY

RECEIVER AND

AP2

16

Technical Information

Page 19

Service Manual

ROOM PIPE

FAN MOTOR

BN(BK)

R(M,V)

D

D

TEMP. SENSOR

ROOM TUBE

TRANSFORMER

BU(WH)

BN(BK)

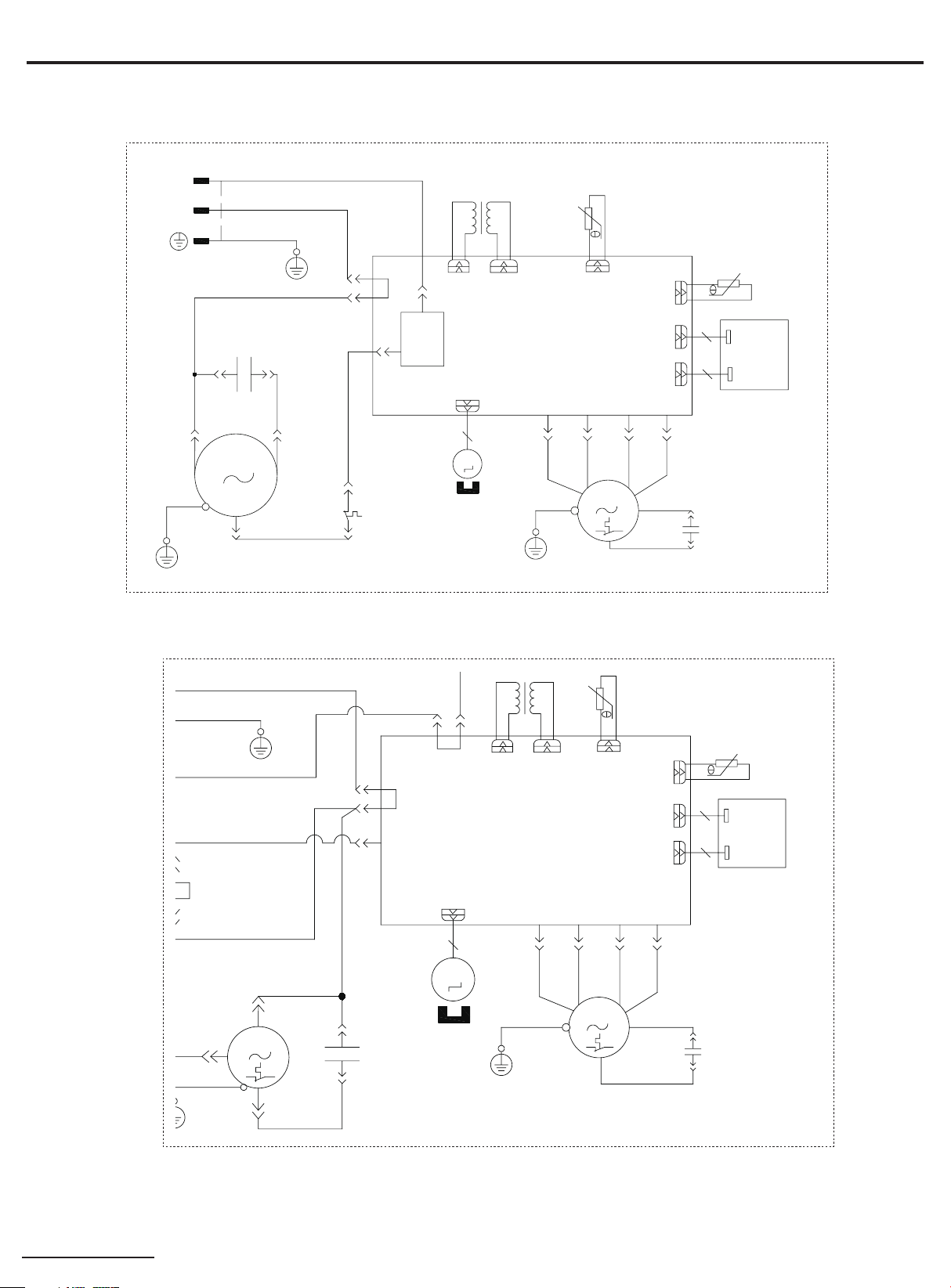

(2)Model:AEE18KP

L

N

POWER

BU

BU

YEGN

PE

COMPRESSOR

(3)Model:AEE24KP

BU

PE

BU(WH)

YEGN(GN)

CAP.

C1

COMP

PE

C(T,U)

YE

S(W,X)

BK

(RD)

X107

COMP

K101

SAT

OVERLOAD

PROTECTOR

TRANSFORMER

TR-INTR-OUT

L

CN2

5

M2

STEPPING

MOTOR

TEMP. SENSOR

AP1

CONTROLLER

X113

X112

(FL)

(FM)

BU

YE

YEGN

PE

PE

TUBE

M1

BK

X114

(FH)

ROOM

CN1

CN3

WH

BN

RD

10

X4

C2

ROOM TEMP.

SENSOR

7

AP2

DISPLAY

RECEIVER AND

DISPLAY BOAR

CAP.

YEGN(GN)

PE

W7BK

5

RELAY

1

6

R(M)

C

COMP

W8BU

S

W3BU

C1

COMP.

W5BU

J

W4BU

CAP.

W2YE

X5(AC-L)

X107(N1)

COMP

PRINTEDCIRCUIT

CN2

5

M2

SWING

MOTOR

PE

TR-OUTTR-IN

AP1

X112

(FL)

YEGN

X113

(FM)

FAN

MOTOR

TUBE

BOARD

X114

(FH)

M1

ROOM

WHBU YE BK

RD

CN1

CN3

X4(N2)

BN

C2

ROOM TEMP.

SENSOR

7

AP2

DISPLAY

10

RECEIVER AND

DISPLAY BOAR

CAP.

Technical Information

These circuit diagrams are subject to change without notice, please refer to the one supplied with the unit.

