Page 1

Provided By

http://www.MyBinding.com

http://www.MyBindingBlog.com

GBC Quantum P70iX

Automated Punch

User's Manual

Page 2

US/Canada – 230V 50/60 Hz

Assembly Number 7707010

Operator Manual #

7707286

Date Issued October 15, 2003

Revision C-1

P70iX

Operator Manual

Page 3

Table of Contents

Section Page

Safety Information i

1. Introduction

Introduction 1-1

2. Getting to Know your Quantum P70iX

Operating Controls 2-1

Plastic Covers 2-2

3. Operation

Operating Controls 3-1

4. Options and Accessories

Die Set 4-1

Die Set Storage 4-2

5. Home Screen

Operation 5-1

Service 5-1

6. Maintenance

Problem solving 6-1

Paper Jam 6-2

7. Specifications

Specifications Quantum P70iX 7-1

Power Cord Specifications 7-2

Page 4

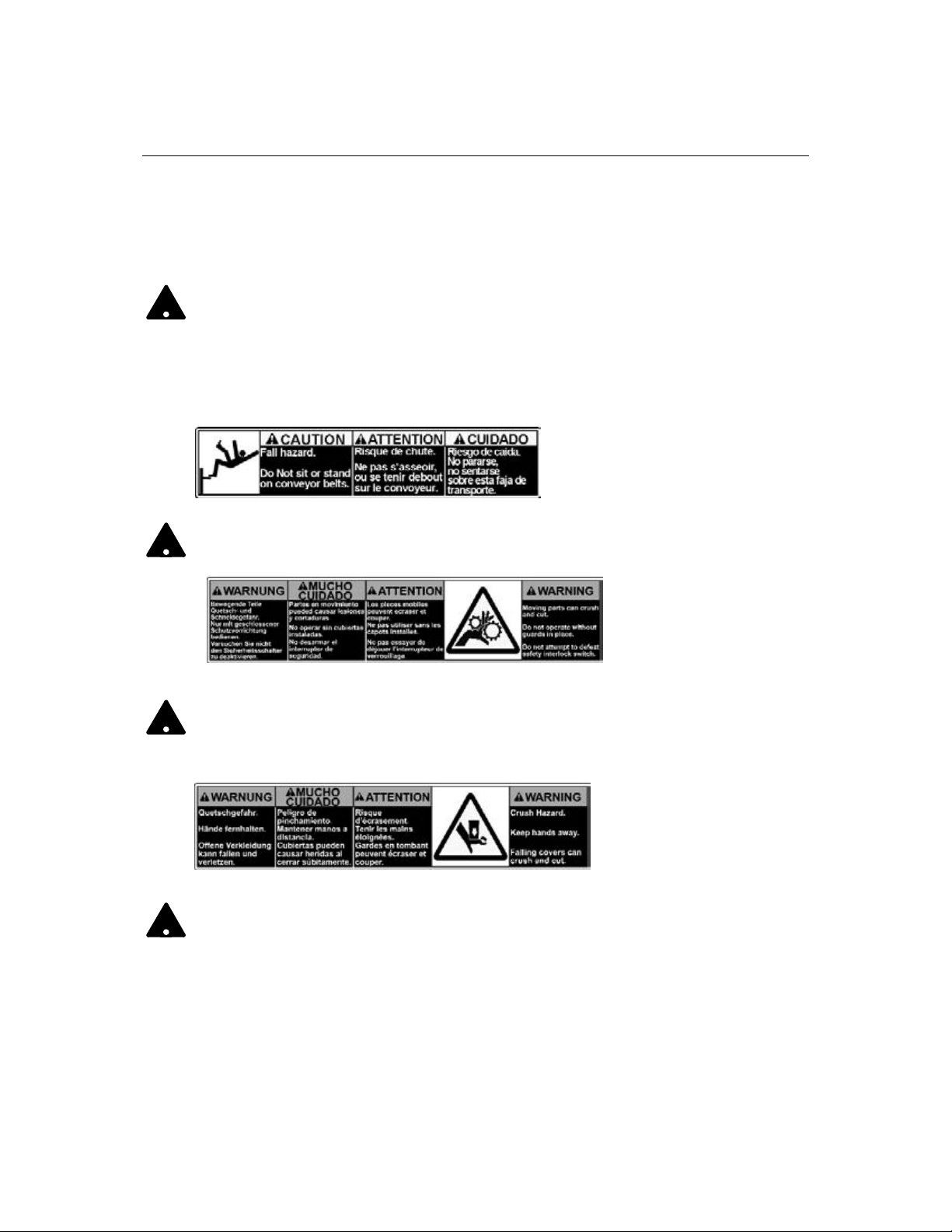

SAFETY MESSAGES

The safety of you and others is very impor tant to GBC. Important safety messages and information are contained within this manual as well as on the

machine itself. Please be certain to carefully read and understand all of these

before operating the machine.

The safety alert symbol precedes each safety message in this Operating

Instruction Manual.This symbol indicates a potential personal safety

hazard that could hurt you or others, as well as cause product or

property damage.

