Page 1

INSTRUCTION MANUAL

1M23N21902

YAW-AXIS STABILIZER FOR MODEL HELICOPTER

(RATE GYRO)

Page 2

ABLE OF CONTENTS

T

• Precautions ----------------------------------------------------- 3

• Warranty and Repair Service (in U.S.A.) ------------------ 6

• Contents -------------------------------------------------------- 7

• Specifi cations -------------------------------------------------- 8

• Recommended Servos ---------------------------------------- 9

• Replacement and Optional Items --------------------------- 9

• Function and Connection Diagram ----------------------- 10

• LED Indicator Description ----------------------------------11

• Introduction ---------------------------------------------------11

• Mechanics Preparation ------------------------------------- 12

• GY520 Installation ------------------------------------------ 13

• Connecting the GY520 to your Receiver ---------------- 15

• GY520 Programming --------------------------------------- 16

• Tail Rotor Servo Installation and Setup ------------------ 25

• Before Flight Checklist ------------------------------------- 28

• Adjustments During the Test Flight ---------------------- 29

• Using Normal Mode ---------------------------------------- 30

• Setting the Gain --------------------------------------------- 31

Technical updates and additional programming

examples can be found at:

www.futaba-rc.com/faq

2

Page 3

RECAUTIONS

P

WARNING!

Failure to follow these safety precautions may result in

severe injury to yourself and others.

• Read through the entire manual before operating this product.

• The GY520 requires 5-10 seconds to initialize when the

power is turned on. Do not move the helicopter and do

not move the tail rotor stick during this initialization

or the gyro may not initialize properly. Once the

initialization process is complete, the tail rotor servo will

move to the left extent and then to the right extent. This

will occur twice. The indicator light will change to solid

blue for AVCS Mode or solid red for Normal Mode.

BEFORE EACH FLIGHT:

• Always check the transmitter and receiver battery voltage to

ensure they have enough remaining capacity to complete

the fl ight.

• Verify that the gyro is operating correctly.

• Verify that the gyro compensates in the correct direction

before flight. If the compensation direction is incorrect the

model will pirouette uncontrollably, at a very high rate.

• Verify that the gyro is operating in the desired mode.

• Verify that the gyro mounting pads are in good condition.

• Verify that the gyro wires are not contacting the frame of

the helicopter.

• The servo type parameter within the GY520 must match the

type of servo you are using. Incorrect setting may damage

the GY520 or the servo, possibly resulting in a loss of control

during fl ight.

3

Page 4

RECAUTIONS

P

• Only use the GY520 with a 2.4GHz system such as the

Futaba FASST™ system, or a PCM system. Use with a FM

system is strongly discouraged since interference can

cause serious operational problems. In addition to this

the latest high performance tail rotor servos generate

electrical noise which may also cause interference to an

FM receiver.

• Always ensure that there is some slack in the gyro cables

to help maximize performance. Always use the supplied

gyro mounting pads to attach the gyro to the helicopter

mechanics. Do not use a strap that encompasses the GY520.

This may affect the overall performance of the gyro.

• Always allow the gyro to adjust to the surrounding

environmental temperature before fl ight. A large temperature

change during use will cause drift and other operational issues.

• The GY520 uses a conductive resin case to prevent

electromagnetic interference. Do not allow anything to touch

the gyro case as it may cause a short circuit.

• If you are switching between Normal Mode and AVCS Mode

in flight, please keep in mind that you must have the gyro

re-learn the center position after making a trim change within

the transmitter. To memorize the new center position simply

flip the gain switch on the transmitter three times between

Normal Mode and AVCS Mode within one second. The tail

rotor servo will center indicating that the new center position

has been memorized.

• When the GY520 is used in Normal Mode, tail rotor

compensation or revolution mixing must be used within

the transmitter.

4

Page 5

RECAUTIONS

P

• When operating the gyro in AVCS Mode, all tail rotor

compensation and revolution mixing must be disabled and

any tail rotor offsets for fl ight modes must be disabled.

• When the GY520 is operated in AVCS mode the tail rotor

servo will not center when the stick is released. This is

normal operation for AVCS mode. The servo may also move

to the extent while the model is being carried out to the fl ight

line. Before take off, you must center the tail rotor servo by

moving the tail rotor stick full left, then full right, back to full

left and then allow the stick to center within one second. You

can also visually center the tail rotor pitch slider by using the

tail rotor stick.

• Do not drop the GY520 onto a hard surface or subject the

GY520 to a strong shock as this may damage the sensor.

Always use the supplied mounting pads or the Futaba

replacement mounting pads available from your local

hobby dealer.

• Always exit programming mode before attempting to fl y

the model.

• Do not use any type of priority mixing or gain reduction

mixing on the GY520.

5

Page 6

ARRANTY & REPAIR SERVICE (IN U.S.A.)

