Page 1

DTO_ERV002E_01

2013.04.26

DESIGN & TECHNICAL MANUAL

UTZ-BD025B

UTZ-BD035B

UTZ-BD050B

UTZ-BD080B

UTZ-BD100B

ENERGY RECOVERY VENTILATORS

Page 2

CONTENTS

1. SPECIFICATIONS

1-1. SPECIFICATIONS ........................................................................

01-01

2. DIMENTIONS

2-1. UTZ-BD025B ................................................................................

01-03

2-2. UTZ-BD035B ................................................................................

01-05

2-3. UTZ-BD050B ................................................................................

01-07

2-4. UTZ-BD080B ................................................................................

01-09

2-5. UTZ-BD100B .................................................................................

01-11

3. WIRING DIAGRAMS

3-1. UTZ-BD025B ................................................................................

01-13

3-2. UTZ-BD035B, UTZ-BD050B ........................................................

01-13

3-3. UTZ-BD080B, UTZ-BD100B ........................................................

01-14

3-4. INTERLOCKED CONNECTION TO AIR CONDITIONER ............

01-15

Page 3

4. DESIGN SECTION

4-1. ABOUT HEAT EXCHANGE UNIT ................................................

01-17

4-1-1. BASIC ENGIN .........................................................................................

01-17

4-1-2. INTERNAL STRUCTURE .......................................................................

01-18

4-1-3. HEAT EXCHANGE VENTILATION AND NORMAL VENTILATION .......

01-19

4-2. NEEDS FOR VENTILATION .........................................................

01-20

4-2-1. OBJECTIVES AND EFFECTS OF VENTILATION .................................

01-20

4-3. METHODS OF VENTILATION ......................................................

01-21

4-4. DESIGN PRECAUTIONS .............................................................

01-22

4-4-1. CAUTION ON SAFETY ...........................................................................

01-22

4-4-2. INSPECTION OPENING AND INSTALLATION MODELS .....................

01-23

4-4-3. USE ENVIRONMENTS ...........................................................................

01-24

4-4-4. HEAT EXCHANGE EFFICIENCY ...........................................................

01-25

4-4-5. DUST COLLECTION EFFICIENCY ........................................................

01-27

4-4-6. NOISE .....................................................................................................

01-28

4-4-7. NOISE CONTROL ...................................................................................

01-29

4-5. VENTILATION DESIGN ................................................................

01-31

4-5-1. QUANTITY, DYNAMIC PRESSURE / STATIC PRESSURE ....................

01-31

4-5-2.

HOW TO CALCULATE REQUIRED VENTILATION VOLUME .................

01-32

4-6. DUCT DESIGN ..............................................................................

01-33

4-6-1. CALCULATION OF PRESSURE LOSSES DUE TO VENTILATION

THROUGH DUCT ....................................................................................

01-33

Page 4

- (01-01) -

1. SPECIFICATIONS

1-1. SPECIFICATIONS

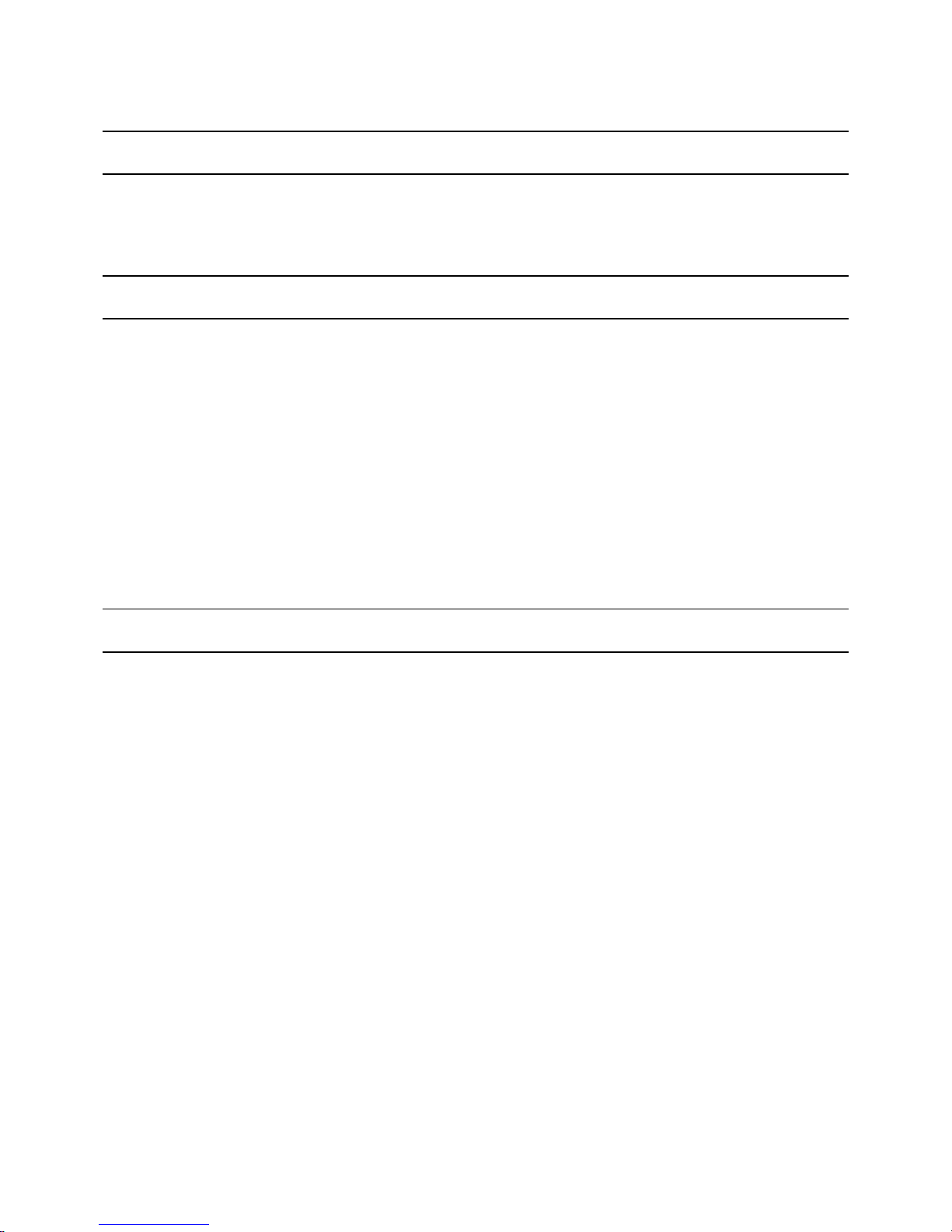

Model No.

Item

UTZ-BD025B

Power Source 220–240V~ 50Hz

Ventilation Mode Heat Exchange Ventilation Normal Ventilation

Notch (Extra high) High Low (Extra high) High Low

Input (W) 112-128 108-123 87-96 112-128 108-123 87-96

Air Volume (m3/h) 250 250 190 250 250 190

External Static Pressure (Pa) 105 95 45 105 95 45

Sound Pressure Level (dB) 30.0-31.5 29.5-30.5 23.5-26.5 30.0-31.5 29.5-30.5 23.5-26.5

Temperature Exchange

Efciency (%)

75 75 77 — — —

Dimensions (mm)

(H x W x D)

Net 270 x 882 x 599

Gross 349 x 1132 x 795

Weight (kg)

Net 29

Gross 35

Outlet Duct Diameter (mm) 150

Operation Range (°C) -10 to 40

Maximum Humidity (%) 85

Model No.

Item

UTZ-BD035B

Power Source 220–240V~ 50Hz

Ventilation Mode Heat Exchange Ventilation Normal Ventilation

Notch (Extra high) High Low (Extra high) High Low

Input (W) 182-190 178-185 168-175 182-190 178-185 168-175

Air Volume (m3/h) 350 350 240 350 350 240

External Static Pressure (Pa) 140 60 45 140 60 45

Sound Pressure Level (dB) 32.5-33.0 30.5-31.0 22.5-25.5 32.5-33.0 30.5-31.0 22.5-25.5

Temperature Exchange

Efciency (%)

75 75 78 — — —

Dimensions (mm)

(H x W x D)

Net 317 x 1050 x 804

Gross 396 x 1250 x 1000

Weight (kg)

Net 49

Gross 57

Outlet Duct Diameter (mm) 150

Operation Range (°C) -10 to 40

Maximum Humidity (%) 85

Model No.

Item

UTZ-BD050B

Power Source 220–240V~ 50Hz

Ventilation Mode Heat Exchange Ventilation Normal Ventilation

Notch (Extra high) High Low (Extra high) High Low

Input (W) 263-289 204-225 165-185 263-289 204-225 165-185

Air Volume (m3/h) 500 500 440 500 500 440

External Static Pressure (Pa) 120 60 35 120 60 35

Sound Pressure Level (dB) 36.5-37.5 34.5-35.5 31.0-32.5 36.5-37.5 34.5-35.5 31.0-32.5

Temperature Exchange

Efciency (%)

75 75 76 — — —

Dimensions (mm)

(H x W x D)

Net 317 x 1090 x 904

Gross 396 x 1290 x 1100

Weight (kg)

Net 57

Gross 66

Outlet Duct Diameter (mm) 200

Operation Range (°C) -10 to 40

Maximum Humidity (%) 85

Page 5

- (01-02) -

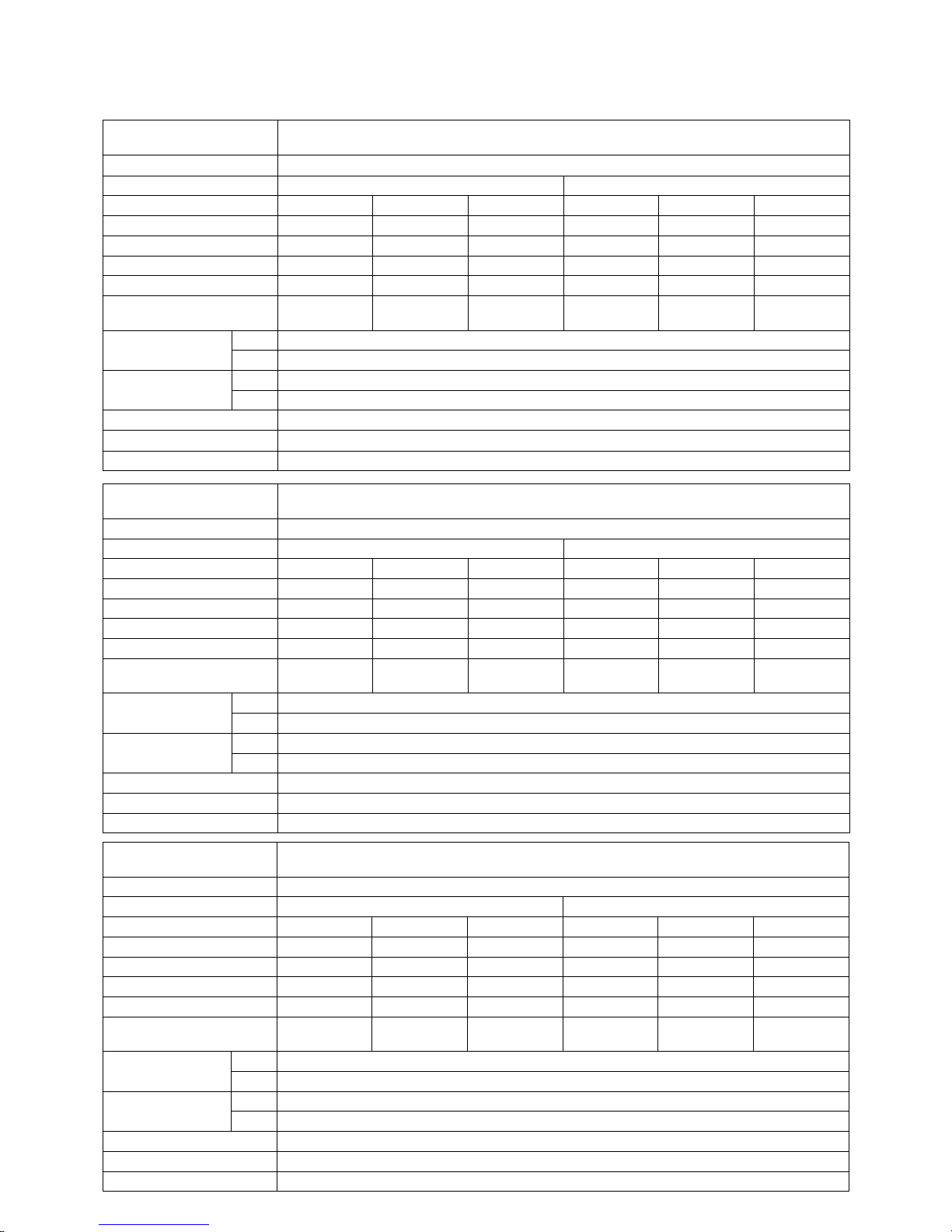

Model No.