The following pictorial is found on the Quantum P70iX:

CAUTION:This means you could fall and be injured if you try to stand or

sit on the conveyor belts.

WARNING: This means you can be seriously injured by crushing and cutting, moving parts. Do not operate without guards in place. Do not attempt

to defeat any of the safety interlock switches.

WARNING: This means you can be seriously injured by the covers falling

on you. Keep your hands and other body parts away to avoid getting them

crushed or cut.

Safety Information

i

!!!

!

Page 5

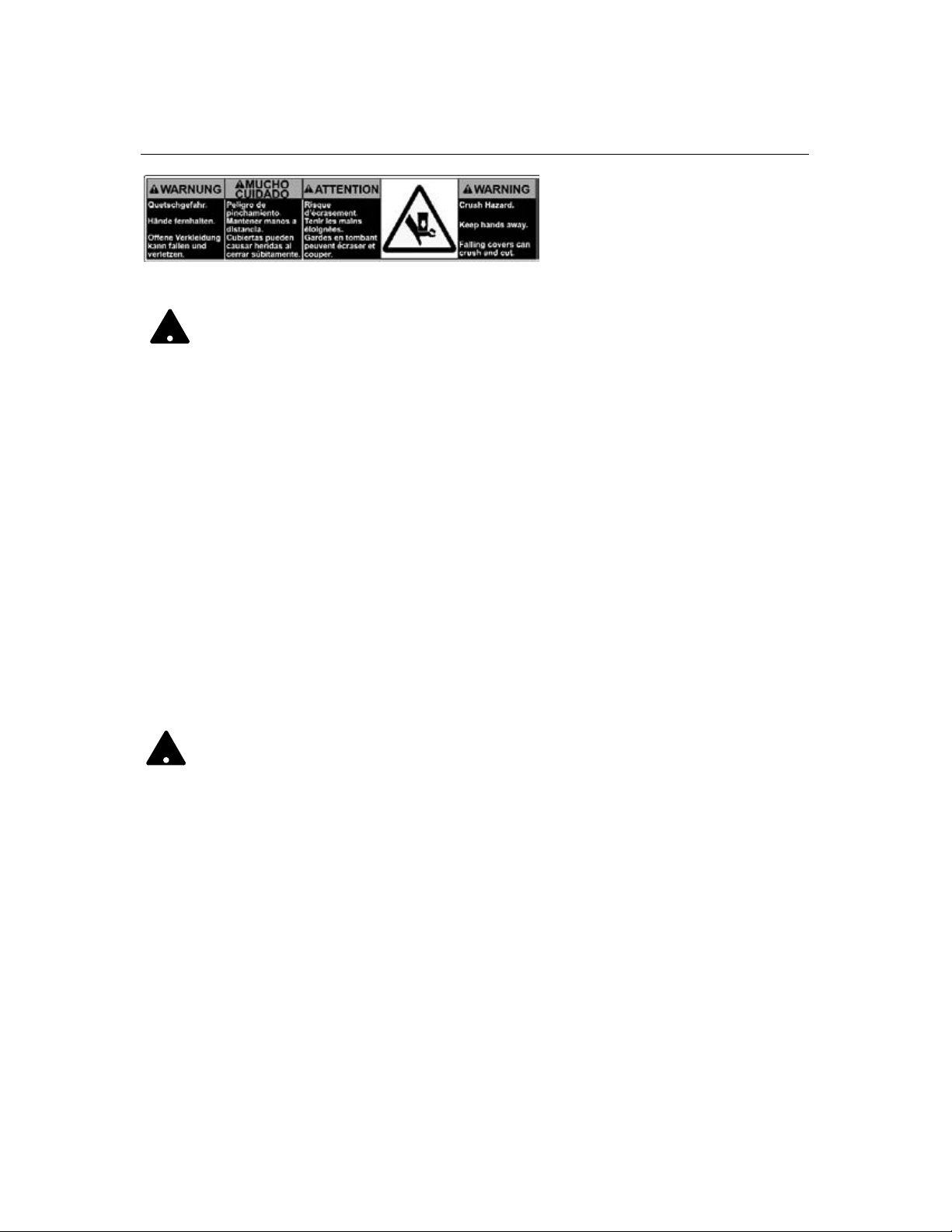

SAFETY MESSAGES continued

WARNING:This means you can be seriously injured by crushing

and cutting, moving parts. Do not operate without guards in place.

Do not attempt to defeat any of the safety interlock switches.

The following symbols appear on this product, and their meaning is as follows:

I Means the electrical power is “ON”.

O Means the electrical power is “OFF”.

IMPORTANT SAFEGUARDS

• Use the Quantum P70iX only for its intended purpose of punching paper and

covers according to the indicated specifications.

• Retain this Operating Instructions manual for later use.

CAUTION: IN CASE OF EMERGENCY, USE THE POWER CORD AS A

MAIN DISCONNECT.

Safety Information

ii

!

!