W

If any diffi culties are encountered while setting up or operating

your GY520, please consult the instruction manual fi rst. For

further assistance you may also refer to your hobby dealer,

or contact the Futaba Service Center at the web site, fax or

telephone number listed below:

www.futaba-rc.com or www.hobbyservices.com

Fax (217)-398-7721, Tel (217) 398-0007

If you are unable to resolve the issue, pack the system in its

original container with a note enclosed and a thorough, accurate

description of the diffi culty. Include the following in your note:

• Symptoms (including when the problem occurred)

• System (Transmitter, Receiver, Servos and model numbers)

• Model (Model name)

• Model numbers and quantity

• Your Name, Address and Telephone number

Send the respective items to the authorized Futaba Service

Center Address below:

Futaba Service Center

3002 N Apollo Drive Suite 1

Champaign, IL 61822

6

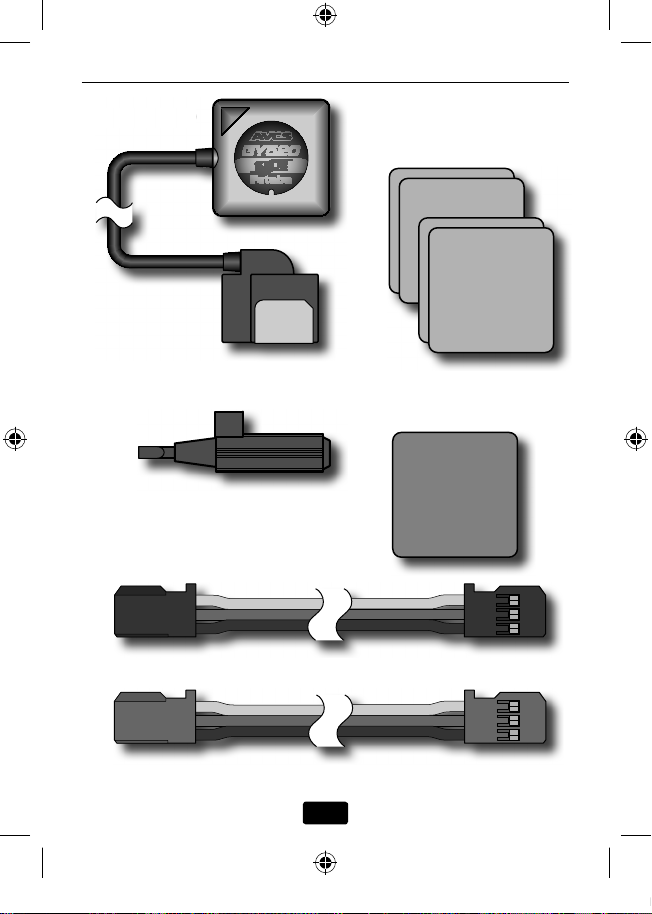

Page 7

ONTENTS

o

C

GY520 Gyro

Y520 Gyr

Adjustment Screwdriver

Extensions

Tail Rotor Extension (Black)

Mounting Pads

2mm Thick (two)

3mm Thick (two)

Damping and

Shield Plate

Gain Extension (Red)

7

Page 8

PECIFICATIONS

S

Width: 0.79in [20mm]

Length: 0.79in [20mm]

Height: 0.39in [10mm]

Weight: 0.243oz [6.9g]

Maximum* Operating Voltage: 3.8V to 6.0V DC (Gyro only)

Current Drain: 40mA (Gyro only)

Selectable Servo Frame Rate: 70Hz, 280Hz and 560Hz

Center Pulse Width: 1520 S (70Hz & 280Hz Frame Rate)

Flight Mode: User selectable F3C or 3D

Operating Temperature: 14ºF to 113ºF

Control System: Advanced PID control

Sensor: MEMS vibrating structure gyro

Angular Velocity Range: ±800 Degrees Per Second

*The maximum operating voltage listed only applies to the GY520.

Always verify that your receiver, servos, tail rotor servo, governor, switch

and any other electronic components used in your installation are capable

of operating at the voltage you plan to use.

