Page 1

Futaba

DIGITAL PROPORTIONAL

RADIO CONTROL

FP-7UAP

PCM 1024 SYSTEM

FP-7UAF

FM SYSTEM

D60460

Page 2

a Futaba digital proportional radio control set.

Please open it when reading this manual.

• FEATURES

• High resolution and fast response

Thank you for purchasing

Please read this manual

carefully before using your set

The last page of this manual

is a double foldout showing the name

of each part of the transmitter.

PCM 1024 system (FP-7UAP)

FM system (FP-7UAF)

7 channels system

foldout

• RF module

• Trainer system

(Trainer cable optional)

Dual rate switch

w/combination function

• Normal display mode

• Error display mode

• Edit display mode

Liquid crystal panel

displays all the

information necessary

in each display mode.

Six edit keys provide

fo r easy data setting.

• Set data is not lost

even when the battery is changed.

• Complete mixing functions

—Snap-roll!

4 channels

—Flaperon & aileron differential -Programmable mixing 2 separate systems

—Flap -> elevator mixing

—Elevator

->

flap

mixing

Page 3

• TABLE OF C ONTENTS

SET CONTENTS ...........................................

BEFORE USING ..........................................

DISPLAY FUNCTIONS

NORMAL DISPLAY

ERROR

EDIT

FUNCTIONS AND DATA SETTING

ADJUSTABLE TRAVEL

DUAL

EXPONENTIAL........................................ 9

REVERSE

FAIL

PROGRAMMABLE MIXING 1

PROGRAMMABLE MIXING 2 ............................

ELEVATOR -> FLAP MIXING ............................

FLAP -> ELEVATOR MIXING ............................

SNAP-ROLL

AILERON

FLAPERON ...........................................

FLAP TRIM ...........................................

SUB

COMBINATION SWITCH

MODULATION ........................................

OTHER FUNCTIONS ....................................

USING THE ACCESSORIES ...............................

NOMENCLATURE (DOUBLE FOLDOUT) ......................

SERVO EXPLODED VIEW ...................................

DISPLAY

DISPLAY

RATE

SAFE

TRIM.............................................18

..........................................

............................................

...........................................

..........................................

DIFFERENTIAL

MODE

MODE

MODE

..............................

................................

..................................

VOLUME

................................

........................

............................

..............................

2

3-5

6

7

7

8

8

9

10

11

12

13

14

15

16

17

18

18

19

19-20

20-21

22

23

ABBREVIATIONS

ATV

D/R DUAL RATE STRM SUB TR I M

EXP EXPONENTIAL COMB COMBINATION SWITCH

REV REVERSE MOD MODULATION

F/S FAILSAFE AUX AUXILIARY

PMX PROGRAMMABLE MIXING PCM PULSE CODE MODULATI

2->6 ELEVATOR^ FLAP MIXING PPM PULSE POSITION

6->2 FLAP -> ELEVATOR MIXING MODULATION

SNP SNAP-ROLL B.F/S BATTERY FAIL SAFE

DIFF AILERON DIFFERENTIAL

ADJUSTABLE TRAVEL FLPR FLAPERON

VOLUME FLTR FLAP TRIM

—1

—

Page 4

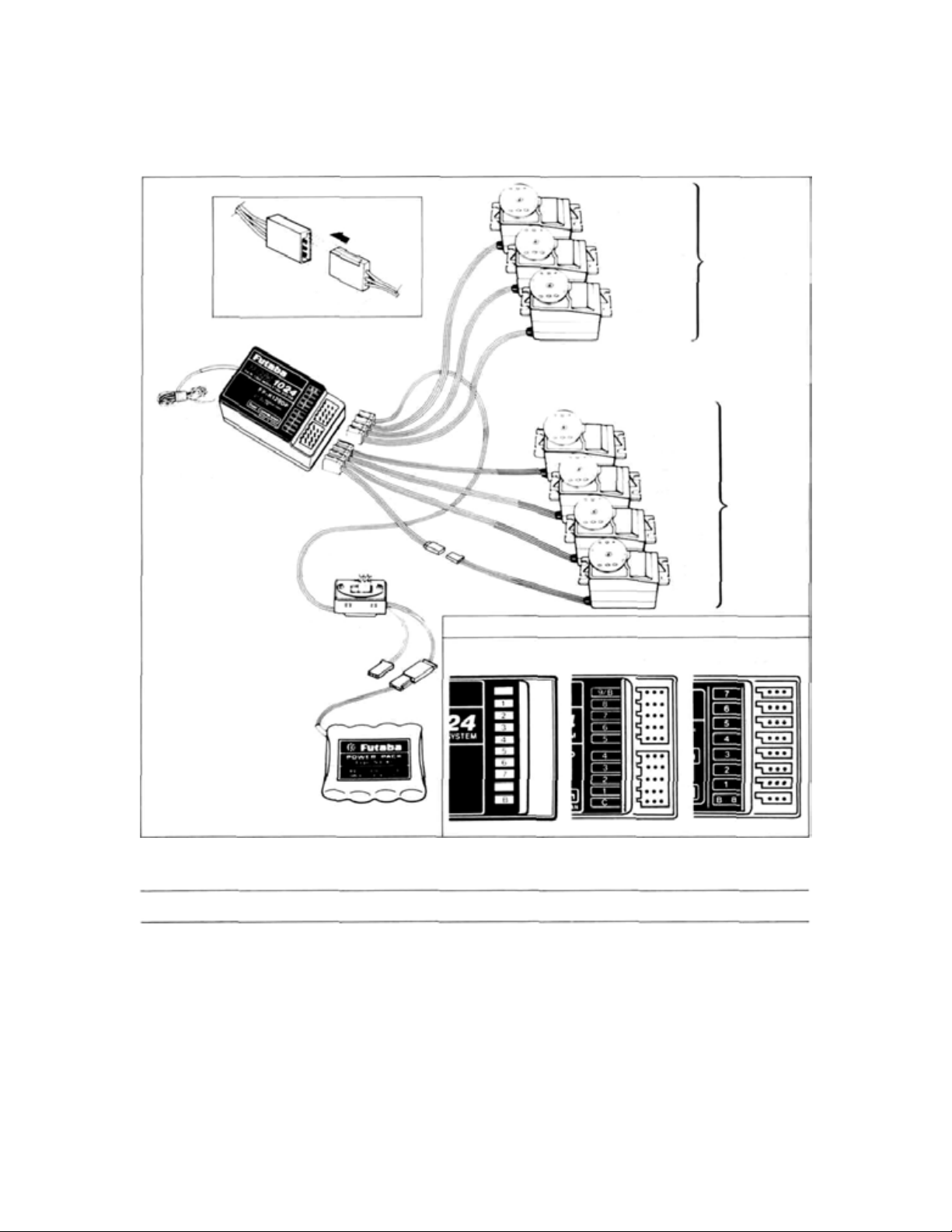

• SET CONTENTS

FP-7UAP

• FP-T7UAP ( X1 )

• FP-TP-FM (X1 )

*Specifications are subject to change without prior notice.