Page 6

Safety Information

iii

IMPORTANT SAFEGUARDS continued

• The Quantum P70iX must be connected to a supply voltage corresponding

to the electrical rating of the machine operating instructions (also listed on

the serial number label).

• The socket-outlet shall be located near the equipment and shall be easily

accessible.

• The grounding plug is a safety feature and will only fit into the proper grounding-type power outlet. If you are unable to insert the plug into an outlet, contact a qualified electrician to have a suitable outlet installed.Do not alter the

plug on the end of the cordset (if provided) of the Quantum P70iX. It was

provided for your safety.

• Unplug the Quantum P70iX before moving the machine or whenever the

machine is not in use for an extended period of time.

• Do not operate the Quantum P70iX if the machine has a damaged power

supply cord or plug. Do not operate the machine after any malfunction, if liquid has been spilled into the machine, or it the machine has been damaged

in any way.

• Do not overload electrical outlets beyond their capacity. To do so can result in

fire or electrical shock.

• Do not attempt to bypass the safety interlocks, if you do so you may be

injured

SERVICE

Do not attempt to service your Quantum P70iX yourself. Contact an authorized

GBC service representative for any required repairs or major maintenance for

your Quantum P70iX.

There are NO user-serviceable parts inside the machine. To avoid potential personal injury and/or proper ty or machine damage.

DO NOT REMOVE THE MACHINE’S SIDE COVERS AND TOP

COVERS.

CLEANING

You may clean the exterior of the Quantum P70iX using a soft, damp cloth. Do

not use detergent or solvents as damage to the machine may occur.

!

Page 7

Safety Information

iv

MAIN CORDSET SELECTION

(THE FOLLOWING NOTE APPLIES ONLY TO EUROPEAN UNITS)

CAUTION:WHEN CHOOSING A DETACHABLE LINE CORD FOR USE

WITH YOUR Quantum P70iX, ALWAYS OBSERVE THE FOLLOWING

PRECAUTIONS

The cordset consist of three parts; the attachment plug, cordage and appliance

inlet. Each of these components must have European regulatory approvals for

safety.

The following minimum electrical ratings for the specific cordset are published

for safety purposes. DO NOT USE CORDSETS THAT DO NOT MEET THE

FOLLOWING MINIMUM ELECTRICAL REQUIREMENTS.

PLUG: 3 amperes, 250 volts, 50/60 Hz, Class 1, 3 conductor, European safety

approved.

CORDAGE: Type H05VV-F3G0.75, Har monized ( < HAR> ). The “< >” sym-

bols indicate cordage approved to appropriate European standard (NOTE:

“HAR” may be substituted for approval mark of European safety agency, which

approved the cordage.An example would be “ < VDE > “).

APPLIANCE CONNECTOR: 3 ampere, 250 volts, 50/60 Hz, European safety

approved, Type IEC 320. The cordset shall not exceed 3 meters in length. A

cordset with component electrical ratings greater than the minimum specified

electrical ratings may be substituted.

!

Page 8

Safety Information

1-1

MAIN CORDSET SELECTION continued

(THE FOLLOWING NOTE APPLIES ONLY TO THE U.S. UNITS.)

FCC NOTE

This equipment has been tested and found to comply with the limits for a Class

A digital device, pursuant to Part 15 of the FCC Rules.These limits are

designed to provide reasonable protection against harmful interference when the

equipment is operated in a commercial environment.

This equipment generates, uses, and can radiate radio frequency energy and, if

not installed and used in accordance with the Operator Manual, may cause

harmful interference to radio communications.Operation of this equipment in a

residential area is likely to cause harmful interference in which case the user will

be required to correct the interference at his/her own expense.

CAUTION: CHANGES OR MODIFICATIONS NOT EXPRESSLY APPROVED

BY GENERAL BINDING CORPORATION COULD VOID YOUR

AUTHORITY T O OPERA TE THE EQUIPMENT.

This Class A digital apparatus complies with Canadian ICES-003.

Cet appareil numerique dela classe A est conforme a la norme NMB-003 du

Canada.

SERVICE AND EQUIPMENT MAINTENANCE AGREEMENT

By purchasing the P70iX you have invested in a highly capable punching machine that

will give you years of reliable service.To help protect this investment be certain to take

advantage of the GBC Equipment Maintenance Agreement (EMA).The EMA provides

your P70iX with proper ongoing maintenance and care, helping to ensure the years of

quality performance and long life built into the machine.Without an EMA, a charge for

parts and labor would result from every normal maintenance or repair service call. An

EMA for your P70iX eliminates this possibility by providing you with a low, fixed annual

cost for protecting your valuable machine investment. For full details about purchasing

an EMA, consult with your GBC Sales Representative or contact:

General Binding Corporation

500 Bond Street

Lincolnshire, IL 60069

Or Call: 1-800-790-7787

A GBC Authorized Technician must perform all service and maintenance unless it is

operator maintenance in accordance with the P70iX Automatic Punch User Guide.Use

of the P70iX Automatic Punch in any manner not in accordance with the GBC P70iX

User Guide is not recommended and may void your warranty or maintenance contract

Trained operators and regular operator maintenance of the P70iX A can optimize performance and minimize service calls.

