Page 1

Gaggenau

en-us Installation Instructions

fr-ca Instructions d’installation

es-mx Instrucciones de instalación

2

18

36

CG280211CA

Gas cooktop

Surface de cuisson au gaz

Placa a gas

Page 2

Table of contents

1 IMPORTANT SAFETY INSTRUCTIONS.....................3

1.1 Safety definitions........................................................4

1.2 General information....................................................4

1.3 General safety instructions.........................................4

1.4 Appliance handling safety ..........................................4

1.5 Safety codes and standards.......................................5

1.6 Electrical safety..........................................................5

1.7 Gas safety..................................................................5

1.8 Propane gas installation.............................................6

1.9 Ventilation recommendations .....................................6

1.10 High altitude installation ...........................................6

1.11 State of California Proposition 65 Warnings .............6

2 Before you begin........................................................7

2.1 Parts included ............................................................7

2.2 Tools and parts needed .............................................7

2.3 General requirements ................................................7

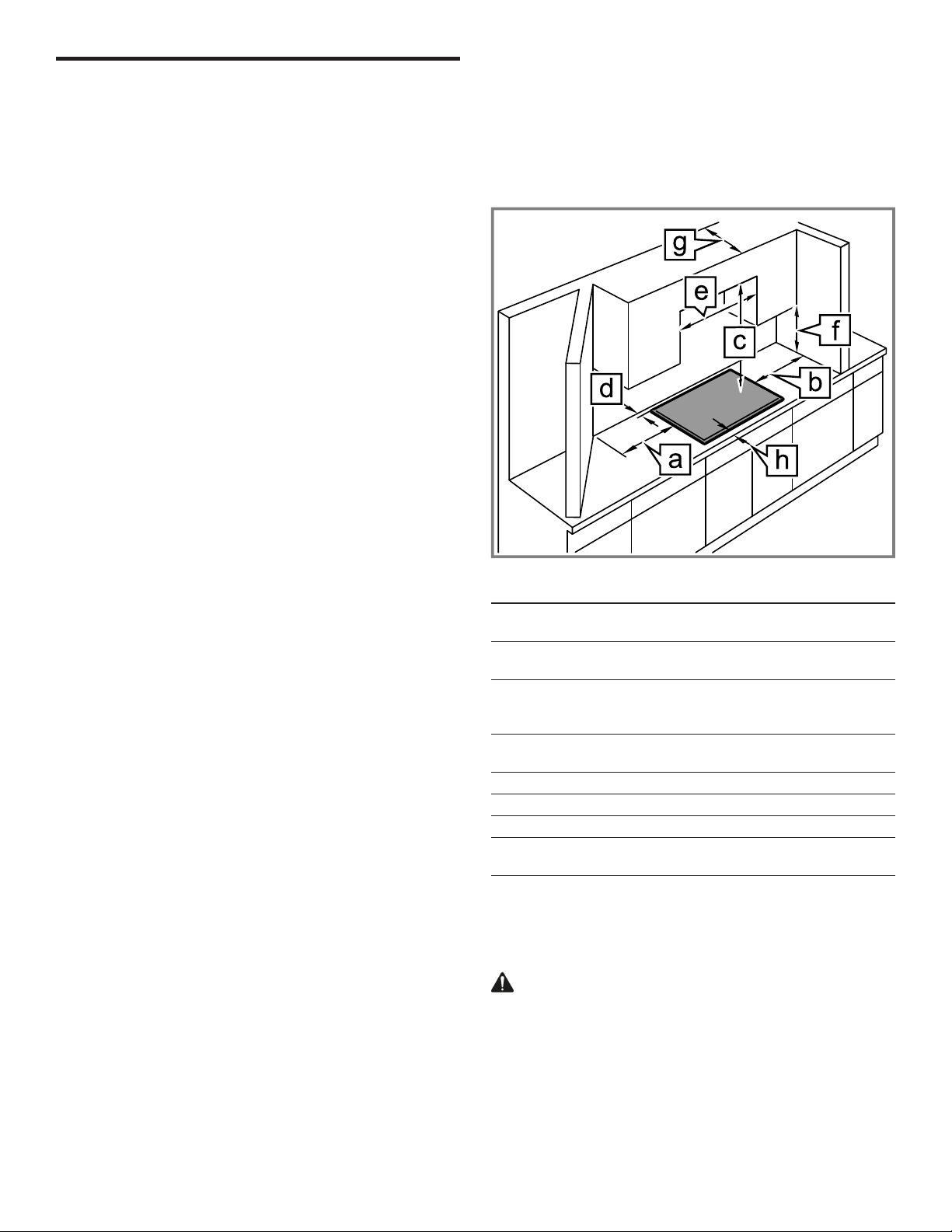

2.4 Cabinet requirements.................................................7

2.5 Countertop requirements ...........................................7

2.6 Gas requirements ......................................................8

2.7 Electrical requirements...............................................8

3 Prepare installation space.........................................8

3.1 Installation dimensions...............................................8

4 Installation procedure ...............................................9

4.1 Preparing the cooktop................................................9

4.2 Installing the pressure regulator ...............................10

4.3 Securing the cooktop to the countertop....................10

4.4 Connection overview................................................11

4.5 Connecting the gas supply line ................................11

4.6 Connecting the electrical supply...............................12

4.7 Assembling the burner parts ....................................12

4.8 Installing the burner grates.......................................12

4.9 Checking the installation ..........................................12

5 Conversion to LP gas ..............................................13

5.1 Converting the pressure regulator............................13

5.2 Replacing the orifices...............................................14

5.3 Adjusting the gas valves ..........................................15

5.4 Burner chart .............................................................16

6 Customer Service ....................................................17

6.1 Model number (E-Nr.) and production number

(FD) .........................................................................17

6.2 Rating plate location.................................................17

2

Page 3

en-us

IMPORTANT SAFETY INSTRUCTIONS

READ AND SAVE THESE INSTRUCTIONS

Read all instructions carefully before use. These precautions will reduce the risk of electrical shock, fire and injury to

persons. When using kitchen appliances, basic safety precautions must be followed including those in the following

pages.

3

Page 4

en-us

IMPORTANT SAFETY INSTRUCTIONS

READ AND SAVE THESE INSTRUCTIONS

1.1 Safety definitions

Here you can find explanations of the safety signal words

used in this manual.

WARNING

This indicates that death or serious injuries may occur as

a result of non-observance of this warning.

CAUTION

This indicates that minor or moderate injuries may occur

as a result of non-observance of this warning.

NOTICE:

This indicates that damage to the appliance or property

may occur as a result of non-compliance with this advisory.

Note:This alerts you to important information and/or tips.

1.2 General information

¡ Read this manual carefully.

¡ Keep the manual and the product information in a safe

place for future reference or for the next owner.

¡ Do not connect the appliance if it has been damaged in

transit.

1.3 General safety instructions

IMPORTANT: THE APPLIANCE MUST BE INSTALLED

BY A QUALIFIED INSTALLER.

IMPORTANT: SAVE THESE INSTRUCTIONS FOR THE

LOCAL ELECTRICAL INSPECTOR’S USE.

OWNER: PLEASE RETAIN THESE INSTRUCTIONS

FOR FUTURE REFERENCE.

INSTALLER: LEAVE THESE INSTRUCTIONS WITH

THE APPLIANCE AFTER INSTALLATION IS COMPLETE.

Examine the appliance after unpacking it. In the event of

transport damage, do not plug it in.

WARNING

If the information in this manual is not followed exactly, fire

or shock may result causing property damage or personal

injury.

Do not repair, replace or remove any part of the appliance

unless specifically recommended in the manuals. Improper installation, service or maintenance can cause injury or property damage.

▶ Refer to this manual for guidance.

▶ All other servicing should be done by an authorized ser-

vice provider.

Disconnect electrical and gas supply before servicing.

When installing a cooktop over a single oven, be sure to

follow the instructions in both the oven's and the cooktop's

installation manuals.

Never modify or alter the construction of the appliance.

The appliance should only be used if installed by a qualified technician in accordance with these installation instructions. The manufacturer is not responsible for any

damage resulting from incorrect installation.

To eliminate the risk of burns or fire by reaching over

heated surface units, cabinet storage space located above

the surface units should be avoided.

▶ If cabinet storage is to be provided, the risk can be re-

duced by installing a hood that projects horizontally a

minimum of 5" (127mm) beyond the bottom of the cabi-

net.

▶ Verify that cabinets above the cooktop are a maximum

of 13" (330mm) deep.

WARNING

The bottom of the cooktop can become hot.

▶ If the cooktop is not installed in combination with an

oven, install a horizontal panel below the cooktop to

prevent accidental contact. Refer to the section on in-

stalling a horizontal panel. →

WARNING

Remove all tape and packaging before using the appliance.

Page9

▶ Destroy the packaging after unpacking the appliance.

▶ Dispose of packaging in an environmentally responsible

manner.

▶ Never allow children to play with packaging material.

▶ Store small parts safely as they can be a choke hazard.

1.4 Appliance handling safety

WARNING

Hidden surfaces may have sharp edges.

▶ Use caution when reaching behind or under appliance.

4

Page 5

IMPORTANT SAFETY INSTRUCTIONS

READ AND SAVE THESE INSTRUCTIONS

en-us

1.5 Safety codes and standards

This appliance complies with the latest version of one or

more of the following standards:

¡ ANSI Z21.1 / CSA 1.1 Household Cooking Gas Appli-

ances

¡ Installation must conform with local codes or, in the ab-

sence of local codes, with the National Fuel Gas Code,

ANSI Z223.1/NFPA 54 or, in Canada, the Natural Gas

and Propane Installation Code, CSA B149.1.

It is the responsibility of the owner and the installer to determine if additional requirements and/or standards apply

to specific installations.

1.6 Electrical safety

¡ Installer - show the owner the location of the circuit

breaker or fuse. Mark it for easy reference.

¡ If required by the National Electrical Code (or Canadian

Electrical Code), this appliance must be installed on a

separate branch circuit.

¡ Local codes vary. The installer is responsible for ensur-

ing that the installation, connections, and grounding

comply with all applicable codes. The manufacturer is

not responsible for any issues associated with the improper installation of this product.

¡ The appliance must be electrically grounded in accor-

dance with local codes or, in the absence of local

codes, with the National Electrical Code, NFPA 70 latest edition or, in Canada, the Canadian Electric Code,

CSA C22.1-02.

¡ Be sure your appliance is properly installed and

grounded by a qualified technician. Installation, electrical connections and grounding must comply with all applicable codes.

¡ Do not use an extension cord.

¡ Do not use an adapter.

¡ Refer to the rating plate for more information.

→

"Rating plate location", Page17

WARNING

Before installing, turn power OFF at the service panel.

▶ Lock service panel to prevent power from being turned

ON accidentally.

For appliances equipped with a cord and plug, do not cut

or remove the ground prong.

▶ It must be plugged into a matching grounding type re-

ceptacle to avoid electrical shock.

▶ If there is any doubt as to whether the wall receptacle is

properly grounded, the customer should have it

checked by a qualified electrician.

GROUNDING INSTRUCTIONS

▶ This appliance must be grounded.

▶ Grounding reduces the risk of electric shock by provid-

ing a safe pathway for electric current in the event of a

short circuit.

▶ Be sure your appliance is properly installed and

grounded by a qualified technician.

▶ Installation, electrical connections and grounding must

comply with all applicable codes.

Do not use an extension cord. If the power supply cord is

too short, have a qualified electrician install an outlet near

the appliance.

Before you plug in an electrical cord, be sure all controls

are in the OFF position.

Before you turn on power supply, make sure all controls

are in the OFF position.

1.7 Gas safety

Requirements for gas supply:

¡ Install a gas shutoff valve near the appliance. It must be

easily accessible in an emergency.

¡ Leak testing must be conducted by the installer accord-

ing to the instructions in this manual.

¡ The appliance and its individual shutoff valve must be

disconnected from the gas supply piping system during

any pressure testing at pressures in excess of ½psi

(3.5kPa).