FP-7UAF

• FP-T7UAF (X1)

2 st ic ks , 7 channels, PCM or FM transmitter

Transmitting frequency: 72MHz, 50MHz,

35/36MHz, 40/41 MHz or 29MHz band

Modulation: FM-PCM/PPM Selectable

Power requirement: 9.6V Nicd battery pack

Current drain: 200mA

Rating

• FP-R129DP (X1)

(Dual Conversion Type)

or FP-R137GP (X1)

• FP-S148 (X4)

or FP-S3001 (X4)

•

NT-8LP(X1)

• FP-R128DF (X1)

(Dual Conversion Type)

Receiving frequency: 72MHz, 50MHz,

35/36MHz, 40/41 MHz or 29MHz band

Intermediate frequency: 1st IF 10.7MHz,

2nd IF 455kHz (R129DP, R128DF), 455kHz

(R137GP)

Power requirement; 4.8V Nicd battery pack

Current drain: 35mA (R129DP),

26mA (R128DF), 25mA (R137GP)

Dimensions: 63.0x37.8x24.1mm (R129DP).

63.8x35.4x20.3mm (R128DF) (excluding

protruding parts), 57x42x24mm (R137GP)

Weight: 45g (R129DP),40g (R128DF ),

45g(R137GP)

Receiving range: 500m on the ground. 1000m

in the air (range differs with the surroundings]

Control system: + pulse widt h control

Operating angle: Rotary system, one side 45

or greater (including trim)

Power requirement: 4.8V or

with receiver)

Current drain: 8mA at 6V (at idle)

Output torque; 3kg/cm

Operating speed; 0.22sec/60°

Dimensions: 40.4x1 9.8x36mm

Weight: 44.4g, 1.56oz. (S148),

45.1q, 1.59oz. (S3001)

Voltage: 9.6V

Capacity: 800mAh

(shared wi th servo)

6.0V (shared

• NR-4J (X1)

• Charger

• FM crystal set (Transmitter and Receiver)

However use the following crystal types for dual conversion receiver (R129DP, R128DF).

The set does not include t he following:

• Trainer cable (6-conductor)

• Receiver switch

• Servo horn

• Servo tray

• Tx hook band

• Frequency flag

or ribbon

- 2

-

Voltage: 4.8V

Capacity: 500mAh

Dimensions: 51x58x1 5mm

Weight: 95g,3.35oz.

Page 5

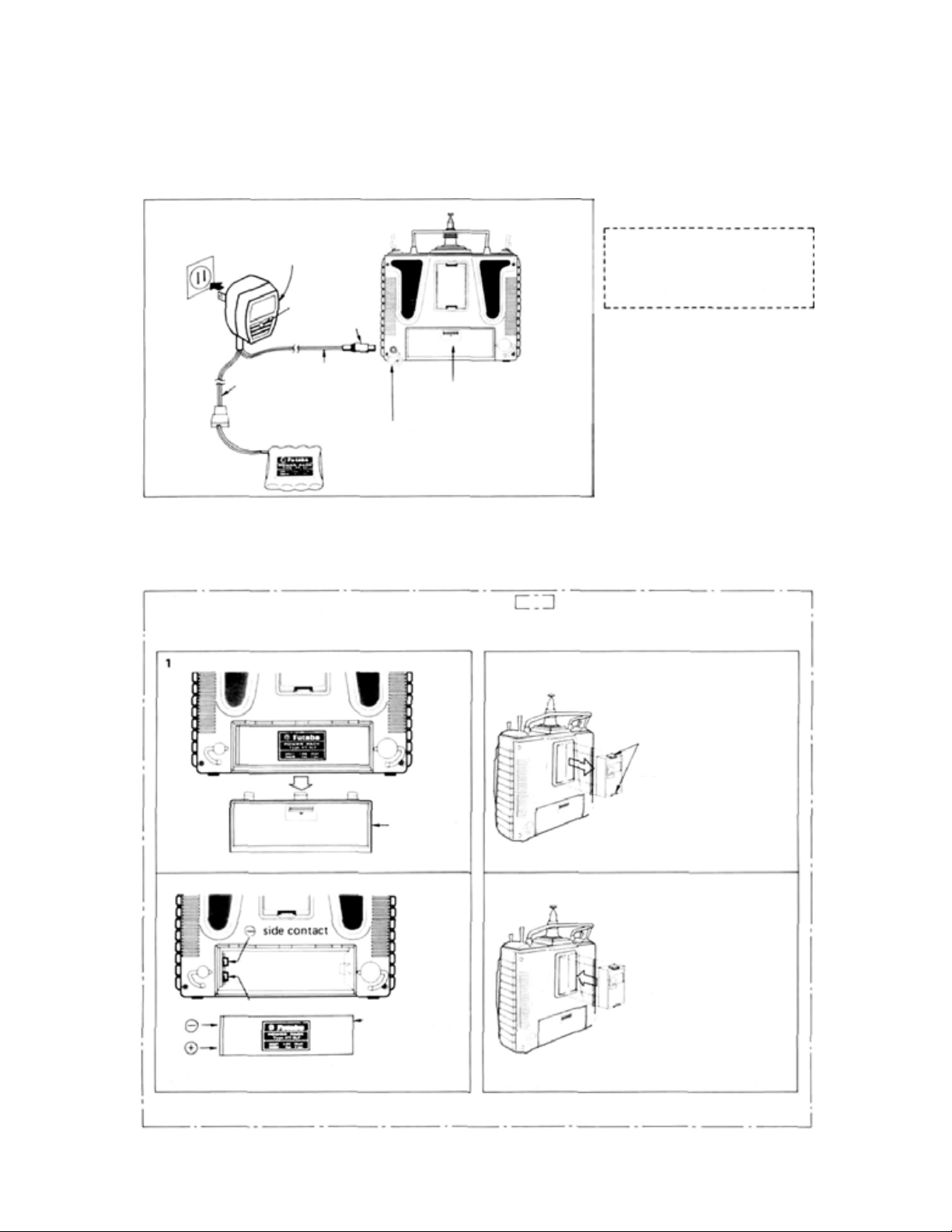

• BEFORE USING

• Charging the transmitter and receiver Nicd battery

FP-7UAPor FP-7UAF

Charger

LED

Power plug

Rx side

Male

Female

• Factory setting of transmitter modulation system

The transmitter modulation system (PCM/PPM mode) is switched by

data setting. (For the setting method, see P19.). However, it is set as

follows at the factory:

FP-T7UAP ..... PCM mode FP-T7UAF ..... PPM mode

Refer to only the necessary items of the items enclosed in

• Changing the transmitter Nicd battery

Remove the battery cover.

Tx side

Receiver

Nicd battery NR-4J

(NT-8LP inside)

Remove the charging cap

and connect the charger.

pack

• Changing the R F module to change the

frequency band

1 Remove the RF module.

*Use the special Futaba charger.

• The charging time is 15 hours.

[However when the battery was

not used fo r some time , charge and

discharge it 2 — 3 times. Otherwise,

the battery will not be charged even

after t h e specified charging time !

A fully-charged transmitter battery

can be used for about 10 flights of

10 minutes each. The airborne NR4J Nicd battery pack can be used

for about 6 flights when 6 servos

are used.

Notes: (PBC-8B)

1) First, connect to

red lamp goes on.

2) Then, connect to RX Nicad after

connecting, L, E, D, changes

color from red to greenish red

(orange) which indicates that

both TX and RX Nicads are

being charged.

