Page 1

Lidar Lite v3 Operation Manual

and Technical Specications

Laser Safety

WARNING

This device requires no regular maintenance. In the event that the device

becomes damaged or is inoperable, repair or service must be handled by

authorized, factory-trained technicians only. Attempting to repair or service

the unit on your own can result in direct exposure to laser radiation and the

risk of permanent eye damage. For repair or service, contact your dealer or

Garmin® for more information. This device should not be modied or operated

without its housing or optics. Operating this device without a housing and

optics, or operating this device with modied housing or optics that expose the

laser source, may result in direct exposure to laser radiation and the risk of

permanent eye damage. Removal or modication of the diffuser in front of the

laser optic may result in the risk of permanent eye damage.

Use of controls or adjustments or performance of procedures other than those

specied in this documentation may result in hazardous radiation exposure.

Garmin is not responsible for injuries caused through the improper use or

operation of this product.

CAUTION

This device emits laser radiation. This Laser Product is designated Class 1

during all procedures of operation. This designation means that the laser is

safe to look at with the unaided eye, however it is advisable to avoid looking

into the beam when operating the device and to turn off the module when not

in use.

Documentation Revision Information

Rev Date Changes

0A 09/2016 Initial release

Table of Contents

Lidar Lite v3 Operation Manual and Technical Specications ������� 1

Laser Safety ......................................................................................................1

Documentation Revision Information .................................................................1

Specications ������������������������������������������������������������������������������������� 2

Physical .............................................................................................................2

Electrical ............................................................................................................2

Performance ......................................................................................................2

Interface .............................................................................................................2

Laser ..................................................................................................................2

Connections ���������������������������������������������������������������������������������������� 2

Wiring Harness ..................................................................................................2

Connector ..........................................................................................................2

Connector Port Identication .......................................................................2

I2C Connection Diagrams .................................................................................3

Standard I2C Wiring ....................................................................................3

Standard Arduino I2C Wiring .......................................................................3

PWM Wiring .................................................................................................3

PWM Arduino Wiring....................................................................................3

Operational Information ��������������������������������������������������������������������� 4

Technology ........................................................................................................4

Theory of Operation ...........................................................................................4

Interface .............................................................................................................4

Initialization ..................................................................................................4

Power Enable Pin ........................................................................................4

I2C Interface ................................................................................................4

Mode Control Pin .........................................................................................4

Settings ........................................................................................................4

I2C Protocol Information �������������������������������������������������������������������� 6

I2C Protocol Operation ......................................................................................7

Register Denitions ...........................................................................................7

Control Register List ....................................................................................7

Detailed Control Register Denitions ...........................................................8

Frequently Asked Questions ����������������������������������������������������������� 12

Must the device run on 5 Vdc? Can it run on 3.3 Vdc instead? .......................12

What is the spread of the laser beam? ............................................................12

How do distance, target size, aspect, and reectivity effect returned signal

strength? ..........................................................................................................12

How does the device work with reective surfaces? .......................................12

Diffuse Reective Surfaces ........................................................................12

Specular Surfaces .....................................................................................12

How does liquid affect the signal? ...................................................................13

1

Page 2

Specications

Connections

Physical

Specication Measurement

Size (LxWxH) 20 × 48 × 40 mm (0.8 × 1.9 × 1.6 in.)

Weight 22 g (0.78 oz.)

Operating temperature -20 to 60°C (-4 to 140°F)

Electrical

Specication Measurement

Power 5 Vdc nominal

4.5 Vdc min., 5.5 Vdc max.

Current consumption 105 mA idle

135 mA continuous operation

Performance

Specication Measurement

Range (70% reective

target)

Resolution +/- 1 cm (0.4 in.)

Accuracy < 5 m ±2.5 cm (1 in.) typical*

Accuracy ≥ 5 m ±10 cm (3.9 in.) typical

Update rate (70%

Reective Target)

Repetition rate ~50 Hz default

40 m (131 ft)

Mean ±1% of distance maximum

Ripple ±1% of distance maximum

270 Hz typical

650 Hz fast mode**

>1000 Hz short range only

500 Hz max

*Nonlinearity present below 1 m (39.4 in.)

**Reduced sensitivity

Interface

Specication Measurement

User interface I2C

PWM

External trigger

l2C interface Fast-mode (400 kbit/s)