¡ The appliance must be isolated from the gas supply

piping system by closing its individual manual shutoff

valve during any pressure testing of the gas supply pip-

ing system at test pressures equal to or less than ½psi

(3.5kPa).

¡ The minimum supply pressure must be 1" water column

above the manifold pressure printed on the rating label.

The maximum supply pressure must not exceed 14.0

inches water column (34.9Millibars).

¡ A metal flex line or fixed metal pipe shall be used to

connect gas to the appliance. If a metal gas line cannot

be used, consult your local certified electrician or local

electric codes for proper grounding.

IMPORTANT SAFETY NOTICE: Burning gas cooking fuel

generates some by-products which are on the list of substances which are known by the State of California to

cause cancer or reproductive harm. To minimize exposure

5

Page 6

en-us

IMPORTANT SAFETY INSTRUCTIONS

READ AND SAVE THESE INSTRUCTIONS

to these substances, always operate this unit according to

the instructions contained in this booklet and provide good

ventilation.

1.8 Propane gas installation

¡ The propane gas tank must be equipped with its own

high pressure regulator. In addition, the regulator supplied with this unit must also be used.

¡ The appliance is shipped from the factory for use with

natural gas. It must be converted for use with propane.

A qualified technician or certified installer must do the

conversion.

¡ For use with propane the appliance must be converted

per the LP conversion instructions.

→

"Conversion to LP gas", Page13

For Massachusetts installations

¡ Installation must be performed by a qualified or li-

censed contractor, plumber or gas fitter qualified or licensed by the state, province or region where this appliance is being installed.

¡ Shut-off valve must be a “T” handle gas cock.

¡ Flexible gas connector must not be longer than

36inches.

Burners should be checked at the lowest setting, if the

flame is not stable the simmer should be increased until

the flame is stable. This can be done by adjusting the bypass screw in the valve. If flame performance is satisfactory, adjustment will not be required. It is required that a

certified professional make the high altitude adjustments

during installation.

1.11 State of California Proposition 65

Warnings

This product may contain a chemical known to the State

of California, which can cause cancer or reproductive

harm. Therefore, the packaging of your product may bear

the following label as required by California:

Installer - show the owner where the gas shut-off valve is

located.

1.9 Ventilation recommendations

We strongly recommend the installation of a ventilation

hood above this appliance.

The hood must be installed according to instructions furnished with the hood.

WARNING

The appliance should not be installed with a ventilation

system that blows air downward toward the burners. This

type of ventilation system may cause ignition and combustion problems with the gas cooking appliance resulting in

personal injury or unintended operation.

1.10 High altitude installation

This appliance has been tested for operation up to an altitude of 10,100ft (3,080m) elevation above sea level.

For altitudes above 2,000ft (610m) elevation above sea

level, burner flame adjustments may be necessary.

6

Page 7

Before you begin en-us

Before you begin

2 Before you begin

Before you begin

Read these instructions before you begin to install your

appliance.

2.1 Parts included

After unpacking all the parts, check for any damage in

transit and for completeness of delivery.

¡ Cooktop

¡ Foam tape

¡ Hold-down brackets (4)

¡ Screws, #10-32 x 2½" (63.8mm), (4)

¡ Sheet metal screws, #8 x 3/8" (9.5mm), (4)

¡ Washers (4)

¡ Burner grates (3)

¡ Burners (5)

¡ Burner caps (6)

¡ Pressure regulator

¡ LP gas conversion kit

2.2 Tools and parts needed

Prepare these tools and accessories before you start to install your appliance.

¡ Pencil

¡ Measuring tape

¡ Cross head screwdriver

¡ Drill with bit 1/4" (6mm)

¡ Jigsaw

¡ Adjustable wrench

¡ Teflon® tape - gas rated

¡ Flathead screwdriver, 1/8"

Additional tools needed for LP gas conversion

¡ 7mm socket wrench

¡ 7mm open end wrench

¡ T10 star bit screwdriver

¡ T20 star bit screwdriver

¡ Small piece of tape

Notes

¡ For stand-alone installation a horizontal panel below the

cooktop may be needed.

→

"Installation with horizontal panel", Page9

¡ Additional materials may be necessary for installation in

solid surface countertops. Contact the countertop manufacturer.

2.3 General requirements

¡ If the cooktop will be installed in combination with an

oven, refer to the Approved Combination Matrix included with the product for cutout and clearance dimensions.

2.4 Cabinet requirements

Ensure that the cabinetry at the installation location meets

the requirements for a safe installation.

The minimum spaces that must be maintained when installing the gas cooktop shall be the following:

a min. 13" (330mm)

for installation next to oven min. 13" (330mm)

b min. 13" (330mm)

for installation next to oven min. 13" (330mm)

c min. 30" (762mm) clearance between the top of

the cooking surface and the bottom of combustible

constructions

d min 3" (76mm);

for installation in kitchen islands, min. 4" (100mm)

e min. 30" (760mm) centered over cooktop

f min. 18" (458mm)

g max. 13" (330mm)

h min. 1¾" (48mm);

for installation in kitchen islands, min. 4" (100mm)

Ensure that the following requirements are met when planning the installation of your appliance.

¡ Plan the installation of the unit so that the power cord,

gas shut-off valve and gas pressure regulator are accessible from the front of the cabinet.

¡ Make sure the gas supply line does not interfere with

the back of the appliance.

¡ The cabinet in which the cooktop is installed must be

properly secured, level and stable.

¡ Any laminated coverings and glue on cabinets next to

the cooktop must be made of non-flammable and heat

resistant materials. Refer to local building codes for acceptable materials.

¡ This appliance cannot be installed above refrigerators,

washing machines, dishwashers or similar.

2.5 Countertop requirements

Ensure that the countertop into which the cooktop is to be

installed meets these requirements for a safe installation.

WARNING

To reduce the risk of ignition of surrounding combustible

materials, install at least 13" (330mm) from both sidewalls

and at least 3" (76mm) from the rear wall.

¡ The countertop must be level.

¡ The stability of the countertop must be maintained after

the cut-out has been made.

7

Page 8

en-us Prepare installation space

¡ Solid surface or laminate countertops often require spe-

cial installations. For example, heat-reflective tape and

rounded corners may be necessary. Contact the countertop manufacturer for instructions specific to your

countertop.

2.6 Gas requirements

Ensure that the requirements for the gas supply are met.

The cooktop is shipped from the factory for use with natural gas. For use with LP conversion, a certified technician

or installer must do the conversion.

Supply pressure:

¡ Natural Gas: 7 inches water column (17.4 Millibars)

¡ Propane Gas: 11 inches water column (27.4 Millibars)

¡ The propane gas tank must be equipped with its own

high pressure regulator in addition to the pressure regulator supplied with this unit.

2.7 Electrical requirements

Ensure that the following electrical requirements are met.

CAUTION

Do not use an extension cord with this appliance.

¡ This appliance requires a 60Hz, 15Amp, 120V/AC

connection.

¡ The appliance is equipped with a 40" (1000mm) power

cord.

¡ The power connection must remain accessible from the

front of the cabinet after the installation is complete.

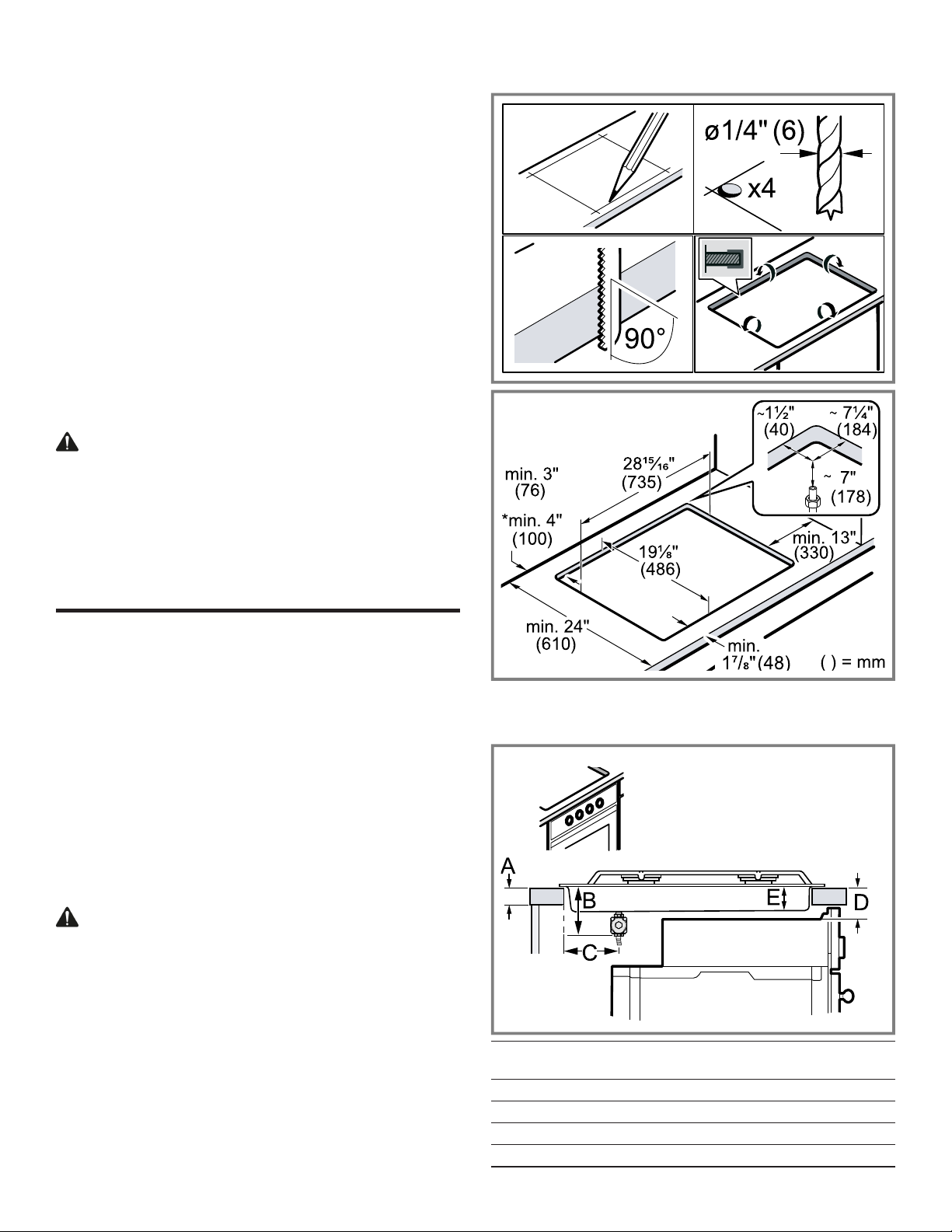

3.1 Installation dimensions

Prepare installation space

3 Prepare installation space

Prepare installation space

Create the cutout in the countertop according to the instructions.

General countertop requirements:

¡ The angle of the cut surface to the countertop surface

must be 90°.

¡ With multi-layered countertops, secure strips laterally in

the cutout if necessary.

¡ After creating the cutout, remove all debris.

¡ Follow the countertop manufacturer's recommendations

for protecting the cut edges, e.g. apply heat resistant foil

tape.

¡ If the cooktop will be installed in combination with an

oven, refer to the Approved Combination Matrix included with the product for cutout and clearance dimensions.

WARNING

The bottom of the cooktop can become hot.

▶ If the cooktop is not installed in combination with an

oven, install a horizontal panel below the cooktop to

prevent accidental contact. Refer to the section on installing a horizontal panel. →

Page9

*For installation in a kitchen island.

