Page 1

OPERATOR'S MANUAL

INTEGRATED

HEADING SENSOR

Model

PG-700

www.furuno.com

Page 2

Page 3

IMPORTANT NOTICES

General

• This manual has been authored with simplified grammar, to meet the needs of the international

users.

• The operator of this equipment must read and follow the descriptions in this manual. Wrong operation or maintenance can cancel the warranty or cause injury.

• Do not copy any part of this manual without written permission from FURUNO.

• If this manual is lost or worn, contact your dealer about replacement.

• The contents of this manual and equipment specifications can change without notice.

• The example screens (or illustrations) shown in this manual can be different from the screens

you see on your display. The screens you see depend on your system configuration and equipment settings.

• Save this manual for future reference.

• Any modification of the equipment (including software) by persons not authorized by FURUNO

will cancel the warranty.

• All brand and product names are trademarks, registered trademarks or service marks of their

respective holders.

How to discard this product

Discard this product according to local regulations for the disposal of industrial waste. For disposal

in the USA, see the homepage of the Electronics Industries Alliance (http://www.eiae.org/) for the

correct method of disposal.

How to discard a used battery

Some FURUNO products have a battery(ies). To see if your product has a battery, see the chapter

on Maintenance. Follow the instructions below if a battery is used. Tape the + and - terminals of

battery before disposal to prevent fire, heat generation caused by short circuit.

In the European union

The crossed-out trash can symbol indicates that all types of batteries

must not be discarded in standard trash, or at a trash site. Take the

used batteries to a battery collection site according to your national

legislation and the Batteries Directive 2006/66/EU.

In the USA

The Mobius loop symbol (three chasing arrows) indicates that Ni-Cd

and lead-acid rechargeable batteries must be recycled. Take the

used batteries to a battery collection site according to local laws.

Cd

Ni-Cd Pb

In the other countries

The Mobius loop symbol (three chasing arrows) indicates that Ni-Cd and lead-acid rechargeable

batteries must be recycled. Take the used batteries to a battery collection site according to local

laws.

i

Page 4

SAFETY INSTRUCTIONS

Read these safety instructions before you operate the equipment.

Indicates a condition that can cause death or serious injury if

WARNING

CAUTION

Warning, Caution

not avoided.

Indicates a condition that can cause minor or moderate injury if

not avoided.

Prohibitive Action

Mandatory Action

Instructions for the installer

WARNING

Turn off the power at the mains switchboard before beginning the installation.

Post a sign near the power switch

indicating it should not be turned while

the equipment is being installed.

Fire, electrical shock or serious injury can

result if the power is left on or is applied

while the equipment is being installed.

Use specified cable to connect the

Junction Box.

Use of the wrong cable can result in

bodily injury and cause fire.

CAUTION

Be sure to connect to the correct

power supply.

Instructions for the user

WARNING

Turn off power at the switchboard if the

equipment is emitting smoke or fire.

Fire or electrical shock can result if the

power remains on

Turn off the power at the switchboard

if you feel the equipment is not

working properly.

If the equipment feels hot or is emitting

odd noises, immediately turn off the power

at the switchboard.

Do not dissassemble or modify the

equipment.

Fire, electrical shock or bodily injury

can result.

Connection to a wrong power supply

can cause fire or bodily injury.

Observer the following compass safe

distances to prevent interference to

a magentic compass.

Std. Compass Steering compass

0.3 m 0.3 m

Before doing deviation correction

and heading adjustment, turn off

the autopilot.

The rudder may jerk violently, which

can result in a dangerous situation.

ii

Page 5

TABLE OF CONTENTS

FOREWORD................................................................................................................... iv

SYSTEM CONFIGURATION ...........................................................................................v

EQUIPMENT LIST .......................................................................................................... vi

1. HOW TO INSTALL THE EQUIPMENT ..................................................................... 1

1.1 Installation Considerations ............................................................................................1

1.2 Wiring ............................................................................................................................6

1.3 Compensation of Deviation ...........................................................................................9

1.4 Heading Adjustment ....................................................................................................11

1.5 Input/Output Data List..................................................................................................13

2. OPERATION ........................................................................................................... 14

2.1 Key and Lamp Explanation..........................................................................................14

2.2 How to Turn on the PG-700 ........................................................................................15

3. MAINTENANCE AND TROUBLESHOOTING........................................................ 16

3.1 General Maintenance ..................................................................................................16

3.2 Lamp status display ....................................................................................................16

3.3 Troubleshooting ..........................................................................................................18

3.4 How to restore default settings....................................................................................18

Specifications...........................................................................................................SP-1

Outline Drawings........................................................................................................ D-1

Interconnection Diagram........................................................................................... S-1

iii

Page 6

FOREWORD

Congratulations on your choice of the PG-700 Integrated Heading Sensor. We are confident you

will see why the FURUNO name has become synonymous with quality and reliability.

Since 1948, FURUNO Electric Company has enjoyed an enviable reputation for innovative and

dependable marine electronics equipment. This dedication to excellence is furthered by our extensive global network of agents and dealers.

Your equipment is designed and constructed to meet the rigorous demands of the marine environment. However, no machine can perform its intended function unless properly operated and

maintained. Please carefully read and follow the operation and maintenance procedures set forth

in this manual.

Features

• Angular velocity sensor and magnetic bearing sensor incorporated.

• Automatic determination of installation site suitability.

• L-shaped mounting base for mounting on bulkhead.

• Output of magnetic bearing data to FURUNO CAN bus device.

