Page 1

Autotrol® Brand 255 Valve / 400 Series Controls

Water Conditioning Control System

Home Owner Installation, Operation, and

Maintenance Manual

For sales or service questions please

contact your local dealer:

Your Local Dealer Is:

Page 2

Table of Contents

Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Valve Illustration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

System Regeneration Cycles (7-Cycle Operation) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Disinfection of Water Conditioners. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Placing Conditioner into Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Valve Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

255/440i Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

260 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Valve Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Safety Information

This water conditioner’s control valve conforms to NSF/ANSI 44 and 61 for materials and

structural integrity only. Generic systems were tested and certified by WQA as verified

by the performance data sheet.

• Please review this entire Installation and Operation manual before installing unit.

• We recommend that this water conditioning unit be installed by a trained

professional water treatment dealer. Follow all local codes for plumbing this unit.

• Follow local electrical codes. Install a correctly sized electrical bonding jumper

between the inlet and outlet pipes when these devices are installed in metallic

plumbing systems.

• Inspect this unit carefully for carrier shortage or shipping damage before beginning

installation of unit.

• This system is not intended to be used for treating water that is microbiologically

unsafe or of unknown quality without adequate disinfection before or after the

system.

• This system is to be used only for potable water.

• Use only lead-free solder and flux, as required by federal and state codes, when

installing soldered copper plumbing.

• Use caution when sweat joining metal pipes near this water conditioning system.

Heat can adversely affect the plastic used in this system and bypass valve.

• Use only silicone grease for lubrication of this unit.

• Use only the power transformers supplied with this conditioning systems control

valve unit.

• Do not allow this water conditioning unit to freeze. Damage from freezing will void

this water conditioning unit’s warranty.

• Do not store flammable or volatile chemicals near this water conditioning unit.

• For the purpose of plumbing system sizing, only the rated service (i.e. "Normal") flow

and corresponding pressure loss may be used. The rated service flow rates are the

flow rates at which the performance capabilities of these devices were evaluated.

Contact your local Professional Water Dealer for system service, and to obtain

Autotrol brand replacement parts for this control valve unit.