Installation over oven

A min. ¾" (19 mm)

max. 2" (50 mm)

B 5⅞" (150 mm)

C 2¾" (70 mm)

D Refer to Approved Combination Matrix

E 2⅜" (60)

8

Page 9

Installation procedure en-us

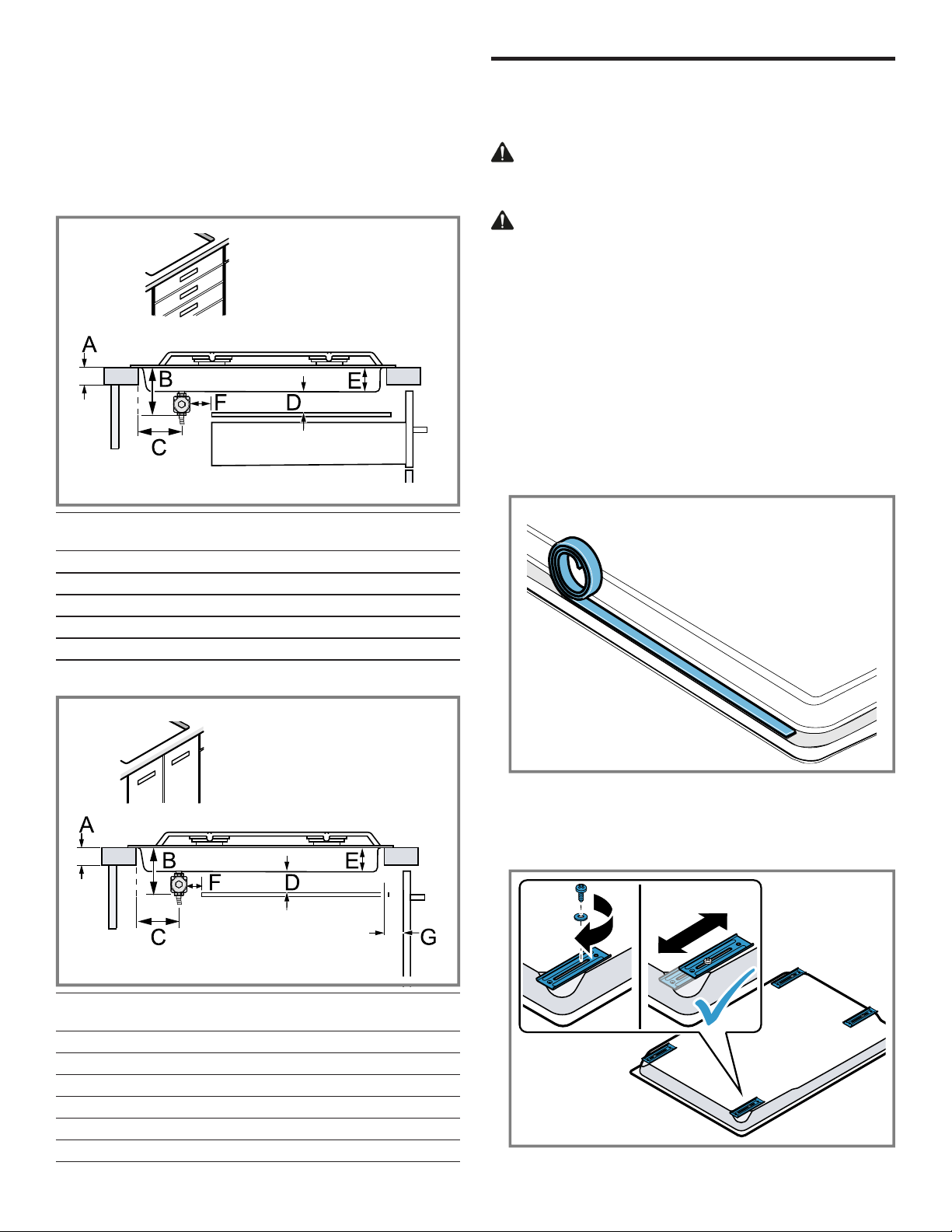

Installation with horizontal panel

If there is no oven beneath the cooktop, install a horizontal

panel. To allow access to the power supply connection

and regulator maintain a minimum clearance of

⅜" (10mm) from the edges of the panel(F).

IMPORTANT: Complete the installation of the cooktop before installing the horizontal panel.

Installation above a drawer

Installation procedure

4 Installation procedure

Installation procedure

Follow these instructions to install the cooktop into the

countertop.

CAUTION

Sharp edges.

▶ Use protective gloves when installing the appliance.

CAUTION

The appliance is heavy.

▶ It is recommended that two people install this appliance.

4.1 Preparing the cooktop

Note:ONLY FOR MODEL NGM8648UC: If the appliance

is to be used with LP gas, carry out the LP gas conversion

BEFORE installing the appliance in the countertop.

→

"Conversion to LP gas", Page13

1. Place the cooktop face down on a soft and stable sur-

face. Use the foam sheet from the packaging to protect

surfaces from scratching.

2. Apply the included foam sealing tape around the edges

of the underside of the appliance along the rough-in box

flange.

A min. ¾" (19 mm)

max. 2" (50 mm)

B 5⅞" (150 mm)

C 2¾" (70 mm)

D min. 0" (0 mm)

E 2⅜" (60)

F min. ⅜" (10 mm)

Installation above a cabinet door

3. Attach the hold-down brackets to the underside of the

cooktop with the provided short screws and washers.

Loosely tighten the screws so the clamps do not move

freely. Rotate the hold-down brackets so that the appliance can be placed in the cutout.

A min. ¾" (19 mm)

max. 2" (50 mm)

B 5⅞" (150 mm)

C 2¾" (70 mm)

D min. 0" (0 mm)

E 2⅜" (60)

F min. ⅜" (10 mm)

G min. 1" (25)

9

Page 10

en-us Installation procedure

Note:The rating plate will not be accessible after installation. Make a note of your appliance's details or refer to the

enclosed appliance certificate.

→

"Rating plate location", Page17

4.2 Installing the pressure regulator

WARNING

Do not attempt any adjustment of the pressure regulator,

except when converting to propane. Adjustments could

lead to leaks or cause incorrect gas pressure to the appliance.

Make sure the used gas connection line is not connected

to the gas supply, before carrying out the following steps.

Note:All pipe connections must be sealed in accordance

with local codes.

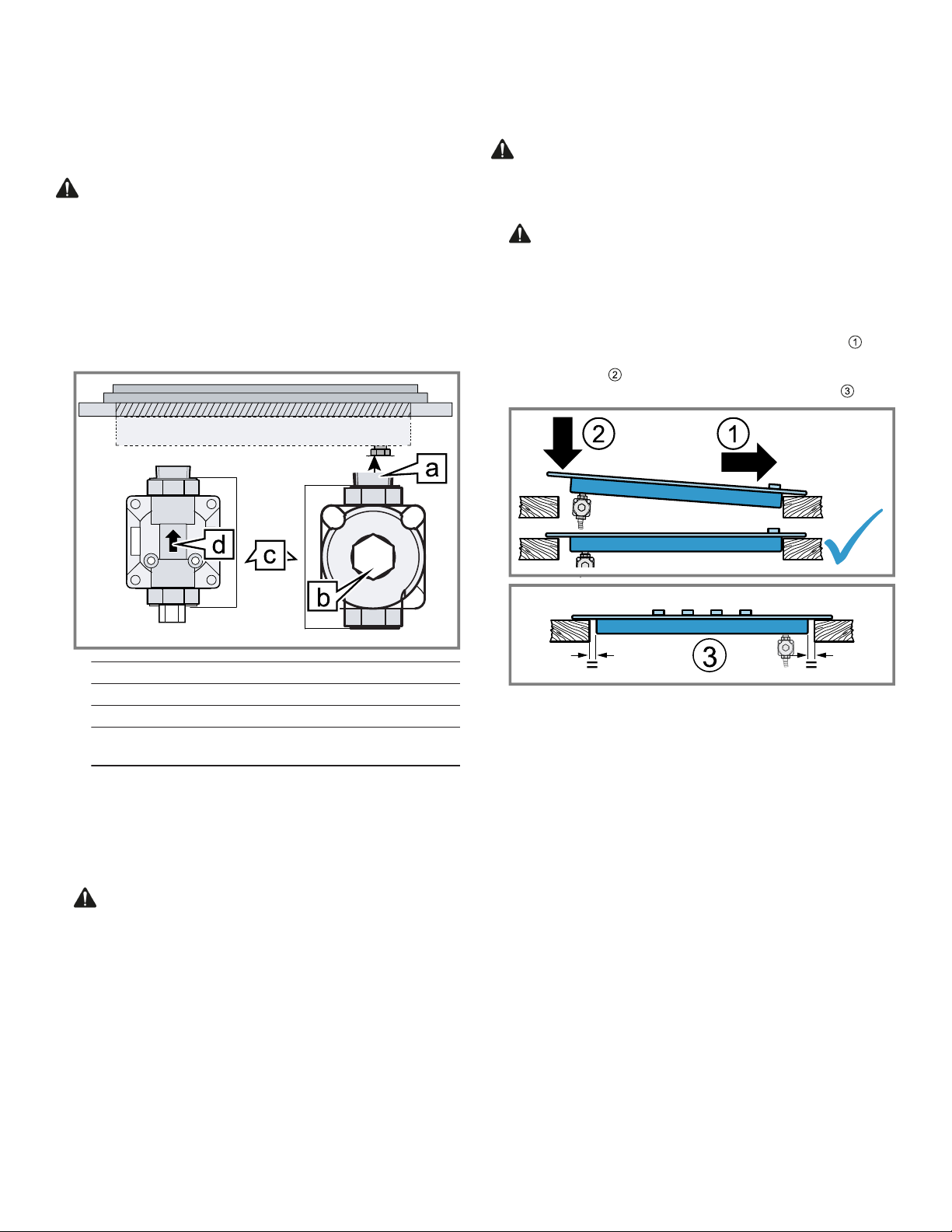

1. Identify the parts of the pressure regulator.

4.3 Securing the cooktop to the countertop

The cooktop must be secured from below using the holddown brackets provided.

WARNING

Before installing, turn power OFF at the service panel.

▶ Lock service panel to prevent power from being turned

ON accidentally.

1.

CAUTION Do not let the cooktop drop into place.

▶ Make sure that the cooktop is supported along the

edges when carefully placing it into the cutout.

Turn the cooktop over carefully making sure not to damage the pressure regulator and gas line.

‒ Place the cooktop carefully into the countertop

cutout, pulling it towards the front of the cutout .

‒ Lower the rear of the cooktop so that is rests flat on

the counter .

‒ Center the cooktop left and right in the cutout .

a Appliance manifold connection

b Conversion cap

c Pressure regulator

d Arrow on pressure regulator, shows the direc-

tion of gas flow

2. Apply Teflon® tape on the threads of the manifold pipe.

Install the pressure regulator (supplied with cooktop) to

the gas inlet with the gas flow arrow facing the manifold

inlet.

3. Firmly hand tighten the regulator, then further tighten ¼

turn to a maximum of one complete turn. Align the regulator so that the conversion cap is easily accessible.

4.

WARNING Never reuse a gas connector. Repeated bending, flexing, or extreme vibration will cause

metal fatigue and must be avoided.

Apply Teflon® tape to the male threads, then connect a

new ½" metal flex line or fixed metal pipe connection to

the pressure regulator.

Note:For installations with little space, use a 90° street

elbow (not supplied) to orient the regulator horizontally.

10

Page 11

Installation procedure en-us

2. Insert the 2½" clamping screws into the threaded holes

of the hold-down brackets, slide or rotate the brackets

so that the clamping screws will contact the underside

of the countertop.

‒ Protect delicate countertops by placing a wooden

disk underneath.

‒ Hand-tighten the first screw and check the cooktop

position, then secure the cooktop by tightening all

clamping screws .

‒ Tighten the screws to the cooktop .

Note:Do not use silicone to glue the cooktop to the

countertop surface.

4.4 Connection overview

Refer to this illustration for the location of the gas and

electric connection of the appliance.

Note:Your appliance is equipped for use with natural gas

on delivery. If you want to use your appliance with LP gas

refer to the section on LP gas conversion before continuing with the installation. →

Page13

g 120V receptacle

h Gas cut-off valve

i Gas supply line connection fitting

j Floor

4.5 Connecting the gas supply line

The appliance is shipped from the factory for use with natural gas. If you want to use propane gas it must be converted. A qualified technician or installer must do the conversion.

Note

Ensure the following requirements are met before you try

to connect the appliance to the gas supply:

¡ Before connecting the appliance, check whether the lo-

cal connection conditions such as gas type and gas

pressure match the appliance settings.