Default 7-bit address 0x62

Internal register access & control

PWM interface External trigger input

PWM output proportional to distance at 10 μs/cm

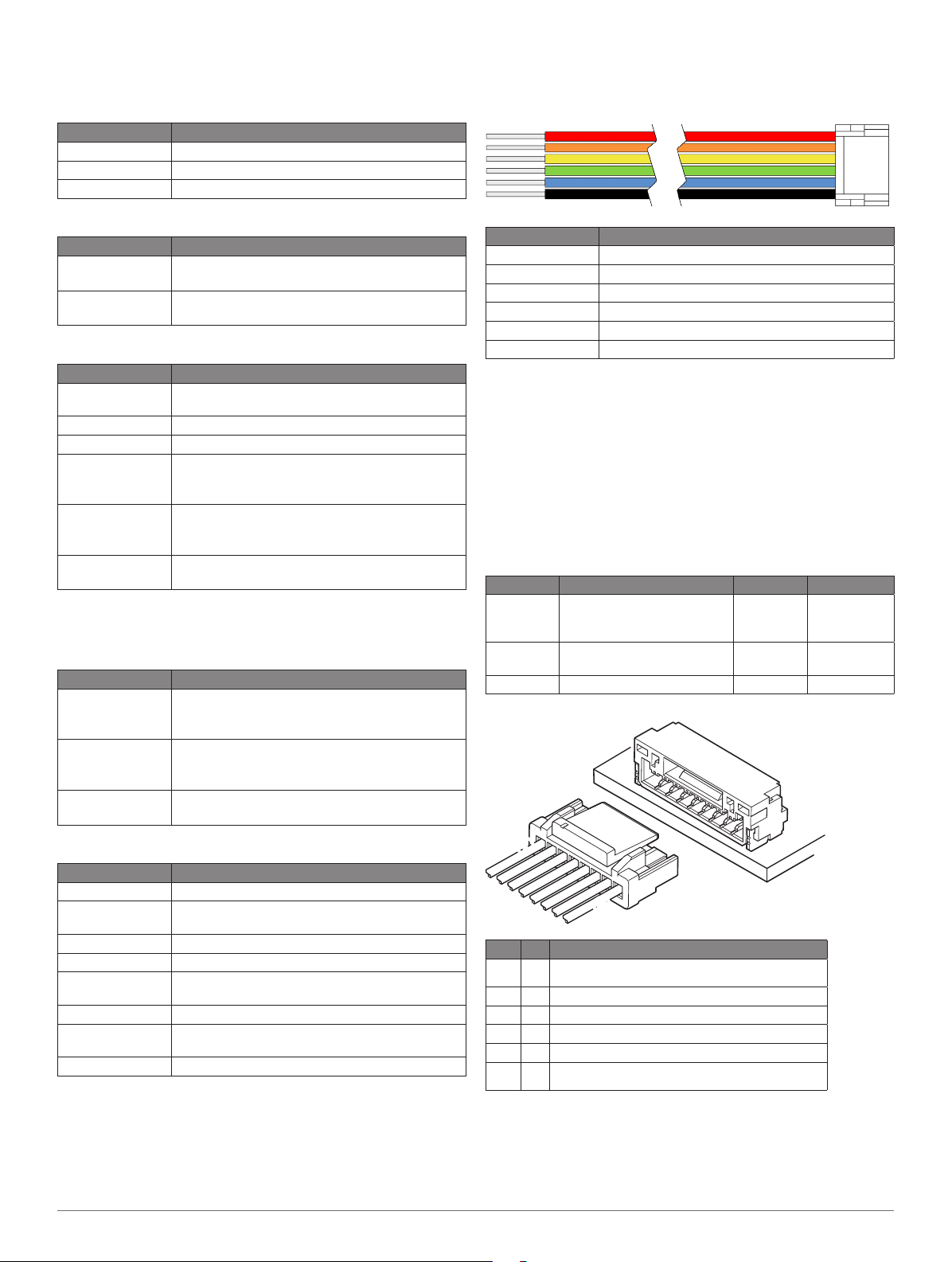

Wiring Harness

Wire Color Function

Red 5 Vdc (+)

Orange Power enable (internal pull-up)

Yellow Mode control

Green I2C SCL

Blue I2C SDA

Black Ground (-)

There are two basic congurations for this device:

• I2C (Inter-Integrated Circuit)—a serial computer bus used to

communicate between this device and a microcontroller, such as an

Arduino board (“I2C Interface”, page 4).

• PWM (Pulse Width Modulation)—a bi-directional signal transfer method

that triggers acquisitions and returns distance measurements using the

mode-control pin (“Mode Control Pin”, page 4).

Connector

You can create your own wiring harness if needed for your project or

application. The needed components are readily available from many

suppliers.

Part Description Manufacturer Part Number

Connector

housing

Connector

terminal

Wire UL 1061 26 AWG stranded copper N/A N/A

Connector Port Identication

6-position, rectangular housing,

latch-lock connector receptacle with

a 1.25 mm (0.049 in.) pitch.

26-30 AWG crimp socket connector

terminal (up to 6)

JST GHR-06V-S

JST SSHL-002T-P0.2

Laser

Specication Measurement

Wavelength 905 nm (nominal)

Total laser power

(peak)

Mode of operation Pulsed (256 pulse max. pulse train)

Pulse width 0.5 μs (50% duty Cycle)

Pulse train repetition

frequency

Energy per pulse <280 nJ

Beam diameter at

laser aperture

Divergence 8 mRadian

2

1.3 W

10-20 KHz nominal

12 × 2 mm (0.47 × 0.08 in.)

➊

➏

Item Pin Function

1 5 Vdc (+)