2

Page 3

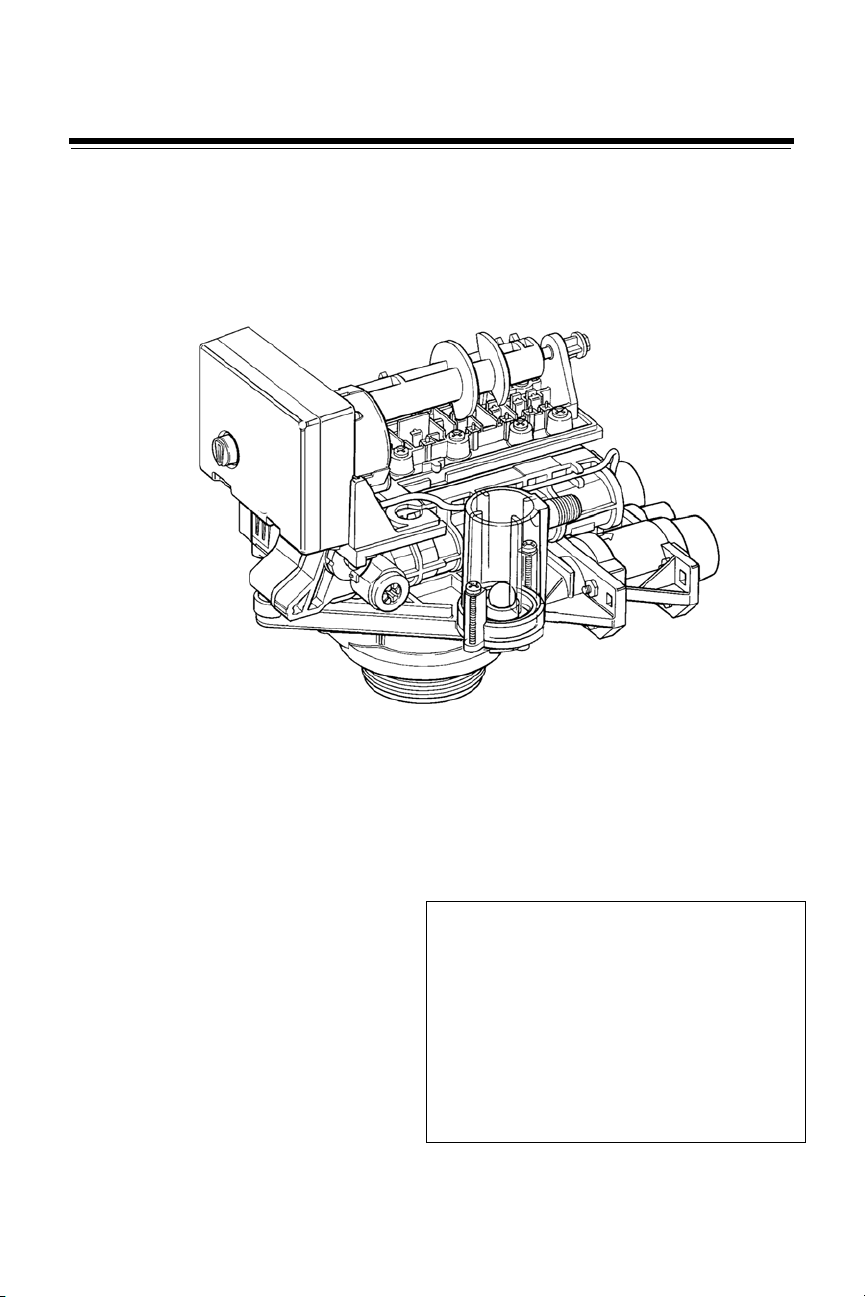

Valve Illustration

Autotrol 255 Valve Control Module

400 Series Control

Standard L-Lid Cover

Variable

Brine Control

Injector Access Plug

Tank Adapter Module

Brine Line Fitting Connection

1/4-inch NPT

Air Check

Air Check

Figure 1

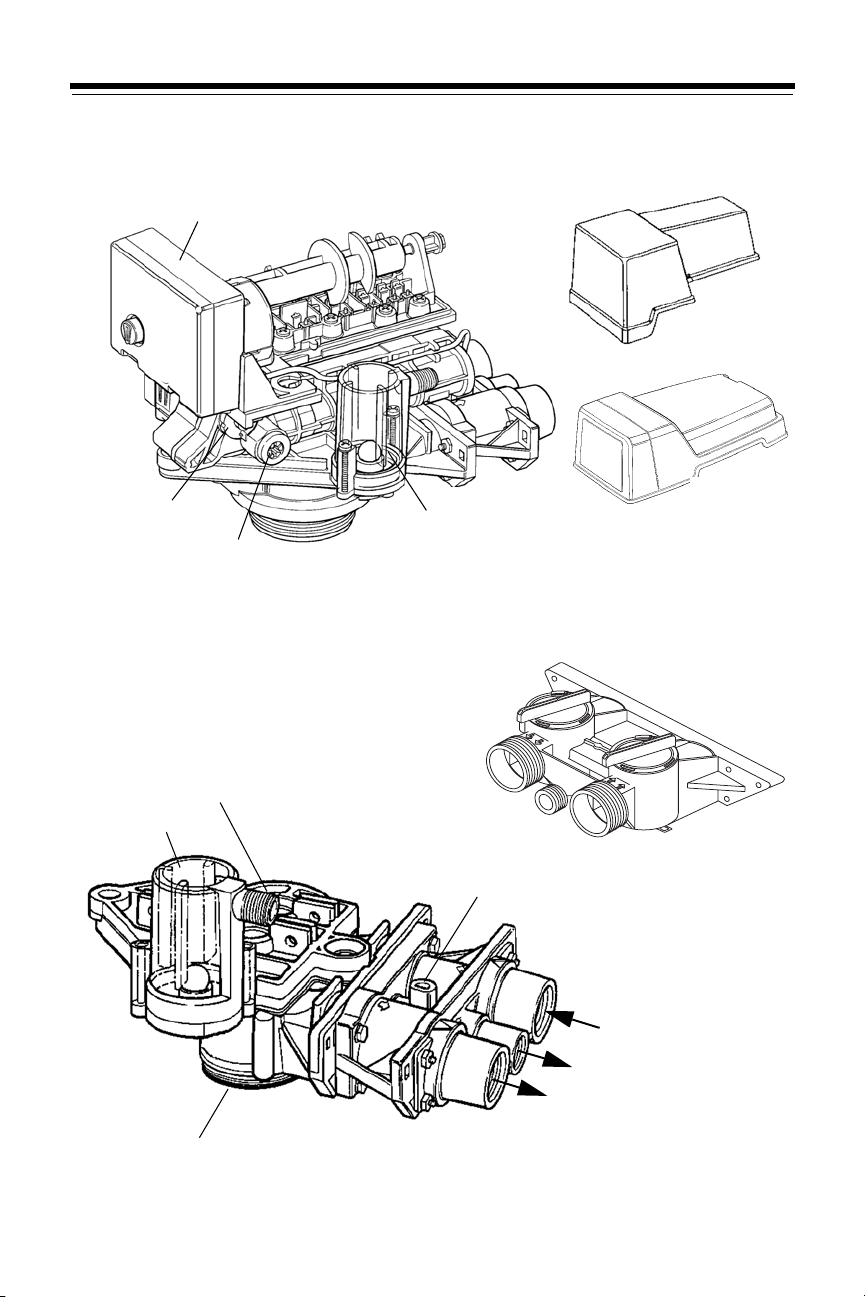

Probe Connection Slot

Optional

Optional i-lid Cover

i-lid Cover

Optional Bypass

S

S

A

P

Y

B

S

S

A

P

Y

B

Inlet Connection 3/4-inch

or 1-inch NPT or BSPT

Drain Connection 3/8-inch

or 1/2-inch NPT or BSPT

Tank Thread 2-1/2-inch - 8 male

Outlet connection 3/4-inch

or 1-inch NPT or BSPT

Figure 2

3

Page 4

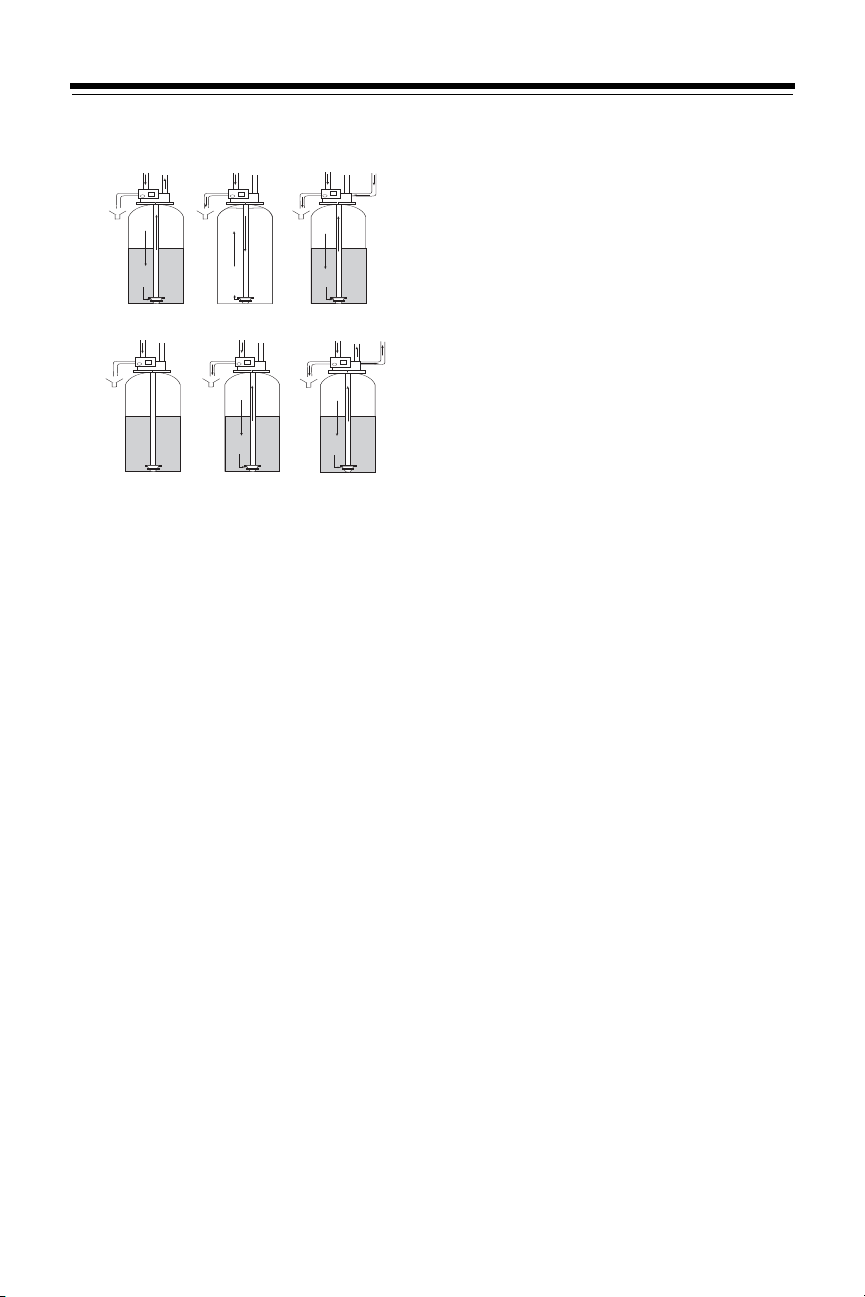

System Regeneration Cycles (7-Cycle Operation)

1. Service (Downflow) — Cycle C0:

Untreated water is directed down through the resin bed and up through the riser

tube. The hardness ions attach themselves to the resin and are removed from the

water. The water is conditioned as it passes through the resin bed.