760 S (560Hz Frame Rate)

8

Page 9

ECOMMENDED SERVOS

R

250 – 450 Sized Electric

Futaba S9257 EP Heli Digital (280Hz/1520μS): FUTM0667

.30 – .91 Size Helicopters

Futaba S9254 Digital Servo Heli (280Hz/1520μS): FUTM0224

Futaba S9256 Digital Hi Speed (560Hz/760μS): FUTM0226

Futaba BLS251 Brushless Heli Servo (560Hz/760μS): FUTM0521

EPLACEMENT & OPTIONAL ITEMS

R

Futaba PC Interface CIU-2 for GY520: FUTM0951

FSH64 GY520 Extension 200 mm (2): FUTM4664

FSH65 GY520 Extension 350 mm (2): FUTM4665

FSH66 GY520 Extension 55 mm (2): FUTM4666

FSH67 GY520 Extension 80 mm (2): FUTM4667

FSH68 GY520 Extension 130 mm (2): FUTM4668

FSH69 GY520 Mounting Pad 2x22x22 mm (10): FUTM4669

FSH70 GY520 Mounting Pad 3x22x22 mm (10): FUTM4670

FSH71 GY520 Shield Plate 1x22x22 mm (3): FUTM4671

9

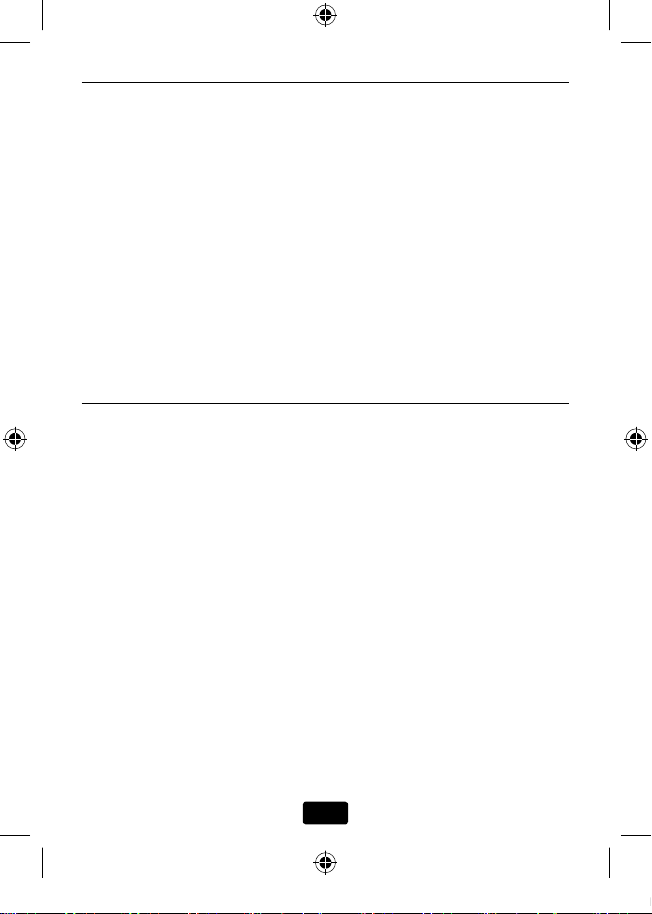

Page 10

UNCTIONS & CONNECTIONS

F

LED Indicator

Button

Tail Rotor Servo

10

Gain

Channel

Tail Rotor

Channel

Page 11

NDICATOR DESCRIPTION

LED I

Slow Flash: 1/2 Second or longer

Fast Flash: 1/4 Second or shorter

CONDITION LED INDICATOR DESCRIPTION

Initialization Slow Red Flash No Receiver Pulse or Sensor Error

Slow Blue Flash Warm-Up

Fast Blue Flash Sensor Initialization

Operating Solid Blue Normal Mode, Ready for Flight

Solid Red AVCS Mode, Ready for Flight

Slow Violet Flash Offset from the Neutral Position

Fast Blue or Red Flash Gyro is Rotating

NTRODUCTION

I

The Futaba® GY520 is the smallest and lightest heading hold

AVCS gyro available today. Its cutting-edge MEMS (Micro Electro

Mechanical System) sensor design, ultra high-speed processing

speed and advanced PID control algorithm put it a quantum

leap ahead of all other heading hold gyros in size, weight and

performance. The GY520 has been optimized to work with small

electric models and larger nitro (.30 through .91) sized helicopters.

11

Page 12

ECHANICS PREPARATIONS

M

WARNING!

• Newer high end servos and other radio equipment are

capable of placing large demands on the power systems

in use today. When using a regulator you must ensure

that the regulator is capable of delivering the current

demands of the equipment you have selected. In addition

to this make sure the wiring and switch you have

selected are capable of handling high current draws.

• Even though the GY520 is a high performance gyro it will be

necessary to ensure that the helicopter mechanics are also

in optimum operating condition. Please use the guidelines

below and address all issues before installing and test fl ying

the GY520.

• The GY520 must be used with a rigid tail rotor drive system.

Any modern torque tube or belt drive system should be

adequate. Do not attempt to fly the GY520 using a wire

driven tail rotor system.

• Always ensure the drive gears, torque tube, pulleys, belt,

bearings and shafts are in proper working condition. If any of

these items are damaged or worn they must be replaced.

• The linkage rod, tail rotor bell crank, pitch slider and tail

rotor grips must operate without friction to obtain the best

performance from the GY520. If any binding is present it

must be fi xed before the helicopter can be fl own. Binding in

the tail rotor control linkage will decrease the performance of

the GY520 gyro and this may also shorten the servo lifespan.