➊

2 Power enable (internal pull-up)

3 Mode control

4 I2C SCL

5 I2C SDA

6 Ground (-)

➏

Page 3

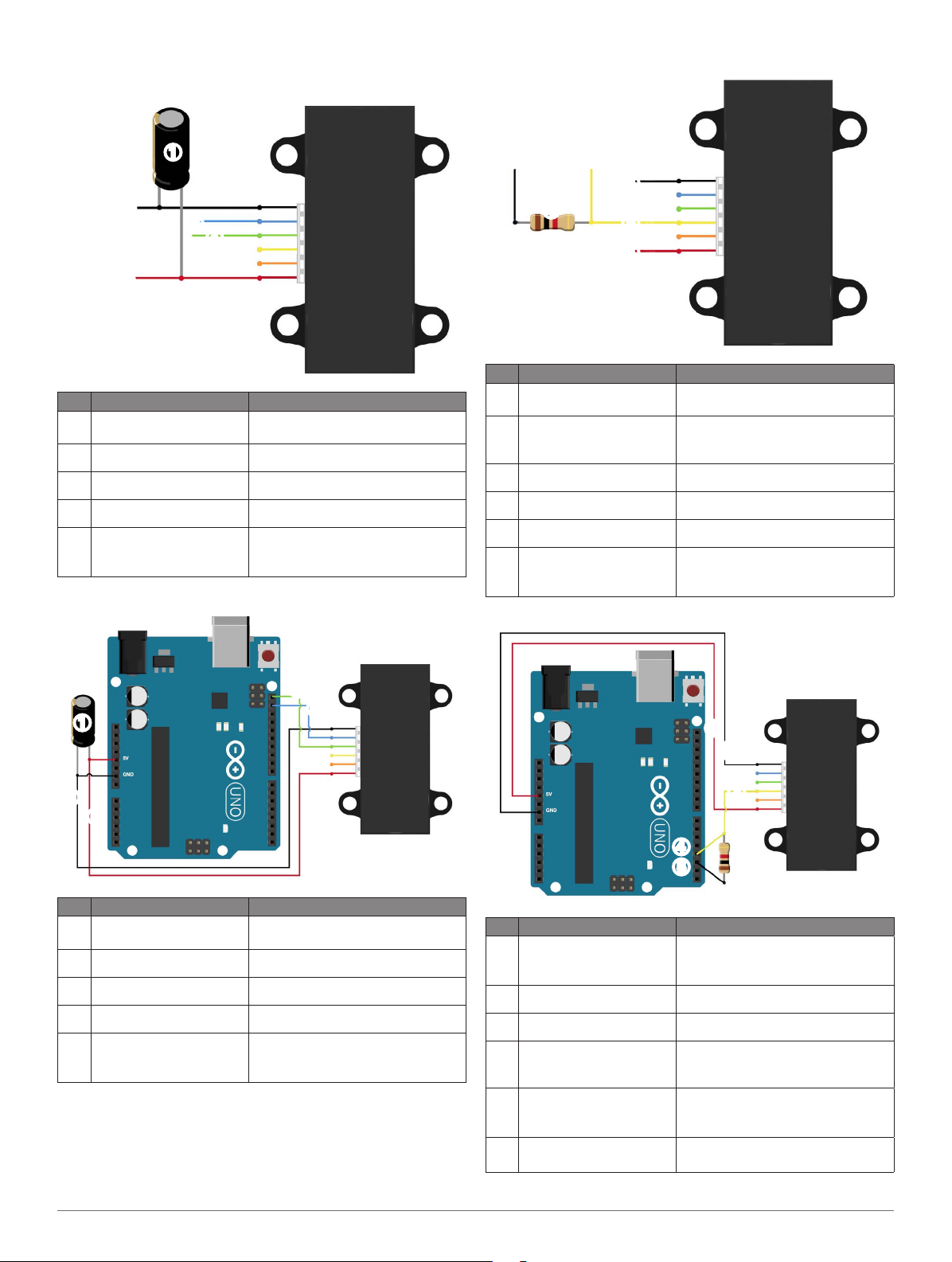

I2C Connection Diagrams

Standard I2C Wiring

PWM Wiring

➊

➋

➌

➍

➎

Item Description Notes

680µF electrolytic capacitor You must observe the correct polarity when

➊

Power ground (-) connection Black wire

➋

I2C SDA connection Blue wire

➌

I2C SCA connection Green wire

➍

5 Vdc power (+) connection Red wire

➎

Standard Arduino I2C Wiring

installing the capacitor.

The sensor operates at 4.75 through 5.5 Vdc,

with a max. of 6 Vdc.

➊

➋

➌

➍

➎

➏

Item Description Notes

Trigger pin on microcontroller Connect the other side of the resistor to the

➊

Monitor pin on microcontroller Connect one side of the resistor to the mode-

➋

Power ground (-) connection Black Wire

➌

1kΩ resistor

➍

Mode-control connection Yellow wire

➎

5 Vdc power (+) connection Red wire

➏

PWM Arduino Wiring

trigger pin on your microcontroller.

control connection on the device, and to a

monitoring pin on your microcontroller.

The sensor operates at 4.75 through 5.5 Vdc,

with a max. of 6 Vdc.

➋

➌

➊

➍

➎

Item Description Notes

680µF electrolytic capacitor You must observe the correct polarity when

➊

I2C SCA connection Green wire

➋

I2C SDA connection Blue wire

➌

Power ground (-) connection Black wire

➍

5 Vdc power (+) connection Red wire

➎

installing the capacitor.

The sensor operates at 4.75 through 5.5 Vdc,

with a max. of 6 Vdc.

➊

➋

➌

➍

➎

Item Description Notes

5 Vdc power (+) connection Red wire

➊

Power ground (-) connection Black Wire

➋

Mode-control connection Yellow wire

➌

Monitor pin on microcontroller Connect one side of the resistor to the mode-

➍

Trigger pin on microcontroller Connect the other side of the resistor to the

➎

1kΩ resistor

➏

The sensor operates at 4.75 through 5.5 Vdc,

with a max. of 6 Vdc.

control connection on the device, and to a

monitoring pin on your microcontroller.

trigger pin on your microcontroller.

➏

3

Page 4

Operational Information

Technology

This device measures distance by calculating the time delay between the

transmission of a Near-Infrared laser signal and its reception after reecting

off of a target. This translates into distance using the known speed of light.

Our unique signal processing approach transmits a coded signature and looks

for that signature in the return, which allows for highly effective detection with

eye-safe laser power levels. Proprietary signal processing techniques are

used to achieve high sensitivity, speed, and accuracy in a small, low-power,

and low-cost system

Theory of Operation

To take a measurement, this device rst performs a receiver bias correction

routine, correcting for changing ambient light levels and allowing maximum

sensitivity.

Then the device sends a reference signal directly from the transmitter to

the receiver. It stores the transmit signature, sets the time delay for “zero”

distance, and recalculates this delay periodically after several measurements.

Next, the device initiates a measurement by performing a series of

acquisitions. Each acquisition is a transmission of the main laser signal while

recording the return signal at the receiver. If there is a signal match, the result

is stored in memory as a correlation record. The next acquisition is summed

with the previous result. When an object at a certain distance reects the

laser signal back to the device, these repeated acquisitions cause a peak

to emerge, out of the noise, at the corresponding distance location in the

correlation record.

The device integrates acquisitions until the signal peak in the correlation

record reaches a maximum value. If the returned signal is not strong enough

for this to occur, the device stops at a predetermined maximum acquisition

count.