iv

Page 7

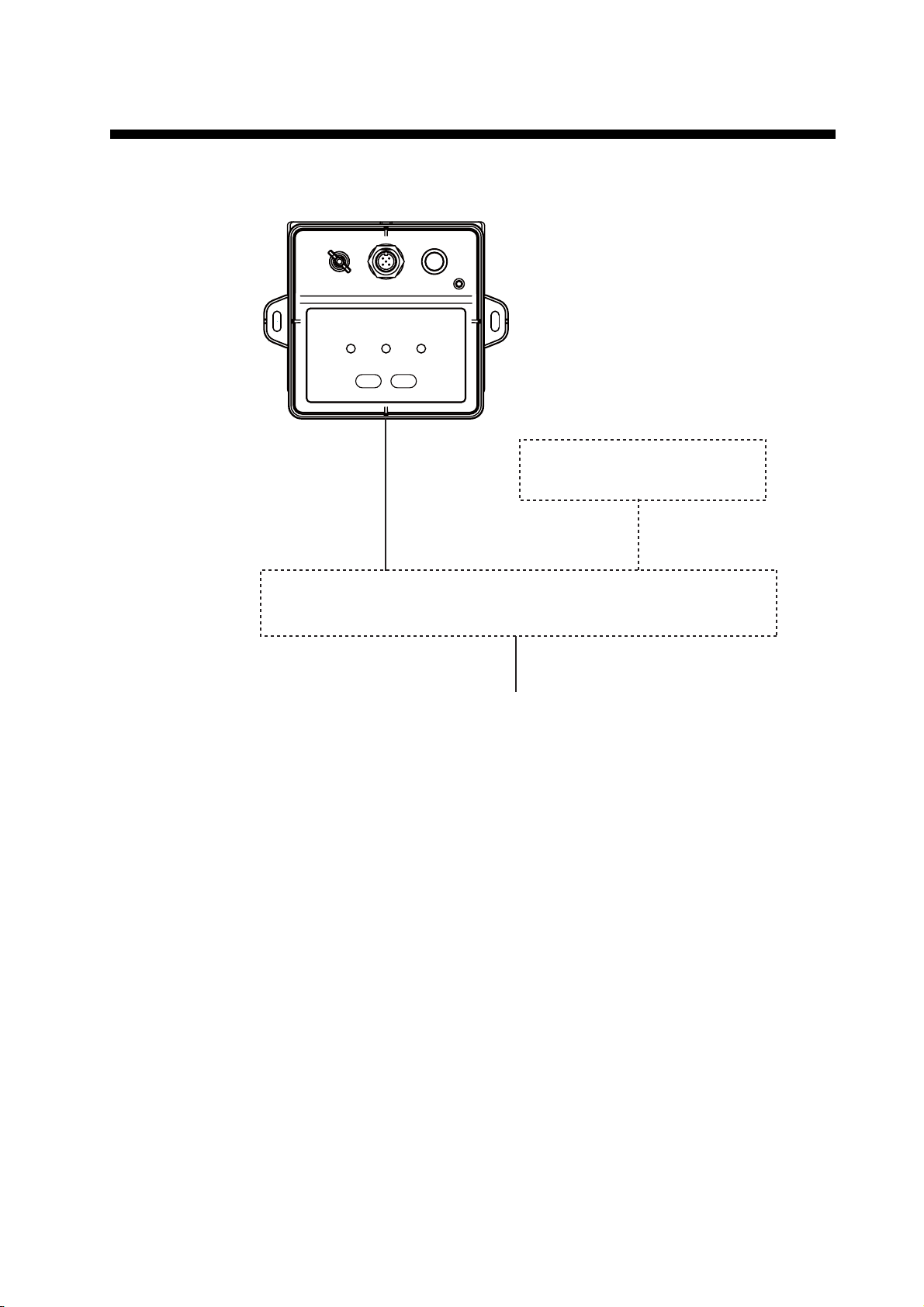

SYSTEM CONFIGURATION

The solid line below shows the basic system configuration.

SENSOR

PG-700

FURUNO CAN bus Device*

JUNCTION BOX

FI-5002

12 VDC**

*: NavNet 3D, FI series instrument, etc.

**: Not necessary if FURUNO CAN bus network supplies power.

v

Page 8

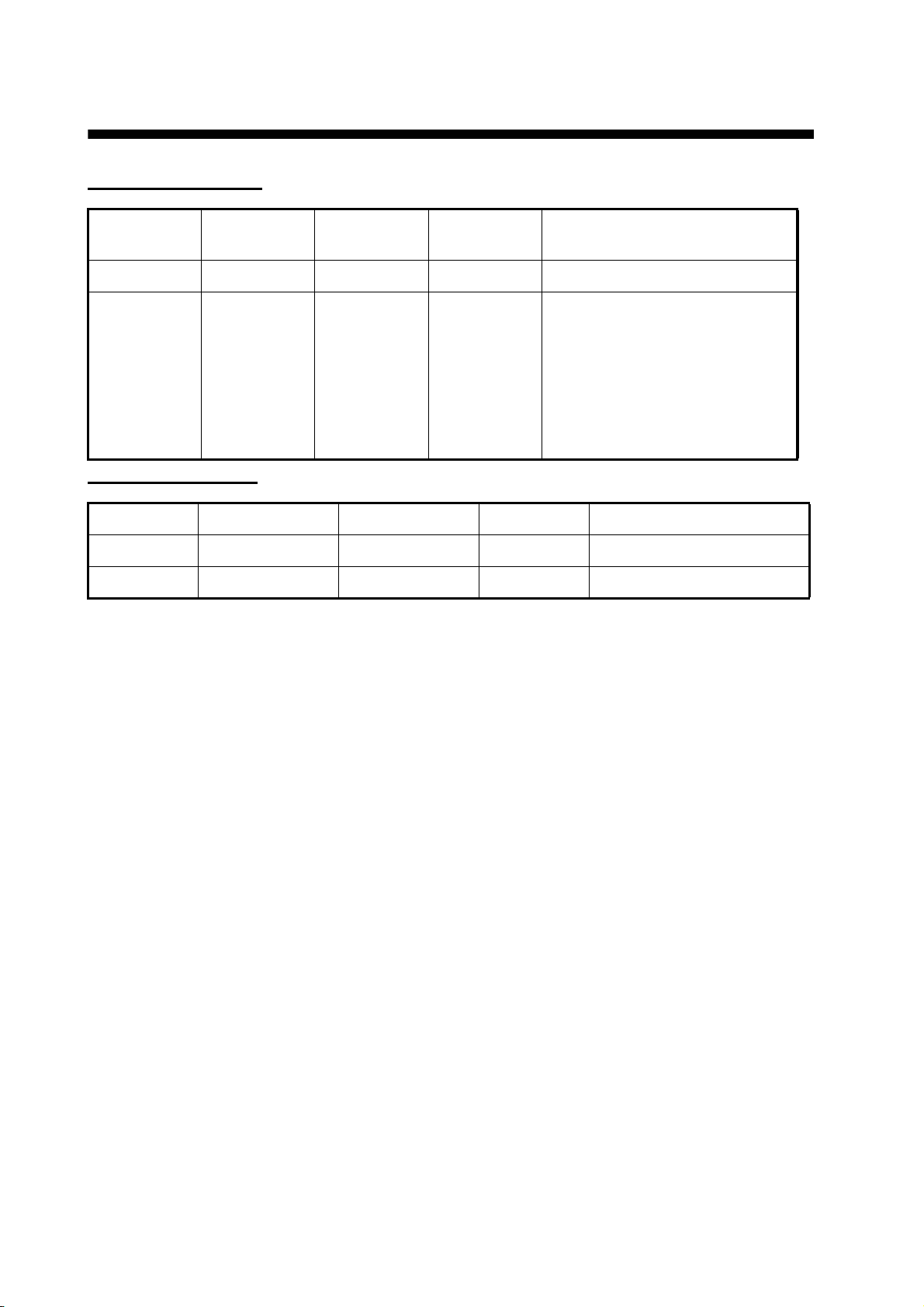

EQUIPMENT LIST

Standard Equipment

Name Model

Sensor PG-700 - 1

Installation

materials

CP64-02800 - 1 set • Cable set

Code

number

Quantity Remark

Type: M12-05BM+05BF-060

Code number: 000-167-964-11

Quantity: 1

• Self-tapping screws

Type: 4x16 SUS304

Code number: 000-162-605-10

Quantity: 3

Optional Equipment

Name Model Code number Quantity Remark

Junction box FI-5002 000-010-765 1 set

Cable set FI-50-DROP-6M 001-105-810-10 1 6m

vi

Page 9

1. HOW TO INSTALL THE EQUIPMENT

1.1 Installation Considerations

Mount the unit with the lamps and keys face up on a horizontal surface. The unit can be mounted