2. Backwash (Upflow) — Cycles C1, C6:

The flow of water is reversed by the control valve and directed down the riser

tube and up through the resin bed. During the backwash cycle, the bed is

expanded and debris is flushed to the drain.

3. Brine/Slow Rinse (Downflow) — Cycles C3:

The control directs water through the brine injector and brine is drawn from the

regenerant tank. The brine is then directed down through the resin bed and up

through the riser tube to the drain. The hardness ions are displaced by sodium

ions and are sent to the drain. The resin is regenerated during the brine cycle.

Brine draw is completed when the air check closes.

4. Fast Rinse (Downflow) — Cycles C5, C7:

The control directs water down through the resin bed and up through the riser

tube to the drain. Any remaining brine residual is rinsed from the resin bed.

5. Brine Refill (Downflow) — Cycle C8:

Brine refill occurs during a portion of the fast rinse cycle. Water is directed to the

regenerant tank at a controlled rate, to create brine for the next regeneration.

6. Repressurize Cycle — (No Flapper Open), Cycle C4:

This cycle closes all flappers for a short time to allow the air and water to

hydraulically balance in the valve before continuing the regeneration.

4

Page 5

SERVICE BACKWASH BRINE/SLOW RINSE

C0 C1 and C6 C2 and C3

From Regenerant

Tank

To Regenerant

Tank

REPRESSURIZE

C4 C5 and C7 C8

FAST RINSE

BRINE REFILL

Figure 3

Installation

All plumbing must conform to local codes.

Inspect unit carefully for carrier shortage or shipping damage.

Location Selection

1. The distance between the unit and a drain should be as short as possible.

2. If it is likely that supplementary water treating equipment will be required, make

certain adequate additional space is available.

3. Since salt must be added periodically to the brine tank, the location should be

easily accessible.

4. Do not install any unit closer to a water heater than a total run of 10 feet (3 m) of

piping between the outlet of the conditioner and the inlet to the heater. Water

heaters can sometimes overheat to the extent they will transmit heat back down

the cold pipe into the unit control valve.

Hot water can severely damage the conditioner. A 10-foot (3-m) total pipe run,

including bends, elbows, etc., is a reasonable distance to help prevent this

possibility. A positive way to prevent hot water from flowing from heat source to

the conditioner, in the event of a negative pressure situation, is to install a check

valve in the soft water piping from the conditioner. If a check valve is installed,

make certain the water heating unit is equipped with a properly rated

temperature and pressure safety relief valve. Also, be certain that local codes

are not violated.

5. Do not locate unit where it or it’s connections (including the drain and overflow

lines) will ever be subjected to room temperatures under 34

o

(49

C).

o

F (1oC) or over 120oF

5

Page 6

6. Do not install unit near acid or acid fumes.

7. The use of resin cleaners in an unvented enclosure is not recommended.

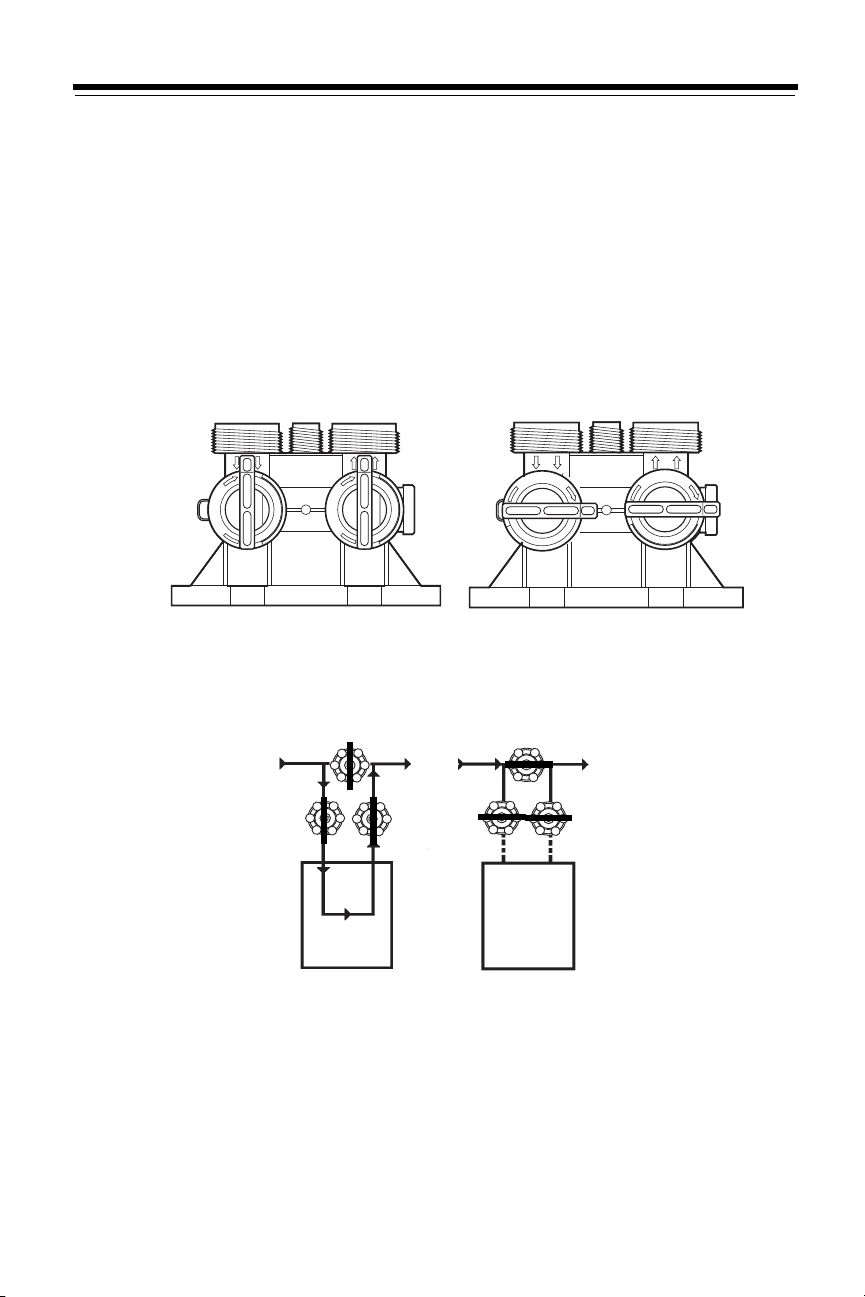

Water Line Connection

The installation of a bypass valve system is recommended to provide for occasions

when the water conditioner must be bypassed for hard water or for servicing.

The most common bypass systems are the Autotrol

(Figure 4) and plumbed-in globe valves (Figure 5). Though both are similar in function,

the 256 Autotrol bypass offers simplicity and ease of operation.

