Page 1

Rev.

Date

Description of Change

1

04/22/2014

Initial release.

Confidential

This drawing and the specifications contained herein

written permission.

Instructions for Continued Airworthiness

for the Garmin G500H Installa t ion in Eurocopter EC130

Garmin International, Inc.

1200 E. 151st Street

Olathe, Kansas 66062 USA

Dwg. Number:

190-01527-15 Rev. 1

Note: Document was RSG P/N 16E08 310 001 Re v. E

are the property of Garmin Ltd. or its subsidiaries and

may not be reproduced or used in whole or in part as

the basis for manufacture or sale of products without

Page 2

Table of Contents

CHAPTER 1 .................................................................................................................................. 4

Section 01-00-00

Introduction ......................................................................................................... 4

CHAPTER 4 .................................................................................................................................. 5

Section 04-00-00

Airworthiness Limitations .................................................................................. 5

CHAPTER 5 .................................................................................................................................. 6

Section 05-00-00

Continued Airworthiness Inspections ................................................................ 6

Section 05-20-10

Continued Airworthiness Scheduled Inspections .............................................. 9

Section 05-20-20

Continued Airworthiness Special Inspections ................................................... 17

CHAPTER 6 .................................................................................................................................. 19

Section 06-00-00

Dimensions and Access ....................................................................................... 19

CHAPTER 8 .................................................................................................................................. 27

Section 8-00-00

Weight and Balance Information ........................................................................ 27

CHAPTER 11 ................................................................................................................................ 28

Section 11-00-00

Placards and Markings ........................................................................................ 28

CHAPTER 12 ................................................................................................................................ 30

Section 12-00-00

Servicing Maintenance Practices ........................................................................ 30

Section 12-10-00

Return-to-Service Practices ................................................................................ 31

Section 12-20-00

Calibration Requirements ................................................................................... 32

CHAPTER 20 ................................................................................................................................ 33

Section 20-00-00

Standard Practices ............................................................................................... 33

Section 20-10-00

Torques Maintenance Practices .......................................................................... 34

Section 20-30-00

Painting Maintenance Practices .......................................................................... 38

Section 20-40-00

Corrosion Control Maintenance Practices .......................................................... 39

Section 20-90-00

Dye Penetrant Inspection Methods ..................................................................... 42

CHAPTER 31 ................................................................................................................................ 43

Section 31-00-00

Instruments ......................................................................................................... 43

CHAPTER 98 ................................................................................................................................ 68

Instructions for Continued Airworthiness 190-01527-15 Rev 1

for the Garmin G500H Installation in Eurocopter EC130 Page 2 of 82

Page 3

Section 98-00-00

Wiring Diagrams and Pitot-Static System Schematics ....................................... 68

Section 98-10-00

Wiring Diagrams .................................................................................................. 69

Section 98-20-00

Pitot-Static System Schematic ............................................................................. 82

Instructions for Continued Airworthiness 190-01527-15 Rev 1

for the Garmin G500H Installation in Eurocopter EC130 Page 3 of 82

Page 4

CHAPTER 1

Section 01-00-00 Introduction

These are accepted Instructions for Continued Airworthiness for modifications performed in

accordance with Eurocopter EC130 B4 Garmin G500H Flight Display System Installation STC. All

references to the G500H in this document will refer to the Garmin G500H Flight Display System

Installation and other related components specified in these Instructions for Continued

Airworthiness (ICA). A STC permission letter and Instructions for Continued Airworthiness (ICA)

should be supplied to the owner/operator of the STC at the time of completion. Subsequent

accepted changes to the ICA will be distributed to owners and operators of the STC.

This Instructions for Continued Airworthiness is intended to supplement the Model EC130 B4

rotorcraft maintenance manuals provided by Eurocopter. The information, procedures,

requirements, and limitations contained in this Instructions for Continued Airworthiness for this

type design change supersedes the information, procedures, requirements, and limitations

contained in the rotorcraft’s maintenance manual when the type design change is installed on

the Type Certificate Holder’s rotorcraft.

01-00-00

Instructions for Continued Airworthiness 190-01527-15 Rev 1

for the Garmin G500H Installation in Eurocopter EC130 Page 4 of 82

Page 5

CHAPTER 4

Section 04-00-00 Airworthiness Limitations

There are no additional Airworthiness Limitations as defined in 14 CFR Part 27, Appendix A.

A27.4 that result from this modification. The Airworthiness Limitations section is FAA approved

and specifies inspections and other maintenance required under 14 CFR §§ 43.16 and 91.403

of the Federal Aviation Regulations unless an alternative program has been FAA approved.

04-00-00

Instructions for Continued Airworthiness 190-01527-15 Rev 1

for the Garmin G500H Installation in Eurocopter EC130 Page 5 of 82

Page 6

CHAPTER 5

Section 05-00-00 Continued Airworthiness Inspections

1. General

This chapter contains time limit intervals for the Component Overhaul Schedule and Scheduled

Inspections for the G500H Installation. This chapter is to be added to the approved scheduled

inspection for the rotorcraft.

2. Component Overhaul Schedule

The system does not require overhaul at a specific time period. Power on self-test and

continuous BIT will monitor the health of the G500H system. If any LRU indicates an internal

failure, the unit may be removed and replaced.

3. Scheduled Inspections Overview

The G500H Installation requires a 90 Day Inspection that must be performed 90 days after

installation and then afterwards within 90 days of the last G500H Installation 90 day inspection.

The 90 Day Inspection requirements are specified in Table 5-01.

The G500H Installation requires an Annual Inspection that must be performed within 1 year (12

months) of initial installation and then afterwards within 1 year (12 months) of the last G500H

Installation annual inspection. The annual inspection requirements are specified in Table 5-02.

The G500H Installation requires a 5 Year Inspection that must be performed within 60 months

of initial installation and then afterwards within 60 months of the last G500H Installation

inspection. The 5 Year Inspection requirements are specified in Table 5-03.

The G500H Installation requires a 10 Year/2000 Flight Hours Inspection that must be performed

within 120 months or 2000 flight hours, whichever occurs first, of initial installation and then

afterwards within 120 months or 2000 flight hours, whichever occurs first, of the last G500H

Installation 10 year/2000 flight inspections. The 10 Year/2000 Flight Hour Inspection

requirements are specified in Table 5-04.

4. Special Inspection Practices

Conditions may arise from incidents or accidents that may warrant additional inspection

requirements. A Special Inspection is required if the aircraft is involved in a hard landing or is

subjected to total immersion in water. If either of these conditions occurs, the G500H

Installation must be inspected using the same procedures called out in the Annual Inspection

Procedures in Table 5-02.

05-00-00

Instructions for Continued Airworthiness 190-01527-15 Rev 1

for the Garmin G500H Installation in Eurocopter EC130 Page 6 of 82

Page 7

The G500H Installation has a Post-Lightning Strike Inspection that must be performed in the

FOV-

Field of View

ICA-

Instructions for Continued Airworthiness

PFD-

Primary Flight Display

MFD-

Multifunction Display

VOM-

Volt Ohm Meter

GDC-

Garmin Data Computer

GRS-

Garmin Reference System

GMU-

Garmin Magnetometer Unit

GDU-

Garmin Display Unit

event of a suspected or actual lightning strike to the aircraft. The Post-Lightning Strike

Inspection requirements are specified in Table 5-05.

5. Definitions and Acronyms

The following is short descriptions of words and terms used in the procedures for the required

scheduled inspections.

• Examine – Look carefully to find the condition of the component. Find how that condition

is related to a specific standard.

• Condition – The state of an item or component compared to a known standard.

• Standard – A specified rule or measure that is used to find the condition of a component.

• Damage – Physical deterioration of a component.

• Inspection – A procedure that includes checking, inspecting, and examining a system or

component.

• Scheduled Inspection – An inspection procedure that must occur at a specified calendar

interval or at specified operational time intervals. Scheduled Inspections are required to

help ensure the rotorcraft stays airworthy.

• Maintenance – The servicing and / or repair of a rotorcraft, a system, or a component that

keeps it serviceable.

• Security – Term used for inspection of hardware and components to make sure they are

properly attached and tightened.

Acronyms

Instructions for Continued Airworthiness 190-01527-15 Rev 1

for the Garmin G500H Installation in Eurocopter EC130 Page 7 of 82

05-00-00

Page 8

OAT-

Outside Air Temperature

GTP-

Garmin Temperature Probe

ADC-

Air Data Computer

STC-

Supplemental Type Certificate

AHRS-

Attitude Heading Reference System

05-00-00

Instructions for Continued Airworthiness 190-01527-15 Rev 1

for the Garmin G500H Installation in Eurocopter EC130 Page 8 of 82

Page 9

Section 05-20-10 Continued Airworthiness Scheduled Inspections

1. General

This section contains requirements for scheduled inspections. Also included is a list of special

tools required to perform the scheduled inspections. If any part of the installation appears to

be functioning improperly, consult the troubleshooting guide. If a major component is

damaged or continues to malfunction, the component in question should be returned to the

manufacturer for replacement.

2. Scheduled Inspection Program

The G500H Installation requires scheduled inspections in order to maintain continued

airworthiness. Every effort should be made to perform the inspections with the aircraft placed

in a clean well lit environment. There are four different scheduled inspections required for the

G500H Installation.

a) 90 Day Inspection

The 90 day inspection is required to be performed every 90 day period of calendar elapsed

time, regardless of hours of operation. Inspection Table 5-01 the requirements of the 90 day

inspection.

b) 1 Year (Annual) Inspection

The 1 year (annual) inspection is required to be performed every 1 year period of calendar

elapsed time, regardless of hours of operation. Inspection Table 5-02 the requirements of the

1 year (annual) inspection.

c) 5 Year Inspection

The 5 year inspection is required to be performed every 5 year period of calendar elapsed

time, regardless of hours of operation. Inspection Table 5-03 the requirements of the 5 year

inspection

d) 10 Year / 2000 Flight Hours

The 10 year /2000 Flight Hour inspection is required to be performed at a 10 year period of

calendar elapsed time, or at 2000 flight hours of operation, whichever occurs first. Inspection

Table 5-04 specifies the requirements of the 10 year/2000 flight hour inspection.

3. Tools and Special Tools for Scheduled Inspection

Although not necessarily considered special tools, the adjustable ball swivel mirror and bright

flashlight and / or drop light are standard requirements for doing inspections. These items

should be used freely and frequently to enhance inspection quality and help ensure

05-20-10

Instructions for Continued Airworthiness 190-01527-15 Rev 1

for the Garmin G500H Installation in Eurocopter EC130 Page 9 of 82

Page 10

discrepancies are not missed. It is important to have adequate lighting for all phases of the

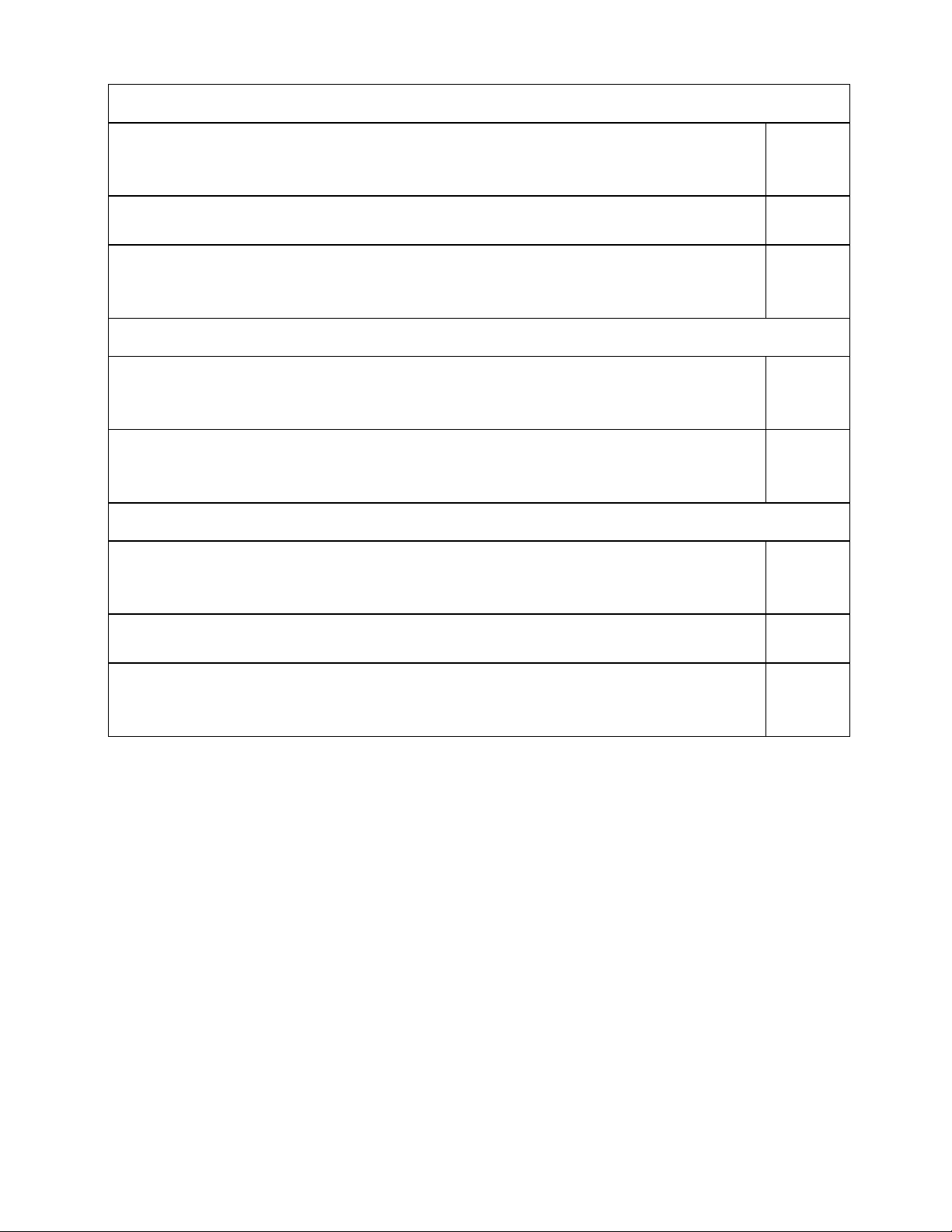

Registration No.

Serial No.

Helicopter Total Hours

90 Day Scheduled Inspection

90 Day Pre-inspection

Requirement

Initial

1. Review Airworthiness Directives.

90 Day Inspection

Requirement

Initial

GDC 74H ADC

1. Access GDC 74H (reference Section 6-00-00- Dimensions and Access). Drain the pitot-

2. Re-install the plug, nut and safety wire.

3. Reference Section 12-10-00 Return-to-Service Practices for the GDC 74H

inspection

The special tools necessary for the G500H inspection are listed as follows:

a) Milliohm meter (for electrical bonding testing).

• The 90 Day Inspection shall be accomplished at least at an interval of once every 90 days of

elapsed calendar time.

• Initial each item after accomplishing the inspection.

• Record all findings and attach a copy of findings to this inspection form.

• After correction of all findings, make maintenance record entry.

.

Table 5-01 -90 Day Inspection

static system by removing the safety wire, nut and plug.

