Page 1

Gateway TP-A60W/ TP-A60G

SERVICE GUIDE

Page 2

Revision History

Refer to the table below for the updates made to this service guide.

Date Chapter Updates

Service guide files and updates are available on the ACER/CSD Website. For more

information, go to http://csd.acer.com.tw

without notice.

. The information in this guide is subject to change

Copyright

Copyright © 201 1 by Gateway Incorpor ated. All rights reserv ed. No part of this publication may

be reproduced, transmitted, tran sc rib ed , sto re d in a retrieva l s yst em , or tran sla te d int o any

language or computer language, in any form or by any means, electronic, mechanical,

magnetic, optical, chemical, manual or otherwise, without the prior written permission of

Gateway Incorporated.

Disclaimer

The information in this guide is subject to change without notice.

There are no representations or warranties, either expressed or implied, with respect to the

contents hereof and specifically disclaims any warranties of merchantability or fitness for any

particular purpose. The software described in this manual is sold or licensed "as is". Should

the programs prove defective following th eir pur ch as e, th e bu ye r (n ot the ma n uf ac tur e r,

distributor, or its dealer) assumes the entire cost of all necessary servicing, repair, and any

incidental or consequential damages resulting from any defect in the software.

ii

Page 3

Conventions

WARNING:

!

CAUTION:

!

IMPORTANT:

+

NOTE:

NOTE:

The following conventions are used in this manual:

Indicates a potential for personal injury.

Indicates a potential loss of data or damage to equipment.

Indicates information that is important to know for the proper completion of a

procedure, choice of an option, or completing a task.

N/A: Indicates that a component or a procedure is not applicable to this model.

Follow local regulations for battery and circuit board disposal. Batteries and Circuit

Boards >10 cm² have been highlighted with a yellow rectangle.

The following typographical conventions are used in this document:

Book titles, directory names, file names, path names, and program/process names are

shown in italics.

Example:

the DRS5 User's Guide

/usr/local/bin/fd

the /TPH15spool_M program

Computer output (text that represents information displayed on a computer screen,

such as menus, prompts, responses to input, and error messages) are shown in

constant width.

Example:

[01] The server has been stopped

User input (text that represents information entered by a computer user, such as

command names, option letters, and words) are shown in constant width bold.

Variables contained within user input are shown in angle brackets (< >).

Example:

At the prompt, type run <file name> -m

Keyboard keys are shown in bold italics.

Example:

After entering data, press Enter.

iii

Page 4

General Information 0

This service guide provides all technical information relating to the basic configuration for

Gateway global product offering. To better fit local market requirements and enhance product

competitiveness, your regional office may have decided to extend the functionality of a

machine (such as add-on cards, modems, or extra memory capabilities). These localized

features are not covered in this generic service guide. In such cases, contact your regional

offices or the responsible personnel/channel to provide further technical details.

When ordering FRU parts:

Check the most up-to-date information available on your regional Web or channel. If, for

whatever reason, a part number change is made, it may not be noted in this printed service

guide.

Acer-authorized Service Providers:

Your Acer office may have a different part number code than those given in the FRU list in this

service guide. The list provided by your regional Acer office must be used to order FRU parts

for repair and service of customer machines.

iv

Page 5

CHAPTER 1

Hardware Specifications

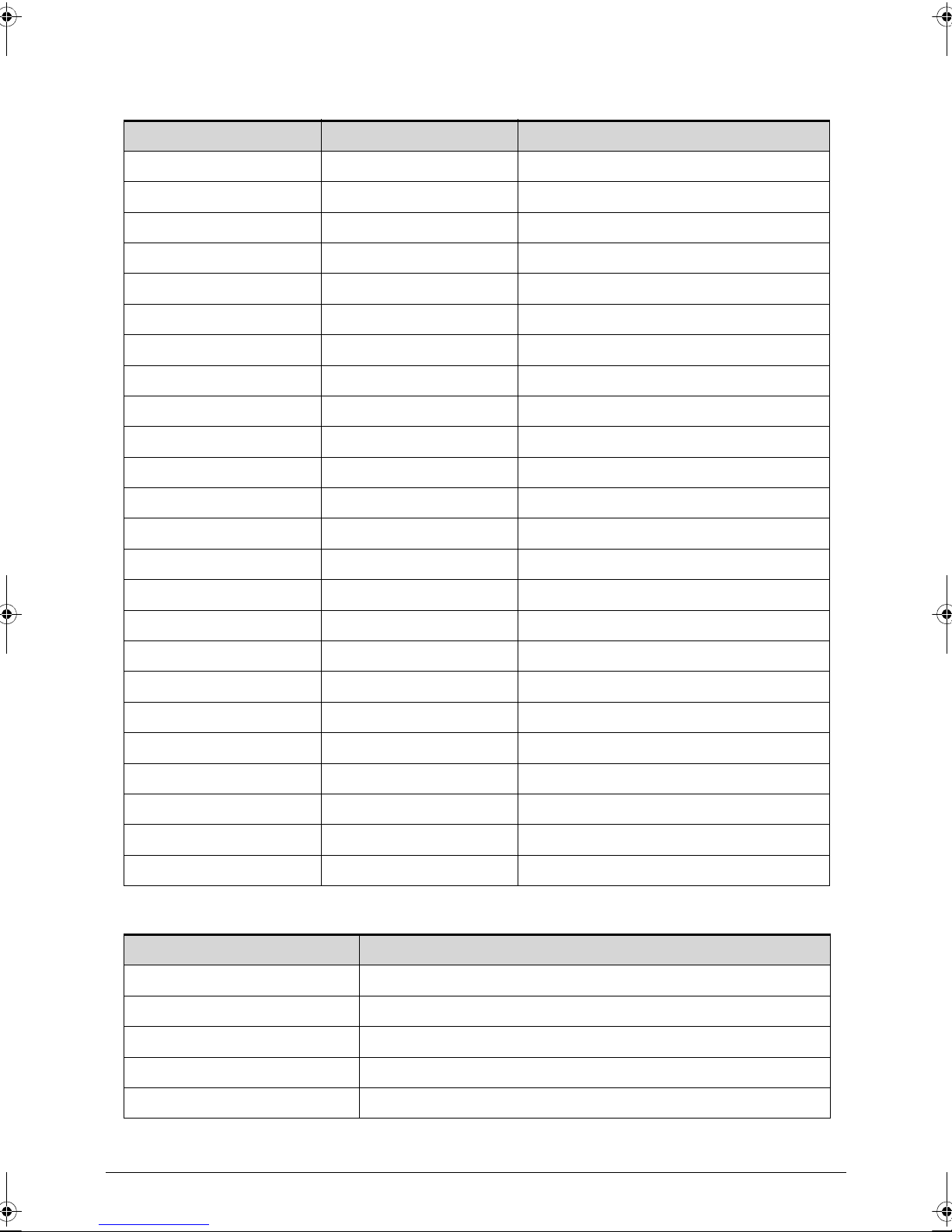

Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Operation System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Platform . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

System Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Display. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Graphics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Audio Subsystem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Special Keys and Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

I/O Ports. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Dimensions and Weight. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Power Adapter and Battery. . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Optional Items . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Notebook Tour. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

Front View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

Back View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

Left View. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

Bottom View. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

Top View. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

Right View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12

System Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-13

Specification Tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-14

Computer specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-14

System Board Major Chips . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-15

Processor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-15

Processor Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-16

System Memory. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-16

Video Interface (Integrated). . . . . . . . . . . . . . . . . . . . . . . . . . . 1-17

Embedded MultiMediaCard (AVL components) . . . . . . . . . . . 1-20

LED 10.1”. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-21

Display Supported Resolution (LCD). . . . . . . . . . . . . . . . . . . . 1-22

Graphics Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-22

Display Supported Resolution (GPU) . . . . . . . . . . . . . . . . . . . 1-22

Bluetooth Interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-22

Bluetooth Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-22

Front Camera. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-23

Rear Camera. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-23

Mini Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-23

3G Card. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-23

Audio Codec and Amplifier . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-24

Audio Interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-24

Wireless Module 802.11b/g/n . . . . . . . . . . . . . . . . . . . . . . . . . 1-25

v

Page 6

Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-25

VRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-25

USB Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-25

HDMI Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-25

AC Adapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-26

System Power Management . . . . . . . . . . . . . . . . . . . . . . . . . . 1-26

Card Reader . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-26

System LED Indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-26

System DMA Specification . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-27

CHAPTER 2

Diagnostic Utilities

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

NGA EUU Installation Procedure. . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Picasso Diagnostic Tool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

CHAPTER 3

Maintenance Procedures

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Recommended Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Maintenance Flowchart. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Getting Started . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

SIM/Micro-SD Card Removal . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

SIM/Micro-SD Card Installation . . . . . . . . . . . . . . . . . . . . . . . 3-8

Lower Case Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

Lower Case Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

DC-In Cable Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-16

DC-In Cable Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-18

Battery Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-19

Battery Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-20

3G Module Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-21

3G Module Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-23

Docking Board Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-24

Docking Board Installation . . . . . . . . . . . . . . . . . . . . . . . . . . 3-26

GPS Antenna Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-28

GPS Antenna Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-29

Mainboard Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-30

Mainboard Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-32

Rear CCD Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-35

Rear CCD Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-37

Front CCD Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-38

vi

Page 7

Front CCD Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-38

Two-Piece Microphone Removal. . . . . . . . . . . . . . . . . . . . . . 3-39

Two-Piece Microphone Installation. . . . . . . . . . . . . . . . . . . . 3-39

Speakers Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-41

Speakers Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-41

USB Module Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-42

USB Module Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-43

LCD Support Plate Removal. . . . . . . . . . . . . . . . . . . . . . . . . . 3-44

LCD Support Plate Installation. . . . . . . . . . . . . . . . . . . . . . . . 3-47

Control Board Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-48

Control Board Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-49

3G Antenna Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-51

3G Antenna Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-51

WLAN Antenna Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-53

WLAN Antenna Installation. . . . . . . . . . . . . . . . . . . . . . . . . . 3-53

CHAPTER 4

Troubleshooting

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

CHAPTER 5

Power On Issues . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

No Display Issues. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

LCD Picture Failure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Touch Screen Failure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

Internal Speaker Failure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

Internal Microphone Failure . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

USB Failure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

Front Camera Failure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

Back Camera Failure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

P-Sensor Failure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-13

3G Function Failure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-14

Wireless Function Test Failure . . . . . . . . . . . . . . . . . . . . . . . . 4-15

GPS Function Test Failure (Wi-Fi SKU). . . . . . . . . . . . . . . . . . 4-16

GPS Function Test Failure (3G SKU). . . . . . . . . . . . . . . . . . . . 4-17

Docking Station Test Failure . . . . . . . . . . . . . . . . . . . . . . . . . 4-18

Other Functions Failure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-19

Jumper and Connector Locations

Mainboard Top . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Mainboard Bottom . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-4

vii

Page 8

CHAPTER 6

Field Replaceable Unit List

Exploded Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

Main Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

LCD Exploded Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-8

FRU List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-9

Screw List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-15

CHAPTER 7

Model Definition and Configuration

TP-A60W. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

CHAPTER 8

Test Compatible Components

Android OS Environment Test. . . . . . . . . . . . . . . . . . . . . . . . . . . 8-4

TP-A60W/ TP-A60G. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-4

CHAPTER 9

Online Support Information

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-3

viii

Page 9

CHAPTER 1

Hardware Specifications

Page 10

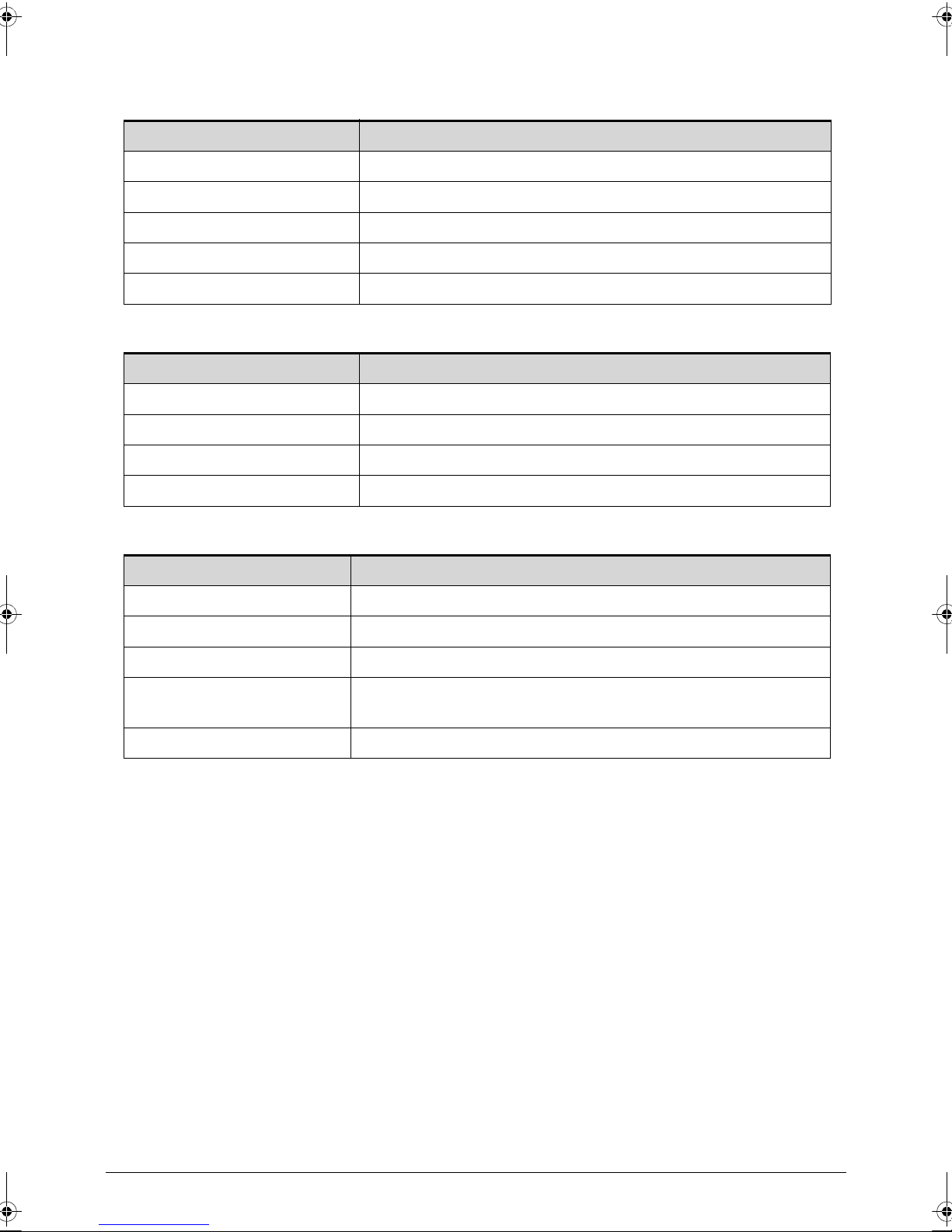

Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Operation System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Platform . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

System Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Display. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Graphics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Audio Subsystem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Special Keys and Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

I/O Ports. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Dimensions and Weight. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Power Adapter and Battery. . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Optional Items . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Notebook Tour. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

Front View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

Rear View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

Top View. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

Left View. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

Right View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

Bottom View. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12

System Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-13

Specification Tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-14

Computer specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-14

Processor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-15

Processor Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-16

System Memory. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-16

Video Interface (Integrated). . . . . . . . . . . . . . . . . . . . . . . . . . . 1-17

Graphics Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-22

Display Supported Resolution (GPU) . . . . . . . . . . . . . . . . . . . 1-22

Bluetooth Interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-22

Bluetooth Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-22

Rear Camera. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-23

Mini Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-23

3G Card. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-23

Audio Interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-24

Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-25

VRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-25

USB Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-25

HDMI Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-25

AC Adapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-26

System Power Management . . . . . . . . . . . . . . . . . . . . . . . . . . 1-26

Card Reader . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-26

System LED Indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-26

System DMA Specification . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-27

1-2

Page 11

Hardware Specifications and Configurations

Features 0

The following is a summary of the computer’s many features:

Operation System 0

Android Honeycomb

Platform 0

Tegra 250 Du al cor te x A 9, 1G Hz

GPU Ultra Low Power GeForce

System Memory 0

RAM: LP DDR2 1GB

eMMC: eMMC: 16G / 32G two SKU (SanDisk / Samsung)

®

GPU

Display 0

LCM

10.1" WXGA, 262K LCM (1280*800 AUO)

Wide view angle

LVDS interface

Graphics 0

ULP GeForce

Audio Subsystem 0

Dual analog Microphone (Beam-forming, Noise /echo cancella tion)

Dual Speaker

3.5mm Audio Jack 4ring (with Mic)

Dolby mobile

Hardware Specifications and Configurations 1-3

Page 12

Storage Subsystem (N/A) 0

Optical Media Drive (N/A) 0

Privacy Control (N/A) 0

Communication 0

Camera (Webcam)

Main camera: 5M Camera with Auto focus

with flash lights (single LED)

Second camera: 2M FF

WLAN

3G Module HUAWEI EM770W (with GPS/AGPS)

UMTS /WCDMA 1, 2, 5, 8 2100/1900/850/900

HSPA: HSDPA up to 7.2 Mbps/ HSUPA up to 5.76Mbps

GSM/GPRS/EDGE 850MHz / 900MHz / 1800Mhz / 1900Mhz

3G Module Ericsson F5521gw (with GPS/AGPS)

UMTS /WCDMA 1, 2, 5, 8 2100/1900/850/900

HSPA+: HSDPA up to 21Mbps/ HSUPA up to 5.76Mbps

GSM/GPRS/EDGE 850MHz / 900MHz / 1800Mhz / 1900Mhz

3G Module HUAWEI EM820W (with GPS/AGPS)

UMTS /WCDMA 1, 2, 5, 8 2100/1900/850/900

HSPA+: HSDPA up to 21Mbps / HSUPA up to 5.76Mbps

GSM/GPRS/EDGE 850MHz / 900MHz / 1800Mhz / 1900Mhz

802.11 b/g/n WiFi (802.11n 2.4GHz on ly)

WPAN

Bluetooth

®

2.1+EDR

GPS/A GPS

WIFI SKU: Broadcom - stand alone, not support A-GPS

3G SKU: on 3G module, support GPS and A-GPS

Special Keys and Controls 0

Capacitive Multi-Touch Screen (Real 4 touch, up to 10)

Function buttons

Side (mechanical key):

Volume Up, Volume Down, screen lock

Power:with back light-white/orange

Sensors

G-Sensor

E-Compass

1-4 Hardware Specifications and Configurations

Page 13

L Sensor

Gyro-meter

Power reset hole

I/O Ports 0

MicroSD memory card up to 32G (SDHC 2.0 compatible)

HDMI D-type (support Dual Display)

USB

Micro USB 2.0 type B for Client

USB 2.0 Host

Docking (Support s Charging , Audio out and IR remote contr ol; does not supp ort HDM I)

Dimensions and Weight 0

Dimensions

260 (L) x 179 (W) x 14 (H) mm

Weight

WIFI SKU: 740g

3G SKU: 750g

Power Adapter and Battery 0

Rohs compliance

WEEE compliance

Hologen free, at least PVC free

SMT Green process

Battery

Rechargeable Lithium-ion polymer battery

Capacity: 24.1W (3260mAh cell, 2S1P)

Power Adapter

Voltage range/frequency: 100 ~ 240V AC, 50/60 Hz

DC output: 12V and 1.5 A, 18W

Environment 0

Temperature:

Operating: 0°C to 50°C (32°F to 122°F)

Non-operating: -20°C to 60°C (-4 ° F to 140 °F )

Humidity (non-condensing):

Operating: 10% to 90%

Non-operating: 5% to 95%

Hardware Specifications and Configurations 1-5

Page 14

Optional Items 0

NOTE:

NOTE:

Micro SD Card

Dock with IR remote control

HDMI Cable

Pouch

In Box

USB Cable

Charger + Plug

QSG

Protective film is not available

Warranty (N/A) 0

Software (N/A) 0

1-6 Hardware Specifications and Configurations

Page 15

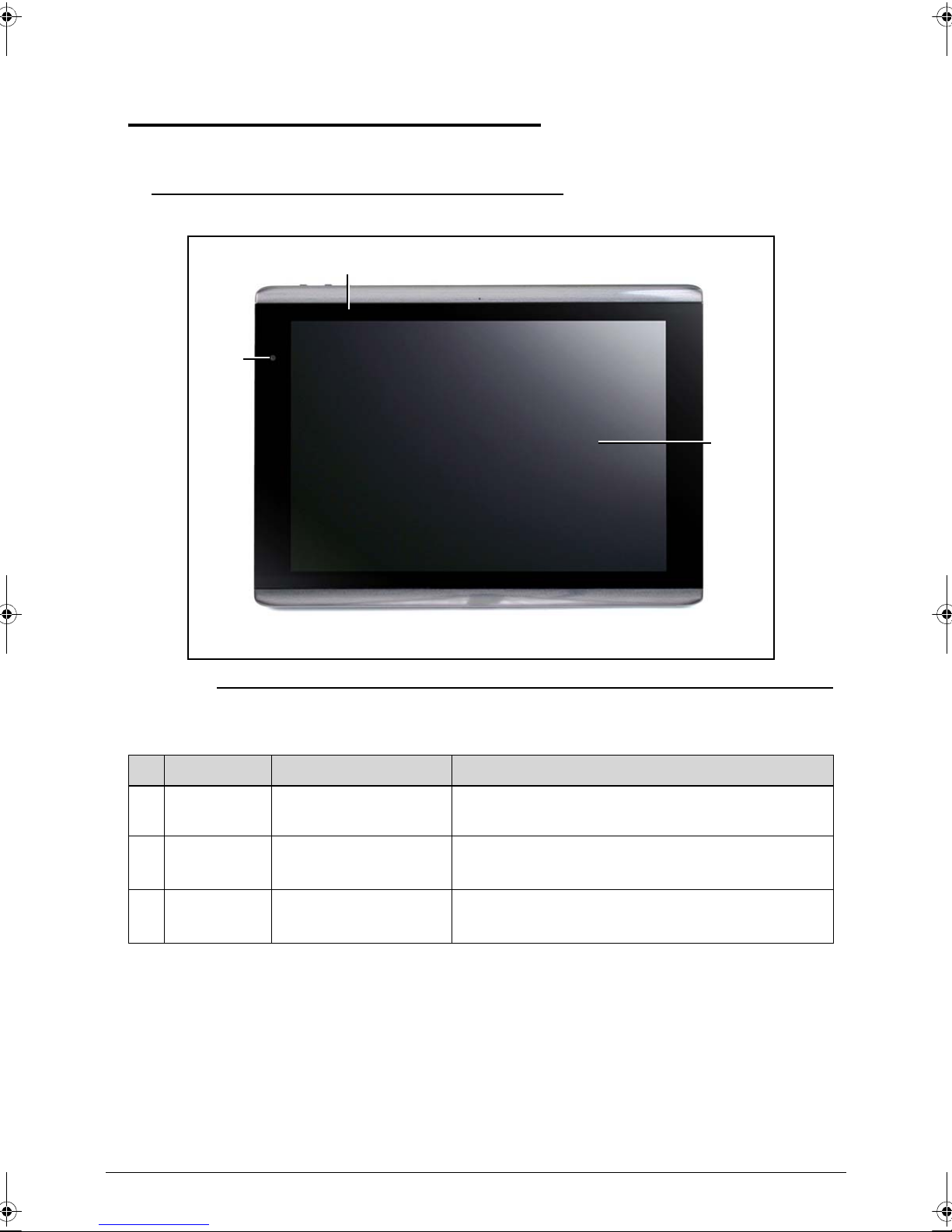

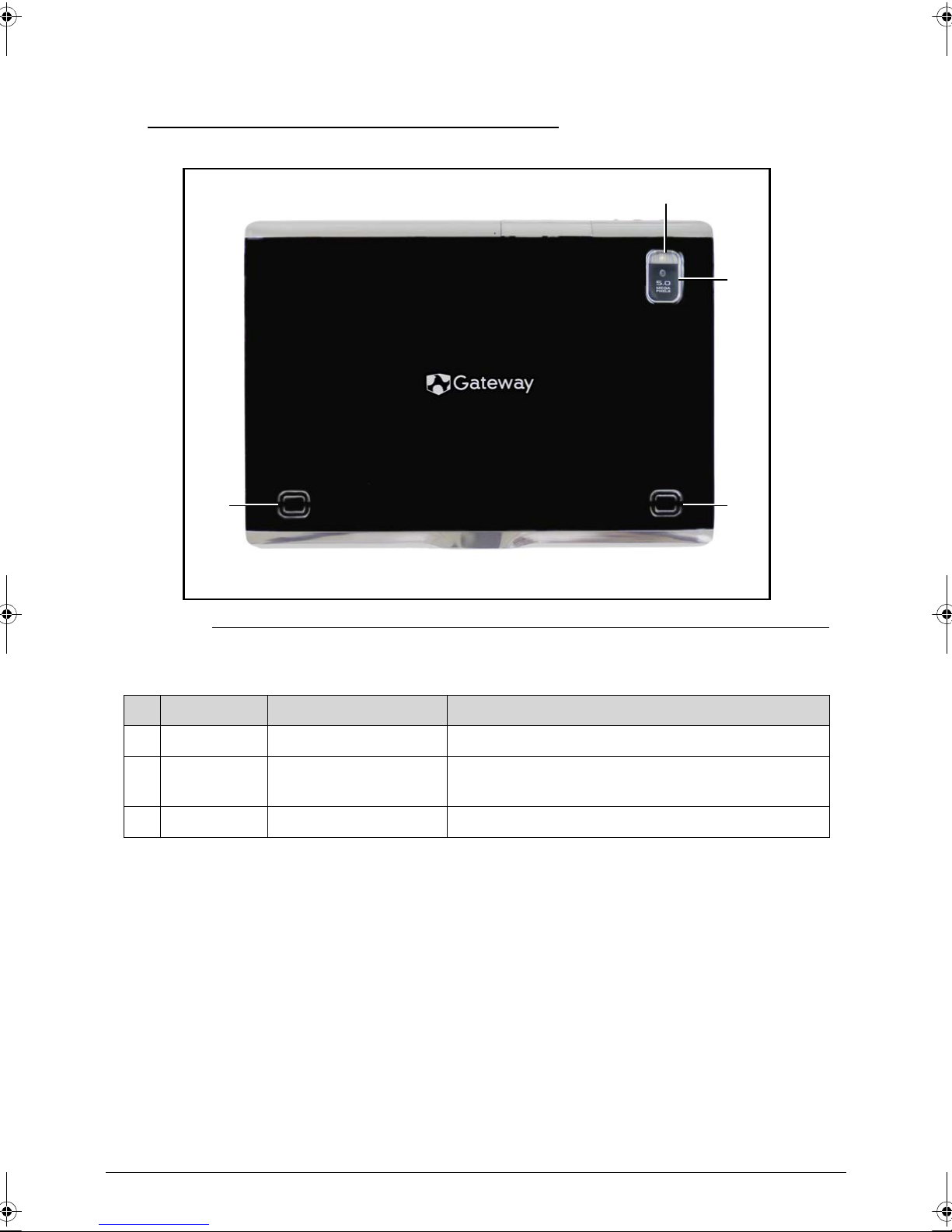

Notebook Tour 0

1

2

3

Front View 0

Figure 1-1. Front View

Table 1-1. Front View

# Icon Item Description

1 Touchscreen 10.1-inch, 1280 x 800 pixel capacitive

2 Front-facing Camera A 2-megapixel camera for video chatting and

3 Light Sensor Detects ambient light and automatically adjusts

touchscreen.

self-portrait images.

the screen brightness.