Not in Bypass In Bypass

B

Y

P

A

S

S

B

Y

P

A

S

S

Figure 4 Autotrol Series 256 Bypass Valve

®

Series 256 bypass valve

A

P

A

P

S

Y

S

B

S

Y

S

B

Not in Bypass

Wate r

Conditioner

In Bypass

Wate r

Conditioner

Figure 5 Typical Globe Valve Bypass System

Drain Line Connection

1. Ideally located, the unit will be above and not more than 20 feet (6.1 m) from the

drain. For such installations, use an appropriate adapter fitting (not supplied), to

connect 1/2-inch (1.3-cm) plastic tubing to the drain line connection of the control

valve.

6

Page 7

2. If the unit is located more than 20 feet (6.1 m) from drain, use 3/4-inch (1.9-cm)

tubing for runs up to 40 feet (12.2 m). Also, purchase appropriate f itting to connect

the 3/4-inch tubing to the 1/2-inch NPT drain connection.

3. If the unit is located where the drain line must be elevated, you may elevate the

line up to 6 feet (1.8 m) providing the run does not exceed 15 feet (4.6 m) and water

pressure at conditioner is not less than 40 psi (2.76 bar). You may elevate an

additional 2 feet (61 cm) for each additional 10 psi (0.69 bar).

4. Where the drain line is elevated but empties into a drain below the level of the

control valve, form a 7-inch (18-cm) loop at the far end of the line so that the

bottom of the loop is level with the drain line connection. This will provide an

adequate siphon trap.

5. Where the drain empties into an overhead sewer line, a sink-type trap must be

used.

IMPORTANT: Never insert drain line into a drain, sewer line or trap. Always allow

an air gap between the drain line and the wastewater to prevent the possibility of

sewage being back-siphoned into conditioner.

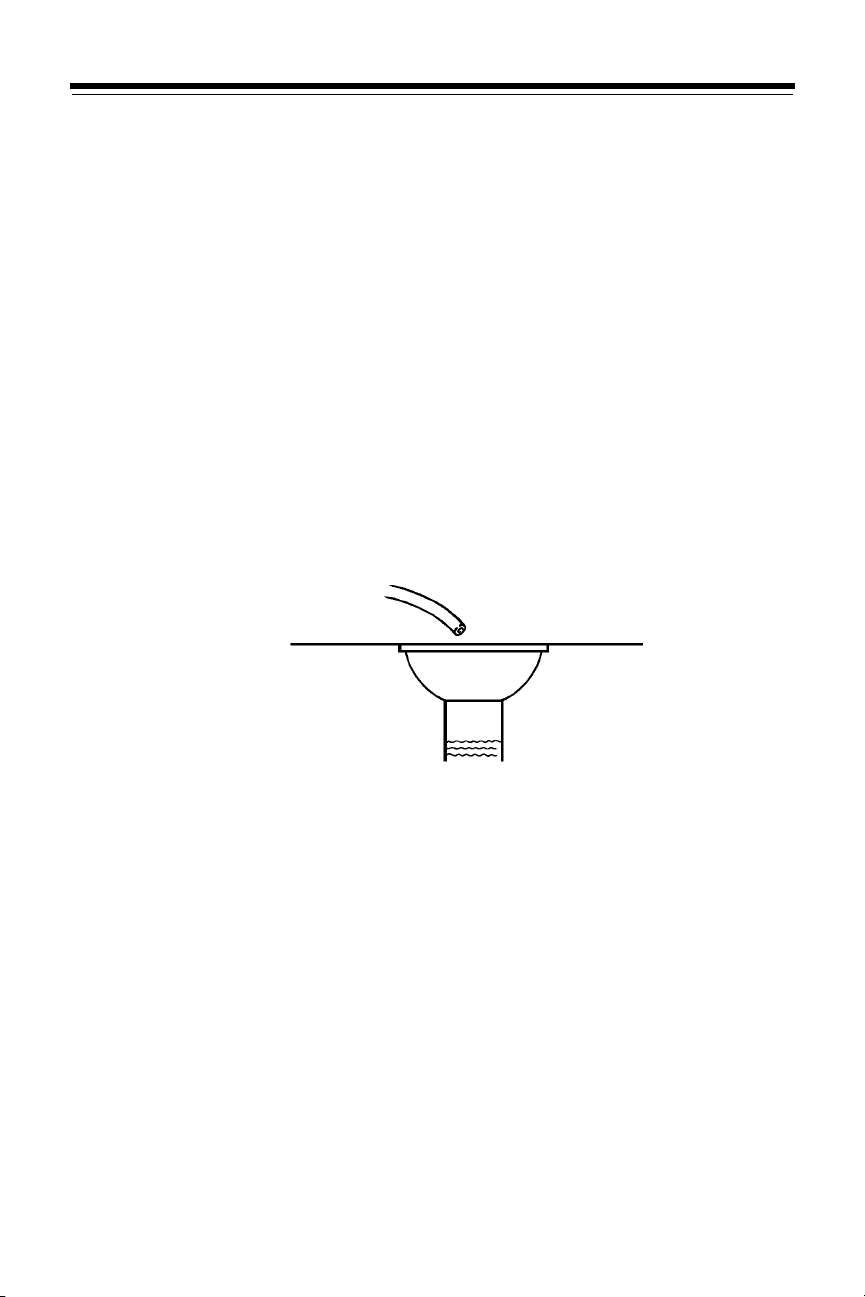

Correct Way

Drain Line Tube

Right Way

Drain

Figure 6

Note: Standard commercial practices have been expressed here. Local codes may

require changes to these suggestions.

Brine Line Connection

It will be necessary to install the brine tube and line to a fitting installed on the air

check. Teflon

Be sure all fittings and connections are tight so that premature checking does not take

place. Premature checking is when the ball in the air check falls to the bottom before

all brine is drawn out of the brine tank. See Placing Conditioner into Operation

section.

*Teflon is a regis tered trademark of E.I. DuPont de Nemours and Company, Inc .

*

tape all threaded connections.

Overflow Line Connection

In the absence of a safety overflow and in the event of a malfunction, the BRINE TANK

OVERFLOW will direct “overflow” to the drain instead of spilling on the floor where it

could cause considerable damage. This fitting should be on the side of the cabinet or

brine tank.