17

Page 20

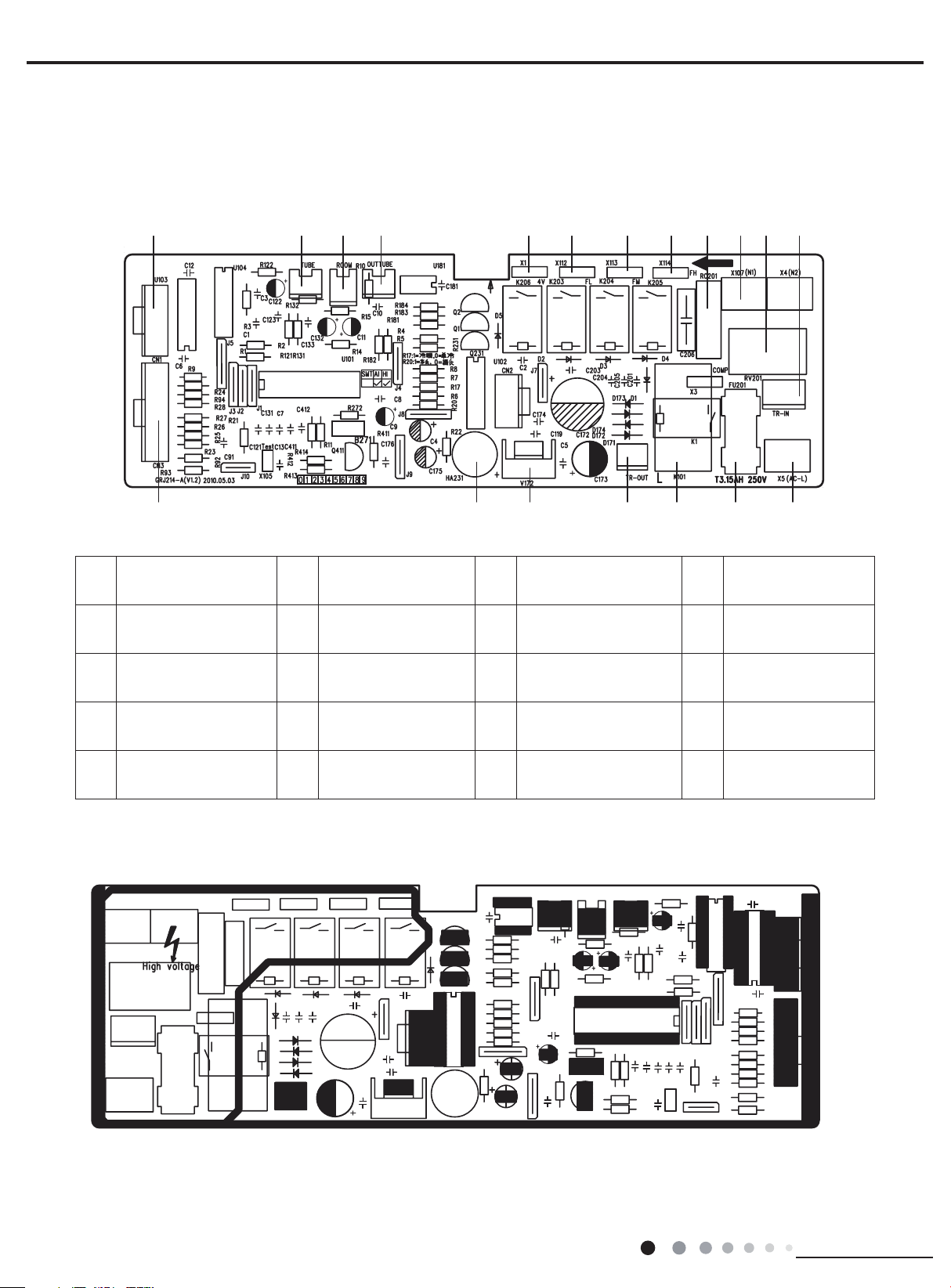

5.3 Printed Circuit Board

Main board

● TOP VIEW

Service Manual

10111415 13 12 9819 18 17 16

Board connection wire

1

interface needle

2 Buzzer 7 Live wire copper insert 12 High fan speed interface 17

3 7805 regulated block 8 Transformer input port 13

4 Transformer outlet port 9 Piezoresistance 14 Low fan speed interface 19

5 Compressor relay 10

● BOTTOM VIEW

6 Fuse 11

Neutral wire copper

insert

resistance-capacitor

module

Medium fan speed

interface

15 4-way valve interface 20 /

Outdoor tube

16

temperature sensor

Indoor ambient

temperature sensor

Indoor tube

18

temperature sensor

Board connection

wire needle interface

7654321

18

Technical Information

Page 21

Service Manual

elay ON-When the air conditioner is off,

1

n

settings.

6. Function and Control

6.1 Remote Control Operations

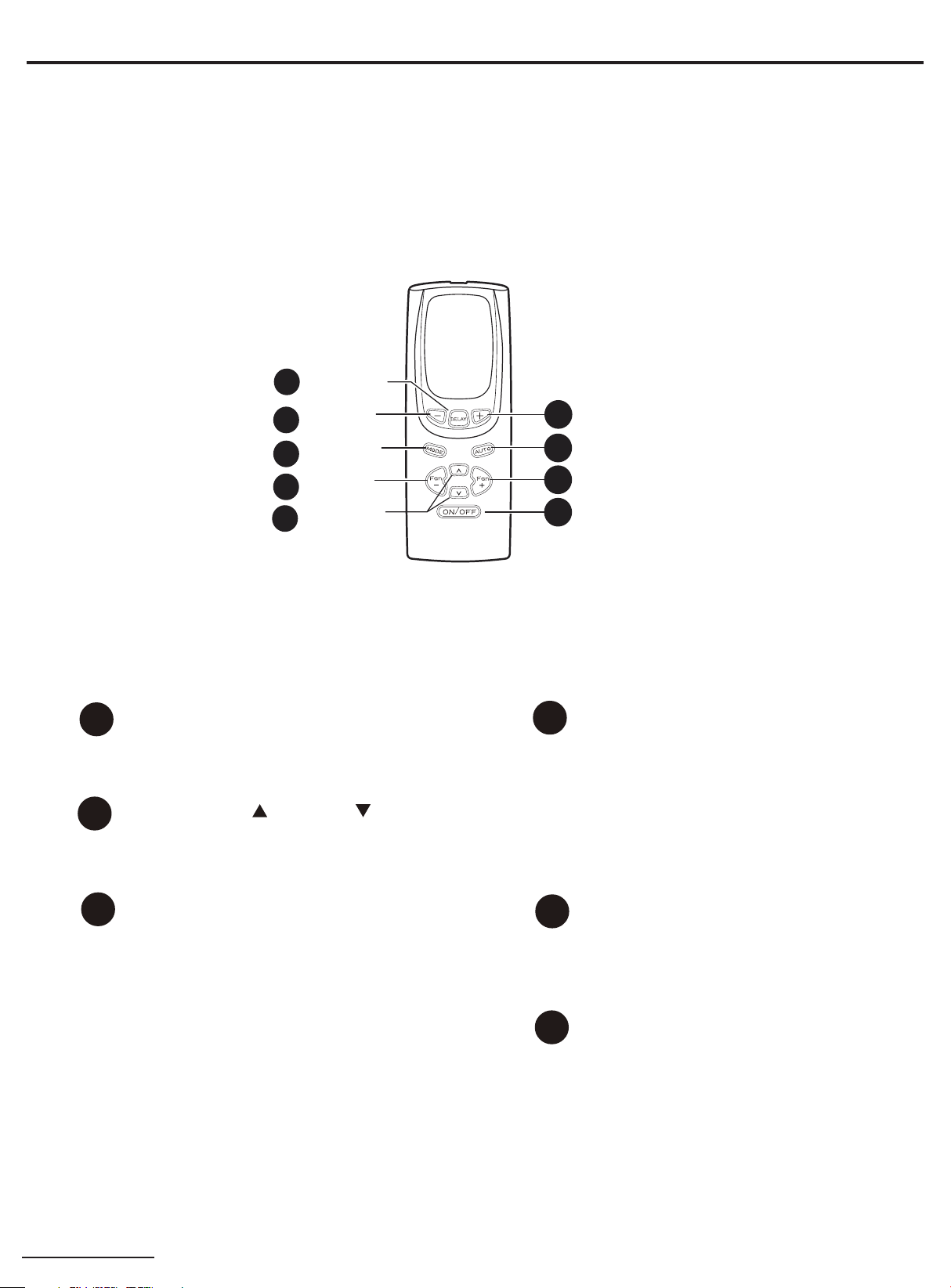

(1)Models:YK4EB (AEE07KP,AEE09KP,AEE12KP,AEE18KP,AEE24KP)

Delay 1–24hr

6

Delay timer

3

Decrease

Mode select

5

Fan speed

4

Decrease

Temperature

2

set Increase

and Decrease

Power Pad

1

Turns air conditioner on and off.when

turned on, the display will show the rooom temperature.