Item

UTZ-BD080B

Power Source 220–240V~ 50Hz

Ventilation Mode Heat Exchange Ventilation Normal Ventilation

Notch (Extra high) High Low (Extra high) High Low

Input (W) 387-418 360-378 293-295 387-418 360-378 293-295

Air Volume (m3/h) 800 800 630 800 800 630

External Static Pressure (Pa) 140 110 55 140 110 55

Sound Pressure Level (dB) 37.0-37.5 36.5-37.0 33.5-34.5 37.0-37.5 36.5-37.0 33.5-34.5

Temperature Exchange

Efciency (%)

75 75 76 — — —

Dimensions (mm)

(H x W x D)

Net 388 x 1322 x 884

Gross 467 x 1552 x 1170

Weight (kg)

Net 71

Gross 82

Outlet Duct Diameter (mm) 250

Operation Range (°C) -10 to 40

Maximum Humidity (%) 85

Model No.

Item

UTZ-BD100B

Power Source 220–240V~ 50Hz

Ventilation Mode Heat Exchange Ventilation Normal Ventilation

Notch (Extra high) High Low (Extra high) High Low

Input (W) 437-464 416-432 301-311 437-464 416-432 301-311

Air Volume (m3/h) 1000 1000 700 1000 1000 700

External Static Pressure (Pa) 105 80 75 105 80 75

Sound Pressure Level (dB) 37.5-38.5 37.0-37.5 33.5-34.5 39.5-40.5 39.0-39.5 35.5-36.5

Temperature Exchange

Efciency (%)

75 75 76 — — —

Dimensions (mm)

(H x W x D)

Net 388 x 1322 x 1134

Gross 467 x 1552 x 1420

Weight (kg)

Net 83

Gross 98

Outlet Duct Diameter (mm) 250

Operation Range (°C) -10 to 40

Maximum Humidity (%) 85

(Note) This noise of the product is the value which was measured at the acoustic room.

Actually, in the established condition, that undergo inuence by the echoing of the room and so that become bigger

than the display numerical value.

Page 6

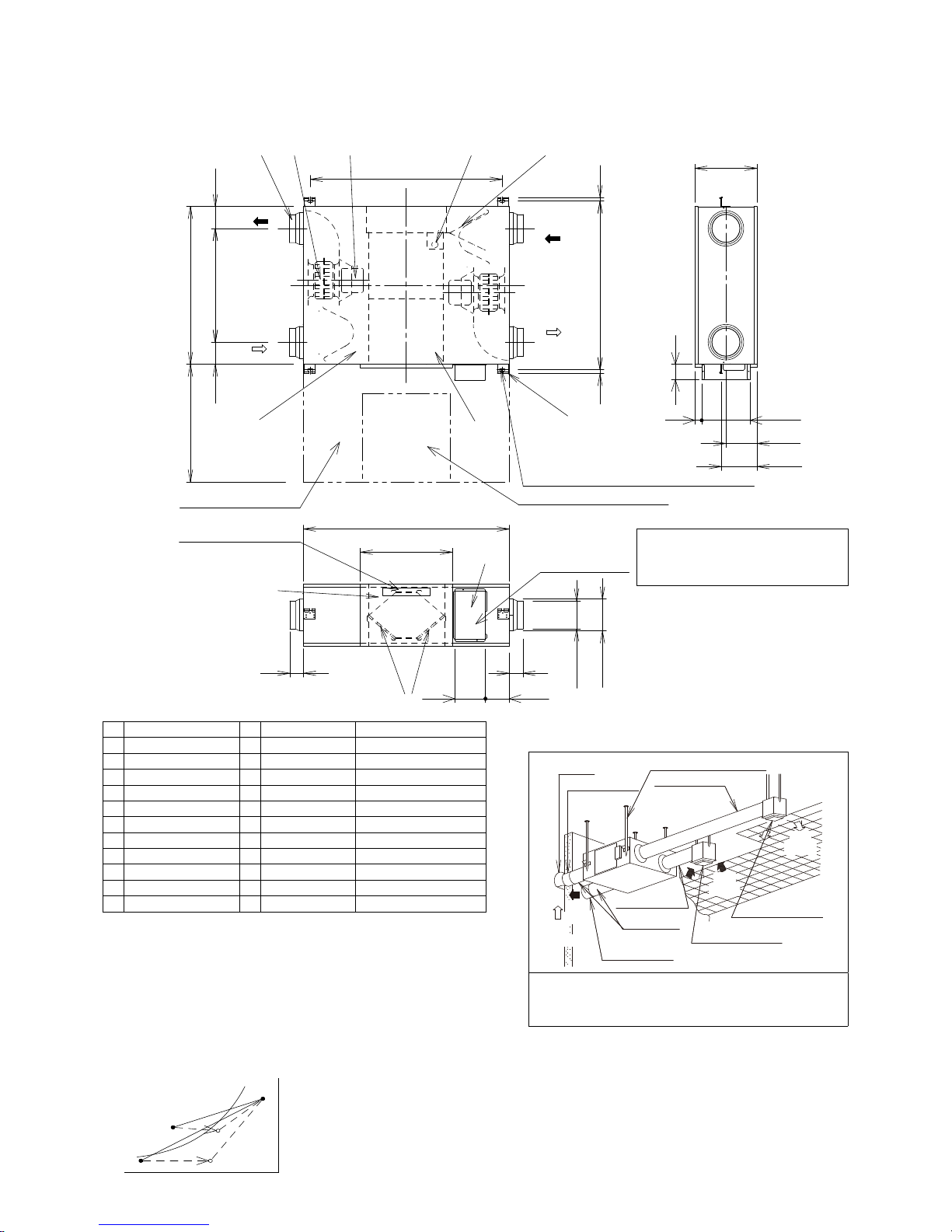

- (01-03) -

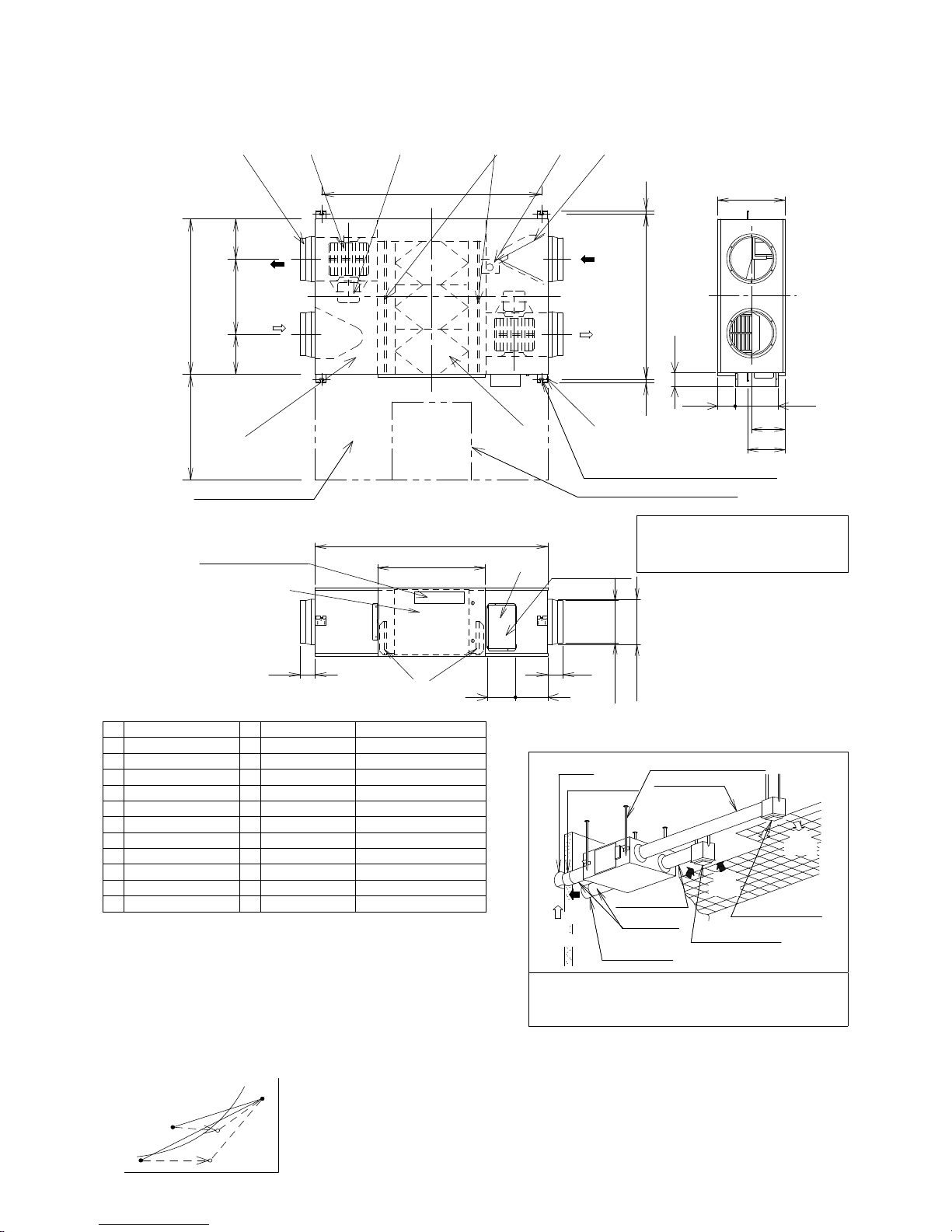

2. DIMENTIONS

2-1. UTZ-BD025B

NO.

Parts Name

Qty.

Material Remarks

1

Frame

1

Galvanized sheets

2

Adapter

4

ABS

3

Electrical Equipment Box

1

4

Inspection Cover

1

Galvanized sheets

5

Fan

2

ABS

6

Motor

2

7

Heat Exchange Element1Special paper + Resin

8

Filter

2

Nylon-Polyester Fiber Collection Efciency AFI 82%

9

Damper

1

10

Damper Motor

1

11

Ceiling Suspension Fixture4Galvanized sheets

BE CAREFUL OF DEWING AND

FROSTING

As shown in the Figure, suppose a high temp absorbing air condition

A and a low temp absorbing air condition B are plotted on the air line

gure, then a high temp air A is heat-exchanged by the unit and goes

out of the saturation curve as shown by Point C.

In this case, the unit will be dewed or frosted.

To aboid this, you are required to heat a low temp air B up to B’ so as

to get C’ below the saturation curve, before using the unit.

saturationcurve

Dry-bulb temperature(˚C)

Absolite humidity (kg/kg’)

C’

C

B

B’

A

REFERENCE SKETCH

Pipe Hood

Outside Intake Duct

Ceilling Suspension Bolts

Supply Air Duct

EA

(Exhaust

Air)

OA

(Outside intake Air)

RA

(Room Air)

SA

(Supply Air)

Inside Supply Opening

(Supply/Exhaust Air Grill)

Room Intake Opening

(Supply/Exhaust Air Grill)

Room Intake Duct

Heat Insulation Material

Exhaust Air Duct

The two outside ducts(the Outside Intake Duct and the

Exhaust Duct)must be insulated to prevent condensation.

(Material; Glass wool, Thickness; 25)

Duct size (Nominal Diameter): ø150

The above dimensions do not include the thickness of

the insulasion material on the unit body.

② ⑤ ⑥ ⑩ ⑨

①

⑦

⑪

599600

142 315 142

EA

OA

(Exhaust Air)

(Outside Air)

810

Maintenance Space

Inspection Opening □450

(For the inspection of the lters, heat exchange elements, fans, motors, and damper)

4-13×30 Oval hole · Suspension Fittings

1965519

RA

SA

(Room Air)

(Supply Air)

An inspection opening is necessary to

clean the heat exchange element and

lter once or twice a year.

