Garmin DA 40 User Manual

G1000 System

Maintenance Manual

Diamond DA 40

190-00303-03 January 2007 Revision 6

© Copyright 2007

Garmin Ltd. or its subsidiaries

All Rights Reserved

Except as expressly provided herein, no part of this manual may be reproduced, copied, transmitted,

disseminated, downloaded or stored in any storage medium, for any purpose without the express prior

written consent of Garmin. Garmin hereby grants permission to download a single copy of this manual

and of any revision to this manual onto a hard drive or other electronic storage medium to be viewed and

to print one copy of this manual or of any revision hereto, provided that such electronic or printed copy of

this manual or revision must contain the complete text of this copyright notice and provided further that

any unauthorized commercial distribution of this manual or any revision hereto is strictly prohibited.

Garmin International, Inc.

1200 E. 151

st

Street

Olathe, KS 66062 USA

Telephone: 913-397-8200

www.garmin.com

Garmin (Europe) Ltd.

Unit 5, The Quadrangle

Abbey Park Industrial Estate

Romsey, SO51 9DL U.K.

Telephone: 44/1794.519944

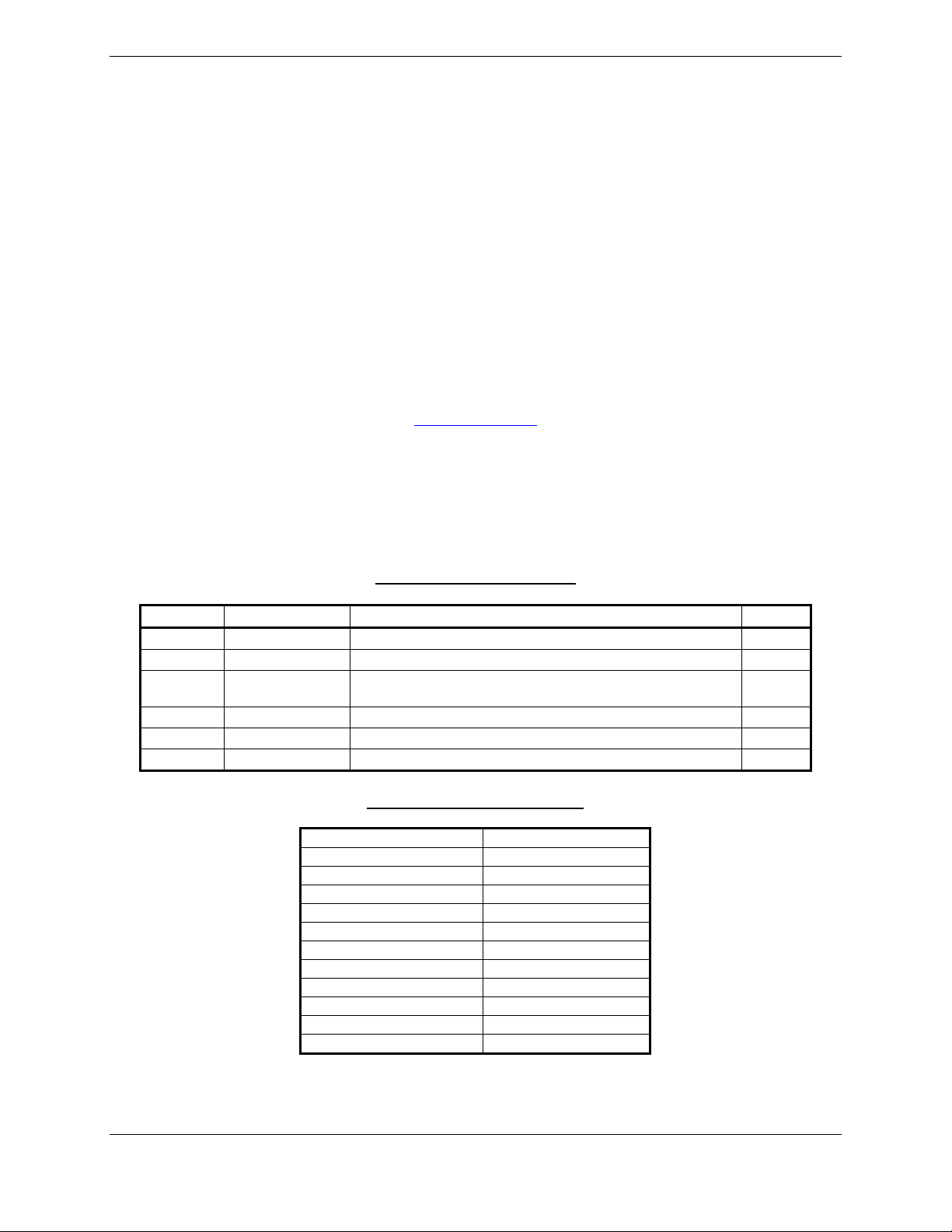

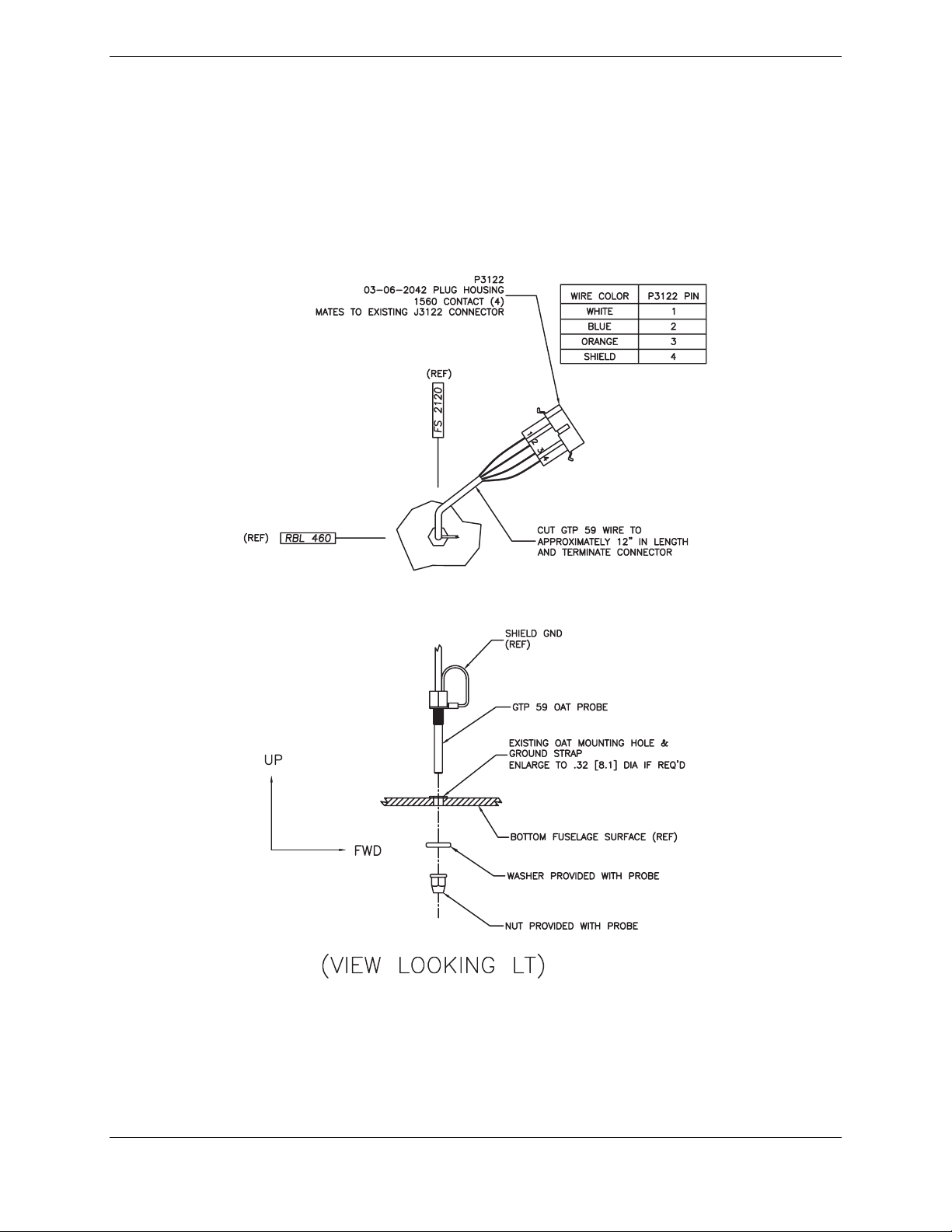

RECORD OF REVISIONS

Revision Revision Date Description ECO #

1 06/04/04 Experimental Release ------

2 6/17/04 Update for STC 26291

3 6/21/04 Update AW Limitations, Add Document Pagination

Table.

4 8/24/04 Update for new GTX 33 SW

26344

27110

5 9/3/04 Update for optional KAP 140 AFCS 27244

6 1/25/07 Update GDC Testing Process 42752

DOCUMENT PAGINATION

Section Pagination

Table of Contents i – vi

Section 1 1-1 – 1-4

Section 2 2-1 – 2-26

Section 3 3-1 – 3-12

Section 4 4-1 – 4-12

Section 5 5-1 – 5-24

Section 6 6-1 – 6-8

Section 7 7-1 – 7-34

Section 8 8-1 – 8-4

Appendix A A-1 – A-6

Appendix B B-1 – B-16

Page A G1000/DA40 System Maintenance Manual

Revision 6 190-00303-03

INFORMATION SUBJECT TO EXPORT CONTROL LAWS

This document may contain information which is subject to the Export Administration Regulations

("EAR") issued by the United States Department of Commerce (15 CFR, Chapter VII, Subchapter C) and

which may not be exported, released, or disclosed to foreign nationals inside or outside of the United

States without first obtaining an export license. A violation of the EAR may be subject to a penalty of up

to 10 years imprisonment and a fine of up to $1,000,000 under Section 2410 of the Export Administration

Act of 1979. Include this notice with any reproduced portion of this document.

WARNING

This product, its packaging, and its components contain chemicals known to the State of California to

cause cancer, birth defects, or reproductive harm. This Notice is being provided in accordance with

California's Proposition 65. If you have any questions or would like additional information, please refer

to our web site at www.garmin.com/prop65

.

CAUTION

The GDU 1040s use a lens coated with a special anti-reflective coating that is very sensitive to skin oils,

waxes and abrasive cleaners. CLEANERS CONTAINING AMMONIA WILL HARM THE ANTIREFLECTIVE COATING. It is very important to clean the lens using a clean, lint-free cloth and an

eyeglass lens cleaner that is specified as safe for anti-reflective coatings.

CAUTION

All G1000 screen shots used in this document are current at the time of publication. Screen shots are

intended to provide visual reference only. All information depicted in screen shots, including software

file names, versions and part numbers, is subject to change and may not be up to date.

G1000/DA40 System Maintenance Manual Page i

190-00303-03 Revision 6

This page intentionally left blank.

