Page 1

__________________________________________________________

Note: This document is to be used in conjunction with the applicable Installation, Operation, and

Maintenance Manual. Content subject to change without notice.

TABLE OF CONTENTS

Lead/Lag Outdoor Reset Configuration Using Communication Port 2 (second display port)

Stand Alone Boilers Controlled by a Third Party Control

Gateways

Setup for the Sola 7999D display of Com 2 for BMS Communication

Protocol Gateway Setup Guide

BACnet UDP IP / MSTP / Metasys N2 Module: General and Connection Overview

Lonworks Module: General and Connection Overview (Bacnet is the only option for Pulse

boilers)

Module Dipswitch Overview

Module Service Pin (Lonworks Module Only)

Downloading New Configuration Files

Connection Help

Setting the Static IP Address

Temporarily Disabling the Wireless Connection

Connection Troubleshooting

Node Address Setup

Baud Rate Settings

Modbus to Bacnet Pre-Loaded Gateway Points

Lead/Lag Outdoor Reset Configuration Using Communication Port 2 (second

display port)

If the boilers are set up to be lead/lag with outdoor reset, all the communication connections on the

J3 plug of the Sola control will be used. The third party control can be wired to the Sola display on

communication port 2. If requested at the time of the boiler order, the communication port will be

activated at the factory. Only the baud rate may have to be changed in the field. When multiple

boilers are configured for a system for lead/lag outdoor reset, only the master boiler needs to have

_____________________________________________________________________________________

Questions? Call (315) 298-5121 or visit us online at www.fulton.com

©The Fulton Companies 2013

Supplement SOLA-IOM-2013-0220

Page 2

__________________________________________________________

the third party connection. The lag boiler(s) points that can be viewed through the master are

limited, so please review the Modbus to Bacnet Pre-Loaded Gateway Points that would be in the

master boilers gateway to see if they are sufficient for your application. Please refer to electrical

diagram in manual, which shows wiring connection to the display's communication port 2.

Return to Table of Contents

Stand Alone Boilers Controlled by a Third Party Control

If the boilers are not set up to be lead/lag outdoor reset, a third party control can land the boilers’

connection to J3, MB1 on the Sola control. If this is known at the time the boiler order is entered,

the control will be set up for this type of control. Please refer to electrical diagram in manual for J3,

MB1 connections. The communication wires can be daisy chained to each boiler.

Return to Table of Contents

Gateways

Fulton offers (as an option) a Modbus to Bacnet gateway. The gateway will come pre-programmed

and wired in one, or if desired, all of the boilers. If the boilers are daisy chained together through J3,

MB1, one gateway can be used on the master boiler which will be wired to communication port 2 of

the master display. Please refer to Setup for the Sola 7999D display of Com 2 for BMS

Communication to verify setup or initial setup of Com 2 port.

and set-up instructions.

Note: Although there are many points that are available through Modbus, not all of them should be

considered to be continuously written to, all writes should be on a change only. There are specific

write addresses that will fill an internal Sola control EEPROM that should not be continuously written

to. Also all the information out of the control is in Celsius; this may have to be converted to

Fahrenheit if desired. Firing rate also requires a conversion.

Return to Table of Contents

Setup for the Sola 7999D display of Com 2 for BMS Communication

The following information will help set-up for communication when using a Sola control with a

Protonode Gateway (Modbus to Bacnet).

_____________________________________________________________________________________

Questions? Call (315) 298-5121 or visit us online at www.fulton.com

©The Fulton Companies 2013

Supplement SOLA-IOM-2013-0220

Page 3

__________________________________________________________

Note: If a Proto node Gateway is being used, it was fully programmed at the Fulton Factory and

should not require any changes on the Sola side. The customer connection side of the gateway may

require dip switch changes for baud rate and the required address. See the end of these instructions

for information on customer gateway setup.

1. From the Home Screen press Setup

2. Then Press Display setup

3. Then press tab Com 2

- Check the Enable box

- Choose baud rate if known or if a Proto Node Gateway is being used it should be 19,200

- Press the save button

4. Then press the Gateway tab

- Check Enable Modbus gateway

- Press Gateway on COM2 Port

- Press Save

5. Press the upper right Arrow to back out

6. Press Control Setup

7. Press Change Address

8. Password "sola" is required

- Change the address to the required address

o If Protonode is used, Com 1 will be preset to address 2 on all boilers.

Note: The address in Yellow will say Com 1, Com 1 is an actual pass through of the

communication when a BMS is communicating directly to Com 2 through Modbus or a

Gateway. Any communication will "piggy back" on all the standard communication from

the display to the Sola base. Changing this address will not affect the communication

between the Display and the Sola.

9. Back out to the Home Screen and press the Sola

- Press Configure

- Press System Identification and Access

o When you change the above Com address the Sola will change the MB1 and

MB2 address. If boilers are being daisy-chained together through MB1 the

address will need to be changed back to what it was. For example: If the BMS is

communicating with is the Master boiler, MB1 should be 1, the next boiler MB1

would be 2 and so on up to 8 boilers.