Please take the time now to ensure the tail rotor system on

your helicopter is working correctly, without friction or binding.

• Vibration will affect the gyro’s overall performance. All

rotating components on the helicopter should be balanced

to minimize vibrations in flight. Ensure that your motor is

running smooth and all vibrations have been addressed

before installing and test fl ying the GY520.

1212

Page 13

GY520 I

NSTALLATION

The gyro should be mounted on a rigid platform, at least

6in [152mm] away from a Nitro Engine. It is not necessary

to mount the gyro near the main shaft of the helicopter but

it is very important that the mounting area chosen is rigid.

Please refer to your helicopter manufacturer’s instructions for

recommended mounting locations.

Installing the gyro

The GY520 is supplied with two 2mm Mounting Pads, two

3mm Mounting Pads, and one 1mm Damping and Shield

Plate to help accommodate several installation methods. Most

electric helicopters with minimal vibrations can use one 2mm

mounting pad to mount the gyro onto the Gyro Mount. If the

GY520 is mounted near the ESC, near a servo, or near the tail

rotor belt we highly recommend using two 2mm Mounting

Pads and the steel Damping/Shield Plate to help prevent

electromagnetic interference from reaching the gyro.

Recommended Installation for Smaller Electric Helicopters

(250, 450, and 500 size helis)

2mm Mounting Pad

Gyro Mount

13

Page 14

GY520 I

NSTALLATION

Recommended Installation for Larger Electric Helicopters

and All Nitro Helicopters

Damping and

Shield Plate

2mm or 3mm

Mounting Pads

Gyro Mount

On smaller electric helicopters it is best to mount the gyro using

one 2mm mounting pad. When mounting the gyro in a larger

electric or .50 through .91 size nitro helicopter we recommend

using two 3mm Mounting Pads and the Damping/Shield Plate.

TROUBLESHOOTING

If you experience erratic gyro operation (drifting, not holding

well or inconsistent pirouette rate), please follow the

troubleshooting tips listed below.

1. Always verify that your model’s tail rotor control and drive

system are working correctly.

2. Electromagnetic interference could affect the gyro or

tail rotor servo. Use the metal damping and shield plate

or mount the gyro in a different location, away from the

electronic speed control, servos and drive motor.

3. The trouble may be caused by vibration. Verify that your

helicopter’s components are balanced. If problems persist,

try mounting the gyro in a different location. Various

combinations of the gyro mounting tape may help to mask

the issue.

14

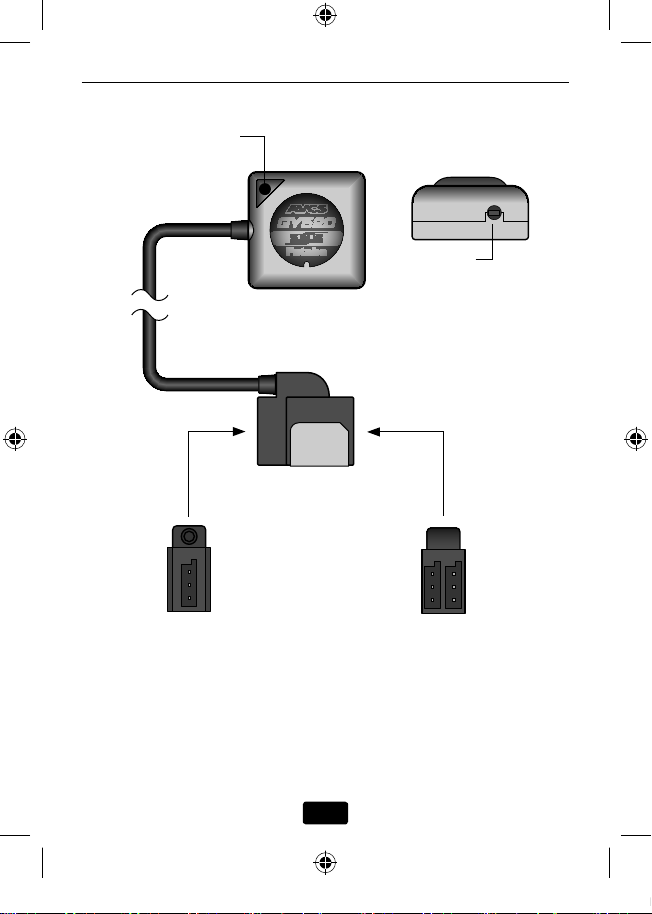

Page 15

ONNECTING THE

C

GY520

TO YOUR RECEIVER

Tail Rotor

Servo

Red: Gain

Channel

Black:

Tail Rotor

Channel

Connect the supplied extensions to the GY520 connecter block as

indicated. Route the wires through the helicopter mechanics and

connect them to the appropriate receiver channels. To determine

the appropriate receiver channels please check your transmitter’s

instruction manual. Using a piece of double sided tape, mount

the GY520 connector block onto the helicopter, ensuring that

you leave some slack in the wire leading to the gyro. Using wire

mounts, wiring fixtures molded into the helicopter, or hook and

loop material, route the extensions to the receiver. Ensure that the

extensions leading to the receiver cannot become entangled in

rotating components and make sure the extensions are not rubbing

against metal or carbon fi ber which may damage the wires.