3) In case of separate charging, L,

E, D, color wil l be:

RX Nicad - Green

TX Nicad- Red

TX Nicad and

Battery cover

2 Change the Nicd battery.

® side contact

*Load the battery while paying careful attention to

the direction of the contacts.

-Nicd battery

(Only the NT-8LP

can be used.)

—3—

Pull the RF module forward

while pressing these tabs to

the inside

2 Change the RF module.

Push in the new module,

while being careful not to

bend the pins, until the tabs

at

both

sides

lock

into

with a "click".

*Use the special FP-TP-FM RF module for the FP-

7UAP and 7UAF. Other RF modules cannot be used.

•When the transmitter frequency band is changed,

receiver frequency band must be changed also.

place

the

Page 6

• BEFORE USING

• RECEIVER AND SERVO CONNECTIONS

CH7 (A UX)

Pay careful attention to the

polarity of the connector.

Antenna

wire

PCM receiver

FP-R129DP, FP-R137GPor

FM receiver FP-R-128DF

Charging jack

Extension cord

Receiver switch

FP-R137GP

servo

CH2

Elevator

servo

CH1

Aileron

servo

Option

(sol d separately)

CH6 Flap servo

CH5

Landing gear

servo

CH4

Rudder

CH3

Throttle

servo

Receiver connector arrangement

FP-R129DP

Four servos

are supplied

as standard.

FP-R128DF

Nicd battery pack

NR-4J

PRECAUTIONS

• Connect the receiver, servos, switches, and battery as shown in the figure. Extend the transmitter and receiver antennas to their full

length.

•Turn

on the transmitter power

turn on the receiver power switch.

servos

will

go

to

The

their

Move the transmitter sticks one at a time to

check that each servo follows its control stick

movement.

switch,

neutral

then

position.

• Connect the pushrods to the servos and check

that the direction of travel of each servo

matches the direction of movement of its control

stick. If a servo

does

not

move

er direction, switch its direction with the servo

reversing function.

•

Operate

each

servo

horn

over its

full

check that the pushrod does not bind or is not

too loose. Unreasonable force applied to the

horn

will

servo

adversely

affect the

- 4 -

in the prop-

stroke and

servo

and

Page 7

• BEFORE USING

drain the battery pack very quickly. Make the

travel of each control mechanism somewhat

larger than the full stroke (including trim) of

the servo horn. Adjust the servo horns so that

they move smoothly even when the trim lever

and stick are operated simultaneously in the

same direction.

• Be alert for noise.

This set is noise-resistant, but not completely

immune to noise. The use of noiseless parts is

recommended.

•When installing the switch harness, cut a rectangular hole slightly larger than the full stroke

of the switch and install the switch so that it

moves smoothly from ON to OFF. Also do this

when the switch is installed inside the fuselage

and is turned on and off from the outside with

a piece of wire. Install the switch where it will

not be exposed to engine oil or dust and dirt.

• Although the antenna appears to be too long,

do not cut it or fold it back.

• Install the servos securely. Tighten the mounting screws until the rubber damper is crushed

slightly. If the screws are too tight, the cushioning effect will be adversely effected.

• The crystal can be changed from the outside of

the receiver case. Always use the Futaba transmitter/receiver matched crystal set to change

the band.

• The receiver that is used with the 7UAP and

7UAF is a dual conversion receiver. This receivers requires a special crystal so please order

the correct crystal set.

• Spare servo horns are supplied. Use them as

needed.

• Use extension cords matched to the model.

• Wrap the r eceiver in sponge rubber. Place it

inside a waterproof plastic bag and secure the

end of the bag with a rubber band. Do the

same with the airborne battery pack.

• Use th e rubber bands wrapped around the re-

ceiver to hold the servo and switch leads.

• After installation and checking are complete,

perform a range check by collapsing the transmitter antenna and extending the receiver

antenna to its full length and operating the

transmitter from a distance of 20 to 30 meters

from the receiver. The servos should operate

normally at this distance.

• Differs with the weather and surroundings.

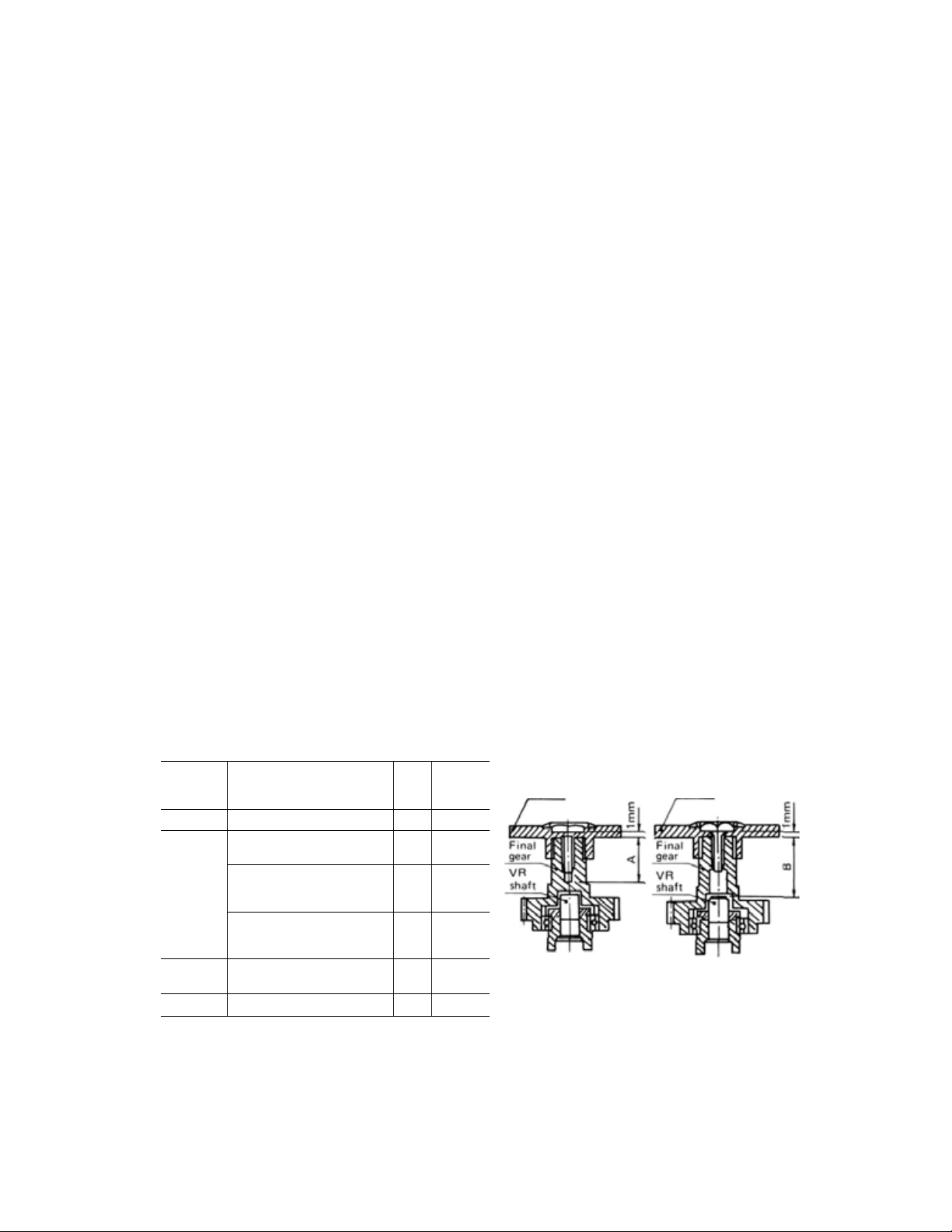

SERVO HORN MOUNTING SCREW PRECAUTIONS

Servo horn screws

Horn

mounting

screw size

2.6x6

2.6x8

2.6x10

2.6x12

Notes

• The screws are 2.6m/m tapping screws.