Return to Table of Contents

_____________________________________________________________________________________

Questions? Call (315) 298-5121 or visit us online at www.fulton.com

©The Fulton Companies 2013

Supplement SOLA-IOM-2013-0220

Page 4

__________________________________________________________

_____________________________________________________________________________________

Questions? Call (315) 298-5121 or visit us online at www.fulton.com

©The Fulton Companies 2013

Supplement SOLA-IOM-2013-0220

Page 5

__________________________________________________________

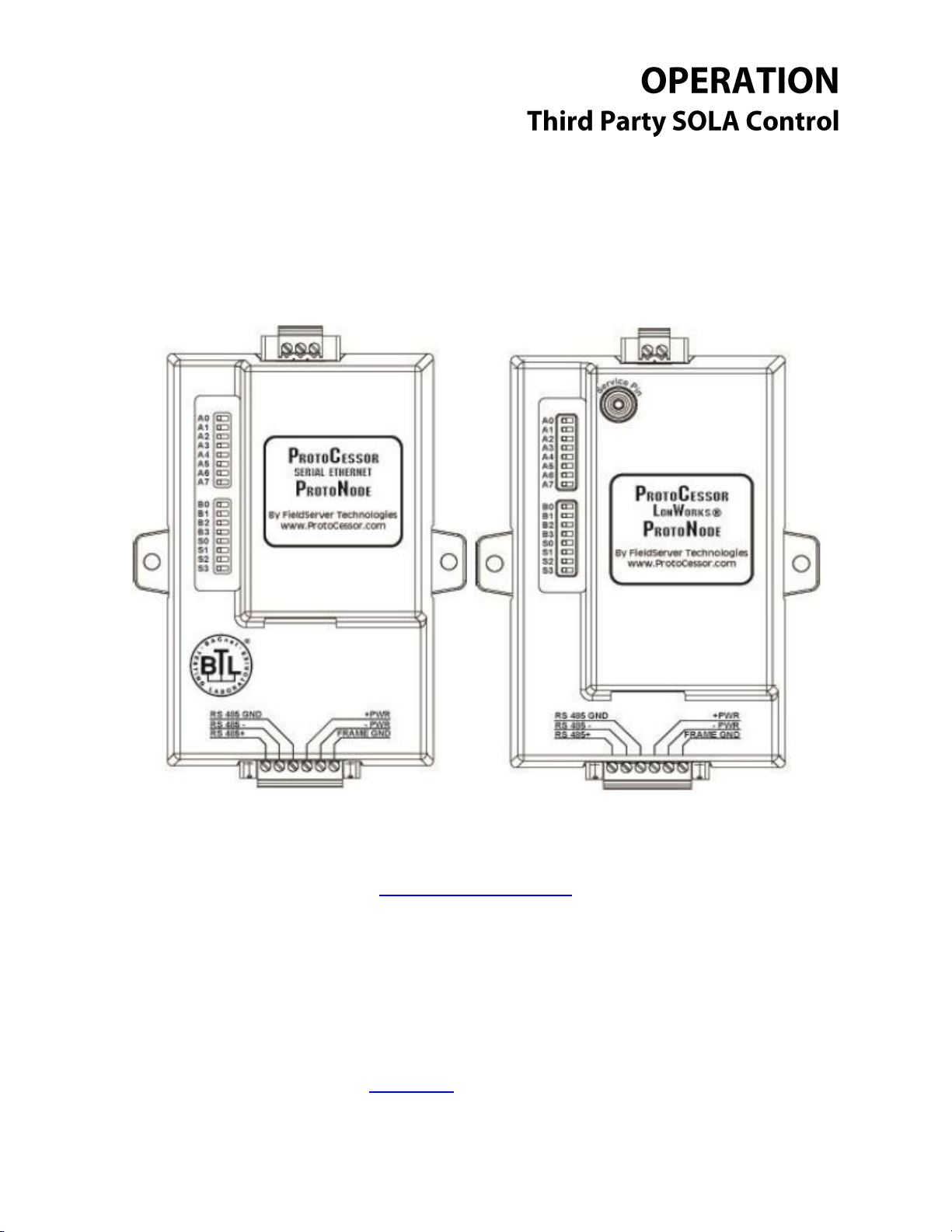

Protocol Gateway Setup Guide

Return to Table of Contents

_____________________________________________________________________________________

Questions? Call (315) 298-5121 or visit us online at www.fulton.com

©The Fulton Companies 2013

Supplement SOLA-IOM-2013-0220

Page 6

__________________________________________________________

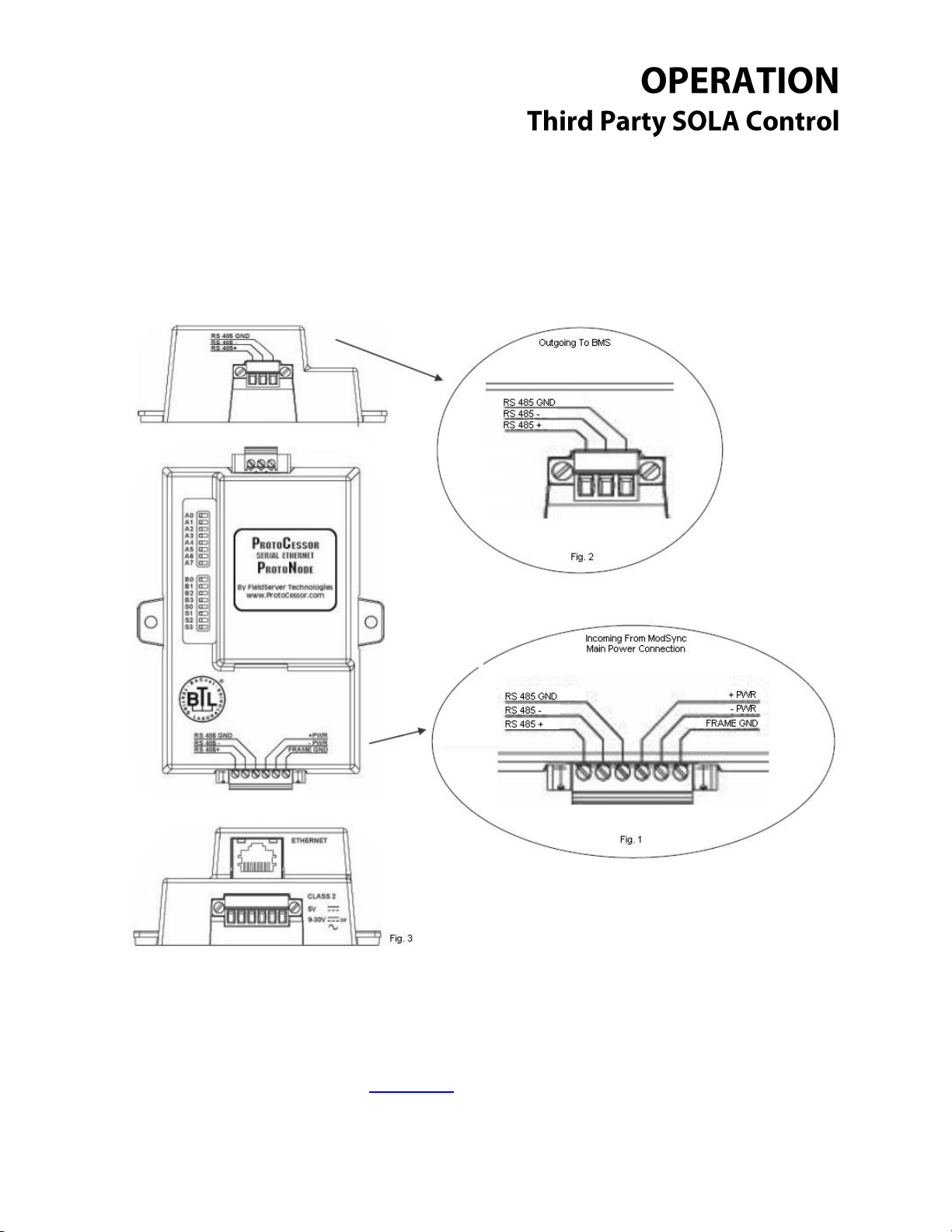

BACnet UDP IP / MSTP / Metasys N2 Module: General and Connection

Overview

The BACnet ProtoNode provides three access ports (one server side, one client side and a service

port/UDP IP port). The six pin connector (Fig. 1) provides RS 485 connection to the ModSync as well

as provides the 24vdc power to the ProtoNode itself. The three pin connector (Fig. 2) provides RS 485

_____________________________________________________________________________________

Questions? Call (315) 298-5121 or visit us online at www.fulton.com

©The Fulton Companies 2013

Supplement SOLA-IOM-2013-0220

Page 7

__________________________________________________________

connection to the Building Management System. The last available port is the Ethernet port (Fig. 3),

which is used for service situations such as downloading configuration files.

The bank of dipswitches (see top view), are used to configure the ProtoNode in the field. Available

configurations are node address, baud rate and configurations profile. See Node Address Setup

And Baud Rate Settings for more details.

Return to Table of Contents

_____________________________________________________________________________________

Questions? Call (315) 298-5121 or visit us online at www.fulton.com

©The Fulton Companies 2013

Supplement SOLA-IOM-2013-0220

Page 8

__________________________________________________________

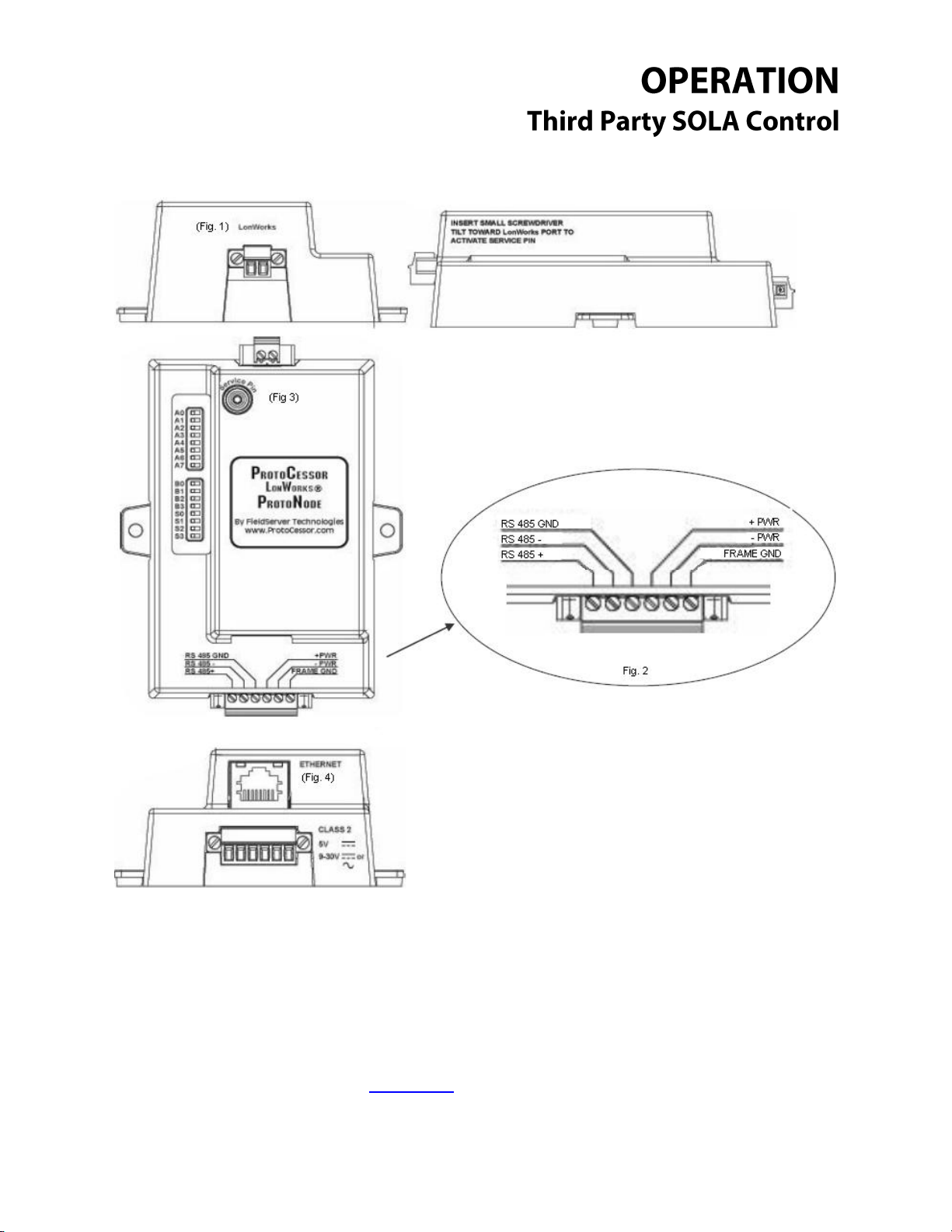

Lonworks Module: General and Connection Overview

The Lonworks ProtoNode provides three access ports (one server side, one client side and a service

port). The six pin connector (Fig. 2) provides RS 485 connection to the ModSync as well as provides the