¡ Make sure the gas supply is turned off at the manual

shutoff valve before connecting the appliance.

¡ The gas connection must be in a location that permits

access to the manual shut-off valve and which, if applicable, is visible after opening the door or drawers of the

cabinet.

¡ The metal flex gas line must not come into contact with

moving parts of the fitted unit (e.g. drawers) or be laid in

areas where it could become trapped or damaged.

¡ The metal flex gas line must not come into contact with

a cooktop, oven, dishwasher, refrigerator, washing machine, hot water pipe, radiator or any other appliance installed in the vicinity of the gas cooktop.

¡ The metal flex gas line must not be subject to rubbing,

vibrations, kinking or any other kind of deformation. It

should be checked along its entire length with the cooktop in the installation position.

¡ All pipe connections must be sealed in accordance with

local codes.

▶ Connect the metal flex gas line or fixed metal pipe con-

nection from the cooktop pressure regulator to the manual shut-off valve.

a Cooktop rough-in box

b Arrow on pressure regulator, shows the direction of

gas flow

c Pressure regulator

d ½" female pipe threads

e Metal flex gas line

f Power cord (40"/1m)

Checking the gas line for leaks

Check the gas supply line connections for leaks using a

soap solution or non-corrosive leak detection fluid. Do not

use a flame of any sort.

Note

Important notes for gas connection:

¡ The appliance and its individual shutoff valve must be

disconnected from the gas supply piping system during

any pressure testing at pressures in excess of ½psi

(3.5kPa).

¡ The appliance must be isolated from the gas supply pip-

ing system by closing its individual manual shutoff valve

during any pressure testing of the gas supply piping

system at test pressures equal to or less than ½psi

(3.5kPa).

1. Turn on gas.

2. Apply a soap solution or non-corrosive leak detection

fluid to all joints and fittings in the gas connection between the shut-off valve and the cooktop. Also check

gas fittings and joints in the cooktop if the connections

may have been disturbed during installation.

a Bubbles appearing around fittings and connections indi-

cate a leak.

11

Page 12

en-us Installation procedure

1

2

3

4

4

3

2

1

1

2

3

4

3. If a leak appears, turn off the supply line gas shut-off

valve and tighten the connections.

4. Retest for leaks by turning on the supply line gas shutoff

valve.

a When the leak check is complete and no bubbles ap-

pear, the test is complete.

5. Wipe off all soap solution or detection fluid residue.

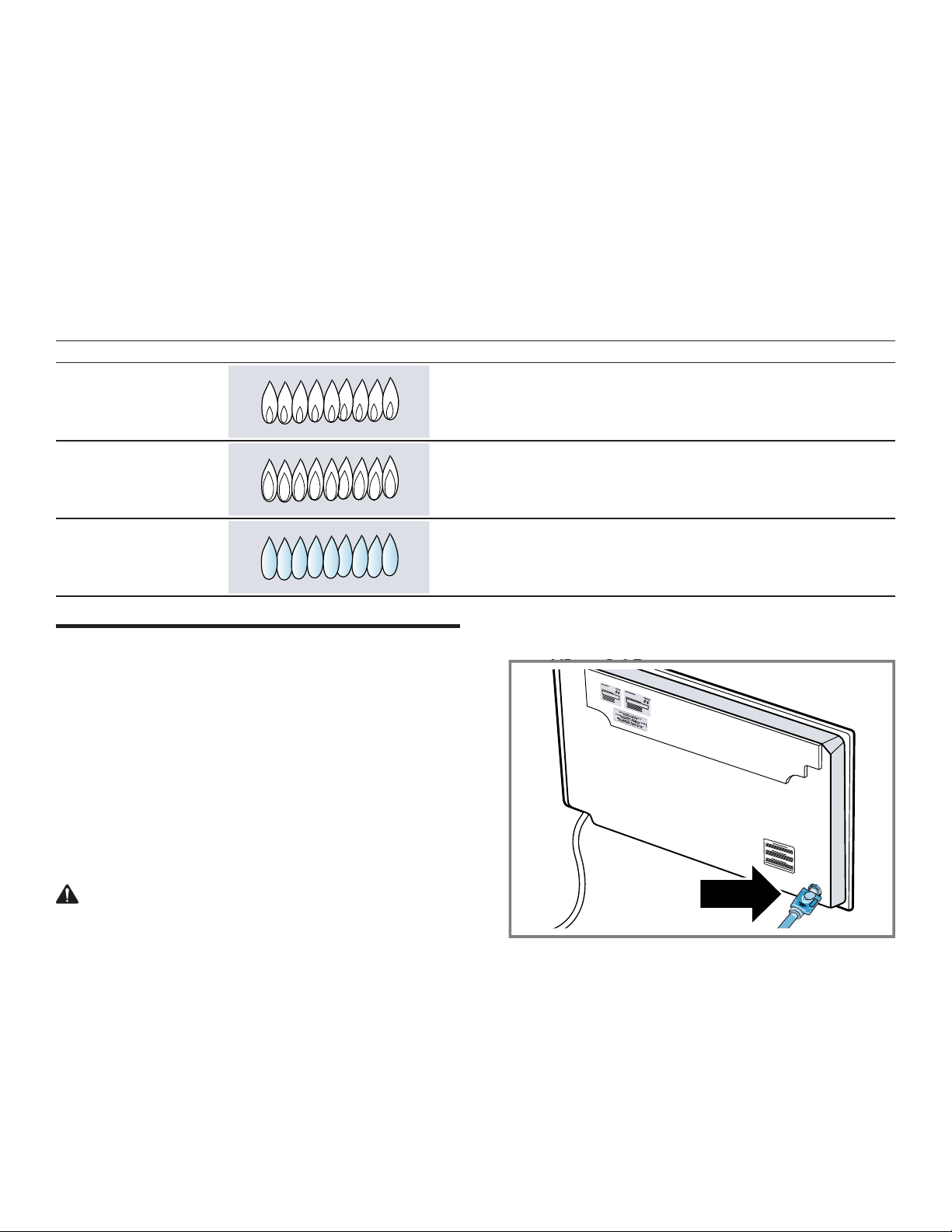

4.6 Connecting the electrical supply

CAUTION

Before you plug in the electrical cord, make sure that the

gas shut-off valve and all burner controls are in the OFF

position.

▶ Connect the plug of the electrical cord to a grounded

power outlet. The outlet must be accessible after the installation of the appliance is complete.

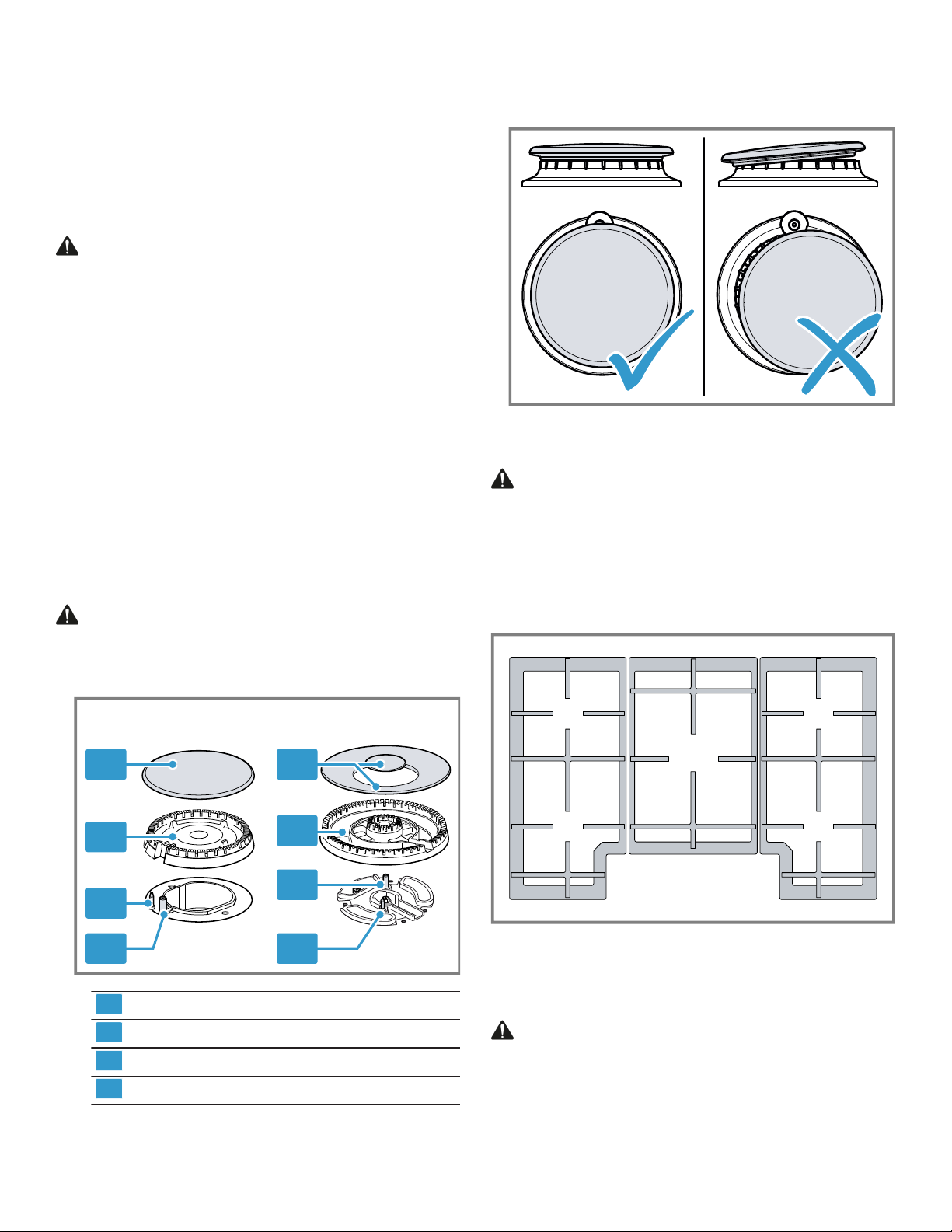

4.7 Assembling the burner parts

The burner parts must be properly placed for the cooktop

to function properly.

Note

If the burner parts are not properly placed, one or more of

the following problems may occur:

¡ The burner flames are too high.

¡ Flames shoot out of the burners.

¡ The burners do not ignite.

¡ The burner flames light unevenly.

¡ The burners emit gas odor.

WARNING

Remove all tape from the burner parts and the cooktop

surface before using the appliance.

2. Check to make sure that there is no gap between the

burner parts. You may gently try to move the burner

parts from side to side to check if they are properly

seated.

4.8 Installing the burner grates

WARNING

Improperly positioned grates can cause flare-ups.

▶ Position all grates properly on the cooktop whenever

the cooktop is in use to properly support pots and avoid

spills.

▶ Make sure each of the four feet of the grates is placed

into the corresponding dimples on the cooktop surface.

▶ Do not use a grate if the rubber feet are missing or

damaged.

1. Assemble the burner parts according to the illustration.

Burner cap

Burner base

Thermocouple

Igniter

Make sure that the prongs of the burner cap fit snugly

into the groove of the burner base.

4.9 Checking the installation

Check if your unit is working properly after you have completed the installation steps.

WARNING

Before you turn on power supply, make sure all controls

are in the OFF position.

1. Ensure that the burner caps are properly positioned.

2. Turn each burner on in turn and verify that the electric

igniters are working.

12

Page 13

Conversion to LP gas en-us

3. Turn the control knob between the highest and lowest

setting. Make sure the flame does not go out and there

are no flashbacks.

4. If you have carried out an LP gas conversion, check the

lowest setting to confirm the flames are stable on the

ports and the set screws do not need to be readjusted.

5. Check the flame characteristics.

6. After completing all checks, complete the installation of

the horizontal panel or oven. →

Page9

Note:The appliance is shipped from the factory for use

with natural gas. If you want to use propane gas, it must

be converted. A qualified technician or installer must do

the conversion. Refer to Conversion to LP gas.

→

Page13

The flame should be blue with a minimal yellow tip on

the outer cone.

Flame characteristics

The color of the flame tells you if the gas supply is properly adjusted.