Page ii G1000/DA40 System Maintenance Manual

Revision 6 190-00303-03

TABLE OF CONTENTS

PARAGRAPH PAGE

1 INTRODUCTION

1.1 C

1.2 O

1.3 D

1.4 R

1.5 D

ONTENT, SCOPE, PURPOSE ...........................................................................................................1-1

RGANIZATION ..............................................................................................................................1-1

EFINITIONS/ABBREVIATIONS.......................................................................................................1-2

EFERENCE PUBLICATIONS............................................................................................................1-3

ISTRIBUTION ................................................................................................................................1-3

2 SYSTEM DESCRIPTION

2.1 E

2.2 E

2.3 R

2.4 E

2.5 L

2.6 SPIDER

2.7 S

2.8 G1000

QUIPMENT DESCRIPTIONS............................................................................................................2-1

QUIPMENT LOCATIONS ................................................................................................................ 2-8

EMOTE AVIONICS ENCLOSURE ....................................................................................................2-9

LECTRICAL POWER DISTRIBUTION ............................................................................................2-11

IGHTNING STRIKE PROTECTION .................................................................................................2-12

GROUNDS....................................................................................................................... 2-16

ENSOR INSTALLATIONS ..............................................................................................................2-17

SYSTEM COMMUNICATIONS .............................................................................................2-23

3 G1000 CONTROL & OPERATION

3.1 U

3.2 G1000

3.3 R

3.4 C

3.5 C

SER INTERFACE............................................................................................................................3-2

NORMAL MODE ..................................................................................................................3-3

EVERSIONARY MODE...................................................................................................................3-4

ONFIGURATION MODE OVERVIEW .............................................................................................. 3-5

ONFIGURATION MODE NAVIGATION .........................................................................................3-11

4 G1000 CONTINUED AIRWORTHINESS

4.1 A

4.2 S

4.3 O

4.4 M

4.5 1000

4.6 E

4.7 F

4.8 GRS

IRWORTHINESS LIMITATIONS ......................................................................................................4-1

ERVICING INFORMATION..............................................................................................................4-1

N CONDITION SERVICING ............................................................................................................4-1

AINTENANCE REQUIREMENTS .................................................................................................... 4-3

HOUR INSPECTION .................................................................................................................4-5

LECTRICAL BONDING TEST.......................................................................................................... 4-7

UEL TANK PROBE RE-CALIBRATION............................................................................................4-8

77 EARTH MAGNETIC FIELD UPDATES................................................................................ 4-11

5 TROUBLESHOOTING

5.1 G1000 ALERTING SYSTEM .............................................................................................................5-2

5.2 S

5.3 DA

5.4 GDU

5.5 GDU

5.6 GMA

5.7 GIA

5.8 GIA

5.9 GEA

5.10 GTX

5.11 GRS

5.12 GDC

YSTEM ANNUNCIATIONS ..............................................................................................................5-4

40-SPECIFIC ALERTS................................................................................................................5-8

1040 TROUBLESHOOTING .....................................................................................................5-9

1040 ALERTS ........................................................................................................................5-9

ALERTS...............................................................................................................................5-12

63 TROUBLESHOOTING......................................................................................................... 5-13

ALERT MESSAGES ................................................................................................................5-14

TROUBLESHOOTING ............................................................................................................5-19

TROUBLESHOOTING ...........................................................................................................5-20

77/GMU 44 TROUBLESHOOTING........................................................................................ 5-21

74A TROUBLESHOOTING ...................................................................................................5-23

6 G1000 EQUIPMENT REMOVAL & REPLACEMENT

6.1 GDU

6.2 GMA

6.3 GIA

1040 MFD & PFD.................................................................................................................6-2

1347 AUDIO PANEL..............................................................................................................6-2

63 INTEGRATED AVIONICS UNITS ..........................................................................................6-3

G1000/DA40 System Maintenance Manual Page iii

190-00303-03 Revision 6

6.4 GEA 71 ENGINE/AIRFRAME UNIT ................................................................................................. 6-3

6.5 GTX

6.6 GDC

6.7 GTP

6.8 GRS

6.9 GMU

6.10 C

6.11 GEA

33 TRANSPONDER ................................................................................................................. 6-4

74A AIR DATA COMPUTER ...................................................................................................6-4

59 OAT PROBE ......................................................................................................................6-4

77 AHRS ...............................................................................................................................6-5

44 MAGNETOMETER.............................................................................................................6-5

ONFIGURATION MODULE REMOVAL & REPLACEMENT .............................................................6-6

71 BACKSHELL THERMOCOUPLE REMOVAL & REPLACEMENT...........................................6-7

7 G1000 EQUIPMENT CONFIGURATION & TESTING

7.1 GDU

7.2 GMA

7.3 GIA

7.4 GEA

7.5 GTX

7.6 GDC

7.7 GRS

7.8 S

1040 MFD & PFD.................................................................................................................7-1

1347 AUDIO PANEL..............................................................................................................7-5

63 INTEGRATED AVIONICS UNIT ............................................................................................7-8

71 ENGINE/AIRFRAME UNIT ............................................................................................... 7-14

33 TRANSPONDER ............................................................................................................... 7-17

74A AIR DATA COMPUTER .................................................................................................7-21

77 AHRS / GMU 44 MAGNETOMETER................................................................................7-25

OFTWARE/CONFIGURATION TROUBLESHOOTING ......................................................................7-34

8 SYSTEM RETURN TO SERVICE PROCEDURE

8.1 GPS

8.2 GIA

8.3 D

8.4 AHRS/ADC

8.5 F

8.6 M

FAILURE TEST ........................................................................................................................8-1

FAILURE TEST ........................................................................................................................8-2

ISPLAY FAILURE TEST .................................................................................................................8-2

BACKUP PATH TEST ..................................................................................................8-3

LIGHT TEST ..................................................................................................................................8-4

AINTENANCE RECORDS...............................................................................................................8-4

APPENDIX A INSTALLATION DATA

A.1 G1000

A.2 A

A.3 O

A.4 P

A.5 W

EQUIPMENT LIST ..............................................................................................................A-1

DDITIONAL EQUIPMENT REQUIRED........................................................................................... A-2

PTIONAL EQUIPMENT ................................................................................................................ A-2

ARTS LIST................................................................................................................................... A-3

EIGHT & BALANCE ...................................................................................................................A-5

APPENDIX B G1000 SOFTWARE/CONFIGURATION PROCEDURE

B.1 S

B.2 MFD

B.3 I

B.4 GIA

B.5 GIA

B.6 F

B.7 F

B.8 S

B.9 A

B.10 F

YSTEM POWER UP ...................................................................................................................... B-2

& PFD SOFTWARE LOAD.................................................................................................... B-3

NITIAL G1000 CONFIGURATION ................................................................................................. B-4

SOFTWARE LOAD ................................................................................................................. B-5

CONFIGURATION .................................................................................................................. B-7

INAL LRU SOFTWARE LOAD ..................................................................................................... B-8

INAL LRU CONFIGURATION .................................................................................................... B-14

OFTWARE LOAD CONFIRMATION............................................................................................. B-15

VIATION DATABASE LOADING ................................................................................................ B-16

INAL SYSTEM TESTING ............................................................................................................ B-16

Page iv G1000/DA40 System Maintenance Manual

Revision 6 190-00303-03

LIST OF ILLUSTRATIONS

FIGURE PAGE

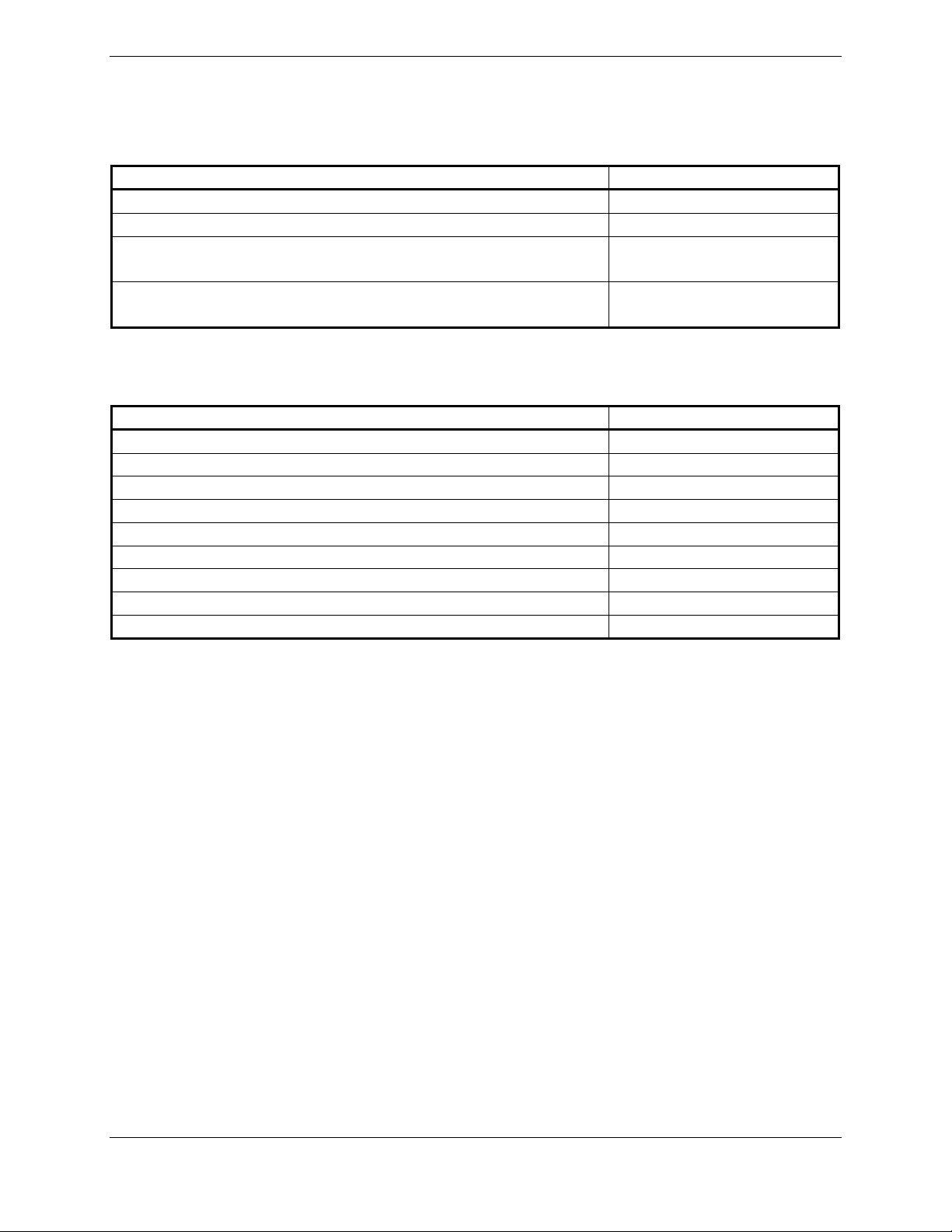

Figure 2-1. G1000 / DA 40 Panel Installation ..........................................................................................2-2