Signal strength is calculated from the magnitude of the signal record peak

and a valid signal threshold is calculated from the noise oor. If the peak is

above this threshold the measurement is considered valid and the device will

calculate the distance, otherwise it will report 1 cm. When beginning the next

measurement, the device clears the signal record and starts the sequence

again.

Interface

Initialization

On power-up or reset, the device performs a self-test sequence and initializes

all registers with default values. After roughly 22 ms distance measurements

can be taken with the I2C interface or the Mode Control Pin.

Power Enable Pin

The enable pin uses an internal pullup resistor, and can be driven low to shut

off power to the device.

I2C Interface

This device has a 2-wire, I2C-compatible serial interface (refer to I2C-

Bus Specication, Version 2.1, January 2000, available from Philips

Semiconductor). It can be connected to an I2C bus as a slave device, under

the control of an I2C master device. It supports 400 kHz Fast Mode data

transfer.

The I2C bus operates internally at 3.3 Vdc. An internal level shifter allows the

bus to run at a maximum of 5 Vdc. Internal 3k ohm pullup resistors ensure this

functionality and allow for a simple connection to the I2C host.

The device has a 7-bit slave address with a default value of 0x62. The

effective 8-bit I2C address is 0xC4 write and 0xC5 read. The device will not

respond to a general call. Support is not provided for 10-bit addressing.

Setting the most signicant bit of the I2C address byte to one triggers

automatic incrementing of the register address with successive reads or writes

within an I2C block transfer. This is commonly used to read the two bytes of a

16-bit value within one transfer and is used in the following example.

The simplest method of obtaining measurement results from the I2C interface

is as follows:

Write 0x04 to register 0x00.

1

Read register 0x01. Repeat until bit 0 (LSB) goes low.

2

Read two bytes from 0x8f (High byte 0x0f then low byte 0x10) to obtain the

3

16-bit measured distance in centimeters.

A list of all available control resisters is available on page 7.

For more information about the I2C protocol, see I2C Protocol Operation

(page 7).

Mode Control Pin

The mode control pin provides a means to trigger acquisitions and return the

measured distance via Pulse Width Modulation (PWM) without having to use

the I2C interface.

The idle state of the mode control pin is high impedance (High-Z). Pulling

the mode control pin low will trigger a single measurement, and the device

will respond by driving the line high with a pulse width proportional to the

measured distance at 10 μs/cm. A 1k ohm termination resistance is required to

prevent bus contention.

The device drives the mode control pin high at 3.3 Vdc. Diode isolation allows

the pin to tolerate a maximum of 5 Vdc.

As shown in the diagram PWM Arduino Wiring (page 3), a simple

triggering method uses a 1k ohm resistor in series with a host output pin to

pull the mode control pin low to initiate a measurement, and a host input pin

connected directly to monitor the low-to-high output pulse width.

If the mode control pin is held low, the acquisition process will repeat

indenitely, producing a variable frequency output proportional to distance.

The mode control pin behavior can be modied with the ACQ_CONFIG_REG

(0x04) I2C register as detailed in 0x04 (page 8).

Settings

The device can be congured with alternate parameters for the distance

measurement algorithm. This can be used to customize performance by

enabling congurations that allow choosing between speed, range and

sensitivity. Other useful features are also detailed in this section. See the full

register map (Control Register List (page 7) for additional settings not

mentioned here.

Receiver Bias Correction

Address Name Description Initial Value

0x00 ACQ_COMMAND Device command --

• Write 0x00: Reset device, all registers return to default values

• Write 0x03: Take distance measurement without receiver bias correction

• Write 0x04: Take distance measurement with receiver bias correction

Faster distance measurements can be performed by omitting the receiver

bias correction routine. Measurement accuracy and sensitivity are adversely

affected if conditions change (e.g. target distance, device temperature, and

optical noise). To achieve good performance at high measurement rates

receiver bias correction must be performed periodically. The recommended

method is to do so at the beginning of every 100 sequential measurement

commands.

Maximum Acquisition Count

Address Name Description Initial Value

0x02 SIG_COUNT_VAL Maximum acquisition count 0x80

The maximum acquisition count limits the number of times the device will

integrate acquisitions to nd a correlation record peak (from a returned signal),

which occurs at long range or with low target reectivity. This controls the

minimum measurement rate and maximum range. The unit-less relationship

is roughly as follows: rate = 1/n and range = n^(1/4), where n is the number of

acquisitions.

4

Page 5

Measurement Quick Termination Detection

Address Name Description Initial Value

0x04 ACQ_CONFIG_REG Acquisition mode control 0x08

You can enable quick-termination detection by clearing bit 3 in this register.

The device will terminate a distance measurement early if it anticipates that

the signal peak in the correlation record will reach maximum value. This allows

for faster and slightly less accurate operation at strong signal strengths without

sacricing long range performance.

Detection Sensitivity

Address Name Description Initial Value

0x1c THRESHOLD_

BYPASS

Peak detection threshold bypass 0x00

The default valid measurement detection algorithm is based on the peak

value, signal strength, and noise in the correlation record. This can be

overridden to become a simple threshold criterion by setting a non-zero value.

Recommended non-default values are 0x20 for higher sensitivity with more

frequent erroneous measurements, and 0x60 for reduced sensitivity and fewer

erroneous measurements.

Burst Measurements and Free Running Mode

Address Name Description Initial Value

0x04 ACQ_CONFIG_REG Acquisition mode control 0x08

0x11 OUTER_LOOP_

COUNT

0x45 MEASURE_DELAY Delay between automatic

Burst measurement count control 0x00

0x14

measurements

The device can be congured to take multiple measurements for each

measurement command or repeat indenitely for free running mode.

OUTER_LOOP_COUNT (0x11) controls the number of times the device will

retrigger itself. Values 0x00 or 0x01 result in the default one measurement per

command. Values 0x02 to 0xfe directly set the repetition count. Value 0xff will

enable free running mode after the host device sends an initial measurement

command.