Once the power system is installed into your helicopter please

move onto the next section to learn how to program the gyro.

15

Page 16

GY520 P

ROGRAMMING

Button

Entering Programming Mode

Press and hold the button on the side of the GY520. After

3 seconds the LED indicator will momentarily change to violet.

Release the button and the gyro will begin fl ashing once per

second. The color shown is the option selected for the 1st

parameter [Servo Type]. For example, if you see one Blue Flash

then the [Servo Type] is set to Digital 1520 S. If you see one

Red Flash then the [Servo Type] is set to Digital 760 S servo.

The number of fl ashes is the parameter number you are viewing

and the color of the LED indicates the setting that has been

selected. Please see the GY520 Parameters and Settings Table.

Changing the setting within a parameter

To move to the next setting within a parameter, quickly (less

than one second) press and release the button on the gyro. The

LED will begin fl ashing rapidly. This indicates that the gyro

needs confi rmation of the change. While the LED is fl ashing,

rapidly press and release the button again to confirm the

change. The confirmation request flash will last one second,

after this period of time the gyro will return to the parameter

menu without making a change. Always ensure that the change

has taken place by counting the number of fl ashes and verify

the color of the indicator LED.

Moving to the next Parameter

Press and continue to hold the button on the side of the GY520.

After 2 seconds the LED indicator will momentarily change to

violet. Release the button and the gyro will move to the next

parameter. The number of fl ashes will change to refl ect this.

16

Page 17

GY520 P

S

D

4. F

R

2. G

D

3.

S

ROGRAMMING

GY520 Parameters and Settings Table

PARAMETER SETTING LED INDICATION

Digital 1520μS Servo* Blue, 1 Flash

1. Servo Selection

.

2. Gyro Compensation

Direction

3. Servo Limits

4. Flight Mode

5. Response

.

6. Data Reset

.

Digital 760μS Servo Red, 1 Flash

Analog Servo Violet, 1 Flash

Normal* Blue, 2 Flashes

Reverse Red, 2 Flashes

Red, 3 Flashes

F3C Mode*

3D Mode Red, 4 Flashes

Standard* Blue, 5 Flashes

Fast Red, 5 Flashes

Slow Violet, 5 Flashes

(Resets Settings 1 – 5) Blue, 6 Flashes

* Default Setting

Blue, 4 Flashes

17

Page 18

GY520 P

ROGRAMMING

Parameter 1: Servo Type [1 FLASH]

Select the appropriate setting for the servo you are using.

LED INDICATOR

SERVO TYPE SERVO COMPATIBILITY

Futaba S9650 EP Heli Digital Servo

Blue, 1 Flash

Digital 1520μS Servo*

Red, 1 Flash

Digital 760μS Servo

Violet, 1 Flash

Futaba S9257 EP Heli Digital Servo

Futaba S9253 Digital Servo

Futaba S9254 Digital Servo

Any digital servo capable of a 280 Hz update rate.

Futaba S9251 Digital High Speed Servo

Futaba S9256 Digital High Speed Servo

Futaba BLS251 Brushless Heli Servo

All analog (non-digital) servos.

* Default Setting

WARNING!

The servo type parameter within the GY520 must match the

type of servo you are using. Incorrect setting may damage the

GY520 or the servo, possibly resulting in a loss of control of

the model during fl ight.

18

Page 19

GY520 P

ROGRAMMING

Parameter 2: Gyro Compensation Direction [2 FLASHES]

LED INDICATOR DESCRIPTION

Red, 2 Flashes

Blue, 2 Flashes

Normal Compensation*

Reverse Compensation

* Default Setting

WARNING!

Verify that the gyro compensates the correct direction before

fl ight. If the compensation direction is incorrect the model will

pirouette uncontrollably at a very high rate.

This parameter controls which direction the gyro will compensate

when the helicopter rotates. Once the tail rotor linkage is connected

to the servo, pick the helicopter up by the main shaft and rotate

the mechanics counter-clockwise. The gyro should compensate

by adding clockwise rotation pitch to the tail rotor blades. If the

gyro compensates by adding counter-clockwise rotation pitch to

the tail rotor blades then it will be necessary to reverse the Gyro

Compensation Direction setting.