Hardware Specifications and Configurations 1-7

Page 16

Back View 0

3

1

3

2

Figure 1-2. Back View

Table 1-2. Back View

# Icon Item Description

1 LED Flash Lights to illuminate images.

2 5 MP Camera A 5-megapixel camera for taking highresolution

images.

3 Speakers Emits stereo audio.

1-8 Hardware Specifications and Configurations

Page 17

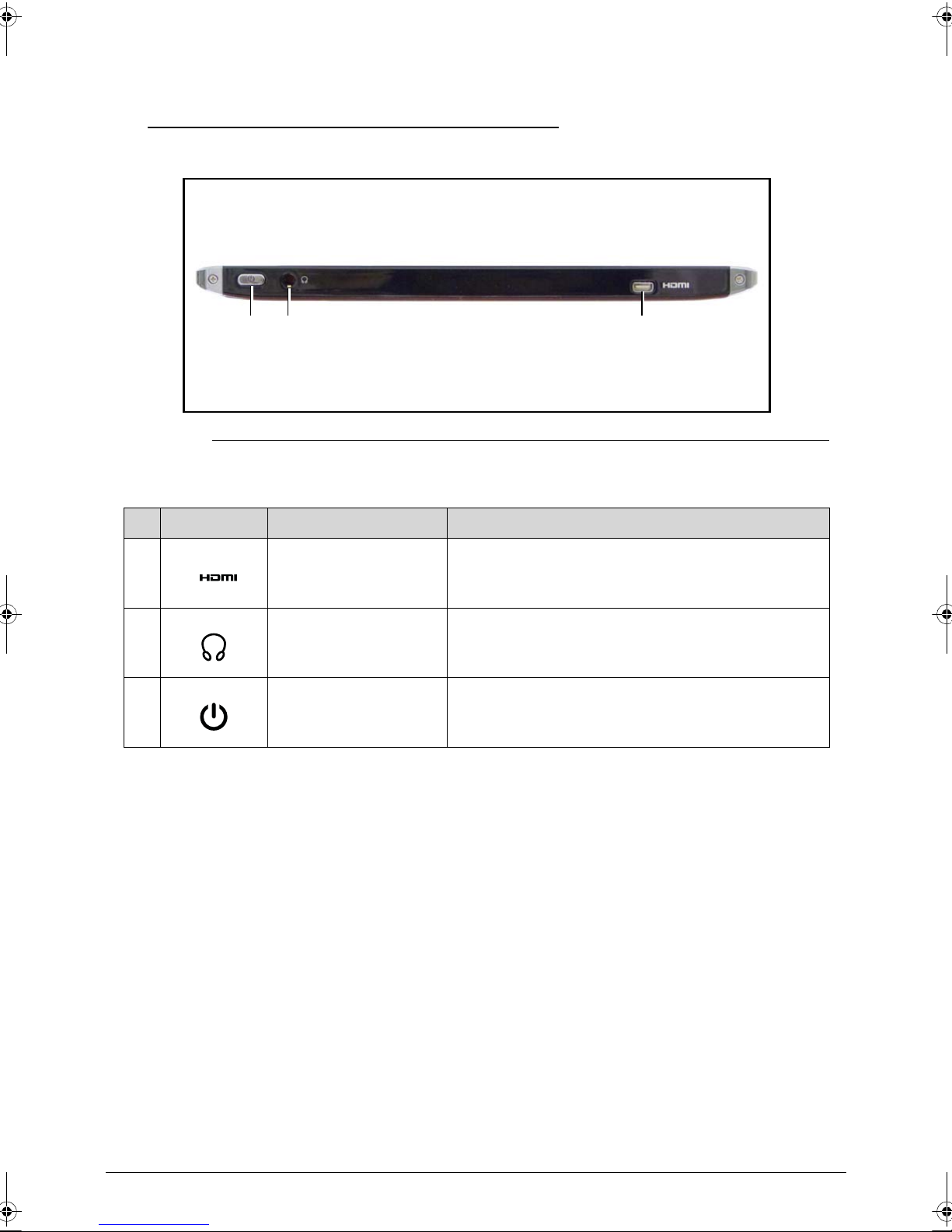

Left View 0

12

3

Figure 1-3. Left View

Table 1-3. Left View

# Icon Item Description

1 HDMI Micro (Type D)

Port

2 3.5 mm Headphone

Jack

3 Power Button Long press to turn the tablet on, press briefly to

Connects to an HDMI cable with a Type D

connector.

Connects to stereo headphones.

turn the screen on/off or enter sleep mode; press

and hold to turn the tablet off.

Hardware Specifications and Configurations 1-9

Page 18

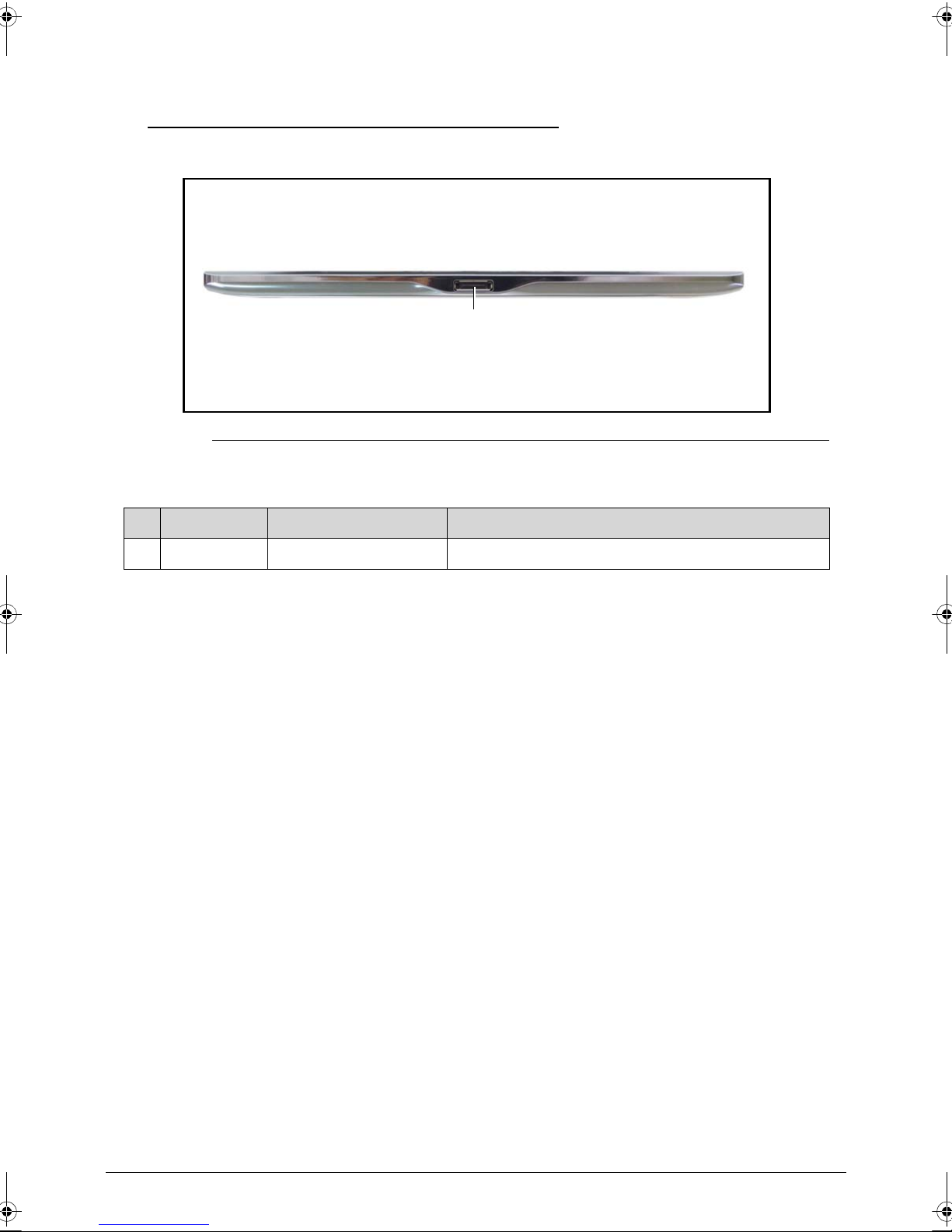

Bottom View 0

1

Figure 1-4. Bottom View

Table 1-4. Bottom View

# Icon Item Description

1 Docking port Connects your tablet to the dock accessory.

1-10 Hardware Specifications and Configurations

Page 19

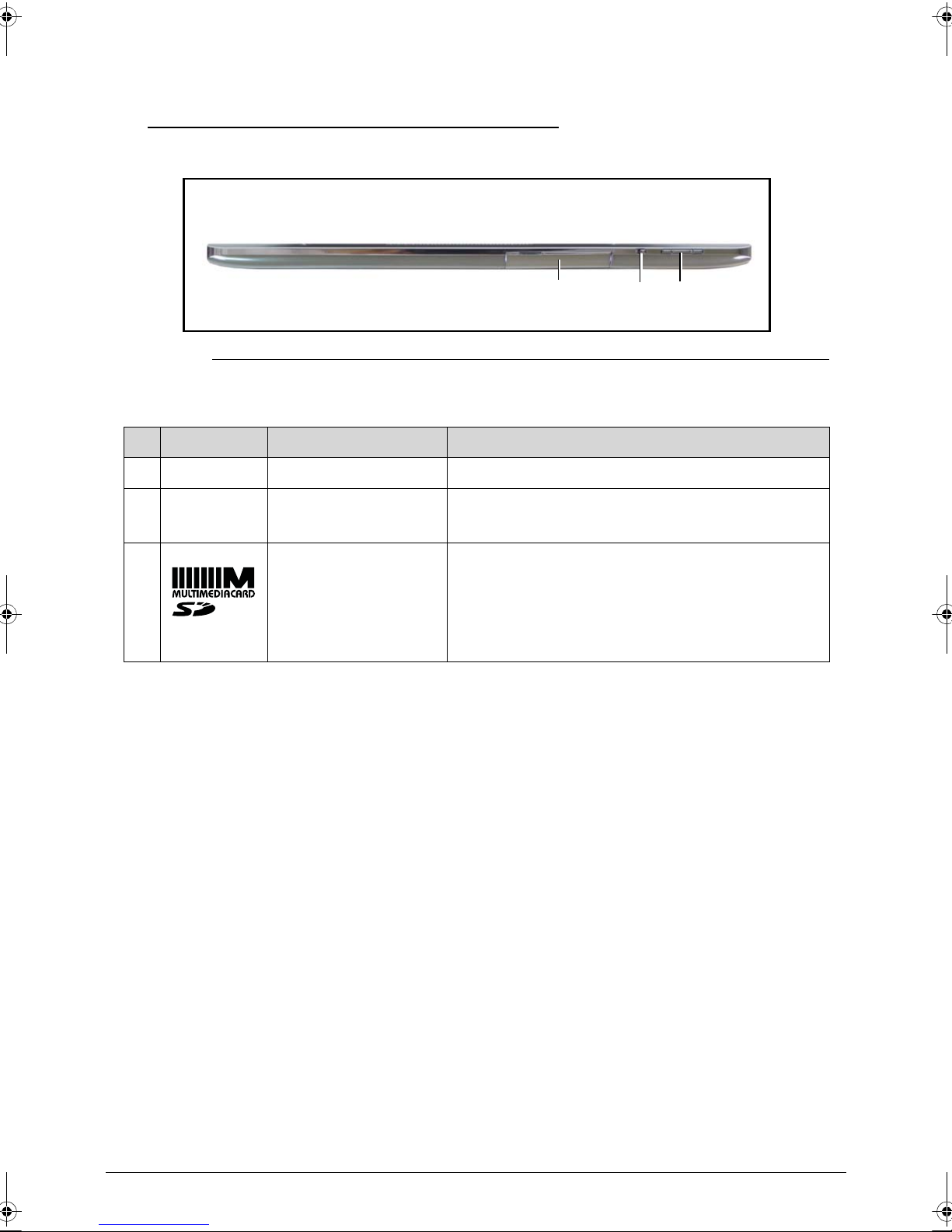

Top View 0

123

Figure 1-5. Top View

Table 1-5. Top View

# Icon Item Description

1 Volume Control Key Increases and decreases the tablet volume.

2 Screen Rotation Lock

Switch

3 Card Slot Cover

Use this switch to lock the screen rotation or allow

the screen to match the tablet’s orientation.

Insert a microSD card into the slot under this

cover.

The SIM card (only for Wi-Fi+3G models) slot

allows you to access the Internet if you have a

cellular data subscription.