Temp Increase /Decrease Pads

2

Use to set temperature when in

Cool/Energy Saver .The Set light will

turn on while setting.

Delay Timer Increase (+) /Decrease

3

(-) Pads

Each touch of the Increase / Decrease

pads on the unit or the Increase +/De-

crease - pads on the remote control will

set the delay time when using the Delay

1-24hr timer.The Set light will turn on

while setting.

Remote Control

Delay timer Increase

3

Auto Fan on

4

Fan speed Increase

4

Unit power on/off

1

Fan Speed Pads

4

Use the Fan Speed Pads on the unit to

set the fan speed to Low,Med,High or

Auto fan.NOTE: On the remote control, use

the fan speed Increase+/Decrease- pads

to set the fan speeds to Low, Med or High.

Use the Auto pad to turn Auto fan on.

Mode Pad

5

Use to set the air conditioner to Cool,

Energy Saver,Fan only mode.

Delay Pads

6

D

it can be set to automatically come on in

to 24 hours at its previous mode and fa

Technical Information

19

Page 22

Service Manual

begin.

Cooling Descriptions

Delay OFF-When the air conditioner is on,it can be

set to auto matically turn off in 1 to 24 hours.

How to set:

Press the Delay 1-24hr pad on the unit or the DELAY

pad on the remote control. Each touch of the Increase/

Decrease pads on the unit or the Increase + / De-

crease - pads on the remote control will set the timer

in 1 hour intervals.

setting.

To review the remaining time on the Delay 1-24hr

timer, press the Delay 1-24hr pad on the unit or

the DELAY pad on the remote control. Use the Increase/

Decrease pads on the unit or the Increase+/De-

crease- pads on the remote control to set a new

time if desired.

setting,press Delay 1-24hr button on the panel

or Delay button on the remote controller to cancel the timer setting.

The Set

During preview of time or timer

light will turn on while

Remote Control

To ensure proper operation, aim the remote control

at the signal receiver on the air conditioner.

The remote control signal has a range of up to 20

feet.Make sure nothing is between the air

conditioner and the remote control that could block

the signal.

Make sure batteries are fresh and installed correctly

as indicated on the remote control.

Cool Mode

Use the Cool mode at Low, Med, High or Auto Fan

Speed for cooling. Use the Temperature Increase/

Decrease pads to set the desired temperature be-

tween 64

The compressor will cycle on and off to keep the

room at the set level of comfort. Set the thermostat at

a lower number and the indoor air will become

cooler. Set the thermostat at a higher number and

the indoor air will become warmer.

NOTE: If the air conditioner is off and is then turned

on while set to a Cool setting or if turned from a fan

setting to a Cool setting, it may take approximately 3

minutes for the compressor to start and cooling to

F in 1F increments.F and 86

For Normal Cooling Select the Cool mode and

or Med fan with a middle set temperature.

For Maximum Cooling Select the Cool mode and

High

fan

& Night time Co

ow fan with a middle set

Energy Saver Mode

The fan will cycle on and off with the compressor.T-

results

his

nd humidity.

ied. NOTE:The

me after the compressor

Fan Only Mode

Use the Fan Only Mode at Low, Med or High fan sp-

eed to pr

ooling. Since fan

ing, a Set temperature can

temperature will appear in the

NOTE:Auto Fan Speed cannot be used when in the

Fan Only Mode.

Auto Fan Speed

Set to Auto fan speed for the fan speed to autom-

atically set

um comfort settings

the room needs more cooling,

automatically increase.If the room needs

NOTE:Auto Fan Speed cannot be used when in the

Fan

Only Mode.

Power Outage Recovery Feature

In the case of a power outage or interruption, the u-

automati

nit will

after the po

ure was set, it will

morized time

desired.

with a

lower set temperature. For Quieter

oling Select the

temperature.

wider variations of room temperature a-

in

Normally used

may continue to run

fan

cycles off.

ovide air

circulation and filtering without c-

only settings do

to the

speed needed to provide optim-

with the set

will automatically decrease. the fan speed

cally restart in the settings last used

wer

is restored. If

countdown

may

.You

need

Cool mode and L-

when the room is unoccup-

for a short ti-

not provide cool-

not be entered. The room

display.

temperature.If

the fan speed will

less cooling,

the Delay 1-24hr feat-

according to

set a

to

ne

w

the

time if

High

me-

20

Technical Information

Page 23

Service Manual

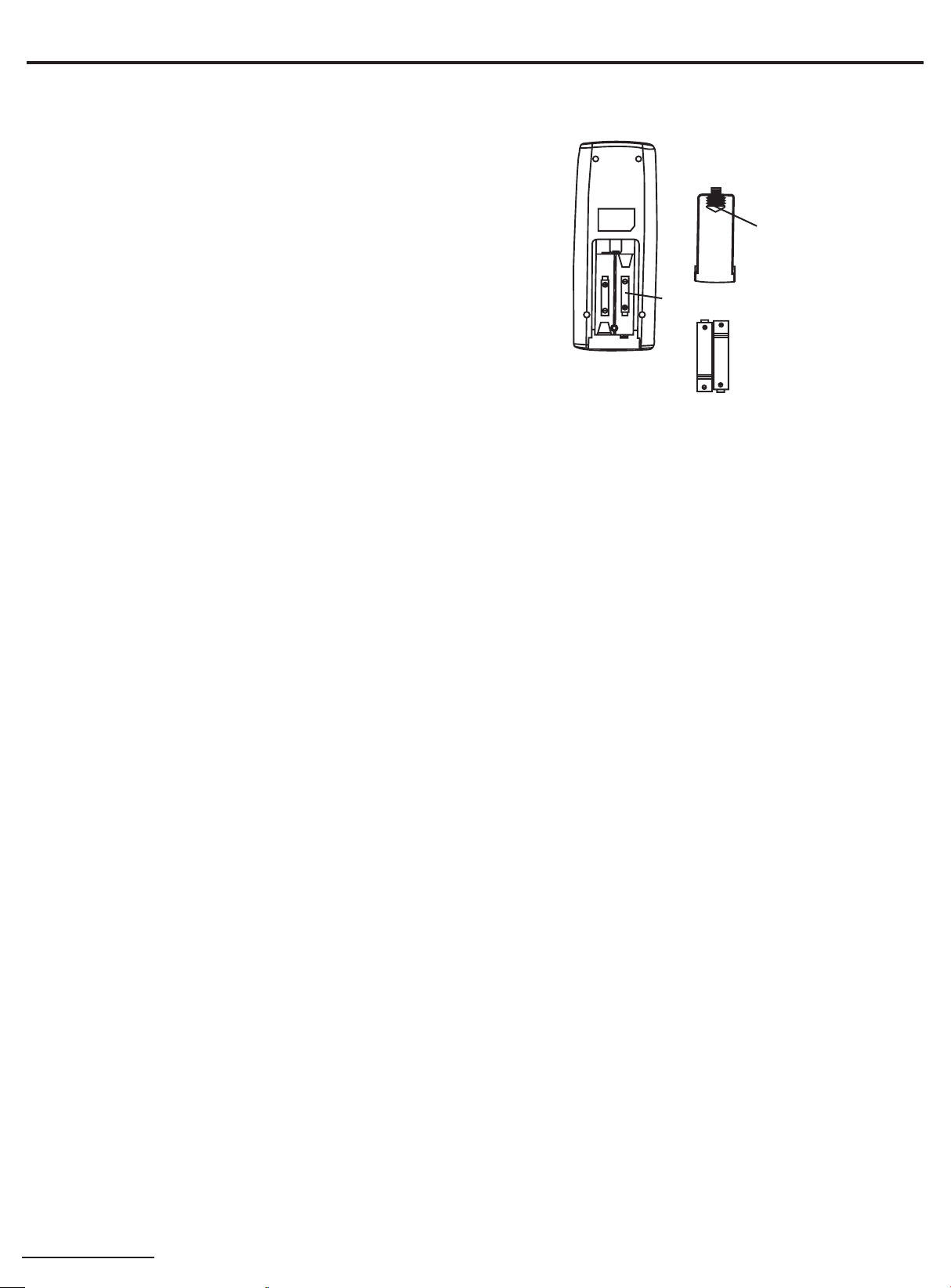

Replacement of Batteries

NOTE:

1.Don’t confuse the new and worn or different types of batteries.

