Garmin echoMAP 42dv, echoMAP 43dv, echoMAP 44dv, echoMAP 45dv, echoMAP 52dv Installation Instructions

...Page 1

echoMAP™ 40/50 Series Installation

Instructions

To obtain the best performance and to avoid damage to your

boat, install the device according to these instructions.

Read all installation instructions before proceeding with the

installation. If you experience difficulty during the installation,

contact Garmin® Product Support.

Important Safety Information

WARNING

See the Important Safety and Product Information guide in the

product box for product warnings and other important

information.

When connecting the power cable, do not remove the in-line

fuse holder. To prevent the possibility of injury or product

damage caused by fire or overheating, the appropriate fuse

must be in place as indicated in the product specifications. In

addition, connecting the power cable without the appropriate

fuse in place voids the product warranty.

CAUTION

Always wear safety goggles, ear protection, and a dust mask

when drilling, cutting, or sanding.

NOTICE

When drilling or cutting, always check what is on the opposite

side of the surface.

To obtain the best performance and to avoid damage to your

boat, install the device according to these instructions.

Read all installation instructions before proceeding with the

installation. If you experience difficulty during the installation,

contact Garmin Product Support.

Registering Your Device

Help us better support you by completing our online registration

today.

• Go to http://my.garmin.com.

• Keep the original sales receipt, or a photocopy, in a safe

place.

Contacting Garmin Product Support

• Go to www.garmin.com/support for in-country support

information.

• In the USA, call 913-397-8200 or 1-800-800-1020.

• In the UK, call 0808 238 0000.

• In Europe, call +44 (0) 870 850 1241.

Mounting Considerations

The device can be mounted using the included bracket, or it can

be mounted flush with the dashboard using a flush-mount kit

(may be sold separately).

Before permanently installing any part of your device, you

should plan the installation by determining the location of the

various components.

• The mounting location must provide a clear view of the

screen and access to the keys on the device.

• The mounting location must be sturdy enough to support the

device and the mount.

• The cables must be long enough to connect the components

to each other and to power.

• The cables can be routed under the bail mount or behind the

device.

• To avoid interference with a magnetic compass, the device

should not be installed closer to a compass than the

compass-safe distance value listed in the product

specifications.

Flush Mounting the Device

NOTICE

Be careful when cutting the hole to flush mount the device.

There is only a small amount of clearance between the case and

the mounting holes, and cutting the hole too large could

compromise the stability of the device after it is mounted.

Using a metal pry tool such as a screwdriver can damage the

trim caps and the device. Use a plastic pry tool when possible.

A flush-mount template and hardware can be used to mount the

device in your dashboard.

Trim the template and make sure it fits in the location where

1

you want to mount the device.

Secure the template to the selected mounting location.

2

Using a 9.5 mm (3/8 in.) drill bit, drill one or more of the holes

3

inside the corners of the solid line on the template to prepare

the mounting surface for cutting.

Using a jigsaw or rotary cutting tool, cut the mounting surface

4

along the inside of the solid line indicated on the template.

Place the device into the cutout to test the fit.

5

If necessary, use a file and sandpaper to refine the size of

6

the hole.