Hardware Specifications and Configurations 1-11

Page 20

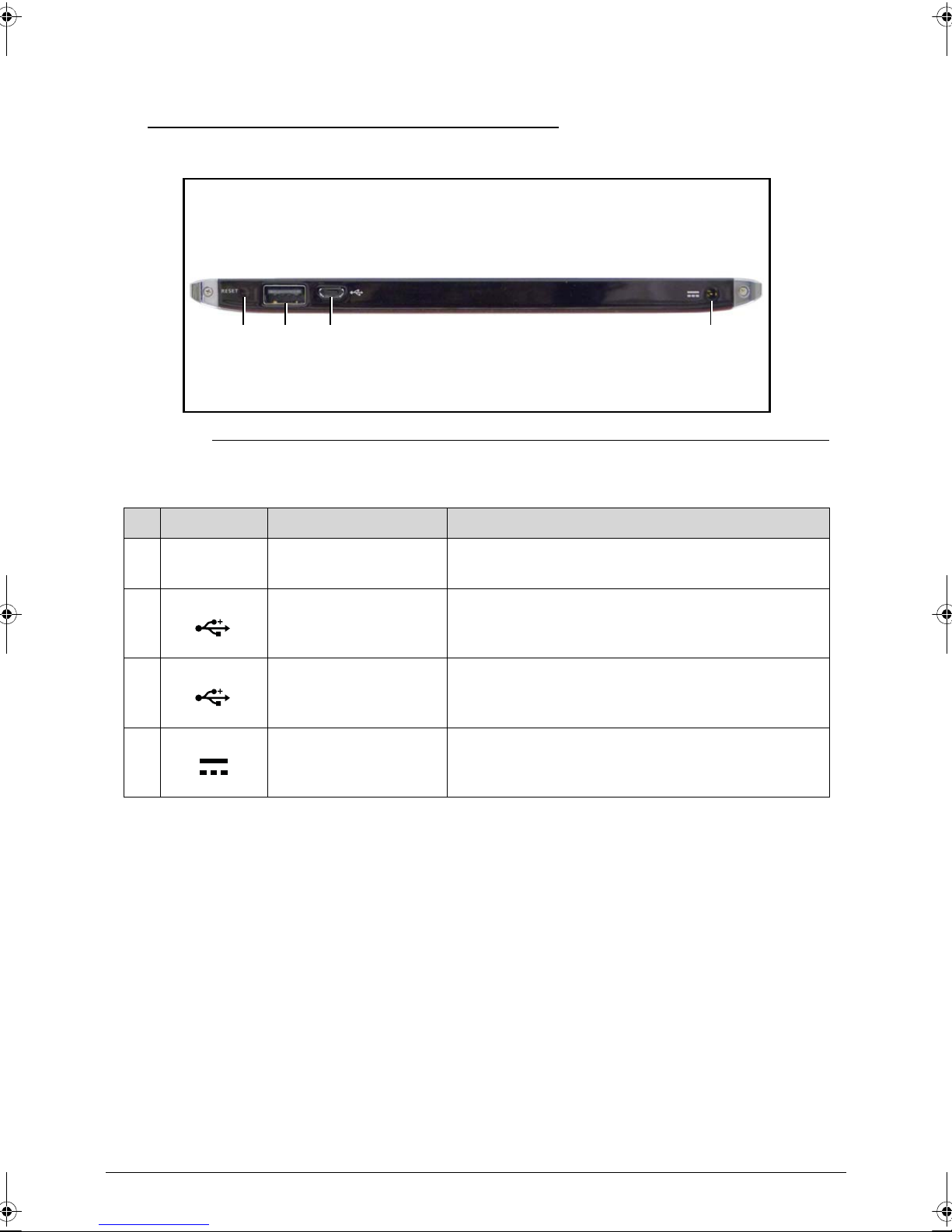

Right View 0

41 23

Figure 1-6. Right View

Table 1-6. Right View

# Icon Item Description

1 Reset Button Insert a small thin object (such as a paperclip) to

reset power to the tablet.

2 USB Port (Host) Connects USB devices to your tablet.

3 Micro USB port

(Slave)

4 DC-in Jack Connects to the DC power supply.

Connects to a computer with a USB cable.

1-12 Hardware Specifications and Configurations

Page 21

System Block Diagram 0

SIM card

USB2

3G card

WIFI

BT_MIC

BT

WM-8903

GEN1_I2C(1.8V)

Light Sensor

Touch Screen

I2C Level shifter

GEN1_I2C(3.3V)

Audio Codec

GYRO PMU-3050

Accelerometer

KXTF9-4100

AL3000A

SDIO Card Slot

USB3

ULPI

SDIO1(1.8V)

SDIO1

to USB board

HDMI

HDMI Conn.

eMMC NAND 4.3 / 4.41

8 bits HSMMC

LVDS bridge

RGB (1.8V)

HDMI

5M CAMERA Module

CSI A (1.2V)

DDR

NAND Ctrl

LPDDR2 X 1

512MB / 1GB

VI&DSI/CSI

OSC,PLL,

LCD

VGA

AUDIO

USB +

mini-B

connector

SDIO3

HSIC

core & fuse

DDR2 32bits

Nvidia Tegra T20

12MHz

DDC_I2C(5V)

ULPI to USB

(SMSC USB3315)

ULPI (1.8V)

2M CAMERA Module

10.1" LVDS panel

CSI B (1.2V)

UART3 (1.8V)

SDIO3(3.3V)

BC4329

WIFI / BT

module

GPS Module

UART2 (1.8V)

UART

DAP4(1.8V)

to USB board

Audio Codec

Wolfson WM8903

HeadPhone

USB1

DAP1(1.8V)

Front MIC

SPKR AMP

ALC105

INT Speaker

Rear MIC

FM2018

Echo & Noise Cancel

Flash LED

Controller

2M CAMERA

Module

5M CAMERA

Module

CAM_I2C(1.8V)

Flash LED

CANDO + Atmel

+5V_ALW Input

PWR_I2C(1.8V)

Temperature

Sensor NCT-1008

Compass

AKM8975C

+1V_SM0 for CPU

+1.2V_SM1 for CPU

+3.7V_SM2

LDO 0 ~ 9 for CPU

PMU TI TPS658621C

GPIO

P-SENSOR

CM3607

I2C

FM2018

EC_SMB

2S1P BATT

SPI

SPI ROM

EC KB930

EC_RESMUE

GEN2_I2C(1.8V)

I2C Level shifter

ON/OFF#

AP_SMB(3.3V)

AP_SMB(3.3V)

EDID

T20 GEN2 I2C

GPIO

EC_SMB

DAP4

(1.2V,1.8V)

AP_SMB(3.3V)

Hardware Specifications and Configurations 1-13

Figure 1-7. System Block Diagram

Page 22

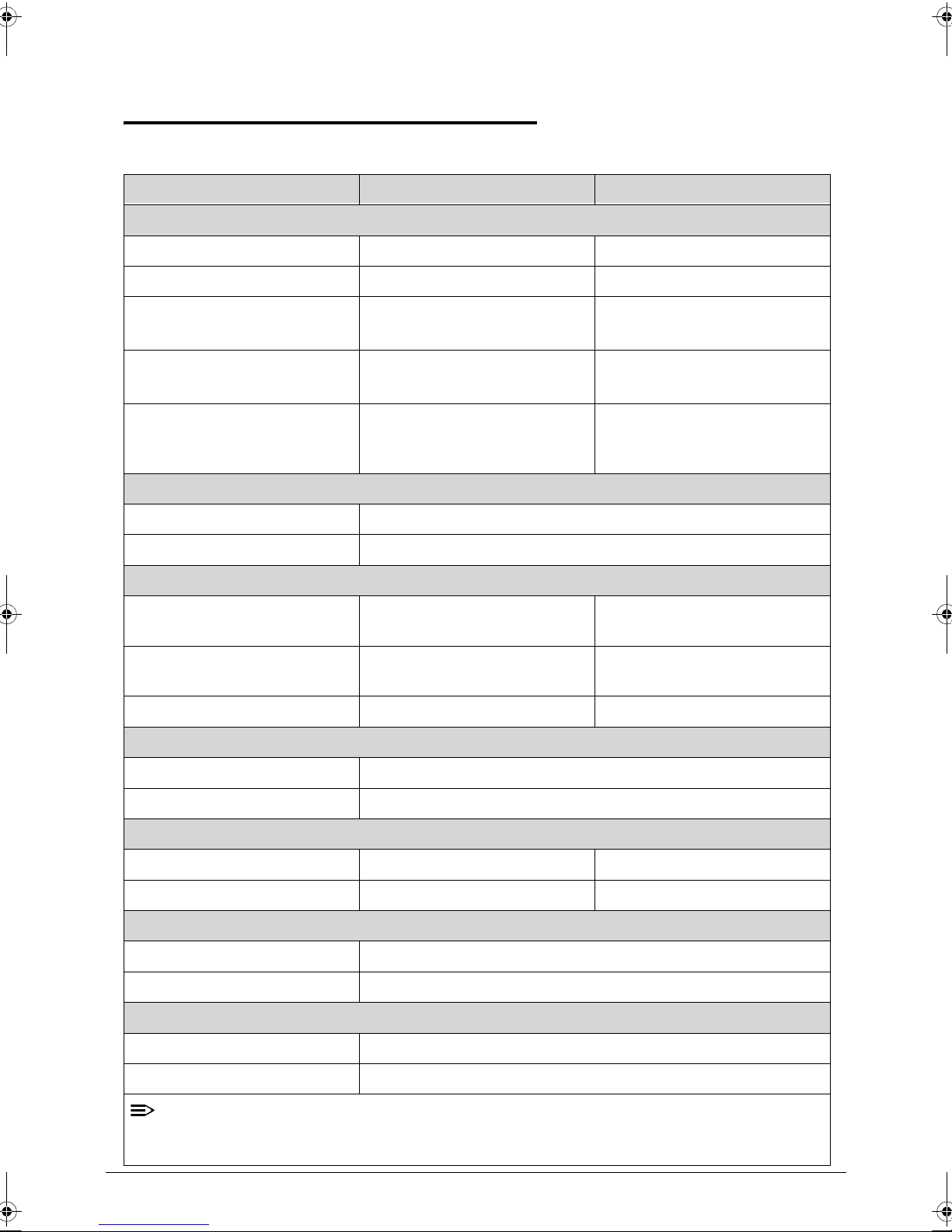

Specification Tables 0

NOTE:

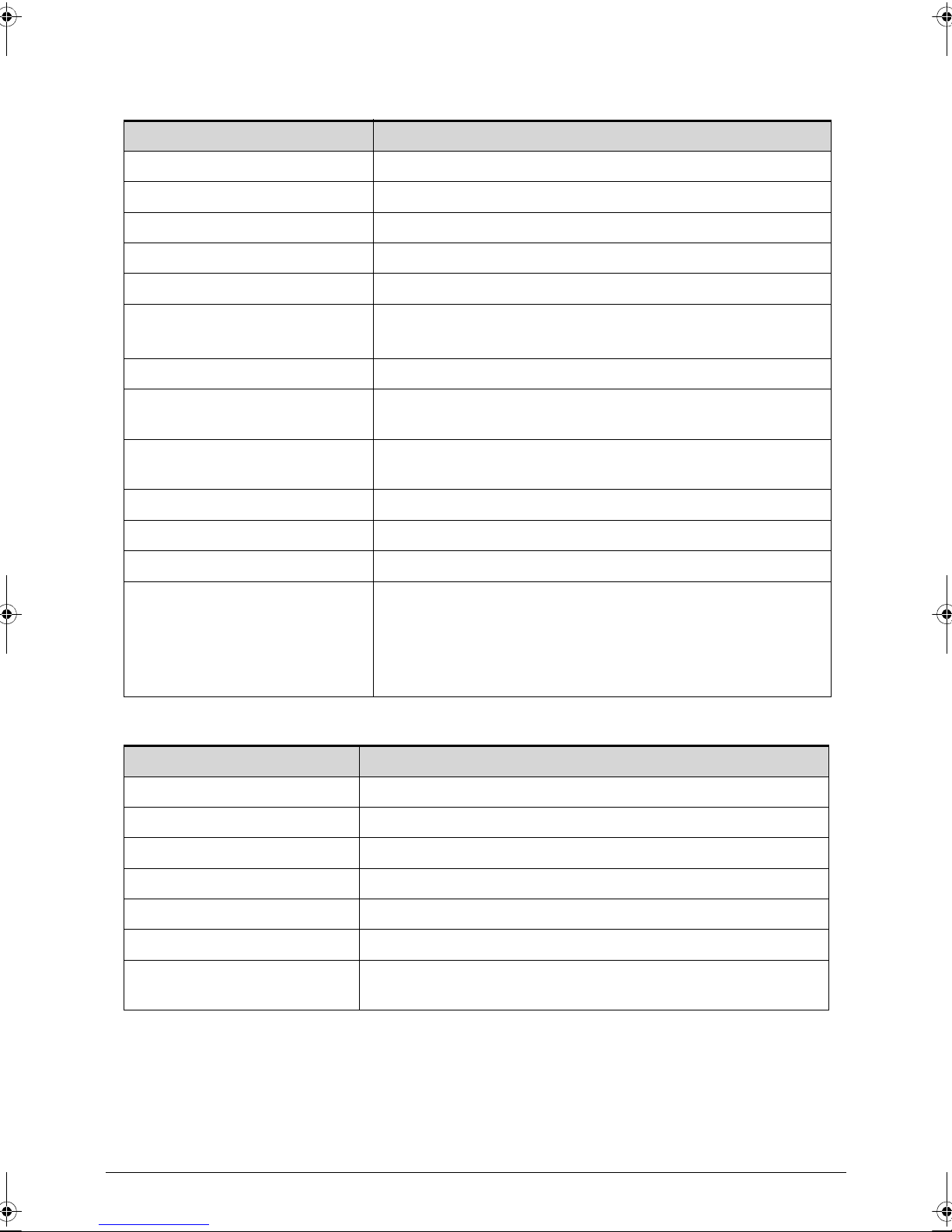

Computer specifications

Item Metric Imperial

Dimensions

Length 260mm 10.23in

Width 179mm 6.97in

Height

14mm 0.53in

(front to rear)

Weight (equipped with optical

drive, flash drive, and battery)

Weight (equipped with optical

740g (WiFi)

750g (3G)

1.63lb (WiFi)

1.65lb (3G)

Build-in battery Build-in battery

drive, flash drive, and without

battery)

Input power

Operating voltage 12.0 V dc @ 1.5 A - 18 W

Operating current 1.5 A

Temperature

Operating (not writing to

0°C to 50°C 32°F to 122°F

optical disc)

Operating (writing to optical

0°C to 50°C 32°F to 122°F

disc)

Nonoperating -20°C to 60°C -4°F to 140°F

Relative humidity

Operating 10% to 90%

Nonoperating 5% to 95%

Maximum altitude (unpressurized)

Operating -15 m to 3,048 m -50 ft to 10,000 ft

Nonoperating -15 m to 12,192 m -50 ft to 40,000 ft

Shock

Operating 125 g, 2 ms, half-sine

Nonoperating 200 g, 2 ms, half-sine

Random vibration

Operating 0.75 g zero-to-peak, 10 Hz to 500 Hz, 0.25 oct/min sweep rate

Nonoperating 1.50 g zero-to-peak, 10 Hz to 500 Hz, 0.25 oct/min sweep rate

Applicable product safety standards specify thermal limits for plastic surfaces. The computer

operates well within this range of temperatures.