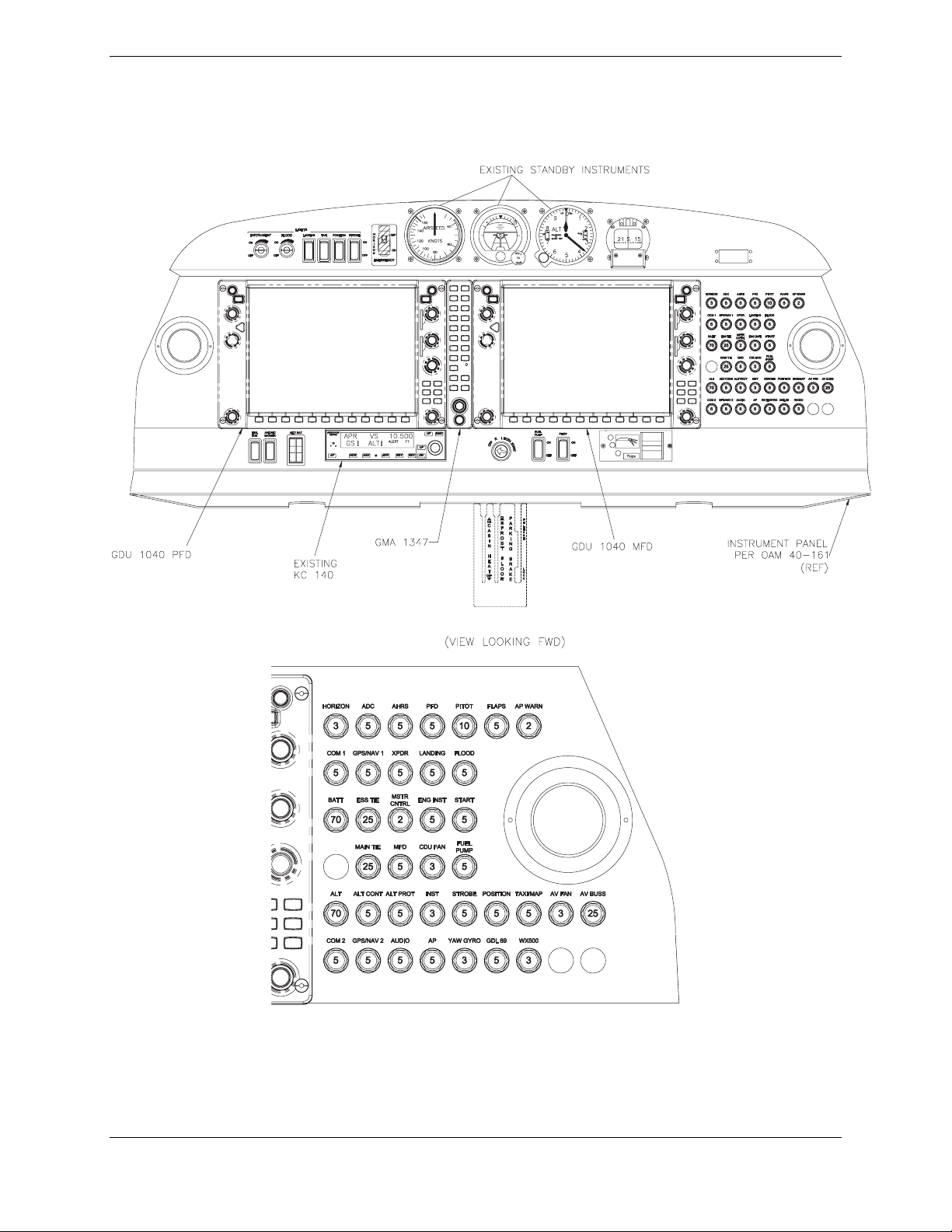

Figure 2-2. DA40 Panel (Rear View) .......................................................................................................2-4

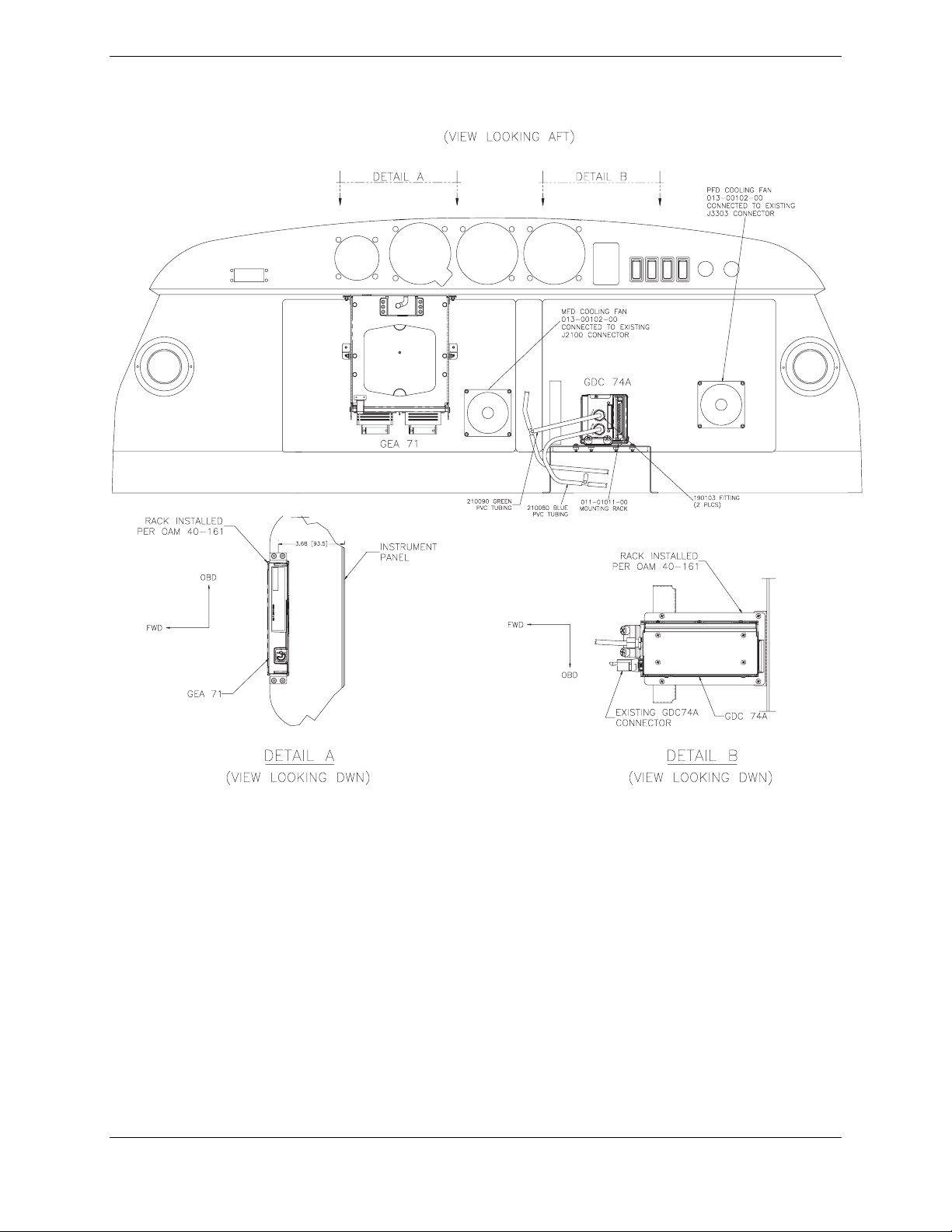

Figure 2-3. GTP 59 OAT Probe................................................................................................................2-5

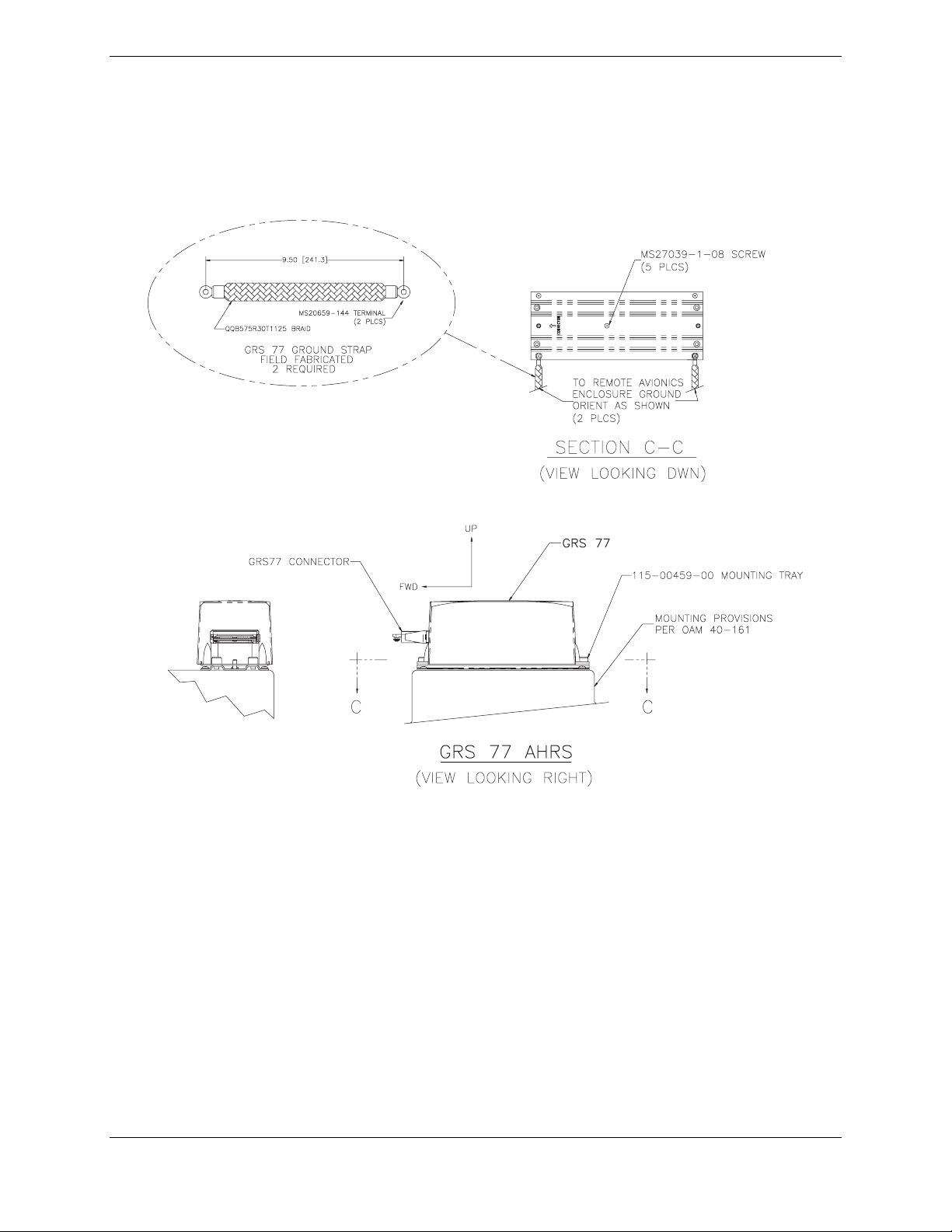

Figure 2-4. GRS 77 Mount .......................................................................................................................2-6