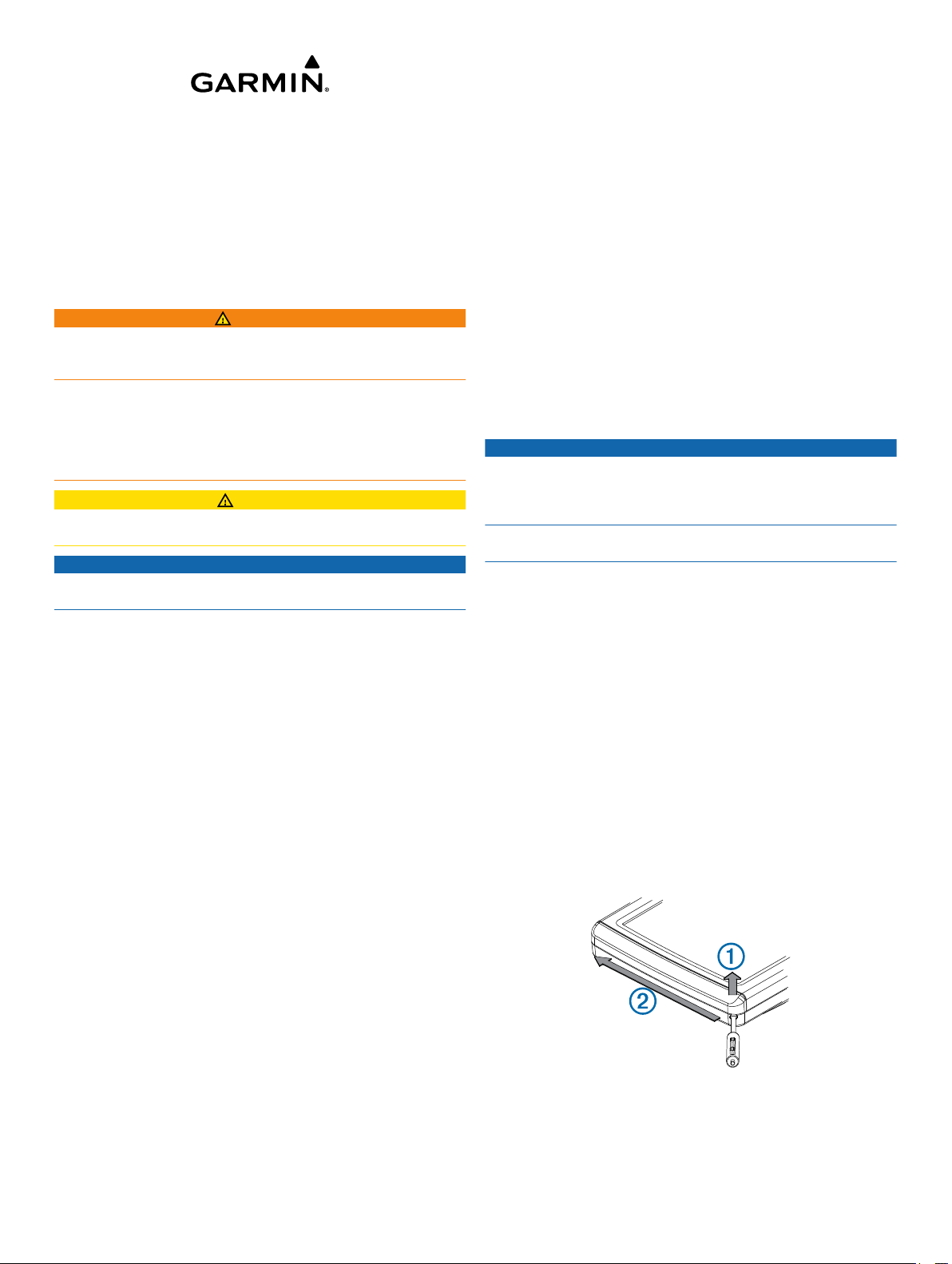

NOTE: Not all devices have trim caps.

7

Using a pry tool such as a flat piece of plastic or a

screwdriver, carefully pry up the corners of the trim caps

and slide the pry tool to the center Á to remove the trim caps.

À

Tools Needed

• Drill and drill bits

• #2 Phillips screwdriver

• Marine sealant

•3/8 in. wrench or socket

• Masking tape

• Hardware for the swivel mount (not included)

◦ Self-tapping, pan-head wood screws or pan-head bolts,

either size #8 or a diameter of 5/32 in. (4 mm)

◦ Appropriate washers and nuts (if selecting bolts)

◦ Appropriate drill bit for drilling the pilot hole

December 2014

Ensure the mounting holes on the device line up with the pilot

8

holes on the template.

If the mounting holes on the device do not line up, mark the

9

new pilot-hole locations.

Using a 3.2 mm (1/8 in.) drill bit, drill the pilot holes.

10

Remove the template from the mounting surface.

11

Printed in Taiwan 190-01834-02_0B

Page 2

If you will not have access to the back of the device after you

12

mount it, connect all necessary cables to the device before

placing it into the cutout.

NOTE: To prevent corrosion of the metal contacts, cover

unused connectors with weather caps.

Install the rubber gasket pieces on the back of the device.

13

The pieces of the rubber gasket have adhesive on the back.

Make sure you remove the protective liner before installing

them on the device.

Place the device into the cradle.

14

Securely connect each cable to a port on the cradle.

15

Place the locking bracket over the cables.

16

Place the device into the cutout.

17

Secure the device to the mounting surface using the included

18

screws.

Install the trim caps by snapping them in place around the

19

edges of the device.

Mark the cable routing hole Å.

4

Using the appropriate drill bit for the hardware, drill the three

5

pilot holes.

Using a 5/8 in. (16 mm) drill, drill a hole through the mounting

6

surface at the location you marked in step 4.

