Page 1

www.furuno.com

FURUNO GNSS Receiver

eRideOPUS 6/ eRideOPUS

7

Model

GV-86/ GV-87

Dead Reckoning Solution

User’s Guide

(Document No. SE16-900-002-00)

Page 2

eRideOPUS 6/ eRideOPUS 7 GV-86/ GV-87

Dead Reckoning User’s Guide

SE16-900-002-00

FURUNO ELECTRIC CO., LTD. All rights reserved.

Important Notice

No part of this manual may be reproduced or transmitted in any form or by any means, electronic or

mechanical, including photocopying and recording, for any purpose without the express written permission of

the publisher, FURUNO ELECTRIC CO., LTD.

FURUNO ELECTRIC CO., LTD. reserves the right to make changes to its products and specifications without

notice.

You expressly acknowledge and agree that use of the "Application Note" is at your sole risk.

This "Application Note" is provided 'AS IS' and without warranty of any kind and FURUNO expressly disclaims

all other warranties, express or implied, including, but not limited to, the implied warranties of merchantability,

fitness for a particular purpose and no infringement.

FURUNO does not warrant that the functions contained in the "Application Note" will meet your requirements,

or that the operation of the "Application Note" will be uninterrupted or error-free, or that defects in the

"Application Note" will be corrected.

Furthermore, FURUNO does not warrant or make any representations regarding the use or the results of the

use of the "Application Note" in terms of their correctness, accuracy, reliability, or otherwise.

No oral or written information or advice given by FURUNO authorized representative shall create a warranty or

in any way increase the scope of this warranty.

Without limiting the foregoing, FURUNO disclaims any and all express or implied warranties of any kind, and

you expressly assume all liabilities and risks, for use or operation of the "Application Note", including without

limitation.

Should the "Application Note" prove defective, you assume the entire cost of all necessary servicing, repair or

correction.

Some jurisdictions do not allow the exclusion of implied warranties, so the above exclusion may not apply to

you.

All brand and product names are registered trademarks, trademarks or service marks of their respective

holders.

Page 3

eRideOPUS 6/ eRideOPUS 7 GV-86/ GV-87

Dead Reckoning User’s Guide

SE16-900-002-00

FURUNO ELECTRIC CO., LTD. All rights reserved.

Revision History

Revision

Description

Date

0

Initial release

2017.10.24

Page 4

eRideOPUS 6/ eRideOPUS 7 GV-86/ GV-87

Dead Reckoning User’s Guide

SE16-900-002-00

FURUNO ELECTRIC CO., LTD. All rights reserved.

Table of Contents

1 General Description ············································································································· 1

2 FURUNO DR GNSS Receiver ································································································ 1

3 System Configuration ·········································································································· 2

3.1 Available Signal Combination and Supported Sensor ······················································· 2

3.2 Sensor Interface Configuration ······················································································· 3

4 Reference Circuit ················································································································ 4

4.1 SMI130 ························································································································ 4

4.2 MPU-6500 ···················································································································· 5

4.3 XV-4001BC and AIS328DQ ····························································································· 6

4.4 ITG-3500 and AIS328DQ ································································································· 7

4.5 A3G4250D and AIS328DQ ······························································································ 8

4.6 XV-8000CB and AIS328DQ ····························································································· 9

4.7 XV-8100CB and AIS328DQ ···························································································· 10

5 IMU Sensor Installation ······································································································ 12

5.1 Automatic Correction by Auto Orientation Function························································· 13

5.2 Expand Auto Orientation Range by PERDAPI,AUTOORIENT Command ····························· 13

5.3 Set Installation Angle by Misalignment ··········································································· 14

5.4 Sensor Installation Examples ························································································ 15

5.4.1 Zero Angle against Axis of IMU Sensor ···································································· 15

5.4.2 Auto Orientation Default Range ·············································································· 16

5.4.3 Auto Orientation Expansion Range ········································································· 17

5.4.4 Out of Auto Orientation Range ················································································ 18

6 Calibration ······················································································································· 19

6.1 Power on to GNSS Position Fix ····················································································· 19

6.2 GNSS Position Fix to DR Valid by Calibration Driving ······················································ 20

6.3 Calibration of Vehicle Speed Pulse and Accelerometer ···················································· 20

6.4 Calibration of Gyro Sensor ··························································································· 21

6.5 Aging and Temperature Fluctuations ············································································· 21

7 Operating of DR Backup ···································································································· 22

8 Recommended NMEA Output Sentence at Customer Evaluation Stage ··································· 22

9 Important Notice ··············································································································· 23

9.1 Important Notice for IMU Sensor ···················································································· 23

9.2 Characteristics of IMU Sensor ······················································································· 23

9.3 Layout Design against Influence of IMU Sensor by External Environment Factor ················ 23

9.4 Calibrating Operation ··································································································· 23

9.5 Receiver Start Operation ······························································································ 24

10 FAQ ······························································································································ 25

Page 5

eRideOPUS 6/ eRideOPUS 7 GV-86/ GV-87

Dead Reckoning User’s Guide

SE16-900-002-00

1

FURUNO ELECTRIC CO., LTD. All rights reserved.

1 General Description

This document describes user’s guide for achieving best performance of FURUNO Dead Reckoning (DR)

GNSS receiver (GNSS+DR receiver).

- eRideOPUS 6 (P/N: ePV6010B) Dead Reckoning Chip solution

- eRideOPUS 7 (P/N: ePV7010B) Dead Reckoning Chip solution

- GV-8720

- GV-8620

Available software: As from ENP6.33D

GNSS+DR receiver has the following external interface for DR function.

<Signal input from sensor or vehicle>

This configuration is the way of direct input from vehicle.

- FURUNO supported gyro sensor and accelerometer.

- Vehicle speed pulse signal.

- Vehicle reverse signal.

2 FURUNO DR GNSS Receiver

GNSS+DR receiver can keep the following high accuracy position and velocity performance under non GNSS

signal reception or unstable area

GNSS stand alone

GNSS+DR hybrid / DR only

GNSS stand alone

GNSS+DR hybrid

Figure 2.1 Ground Tracking Test of GNSS Stand Alone and GNSS+DR

(Upper: Tunnel, Lower: Urban Canyon)

Page 6

eRideOPUS 6/ eRideOPUS 7 GV-86/ GV-87

Dead Reckoning User’s Guide

SE16-900-002-00

2

FURUNO ELECTRIC CO., LTD. All rights reserved.

3 System Configuration

3.1 Available Signal Combination and Supported Sensor

Table 3.1 shows available signal source combinations. Based on Table 3.2, which shows FURUNO supported

IMU sensor (Gyro, Accelerometer and Gyro/Accelerometer combo sensor), please design optimized system

on customer platform.

Table 3.1 Signal Source Combination

Combination

Gyro

Accelerometer

Vehicle

speed

pulse

(*1)

Reverse

signal

(*1)

Notes

A

Detection of elevation pitch

angle is available.