Note:Allow the appliance to operate for 4 to 5minutes before evaluating the flame. Some yellow streaking is normal dur-

ing the initial startup.

Flame Image Measure

Completely or mostly

yellow

Yellow tips on outer

Verify that the regulator is set for the correct fuel. Retest after adjustment.

Normal for LP gas

cone

Soft blue Normal for natural gas

Conversion to LP gas

5 Conversion to LP gas

Conversion to LP gas

Your appliance is equipped for use with natural gas on de-

1. Locate the pressure regulator on the bottom right end of

the appliance.

livery. It can be converted to LP gas supply.

The components required for conversion to LP gas are

contained in the LP conversion kit included with this appliance, or are available from Customer Service.

→

"Customer Service", Page17

Only a qualified technician or installer is authorized to convert the appliance to another gas type.

Before carrying out the conversion, turn off the electricity

and gas supply.

5.1 Converting the pressure regulator

WARNING

Turn off the electricity and gas supply before carrying out

the conversion.

Requirement:Complete the installation instructions in this

manual up to and including section

→

"Securing the cooktop to the countertop", Page10

fore starting the LP conversion.

be-

13

Page 14

en-us Conversion to LP gas

2. Remove the hexagon shaped conversion cap from the

regulator. Make sure not to dislodge the gasket on

the cap or the spring inside the regulator.

3. Grasp the plastic orifice stem firmly and pull it force-

fully from the conversion cap . The stem snaps snugly

into an indent in the cap and may require a strong pull

to remove. It may be helpful to gently “rock” the plastic

stem while pulling it from the metal cap.

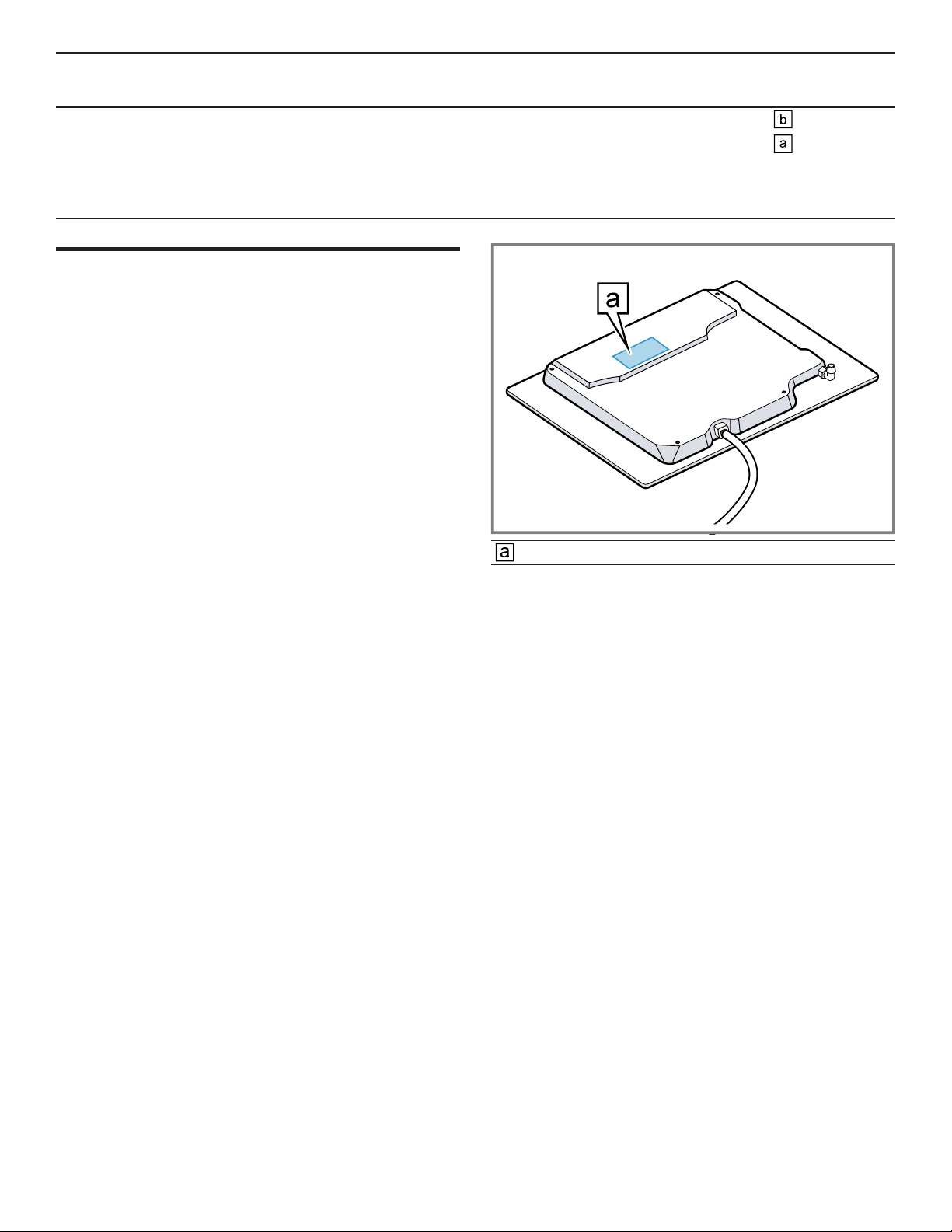

7. IMPORTANT: Attach the metallic sticker included with

the LP conversion kit to the bottom of the appliance as

shown. This sticker provides notice that the appliance

has been converted for use with LP gas. It should be located near the appliance rating plate.

→

"Rating plate location", Page17

Note:If you change the type of gas back to natural gas

at a later point, remove the sticker.

4. Rotate the stem 180° .

a Confirm that the button end of the orifice stem is away

from the conversion cap.

a Confirm that the letters “LP” on the orifice stem are up-

side down when the conversion cap is set flat on its

head.

5. Snap the orifice stem back in place in this position in-

serting it into the indent in the conversion cap .

6. Insert the hexagon cap back into the regulator and

tighten, do not over-tighten.

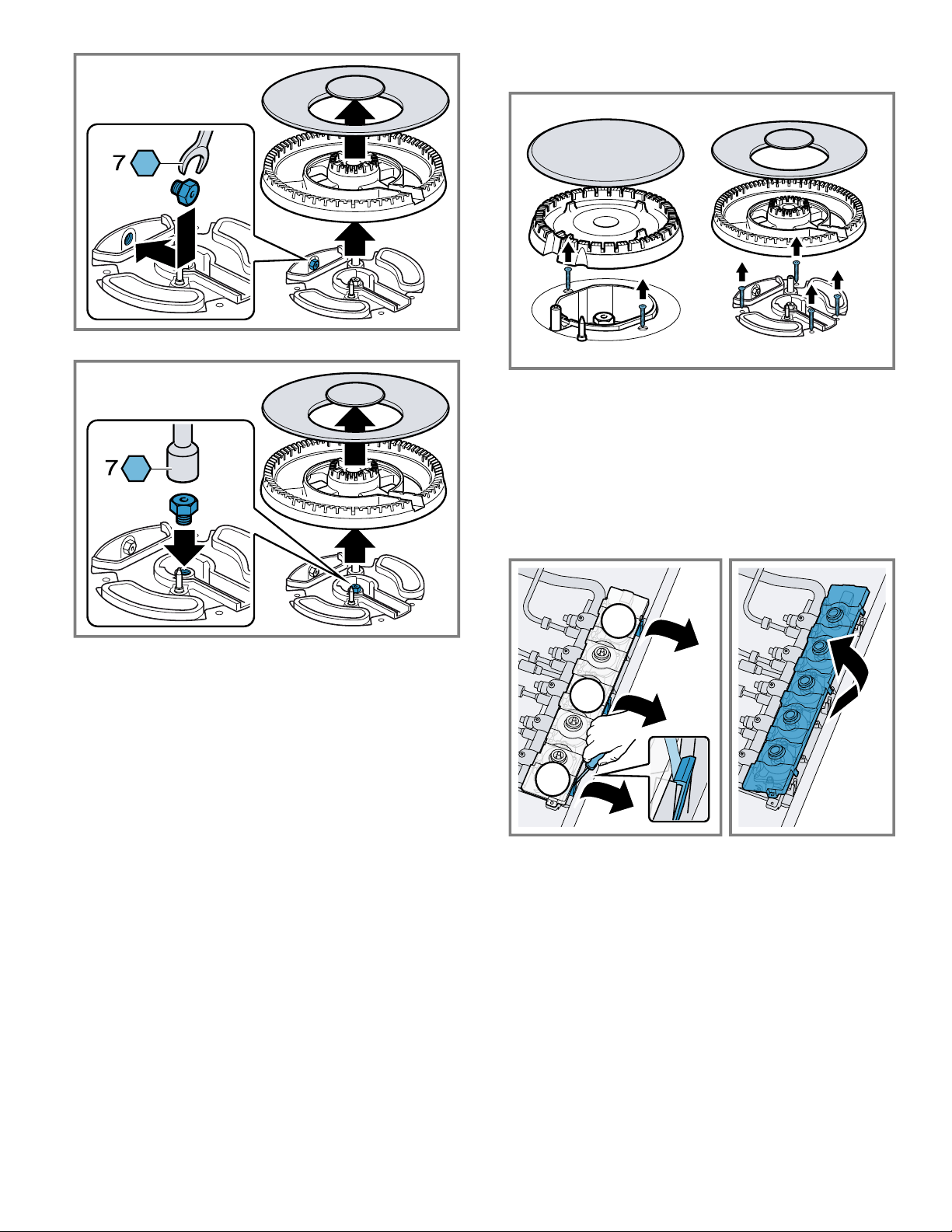

5.2 Replacing the orifices

1. Remove all burner grates, burner caps and burner

bases.

2. Remove the natural gas orifices and replace them with

LP orifices using a 7mm socket wrench. See burner

chart →

‒ For ease of installation use a small piece of tape and

‒ It is important to make sure that the orifices do not

Page16

.

insert it in the socket wrench to prevent the orifice

from falling out.

become detached during removal or fastening. They

must be properly tightened to ensure that there are

no leaks.

14

Normal burner with one orifice

Page 15

Double burner, first orifice

1

2

3

Conversion to LP gas en-us

3. Remove the screws at each burner and lift off the main

top from the cooktop.

Note:Do not remove the illuminated rings under any

circumstances. You will require Customer Service to refit them.

4. Remove the electronics pack from the control panel:

‒ With a flat head screwdriver carefully pry the black

tabs at the front away from the panel one by one,

while lifting up the transparent cover of the electronics pack to disengage the tabs.

‒ When all tabs are unlocked you can lift off the elec-

tronics pack.

Double burner, second orifice

3. Fasten the orifices.

4. Save the orifices removed from the appliance for future

use.

5.3 Adjusting the gas valves

1. Turn the control knobs to position 0.

2. Pull off the control knobs.

5. Remove the black disks from the valve stems. Make

sure the springs underneath the black disks do not

come off.

15

Page 16

en-us Conversion to LP gas

6. Adjust the black T10 star head setting screw with a T10

star head screwdriver. Refer to the burner chart for the

correct setting of the setting screws(M).

→

"Burner chart", Page16

‒ Use setting for LP Gas. The setting screws must

be tightened properly.

‒ Use setting for natural gas. The setting screws

must finish flush with the fitting.

The dual-flame burner has 2setting screws.

7. Replace the black disks.

8. Replace the electronics pack applying light pressure so

the tabs engage. Make sure not pinch any connecting

cables.

9. Ensure that the gaskets around the burner bases are in

place.

5.4 Burner chart

Refer to this overview for specifications of the individual burners.

Burner

cap

Small

burner

Gas type Pressure

in inch

wc

Natural gas

Propane gas

6

10

Orifice BTU/h kW M (valve ad-

77

54

10.Reinstall the main top and the control knobs.

11.Replace all burner bases, burner caps and burner

grates.

12.Continue the installation procedure from

→

"Connection overview", Page11

13.When the installation is complete, verify that the appli-

ance works properly.

→

"Checking the installation", Page12

.