Fastening the Swivel Mount without the Cables Running through the Mount

You should complete this procedure only if you are not running

the power and transducer cables under the mounting surface

and through the swivel-mount base.

Place the base À on the mounting surface, and fasten it

1

using the appropriate screws or bolts Á.

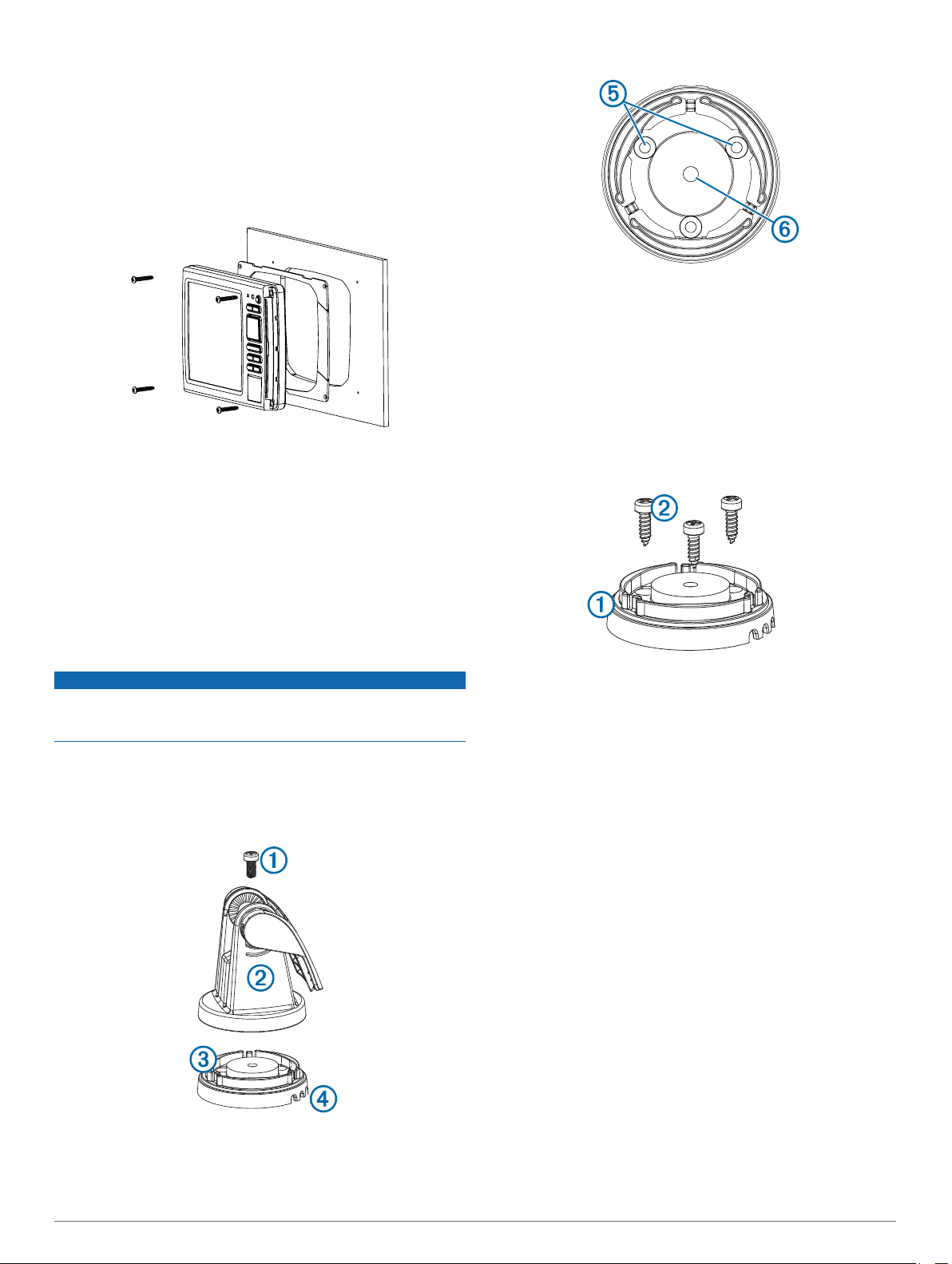

Installing the Swivel Base

Preparing to Run Cables under the Mounting Surface

NOTICE

Use pan-head screws or bolts when securing the swivel-mount

base. Screws or bolts with countersunk heads damage the

base.

Before you can prepare the swivel-mount base, you must

choose the location to install the mount and decide whether to

attach the mount using screws or bolts.