B -

: Necessary signal source

Table 3.2 Supported Gyro Sensor and Accelerometer

(*2)

Sensor category

Product number

Vendor

# of

axis

Automotive

Gyro/Accelerometer

combo sensor

SMI130

Bosch

6

MPU-6500

InvenSense

6

Gyro sensor

XV-4001BC

Seiko Epson

1

ITG-3500

InvenSense

3 A3G4250D

STMicroelectronics

3 XV-8000CB

(*3)

Seiko Epson

1

XV-8100CB

(*4)

Seiko Epson

1

Accelerometer

AIS328DQ

STMicroelectronics

3 LIS331DLH

STMicroelectronics

3

Notes:

(*1) Specification of vehicle speed pulse and reverse signal

Please check the regulation and electric characteristics by GNSS+DR receiver data sheet and keep it,

otherwise customer may have risk of out of performance guarantee. It is necessary to take vehicle speed pulse

together reverse signal.

(*2) Supported IMU sensor

We verified that GNSS+DR receiver with sensor in Table 3.2 could achieve target performance by proper

calibration described at Chapter 6.

(*3) In case of using XV-8000CB, it is necessary to implement the following devices.

-AD convertor (ADS1100A3: Texas Instruments)

-Thermo sensor (LM73CIMKX-0: Texas Instruments)

-Level shifter from 5V to 3V

(*4) In case of using XV-8100CB, it is necessary to implement the following devices.

-AD convertor (ADS1100A3: Texas Instruments)

-Thermo sensor (LM73CIMKX-0: Texas Instruments)

Page 7

eRideOPUS 6/ eRideOPUS 7 GV-86/ GV-87

Dead Reckoning User’s Guide

SE16-900-002-00

3

FURUNO ELECTRIC CO., LTD. All rights reserved.

3.2 Sensor Interface Configuration

Figure 3.1shows I/O relation between the GNSS+DR receiver and the supported sensor in Table 3.2.

Sensor information

I/O signal

Pin #

ePV6010B /

ePV7010B

GV-86/

GV-87

Gyro sensor,

I2C serial clock

(SCL)

TXD2_SCL

F8

#19

Accelerometer,

Gyro/Accelerometer

combo sensor

I2C serial data

(SDA)

RXD2_SDA

G8

#18

Vehicle speed pulse

ECNT

C7

#7

Reverse signal

GPIO

E6

#1

FURUNO Dead Reckoning GNSS Receiver

ECNT

GPIO

RXD2_SDA

TXD2_SCL

RXD1

TXD1 Output data (Position, Time, Sensor status, …)

Command data (NMEA setting, Mis-alignment, …)

I2C serial address and data between sensor block

I2C serial clock from sensor block

Vehicle speed pulse

Reverse signal

UART1

I2C

Figure 3.1 Sensor Interface Configuration Block Level Diagram

Page 8

eRideOPUS 6/ eRideOPUS 7 GV-86/ GV-87

Dead Reckoning User’s Guide

SE16-900-002-00

4

FURUNO ELECTRIC CO., LTD. All rights reserved.

4 Reference Circuit

This section shows reference circuits of FURUNO supported sensor. Operation guarantee of these circuits is

just based on FURUNO original development environment, which means that FURUNO is not able to

guarantee operation at customer development environment. Therefore, please verify and check expected

operation at customer end.

For example, in the schematics below, the both I2C lines (TXD2_SCL, RXD2_SDA) are pulled up with the

10kΩ resistors (R1, R2). Depending on the wiring capacity of the I2C line, the H and L levels may deviate from

the specified values, or the rising slope may become slow, causing timing errors. In such a case, it can be

adjusted by decreasing the value of the pull-up resistors (R1, R2) within the range that the IC can drive. Since

the wiring capacity varies according to the customer's actual layout of the circuit board, the design should be

decided by customer's evaluation.

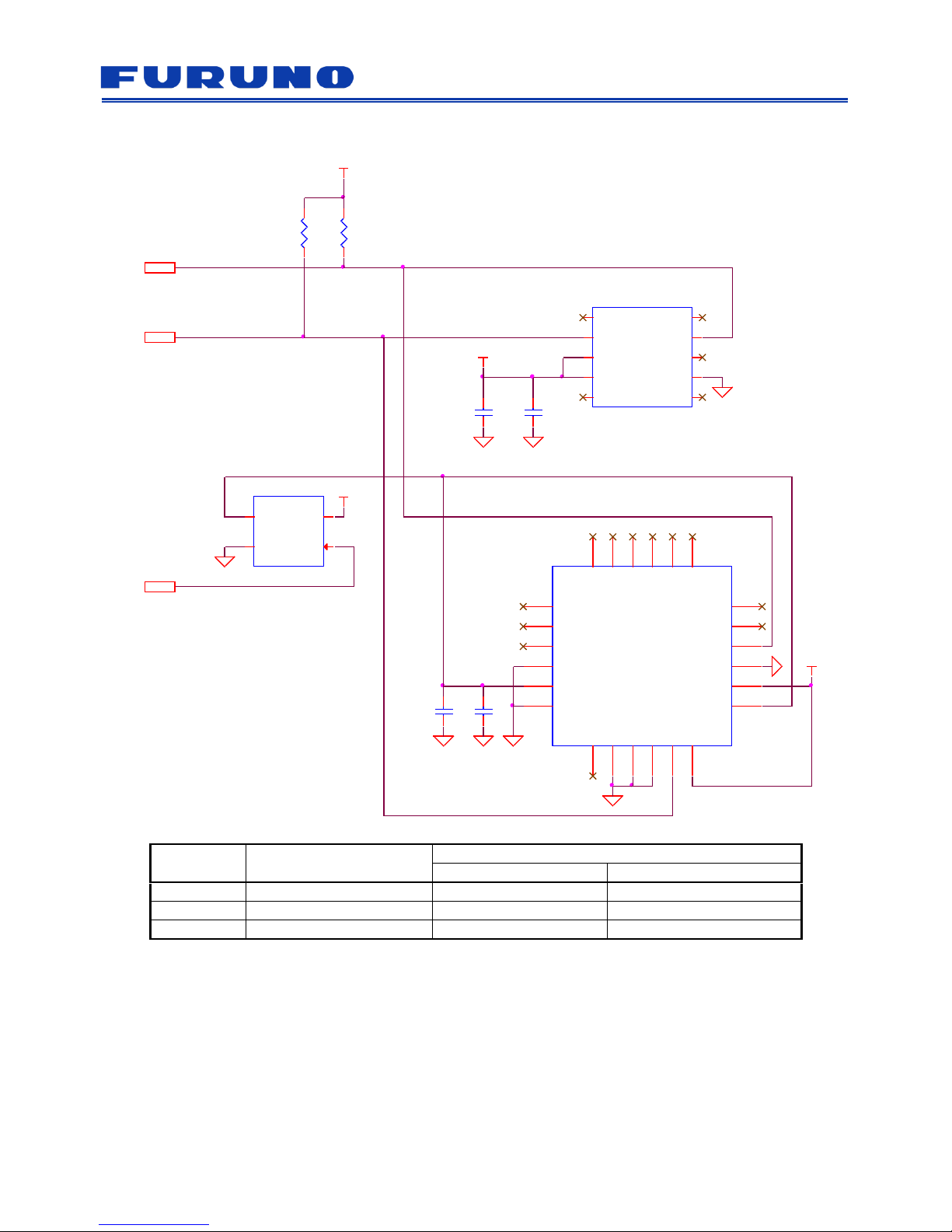

4.1 SMI130

I/O signal

Description

Interface connection destination

eRideOPUS 6/7

GV-86/ 87

SCL

I2C clock

TXD2_SCL

TXD2_SCL

SDA

I2C address/data bus

RXD2_SDA

RXD2_SDA

Figure 4.1 Reference Circuit of SMI130

SCL

SDA

R2

10k

C1

0.1uF

R1

10k

C2

0.1uF

U1

SMI130

INT2

1

NC

2

VDD

3

GND

4

CSB2

5

GNDIO

6

PS

7

SCK

8

SDI

9

SDO2

10

VDDIO

11

INT3

12

INT4

13

CSB1

14

SDO1

15

INT1

16

VCC

VCC

VCC

(*1)