05-20-10

Instructions for Continued Airworthiness 190-01527-15 Rev 1

for the Garmin G500H Installation in Eurocopter EC130 Page 10 of 82

Page 11

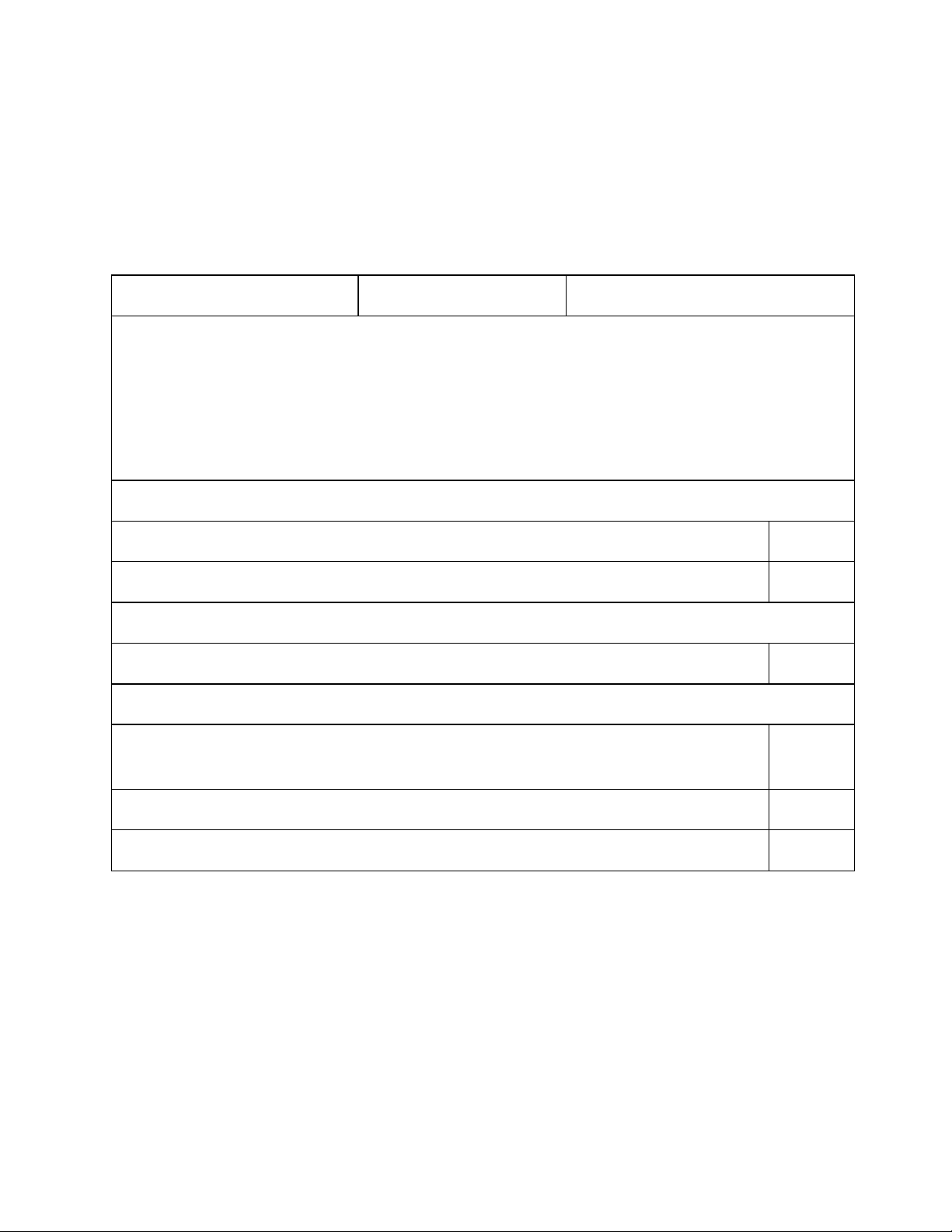

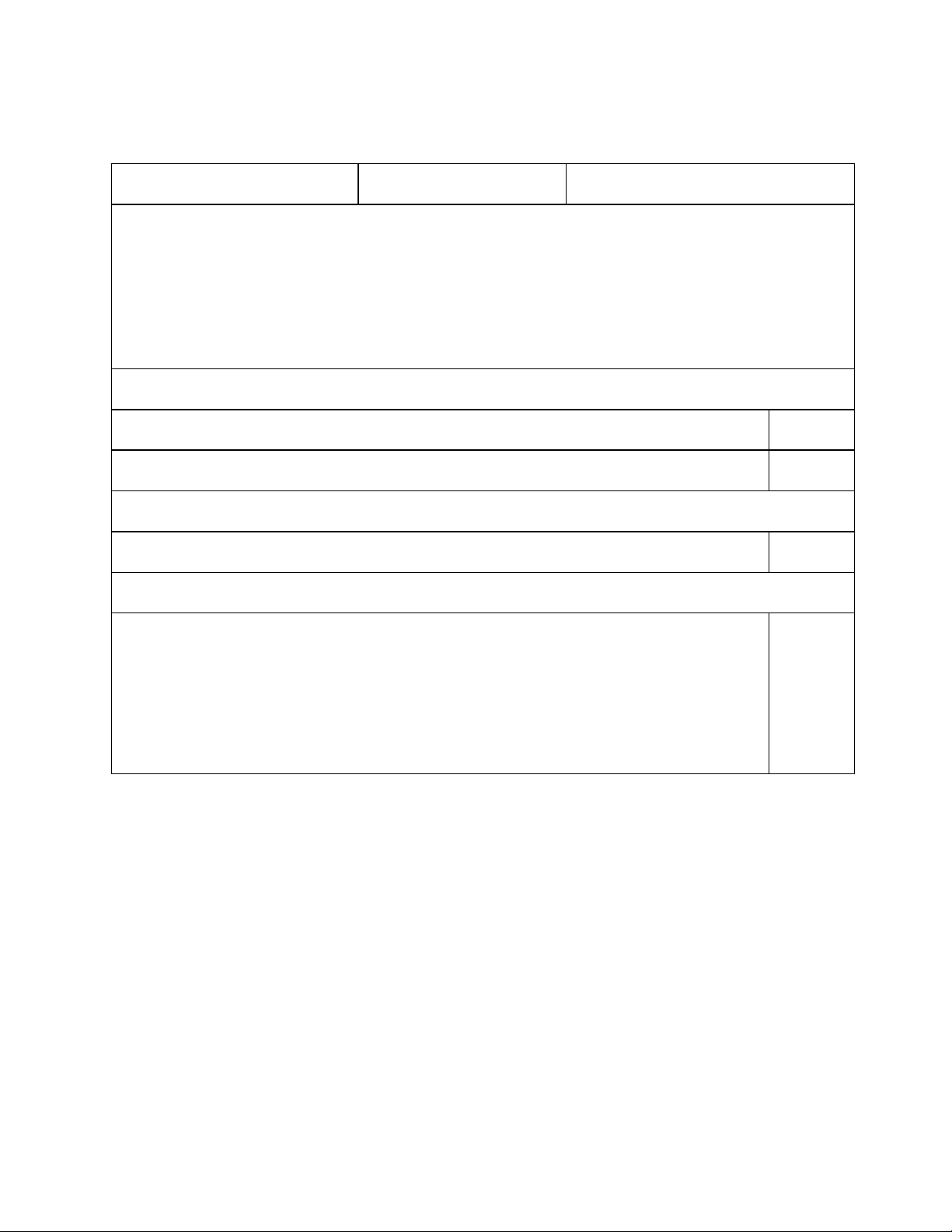

Table 5-02 -1 year (Annual) Inspection

Registration No.

Serial No.

Helicopter Total Hours

1 Year (Annual) Scheduled Inspection

1 year (Annual) Pre-inspection

Requirement

Initial

1. Review Airworthiness Directives. 1 year (Annual) Inspection

Requirement

Initial

1. Locate GDU 620 (reference Section 6-00-00 Access and Dimension). Inspect all knobs

2. Inspect instrument panel for damage, corrosion, and security. If damaged, replace

3. Inspect unit for security of attachment. Replace the damaged or corroded hardware.

4. Conduct visual inspection of wires, backshells, and connectors looking for signs of wear,

5. Inspect harness connections in back of unit. Secure any loose connections and support

1. Access GRS 77H (reference Section 6-00-00- Dimensions and Access). Inspect AHRS and

• The 1 Year inspection shall be accomplished at least at an interval of once every year of elapsed

calendar time.

• Initial each item after accomplishing the inspection.

• Record all findings and attach a copy of findings to this inspection form.

• After correction of all findings, make maintenance record entry.

GDU 620

and buttons for legibility.

damaged or cracked Instrument panel. Treat and repair corrosion as required in Section

20-40-00 Corrosion Control Maintenance Practices. Tighten any loose hardware to values

listed in Section 20-10-00.

Replace any missing hardware. Torque all screws in accordance with Section 20-10-00

Torques Maintenance Practice.

deterioration or damage. Replace as required.

unsecure wiring harness with additional clamping and / or tie rap supports if required.

GRS 77H AHRS

mount for physical damage cracks, and corrosion. Treat and repair corrosion as required in

Section 20-40-00 Corrosion Control Maintenance Practices.

05-20-10

Instructions for Continued Airworthiness 190-01527-15 Rev 1

for the Garmin G500H Installation in Eurocopter EC130 Page 11 of 82

Page 12

2. Conduct visual inspection of wires, backshells, and connectors looking for signs of wear,

deterioration or damage. Replace as required.

3. Inspect harness connections in back of unit. Secure any loose connections and support

4. Inspect unit for security of attachment. Replace the damaged or corroded hardware.

1. Access GMU 44 (reference Section 6-00-00- Dimensions and Access). Inspect GMU 44

2. Conduct visual inspection of wires, backshells, and connectors looking for signs of wear,

3. Inspect hardware. Replace the damaged or corroded hardware. Replace any missing

4. Inspect harness connections in back of unit. Secure any loose connections and support

1. Access Shelf Installation (reference Section 6-00-00- Dimensions and Access). Inspect for

2. Inspect hardware. Replace the damaged or corroded hardware. Replace any missing

1. Access GDC 74H (reference Section 6-00-00- Dimensions and Access). Inspect GDC 74H

2. Inspect unit for security of attachment. Replace the damaged or corroded hardware.

3. Conduct visual inspection of wires, backshells, and connectors looking for signs of wear,

deterioration or damage. Replace as required.

4. Inspect harness connections in back of unit. Secure any loose connections and support

5. Inspect Pitot-Static System for damage. Replace parts as needed. Complete the 90 Day

unsecure wiring harness with additional clamping and / or tie rap supports if required.

Replace any missing hardware. Torque all screws in accordance with Section 20-10-00

Torques Maintenance Practice.

GMU 44 Magnetometer Installation

and mount for physical damage cracks, and corrosion. Treat and repair corrosion as

required in Section 20-40-00 Corrosion Control Maintenance Practices.

deterioration or damage. Replace as required.

hardware. Torque all screws in accordance with Section 20-10-00 Torques Maintenance

Practice.

unsecure wiring harness with additional clamping and / or tie rap supports if required.

Shelf Installation

physical damage cracks, and corrosion. Treat and repair corrosion as required in Section 2040-00 Corrosion Control Maintenance Practices

hardware. Torque all screws in accordance with Section 20-10-00 Torques Maintenance

Practice.

GDC 74H ADC Installation

and mount for physical damage cracks, and corrosion. Treat and repair corrosion as

required in Section 20-40-00 Corrosion Control Maintenance Practices.

Replace any missing hardware. Torque all screws in accordance with Section 20-10-00

Torques Maintenance Practice.

unsecure wiring harness with additional clamping and / or tie rap supports if required.

Inspection found in Table 5-01.

05-20-10

Instructions for Continued Airworthiness 190-01527-15 Rev 1

for the Garmin G500H Installation in Eurocopter EC130 Page 12 of 82

Page 13

GTP 59 OAT Probe Installation

1. Access GTP 59 OAT Probe (reference Section 6-00-00- Dimensions and Access). Inspect

2. Inspect harness connections in back of unit. Secure any loose connections and support

3. Inspect unit for security of attachment. Replace the damaged or corroded hardware.

1. Access Terminal Block Installation (reference Section 6-00-00- Dimensions and Access).

2. Inspect unit for security of attachment. Replace the damaged or corroded hardware.

1. Access Cooling Fan Installation (reference Section 6-00-00 Dimensions and Access).

2. Inspect cooling fan hoses for physical damage and security. Repair or replace any

3. Inspect unit for security of attachment. Replace the damaged or corroded hardware.

GTP 59 OAT and mount for physical damage cracks, and corrosion. Treat and repair

corrosion as required in Section 20-40-00 Corrosion Control Maintenance Practices.

unsecure wiring harness with additional clamping and / or tie rap supports if required.

Replace any missing hardware. Torque all screws in accordance with Section 20-10-00

Torques Maintenance Practice.

Terminal Block Installation

Inspect installation for physical damage cracks, and corrosion. Treat and repair corrosion as

required in Section 20-40-00 Corrosion Control Maintenance Practices.

Replace any missing hardware. Torque all screws in accordance with Section 20-10-00

Torques Maintenance Practice.

Cooling Fan Installation (If option is installed)

Inspect installation for physical damage, cracks, and corrosion. Treat and repair corrosion as

required in Section 20-40-00 Corrosion Control Maintenance Practices.

damaged hoses. Replace any damaged or missing Tywraps

Replace any missing hardware. Torque all screws in accordance with Section 20-10-00

Torques Maintenance Practices.