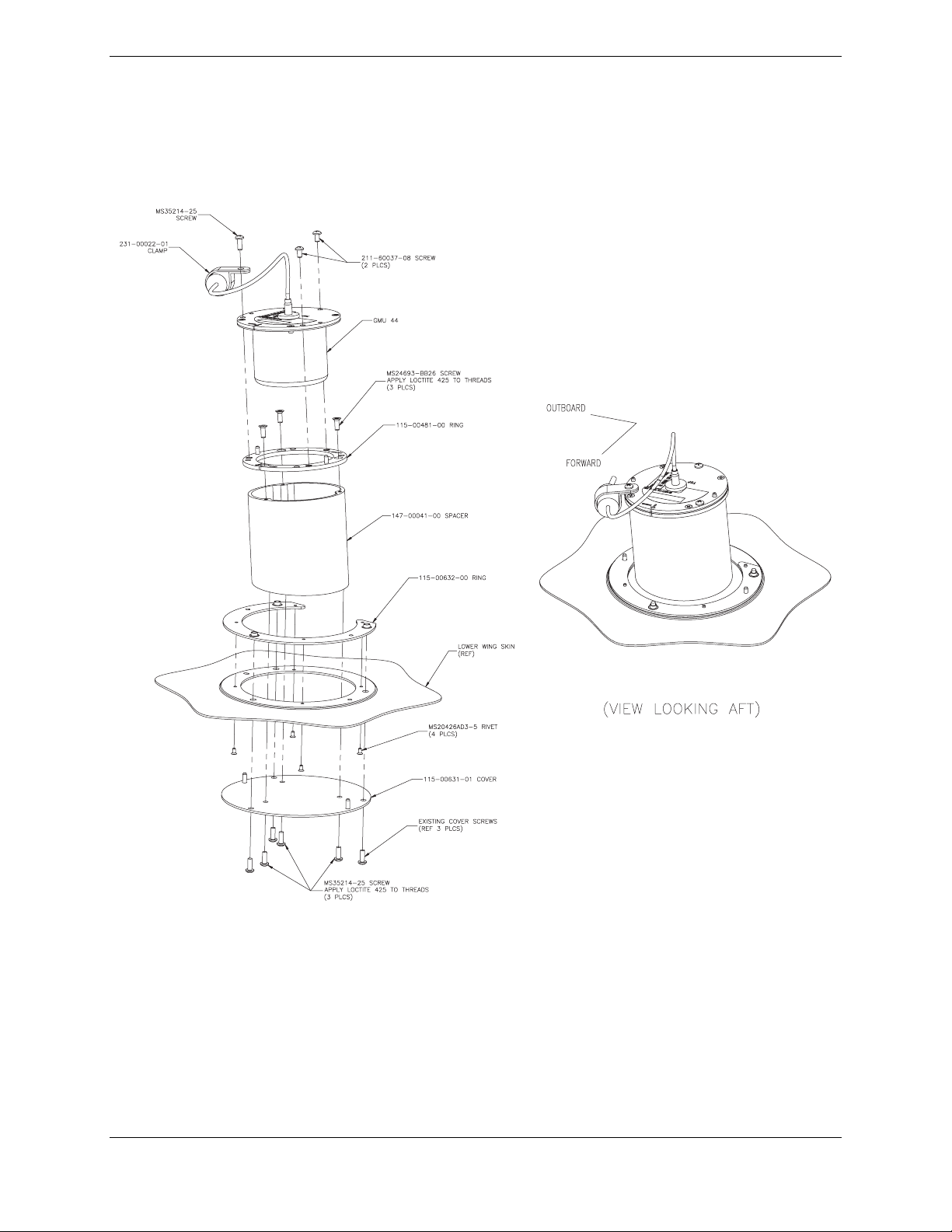

Figure 2-5. GMU 44 Installation...............................................................................................................2-7

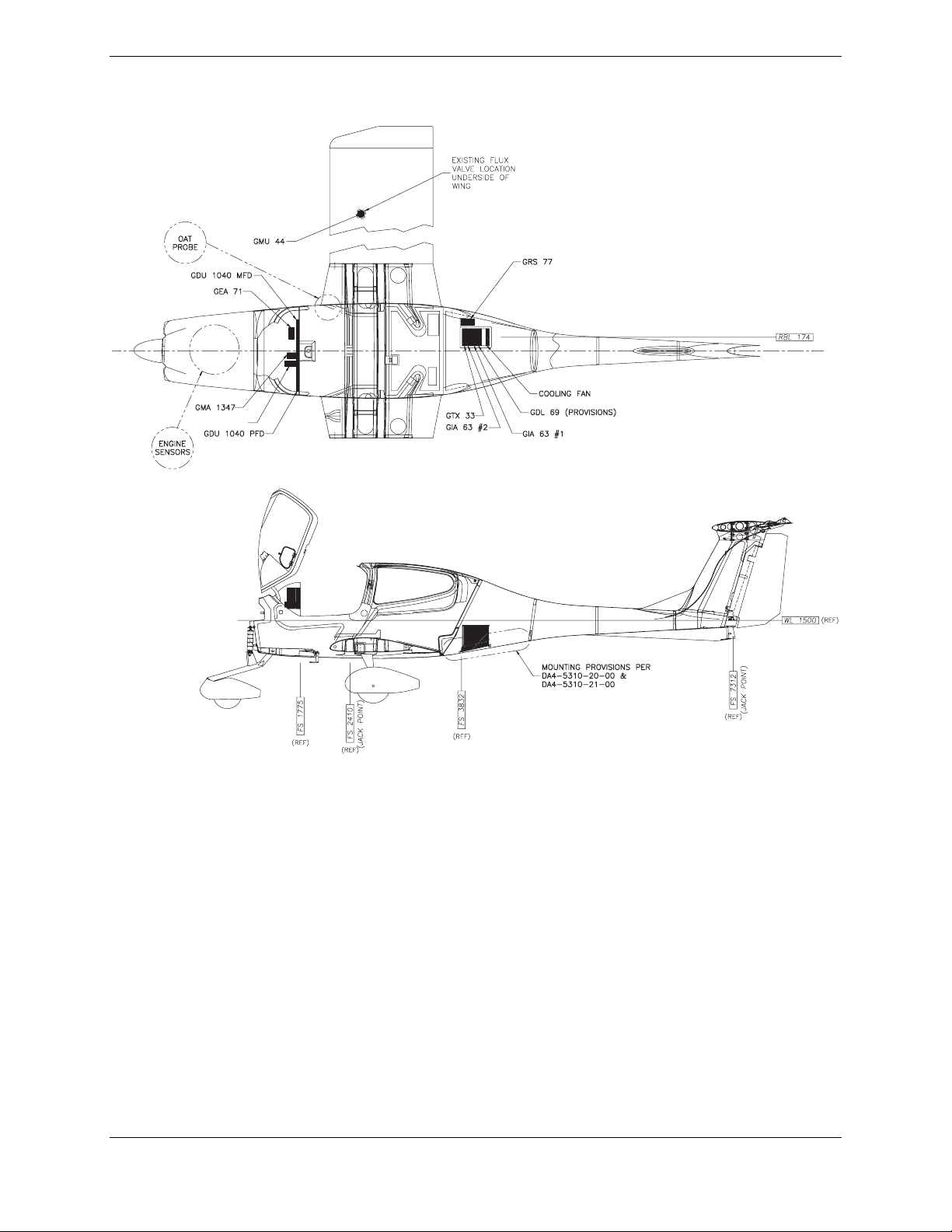

Figure 2-6. G1000 in DA 40 Equipment Locations..................................................................................2-8

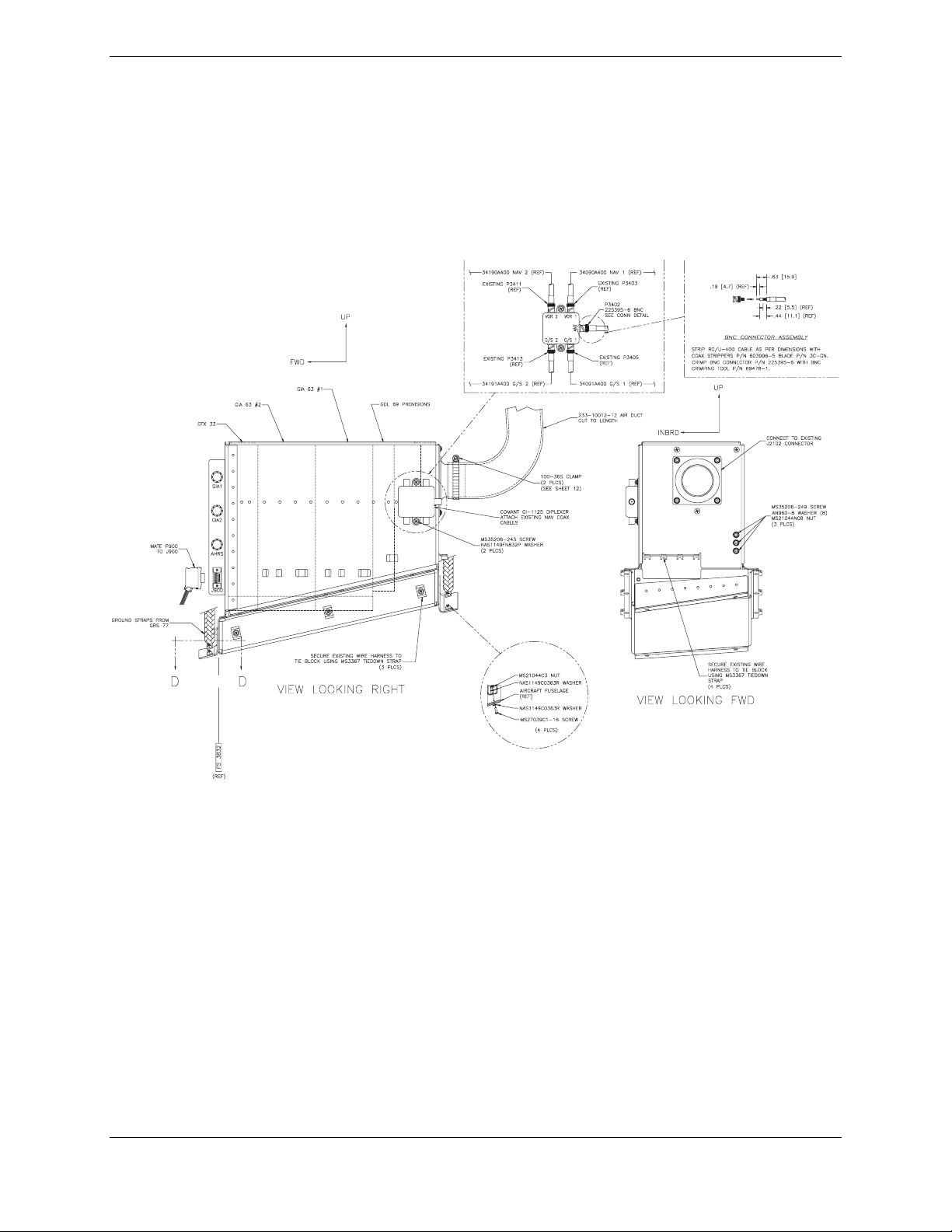

Figure 2-7. Remote Avionics Enclosure...................................................................................................2-9

Figure 2-8. G1000/DA40 Electrical Distribution....................................................................................2-11

Figure 2-9. TVS & Fuse Installation.......................................................................................................2-12

Figure 2-10. Lightning Protection Components .....................................................................................2-13

Figure 2-11. Component Plate Dimensions ............................................................................................2-13

Figure 2-12. Component Wiring Diagram..............................................................................................2-14

Figure 2-13. SPIDER Ground Installation..............................................................................................2-16