270

247

159

135

12

80

④

⑧

③

882

414

95

95

Wiring Diagram

Earth Terminal

Ø219

Ø164

Ø144

67

157

Page 7

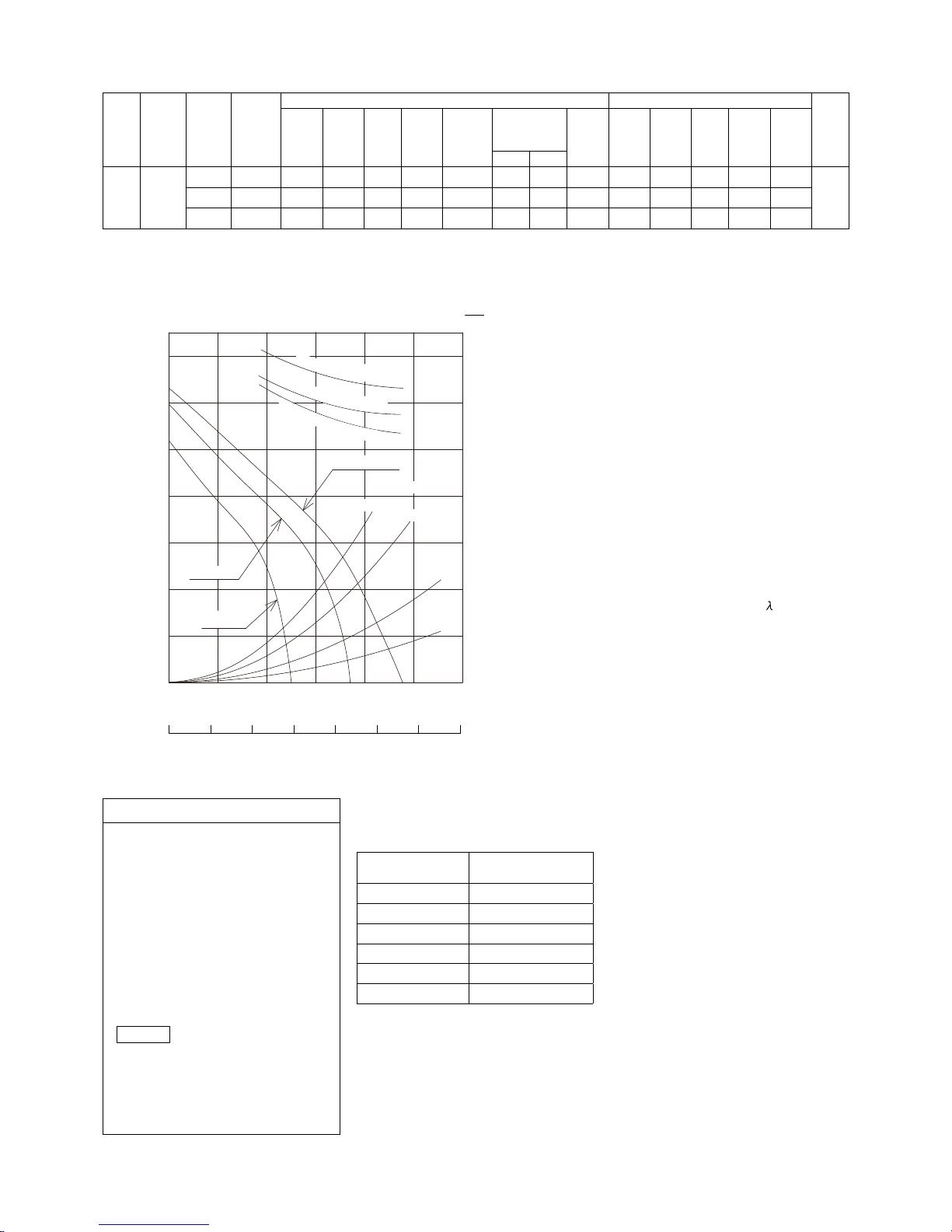

- (01-04) -

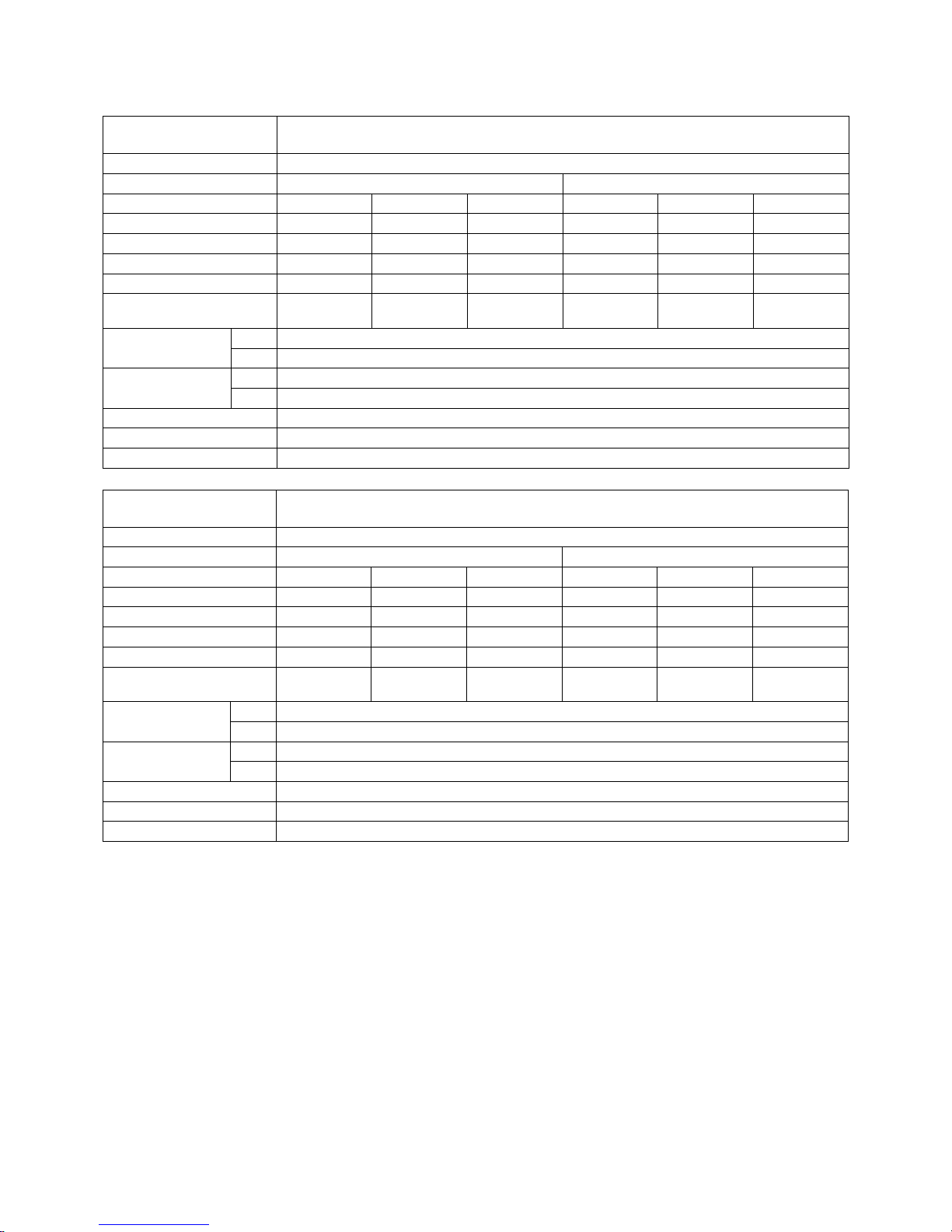

SPECIFICATIONS

Model

No.

Power

Source

Notch

Frequency

Heat Exchange Ventilation Normal Ventilation

Product

Weight

Input Current

Air

Volume

External

Static

Pressure

Temperature

Exchange

Efciency

Enthalpy

Exchange

Efciency (%)

Noise Input Current

Air

Volume

External

Static

Pressure

Noise

(Hz) (W) (A) (m3/h) (Pa) (%) Cooling Heating (dB) (W) (A) (m3/h) (Pa) (dB) (kg)

UTZ-

BD025B

220-240V

a.c.

Extra High

50 112-128 0.51-0.53 250 105 75 63 70 30.0-31.5 112-128 0.51-0.53 250 105 30.0-31.5

29

High

50 108-123 0.49-0.51 250 95 75 63 70 29.5-30.5 108-123 0.49-0.51 250 95 29.5-30.5

Low

50 87-96 0.40-0.41 190 45 77 65 72 23.5-26.5 87-96 0.40-0.41 190 45 23.5-26.5

This noise of the product is the value which was measured at the acoustic room. Actually, in the established condition, that undergo inuence

by the echoing of the room and so that become bigger than the display numerical value .

PERFORMANCE

Use conditions

Outdoor air conditions

Temperature range -10˚C ~ 40˚C

Relative humidity 85% or less

Indoor air conditions

Temperature range -10˚C ~ 40˚C

Relative humidity 85% or less

Installation requirements

Same as the indoor air conditions

*

Indoor air here means air in air-conditioned

living rooms.

Its use in refrigerators or other place s

where temperature can uctuate greatly is

prohibited even if a temperature range is

acceptable.

Example

Indoor air conditions

During cooling period

Temperature 27˚C

Relative humidity 50%

During heating period

Temperature 20˚C

Relative humidity 40%

• The Input, the current and the exchange

efficiency are values at the time of the

mentioned air volume.

• The noise level shall be measured 1.5m

below the center of the unit.

• Th e temp erat ure exch ange effic ienc y

averages that of when cooling and when

heating.

MOTOR

SPECIFICATIONS

Type

4 Poles open type

induction motor

Rating Cont.

Insulation Class class E

Temperature Rise under 75 K

Sorrounding Temperature

-10˚C ~ 40˚C

Insulation Resistance

over 1MΩ (by DC500V)

Withstand Voltage AC 1,500V for 1min

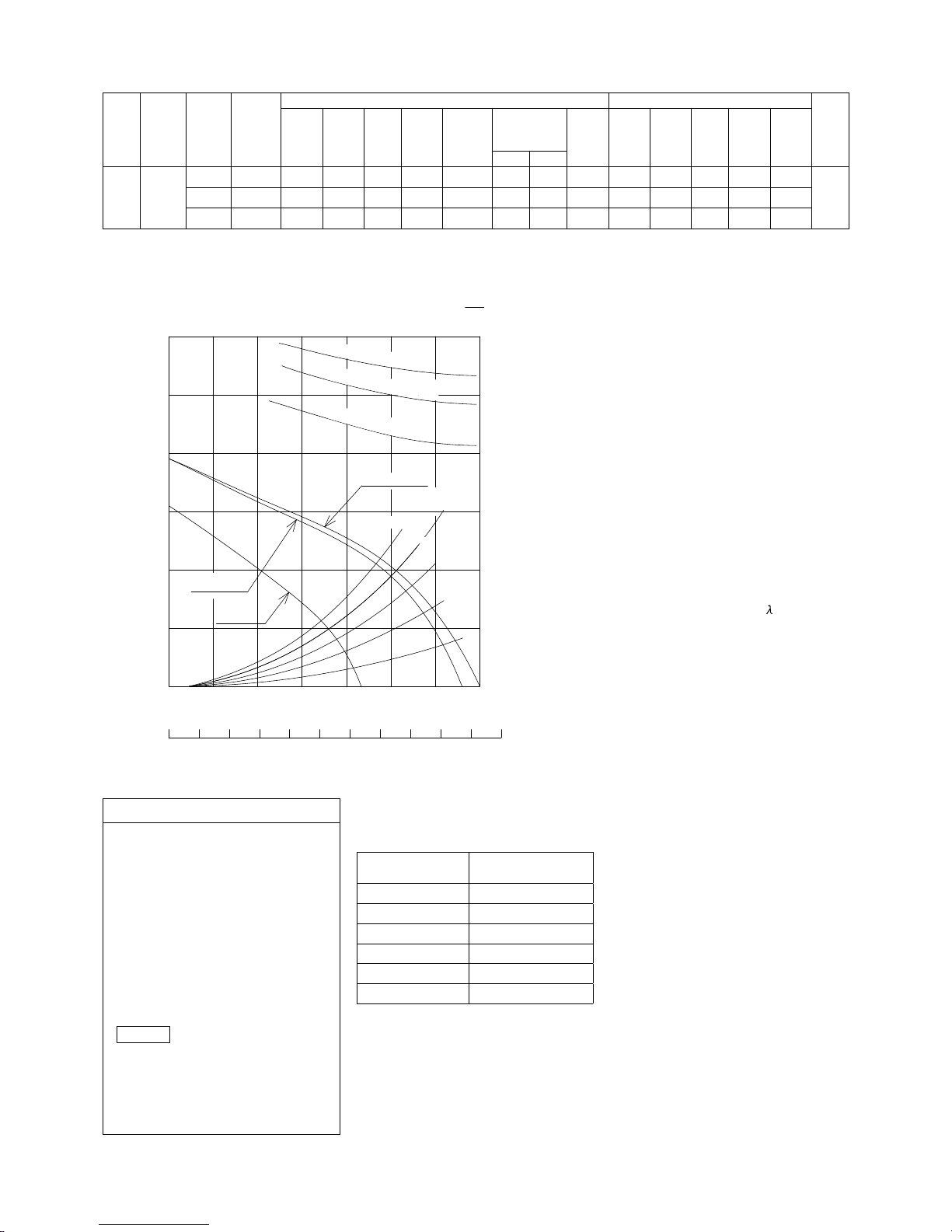

300

0 50 100 150 200 250 300 350

50

100

150

200

250

0 20 40 60 80 100 120 140 160 180 200 220

Air Volume (m

3

/h)