24vdc power to the ProtoNode itself. The two pin connector (Fig. 1) provides Lonworks connection to

the Building Management System. The last available port is the Ethernet port (Fig. 4), which is used for

service situations such as downloading configuration files.

_____________________________________________________________________________________

Questions? Call (315) 298-5121 or visit us online at www.fulton.com

©The Fulton Companies 2013

Supplement SOLA-IOM-2013-0220

Page 9

__________________________________________________________

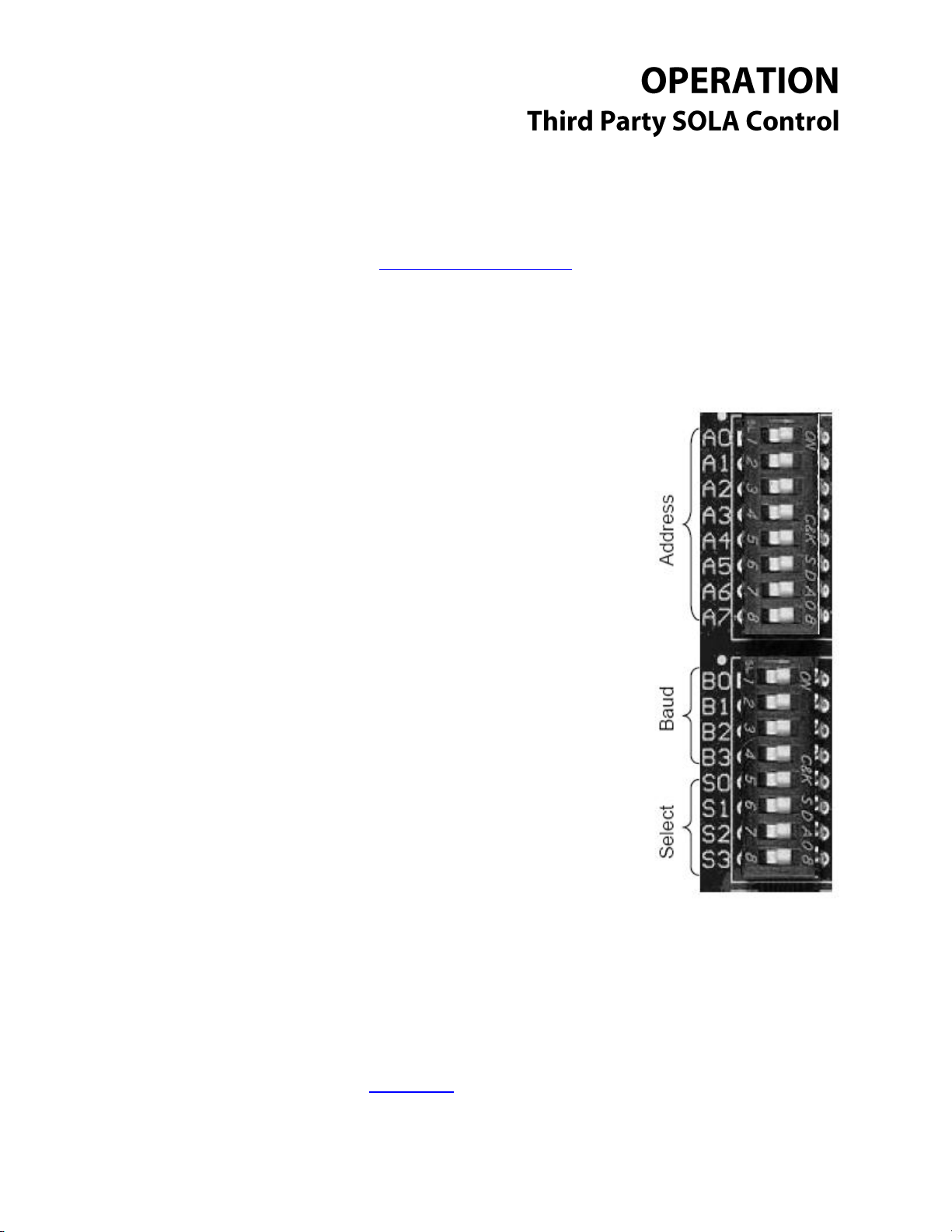

Dipswitches A0 – A7 are used to set the node

address of the ProtoNode device. See Addendum 1

for full address list and settings.

Dipswitches B0 – B3 are used to set the ProtoNode

baud rate. See Addendum 2 for full list and settings.

Dipswitches S0 – S3 are used to set which profile the

ProtoNode uses when it loads the config files it

requires to function. See Addendum 3 for full profile

list and settings.

The bank of dipswitches (see top view), are used to configure the ProtoNode in the field. Available

configurations are node address, baud rate and configurations profile.