The default delay between automatic measurements corresponds to a 10

Hz repetition rate. Set bit 5 in ACQ_CONFIG_REG (0x04) to use the delay

value in MEASURE_DELAY (0x45) instead. A delay value of 0x14 roughly

corresponds to 100Hz.

The delay is timed from the completion of each measurement. The means that

measurement duration, which varies with returned signal strength, will affect

the repetition rate. At low repetition rates (high delay) this effect is small, but

for lower delay values it is recommended to limit the maximum acquisition

count if consistent frequency is desired.

Velocity

Address Name Description Initial Value

0x09 VELOCITY Velocity measurement output --

The velocity measurement is the difference between the current measurement

and the previous one, resulting in a signed (2’s complement) 8-bit number in

cm. Positive velocity is away from the device. This can be combined with free

running mode for a constant measurement frequency. The default free running

frequency of 10 Hz therefore results in a velocity measurement in .1 m/s.

Congurable I2C Address

Address Name Description Initial Value

0x16 UNIT_ID_HIGH Serial number high byte Unique

0x17 UNIT_ID_LOW Serial number low byte Unique

0x18 I2C_ID_HIGH Write serial number high byte for

I2C address unlock

0x19 I2C_ID_LOW Write serial number low byte for

I2C address unlock

0x1a I2C_SEC_ADDR Write new I2C address after

unlock

0x1e I2C_CONFIG Default address response

control

--

--

--

0x00

The I2C address can be changed from its default value. Available addresses

are 7-bit values with a ‘0’ in the least signicant bit (even hexadecimal

numbers).

To change the I2C address, the unique serial number of the unit must be read

then written back to the device before setting the new address. The process is

as follows:

Read the two byte serial number from 0x96 (High byte 0x16 and low byte

1

0x17).

Write the serial number high byte to 0x18.

2

Write the serial number low byte to 0x19.

3

Write the desired new I2C address to 0x1a.

4

Write 0x08 to 0x1e to disable the default address.

5

This can be used to run multiple devices on a single bus, by enabling one,

changing its address, then enabling the next device and repeating the

process.

The I2C address will be restored to default after a power cycle.

Power Control

Address Name Description Initial Value

0x65 POWER_CONTROL Power state control 0x80

NOTE: The most effective way to control power usage is to utilize the enable

pin to deactivate the device when not in use.

Another option is to set bit 0 in this register which disables the receiver circuit,

saving roughly 40mA. After being re-enabled, the receiver circuit stabilizes by

the time a measurement can be performed. Setting bit 2 puts the device in

sleep mode until the next I2C transaction, saving 20mA. Since the wake-up

time is only around 2 m/s shorter than the full power-on time, and both

will reset all registers, it is recommended to use the enable pin instead.

5

Page 6

I2C Protocol Information

This device has a 2-wire, I2C-compatible serial interface (refer to I2C-Bus Specication, Version 2.1, January 2000, available from Philips Semiconductor). It

can be connected to an I2C bus as a slave device, under the control of an I2C master device. It supports standard 400 kHz data transfer mode. Support is not

provided for 10-bit addressing.

The Sensor module has a 7-bit slave address with a default value of 0x62 in hexadecimal notation. The effective 8 bit I2C address is: 0xC4 write, 0xC5 read. The

device will not presently respond to a general call.

Notes:

• This device does not work with repeated START conditions. It must rst receive a STOP condition before a new START condition.

• The ACK and NACK items are responses from the master device to the slave device.

• The last NACK in the read is technically optional, but the formal I2C protocol states that the master shall not acknowledge the last byte.

6

Page 7

I2C Protocol Operation

The I2C serial bus protocol operates as follows:

The master initiates data transfer by establishing a start condition, which is when a high-to-low transition on the SDA line occurs while SCL is high. The

1

following byte is the address byte, which consists of the 7-bit slave address followed by a read/write bit with a zero state indicating a write request. A write

operation is used as the initial stage of both read and write transfers. If the slave address corresponds to the module’s address the unit responds by pulling

SDA low during the ninth clock pulse (this is termed the acknowledge bit). At this stage, all other devices on the bus remain idle while the selected device

waits for data to be written to or read from its shift register.

Data is transmitted over the serial bus in sequences of nine clock pulses (eight data bits followed by an acknowledge bit). The transitions on the SDA line

2

must occur during the low period of SCL and remain stable during the high period of SCL.

An 8 bit data byte following the address loads the I2C control register with the address of the rst control register to be read along with ags indicating if auto

3

increment of the addressed control register is desired with successive reads or writes; and if access to the internal micro or external correlation processor

register space is requested. Bit locations 5:0 contain the control register address while bit 7 enables the automatic incrementing of control register with

successive data blocks. Bit position 6 selects correlation memory external to the microcontroller if set. (Presently an advanced feature)

If a read operation is requested, a stop bit is issued by the master at the completion of the rst data frame followed by the initiation of a new start condition,

4

slave address with the read bit set (one state). The new address byte is followed by the reading of one or more data bytes succession. After the slave has

acknowledged receipt of a valid address, data read operations proceed by the master releasing the I2C data line SDA with continuing clocking of SCL. At the

completion of the receipt of a data byte, the master must strobe the acknowledge bit before continuing the read cycle.

For a write operation to proceed, Step 3 is followed by one or more 8 bit data blocks with acknowledges provided by the slave at the completion of each

5

successful transfer. At the completion of the transfer cycle a stop condition is issued by the master terminating operation.