on a desktop or bulkhead. Overhead mounting is not allowed. When selecting a mounting location,

observe the following to ensure optimal performance:

• Do not mount in an area where water can collect.

• Mount the unit in an area with a temperate between -15 and +55 °C (5 -131°F).

• Mount the unit in an area with low shock and vibration (near the center of gravity to the hull as

possible).

• Mount far away from any electromagnetic wave sources (radio antennas, etc.).

• Mount horizontally, and not on the ceiling.

• Mount as far away as possible from any magnetic interference and power cables.

• Mount at least 50cm (20”) away from the following:

• Engines, generators, steel fuel and water tanks

• Bilge pump, anchor, anchor chain

• Radio antenna cables

• Metal mast support and keel

• Mount in a location where it is easy to adjust or perform maintenance.

• Mount close to the ship’s draft (do not mount to the mast or Tuna tower).

1

Page 10

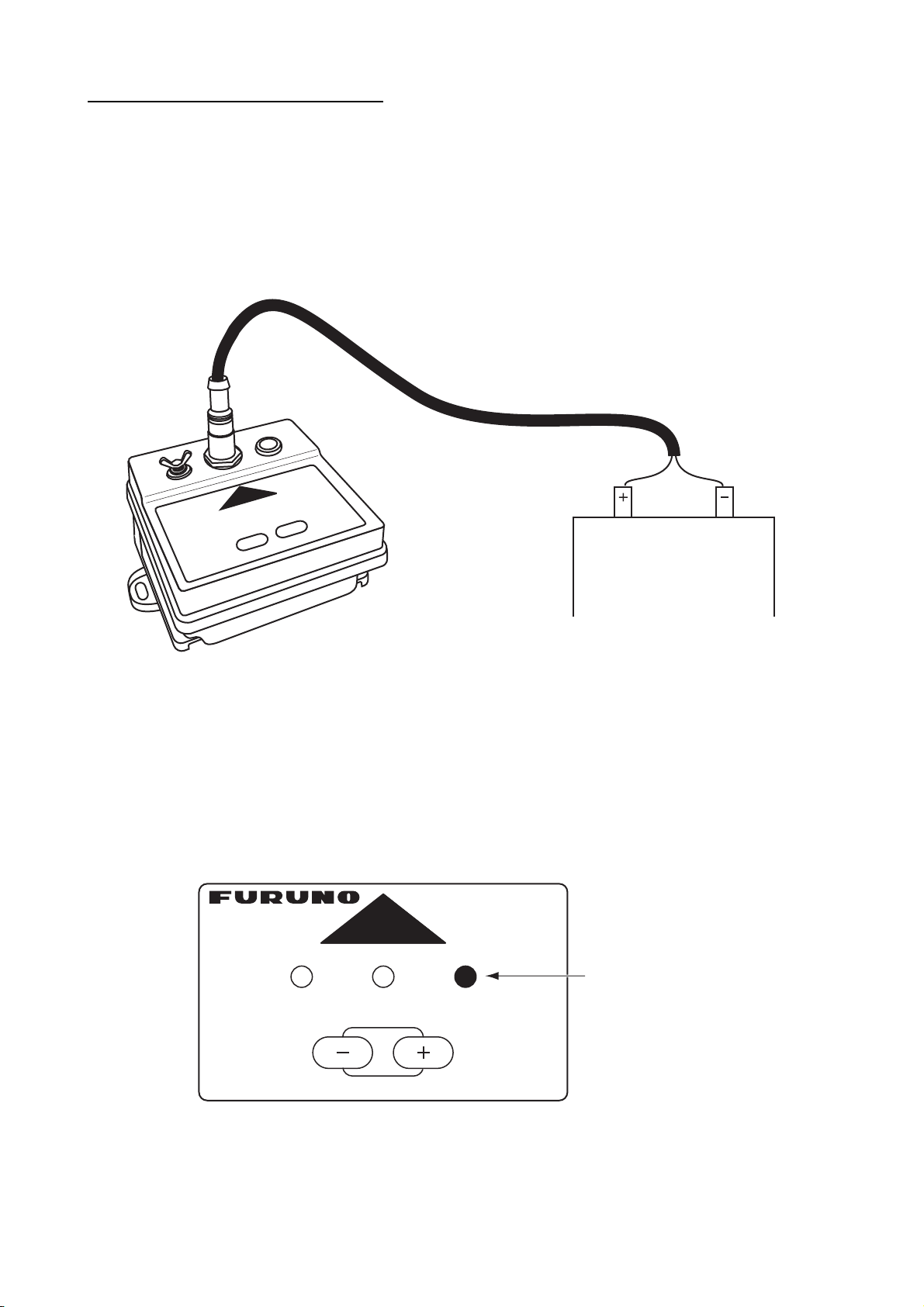

1. HOW TO INSTALL THE EQUIPMENT

Determining the mounting location

After choosing the approximate mounting location to a table or bulkhead, ensure that the location

is suitable to supply power to the unit.

1. Connect the power cable to the unit.

If the sensor unit is connected last to the optional Junction Box FI-5002, cut off the connector

(supplied) of the cable M12-05BM+05BF-060 from the FI-5002 side, and connect the red wire

of the cable to the positive terminal (+) of the battery (12 VDC) and the black wire to the negative terminal (-).

Red Black

Ship's Switchboard

Battery

12 VDC

If you connect PG-700 directly to the instrument, or to a network, each device must be temporarily connected to each other, and a power supply 12 VDC (see page 6).

2. Place the unit at the intended mounting position and supply power. Verify that the STATUS

lamp is not lit red.

If the STATUS lamp illuminates red, there may be a problem with the internal magnetic sensor.

3. Press and hold the [+] and [-] keys simultaneously for seven seconds, and release both keys.

The CHECK lamp blinks, and the CALIB and STATUS lamps turn off.