(*1)

(*2)

(*2)

(*2)

(*3)

(*3)

Page 9

eRideOPUS 6/ eRideOPUS 7 GV-86/ GV-87

Dead Reckoning User’s Guide

SE16-900-002-00

5

FURUNO ELECTRIC CO., LTD. All rights reserved.

4.2 MPU-6500

I/O signal

Description

Interface connection destination

eRideOPUS 6/7

GV-86/ 87

RESET

External reset signal

NRST

RST_N

SCL

I2C clock

TXD2_SCL

TXD2_SCL

SDA

I2C address/data bus

RXD2_SDA

RXD2_SDA

Figure 4.2 Reference Circuit of MPU-6500

U1

XC8101AA01-GR-G

VOUT

1

VSS

2

CE

3

VIN

4

R2

10k

VCC

R1

10k

VCC

SDA

SCL

RESET

U2

MPU-6500

NC

1

NC

2

NC

3

NC

4

NC

5

NC

6

AUX_CL7VDDIO8SDO/AD09REGOUT10FSYNC11INT

12

VDD

13

NC

14

NC

15

NC

16

NC

17

GND

18

RESV

19

RESV

20

AUX_DA

21

nCS

22

CSL/SCLK

23

SDA/SDI

24

C1

0.1uF

C3

0.1uF

C2

0.01uF

VCC

VCC

(*4)

(*3)

(*3)

(*1)

(*1)

(*1)

(*2)

(*2)

(*2)

(*2)

Page 10

eRideOPUS 6/ eRideOPUS 7 GV-86/ GV-87

Dead Reckoning User’s Guide

SE16-900-002-00

6

FURUNO ELECTRIC CO., LTD. All rights reserved.

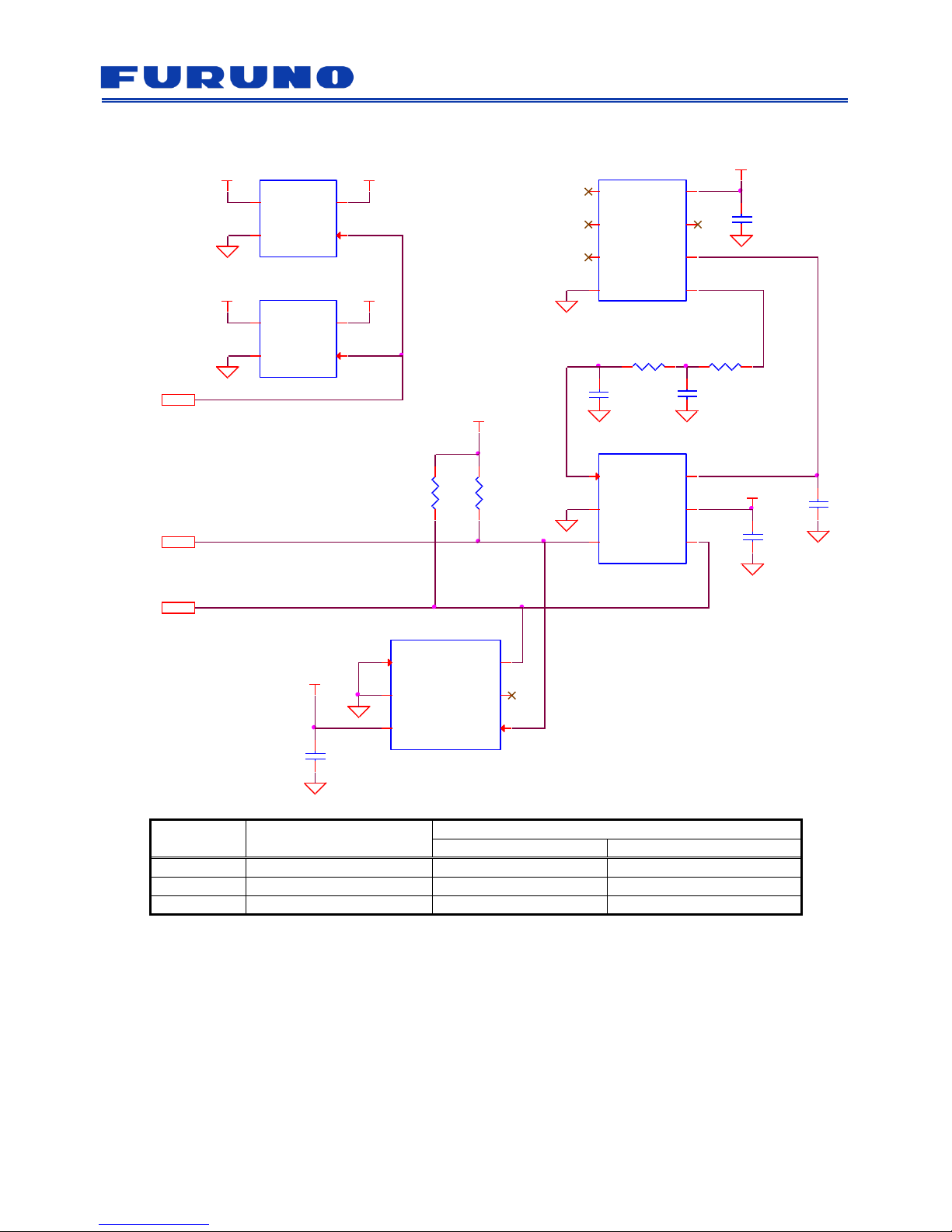

4.3 XV-4001BC and AIS328DQ

I/O signal

Description

Interface connection destination

eRideOPUS 6/7

GV-86/ 87

RESET

External reset signal

NRST

RST_N

SCL

I2C clock

TXD2_SCL

TXD2_SCL

SDA

I2C address/data bus

RXD2_SDA

RXD2_SDA

Figure 4.3 Reference Circuit of XV-4001BC and AIS328DQ

R1

10k

R2

10k

VCC

VCC

U2

XC8101AA01-GR-G

VOUT

1

VSS2CE

3

VIN

4

SDA

RESET

SCL

U3

AIS328DQ

NC

1

NC

2

INT_2

3

Reserv ed

4

VDD

5

GND

6

INT_17GND8GND9GND10SPC/SCL11CS

12

Reserv ed

13

VDD_IO

14

SDO/SA0

15

SDI/SDO/SDA

16

NC

17

NC

18

NC

19NC20NC21NC22NC23NC24

C3

10uF

C4

0.1uF

VCC

U1

XV-4001BC

Reserv ed

1

SCL

2

SS

3

VDD

4

Reserv ed5Reserv ed

6

GND

7

MOSI

8

SDA

9

Reserv ed

10

VCC

C2

10uFC10.1uF

(*1)

(*1)

(*1)

(*4)

(*3)

(*3)

(*2)

(*2)

(*2)

Page 11

eRideOPUS 6/ eRideOPUS 7 GV-86/ GV-87

Dead Reckoning User’s Guide

SE16-900-002-00

7

FURUNO ELECTRIC CO., LTD. All rights reserved.