7

Page 8

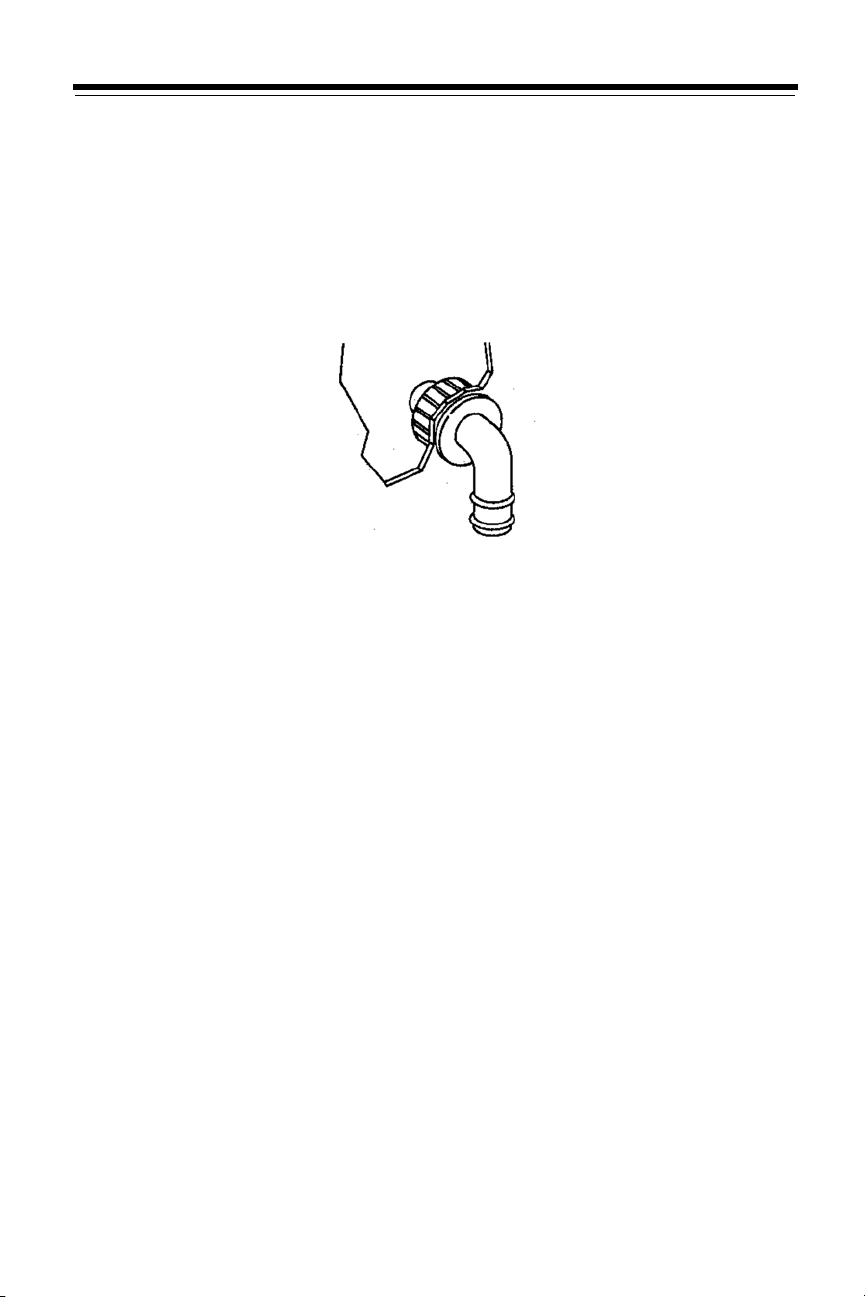

To connect overflow, locate hole on side of brine tank. Insert overflow fitting (not

supplied) into tank and tighten with plastic thumb nut and gasket as shown (Figure 7).

Attach length of 1/2-inch (1.3-cm) I.D. tubing (not supplied) to fitting and run to drain.

Do not elevate overflow line higher than 3 inches (7.6 cm) below bottom of overflow

fitting. Do not tie into drain line of control unit. Overflow line must be a direct,

separate line from overflow fitting to drain, sewer or tub. Allow an air gap as per drain

line instructions (Figure 6).

Overflow Fitting

Brine Tank

Installed

Connect 1/2-inch (1.3-cm)

Tubing or Hose and Run

to Drain

Figure 7

Low Voltage Transformer

Use only the included transformer for powering the 400 series timers. Connect the

plug of the transformer secondary cable to the mating socket on the control (see

Figure 8).

Be certain that the transformer is plugged into a correct voltage source that is not

controlled by a wall switch.

8

Page 9

Increasing the Length of the Transformer Cord

If it is necessary to extend the length of the transformer cord, an optional 15-foot (4.6m) extension is available (see Figure 9).

Figure 8

Figure 9

Disinfection of Water Conditioners

The materials of construction of the modern water conditioner will not support

bacterial growth, nor will these materials contaminate a water supply. In addition,

during normal use, a conditioner may become fouled with organic matter, or in some

cases with bacteria from the water supply. This may result in an off-taste or odor in

the water.

Thus, your conditioner may need to be disinfected after installation. Some

conditioners will require periodic disinfection during their normal life. Consult your

installing dealer for more information on disinfecting your conditioner.

Depending upon the conditions of use, the style of conditioner, the type of ion

exchanger, and the disinfectant available, a choice can be made among the following

methods.

9

Page 10

Sodium or Calcium Hypochlorite

Application

These materials are satisfactory for use with polystyrene resins, synthetic gel zeolite,

greensand and bentonites.

5.25% Sodium Hypochlorite

These solutions are available under trade names such as Clorox*. If stronger solutions

are used, such as those sold for commercial laundries, adjust the dosage accordingly.

1. Dosage

a. Polystyrene resin; 1.2 fluid ounce per cubic foot .

b. Non-resinous exchangers; 0.8 fluid ounce per cubic foot.

2. Brine tank conditioners

a. Backwash the conditioner and add the required amount of hypochlorite solution to the brine

well of the brine tank. The brine tank should have water in it to permit the solution to be

carried into the conditioner.

b. Proceed with the normal regeneration.

Calcium Hypochlorite

Calcium hypochlorite, 70% available chlorine, is available in several forms including

tablets and granules. These solid materials may be used directly without dissolving

before use.

1. Dosage

a. Two grains (approximately 0.1 ounce) per cubic foot .

2. Brine tank conditioners

a. Backwash the conditioner and add the required amount of hypochlorite to the brine well of

the brine tank. The brine tank should have water in it to permit the chlorine solution to be

carried into the conditioner.

b. Proceed with the normal regeneration.

Placing Conditioner into Operation

Initial Start-Up

After the water conditioning system is installed, the conditioner should be disinfected

before it is used to treat potable water. Refer to the Disinfection of Water

Conditioners section in this manual. Complete the following steps to place the

conditioner into operation:

1. Remove control valve cover.

Note: The following steps will require turning the indicator knob (Figure 11) to

various positions. Insert a wide-blade screwdriver into arrow slot in indicator knob

and press in firmly. With knob held in, rotate COUNTERCLOCKWISE only until

arrow or knob points to desired position. Rotation is made much easier if you

grasp the camshaft with your free hand and turn it at the same time. Then permit

10

Page 11

knob to spring back out.

2. Insert screwdriver into slot in indicator knob (Figure 11). Press in and rotate knob

COUNTERCLOCKWISE until arrow points directly to the word BACKWASH.

3. Fill resin tank with water.

a. With water supply off, place the bypass valve(s) into the “NOT IN BYPASS” position.

b. Open water supply valve very slowly to approximately the 1/4 open position.

IMPORTANT: If opened too rapidly or too far, resin may be lost. In this position, you

should hear air escaping slowly from the drain line.

c. When all of the air has been purged from the tank (water begins to flow steadily from the

drain), open the water supply valve all the way.

d. Allow water to run to drain until clear.

e. Turn off water supply and let the unit stand for about five minutes. This will allow all trapped

air to escape from the tank.