THIS SIDE UP

PG-700

BOW

CALIB STATUS CHECK

Flashing (green)

2

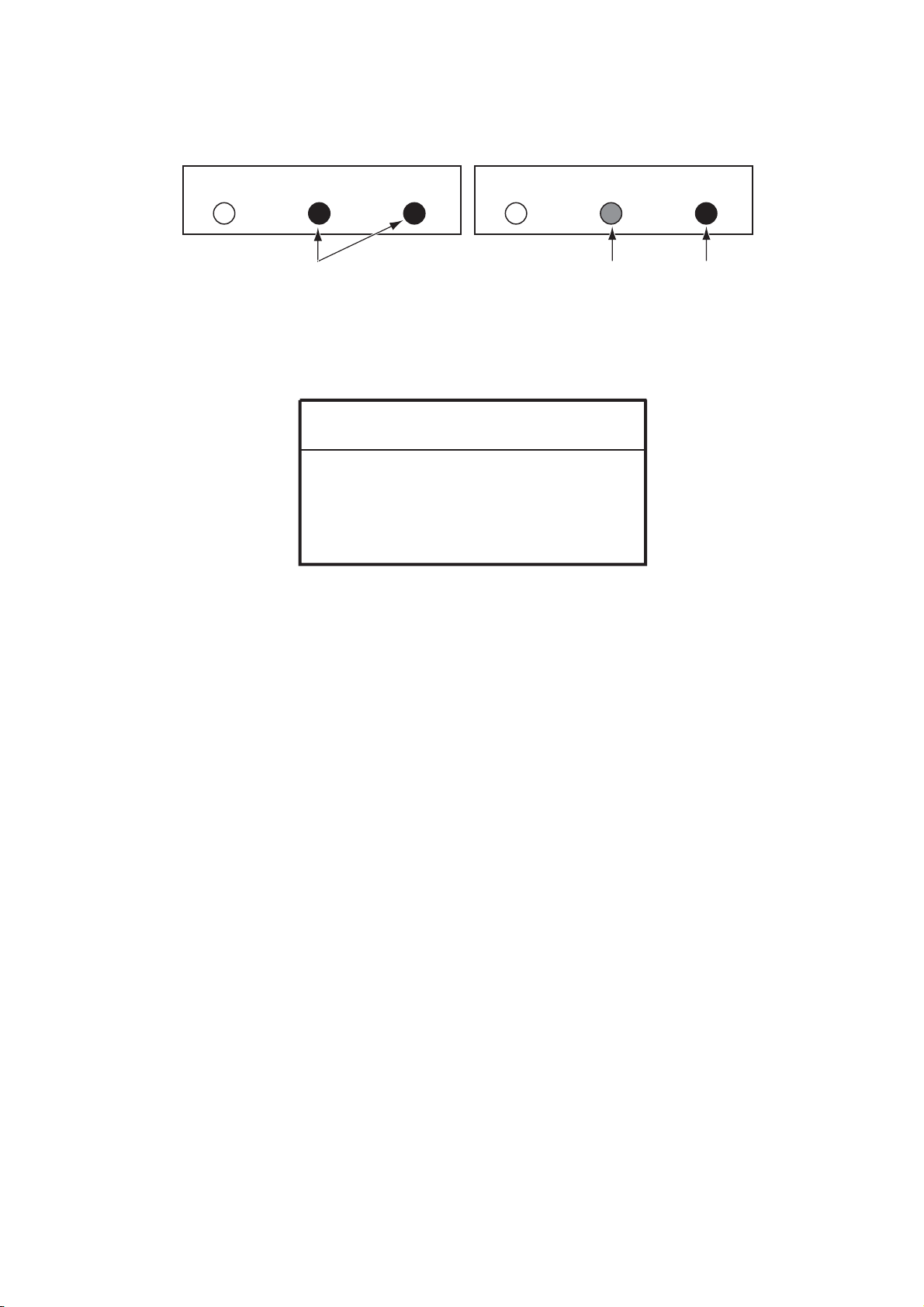

Page 11

1. HOW TO INSTALL THE EQUIPMENT

4. Slowly turn the unit (one turn per minute) at the mounting position (turn one - two times to

achieve the results as shown in the left figure below).

If successful, the STATUS and CHECK lamps light green. If fails, the STATUS lamp lights red.

CALIB STATUS CHECK CALIB STATUS CHECK

On (green)

(a) Installation site OK

If you interrupt the unit operation, press and hold the [+] and [-] keys simultaneously for three

seconds.

(b) Installation site no good

On (red)

On (green)

NOTICE

This location check procedure requires

only 90 seconds or less to complete.

If STATUS and CHECK lamps light green, fix

the unit to the acceptable location properly.

5. If fails, press and hold the [+] and [-] keys simultaneously for 3 seconds. Change the location,

and repeat steps 3 - 4 as above.

6. If successful, disconnect the power cable and follow the next steps to mount the unit firmly.

3

Page 12

1. HOW TO INSTALL THE EQUIPMENT

Tabletop mounting

Fix the unit with two self-tapping screws, facing the bow mark on the unit toward the bow (within

±10°) of the vessel. The long and round holes on the unit allow you to fine tune the direction of the

unit. See the outline drawing at the back of the manual for dimensions.

Self-tapping screws (supplied) (4x16)

BOW

BOW mark

4

Page 13

1. HOW TO INSTALL THE EQUIPMENT

Bulkhead mounting

The unit can be mounted to the bulkhead either parallel or vertical to the bow.

1. Remove two screws at the bottom to detach the mounting base.

2. Remount the base upside down using the two screws which were unscrewed in the above

step. It is possible to mount the unit in any horizontal direction in 90° steps. Mount the unit so

that the bow mark faces in the direction of the ship’s bow.

BOW

BOW mark

Mounting base

3. Fix the mounting base to the bulkhead with three self-tapping screws supplied.

Mounting

base

Self-tapping screw (4x16, 3 pcs.)

1

Notched

hole

2

Long round hole

1) Insert one screw in the place for the notched hole, halfway.

2) Set the notched hole in the center of the mounting base to the screw inserted into the bulkhead at step 1. Set a self-tapping screw in the long round hole. Adjust the mounting base

so it is horizontal and then tighten the self-tapping screws in the long round hole, and the

notched hole, in that order.

3) Fasten the remaining left self-tapping screw.

5

Page 14

1. HOW TO INSTALL THE EQUIPMENT

1.2 Wiring

Connect a termination resistor at both ends of the backbone of CAN bus devices. PG-700 incorporates a termination resistor. Turn the switch on/off as applicable.