05-20-10

Instructions for Continued Airworthiness 190-01527-15 Rev 1

for the Garmin G500H Installation in Eurocopter EC130 Page 13 of 82

Page 14

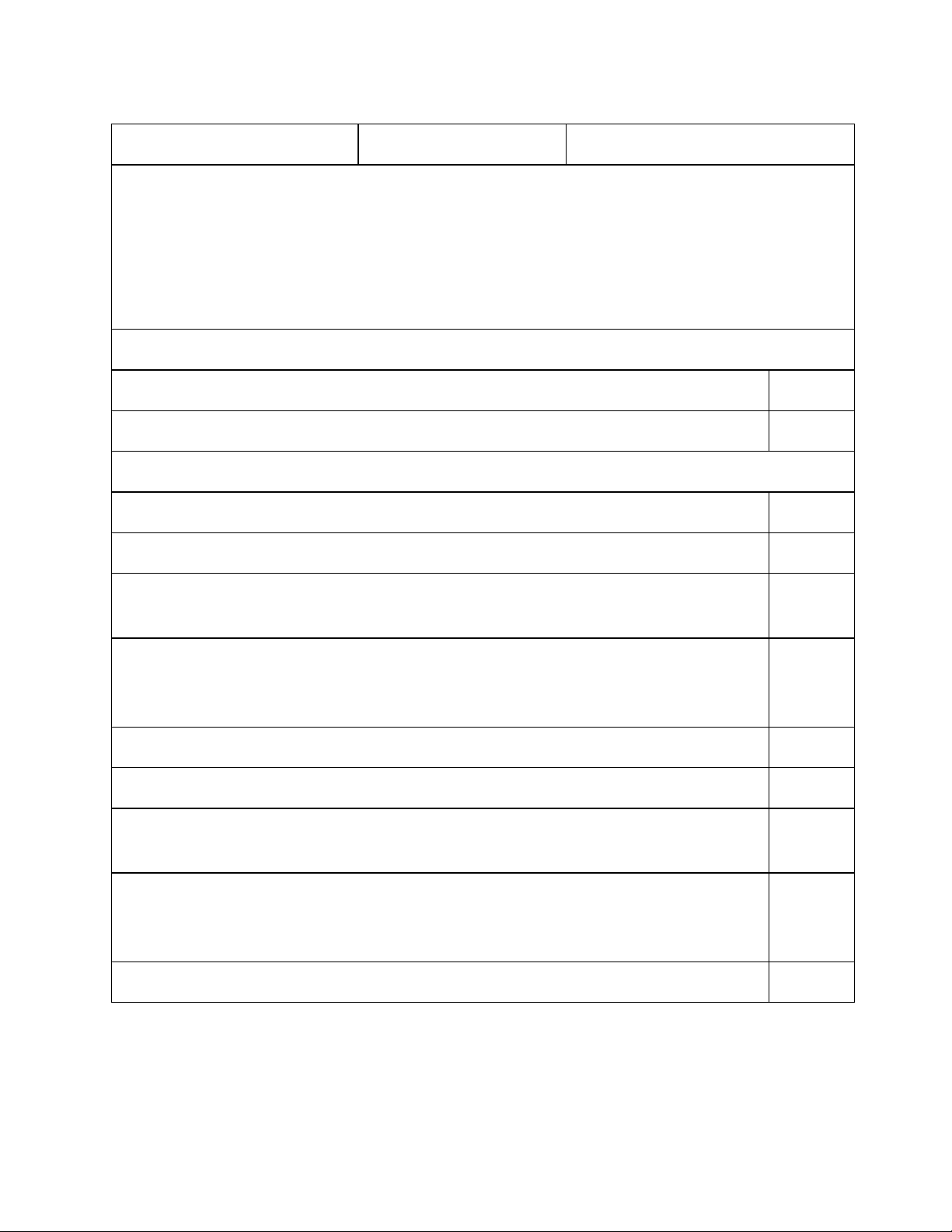

Registration No.

Serial No.

Helicopter Total Hours

5 Year Scheduled Inspection

5 Year Pre-inspection

Requirement

Initial

1. Review Airworthiness Directives.

5 Year Inspection

Requirement

Initial

GRS 77H AHRS

1. The GRS 77 utilizes an Earth magnetic field model which is updated once every five years

Table 5-03 -5 Year Inspection

• The 5 Year Inspection shall be accomplished at least at an interval of once every 5 years of

elapsed calendar time.

• Initial each item after accomplishing the inspection.

• Record all findings and attach a copy of findings to this inspection form.

• After correction of all findings, make maintenance record entry.

as part of the Aviation Database maintained by the owner/operator. If the magnetic model

is not current, the unit will issue an alert upon startup indicating the model has expired. The

model can be updated by inserting an aviation database card with an updated IGRF model

and powering on the system. A prompt will direct the user to press ENT to update the

model.

05-20-10

Instructions for Continued Airworthiness 190-01527-15 Rev 1

for the Garmin G500H Installation in Eurocopter EC130 Page 14 of 82

Page 15

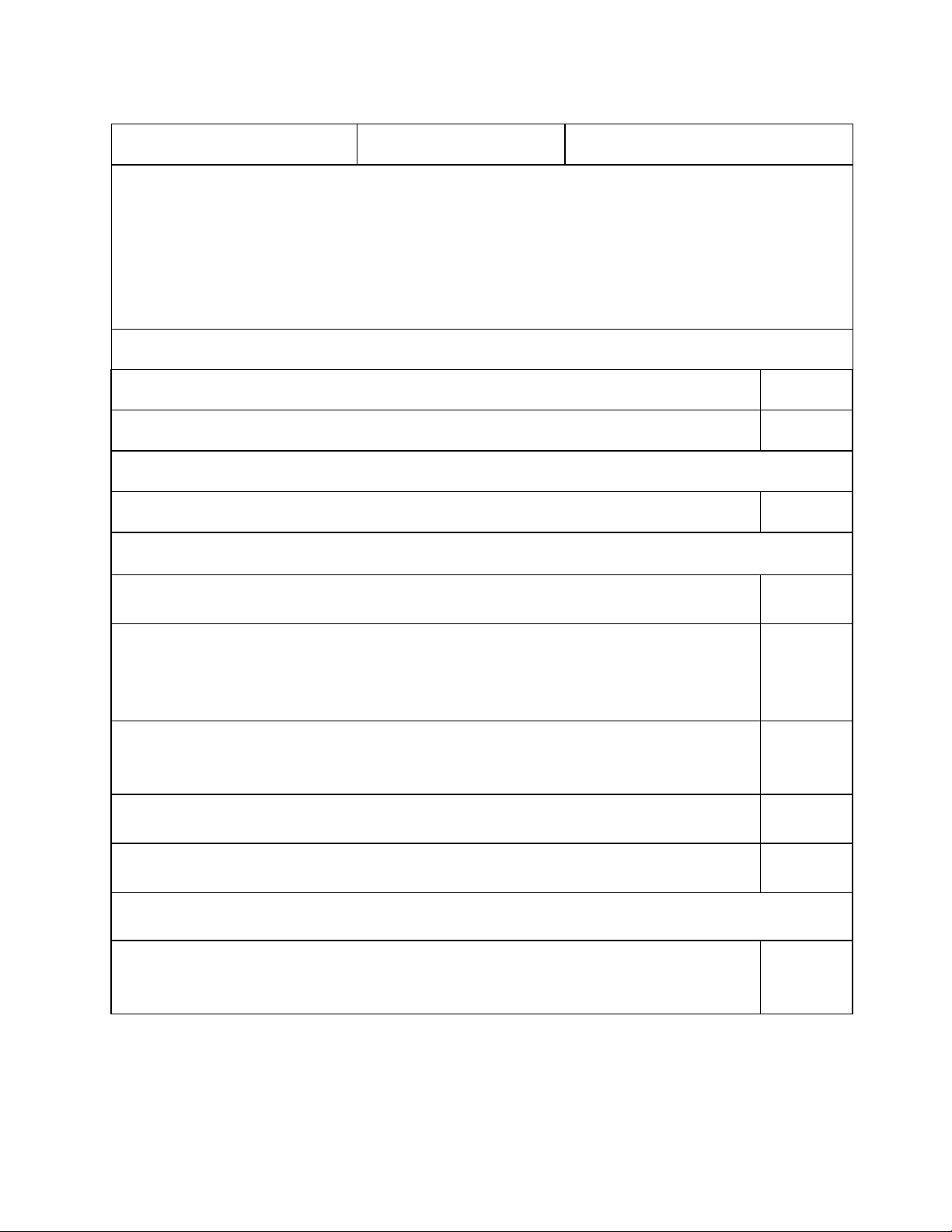

Table 5-04 -10 Year/2000 Flight Hour Inspection

Registration No.

Serial No.

Helicopter Total Hours

10 Year/ 2000 Flight Hour Scheduled Inspection

10 Year/2000 Flight Hour Pre-inspection

Requirement

Initial

1. Review Airworthiness Directives. 10 Year/2000 Flight Hour Inspection

Requirement

Initial

GRS 77H AHRS

1. Access GRS 77H, (Reference Section 6-00-00 Dimensions and Access) and disconnect all

2. Measure the resistance between the GRS 77H and a nearby exposed portion of aircraft

3. Reconnect all disconnected harness connectors and ensure they are secure.

GDU 620

4. Access GDU 620, (Reference Section 6-00-00 Dimensions and Access) and disconnect all

5. Measure the resistance between the GDU 620 and a nearby exposed portion of aircraft

6. Reconnect all disconnected harness connectors and ensure they are secure.

• The 10 Year/ 2000 Flight Hour Inspection shall be accomplished at least at an interval of once

every 10 years of elapsed calendar time or 2000 Flight Hours, whichever occurs first.

• Initial each item after accomplishing the inspection.

• Record all findings and attach a copy of findings to this inspection form.

• After correction of all findings, make maintenance record entry.

harness connectors.

metallic structure. Verify that the resistance is less than or equal to 20 milliohms. If greater

must be restored to the value specified in the G500H STC Installation Manual.

harness connectors.

metallic structure. Verify that the resistance is less than or equal to 40 milliohms. If greater

must be restored to the value specified in the G500H STC Installation Manual.

05-20-10

Instructions for Continued Airworthiness 190-01527-15 Rev 1

for the Garmin G500H Installation in Eurocopter EC130 Page 15 of 82

Page 16

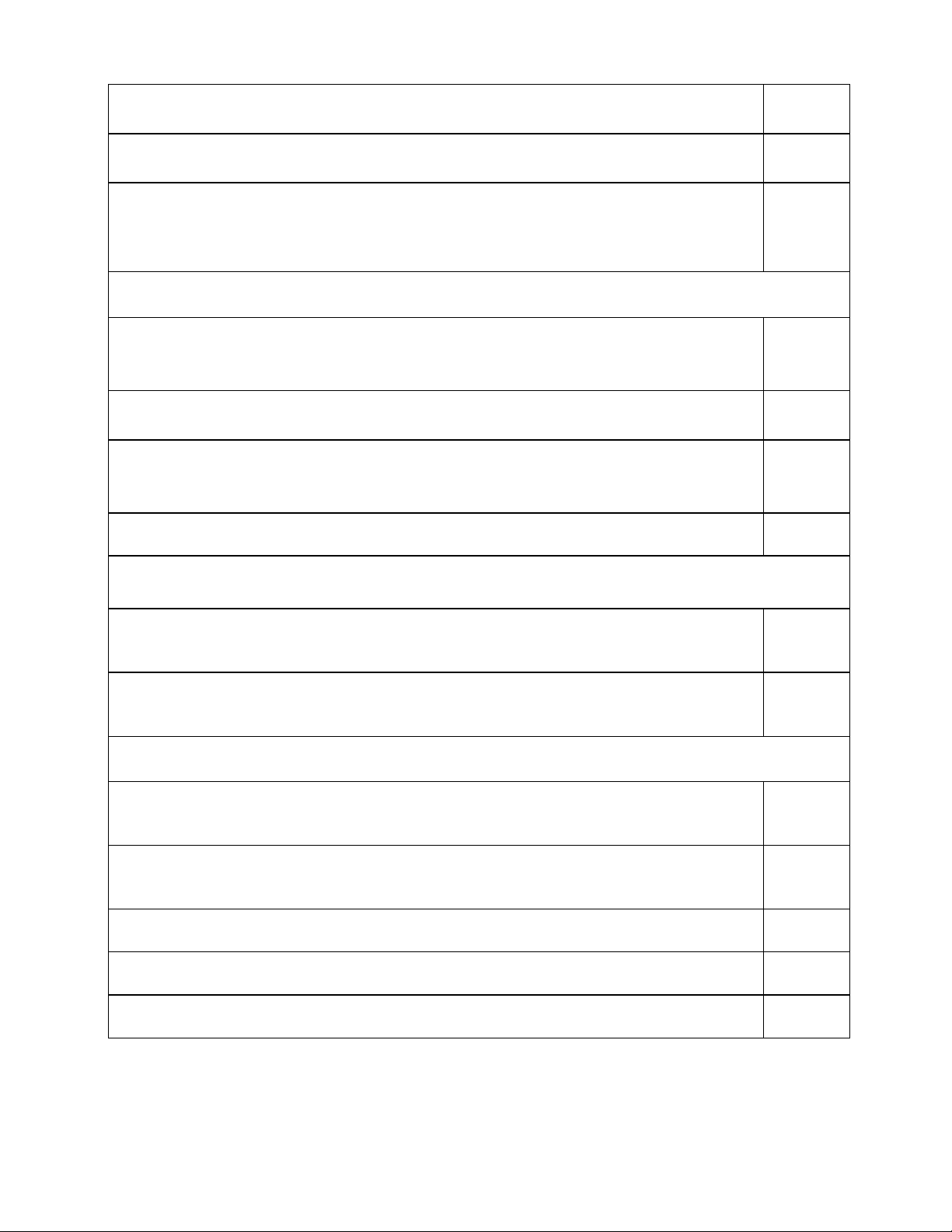

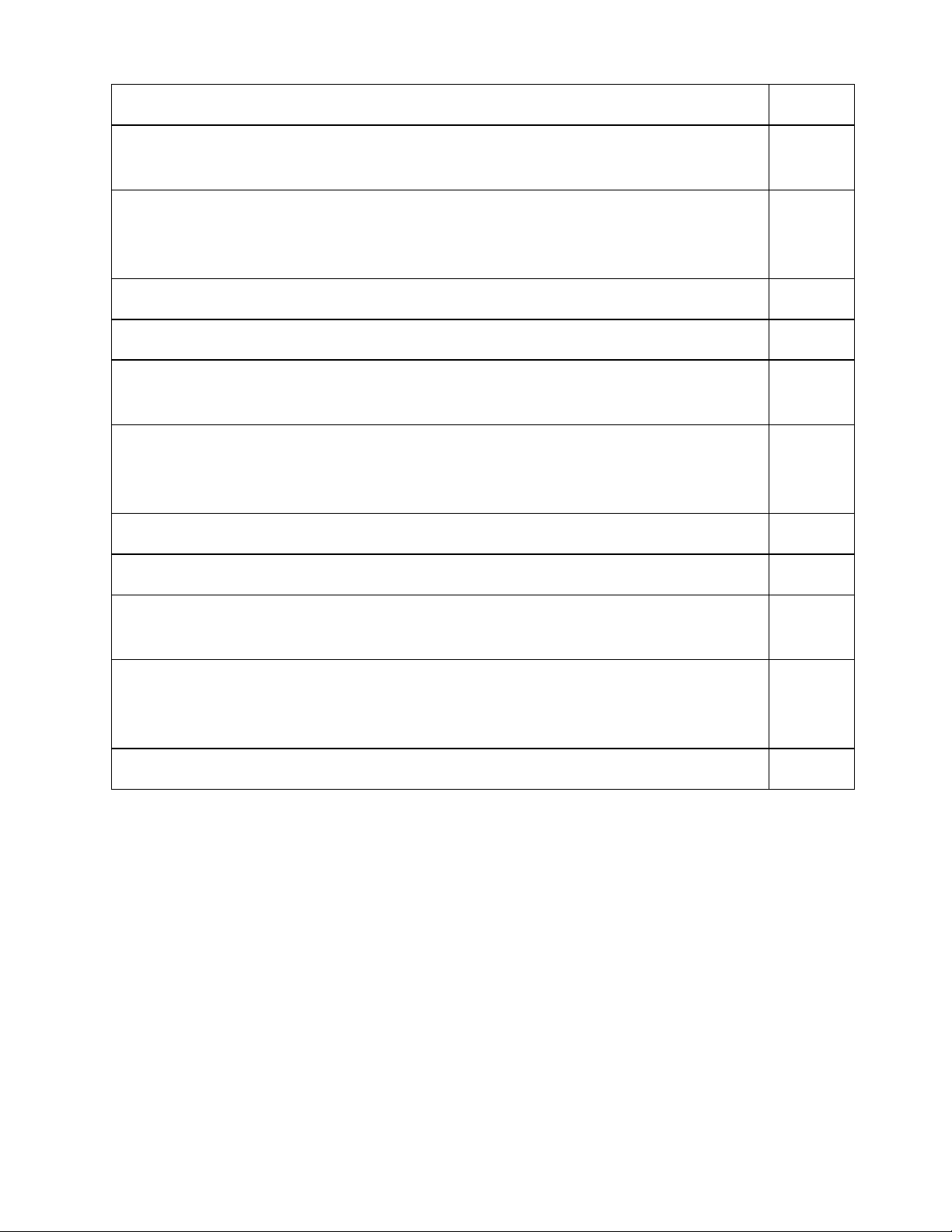

GDC 74H ADC

7. Access GDC 74H, (Reference Section 6-00-00 Dimensions and Access) and disconnect all

harness connectors.