Figure 2-14. MAP Sensor .......................................................................................................................2-17

Figure 2-15. Oil Pressure Sensor ............................................................................................................2-17

Figure 2-16. Oil Temperature Sensor .....................................................................................................2-18

Figure 2-17. Fuel Pressure Sensor ..........................................................................................................2-18

Figure 2-18. Tachometer Sensor.............................................................................................................2-19

Figure 2-19. Fuel Flow Sensor & Fire Sleeve ........................................................................................2-19

Figure 2-20. Fuel Flow Assembled.........................................................................................................2-20

Figure 2-21. Fuel Flow Bracket ..............................................................................................................2-20

Figure 2-22. CHT Probe .........................................................................................................................2-21

Figure 2-23. EGT Probe..........................................................................................................................2-21

Figure 2-24. Alternator Current Sensor Installation ...............................................................................2-22

Figure 2-25. Flight Instrumentation Interface.........................................................................................2-23

Figure 2-26. G1000 Engine/Airframe Interface......................................................................................2-24

Figure 2-27. G1000 Navigation/Communications..................................................................................2-25

Figure 3-1. GDU 1040 Control Interface..................................................................................................3-1

Figure 3-2. GMA 1347 Controls...............................................................................................................3-1

Figure 3-3. G1000 Softkeys......................................................................................................................3-2

Figure 3-4. Normal Mode .........................................................................................................................3-3

Figure 3-5. MFD Failure Mode.................................................................................................................3-4

Figure 3-6. PFD Failure Mode..................................................................................................................3-4

Figure 3-7. G1000 LRU Configuration File Storage ................................................................................3-7

Figure 3-8. GRS/GDC Configuration Settings Storage ............................................................................3-8

Figure 3-9. SET>ACTV Diagram.............................................................................................................3-9

Figure 3-10. Loss of Communication .....................................................................................................3-10

Figure 3-11. Configuration Status...........................................................................................................3-10

Figure 3-12. Data Transmission Indicators.............................................................................................3-10

Figure 3-13. Configuration Page Navigator............................................................................................3-11

Figure 5-1. System Status Page (AUX Group Normal Mode)..................................................................5-1

Figure 5-2. Alerts & Annunciations..........................................................................................................5-2

Figure 5-3. WARNING Softkey Annunciation ........................................................................................5-3

Figure 5-4. CAUTION Softkey Annunciation..........................................................................................5-3

Figure 5-5. ADVISORY Softkey Annunciation .......................................................................................5-3

Figure 5-6. System Annunciations............................................................................................................5-4

Figure 5-7. GMA 1347 Data Paths .........................................................................................................5-12

Figure 5-8. GEA 71 Data Paths ..............................................................................................................5-19

Figure 5-9. GTX 33 Data Paths .................................................................................................

.............5-20

Figure 5-10. GRS 77 Data Paths.............................................................................................................5-22

G1000/DA40 System Maintenance Manual Page v

190-00303-03 Revision 6

Figure 5-11. GDC 74A Data Paths .........................................................................................................5-23

Figure 6-1. System Status Page (Configuration Mode) ............................................................................6-1

Figure 6-2. Configuration Module Installation .........................................................................................6-6

Figure 6-3. GEA Backshell Thermocouple...............................................................................................6-7

Figure 7-1. G1000 Normal Mode Check ..................................................................................................7-4

Figure 7-2. G1000 Reversionary Mode Check .........................................................................................7-4

Figure 7-3. Marker Beacon Symbology....................................................................................................7-7

Figure 7-4. GPS Signal Status.................................................................................................................7-11

Figure 7-5. G1000 Engine/Airframe Indicators......................................................................................7-16

LIST OF TABLES

TABLE PAGE

Table 1-1. Required Documents ...............................................................................................................1-3

Table 1-2. Reference Documents..............................................................................................................1-3

Table 4-1. Required Maintenance.............................................................................................................4-3

Table 4-2. 1000 Hour Inspection Procedure .............................................................................................4-5

Table 6-1. Thermocouple Kit (011-00981-00) .........................................................................................6-7

Page vi G1000/DA40 System Maintenance Manual

Revision 6 190-00303-03

1 INTRODUCTION

1.1 Content, Scope, Purpose

This document provides Instructions for Continued Airworthiness (ICA) for the Garmin G1000 Integrated

Cockpit avionics suite as installed in the Diamond Model DA 40 in accordance with the STC issued under

FAA STC SA01254WI. This document satisfies the requirements for continued airworthiness as defined

by 14 CFR Part 23.1529 and Appendix G. Information in this document is required to maintain the

continued airworthiness of the G1000 integrated cockpit system, as installed in the Diamond DA 40.

1.1.1 Applicability

This document applies to all Diamond Aircraft Industries, Inc., Model DA 40 aircraft equipped with the

G1000 cockpit installed in accordance with the STC issued under FAA STC SA01254 “original issue”

configuration. G1000 System Maintenance Manual – Diamond DA40 190-00545-00 applies to later

configurations.

1.2 Organization

The following outline briefly describes the organization of this manual:

Section 2: System Description

Provides a complete description of the type design change associated with installing the G1000

integrated cockpit system in the Diamond DA 40. An overview of the G1000 system interface is also

provided.

Section 3: G1000 Control & Operation

Presents basic control and operation information specifically tailored to maintenance practices. Basic

G1000 Configuration Mode operation is also described.

Section 4: G1000 Continued Airworthiness

Provides maintenance instructions for continued airworthiness of the G1000 system.

Section 5: Troubleshooting

Provides troubleshooting information to aid in diagnosing and resolving potential problems with the

G1000 system.

Section 6: G1000 Equipment Removal & Replacement

Gives instructions for the removal and replacement of G1000 equipment.

Section 7: G1000 Equipment Configuration & Testing

Gives instructions for loading software, configuring, and testing of G1000 equipment.

Section 8: System Return to Service Procedure

Specifies return-to-service procedures to be performed upon completion of maintenance of the G1000

system.

Appendix A: Installation Data

Gives a complete equipment/parts list and weight/balance data for the G1000 installation in the

Diamond DA 40.

Appendix B: G1000 Software/Configuration Procedure

Provides a complete software/configuration loading procedure in cases where the G1000 system as a

whole requires complete software/configuration update or reload. This is given in addition to

individual LRU configuration instructions presented in Section 7.

G1000/DA 40 System Maintenance Manual Page 1-1

190-00303-03 Revision 6

1.3 Definitions/Abbreviations

ADI: Attitude Display Indicator

AHRS: Attitude Heading Reference System

AMM: Airplane Maintenance Manual

CDU: Control Display Unit

CFR: Code of Federal Regulations

EAU: Engine/Airframe Unit

EIS: Engine Instrumentation Systems

HIRF: High Intensity Radiated Fields

HSDB: High-Speed Data Bus (Ethernet)

IAU: Integrated Avionics Unit

ICS: Inter-Com System

LRU: Line Replaceable Unit

MFD: Multi-Function Flight Display

OAT: Outside Air Temperature

PFD: Primary Flight Display

STC: Supplemental Type Certificate

S/W: Software

TC: Type Certificate

TSO: Technical Standard Order

TVS: Transient Voltage Suppressor

VHF: Very High Frequency

1.3.1 Units of Measure

Unless otherwise stated, all units of measure are English units.

Page 1-2 G1000/DA40 System Maintenance Manual

Revision 6 190-00303-03

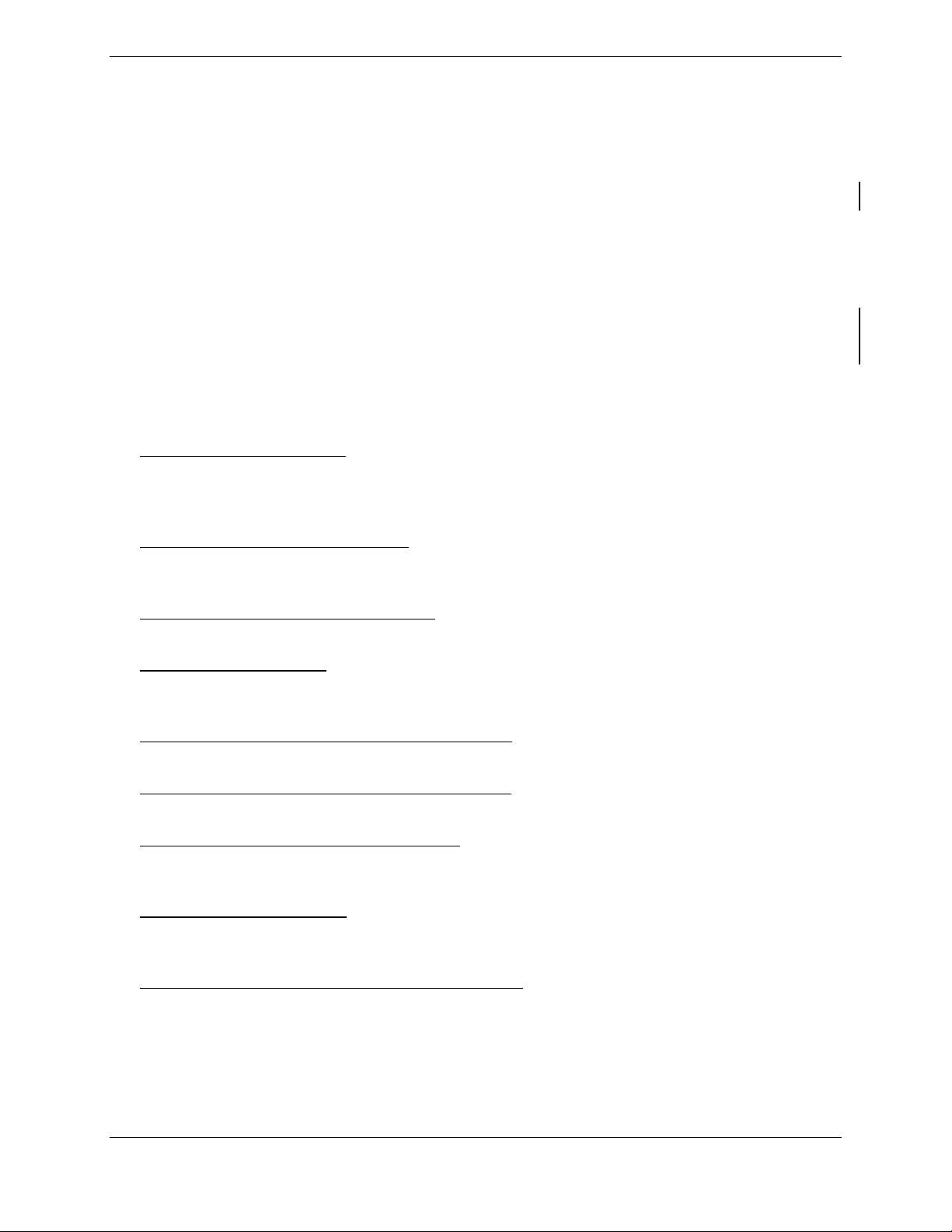

1.4 Reference Publications

The following documents are required by this maintenance manual to perform maintenance:

Table 1-1. Required Documents

Document Garmin Part Number

G1000 Cockpit Reference Guide for DA40 190-00324-00

G1000/DA 40 Airplane Flight Manual Supplement 190-00303-02

Diamond DA 40 Wiring Diagram Diamond P/N:

DA4-9231-60-1

Diamond DA 40 Airplane Maintenance Manual Diamond P/N

6.02.01 (Rev. 4 or later)

The following documents provide additional information above and beyond the scope of this document:

Table 1-2. Reference Documents

Document Garmin Part Number

G1000/DA 40 Master Drawing List 005-C0004-00

G1000/DA 40 Required Equipment List 005-00149-28

G1000/DA 40 Install Drawing 005-00149-01

G1000/DA 40 Post Installation Checkout Procedure 190-00303-06

G1000 Configuration Manual 190-00303-04

Aircraft Fastener Assembly Torque 005-00249-00

Aircraft Contact and Terminal Crimping 005-00249-01

Heat Shrink Tubing Application 005-00249-02

Aircraft Soldering 005-00249-03

1.5 Distribution

This document is to be a permanent aircraft record and is distributed with a new G1000-equipped

Diamond DA 40. Revisions to this document will be made by Garmin and will be distributed by Garmin

per standard documentation revision procedures.