Air Volume (ft

3

/min)

External Static Pressure (Pa)

80

50

60

70

Exchange Efciency (%)

Duct resistance Curve

P-Q Curve

220 - 240V ~ 50HzEfciency Curve

T

e

m

pe

ra

t

u

r

e

E

nt

h

al

p

y

(i

n

h

e

a

t

i

n

g

)

E

nt

h

al

p

y

(i

n

c

o

o

li

n

g

)

Extra High

Equivalent pipe length

High

Low

When friction coefcient of pipe (duct) :

=0.02

100m

80

60

20

40

Page 8

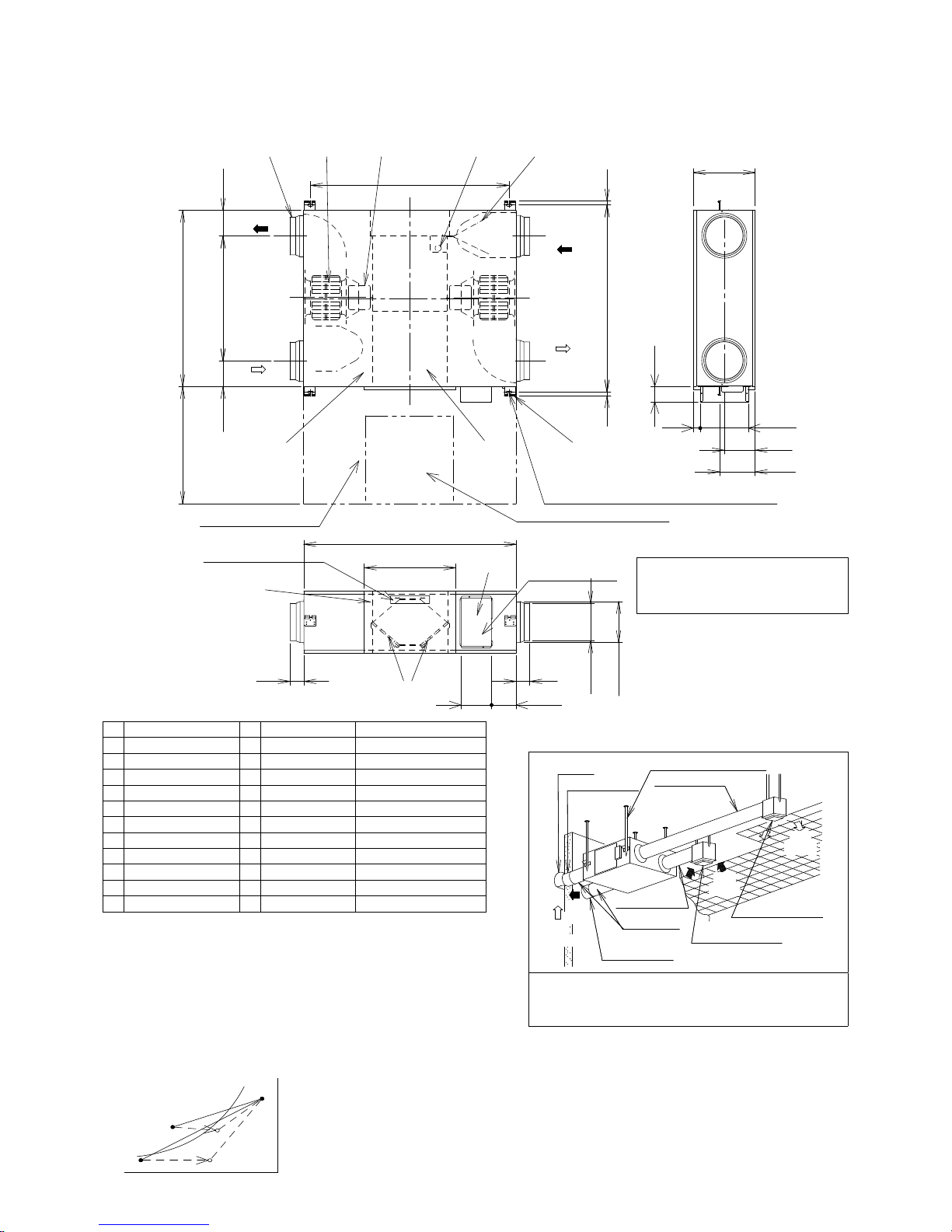

- (01-05) -

2-2. UTZ-BD035B

NO.

Parts Name

Qty.

Material Remarks

1

Frame

1

Galvanized sheets

2

Adapter

4

ABS

3

Electrical Equipment Box

1

4

Inspection Cover

1

Galvanized sheets

5

Fan

2

ABS

6

Motor

2

7

Heat Exchange Element2Special paper + Resin

8

Filter

2

Nylon-Polyester Fiber Collection Efciency AFI 82%

9

Damper

1

10

Damper Motor

1

11

Ceiling Suspension Fixture4Galvanized sheets

BE CAREFUL OF DEWING AND

FROSTING

As shown in the Figure, suppose a high temp absorbing air condition

A and a low temp absorbing air condition B are plotted on the air line

gure, then a high temp air A is heat-exchanged by the unit and goes

out of the saturation curve as shown by Point C.

In this case, the unit will be dewed or frosted.

To aboid this, you are required to heat a low temp air B up to B’ so as

to get C’ below the saturation curve, before using the unit.

saturationcurve

Dry-bulb temperature(˚C)

Absolite humidity (kg/kg’)

C’

C

B

B’

A

REFERENCE SKETCH

Pipe Hood

Outside Intake Duct

Ceilling Suspension Bolts

Supply Air Duct

EA

(Exhaust

Air)

OA

(Outside intake Air)

RA

(Room Air)

SA

(Supply Air)

Inside Supply Opening

(Supply/Exhaust Air Grill)

Room Intake Opening

(Supply/Exhaust Air Grill)

Room Intake Duct

Heat Insulation Material

Exhaust Air Duct

The two outside ducts(the Outside Intake Duct and the

Exhaust Duct)must be insulated to prevent condensation.

(Material;Glass wool, Thickness;25)

Duct size (Nominal Diameter): ø150

The above dimensions do not include the thickness of

the insulasion material on the unit body.

978

② ⑤ ⑥

⑩

⑨

①

⑦

⑪

804600

112 580 112

EA

OA

(Exhaust Air)

(Outside Air)

Maintenance Space

Inspection Opening □450

(For the inspection of the lters, heat exchange elements, fans, motors, and damper)

4-13×30 Oval hole · Suspension Fittings

1986019

RA

SA

(Room Air)

(Supply Air)

An inspection opening is necessary to

clean the heat exchange element and

lter once or twice a year.

317

247

182

159

35

80

④

⑧

③

1050

470

70

70

Wiring Diagram

Earth Terminal

Ø162

Ø144

122

157

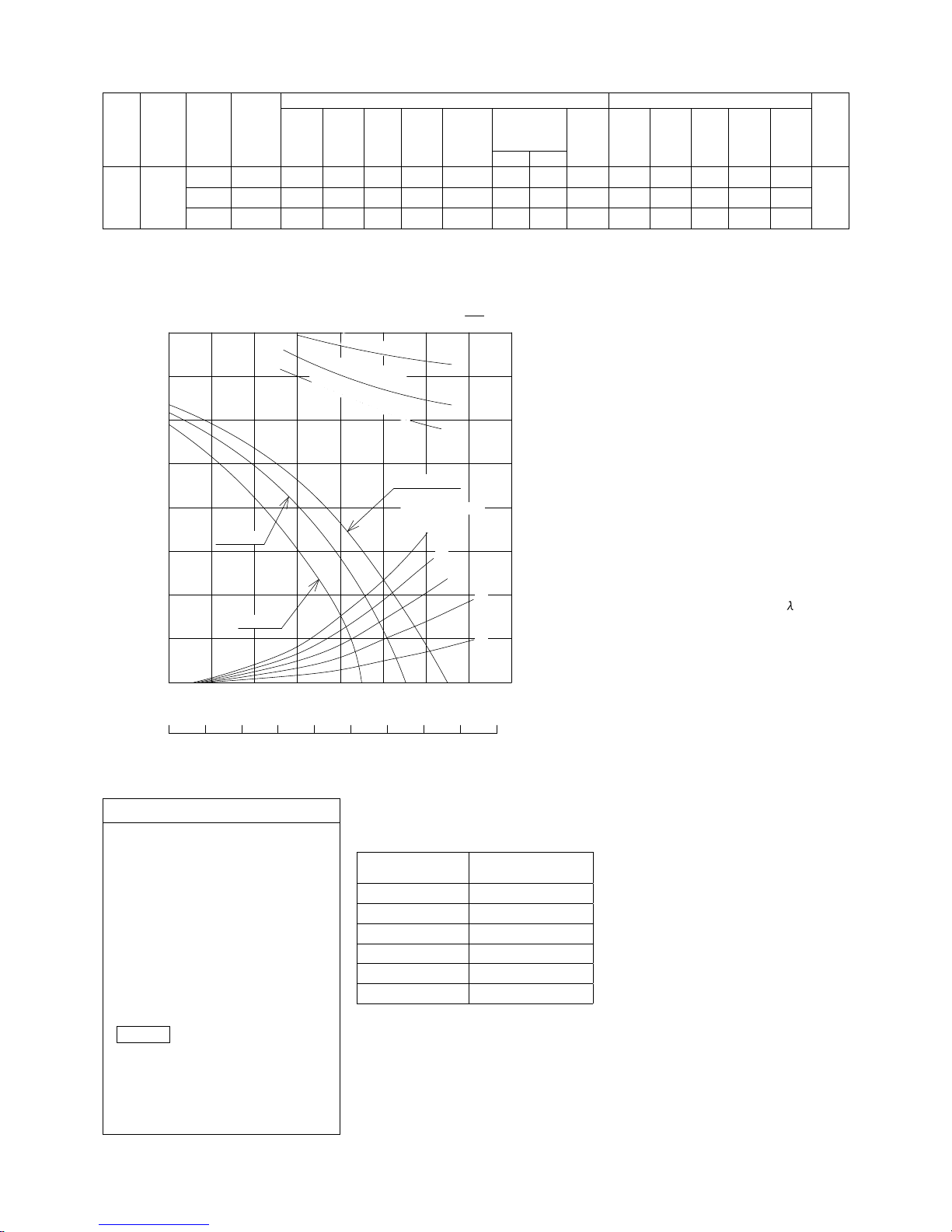

Page 9

- (01-06) -

SPECIFICATIONS

Model

No.

Power

Source

Notch

Frequency

Heat Exchange Ventilation Normal Ventilation

Product

Weight

Input Current

Air

Volume

External

Static

Pressure

Temperature

Exchange

Efciency

Enthalpy

Exchange

Efciency (%)

Noise Input Current

Air

Volume

External

Static

Pressure

Noise

(Hz) (W) (A) (m3/h) (Pa) (%) Cooling Heating (dB) (W) (A) (m3/h) (Pa) (dB) (kg)

UTZ-

BD035B

220-240V

a.c.