Register Denitions

Control Register List

Address R/W Name Description Intial Value Details

0x00 W ACQ_COMMAND Device command -- page 8

0x01 R STATUS System status -- page 8

0x02 R/W SIG_COUNT_VAL Maximum acquisition count 0x80 page 8

0x04 R/W ACQ_CONFIG_REG Acquisition mode control 0x08 page 8

0x09 R VELOCITY Velocity measurement output -- page 8

0x0c R PEAK_CORR Peak value in correlation record -- page 8

0x0d R NOISE_PEAK Correlation record noise oor -- page 8

0x0e R SIGNAL_STRENGTH Received signal strength -- page 9

0x0f R FULL_DELAY_HIGH Distance measurement high byte -- page 9

0x10 R FULL_DELAY_LOW Distance measurement low byte -- page 9

0x11 R/W OUTER_LOOP_COUNT Burst measurement count control 0x01 page 9

0x12 R/W REF_COUNT_VAL Reference acquisition count 0x05 page 9

0x14 R LAST_DELAY_HIGH Previous distance measurement high byte -- page 9

0x15 R LAST_DELAY_LOW Previous distance measurement low byte -- page 9

0x16 R UNIT_ID_HIGH Serial number high byte Unique page 9

0x17 R UNIT_ID_LOW Serial number low byte Unique page 9

0x18 W I2C_ID_HIGH Write serial number high byte for I2C address unlock -- page 9

0x19 W I2C_ID_LOW Write serial number low byte for I2C address unlock -- page 9

0x1a R/W I2C_SEC_ADDR Write new I2C address after unlock -- page 9

0x1c R/W THRESHOLD_BYPASS Peak detection threshold bypass 0x00 page 9

0x1e R/W I2C_CONFIG Default address response control 0x00 page 9

0x40 R/W COMMAND State command -- page 10

0x45 R/W MEASURE_DELAY Delay between automatic measurements 0x14 page 10

0x4c R PEAK_BCK Second largest peak value in correlation record -- page 10

0x52 R CORR_DATA Correlation record data low byte -- page 10

0x53 R CORR_DATA_SIGN Correlation record data high byte -- page 10

0x5d R/W ACQ_SETTINGS Correlation record memory bank select -- page 10

0x65 R/W POWER_CONTROL Power state control 0x80 page 10

7

Page 8

Detailed Control Register Denitions

NOTE: Unless otherwise noted, all registers contain one byte and are read

and write.

0x00

R/W Name Description Initial Value

W ACQ_COMMAND Device command --

Bit Function

7:0 Write 0x00: Reset FPGA, all registers return to default values

Write 0x03: Take distance measurement without receiver bias correction

Write 0x04: Take distance measurement with receiver bias correction

0x01

R/W Name Description Initial Value

R STATUS System status --

Bit Function

6 Process Error Flag

0: No error detected

1: System error detected during measurement

5 Health Flag

0: Error detected

1: Reference and receiver bias are operational

4 Secondary Return Flag

0: No secondary return detected

1: Secondary return detected in correlation record

3 Invalid Signal Flag

0: Peak detected

1: Peak not detected in correlation record, measurement is invalid

2 Signal Overow Flag

0: Signal data has not overowed

1: Signal data in correlation record has reached the maximum value before

overow. This occurs with a strong received signal strength

1 Reference Overow Flag

0: Reference data has not overowed

1: Reference data in correlation record has reached the maximum value

before overow. This occurs periodically

0 Busy Flag

0: Device is ready for new command

1: Device is busy taking a measurement

0x04

R/W Name Description Initial Value

R/W ACQ_CONFIG_REG Acquisition mode control 0x08

Bit Function

6 0: Enable reference process during measurement

1: Disable reference process during measurement

5 0: Use default delay for burst and free running mode

1: Use delay from MEASURE_DELAY (0x45) for burst and free running mode

4 0: Enable reference lter, averages 8 reference measurements for increased

consistency

1: Disable reference lter

3 0: Enable measurement quick termination. Device will terminate distance

measurement early if it anticipates that the signal peak in the correlation

record will reach maximum value.

1: Disable measurement quick termination.

2 0: Use default reference acquisition count of 5.

1: Use reference acquisition count from REF_COUNT_VAL (0x12).

1:0 Mode Select Pin Function Control

00: Default PWM mode. Pull pin low to trigger measurement, device will

respond with an active high output with a duration of 10us/cm.

01: Status output mode. Device will drive pin active high while busy. Can be

used to interrupt host device.

10: Fixed delay PWM mode. Pulling pin low will not trigger a measurement.

11: Oscillator output mode. Nominal 31.25 kHz output. The accuracy of the

silicon oscillator in the device is generally within 1% of nominal. This affects

distance measurements proportionally and can be measured to apply a

compensation factor.

0x09

R/W Name Description Initial Value

R VELOCITY Velocity measurement output --

Bit Function

7:0 Velocity measurement output. The difference between the current

measurement and the previous one, signed (2’s complement) value in

centimeters.

0x0c

R/W Name Description Initial Value

R PEAK_CORR Peak value in correlation record --

0x02

R/W Name Description Initial Value

R/W SIG_COUNT_VAL Maximum acquisition count 0x80

Bit Function

7:0 Maximum number of acquisitions during measurement

8

Bit Function

7:0 The value of the highest peak in the correlation record.

0x0d

R/W Name Description Initial Value

R NOISE_PEAK Correlation record noise oor --

Bit Function

7:0 A measure of the noise in the correlation record. Will be slightly above the

third highest peak.

Page 9

0x0e

R/W Name Description Initial Value

R SIGNAL_STRENGTH Received signal strength --

0x16

R/W Name Description Initial Value

R UNIT_ID_HIGH Serial number high byte Unique

Bit Function

7:0 Received signal strength calculated from the value of the highest peak in the

correlation record and how many acquisitions were performed.

0x0f

R/W Name Description Initial Value

R FULL_DELAY_HIGH Distance measurement high byte --

Bit Function

7:0 Distance measurement result in centimeters, high byte.

0x10

R/W Name Description Initial Value

R FULL_DELAY_LOW Distance measurement low byte --

Bit Function

7:0 Distance measurement result in centimeters, low byte.