If using the optional Junction Box FI-5002

Connect the unit and the FI-5002 using cable M12-05BM+05BF-060 (supplied as installation materials). For connection at the FI-5002, cut the cable at the pre-connected connector, fabricate the

cable as shown below, then connect the cable to the MC connector at the FI-5002. Ground the

unit to the hull using the shortest IV-2sq cable possible.

Crimp-on lug

(inner dia. 3mm)

To ground

*2

Ground wire*2

IV-2sq

*1: Turn the Termination switch

OFF to connect CN3 - CN5;

ON to connect CN2.

*2: Prepared locally

M12-05BM+05BF-060 (6m)

Termination switch*1

FI-5002

Power cable (2m)

Red

Sensor

PG-700

Black

–

+

12VDC

Fix cable with

supplied cable ties.

12VDC

Connect to

CN2 - CN5.

CN3 - CN5

DROP

MC connector

JUNCTION BOX

FI-5002 (option)

• How to fabricate cable M12-05BM+05BF-060 and connect MC connector

Side view

CN2

BACKBONE

Top view

Core

6 mm

Cable Fabrication

Twist

MC connector

Drain wire

Sheath

Screw

Wire Conn. Pt.

Drain 1

RED 2

BLK 3

WHT 4

BLU 5

How to insert cores:

1. Twist core.

2. Unfasten screw with flathead screwdriver.

3. Set core to hole.

4. Tighten screw.

5. Pull wire to confirm connection.

6

Page 15

1. HOW TO INSTALL THE EQUIPMENT

If connecting directly to the instrument

When connecting FI-502/FI-504/FI505 instruments, use supplied cable M12-05BM+05BF-060.

Do not cut the cable. Turn on the PG-700 termination switch.

M12-05BM+05BF-060

(Connector at both

ends, 6 m cable)

FI-50-DROP-6M

Ground

wire

SENSOR

PG-700

Termination switch

ON

Lamp ON

Instrument

FI-503/504/505/506/507

(Rear view)

cable (6 m)

Black

–

12 VDC

Red

+

If connecting to NavNet 3D network

• If connecting M12-05BM+05BF-060 as a drop cable to a T-type connector below, turn the termination switch off.

GOTO

S

O

R

U

R

C

Ground

wire

Termination

switch OFF

Lamp OFF

Example: NavNet 3D

M12-05BM+05BF-060

(connector at both ends,

6 m cable)

T-type connector T-type connector

POINTS

ROUTE

CTRL

SAVE

MOB

LIST

CANCEL

DISP

DATA

VOL

GAIN

MENU

TX

OUT

RANGE

IN

L

O

L

R

I

N

C

G

S

SHIP

3D

7

Page 16

1. HOW TO INSTALL THE EQUIPMENT

r

• If connecting M12-05BM+05BF-060 cable to a T-type connector as a backbone, as shown below, turn the termination switch on.

Termination switch ON

Lamp ON

GOTO

S

O

R

U

R

C

Ground

wire

FI-50

UPPER

DIGITAL

MIDDLE

LOWER

CAL

ADJ

SELECT

CLER

BRILL

Example: Instrument Example: NavNet 3D

T-type connectorT-type connector

LIST

POINTS

ROUTE

DATA

CANCEL

VOL

GAIN

DISP

MENU

TX

OUT

RANGE

IN

L

O

L

R

CTRL

I

N

C

G

S

SHIP

3D

SAVE

MOB

Terminator resisto

Termination switch

This switch is set according to the network topology. Generally, turn on the switch at the end of

the backbone cable. When ON, the lamp lights green.

8

Page 17

1. HOW TO INSTALL THE EQUIPMENT

1.3 Compensation of Deviation

The unit’s magnetic sense of direction may be affected by the metal of the vessel (including engines and power cables) as well as metal machinery or equipment on board. This discrepancy between true magnetic north and the indication of the unit is called “deviation”. Deviation may cause

incorrect heading data. The unit has the ability to automatically correct the deviation.

Note: In order to ensure the correct output orientation to a connected device, be sure to correct

the deviation.

CAUTION

Before doing the compensation of

deviation, turn off the autopilot.

The rudder may jerk violently if the

autopilot is powered, creating a

dangerous condition.

After finishing the installation completely, do the compensation of deviation in calm sea conditions

as follows:

1. Turn the PG-700 on and verify that the STATUS lamp is not lit red.

2. Press and hold the [+] and [-] key together for 3 seconds, and release both keys.

Deviation correction starts. The CALIB lamp flashes, and the STATUS and CHECK lamps

turn off.

CALIB STATUS CHECK

3. Turn the ship in as accurate a circle as possible, at a constant speed.

Steer in a controlled circle at approx. three knots, for about two minutes. It does not matter if

you turn in a left or right direction.

Run circle in two minutes

at speed of appox. three knots.

: Flashing (green)

: OFF

Note 1: Turning too fast may cause a large bearing error after the deviation correction.

Note 2: Be sure not to turn off the power to the switchboard when fixing deviation. Damage

of data may occur.

4. Continue turning until deviation correction is completed (about 3 to 5 turns).

When deviation correction is successful, the CALIB and STATUS lamps light for five seconds

and the initialization of the angular velocity sensor starts. After all lamps light, go to step 6.

9

Page 18

1. HOW TO INSTALL THE EQUIPMENT

A

Note: When doing deviation correction, the surrounding environment and ship position will

have an effect on the time it takes to succeed in the correction.

: ON (green)

: OFF

: Flashing (green)

t start of initialization of

angular velocity sensor

CALIB STATUS CHECK

After five sec.

CALIB STATUS CHECK

After two min.

CALIB STATUS CHECK

Initialization completed

(Normal condition)

Successful status for deviation correction

If deviation correction fails, the CALIB lamp lights green and the STATUS lamp lights red. The

deviation correction results remain until you proceed to step 5.

CALIB STATUS CHECK

: ON (green)

: ON (red)

: OFF

Failed status for deviation correction

5. If deviation correction fails, press the [+] and [-] keys simultaneously for 3 seconds to repeat

the process again from the beginning.

6. Anchor the vessel to a quay. Point the vessel toward a stationary object (lighthouse, etc., a

bearing which you can confirm on a nautical map) and confirm the bearing indication is correct. If it is not correct, measure the difference correctly and go to the procedure in section 1.4.

10

Page 19

1. HOW TO INSTALL THE EQUIPMENT

1.4 Heading Adjustment

The amount of adjustment required for the heading depends on the outcome of the previous section [1.3 Compensation of Deviation]. Do the following to correct the discrepancy.

CAUTION

Before doing the heading adjustment, turn off the autopilot.

The rudder may jerk violently if the

autopilot is powered, creating a

dangerous condition.