• If screws longer than necessary are used, the final gear may be broken or the potentiometer may be damaged or

may fall out.

Applicable servo

S133, S143 series

S 129 series

S130 series, S9101, S5101

S128 series

S132 series

S135 series, S9601

S136G

S138 series

S148 series

S131S series, S9201,S9301

89401

8134 series, 83301

Type

B

A

A

B

B

B

A

B

B

A

A

Dimen-

sions

(m/m)

5.7

7.9

7.9

11.9

7.3

8.7

9.0

9.9

10.5

9.0

11.3

Horn

Waterproof type A Non-waterproof type B

Horn

-5-

Page 8

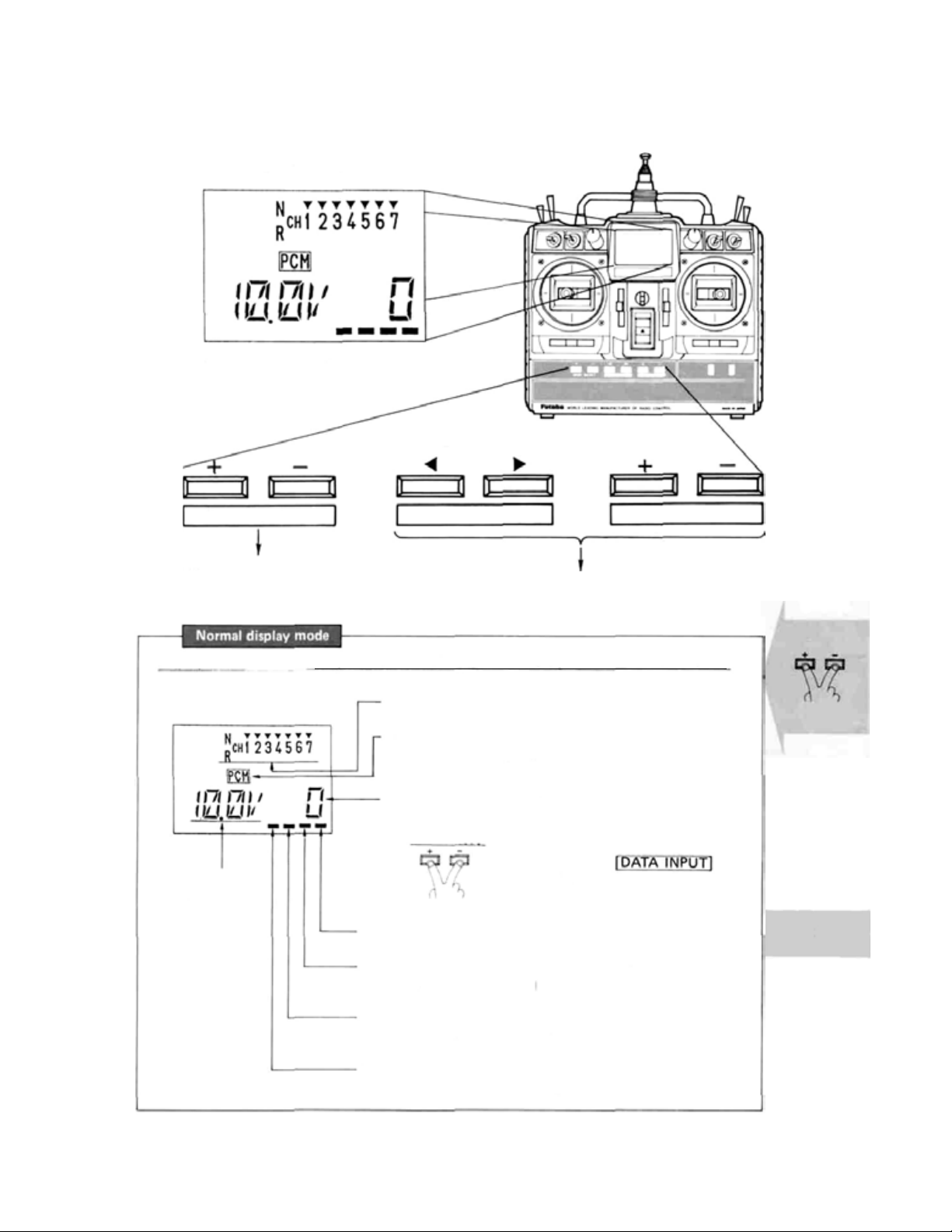

• DISPLAY FUNCTION

Liquid crystal panel

• Operated in three display modes

ED I T KEY

MODE SELECT

• Used in display mode switching.

• Used in setting function selection

Display mode at_normal use (Mode which is displayed when the power switch is turned on.)

(Display)

Battery voltage

display

• Reverse function display

(N: Normal, R: Reverse)

• PCM/PPM mode d isp lay

(PCM: PCM mode, PPM: PPM mode)

• Integrated time display (0—199 minutes)

(Displays the integrated time after reset.)

• Flashes at a 1 second period

CURSOR

• Used at data setting.

Clock reset

Reset by pressing the

simultaneously.

DATA INPUT

Display

keys

Error

• F/S data transfer display (FP-7UAP only)

(Lights momentarily each minute)

• RF indicator

(Lights when radiowaves are transmitted.)

• Mixing indicator

(Flashes when

snap roll mixing or 6 -> 2 mixing is ON.)

—6—

Page 9

Function data setting display mode

(Display)

• DISPLAY FUNCTION

ATV

P.8

MOD

P.19

mode switching

The display mode is

switched by pressinq the

keys simul-

taneously.

Function name

Function setting parameters

(See the individual function

setting items.)

(Set function recall)

• The function is selected by

I MODE SELECT | key.

D/R

EXP

REV

F/S

PMX1

PMX2

2->6

+ direction

P.8

P.9

P.9

P.10

P.11

P.12

P.13

COMB

STRM

FLTR

FLPR

DIFF

SNP

6->2

P.18

P.18

P.18

P.17

P.16

P.15

P.14

Error

generation

Display mode at error generation (Switched automatically from other modes)

(LOW BATTER Y error display)

• The characters flash and a buzzer sounds.

Charge, or change, the battery.

Charqinq method P4

(BACK-UP error display)

• Characters flash and a buzzer sounds.

Turn off the power switch and then turn on.

-7-

Page 10

• FUNCTION AN D DATA SETTING

Function

ATV

ADJUSTABLE TRAVEL

VOLUME

This function adjusts the servo left

and right throws and is used in

linkage correction.

• The rate can be set for each channel.

• The left and right (up, down) rate

can

be

set.

• The rate setting range is 30% to

110%.

Display

R/U: Right or up

L/D: Left or down

Press th e [MODE

CH selection

Direction selection

Rate setting

Set for a different CH and direction by re-

peating steps

SELECT]

Data setting

Select the CH to which ATV is

to be applied with the

keys.