Note:In the event of damage, the valve must be completely replaced.

justment screw

setting)

3,400

3,400

1.00

1.00

Large

burner

Medium

burner

16

Natural gas

Propane gas

Natural gas

Propane gas

6

10

6

10

133

93

102

71

10,300

10,300

6,000

6,000

3.00

3.00

1.75

1.75

Page 17

Customer Service en-us

Burner

cap

Gas type Pressure

in inch

Orifice BTU/h kW M (valve ad-

wc

Dual

burner

Natural gas

Propane gas

6

10

NG:

¡ outer: 161

¡ inner: 74

PG:

¡ outer: 105

¡ inner: 39

Customer Service

6 Customer Service

Customer Service

If you have any questions on use, are unable to eliminate

an issue in the appliance yourself, or the appliance needs

to be repaired, please contact our Customer Service.

With any warranty repair, we will make sure your appliance is repaired by an authorized service provider using

genuine replacement parts. We use only genuine replacement parts for all repairs.

Detailed information on the warranty period and terms of

warranty can be found in the Statement of Limited Product

Warranty, from your retailer, or on our website.

If you contact the Customer Service, you will need the

model number (E-Nr.) and the production number (FD) of

your appliance.

USA:

1-877-442-4436

www.gaggenau.com

www.gaggenau.com/us/appliances/eshop

CA:

1-877-442-4436

www.gaggenau.com

www.gaggenau.ca

17,000

14,500

Rating plate

justment screw

setting)

5.00

4.30

6.1 Model number (E-Nr.) and production number (FD)

You can find the model number (E-Nr.) and the production

number (FD) on the appliance's rating plate.

Making a note of your appliance's details and the Customer Service telephone number will enable you to find

them again quickly.

6.2 Rating plate location

You can find the rating plate of your appliance:

¡ On the appliance certificate.

¡ On the underside of the appliance.

17

Page 18

fr-ca

Table des matières

1 IMPORTANTES CONSIGNES DE SÉCURITÉ .........19

1.1 Définitions des termes de sécurité ...........................20

1.2 Indications générales ...............................................20

1.3 Consignes générales de sécurité .............................20

1.4 Manipulation sécuritaire des appareils .....................21

1.5 Codes et normes de sécurité ...................................21

1.6 Sécurité électrique ...................................................21

1.7 Sécurité des gaz ......................................................22

1.8 Installation au gaz propane ......................................22

1.9 Recommandations de ventilation .............................22

1.10 Installation à haute altitude.....................................22

1.11 Mises en garde conformément à la proposition

65 de l'État de Californie ........................................23

2 Avant de commencer...............................................24

2.1 Pièces incluses ........................................................24

2.2 Outils et pièces nécessaires.....................................24

2.3 Conditions générales ...............................................24

2.4 Exigences concernant les armoires..........................24

2.5 Exigences du comptoir.............................................25

2.6 Exigences en matière de gaz ...................................25

2.7 Exigences électriques ..............................................25

3 Préparation préalable au montage .........................25

3.1 Dimensions de l’installation......................................25

4 Procédure d’installation ..........................................26

4.1 Préparation de la table de cuisson ...........................26

4.2 Installation du régulateur de pression.......................27

4.3 Fixation de la table de cuisson au comptoir..............27

4.4 Aperçu de la connexion............................................28

4.5 Raccordement de la conduite d’alimentation en

gaz...........................................................................28

4.6 Connexion de l'alimentation électrique .....................29

4.7 Assemblage des pièces du brûleur ..........................29

4.8 Installation des grilles de brûleur..............................30

4.9 Inspecter l’installation...............................................30

5 Conversion au gaz LP..............................................31

5.1 Conversion du régulateur de pression......................31

5.2 Remplacement des orifices......................................32

5.3 Ajustement des soupapes de gaz ............................32

5.4 Tableau des brûleurs ...............................................34

6 Service à la clientèle................................................34

6.1 Numéro de modèle (E-Nr.) et numéro de

fabrication (FD) ........................................................34

6.2 Emplacement de la plaque signalétique...................34

18

Page 19

fr-ca

IMPORTANTES CONSIGNES DE SÉCURITÉ

LIRE ET CONSERVER CES INSTRUCTIONS

Lisez toutes les instructions attentivement avant l’utilisation. Ces précautions réduiront le risque d’électrocution,

d’incendie et de blessure pour les personnes utilisant l’appareil. Lorsque vous utilisez des appareils électroménagers,

il importe de suivre les précautions de sécurité de base, y compris celles indiquées dans les pages suivantes.

19

Page 20

fr-ca

IMPORTANTES CONSIGNES DE SÉCURITÉ

LIRE ET CONSERVER CES INSTRUCTIONS

1.1 Définitions des termes de sécurité

Vous trouverez ici des explications sur les mots de

signalisation de sécurité utilisés dans ce manuel.

AVERTISSEMENT

Signale un risque de mort ou de blessure grave si

l’avertissement n’est pas respecté.

MISE EN GARDE

Signale un risque de blessures mineures ou modérées si

l’avertissement n’est pas respecté.

AVIS :

Ceci indique que la non-conformité à cet avis de sécurité

peut entraîner des dégâts matériels ou endommager

l'appareil.

Remarque:Ceci vous signale des informations et/ou

indications importantes.

1.2 Indications générales

¡ Lisez attentivement cette notice.

¡ Veuillez conserver la notice et les renseignements sur

le produit en vue d’une réutilisation ultérieure ou pour

un futur nouveau propriétaire.

¡ Ne branchez pas l’appareil si ce dernier a été

endommagé durant le transport.

1.3 Consignes générales de sécurité

IMPORTANT: L'APPAREIL DOIT ÊTRE INSTALLÉ PAR

UN INSTALLATEUR QUALIFIÉ.

IMPORTANT: CONSERVEZ CES INSTRUCTIONS

POUR L’UTILISATION DE L’INSPECTEUR

ÉLECTRIQUE LOCAL.

PROPRIÉTAIRE: VEUILLEZ CONSERVER CES

INSTRUCTIONS POUR RÉFÉRENCE FUTURE.

INSTALLATEUR: LAISSEZ CES INSTRUCTIONS AVEC

L'APPAREIL UNE FOIS L'INSTALLATION COMPLÈTE.

Examinez l'appareil après l'avoir déballé. En cas de

dommage en cours de transport, ne branchez pas

l'appareil.

AVERTISSEMENT

Si les consignes du présent manuel ne sont pas suivies à

la lettre, il y a un risque d’incendie ou d’électrocution

pouvant entraîner des dommages matériels ou des

blessures.

Ne pas réparer, remplacer ni retirer toute pièce de

l’électroménager à moins que cela ne soit spécifiquement

recommandé par les manuels. L’installation, les

réparations ou l’entretien inadéquats pourraient causer

des blessures ou des dégâts matériels.

▶ Consulter ce manuel pour les directives d’utilisation.

▶ Toutes les autres réparations doivent être effectuées

par un prestataire de services agréé.

Couper l’alimentation électrique et de gaz avant toute

réparation.

Lorsque vous installez une table de cuisson sur un seul

four, veillez à suivre les instructions des manuels

d'installation du four et de la table de cuisson.

Ne jamais modifier ni altérer la structure de l’appareil

électroménager.

Utilisez uniquement l’appareil électroménager s’il a été

installé par un technicien qualifié conformément aux

présentes instructions d’installation. Le fabricant ne peut

pas être tenu responsable de tous dommages causés par

une installation inadéquate.

Pour éliminer le risque de brûlure ou d'incendie lorsque

vous vous étirez au-dessus des surfaces chauffantes de

l'électroménager, il faut éviter d'installer des armoires de

rangement au-dessus de la surface de l'électroménager.

▶ Si une armoire de rangement est installé, il est possible

de réduire le risque en installant une hotte qui dépasse

(horizontalement) d'au moins 5po (127mm) le bord du

fond de l'armoire.

▶ Vérifier que la profondeur des armoires au-dessus de la

table de cuisson est au maximum de 13po (330mm).

AVERTISSEMENT

Le dessous de la table de cuisson peut devenir chaud.

▶ Si la table de cuisson n'est pas installée en

combinaison avec un four, installez un panneau

horizontal sous la table de cuisson pour éviter tout

contact accidentel. Reportez-vous à la section sur

l'installation d'un panneau horizontal. →

AVERTISSEMENT

Retirer tout le ruban adhésif et l'emballage avant d'utiliser

l'électroménager.

Page26

▶ Jetez l'emballage après avoir déballé l'électroménager.

▶ Éliminez l'emballage d'une manière respectueuse de

l'environnement.

▶ Ne laissez jamais les enfants jouer avec le matériel

d’emballage.

20

Page 21

IMPORTANTES CONSIGNES DE SÉCURITÉ

LIRE ET CONSERVER CES INSTRUCTIONS

fr-ca

▶ Conservez les pièces de petite taille dans un endroit

sûr, car elles peuvent être avalées facilement.

1.4 Manipulation sécuritaire des appareils

AVERTISSEMENT

Certaines surfaces cachées peuvent avoir des

rebords tranchants.

▶ Redoubler de vigilance quand vous passez la main

derrière ou sous l'appareil électroménager.

1.5 Codes et normes de sécurité

Cet appareil est conforme aux plus récentes versions de

l'une ou plus des normes suivantes:

¡ ANSIZ21.1/CSA1.1, Appareils électroménagers pour

la cuisson à gaz

¡ L’installation doit être conforme aux codes locaux ou,

en l’absence de tels codes, au National Fuel Gas Code

ANSIZ223.1/NFPA54 ou, au Canada, au code

national CSAB149.1 d’installation du gaz naturel et du

propane.

Il est de la responsabilité du propriétaire et de l'installateur

de déterminer si des exigences et/ou des normes

supplémentaires s'appliquent à des installations

spécifiques.

1.6 Sécurité électrique

¡ Installateur - indiquez au propriétaire l’emplacement

du disjoncteur ou du fusible. Identifiez sa position pour

pouvoir le retrouver facilement.

¡ S’il y a lieu, conformément au Code national de

l’électricit (ou au Code canadien de l’électricité), cet

appareil doit être installé sur un circuit de dérivation

séparé.

¡ Les codes locaux peuvent varier. L'installateur est

responsable de s'assurer que l'installation, les

connexions et la mise à la terre sont conformes à tous

les codes applicables. Le fabricant n'est pas

responsable des problèmes associés à une mauvaise

installation de ce produit.

¡ L’appareil doit être mise à la terre en conformité aux

codes locaux, ou en l’absence de tels codes, à la

dernière version du National Electric CodeNFPA70

ou, au Canada, au code canadien de

l’électricitéCSAC22.1-02.

¡ Assurez-vous que l’appareil est correctement installé et

mis à la terre par un technicien qualifié. L’installation,

les raccordements électriques et la mise à la terre

doivent être conformes avec tous les codes en vigueur.

¡ N'utilisez pas de rallonge.

¡ N'utilise pas un adaptateur.

¡ Voir la fiche signalétique pour plus d'information.

→

"Emplacement de la plaque signalétique", Page34

AVERTISSEMENT

Avant l'installation, couper l'alimentation au panneau de

service.

▶ Verrouiller le panneau de service pour empêcher que

l'alimentation ne soit rétablie par accident.

Pour les électroménagers dotés d'un cordon

d'alimentation avec fiche, ne pas couper ni enlever la

broche de mise à la terre.

▶ Pour éviter toute électrocution, brancher le cordon dans

une prise de courant correspondante avec mise à la

terre.

▶ En cas de doute concernant la mise à la terre

appropriée de la prise murale, le client doit faire vérifier

celle-ci par un électricien qualifié.

INSTRUCTIONS DE MISE À LA TERRE

▶ Cet appareil doit être mis à la terre.

▶ La mise à la terre réduit le risque de choc électrique en

fournissant une voie sûre pour le courant électrique en

cas de court-circuit.

▶ Assurez-vous que l’appareil est correctement installé et

mis à la terre par un technicien qualifié.

▶ L’installation, les raccordements électriques et la mise

à la terre doivent être conformes avec tous les codes

en vigueur.