!

Page 9

1. Introduction

1-1

INTRODUCTION

The Quantum P70iX is designed to meet the unique requirements of the digital print

marketplace. It is designed to support all commonly required punching patterns, including three-hole, comb, VeloBind, Twin-Loop wire, and Color Coil. Custom die patterns are

also available.This new system is designed to deliver the quick changeover requirements of the short-run digital pr inter.

Virtually all set-ups are quickly and easily accomplished from the digital print display

panel, overcoming a major time-consuming aspect of traditional production punches.

Die changes can be accomplished in a short time without tools. The system is pre-programmed with all common paper sizes, and can store 20 custom jobs.

The P70iX is designed to handle a wide range of media. It can handle sheet sizes from

5 ?” x 5 ?” to 9” x 12”, including mixed paper-weights and cover stocks. Another key feature is the system’s ability to process intermixed index tabs without any special adjustments.

The P70iX incorporates GBC’s new “stack processing” technology, which is designed to

reduce operator labor cost.This new architecture allows the system to process a 14”

stack (3,500 sheets 20# bond) without operator attendance.The P70iX offers a maximum throughput speed of 60,000 sheets per hour.

The Quantum P70iX is GBC’s revolutionary new, near-line, high-speed Digital

Production Punch. It sets up in minutes and keeps up, side-by-side, with banks of

today’s fastest digital print engines.

These instructions have been prepared to acquaint you with the Quantum P70iX punch

and it’s operation.Please read them carefully. Keep these operating instructions for

future reference.

UNPACKING AND SETUP

The Quantum P70iX punch must be installed by a qualified GBC Technician.

Your Technician will ensure that the system is properly leveled and ready to run.

Page 10

2. Getting to Know your Quantum P70iX

2-1

GETTING TO KNOW YOUR QUANTUM P70iX

External factors can affect performance of your P70iX.These factors include

customer requirements for hole quality, throughput materials (paper/transparencies/covers), toner coverage on the pr inted page, and environmental factors.

STATIC in the paper can result in poor performance. If your P70iX runs a fresh

ream of clean white paper but has trouble with your printed job, it may be due to

static.The following tips might help you to correct this problem.

Suggestions for static: If you’re P70iX Automatic Punch is having trouble

running certain jobs, it may be due to excessive static build-up in the

paper. Here are some suggestions that may help to minimize the static

effect.

1. Fan the paper before loading it into the P70iX. Do not jog the paper; this

will only cause more static build-up.

2. Slow the speed down on the P70iX.This will give the paper more time to

settle down into the die.

3. Consider the purchase of a room humidifier to add moisture into the air.

Dry air helps to produce more static.

4. Move your punching operation to an environmentally controlled room.

5. Pay close attention to seasonal conditions. Procedures you follow in the

hot humid days may need to be modified during dry winter months when

static is most common.

6. Consider storing your unwrapped paper jobs in very large Tupperware

type containers to retain the moisture. Using these containers along with

humidor type products can actually reintroduce moisture into the paper

that was lost during the fusing process.

7. Contact your copier/printer service depar tment and enquire as to the

possibility of lowering your fuser temperature.

General areas to watch for maximum satisfaction.

Tabs must have a _” shoulder.

• When r unning mixed stocks, you must ensure the dimensions are consistent.

One stock smaller than the other will prevent proper hole registration.

• Very slippery paper or cover stocks may not run in the P70iX. Test small

stacks at slower speeds and/or smaller lift sizes before committing to a large

job.

• Cover stocks mixed with paper usually run best at slower speeds.

• If a very straight output stack is impor tant for a particular job, you may find

the stack quality best when run at a slower speed.

• When r unning cover stock alone, performance is best at slower speeds.

• Improper loading of stack will result in feeding problems.

• Some specialty papers (NCR paper for example) will show handling marks.

• The punched edge of a stack will be taller than when it went in. With some

papers, paper sizes and die set combinations; you may want to reduce the

input stack to prevent slumping, instability or excessive height.

• Excessive paper curl can result in poor feeding or jams. If curl is not

excessive (more than ?”2” from edge) you will have best results with curl

down. For our purposes, curl down is defined as the outside front edges are

down and the middle is up.

Page 11

2-2

GETTING TO KNOW YOUR QUANTUM P70iX continued

Suggestions for clear plastic covers:

The Quantum P70iX is capable of handling and punching some types of clear cover

materials. In fact, every Quantum P70iX is tested with clear covers before it leaves the

factory. The following guidelines will help you to understand the capabilities of the

Quantum P70iX system. In cases where your particular clear cover stock is not suitable

to run through the Quantum P70iX, you may want to try separating the clear covers

from the book contents and punching the clear covers using a GBC Magnapunch heavy

duty table top punch.