Extra High

50 182-190 0.63-0.65 350 140 75 66 69 32.5-33.0 182-190 0.63-0.65 350 140 32.5-33.0

49

High

50 178-185 0.59-0.60 350 60 75 66 69 30.5-31.0 178-185 0.59-0.60 350 60 30.5-31.0

Low

50 168-175 0.56-0.57 240 45 78 71 73 22.5-25.5 168-175 0.56-0.57 240 45 22.5-25.5

This noise of the product is the value which was measured at the acoustic room. Actually, in the established condition, that undergo inuence

by the echoing of the room and so that become bigger than the display numerical value .

PERFORMANCE

Use conditions

Outdoor air conditions

Temperature range -10˚C ~ 40˚C

Relative humidity 85% or less

Indoor air conditions

Temperature range -10˚C ~ 40˚C

Relative humidity 85% or less

Installation requirements

Same as the indoor air conditions

*

Indoor air here means air in air-conditioned

living rooms.

Its use in refrigerators or other place s

where temperature can uctuate greatly is

prohibited even if a temperature range is

acceptable.

Example

Indoor air conditions

During cooling period

Temperature 27˚C

Relative humidity 50%

During heating period

Temperature 20˚C

Relative humidity 40%

• The Input, the current and the exchange

efficiency are values at the time of the

mentioned air volume.

• The noise level shall be measured 1.5m

below the center of the unit.

• Th e temp erat ure exch ange effic ienc y

averages that of when cooling and when

heating.

MOTOR

SPECIFICATIONS

Type

4 Poles open type

induction motor

Rating Cont.

Insulation Class class E

Temperature Rise under 75 K

Sorrounding Temperature

-10˚C ~ 40˚C

Insulation Resistance

over 1MΩ (by DC500V)

Withstand Voltage AC 1,500V for 1min

350

0 100 200 300 400 500 600

50

100

150

200

300

0 50 100 150 200 250 300 350

Air Volume (m

3

/h)

Air Volume (ft

3

/min)

External Static Pressure (Pa)

80

50

60

70

Exchange Efciency (%)

Duct resistance Curve

P-Q Curve 220 - 240V ~ 50HzEfciency Curve

T

e

m

p

e

r

a

t

u

r

e

E

n

t

h

a

l

p

y

(

i

n

h

e

a

t

i

n

g

)

E

n

t

h

a

l

p

y

(

i

n

c

o

o

l

i

n

g

)

Extra High

Equivalent pipe length

High

Low

When friction coefcient of pipe (duct) :

=0.02

60m

40

20

250

10

Page 10

- (01-07) -

2-3. UTZ-BD050B

NO.

Parts Name

Qty.

Material Remarks

1

Frame

1

Galvanized sheets

2

Adapter

4

Galvanized sheets

3

Electrical Equipment Box

1

4

Inspection Cover

1

Galvanized sheets

5

Fan

2

ABS

6

Motor

2

7

Heat Exchange Element2Special paper + Resin

8

Filter

2

Nylon-Polyester Fiber Collection Efciency AFI 82%

9

Damper

1

10

Damper Motor

1

11

Ceiling Suspension Fixture4Galvanized sheets

BE CAREFUL OF DEWING AND

FROSTING

As shown in the Figure, suppose a high temp absorbing air condition

A and a low temp absorbing air condition B are plotted on the air line

gure, then a high temp air A is heat-exchanged by the unit and goes

out of the saturation curve as shown by Point C.

In this case, the unit will be dewed or frosted.

To aboid this, you are required to heat a low temp air B up to B’ so as

to get C’ below the saturation curve, before using the unit.

saturationcurve

Dry-bulb temperature(˚C)

Absolite humidity (kg/kg’)

C’

C

B

B’

A

REFERENCE SKETCH

Pipe Hood

Outside Intake Duct

Ceilling Suspension Bolts

Supply Air Duct

EA

(Exhaust

Air)

OA

(Outside intake Air)

RA

(Room Air)

SA

(Supply Air)

Inside Supply Opening

(Supply/Exhaust Air Grill)

Room Intake Opening

(Supply/Exhaust Air Grill)

Room Intake Duct

Heat Insulation Material

Exhaust Air Duct

The two outside ducts(the Outside Intake Duct and the

Exhaust Duct)must be insulated to prevent condensation.

(Material;Glass wool, Thickness;25)

Duct size (Nominal Diameter): ø200

The above dimensions do not include the thickness of

the insulasion material on the unit body.

②

⑤

⑥

⑩

⑨

①

⑦

⑪

904600

132 640 132

EA

OA

(Exhaust Air)

(Outside Air)

1018

Maintenance Space

Inspection Opening □450

(For the inspection of the lters, heat exchange elements, fans, motors, and damper)

4-13×30 Oval hole · Suspension Fittings

1996019

RA

SA

(Room Air)

(Supply Air)

An inspection opening is necessary to

clean the heat exchange element and

lter once or twice a year.

317

159

182

247

35

80

④

⑧

③

1090

470

127

70

Wiring Diagram

Earth Terminal

Ø210

Ø194

157

70

Page 11

- (01-08) -

SPECIFICATIONS

Model

No.

Power

Source

Notch

Frequency

Heat Exchange Ventilation Normal Ventilation

Product

Weight

Input Current

Air

Volume

External

Static

Pressure

Temperature

Exchange

Efciency

Enthalpy

Exchange

Efciency (%)

Noise Input Current

Air

Volume

External

Static

Pressure

Noise

(Hz) (W) (A) (m3/h) (Pa) (%) Cooling Heating (dB) (W) (A) (m3/h) (Pa) (dB) (kg)

UTZ-

BD050B

220-240V

a.c.

Extra High

50 263-289 1.20-1.21 500 120 75 62 67 36.5-37.5 263-289 1.20-1.21 500 120 36.5-37.5

57

High

50 204-225 0.93-0.94 500 60 75 62 67 34.5-35.5 204-225 0.93-0.94 500 60 34.5-35.5

Low

50 165-185 0.75-0.77 440

35

76 64 69 31.0-32.5 165-185 0.75-0.77 440

35

31.0-32.5

This noise of the product is the value which was measured at the acoustic room. Actually, in the established condition, that undergo inuence

by the echoing of the room and so that become bigger than the display numerical value .

PERFORMANCE

Use conditions

Outdoor air conditions

Temperature range -10˚C ~ 40˚C

Relative humidity 85% or less

Indoor air conditions

Temperature range -10˚C ~ 40˚C

Relative humidity 85% or less

Installation requirements

Same as the indoor air conditions

*

Indoor air here means air in air-conditioned

living rooms.

Its use in refrigerators or other place s

where temperature can uctuate greatly is

prohibited even if a temperature range is

acceptable.

Example

Indoor air conditions

During cooling period

Temperature 27˚C

Relative humidity 50%

During heating period

Temperature 20˚C

Relative humidity 40%

• The Input, the current and the exchange

efficiency are values at the time of the

mentioned air volume.

• The noise level shall be measured 1.5m

below the center of the unit.

• Th e temp erat ure exch ange effic ienc y

averages that of when cooling and when

heating.

MOTOR

SPECIFICATIONS

Type

4 Poles open type

induction motor

Rating Cont.

Insulation Class class E

Temperature Rise under 75 K

Sorrounding Temperature

-10˚C ~ 40˚C

Insulation Resistance

over 1MΩ (by DC500V)

Withstand Voltage AC 1,500V for 1min

400

0 100 200 300 400 500 600 700 800

50

100

150

200

300

0 50 100 150 200 250 300 350 400 450

Air Volume (m

3

/h)

Air Volume (ft

3

/min)

External Static Pressure (Pa)

80

50

60

70

Exchange Efciency (%)

Duct resistance Curve

P-Q Curve

220 - 240V ~ 50HzEfciency Curve

T

e

m

p

e

r

a

t

u

r

e

E

n

t

h

a

l

p

y

(

i

n

h

e

a

t

i

n

g

)

E

n

t

h

a

l

p

y

(

i

n

c

o

o

l

i

n

g

)

Extra High

Equivalent pipe length

High

Low

When friction coefcient of pipe (duct) :

=0.02

100m

60

40

250

20

350

80

Page 12

- (01-09) -

2-4. UTZ-BD080B

NO.

Parts Name

Qty.

Material Remarks

1

Frame

1

Galvanized sheets

2

Adapter

4

Galvanized sheets

3

Electrical Equipment Box

1

4

Inspection Cover

1

Galvanized sheets

5

Fan

2

ABS

6

Motor

2

7

Heat Exchange Element3Special paper + Resin

8

Filter

2

Nylon-Polyester Fiber Collection Efciency AFI 82%

9

Damper

1

10

Damper Motor

1

11

Ceiling Suspension Fixture4Galvanized sheets

BE CAREFUL OF DEWING AND

FROSTING

As shown in the Figure, suppose a high temp absorbing air condition

A and a low temp absorbing air condition B are plotted on the air line

gure, then a high temp air A is heat-exchanged by the unit and goes

out of the saturation curve as shown by Point C.

In this case, the unit will be dewed or frosted.

To aboid this, you are required to heat a low temp air B up to B’ so as

to get C’ below the saturation curve, before using the unit.

saturationcurve

Dry-bulb temperature (˚C)

Absolite humidity (kg/kg’)

C’

C

B

B’

A

REFERENCE SKETCH

Pipe Hood

Outside Intake Duct

Ceilling Suspension Bolts

Supply Air Duct

EA

(Exhaust

Air)

OA

(Outside intake Air)

RA

(Room Air)

SA

(Supply Air)

Inside Supply Opening

(Supply/Exhaust Air Grill)

Room Intake Opening

(Supply/Exhaust Air Grill)

Room Intake Duct

Heat Insulation Material

Exhaust Air Duct

The two outside ducts(the Outside Intake Duct and the

Exhaust Duct)must be insulated to prevent condensation.

(Material;Glass wool, Thickness;25)

Duct size (Nominal Diameter): ø250

The above dimensions do not include the thickness of

the insulasion material on the unit body.

②

⑤

⑥

⑩

⑨

①

⑦

⑪

884600

228 428 228

EA

OA

(Exhaust Air)

(Outside Air)

1250

Maintenance Space

Inspection Opening □450

(For the inspection of the lters, heat exchange elements, fans, motors, and damper)

4-13×30 Oval hole · Suspension Fittings

1994019

RA

SA

(Room Air)

(Supply Air)

⑧

An inspection opening is necessary to

clean the heat exchange element and

lter once or twice a year.

388

194

218

247101

80

④

⑧

③

1322

612

85

85

Wiring Diagram

Earth Terminal

Ø258

Ø242

184157

Page 13

- (01-10) -

SPECIFICATIONS

Model

No.

Power

Source

Notch

Frequency

Heat Exchange Ventilation Normal Ventilation

Product

Weight

Input Current

Air

Volume

External

Static

Pressure

Temperature

Exchange

Efciency

Enthalpy

Exchange

Efciency (%)

Noise Input Current

Air

Volume

External

Static

Pressure

Noise

(Hz) (W) (A) (m3/h) (Pa) (%) Cooling Heating (dB) (W) (A) (m3/h) (Pa) (dB) (kg)

UTZ-

BD080B

220-240V

a.c.

Extra High

50 387-418 1.74-1.76 800 140 75 65 71 37.0-37.5 387-418 1.74-1.76 800 140 37.0-37.5

71

High

50 360-378 1.58-1.64 800 110 75 65 71 36.5-37.0 360-378 1.58-1.64 800 110 36.5-37.0

Low

50 293-295 1.23-1.33 630 55 76 68 74 33.5-34.5 293-295 1.23-1.33 630 55 33.5-34.5

This noise of the product is the value which was measured at the acoustic room .Actually, in the established condition, that undergo inuence

by the echoing of the room and so that become bigger than the display numerical value .

PERFORMANCE

400

0 100 200 300 400 500 600 700 800 900 1000 1100 1200

50

100

150

200

300

0 100 200 300 400 500 600 700

Air Volume (m

3

/h)

Air Volume (ft

3

/min)

External Static Pressure (Pa)

80

50

60

70

Exchange Efciency (%)

Duct resistance Curve

P-Q Curve

220 - 240V ~ 50HzEfciency Curve

T

e

m

p

e

r

a

t

u

r

e

E

n

t

h

a

l

p

y

(

i

n

h

e

a

t

i

n

g

)

E

n

t

h

a

l

p

y

(

i

n

c

o

o

l

i

n

g

)

Extra High

Equivalent pipe length

High

Low

When friction coefcient

of pipe (duct) :

=0.02

100m

60

40

250

20

350

80

90450

500

Use conditions

Outdoor air conditions

Temperature range -10˚C ~ 40˚C

Relative humidity 85% or less

Indoor air conditions

Temperature range -10˚C ~ 40˚C

Relative humidity 85% or less

Installation requirements

Same as the indoor air conditions

*

Indoor air here means air in air-conditioned

living rooms.