8. Measure the resistance between the GDC 74H and a nearby exposed portion of aircraft

9. Reconnect all disconnected harness connectors and ensure they are secure.

GMU 44

10. Access GMU 44, (Reference Section 6-00-00 Dimensions and Access) and disconnect all

11. Measure the resistance between the GMU 44 and a nearby exposed portion of aircraft

12. Reconnect all disconnected harness connectors and ensure they are secure.

GTP 59

13. Access GTP 59, (Reference Section 6-00-00 Dimensions and Access) and disconnect all

14. Measure the resistance between the GTP 59 and a nearby exposed portion of aircraft

15. Reconnect all disconnected harness connectors and ensure they are secure.

metallic structure. Verify that the resistance is less than or equal to 20 milliohms. If greater

must be restored to the value specified in the G500H STC Installation Manual.

harness connectors.

metallic structure. Verify that the resistance is less than or equal to 20 milliohms. If greater

must be restored to the value specified in the G500H STC Installation Manual.

harness connectors.

metallic structure. Verify that the resistance is less than or equal to 5 milliohms. If greater

must be restored to the value specified in the G500H STC Installation Manual.

4. Post Inspection Maintenance Practices

After completion of the 1 Year (Annual) Inspection, 5 Year Inspection and 10 Year/2000 Flight

Hour Inspection and all discrepancies found have been corrected, the Return-to-Service

Practices (Reference Section 12-00-00 Return-to-Service Practices) should be accomplished in

preparation for returning the rotorcraft to service

05-20-10

Instructions for Continued Airworthiness 190-01527-15 Rev 1

for the Garmin G500H Installation in Eurocopter EC130 Page 16 of 82

Page 17

Section 05-20-20 Continued Airworthiness Special Inspections

1. General

This section contains requirements for special inspections. Also included is a list of special tools

required to perform the scheduled inspections. If any part of the installation appears to be

functioning improperly, consult the troubleshooting guide. If a major component is damaged or

continues to malfunction, the component in question should be returned to the manufacturer

for replacement.

2. Special Inspection Program

Conditions may arise from incidents or accidents that may warrant additional inspection

requirements. A Special Inspection is required if the aircraft is involved in a hard landing or is

subjected to total immersion in water. If either of these conditions occurs, the G500H

Installation must be inspected using the same procedures called out in the Annual Inspection

Procedures in Table 5-02.

The G500H Installation has a Post-Lightning Strike Inspection that must be performed in the

event of a suspected or actual lightning strike to the aircraft. The Post-Lightning Strike

Inspection requirements are specified in Table 5-05.

3. Tools and Special Tools for Special Inspections

Although not necessarily considered special tools, the adjustable ball swivel mirror and bright

flashlight and / or drop light are standard requirements for doing inspections. These items

should be used freely and frequently to enhance inspection quality and help ensure

discrepancies are not missed. It is important to have adequate lighting for all phases of the

inspection

The special tools necessary for the G500H inspection are listed as follows:

a) Milliohm meter (for electrical bonding testing).

.

05-20-20

Instructions for Continued Airworthiness 190-01527-15 Rev 1

for the Garmin G500H Installation in Eurocopter EC130 Page 17 of 82

Page 18

Table 5-05 -Post-Lightning Strike Inspection

Registration No.

Serial No.

Helicopter Total Hours

Post-Lightning Strike Inspection

Post-Lightning Strike Pre-inspection

Requirement

Initial

1. Review Airworthiness Directives. Post-Lightning Strike Inspection

Requirement

Initial

GTP 59 OAT Probe Installation

1. Access the GTP 59 OAT Probe Installation. Reference Section 6-00-00 Dimensions and

2. Inspect the probe and the doubler (P/N: 115-01812-00) for signs of structural damage. If

Post-Lightning Strike Post- Inspection

Requirement

Initial

1. Verify that the OAT is displayed on the GDU 620 PFD normally.

• The Post-Lightning Strike Inspection shall be accomplished in the event of a suspected or actual

lightning strike to the aircraft.

• Initial each item after accomplishing the inspection.

• Record all findings and attach a copy of findings to this inspection form.

• After correction of all findings, make maintenance record entry.

Access.

there are visible signs of damage, replace the parts as needed.

05-20-20

Instructions for Continued Airworthiness 190-01527-15 Rev 1

for the Garmin G500H Installation in Eurocopter EC130 Page 18 of 82

Page 19

CHAPTER 6

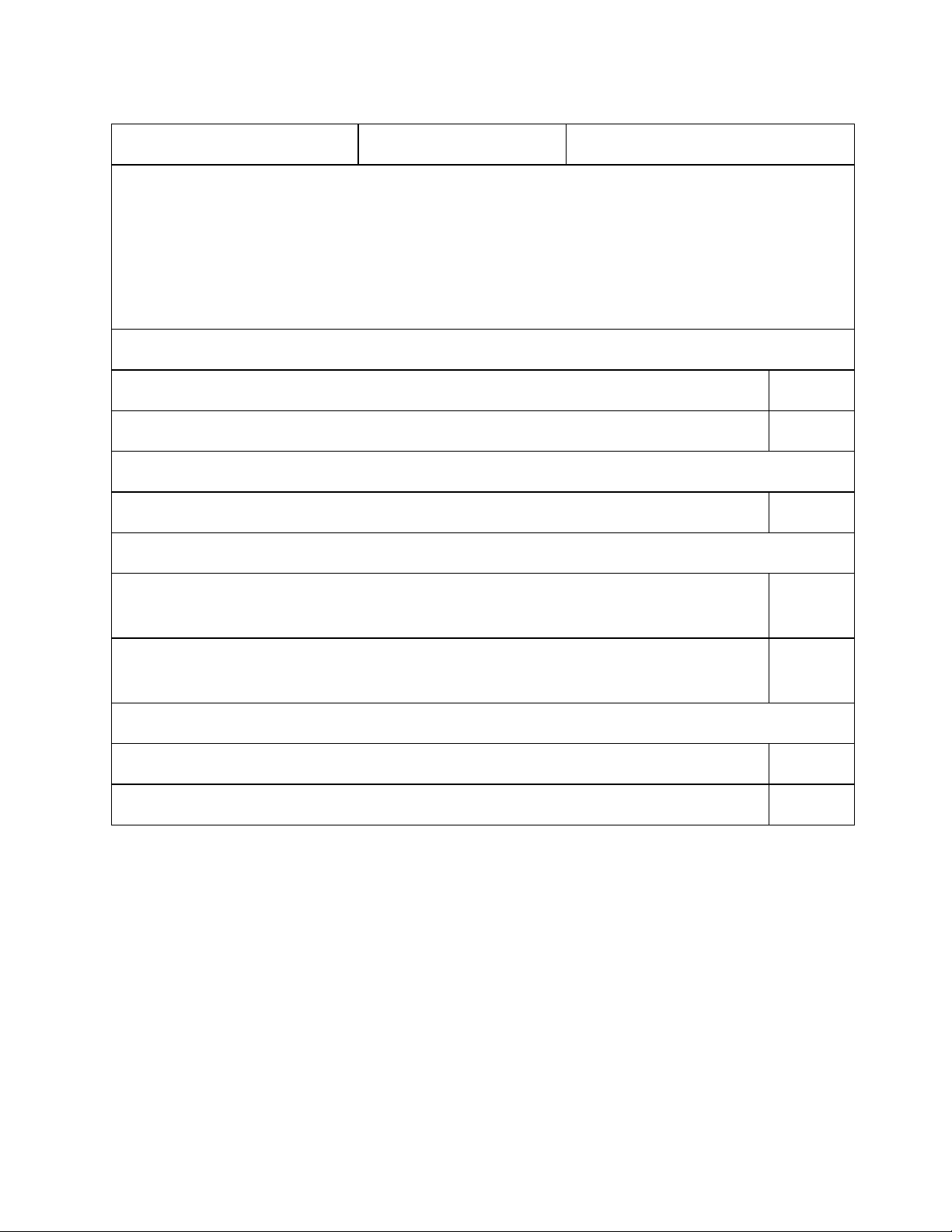

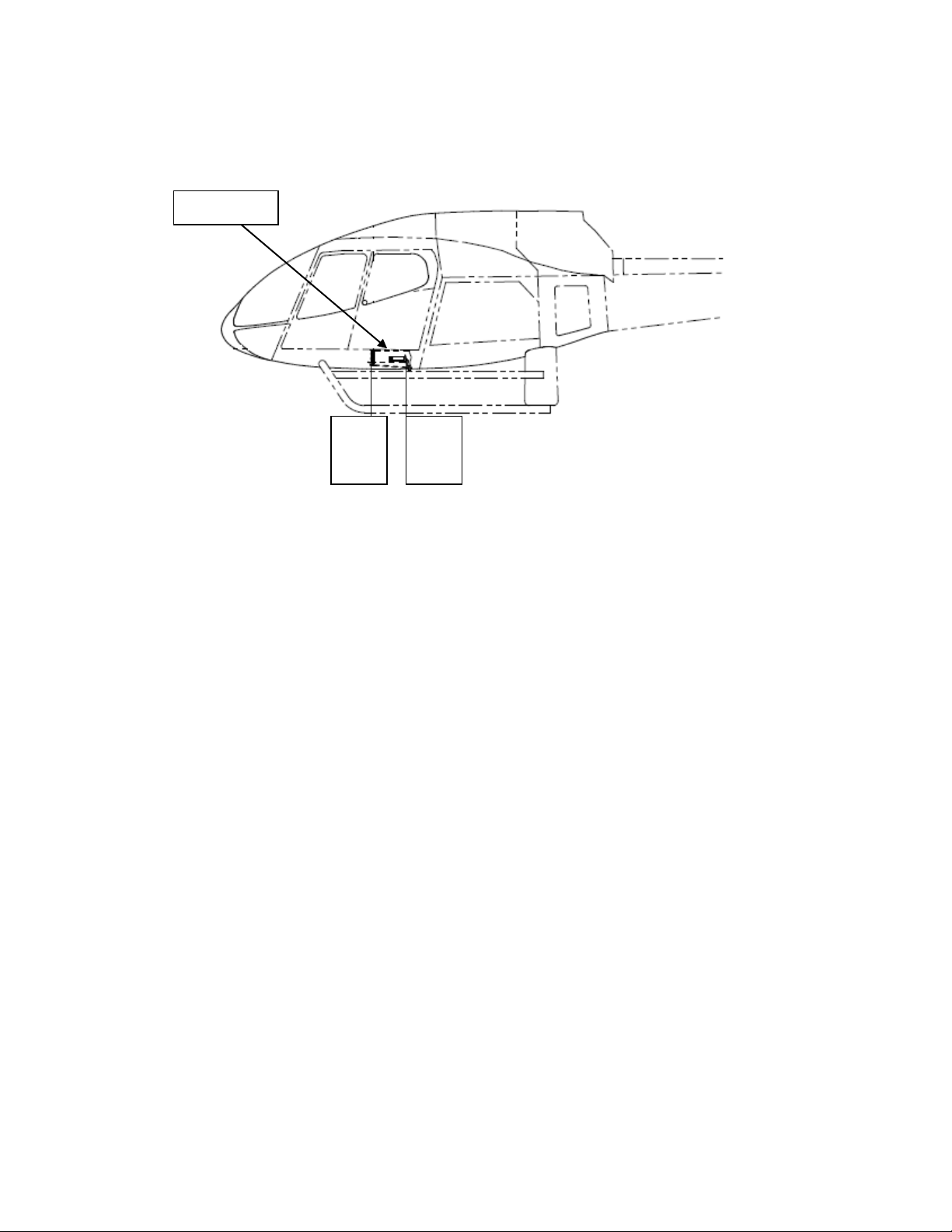

Figure 6-01

GMU 44

TB

REF

TB

REF

Section 06-00-00 Dimensions and Access

1. Access Methods

For removal and installation of specific components, reference Section 31-00-00 Instruments,

Removal and Replacement

a) GMU 44, Magnetometer

Magnetometer is located in the tail boom between TB 868 and 1578. (Figure 6-01)

868

1578

Access Methods

i. Removal

1. Un-latch and open the battery door on the left side of the aircraft.

2. If a battery is installed it may be necessary to remove the battery to gain access to

the magnetometer. Consult the manufacturers Installation and removal

instructions for proper removal of unit.

ii. Installation

1. Re-install battery if removed to gain access to the magnetometer. Consult the

manufacturers Installation and Removal instructions for proper installation of unit.

2. Close the battery access door and latch it.

Caution: Use of power tools during removal or installation of

panels and attaching hardware may damage nut plates or

deform holes in composite doors, covers, panels, and fairings.