19

Page 20

GY520 P

ROGRAMMING

Parameter 3: Servo Limits [3 FLASHES]

LED INDICATOR DESCRIPTION

Red, 3 Flashes

Blue, 3 Flashes

Limit Testing Mode

Set limit using tail rotor stick.

The Servo Limit parameter is used to set the mechanical limits for the

tail rotor servo. To obtain the highest performance it is recommended

to adjust the servo arm length to set the mechanical limits and then

use the servo limits parameter to make small adjustments.

WARNING!

• To prevent damage to the servo always perform limit setup

with the tail rotor linkage disconnected and simply hold the

linkage over the linkage ball to verify settings.

• While in the servo limits parameter the gyro no longer

functions. Always ensure that the gyro is functioning correctly

and it is not in the servo limits parameter before flying

the helicopter.

Setting the servo limits:

Go to the SERVO LIMITS parameter. While in the servo limits

parameter the gyro compensation no longer functions and the tail

rotor servo will always center. This can be used to set the centering

position for the tail rotor linkage and the tail rotor stick can be

moved to verify that the limits are set correctly. While in the servo

limits parameter the tail rotor stick is 150% more effective to

compensate for any tail rotor AFR or D/R adjustments made within

the radio. Please do not be concerned if the tail rotor servo reaches

its limit before the tail rotor stick reaches its physical limit.

20

Page 21

GY520 P

ROGRAMMING

WARNING!

If one of the servo limits is set to a position less than 50% of the

total throw, the LED on the gyro will turn red. When the LED is

red, you will not be able to move to the next limit setting or exit

the limit setting parameter. If the current value is greater than

50% then the LED will be blue and the setting is acceptable.

Quickly press and release the button once to enter limit setting

mode. The LED will fl ash quickly and the tail rotor servo will travel

to the set limit. When the transmitter’s tail rotor stick is moved to

the left or to the right the servo limit will increase or decrease. Hold

the tail rotor linkage over the linkage ball and adjust the servo limit

using the tail rotor stick until no binding occurs. If the LED turns

red, then the travel value is less than 50% and this is not acceptable.

Please decrease the servo arm length to reduce throw.

Quickly press and release the button once. If the limit is acceptable

the LED will momentarily change to Violet and the servo will

travel to the opposite limit setting. Hold the tail rotor linkage over

the linkage ball and adjust the servo limit using the tail rotor stick

until no binding occurs. If the LED is fl ashing red then the travel

value is less than 50% and this is not acceptable. Please decrease

the servo arm length to reduce throw.

Quickly press and release the button once to return to the SERVO

LIMITS parameter. If the limit settings are accepted the LED will

momentarily change to violet. You can now move the tail rotor stick

again to verify that the settings are correct. If you need to adjust the

settings again simply repeat the above procedure to adjust the servo

limit settings.

21

Page 22

GY520 P

ROGRAMMING

Parameter 4: Flight Mode [4 FLASHES]

WARNING!

Always make small (1%) adjustments to the tail rotor D/R or

EPA once the value exceeds 100%. Over 100%, it is possible

to exceed the sensor’s Angular Velocity Sensing Range

(+/- 800° per second). The gyro will then no longer control

the pirouette rate or consistency. The pirouette rate will be

extremely fast.

If you experiment with the ultra-fast pirouette rate, make

sure that your fl ight battery and fuel tank are secure. Also be

certain that your model’s tail rotor drive train is up to the task.

LED INDICATOR/MODE DESCRIPTION

Blue, 4 Flashes

F3C Flight Mode*

Red, 4 Flashes

3D Flight Mode

450 deg/sec pirouette rate at 100% D/R

Softer pirouette starts and stops.

720 deg/sec pirouette rate at 100% D/R

Aggressive pirouette starts and stops.

* Default Setting

Selects the fl ight mode. Always try the F3C fl ight mode fi rst and if

you determine that the gyro is not aggressive enough, then try the 3D

fl ight mode. The F3C Flight Mode will satisfy most pilots.

22

Page 23

GY520 P

ROGRAMMING

Parameter 5: Gyro Response Rate [5 FLASHES]

LED INDICATOR DESCRIPTION

Blue, 5 Flashes

Red, 5 Flashes

Violet, 5 Flashes

Standard Response*

Fast Response

Slow Response

* Default Setting

Sets the gyros response rate. The standard setting is acceptable

for most helicopters. We recommend trying this setting first. On

extremely small or lightweight helicopters with high performance

tail servos and high performance tail setups, the Fast response rate

may work better. The slow response rate should be used on larger

and heavier scale models. This setting will affect the pirouette rate,

pirouette starts and stops, and the gyro compensation response

as well.

23

Page 24

GY520 P

ROGRAMMING

Parameter 6: Data Reset [6 FLASHES]

Restores the gyro to the factory default settings. It will be necessary

to reprogram all parameters again before fl ying the model.