Return to Table of Contents

Module Dipswitch Overview: All Modules

_____________________________________________________________________________________

Questions? Call (315) 298-5121 or visit us online at www.fulton.com

©The Fulton Companies 2013

Supplement SOLA-IOM-2013-0220

Page 10

__________________________________________________________

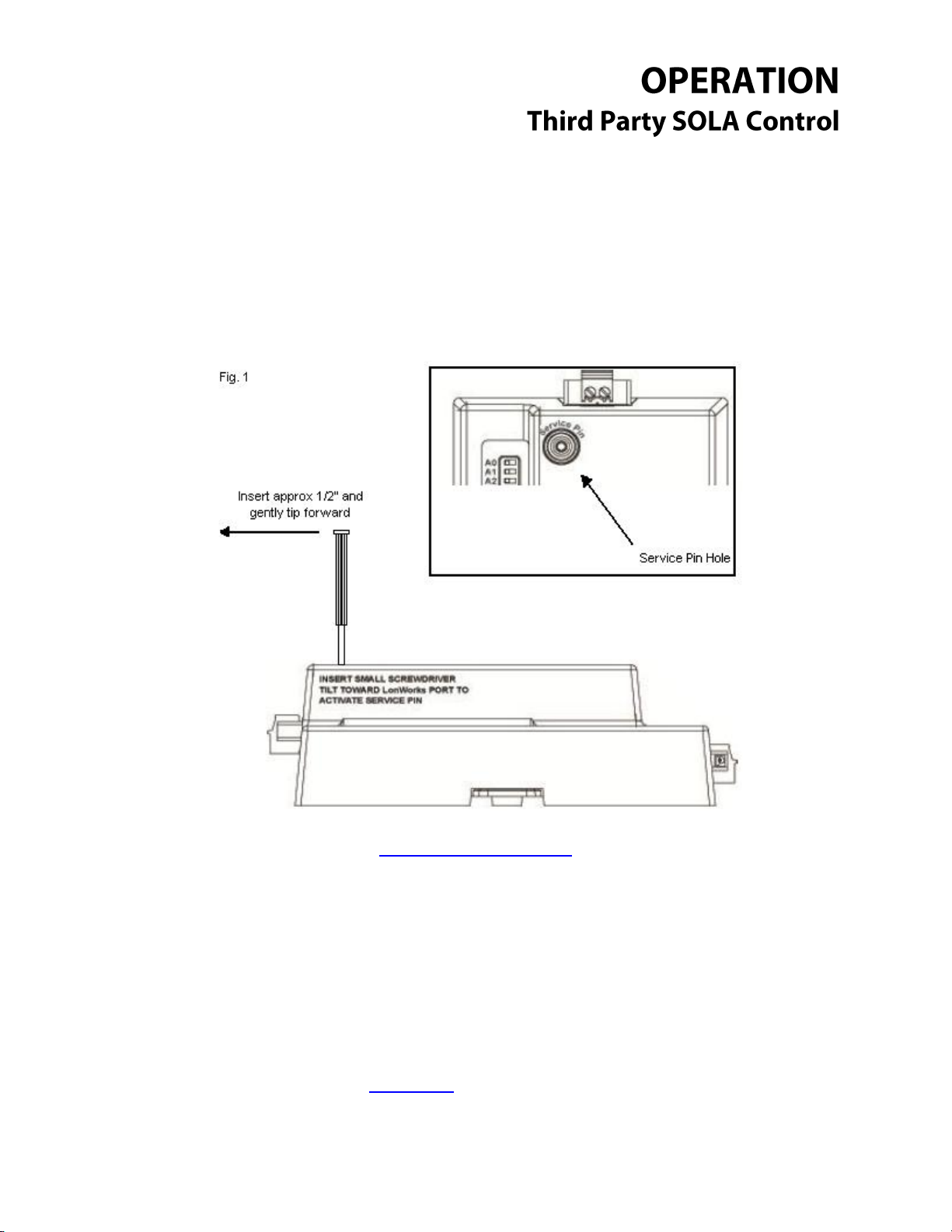

Module Service Pin: Lonworks Module Only

The service pin is used during the commissioning process on a Lonworks network. In order to use the

service pin on this module you will need a small screwdriver, small enough to fit into the service pin

hole. Put the screwdriver into the service pin hole and tilt gently forward towards the Lonworks 2 pin

connector. See Fig. 1.

Return to Table of Contents

_____________________________________________________________________________________

Questions? Call (315) 298-5121 or visit us online at www.fulton.com

©The Fulton Companies 2013

Supplement SOLA-IOM-2013-0220

Page 11

__________________________________________________________

Downloading New Configuration Files: All Modules

The ProtoNode modules come with all the standard configuration files already installed for use.

However, under certain circumstances configuration files may have to be updated in the field. Use

the following steps to update the configuration files for a module already in service in the field. The

steps are the same for all modules with the slight exception to the Lonworks module; see the

exceptions note at the end.

1. Once you have gone through all the proper channels to get the point mapping completed, you

will receive a ZIP file that contains several files. While the total amount of files in the ZIP will vary,

two files will remain constant:

a. Ruinet.exe

b. Profile.bat

These files can be run from any folder on your computer, so long as all files in the ZIP stay

together in the same folder. In most cases it is advantageous to extract the files to a single

folder on your desktop or another easy to locate place for easy access.

* Example folder containing the new configuration files.

_____________________________________________________________________________________

Questions? Call (315) 298-5121 or visit us online at www.fulton.com

©The Fulton Companies 2013

Supplement SOLA-IOM-2013-0220

Page 12

__________________________________________________________

2. Connect your computer to the ProtoNode via the Ethernet port, using a standard Cat5 cable.

Please keep the following points in mind when trying to connect to the ProtoNode in this

manner:

a. The ProtoNode must be powered and running during this process.

b. If your computer has both Ethernet and Wireless connections available you will have to

disable the wireless connection temporarily during this process. See Temporarily

Disabling the Wireless Connection for a basic tutorial on disabling your wireless connection.

c. You must set your Ethernet connection to a static IP address and subnet. See Setting the

Static IP Address for a basic tutorial on static IP or if you have trouble connecting.

Static IP Address: 192.168.1.101

Static Subnet Address: 255.255.255.0

* Please note: if you already have a static IP address loaded in your computer write

that information down so you can restore that IP when you are complete. *

d. Plug the Cat5 cable into the Ethernet port on the ProtoNode and then into your

computer’s Ethernet port. Connection will take some time to complete. If you’re using

Windows, you should receive a notification at the task bar when it’s complete.

3. Once you have successfully made a connection, double left click on the Profile.bat file and wait

for it to complete. A window that resembles this one will pop up; when it disappears the

download is nearly complete.

* Example window showing Profile.bat running.

4. After the window disappears, the ProtoNode will automatically restart itself to complete the

downloading process. This process can take several minutes, so now would be a good time to

_____________________________________________________________________________________

Questions? Call (315) 298-5121 or visit us online at www.fulton.com

©The Fulton Companies 2013

Supplement SOLA-IOM-2013-0220

Page 13

__________________________________________________________

grab a cup of coffee. Once the ProtoNode has restarted, the new configuration files will be

ready to use.

5. Disconnect your Ethernet cable, and don’t forget to re-enable your wireless if you shut it down.

If you already had a static IP address loaded on your computer, restore it now or you might have

trouble connecting to the internet later.

6. Lonworks Exception: After new configuration files have been loaded into the Lonworks module,

it will most likely have to be re-commissioned into the Lonworks Network.

Return to Table of Contents

Connection Help

Setting the Static IP Address

For most windows users following these steps will allow you to temporarily set the static IP address

for connection to the ProtoNode module:

1. Click the Start Menu and go to Control Panel.

2. Double Left Click on the Network Connections Icon.

3. Right Click on the Local Area Connection Icon and select Properties.

4. Highlight Internet Protocol (TCP/IP) and press the Properties Button.

5. Select “Use the following IP Address” option.

6. In the IP address box input 192.168.1.101

7. In the Subnet mask input 255.255.255.0

8. Leave the Default gateway blank.

9. Press the OK Button on the two properties windows.

To remove the static IP Address when finished, follow steps 1 through 4. At step 5 Select “Obtain IP

Address Automatically” instead.

To restore a previous static IP Address follow all steps 1 through 9, substituting your static IP

information at steps 6 and 7.

Return to Table of Contents

_____________________________________________________________________________________

Questions? Call (315) 298-5121 or visit us online at www.fulton.com

©The Fulton Companies 2013

Supplement SOLA-IOM-2013-0220

Page 14

__________________________________________________________

Temporarily Disabling the Wireless Connection

For most windows users, following these steps will allow you to temporarily disable your wireless

connection while connecting to the ProtoNode module:

1. Click the Start Menu and go to Control Panel.

2. Double Left Click on the Network Connections Icon.

3. Right Click on the Wireless Network Connections Icon and Select Disable.

To re-enable the wireless connection follow these steps:

1. Click the Start Menu and go to Control Panel.

2. Double Left Click on the Network Connections Icon.

3. Right Click on the Wireless Network Connections Icon and Select Enable.

4. This should automatically reconnect you with the first available wireless signal. In some cases it

may require step 5 to complete the task.

5. If the wireless still has not come back online, Right Click on the Wireless Network Icon and Select

Repair. Please make sure that there is a wireless signal available.

Please keep in mind that these steps were written with Windows users in mind, and that because each

computer system is different you might have to change some of these steps. When in doubt ask your

local network administrator or IT person for assistance.

Return to Table of Contents

Connection Troubleshooting

After following the connection guide, if you’re still having trouble connecting to the ProtoNode try the

following trouble shooting steps:

- Is the ProtoNode powered up? If not, check the wiring. Also check to ensure there is a solid

24vdc to the unit.

- Make sure all the connectors are secured on the ProtoNode including the 6 pin connector

and either the 3 pin or 2 pin connector, depending on whether you’re using the BACnet or

Lonworks module.

- Check the voltage between the customer connection terminal blocks (usually P2+/- in the

ModSync) and the outgoing voltage at the ProtoNode (either the 3 pin connector or 2 pin

depending on whether you’re using the BACnet or Lonworks module). While this voltage

may vary some, make sure that they are in the same average range. (For example, if you

_____________________________________________________________________________________

Questions? Call (315) 298-5121 or visit us online at www.fulton.com

©The Fulton Companies 2013

Supplement SOLA-IOM-2013-0220

Page 15

__________________________________________________________

A7

A6

A5

A4

A3

A2

A1

A0

Address

Off

Off

Off

Off

Off

Off

Off

Off

0

Off

Off

Off

Off

Off

Off

Off

On

1

Off

Off

Off

Off

Off

Off

On

Off

2

Off

Off

Off

Off

Off

Off

On

On

3

Off

Off

Off

Off

Off

On

Off

Off

4

Off

Off

Off

Off

Off

On

Off

On

5

Off

Off

Off

Off

Off

On

On

Off

6

Off

Off

Off

Off

Off

On

On

On

7

Off

Off

Off

Off

On

Off

Off

Off

8

Off

Off

Off

Off

On

Off

Off

On

9

Off

Off

Off

Off

On

Off

On

Off

10

Off

Off

Off

Off

On

Off

On

On

11

Off

Off

Off

Off

On

On

Off

Off

12

Off

Off

Off

Off

On

On

Off

On

13

have 1.4v at the 3 pin connector you should have something close to that at the ModSync

terminal blocks.)