G1000/DA 40 System Maintenance Manual Page 1-3

190-00303-03 Revision 6

This page intentionally left blank.

Page 1-4 G1000/DA40 System Maintenance Manual

Revision 6 190-00303-03

2 SYSTEM DESCRIPTION

G1000 system installation can be accomplished only after the following Diamond aircraft modifications

have been installed:

• OAM 40-061 Autopilot (optional)

• OAM 40-68 Essential Bus

• OAM 40-073/b Slick Start System

• OAM 40-082/b IFR Lightning Protection

• OAM 40-146 Remote Avionics Provisions

• OAM 40-161/e G1000 Provisions Provisions with KAP 140 AFCS

Or OAM 40-196 G1000 Provisions without KAP 140 AFCS

• STC SA1850CH Hartzell Propeller

The G1000 integrated cockpit is installed in the DA 40 using the equipment listed in this section as well

as parts listed in Appendix A.

2.1 Equipment Descriptions

2.1.1 GDU 1040 MFD & PFD

Two Garmin GDU 1040 CDUs are installed in the Diamond instrument panel. One is configured as a

PFD and the other as a MFD (Configuration is determined by wiring harness). Both displays provide

control and display of nearly all functions of the G1000 integrated cockpit system. The displays are

located side-by-side with the GMA 1347 Audio Panel located in the middle (See Figure 2-1).

Electrical power to the PFD is from the ‘Essential’ power bus, whereas the MFD receives power from the

‘Main’ bus. Therefore, both displays power-up immediately when the aircraft master switch is turned on.

To provide proper electrical bonding, beryllium copper ‘finger’ strips are installed on the lower lip of the

display. This provides sufficient contact area to which the displays can be grounded to the airframe.

Both displays are installed in the Diamond panel using built-in ¼-turn fasteners. Each display uses an

existing connector per OAM 40-161. The ‘GDL 69’ and ‘WX500’ circuit breakers, if installed, are

pulled, banded with collars, and associated wires are disconnected and dressed with shrink tube.

Two CDU cooling fans are also installed behind the panel as shown in Figure 2-2.

G1000/DA40 System Maintenance Manual Page 2-1

190-00303-03 Revision 6

Figure 2-1. G1000 / DA 40 Panel Installation

Page 2-2 G1000/DA40 System Maintenance Manual

Revision 6 190-00303-03

2.1.2 GMA 1347 Audio Panel

The Garmin GMA 1347 Audio Panel is a digital audio panel with integrated marker beacon receiver. The GMA

1347 provides control of all cockpit intercom/mic systems as well as NAV/COM/ILS audio. The unit also provides

display reversion mode control through a large red button. Power is received from the ‘Avionics’ bus. The unit

only powers up when the avionics master switch is turned on. The GMA 1347 interfaces with the existing marker

beacon antenna as well as existing mic and phone jacks.

2.1.3 GIA 63 Integrated Avionics Unit (2)

Two Garmin GIA 63 IAUs provide VHF COM, VHF NAV, GPS NAV and other various navigation functions.

GIAs provide communication interface to all other G1000 LRUs in the system. Both GIAs are located remotely

beneath the baggage compartment in a sheetmetal enclosure, as shown in Figure 2-6 and Figure 2-7. The #1 GIA is

powered through the ‘Essential’ power bus and immediately powers up when the aircraft master switch is turned on.

The #2 GIA receives power through the ‘Avionics’ bus and powers up when the avionics master switch is turned on.

Both GIA 63s interface to the following equipment:

• .....Existing KAP 140 Flight Control System (GIA 2)

• .....Existing VOR/LOC/Glideslope Antenna System

• .....Existing VHF COM 1 & 2 Antennas

• .....Existing GPS 1 & 2 Antennas

2.1.4 GEA 71 Engine/Airframe Unit

The Garmin GEA 71 Engine/Airframe Unit provides engine/airframe data to the G1000 system. Data received from

transducers/sensors is processed, then sent to GIA 63, and subsequently to the GDU 1040 MFD. In display

reversionary mode, engine instrumentation is displayed on the PFD as well. The GEA is located behind the

instrument panel and is mounted in a vertical orientation as depicted in Figure 2-2 and Figure 2-6. Power is received

from the ‘Essential’ power bus. The GEA interfaces to the following:

• .....Manifold Pressure Sensor (MAP)

• .....Oil Pressure Sensor

• .....Fuel Pressure Sensor

• .....Tachometer Sensor

• .....Oil Temperature Sensor

• .....Fuel Flow Sensor

• .....4 Cylinder Head Temperature (CHT) Sensors

• .....4 Exhaust Gas Temperature (EGT) Sensors

• .....Alternator Current Sensor

• .....Existing Fuel Probes

• .....Existing Pitot Heat System

• .....Existing Open Door Detection Switches

• .....Existing Starter Engage System

2.1.5 GTX 33 Mode S Transponder

The Garmin GTX 33 provides Mode A, C, and S altitude and position reporting information to the G1000

system. The unit is mounted in the remote avionics enclosure below the baggage compartment (See

Figure 2-6 and Figure 2-7). Power is received from the ‘Essential’ bus. The GTX 33 interfaces with the

existing transponder antenna.

G1000/DA40 System Maintenance Manual Page 2-3

190-00303-03 Revision 6

Figure 2-2. DA40 Panel (Rear View)

Page 2-4 G1000/DA40 System Maintenance Manual

Revision 6 190-00303-03

2.1.6 GDC 74A Digital Air Data Computer

The Garmin GDC 74A provides digital air data computations to the G1000 system. The unit is mounted

horizontally behind the instrument panel and is fastened to a sheetmetal rack. Power is received from the

‘Essential’ bus. The GDC 74A connects to existing pitot/static ports as shown in Figure 2-2 and Figure

2-6.

2.1.7 OAT Probe

The Garmin GTP 59 OAT Probe provides the GDC 74A with air temperature data. The OAT probe is

mounted to the bottom starboard side of the DA 40 fuselage as shown in Figure 2-3.

Figure 2-3. GTP 59 OAT Probe

G1000/DA40 System Maintenance Manual Page 2-5

190-00303-03 Revision 6

2.1.8 GRS 77 Attitude & Heading Reference System

The Garmin GRS 77 AHRS provides attitude and heading information to the G1000 system. The unit is

mounted remotely in the baggage compartment, to the starboard side of the remote avionics enclosure

(see Figure 2-4 and Figure 2-6). Power is received from the ‘Essential’ bus. The GRS 77 interfaces with

and provides power to the GMU 44 Magnetometer. The GRS 77 supplies attitude and heading

information directly to the PFD, MFD, and to both GIAs.

Figure 2-4. GRS 77 Mount

Page 2-6 G1000/DA40 System Maintenance Manual

Revision 6 190-00303-03

2.1.9 GMU 44 Magnetometer

The GMU 44 provides horizontal and vertical magnetic field information to the GRS 77 AHRS. This

allows heading to be calculated and provides assistance during AHRS alignment. The GMU 44 is

mounted beneath the starboard wing as shown in Figure 2-5 and Figure 2-6.

Figure 2-5. GMU 44 Installation

G1000/DA40 System Maintenance Manual Page 2-7

190-00303-03 Revision 6

GDC 74A

2.2 Equipment Locations

GDC 74A

Figure 2-6. G1000 in DA 40 Equipment Locations

Page 2-8 G1000/DA40 System Maintenance Manual

Revision 6 190-00303-03

2.3 Remote Avionics Enclosure

A remote avionics enclosure allows LRUs to be inserted vertically, from above. The enclosure is also

cooled with an avionics fan and duct assembly as shown in Figure 2-6 and Figure 2-7. The enclosure is

installed as shown in Figure 2-7. The assembly is grounded to an existing grounding station using a fieldfabricated aluminum ground strap. Two braided grounding straps are also attached to the GRS 77 rack

from the enclosure. A Comant diplexer is installed on the enclosure as shown. A field-fabricated

component bracket with resistors, voltage suppressors and attached wiring is fastened to the forward

portion of the enclosure (see Section 2.5).

Figure 2-7. Remote Avionics Enclosure

G1000/DA40 System Maintenance Manual Page 2-9

190-00303-03 Revision 6

Figure 2-7. Remote Avionics Enclosure, Cont.