2.Remove batteries when the remote controller is not in use for a long time.

3.The lifetime of the batteries is about one yea

4.The remote controller should be placed about 1m or more away from the TV

5.Bad batteries are forbidden.

Re - attach the cover.

1.Remove the cover from the back of the remote control.

2.Insert the two batteries (T

3.Re-attach the cove

wo AAA dry-cell batteries).

r.

①Remove the cover.

③

②Insert the AAA batteries.

r.

. Or any other electric appliances.

Technical Information

21

Page 24

(2)Model:YS1FA (AED07KP,AED09KP)

Name and Function of Wireless Remote Control

Note: This wireless remote control is universal,and it could be used for many

is not available under FAN or AUTO mode.

other models. The buttons that are not relevant to this unit will not be

described below.

Service Manual

Signal Transmitter

SLEEP

SLEEP button

Press SLEEP button to select sleep on

or sleep off. It is defaulted sleep off after

powering on. will be displayed once

sleep function is set on. The

Remote Control

ON/OFF

MODE

ON/OFF button

Press this button to turn on the unit,

press it again to turn off the unit.

MODE button

Press this button, AUTO,COOL,

FAN,

DRY,

selected

AUTO mode after

unit while the setting

will not be displayed.The initial

setting temperature is 28

under HEAT mode,

under other modes.

HEAt mode can be

circularly.

It is defaulted

powering on the

temperature

℃

(77 F)

℃

25

o

(82 F)

o

FAN

CLOCK

FAN button

Press this button, AUTO,LOW,MED,HIGH

speed can be circularly selected. After

powering on the unit, auto fan speed

is defaulted.Under DRY mode, only

low fan speed can be set up.

AUTO

LOW

HIGH

CLOCK button

Press this button, the clock can be set up,

blinks and displays.Within 5

seconds, the value can be adjusted by

pressing + or - button,if consecutively

press this button for more than 2 seconds,

the value will be fast increasing. Press

CLOCK again during blinking, will be

displayed

is defaulted displaying 12:00 and

after powering on.Either clock time or

timer time could be displayed.

sleep function

MED

and the clock setting is done. It

22

AUTO

COOL

DRY

FAN

HEAT

(Only available for heating unit)

SWING button

When it is pressed,the louvers start to

rotate automatically and stop when

repressed.

Technical Information

Page 25

Service Manual

Note: This wireless remote control is universal,and it could be used for many

other models. The buttons that are not relevant to this unit will not be

described below.

+

+ button

Press this button to increase setting

temperature,

to rapidly

AUTO mode,

adjustable.Setting temperature Range of

Celsius degree:

61-86

increase setting temperature.In

o

F.

-

- button

Remote Control

ENERGY

SAVER

ENERGY SAVER button

Under the COOL and DRY mode,

press

enter

this button again, the unit will exit

ENERGY SAVER mode.

LIGHT

LIGHT button

Press this button to turn ON or OFF

the light or display on the unit.

The light or display is defaulted on

after powering on

this button once, the unit will

ENERGY SAVER mode.Press

the unit.

TIMER

ON

Press this button to decrease setting

temperature,hold for more than 2 seconds

to rapidly

In AUTO mode,setting temperature is

not adjustable.

decrease setting temperature.

TIMER ON button

At unit off,press TIMER ON button,HOUR

ON will blink and display,

concealed in the TIMER ON setting.During

5 seconds blinking,the value can be

adjusted by pressing + or - button,every

press of this button,0.5hour will be increased

or decreased,by continuous pressing the +

or - button,2 seconds later,the value will be

changed quickly,0.5hour will be changed in

every 0.25second automatically by the

remote control.During blinking,press the

TIMER ON button to confirm the time.After

TIMER ON set up,with repressing the TIMER

ON button,the TIMER ON setting will be

canceled.After powered on,no timer is

defaulted, HOUR ON(OFF)will not display,

and only the clock is displayed.After the timer

reached the setting time,HOUR ON(OFF)

will conceal.Before setting the timer,please

adjust the clock to the current actual time.

hold for more than 2 seconds

setting temperature is not

16-30

,Fahrenheit degree:

℃

will be

Technical Information

TIMER

OFF

TIMER OFF button

At unit on,press TIMER OFF button to enter

into TIMER OFF setting.The method of setting

up is the same as TIMER ON.

23

Page 26

Guide for Operation -General Operation

1. After powering on,press ON/OFF button,the unit will start to run.(Note:When

At unit off,press MODE and - button simultaneously to switch between and .

it is powered on,the guide louver of indoor unit will close automatically.)

2. Press MODE button to select desired running mode.

3. Pressing + or - button, to set the desired temperature.

4. Press FAN button to set AUTO,LOW,MED or HIGH fan speed.

5. Pressing button, to select the swing.

Service Manual

Guidefor Operation - Optional Operation

1. Press SLEEP button, to set sleep.

2. Press TIMER ON and TIMER OFF button,to set the scheduled timer on

or timer off.

3. Press LIGHT button, to control the on and off of the light or display

on the unit.

4. Press ENERGY SAVER button to activate the function.

Introduction for Special Function

About AUTO mode

When AUTO mode is selected,the setting temperature will not be displayed on the

remote control,the unit will be in accordance with the room temperature,and automatically

select the suitable running method to make ambient comfortable.

About Lock

Press + and - buttons simultaneously to lock or unlock the keyboard of the remote control.

If the keyboard

three times. If the keyboard is unlocked, the will not display.

is locked, will be displayed on it,press any button, will blink

About Switch Between Fahrenheit and Centigrade

24

ć

Technical Information

Page 27

Service Manual

Changing Batteries

sunlight or any place where is very hot.

1.

Slightly press the place with

2. Take out the used batteries. (As show in figure)

3. Insert two new AAA1.5V batteries,and pay attention to the polarity.

(As show in figure)

4. Push the back cover of remote control.(As show inf figure)

,and push the cover along the arrow.

2

NOTE:

When changing the batteries, do not mix used and new batteries,

do not mix different batteries,otherwise, it can cause the malfunction

of the remote control.

Notices

If the remote control will not be used for a long time,please take out

batteries to prevent any damage from liquid leakage.

The operation should be in its receiving range.

It should be placed 1m away from the TV or stereo sound sets.

If the remote control can not work normally, please take out the

batteries,then reinsert 30S after, if it does not run normally,change the

batteries.