1-14 Hardware Specifications and Configurations

Page 23

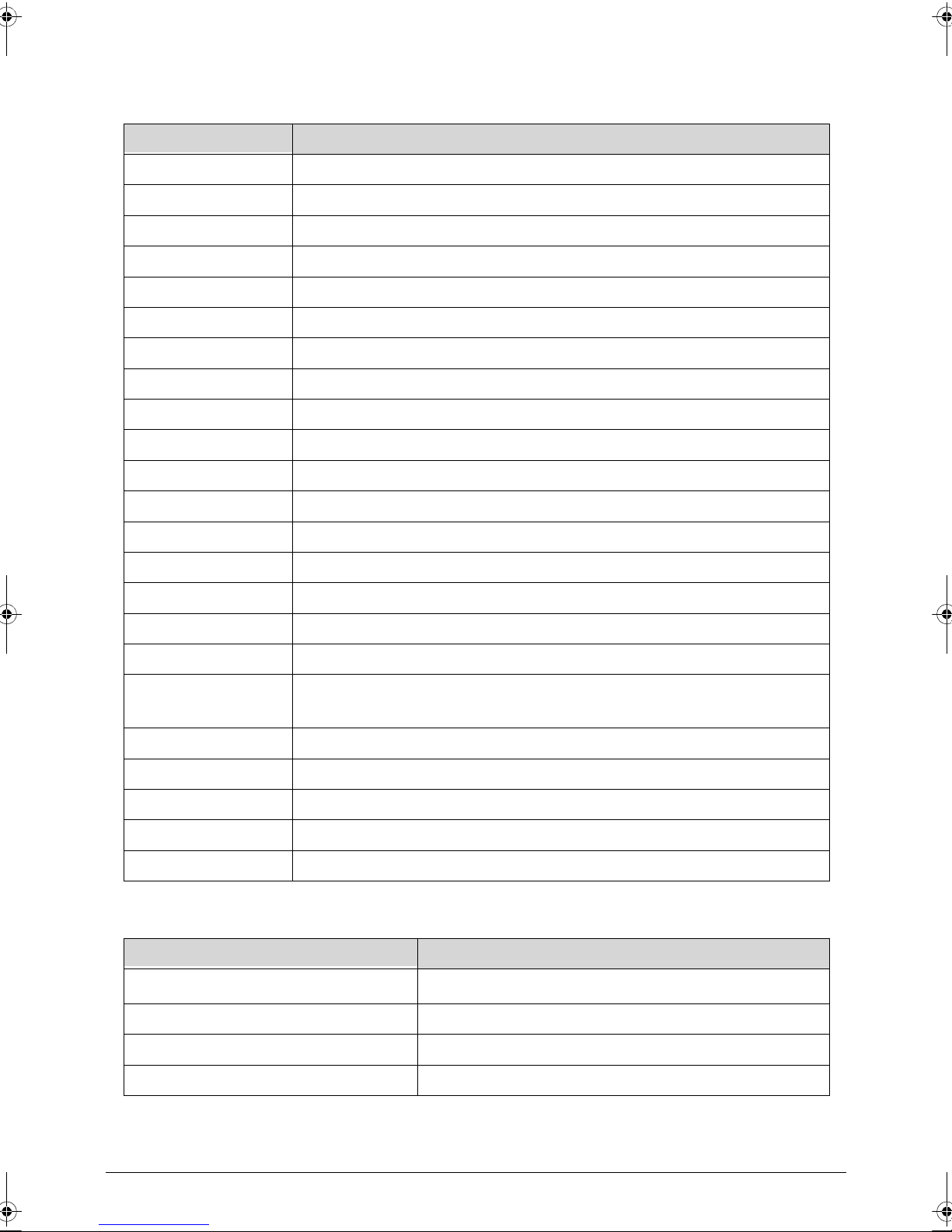

System Board Major Chips

Item Specification

Core logic Tegra 250 Dual cortex A9, 1GHz

Graphics Integrated in Tegra 250 CPU (ULP GeFor ce )

LAN N/A

USB 2.0 Integrated in Tegra 250 CPU (ULP GeForce)

Super I/O controller N/A

Bluetooth Broadcom BCM4329

Wireless Broadcom BCM4329

PCMCIA N/A

Audio codec Wolfson WM8903

Card reader SD 2.0 Integrated in Tegra 250 CPU

LVDS transmitter SN75LVDS83B

PMU TI TPS658621C

LDDR2 Elpida EDB8132B2PB 1GB

ULPI Phy for USB SMSC USB3315

GPS Broadcom BCM4751

TOUCH controller Atmel ATMXT 1386-CHIPSET1PJA101

eMMC Hynix H26M32001DAR

CAMERA

Omnivison OV5650: 5M

Various CSI: 2M

Thermal Sensor Onsemi NTC1008

Battery Charger TI BQ24617

Compass Asahi Kasei AKM8975C

Gyro Invensense MPU-3050

ALS/Proximity Lite On AL3000A / AZOTEK IQS128

Processor

Item Specification

CPU type

Dual-core ARM

®

Coretex-A9 MPcore Processor

CPU package 23 x 23 FCBGA

Core Logic Integrated in Tegra 250 CPU

Chipset Integrated in Tegra 250 CPU

Hardware Specifications and Configurations 1-15

Page 24

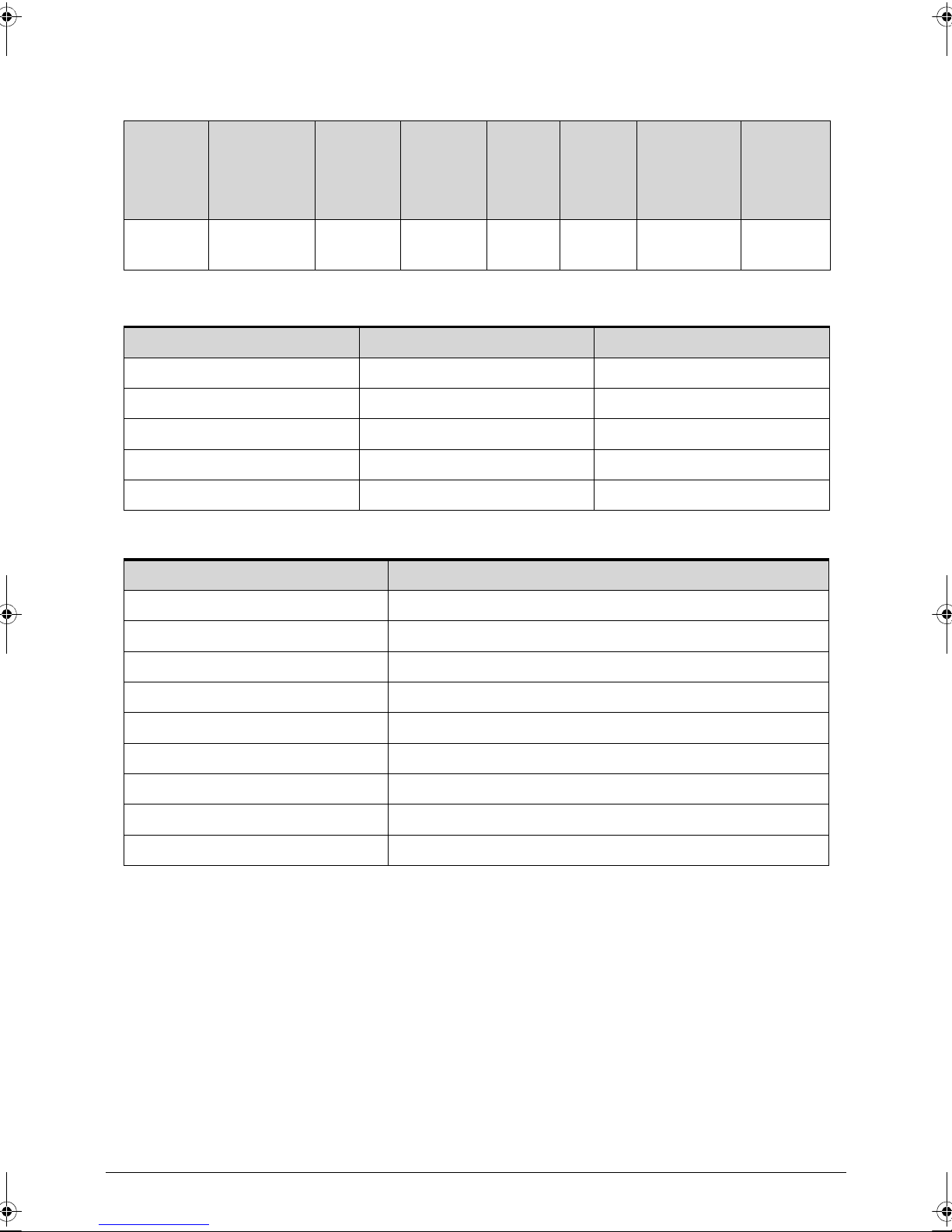

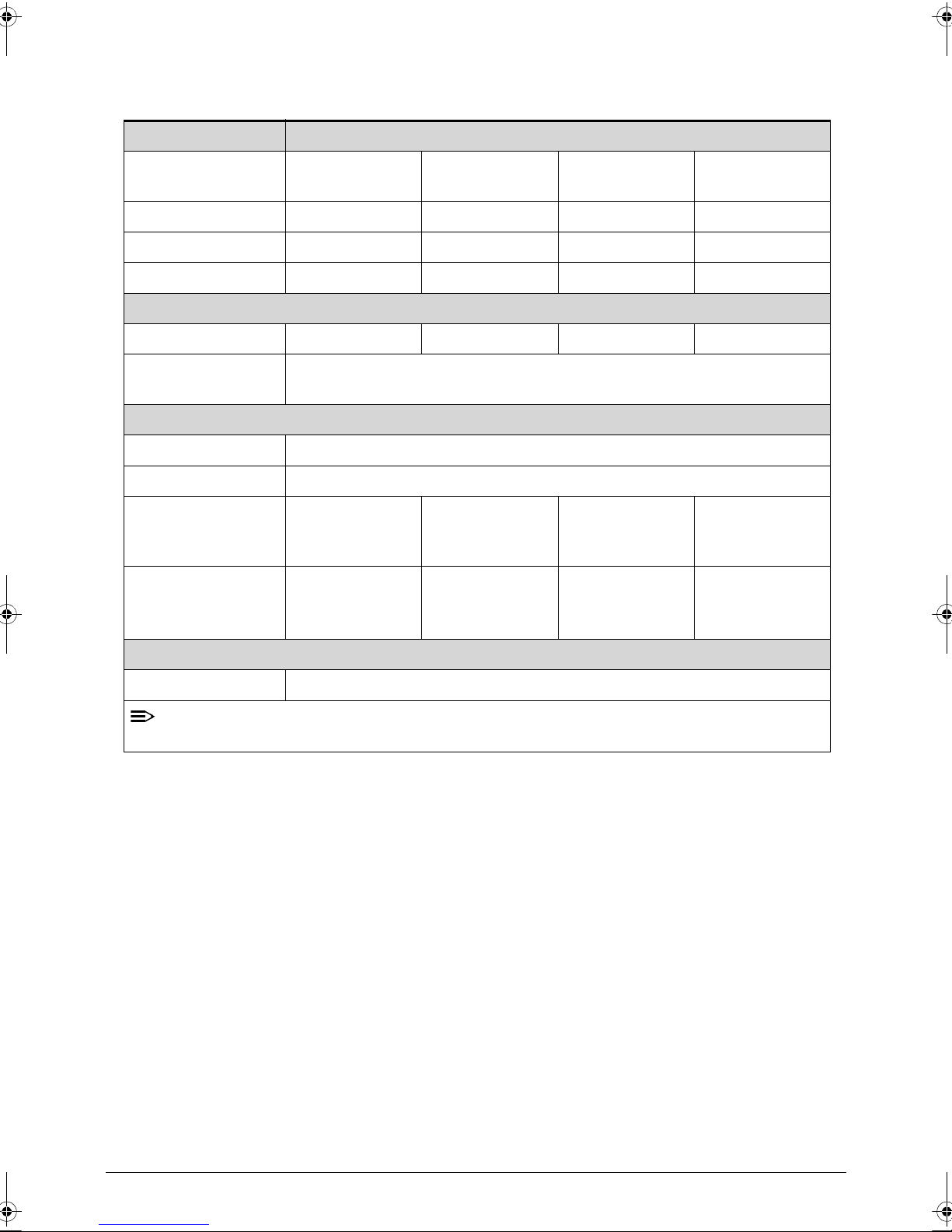

Processor Specifications

Item CPU Speed

(GHz)