Select the Direction with the

The rat e described below is set

Set the rate with the

— keys are pressed simultaneously,

100%

To normal display mod*

, or

keys. (When the + and

is

set.)

The rate can be switched with the

• D/R can be set for CH1 (aileron),

CH2 (elevator), and CH4 (rudder).

• D/R can be set fo r each direction

of

the

With this feature you can select

which switch position you want

for high rate and low rate.

• The rate setting range is 30% to

110%.

•Related function COMBINATION

SWITCH.

To D /R

D/R switch direction selection

Set for a different CH and

direction by repeating steps

Select the CH f or which D/R is

to be set with the

keys.

Switch to the direction for

which the

be

set.

Set the rate with the

— key s are pressed simultaneously.

keys. (When the + and

100%

is

set.)

to

is

to

8

Page 11

• FUNCTION AN D DATA SETTING

Function

EXP

EXPONENTIAL

This function modifies the operating curve so that operation is easy

when the movement of the servos

becomes sluggish or sensitive near

the neutral position.

•EXP can be set for CH1 (aileron),

CH2 (elevator), CH3 (throttle),

and CH4 (r ud de r) .

• The rat e can be set for each direction of the

(However, there is no

•The

(slow side) to +100% (quick side)

in 4% steps.

for the throttle.)

rate setting range

is

—100%

Display

Press the [MODE SEL ECT]

Data setting

CH selection

Select the CH to which EXP is

to be applied with the

keys.

D/R switch direction selection

Switch to the direction to which

the

Rate setting

Set the rate with the

- keys are pressed simultaneously,

0%

is

Set for a different CH and

direction by repeating steps

(Note) At initial flight, test at EXP 0%. Adju stm ent as desired in accordance with flight

is recommended.

To normal display mode

is

to

be set.

keys. (When th e + and

set.)

Function

REV

REVERSE

Used when modifying servo direc-

tion of operation.

• Can be set fo r each channel.

Display

N: Normal side

R: Reverse side

To

REV

Data setting

CH selection

Select the CH for which REV is

to be set with the

keys. (CH NO. flashes)

Direction of operation setting

Set the direction with the

+ : Normal

—: Reverse

Set for another channel by repeating steps

and

(Note) Be especially careful in the aileron

direction.

keys.

-9-

To F/S

Page 12

• FUNCTION AND DATA SETTING

F/S

FAIL SAFE

F/S and HOLD functions

• F/S and

• The F/S and HOLD functions can

(HOLD function setting)

When interference makes reception

impossible, the servos are stopped

in position just before erroneous

operation is performed.

When the interference ceases, the

HOLD mode is released.

(F/S function setting)

When interference makes reception

impossible, the servos move to the

position set at t h e transmitter.

When the interference ceases, the

F/S function is reset.

HOLD can be set for all

channels.

be selected f or each channel.

Press

the

CH selection

[MODE

SELECT]

Select the CH which is to be

set to F/S or HOLD with the

To normal display mode

keys. (CH NO.

flashes)

Function selection

Select the function with the

+ : HOLD function

—: F/S function

Select the function for another channel by

repeating steps

F/S function selected CH servo operating

position setting

and

Set the flashing display to

"SET" with the

keys.

The channel

or

F/S function was selected is

held in the desired position.

Press the

simultaneously. (The servo operating position is set. At the same

time, data is automatically sent

to the receiver.)

keys.

for which the

keys

*The F/S set data is automatically

sent every minute.

*The PPM mode does not have an

F/S function. (FP-7UAF)

*When using the B.F/S function,

set the throttle channel F/S function.

-10-

To

PMX1

Page 13

• FUNCTION AN D DATA SETTING

PMX1

PROGRAMMABLE MIXING 1

This mixing is useful in correcting

bad tendencies of the aircraft and

in making operation more pleasant.

• Mixing of any two channels is

possible.

• The left and right (up and down)

mixing rate can be set independently.

• Setting range: 0 — 100% (mixing

maximum)

(INH: Inhibit state)

Activate state

ON:

OFF:

ON

OFF

Press the [MODE SE LECT ]

Mixing activate/inhibit mode setting

Set the mode with the

+ : Activate

—:

Inhibit

Master channel selection

Set the flashing display to the

mark with the

keys.

Select the channel to be set wit h

the

Slave channel selection

Set the flashing display to the

mark with the

keys.

Select the channel to be set wi th

the

To normal display mod e

keys.

keys.

keys.

R/U: Right or up

L/D: Left or down

Mixing servo direction of operation setting

Set the flashing display to "+"

(or "—") with the

keys.

Held as long as the master channel stick (VR or switch) is in the

R/U or L/D direction.

Set the direction of operation

with the

+ : Normal direction

—: Reverse direction

Set another direction by repeating steps

Mixing rate setting

Set the flashing display to "%"

with

Set the same as

Set the mixing rate with the

(When the + and — keys are

pressed simultaneously, 50% is

set.)

Set the same as

and

keys.

keys.

keys.