Page 2-10 G1000/DA40 System Maintenance Manual

Revision 6 190-00303-03

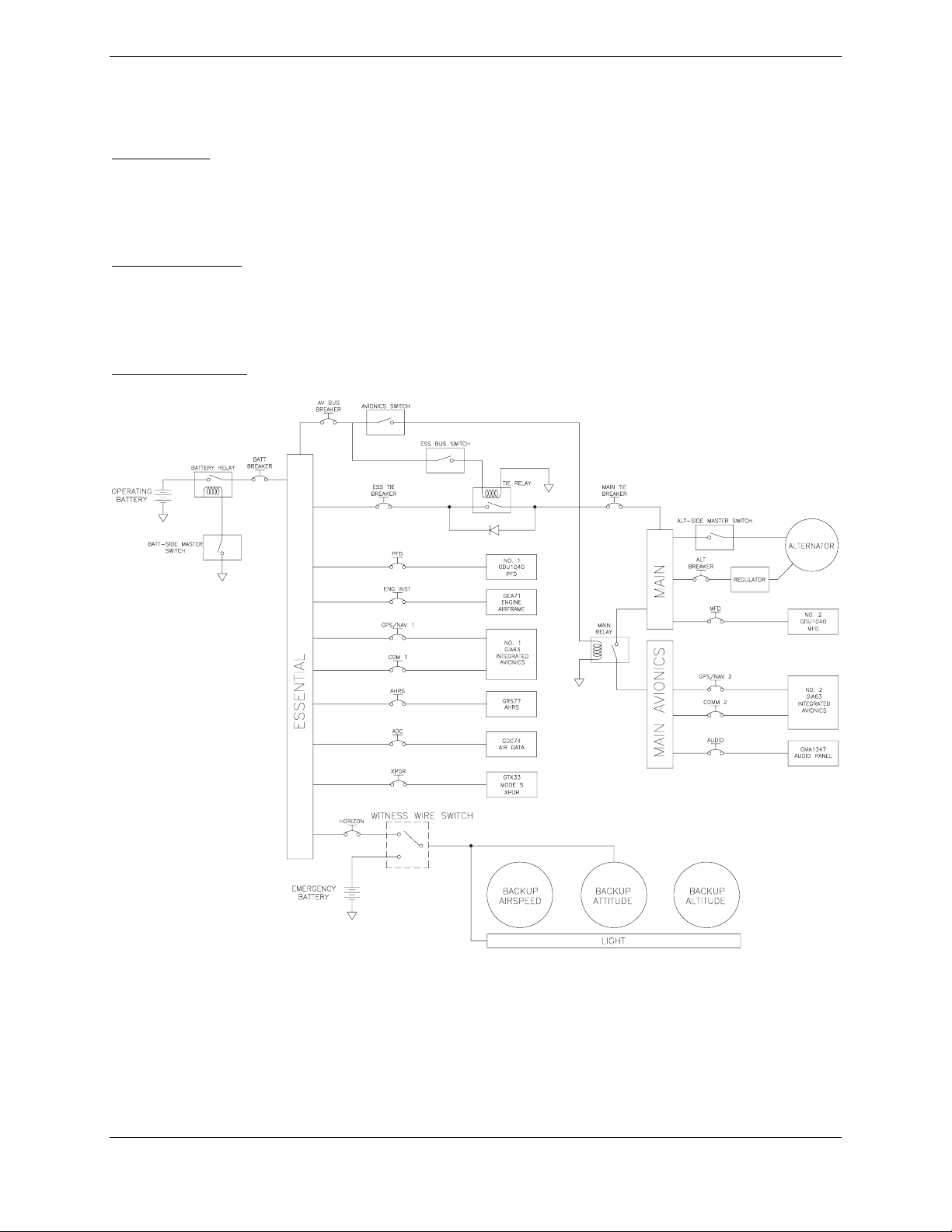

2.4 Electrical Power Distribution

Distribution of power to the G1000 occurs on three buses:

Essential Bus:

The ‘Essential’ bus is tied directly to the aircraft battery via the master switch. When the

master switch is turned on, power is immediately supplied the ‘Essential’ bus. The ‘Essential’ bus is tied

via a relay switch to the ‘Main’ aircraft bus. There are two circuit breakers on either side of the relay,

combined with a single diode, allowing the battery to be charged by the alternator. Only equipment

deemed essential for safe flight is connected to this bus.

Main Aircraft Bus:

The ‘Main’ bus receives power from the aircraft battery when tied to the ‘Essential’

bus. After the aircraft engine is started, the alternator supplies power to the aircraft ‘Main’ bus, and to the

rest of the system. In the event of an alternator or other power failure, the ‘Essential’ bus can be isolated

with the ‘Essential Bus’ switch. This causes the ‘Essential’ bus to revert to battery power. Only the MFD

receives power from the ‘Main’ bus.

Main Avionics Bus:

A ‘Main Avionics’ bus is tied to the ‘Main’ aircraft bus via the ‘Avionics Master’

switch and switch relay. Only the #2 GIA 63 and the GMA 1347 are connected to this bus.

Figure 2-8. G1000/DA40 Electrical Distribution

G1000/DA40 System Maintenance Manual Page 2-11

190-00303-03 Revision 6

2.5 Lightning Strike Protection

The following modifications to the aircraft provide additional protection of G1000 equipment from the effects of

lightning strike.

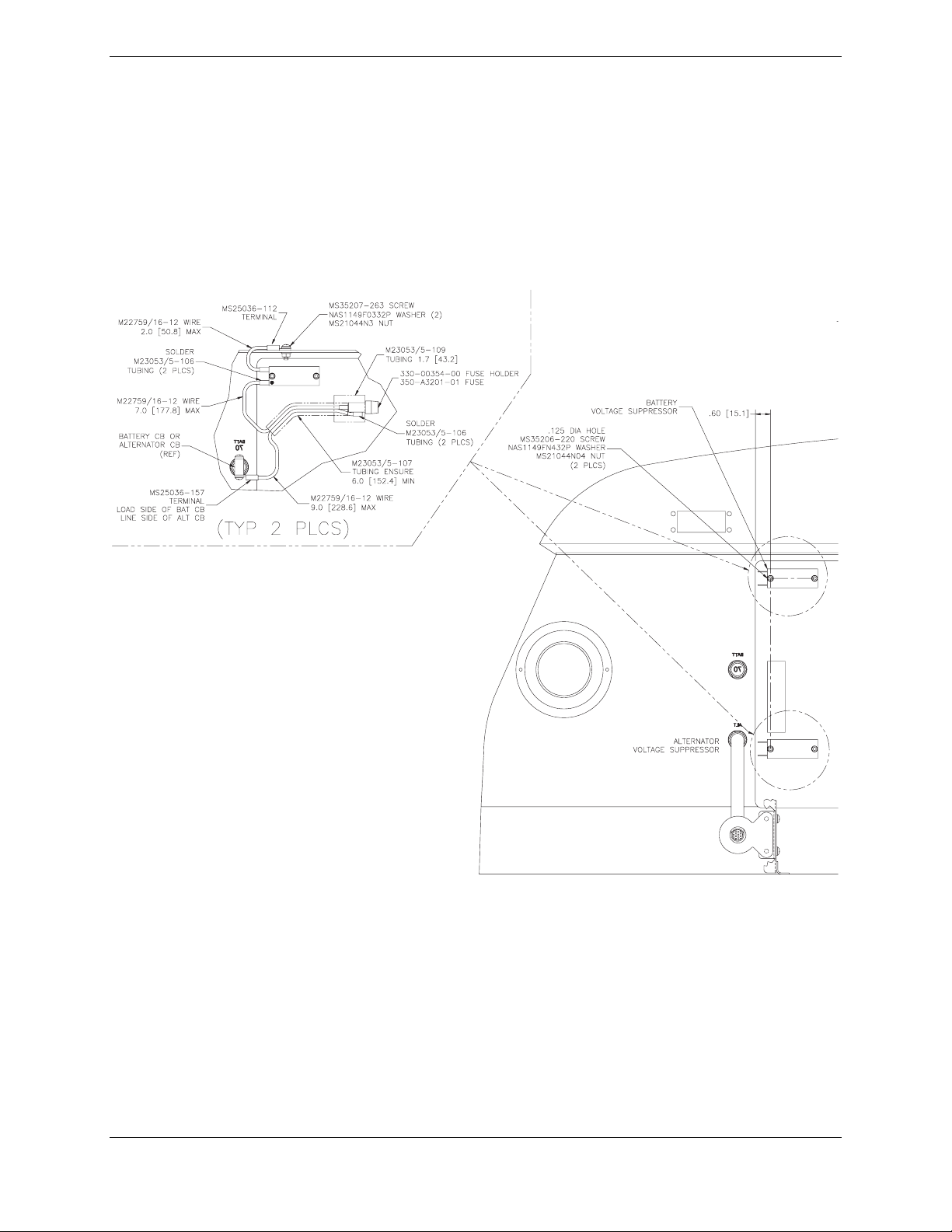

2.5.1 Alternator / Battery Voltage Suppressors & Fuses

Two Transient Voltage Suppressors (TVS) are installed behind the instrument panel near the circuit

breakers

strike. One

other is connected to the line side of the alternator circuit breaker. One 3.2 Amp slow-blow fuse is wired

in line with each

holder cap counter-clockwise and removing the fuse.

. Voltage suppressors help protect the avionics/electrical equipment against the effects of lighting

voltage suppressor is connected to the load side of the aircraft battery circuit breaker, and the

voltage suppressor, as shown in Figure 2-9. Fuses are easily removed by twisting the fuse