Cores/

Threads

Bus

Speed

(FSB/

Mfg

Tech

(nm)

Cache

Size

Package Voltage

DMI/QBI)

T20 1 2 Cores 40 23x23

FCBGA

CPU Fan True Value Table (N/A)

CPU Temperature Fan Speed (RPM) S PL Spec (dBA)

60

70

80

90

100

System Memory

Item Specification

1.0-1.2V

Memory controller Build in CPU

Memory size 1G LPDDRII

DIMM socket number N/A. On board memory

Supports memory size per socket N/A

Supports maximum memory size On board LP-DDR2 1GB

Supports DIMM type N/A

Supports DIMM Speed N/A

Support DIMM voltage N/A

Supports DIMM package N/A

1-16 Hardware Specifications and Configurations

Page 25

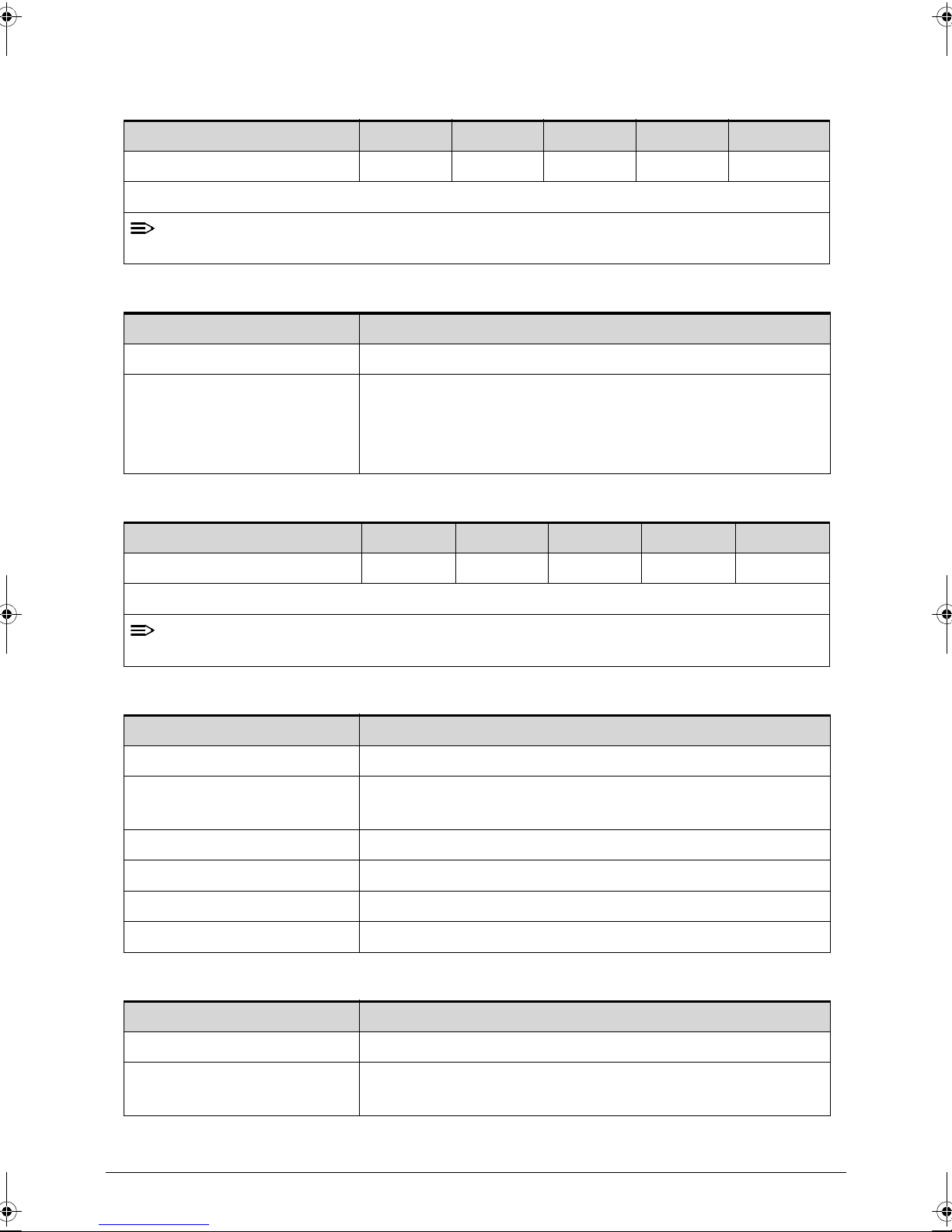

Memory Combinations (N/A)

Slot 1 (MB) Slot 2 (MB) Total Memory (MB)

Video Interface (Integrated)

Item Specification

Chipset Wolfson WM8903

Package QFN 5X5 40 pin

Interface I2S

Compatibility I2S audio Interface.

Sampling rate 44.1KHz

Hardware Specifications and Configurations 1-17

Page 26

BIOS (N/A)

Item Specification

BIOS vendor

BIOS Version

BIOS ROM type

BIOS ROM size

Features

LAN Interface (N/A)

Item Specification

LAN Chipset

LAN connector type

LAN connector location

Features

Keyboard (N/A)

Item Specification

Type

Total number of keypads

Windows logo key

Internal & external keyboard

work simultaneously

Features

1-18 Hardware Specifications and Configurations

Page 27

Hard Disk Drive (AVL components) (N/A)

NOTE:

Item Specification

Vendor & Model

Name

Capacity (GB)

Bytes per sector

Data heads

Drive Format

Disks

Spindle speed

(RPM)

Performance Specifications

Buffer size

Interface

Fast data transfer

rate (Mbits / sec,

max)

Media data transfer

rate

(Mbytes/sec max)

DC Power Requirements

Voltage tolerance

Hardware Specifications and Configurations 1-19

Page 28

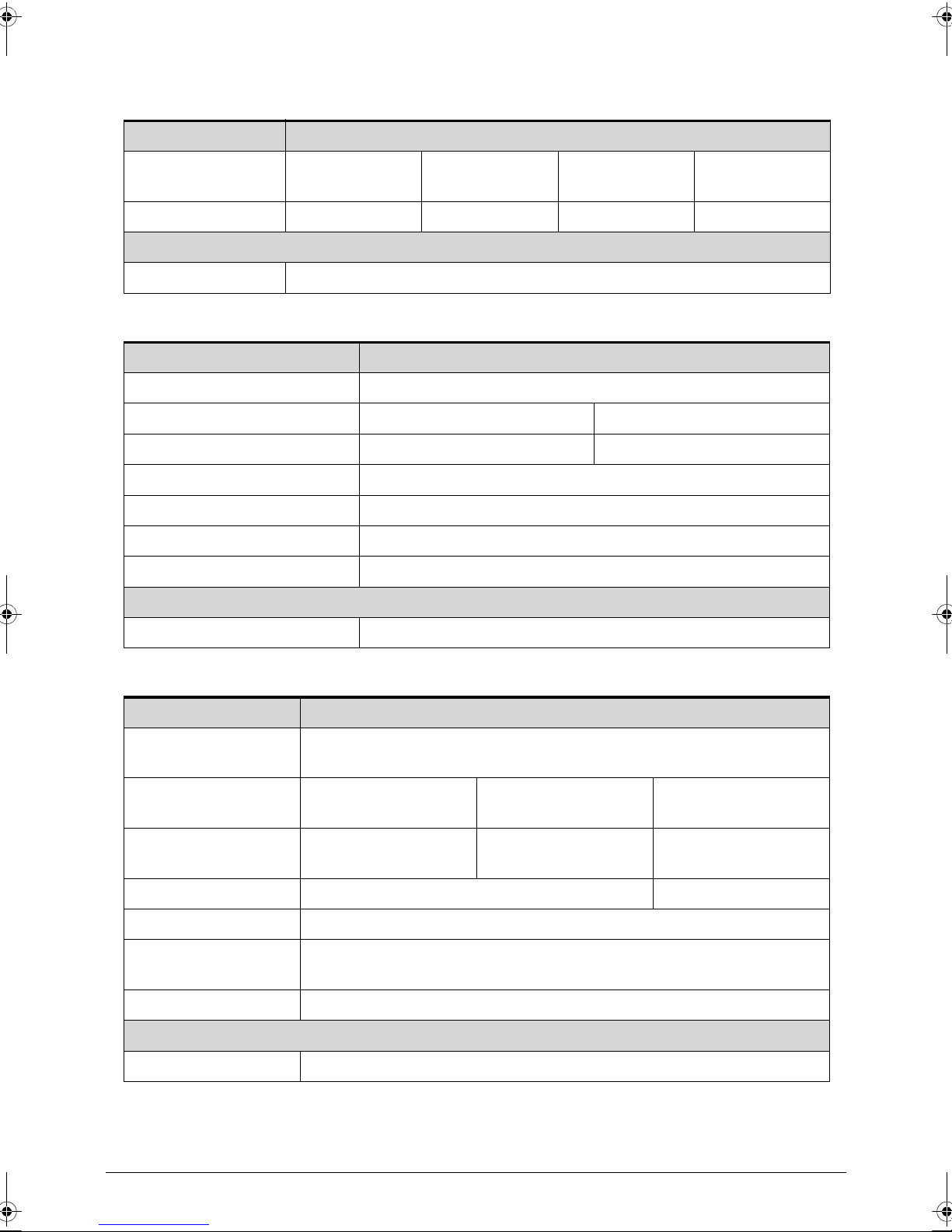

Embedded MultiMediaCard (AVL components)

Item Specification

Vendor & Model

Name

Capacity (GB)

Sandisk

SDIN4C2-16G

Samsung

KLMAG4EEHM

16G 16G 32G 32G

DC Power Requirements

Voltage tolerance 1.8 V

Super-Multi Drive (N/A)

Item Specification

Vendor & Model name

Performance Specification

Transfer rate (KB/sec)

Buffer Memory

Interface

Applicable disc format

Loading mechanism

Power Requirement

Sandisk

SDIN4E2-32G

Samsung

KLMBG8FEJA

Input Voltage

BD Drive (N/A)

Items Specifications

Vendor & Model

name

Performance

Specification

Transfer rate

(KB/sec)

Buffer Memory

Interface

Applicable disc

format

Loading mechanism

Power Requirement

Input Voltage

1-20 Hardware Specifications and Configurations

Page 29

LED 10.1”

Item Specification

Vendor/Model name AUO/B101EW05 V1

Screen Diagonal (mm) 255.85 mm

Active Area (mm) 216.96 mm x 135.6 mm

Display resolution (pixels) 1280 x 3(RGB) x 800

Pixel Pitch (mm) 0.1695mm x 0.1695mm

Typical White Lumina nce

2

(cd/m

) also called Brightness

300 cd/m

2

Contrast Ratio 1000 min / 1300 type

Response Time (Optical Rise

25 ms / 35 ms

Time/Fall Time) msec

Typical Power Consumption

3.4 W

(watt)

Weight (without inverter) 180 max

Physical Size (mm) 229.46 mm x 149.1mm x 5.2 max

Electrical Interface 1 channel LVDS

Viewing Angle (degree)

85 (Right) / 85 (Left) / 85 (Upper) / 85 (Lower) Typ.

Horizontal (Right) CR = 10

(Left)

Vertical (Upper) CR = 10

(Lower)

LCD Inverter (N/A)

Item Specification

Vendor & Model name

Brightness conditions

Input voltage (v)

Input current (mA)

Output voltage (V, RMS)

Output current (mA, RMS)

Output voltage frequency

(KHz)

Hardware Specifications and Configurations 1-21

Page 30

Display Supported Resolution (LCD)

NOTE:

NOTE:

Resolution 16 bits 32 bits 36 bits 48 bits others

1280x 3(RGB) x 800 X X X V X

Legend: V = Supported; X = Not supported

Resolution fixed at 1280 x 800. Not adjustable by end user.

Graphics Controller

Item Specification

VGA Chip ULP GeForce

Supports

Fully Programmable Yes

OpenGL ES Version 2

OpenVG 1.1

EGL 1.4

Display Supported Resolution (GPU)

Resolution 16 bits 32 bits 36 bits 48 bits others

1280x 3(RGB) x 800 X X X V X

Legend: V = Supported; X = Not supported

Resolution fixed at 1280 x 800. Not adjustable by end user.