To PMX2

—

11

—

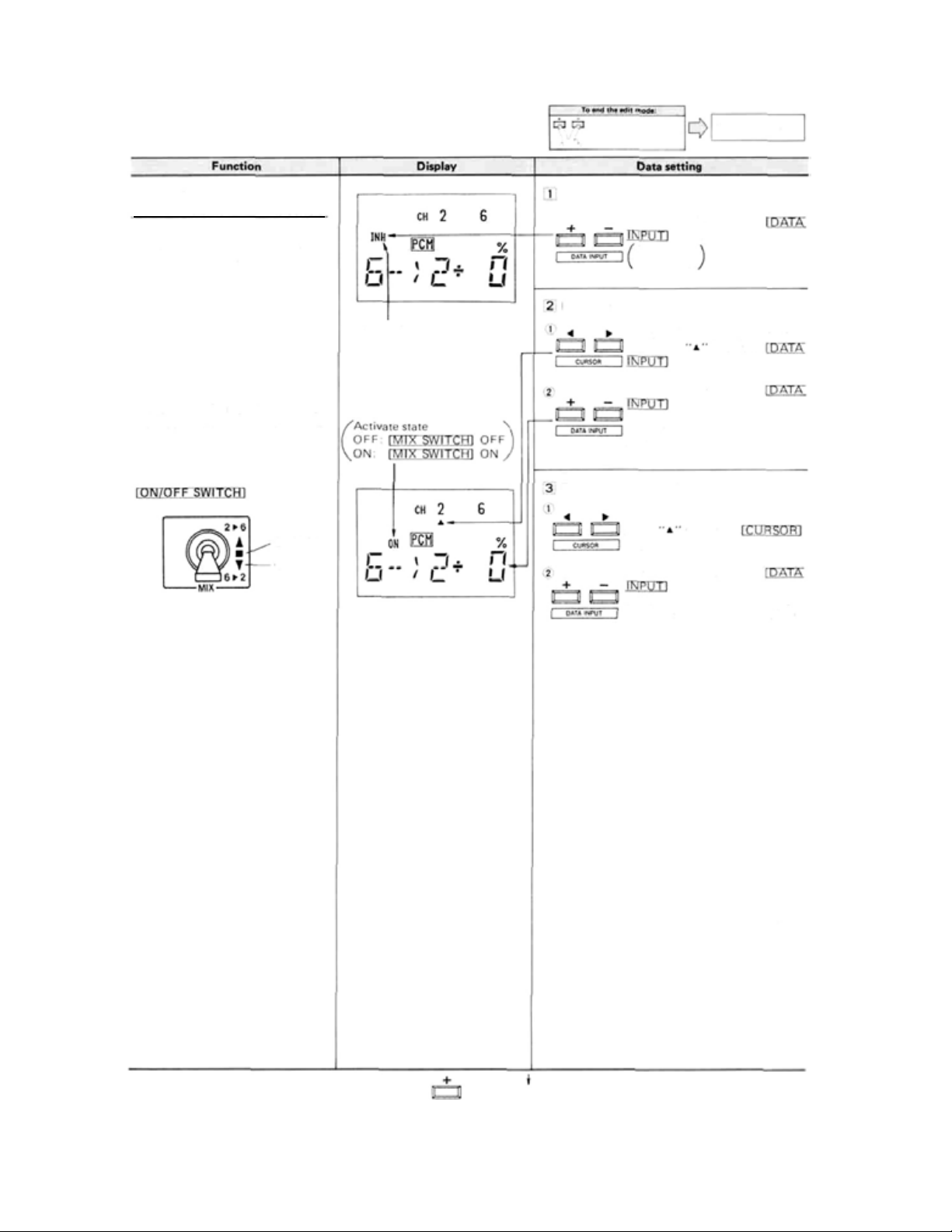

Page 14

• FUNCTION AND DATA SETTING

PMX2

PROGRAMMABLE MIXING 2

This mixing is useful in correcting

bad tendencies of the aircraft and

in making operation more pleasant.

• Mixing of any two channels is

possible.

• The left and right (up and down)

mixing rate can be set independently.

Press the [MODE SELECT]

Mixing activate/inhibit mode setting

Set the mode wi th the

+ : Activate

-: Inhibit

Master channel selection

Set the flashing display to the

mark with the

keys.

Select the channel t o be set with

the

Slave channel selection

Set the flashing display to the

mark with the

keys.

Select the channel to be set with

the

To normal display mode

keys.

keys.

keys.

R/U: Right or up

L/D: Left or down

Mixing servo direction of operation setting

Set the flashing display to "+'

(or "—")

keys.

Held as long as the master channel stick (VR or switch) is in the

R/U or L/D direction.

Set the direction of operation

with the

+ : Normal direction

-:

Set another direction by repeating steps

Mixing rate setting

Set the flashing display to "%"

with

Set the same as

Set the mixing rate with the

(When the + and — keys are

pressed simultaneously, 50% is

set.)

Set the same as

with the

keys.

Reverse direction

and

keys.

keys.

—12—

To

2-6

Page 15

• FUNCTION AND DATA SETTING

2-6

ELEVATOR ->> FLAP MIXING

This is used to apply mixing from

elevator to flap. Mixing is usually

used so that the flaps are lowered

when the elevator is raised. It

makes circular maneuvers with

stunt aircraft smoother.

• The elevator up side and down

side mixing rate can be set independently.

(INH: Inhibit state)

Pressthe [MODE SELECT]

Mixing activate/inhibit mode setting

Set the mode with the

+ : Activate

-: Inhibit

Mixing servo direction of operation setting

Set the flashing display to "+"

(or "—") with the

keys.

Held as long as the elevator

direction.

Set the direction of operation

with t h e

+ : Normal direction

—: Reverse direction

Set for another direction of the

elevator

steps

To normal display mode

keys.

is

in the R/U or

and

keys.

by repeating

L/D

ON side

OF F side

R/U: Right or up

L/D: Left or down

Mixing rate setting

Set the flashing display to "%"

with the

Held as long as the elevator

direction.

Set the mixing rate with the

(When the + and — keys are

pressed simultaneously, 50% is

set.)

Set a different elevator

direction by repeating steps

and

keys.

is

in the R/U or

keys.

L/D

To

6->2

13

-

Page 16

• FUNCTION AN D D AT A SETTING

6-2

FLAP -> ELEVATOR MIXING

Use this mixing when an air brake

is necessary when landing or diving,

etc. during flight.

• The operating position of the

elevator and flap servos can be

set.

OFF side

ON side

(INH: Inhibit state)

Press the [MODE SELECT]

Activate/inhibit mode setting

Set the mode with the

Elevator servo throw setting

Set the flashing display to the

channel 2

Set the rate with the

(When the + and — keys

pressed simultaneously, 0%

set.)

Flap servo throw setting

Set the flashing display to channel

keys.

Set the throw

(When the + and — keys are

pressed simultaneously, 0% is

set.)

keys.

+ : Activate

-: Inhibit

keys.

keys.

6

keys.

with the

To normal display mode

with the

are

is

with the

-14

ToSNP

-

Page 17

• FUNCTION AN D DATA SETTING

SNP

SNAP-ROLL

Avalanche and other snap rolls can

be performed by switch.

• Four snap roll directions can be

set.

R/U: Right up snap

R/D: Right down snap

L/U: Left up snap

L/D: Left down snap

• The throw of the channel 1 (aileron), channel 2 (elevator), and

channel 4 (rudder) servos can be

set.

• The SAFETY mode can be set.

(Mode in which operation is not

performed when the landing gear

is down even if the switch is turn-

ed on by mistake.)

(I NH: Inhibit state)

"1" to "4" is displayed

according to the

position.

1:

R/U

R/D

2:

3:

L/U

4:

L/D

Press

the [MODE SELECT]

Activate/inhibit mode setting

Set the mode with the

keys.

+ : Activate

-: Inhibit

Select the direction

RIGHT

UP

Switch

the

to the combination

DOWN

of directions to be set.

LEFT

Aileron servo throw setting

Set the flashing display

with the

Set the rate with the

keys.

(When the + and — keys are

pressed simultaneously, 100% is

set.)

Elevator servo throw setting

Set the same as

Rudder servo throw setting

Set the same as

Set for each direction of the

by repeating steps

To normal display mode

to CH1

keys.

to

SNAP ROLL

UP

DOWN

RIGHT

LEFT

F: SAFETY mode released

5L: SAFETY mode set and

ON

5F: SAFETY mode set and

OFF

-

15

—

ToDIFF

SAFETY mode setting

Set

the

Set

the

direction for which snap roll is

to be turned off (direction in

which landing gear is down).

Press the — side of the

SAFETY mode release

Set

the

Press the + side of the

to CH5 with

keys.

keys.

to CH5 with the

keys.

keys.

the

to

the

Page 18

• FUNCTION AND DATA SETTING

DIFF

AILERON DIFFERENTIAL

A left and right differential can be

applied to the ailerons. This is effective in roll axis correction. (Left

and right aileron servos are necessary.)

• The operating channels are CH1

and CH7.

•AIL

DIFF

AND

not be on simultaneously. The

FLAPERON

function turned on last has priority.

can-

(INH: Inhibit state)

(ON: Activate state)

Pressthe (MODE SELECT]

keys simultaneously

Activate/inhibit mode setting

Set the mode with the

+ : Activate

-: Inhibit

Set the CH1 servo direction of operation.

Set the flashing display to "+"

or "—" with the

keys.