Be sure that there are no obstructions between receiver and remote

control,

Don't drop or throw the remote control,Don't let any liquid get

into the remote control or

1

3

4

Sketch map for

changing batteries

put the remote control directly under the

Technical Information

25

Page 28

(3)Model:YX1F(AED12KP)

Icon Display on Remote

Operation introduction of remote controll

Buttons on Remote Controller

Note:

will blink once. If the air conditioner gives out a beep sound, it means the signal has been sent.

corresponding icon will be displayed); When unit is on, it will display the icon of the on-going function.

1. ON/OFF Button

Press this button to turn unit on/of

2. MODE Button

Pressing this button once can select your required mode circularly as below(the corresponding icon

selected):

Service Manual

ON/OFF button

AUTO

COOL

DRY

FAN

HEAT

ON/OFF

T-ON T-OFF

_

FAN SWING

SLEEP

For auto operation

SWING

SLEEP

LOCK

SPEED

MODE

+

TIMER

Controller

For cooling

For drying

For fan only

For heating

Timer on Timer off

T-ON T-OFF

AUTO

COOL

DRY

FAN

HEAT

SWING

SLEEP

LOCK

SPEED

MODE button

+/- botton

FAN button

SWING button

SLEEP button

TIMER button

Sending signal

For air swing

For sleeping

For locking

For setting fan speed

Set temperature

Set time

er

When power is connected(stand by condition), you can operate the air conditioner through the remote controller.

When unit is on, each time you press the button on remote controller, the sending signal icon on the display of remote controller

When unit is off, set temperature will be displayed on the remote controller(If the light of indoor unit display is turned on, the

f.

AUTO COOL DRYFAN HEAT

26

will be lit up after the mode is

Technical Information

Page 29

Service Manual

When selecting auto mode, air conditioner will operate automatically according to ex-factory setting. Set temperature can't be

adjusted and won't be displayed either

FA

ess

FA

3. +/- butto

remote controller will change quickl

4.

Pressing this button can select fan speed circularly as:

5. SWING Butto

Press this button to turn on up&down air swing.

6. SLEEP

Under Cool, Heat, Dry mode, press this button to turn on Sleep function. Press this button to cancel Sleep function. Under Fan

A

Simple operationfi

1.After putting through power

as third notch for this air conditioner.)

. Press FAN button to adjust fan speed. (This function is not available in this air conditioner.)

When selecting cool mode, air conditioner will operate under cool mode. Then press + or -- button to adjust set temperature. Press

N button to adjust fan speed.

When selecting dry mode, air conditioner will operate at low fan speed under dry mode. In dry mode, fan speed can't be adjusted.

When selecting fan mode, air conditioner will operate in fan mode only. Then press FAN button to adjust fan speed.

When selecting heat mode, air conditioner will operate under heat mode. Then press + or -- button to adjust set temperature. Pr

N button to adjust fan speed.

Pressing + or - button once will increase or decrease set temperature by 1 °F(°C). Hold + or -- button for 2s, set temperature on

When setting Timer On, Timer Off or Clock, press + or -- button to adjust the time (See TIMER Button for setting details).

FAN Button

in this air conditioner. Speed 4 is the same with speed 3).

Note:

Under Auto mode, air conditioner will select proper fan speed automatically according to ex-factory setting.

Fan speed can't be adjusted under Dry mode.

uto mode, this function is unavailable.

7. TIMER Button

When unit is on, press this button to set Timer Off. T-OFF and H icon will be blinking. Within 5s, press + or - button to adjust the

time for Timer Off. Pressing + or - button once will increase or decrease the time by 0.5h. Hold + or - button for 2s, time will change

quickly. Release the button after your required set time is reached. Then press TIMER button to confirm it. T-OFF and H icon will

stop blinking.

When unit is off, press this button to set Timer On. T-ON and H icon will be blinking. Within 5s, press + or - button to adjust the

time for Timer On. Pressing + or - button once will increase or decrease the time by 0.5h. Hold + or - button for 2s, time will change

quickly. Release the button after your required set time is reached. Then press TIMER button to confirm it. T-ON and H icon will stop

blinking.

Cancel Timer On/Off: If Timer function is set up, press TIMER button once to review the remaining time. Within 5s, press TIMER

button again to cancel this function.

Note:

Range of time setting is: 0.5~24h

The interval between two motions can't exceed 5s, otherwise the remote controller will exit setting status.

n

y. Release the button after your required set temperature is reached.

AUTO, SPEED 1( ), SPEED 2( ), SPEED 3( ), SPEED 4( ) (unavailable

AUTO

SPEED 2 (equals to medium fan speed)SPEED 1 (equals to low fan speed)

SPEED 3 (equals to high fan speed) SPEED 4

n

Button

and

rst

2.Press “

3.Press “+” or “-” button to set your required temperature.(temperature can’t adjusted under AUTO mode)

4.Press “

Technical Information

” button to select your required operation mode: AUTO, COOL, DRY, FA N.

” button to select your required fan speed: auto, fi rst notch, second notch, third notch, fourth notch (fourthnotch is same

“

” button on remote controller to turn on the air conditioner.

27

Page 30

Service Manual

1. Press the back side of remote controller on the spot marked with

push out the cover of battery box along the arrow direction.

2. Replace two No.7 (AAA

polar are correct

3. Reinstall the cover of battery box.

Note:

window of the indoor unit;

There should be no obstacle between them.

or wireless telephone; Remote controller should be close to indoor unit during

operation.

batteries.

remove

Replacement of Batteries in Remote Controller

, and then

1.5V) dry batteries and make sure the positions of + and --

.

During operation, point the signal sender of the remote controller at the receiving

The distance between signal sender and receiving window should be within 8m.

Signal may be interfered easily in the room where there is fl uorescent lamp

Replace new batteries of the same model when replacement is required.

If you don't use remote controller for a long time, please take out the batteries.

If the display on remote controller is fuzzy or if there's no display, please replace

battery

reinstall

cover of battery box

28

Technical Information

Page 31

Service Manual

time seting range is from 0.5~24 hours.

t

Remote control panel

AED07KP,AED09KP,AED12KP

1

POWER BUTTON

Operation starts when pressing this button, and stops

when pressing this button again.

2

SWING BUTTON

Activate the automatic air swing function.

3

FAN SPEED BUTTON

Select the fan speed TURBO, HIGH, LOW and AUTO

in sequence.

4

TEMP/TIMER BUTTON

Press the keypad to increase the set (operating)

temperature of the unit and Press the keypad to

decrease the set (operating) temperature of the unit.

The temperature seting range is from 16~30

Press the keypad also to increase the selected time

in 0.5 hour increments,and Press the keypad to

decrease the selected time in 0.5 hour decrements,the

2

3

7

SWING

FAN

SPEED

FILTER

TURBO

HIGH

LOW

AUTO

ON/OFF

COOL

DRY

MODE

FAN

TIMER

5

SIGNAL RECEIVER

6

MODEBUTTON

1

5

6

4

4

Select the operation mode, COOL, DRY, FAN

7

FILTERBUTTON

This feature is a reminder to clean the Air Filter (See

Care and Cleaning) for more efficient operation and

cooling.The LED (light) will illuminate after 250 hours

of operation.To reset after cleaning the filter , press the

"Check Filter" button and the light will go off.