06-00-00

Instructions for Continued Airworthiness 190-01527-15 Rev 1

for the Garmin G500H Installation in Eurocopter EC130 Page 19 of 82

Page 20

b) GDC 74H, Air Data Computer

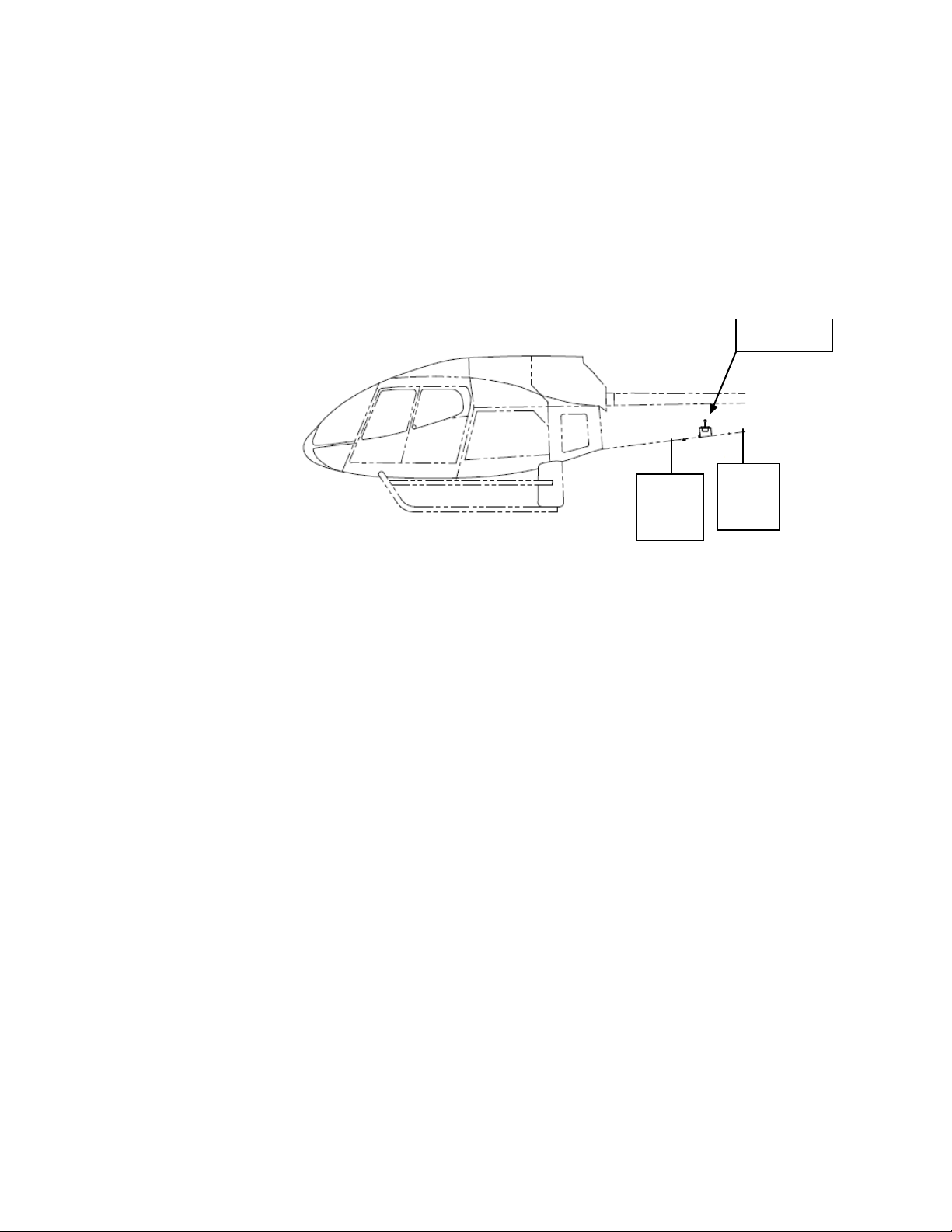

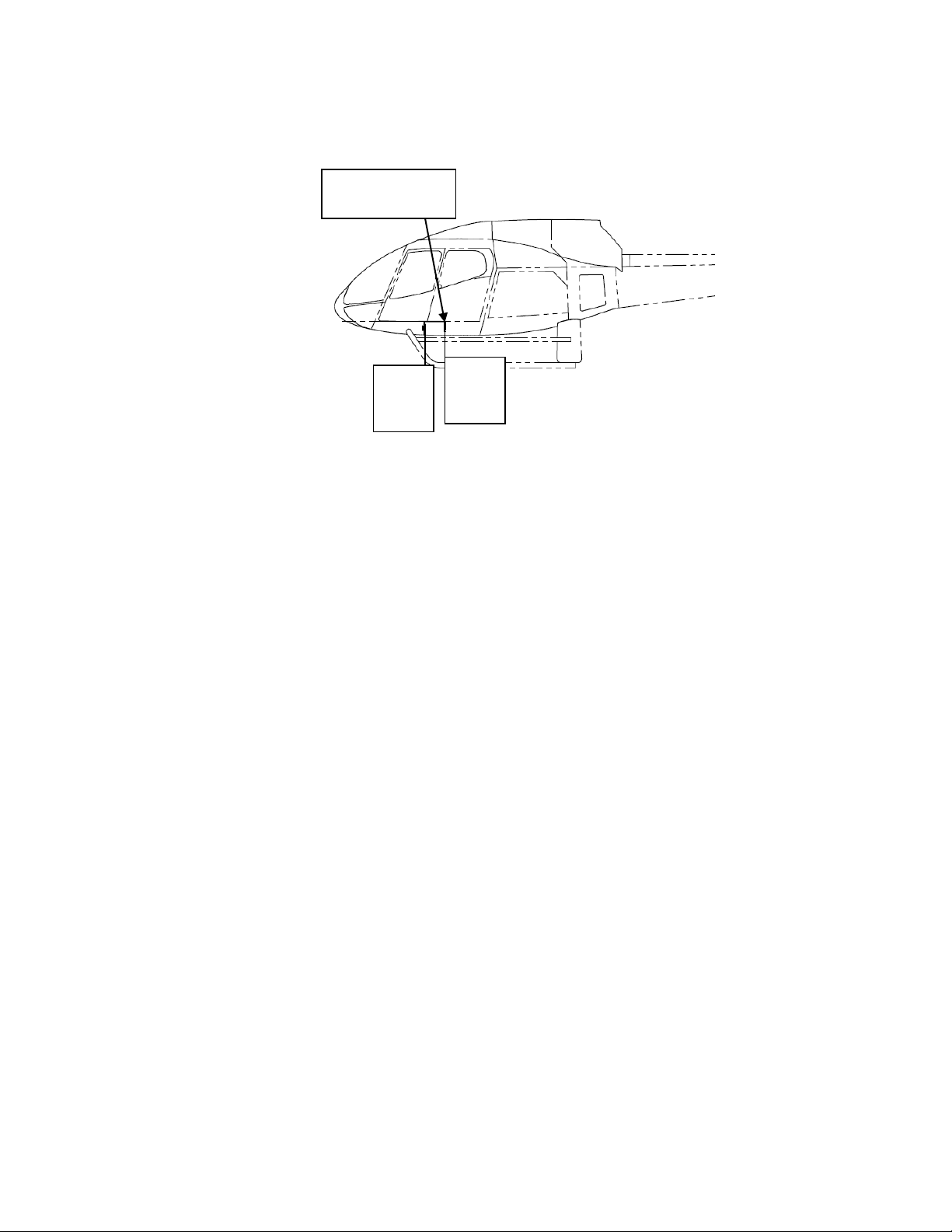

Figure 6-02

GDC 74H

STA

REF

STA

REF

GDC 74H is located underneath the cabin floor between station 2249 and 2737 on the left

side of the aircraft. (Figure 6-02)

2249

2737

Access Methods

i. Removal

1. Un-latch the Center lower belly access panel.

2. Disconnect the retaining straps that prevent the panel from falling to the floor.

3. If aftermarket items are attached to the Center lower belly panel it may be

necessary to remove or disconnect them in order to remove the lower belly panel.

Consult the manufacturers Installation and Removal instructions for proper

removal of items.

ii. Installation

1. Re-install aftermarket items if removed to gain access to the air data computer.

Consult the manufacturers Installation and Removal instructions for proper

installation of items.

2. Connect the retaining strap that was disconnected to gain access to the air data

computer.

3. Close the Center lower belly access panel and latch it.

Caution: Use of pow er tools during removal or installation

of panels and attaching hardware may damage nut plates

or deform holes in composite doors, covers, panels, and

fairings.

06-00-00

Instructions for Continued Airworthiness 190-01527-15 Rev 1

for the Garmin G500H Installation in Eurocopter EC130 Page 20 of 82

Page 21

c) GRS 77H, AHRS

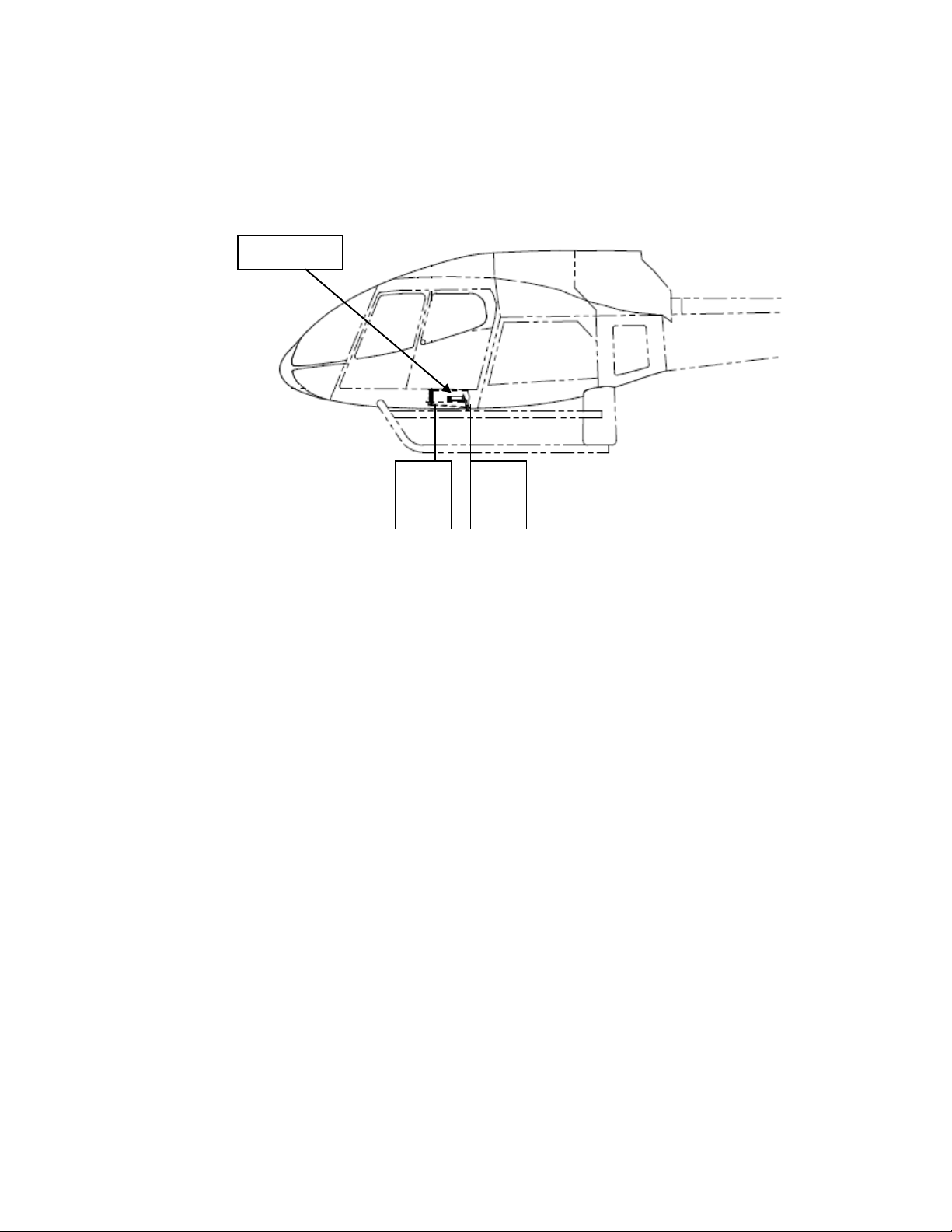

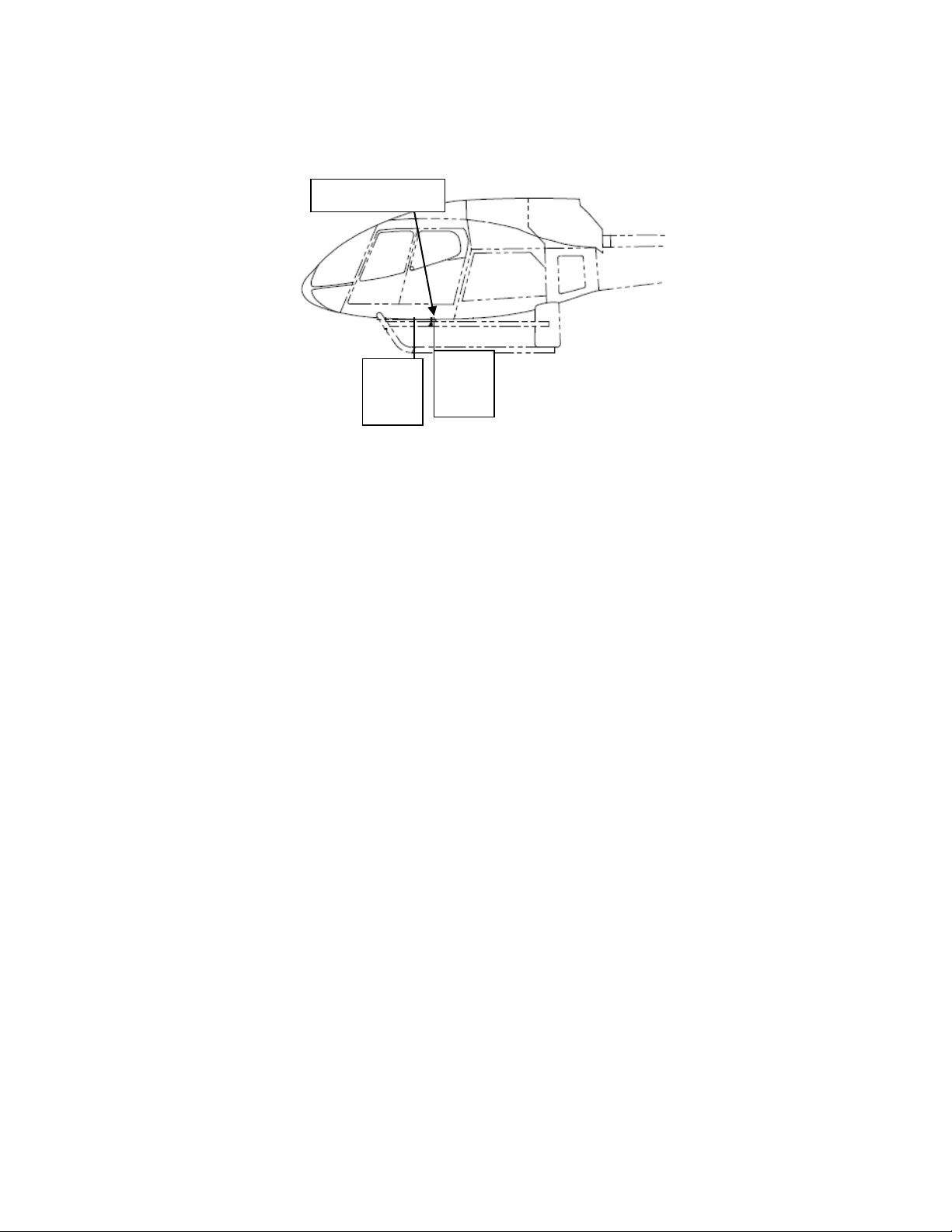

Figure 6-03

GDC 77H

STA

REF

STA

REF

GRS 77H is located underneath the cabin floor between station 2249 and 2737 on the left

side of the aircraft. (Figure 6-03)

2249

2737

Access Methods

i. Removal

1. Un-screw the Center lower belly access panel.

2. Disconnect the retaining straps that prevent the panel from falling to the floor.

3. If aftermarket items are attached to the Center lower belly panel it may be

necessary to remove or disconnect them in order to remove the lower belly panel.

Consult the manufacturers Installation and Removal instructions for proper

removal of items.

ii. Installation

1. Re-install aftermarket items if removed to gain access to the AHRS. Consult the

manufacturers Installation and Removal instructions for proper installation of

items.

2. Connect the retaining strap that was disconnected to gain access to the AHRS.

3. Close the Center lower belly access panel and attach screws.

Caution: Use of power tools during removal or installation

of panels and attaching hardware may damage nut plates

or deform holes in composite doors, covers, panels, and

fairings.