N'utilisez pas de rallonge. Si lecordon d'alimentation est

trop court, demandez à unélectricienouun technicien

qualifié d'installerune prise à proximité de l'appareil.

Avant de brancher le cordon électrique, vérifie que toutes

les commandes sont à la position OFF (Arrêt).

Avant de mettre sous tension la source d'alimentation,

vérifiez que toutes les commandes sont à la position OFF

(Arrêt).

21

Page 22

fr-ca

IMPORTANTES CONSIGNES DE SÉCURITÉ

LIRE ET CONSERVER CES INSTRUCTIONS

1.7 Sécurité des gaz

Exigences pour l'alimentation en gaz:

¡ Installer un robinet d'arrêt près de l'électroménager. Il

doit être facilement accessible en cas d'urgence.

¡ L'installateur doit procéder au test de fuites selon les

consignes fournies dans le présent manuel.

¡ L'appareil et son propre robinet d'arrêt doivent être

déconnectés de la canalisation du système

d'alimentation en gaz au cours de test aux pressions

qui dépassent ½PSI (3,5kPa).

¡ L’électroménager doit être isolé de la canalisation du

système d'alimentation en gaz en fermant son propre

robinet d'arrêt manuel pour tout test de pression à des

pressions égales ou inférieures à ½PSI (3,5kPa).

¡ La pression d'alimentation minimale doit être de 1po

de colonne d'eau au-dessus de la pression d'admission

imprimée sur l'étiquette signalétique. La pression

d'admission maximum ne doit pas excéder 14po de

colonne d'eau (34,5millibars).

¡ Une ligne de production métallique souple ou un tuyau

métallique fixe doit être utilisé pour raccorder le gaz à

l'appareil. Si une conduite de gaz en métal ne peut pas

être utilisée, veuillez vous adresser à un électricien

agréé local ou aux codes électriques locaux pour

obtenir une mise à la terre appropriée.

AVIS DE SÉCURITÉ IMPORTANT: La combustion du

combustible de cuisson au gaz génère certains sousproduits qui figurent sur la liste des substances reconnues

par l'État de Californie comme cancérigènes ou pour la

reproduction. Pour minimiser l'exposition à ces

substances, faites toujours fonctionner cet appareil

conformément aux instructions contenues dans ce livret et

assurez une bonne ventilation.

1.8 Installation au gaz propane

¡ Le réservoir de gaz propane doit être doté de son

propre régulateur de pression élevée. De plus, le

régulateur de pression livré avec cet appareil doit aussi

être utilisé.

¡ L'électroménager est livré de l'usine prêt à utiliser avec

du gaz naturel. Il doit être converti pour usage avec gaz

propane. Un technicien qualifié ou un installateur

certifié doit procéder à la conversion.

¡ Pour une utilisation avec du propane, l'appareil doit être

converti selon les instructions de conversion LP.

→

"Conversion au gaz LP", Page31

Pour les installations au Massachusetts

¡ L'installation doit être exécutée par un entrepreneur, un

plombier ou un ajusteur d'appareils à gaz qualifié ou

autorisé par l'État, la province ou la région d'installation

de cet électroménager.

¡ Le robinet d'arrêt doit être robinet à gaz avec poignées

en T.

¡ Le connecteur à gaz souple ne doit pas dépasser

36pouces.

Installateur: prière d'indiquer au propriétaire,

l'emplacement du robinet d'arrêt.

1.9 Recommandations de ventilation

Nous recommandons fortement l'installation d'une hotte

de ventilation au-dessus de cet appareil.

La hotte doit être installée conformément aux instructions

fournies avec la hotte.

AVERTISSEMENT

L'électroménager ne doit pas être installé avec un

système de ventilation qui souffle l'air vers le bas en

direction des brûleurs. Ce type de système de ventilation

peut entraîner des problèmes d'allumage et de

combustion avec l'appareil de cuisson au gaz pouvant

causer des blessures corporelles ou un fonctionnement

indésirable.

1.10 Installation à haute altitude

Cet appareil a été testé pour fonctionner à une altitude

allant jusqu'à 10100pi (3078m) au-dessus du niveau de

la mer.

Pour des altitudes supérieures à 2000pi (610m) audessus du niveau de la mer, des ajustements de flamme

du brûleur peuvent être nécessaires.

Veuillez vérifier les brûleurs au réglage le plus bas. Si la

flamme est instable, haussez la flamme de mijotage

jusqu'à ce qu'elle soit stable. Vous pouvez le faire en

réglant la vis de dérivation de la soupape. Si la flamme

réagit de manière satisfaisante, aucun ajustement n'est

requis. Lors de l'installation, il est obligatoire de faire

appel à un professionnel certifié pour procéder aux

réglages d'utilisation à altitude élevée.

22

Page 23

IMPORTANTES CONSIGNES DE SÉCURITÉ

LIRE ET CONSERVER CES INSTRUCTIONS

1.11 Mises en garde conformément à la proposition 65 de l'État de Californie

Ce produit pourrait contenir un produit chimique reconnu

par l'État de la Californie comme cancérigène ou ayant

des effets nocifs sur la reproduction. Par conséquent,

vous pourriez devoir apposer l'étiquette suivante sur

l'emballage du produit comme requis par la Californie:

fr-ca

23

Page 24

fr-ca Avant de commencer

Avant de commencer

2 Avant de commencer

Avant de commencer

Lisez ces instructions avant de commencer l'installation de

votre appareil.

2.1 Pièces incluses

Après avoir déballé le produit, inspectez toutes les pièces

pour détecter d’éventuels dégâts dus au transport et pour

vous assurer de l'intégralité de la livraison.

¡ Table de cuisson

¡ Ruban de mousse

¡ Supports de fixation (4)

¡ Vis, no10-32 x21/2po (63,8mm), (4)

¡ Vis à tôle, no8x3/8po (9,5mm), (4)

¡ Rondelles(4)

¡ Grilles de brûleur (3)

¡ Brûleurs (5)

¡ Chapeaux de brûleur (6)

¡ Régulateur de pression

¡ Trousse de conversion au gaz de PL

2.2 Outils et pièces nécessaires

Préparez ces outils et accessoires avant de commencer à

installer votre électroménager.

¡ Crayon

¡ Ruban à mesurer

¡ Tournevis cruciforme

¡ Perceuse avec mèche de 1/4po (6mm)

¡ Scie sauteuse

¡ Clé réglable

¡ Ruban Teflon® - évalué pour le gaz

¡ Tournevis à tête plate, 1/8po

¡ Tous les revêtements stratifiés et la colle sur les

armoires à côté de la table de cuisson doivent être faits

de matériaux ininflammables et résistants à la chaleur.

Reportez-vous aux codes du bâtiment locaux pour les

matériaux acceptables.

¡ Cet appareil électroménager ne peut pas être installé

au-dessus d’un réfrigérateur, d’une laveuse, d’un lavevaisselle ou d’appareils semblables.

¡ Si la table de cuisson doit être installée en combinaison

avec un four, reportez-vous à la matrice de

combinaisons approuvées incluse avec le produit pour

les dimensions de découpe et de dégagement.

2.4 Exigences concernant les armoires

Assurez-vous que les armoires du site d'installation

répondent aux exigences d'une installation sécuritaire.

Outils supplémentaires nécessaires pour la conversion

au GPL

¡ Clé à douille de 7mm

¡ Clé à fourche de 7mm

¡ Tournevis à embout étoile T10

¡ Tournevis à embout étoile T20

¡ Petit morceau de ruban adhésif

Remarques

¡ Pour une installation autonome, un panneau horizontal

sous la table de cuisson peut être nécessaire.

→

"Installation avec panneau horizontal", Page26

¡ Des matériaux supplémentaires peuvent être

nécessaires pour l'installation de comptoirs à surface

solide. Contactez le fabricant du comptoir.

2.3 Conditions générales

Assurez-vous que les conditions suivantes sont remplies

lors de la planification de l'installation de votre appareil.

¡ Planifier l’installation de l’appareil de sorte que le

cordon d’alimentation, le robinet d’arrêt et le régulateur

de pression du gaz sont accessibles de l’avant de

l’armoire.

¡ Assurez-vous que la conduite d'alimentation en gaz

n'interfère pas avec l'arrière de l'appareil.

¡ Les armoires qui recevront la table de cuisson doivent

être solides, de niveau et stables.

Les espaces minimaux qui doivent être maintenus lors de

l'installation de la table de cuisson à gaz doivent être les

suivants:

a min. 13po (330mm)

pour l'installation à côté du four min. 13po

(330mm)

b min. 13po (330mm)

pour l'installation à côté du four min. 13po

(330mm)

c dégagement 30po (762mm) min. entre le haut de

la surface de cuisson et le bas des constructions

combustibles

d min. 3po (76mm);

pour installation dans un îlot de cuisine, min. 4po

(100mm)

e min. 30po (760mm) centrée au-dessus de la table

de cuisson

f min. 18po (458mm)

g max. 13po (330mm)

h min. 1¾po (48mm);

pour installation dans un îlot de cuisine, min. 4po

(100mm)

24

Page 25

Préparation préalable au montage fr-ca

2.5 Exigences du comptoir

Assurez-vous que le comptoir dans lequel la table de

cuisson doit être installée répond à ces exigences pour

une installation sécuritaire.

AVERTISSEMENT

Pour réduire le risque d'allumage dans un environnement

combustible, installer à au moins 13po (330mm) des

parois et à au moins 3po (76mm) du mur arrière.

¡ Le comptoir doit être de niveau.

¡ La stabilité du comptoir doit être maintenue une fois la

découpe effectuée.

¡ Les comptoirs en surface solide ou en stratifié

nécessitent souvent des installations spéciales. Par

exemple, il peut être nécessaire d’appliquer du ruban

réflecteur de chaleur et de découper des coins ronds.

Communiquez avec le fabricant du plan de travail pour

connaître les directives spécifiques à ce dernier.

2.6 Exigences en matière de gaz

Assurez-vous que les exigences relatives à l'alimentation

en gaz sont respectées.

La table de cuisson est livrée de l’usine prête à

fonctionner au gaz naturel. Pour une conversion au gaz de

PL, un technicien ou un installateur qualifié doit y

procéder.

Pression d’admission:

¡ Gaz naturel: 7po de colonne d’eau (17,4millibars)

¡ Gaz propane: 11po de colonne d’eau (27,4millibars)

¡ Le réservoir de gaz propane doit être doté de son

propre régulateur de pression élevée en plus du

régulateur de pression fourni avec cet appareil.

AVERTISSEMENT

Le dessous de la table de cuisson peut devenir chaud.

▶ Si la table de cuisson n'est pas installée en

combinaison avec un four, installez un panneau

horizontal sous la table de cuisson pour éviter tout

contact accidentel. Reportez-vous à la section sur

l'installation d'un panneau horizontal. →

Page26

3.1 Dimensions de l’installation

2.7 Exigences électriques

Assurez-vous que les exigences électriques suivantes

sont respectées.

MISE EN GARDE

N'utilisez pas de rallonge avec cet appareil.

¡ Cet appareil nécessite une connexion de 60Hz, 15A,

120V/AC.

¡ Votre appareil est équipé d'un cordon d'alimentation.

40po (1000mm).

¡ La connexion électrique doit rester accessible depuis

l'avant de l'armoire une fois l'installation terminée.

Préparation préalable au montage

3 Préparation préalable au montage

Préparation préalable au montage

Créez la découpe dans le comptoir selon les instructions.

Exigences générales du comptoir:

¡ Maintenez un angle de de coupe de 90degrés par

rapport au plan de travail.

¡ Avec les comptoirs multi-couches, fixez les bandes

latéralement dans la découpe si nécessaire.

¡ Après avoir créé la découpe, retirez tous les débris.

¡ Suivez les recommandations du fabricant du plan de

travail pour protéger les bords coupés, par ex. appliquer

du ruban adhésif résistant à la chaleur.

¡ Si la table de cuisson doit être installée en combinaison

avec un four, reportez-vous à la matrice de

combinaisons approuvées incluse avec le produit pour

les dimensions de découpe et de dégagement.