PARAMETER DEFAULT SETTING

1. Servo Type Digital 1520μS

2. Gyro Compensation Direction Normal

3. Servo Limits 100% / 100%

4. Flight Mode F3C

5. Gyro Response Standard

To perform the Data Reset:

Quickly press and release the button on the gyro. The gyro LED will

begin fl ashing quickly requesting confi rmation of the Data Reset. To

confi rm the Data Reset the gyro button must be quickly pressed and

released 3 times, within 2 seconds. Once the data reset is performed

the gyro will automatically return to the Servo Type Selection [Blue,

1 Flash] parameter.

Exiting Programming Mode:

Once you have completed setting up the parameters simply turn the

receiver power off.

24

Page 25

AIL ROTOR SERVO INSTALLATION AND SETUP

T

Following your transmitter instructions, program your

transmitter as follows:

❏ Enable the gyro function within the transmitter.

❏ Set the gyro mode to AVCS (GY) within the transmitter.

❏ Set the remote gyro gain to 70% AVCS in the transmitter for

the Normal and Hold fl ight conditions and use 40% AVCS for

all idle up conditions. See “Setting The Gain” section later in

this manual for more details.

❏ Set the Tail Rotor ATV/EPA to 100% for both left and right.

❏ Set D/R to 75% for both left and right. This will reduce the

maximum pirouette rate. Make adjustments to these values

once the initial test fl ight has been completed.

❏ It is recommended that you run 30% softening expo on the tail

rotor channel.

WARNING!

Do not connect the tail rotor servo to the gyro until the servo

type has been selected. Operating the servo using the

incorrect setting may damage the GY520 or the servo.

Once these steps are completed, turn the receiver power on and

allow the gyro to initialize. Follow the instructions within the

“GY520 Programming” section of the manual and select the

Servo Type that matches the servo you have chosen to use. Power

down the receiver for now.

25

Page 26

AIL ROTOR SERVO INSTALLATION AND SETUP

T

❏ Install the tail rotor servo into the mechanics and connect the

servo to the gyro. Remove the servo arm screw from the servo.

Turn the receiver power on and allow the gyro to initialize.

Enter programming mode and go to parameter 3 – Servo Limits

[Red, Three Flashes]. While in the servo limits parameter the

servo will remain centered.

90˚

❏ Place an appropriate servo arm onto the servo and ensure that it

is perpendicular to the tail rotor pushrod as shown. Remove the

unused sides of the servo arm.

❏ Install the control ball supplied with your helicopter onto the

servo arm. For smaller electric helicopters (250, 300, 450

and 500 size) we recommend placing the ball 7.5mm from

center. For larger electric models or nitro powered models we

recommend placing the ball 13.5mm from center. Once the

control ball has been installed place the arm back onto the servo

ensuring that it is perpendicular to the tail rotor pushrod. Install

the servo arm screw.

26

Page 27

AIL ROTOR SERVO INSTALLATION AND SETUP

m

T

Smaller Electric Helis

(250, 300, 450 and 500)

7.5mm

Larger Electric and

All Nitro Helis

13.5m

❏ Follow the instructions within the GY520 programming section

and set the servo limits for the tail rotor servo. Hold the tail

rotor linkage over the linkage ball to avoid damaging the servo.

Once the limits are set you can place the linkage onto the

linkage ball. When using AVCS mode the optimum setup is to

have 0° of pitch with the tail rotor servo centered and use all of

the available pitch range available in the tail without binding.

❏ Turn the receiver power off to exit programming mode and then

turn the receiver power back on. Once the gyro has completed

initialization move the tail rotor stick to the right on the

transmitter and verify that right (clockwise rotation) tail rotor

pitch is inputted to the tail rotor blades. If left tail rotor pitch

is inputted to the tail rotor blades, then it will be necessary to

reverse the tail rotor channel in the transmitter.

❏ Pick the helicopter up by the main shaft and rotate the mechanics

counter-clockwise (from the top). The gyro should compensate

by adding clockwise rotation pitch to the tail rotor blades. If the

gyro compensates by adding counter-clockwise rotation pitch to

the tail rotor blades then it will be necessary to reverse the Gyro

Compensation Direction setting within the gyro (refer to the

GY520 Programming section earlier in this manual).

If you are going to fly AVCS Heading Hold mode exclusively,

then the gyro setup is now complete.

27

Page 28

EFORE FLIGHT CHECKLIST

B

❏ Transmitter and Receiver batteries are fully charged.

❏ The gyro mounting pads are in good condition.

❏ The gyro wiring has some slack in it and all wires are clear

of the main frame.

❏ Power on the transmitter and receiver. Allow the gyro

to initialize.

❏ The GY520 servo type parameter matches the servo you

are using.

❏ The Tail rotor servo arm is perpendicular to the pushrod

and the pitch slider is centered.

❏ The servo does not bind when full left or full right tail rotor

is applied.