Remove the 10 mm M6x1 Phillips screw À and separate the

1

swivel mount Á from the base Â.

Orient the swivel base so the pass-through holes à face the

2

desired direction.

Using the swivel base as a template, mark the pilot hole

3

locations Ä.

Place the swivel mount on the base, and replace the 10 mm

2

M6×1 Phillips screw.

Seal the cable pass-through holes with marine sealant.

3

Fastening the Swivel Mount with the Cables Running through the Mount

You should complete this procedure only when running the

power and transducer cables under the mounting surface and

through the swivel-mount base.

Feed the cables through the 16 mm (5/8 in.) center hole you

1

drilled when preparing to run cables beneath the mounting

surface.

Place the base on the mounting surface.

2

Route the cables through the cable pass-through holes.

3

Loosely fasten the base using the appropriate screws or

4

bolts.

Place the swivel mount on the base, but do not fasten it.

5

Place the cradle or device into the swivel mount (Installing

6

the Device in the Cradle).

Pull out enough slack from the power and transducer cables

7

so the mount can fully swivel to the desired positions when

the cables are connected.

Remove the cradle and the swivel mount from the base.

8

Apply marine sealant to the 16 mm (5/8 in.) center hole and to

9

the cable pass-through holes.

Securely fasten the base with the appropriate screws or

10

bolts.

Place the swivel mount on the base, and fasten it using the

11

included 10 mm M6×1 Phillips screw.

2

Page 3

Installing the Cradle in the Mount

Pull up the locking arm À.

1

Place the cradle into the swivel mount Á.

2

Tilt the mount to the desired viewing angle.

3

Press down the locking arm.

4

Installing the Cables and Connectors

Wiring to Power

Route the power cable from the swivel mount to the boat

1

battery or fuse block.

If necessary, extend the wires using .52 mm2 (20 AWG) or

2

larger wire.

Connect the red wire to the positive terminal on the battery or

3

fuse block, and connect the black wire to the negative

terminal.

Connecting the Device to a Transducer

NOTE: The device goes into simulator mode if the connection is

not secure between the device and transducer.

Go to www.garmin.com or contact your local Garmin dealer to

determine the appropriate type of transducer for your needs.

Follow the instructions provided with your transducer to

1

correctly install it on your boat.

Route the transducer cable to the back of your device, away

2

from sources of electrical interference.

Connect the transducer cable to the appropriate port on your

3

device.

Connecting the Cables to the Cradle

The connectors on the cables are keyed to fit only in the correct

ports on the device or cradle. The connected cables are held in

place by a locking bracket.

Remove the cable locking bracket from the cradle.

1

Compare the divots À on each cable connector to the keying

2

on each port to determine which cable corresponds to each

port.

There is an audible click when the locking bracket is installed

correctly.

Installing the Device in the Cradle

If your device uses a cradle and you have connected the cables

to the cradle, you can quickly place the device in the cradle

without plugging in any cables.

Place the base of the device in the bottom of the cradle.

1

Tilt the device toward the cradle until it fastens in place.

2

There is an audible click when the device is secured in the

cradle.

Removing the Device from the Cradle

Press the release lever À on the cradle until the device is

1

released.

Tilt the device forward, and lift it out of the cradle.

2

Wiring Harness

• The wiring harness connects the device to power and NMEA

0183 devices.

• The device has one internal NMEA 0183 port that is used to

connect to NMEA 0183 compliant devices.

• If it is necessary to extend the power and ground wires, you

must use .52 mm2 (20 AWG) or larger wire.

• If it is necessary to extend the NMEA 0183 or alarm wires,

you must use .33 mm2 (22 AWG) wire.

®

Securely connect each cable to a port.

3

Place the locking bracket Á over the cables and slide the

4

bracket down to lock the cables in place.

Item Wire Function Wire Color

NMEA 0183 internal port Rx (in) Brown

À

NMEA 0183 internal port Tx (out) Blue

Á

3

Page 4

Item Wire Function Wire Color

+

-

Ground (power and NMEA 0183) Black

Â

Power Red

Ã

Connecting the Wiring Harness to Power

Route the wiring harness to the power source and to the

1

device.

Connect the red wire to the positive (+) battery terminal, and

2

connect the black wire to the negative (-) battery terminal.

NMEA 0183 Connection Considerations

• The installation instructions provided with your NMEA 0183

compatible device should contain the information you need to

identify the transmitting (Tx) and receiving (Rx) A (+) and B

(-) wires.