4.4 ITG-3500 and AIS328DQ

I/O signal

Description

Interface connection destination

eRideOPUS 6/7

GV-86/ 87

RESET

External reset signal

NRST

RST_N

SCL

I2C clock

TXD2_SCL

TXD2_SCL

SDA

I2C address/data bus

RXD2_SDA

RXD2_SDA

Figure 4.4 Reference Circuit of ITG-3500 and AIS328DQ

U7

AIS328DQ

NC

1

NC

2

INT_2

3

Reserv ed

4

VDD

5

GND

6

INT_17GND8GND9GND10SPC/SCL11CS

12

Reserv ed

13

VDD_IO

14

SDO/SA0

15

SDI/SDO/SDA

16

NC

17

NC

18

NC

19NC20NC21NC22NC23NC24

VCC

C5

10uF

C4

0.1uF

U1

XC8101AA01-GR-G

VOUT

1

VSS2CE

3

VIN

4

C2

0.1uF

U2

ITG-3500

SDA/SDI

1

NC

2

VDDIO

3

/CS

4

RESV5AD0/SD06REGOUT7FSYNC

8

VDD

9

INT

10

NC

11

GND

12

NC

13

RESV-G

14NC15

SCL/SCLK

16

C3

0.1uF

C1

0.01uF

VCC

R2

10k

R1

10k

VCC

VCC

RESET

SDA

SCL

(*4)

(*3)

(*3)

(*1)

(*1)

(*1)

(*2)

(*2)

(*2)

Page 12

eRideOPUS 6/ eRideOPUS 7 GV-86/ GV-87

Dead Reckoning User’s Guide

SE16-900-002-00

8

FURUNO ELECTRIC CO., LTD. All rights reserved.

4.5 A3G4250D and AIS328DQ

I/O signal

Description

Interface connection destination

eRideOPUS 6/7

GV-86/ 87

RESET

External reset signal

NRST

RST_N

SCL

I2C clock

TXD2_SCL

TXD2_SCL

SDA

I2C address/data bus

RXD2_SDA

RXD2_SDA

Figure 4.5 Reference Circuit of A3G4250D and AIS328DQ

R1 10k

U2

A3G4250D

Vdd_IO

1

SCL/SPC

2

SDA/SDI/SDO

3

SDO/SA0

4

CS5DRDY/INT26INT7RES

8

RES

9

RES

10

RES

11

RES

12

GND

13

PLLFILT

14

RES

15

VDD

16

R3

10k

R2

10k

C5

0.1uF

VCC

VCC

VCC

VCC

C2

10uF

C4 0.47uF

C1 0.01uF

C3

0.1uF

U1

XC8101AA01-GR-G

VOUT

1

VSS2CE

3

VIN

4

SDA

RESET

SCL

U3

AIS328DQ

NC

1

NC

2

INT_2

3

Reserv ed

4

VDD

5

GND

6

INT_17GND8GND9GND10SPC/SCL11CS

12

Reserv ed

13

VDD_IO

14

SDO/SA0

15

SDI/SDO/SDA

16

NC

17

NC

18

NC19NC20NC21NC

22NC23NC24

C7

10uF

C6

0.1uF

VCC

(*4)

(*3)

(*3)

(*1)

(*1)

(*1)

(*2)

(*2)

(*2)

(*2)

Page 13

eRideOPUS 6/ eRideOPUS 7 GV-86/ GV-87

Dead Reckoning User’s Guide

SE16-900-002-00

9

FURUNO ELECTRIC CO., LTD. All rights reserved.

4.6 XV-8000CB and AIS328DQ

I/O signal

Description

Interface connection destination

eRideOPUS 6/7

GV-86/ 87

RESET

External reset signal

NRST

RST_N

SCL

I2C clock

TXD2_SCL

TXD2_SCL

SDA

I2C address/data bus

RXD2_SDA

RXD2_SDA

Figure 4.6 Reference Circuit of XV-8000CB and AIS328DQ

C4

2.2uF

VCCI_3V3

U6

LM73CIMKX-0

ADDR

1

GND

2

VDD3SMBCLK

4

ALERT_N

5

SMBDAT

6

C9

0.1uF

R6

10k

VCCI_3V3

R5

10k

U8

AIS328DQ

NC

1

NC

2

INT_2

3

Reserv ed

4

VDD

5

GND

6

INT_17GND8GND9GND10SPC/SCL11CS

12

Reserv ed

13

VDD_IO

14

SDO/SA0

15

SDI/SDO/SDA

16

NC

17

NC

18

NC19NC20NC21NC22NC23NC

24

VCC_3V3

C11

10uF

C10

0.1uF

VCCI_3V3

U2

XC8101AA01-GR-G

VOUT

1

VSS2CE

3

VIN

4

VCC_3V3

RESET

VCCI_3V3

U1

XC8101AA01-GR-G

VOUT

1

VSS2CE

3

VIN

4

VCC_5V0

VCCI_3V3

VCCI_5V0

C8

1uF

C2

0.1uF

R1 3.3k R2 3.3k

C1

2.2uF

C3

2.2uF

U3

XV-8000CB

NC

1

GND

2

VDD

3

NC

4

NC

5

VOUT

6

VTEMP

7

NC

8

VCCI_5V0

R3

3.3k +/- 1%

R4

3.3k +/- 1%

VCCI_5V0

VCCI_3V3

C6

0.1uF

VCCI_5V0

U5

TCA9517DGKR

VCCA

1

SCLA

2

SDAA

3

GND

4

EN

5

SDAB

6

SCLB

7

VCCB

8

C7

0.1uF

SCL

SDA

U4

ADS1100A3IDBVT

Vin+

1

GND

2

SCL3SDA

4

VDD

5

Vin-

6

VCCI_5V0

R8

10k

R7

10k

VCCI_5V0

C5

0.1uF

(*4)

(*4)

(*3)

(*3)

(*1)

(*1)

(*1)

(*5)

(*5)

(*5)

(*5)

(*6)

(*6)

Page 14

eRideOPUS 6/ eRideOPUS 7 GV-86/ GV-87

Dead Reckoning User’s Guide

SE16-900-002-00

10

FURUNO ELECTRIC CO., LTD. All rights reserved.

