Page 1

Note:

Always read this manual before using your MSA-10.

MULTI SERVO ADJUSTER

MSA-10

INSTRUCTION MANUAL

Store this manual in a safe place where it can be used at any time.

The MSA-10 can use one servo input signal to

simultaneously drive up to four servos. It exhibits

its functions when using multiple servos to drive

one control surface. The servo and receiver power

supplies can be separated by using a separate

battery pack for the servos.

[Example of primary use]

•When installing two servos each for the left and right ailerons with a model that use

four servos to drive the ailerons, maximum servo torque can be obtained without

applying unreasonable force to the servos by connecting the two right aileron servos

to the MSA-10, trimming the neutral position of each servo and setting the servo

throws individually. The left aileron can also be set by following the same procedure

as the right aileron.

•With scale models, the left and right flap servos can be connected to the MSA-10 and

the left and right through of flaps can be adjusted separately. The steering and the

rudder servos can be connected to the MSA-10 and adjusted individually for easy

handling.

•The left and right engine RPM can be unified using multi-engine plane throttle

control. The left and right throttle control servos can be connected to the MSA-10

and medium speed can be adjusted using the neutral adjustment function and idle and

maximum speed can be adjusted using left and right throw adjustment.

WARNING

Always use a NiCd battery as the

power supply. Check the battery voltage

and charge the battery quickly.

[Usage Method]

1 Connect the servo input connector to the receiver servo output

channel.

2 Connect the servos (maximum 4) to the servo output

connectors (1/5 to 4/8) of the MSA-10.

3 Set the transmitter stick and trim to the neutral position and

install the horn to each servo.

4 Adjust the neutral position of each servo using the neutral

position adjustment function of the MSA-10.

5 Connect the linkage and adjust the linkage so that unreasonable

force is not applied to the servo at the neutral position.