- Verify that your computer has connected to the ProtoNode. By Right Clicking on the Local

Area Connection and Selecting “Status” you can see whether or not your computer has

connected to the ProtoNode. If not double check your settings (step 2 on Page 8.)

- Verify all dipswitch settings on the ProtoNode module. Use Addendums 1, 2 and 3 as a

guide. *If any dipswitches are changed you will have to restart the ProtoNode before they

take effect.

- If you have connected, but all information to the BMS has a value of zero, check the BMS

settings on the BMS screen at the ModSync. Standard settings are Node 2, Baud 19200,

RS485. *If you change any of those settings at the ModSync make sure you press the

“ModSync Reset” button to allow those changes to take place. You will know the ModSync is

resetting when the screen goes blank for a few seconds.

Return to Table of Contents

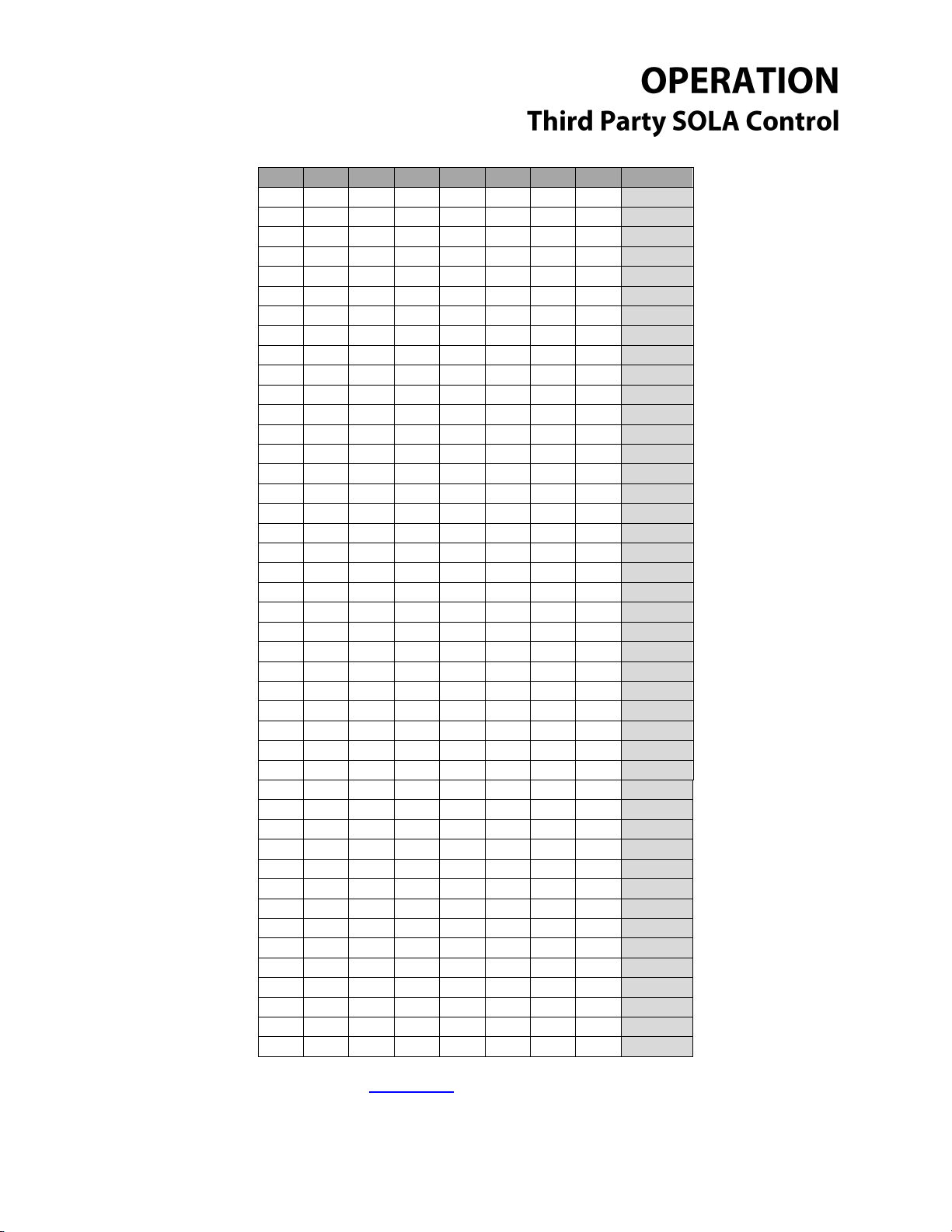

Node Address Setup

Please note that any changes made to ANY of the dipswitches require the ProtoNode to be restarted.

For this reason it is suggested that the all the dipswitches be configured BEFORE powering up the

ProtoNode. Restarting the ProtoNode on a Lonworks network may require the ProtoNode to be recommissioned into the network.