4.7 XV-8100CB and AIS328DQ

I/O signal

Description

Interface connection destination

eRideOPUS 6/7

GV-86/ 87

RESET

External reset signal

NRST

RST_N

SCL

I2C clock

TXD2_SCL

TXD2_SCL

SDA

I2C address/data bus

RXD2_SDA

RXD2_SDA

Figure 4.7 Reference Circuit of XV-8100CB and AIS328DQ

C4

0.1uF

VCCI_3V3

U5

LM73CIMKX-0

ADDR

1

GND

2

VDD

3

SMBCLK

4

ALERT_N

5

SMBDAT

6

C6

0.1uF

VCCI_3V3

R4

10k

R3

10k

U3

XC8101AA01-GR-G

VOUT

1

VSS

2

CE

3

VIN

4

VCC_3V3

RESET

U2

XC8101AA01-GR-G

VOUT

1

VSS

2

CE

3

VIN

4

VCCI_3V3

VCC_3V0VCCI_3V0

C1

0.1uF

R13.3k

C3

2.2uF

C2

2.2uF

VCCI_3V0

SDA

SCL

U4

ADS1100A3IDBVT

Vin+

1

GND

2

SCL

3

SDA

4

VDD

5

Vin-

6

VCCI_3V0

C5

0.1uF

U1

XV-8100CB

NC

1

NC

2

NC

3

GND4VOUT

5

VREF

6

NC

7

VDD

8

R23.3k

(*7)

(*7)

(*7)

(*4)

(*4)

(*3)

(*3)

(*1)

(*1)

(*1)

Page 15

eRideOPUS 6/ eRideOPUS 7 GV-86/ GV-87

Dead Reckoning User’s Guide

SE16-900-002-00

11

FURUNO ELECTRIC CO., LTD. All rights reserved.

Notes:

(*1) When the I2C master device is eRideOPUS 6/eRideOPUS 7 and using 1.8V I/O power supply, please

change to 3.3V I/O signal voltage with level shifter.

(*2) The power supply (VCC) should be common with the receiver.

(*3) Since this resistance value may not satisfy the electrical characteristics due to the floating capacitance of

the line, please decide the resistance value in consideration of the floating capacitance of the line.

(*4) In case only receiver which is eRideOPUS 6/ eRideOPUS 7 or GV-86/GV-87 (I2C master device) has

reset from normal operation, there is a risk of misreading data from sensor after releasing reset. In order to

avoid this issue, it is necessary to be activating reset of sensor when I2C master device has reset.

Therefore, it is necessary to control power supply of sensor by using power switch with the reset control

port due to no reset port at the sensor.

(*5) In case of using XV-8000CB, it is necessary to implement the following devices.

- AD convertor (ADS1100A3: Texas Instruments).

- Thermo sensor (LM73CIMKX-0: Texas Instruments).

- Level shifter from 5V to 3.3V.

(*6) 1% resistor is necessary.

(*7) In case of using XV-8100CB, it is necessary to implement the following devices.

- AD convertor (ADS1100A3: Texas Instruments).

- Thermo sensor (LM73CIMKX-0: Texas Instruments).

Page 16

eRideOPUS 6/ eRideOPUS 7 GV-86/ GV-87

Dead Reckoning User’s Guide

SE16-900-002-00

12

FURUNO ELECTRIC CO., LTD. All rights reserved.

5 IMU Sensor Installation

For the installation of the IMU sensor, the GNSS+DR receiver has specification values for the inclination and

the deviation of the coordinate system of the vehicle and the IMU sensor. The GNSS+DR receiver has a

function to correct the inclination and the deviation within the specification value.

(1) Method of automatically correcting the inclination and the deviation of installation angle by the Auto

Orientation function

(2) Method of presetting the inclination of the known installation angle by the misalignment command

With these functions, it is possible to correct and eliminate the output error of the IMU sensor caused by the

inclination and deviation.

The Auto Orientation function can also expand the range of angles that can be automatically corrected by

AUTOORIENT command.

<Definition of coordinate system and axis>

Here are definitions of axis against sensor unit installation angle:

- Direction of forward movement: X-axis

- Horizontal to the direction of movement: Y-axis

- Vertical to the direction of movement: Z-axis

Rotation angles to the each axis are defined as follows:

- Rotation angle around the X axis: ΔθX Roll angle

- Rotation angle around the Y axis: ΔθY Pitch angle

-

Rotation angle around the Z axis: ΔθZ Yaw angle

Figure 5.1 (a) to (d) shows inclination against each axis.

Z

X

Y

(a) No inclination

Z

X

Y

(b) Inclines ΔθZ to the direction of movement

Z

X

Y

(c) Inclines ΔθX to the horizontal direction

Z

X

Y

(d) Inclines ΔθY to the height direction

Δθ

Y

0

0

0

Surface

0

Direction of

movement

Δθ

Z

Δθ

X

Figure 5.1 Sensor Unit Installation Angle Definition

Page 17

eRideOPUS 6/ eRideOPUS 7 GV-86/ GV-87

Dead Reckoning User’s Guide

SE16-900-002-00

13

FURUNO ELECTRIC CO., LTD. All rights reserved.

When the axis described in the IMU sensor data sheet defines the Z-axis and the Y-axis opposite to the DR

receiver axis definition, the DR receiver changes the Z-axis and Y-axis direction to correspond to the definition

described in this document.

5.1 Automatic Correction by Auto Orientation Function

Auto Orientation is a function to automatically correct the output error due to the inclination and deviation of the

IMU sensor. Table 5.1 shows the IMU sensor combination and the allowable angle range in which the Auto

Orientation operates.

Table 5.1 Functional Range of Auto Orientation (Default)

#

Sensor combination

ΔθZ

Yaw angle

ΔθX

Roll angle

ΔθY

Pitch

angle

Notes

1

3-axis gyro sensor,

3-axis accelerometer,

vehicle speed pulse

±15

±60

±60

2 ±45

±45

In case of using A3G4250D

3

1-axis gyro sensor,

3-axis accelerometer,

vehicle speed pulse

±15

±30

4

3-axis or 1-axis gyro sensor,

vehicle speed pulse

±15

±15

5.2 Expand Auto Orientation Range by PERDAPI,AUTOORIENT Command

In case of using 3-axis gyro sensor, 3-axis accelerometer and vehicle speed pulse, it is possible to expand the

Auto Orientation range for the Roll angle or the Pitch angle by $PERDAPI,AUTOORIENT,1*6E. Table 5.2

shows the expanded range.

Table 5.2 Functional Range of Auto Orientation (Expansion)

#

Sensor

combination

ΔθZ

Yaw angle

ΔθX

Roll angle

ΔθY

Pitch angle

Notes

5

3-axis gyro sensor,

3-axis accelerometer,

vehicle speed pulse

±15

±15

±75

Pitch angle expansion

Using SMI130, MPU6500/ ITG3500

6

±180

±45

Roll angle expansion

Using SMI130, MPU6500/ ITG3500

7

±45

-165 to -180

+165 to +180

±45

Roll angle expansion

Using A3G4250D

Page 18

eRideOPUS 6/ eRideOPUS 7 GV-86/ GV-87

Dead Reckoning User’s Guide

SE16-900-002-00

14

FURUNO ELECTRIC CO., LTD. All rights reserved.