1. Press the [+] or [-] key. All lamps flash green and the unit enters heading adjustment mode.

CALIB STATUS CHECK

Note: Perform step 2 within five seconds. Heading adjustment mode stays active for 5 seconds after the key is pressed. If you do nothing, the unit returns to normal mode automatically.

2. Use the [+] or [-] key to adjust the difference between the sensor output heading and the actual

heading.

Heading can be adjusted at intervals of 0.1° or 1.0°. (see table below).

Key Set interval Lamp Status

Short press [-] key within 5 seconds

-0.1°

(decreases 0.1°

with every press)

Each time you press the [-] key, the STATUS lamp

will light on and off.

: Flashing (green)

CALIB STATUS CHECK

st time

CALIB STATUS CHECK

nd time

CALIB STATUS CHECK

3rd time

Long press [-] key within 5 seconds

-1.0°

(decreases in 1.0°

increments while

key is pressed)

Repeats

CALIB STATUS CHECK

11

Page 20

1. HOW TO INSTALL THE EQUIPMENT

Key Set interval Lamp Status

Short press [+] key

within 5 seconds

Long press [+] key

within 5 seconds

+0.1°

(increases 0.1°

with every press)

+1.0°

(increases in 1.0°

increments while

key is pressed)

Each time you press the [+] key, the STATUS lamp

will light on and off.

CALIB STATUS CHECK

1st time

CALIB STATUS CHECK

2nd time

CALIB STATUS CHECK

3rd time

Repeat

CALIB STATUS CHECK

: ON (green) : Flashing (green) : OFF

For example, in the case that the bearing displayed on a instrument connected to the unit is

70°, and the actual bearing is 75°, there is a 5° difference. To set to +5°, press and hold the

[+] key.

3. To exit heading adjustment mode, do not press any key for five seconds. The unit automatically returns to normal status.

Note: Press and hold the [+] and [-] keys for approx. one second at the lamp status after step 1 to

reset to 0.

Correction

value

resets to 0

Normal

condition

CALIB STATUS CHECK

Each lamp flashes

several times

CALIB

STATUS CHECK

: Flashing (green)

: Flashing (red)

: ON (green)

12

Page 21

1.5 Input/Output Data List

This unit uses the following input/output data

1. HOW TO INSTALL THE EQUIPMENT

Input/

output

Input

Output

Specification Remark

ISO request (PGN: 059904) PGN send request

Address claim (PGN: 060928) Address request

Self Test Group Function (PGN: 061184) Self test request

Memory Clear Group Function (PGN: 126720) Corresponding to clear all

Reset Group Function (PGN: 126720) Corresponding to reset all

NMEA-Request Group Function (PGN: 126208)

NMEA-Command Group Function (PGN: 126208)

+ (PGN: 130818, #4)

+ (PGN: 065283, #4, #5, #6, #7)

Vessel Heading (PGN: 127250)*1

Magnetic Compass Status (PGN: 065284)*2

ISO Acknowledgement (PGN: 059392)

ISO Request (PGN: 059904)

Address Claim (PGN: 060928)

NMEA Acknowledge (PGN: 126208)

PGN List (PGN: 126464)

Product Information (PGN: 126996)

Self Test Report (PGN: 130816)*2

Heading & Attitude Sensor Control Status (PGN:

130818)*2

Unit Division Code (PGN: 130822)*2

Browser Control Status (PGN: 130823)*2

Magnetic Compass Control Status (PGN: 065283)*2

Rate Gyro Data (PGN: 065285) *1*2

GMM Message (PGN: 126720, #4=4)*2

Input bearing adjustment

Change setting

Specific setting

Regular output.

100 ms (default)

1sec.

Irregular output. (Send only

when there is a request during

startup and changes). Displays each setting

PGN: Parameter Group Number. Equivalent to NMEA0183 sentence.

*1: Data can be output at an interval of 25ms and over (5ms steps) according to the request from

another device.

*2: PGN registered to Furuno Electric Co. Ltd.

13

Page 22

2. OPERATION

Before operating:

• This unit contains magnetic components. Keep away from metals (when the ship inclines, be

sure no metal objects roll towards the PG-700).

• When navigating in the vicinity of large structures (bridges, etc.), an bearing error may occur.

• If the distance between the unit and metal objects or magnets changes, an error may occur. In

that case, the deviation correction may have to be set again (see section 1.3).

• Do not disconnect power when using the automatic steering system.

2.1 Key and Lamp Explanation

THIS SIDE UP

PG-700

CALIB STATUS CHECK

BOW

Lamp Lamp state Color Key Function

CALIB These lamps

turn on, off, or

flash with

STATUS Green, Red • Push together for three seconds to

CHECK Green • Push either key to get to the Head-

Termination switch

The termination switch is turned on or off at installation. DO NOT change the setting.

equipment

state. (See

section 3.2)

Green • Push together for seven seconds to

determine suitability of installation

location.

start deviation correction.

ing adjustment mode.

Termination switch

14

Page 23

2. OPERATION

2.2 How to Turn on the PG-700

The unit has no power switch. Supply the +12 VDC power via the optional junction box FI-5002 or

FURUNO CAN bus device. When power is received by the sensor, the unit will automatically

check ROM and RAM status. After this, the lamps light as shown below:

CALIB STATUS CHECK

CALIB STATUS CHECK

CALIB STATUS CHECK

CALIB STATUS CHECK

: ON (green)

: ON (red/green)

: OFF

: Flashing (green)

CALIB STATUS CHECK

Angular velocity sensor initialization

(Approx. two minutes)

CALIB STATUS CHECK

Normal display

Note: If there is a problem with the ROM and/or RAM, the CALIB and CHECK lamps turn off, and

the STATUS lamp flashes red. Contact your dealer.

15

Page 24

3. MAINTENANCE AND TROUBLE-

SHOOTING

This chapter discusses maintenance and troubleshooting procedures to ensure optimal performance of the equipment.

NOTICE

D

o not apply paint, anti-corrosive

sealant or contact spray to plastic

parts or equipment coating.

Those items contain products that can

damage plastic parts and equipment

coating.

3.1 General Maintenance

To maintain full performance of the equipment, periodic inspection is required. Refer to the following table:

Inspection

item

Cable Check that cable is secure-

ly connected and there is

no rust or corrosion.

Ground Terminal

Sensor Unit Make sure the unit is free of

Ensure the ground terminal

is free of rust and not loose.

dust and dirt.

Checkpoint Action

If necessary, reconnect the cable or replace if damaged.

Tighten the terminal and clean off rust.

Wipe off dust and dirt with a soft, dry cloth. You may

use a cloth moistened with a diluted detergent. Do

not use thinner, acetone, alcohol, benzene, or any

plastic solvent, as they may remove markings from

the panel.