Held as long as the aileron

(Channel 1 side selected.)

Set the direction of operation

with the

+ : Normal direction

—: Reverse direction

CH7 servo direction of operation setting

Held as long

To normal display mode

keys.

is at the right.

as the aileron

is at the left.

keys.

Set the direction of operation

with the

+ : Normal direction

—: Reverse direction

CH1 servo throw setting

Set the flashing display to "%"

with the

Held as lonq as the aileron

Set the rate with the

keys.

(When the + and — keys are

pressed simultaneously, 100% is

set.)

CH7 servo throw setting

Held as long as the aileron

is at the left.

Set the rate with the

keys.

(When the + and — keys

pressed simultaneously, 100% is

set.)

keys.

keys.

is at the riqht.

are

—

16

To FLPR

-

Page 19

• FUNCTION AND DATA SETTING

FLPR

FLAPERON

This is a mixing function which

gives the ailerons a flap function.

The ailerons can be raised and

lowered simultaneously. Aileron

operation is also performed.

• The operating channels are CH1

and CH6.

Ailerons can be raised and lowered simultaneously.

*AIL DIFF and FLAPERON can-

not be on simultaneously. The

function set last has priority.

(INH: Inhibit state)

(ON: Activate state)

Press

the

[MODE

SELECT]

Activate/inhibit mode setting

Set the mode with the

+ : Activate

-: Inhibit

Set the CH1 servo direction of operation

Set the flashing display to "+"

or "—" with the

keys.

Held as lonq as the aileron

(Channel 1 side selected.)

Set the direction of operation

with the

+ : Normal direction

—: Reverse direction

CH6 servo direction of operation setting

Held as long as the aileron

Set the direction of operation

with the

+ : Normal direction

—: Reverse direction

To normal display mode

keys.

is at the right.

is at the left.

keys.

keys.

To FLTR

CH1 servo throw setting

Set the flashing display to "%"

with the

Held as long as the aileron

Set the rate with the

keys.

(When the + and — keys

pressed simultaneously, 100% is

set.)

CH6 servo throw setting

Held as long as the aileron

Set the rate with the

keys.

(When the + and — keys are

pressed simultaneously, 100% is

set.)

keys.

is at the right.

are

is at the left.

—

17—

Page 20

• FUNCTION AND DATA SETTING

FLTR

FLAP TRIM

FLAP TRIM (CH6) lever operation

<-> normal operation switching is

possible.

*For operation when FLAPERON

is used, see the FLAPERON function item.

STRM

SUB TRIM

The stick channel (CH1 — 4) trim

lever operating position can be

adjusted.

*0ne

notch

of the

trim

lever

responds to a sub trim of about

6%.

cor-

(INH: Normal operation)

(ON: Trim operation)

To STRM

Press the. [MODE SE LECT]

Trim/normal mode setting

Set the mode with the

keys.

+ : Trim mode

—: Normal mode

Trim rate setting

Set the flashing display to "%'

with the

Set the rate with the

keys.

(When the + and — keys are

pressed simultaneously, 30% is

set.)

CH selection

Select the channel with the

Operating position setting

Set the operating position with

the

(When the + and - keys are

pressed simultaneously, 0% is

set.)

To normal display mod e

keys.

keys.

keys.

COMB

COMBINATION SWITCH

Other D/R switch functions can be

combined by aileron D/R switch.

• Three modes can be set.

Mode

1

2

3

D/R switch to be

combined

AIL only

AIL.

ELV

AIL,

ELV, RUD

Displays the channel

No. of the D/R switch

to be combined.

Displays the mode

No.

1: Mode 1

2: Mode 2

3: Mode 3

—

18

To COMB

Mode setting

Set the mode with the

keys.

To MOD

-

Page 21

• FUNCTION AN D D ATA SETTING

• OTHER FUNCTIONS

MOD

MODULATION

The modulation can be switched

PCM

<->

PPM

mode.

* Select the PCM mode for the FP-

7UAP and the PPM mode for the

FP.7UAF.

*When using the trainer function.

select the same mode at the instructor side and student side

transmitters.

• Stick lever tension adjustment

1 Remove the transmitter back cover.

When the mode is changed, the

display flashes.

The actual transmit output at

that time is the mode before the

change.

Press the [MODE SELECT]

Mode selection

Select the mode with

To normal display mode

keys.

*When the mode was switched, the transmit-

ter power sw itch is turned off and transmit

C:PCM

F:PPM

output is obtained the next time the transmitter power switch is turned on.

ToATV

• Non-slip adjustable lever head adjustment

The length of the lever head can be changed.

the

2 Adjust the spring strength.

Set to the desired spring

Elevator

Aileron

Strength by turning the

screw of each stick.

Remove the four

screws and remove

the back cover.

Rudder

Use a small Phillips

screwdriver.

Lever head

Unlock lever heads

opposite directions as shown by the arrows and

adjust the sti ck to the most co m f or table length.

• Receiver B.F/S function

Lever head

and

by turning them in

When the receiver battery voltage drops below a

certain value, the throttle servo moves to a preset

position. (B.F/S mode)

At this time, reset the B.F/S mode and immediately land the aircraft.

1 B.F/S mode position setting

• Set the throttle channel (CH3) to the F/S

function.

Settinq method

•The

set

position should

be

close

to

maxi-

mum slow.

2 B.F/S mode resetting method

Throttle stick

•When the throttle stick

is set to the maximun

slow position, the B.F/S

mode is reset.