5.3 Set Installation Angle by Misalignment

When the IMU sensor is not installed within the Auto Orientation range, which means that the installation angle

is exceeded the range described in Table 5.1 and Table 5.2, it is possible to set the installation angle by the

misalignment command

(*1)

(Gyro sensor: PERDAPI,GYROALIGN, Accelerometer: PERDAPI,ACCELALIGN).

Misalignment operating necessity condition and flow is as follow:

Operating necessity condition:

- Initial installation

- Change installation angle.

Operating process flow:

1. Install the unit with IMU sensor.

2. Check the installation angle of IMU sensor.(delta angle)

3. Operate the GNSS+DR receiver with vehicle stop condition.

4. Send $PERDAPI,STOP,DRPARK*5D command and stop normal operating of GNSS+DR receiver.

5. Send delta angle by misalignment set command.

(Gyro sensor misalignment command)

$PERDAPI,GYROALIGN,Δθx,Δθy,Δθz*hh

(Accelerometer sensor misalignment command)

$PERDAPI,ACCELALIGN,Δθx,Δθy,Δθz*hh

*Setting sequence of misalignment angle against absolute axis is ΔθX -> ΔθY -> ΔθZ.

6. Send $PERDAPI,START,SIMCOLD*48 command and initiate normal operating GNSS+DR receiver.

(*2)

Notes:

(*1) As the misalignment data returns to the default in the following condition, it is recommended to register the

commands in ESIPLIST.

- Send PERDAPI,STOP,DRPARK command

- Power off

- Hardware reset

(*2) Do not change the installation angle of IMU sensor during normal operating.

Page 19

eRideOPUS 6/ eRideOPUS 7 GV-86/ GV-87

Dead Reckoning User’s Guide

SE16-900-002-00

15

FURUNO ELECTRIC CO., LTD. All rights reserved.

5.4 Sensor Installation Examples

Here are sensor, which is 3-axis gyro and 3-axis accelerometer, installation examples with the GNSS+DR

receiver evaluation kit (VN-871 or VN-861).

5.4.1 Zero Angle against Axis of IMU Sensor

X

Y

Z

Traveling

direction

O

This installation is ideal, which means that this

installation angle meets requirement specifications

of IMU sensor based on data sheet.

(a) (ΔθX, ΔθY, ΔθZ) = (0, 0, 0)

Figure 5.2 Zero Angle against Axis of IMU Sensor

Page 20

eRideOPUS 6/ eRideOPUS 7 GV-86/ GV-87

Dead Reckoning User’s Guide

SE16-900-002-00

16

FURUNO ELECTRIC CO., LTD. All rights reserved.

5.4.2 Auto Orientation Default Range

In case of Figure 5.3 (b), (c) and (d), it is possible to automatically correct the inclination of IMU sensor by

using 3-axis gyro sensor and 3-axis accelerometer.

X

Z

Y

Traveling

direction

+15°

O

This installation is that the rotate angle against

Z-axis is +15 degrees, which means that heading of

IMU sensor is -15 degrees at clockwise against

traveling direction.

(b) (ΔθX, ΔθY, ΔθZ) = (0, 0, +15)

Z

X

Traveling

direction

Y

-15°

O

This installation is that the rotate angle against

X-axis is -15 degrees, which means that horizontal

plane of IMU sensor is -15 degrees at counter

clockwise against Y-axis.

(c) (ΔθX, ΔθY, ΔθZ) = (-15, 0, 0)

Z

Y

X

Traveling

direction

O

+30°

This installation is that the rotate angle against

Y-axis is +30 degrees, which means that elevation

angle of IMU sensor is +30 degrees against traveling

direction.

(d) (ΔθX, ΔθY, ΔθZ) = (0, +30, 0)

Figure 5.3 Installation Examples within Auto Orientation Default Range

Page 21

eRideOPUS 6/ eRideOPUS 7 GV-86/ GV-87

Dead Reckoning User’s Guide

SE16-900-002-00

17

FURUNO ELECTRIC CO., LTD. All rights reserved.

5.4.3 Auto Orientation Expansion Range

In case of Figure 5.4 (e), (f) and (g), it is possible to automatically correct the inclination of IMU sensor by using

3-axis gyro sensor and 3-axis accelerometer and “$PERDAPI,AUTOORIENT,1*6E” command.

+75°

X

Y

Z

Traveling

direction

O

This installation is that the rotate angle against

Y-axis is +75 degrees, which means that elevation

angle of IMU sensor is +75 degrees against traveling

direction.

(e) (ΔθX, ΔθY, ΔθZ) = (0, +75, 0)

X

Y

Z

Traveling

direction

O

+180°

This installation is that the rotate angle against

X-axis is +180 degrees, which means that the top

side of IMU sensor faces downward.

(f) (ΔθX, ΔθY, ΔθZ) = (+180, 0, 0)

O

X

Y

Z

Traveling

direction

+180°

+45°

This installation is that the rotate angle against

X-axis is +180 degrees and against Y-axis is +45

degrees, which means that the top side of IMU

sensor faces downward and the elevation angle

inclines +45 degrees.

(g) (ΔθX, ΔθY, ΔθZ) = (+180, +45, 0)

Figure 5.4 Installation Examples within Auto Orientation Expansion Range

Page 22

eRideOPUS 6/ eRideOPUS 7 GV-86/ GV-87

Dead Reckoning User’s Guide

SE16-900-002-00

18

FURUNO ELECTRIC CO., LTD. All rights reserved.

5.4.4 Out of Auto Orientation Range

In case of Figure 5.5 (h), (i) and (j), it is necessary to set misalignment data due to out of Auto Orientation

range.

Z

Y

X

Traveling

direction

O

+30°

This installation is that the rotate angle against

Z-axis is +30 degrees, which means that the heading

of IMU sensor is +30 degrees at clockwise against

the traveling direction. When the heading error is

more than +15 degrees, it is necessary to set

misalignment data. In this case (the rotate angle

against Z-axis is +30 degrees), since ΔθZ is out of

Auto Orientation range, it is necessary to send the

following commands as misalignment data.

$PERDAPI,GYROALIGN,0,0,30*16

$PERDAPI,ACCELALIGN,0,0,30*5D

(h) (ΔθX, ΔθY, ΔθZ) = (0, 0, +30)

+90°

+90°

O

X

Y

Z

Traveling

direction

This installation is that the rotate angle against

X-axis is +90 degrees and the rotate angle against

Z-axis is +90 degrees, which means that heading of

IMU sensor is +90 degrees at clockwise and the

elevation angle of IMU sensor is +90 degrees

against the traveling direction. In this case, since

Δθ

X

and ΔθZ is out of Auto Orientation range, it is

necessary to send the following commands as

misalignment data.