06-00-00

Instructions for Continued Airworthiness 190-01527-15 Rev 1

for the Garmin G500H Installation in Eurocopter EC130 Page 21 of 82

Page 22

d) Shelf Installation

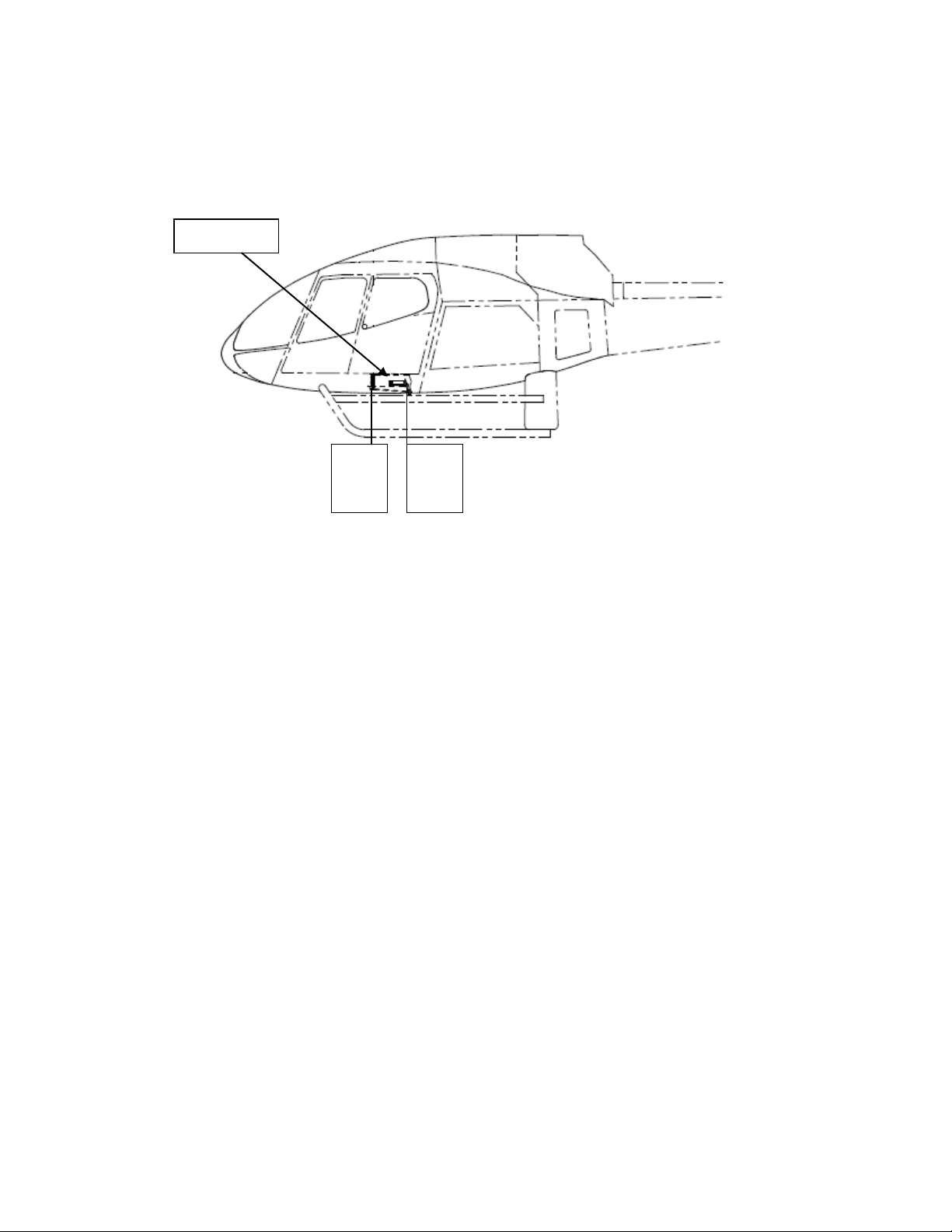

Figure 6-04

Shelf

STA

REF

STA

REF

The shelf installation is located underneath the cabin floor between station 2249 and 2737

on the left side of the aircraft. (Figure 6-04)

2249

2737

Access Methods

i. Removal

1. Un-screw the Center lower belly access panel.

2. Disconnect the retaining straps that prevent the panel from falling to the floor.

3. If aftermarket items are attached to the Center lower belly panel it may be

necessary to remove or disconnect them in order to remove the lower belly panel.

Consult the manufacturers Installation and Removal instructions for proper

removal of items.

ii. Installation

1. Re-install aftermarket items. Consult the manufacturers Installation and Removal

instructions for proper installation of items.

2. Connect the retaining strap that was disconnected to gain access to the air data

computer.

3. Close the Center lower belly access panel and attach screws.

Caution: Use of power tools during removal or installation

of panels and attaching hardware may damage nut plates

or deform holes in composite doors, covers, panels, and

fairings.

06-00-00

Instructions for Continued Airworthiness 190-01527-15 Rev 1

for the Garmin G500H Installation in Eurocopter EC130 Page 22 of 82

Page 23

e) Terminal Block Installation

Figure 6-05

Terminal

Block

STA

REF

STA

REF

Terminal Block is located underneath the cabin floor between station 1703 and 1766 on

the left side of the aircraft. (Figure 6-05)

1703

1766

Access Methods

i. Removal

1. Un-latch the Center lower belly access panel.

2. Disconnect the retaining straps that prevent the panel from falling to the floor.

3. If aftermarket items are attached to the Center lower belly panel it may be

necessary to remove or disconnect them in order to remove the lower belly panel.

Consult the manufacturers Installation and Removal instructions for proper

removal of items.

ii. Installation

1. Re-install aftermarket items if removed to gain access to the terminal block.

Consult the manufacturers Installation and Removal instructions for proper

installation of items.

2. Connect the retaining strap that was disconnected to gain access to the terminal

block.

3. Close the Center lower belly access panel and latch it.

Caution: Use of power tools during removal or installation

of panels and attaching hardware may damage nut plates

or deform holes in composite doors, covers, panels, and

fairings.

06-00-00

Instructions for Continued Airworthiness 190-01527-15 Rev 1

for the Garmin G500H Installation in Eurocopter EC130 Page 23 of 82

Page 24

f) GTP 59 OAT Probe Installation

Figure 6-06

GTP 59

STA

REF

STA

REF

The GTP 59 OAT Probe is located on the existing belly panel between station 2205 and

2269. (Figure 6-06)

2205

2269

Access Methods

i. Removal

1. Un-latch the Center lower belly access panel.

2. Disconnect the retaining straps that prevent the panel from falling to the floor.

3. If other aftermarket items are attached to the Center lower belly panel it may be

necessary to remove or disconnect them in order to remove the lower belly panel.

Consult the manufacturers Installation and Removal instructions for proper

removal of items.

ii. Installation

1. Re-install any other aftermarket items if removed to gain access to the GTP59 OAT

Probe. Consult the manufacturers Installation and Removal instructions for proper

installation of items.

2. Connect the retaining strap that was disconnected to gain access to the GTP59 OAT

Probe.

3. Close the Center lower belly access panel and latch it.

Caution: Use of power tools during removal or installation of

panels and attaching hardware may damage nut plates or

deform holes in composite doors, covers, panels, and fairings

06-00-00

Instructions for Continued Airworthiness 190-01527-15 Rev 1

for the Garmin G500H Installation in Eurocopter EC130 Page 24 of 82

Page 25

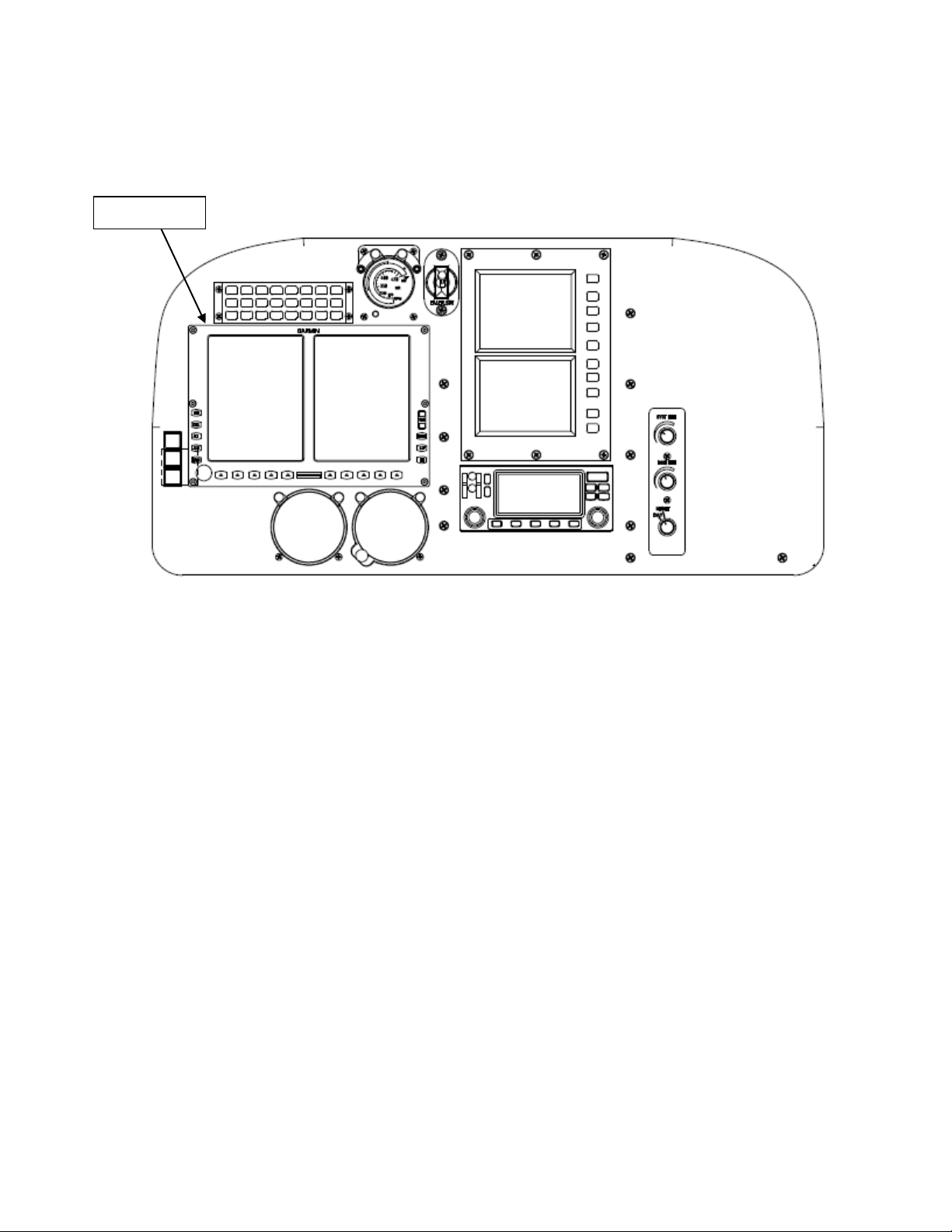

g) GDU 620 Installation

Figure 6-07

GDU 620

The GDU 620 is located in the left hand side of the instrument panel (Reference Section 3100-00 Instruments, Figures 31-08 through 31-11 for specific location based on installation

configuration)

Access Methods

i. Removal

1. Un-screw the screws on the front of the instrument panel.

2. For items that are attached to the instrument panel it may be necessary to remove

or disconnect them in order to remove the instrument panel. Consult the

manufacturers Installation and Removal instructions for proper removal of items.

ii. Installation

1. Re-install items if removed or disconnected to remove the instrument panel.

Consult the manufacturers Installation and Removal instructions for proper

installation of items.

2. Re-install screw on front of instrument panel.

Caution: Use of power tools during removal or installation

of panels and attaching hardware may damage nut plates

or deform holes in composite doors, covers, panels, and

fairings.

Instructions for Continued Airworthiness 190-01527-15 Rev 1

for the Garmin G500H Installation in Eurocopter EC130 Page 25 of 82

06-00-00

Page 26

h) Cooling Fan Installation (If option is installed)

Cooling

The Cooling Fan is located on the forward side of the flight control pedestal (Figure 6-08)

Access Methods

i. Unlatch and open door to enter cabin.

ii. Access forward side of the flight control pedestal.

Caution: Use of power tools during removal or installation of

panels and attaching hardware may damage nut plates or

deform holes in composite doors, covers, panels, and fairings.

06-00-00

Instructions for Continued Airworthiness 190-01527-15 Rev 1

for the Garmin G500H Installation in Eurocopter EC130 Page 26 of 82

Page 27

CHAPTER 8

Installation #

Description

Weight

CG Location

190-01527-07

GTP 59 OAT Probe

0.08 lbs

STA 2208, WL -2547, BL 7.2

190-01527-02

GMU 44 Magnetometer

3.49 lbs

STA 6783, WL -2066, BL 0.0

190-01527-03

LH Shelf

2.00 lbs

STA 2463, WL -2780, BL -756.7

190-01527-04

GDC 74H

1.92 lbs

STA 2615, WL -2744, BL -731.9

190-01527-05

GRS 77H AHRS

3.46 lbs

STA 2565, WL -2747, BL -817.9

190-01527-01

Instrument Panel

47.80 lbs

STA 872, WL -2066, BL 0.0

190-01527-06

Terminal Block

0.47 lbs

STA 1766, WL -2600, BL -592.3

190-01527-12

Cooling Fan

0.70 lbs

STA 427, WL -2491, BL 0.0

Section 8-00-00 Weight and Balance Information

Instructions for Continued Airworthiness 190-01527-15 Rev 1

for the Garmin G500H Installation in Eurocopter EC130 Page 27 of 82

8-00-00

Page 28

CHAPTER 11

Section 11-00-00 Placards and Markings

1. Placards and Decals

Shelf Installation

The Shelf Installation requires one (1) placard that is mounted to the upper surface of the Shelf in plain

view. The placard will read: “MAX LOAD 30 LBS”.

Instrument Panel Installation

When NAV 2 is not displayed on the GDU 620, the Instrument Panel Installation requires one (1)

placard that is mounted to the top of the pedestal, just below the Instrument Panel in plain view.

EFIS Master Circuit Breaker Installation

The EFIS Master Circuit Breaker Installation requires one (1) placard that is mounted to the left side of

the pedestal with a .50 in diameter hole cut-out in the middle so the circuit breaker can stick through

the placard.

11-00-00

Instructions for Continued Airworthiness 190-01527-15 Rev 1

for the Garmin G500H Installation in Eurocopter EC130 Page 28 of 82

Page 29

E.F.I.S. Circuit Breaker Installation

Circuit Breaker Installation requires one (1) placard that is mounted to the top of the lower pedestal

with three .50 in diameter hole cut-outs in the middle so the circuit breakers can stick through the

placard.

2. Decal and Placard Application

a) Wipe the surface area with isopropyl alcohol or acetone to thoroughly clean, before

applying the decal or placard. Allow cleaned area to dry. Separate backing from adhesive

side of decal and apply to cleaned, dry surface. Roll out all wrinkles.

b) Mask around edges, where practical, (do not put tape on decal surface) with masking tape.

Seal edges of placard or decal with 3M #3950 Edge Sealer. Remove any masking tape after

1-2 minutes.