4. Add water to brine tank (initial fill).

With a bucket or hose, add approximately 4 gallons (15 liters) of water to brine

tank. If the tank has a salt platform above the bottom of the tank, add water until

the level is approximately 1 inch (25 mm) above the platform.

*Clorox is a trademark of the Clorox Company.

11

Page 12

Control Valve

Air Check

Check Ball

Female Elbow

Brine Line

Figure 10 - Control Valve

5. Put into operation.

a. Open water supply valve slowly to full open position.

b. Carefully advance indicator knob COUNTERCLOCKWISE to center of FAST RINSE/REFILL

position and hold there until air check (Figure 10) f ills with water and water starts to flow

through brine line into brine tank. Do not run for more than two minutes.

c. Advance indicator knob COUN TERCLOCKWISE until arrow points to the center of the BRINE/

SLOW RINSE position.

d. With the conditioner in this position, check to see if water is being drawn from the brine tank.

The water level in the brine tank will recede very slowly. Observe for at least three minutes.

If the water level does not recede or goes up, or if air enters the transparent air check

chamber and the ball falls and seats, reference Troubleshooting section.

e. Advance indicator knob COUNTERCLOCKWISE to CONDITIONED WATER.

f. Run water from a nearby faucet until the water is clear and soft .

12

Page 13

400 Series Control Settings

440i Control

Day Arrow

PRESS KNOB AND TURN COUNTERCLOCKWI SE TO "START" RELEASE

Skipper Pins

Skipper Wheel

Indicator Knob

Timer

Locking Pin

Time Arrow

Timer Knob

Figure 11

Programming

1. Set days of regeneration on skipper wheel (Figure 11).

• Pull all skipper pins outward (away from control).

• Rotate skipper wheel until day arrow points to current day or number 1.

• Depress skipper pin(s) at day(s) for which regeneration is desired.

2. Set the time of day.

• Grasp timer knob and pull outward.

• Rotate in either direction until the timer arrow points to the actual time of day.

• Release timer knob.

Note: With the time of day properly set, the conditioner will regenerate at about 2:30

a.m. If you prefer to have the unit regenerate at an earlier or later time, simply set

current time-of-day accordingly (e.g., to have the unit regenerate at 4:30 a.m.—two

hours later—set the clock two hours earlier than the actual time of day.)

Note: The Timer Locking Pin should always be horizontal (Figure 11) during

operation.

13

Page 14

460i Control

Programming

Water Flow Indicator

PM Indicator

Indicator Knob

Timer

Locking Pin

Time Set Button

Figure 12

Hour T ime Display

Transformer Plug

Receptacle

Access Door

Raised

Tab

Jumper

Spare

Jumper

Plug the wall-mount transformer into a functioning electrical outlet that is not

controlled by a switch. Plug the transformer into the transformer plug receptacle on

the control.

Open the access door by pushing the raised tab on the door toward the left while

pulling the tab out (Figure 12).

Time of Day Setting

With the jumper on the set of pins next to the word TIME (Figure 13), set the time of

day to the closest hour by pressing the black TIME SET button. PM hours are indicated

by a light next to the letters PM on the display window.

Note: The use of a small needle-nose pliers will aid in moving the jumper.

Note: The unit is factory set to regenerate at 2:00 a.m. If you prefer to have the unit

regenerate at an earlier or later time, simply set the current time of day accordingly

(e.g., to have the unit regenerate at 4:00 a.m.—two hours later—set the clock two hours

earlier than the actual time of day).

Note: The Timer Locking Pin should always be horizontal (Figure 12) during

operation.

14

Page 15

Hardness Setting

Move the jumper to the set of pins next to the word HARDNESS (Figure 14). Press the

black TIME SET button until the hardness of the incoming water supply is displayed.

The hardness range is from 1 to 99 grains per gallon.

To change water hardness stated in parts per million (PPM) to grains per gallon (GPG)

use this formula:

Parts per Million

17.1

Capacity Setting

Move the jumper to the set of pins next to the word CAPACITY (Figure 15). Press the

black TIME SET button until the correct capacity value is displayed. The capacity

range is 1 to 99 kilograins. Refer to the Suggested Salt Dial Settings table.

Return the jumper to the top set of pins next to the word TIME and replace the access

door. The jumper must NOT be left on any pins other than the top pair next to the

word TIME. Otherwise, the unit may show a blank display.

=

Grains per Gallon

Figure 13 Figure 14

Figure 15

Note: A spare jumper is located on the bottom set of pins.

In the event that the hardness or capacity setting must be changed, simply follow the

appropriate steps described above.

Calendar Override Setting

1. Disconnect power.

2. Place jumper on Pin A and reconnect power.

3. Move jumper to Pin B. A zero will appear, indicating zero days of calendar override.

All 460i controllers are preprogrammed in this manner at the manufacturer.

15

Page 16

4. Depress the black TIME SET button. The numbers will roll from “0” to “15.” Release

the switch at the desired number of days for the calendar override. For example,

releasing the switch at “10” would program a 10-day calendar override.

5. Disconnect power.

6. Place jumper back on TIME and reconnect power.

7. The calendar override program is maintained during power outages by the

NOVRAM circuitry.

8. To remove the calendar override, follow the same steps above and program back

to “0.”

Common Features

When using the 255 valve with the 440i or 460i controls, there are several features

and procedures that are unique to the 400 series controls. They are as follows:

Salt Dial Adjustment

These models may be adjusted to produce maximum to minimum conditioning

capacities by setting the salt dial, which controls the amount of salt used per

regeneration. When desired, the minimum setting may be used on installations if the

frequency of regeneration is increased to compensate for lower regenerated

conditioning capacity. The installing dealer will set the unit for proper salt usage.

Further adjustments are needed only if the hardness of the water supply changes or if

water use changes dramatically. Capacity will need to be adjusted accordingly.

To adjust salt dosage, insert a small screwdriver into the white indicator knob and

move pointer to proper salt setting (Figure 13).

Note: To convert the salt settings from English to metric, divide by 2.2 (e.g., 12

pounds ÷ 2.2 = 5.5 kg of salt).

Figure 13

16

Page 17

Table 1 – Suggested Salt Dial Settings (Pounds of Salt) For Various Size Softeners

Capacity Setting

(Kilograins)

12 4.5——————

16 9.05.5—————

20 — 8.5 6.0 — — —

24 — 14.0 8.5 7.0 — — —

30 — — 15.0 11.0 9.0 — —

32 — — 18.5 12.5 10.0 9.0 —

35 — — — 16.0 12.0 10.0 9.0

40 — — — 11.5* 17.0 14.0 12.0

48 — — — — 14.0* 10.5* 17.0

60 — — — — — — 15.0*

0.5 Ft

3

0.75 Ft31.0 Ft31.25 Ft31.5 Ft31.75 Ft32.0 Ft

3

*This setting requires the use of “XS” (extra salt) cam and doubles the amount of the

setting.