*Pour installation dans un îlot de cuisine.

Installation au-dessus du four

25

Page 26

fr-ca Procédure d’installation

A min. ¾po (19mm)

max. 2po (50mm)

B 5⅞(150mm)

C 2¾po (70mm)

D Reportez-vous à la matrice de combinaison

approuvée

E 2⅜po (60)

Installation avec panneau horizontal

S'il n'y a pas de four sous la table de cuisson, installez un

panneau horizontal. Pour permettre l'accès à la connexion

d'alimentation et au régulateur, maintenez un dégagement

minimum de ⅜po (10mm) des bords du panneau(F).

IMPORTANT: Terminez l'installation de la table de

cuisson avant d'installer le panneau horizontal.

Installation au-dessus d'un tiroir

max. 2po (50mm)

B 5⅞po (150mm)

C 2¾po (70mm)

D min. 0po (0mm)

E 2⅜" (60)

F min. ⅜po (10mm)

G min. 1po (25)

Procédure d’installation

4 Procédure d’installation

Procédure d’installation

Suivez ces instructions pour installer la table de cuisson

dans le comptoir.

MISE EN GARDE

Bords tranchants.

▶ Utilisez des gants de protection lors de l'installation de

l'appareil.

MISE EN GARDE

Cet appareil est lourd.

▶ Il est recommandé que deux personnes installent cet

appareil.

4.1 Préparation de la table de cuisson

A min. ¾po (19mm)

max. 2po (50mm)

B 5⅞po (150mm)

C 2¾po (70mm)

D min. 0po (0mm)

E 2⅜" (60)

F min. ⅜po (10mm)

Installation au-dessus d'une porte d'armoire

Remarque:UNIQUEMENT POUR LE MODÈLE

NGM8648UC: Si l'appareil doit être utilisé avec du GPL,

effectuez la conversion au GPL AVANT d'installer

l'appareil dans le comptoir.

→

"Conversion au gaz LP", Page31

1. Placez la table de cuisson face vers le bas sur une

surface douce et stable. Utilisez la feuille de mousse de

l'emballage pour protéger les surfaces contre les

rayures.

2. Appliquez le ruban d'étanchéité en mousse inclus

autour des bords du dessous de l'appareil le long de la

bride brute de la boîte.

A min. ¾po (19mm)

26

Page 27

Procédure d’installation fr-ca

3. Fixez les supports de fixation au dessous de la table de

cuisson à l'aide des vis courtes et des rondelles

fournies. Serrez légèrement les vis afin que les pinces

ne bougent pas librement. Faites pivoter les supports

de fixation pour que l'appareil puisse être placé dans la

découpe.

Remarque:La plaque signalétique ne sera pas

accessible après l'installation. Notez les détails de votre

appareil ou reportez-vous au certificat d'appareil ci-joint.

→

"Emplacement de la plaque signalétique", Page34

4.2 Installation du régulateur de pression

AVERTISSEMENT

N'essayez pas de régler le régulateur de pression, sauf

lors de la conversion au propane. Les réglages peuvent

entraîner des fuites ou une mauvaise pression en direction

de l'appareil électroménager.

Assurez-vous que la conduite de raccordement de gaz

usagée n'est pas connectée à l'alimentation en gaz avant

d'effectuer les étapes suivantes.

Remarque:Tous les raccords de tuyauterie doivent être

scellés conformément aux codes locaux.

1. Identifiez les pièces du régulateur de pression.

a Raccord du tuyau collecteur de l'appareil

b Couvercle de conversion

c Régulateur de pression

d La flèche sur le régulateur de pression

indique la direction du débit de gaz

2. Appliquez du ruban Teflon® sur les filets du tuyau du

collecteur. Installez le régulateur de pression (fourni

avec la table de cuisson) sur l'entrée de gaz avec la

flèche de débit de gaz face à l'entrée du collecteur.

3. Serrez fermement le régulateur à la main, puis serrez

davantage d'un quart de tour jusqu'à un maximum d'un

tour complet. Alignez le régulateur de manière à ce que

le capuchon de conversion soit facilement accessible.

4.

AVERTISSEMENT Ne jamais réutiliser un

connecteur de gaz. Des flexions ou des vibrations

extrêmes répétées provoquent une fatigue du métal et

doivent être évitées.

Appliquez du ruban Teflon® sur les filetages mâles,

puis connectez une nouvelle conduite flexible

métallique de ½po ou un raccord de tuyau métallique

fixe au régulateur de pression.

Remarque:Pour les installations avec peu d'espace,

utilisez un coude de rue à 90 degré (non fourni) pour

orienter le régulateur horizontalement.

4.3 Fixation de la table de cuisson au comptoir

La table de cuisson doit être fixée par le bas à l'aide des

supports de fixation fournis.

AVERTISSEMENT

Avant l'installation, couper l'alimentation au panneau de

service.

▶ Verrouiller le panneau de service pour empêcher que

l'alimentation ne soit rétablie par accident.

27

Page 28

fr-ca Procédure d’installation

1.

MISE EN GARDE Ne laissez pas la table de

cuisson tomber en place.

▶ Assurez-vous que la table de cuisson est soutenue le

long des bords lorsque vous la placez

soigneusement dans la découpe.

Retournez la table de cuisson avec précaution en vous

assurant de ne pas endommager le régulateur de

pression et la conduite de gaz.

‒ Placez délicatement la table de cuisson dans la

découpe du plan de travail, en la tirant vers l'avant de

la découpe .

‒ Abaissez l'arrière de la table de cuisson pour qu'elle

repose à plat sur le comptoir .

‒ Centrez la table de cuisson à gauche et à droite dans

la découpe .

4.4 Aperçu de la connexion

Reportez-vous à cette illustration pour l'emplacement du

raccordement au gaz et électrique de l'appareil.

Remarque:Votre appareil est équipé pour une utilisation

avec du gaz naturel à la livraison. Si vous souhaitez

utiliser votre appareil avec du GPL, reportez-vous à la

section sur la conversion au GPL avant de poursuivre

l'installation. →

Page31

2. Insérez les vis de serrage de 2½po dans les trous

filetés des supports de maintien, faites glisser ou faites

pivoter les supports de sorte que les vis de serrage

entrent en contact avec le dessous du comptoir.

‒ Protégez les comptoirs délicats en plaçant un disque

en bois en dessous.

‒ Serrez à la main la première vis et vérifiez la position

de la table de cuisson, puis fixez la table de cuisson

en serrant toutes les vis de serrage .

‒ Serrez les vis à la table de cuisson .

Remarque:Ne pas utiliser de silicone pour coller la

table de cuisson à la surface du plan de travail.

a Boîtier de la robinetterie brute de la table de cuisson

b La flèche sur le régulateur de pression indique la

direction du débit de gaz

c Régulateur de pression

d Tuyau de ½po à filets femelles

e Conduite de gaz flexible en métal

f Cordon d'alimentation (40po/1m)

g Réceptacle de 120V

h Robinet d'arrêt du gaz

i Raccord de raccordement de la conduite

d'alimentation en gaz

j Plancher

4.5 Raccordement de la conduite d’alimentation en gaz

L'électroménager est livré de l'usine prêt à utiliser avec du

gaz naturel. Si vous souhaitez utiliser du gaz propane, il

doit être converti. Un technicien ou un installateur qualifié

doit procéder à la conversion.

Remarque

Assurez-vous que les conditions suivantes sont remplies

avant d'essayer de connecter l'appareil à l'alimentation en

gaz:

¡ Avant de connecter l'appareil, vérifiez si les conditions

de connexion locales telles que le type de gaz et la

pression de gaz correspondent aux réglages de

l'appareil.

¡ S'assurer que le robinet d'arrêt manuel est fermée pour

couper l'alimentation en gaz avant de raccorder

l'appareil électroménager.

¡ Le raccordement au gaz doit se trouver dans un endroit

permettant l'accès au robinet d'arrêt manuel et qui, le

cas échéant, est visible après l'ouverture de la porte ou

les tiroirs de l'armoire.

28

Page 29

Procédure d’installation fr-ca

1

2

3

4

4

3

2

1

1

2

3

4

¡ La conduite de gaz flexible métallique ne doit pas entrer

en contact avec les pièces mobiles de l'unité montée

(par ex. Tiroirs) ou être posée dans des zones où elle

pourrait être coincée ou endommagée.

¡ La conduite de gaz métallique flexible ne doit pas entrer

en contact avec une table de cuisson, un four, un lavevaisselle, un réfrigérateur, une machine à laver, une

conduite d'eau chaude, un radiateur ou tout autre

appareil installé à proximité de la table de cuisson à

gaz.

¡ La conduite de gaz flexible métallique ne doit pas être

soumise à des frottements, des vibrations, des vrilles ou

tout autre type de déformation. Il doit être vérifié sur

toute sa longueur avec la table de cuisson en position

d'installation.

¡ Tous les raccords de tuyauterie doivent être scellés

conformément aux codes locaux.

▶ Connectez la conduite de gaz flexible en métal ou le

raccord de tuyau métallique fixe du régulateur de

pression de la table de cuisson à la valve d'arrêt

manuel.

Vérification de la conduite de gaz pour les fuites

Vérifiez l'étanchéité des raccords de la conduite

d'alimentation de gaz à l'aide d'une solution savonneuse

ou d'un liquide de détection de fuites non corrosif. Ne

jamais utiliser une flamme sans égard au type de flamme.

Remarque

Remarques importantes pour les raccords de gaz:

¡ L'appareil et son propre robinet d'arrêt doivent être

déconnectés de la canalisation du système

d'alimentation en gaz au cours de test aux pressions qui

dépassent ½PSI (3,5kPa).

¡ L’électroménager doit être isolé de la canalisation du

système d'alimentation en gaz en fermant son propre

robinet d'arrêt manuel pour tout test de pression à des

pressions égales ou inférieures à ½PSI (3,5kPa).

1. Ouvrez le gaz.

2. Appliquez une solution savonneuse ou un liquide de

détection de fuites non corrosif à toutes les jonctions et

tous les raccords des conduites de gaz entre le robinet

d’arrêt et la table de cuisson. Vérifiez également les

raccords de gaz et les joints de la table de cuisson si

les connexions peuvent avoir été perturbées pendant

l'installation.

a Les bulles qui apparaissent autour des raccords

indiquent une fuite.

3. En présence d’une fuite, coupez l’alimentation en gaz

en fermant le robinet d’arrêt et serrez le ou les raccords

qui fuient.

4. Tester de nouveau la présence de fuites en ouvrant le

robinet d'arrêt de l'alimentation de gaz.

a Lorsque la vérification des fuites est terminée et

qu'aucune bulle n'apparaît, le test est terminé.

5. Essuyez toute solution savonneuse ou résidu de liquide

de détection.

4.6 Connexion de l'alimentation électrique

▶ Branchez la fiche du cordon électrique sur une prise

électrique reliée à la terre. La prise doit être accessible

une fois l'installation de l'appareil terminée.

4.7 Assemblage des pièces du brûleur

Il faut que les pièces de brûleurs soient correctement

positionnées pour le bon fonctionnement de la table de

cuisson.

Remarque

Un ou plusieurs problèmes peuvent survenir si une pièce

de brûleur n’est pas bien positionnée:

¡ Les flammes du brûleur sont trop élevées.

¡ Des flammes jaillissent des brûleurs.

¡ Les brûleurs ne s’allument pas.

¡ Les flammes du brûleur ne sont pas uniformes.

¡ Les brûleurs dégagent une odeur de gaz.

AVERTISSEMENT

Retirez tout le ruban adhésif des pièces du brûleur et de la

surface de cuisson avant d'utiliser l'appareil.

1. Assemblez les pièces du brûleur conformément à

l'illustration.

Chapeau du brûleur

Base du brûleur

Thermocouple

Allumeur

Assurez-vous que les broches du chapeau du brûleur

s'insèrent parfaitement dans la rainure de la base du

brûleur.

MISE EN GARDE

Avant de brancher le cordon électrique, assurez-vous que

le robinet d'arrêt de gaz et toutes les commandes du

brûleur sont en position OFF (ARRÊT).

29

Page 30