Bluetooth Interface

Item Specifications

Chipset Azurewave AW-NH611- Broadcom 4329 SIP

Data throughput

TX 1.2Mbits/sec

RX 1.2Mbits/sec

Protocol 2.1 + EDR 3.0 upgradable

Interface SIP

Connector type SIP

Supported protocol (Add BT supported protocol here such as A2DP)

Bluetooth Module

Item Specifications

Controller Azurewave AW-NH611 - Broadcom BCM4329 SoC

Features

1-22 Hardware Specifications and Configurations

Fully support BT 2.1 +EDR

UART Interface

Page 31

Front Camera

Item Specification

Vendor and Model Chicony / Aptina 2031

Type 2M

Rear Camera

Item Specification

Vendor and Model

Liteon / OV5650 CSI

Liteon / Aptina 5140

Type 5M

Mini Card

Item Specification

Number supported 1

Features 1 mini card slot (for WWAN)

3G Card

Item Specification

Features 3G Module with Ericsson 5521gw

Hardware Specifications and Configurations 1-23

Page 32

Audio Codec and Amplifier

Item Specification

Audio Controller Wolfson WM8903

Features

4.5mW Power consumption for DAC to headphone playback

DAC SNR 96dB typical, THD -86dB typical

ADC SNR 92dB typical, THD -80dB typical

Control sequencer for pop minimized start-up and shut-down

Single register write for default start-up sequence

Stereo digital microphone input

3 single ended inputs per stereo channel

2 pseudo differential inputs per stereo channel

1 fully differential mic inputs per stereo channel

Digital Dynamic Range Controller

Digital sidetone mixing

Ground-referenced headphone driver

Ground-referenced line input

Stereo differential line driver for direct interface to WM9001

40-pin5x5mm QFN package

Amplifier N/A

Features N/A

Audio Interface

speaker driver

Item Specification

Audio Controller Wolfson WM8903

Audio onboard or optional On board

Mono or Stereo Stereo

Resolution Support 24bit

Compatibility I2S audio Interface

Sampling rate Sample rate up to 44.1KHz

Internal microphone Yes

Internal speaker/quantity Yes/(1W speakers x2)

1-24 Hardware Specifications and Configurations

Page 33

Wireless Module 802.11b/g/n

Item Specification

Chipset Azurewave AW-NH611 - Broadcom BCM4329 SoC

Data throughput

802.11b/g: 11~54 Mbps

802.11n: MCS 0-7

Protocol IEEE 802.11b/g/n

Interface SDIO/SPI interface.

Battery

Item Specification

Vendor & Model name SIMPLO BAT-1010 SANYO BAT100

Battery Type Li-ion

Pack capacity 3260mAh/24Wh

Number of battery cell 2

Package configuration 2S1P

VRAM

Item Specification

Chipset T20 UMA architecture

Memory size Share 16 ~ 256MB

Interface LPDDR2

USB Port

Item Specification

USB compliance level USB2.0

Protocol EHCI

Number of USB port(s) 2

Location two at the right side

Output Current 1.5A (for USB host port)

HDMI Port

Item Specification

Compliance level HDMI1.3a

Data throughput Up to 16.7 million colors

Number of HDMI port(s) 1

Location JHDMI1 at the left side

Hardware Specifications and Configurations 1-25

Page 34

AC Adapter

Item Specification

Input rating 18W

Maximum input AC current 0.5A(RMS) at 100Vac

Inrush current 60A Max. @230Vac

Efficiency Refer to EPS 2.0 standard level V

System Power Management

Item Specification

Mech. Off (G3) Only EC working.

Soft Off (G2/S5) Only EC working.

Working (G0/S0) Individual devices such as the CPU and eMMC may be power

managed in this state.

Suspend to RAM (S3)

CPU suspend

Audio Power Down

eMMC Power Down

LCD power off

MIC power off

Save to Disk (S4) N/A

Card Reader

Item Specification

Chipset

Embedded in T20 SOC.

Package FCBGA -664 23 X23

Maximum supported size SD: 32G

Features Storage cards with adapter: micro SD™

System LED Indicator

Item Specification

Lock

System state

HDD access state N/A

Wireless state N/A

Power button backlight Same as system state

Battery state Same as system state

1-26 Hardware Specifications and Configurations

White color: Flash on booting

White color and amber color off: System off / suspend

Amber color: Battery in charging

Page 35

System DMA Specification

NOTE:

Legacy Mode Power Management

DMA0 Not applicable

DMA1 Not applicable

DMA2 Not applicable

DMA3 Not applicable

DMA4 Direct memory access controller

DMA5 Available for ExpressCard

DMA6 Not Assigned

DMA7 Not Assigned

*ExpressCard controller can use DMA 1, 2, or 5.

System Interrupt Specification (N/A)

Hardware IRQ System Function

IRQ0

IRQ1

IRQ2

IRQ3

IRQ5*

IRQ6

IRQ7*

IRQ8

IRQ9*

IRQ10*

IRQ11

IRQ12

IRQ13

IRQ14

IRQ15

*Default configuration; audio possible configurations are IRQ5, IRQ7, IRQ9, IRQ10, or none.

ExpressCards may assert IRQ3, IRQ4, IRQ5, IRQ7, IRQ9, IRQ10, IRQ11, or IRQ15. Either

the infrared or the serial port may assert IRQ3 or IRQ4.

Hardware Specifications and Configurations 1-27

Page 36

System IO Address Map (N/A)

I/O address (hex) System Function (shipping configuration)

000 - 00F

010 - 01F

020 - 021

022 - 024

025 - 03F

02E - 02F

040 - 05F

044 - 05F

060

061

062 - 063

064

065 - 06F

070 - 071

072 - 07F

080 - 08F

090 - 091

092

093 - 09F

0A0 - 0A1

0A2 - 0BF

0C0 - 0DF

0E0 - 0EF

0F0 - 0F1

0F2 - 0FF

100 - 16F

170 - 177

178 - 1EF

1F0 - 1F7

1F8 - 200

201

202 - 21F

1-28 Hardware Specifications and Configurations

Page 37

System I/O Address Specifications (N/A)

I/O address (hex) System Function (shipping configuration)

220 - 22F

230 - 26D

26E - 26

278 - 27F

280 - 2AB

2A0 - 2A7

2A8 - 2E7

2E8 - 2EF

2F0 - 2F7

2F8 - 2FF

300 - 31F

320 - 36F

370 - 377

378 - 37F

380 - 387

388 - 38B

38C - 3AF

3B0 - 3BB

3BC - 3BF

3C0 - 3DF

3E0 - 3E1

3E2 - 3E3

3E8 - 3EF

3F0 - 3F7

3F8 - 3FF

CF8 - CFB

(PCIDIVO-1)

(PCIDIVO-1)

Hardware Specifications and Configurations 1-29

Page 38

1-30 Hardware Specifications and Configurations

Page 39

CHAPTER 2

Diagnostic Utilities

Page 40

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

NGA EUU Installation Procedure. . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Picasso Diagnostic Tool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

2-2

Page 41

Diagnostic Utilities

NOTE:

NOTE:

Introduction 0

The Gateway TP-A60W/ TP-A60G has a set of software tools designed to diagnose pr oblems

with its hardware components.

NGA EUU Installation Procedure 0

Before installing EEU software, make sure the TP-A60W/ TP-A60G tablet is not

connected to a computer.

1. Install EUU software on a PC. When the following dialog is shown, click OK to continue.

Figure 2-1. Starting Installation

2. Select installation procedure language from drop-down list. Click Next to continue or

Cancel to exit program.

Figure 2-2. Installation Procedure Language

3. Install USB driver. (Figure 2-3)

Diagnostic Utilities 2-3

Page 42

Figure 2-3. USB Driver Installation

4. To enable USB debugging, on the device, go to the Settings/Applications/Development

menu and click the USB debugging checkbox. (Figure 2-4.)

Figure 2-4. USB Debugging

2-4 Diagnostic Utilities

Page 43

5. Follow the instructions shown in Figure 2-5 to find OS image version.

Figure 2-5. Finding OS Image Version

6. If image version is not available, follow instructions in Figure 2-6 to manually reset device.

When procedure is complete, go to Step 1 of this procedure.

Figure 2-6. Device Reset Instructions

Diagnostic Utilities 2-5

Page 44

7. If image version is available, current and new version information is shown. Click Next to

NOTE:

NOTE:

continue. (Figure 2-7)

Figure 2-7. Image Versions

8. Enter CPU ID of device. Click Next to continue. (Figure 2-8)

Maximum number of characters for ID is sixteen (16).

Figure 2-8. CPU ID

2-6 Diagnostic Utilities

Page 45

9. Upgrade process begins as shown in Figure 2-9

IMPORTANT:

+

Upgrade process will not complete if USB cable is unplugged.

Figure 2-9. Upgrade Process

10. If upgrade process is successful, Figure 2-10 is shown. If an upgrade error is shown, go to

step 12, If a CPU ID value error is identified, go to step 19.

Figure 2-10. Upgrade Process Success

11. Click Finish to exit.

Diagnostic Utilities 2-7

Page 46

12. If CPU ID is correct but upgrade process is not successful, Figure 2-11 is shown.

Figure 2-11. Upgrade Process Failure

13. Click Retry to start upgrade process. Go to Step 8.

14. Click Exit to cancel upgrade process.

15. If upgrade process is cancelled, a confirmation dialog is shown. (Figure 2-12)

Figure 2-12. Upgrade Process Cancellation Confirmation Dialog

16. Click No to return to Retry dialog in Step 12.

17. Click Yes to confirm cancellation.

2-8 Diagnostic Utilities

Page 47

18. Click OK to exit the program. (Figure 2-13)

Upgrade process failed because wrong CPU ID

value was entered. Follow instructions for

recovery.

Figure 2-13. Final Cancellation Dialog

19. If CPU ID value is not correct, Figure 2-14 is shown.

Figure 2-14. Wrong CPU ID

20. Click Retry to start upgrade process. Go to Step 8.

21. Click Exit to cancel upgrade process.

Diagnostic Utilities 2-9

Page 48

22. If upgrade process is cancelled, a confirmation dialog is shown. (Figure 2-15)

Figure 2-15. Upgrade Process Cancellation Confirmation Dialog

23. Click No to return to Retry dialog in Step 19.

24. Click Yes to confirm cancellation.

25. Click OK to exit progra m. (Figure 2-16)

Figure 2-16. Final Cancellation Dialog

2-10 Diagnostic Utilities

Page 49

Q

&

I

20 11

ICONIA tab A500

Diagnostic Tool SOP

Release date : Apr. 14, 2011

Page 50

Q

&

I

20 11

Preparation

Diagnostic tool - A500 Diagnostic Tool.zip

USB Driver of A500 for PC

USB cable

Micro SD card

Page 51

Q

&

I

20 11

Tool installation

1. Install USB driver in PC/NB.

2. Connect A500 device to PC/NB via USB cable

3. Enable “USB debugging” in A500 (Settings Applications USB

debugging)

Page 52

Q

&

I

20 11

Tool installation

4. Unzip file “A500 Diagnostic Tool.zip”. There are four files in the folder.

5. Run “Install_A500_DiagTool.bat”.

Page 53

Q

&

I

20 11

Tool installation

6. On the “All” apps screen, look for the application called “ACTP”. This

is the diagnostic tool.

7. Tap the icon to start the testing process.

Page 54

Q

&

I

20 11

Main Menu

The diagnostic tool tests the Touch Panel, Display, Buttons, Speaker, MIC,

Camera, SD and Vibrator functionality. Select the function(s) you want to

test. Tap “OK” to start.

Step 1 –

Select item(s)

Step 2 –

Click “OK” to start testing

Page 55

Q

&

I

20 11

1. Multi-touch Test (Touch Panel)

Draw your finger along the yellow squares. The result is a pass if you fill

all yellow squares and fail if you do not. The program returns to the main

menu after the test is finished.

Page 56

Q

&

I

20 11

2. Touch Linearity Test (Touch Panel)

Draw your finger along the yellow squares. The result is a pass if you fill

all yellow squares and fail if you do not. The program returns to the main

menu after the test is finished.

Page 57

Q

&

I

20 11

3. RGB (Display)

Continue to tap screen to display changes. Use this test to verify

abnormal lines or dead pixels on LCD screen.

Finish

Page 58

Q

&

I

20 11

4. Hardware Keys Test (Keys)

Press volume up, volume down and lock keys to verify if all keys work.

A color change to green means key function works.

Page 59

Q

&

I

20 11

5. Rear Camera

Point rear side of device at an object. Tap “Photograph” icon to test

picture taking functionality.

Page 60

Q

&

I

20 11

6. Speaker

Loud tone sounds in left speaker then switches to right speaker.

Page 61

Q

&

I

20 11

7. Front Microphone

Tap screen to start the test. When “Recording” screen appears, speak into

front side of device. Check if voice recorded when screen switches to

“Playing” screen.

Page 62

Q

&

I

20 11

8. Rear Microphone

Tap screen to start the test. When “Recording” screen appears, speak into

front side of device. Check if voice recorded when screen switches to

“Playing” screen.

Page 63

Q

&

I

20 11

9. Front Camera

Point front side of device at an object. Tap “Photograph” icon to test

picture taking functionality.

Page 64

Q

&

I

20 11

10. SD Card (SD read/write test)

Insert a micro SD card into device. Start the SD read and write test. The

screen shows success if the test is passed.

System requests to insert a micro SD if you forget to insert a card.

Page 65

Q

&

I

20 11

11. Vibrator

It starts vibrating for two seconds then switches to success screen if test is

passed.

Page 66

Q

&

I

20 11

Un-installation procedure

The diagnostic tool MUST be uninstalled once testing is done. DO NOT

distribute this tool outside of the service center.

Step 1

Tap “Running services” (Settings Applications Running services).

Page 67

Q

&

I

20 11

Un-installation procedure

Step 2

In “Running services” screen, tap “All” and select the application “ACTP”.