Figure 2-9. TVS & Fuse Installation

Page 2-12 G1000/DA40 System Maintenance Manual

Revision 6 190-00303-03

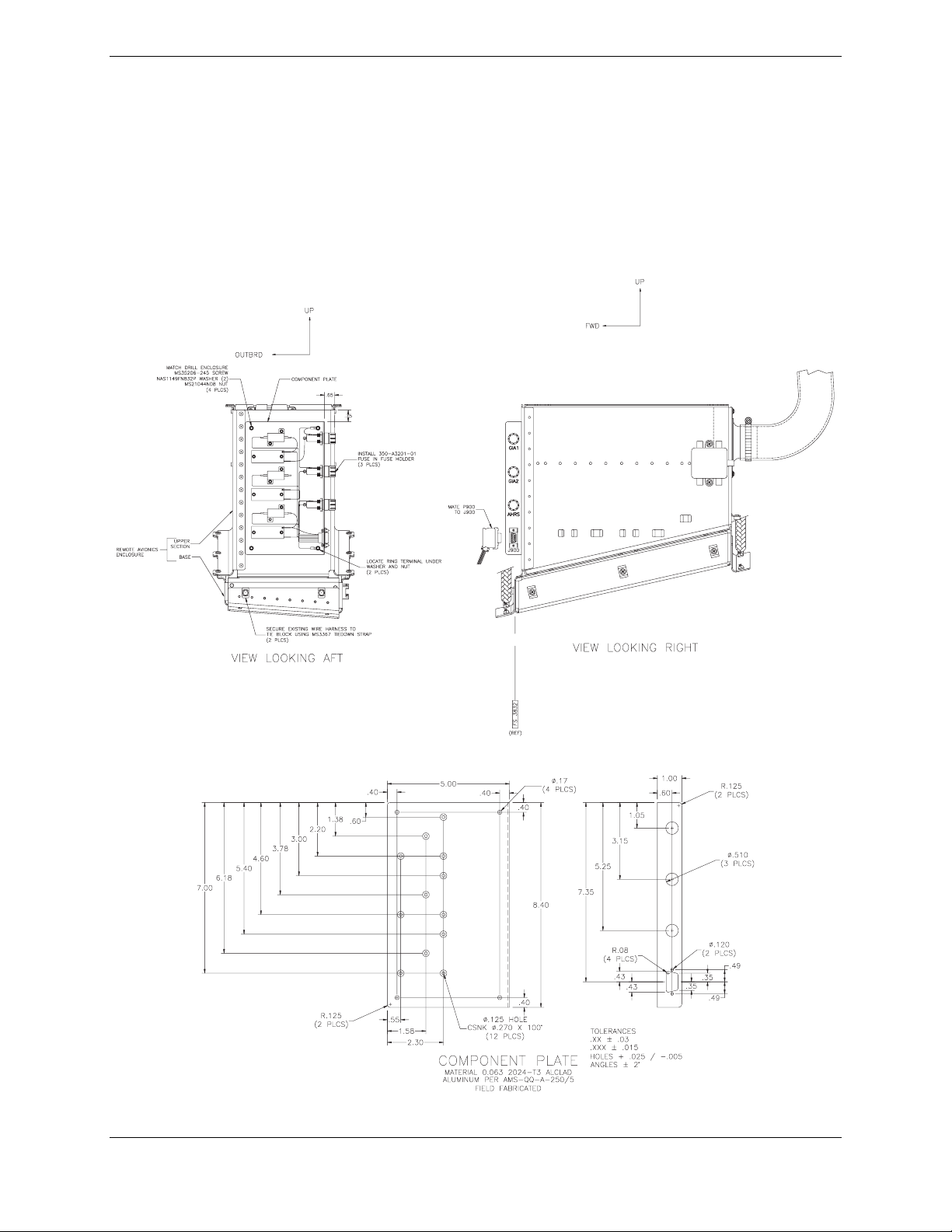

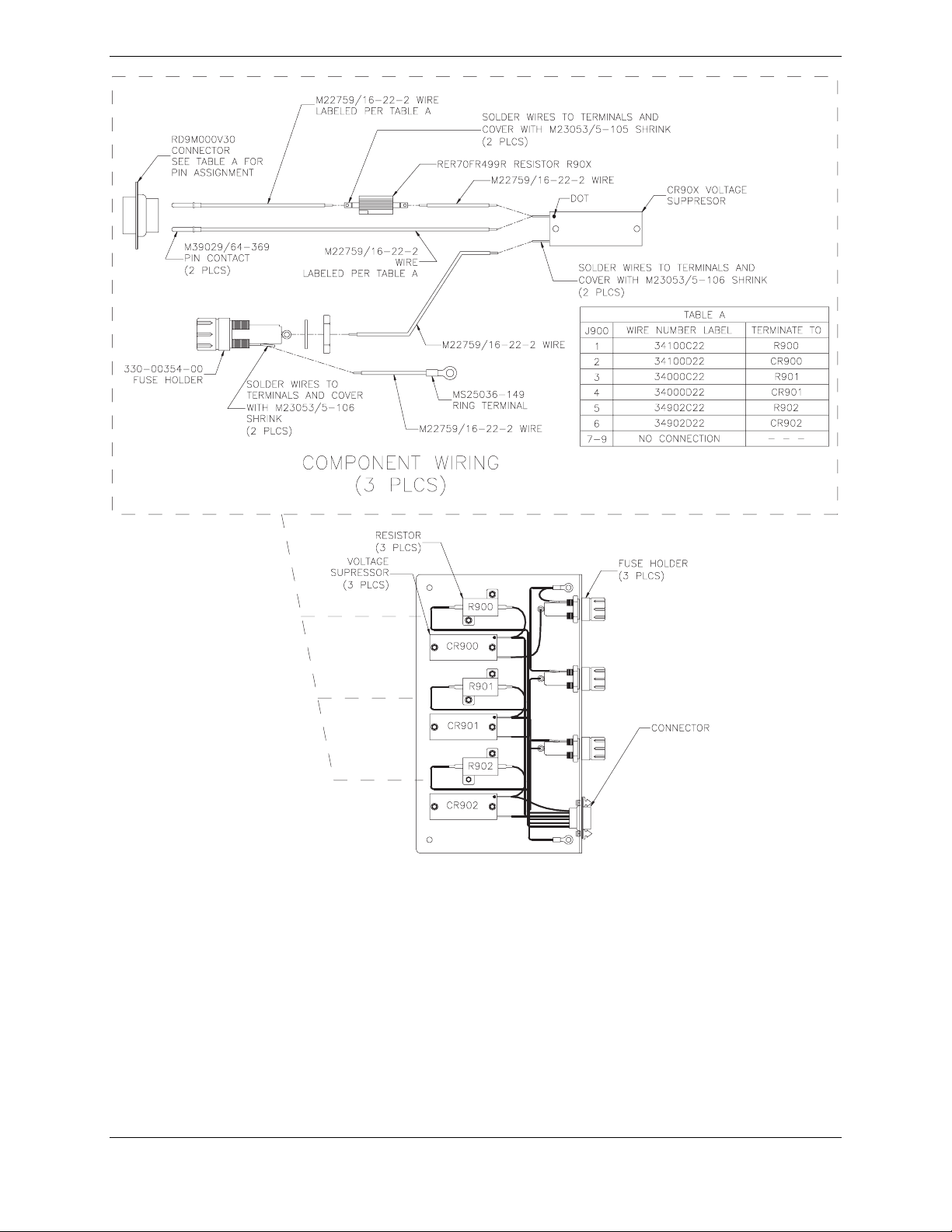

2.5.2 GIA / AHRS Lightning Protection

The GRS 77 and both GIA 63s are uniquely protected from the effects of lightning. A 0.499Ω resistor, a

transient voltage suppressor, and a 3.2 Amp slow-blow fuse are used for each GIA and the AHRS. These

components are installed on a field-fabricated aluminum block, which is mounted to the front of the

remote avionics enclosure (see Figure 2-7 and Figure 2-10). The dimensions for the mounting block are

provided in Figure 2-11. Power leads for the AHRS and both GIAs are routed from the aircraft harness to

a 9-pin connector (P900), whose mating connector is mounted to the fabricated block (J900). Figure 2-12

shows the wiring setup on the block for one set of components. Power is returned to the LRU after

passing through the resistor and voltage suppressor.

Figure 2-10. Lightning Protection Components

Figure 2-11. Component Plate Dimensions

G1000/DA40 System Maintenance Manual Page 2-13

190-00303-03 Revision 6

Figure 2-12. Component Wiring Diagram

Page 2-14 G1000/DA40 System Maintenance Manual

Revision 6 190-00303-03

2.5.3 Lightning Strike Maintenance

Proper electrical bonding of all metallic components is critical for the protection against the effects of

lighting. Severe corrosion may inhibit a component’s ability to bond to the aircraft’s electrical ground

plane.

The following summarizes maintenance practices which are implemented to maintain adequate lightning

protection for the aircraft. See Section 4, Table 4-1 for exact maintenance requirements and associated intervals:

• A 1000-hour visual inspection of all G1000 equipment, including voltage suppressors, resistors, fuses,

etc.

• An electrical bonding check of G1000 equipment every 1000 hours or anytime a lightning strike occurs

or is suspected

• Regular replacement (every 2 years) of all five 3.2 Amp slow-blow fuses ensures they are in fresh

condition.

• Replacement of voltage suppressors, resistors, and fuses anytime a lightning strike occurs or is suspected.

.

G1000/DA40 System Maintenance Manual Page 2-15

190-00303-03 Revision 6

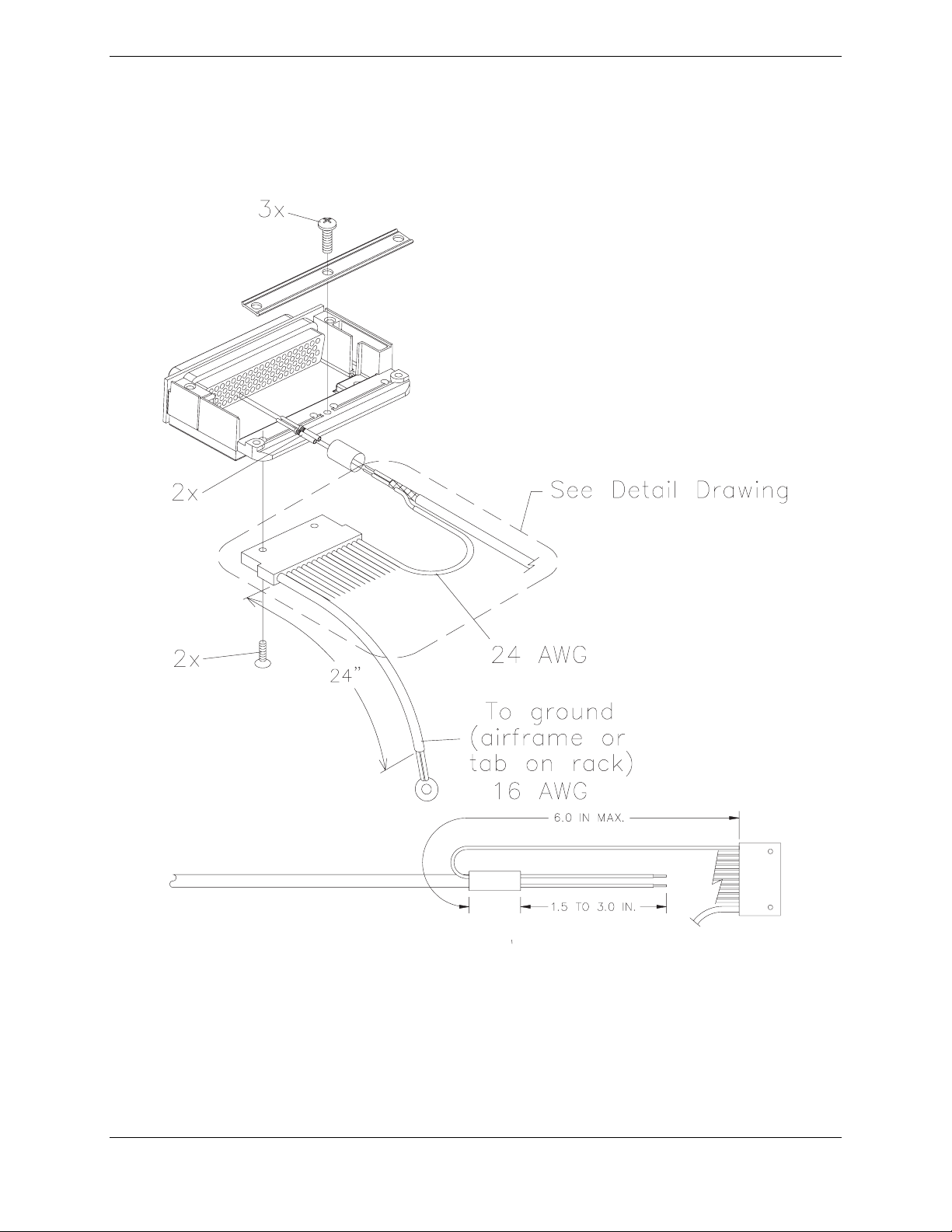

2.6 SPIDER Grounds

Most G1000 connectors employ a SPIDER grounding system to provide necessary ground reference to

shielding and/or transducers. A single 16-gauge wire is connected locally to the airframe. Additional

‘spider’ wires, 24-gauge, are used to connect shield grounds. The assembly is fastened directly to the

backshell housing with two screws. Figure 2-13 shows an example SPIDER installation.

Figure 2-13. SPIDER Ground Installation

Page 2-16 G1000/DA40 System Maintenance Manual

Revision 6 190-00303-03

2.7 Sensor Installations

2.7.1 Manifold Air Pressure

A Kulite MAP sensor measures manifold air pressure. The sensor, manifold hose, and adapter fittings are

installed as shown in Figure 2-14.

Figure 2-14. MAP Sensor

2.7.2 Oil Pressure

A Kulite pressure sensor measures oil pressure. The sensor, oil pressure hose, and fittings are installed as

shown in Figure 2-15.

Figure 2-15. Oil Pressure Sensor

2.7.3 Oil Temperature

A Norwich Aero Products oil temperature sensor is used to measure oil temperature. The sensor is

installed as shown in Figure 2-16.

G1000/DA40 System Maintenance Manual Page 2-17

190-00303-03 Revision 6

Figure 2-16. Oil Temperature Sensor

2.7.4 Fuel Pressure

A Kulite pressure sensor is used to measure fuel pressure. The sensor, fuel hose, O-rings, and associated

fittings are installed as shown in Figure 2-17.

Figure 2-17. Fuel Pressure Sensor

2.7.5 Tachometer

A tachometer provides engine RPM measurements to the G1000 system. The tachometer is installed as

shown in Figure 2-18.

Page 2-18 G1000/DA40 System Maintenance Manual

Revision 6 190-00303-03

Loading...

Loading...