Its use in refrigerators or other place s

where temperature can uctuate greatly is

prohibited even if a temperature range is

acceptable.

Example

Indoor air conditions

During cooling period

Temperature 27˚C

Relative humidity 50%

During heating period

Temperature 20˚C

Relative humidity 40%

• The Input, the current and the exchange

efficiency are values at the time of the

mentioned air volume.

• The noise level shall be measured 1.5m

below the center of the unit.

• Th e temp erat ure exch ange effic ienc y

averages that of when cooling and when

heating.

MOTOR

SPECIFICATIONS

Type

4 Poles open type

induction motor

Rating Cont.

Insulation Class class E

Temperature Rise under 75 K

Sorrounding Temperature

-10˚C ~ 40˚C

Insulation Resistance

over 1MΩ (by DC500V)

Withstand Voltage AC 1,500V for 1min

Page 14

- (01-11) -

2-5. UTZ-BD100B

NO.

Parts Name

Qty.

Material Remarks

1

Frame

1

Galvanized sheets

2

Adapter

4

Galvanized sheets

3

Electrical Equipment Box

1

4

Inspection Cover

1

Galvanized sheets

5

Fan

2

ABS

6

Motor

2

7

Heat Exchange Element4Special paper + Resin

8

Filter

2

Nylon-Polyester Fiber Collection Efciency AFI 82%

9

Damper

1

10

Damper Motor

1

11

Ceiling Suspension Fixture4Galvanized sheets

BE CAREFUL OF DEWING AND

FROSTING

As shown in the Figure, suppose a high temp absorbing air condition

A and a low temp absorbing air condition B are plotted on the air line

gure, then a high temp air A is heat-exchanged by the unit and goes

out of the saturation curve as shown by Point C.

In this case, the unit will be dewed or frosted.

To aboid this, you are required to heat a low temp air B up to B’ so as

to get C’ below the saturation curve, before using the unit.

saturationcurve

Dry-bulb temperature (˚C)

Absolite humidity (kg/kg’)

C’

C

B

B’

A

REFERENCE SKETCH

Pipe Hood

Outside Intake Duct

Ceilling Suspension Bolts

Supply Air Duct

EA

(Exhaust

Air)

OA

(Outside intake Air)

RA

(Room Air)

SA

(Supply Air)

Inside Supply Opening

(Supply/Exhaust Air Grill)

Room Intake Opening

(Supply/Exhaust Air Grill)

Room Intake Duct

Heat Insulation Material

Exhaust Air Duct

The two outside ducts(the Outside Intake Duct and the

Exhaust Duct)must be insulated to prevent condensation.

(Material;Glass wool, Thickness;25)

Duct size (Nominal Diameter): ø250

The above dimensions do not include the thickness of

the insulasion material on the unit body.

②

⑤

⑥

⑩

⑨

①

⑦

⑪

1134600

228 678 228

EA

OA

(Exhaust Air)

(Outside Air)

1250

Maintenance Space

Inspection Opening □450

(For the inspection of the lters, heat exchange elements, fans, motors, and damper)

4-13×30 Oval hole

· Suspension Fittings

19119019

RA

SA

(Room Air)

(Supply Air)

⑧

An inspection opening is necessary to

clean the heat exchange element and

lter once or twice a year.

388

194

218

247101

80

④

⑧

③

1322

612

85

85

Wiring Diagram

Earth Terminal

Ø258

Ø242

157 184

Page 15

- (01-12) -

SPECIFICATIONS

Model

No.

Power

Source

Notch

Frequency

Heat Exchange Ventilation Normal Ventilation

Product

Weight

Input Current

Air

Volume

External

Static

Pressure

Temperature

Exchange

Efciency

Enthalpy

Exchange

Efciency (%)

Noise Input Current

Air

Volume

External

Static

Pressure

Noise

(Hz) (W) (A) (m3/h) (Pa) (%) Cooling Heating (dB) (W) (A) (m3/h) (Pa) (dB) (kg)

UTZ-

BD100B

220-240V

a.c.

Extra High

50 437-464 1.93-1.99 1000 105 75 65 71 37.5-38.5 437-464 1.93-1.99 1000 105 37.5-38.5

83

High

50 416-432 1.80-1.89 1000 80 75 65 71 37.0-37.5 416-432 1.80-1.89 1000 80 37.0-37.5

Low

50 301-311 1.29-1.37 700 75 79 70 76 33.5-34.5 301-311 1.29-1.37 700 75 33.5-34.5

This noise of the product is the value which was measured at the acoustic room. Actually, in the established condition, that undergo inuence

by the echoing of the room and so that become bigger than the display numerical value .

PERFORMANCE

400

0 100 200 300 400 500 600 700 800 900 1000 1100 1200 1300

50

100

150

200

300

0 100 200 300 400 500 600 700

Air Volume (m

3

/h)

Air Volume (ft

3

/min)

External Static Pressure (Pa)

80

50

60

70

Exchange Efciency (%)

Duct resistance Curve

P-Q Curve

220 - 240V ~ 50HzEfciency Curve

T

e

m

p

e

r

a

t

u

r

e

E

n

t

h

a

l

p

y

(

i

n

h

e

a

t

i

n

g

)

E

n

t

h

a

l

p

y

(

i

n

c

o

o

l

i

n

g

)

Extra High

Equivalent pipe length

High

Low

When friction coefcient

of pipe (duct) :

=0.02

100m

60

40

250

20

350

80

90

500

450

Use conditions

Outdoor air conditions

Temperature range -10˚C ~ 40˚C

Relative humidity 85% or less

Indoor air conditions

Temperature range -10˚C ~ 40˚C

Relative humidity 85% or less

Installation requirements

Same as the indoor air conditions

*

Indoor air here means air in air-conditioned

living rooms.

Its use in refrigerators or other place s

where temperature can uctuate greatly is

prohibited even if a temperature range is

acceptable.

Example

Indoor air conditions

During cooling period

Temperature 27˚C

Relative humidity 50%

During heating period

Temperature 20˚C

Relative humidity 40%

• The Input, the current and the exchange

efficiency are values at the time of the

mentioned air volume.

• The noise level shall be measured 1.5m

below the center of the unit.

• Th e temp erat ure exch ange effic ienc y

averages that of when cooling and when

heating.

MOTOR

SPECIFICATIONS

Type

4 Poles open type

induction motor

Rating Cont.

Insulation Class class E

Temperature Rise under 75 K

Sorrounding Temperature

-10˚C ~ 40˚C

Insulation Resistance

over 1MΩ (by DC500V)

Withstand Voltage AC 1,500V for 1min

Page 16

- (01-13) -

3. WIRING DIAGRAMS

3-1. UTZ-BD025B

SW1

Switch

Low

Damper

High

Power Source

220-240V~single

phase 50Hz

Yellow Yellow

White

White

Black

Black

Blue

Connector

Connector

(Connector)

Connector

White

White(Extra high)

White

Black

Black

Black

Black

(Connector)

Capacitor

Capacitor

White

White

Yellow

Red

Blue(High)

Orange Orange

Red

Yellow

Blue

White(Extra high)

Blue(High)

Yellow

Red

Orange

Orange

Connector

Red

Yellow

Blue

Supply

Air Fan

Exhaust

Air Fan

Micro switch

Damper

Motor

Power Source

(Line)

Power Source

(Neutral)

High

Main unit

L

(Voltage)

N

(Ground)

SW1

SW2

Common

Low

Damper

Terminal

board

Grey

White

White

Blue

Black

Black

Red

Red

White

Black

Brown

Blue

Black

Red

Red

Black

White

Brown

Black

Black

Black

White

White

Yellow

Yellow

Relay 1

Relay 2

Relay 3

White

White

Yellow

Grey

Second main body

Function Select Switch

(3) Energy Recovery

Ventilation

(1) Normal Ventilation

To find out the function of

each switch, refer to Page 7

of the Owner’s manual.

Air Flow Switch

(3) High

(1) Low

Operation Switch

(3) (ON)

(1) (OFF)

UTZ-BD025B

3-2. UTZ-BD035B, UTZ-BD050B

SW1

Switch

Low

Damper

High

Power Source

220-240V~single

phase 50Hz

Power Source

(Line)

Power Source

(Neutral)

Second main body

High

Main unit

L

N

SW1

SW2

Common

Low

Damper

Terminal

board

Grey

White

White

Blue

Black

Black

Red

Red

White

Black

Brown

Blue

Black

Red

Red

Black

White

Brown

Black

Black

Black

White

White

Yellow

Yellow

Relay 1

Relay 2

Relay 3

White

White

Yellow

Grey

Black

Black

(Connector)

Capacitor

White

White

White(Extra high)

Blue(High)

Yellow

Red

Orange

Orange

Connector

Red

Yellow

Blue

Supply

Air Fan

(Connector)

Connector

White

White(Extra high)

White

Black

Black

Capacitor

Yellow

Red

Blue(High)

Orange Orange

Red

Yellow

Blue

Exhaust

Air Fan

Yellow Yellow

White

White

Black

Black

Blue

Connector

Connector

Micro switch

Damper

Motor

Function Select Switch

(3) Energy Recovery

Ventilation

(1) Normal Ventilation

Air Flow Switch

(3) High

(1) Low

Operation Switch

(3) (ON)

(1) (OFF)

UTZ-BD035B

Model No, Capacitor

3.5 µF 450VAC

6.0 µF 450VAC

UTZ-BD050B

Page 17

- (01-14) -

3-3. UTZ-BD080B, UTZ-BD100B

UTZ-BD080B

Model No, Capacitor

10.0 µF 450VAC

10.0 µF 450VAC

UTZ-BD100B

SW1

Switch

Low

Damper

High

Blue

Black

Grey

Grey

Brown

Relay 4

Black

Red

Red

Black

White

Black

Black

White

White

Yellow

Yellow

Relay 1

Grey

Black

Relay 2

Relay 3

White

White

Yellow

Grey

Black

Black

(Connector)

Capacitor

White

White

White(Extra high)

Blue(High)

Yellow

Red

Orange

Orange

Connector

Red

Yellow

Blue

Supply

Air Fan

(Connector)

Connector

White

White(Extra high)

White

Black

Black

Capacitor

Yellow

Red

Blue(High)

Orange Orange

Red

Yellow

Blue

Exhaust

Air Fan

Yellow Yellow

White

White

Black

Black

Blue

Blue

Connector

Connector

Micro switch

Damper

Motor

Power Source

(Line)

Power Source

(Neutral)

High

Main unit

L

N

SW1

SW2

Common

Low

Damper

Terminal

board

Grey

White

White

Blue

Black

Black

Red

Red

White

Black

Brown

Blue

Second main body

Power Source

220-240V~single

phase 50Hz

Function Select Switch

(3) Energy Recovery

Ventilation

(1) Normal Ventilation

Air Flow Switch

(3) High

(1) Low

Operation Switch

(3) (ON)

(1) (OFF)

Page 18

- (01-15) -

3-4. INTERLOCKED CONNECTION TO AIR CONDITIONER

● Operation is performed simultaneously with the air conditioner.

● Setting changes are made by energy recovery ventilator switch.

Relay

Air conditioner

Energy recovery ventilator

Air conditioner

remote controller

Energy recovery

ventilator switch

Connection method

● Perform electrical work in accordance with the laws and regulations of each country.

● Check whether or not there is an external output and the necessary connector terminals at the air conditioner using the air conditioner technical

manual beforehand. The external output (operation status output) of the indoor unit PC board is used.

● There is a type of external output from the air conditioner which requires an external power source and a type which does not require an

external power source. The type is different depending on the model.

● The allowable voltage/current of the external output circuit from the air conditioner varies depending on the model. Check it with the air

conditioner technical manual.

● Do not connect the energy recovery ventilator power source (AC220-240V) to the external output terminals from the air conditioner.