11-00-00

Instructions for Continued Airworthiness 190-01527-15 Rev 1

for the Garmin G500H Installation in Eurocopter EC130 Page 29 of 82

Page 30

CHAPTER 12

Section 12-00-00 Servicing Maintenance Practices

This chapter includes Return-to-Service Practices and Calibration Practices to be used with the G500H

Flight Display System Installation.

12-00-00

Instructions for Continued Airworthiness 190-01527-15 Rev 1

for the Garmin G500H Installation in Eurocopter EC130 Page 30 of 82

Page 31

Section 12-10-00 Return-to-Service Practices

1. General

a) GMU 44 Magnetometer

1. Power up the G500H system with the GDU 620 in normal mode.

2. Verify that the GDU displays valid heading within approximately one minute. Note that

heading can remain invalid if the magnetometer is near a large metal structure such as a

hangar wall or if the magnetometer is close to a large ground power cart.

3. Verify that no unexpected alerts are present. If alerts are present, troubleshoot using Section

31-00-00 Troubleshooting.

b)

GDC 74H

1. Power up the G500H system with the GDU 620 in normal mode.

2. Verify that the GDU displays valid air data within approximately one minute.

3. Verify that no unexpected alerts are present. If alerts are present, troubleshoot using Section

31-00-00 Troubleshooting.

4. Drain pitot-static system (reference table 5-01 90 Day Inspection)

5. Perform a leak check of the pitot-static system and observe the airspeed, altitude, and vertical

speed for proper operation.

c)

GRS 77H

1. Power up the G500H system with the GDU 620 in normal mode.

2. Verify that the GDU displays valid heading and attitude within approximately one minute. Note

that heading can remain invalid if the magnetometer is near a large metal structure such as a

hangar wall or if the magnetometer is close to a large ground power cart.

3. Verify that no unexpected alerts are present. If alerts are present, troubleshoot using Section

31-00-00 Troubleshooting.

d) GDU 620

1. Power up the G500H system with the GDU 620 in normal mode.

2. Verify that there are no red-Xs and that no alerts are present. If red Xs or alerts are present,

troubleshoot using Section 31-00-00 Troubleshooting.

12-10-00

Instructions for Continued Airworthiness 190-01527-15 Rev 1

for the Garmin G500H Installation in Eurocopter EC130 Page 31 of 82

Page 32

Calibrations Required

Engine Run-up

Manual

GRS 77H AHRS was removed and/or

GRS 77H AHRS was removed and/or

GRS 77H AHRS Configuration Module

Section 12-20-00 Calibration Requirements

Condition

replaced. The mounting tray was NOT

removed and the mounting tray bolts

were NOT loosened.

replaced. The mounting tray WAS

removed and/or mounting tray bolts

WERE loosened.

was replaced.

GRS 77H

Pitch/Roll

Offset

See Section 5

of the G500H STC

Installation Manual

X

X X X

GRS/GMU

Magnetic

Calibration

See Section 5

of the G500H STC

Installation Manual

None Required.

X

Vibration

Test

See Section 5

of the G500H

STC Installation

X

Instructions for Continued Airworthiness 190-01527-15 Rev 1

for the Garmin G500H Installation in Eurocopter EC130 Page 32 of 82

12-20-00

Page 33

CHAPTER 20

Section 20-00-00 Standard Practices

This chapter contains maintenance information and procedures that are common standard

practices used on the G500H installation. Information contained in this chapter is standard

torque charts and application procedures, corrosion prevention, painting, mechanical

fastener sealing, and dye penetrant inspection techniques.

20-00-00

Instructions for Continued Airworthiness 190-01527-15 Rev 1

for the Garmin G500H Installation in Eurocopter EC130 Page 33 of 82

Page 34

Section 20-10-00 Torques Maintenance Practices

1. Torque Wrenches

a) Torque Wrench Accuracy

Torque wrenches must be of good quality and calibrated at least once a year. Any torque

wrench that has been dropped or abused should be calibrated to ensure continued

accuracy.

b) Application of Torque Wrench Loads

(1) Be sure the bolt and nut and the surface they bear on are clean and dry, unless otherwise

specified by the manufacturer.

(2) Run the nut down to near contact with the washer or bearing surface and check the friction

drag torque required to turn the nut. Add the friction drag torque to the desired torque to

arrive at the “final torque” to be registered on the torque wrench indicator.

(3) Whenever possible, apply the torque to the nut instead of the bolt. This will reduce

rotation of the bolt in the hole and reduce wear.

(4) Apply a smooth even pull when applying torque pressure.

(5) If special adapters are used which will change the effective length of the torque wrench,

the final torque indication or wrench setting must be adjusted accordingly. To determine

the torque wrench setting or indication with adapter installed reference Figure 20-01.

20-10-00

Instructions for Continued Airworthiness 190-01527-15 Rev 1

for the Garmin G500H Installation in Eurocopter EC130 Page 34 of 82

Page 35

Figure 20-01

20-10-00

Instructions for Continued Airworthiness 190-01527-15 Rev 1

for the Garmin G500H Installation in Eurocopter EC130 Page 35 of 82

Page 36

2. Torque Wrenches

Thread Size

Shear

Tension

Recommended

in-lb (N m)

Maximum

in-lb (N m)

Recommended

in-lb (N m)

Maximum

in-lb (N m)

8-36

7-9

12

12-15

20

10-32

12-15

25

20-25

40

¼-28

30-40

60

50-70

100

5/16-24

60-85

140

100-140

225

3/8-24

(0.3750-24)

95-110

(10.73-12.42)

240

(27.11)

160-190

(18.07-21.46)

390

(44.05)

7/16-20

270-300

500

450-500

840

½-20

290-410

660

480-690

1,100

9/16-18

480-600

960

800-1,000

1,600

5/8-18

660-780

1,400

1,100-1,300

2,400

¾-16

1,300-1,500

3,000

2,300-2,500

5,000

7/8-14

(0.8750-14)

1,500-1,800

(169.44-203.32)

4,200

(474.43)

2,500-3,000

(282.40-338-88)

7,000

(790.72)

1-12

(1.0000-12)

2,200-3,300

(248.51-372.76)

6,000

(677.76)

3,700-5,500

(417.95-621.28)

10,000

(1129.6)

1-1/8-12

3,000-4,200

9,000

5,000-7,000

15,000

1-1/4-12

5,400-6,600

15,000

9,000-11,000

25,000

Warning: Do not exceed maximum allowable torque value. Overstressing of fastener may

result.

Standard hardware torque values are given in the following tables 20-01 through table 20-03.

Table 20-01 gives recommended torque values for fine thread fasteners, shear and tension

applications. Table 20-02 gives recommended torque values for coarse thread fasteners, shear

and tension applications. Table 20-03 gives recommended torque values for phillips head

screws.

Table 20-01- Recommended Torque Values for Fine Thread Fasteners

Fractional (decimal)

(0.1640-36)

(0.1900-32)

(0.2500-28)

(0.3125-24)

(0.4375-20)

(0.5000-20)

(0.5625-18)

(0.6250-18)

(0.7500-16)

(0.79-1.02)

(1.36-1.69)

(3.38-4.51)

(6.77-9.60)

(30.49-33.88)

(32.75-46.31)

(54.22-67.77)

(74.55-88.10)

(146.84-169.44)

(1.36)

(2.82)

(6.77)

(15.81)

(56.48)

(74.55)

(108.44)

(158.14)

(338.88)

(1.36-1.69)

(2.25-2.82)

(5.64-7.90)

(11.29-15.81)

(50.83-56.48)

(54.22-77.94)

(90.36-112.96)

(124.25-146.84)

(259.80-282.40)

(2.26)

(4.51)

(11.29)

(25.41)

(94.88)

(124.25)

(180.73)

(271.10)

(564.80)

(1.1250-12)

(1.2500-12)

(338.88-474.43)

(609.98-745.53)

(1016.6)

(1694.4)

(564.80-790.72)

(1016.6-1242.6)

(1694.4)

(2824.0)

20-10-00

Instructions for Continued Airworthiness 190-01527-15 Rev 1

for the Garmin G500H Installation in Eurocopter EC130 Page 36 of 82

Page 37

Thread Size

Fractional (decimal)

Shear

Tension

Recommended

Maximum

Recommended

Maximum

8-32

7-9

12

12-15

20

10-24

12-15

21

20-25

35

¼-20

25-30

45

40-50

75

5/16-18

48-55

100

80-90

160

3/8-16

95-100

170

160-185

275

7/16-14

140-155

280

235-255

475

½-13

240-290

520

400-480

880

9/16-12

300-420

650

500-700

1,100

5/8-11

(0.6250-11)

420-540

(47.44-60.99)

900

(101.66)

700-900

(79.07-101.66)

1,500

(169.44)

¾-10

(0.7500-10)

700-950

(79.07-107.31)

1,500

(169.44)

1,150-1,600

(129.90-180.73)

2,500

(282.40)

7/8-9

1,300-1,800

2,700

2,200-3,000

4,600

1-8

2,200-3,000

4,500

3,700-5,000

7,600

1-1/8-8

3,300-4,000

7,200

5,500-6,500

12,000

1-1/4-8

4,000-5,000

10,000

6,500-8,000

16,000

Thread Size

Recommended in-lb (N m)

Maximum in-lb (N m)

8-32 (0.1640-32

12-15 (1.36-1.69)

23 (2.59)

10-32 (0.1900-32)

20-25 (2.25-2.82)

35 (3.95)

¼-28 (0.2500-28)

60-70 (6.77-7.90)

90 (10.16)

5/16-24 (0.3125-24)

110-125 (12.42-14.12)

150 (16.94)

3/8-24 (0.3750-24)

150-175 (16.94-19.76)

225 (25.41)

7/16-20 (0.4375-20)

230-280 (25.98-31.62)

450 (50.83)

½-20 (0.5000-20)

550-650 (62.12-73.42)

850 (96.01)

9/16-18 (0.5625-18)

750-900 (84.72-101.66)

1,200 (135.55)

5/8-18 (0.6250-18)

1,100-1,300 (124.25-146.84)

1,600 (180.73)

Table 20-02. Recommended Torque Values for Coarse Thread Fasteners

in-lb (N m)

in-lb (N m)

in-lb (N m)

in-lb (N m)

(0.1640-32)

(0.1900-24)

(0.2500-20)

(0.3125-18)

(0.3750-16)

(0.4375-14)

(0.5000-13)

(0.5625-12)

(0.8750-9)

(1.0000-8)

(0.79-1.02 )

(1.36-1.69)

(2.82-3.38)

(5.42-6.21)

(10.73-11.29)

(15.81-17.50)

(27.11-32.75)

(33.88-47.44)

(146.84-203.32)

(248.51-338.88)

(1.36)

(2.37)

(5.08)

(11.29)

(19.20)

(31.62)

(58.73)

(73.42)

(474.43)

(508.32)

(1.36-1.69)

(2.25-2.82)

(4.51-5.64)

(9.03-10.16)

(18.07-20.89)

(26.54-28.8)

(45.18-54.22)

(56.48-79.07)

(248.51-338-88)

(417.95-564.80)

(2.26)

(3.95)

(8.47)

(18.07)

(31.06)

(53.65)

(99.40)

(124.25)

(519.61)

(858.49)

(1.1250-8)

(1.2500-8)

Fractional (decimal)

(372.76-451.84)

(451.84-564.80)

(813.31)

(1129.6)

(621.28-734.24)

(734.24-903.68)

Table 20-03. Recommended Torque Values for Phillips Head Fasteners

20-10-00

(1355.5

(1807.4 N m)

Instructions for Continued Airworthiness 190-01527-15 Rev 1

for the Garmin G500H Installation in Eurocopter EC130 Page 37 of 82

Page 38

Section 20-30-00 Painting Maintenance Practices

The following procedures should be used to touch-up paint flaking, scratches, nicks, and gouges.

Warning: Cleaning solvents and epoxy primer are flammable. Cleaning solvents, epoxy

primer, and alodine can cause burns and irritation when skin is contacted. Vapors are

harmful and caustic to eyes; Goggles must be worn for eye protection. Cleaning solvents

and alodine are poisonous. Vapors are harmful to life or health; work should be

performed with proper ventilation and / or respirators should be worn while working

with Cleaning solvents, epoxy primer and alodine.

1. Paint Touch-Up of Small Areas

Use the following procedures to touch-up paint of small sanded areas and Nicks, Scratches,

Gouges, Etc., that do not go through paint and primer to bare metal.

a. Wipe surface clean with trichloroethane, MIL-T-81533, or equivalent cleaning

solvent, and wipe dry immediately.

b. Apply coat of epoxy polymide primer, MIL-P-23377F or equivalent, to match

original. Feather primer coating onto surrounding color coat. Allow primer to air

dry for 30 minutes.

c. Apply topcoat to match original finish.

20-30-00

Instructions for Continued Airworthiness 190-01527-15 Rev 1

for the Garmin G500H Installation in Eurocopter EC130 Page 38 of 82

Page 39

Section 20-40-00 Corrosion Control Maintenance Practices

1. Corrosion Control

The G500H mounting components are fabricated primarily of aluminum. All components

should be inspected regularly for any signs of corrosion. The following procedures should be

used for removing corrosion and treating affected areas.

2. Corrosion Removal

Remove corrosion by either chemical or mechanical means.

a) Paint Removal, Chemical

Caution: Do not use chemical paint stripper on composite materials. Chemical paint

strippers can cause composite components to debond and / or loose adhesion of the

epoxy matrix.

(1) Mask all non-metallic surfaces in area to be stripped as well as areas where

solution may get entrapped.

Warning: Paint stripper can cause burns and irritation when it contacts skin; proper

gloves should be worn. Vapors are harmful and caustic to eyes; Goggles must be worn

for eye protection. Paint stripper is poisonous. Vapors are harmful to life or health; work

should be performed with proper ventilation and / or respirators should be worn while

working with paint stripper.

(2) Using a fiber brush, apply sufficient paint stripper, (Turco 5873), to cover area of

removal.

Note: If paint stripper evaporates quickly or works slowly, cover area with plastic sheet.

(3) Allow paint remover to remain on surface for a time sufficient to cause wrinkling

and lifting of paint (about 10-30 minutes).

(4) Using non-metallic scraper or abrasive pads, (3M scotchbrite 63), scrub area to

further loosen paint.

(5) Re-apply paint stripper, (Turco 5873), as necessary in areas where paint remains

tightly adherent.

(6) Wash and scrub surface with demineralized water and alkaline cleaner to

neutralize paint stripper.

(7) Remove masking materials and any residual paint or stripper

20-40-00

Instructions for Continued Airworthiness 190-01527-15 Rev 1

for the Garmin G500H Installation in Eurocopter EC130 Page 39 of 82

Page 40

(8) Rinse with demineralized water.

b) Paint Removal, Mechanical

Caution: Do not sand into or expose composite fibers. Do not remove more material

than necessary. Do not use aluminum oxide abrasive materials on epoxy/graphite

materials.

Use abrasive flap wheel, abrasive disk, abrasive paper, or plastic media blast to remove

paint.

c) Corrosion Removal

Note: Aircraft shall be electrically grounded during corrosion removal operations. When removing exterior corrosion from electronic boxes, the unit case shall be electrically grounded during the complete operation.

(1) Corrosion shall be removed by the mildest method possible.