$PERDAPI,GYROALIGN,90,0,90*25

$PERDAPI,ACCELALIGN,90,0,90*6E

(i) (ΔθX, ΔθY, ΔθZ) = (+90, 0, +90)

O

X

Y

Z

Traveling

direction

+180°

+180°

This installation is that the rotate angle against

X-axis is +180 degrees and the rotate angle against

Z-axis is +180 degrees, which means that the

heading of IMU sensor is +180 degrees at clockwise

and the top side of IMU sensor faces downward. In

this case, since ΔθX and ΔθZ is out of Auto

Orientation range, it is necessary to send the

following commands as misalignment data.

$PERDAPI,GYROALIGN,180,0,180*25

$PERDAPI,ACCELALIGN,180,0,180*6E

(j) (ΔθX, ΔθY, ΔθZ) = (+180, 0, +180)

Figure 5.5 Installation Examples with Misalignment Command

Page 23

eRideOPUS 6/ eRideOPUS 7 GV-86/ GV-87

Dead Reckoning User’s Guide

SE16-900-002-00

19

FURUNO ELECTRIC CO., LTD. All rights reserved.

6 Calibration

Calibration is a function to estimate the output errors of IMU sensor and vehicle speed pulse. Estimated output

errors are bias and gain. The bias is an output value when the input value is 0, and the gain is a ratio of the

input value to the output value. Using the estimated bias and gain, the GNSS+DR receiver corrects the output

value of IMU sensor and vehicle speed pulse, and outputs high precision position.

The calibration method is described in the following sections.

6.1 Power on to GNSS Position Fix

[Operation]

It is necessary to do position fix in open sky as a good GNSS signal reception environment

(*1)

before starting

calibration driving.

[Check]

1. Check the position fix status with GNS and RMC sentence

Make sure that the position fix status is A or D.

Example:

Yellow high-light shows the position fix status (GNS sentence shows the position fix status of GPS,

GLONASS and Galileo from left hand).

$GNRMC,071201.776,A,3442.7276,N,13520.1229,E,0.00,30.96,130614,,,A,V*3C

$GNGNS,071201.776,3442.7276,N,13520.1229,E,AAN,18,0.5,3.6,36.7,,,V*5C

2. Check the C/N0 value with GSV sentence

The more number of satellites with C/N0 with over 40 dB-Hz, the better reception environment.

Example:

Yellow high-light shows the C/N0 value.

$GPGSV,4,1,14,19,73,309,50,03,70,345,52,27,55,031,52,16,46,084,50,1*6A

$GPGSV,4,2,14,07,40,307,52,11,39,211,49,08,19,320,46,01,15,199,40,1*61

$GPGSV,4,3,14,13,15,247,43,30,13,319,,22,11,090,46,23,05,219,42,1*6F

$GPGSV,4,4,14,42,00,000,46,93,32,161,43,,,,,,,,,1*6F

$GLGSV,2,1,07,82,71,317,56,80,67,326,53,79,50,152,52,81,30,031,55,1*7C

$GLGSV,2,2,07,83,25,238,53,73,14,329,29,78,01,151,34,,,,,1*42

Notes:

(*1) As an index of a good GNSS signal reception environment, it is more than 50% of the number of satellites

in use with signal level of over 40 dB-Hz.

Page 24

eRideOPUS 6/ eRideOPUS 7 GV-86/ GV-87

Dead Reckoning User’s Guide

SE16-900-002-00

20

FURUNO ELECTRIC CO., LTD. All rights reserved.

6.2 GNSS Position Fix to DR Valid by Calibration Driving

[Operation]

Calibration function is available by driving with more than 20 km/h at open sky. Keep the vehicle speed of more

than 20km/h at open sky. Otherwise calibration function may not work.

20Km/h overRun

Position status changes from GPS only to DR/GNSS mixed, which means that DR is valid, for a several

minutes with this condition. While DR is valid, it is not equal to complete the calibration operation.

[Check]

a) Check the IMU result verified mode with PERDCRD,R sentence

When Field 3 is 1, DR is valid.

b) Check the DR use mode with PERDCRD,R sentence

When Field 4 is 2, DR/GNSS mixed (hybrid position fix status) is valid.

Example:

$PERDCRD,R,1,2,-0.68,-8.85,-0.01,-0.4,0.1,265.6,1,10*23

6.3 Calibration of Vehicle Speed Pulse and Accelerometer

[Operation]

Same as Section 6.2.

[Check]

Check the calibration status of vehicle speed pulse and accelerometer with the following sentences.

-Vehicle speed pulse:

When Field 3 is 7 or 15

(*1)

at PERDCRI,O sentence, the calibration of vehicle speed pulse is completed.

Example:

$PERDCRI,O,7,29,2,4.00,1.569858*10

$PERDCRI,O,15,0,0,4.02,1.569858*18

Notes:

(*1) In case of detecting reverse signal at status 7, the status becomes 15. It is necessary to check valid of

reverse signal before starting calibration of vehicle speed pulse.

-Accelerometer:

When Field 17 is 3 at PERDCRI,A sentence, the calibration of accelerometer is completed.

Example:

$PERDCRI,A,3,7,724,-701,-25,2572,2572,2572,689,-717,-22,88,44,0,3*19

Page 25

eRideOPUS 6/ eRideOPUS 7 GV-86/ GV-87

Dead Reckoning User’s Guide

SE16-900-002-00

21

FURUNO ELECTRIC CO., LTD. All rights reserved.

6.4 Calibration of Gyro Sensor

[Operation]

Calibration function of gyro sensor is available by driving with a several times (8 to 12 times) of right or left turn

at GNSS or GNSS+DR status of open sky level. It is available to do mix calibration with Section 6.2 and 6.3.

Turn Left Turn Right

[Check]

When Field 17 is 5,7,13 or 15 at PERDCRI,G sentence, the calibration of gyro sensor is completed.

Example:

$PERDCRI,G,3,7,79,-8,-27,2601,2601,2601,79,-8,-27,88,44,0,7*1A

6.5 Aging and Temperature Fluctuations

Even after completion of calibration, the GNSS+DR receiver will continue to estimate bias and gain during

actual operation. This is to follow changes in characteristics due to aging and temperature fluctuations.

Page 26

eRideOPUS 6/ eRideOPUS 7 GV-86/ GV-87

Dead Reckoning User’s Guide

SE16-900-002-00

22

FURUNO ELECTRIC CO., LTD. All rights reserved.

7 Operating of DR Backup

The GNSS+DR receiver has two kinds of backup source, which are the backup RAM and the Flash ROM. The

backup data is stored into the backup RAM while a backup power is supplied to the GNSS+DR receiver. The

GNSS+DR receiver can also store the backup data into the Flash ROM by sending PERDAPI,STOP,DRPARK

command.

When the backup data is valid at the next operating, the GNSS+DR receiver outputs the position in DR only

mode based on the backup data until GNSS position fix. When the GNSS+DR receiver receives GNSS signals

and confirms the GNSS positioning result is correct, the position fix status changes to DR/GNSS mixed mode.