The amount of salt placed in the brine tank has nothing to do with the amount of salt

used during the regeneration cycle. Water will dissolve and absorb salt only until it

becomes saturated. A given amount of brine (salt-saturated water) contains a specific

amount of salt. The salt dial controls the amount of brine used during the

regeneration cycle (e.g., when set at 15 pounds (6.8 kg) the amount of brine the

conditioner will use for each regeneration will contain 15 pounds (6.8 kg) of salt, etc.)

Never let the amount of salt in the brine tank be lower than the normal liquid level. Do

not overload the brine tank with salt .

Guest Cycle (Manual Regeneration)

When abnormally high water usage exhausts your water conditioner’s capacity

ahead of schedule, an extra regeneration can be achieved. Depress the indicator knob

on the 440i (Figure 11) with a wide-blade screwdriver and turn COUNTERCLOCKWISE

to START to initiate a regeneration. For the 460i, simply depress the indicator knob

(Figure 12). It will take a few minutes for regeneration to start . A normal regeneration

will take approximately two hours.

17

Page 18

Preventive Maintenance

Inspect and clean brine tank and screen filter on end of brine pickup tube once a year

or when sediment appears in the bottom of the brine tank.

Clean injector screen and injector once a year:

1. Unplug the wall-mount transformer.

2. Shut off water supply or put bypass valve(s) into bypass position.

3. Relieve system pressure by opening valve No. 5

(at rear) with a screwdriver.

4. Using a screwdriver, remove injector screen and injector cap (Figure 16).

5. Clean screen using a fine brush. Flush until clean.

6. Using a needle-nose pliers, pull injector straight out.

7. Flush water into the injector screen recess of the valve body to flush debris out

through the injector recess.

8. Clean and flush the injector.

9. Lubricate the O-rings on the injector, injector cap and injector screen with silicone

lubricant.

10. Reinstall the injector, injector cap and injector screen. See IMPORTANT note.

11. Plug the wall-mount transformer into outlet; reset time of day.

12. Slowly open water supply valve or return bypass valve(s) to the “not in bypass”

position.

IMPORTANT: Do not overtighten the plastic cap. Seat the cap lightly into position.

Overtightening may cause breakage of the plastic cap that may not be immediately

evident.

Figure 16

18

Page 19

Replacement Parts for Autotrol Brand 255 Control

Valve Body

18

19

16

15

4

Tank Adapter

Module

6

2

21

20

3

5

7

17

1

9

8

10

22

t

21

23

21

7

22

22

t

e

l

n

i

n

i

a

r

d

e

l

t

u

o

11

13

12

23

14

22

19

Page 20

255 Valve & Tank Adapter Module

Code Part No. Description Qty.

1 1000232 Valve Assembly, w/o Flow Controls 1

2 Camshaft: 1

1031950 Standard, One-Piece

1033024 Standard, Segmented

1033025 Extra Salt, Segmented

1033026 Long Rinse, Segmented

1032969 Water Saver, Segmented

3 1030501 Camshaft Bearing 1

4 1031391 Timer Locking Pin 1

5 1000226 Screen/Cap Assembly w/O-Ring 1

6 Drain Control Assembly w/O-Rings: 1

1000209 No. 7 (1.2 gpm; 4.5 Lpm)

1000210 No. 8 (1.6 gpm; 6.1 Lpm)

1000211 No. 9 (2.0 gpm; 7.6 Lpm)

1000212 No. 10 (2.5 gpm; 9.5 Lpm)

1000213 No. 12 (3.5 gpm; 13.2 Lpm)

1000214 No. 13 (4.1 gpm; 15.5 Lpm)**

1000215 No. 14 (4.8 gpm; 18.2 Lpm)**

7 1030502 Ball, Flow control 2

8 Brine Refill Control: 1

1034261 1 to 10 lbs Salt

1034263 3 to 19 lbs Salt

9 Injector Assembly with O-Rings: 1

1032970 “A” Injector - White

1032971 “B” Injector - Blue

1032972 “C” Injector - Red

10 1000269 Injector Cap with O-Ring 1

12 1032416 Air Check Kit 1

13 1010429 O-Ring BN 1

14 1010428 O-Ring EP 1

15 Locking Bar: 1

1031402 English Language

1031403 French Language

1031404 German Language

1031405 Italian Language

1031406 Japanese Language

1031407 Spanish Language

16 1006093 Screw, No. 8 x 9/16 inch 1

17 1001580 Spring, Valve Discs 9

18 1032565 Valve Cover, Standard, Black 1

19 1000062 i-Lid Cover 1

20 1000297 Extended Connector (For use with i-Lid Cover) 1

Kits:

20

Page 21

21 1001404 O-Ring Group: Tank Adapter, 1010117 (1), 1010407

(1), 1010410 (4)

22 1040459 O-Ring Group: Piping Boss 1010431 (1), 1010411 (2)

23 1041010 13/16 Rubber Insert (Optional)

Valve Discs:

* 1000250 Standard

* Not Shown

**Flow control does not use Flow Control Ball (1030502).

21

Page 22

Replacement Parts

440i

DAY

BRINE/

SLOW RINSE

FAST RINSE /

REFILL

CONDITIONED

WATER

M

ANUAL REGE

PRESS KNOB AND TURN COUNTERCLOCKWISE TO"START" Ð RELEASE

MIDNIGHT

BACKWASH

NER

AION

START

:

TO SET

TIME OF DAY

PULL KNOB

AND ROTATE

3AM

Meter Adapter

1

460i

1

6PM

3PM

NOON

6AM

9AM

2

2

3

256 Bypass Valve

Piping Boss

1

1

S

S

A

P

Y

B

S

S

A

P

Y

B

2

Note: Do not use pipe joint compound when

threading pipe into the Noryl piping boss. Use

only Teflon* pipe tape. Do not overtighten pipe

into Noryl piping boss.

2

22

Page 23

255 Series Accessories

Part

Code

1 440i Assembly 1

2 460i Assembly 1

3 Transformer 1

* 1030234 Transformer Extension Cord 15 foot (4.5 m) 1

No. Description Qty.