0x11

R/W Name Description Initial Value

R/W OUTER_LOOP_COUNT Burst measurement count control 0x01

Bit Function

7:0 0x00-0x01: One measurement per distance measurement command.

0x02-0xfe: Repetition count per distance measurement command.

0xff: Indenite repetitions after initial distance measurement command.

See ACQ_CONFIG_REG (0x04) and MEASURE_DELAY (0x45) for non-

default automatic repetition delays.

0x12

R/W Name Description Initial Value

R/W REF_COUNT_VAL Reference acquisition count 0x05

Bit Function

7:0 Non-default number of reference acquisitions during measurement. ACQ_

CONFIG_REG (0x04) bit 2 must be set.

0x14

R/W Name Description Initial Value

R LAST_DELAY_HIGH Previous distance measurement high

byte

Bit Function

7:0 Previous distance measurement result in centimeters, high byte.

--

0x15

R/W Name Description Initial Value

R LAST_DELAY_LOW Previous distance measurement low

byte

Bit Function

7:0 Previous distance measurement result in centimeters, low byte.

--

Bit Function

7:0 Unique serial number of device, high byte.

0x17

R/W Name Description Initial Value

R UNIT_ID_LOW Serial number low byte Unique

Bit Function

7:0 Unique serial number of device, high byte.

0x18

R/W Name Description Initial Value

W I2C_ID_HIGH Write serial number high byte for I2C

address unlock

Bit Function

7:0 Write the value in UNIT_ID_HIGH (0x16) here as part of enabling a non-

default I2C address. See I2C_ID_LOW (0x19) and I2C_SEC_ADDR (0x1a).

--

0x19

R/W Name Description Initial Value

W I2C_ID_LOW Write serial number low byte for I2C

address unlock

Bit Function

7:0 Write the value in UNIT_ID_LOW (0x17) here as part of enabling a non-default

I2C address. See I2C_ID_HIGH (0x18) and I2C_SEC_ADDR (0x1a).

--

0x1a

R/W Name Description Initial Value

R/W I2C_SEC_ADDR Write new I2C address after unlock --

Bit Function

7:0 Non-default I2C address.

Available addresses are 7-bit values with a ‘0’ in the least signicant bit (even

hexadecimal numbers).

I2C_ID_HIGH (0x18) and I2C_ID_LOW (0x19) must have the correct value for

the device to respond to the non-default I2C address.

0x1c

R/W Name Description Initial Value

R/W THRESHOLD_

BYPASS

Bit Function

7:0 0x00: Use default valid measurement detection algorithm based on the peak

value, signal strength, and noise in the correlation record.

0x01-0xff: Set simple threshold for valid measurement detection. Values 0x20-

0x60 generally perform well.

Peak detection threshold bypass 0x00

0x1e

R/W Name Description Initial Value

R/W I2C_CONFIG Default address response control 0x00

Bit Function

9

Page 10

3 0: Device will respond to I2C address 0x62. Device will also respond to

non-default address if congured successfully. See I2C_ID_HIGH (0x18),

I2C_ID_LOW (0x19), and I2C_SEC_ADDR (0x1a).

1: Device will only respond to non-default I2C address. It is recommended to

congure the non-default address rst, then use the non-default address to

write to this register, ensuring success.

0x40

R/W Name Description Initial Value

R/W COMMAND State command --

Bit Function

2:0 000: Test mode disable, resume normal operation

111: Test mode enable, allows download of correlation record

Select correlation memory bank in ACQ_SETTINGS (0x5d) prior to enabling

test mode.

Once test mode is enabled, read CORR_DATA (0x52) and CORR_DATA_

SIGN (0x53) in one transaction (read from 0xd2). The memory index is

incremented automatically and successive reads produce sequential data.

0x45

R/W Name Description Initial Value

R/W MEASURE_

DELAY

Bit Function

7:0 Non-default delay after completion of measurement before automatic retrigger,

in burst and continuous modes. ACQ_CONFIG_REG (0x04) bit 5 must be set.

Value 0xc8 corresponds to 10 Hz repetition rate and 0x14 to roughly 100 Hz.

Delay between automatic measurements 0x14

0x5d

R/W Name Description Initial Value

R/W ACQ_SETTINGS Correlation record memory bank select --

Bit Function

7:6 11: Access correlation memory bank. Write prior to test mode enable, see

COMMAND (0x40).

0x65

R/W Name Description Initial Value

R/W POWER_CONTROL Power state control 0x80

Bit Function

2 1: Device Sleep, wakes upon I2C transaction. Registers are reinitialized,

wakeup time similar to full reset using enable pin.

0: Device awake

0 1: Disable receiver circuit

0: Enable receiver circuit. Receiver circuit stabilizes by the time a

measurement can be performed.

0x4c

R/W Name Description Initial Value

R PEAK_BCK Second largest peak value in correlation

record

Bit Function

7:0 The value of the second highest peak in the correlation record.

--

0x52

R/W Name Description Initial Value

R CORR_DATA Correlation record data low byte --

Bit Function

7:0 Correlation record data low byte. See CORR_DATA_SIGN (0x53), ACQ_

SETTINGS (0x5d), and COMMAND (0x40).

0x53

R/W Name Description Initial Value

R CORR_DATA_SIGN Correlation record data high byte --

Bit Function

7:0 Correlation record data high byte. Correlation record data is a 2’s complement

9-bit value, and must be sign extended to be formatted as a 16-bit 2’s

complement value. Thus when repacking the two bytes obtained for the I2C

transaction, set the high byte to 0xff if the LSB of the high byte is one.

10

Page 11

11

Page 12

Frequently Asked Questions

Must the device run on 5 Vdc? Can it run on 3.3 Vdc instead?

The device requires 5 Vdc to run properly, so this specication is

recommended and supported.

What is the spread of the laser beam?