When changing the vehicle, installation angle and installation position of IMU sensor, the backup data should

be deleted by sending PERDAPI,START,SIMCOLD command. And then, calibrate the IMU sensor parameters

again.

8 Recommended NMEA Output Sentence at Customer Evaluation Stage

When evaluating the DR performance, it is recommended to collect PERDCRD, PERDCRI sentences and

Diag data. It is very useful for analyzing the log data at FURUNO.

The recommended operating is as follow:

1. Send STOP command ($PERDAPI,STOP,DRPARK*5D).

2. Send output command ($PERDAPI,CROUT,DI*09) for output valid of PERDCRD and PERDCRI

sentence.

3. Send Diag data output command ($PERDSYS,RECPLAY,ON*0B).

4. Send START command ($PERDAPI,START*37).

Notes:

When outputting the Diag data, it is necessary to change the baud rate to 460800 bps by the following

command.

$PERDCFG,UART1,460800*68

In case of using 460800 bps, taka care about UART communication error rate and do not use this baud rate

except Diag data collection.

Page 27

eRideOPUS 6/ eRideOPUS 7 GV-86/ GV-87

Dead Reckoning User’s Guide

SE16-900-002-00

23

FURUNO ELECTRIC CO., LTD. All rights reserved.

9 Important Notice

9.1 Important Notice for IMU Sensor

Please design and implement based on the data sheet of IMU sensor. In addition, please verify the products to

achieve the target performance.

9.2 Characteristics of IMU Sensor

The GNSS+DR receiver is designed to provide accurate performance by estimating errors of bias and gain

described in the data sheet of IMU sensor. The performance may be degraded by influence of some

characteristics not described in the data sheet of IMU sensor.

9.3 Layout Design against Influence of IMU Sensor by External Environment Factor

Since the IMU sensor is a very sensitivity device against the following three external environment factors, keep

the layout design of IMU sensor based on the below guideline.

(1) Temperature factor

External temperature has a negative impact on the angular velocity and the acceleration of IMU sensor. In

order to avoid this influence, consider the following guideline of design.

a) Implement the IMU sensor apart from heat sources.

b) Protect influences of dynamic temperature change by surrounding air.

(2) Mechanical factor

The vibration and impulse against IMU sensor has a negative impact on the angular velocity and the

acceleration of IMU sensor. Below are examples to avoid this influence.

a) Implement the IMU sensor nearby the holding part of the board.

b) Clip the board by shock-absorbing material with labor.

c) Fix the unit or board, which IMU sensor is implemented, by screws.

(3) Other factor

Because of the gyro sensor and the accelerometer are MEMS devices, these devices have a resonant

frequency for operating MEMS mechanically and electric frequency characteristics internally. In case the

MEMS device has an external mechanical or electrical impact which is close to the frequency characteristics of

MEMS device, there is a risk of significant degradation regarding the output characteristics of sensor.

Therefore, user should design the circuit of surrounding area of sensor for preventing influences of external

mechanical vibration or electrical signal characteristics such as system clock signal.

9.4 Calibrating Operation

Good GNSS signal reception environment provides suitable calibration of IMU sensor. Therefore, install the

antenna on the place which good GNSS signals can be received. Also, take care that there is enough antenna

gain and no degrade of reception signal by noise on actual operation.

For calibrating the vehicle speed pulse, it needs to drive faster than 20km/h under good GNSS signal reception

environment. When an actual operation is traveling at a low-speed (ex. the bus drives in an urban area.), it

needs much time for calibration or the calibration may not be finished. Therefore, it is recommended to start

the actual operation after the calibration.

Page 28

eRideOPUS 6/ eRideOPUS 7 GV-86/ GV-87

Dead Reckoning User’s Guide

SE16-900-002-00

24

FURUNO ELECTRIC CO., LTD. All rights reserved.

9.5 Receiver Start Operation

The GNSS+DR receiver backs up the last updated position, the direction and the DR parameters. At the next

power on, the GNSS+DR receiver starts the positioning in DR only mode by using the backup data. After that,

when the direction calculated by DR is coincident with the GNSS direction, the position mode changes to

DR/GNSS mixed mode. The GNSS+DR receiver outputs the positioning result by DR only until the position

mode changes to the DR/GNSS mixed mode.

Page 29

eRideOPUS 6/ eRideOPUS 7 GV-86/ GV-87

Dead Reckoning User’s Guide

SE16-900-002-00

25

FURUNO ELECTRIC CO., LTD. All rights reserved.

10 FAQ

Q1. How do we check calibration completion status?

A1. As a first step, please check “PERDCRD,R” sentence as DR valid. When Field 3 of this sentence is

indicated as “1”, DR mode is valid. The example of the sentence is as below.

Example:$PERDCRD,R,1,2,-2.28,-12.12,0.16,-1.3,-0.5,260.5,3,17*17

Check this value is indicated as “1”

As the next step, please check the following sentence status as calibration completion with calibration

driving.

Calibration completion status of vehicle speed pulse:

Field 3 (odomtrConf) of PERDCRI,O is 7 or 15

Calibration completion status of accelerometer :

Field 17 (learnmode) of PERDCRI,A is 3

Calibration completion status of accelerometer :

Field 17 (learnmode) of PERDCRI,G is 5, 7, 13 or 15

Q2. The sensors do not become valid.

A2. Please check if the gyro sensor and the accelerometer are installed in accordance with the direction

explained in the chapter 5. In case vehicle speed pulse is used, please confirm the vehicle speed pulse

satisfies the electrical specifications and the count of vehicle speed pulse.

Q3. Is it possible to make DR positioning with gyro sensor only?

A3. No, it is not. It is required to use vehicle speed pulse together with gyro sensor.

Q4. Is the reverse signal required when using vehicle speed pulse?

A4. Yes.

Q5. How do we check the elevation pitch angle based on the sensor information?

A5. Refer Field 9 (pitch) of PERDCRD,R sentence.

Q6. Does altitude data reflect on elevation pitch angle based on sensor information?

A6. No. altitude data with GNS sentence does not reflect on elevation pitch angle.

Q7. In case we lost vehicle speed pulse with combination of gyro sensor, accelerometer and vehicle speed

pulse, what kind of behavior we observe.

A7. In case of non-vehicle speed pulse at first time, position fix status change to DR status by using

information of accelerometer as velocity source. In case of non-vehicle speed pulse on the way, user

observes irregular ground tracking performance for a while until calibration reset. When user observes

Field 11 (counts Status) of PERDCRD,R is 0, accelerometer is available as velocity source.

Q8. Do you have reference circuit regarding IMU sensor interface?

A8. Please refer chapter 4.

Page 30

eRideOPUS 6/ eRideOPUS 7 GV-86/ GV-87

Dead Reckoning User’s Guide

SE16-900-002-00

26

FURUNO ELECTRIC CO., LTD. All rights reserved.

Q9. Is it possible to use other than vehicles?

A9. No. The DR receiver is designed for car navigation systems and telematics terminals.

Q10. Not completed calibration of Gyro.

A10. Please check whether there are more than the 50% of the number of satellites in use with signal level of

over 40dBHz signal level.

Loading...

Loading...