_____________________________________________________________________________________

Questions? Call (315) 298-5121 or visit us online at www.fulton.com

©The Fulton Companies 2013

Supplement SOLA-IOM-2013-0220

Page 16

__________________________________________________________

A7

A6

A5

A4

A3

A2

A1

A0

Address

Off

Off

Off

Off

On

On

On

Off

14

Off

Off

Off

Off

On

On

On

On

15

Off

Off

Off

On

Off

Off

Off

Off

16

Off

Off

Off

On

Off

Off

Off

On

17

Off

Off

Off

On

Off

Off

On

Off

18

Off

Off

Off

On

Off

Off

On

On

19

Off

Off

Off

On

Off

On

Off

Off

20

Off

Off

Off

On

Off

On

Off

On

21

Off

Off

Off

On

Off

On

On

Off

22

Off

Off

Off

On

Off

On

On

On

23

Off

Off

Off

On

On

Off

Off

Off

24

Off

Off

Off

On

On

Off

Off

On

25

Off

Off

Off

On

On

Off

On

Off

26

Off

Off

Off

On

On

Off

On

On

27

Off

Off

Off

On

On

On

Off

Off

28

Off

Off

Off

On

On

On

Off

On

29

Off

Off

Off

On

On

On

On

Off

30

Off

Off

Off

On

On

On

On

On

31

Off

Off

On

Off

Off

Off

Off

Off

32

Off

Off

On

Off

Off

Off

Off

On

33

Off

Off

On

Off

Off

Off

On

Off

34

Off

Off

On

Off

Off

Off

On

On

35

Off

Off

On

Off

Off

On

Off

Off

36

Off

Off

On

Off

Off

On

Off

On

37

Off

Off

On

Off

Off

On

On

Off

38

Off

Off

On

Off

Off

On

On

On

39

Off

Off

On

Off

On

Off

Off

Off

40

Off

Off

On

Off

On

Off

Off

On

41

Off

Off

On

Off

On

Off

On

Off

42

Off

Off

On

Off

On

Off

On

On

43

Off

Off

On

Off

On

On

Off

Off

44

Off

Off

On

Off

On

On

Off

On

45

Off

Off

On

Off

On

On

On

Off

46

Off

Off

On

Off

On

On

On

On

47

Off

Off

On

On

Off

Off

Off

Off

48

Off

Off

On

On

Off

Off

Off

On

49

Off

Off

On

On

Off

Off

On

Off

50

Off

Off

On

On

Off

Off

On

On

51

Off

Off

On

On

Off

On

Off

Off

52

Off

Off

On

On

Off

On

Off

On

53

Off

Off

On

On

Off

On

On

Off

54

Off

Off

On

On

Off

On

On

On

55

Off

Off

On

On

On

Off

Off

Off

56

Off

Off

On

On

On

Off

Off

On

57

_____________________________________________________________________________________

Questions? Call (315) 298-5121 or visit us online at www.fulton.com

©The Fulton Companies 2013

Supplement SOLA-IOM-2013-0220

Page 17

__________________________________________________________

A7

A6

A5

A4

A3

A2

A1

A0

Address

Off

Off

On

On

On

Off

On

Off

58

Off

Off

On

On

On

Off

On

On

59

Off

Off

On

On

On

On

Off

Off

60

Off

Off

On

On

On

On

Off

On

61

Off

Off

On

On

On

On

On

Off

62

Off

Off

On

On

On

On

On

On

63

Off

On

Off

Off

Off

Off

Off

Off

64

Off

On

Off

Off

Off

Off

Off

On

65

Off

On

Off

Off

Off

Off

On

Off

66

Off

On

Off

Off

Off

Off

On

On

67

Off

On

Off

Off

Off

On

Off

Off

68

Off

On

Off

Off

Off

On

Off

On

69

Off

On

Off

Off

Off

On

On

Off

70

Off

On

Off

Off

Off

On

On

On

71

Off

On

Off

Off

On

Off

Off

Off

72

Off

On

Off

Off

On

Off

Off

On

73

Off

On

Off

Off

On

Off

On

Off

74

Off

On

Off

Off

On

Off

On

On

75

Off

On

Off

Off

On

On

Off

Off

76

Off

On

Off

Off

On

On

Off

On

77

Off

On

Off

Off

On

On

On

Off

78

Off

On

Off

Off

On

On

On

On

79

Off

On

Off

On

Off

Off

Off

Off

80

Off

On

Off

On

Off

Off

Off

On

81

Off

On

Off

On

Off

Off

On

Off

82

Off

On

Off

On

Off

Off

On

On

83

Off

On

Off

On

Off

On

Off

Off

84

Off

On

Off

On

Off

On

Off

On

85

Off

On

Off

On

Off

On

On

Off

86

Off

On

Off

On

Off

On

On

On

87

Off

On

Off

On

On

Off

Off

Off

88

Off

On

Off

On

On

Off

Off

On

89

Off

On

Off

On

On

Off

On

Off

90

Off

On

Off

On

On

Off

On

On

91

Off

On

Off

On

On

On

Off

Off

92

Off

On

Off

On

On

On

Off

On

93

Off

On

Off

On

On

On

On

Off

94

Off

On

Off

On

On

On

On

On

95

Off

On

On

Off

Off

Off

Off

Off

96

Off

On

On

Off

Off

Off

Off

On

97

Off

On

On

Off

Off

Off

On

Off

98

Off

On

On

Off

Off

Off

On

On

99

Off

On

On

Off

Off

On

Off

Off

100

Off

On

On

Off

Off

On

Off

On

101

_____________________________________________________________________________________

Questions? Call (315) 298-5121 or visit us online at www.fulton.com

©The Fulton Companies 2013

Supplement SOLA-IOM-2013-0220

Page 18

__________________________________________________________

A7

A6

A5

A4

A3

A2

A1

A0

Address

Off

On

On

Off

Off

On

On

Off

102

Off

On

On

Off

Off

On

On

On

103

Off

On

On

Off

On

Off

Off

Off

104

Off

On

On

Off

On

Off

Off

On

105

Off

On

On

Off

On

Off

On

Off

106

Off

On

On

Off

On

Off

On

On

107

Off

On

On

Off

On

On

Off

Off

108

Off

On

On

Off

On

On

Off

On

109

Off

On

On

Off

On

On

On

Off

110

Off

On

On

Off

On

On

On

On

111

Off

On

On

On

Off

Off

Off

Off

112

Off

On

On

On

Off

Off

Off

On

113

Off

On

On

On

Off

Off

On

Off

114

Off

On

On

On

Off

Off

On

On

115

Off

On

On

On

Off

On

Off

Off

116

Off

On

On

On

Off

On

Off

On

117

Off

On

On

On

Off

On

On

Off

118

Off

On

On

On

Off

On

On

On

119

Off

On

On

On

On

Off

Off

Off

120

Off

On

On

On

On

Off

Off

On

121

Off

On

On

On

On

Off

On

Off

122

Off

On

On

On

On

Off

On

On

123

Off

On

On

On

On

On

Off

Off

124

Off

On

On

On

On

On

Off

On

125

Off

On

On

On

On

On

On

Off

126

Off

On

On

On

On

On

On

On

127

On

Off

Off

Off

Off

Off

Off

Off

128

On

Off

Off

Off

Off

Off

Off

On

129

On

Off

Off

Off

Off

Off

On

Off

130

On

Off

Off

Off

Off

Off

On

On

131

On

Off

Off

Off

Off

On

Off

Off

132

On

Off

Off

Off

Off

On

Off

On

133

On

Off

Off

Off

Off

On

On

Off

134

On

Off

Off

Off

Off

On

On

On

135

On

Off

Off

Off

On

Off

Off

Off

136

On

Off

Off

Off

On

Off

Off

On

137

On

Off

Off

Off

On

Off

On

Off

138

On

Off

Off

Off

On

Off

On

On

139

On

Off

Off

Off

On

On

Off

Off

140

On

Off

Off

Off

On

On

Off

On

141

On

Off

Off

Off

On

On

On

Off

142

On

Off

Off

Off

On

On

On

On

143

On

Off

Off

On

Off

Off

Off

Off

144

On

Off