3.2 Lamp status display

Lamp Status Unit operating condition

CALIB STATUS CHECK

Normal state

• Deviation correction: success

• Angular velocity sensor: initialization complete

16

Page 25

Lamp Status Unit operating condition

CALIB STATUS CHECK

CALIB STATUS CHECK

CALIB STATUS CHECK

CALIB STATUS CHECK

3. MAINTENANCE AND TROUBLESHOOTING

• Deviation correction: success

• Angular velocity sensor: initializing

• Deviation correction: not implemented (or failed)

• Angular velocity sensor: initialization complete

• Deviation correction: not implemented (or failed)

• Angular velocity sensor: initializing

• Deviation correction: success

• Angular velocity sensor: failure

• Heading data output of the magnetic sensor only

Light alternately.

CALIB STATUS CHECK

Light alternately.

CALIB STATUS CHECK

• Deviation correction: not implemented (or failure)

• Angular velocity sensor: failure

• Heading data output of the magnetic sensor only

• Magnetic bearing sensor: failure

• No output of magnetic bearing data

: ON (red): ON (green)

: OFF

: Flashing (green)

17

Page 26

3. MAINTENANCE AND TROUBLESHOOTING

3.3 Troubleshooting

If a problem occurs, first do the following inspections. If the problem persists, contact the dealer

or a qualified service technician.

Problem Action

Lamps do not light. • Check to ensure the connector is tightened.

• Check to ensure the cable is not corroded.

• Check to ensure the cable is not damaged.

• Check that the routing of the power supply is functioning properly.

Red lamp is on. Turn the power on and off several times. If the red lamp remains

lit, contact your dealer.

No magnetic bearing data. • Turn the power on and off several times. If the problem persists,

contact your dealer.

• Check the terminal switch.

3.4 How to restore default settings

You can revert the unit to factory settings by doing the following:

1. Disconnect the cable from the unit.

2. Press and hold the [-] key, and reconnect the cable. Continue pressing the [-] key until step 3

is completed. Power is applied to the unit, all lamps flash. When initialization is completed, all

lamps light.

After power

CALIB STATUS CHECK

is applied

Each lamp flashes

several times

Initialization

completed

3. When all lamps light, stop pressing the [-] key.

4. To return to normal state, reconnect the unit cable.

CALIB STATUS CHECK

: Flashing (green)

: Flashing (red/green)

: ON (green)

: ON (red/green)

18

Page 27

FURUNO

SPECIFICATIONS OF INTEGRATED HEADING SENSOR

PG-700

1 GENERAL

1.1 Heading Accuracy ±1.0° (horizontal)

±10.0° (within 30°), ±20.0° (within 45°)

1.2 Display resolution 0.1°

1.3 Follow-up 100°/s rate-of turn

1.4 Interface CAN bus: 1 channel

Output PGN 126720

Input settings Output interval, Bearing offset

1.5 Data Update 25 ms max. (default: 100 ms)

1.6 Delay Within 75 ms

2 POWER SOURCE

PG-700

12 VDC: 0.1 A (LEN: 3)

3 ENVIRONMENTAL CONDITION

3.1 Ambient Temperature -15°C to +55°C

3.2 Relative Humidity 95% at 40°C

3.3 Waterproof IP55 (IEC 60529), CFR-46 (USCG standard)

3.4 Vibration IEC 60945

4 UNIT COLOR

N3.0

SP - 1 E7276S01A

Page 28

This page is intentionally left blank .

Page 29

D-1

4/Sep/09R.Esumi

Page 30

D-2

4/Sep/09R.Esumi

Page 31

PG-700

S-1

ハイブリッドヘディングセンサー

相互結線図

INTEGRATED HEADING SENSOR

43

INTERCONNECTION DIAGRAM

PG-700

SHIELD

NET-S

NET-C

CAN BUS

ハイブリッドヘディングセンサー

INTEGRATED HEADING SENSOR

12345

-SR7000

LTW12-05AFFM

RED

BLK

アカ

クロ

M12-05BM+05BF-060,6m,φ6(*3)

FI-50-DROP,6m,φ6(*2)

NET-H

NET-L

WHT

BLU

シロ

アオ

*1

IV-2sq.

CANバスネットワーク機器

CAN bus DEVICE

同上

DITTO

同上

DITTO

同上

DITTO

同上

DITTO

TITLE

DRAWN

名称

T.YAMASAKI

T.TAKENO

8/Mar/10R.Esumi

28/Jan/10

28/Jan/10

CHECKED

APPROVED

NAME

64-031-5000-0

REF.No.

kg

C7276-C01- B

DWG.No.

SCALE MASS

12345

12345

12345

12345

12345

12345

2

NET-S

NET-C

NET-H

NET-S

NET-C

接続箱

JUNCTION BOX

NET-L

NET-H

NET-L

(BACKBONE)

CAN bus NETWORK

NET-S

NET-C

NET-H

NET-L

SHIELD

CN3 DROP_LCN2 BACKBONE_U

SHIELD

12345

ジャンクションボックス

JUNCTION BOX

SHIELD

CN3 DROP_U

*2

CN1 12VDC

FI-5002

(+)

(-)

123

BLKクロ

シロ WHT

SHIELD

1

(VV-SA0.75x2C)

FI-5002-POWERCABLE,2m

12VDC

A

NET-S

SHIELD

CN4 DROP_U

SHIELD

NET-S

12345

CN2 BACKBONE_L

接続箱

JUNCTION BOX

NET-C

NET-H

NET-C

NET-H

CAN bus NETWORK

NET-L

NET-L

(BACKBONE)

SHIELD

CN4 DROP_L

NET-S

NET-C

NET-H

NET-L

B

SHIELD

CN5 DROP_U

NET-S

NET-C

NET-H

NET-L

SHIELD

CN5 DROP_L

NET-S

NET-C

NET-H

NET-L

NOTE

*1: SHIPYARD SUPPLY.

注記

*1)造船所手配。

*2)オプション。

*3)コネクタを切り離して接続する。

*2: OPTION.

*3: REMOVE THE CONNECTOR FOR FABRICATION.

C

Page 32

FURUNO Worldwide Warranty for Pleasure Boats (Except North America)

This warranty is valid for products manufactured by Furuno

Electric Co. (hereafter FURUNO) and installed on a pleasure

boat. Any web based purchases that are imported into other

countries by anyone other than a FURUNO certified dealer may

not comply with local standards. FURUNO strongly recommends

against importing these products from international websites as

the imported product may not work correctly and may interfere

with other electronic devices. The imported product may also be

in breach of the local laws and mandated technical requirements.

Products imported into other countries as described previously

shall not be eligible for local warranty service.