—

19—

Page 22

• OTHER FUNCTIONS

• USING THE ACCESSORIES

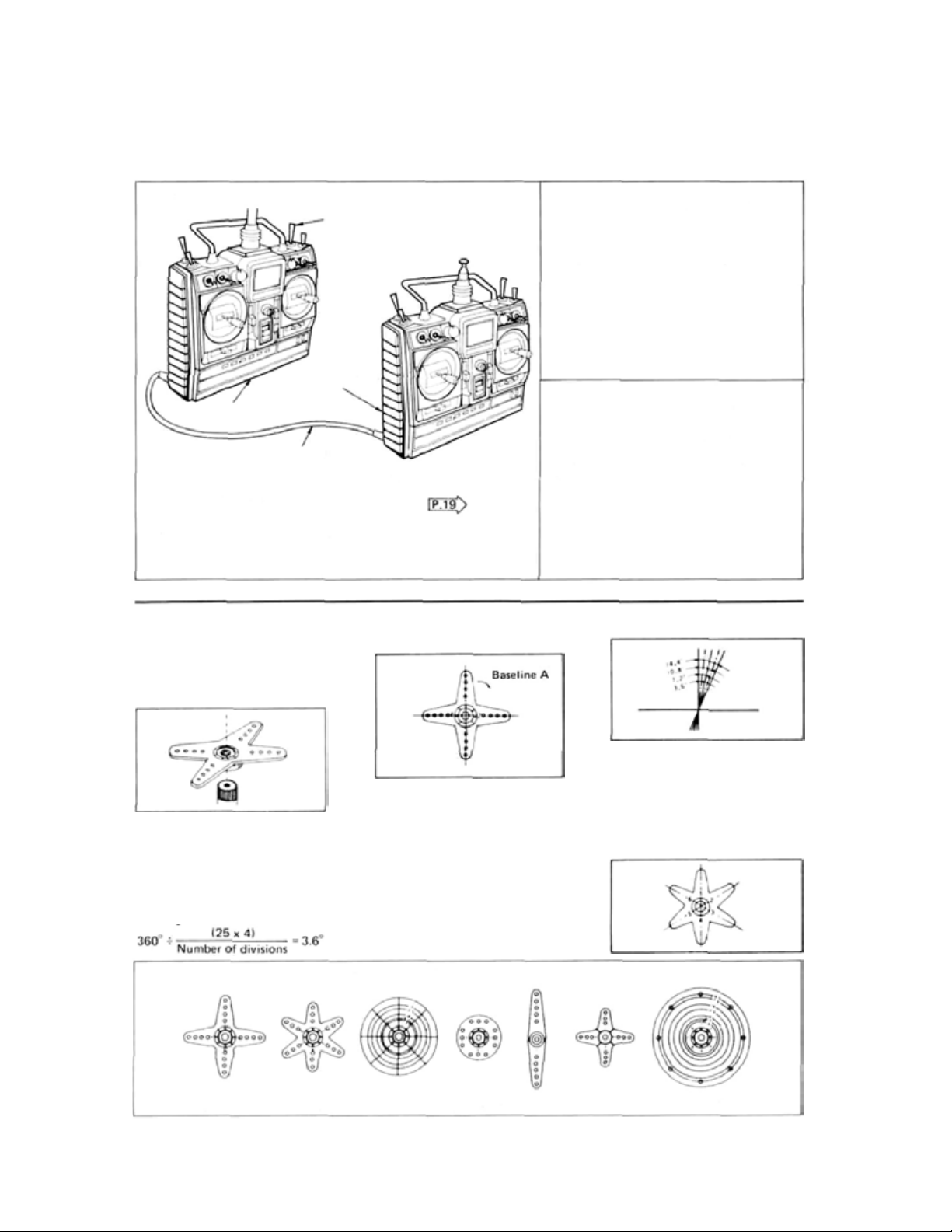

• Trainer function (Trainer cable optional)

1 Connection to transmitter

Trainer switch

Student transmitter

Instructor transmitter

Trainer cable (6-conductor)

*Operation is impossible if the instructor transmitter modulation

mode and student transmitter modulation mode is different.

to the same mode before using. Setting method

Always turn off the student transmitter power switch. Do not

operate the trainer switch either.

*Use the functions of the other two transmitters with the same

setting.

• SPLINED HORNS

This horn permits shifting of the

servo neutral position at the servo

horn. Setting and shifting the

neutral position.

a) Angle divisions

b) Effect

2 Operating at the instructor side

Operation is possible by turning on the

instructor transmitter power switch. At

this time, turn off the trainer switch.

3 Operating at the student side

Operation is possible at the student

transmitter while the trainer switch at

the instructor side is held in the ON

state.

Set

To shift the holes center line to

the right (clockwise) relative to

1) The splined horn has 25 segments. The amount of change per

segment is; 360/25=14.4°.

2) The minimum adjustable angle

is determined by the number of

arms or number of the holes. For

four arms, the minimum adjust-

able angle is:

baseline A, shift arm 2 to the position of arm 1 and set it to the

position closest to baseline A.

[Example] For a four arm horn,

the angular shift per segment is

14.4°. The s hi ft t o the right is 90°

-

(14.4 x 6) = 3.6°.

To shift by the same angle in the

opposite direction, use the opposite arm number.

The following splined horns are optional.

HORN A

(FSH6X)

HORN B

(FSH

6)

HORN C

(FSH

6A)

—

HORN D

(FSH

20—

6W)

HORN E

For a six arm horn, turn the arm

counterclockwise and set arm 2

to the position of arm 1. The ad-

justable angle is 60° - (14.4 x 4)

=2.4°.

Arm 3 shift 4.8° to the right, arm

6 shifts 2.4° to the left, and a rm 4

shifts 7.2° to the right and left.

HORN F

HORN G

Page 23

• USING THE ACCESSORIES

• Digital Proportional Frequencies (FOR U.S.A.)

•

The

frequency

you to choose from (27 MHz and 75 MHz.) Please see chart listed below for specific frequency and its intended use.

Please note there are specific frequencies allocated for aircraft only and surface only use.

•The

frequency can be changed

Futaba recommends that you return your system to our factory service department for frequency changing, as tuning

may be necessary for proper operation. Changing frequency from one band to another is NOT possible.

• Always change frequency flag when frequency is changed. The frequency flag is to be attached to the top of antenna

and th e channel designation to the base. (See Drawing)

•

It

is illegal to change crystals on 75 MHz bands in the

• ANTENNA FREQUENCY FLAG

of

Futaba

digital

proportional

within

the

sets can be

same

BAND

changed

by

U.S.A.

within

using a precisely

their

matched

own

band.

pair

There

are 2 different

of

Futaba crystals.

bands

for

However,

The flag can be attached

to, and removed from, the

antenna with one touch.

Attach the frequency flag to the flag holder

as shown in the figure.

• Frequency Channel No. Flag Color (FOR U.S.A.)

—21

—

Page 24

Liquid crystal panel

Antenna

Carrying

• NOMENCLATURE

bar

Neck strap hook

Aileron trim lever

RF module

Rudder trim

lever

Elevator

Throttle trim lever..... (MODE I)

Power switch

Throttle trim lever..... (MODE II)

Elevator trim lever..... (MODE I)

trim

lever.....

(MODE

II)

Charging jack

(w/dust cap)

Trainer jack

(w/dustcap)

Battery cover

—

22

—

Page 25

• SERVO EXPLODED VIEW

FP-S148 FP-S3001

No.

1

Upper cas e

2

Middle case

Bottom case

3

4

Metal bearin g inner

Metal bearing outer

5

TR133 15

6

7

VR drive plate

Motor

8

Motor pinion

9

10

Motor mounting screw

11

1st gear

2nd gear

12

3rd gear

13

14

Final gear

Intermediate shaft

15

2nd shaft

16

Splined horn 0

17

Horn mounting screw

18

AMP

19

S148 3P8SWRB300C

20

Grommet

21

Case mounting screw

22

Nameplale

23

Part Name

Part No.

S06015

S06005

S06006

S04137

S04136

139668

S02753

S91239

S02461

J50002

S02490

S02491

S03266

S02752

S02495

S02494

SO

1239

J55178

AS1157

AT2453

S90045

S50360

S60099

—23—

No.

Upper case

1

Middle case

2

Bottom case

3

4

Metal bearing inner

Metal bearing outer

5

TR133 15

6

VR drive plate

7

Motor

8

Motor pinion

9

Motor mounting screw

10

11

1st gear

2nd gear

12

3rd gear

13

14

Final gear

Intermediate shaft

15

2nd shaft

16

17

Bearing L 1060

Splined horn D

18

Horn mounting screw

19

AMP

20

3PB-SWRB300C

21

Grommet

22

Case mounting screw

23

24

Nameplate

Part Name

Part No.

S06100

S06005

S06006

S04137

S04136

139668

S02753

S91239

S02461

J50002

S02490

S02491

S03266

S02752

S02495

S02494

S04130

SO

1239

J55178

AS1341

AT2453

S90045

S50085

S60189

Page 26

Printed in Japan/900330CC

Loading...

Loading...