• For clear cover stocks to work in the GBC Quantum P70iX, they require the body

found in GBC Premium covers, which are 10-mil and 14 mil thickness.

• Clear covers must be run intermixed. The photo sensors used on the Quantum

cannot detect clear covers.

• When r unning mixed stocks, you must ensure the dimensions are consistent.One

stock smaller than the other will prevent proper hole-registration.

• With a smaller lift size the punch is more likely to pick a single clear cover. Lift sizes

5-7 works best.

• It is best to r un a job containing clear cover stocks at a slower speed. GBC recom

mends 75 LPM for most jobs.

• Clear covers produce more static sticking than other stock, ambient conditions will

affect performance.

• If a clear cover is picked alone, the punch may shut down with a false jam, however

the stock will not be damaged.

2. Getting to Know your Quantum P70iX

Page 12

3. Operation

3-1

OPERATING CONTROLS

1. Ergonomic

Workflow:

load, unload and program from the same

side without any wasted

steps.

Loading and unloading

stack can be safely

accomplished while the

machine is punching.

2. Die Set Changes:

are completed without

tools and only take seconds to perform.

3. Fully Digital:

push button set-up and

operation.With simple

steps to recall up to 24

custom jobs.

1

1

3

2

Page 13

OPTIONS AND ACCESSORIES:

Die Sets:

The GBC Quantum P70iX Automatic Punch is capable of punching a variety of hole

patterns commonly used in binding today, by simply changing the Die Set. Die sets

can be changed in seconds without tools.

A significant feature of the Quantum P70iX is that it uses GBC Magnapunch Die Sets.

Combined with a Magnapunch, you have the capability to switch the Die Set into the

punching platform best suited to handle the job in just a matter of minutes.

Please note:The PB Plastic Bind with multiple adjust depth of punch Magnapunch Die

Set (is not suitable for use in the automatic paper handling system utilized by the

Quantum.

The Die Sets currently available are listed below.Your GBC Sales Representative can

provide you with price and availability, or contact the

GBC Call Center at 1-800-723-4000.

For more information, visit GBC’s website at

www.gbcconnect.com.

Please note that each punching style listed above requires a separate die set for the

Quantum P70iX.

GBC offers a full suite of binding equipment and supplies to meet your binding needs.

Please see the enclosed Binding Solutions Catalog and Supplies Catalog for more

information.

Custom Die Sets are available for the Quantum P70iX. For additional information, consult with your GBC Sales Representative.

IMPORTANT: A decal on the handle of each interchangeable die set indicates the

punching pattern. When reading the Operating Instructions, please note the special

instructions for the correct punching pattern die set that you have installed in your

Quantum P70iX.

4. Options and Accessories

4-1

Quantum P70iX Automatic Punch - Die Sets Product Code

PB Plastic Bind – Deepest Fixed Back Gauge, .187” 7707230

PB Plastic Bind – Middle Fixed Back Gauge, .141” 7707220

PB Plastic Bind – Shallow Fixed Back Gauge, .094” 7707210

W3 Twin Loop Wire - 3:1 Round 7707150

W3 Twin Loop Wire - 3:1 Square 7707100

W2 Twin Loop Wire - 2:1 Rectangular 7707130

W2 Twin Loop Wire - 2:1 Round 7707160

C4 Color Coil – 4:1 Oval .2475 7707060

C4 Color Coil – 4:1 Round .2475 Pitch 7707040

C4 Color Coil - 4:1 Round .250 Pitch 7707050

C5 Color Coil - 5:1 Round 7707080

VB VeloBind 11 inch 7707180

Ring Binder 2/4 Standard 5/16” Diameter Hole 7707200

Ring Binder 3-5-7 5/16” Diameter Hole 7707190

Page 14

4. Options and Accessories

4-2

OPTIONS AND ACCESSORIES continued

Die Sets Storage:

Helpful Hint:The GBC Die Set Storage Cabinet #7703207 is an excellent way

to store all of your interchangeable die sets for the Quantum P70iX (see figure

3).This special product securely holds three die sets, protecting them from dir t,

dust, and accidental damage. Contact your sales representative for information

on obtaining a Die Set Storage Cabinet.

CAUTION: POSSIBLE PINCH POINT HAZARD.WHEN INSTALLING

DIE SETS INTO YOUR Quantum P70iX, ALWAYS KEEP FINGERS AND

BODY PARTS OUT OF THE MACHINE’S DIE SET SLOT AND AWAY

FROM ALL AREAS OF THE DIE SET EXCEPT FOR THE FINGER GROOVE

IN THE DIE SET’S HANDLE. FAILURE TO OBSERVE THESE

PRECAUTIONS MAY RESULT IN INJURY.

!

Figure 3

Page 15

5. Home Screen

5-1

HOME SCREEN

The Home Screen is the starting point for operation of the Quantum P70iX. At

this screen, you are able to see the job that the Quantum is ready to run. In the

example above, the Quantum is setup to run:

• A paper size of 8.5” x 11” with punching on the 11” side.

• A lift thickness of “7” which is approximately 7 sheets of 24 pound paper.