● Regarding the relay circuit, select the necessary capacity from the allowable current value of the external output terminals and the current value

of the energy recovery ventilator and connect.

(1) When energy recovery ventilator operation is unnecessary

For energy recovery ventilator, airflow switching and heat exchange ventilation / normal ventilation switching cannot be

performed.

The gure shown below indicates the operation with airow HIGH and heat exchange ventilation.

Provided at the site

Power source

AC220-240V

50Hz

Energy recovery ventilator

terminal

Indoor unit PC board

Relay circuit

L

N

SW1

SW2

COMMON

LOW

HIGH

DAMPER

N L

Page 19

- (01-16) -

(2) When you want to operate using the energy recovery ventilator switch

Operation is performed simultaneously by air conditioner remote controller even when the energy recovery ventilator switch

is in the OFF state.

The energy recovery ventilator can be operated by energy recovery ventilator switch even when the air conditioner is in the

stopped state.

Do not make connections to multiple indoor units by duct direct connection system.

Dust may be dispersed depending on the operation condition of the air conditioner.

Energy recovery

ventilator

Dust

Room air

Room air

Stopped

External air

Operating

Power source

AC220-240V

50Hz

Energy recovery ventilator

terminal

Indoor unit PC board

Relay circuit

Provided at the site

Energy recovery

ventilator switch

L

N

SW1

SW2

COMMON

LOW

HIGH

DAMPER

N L

ON

OFF

HIGH

LOW

HEAT EXCHANGE

NORMAL

Page 20

- (01-17) -

4. DESIGN SECTION

4-1. ABOUT HEAT EXCHANGE UNIT

4-1-1. BASIC ENGIN

BASIC PRINCIPLE AND

STRUCTURE OF THE HEAT

EXCHANGER

Basic principle of a heat exchanger

The basic principle of a heat exchanger is as indicated

below. As heat moves from a high-temperature area to a

low-temperature area together with humidity, the heated and

moist air moves the heat and humidity to colder and drier air

by passing through a heat-exchange element.

Warm and moist

ai

r

Heat-exchange element

Heat

Humidity

Cold and

dry air

Function of a heat exchanger

A heat exchanger effectively recovers cooled or heated room

temperatures and simultaneously ventilates air.

Winter

Mechanism of a heat exchange element

The heat exchange element can allow the exhaust air from

inside and the fresh air from outside to transmit temperature

and humidity without being mixed up.

Indoor exhaust

Outdoor inlet

Mechanism of total heat ex-

change

Heat

Indoor air

upply at 14

Humidity

s

Cold air at

0

Indoor air

supply

Outdoor

exhaust

Outdoor

exhaust at 6

Humidity

Heat exchange

element

0°C

6°C 14°C

20°C

Heat exchange

ratio at 70%

Warm air at

20

Heat

ADVANTAGES OF THE HEAT

EXCHANGE ELEMENT

The height of the heat exchange element

reduced by 20%

The upper and lower protrusions have been cut out (see the gure

below). The newly adopted counter-ow

heat exchange system has made the

entire unit much thinner from 287mm

to 230mm, and realized the same

performance as in the conventional

cross-ow heat exchange element.

Comparison of heat exchange elements

C tross-flow elemen

Counter-flow ele-

ment

While airflows are directly crossed in the cross-flow element, the counter-flow element allows airflow to be retained

for longer time (or longer distance). In this manner, the

thinner system can maintain the heat exchange performance attained b

y

its thicker counterpart.

Total heat exchange efciency improved by

6%

The adoption of the counter-flow element has improved

the total heat exchange ratio by about 6%, significantly

contributing to energy saving.

Long-life heat exchange element

By adopting nonwoven fabric filter with excellent dust

collection efficiency and improving the air course shapes,

a long-life heat exchange system has been realized, which

does not require regular cleaning of the heat exchang e

element.

cross-flow element

After cleaning the

cross-flow element

The counter-flow element

Heat exchange element with

extended life

The cross-flow element

requires regular clean-ups.

A

irflow

resistance

Changes in airflow resistance

with the years of use

Cleaned

Used

Initial

level

1st

year

2nd

year

3rd

year

4th

year

5th

year

6th

year

7th

year

8th

year

9th

year

10th

year

Service year

The counter-flow element requires no regula

r

clean-up, as the resistance level hardly rise.

Before cleaning the

cross-flow element

After cleaning the

cross-flow element

The counter-flow element

Heat exchange element with

extended life

The cross-flow element

requires regular clean-ups.

A

irflow

resistance

Changes in airflow resistance

with the years of use

Cleaned

Used

Initial

level

1st

year

2nd

year

3rd

year

4th

year

5th

year

6th

year

7th

year

8th

year

9th

year

10th

year

Service year

The counter-flow element requires no regula

r

clean-up, as the resistance level hardly rise.

Long-life heat exchange element

Conventional element

(corrugated structure)

With the above features, airflow resistance affecting s ervice life har dly rises.

The end section is finished with the resin-formed

structure characterized by robustness

Bigger air-course per cell

The fin structure is seldom crushed or damaged.

Dirt and dust are seldom attached.

New-type element

Heat exchanger

plate (paper)

Hydraulic

diamete

r

Spacing plate

(paper)

Spacing rib (resin)

Heat exchanger

p

late(paper

)

Hydraulic

diamete

r

Before cleaning the

Page 21

- (01-18) -

4-1-2. INTERNAL STRUCTURE

HEAT EXCHANGE UNIT

(CEILING-MOUNTED)

INTERNAL STRUCTURE

(HEAT EXCHANGE VENTILATION)

Bypass air course

Heat exchange

element

Filter (for RA)

Filter (for OA)

HEAT EXCHANGE UNIT

(CEILING-MOUNTED)

INTERNAL STRUCTURE

(NORMAL VENTILATION)

Bypass air course

Heat exchange

element

Filter (for RA)

Filter (for OA)

Page 22

- (01-19) -

4-1-3. HEAT EXCHANGE VENTILATION AND NORMAL

VENTILATION

HEAT EXCHANGE VENTILATION

External air is heat-exchanged with indoor air, and supplied

indoors after the temperature is made closer to the room

temperature

NORMAL VENTILATION

External air is let in without heat-exchange with indoor air.

ATTENTION

When the heating function is on during winter, do no use “normal ventilation.” The dew condensation will take place in the

unit, which may result in stains on the ceiling, etc.

Stale indoor air to be ex-

hausted (EA)

Fresh external air to be

su

pp

lied indoors(SA

)

Outdoor Indoor

Total heat

exchanger

Stale indoor air

(RA)

Fresh external

air (OA)

Fresh external air to be

supplied indoors (SA)

Stale indoor air to be

exhausted (EA)

Outdoor Indoor

Stale Indoor air

(RA)

Fresh external

air (OA)

Total heat

exchanger

Page 23

- (01-20) -

4-2. NEEDS FOR VENTILATION

4-2-1. OBJECTIVES AND EFFECTS OF VENTILATION

EFFECTS OF VENTILATION

Ventilation is not simply designed to exhaust stale air. It also

has deodorizing, dust removal, dehumidification, and room

temperature adjustment functions, in addition to exchanging

air.

(1) Ventilation function

Ventilation supplies fresh air required t o sustain our

normal breathing and exhausts stale air; as well as

supplies oxygen required for combustion and prevents

imperfect combustion.

(2) Deodorizing function

A ventilation fan can quickly exhaust unpleasant odor

derived from various sources, and create comfortable

environment.

(3) Dust removal function

Dust oating in the air may accompany invisibly tiny various

harmful bacteria, etc. Dust and dirt should thus be exhausted

from room to create hygienic and comfortable environment.

(4) Dehumidication function

Humidity in a house is not limited to the bathroom. Moisture is

also emitted from human bodies and combustion appliances.

Particularly, in recent years, heating in a highly airtight

structure has caused dew condensation, resulting in mold

growth and even damaging oors and walls, etc. Eliminating

interior humidity through ventilation will create comfortable and

healthy conditions for both human bodies and buildings.

(5) Room temperature adjustment function

At summer nights, ventilation accompanied by refrigeration

air conditioning can eliminate warm room air by the

ventilator, and let in cool outdoor air. Circulation-type

ventilators can also maintain the room temperatures,

realizing highly efcient heating in winter.

EFFECTS OF STALE AIR ON

BUILDING

Stains on interior surfaces

Brand new white ceilings, walls, furniture, and decorative items

may turn yellowish in a year or two, due to tar contained in

cigarettes and oating dust.

Beware of humidity

Humidity emitted from one human body is said to amount to

about two liters a day. In highly airtight modern structures, in

addition to bathrooms, which are almost always humid, many

places can remain highly humid, such as living rooms, closets,

storerooms, and under-floor areas, etc. If left unattended,

mold and ticks will soon appear, and the wood may be more

likely to be rotted. In addition, heating will also accelerate dew

condensation, which may further damage portions behind walls

and oors, which are not readily visible.

NEEDS FOR AIR SUPPLY

Ventilation is to exchange indoor air with outdoor air. When

ventilation is performed by a ventilating fan (generally for the

exhausting function), if air inlet is limited (in a room or a building),

the capabilities of the ventilator may be greatly reduced, or the

indoor pressure may be lowered, causing drafts and noises, as

well as making it difcult to open or close doors.

Sizes and locations of inlets

(1) Sizes of air inlets

Required sizes of inlets may vary, depending on the sizes of apertures

and openings of the buildings. The effective opening area (cm2) should

be 0.7 times the ventilation airow (m3/h), with the internal and external

pressure difference set at 10Pa.

Effective opening area αA(cm2) = 0.7 x airow (m3/h)

As a reference, the following computation formulas are proposed

in the ventilation/air-conditioning engineering standards.

αA= 0.68V - S αA’ (in the case of Pmax = 10Pa)

αA= 0.39V - S αA’ (in the case of Pmax = 30Pa)

αA: Effective opening area (cm2) of dedicated inlets

V: Effective ventilation air volume (m3/h)

S: Gross oor area of a building (m2)

αA’: Air-tightness of a building (cm2/m2)

A ventilating fan has an exhaust capability specied in the catalog,

for which, however, the amount of air exhausted by the fan needs to

be supplied from the inlet.

In other words, if the air-inlet is small, sufficient air cannot be

supplied indoors, resulting in insufcient ventilation capacities. The

air-inlet should generally be larger than the installation area for the

ventilation fan. As the inlet area gets bigger, the air velocity there

will be reduced, making it less uncomfortable for people near it.

Ex-

haust

Ex-

haust

Smooth airflows

Slow air supply

velocity

High ai

r

supply

velocity,

causing

uncomfortable

feeling

Noisy

Insufficient

ventilation

capacity

Fig. 2-2Fig. 2-1

Ex-

haust

Smooth airflows

Slow air supply

velocity

Fig. 2-2Fig. 2-1

Air-inlet

Air-inlet

Ex-

haust

Ex-

haust

Smooth airflows

Slow air supply

velocity

High ai

r

supply

velocity,

causing

uncomfortable

feeling

Noisy

Insufficient

ventilation

capacity

Fig. 2-2Fig. 2-1

For a large room, air-inlets should

be dispersed and as far distanced

from the ventilating fans as possible,

so that air can be ventilated evenly.

Air-inlet Many portions of the

room remain unventilated.

A bad example

Fewer

portions

of the

room

remain

unventilated.

Air-inlet

A good example

Ventilating fans should also

be dispersed.

A good ex-

ample

Air

-inlet

Fig. 2-3

(2) Locations of exhausts (ventilation fans) and air-inlets

In the case of general ventilation, air-inlets should be located as

far detached from ventilating fans as possible. On the other hand,

in the case of local ventilation, the air-inlet should be as close

to the ventilating fans to minimize any effects to the surrounding

areas.

(3) In bathrooms,…

When ventilating fans are installed in bathrooms, etc., air-inlets should

always be installed (except for simultaneous exhaust/supply systems).

Otherwise, ventilating air volumes may be reduced, or the sealing

water may be disrupted in shallow traps, causing the sewage stench

to ow into the room.

(4)

In rooms where half-enclosed combustion apparatus are used

In a cold region, when a stove with a chimney is installed without

proper air-inlets, and ventilation fan is put into operation, the chimney

may function as an air-inlet and let the exhaust into the room, causing

a dangerous situation.

Page 24

- (01-21) -

4-3. METHODS OF VENTILATION

Ventilation can be divided into natural ventilation based

on natural conditions and mechanical ventilation based on

mechanical power.