Off

On

Off

Off

Off

On

145

_____________________________________________________________________________________

Questions? Call (315) 298-5121 or visit us online at www.fulton.com

©The Fulton Companies 2013

Supplement SOLA-IOM-2013-0220

Page 19

__________________________________________________________

A7

A6

A5

A4

A3

A2

A1

A0

Address

On

Off

Off

On

Off

Off

On

Off

146

On

Off

Off

On

Off

Off

On

On

147

On

Off

Off

On

Off

On

Off

Off

148

On

Off

Off

On

Off

On

Off

On

149

On

Off

Off

On

Off

On

On

Off

150

On

Off

Off

On

Off

On

On

On

151

On

Off

Off

On

On

Off

Off

Off

152

On

Off

Off

On

On

Off

Off

On

153

On

Off

Off

On

On

Off

On

Off

154

On

Off

Off

On

On

Off

On

On

155

On

Off

Off

On

On

On

Off

Off

156

On

Off

Off

On

On

On

Off

On

157

On

Off

Off

On

On

On

On

Off

158

On

Off

Off

On

On

On

On

On

159

On

Off

On

Off

Off

Off

Off

Off

160

On

Off

On

Off

Off

Off

Off

On

161

On

Off

On

Off

Off

Off

On

Off

162

On

Off

On

Off

Off

Off

On

On

163

On

Off

On

Off

Off

On

Off

Off

164

On

Off

On

Off

Off

On

Off

On

165

On

Off

On

Off

Off

On

On

Off

166

On

Off

On

Off

Off

On

On

On

167

On

Off

On

Off

On

Off

Off

Off

168

On

Off

On

Off

On

Off

Off

On

169

On

Off

On

Off

On

Off

On

Off

170

On

Off

On

Off

On

Off

On

On

171

On

Off

On

Off

On

On

Off

Off

172

On

Off

On

Off

On

On

Off

On

173

On

Off

On

Off

On

On

On

Off

174

On

Off

On

Off

On

On

On

On

175

On

Off

On

On

Off

Off

Off

Off

176

On

Off

On

On

Off

Off

Off

On

177

On

Off

On

On

Off

Off

On

Off

178

On

Off

On

On

Off

Off

On

On

179

On

Off

On

On

Off

On

Off

Off

180

On

Off

On

On

Off

On

Off

On

181

On

Off

On

On

Off

On

On

Off

182

On

Off

On

On

Off

On

On

On

183

On

Off

On

On

On

Off

Off

Off

184

On

Off

On

On

On

Off

Off

On

185

On

Off

On

On

On

Off

On

Off

186

On

Off

On

On

On

Off

On

On

187

On

Off

On

On

On

On

Off

Off

188

On

Off

On

On

On

On

Off

On

189

_____________________________________________________________________________________

Questions? Call (315) 298-5121 or visit us online at www.fulton.com

©The Fulton Companies 2013

Supplement SOLA-IOM-2013-0220

Page 20

__________________________________________________________

A7

A6

A5

A4

A3

A2

A1

A0

Address

On

Off

On

On

On

On

On

Off

190

On

Off

On

On

On

On

On

On

191

On

On

Off

Off

Off

Off

Off

Off

192

On

On

Off

Off

Off

Off

Off

On

193

On

On

Off

Off

Off

Off

On

Off

194

On

On

Off

Off

Off

Off

On

On

195

On

On

Off

Off

Off

On

Off

Off

196

On

On

Off

Off

Off

On

Off

On

197

On

On

Off

Off

Off

On

On

Off

198

On

On

Off

Off

Off

On

On

On

199

On

On

Off

Off

On

Off

Off

Off

200

On

On

Off

Off

On

Off

Off

On

201

On

On

Off

Off

On

Off

On

Off

202

On

On

Off

Off

On

Off

On

On

203

On

On

Off

Off

On

On

Off

Off

204

On

On

Off

Off

On

On

Off

On

205

On

On

Off

Off

On

On

On

Off

206

On

On

Off

Off

On

On

On

On

207

On

On

Off

On

Off

Off

Off

Off

208

On

On

Off

On

Off

Off

Off

On

209

On

On

Off

On

Off

Off

On

Off

210

On

On

Off

On

Off

Off

On

On

211

On

On

Off

On

Off

On

Off

Off

212

On

On

Off

On

Off

On

Off

On

213

On

On

Off

On

Off

On

On

Off

214

On

On

Off

On

Off

On

On

On

215

On

On

Off

On

On

Off

Off

Off

216

On

On

Off

On

On

Off

Off

On

217

On

On

Off

On

On

Off

On

Off

218

On

On

Off

On

On

Off

On

On

219

On

On

Off

On

On

On

Off

Off

220

On

On

Off

On

On

On

Off

On

221

On

On

Off

On

On

On

On

Off

222

On

On

Off

On

On

On

On

On

223

On

On

On

Off

Off

Off

Off

Off

224

On

On

On

Off

Off

Off

Off

On

225

On

On

On

Off

Off

Off

On

Off

226

On

On

On

Off

Off

Off

On

On

227

On

On

On

Off

Off

On

Off

Off

228

On

On

On

Off

Off

On

Off

On

229

On

On

On

Off

Off

On

On

Off

230

On

On

On

Off

Off

On

On

On

231

On

On

On

Off

On

Off

Off

Off

232

On

On

On

Off

On

Off

Off

On

233

_____________________________________________________________________________________

Questions? Call (315) 298-5121 or visit us online at www.fulton.com

©The Fulton Companies 2013

Supplement SOLA-IOM-2013-0220

Page 21

__________________________________________________________

A7

A6

A5

A4

A3

A2

A1

A0

Address

On

On

On

Off

On

Off

On

Off

234

On

On

On

Off

On

Off

On

On

235

On

On

On

Off

On

On

Off

Off

236

On

On

On

Off

On

On

Off

On

237

On

On

On

Off

On

On

On

Off

238

On

On

On

Off

On

On

On

On

239

On

On

On

On

Off

Off

Off

Off

240

On

On

On

On

Off

Off

Off

On

241

On

On

On

On

Off

Off

On

Off

242

On

On

On

On

Off

Off

On

On

243

On

On

On

On

Off

On

Off

Off

244

On

On

On

On

Off

On

Off

On

245

On

On

On

On

Off

On

On

Off

246

On

On

On

On

Off

On

On

On

247

On

On

On

On

On

Off

Off

Off

248

On

On

On

On

On

Off

Off

On

249

On

On

On

On

On

Off

On

Off

250

On

On

On

On

On

Off

On

On

251

On

On

On

On

On

On

Off

Off

252

On

On

On

On

On

On

Off

On

253

On

On

On

On

On

On

On

Off

254

On

On

On

On

On

On

On

On

255

Return to Table of Contents

Baud Rate Settings

Please note that any changes made to ANY of the dipswitches require the ProtoNode to be

restarted. For this reason it is suggested that the all the dipswitches be configured BEFORE powering

up the ProtoNode. Restarting the ProtoNode on a Lonworks network may require the ProtoNode to

be re-commissioned into the network.

_____________________________________________________________________________________

Questions? Call (315) 298-5121 or visit us online at www.fulton.com

©The Fulton Companies 2013

Supplement SOLA-IOM-2013-0220

Page 22

__________________________________________________________

2

Auto baud rates are only supported on BACnet MSTP

Return to Table of Contents

Modbus to Bacnet Pre-Loaded Gateway Points

Sola LEAD/LAG Bacnet points as of 12/5/12 V1.00

[Read points] (* points exclusive to lead lag)