NOTE:

(61~86 F)

ć

o

Control panel is capable of displaying temperature in degrees Fahrenhei

or degrees Celsius,To convert from one to the other, Press and hold the

Up and Down buttons on Control panel together for 3 seconds.

Technical Information

29

Page 32

AEE07KP,AEE09KP,AEE12KP,AEE18KP,AEE24KP

The time seting range is from 0.5~24 hours.

Remote control panel

Note:

Open the surface panel and operate manually.

Service Manual

1

POWER BUTTON

Under OFF mode, press the ON/OFF button to

turn on the unit. and stops when pressing this

button again.

SWING BUTTON

2

Activate the automatic air swing function.

3

FAN SPEED BUTTTON

Select the fan speed LOW,HIGH,TURBO,AUTO in

sequence.

TEMP/TIMER BUTTON

4

Press the to increase the set (operating)

temperature of the unit.and Press the to

decrease the set (operating) temperature of the unit.

The temperature seting range is from 16~30℃(61~86℉).

Press the also to increase the selected time,

and Press the to decrease the selected time.

The time setting will be modified in steps of half an hour

at a time when less than 10 hours, and in steps of an

hour for more than 10 hours.

ENERGY

SAVER

ON/OFF

COOL

FAN

MODE

TURBO

HIGH

LOW

TIMERSWING

TIMER/TEMP

FAN

SPEED

SIGNAL RECEIVER

5

6

MODE BUTTON

Select the operation mode FAN,COOL,AUTO.

7

ENERGY SAVER BUTTON

Under energy saving mode, lamp of energy saving

mode is on, and the temperature setting range is

16~30℃

(61~86

).The buzzer will give out a beep

℉

if remote control turbo speed by remote controller

NOTE:

Control panel is capable of displaying temperature

in degrees Fahrenheit or degrees Celsius,

To convert from one to the other, Press and hold

the Up and Down buttons on Control panel

together for 3 seconds.

30

Technical Information

Page 33

Service Manual

1 Basic Functions

1.1 Cooling Mode

1.1.1 Working conditions and process for cooling

a)

turned on and the fan

b) When

c) When

1.1.2 In this mode, the temperature setting range is 61

1.2 Dry Mode

1.2.1

a)

speed.

b)

speed. Compressor

c) When

1.2.2 In this mode, the temperature setting range is 61

1.3 Energy Sa

1.3.1

a) When

b)

running at set fan speed for 60s.

c) When

1.3.2 In this mode, the temperature setting range is 61

1.4 Fan Mode

1.4.1

1.4.2

1.5

1.5.1 When

1.5.2

1.5.3

first time, the unit will run at fan mode.

6.2 Description of Each Control Operation

(1)Models: AED07KP,AED09KP,AED12KP

When T

indoor ambient≥Tpreset

+2 (1 ), the unit will start working in cooling mode. Meanwhile, compressor will be

will run at set fan speed.

T

indoor ambient

T

preset

T

-2 (1 )< T

-2 (1 ), compressor will stop running, while indoor fan will run at the set fan speed.

preset

indoor ambient

Working conditions and process for drying

When T

When Tpreset-4 (2 )T

Working conditions and process

indoor ambient

> T

will run for 6mins and stop for 4mins, and then it runs like that circularly.

T

indoor ambient

< T

ving Mode

T

indoor ambient≥Tpreset

+4 (2 ), the unit will run according to the cooling mode and the fan will run at low fan

preset

indoor ambientTpreset

-4 (2 ), compressor will stop running, while the fan will run at low fan speed.

preset

+2 (1 ), compressor will be turned on and the fan will run at set fan speed.

<Tpreset+2 (1 ), the unit will keep previous running status.

~86 (16~30 ).

+4 (2 ), the unit will run in dry mode and the fan will run at low fan

~86 (16~30 ).

When T

indoor ambientTpreset

-2 (1 ), compressor will stop running, and the indoor fan will also stop running after

preset

indoor ambient

-2 (1 )< T

T

In this mode, compressor tube will also stop running, while the fan will run at set fan speed.

The temperature setting range is 61 ~86 (16 ~30 ).

Auto Mode

When 72 (22 )<T

T

When T

≥79(26 ), the unit is running according to cooling mode, T

ambient

=68(20 ); if it’s the cooling only controller, the unit will run according to fan mode, T

preset

<79(26 ), the unit will keep original running status; if the unit is energized for the

ambient

Technical Information

< T

+2 (1 ), the unit will keep previous running status.

preset

~86 (16~30 ).

=77(25 ).

preset

=68(20 ).

preset

31

Page 34

2. Other Functions

2.1 Swing

r

the running status before

setting temperature and the temperature can’t be adjusted.

c) The auto

When the fan is running, if swing is set, the swing motor will swing; when swing is stopped, it will stop at the current

position.

2.2 Buzzer

Upon energization and operation, the buzzer will give out a beep.

2.3 Sleep

a) At the time of cooling, energy saving or drying, T

1h and it will increase by 4(2) after 2hrs. 2 hrs later, the setting temperature won’t increase any more. The upper

limit for setting temperature is 86 (30).

b) There’s no sleep function for auto mode or fan mode.

c) When setting sleep function, the sleep function wi ll be cancelled at the time of mode switchover.

2.4 Auto Wind

a) Auto fan speed in cooling mode:

T

ambient≥Tpreset

T

preset<Tambient<Tpreset

T

ambient

b) The auto wind in energy saving mode: fan mode is the same at that in cooling mode.

d) It’s the low fan speed in dry mode. Only the low fan speed LED is bright and other fan speed LEDs won’t be bright.

will increase by 2 (1 ) after sleep program has been set fo

preset

+4 (2 ) high fan speed

+4 (2 ) medium fan speed

Tpreset low fan speed

wind in auto mode is controlled by the actual mode’s auto wind.

Service Manual

2.5 Warning Function of Filter

When the fan has run for 250hrs accumulatively, the filter cleaning LED will be bright to remind the user to clean filter.

2.6 Timer Function

a) Timer ON: Timer ON can be set when the system is at off status. The setting time range is 0.5h~24h~0.5h and the

interval is 0.5h. When timer on is reached, the system will run at the preset mode.

b) Timer OFF: Time OFF can be set when the system is at on status. The setting time range is 0.5h~24h~0.5h and the

interval is 0.5h. When timer off is reached, the system will stop running.

2.7 Memory Func tion

System can memory the running status before power failure. System will run automatically at

power failure after power recovery. If the system is at off status before power failure, compressor will delay for 3mins

for protection after power recovery.

2.8 LED, dual 8 nixietbe

a) In running status, when the main unit is in cooling mode, cooling LED will be bright,

b) In running status, when the main unit s in auto mode, no LED is bright, dual 8 nixietube displays the setting

temperature and the temperature can’t be adjusted.

c) In running status, when the main unit is in energy saving mode, no LED is bright, dual 8 nixietube displays the

32

Technical Information

Page 35

Service Manual

d) In fan mode, fan LED is bright;

f) When the fan speed is low, medium and high, the LED for low, medium and high fan speed will bright respectively.

When it

g)

2.9

a)

8

nixietube; If press “UP/DOWN” button successive

meanw

b)

simult

2.10 Func

a)

ON/OFF

b)

SWING button. When the unit isn’t

c)

F

d) UP

e)

run according to AU

f)

g) Sleep function is only controlled by the sleep button on remote controlle

2.

2.

When antifreezing protection is detected, compressor and ou

set

running status.