• At a speed of 90 lifts per minute.

• Punching holes using a PB (Plastic Bind) die with a back gauge of .141”.

• The Quantum is also operating with the controls reading in the English lan

guage.

If these job settings are acceptable, you may start you job by:

• Loading your paper on the input belts.

• Pressing the green star t button.

GBC QUANTUM PUNCH

90 LPM

PB .141

MODE

UNLOAD

7

11"

JOB MANAGER

LANGUAGEPROOF

8.5"

123

456

789

0OK

Page 16

5. Home Screen

5-2

HOME SCREEN continued

Other commands from the HOME SCREEN are:

MODE: allows you to select between Automatic or Manual. Automatic Mode

means the Quantum will continue to run non-stop as long as you place paper on

the Input Belts and remove the punched stack of paper from the Output Belts.

The Manual Mode means the Quantum will stop before it takes the next paper

stack in for processing.This mode is helpful if you want to start a new job that

requires different settings such as a different Die Set for example.

PROOF: you can run a few lifts of your job and have the Quantum stop.This

feature enables you to check the hole positioning and pattern to ensure the

setup is the job you intended.

UNLOAD: means that when pressed, the job currently inside of the Quantum

will exit.This is helpful if you need to start a job over again for some reason.

JOB MANAGER: will take you to the Job Manager screen where a different job

can be selected or created.

LANGUAGE: you may select between English, Spanish, French and German.

GBC QUANTUM PUNCH

90 LPM

PB .141

MODE

UNLOAD

7

11"

JOB MANAGER

LANGUAGEPROOF

8.5"

123

456

789

0OK

Page 17

5. Home Screen

5-3

HOME SCREEN continued

Other commands from the HOME SCREEN:

You have constant control of the Speed by controlling the LPM or Lifts Per

Minute and the size of each Lift by adjusting the number of sheets per Lift.

Lifts Per Minute (LPM) is controlled by pressing the left – right arrow buttons.

You will see the number change in the window. The example above reads “90

LPM”.The choices are 60, 75, 90 and 105 LPM.

NOTE:You would choose a lower speed for harder to handle media such as

jobs with heavier than normal curl or heavier than normal toner coverage.

The size of the lift is controlled by pressing the Up – Down arrows.The numbers

roughly equal the number of sheets of 24 pound bond paper that would be

picked at this setting.This feature does not actually count sheets however and

you should not expect the lift to be exactly this quantity.The example shown is

of a lift size of “7”

NOTE: You would choose a lower lift for harder to handle media such as jobs

with heavier than normal curl or heavier than normal toner coverage.

GBC QUANTUM PUNCH

90 LPM

PB .141

MODE

UNLOAD

7

11"

JOB MANAGER

LANGUAGEPROOF

8.5"

123

456

789

0OK

Page 18

5-4

5. Home Screen

At the Job Manager Screen you are able to scroll between saved jobs (1 – 12)

by simply pressing the right-left and/or the up/down buttons.In the example

above, JOB 1 has been highlighted.To select this job and continue, simply press

“GO JOB 1” button.

Other Job Manager Features:

• VIEW 13-24: press to select a job #13 to #24.

• HOME: press to return directly to the Home screen.

• EDIT: a current job or create a new job,

Scroll to the job you wish to Edit, or,

Scroll to an unused job.In the example above, Job 12 is unused.

Press the EDITOR button.

JOB MANAGER SCREEN

JOB MANAGER — USE ARROWS

PB141

11"

GB4:1

5

11"

3:1RN

9

10"

8.5"

7.5"

8"

PB141

2

11"

PB141

6

11"

P8094

10

10.5"

8.5"

8"

8"

PB141

9"

PB141

7

11"

PB141

11

11"

3-5-7

3

6"

4

9"

9.5"

3:1 RN

mm

8

8.5"

297

8.5"

210

mm

?

12

?

?

HOMEEDITORVIEW 13-24GO JOB 1

123

456

789

0OK

Page 19

5. Home Screen

5-5

To Edit an exiting job or create a new job, press the up – down arrows to select

the desired setting. In the example above, the Punch Edge paper dimension has

been selected and currently reads 11”.

Alternatively, the dimension can be entered directly using the numeric keypad.

The machine will automatically toggle between inches and millimeters depending on the size of the number entered.

Note that the range for this value is 5.50” to 12.00” (139.7 mm to 304.8 mm).

Once the desired value appears on the display, press the “ACCEPT” button.

EDITOR SCREEN

USE ARROWS TO

0 . . 9

ACCEPT

ESCAPE

SAVE

ESCAPE SAVE

CHANGE

OTHER

SIZES

GO TO NEXT

SETTING

NO CHANGE

GO BACK

DATA OK

STORE

EDITOR

PB .141

1

11"

8.5"

ACCEPT

123

456

789

0OK

Page 20

5-6

5. Home Screen

EDITOR SCREEN

In the example above, the Side Edge paper dimension has been selected and

currently reads 8.5”.