Page 68

Q

&

I

20 11

Un-installation procedure

Step 3

In ACTP application screen, select “Uninstall” to remove the tool.

Page 69

Q

&

I

20 11

Un-installation procedure

Step 4

Select “OK” start to uninstall.

Page 70

Q

&

I

20 11

Un-installation procedure

Step 5

“Uninstall finished” message shows when the process is complete.

Page 71

Q

&

I

20 11

Un-installation procedure

Step 6

Make a final check to see if diagnostic tool “ACTP” has been removed

from Apps.

Page 72

CHAPTER 3

Maintenance Procedures

Page 73

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Recommended Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Maintenance Flowchart. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Getting Started . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

SIM/Micro-SD Card Removal . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

SIM/Micro-SD Card Installation . . . . . . . . . . . . . . . . . . . . . . . 3-8

Lower Case Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

Lower Case Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

DC-In Cable Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-16

DC-In Cable Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-18

Battery Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-19

Battery Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-20

3G Module Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-21

3G Module Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-23

Docking Board Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-24

Docking Board Installation . . . . . . . . . . . . . . . . . . . . . . . . . . 3-26

GPS Antenna Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-28

GPS Antenna Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-29

Mainboard Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-30

Mainboard Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-32

Rear CCD Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-35

Rear CCD Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-37

Front CCD Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-38

Front CCD Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-38

Two-Piece Microphone Removal. . . . . . . . . . . . . . . . . . . . . . 3-39

Two-Piece Microphone Installation. . . . . . . . . . . . . . . . . . . . 3-39

Speakers Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-41

Speakers Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-41

USB Module Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-42

USB Module Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-43

LCD Support Plate Removal. . . . . . . . . . . . . . . . . . . . . . . . . . 3-44

LCD Support Plate Installation. . . . . . . . . . . . . . . . . . . . . . . . 3-47

Control Board Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-48

Control Board Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-49

3G Antenna Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-51

3G Antenna Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-51

WLAN Antenna Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-53

WLAN Antenna Installation. . . . . . . . . . . . . . . . . . . . . . . . . . 3-53

3-2

Page 74

Machine Maintenance Procedures

Introduction 0

This chapter contains general info rmation about the notebook, a list o f tools needed to perform

the required maintenance and step by step procedures on how to remove and install

components from the notebook computer.

General Information 0

The product previews seen in the following procedures may not represent the final product

color or configuration. Cable paths and positioning may also differ from the actual model.

During the removal and installation of components, make sure all available cable channels

and clips are used and that the cables are installed in the same position.

All prerequisites must be performed prior to performing maintenan ce.

Recommended Equipment 0

The following tools are required to perform maintenance on the notebook:

Wrist grounding strap and conductive mat

Flat screwdriver

Philips screwdriver

Screw Name Quantity

M1.6x5.0 Ni 4

M2.0x4.0 Ni 16

M2.0x3.0 9

Machine Maintenance Procedures 3-3

Page 75

Maintenance Flowchart 0

The flowchart in Figure 3-1 provides a graphic representation of the module removal and

installation sequences. It provides information on what componen ts need to be removed and

installed during servicing.

Figure 3-1. Maintenance Flow

3-4 Machine Maintenance Procedures

Page 76

Getting Started 0

A

The flowchart (Figure 3-1) identifies sections illustrating the entire removal and install

sequence. Observe the order of the sequence to avoid damage to any of the hardware

components.

Perform the following prior to performing any maintenance procedures:

1. Place system on a flat work surface.

2. Disconnect AC Adapter and remove all cables from system and peripherals.

3. Make sure system is completely powered down.

4. To make sure system is completely powered down, press and hold power button (A) for 4

seconds. (Figure 3-2)

a. If the device is in powered down mode, allow device to complete boot process

(approx. 10 sec.). Then power down normally.

b. If device is in sleep mode, wait for Home Screen to clear. Then power down

normally.

Figure 3-2. Device Overview with Power Button

5. Press and hold Power button for 4 seconds to show Tablet Options dialog.

6. Select Power Off to power down device.

7. From Power Off dialog, select OK.

Machine Maintenance Procedures 3-5

Page 77

SIM/Micro-SD Card Removal 0

1. Open SIM/Micro-SD card cover. (Figure 3-3)

Figure 3-3. Opening SIM/Micro-SD Card Cover

2. Remove SIM card from spring locking mechanism. (Figure 3-4)

Figure 3-4. Removing SIM Card

3. Remove Micro-SD card from spring locking mechanism. (Figure 3-5)

3-6 Machine Maintenance Procedures

Page 78

Figure 3-5. Removing Micro-SD Card

4. Secure SIM/Micro-SD card cover. (Figure 3-6)

Figure 3-6. Securing SIM/Micro-SD Card Cover

Machine Maintenance Procedures 3-7

Page 79

SIM/Micro-SD Card Installation 0

1. Open SIM/Micro-SD card cover. (Figure 3-3)

2. Install and secure SIM card. (Figure 3-4)

3. Install and secure Micro-SD card. (Figure 3-5)

4. Close and secure SIM/Micro-SD card cover. (Figure 3-6)

3-8 Machine Maintenance Procedures

Page 80

Lower Case Removal 0

A

A

Prerequisite:

SIM/Micro-SD Card Removal

1. Remove screws (A) from the top and bottom caps. (Figure 3-7 and Figure 3-8)

Figure 3-7. Top and Bottom Cap Screws (1 of 2)

Figure 3-8. Top and Bottom Cap Screws (2 of 2)

2. Release the corner of the top cap from the locking latches of the bezel as shown in

Figure 3-9.

Figure 3-9. Removing the Top Cap (1 of 3)

Machine Maintenance Procedures 3-9

Page 81

3. Release the top cap from the remaining locking latches of the bezel. (Figure 3-10)

Figure 3-10. Removing the Top Cap (2 of 3)

4. Remove the top cap from the bezel. (Figure 3-11)

Figure 3-11. Removing Top Cap (3 of 3)

3-10 Machine Maintenance Procedures

Page 82

5. Release the corner of the bottom cap from the locking latches of the bezel as shown in

Figure 3-12.

Figure 3-12. Removing the Bottom Cap (1 of 3)

6. Release the bottom cap from the remaining locking latches of the bezel. (Figure 3-13)

Figure 3-13. Removing the Bottom Cap (2 of 3)

Machine Maintenance Procedures 3-11

Page 83

7. Remove the bottom cap from the bezel. (Figure 3-14)

B

B

Figure 3-14. Removing the Bottom Cap (3 of 3)

8. Remove screws (B) from the bezel. (Figure 3-15)

Figure 3-15. Bezel Screws

3-12 Machine Maintenance Procedures

Page 84

9. Release the lower case from the two locking latches (C) on the bottom side of the bezel.

C

(Figure 3-16)

Figure 3-16. Bezel Locking Latches: Bottom Side

10. Rele ase the right, left and top sides of the lower case from the locking latche s of the bezel.

(Figure 3-17)

Figure 3-17. Releasing the Remaining Latches

11. Remove the lower case from the bezel.

Machine Maintenance Procedures 3-13

Page 85

Lower Case Installation 0

D

E

1. Make sure the SD card cover (D) is in the open position before installing the lower case.

(Figure 3-18)

Figure 3-18. Installing the Lower Case (1 of 3)

1. Align the bottom edge of the lower case with the guides (E) on the bezel. (Figure 3-19)

Figure 3-19. Installing the Lower Case (2 of 3)

3-14 Machine Maintenance Procedures

Page 86

2. Secure the lower case to the two locking latches (C) on the bottom side of the bezel.

(Figure 3-16)

3. Secure the remaining sides of the lower case to the locking latches of the bezel.

(Figure 3-20)

Figure 3-20. Installing the Lower Case (3 of 3)

4. Install and secure the screws (B) to the bezel. (Figure 3-15)

5. Install and secure the bottom cap to the bezel locking latches. (Figure 3-14 to Figure 3-12)

6. Install and secure the top cap to the bezel locking latches. (Figure 3-11 to Figure 3-9)

7. Install and secure the top and bottom cap screws. (Figure 3-7 and Figure 3-8)

8. Install SIM/Micro-SD card.

ID Size Quantity Screw Type

A M1.6x5.0 Ni 4

B M2.0x4.0 Ni 5

Machine Maintenance Procedures 3-15

Page 87

DC-In Cable Removal 0

A

B

b

Prerequisite:

Lower Case Removal

1. Remove tape (A) covering DC-In and antenna cables. (Figure 3-21)

Figure 3-21. Removing Protective Tape

2. Disconnect DC-In cable (B) from mainboard connector (b). (Figure 3-22)

Figure 3-22. Disconnecting DC-In Cable

3-16 Machine Maintenance Procedures

Page 88

3. Remove DC-In cable from the LCD support plate (C) and bezel (D) guides. (Figure 3-23)

C

D

Figure 3-23. Removing DC-In Cable

4. Remove DC-In jack from bezel. (Figure 3-24)

Figure 3-24. Removing DC-In Jack

Machine Maintenance Procedures 3-17

Page 89

DC-In Cable Installation 0

1. Install and secure DC-In jack on bezel. (Figure 3-24)

2. Connect DC-In cable (B) to mainboard connector (b). (Figure 3-22)

3. Install and secure DC-In cable to bezel (D) an d LCD support plate (C) guides.

(Figure 3-23)

4. Install and secure tape (A) covering DC-In and antenna cables. (Figure 3-21)

5. Install lower case.

3-18 Machine Maintenance Procedures

Page 90

Battery Removal 0

A

A

A

A

B

b

Prerequisite:

DC-In Cable Removal

1. Remove screws (A) from LCD support plate. (Figure 3-25)

Figure 3-25. Removing Battery Screws

2. Disconnect battery cable (B) from mainboard connector (b). (Figure 3-26)

Figure 3-26. Disconnecting Battery Cable

Machine Maintenance Procedures 3-19

Page 91

3. Remove battery (C). (Figure 3-27)

C

Figure 3-27. Removing Battery

Battery Installation 0

1. Install battery (C) on LCD support plate. (Figure 3-27)

2. Connect battery cable (B) to mainboard connector (b). (Figure 3-26)

3. Install and secure screws (A) to LCD support plate. (Figure 3-25)

4. Install DC-In cable.

ID Size Quantity Screw Type

A M2.0x4.0 Ni 4

3-20 Machine Maintenance Procedures

Page 92

3G Module Removal 0

A

Prerequisite:

Battery Removal

1. Locate 3G module (A) on LCD support plate. (Figure 3-28)

Figure 3-28. 3G Module on LCD Support Plate

2. Disconnect auxiliary (blue) and main (black) cables from 3G module connectors.

(Figure 3-29)

Figure 3-29. Disconnecting 3G Cables

Machine Maintenance Procedures 3-21

Page 93

3. Remove screws (B) from LCD support plate. (Figure 3-30)

B

C

c

Figure 3-30. Removing 3G Module Screws

4. Remove 3G module (C) from mainboard connector (c). (Figure 3-31)

Figure 3-31. Removing 3G Module

3-22 Machine Maintenance Procedures

Page 94

3G Module Installation 0

1. Install and connect 3G module (C) to mainboard connector (c). (Figure 3-31)

2. Install and secure screws (B) to LCD support plate. (Figure 3-30)

3. Connect main 3G antenna cable (black) to 3G module connector labeled M. (Figure 3-29)

4. Connect auxiliary 3G antenna cable (blue) to 3G module connector labeled A.

5. Install battery.

ID Size Quantity Screw Type

B M2.0x3.0 2

Machine Maintenance Procedures 3-23

Page 95

Docking Board Removal 0

A

b

B

Prerequisite:

Battery Removal

1. Locate Docking Board (A). (Figure 3-32)

Figure 3-32. Docking Board Overview

2. Disconnect docking board FFC (B) from docking board connector (b). (Figure 3-33)

Figure 3-33. Disconnecting Docking Board FFC from Docking Board

3-24 Machine Maintenance Procedures

Page 96

3. Disconnect docking board FFC (C), labeled MB, fr om mainboard connector (c).

C

c

D

(Figure 3-34)

Figure 3-34. Disconnecting Docking Board FFC from Mainboard

4. Remove screws (D) from bezel. (Figure 3-35)

Figure 3-35. Removing Docking Board Screws

Machine Maintenance Procedures 3-25

Page 97

5. Remove docking board from bezel. (Figure 3-36)

E

Figure 3-36. Removing Docking Board

Docking Board Installation 0

1. Align docking board with bezel guides (E). (Figure 3-37)

Figure 3-37. Aligning Docking Board Bezel Guides

2. Install board on bezel. (Figure 3-36)

3. Install and secure screws (D) to bezel. (Figure 3-35)

3-26 Machine Maintenance Procedures

Page 98

4. Install and connect docking board FFC (C), labeled MB, to mainboard connector (c).

(Figure 3-34)

5. Install and connect docking board FFC (B) to docking board connector (b). (Figure 3-33)

6. Install battery.

ID Size Quantity Screw Type

D M2.0x3.0 2

Machine Maintenance Procedures 3-27

Page 99

GPS Antenna Removal 0

A

Prerequisite:

Battery Removal

1. Disconnect GPS antenna (A) from mainboard connector. (Fig ure 3-38)

Figure 3-38. Disconnecting GPS Antenna

2. Remove GPS module. (Figure 3-39)

3-28 Machine Maintenance Procedures

Figure 3-39. Removing GPS Module

Page 100

GPS Antenna Installation 0

1. Install GPS module on bezel. (Figure 3-39)

2. Connect GPS antenna (A) to mainboard connecto r. (Figure 3-38)

3. Install battery.

Machine Maintenance Procedures 3-29

Loading...

Loading...