1000810 Japanese

1000811 North American

1000812 Australian

1000813 British

1000814 European

Piping Boss

1 Piping Boss Kit (includes Hardware): 1

1040277 3/4-inch NPT, Brass 3/8-inch NPT Drain

1040278 1-inch NPT, Brass 1/2-inch NPT Drain

1040281 3/4-inch BSPT, Brass 3/8-inch BSPT Drain

1040282 1-inch BSPT, Brass 1/2-inch BSPT Drain

1040279 3/4-inch NPT, Noryl 1/2-inch NPT Drain

1040280 1-inch NPT, Noryl 1/2-inch NPT Drain

1040283 3/4-inch BSPT, Noryl 1/2-inch BSPT Drain

1040284 1-inch BSPT, Noryl 1/2-inch BSPT Drain

2 1040339 Piping Boss installation Kit 1

Meter Adapter

1 1032350 Kit, Meter Adapter 1

2 1032351 Meter Install Kit 1

Bypass Valve

1 1040769 Bypass Body Assembly with Install Kit 1

2 1040524 Bypass Installation Kit 1

Tube Adapter Kits

* 1001606 3/4-inch Copper Tube Adapter Kit 1

* 1001670 1-inch Copper Tube Adapter Kit 1

23

Page 24

* 1041210 1-1/4-inch Copper Tube Adapter Kit 1

* 1040547 90 degree Elbow Adapter Kit 1

* 1001608 22-mm Copper Tube Adapter Kit 1

* 1001613 3/4-inch CPVC Tube Adapter Kit 1

* 1001614 1-inch CPVC Tube Adapter Kit 1

* 1001615 25-mm CPVC Tube Adapter Kit 1

* 1001769 3/4-inch NPT Plastic Pipe Adapter Kit 1

* 1001603 1-inch NPT Plastic Pipe Adapter Kit 1

* 1001604 3/4-inch BSPT Plastic Pipe Adapter Kit 1

* 1001605 1-inch BSPT Plastic Pipe Adapter Kit 1

* 1001611 3/4-inch BSPT Brass Pipe Adapter Kit 1

* 1001610 1-inch NPT Brass Pipe Adapter Kit 1

* 1001612 1-inch BSPT Brass Pipe Adapter Kit 1

24

Page 25

Troubleshooting

The technology upon which the Series 255 control is based is well established and

proven in service over many years. However, should a problem or question arise

regarding the operation of the system, the control can be very easily serviced. The

control module can be quickly replaced or adjustments can be made at the

installation. We recommend that you contact your local professional water treatment

dealer for most concerns. For parts mentioned, refer to exploded views in the

Replacement Parts section of this manual.

IMPORTANT: Service procedures that require the water pressure to be removed

from the system are marked with a ! after the possible cause. Refer to Preventative

Maintenance section for instructions.

Valve Troubleshooting

Problem Possible Cause Solution

1. Brine tank

overflow.

2. Flowing or

dripping

water at drain

or brine line

after

regeneration.

3. Hard water

leakage after

regeneration.

4. Control will

not draw

brine.

a. Uncontrolled brine refill

flow rate.

b. Air leak in brine line to air

check.

c. D rain control clogged with

resin or other debris.

a. Valve stem return spring

weak.

a. Improper regeneration.

b. Leaking of external

bypass valve.

c. O-ring around riser pipe

damaged.

a. Low water pressure.

b. Restricted drain line.

c. Injector plugged !

d. Injector defective !

e. Valve disc 2 and/or 3 not

closed.

f. Air check valve

prematurely closed.

a. Remove brine control to clean ball

and seat.

b. Check all connections in brine line

for leaks. Refer to instructions.

c. Clean drain control.

a. Replace spring. (Contact dealer.)

a. Repeat regeneration after making

certain correct salt dosage was set .

b. Replace bypass valve. (Contact

dealer.)

c. Replace O-ring. (Contact dealer.)

a. Make correct setting according to

instructions.

b. Remove restriction.

c. Clean injector and screen.

d. Replace injector and cap. (Contact

dealer.)

e. Remove foreign matter from disc

and check disc for closing by

pushing in on stem. Replace if

needed. (Contact dealer.)

f. Put control momentarily into brine

refill. Replace or repair air check if

needed. (Contact dealer.)

25

Page 26

255/440i Troubleshooting

Problem Possible Cause Solution

1. Control will not

draw brine.

2. System using more

or less salt than

regenerant setting.

3. Intermittent or

irregular brine

draw.

4. No conditioned

water after

regeneration.

5. Control

backwashes or

purges at

excessively low or

high rate.

a. Low water pressure.

b. Restricted drain line.

c. Injector plugged.

d. Injector defective.

e. Air check valve closes

prematurely.

a. Foreign matter in

controller causing

incorrect flow rates.

a. Low water pressure.

b. Defective injector.

a. No salt in brine tank.

b. Injector plugged.

c. Air check valve closes

prematurely.

a. Incorrect drain controller

used.

b. Foreign matter affecting

controller operation.

a. Set pump to maintain 20 psi

b. Change drain to remove

c. Clean injector and screen.

d. Replace injector. (Contact

e. Put control momentarily into

a. Remove brine control and

a. Set pump to maintain 20 psi

b. Replace injector. (Contact

a. Add salt to brine tank.

b. Clean injector and screen.

c. Put control momentarily into

a. Replace with correct size

b. Remove drain controller and

at softener.

restriction.

dealer.)

brine/slow rinse. Replace or

repair air check if needed.

(Contact dealer.)

flush out foreign matter.

Manually position control to

brine/slow rinse to clean

controller (after so doing

position control to "purge” to

remove brine from tank).

at softener.

dealer.)

brine/slow rinse. Replace or

repair air check if needed.

(Contact dealer.)

controller. (Contact dealer.)

clean ball and seat .

26

Page 27

260 Troubleshooting

Problem Possible Cause Solution

1. No water flow

display when water

is flowing.

2. Continuous

regeneration.

Camshaft does not

stop at the end of

regeneration.

3. Run out of soft

water between

regenerations.

a. Bypass valve in bypass.

b. Meter probe disconnected

or not fully connected to

meter housing.

c. Restricted meter turbine

rotation due to foreign

material in meter !

d. Defective meter probe.

a. Misaligned optical sensor. a. Replace optical sensor.

a. Improper regeneration.

b. Incorrect salt setting.

c. Incorrect hardness or

capacity settings.

d. Water hardness has

increased.

e. Restricted meter turbine

rotation due to foreign

material in meter !

a. Shift bypass valve to not-in-

b. Fully insert probe into meter

c. Remove meter housing, free

d. Replace meter cable (Contact

a. Repeat regeneration, making

b. Set salt control t o proper level.

c. Set to correct values. See

d. Set hardness to new value.

e. Remove meter housing, free

bypass position.

housing.

up turbine and flush with

clean water. Turbine should

spin freely. If not, replace

meter. (Contact dealer.)

dealer.)

(Contact dealer.)

certain that correct salt

dosage is used.

See salt setting chart .

Programming section.

See Programming section.

up turbine and flush with

clean water. Turbine should

spin freely; if not, replace

meter. (Contact dealer.)

Valve Specifications

Working Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20-120 psi (1.38 - 8.27 bar)

Standard 12 Volt Transformer Input Electrical Rating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115V 60 Hz

Optional 12 Volt Transformer Input Electrical Rating . . . . . . . . . . . . . . . . . . . 115V 50 Hz, 230V 50 Hz,

230V 60 Hz, 100V 60 Hz, 100V 50 Hz

Operating Ambient Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34 °F to 120 °F (1 °C to 49 °C)

Operating Water Temperature. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34 °F to 100 °F (1 °C to 38 °C)

27

Page 28

For service or parts, please contact your local professional water

treatment dealer.

© Copyright 2007 Ge neral Electric Company

Printed in the USA P/N 1018075 Rev. L

Loading...

Loading...