2.

a)

for 3s and blink once. It

b) Indoor tube temperature sensor is open circuit or short circuit: dual 8 ni

out for 3s and blink tw

c)

circularly in turn.

e)

In dry mode, dry LED is bright

’s the auto wind, the auto wind LED will be bright.

When timer is set, the timer LED will be bright.

Temp erature Setting

You desired temperature can be set by “UP/DOWN” button and the setting temperature will be displayed on the dual

ly, the setting temperature will be decreased successively and quickly,

hile, the buzzer will give out sound successively.

Dual 8 nixietube can switch the Centigrade and Fahrenheit. They can be switched by pressing “UP” and “DOWN”

aneously for 3s.

tion Setting for Buttons

ON/OFF button is used for turning on or turning off the unit. In off status, the unit will be turned on after pressing

button; in on status, the unit will be turned off after pressing this button.

SWING button is used for turning on/off the swing. At the time of swinging, swing will be turned off by pressing

swing, swing will be turned on by pressing SWING button.

FANSPEED button is used for adjusting the fan speed and it will circulate according to AUTO, FAN, FANL, FANM,

ANH, and AUTO.

and DOWM button is used for increasing/decreasing temperature and timer.

MODE button is used for switching the mode.Cooling only unit won’t receive the signal of HEAT button and it will

TO, COOL, DRY,FAN.

Energy saving mode is only controlled by the energy saving button on remote controller, which can’t be selected by

the MODE button on control panel.

r. There’s no sleep button on control panel.

11 Protection Function

11.1 Antifreezing protection

tdoor fan will stop running, while indoor fan will run at the

fan speed. After antifreezing protection is released and it’s delayed for 3mins, the unit will resume original

Technical Information

11.2 Malfunction Detection for Temperature Sensor

Ambient temperature sensor is open circuit or short circuit: dual 8 nixie tube will displays F1. Cooling LED will go out

will bright for 0.5s and go out for 0.5 when blinking.

ice. It will bright for 0.5s and go out for 0.5 when blinking.

When many kinds of malfunction happen simultaneously, the malfunction protection codes will be displayed

xie tube will displays F2. Cooling LED will go

33

Page 36

Service Manual

(2)Models: AEE07KP,AEE09KP,AEE12KP,AEE18KP,AEE24KP

1. Operation mode

1.1 COOL 1.2 AUTO 1.3 FAN 1.4 DRY

2. System basis function

2.1 Cooling mode

Cooling conditions and process:

a. When Tamb. ≥Tpreset+2℉(1℃), the unit starts cooling operation. In this case, the compressor is tuned onand the indoor

fan operates at set speed;

b. When Tamb. ≤Tpreset-2℉(1℃), the compressor stops operation and the indoor fan runs at set speed;

c. When Tpreset-2℉(1℃)<Tamb. <Tpreset+2℉(1℃), the unit will maintain its previous running status;In this mode,

temperature setting range is 61~86℉ (16~30℃).

2.2 Auto mode

Working condition and process under auto mode

a. When Tamb≥79℉ (26℃), the unit operates in cooling mode. Tpreset=77℃(25℃).

b. When Tamb≤72℉ (22℃), the unit operates in fan mode. Tpreset=68℃(20℃).

c. When 72℉ (22℃)<Tamb.<79℉ (26℃), the unit keeps the originals operation status.

2.3 Fan mode

(1) Under this mode, compressor stops operation and the fan operates at set fan speed;

(2) The temperature setting range is 61~86℉ (16~30℃).

2.4 Dry mode

(1) Drying conditions and process:

a. When Tamb>Tpreset+4℉ (2℃), the unit operates in cooling mode. Compressor is turned on and the fan

operates at low speed;

b. When Tpreset-4℉ (2℃) ≤Tamb≤Tpreset+4℉ (2℃), the unit operates in drying mode. The fan operates at

low speed. The compressor operates for 6 minutes and then stops for 4 minutes, and it will operates like that circularly;

c. When Tamb<Tpreset-4℉ (2℃), compressor stops operation and the fan operates at low speed.

(2) Under this mode, the temperature setting range is 61~86℉ (16~30℃).

3. Other control

3.1 Swing function can be controlled by the swing button on remote controller or control panel.

3.2 Upon energization or availably operating the unit or remote controller, the buzzer will give out a beep.

3.3 Sleep function

a. Under COOL, ENERGY SAVE, or DRY mode, after sleep function is set for 1 hour, Tpreset will increase 2℉ (1℃); 2 hours

later, Tpreset will increase 4℉ (2℃) and then the temperature wont increase any more.

3.4 Timer function

(1) Timer ON can be set at unit OFF. If selected ON time is reached, the unit will start to operate according to previous setting

status. Time setting range is 0.5-24hr in 30-minute increments.

(2)Timer OFF can be set at unit ON. If selected OFF time is reached, the unit will stop operation. Time setting range is 0.5-24hr

in 30-minute increments.

3.5 Indicator, dual-8 nixie tube

Under operation status, the corresponding mode indicator is ON and dual-8 nixie tube displays set temperature.

3.6 Button function setting

(1) ON/OFF button: turn on or turn off the unit;

(2) Swing button: turn on or turn off swing function;

(3) FAN SPEED button: set speed;

(4) UP, DOWN button: adjust the temperature;

(5) Mode button: switch the mode;

(6) Energy save mode can only be set by the button on remote controller, which cant be set by MODE button on control panel;

(7) Sleep function can only be set by the sleep button on remote controller. Sleep button is not available on control button.

34

Technical Information

Page 37

Service Manual

Installation Precaution

1)

2)

3)

e

7. Installation Instructions

Incorrect installation of the unit may lead to death, personal injury, or

property damage. Only trained, qualified installers and service personnel

are allowed to install, start-up, and service this equipment. Casualty, injury

or damage due to incorrect installation or installation by unqualified personel

will not be assumed by us.

Location

Install the unit where:

● The condensate can be easily drained out.

● It is with a minimum distance of 1m away from TV set or any other electric appliance.

● There is no leakage of inflammable gas.

● There is no other heat source or direct sunlight.

● It is out of reach of children.

● Do not install the unit in a laundry, or a bathroom or around a swimming pool, etc.

● Consult your seller before installation when the unit is to be installed in an area where salt-laden air prevails(close

to coastal areas, etc), the air contains sulphurous gas (in hot spring zones), or there are other special conditions.

● For window type air conditioner with a remote controller, contact your seller when it is to be installed in a place

where there is strong electromagnetic interference.

How to Install

● Choose a location where there is not any obstacle surrounding the unit.

● Prepare the installation hole a little bigger than the size of the unit.

● Choose the installation space according to the diagrams in Part 3 Outline and Installation Dimension.

Installation

Remove the sticker from the front panel.

Put the unit into the installation hole.

● When installing, make sure the unit is slanted downward to the back to

minimize the nosie and vibration of operation. (Slant by 6-10mm.)

(See the right figure)

● Make sure the installation place is strong enough to minimize the noise

and vibration of operation.

Fill the gaps in the cabinet with sponge or foam.

Procedure:

.

Horizontal line

6~10mm

Installation of Accessories:

To install iron support

Make sure the installation hole is strong enough to support the air

Installation and Maintenance

conditioner. If not, install an iron support to hold the unit.The iron

support should be fixed on the outside of the building See the

(right figure)

To install sunshade baffle

To avoid dropping anything onto the unit or exposing the unit to direct

sunlight, contact your seller to install a sunshade baffle for the unit. When

installing, make sure the air inlet at the side grille will not be blocked.