Note that the range for this value is 5.50” to 9.00” (139.7 mm to 228.6 mm).

EDITOR SCREEN continued

EDITOR

USE ARROWS TO

CHANGE

0 . . 9

ACCEPT

ESCAPE

SAVE

ESCAPE SAVE

OTHER

SIZES

GO TO NEXT

SETTING

NO CHANGE

GO BACK

DATA OK

STORE

PB .141

1

11"

8.5"

ACCEPT

123

456

789

0OK

Page 21

5-7

5. Home Screen

EDITOR SCREEN

In the example above, the Punch Die type has been selected and currently

reads PB .141. See Table 1 for the Die Sets available for the Quantum.

Once all three settings are correct, press the “SAVE” button which will return to

the Job Manager Screen.

EDITOR SCREEN continued

EDITOR

USE ARROWS TO

CHANGE

PB .141

ACCEPT

ESCAPE

GO TO NEXT

SETTING

NO CHANGE

GO BACK

SAVE

ESCAPE SAVE ACCEPT

DATA OK

STORE

1

8.5"

11"

123

456

789

0OK

Page 22

5-8

5. Home Screen

Selection of a new Die Set will prompt the Die Set screen to come up.This

screen will prompt you to remove the proper Punch Pin numbers for the paper

size you are running. In the example shown, there are two possible pin configurations with this Die Set and Paper combination.The Die Set itself features a

handy reference label to identify the Pin numbers.The Quantum will automatically center the Die Set to the paper size selected if you press buttons 2 or 4.By

pressing buttons 1 or 2, the Quantum will perform all required adjustments (bind

edge, side edge & center the die).You can manually fine-tune the hole centering

by pressing the right-left arrows at this screen.

Note that the pins indicated on the display are the pins that should remain in the

Die Set, i.e. pull the pins to the left and right of the range indicated.

Note: in the screen above, the graphic should sow pins “4 - 23 and 5 – 23”not “1 – 23 and 5 – 23”.

“GO JOB” SCREEN

USE ARROWS TO

CHANGE

EDITOR

PB .141

ACCEPT

ESCAPE

GO TO NEXT

SETTING

NO CHANGE

GO BACK

SAVE

ESCAPE SAVE ACCEPT

DATA OK

STORE

1

8.5"

11"

123

456

789

0OK

Page 23

5-9

5. Home Screen

When the Quantum is running a job, the Graphics will provide you with information about the job that is running.

• The example above is telling you that there is paper on the Input Belts and on

the Output Belts as well as inside the Quantum processing area.

Other graphics would indicate:

• Elevator Positions

• Doors Open

• Die Set is clamped

• Error locations

• Adjusting sheet sizes

RUN SCREEN

GBC QUANTUM PUNCH

90 LPM

PB .141

MODE

UNLOAD

7

11"

JOB MANAGER

LANGUAGEPROOF

8.5"

123

456

789

0OK

Page 24

5-10

5. Home Screen

When the Quantum is running a job, the Graphics will provide you with information about the job that is running.

The example above is telling you that the Die Set is locked.

PAUSE verses STOP commands:

If you need to stop the system immediately, press “STOP” and the Quantum

P70iX will stop in mid-cycle.You may then need to clear paper from the various

points in the paper path if the system does not clear itself when you start-up

again. If you want to stop the punching process, but can allow paper in the path

to continue, press “PAUSE”. This will stop the feeding process, but allows any

paper currently in the paper path to run through the system.

SETUP SCREEN

GBC QUANTUM PUNCH

90 LPM

PB .141

MODE

UNLOAD

7

11"

JOB MANAGER

LANGUAGEPROOF

8.5"

123

456

789

0OK

Page 25

TROUBLESHOOTING Quantum P70iX

Problem Probable Cause

No power, won’t punch

Punches too many holes

Operator familiar with paper sizes

referenced on the Xerox DocuTech

as mm

When manually loading the first

stack of paper onto the Feed Belts,

the bottom sheets of paper catch

After heavy use, the machine begins

to read jam, when there is no jam

Power cord not attached to back of machine or not

properly plugged into the wall

Die Set is not fully inserted

Door or Lid is not closed

Selectable pins have not been pulled

Go to “SETUP” and change the dimensions to “mm”

from inches

The surface of the belts are designed to grab the

paper.You will find that it is not possible to set the

paper stack on the belts and slide it into the alignment corner. Instead, push the stack gently against

the door first, then against the sheet metal right

guide and then set the stack down onto the belt.

Also loading a smaller stack first followed by a couple of larger stacks is best

A blast of air across the lens of each of the three

optical sensors periodically will prevent paper dust

build up from interfering with their performance.

6. Maintenance

6-1

SLUG BIN (PAPER CHIP or PAPER CHAD) CONTAINER

The slug bin container for your Quantum P70iX is located behind the left hand

access door near the bottom of the machine.The container should be periodically pulled out and emptied.This will avoid jamming and damage to the

machine.The Quantum P70iX incorporates microprocessor technology to inform

the operator when the container needs to be emptied.