❏ The gyro is operating in the correct mode (AVCS or

Normal).

❏ The tail rotor stick operates the tail rotor the correct

direction.

❏ The gyro compensates the correct direction when the

helicopter is rotated.

❏ The gain is set correctly and the gyro operates in the correct

mode (AVCS or Normal) in every fl ight condition.

28

Page 29

DJUSTMENTS DURING THE TEST FLIGHT

A

WARNING!

Always make small (1%) adjustments to the tail rotor D/R or

EPA once the value exceeds 100%. Over 100%, it is possible

to exceed the sensor’s Angular Velocity Sensing Range

(+/- 800° per second). The gyro will then no longer control

the pirouette rate or consistency. The pirouette rate will be

extremely fast.

If you experiment with the ultra-fast pirouette rate, make

sure that your fl ight battery and fuel tank are secure. Also be

certain that your model’s tail rotor drive train is up to the task.

The Tail Rotor AFR or D/R function within the transmitter is used

to adjust the pirouette rate of the helicopter. For example at 100%

D/R, with the gyro set to F3C mode, the helicopter will achieve a

450 deg/sec pirouette rate. If you would like the model to pirouette

faster, then increase the AFR or D/R. If you would like the model

to pirouette slower, then decrease the AFR or D/R.

The gain should be raised until the tail begins to oscillate quickly

(also called Tail Wag). Once this point has been achieved, reduce

the gain by a couple of percent and test fl y the model again. Check

and set the gain for each fl ight mode. Typically the gain will be

lower for the Idle up 1 and Idle up 2 fl ight modes due to the higher

head speed being used. The gain for the Hold condition can also be

much higher than other fl ight modes since the head speed is lower

and the engine vibration is minimized.

The tail rotor ratio, tail rotor pitch range and tail blade length play

a large part in achieving optimum tail rotor performance. The gain

value can vary drastically from model to model and the exact value

should not play a part in the evaluation of the gyro’s performance.

How the gyro operates during fl ight is the only concern of ours.

29

Page 30

U

SING

GY520 N

ORMAL MODE

Most pilots today are using AVCS Mode. If you are just starting

out, it is recommended that you use AVCS Mode exclusively from

the start. Normal Mode is rarely used today due to the performance

benefi ts of AVCS mode. When using AVCS mode all trimming of the

tail is automatically handled by the gyro. If you should decide to use

Normal Mode than all trimming and mixing must be setup by you.

If you will be using the Normal Mode (also referred to as Rate

Mode) then a few changes to the setup will be necessary. The tail

rotor should be set to 10 degrees of tail rotor pitch (to counteract

torque) when the tail rotor servo is centered. With clockwise

rotating main rotor blades this means 10 degrees of right tail rotor

pitch will be necessary to counteract torque. In addition to this it

will be necessary to use the tail rotor compensation or revolution

mixing functions of your transmitter to help counteract torque.

Please see your transmitter instruction manual for more information

on how to set this up.

If you decide to switch between Normal Mode and AVCS Mode

in fl ight, you must have the gyro re-learn the center position after

making a trim change within the transmitter. To memorize the new

center position simply fl ip the gain switch on the transmitter three

times between Normal Mode and AVCS Mode within one second.

The tail rotor servo will center, indicating that the new center

position has been memorized.

30

Page 31

ETTING THE GAIN

S

Most modern computer transmitters will have a gyro function

built into them. If this is the case, please refer to your transmitter’s

instruction manual. Most modern gyro functions will allow you to

set the mode of operation and the gains for several fl ight conditions.

The use of these functions is strongly encouraged. Shown below is a

recommendation of settings:

Recommended Gyro

Function Settings:

Switch: Condition

Type: GY or AVCS

Gain Values

Normal: 70% A (AVCS)

Idleup 1: 40% A (AVCS)

2-Position

Switch

Gyro Mode

Gain Channel

ATV or EPA

AB

NORMAL AVCS

70% 70%

Normal Side

100%

AVCS Side

Idleup 2: 40% A (AVCS)

Hold: 70% A (AVCS)

If your transmitter does not

have a Gyro function built

50%

GAIN %

0%

+100% Neutral0%-100%

in then it will be necessary

to use the ATV or EPA function to control the gain. The Gyro Gain

channel will generally be assigned to a switch which provides two

gain values. Simply set the ATV or EPA for the gyro channel to the

desired gain value and set the Gain Switch to the desired mode of

operation. Unfortunately since you will only have one gain value

available it will be necessary to use the lowest value needed (for

example Idleup 2). When using this method of controlling the

gain, one direction of the switch will be AVCS mode and the other

direction of the switch will be Normal mode. Always ensure the gyro

switch is set to the desired mode before fl ying. Do not accidentally

change the gyro switch in fl ight.

31

Page 32

Entire Contents Copyright © 2009

Loading...

Loading...