For products purchased outside of your country please contact

the national distributor of Furuno products in the country where

purchased.

This warranty is in addition to the customer´s statutory legal

rights.

1. Terms and Conditions of Warranty

FURUNO guarantees that each new FURUNO product is the

result of quality materials and workmanship. The warranty is

valid for a period of 2 years (24 months) from the date of the

invoice, or the date of commissioning of the product by the

installing certified dealer.

2. FURUNO Standard Warranty

The FURUNO standard warranty covers spare parts and labour

costs associated with a warranty claim, provided that the product

is returned to a FURUNO national distributor by prepaid carrier.

The FURUNO standard warranty includes:

Repair at a FURUNO national distributor

All spare parts for the repair

Cost for economical shipment to customer

3. FURUNO Onboard Warranty

If the product was installed/commissioned and registered by a

certified FURUNO dealer, the customer has the right to the

onboard warranty.

The FURUNO onboard warranty includes

• Free shipping of the necessary parts

• Labour: Normal working hours only

• Travel time: Up to a maximum of two (2) hours

• Travel distance: Up to a maximum of one hundred

and sixty (160) KM by car for the complete journey

4. Warranty Registration

For the Standard Warranty - presentation of product with serial

number (8 digits serial number, 1234-5678) is sufficient.

Otherwise, the invoice with serial number, name and stamp of

the dealer and date of purchase is shown.

For the Onboard Warranty your FURUNO certified dealer will

take care of all registrations.

5. Warranty Claims

For the Standard Warranty - simply send the defective product

together with the invoice to a FURUNO national distributor.

For the Onboard Warranty – contact a FURUNO national

distributor or a certified dealer. Give the product´s serial number

and describe the problem as accurately as possible.

Warranty repairs carried out by companies/persons other than a

FURUNO national distributor or a certified dealer is not covered

by this warranty.

6. Warranty Limitations

When a claim is made, FURUNO has a right to choose whether

to repair the product or replace it.

The FURUNO warranty is only valid if the product was correctly

installed and used. Therefore, it is necessary for the customer to

comply with the instructions in the handbook. Problems which

result from not complying with the instruction manual are not

covered by the warranty.

FURUNO is not liable for any damage caused to the vessel by

using a FURUNO product.

The following are excluded from this warranty:

a. Second-hand product

b. Underwater unit such as transducer and hull unit

c. Routine maintenance, alignment and calibration

services.

d. Replacement of consumable parts such as fuses,

lamps, recording papers, drive belts, cables, protective

covers and batteries.

d. Magnetron and MIC with more than 1000 transmitting

hours or older than 12 months, whichever comes first.

e. Costs associated with the replacement of a transducer

(e.g. Crane, docking or diver etc.).

f. Sea trial, test and evaluation or other demonstrations.

g. Products repaired or altered by anyone other than the

FURUNO national distributor or an authorized dealer.

h. Products on which the serial number is altered,

defaced or removed.

i. Problems resulting from an accident, negligence,

misuse, improper installation, vandalism or water

penetration.

j. Damage resulting from a force majeure or other natural

k. Damage from shipping or transit.

catastrophe or calamity.

l. Software updates, except when deemed necessary

and warrantable by FURUNO.

m. Overtime, extra labour outside of normal hours such as

weekend/holiday, and travel costs above the 160 KM

allowance

n. Operator familiarization and orientation.

FURUNO Electric Company, March 1, 2011

Page 33

FURUNO Warranty for North America

FURUNO U.S.A., Limited Warranty provides a twenty-four (24) months LABOR and twenty-four (24) months PARTS

warranty on products from the date of installation or purchase by the original owner. Products or components that are

represented as being waterproof are guaranteed to be waterproof only for, and within the limits, of the warranty

period stated above. The warranty start date may not exceed eighteen (18) months from the original date of purchase

by dealer from Furuno USA and applies to new equipment installed and operated in accordance with Furuno USA’s

published instructions.

Magnetrons and Microwave devices will be warranted for a period of 12 months from date of original equipment

installation.

Furuno U.S.A., Inc. warrants each new product to be of sound material and workmanship and through its authorized

dealer will exchange any parts proven to be defective in material or workmanship under normal use at no charge for a

period of 24 months from the date of installation or purchase.

Furuno U.S.A., Inc., through an authorized Furuno dealer will provide labor at no cost to replace defective parts,

exclusive of routine maintenance or normal adjustments, for a period of 24 months from installation date provided the

work is done by Furuno U.S.A., Inc. or an AUTHORIZED Furuno dealer during normal shop hours and within a radius

of 50 miles of the shop location.

A suitable proof of purchase showing date of purchase, or installation certification must be available to Furuno U.S.A.,

Inc., or its authorized dealer at the time of request for warranty service.

This warranty is valid for installation of products manufactured by Furuno Electric Co. (hereafter FURUNO). Any

purchases from brick and mortar or web-based resellers that are imported into other countries by anyone other than a

FURUNO certified dealer, agent or subsidiary may not comply with local standards. FURUNO strongly recommends

against importing these products from international websites or other resellers, as the imported product may not work

correctly and may interfere with other electronic devices. The imported product may also be in breach of the local

laws and mandated technical requirements. Products imported into other countries, as described previously, shall not

be eligible for local warranty service.

For products purchased outside of your country please contact the national distributor of Furuno products in the

country where purchased.

WARRANTY REGISTRATION AND INFORMATION

To register your product for warranty, as well as see the complete warranty guidelines and limitations, please visit

www.furunousa.com

provided through its authorized dealer network. If this is not possible or practical, please contact Furuno U.S.A., Inc.

to arrange warranty service.

and click on “Support”. In order to expedite repairs, warranty service on Furuno equipment is

FURUNO U.S.A., INC.

Attention: Service Coordinator

4400 N.W. Pacific Rim Boulevard

Camas, WA 98607-9408

Telephone: (360) 834-9300

FAX: (360) 834-9400

Furuno U.S.A., Inc. is proud to supply you with the highest quality in Marine Electronics. We know you had several

choices when making your selection of equipment, and from everyone at Furuno we thank you. Furuno takes great

pride in customer service.

Page 34

Page 35

Page 36

9-52 Ashihara-cho,

*

00017182713

**00017182713

*

*

00017182713

**00017182713

*

Nishinomiya, 662-8580, JAPAN

The paper used in this manual

is elemental chlorine free.

・FURUNO Authorized Distributor/Dealer

All rights reserved.

Pub. No. OME-72760-D1

(AKMU ) PG-700

Printed in Japan

A : SEP 2009

D1 : AUG . 03, 2012

* 0 0 0 1 7 1 8 2 7 1 3 *

.

Loading...

Loading...