At very close distances (less than 1 m) the beam diameter is about the size

of the aperture (lens). For distances greater than 1 m, you can estimate the

beam diameter using this equation:

Distance/100 = beam diameter at that distance (in whatever units you

measured the distance).

The actual spread is ~8 milli-radians or ~1/2 degree.

How do distance, target size, aspect, and reectivity

effect returned signal strength?

The device transmits a focused infrared beam that reects off of a target,

and a portion of that reected signal returns to the receiver. The distance is

calculated by taking the difference between the moment of signal transmission

to the moment of signal reception. Successfully receiving a reected signal is

heavily inuenced by several factors. These factors include:

• Target Distance

The relationship of distance (D) to returned signal strength is an inverse

square. So, with increase in distance, returned signal strength decreases

by 1/D^2 or the square root of the distance.

• Target Size

The relationship of a target’s Cross Section (C) to returned signal strength

is an inverse power of four. The device transmits a focused near-infrared

laser beam that spreads at a rate of approximately 0.5º as distance

increases. Up to 1 m it is approximately the size of the lens. Beyond 1 m,

the approximate beam spread in degrees can be estimated by dividing the

distance by 100, or ~8 milliradians. When the beam overlls (is larger than)

the target, the signal returned decreases by 1/C^4 or the fourth root of the

target’s cross section.

• Aspect

The aspect of the target, or its orientation to the sensor, affects the

observable cross section and, therefore, the amount of returned signal

decreases as the aspect of the target varies from the normal.

• Reectivity

Reectivity characteristics of the target’s surface also affect the amount

of returned signal. In this case, we concern ourselves with reectivity of

near infrared wavelengths (“How does the device work with reective

surfaces?”, page 12).

In summary, a small target can be very difcult to detect if it is distant, poorly

reective, and its aspect is away from the normal. In such cases, the returned

signal strength may be improved by attaching infrared reectors to the target,

increasing the size of the target, modifying its aspect, or reducing distance

from the sensor.

How does the device work with reective surfaces?

Reective characteristics of an object’s surface can be divided into three

categories (in the real world, a combination of characteristics is typically

present):

• Diffuse Reective

• Specular

• Retro-reective

Diffuse Reective Surfaces

Purely diffuse surfaces are found on materials that have a textured quality

that causes reected energy to disperse uniformly. This tendency results in a

relatively predictable percentage of the dispersed laser energy nding its way

back to the device. As a result, these materials tend to read very well.

Materials that fall into this category are paper, matte walls, and granite. It

is important to note that materials that t into this category due to observed

reection at visible light wavelengths may exhibit unexpected results in other

wavelengths. The near infrared range used by the device may detect them

as nearly identical. For example, a black sheet of paper may reect a nearly

identical percentage of the infrared signal back to the receiver as a white

sheet.

Specular Surfaces

Specular surfaces, are found on materials that have a smooth quality that

reect energy instead of dispersing it. It is difcult or impossible for the

device to recognize the distance of many specular surfaces. Reections

off of specular surfaces tend to reect with little dispersion which causes

the reected beam to remain small and, if not reected directly back to the

receiver, to miss the receiver altogether. The device may fail to detect a

specular object in front of it unless viewed from the normal.

Examples of specular surfaces are mirrors and glass viewed off-axis.

12

Page 13

How does liquid affect the signal?

There are a few considerations to take into account if your application requires

measuring distances to, or within, liquid:

• Reectivity and other characteristics of the liquid itself

• Reectivity characteristics of particles suspended in the liquid

• Turbidity

• Refractive characteristics of the liquid

Reectivity of the liquid is important when measuring distance to the surface of

a liquid or if measuring through liquid to the bottom of a container(“How does

the device work with reective surfaces?”, page 12).

It is important to note that measuring distance with the device depends on

reected energy from the transmitted signal being detected by the receiver

in the sensor. For that reason, the surface condition of the liquid may play an

important role in the overall reectivity and detectability of the liquid. In the

case of a at, highly reective liquid surface, the laser’s reected energy may

not disperse adequately to allow detection unless viewed from the normal. By

contrast, small surface ripples may create enough dispersion of the reected

energy to allow detection of the liquid without the need to position the sensor

so that the transmitted beam strikes the liquid’s surface from the normal.

Reectivity of suspended particles is a characteristic that may help or hinder

depending on the application.

Turbidity, or the clarity of a liquid created by the presence or absence of

suspended particles, can similarly help or hinder measurement efforts. If

the application requires detecting the surface of the liquid, then suspended

particles may help by reecting more of the transmitted beam back to the

receiver, increasing detectability and permitting measurements to be taken.

It is important to note that, attempting to measure through suspended particles

in a liquid will only be successful if the transmitted beam is allowed to reect

off of the desired target without rst being absorbed or reected by the

suspended particles.

When the near infrared energy transmitted by the device transitions from the

atmosphere to a liquid, the energy may be bent, or refracted, and absorbed

in addition to being dispersed. The degree to which the transmitted beam is

refracted and absorbed is dened by its refraction index. That being said, the

most important criteria impacting successful measurement through a liquid

is the amount of dispersion of the transmitted beam and whether any of the

dispersed beam makes its way back to the receiver on the device.

Remember that electromagnetic energy travels slower through a liquid and

may affect accuracy of the nal measurement output.

13

Page 14

For the latest free software updates (excluding map data) throughout the life of your Garmin products, visit the Garmin Web site at www.garmin.com.

© 2016 Garmin Ltd. or its subsidiaries

1200 East 151st Street, Olathe, Kansas 66062, USA

Liberty House, Hounsdown Business Park, Southampton, Hampshire, SO40 9LR UK

No. 68, Zhangshu 2nd Road, Xizhi Dist., New Taipei City, 221, Taiwan (R.O.C.)

September 2016 190-02088-00_0A Printed in Taiwan

Garmin International, Inc.

Garmin (Europe) Ltd.

Garmin Corporation

www.garmin.com

Loading...

Loading...