Wall

Wooden frame

Rubber plate

Sunshade baffl

6~10mm

Support

Horizontal line

35

Page 38

Drain Water

To maximize cooling efficiency, the air conditioner is designed to spray condensate on to the

Notes for Installation

●

All electrical work should be performed in accordance with local wiring regulations.

condenser coil.

For cooling only unit: Should the spraying sound annoy you, please adopt the method of outside drain

with the following steps, which may however cause a small loss of performance.

1. Slide out the unit from the cabinet.

2. Remove the rubber plug from the body base plate.

3. Install the drain pan to the corner of the cabinet with 2 screws.

4. Connect the drain hose to the outlet on the bottom of the drain pan.

5. Slide the unit into its original place in the cabinet.

Service Manual

Note:

●

Drain pan and drain hose must be installed before operation.

●

Drain hose or tubing can be purchased locally to satisfy your particular needs.

Relocation

Contact your seller when the unit is to be relocated. Relocation of the

unit shall be performed under the guidance or with the assistance of

a trained, qualified technician. Charges concerning relocation of the unit

shall be borne by the user.

Noise

●

Install in a location firm enough to minimize the noise and vibration of

operation.

●

Do not put anything in front of the outlet of the unit to avoid increasing

noise.

●

Make sure the noise and the hot air discharged will not disturb your neighbors.

●

Should there be any abnormal sound during operation, contact your seller instantly

please adopt a safety support.

●

The temperature of refrigerant circuit will be high, please keep the interconnection

cable away from the copper tube.

Screws

Drain Pan

Internal View

Drain Hose

External View

Electrical Wiring

●

Make sure the unit is reliably grounded.

●

Adopt an exclusive circuit for the unit. Never apply removable socket, or the poor

contact between them may lead to overheating or fire.

●

Never pull the power cord with excessive force.

●

In a fixed circuit, make sure there is electricity leakage protection switch with leakage

current less than 30mA.

●

Connection between air conditioner and its power cord, as well as between individual

elements should be in accordance with the wiring diagram on the unit.

●

Make sure the air conditioner is installed in accordance with national wiring regulation.

●

Adopt an all-pole disconnection switch with a minimum contact separation of 3mm in all poles

in a fixed wiring

●

Make sure an air switch (thermal-magnetic breaker) is installed in the circuit.

●

Damaged power cord should be replaced by the manufacturer, an authorized dealer

or a qualified person for fear of hazards.

36

Installation and Maintenance

Page 39

Service Manual

55

8. Exploded Views and Parts List

(1)Model:AEE07KP

5

6

7

16

12

14

15

17

18

19

49

48

46

47

45

11

13

43

44

10

41

42

50

51

52

53

8

9

37

38

39

40

31

36

35

32

33

34

30

3

4

2

1

20

21

22

23

24

25

26

27

28

29

54

The component is only for rererence;please refer to the actual product

Installation and Maintenance

37

Page 40

Service Manual

NO.

10 Step Motor 15211008 1

11 Propeller housing Assy 26151350 1

12 Propeller Housing 12101121 1

13 Base of Swing Louver 10521123 1

14 Air Inlet Door 26111124 1

15 Cross Beam Sub-Assy 24241200 1

16 Air Louver 10511123 1

17 Centrifugal Fan Sub-Assy 10311125 1

18 Front Clapboard of Propeller Housing 01231203 1

19 Evaporator Assy 01001805 1

20 Compressor and Fittings 00101261 1

21 Compressor Overload Proctector(External) 00183101/00181044 1

22 Compressor Gasket 76710232 3

23 Capillary Sub-assy 03001971 1

24 Inhalation Tube Sub-assy 03631865 1

25 Discharge Tube 03611624 1

26 Water Tray 12411003 1

27 Chassis Sub-assy 0120122501P 1

28 Drainage hole Cap 76711012 1

29 Drainage Box 20181125 1

30 Chassis Clamp 01211151 1

31 Power Cord 4002048914 1

32 Electric Box Assy 20101451 1

33 Transformer 43110236 1

34 Electric Box 20101126 1

35 Terminal Board 42010157 2

36 Sleeving 4203240201 1

37 Main Board 30132096 1

38 Temperature Sensor 390000596 1

39 Ambient Temperature Sensor 390000451 1

40 Capacitor CBB61 33010010 1

41 Display Board 30562053 1

42 Control Panel A 20161220 1

Description

Product Code CC052005800_K93320

1 Cabinet Assy 01431010 1

2 Condenser Assy 0110134501 1

3 Axial Flow Fan 10331160 1

4 Rear Isolation Sheet With Spot Welding 01231097 1

5 Motor Support 01701123 1

6 Fan Motor 15011060 1

7 Top Connecting Plate Assy 01381018 1

8 Front Clapboard Sub-Assy 01231388 1

9 Base Plate Of Air Flue 01221154 1

Part Code

QtyAEE07KP

38

Installation and Maintenance

Page 41

Service Manual

43 Membrane 63061325 1

44 Front Panel Assy 20001231_K93320 1

45 Guide Blade Lever 10581203 1

46 Guide Blade 10511126 12

47 Front Case 20001217 1

48 Filter Sub-Assy 11121204 1

49 Air Intake Panel 20001227 1

50 Capacitor Box Assy 20101150 1

51 Capacitor Box Top Cover 20101122 1

52 Capacitor CBB65 33010045 1

53 Capacitor Box Bottom Cover 20101124 1

54 Remote Controller 30510540_K93320 1

55 Remote Control Cover 20161218 1

The data above are subject to change without notice.

Installation and Maintenance

39

Page 42

(2)Models:AEE09KP,AEE12KP

Service Manual

5

6

7

15

12

14

17

18

19

47

48

16

46

44

45

11

13

42

43

10

40

41

8

9

36

37

38

39

31

32

33

34

35

30

3

4

21

20

21

22

23

24

25

26

27

28

29

49

50

51

The component is only for rererence;please refer to the actual product

40

Installation and Maintenance

Page 43

Service Manual

NO.

10 Step Motor 15211008 15211008 1

11 Propeller housing Assy 12101303 12101303 1

12 Propeller Housing 12101362 12101362 1

13 Cross Beam 24241364 24241364 1

14 Air Door Lever 10581303 10581303 1

15 Air Louver 10511127 10511127 1

16 Base of Swing Louver 10521362 10521362 1

17 Centrifugal Fan 10311004 10311004 1

18 Front Clapboard of Propeller Housing 01231314 01231314 1

19 Evaporator Assy 01001306 01001306 1

20 Compressor and Fittings 00100252 00101015 1

21 Compressor Overload Protector(External) 00180031 00181041 1

22 Compressor Gasket 76710217 76710278 3

23 Capillary Sub-assy 03001493 03001494 1

24 Inhalation Tube Sub-assy 03631556 03631859 1

25 Discharge Tube 03611659 03611768 1

26 Water Tray 12411006 12411006 1

27 Chassis Sub-assy 012013072 012013074 1

28 Drainage hole Cap 76711012 76711012 1

29 Drainage Box 20181125 20181125 1

30 Chassis Clamp 01211307 01211307 1

31 Power Cord 4002048914 4002048911 1

32 Electric Box Assy 20101450 20101445 1

33 Transformer 43110215 43110215 1

34 Electric Box(Remote Control) 20101316 20101316 1