NATURAL VENTILATION

This ventilation is based on pressure

derived from external winds and

the outdoor and indoor temperature

differences. However, as natural

ventilation is weaker than mechanical

ventilation and may be greatly

affected by natural conditions,

signicant results cannot be expected

MECHANICAL VENTILATION

Methods of mechanical ventilation

As this method is based on enforced

ventilation with ventilating fans and air

blowers, etc., it is capable of generating

stable amounts of ventilation at

required timing, compared with natural

ventilation.

*

Highly contaminated rooms should

remain in negative pressure to prevent

contaminated air from leaking into

adjacent rooms and corridors (Class 1 or

Class 3 Ventilation). On the other hand,

for rooms that need to be kept clean,

positive pressure should be maintained

to prevent intrusion of contaminated air

(Class 2 Ventilation).

Total ventilation and local ventilation

Total ventilation

This ventilation is designed for an

entire house and for exchanging

the entire air in the house (Fig.

3-5).

The total (general) ventilation can be categorized into the

following three types.

a) Individualized ventilation system

The amount of ventilation required for each room can be

satisfied by installing ventilation facilities at each room.

.………

b) Total ventilation system

The total amount of ventilation for the entire building

can be satisfied by utilizing local exhaust facilities and

installing natural air-supply inlet at each room. E.g., local

exhaust facilities + natural air-supply inlets, etc.

c) Central ventilation system

A single ventilation unit can satisfy the amount of

ventilation required for multiple rooms and the entire

building. …………

Natural air

exhaust

Natural air

supply

A

ir exhaust

A

ir supply

(Natural

ventilation)

Fig. 3-1

Warehouses, gymnasiums, factories

where hot air is generated

Class 1 Ventilation Method

Exhaust

Mechanical

exhaust

A

ir

supply

Mechanical air

supply

Indoor

Ventilating fan

External air

Ventilating

fan

To be applied for buildings, indoor parking

lots, boiler rooms, electric rooms, machine

rooms

,

kitchens, and warehouses, etc.

Fig. 3-2

Class 1 Ventilation Method

Exhaust

Mechanical

exhaust

A

ir

supply

Mechanical air

supply

Indoor

Ventilating fan

Exter-

nal air

Ventilating

fan

To be applied for buildings, indoor parking

lots, boiler rooms, electric rooms, machine

rooms

,

kitchens, and warehouses, etc.

Fig. 3-2

Class 2 Ventilation Method

Exhaust

Mechanical

exhaust

A

ir

supply

Mechanical air

supply

External air

Positive

pressure

Exhaust

outlet

Indoor

Ventilating fan

Fi

g

. 3-3

To be applied for clean rooms and cooling

machinery, etc.

Class 1 Ventilation Method

Exhaust

Mechanical

exhaust

A

ir

supply

Mechanical air

supply

Indoor

Ventilating fan

Exter-

nal air

Ventilating

fan

To be applied for buildings, indoor parking

lots, boiler rooms, electric rooms, machine

rooms

,

kitchens, and warehouses, etc.

Fig. 3-2

Class 2 Ventilation Method

Exhaust

Mechanical

exhaust

A

ir

supply

Mechanical air

supply

Class 3 Ventilation Method

Exhaust

Mechanical

exhaust

A

ir

supply

Mechanical air

supply

Exter-

nal air

External air

Positive

pressure

Exhaust

outlet

Indoor

Ventilating fan

Indoor

Fi

g

. 3-3

Negative

pressure

Air supply

inlet

Ventilating

fan

Fi

g

. 3-4

To be applied for clean rooms and cooling

machinery, etc.

To be applied for kitchens, toilets, rooms where hot-water

heaters can be utilized in residences, and copying

rooms, etc.

Air

supply

Contami-

nated air

Exhaust

Fig. 3-5

Local ventilation

This type of ventilation is performed for particular spots in a

house (rooms or parts).

a) Local exhaust

Local exhaust is performed for particular places in which

contaminants (combustion gases, humidity, smoke, and

smell, etc.) may be generated (Fig. 3-6).

(Ohmsha, Ltd., Ventilation, the

Society of Heating, Air-Conditioning

and Sanitary Engineers of Japan)

This kind of ventilation is applied

specically for kitchens, bathrooms,

and toilets, etc.

a) Room ventilation

Individualized ventilation designed for single rooms, etc.

(When individualized ventilation systems are installed

in all rooms, the entire setup can be referred to as total

ventilation.)

Cooking o

hood fan

ven

The range

covered b

y

ventilation

Exhaust

Oven

Fig. 3-6

Page 25

- (01-22) -

4-4. DESIGN PRECAUTIONS

4-4-1. CAUTION ON SAFETY

SAFETY PRECAUTIONS

Described below is what you are supposed to observe to prevent

dangers to the users or other people as well as damage or loss of the

property.

The degrees of danger or damage that is likely to occur due to the

wrong use ignoring the indications are categorized for explanations as

marked below.

DANGER

The column with this mark shows “Impending Danger

of Death or Serious Injury.”

WARNING

The column with this mark shows “Conceivable Threat

of Death or Serious Injury.”

CAUTION

The column with this mark shows “L ikelihood of

Damage or Loss to Materials Only.”

Kinds of the items to be observed are categorized for clarication

with the following pictorial symbols. (The marks described below

are samples.)

This pictorial indication shows “Prohibited.”

This pictorial indication shows “Forced Execution.”

CAUTIONS FOR INSTALLATION

Do not install, move, or relocate the

unit by yourself without contacting

your dealer or professional installer.

Improper installation could cause

a drop of the unit, an electric

shock, or a fire.

Ask the sales office or the engineering shop to perform the work.

The external air intake opening

should not be positioned where discharged air may directly enter it.

A situation like this will lead to the

room being contaminated and

this may pose a health risk.

The external air intake opening

should be positioned away

from the exhaust openings of

combustion gasses.

The intake of such gasses

could lead to a lack of oxygen in the room.

WARNING

Prohibited

Install the unit inside the

heat-insulating walls (in the space

insulated from the open air).

If you install it outside (in the space

equivalent to the open-air conditions),

dew is condensed inside the unit body

in the winter season, causing electric

shocks or dew condensation water to

drops, etc.

Install at a stable place of sufficient

strength.

Please note that there might be

some places not strong enough

to install due to the building

structure.

Provide an exclusive circuit

breaker.

Depending on the environment for

installation, it becomes necessary

to install an earth leakage breaker.

Unless the earth leakage

breaker is installed, it could

cause an electric shock.

Ask the sales office of the engineering shop to perform the work.

Do not install in locations where

harmful or corrosive gasses may

be present (e.g. acidic, alkali, organic, solvent, paint gasses, etc.

from machinery or chemical plants,

etc.).

Installation in such a location

could cause a gas-poisoning

and a fire.

Carry out GND work.

Never connect the GND wire

to a gas pipe, a water supply

pipe, a lightning conductor, or

a GND line of a telephone,

c. An incomplete GND wire

likely to cause an electric

shock.

et

is

If the unit is accompanied by water

drainage, make sure that the duct

is installed properly.

If it is not installed properly,

the building is likely to be

flooded, wetting the house-

hold effects.

Do not install the unit in locations

with large amounts of oily smoke.

If you use the unit in such a

location, the filter or the heat

exchange element gets

clogged with oily substances,

and unable to be utilized.

Do not install the unit in high

humidity locations, such as bathrooms.

Doing so may cause an electric

shock or a breakdown of the

unit.

(Excluding any humid-

ity-resistant models)

CAUTION

Insulated Walls

DuctUnit Body

External

A

ir

GND wire

connection

Prohibited

Prohibited

Prohibited

Install the unit inside the

heat-insulating walls (in the space

insulated from the open air).

If you install it outside (in the space

equivalent to the open-air conditions),

dew is condensed inside the unit body

in the winter season, causing electric

shocks or dew condensation water to

drops, etc.

Install at a stable place of sufficient

strength.

Please note that there might be

some places not strong enough

to install due to the building

structure.

Provide an exclusive circuit

breaker.

Depending on the environment for

installation, it becomes necessary

to install an earth leakage breaker.

Unless the earth leakage

breaker is installed, it could

cause an electric shock.

Ask the sales office of the engineering shop to perform the work.

Do not install in locations where

harmful or corrosive gasses may

be present (e.g. acidic, alkali, organic, solvent, paint gasses, etc.

from machinery or chemical plants,

etc.).

Installation in such a location

could cause a gas-poisoning

and a fire.

Carry out GND work.

Never connect the GND wire

to a gas pipe, a water supply

pipe, a lightning conductor, or

a GND line of a telephone,

c. An incomplete GND wire

likely to cause an electric

shock.

et

is

If the unit is accompanied by water

drainage, make sure that the duct

is installed properly.

If it is not installed properly,

the building is likely to be

flooded, wetting the house-

hold effects.

Do not install the unit in locations

with large amounts of oily smoke.

If you use the unit in such a

location, the filter or the heat

exchange element gets

clogged with oily substances,

and unable to be utilized.

Do not install the unit in high

humidity locations, such as bathrooms.

Doing so may cause an electric

shock or a breakdown of the

unit.

(Excluding any humid-

ity-resistant models)

CAUTION

Insulated Walls

DuctUnit Body

External

A

ir

GND wire

connection

Prohibited

Prohibited

Prohibited

CAUTIONS FOR OPERATIONS

Do not use as an air circulators for open-type burners (heaters).

When gas or oil stoves are used in the home, separate equipment for circulatin

g

the air should be used.

DANGER

Prohibited

When any abnormal condition

(scorching smell, etc.) is found, stop

the operation immediately and keep

the exclusive circuit breaker “OFF.”

If you continue the operation without

removing the cause, it could cause a

mechanical breakdown, an electric

shock, or a fire.

When the system needs a repair,

consult the sales office or the engineering shop.

Do not push a finger or stick into the

open-air inlet or the exhaust outlet.

A fan rotating with a high rpm

will injure you.

If combustible gas leaks from

the unit, ventilate the room by

opening windows.

If operation were to be attempted in such a situation, sparking at electrical

contact points could cause

an explosion.

Modification of the system is

strictly prohibited.

Improper repair could

cause an electric shock or

a fire.

When the system needs a

repair, consult the sales office

or the engineering shop.

Netting or something similar

should be provided at the external air intake opening to

prevent birds, etc. interfering

with the unit.

Nests or other foreign ob-

jects should be removed.

That could lead to a lack of

oxygen in the room.

WARNING

Prohibited

Prohibited

Combustion apparatus should not be

placed allowing a direct exposure to wind

of the unit.

Incomplete combustion could

occur on the apparatus.

Do not blow directly

against animals or

plants.

Likely to cause bad effects on animals

and plants.

Please check the intended uses in

detail for such special purposes as

preservation of foods, flora and

fauna, precision devices, or work of

art, etc.

For special purposes, please conduct

thorough checks in advance.

Otherwise, it could cause deterioration of quality or other problems.

If the unit is not used for a long period

of time, keep the exclusive circuit

breaker “OFF” for safety reasons.

If the power is left on, any

build-up of dust could

cause a heat generation or

a fire.

Do not wash the unit with water.

It could cause an electric

shock.

Do not handle switches with a

wet hand.

It could cause an electric

shock.

Do not use a spray containing

combustible gas near the unit.

It could cause a fire.

Do not use the unit outside

the rated voltage.

It could cause a fire or an

electric shock.

Do not incline the unit when

taking it out.

Otherwise, water remaining inside is likely to

drop and wet the furniture

or other properties.

() Ask the sales office or the

engineering shop to perform

the work.

CAUTION

Prohibited

Prohibited

Prohibited

Prohibited

Prohibited

Prohibited

Prohibited

CAUTIONS FOR MAINTENANCE

When the filter and the heat exchange element is to be cleaned up, turn the

unit off and keep the exclusive circuit breaker “OFF.”

Cleaning should never be done while the internal fans are running with high

speed. And when using a stepladder, etc., make sure to fix it properly.

WARNING

CAUTION

Do not use benzene or metal brush,

etc., when cleaning the filter and the

heat exchange element.

The filter should be cleaned regularly.

Dust or dirt building-up on it can

lead to a lack of oxygen in the

room.

Use gloves when cleaning the

filter or the heat exchange

element.

Doing so will reduce possibilities of injuries.

Gaso-

Thinner