NOTE:When pull the Slug Bin is pulled out, make sure that it is emptied.To fully

reset the slug counter system, the Slug Bin Container must be fully removed

from the Quantum for a minimum of 5 seconds.

PUNCH PINS

You may need to remove some of the Punch Pins for proper punching of some

combinations of paper sizes and punching patterns.

SERVICE

Should your Quantum P70iX require service contact your local authorized GBC

service representative.

There are NO user-serviceable parts inside the machine. To avoid potential personal injury and/or proper ty damage, DO NOT REMOVE THE MACHINE’S

COVER.

ADDITIONAL INFORMATION

Page 26

7-1

7. Specifications

Speed: Up to 105 cycles / minute, 60,000 sheets per hour

Sheet size: Punch edge 5 1/2” to 12”, side edge 5 ?” to 9”

Paper Stock: 61 gsm (16#) bond to 300 gsm (140#)

Intermixed weights, flush-cut covers, and standard index tabs

Lift Height: Variable, 5 to 12 sheets of 20# bond (75 gsm)

Stack Height: up to 14” (approximately 3,500 sheets of 20# bond (75 gsm)

Dimensions: 60”W x 55”L x 52”H (152cm x 140cm x 132cm)

(Easily breaks down to fit through a 32” doorway) see page 8

Weight: 850 lbs. (386kg)

Power Supply: USA/Canada: 220VAC, 50/60Hz, Single Phase, 2.7 Amps, 0.32 KW, 1,092 BTU/hr

International: 220VAC, 50/60Hz, Single Phase, 2.7 Amps, 0.32 KW, 1,092 BTU/hr

Receptacle Type 6-20R 20A, 250V

Approvals: CSA certified to CAN/CSA-C22.2 No. 60950-00, UL Std No. 60950-00, 3

rd

Ed.

TUV certified to EN 60950:2000

Compliance: Carries CE mark to show compliance with European Union requirement

Die Sets: Interchangeable die sets can be switched in seconds without tools

Specifications are subject to change without notice

GBC recommends ear protection for operators of the Quantum P70iX.Our

sound test levels are as follows:

SPECIFICATIONS Quantum P70iX

Worst Case Operation (speed 4, C4 Die Set,

20# bond, lift #9 – 12 sheets):

Sound Pressure Level = LpA = 83.0 dbA

Sound Pressure Impulse = LpAI = 85.2 dbA

Typical Use Operation (speed 2, PB Die Set,

20# bond, lift #9 – 12 sheets):

Sound Pressure Level = LpA = 78.5 dbA

Sound Pressure Impulse = LpAI = 83.5 dbA

ISO 7779 Test method and microphone placement:

1.5M (59.1”) from Feeder,

1.5M (59.1”) high,

0.25M (9.85”) from vertical lead edge of

Quantum at control panel.

0.25

30°

Dimensions in meters

Standing operator

(9.85”)

1.5

(59.1”)

Page 27

7. Specifications

7-2

Voltage Rating: 250VAC

Current Rating: 15A

Plug: NEMA 6-15P

Connector: IEC 60320 C13

POWER CORD SPECIFICATIONS

®

®

Page 28

®

General Binding Corporation

Northbrook, IL 60062-4195

http://www.GBC.com

Printed in the U.S.A.Rev. A1 / GBC Part # 7707286

Page 29

Guaranteed Lowest Prices on an

Endless Selection of Binding Systems, Laminators,

Paper Shredders, Supplies and Accessories.

We have you covered with Expert Advice

and Support. Our popular blog keeps you up to

date on the latest tips and techniques to make

your most important binding and laminating

tasks a success.

Call Us Today

1-800-944-4573

Our Trusted Partners

GBC / Ibico

Fellowes

Powis Fastback

Unibind

Akiles

Renz

Tamerica

Rhin-O-Tuff

DFG

Pro-Bind

Martin Yale

MBM

Formax

Intimus

Dahle

HSM

Standard

Xyron

Challenge

Lasko-Wizer

GBC Shredmaster

Avery

Wilson Jones

Cardinal

Samsill

Universal

Binding Machines

Binding Supplies

Laminators

I.D. Accessories

Boards & Easels

Paper Shredders

Xyron Laminators

Coil Binding machines

Unibind Binding Machines

Fastback Binding Equipment

Paper Folding Machines

Laminating Pouches

Rotary Trimmers

Clear Covers

Twin Loop Wire

Regency Covers

Plastic Binding Covers

Velobind Binding Machines

Paper Handling Equipment

Thermal Binding Machines

Proclick Binding Systems

Comb Binding Machines

Comb Binding Supplies

Wire Binding Machines

Pouch Laminators

Laminating Rolls

3-Ring Binders

Roll Laminators

Velobind Spines

Paper Cutters

Paper Joggers

Letter Openers

Thermal Covers

Unibind Supplies

Proclick Spines

Zipbind Spines

Linen Covers

Spiral Coil

Index Tabs

Loading...

Loading...