(a) Hand scrub with dry non-metallic brush/pad. (3M scotchbrite 63

cellulose/nylon scouring pad).

(b) Use abrasive cloth. (Aluminum oxide 240 grit). Caution: Do not use on

epoxy/graphite materials.

(c) Use 320 grit sandpaper.

(d) Glass bead blast.

(e) Use 240 grit abrasive wheel.

Note: On high strength steel, do not use power tools other than a flap brush or mandrel with abrasive mat; overheating and notching may occur.

(2) Ensure all active corrosion and corrosion products have been removed.

(3) Using 320 grit sandpaper blend edges of paint (if applicable) surrounding repair

area to create a smooth transition. Vacuum area thoroughly to remove all

contaminates.

(4) Apply aluminum surface treatment if applicable. (Ref. Item 4. Below).

(5) Touch-up primer and paint to match original

3. Mechanical Defects (Nicks, Scratches, Gouges, Etc.)

a) Determine if damage is through the paint. If not touch-up the paint (Ref. Section 20-30-

00,).

20-40-00

Instructions for Continued Airworthiness 190-01527-15 Rev 1

for the Garmin G500H Installation in Eurocopter EC130 Page 40 of 82

Page 41

b) If damage is through the paint surface prepare area for paint touch-up using following

methods.

Note: On high strength steel, do not use power tools other than a flap brush or mandrel with abrasive mat; overheating and notching may occur.

(1) Remove defect using flap wheel, abrasive disk, abrasive paper, or plastic media

blast.

(2) Using 320 grit sandpaper, blend edges of paint surrounding repair area to create a

smooth transition.

(3) Apply aluminum surface treatment if applicable. (Ref. Item 4. Below).

(4) Touch-up primer and paint to match original.

4. Aluminum Alloy Surface Touch-Up Treatment

Note: If there is any question of whether or not the protective coating is removed,

surface treatment shall be applied.

Warning: Alodine and solvents can cause burns and irritation when it contacts skin;

proper gloves should be worn. Vapors are harmful and caustic to eyes; Goggles must be

worn for eye protection. Alodine is poisonous. Vapors are harmful to life or health; work

should be performed with proper ventilation and / or respirators should be worn while

working with Solvents and alodine. Solvent cleaners are flammable.

a) Scuff surface using 3M scotchbrite 63 cellulose/nylon scouring pad.

b) Wipe exposed surface with isopropyl alcohol or aliphatic naphtha. Allow area to air dry

for 10 minutes. Do not touch or otherwise contaminate surface after solvent wipe.

c) Apply Alodine 1200 or equivalent with cotton swap, non-metallic brush, or by dipping.

Maintain moist surface for 1-3 minutes with repeated application. Surface will become

amber or brown in color.

d) Irrigate surface with demineralized or distilled water, to remove surface treatment

chemical. Allow to air dry for approximately 1 hour.

e) If there are any surface without color change, repeat procedure.

f) Apply paint touch-up as required. (Ref Section 20-30-00)

20-40-00

Instructions for Continued Airworthiness 190-01527-15 Rev 1

for the Garmin G500H Installation in Eurocopter EC130 Page 41 of 82

Page 42

Section 20-90-00 Dye Penetrant Inspection Methods

Warning: solvents can cause burns and irritation when it contacts skin; proper gloves

should be worn. Vapors are harmful and caustic to eyes; Goggles must be worn for eye

protection. Vapors are harmful to life or health; work should be performed with proper

ventilation and / or respirators should be worn while working with Solvents. Solvent

cleaners are flammable.

Use the following steps to perform dye penetrant inspection:

1. Using cleaning solvent trichloroethane, MIL-T-81533, clean area to be inspected.

Note: Parts to be inspected must be dry and heated to at least 70° F (21.1° C), but not over

130° F (54.4° C).

Note: Manufacturers instructions on Dye Penetrant Kit take precedence over the following

instructions.

2. Apply penetrant from dye penetrant kit, MIL-25135, by brushing, spraying, or by dipping.

Allow to stand for a minimum of 2 minutes.

3. Remove excess penetrant with remover (available with dye penetrant kit), or by cleaning

with plain water. Allow part to dry.

4. Apply a light even layer of developer from dye penetrant kit by brushing, spraying, or by

dipping. When dipping, avoid excess quantity.

5. Penetrant, which has penetrated into cracks (or other openings) in the surface of the part

will be drawn out by the developer resulting in a bright red indication.

6. If part is serviceable or repairable, clean part free of penetrant and developer with

trichloroethane, MIL-T-81533 cleaning solvent

20-90-00

Instructions for Continued Airworthiness 190-01527-15 Rev 1

for the Garmin G500H Installation in Eurocopter EC130 Page 42 of 82

Page 43

CHAPTER 31

Table 31-01 Circuit Breakers

Label

Unit Controlled

PFD

Garmin Display Unit (PFD/MFD), GDU 620

AHRS

Attitude and Heading Reference System, GRS 77H

ADC

Air Data Computer, GDC 74H

Section 31-00-00 Instruments

1. Description and Operation

The Garmin G500H Flight Display System consists of an instrument panel mounted GDU 620 display and

remote mounted LRUs which provide data to the display. The GDU 620 provides controls for the

G500H system and a PFD and MFD in the pilot’s primary field of view. The remote mounted LRUs

include one GRS 77H AHRS, one GMU 44 Magnetometer, one GDC 74H ADC, and one GTP 59 OAT

probe.

The G500H system depends on electrical power to function. The Garmin Display Unit (GDU), Attitude

and Heading Reference System (AHRS), and Air Data Computer (ADC) are connected to the aircraft

main bus.

The major components of the G500H are circuit breaker protected with push-pull type circuit breakers

available to the pilot. These breakers are located in the pedestal circuit breaker panel (30 α) and are

labeled as shown in Table 31-01.

2. Removal and Installation

If any G500H LRUs are removed and reinstalled or a new unit is installed, verify that the LRU unit

power-up self-test sequence is successfully completed and no failure messages are annunciated on the

GDU 620 display.

If any work has been done on the rotorcraft that could affect the system wiring or any interconnected

equipment, verify the G500H system unit power-up self-test sequence is successfully completed and no

failure messages are annunciated on the GDU 620 display.

Whenever removing or installing units, remove power from the LRU by removing aircraft power or

opening the LRU circuit breaker.

Instructions for Continued Airworthiness 190-01527-15 Rev 1

for the Garmin G500H Installation in Eurocopter EC130 Page 43 of 82

31-00-00

Page 44

a) GMU 44 Magnetometer

i Removal

1. Access the GMU 44 magnetometer (reference Section 6-00-00 Dimensions and

Access).

2. Unscrew the three screws that hold the GMU 44 to its mounting rack.

3. Carefully lift the GMU 44 from the rack.

4. Disconnect the wiring harness.

ii Installation

1. Visually inspect the connectors to ensure there are no bent or damaged pins.

Repair any damage.

2. Connect the wiring harness to the GMU 44.

3. Lower the GMU 44 into the rack and secure the plate with the three Phillips

screws.

Original GMU 44 is Reinstalled

If the original GMU 44 was reinstalled, then software loading is not required. This does

not include units that were returned for repair as their software and configuration files

are deleted during the repair testing process. Recalibration is required only if the

mount for the magnetometer was changed. If the magnetometer mount was changed,

refer to Section 5.6.2 of the G500H STC Installation Manual for the GRS 77H/GMU 44

Magnetic Calibration

.

New, Repaired or Exchange GMU 44 is Installed

If a new, repaired, or exchange GMU 44 unit is installed, then software must be loaded

and the GRS 77H/GMU 44 Magnetic Calibration must be performed. Refer to Section 5

of the G500H STC Installation Manual for instructions on software loading (5.4.3) and

Magnetic Calibration (5.6.2).

iii Return to Service

After removing and reinstalling the GMU 44, the following return-to-service checks

should be performed (reference Section 12-00-10 Return to Service Checks).

b) GDC 74H Air Data Computer

i Removal

1. Access the GDC 74H, (reference Section 6-00-00, Dimensions and Access)

2. Disconnect the pitot/static plumbing from the rear of the unit. Disconnect the

single connector.

3. Remove the two (2) screws on the mounting plate near the pitot/static ports.

Loosen the other two (2) screws.

31-00-00

Instructions for Continued Airworthiness 190-01527-15 Rev 1

for the Garmin G500H Installation in Eurocopter EC130 Page 44 of 82

Page 45

4. Carefully remove the unit from its mounting location.

ii Installation

1. Position the unit and fasten using the four (4) screws.

2. Connect the pitot/static plumbing.

3. Inspect the connector and pins for damage. Repair any damage.

4. Connect the connector to the unit, ensuring that each jackscrew is secured.

Original GDC 74H is Reinstalled

If the original GDC 74H is re-installed, then no software loading is required. This does

not include units that were returned for repair as their software and configuration files

are deleted during the repair testing process.

New, Repaired or Exchange GDC 74H is Installed

If a new, repaired, or exchange GDC 74H unit is installed, then software must be loaded

to the unit. Refer to Section 5.4.4 of the G500H STC Installation Manual for more

information.

GDC 74H Configuration Module is Replaced

If the GDC 74H Configuration Module is replaced, the GDC 74H must be configured.

Refer to Section 5.5.8 of the G500H STC Installation Manual

iii Return to Service

After removing and reinstalling the GDC 74H, the return-to-service checks must be

performed (reference Section 12-00-00 Return-to-Service Check).

C) GRS 77H AHRS

i Removal

1. Disconnect the GRS 77H connector.

2. Loosen the four Phillips thumbscrews with a screwdriver.

3. Gently lift the GRS 77H from the mounting plate (if the supports for the

mounting plate are removed, the GRS 77H must be recalibrated)

ii Installation

1. Place the GRS 77H on the mounting plate, ensuring the orientation is correct.

2. Fasten the unit to the plate using the Phillips thumbscrews. Recommended torque

is 22-25 inch pounds.

31-00-00

Instructions for Continued Airworthiness 190-01527-15 Rev 1

for the Garmin G500H Installation in Eurocopter EC130 Page 45 of 82

Page 46

3. Visually inspect the connectors to ensure there are no bent or damaged pins.

Repair any damage.

4. Connect the connector to the GRS 77H, ensuring that each slidelock is secured on

both sides.

Original GRS 77H is Reinstalled

If the original GRS 77H is reinstalled, then no software loading is required. This does

not include units that were returned for repair as their software and configuration files

are deleted during the repair testing process. Reference Section 12-20-00 Calibration

Requirements to determine whether recalibration is required.

New, Repaired, or Exchange GRS 77H is Installed

If a new, repaired, or exchange GRS 77H unit is installed then software must be loaded

per Section 5.4.2 of the G500H STC Installation Manual. Reference Section 12-20-00

Calibration Requirements to determine whether re-calibration is required.

GRS 77H Configuration Module is Replaced

If the GRS 77H Configuration Module is replaced, the GRS 77H must be re-calibrated.

Reference Section 12-10-20 Calibration Requirements.

iii Return to Service

After removing and reinstalling the GRS 77H, the return-to-service check should be

performed. (Reference Section 12-00-10)

d) GDU 620 MFD

i Removal

1. Remove the six mounting screws from the bezel of the GDU 620.

2. Pull the GDU 620 far enough out from the instrument panel to access the three

rear connectors.

3. Disconnect the rear connectors.

4. Remove the GDU 620.

ii Installation

1. Visually inspect the connectors to ensure that there are no bent or damaged pins.

Repair any damage.

31-00-00

Instructions for Continued Airworthiness 190-01527-15 Rev 1

for the Garmin G500H Installation in Eurocopter EC130 Page 46 of 82

Page 47

2. Connect the rear connectors, ensuring that each slidelock is secured on both sides.

3. Set the GDU 620 into place.

4. Install the six mounting screws into the bezel of the GDU 620.

NOTE: The installation configuration settings are stored in the

configuration module and will be retained when the GDU 620

is replaced with a new unit. User settings, such as map

orientation preferences, are stored internally and will be lost

when the GDU 620 is replaced with a new unit.

Original GDU 620 is Reinstalled

If the original GDU 620 is reinstalled, then no software loading is required. This does

not include units that were returned for repair as their software and configuration files

are deleted during the repair process. No configuration is required.

New, Repaired or Exchange GDU 620 is Installed

If a new, repaired, or exchange GDU 620 unit is installed, then software must be

loaded. No configuration is required

.

NOTE: Upon first power-up after installing a new GDU 620, it is normal

to see a series of “LOADING…” messages appear on the screen.

These messages indicate that the GDU 620 is updating its

configuration settings from the configuration module.

Refer to Section 5 of the G500H STC Installation Manual for the GDU 620 Software

Loading procedure (5.4.1), followed by the Manifest Configuration (5.5.5) and the

Configuration Module Update (5.5.12).

GDU 620 Configuration Module is Replaced

If the GDU 620 Configuration Module is replaced, the GDU 620 will update the

configuration module from its internally-stored settings when the UPDT CFG soft key is

pressed. If the GDU 620 is replaced at the same time as the Configuration Module, then

the System Setup will need to be performed per Section 5.5 of the G500H STC

Installation Manual.

e) Cooling Fan (if option is installed)

i Removal

1. Disconnect the hoses from the cooling fan.

2. Remove the three screws mounting the cooling fan to the pedestal.

31-00-00

Instructions for Continued Airworthiness 190-01527-15 Rev 1

for the Garmin G500H Installation in Eurocopter EC130 Page 47 of 82

Page 48

3. Disconnect the connectors.

Table 31-01 Parts List for Figure 31-01

ITEM

1

1

115-01814-00

DOUBLER

GARMIN

2

8

MS20470AD4-3

RIVET

3

6

MS20426AD5-5

RIVET

4

(3)

211-60037-08

SCREW

GARMIN

5

A/R

MIL-S-8802

SEALING COMPOUND

6

1

011-00870-10

GMU 44 MAGNETOMETER

GARMIN

7

1

115-00481-10

INSTALL RACK

GARMIN

4. Remove the cooling fan.

ii Installation

1. Connect the connectors.

2. Set the cooling fan into place.

3. Install the three mounting screws into the cooling fan.

3. Illustrated Parts List

This section contains information on parts for the G500H Flight Display System, for use in

ordering replacements if necessary.

NUMBER

QUANTITY PART NUMBER DESCRIPTION MANUFACTURER

Instructions for Continued Airworthiness 190-01527-15 Rev 1

for the Garmin G500H Installation in Eurocopter EC130 Page 48 of 82

31-00-00

Page 49

Figure 31-01

GMU 44 MAGNETOMETER INSTALLATION, EXPLODED VIEW

(Reference Table 31-01)

31-00-00

Instructions for Continued Airworthiness 190-01527-15 Rev 1

for the Garmin G500H Installation in Eurocopter EC130 Page 49 of 82

Page 50

Table 31-02 Part Lists for Figures 31-02

ITEM

1

1

115-01815-00

FWD GUSSET SUPPORT

GARMIN

2

1

115-01816-00

AFT GUSSET SUPPORT

GARMIN

3

1

115-01817-00

SHELF

GARMIN

4 8 AN3-3A

BOLT

5 8 AN3-4A

BOLT

6

16

MS20426AD3-3

RIVET

7

8

MS21042L3

NUT

8

16

MS21075L3N

NUT