6 Push either one of the transmitter sticks fully in any direction

and individually adjust the throw of the servos so that

unreasonable force is not applied to the servos. Push the same

transmitter stick fully in the opposite direction and individually

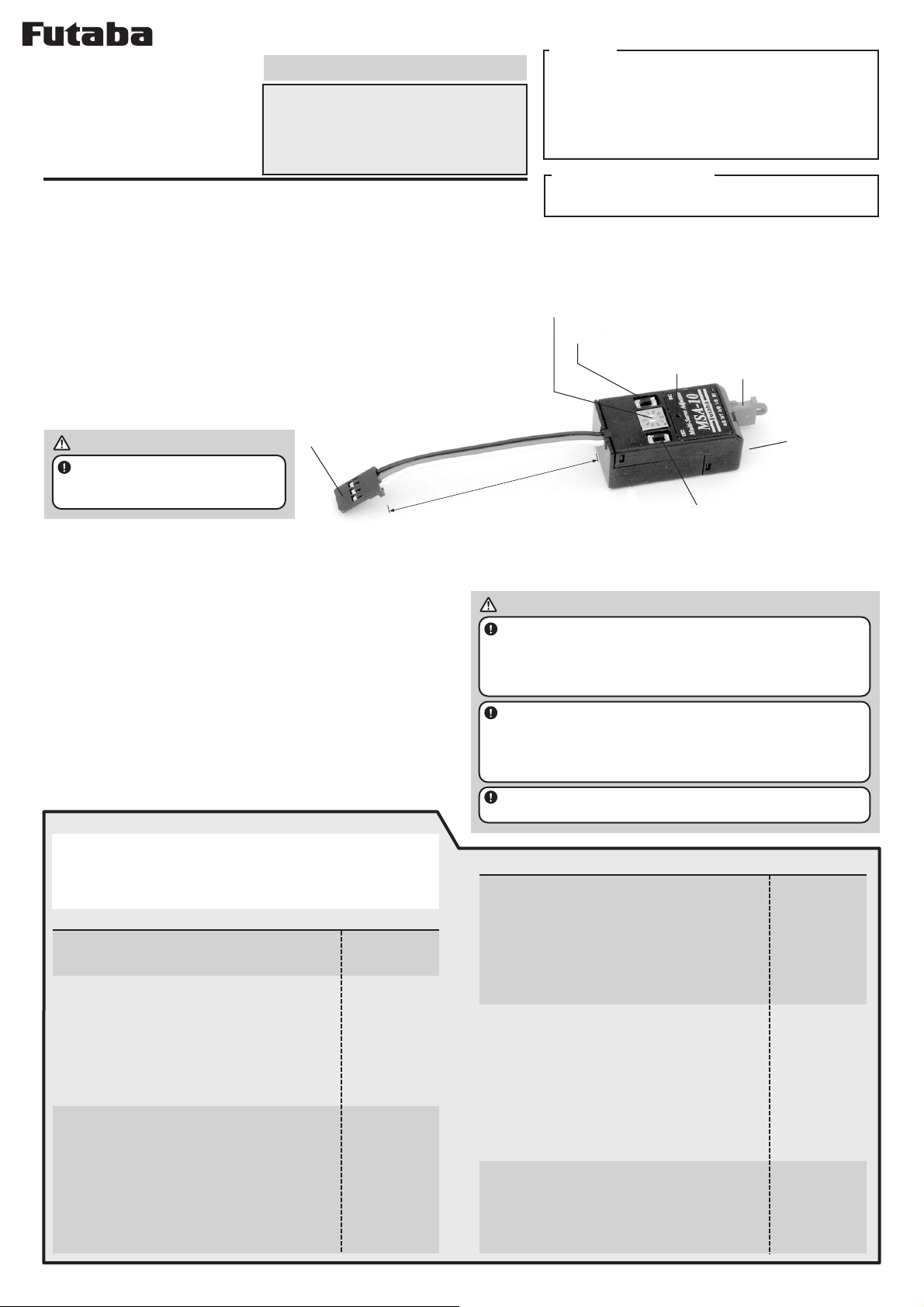

•Servo input connector

approximately 65mm

[When using a separate power supply]

Even if using a receiver with Battery Fail Safe function, it can not detect

the voltage of the separate power supply. Therefore check the battery

voltage and charge the battery quickly.

WAR NI NG

Dislodgement of a connector or breaking of a wire due to vibration

during flight may cause a crash. Especially, since the number of wires

becomes large, be sure to prevent connector dislodgement, broken

wires, etc. If using an extension cord, fasten the input connector

section with a fastener and take vibration countermeasures.

If the extension cord is long, insert an extension cord with filter

between the receiver and the MSA-10 to minimize the effects of noise,

etc. Connection of a large number of short extension cords will cause

a voltage drop. Make the number of extension cord connections as

small as possible.

adjust the throw of the servos so that unreasonable force is not

applied to the servos.

Vibrationproof of the MSA-10 by wrapping it in sponge rubber or

some such material.

[MSA-10 Settings]

Notes:

•If the power switch is turned off without returning the rotary switch to 0

or 9 after function setting, the settings will not be memorized.

•After setting the rotary switch to 1 to 8, always return the it to 0 or 9

and check that the LED are stay on before turning off the power.

Settings

Normal use

Rotary switch (0 or 9)

1 Set the rotary switch to 0 or 9 when operating the

MSA-10.

LED display

LED on

When input signal

abnormal, LED blinks.

Neutral setting Rotary switch (1 to 4)

1 Set the rotary switch to 1, 2, 3, or 4

corresponding to the servo No. (given on the

MSA10 nameplate) whose neutral position you

want to adjust.

LED off

The LED blinks while

the push switch is

being pushed.

2 When the transmitter stick and trim approaches

the neutral position, the LED goes off.

3 When the LED is off, perform neutral adjustment

by pushing the INC or DEC push switch.

Left and right independent endpoint adjustment

Rotary switch (1 to 4)

1 Set the rotary switch to 1, 2, 3, or 4

corresponding to the servo No (given on the

MSA-10 nameplate) whose endpoint you want to

adjust.

LED on

The LED blinks while

the push switch is

being pushed.

2 When the transmitter stick is pushed to the side whose

throw you want to adjust, the LED comes on.

3 When the LED is on, perform throw adjustment

by pushing the INC or DEC push switch.

Settings

Servo reverse

1 Set the rotary switch to 5, 6, 7, or 8 corresponding

to the servo No.+4 (given on the MSA-10

nameplate) whose reverse you want to adjust.

2 When the transmitter stick and trim approaches

the neutral position, the LED goes off.

3 When the LED is off, reverse and normal are

interchanged each time the INC or DEC push

switch is pushed.

Throw adjustment (left and right throw

simultaneous increase/decrease)

Rotary switch (5 to 8)

1 Set the rotary switch to 5, 6, 7, or 8

corresponding to the servo No.+4 (given on the

MSA-10 nameplate) whose throw you want to

increase or decrease.

2 When the transmitter stick is pushed, the LED

comes on.

3 When the LED is on, adjust the throw by pushing

the INC or DEC push switch.

Reset Rotary switch (9)

1 Sets the power supply to the off state.

2 Set the rotary switch to 9.

3 When the power is turned on while

simultaneously pushing the INC and DEC push

switches, all settings return to their initial value.

Features

•One servo signal input can simultaneously drive up to four servos.

•The neutral position, the left and right throw (individually and

simultaneously), and reverse setting of each servo can be adjusted.

•A separate battery pack can be used for the servos connected to

the MSA-10.

•Easy setting by rotary and push switches.

•Setting state display by LED.

Dimensions and weight

•39.8X21.4X1.4mm

•13g

•Common power supply connector

*When receiver and servos use a common power

supply, connect the common power supply connector.

•Separate battery pack

input connector (BT)

•Rotary switch

•Push switch

(INC)

•LED

*When using a separate power supply

(servo only power supply),

disconnect the common power supply

connector and connect the servo

battery pack. The power supply

voltage (4.8 or 6V) depends on

connecting servos.

•Servo output

connector

(1/5, 2/6, 3/7, 4/8)

MSA-10

•Push switch (DEC)

[Mounting Precautions]

LED display

Rotary switch (5 to 8)

LED off

LED on

The LED blinks while

the push switch is

being pushed.

1M23N11101 ©FUTABA CORPORATION 2002,09 (1)

Loading...

Loading...