1. *Lead lag master status [LLMstrStat] 0160

a. 0=Unknown

_____________________________________________________________________________________

Questions? Call (315) 298-5121 or visit us online at www.fulton.com

©The Fulton Companies 2013

Supplement SOLA-IOM-2013-0220

Page 23

__________________________________________________________

b. 1=Disabled

c. 2=Normal

d. 3=Suspended

2. *Lead lag master heat demand [LLMstrHeatD] 0163

a. 0=off

b. 1=on

3. *Master firing rate [MstrFR] 0802

a. 0-100%

4. *Slave burner demand [LLSlvDmd] 0164

a. 0=off

b. 1=on

5. *Slave 1 state [LLSlv1Stat] 0770

a. 0=unknown

b. 1=available

c. 2=add stage

d. 3=suspend stage

e. 4=firing

f. 5=on leave

g. 6=Disabled

h. 7=recovering

_____________________________________________________________________________________

Questions? Call (315) 298-5121 or visit us online at www.fulton.com

©The Fulton Companies 2013

Supplement SOLA-IOM-2013-0220

Page 24

__________________________________________________________

6. *Slave 1 stage order [LLSlv1_Ordr] 0771

a. Relative order that slave 1 has been added to fire

b. 0=Not been staged

7. *Slave 1 firing rate [LLSlv1FR] 0772

a. Current firing rate (0-100%) of slave 1

8. *Slave 2 state [LLSlv2Stat] 0774

a. 0=unknown

b. 1=available

c. 2=add stage

d. 3=suspend stage

e. 4=firing

f. 5=on leave

g. 6=Disabled

h. 7=recovering

9. *Slave 2 stage order [LLSlv2Ordr] 0775

a. Relative order that slave 2 has been added to fire

b. 0=Not been staged

10. *Slave 2 firing rate [LLSlv2FR] 0776

a. Current firing rate (0-100%) of slave 2

_____________________________________________________________________________________

Questions? Call (315) 298-5121 or visit us online at www.fulton.com

©The Fulton Companies 2013

Supplement SOLA-IOM-2013-0220

Page 25

__________________________________________________________

11. *Slave 3 state [LLSlv3Stat] 0778

a. 0=unknown

b. 1=available

c. 2=add stage

d. 3=suspend stage

e. 4=firing

f. 5=on leave

g. 6=Disabled

h. 7=recovering

12. *Slave 3 stage order [LLSlv3Ordr] 0779

a. Relative order that slave 3 has been added to fire

b. 0=Not been staged

13. *Slave 3 firing rate [LLSlv3FR] 0780

a. Current firing rate (0-100%) of slave 3

14. *Slave 4 state [LLSlv4Stat] 0782

a. 0=unknown

b. 1=available

c. 2=add stage

d. 3=suspend stage

e. 4=firing

_____________________________________________________________________________________

Questions? Call (315) 298-5121 or visit us online at www.fulton.com

©The Fulton Companies 2013

Supplement SOLA-IOM-2013-0220

Page 26

__________________________________________________________

f. 5=on leave

g. 6=Disabled

h. 7=recovering

15. *Slave 4 stage order [LLSlv4Ordr] 0783

a. Relative order that slave 4 has been added to fire

b. 0=Not been staged

16. *Slave 4 firing rate [LLSlv4FR] 0784

a. Current firing rate (0-100%) of slave 4

17. *Slave 5 state [LLSlv5Stat] 0786

a. 0=unknown

b. 1=available

c. 2=add stage

d. 3=suspend stage

e. 4=firing

f. 5=on leave

g. 6=Disabled

h. 7=recovering

18. *Slave 5 stage order [LLSlv5Ordr] 0787

a. Relative order that slave 5 has been added to fire

b. 0=Not been staged

_____________________________________________________________________________________

Questions? Call (315) 298-5121 or visit us online at www.fulton.com

©The Fulton Companies 2013

Supplement SOLA-IOM-2013-0220

Page 27

__________________________________________________________

19. *Slave 5 firing rate [LLSlv5FR] 0788

a. Current firing rate (0-100%) of slave 5

20. *Slave 6 state [LLSlv6Stat] 0790

a. 0=unknown

b. 1=available

c. 2=add stage

d. 3=suspend stage

e. 4=firing

f. 5=on leave

g. 6=Disabled

h. 7=recovering

21. *Slave 6 stage order [LLSlv6Ordr] 0791

a. Relative order that slave 6 has been added to fire

b. 0=Not been staged

22. *Slave 6 firing rate [LLSlv6FR] 0792

a. Current firing rate (0-100%) of slave 6

23. *Slave 7 state [LLSlv7Stat] 0794

a. 0=unknown

b. 1=available

_____________________________________________________________________________________

Questions? Call (315) 298-5121 or visit us online at www.fulton.com

©The Fulton Companies 2013

Supplement SOLA-IOM-2013-0220

Page 28

__________________________________________________________

c. 2=add stage

d. 3=suspend stage

e. 4=firing

f. 5=on leave

g. 6=Disabled

h. 7=recovering

24. *Slave 7 stage order [LLSlv7Ordr] 0795

a. Relative order that slave 7 has been added to fire

b. 0=Not been staged

25. *Slave 7 firing rate [LL_SLAVE_7_FR] 0796

a. Current firing rate (0-100%) of slave 7

26. Slave 8 state [LLSlv8Stat] 0798

a. 0=unknown

b. 1=available

c. 2=add stage

d. 3=suspend stage

e. 4=firing

f. 5=on leave

g. 6=Disabled

h. 7=recovering

_____________________________________________________________________________________

Questions? Call (315) 298-5121 or visit us online at www.fulton.com

©The Fulton Companies 2013

Supplement SOLA-IOM-2013-0220

Page 29

__________________________________________________________

27. *Slave 8 stage order [LLSlv8Ordr] 0799

a. Relative order that slave 8 has been added to fire

b. 0=Not been staged

28. *Slave 8 firing rate [LLSlv1FR] 0800

a. Current firing rate (0-100%) of slave 8

29. *Active lead lag setpoint [LLSetpntF] 0018

a. -40˚C - 130˚C (will display as -40˚F - 266˚F)

30. *Active lead lag operating point [LLOprtingF] 0027

a. -40˚C - 130˚C (will display as -40˚F - 266˚F)

31. Inlet Sensor State [InletState] 0049

a. 0=none

b. 1=Normal

c. 2=open

d. 3=shorted

e. 4=outside high range

f. 5=outside low range

g. 6=not reliable

32. Inlet (S1) sensor [InletTempF] 0011

a. -40˚C - 130˚C (will display as -40˚F - 266˚F)

_____________________________________________________________________________________

Questions? Call (315) 298-5121 or visit us online at www.fulton.com

©The Fulton Companies 2013

Supplement SOLA-IOM-2013-0220

Page 30

__________________________________________________________

33. Outlet limit sensor [OutletState1] 0048

a. 0=none

b. 1=Normal

c. 2=Open

d. 3=shorted

e. 4=Outside high range

f. 5=Outside low range

g. 6=Not reliable

34. Outlet Operation sensor [OutletState2] 0046

a. 0=none

b. 1=Normal

c. 2=Open

d. 3=shorted

e. 4=Outside high range

f. 5=Outside low range

g. 6=Not reliable

35. Outlet (S3S4) or Outlet limit (S3) sensor [OutletTempF] 0007

a. -40˚C - 130˚C (will display as -40˚F - 266˚F)

36. S5 Sensor State [HeaderState] 0052

a. 0=none

_____________________________________________________________________________________

Questions? Call (315) 298-5121 or visit us online at www.fulton.com

©The Fulton Companies 2013

Supplement SOLA-IOM-2013-0220

Page 31

__________________________________________________________

b. 1=normal

c. 2=open

d. 3=shorted

e. 4=outside high range

f. 5=outside low range

g. 6=not reliable

37. S5 sensor [HeadTemp] 0013

a. -40˚C - 130˚C (will display as -40˚F - 266˚F)

38. Firing rate [FireRate] 0008

a. 0-100%

39. Outdoor sensor state [OutdrState] 0171

a. 0=none

b. 1=Normal

c. 2=Open

d. 3=shorted

e. 4=Outside high range

f. 5=Outside low range

g. 6=Not reliable

40. Outdoor Temp [OutDoorF] 0170

a. -40˚C - 130˚C (will display as -40˚F - 266˚F)

_____________________________________________________________________________________

Questions? Call (315) 298-5121 or visit us online at www.fulton.com

©The Fulton Companies 2013

Supplement SOLA-IOM-2013-0220

Page 32

__________________________________________________________

41. Boiler pump status [BlrPmpStats] 0108

a. Refer to Sola manual

42. Annunciator I/O [Annunciator] 0003

a. 15-8=reserved

b. 7=annunciator 8

c. 6=annunciator 7

d. 5=annunciator 6

e. 4=annunciator 5

f. 3=annunciator 4

g. 2=annunciator 3

h. 1=annunciator 2

i. 0=annunciator 1

i. Example 194 (decimal) = 11000010 binary

1. Annunciators 2,7&8 are proved.

43. Alarm reason [AlrmReason] 0035

a. 0=none

b. 1=Lockout (see manual)

c. 2= alert (se manual)

d. 3=other

44. Lockout code [LckOutCode] 0034

_____________________________________________________________________________________

Questions? Call (315) 298-5121 or visit us online at www.fulton.com

©The Fulton Companies 2013

Supplement SOLA-IOM-2013-0220

Page 33

__________________________________________________________

a. 0=no lockout

b. 1-4096 (see manual)

45. Flame signal [Flame_Sig] 0010

a. 0.01V or 0.01A precision (0.00-50.00v)

46. Active CH setpoint [CHSetpoint] 0016

a. -40˚C - 130˚C (will display as -40˚F - 266˚F)

47. Burner control status [BrnrCntrlSt] 0032

a. 0=disabled

b. 1=locked out

c. 2=reserved

d. 3=reserved

e. 4=anti-short cycle

f. 5=unconfigured safety data

g. 6-33=reserved

h. 34=standby hold

i. 35=standby delay

j. 36-47=reserved

k. 48=normal standby

l. 49=preparing

m. 50=ignition

n. 51=firing

_____________________________________________________________________________________

Questions? Call (315) 298-5121 or visit us online at www.fulton.com

©The Fulton Companies 2013

Supplement SOLA-IOM-2013-0220

Page 34

__________________________________________________________

o. 52=postpurge

p. 53-65535=reserved

48. CH status [CHStat] 0064

a. 0=unknown

b. 1=disabled

c. 2=normal

d. 3=suspended

49. CH setpoint source [CHStpntSrc] 0065

a. 0=unknown

b. 1=normal setpoint

c. 2=TOD setpoint

d. 3=Outdoor reset

e. 4=Remote control

f. 7=Outdoor reset time of day

g. 9=Outdoor boost

50. Demand Source [DemandSrc] 0006

a. 0=unknown

b. 1=no source demand

c. 2=CH

d. 3=DHW

e. 4=Lead Lag Slave

_____________________________________________________________________________________

Questions? Call (315) 298-5121 or visit us online at www.fulton.com

©The Fulton Companies 2013

Supplement SOLA-IOM-2013-0220

Page 35

__________________________________________________________

f. 5=Lead Lag Master

g. 6=CH frost protection

h. 7=DHW frost protection

i. 8=No demand due to burner switch

j. 9=DHW Storage

k. 10=Reserved

l. 11=warm weather shutdown

51. CH heat demand [CHHeatDmnd] 0066

a. 0=off

b. 1=on

52. CH burner demand [CHBrnrDmnd] 0067

a. 0=off

b. 1=on

[write points]

53. CH setpoint [CHSetpointF] 0211

a. -40˚C - 130˚C (input -40˚F - 266˚F)

54. *Lead lag setpoint [LLSetpntF] 0546

a. -40˚C - 130˚C (input -40˚F - 266˚F)

55. CH enable [CHENABLE] 0208

a. 0=disable central heat

_____________________________________________________________________________________

Questions? Call (315) 298-5121 or visit us online at www.fulton.com

©The Fulton Companies 2013

Supplement SOLA-IOM-2013-0220

Page 36

__________________________________________________________

b. 1=enable central heat

56. *Lead lag CH demand switch [LLDEMAND] 0556

a. 0=disable CH loop

b. 1=stat

c. 2=reserved

d. 3=EnviraCOM remote STAT

e. 4=Modbus STAT

f. 5=Reserved

g. 6=STAT terminal or EnvironCOM remote STAT

57. *Lead Lag outdoor reset enable [LLOutdrRst] 0548

a. 0=disable

b. 1=enable

58. Central Heat Outdoor Enable [CHOutdrRst] 0215

a. 0=disable

b. 1=enable

59. CH priority vs. Lead Lag [CHvsLL] 0582

a. 0=lead lag > central heat

b. 1=central heat > lead lag

Return to Table of Contents

_____________________________________________________________________________________

Questions? Call (315) 298-5121 or visit us online at www.fulton.com

©The Fulton Companies 2013

Supplement SOLA-IOM-2013-0220

Loading...

Loading...