NMEA 0183 Connection Diagram

Item Description

À

Á

Â

Item Garmin Wire

Ê

Ë

Ì

Í

12 Vdc power source

Wiring harness

NMEA 0183-compliant device

Function

Power Red Power

Ground Black Data ground

Tx Blue Rx/A (+)

Rx Brown Tx/A (+)

Garmin Wire

Color

NMEA 0183 Device Wire

Function

Updating the Device Software

Before you can update the software, you must obtain a

software-update memory card or load the latest software onto a

memory card.

Turn on the chartplotter.

1

After the home screen appears, insert the memory card into

2

the card slot.

NOTE: In order for the software update instructions to

appear, the device must be fully booted before the card is

inserted.

Follow the on-screen instructions.

3

Wait several minutes while the software update process

4

completes.

The device returns to normal operation after the software

update process is complete.

Remove the memory card.

5

NOTE: If the memory card is removed before the device

restarts fully, the software update is not complete.

Specifications

Device Specification Measurement

echoMAP 40 Dimensions (W x H x D) 10.2 x 16.8 x 4.6 cm (4 x 6.6 x

Display size (W x H) 5.4 x 9.5 cm (2.1 x 3.7 in.)

Weight 0.4 kg (0.9 lbs.)

Power input From 10 to 18 Vdc

Max. power usage 15 W

Compass-safe distance 20 cm (8 in.)

1.8 in.)

Device Specification Measurement

echoMAP 50 Dimensions (W x H x D) 17.3 x 13.5 x 4.4 cm (6.81 x

5.35 x 1.73 in.)

Display size (W x H) 9 x 9 cm (3.54 x 3.54 in.)

Weight 0.58 kg (1.28 lbs.)

Power input From 10 to 20 Vdc

Max. power usage 7.1 W

Compass-safe distance 75 cm (29.5 in.)

All Models Temperature range From -15 to 55°C (from 5 to

131°F)

Material Polycarbonate plastic

Water rating IEC 60529 IPX7

Transmit power (RMS)** 500 W

Maximum depth*** 701 m (2300 ft) at 77 kHz

Frequencies**** • Traditional: 50,77, or

200 kHz

• DownVü: 260 or 455 kHz.

*The device withstands incidental exposure to water of up to 1 m

for up to 30 min. For more information, go to www.garmin.com

/waterrating.

**Dependent upon transducer rating and depth.

***Maximum depth, dependent upon transducer, water salinity,

bottom type, and other water conditions.

****Dependent upon echoMAP model.

NMEA 0183 Information

Type Sentence Description

Transmit GPAPB APB: Heading or track controller

(autopilot) sentence "B"

GPBOD BOD: Bearing (origin to

destination)

GPBWC BWC: Bearing and distance to

waypoint

GPGGA GGA: Global positioning system

fix data

GPGLL GLL: Geographic position

(latitude and longitude)

GPGSA GSA: GNSS DOP and active

satellites

GPGSV GSV: GNSS satellites in view

GPRMB RMB: Recommended minimum

navigation information

GPRMC RMC: Recommended minimum

specific GNSS data

GPRTE RTE: Routes

GPVTG VTG: Course over ground and

ground speed

GPWPL WPL: Waypoint location

GPXTE XTE: Cross track error

PGRME E: Estimated error

PGRMM M: Map datum

PGRMZ Z: Altitude

SDDBT DBT: Depth below transducer

SDDPT DPT: Depth

SDMTW MTW: Water temperature

SDVHW VHW: Water speed and heading

Receive DPT Depth

DBT Depth below transducer

MTW Water temperature

VHW Water speed and heading

WPL Waypoint location

4

Page 5

Type Sentence Description

DSC Digital selective calling

DSE Expanded digital selective calling

HDG Heading, deviation, and variation

HDM Heading, magnetic

MWD Wind direction and speed

MDA Meteorological composite

MWV Wind speed and angle

VDM AIS VHF data-link message

You can purchase complete information about National Marine

Electronics Association (NMEA) format and sentences from: NMEA,

Seven Riggs Avenue, Severna Park, MD 21146 USA (www.nmea.org)

information

5

Page 6

Garmin® and the Garmin logo are trademarks of Garmin Ltd. or its subsidiaries, registered in the USA and other countries. echoMAP™ is a trademark of Garmin Ltd. or its subsidiaries. These trademarks may

not be used without the express permission of Garmin.

NMEA® is a registered trademark of the National Marine Electronics Association.

© 2014 Garmin Ltd. or its subsidiaries www.garmin.com/support

Loading...

Loading...