Page 1

Global LCD Panel Exchange Center

www.panelook.com

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 2

Global LCD Panel Exchange Center

TABLE OF CONTENTS

A

1. APPLICATIONS.......................................................................................... 2

2. PRODUCT NAME AND MODEL NUMBER

2-1 Product Name .......................................................................................... 2

2-2 Model Name............................................................................................. 2

3. OVERVIEW.................................................................................................... 2

4. CONFIGURATION..................................................................................... 2

5. MECHANICAL SPECIFICATION............................................................. 3

B

6. ABSOLUTE MAXIMUM RATING............................................................. 4

7. RECOMENNED OPERATING CONDITION........................................... 4

8. ELECTRICAL SPECIFICATIONS............................................................ 5

9. OPTICAL SPECIFICATIONS.................................................................... 7

www.panelook.com

10. INTERFACE SPECIFICATION

10.1 Interface signal alignment..................................................................... 12

10.2 Correspondence between input signal and color.................................. 14

10.3 Input Signal Timing............................................................................... 15

C C

10.4 Correspondence between Data and Display position .......................... 17

10.5 Power Supply Sequence......................................................................... 17

10.6 EDID........................................................................................................ 18

11. BACKLIGHT SPECIFI C AT IO N

11.1 Pin Configuration for Back-light ......................................................... 23

11.2 Life ......................................................................................................... 23

12. ENVIRONMENTAL SPECIFICATION................................................... 24

13. INDICATION............................................................................................. 25

D

14. PACKAGING SPECIFICATION.............................................................. 25

15. WARRANTY............................................................................................... 25

16. PRECAUTIONS FOR USE....................................................................... 26

17. OTHERS .................................................................................................... 30

18. RETURN METHOD FOR PRODUCT REPAIR・COMPLAINT........... 31

D

18.1 In case of made in Taiwan ..................................................................... 31

18.2 In case of made in Japan ....................................................................... 33

19. OUTLINE DRAWING................................................................................35

ATE DOCUMENT CONTROL SECTION

D

IT

ED

DES

DATE

IG.

DESIG. DESCRIPTION

20040908

CHECK

Nukiyama Tanaka

APPR.

CHECK

APPR.

TITLE

NA19026----C661

NA19026

NA19026

NA19026

DRAW. NO.

T

ech Bes LCD

Tech Bes LCD----00288

Tech Bes LCD Tech Bes LCD

UJITSU DISPLAY TECHNOLOGIES

F

CORPORATION

1

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

E

C661

C661C661

00288

0028800288

䕣

䕘

䕕

䕕

䕤

CUST.

1

/

36

www.panelook.com

Page 3

Global LCD Panel Exchange Center

PPLICATION

1.A

Th

A

is specification a pp li es to the 15-inch XGA TFT-LCD module.

2. PRODUCT NAME AND MODEL NUMBER

www.panelook.com

2.

1.Product Name

2.2.Model Number

15

-inch XGA TFT-LCD Module

NA19026-C661

B

3. OVERVIEW

is LCD Module is a display unit that uses a liquid crystal panel with a TFT active

Th

matrix method with a display capacity of 1024x3(RGB)x768 dot and screen size of 38cm

(15.0 inch). This LCD module corresponds to the LVDS 1ch interface and can display 260

thousand colors. In addition, this LCD module operates under a non-interlace mode. It has

a backlight of CCFL that is built in and supplies more electric power than the exclusive

inverter places externally. The power supply of this LCD module is +3.3V DC voltage.

C C

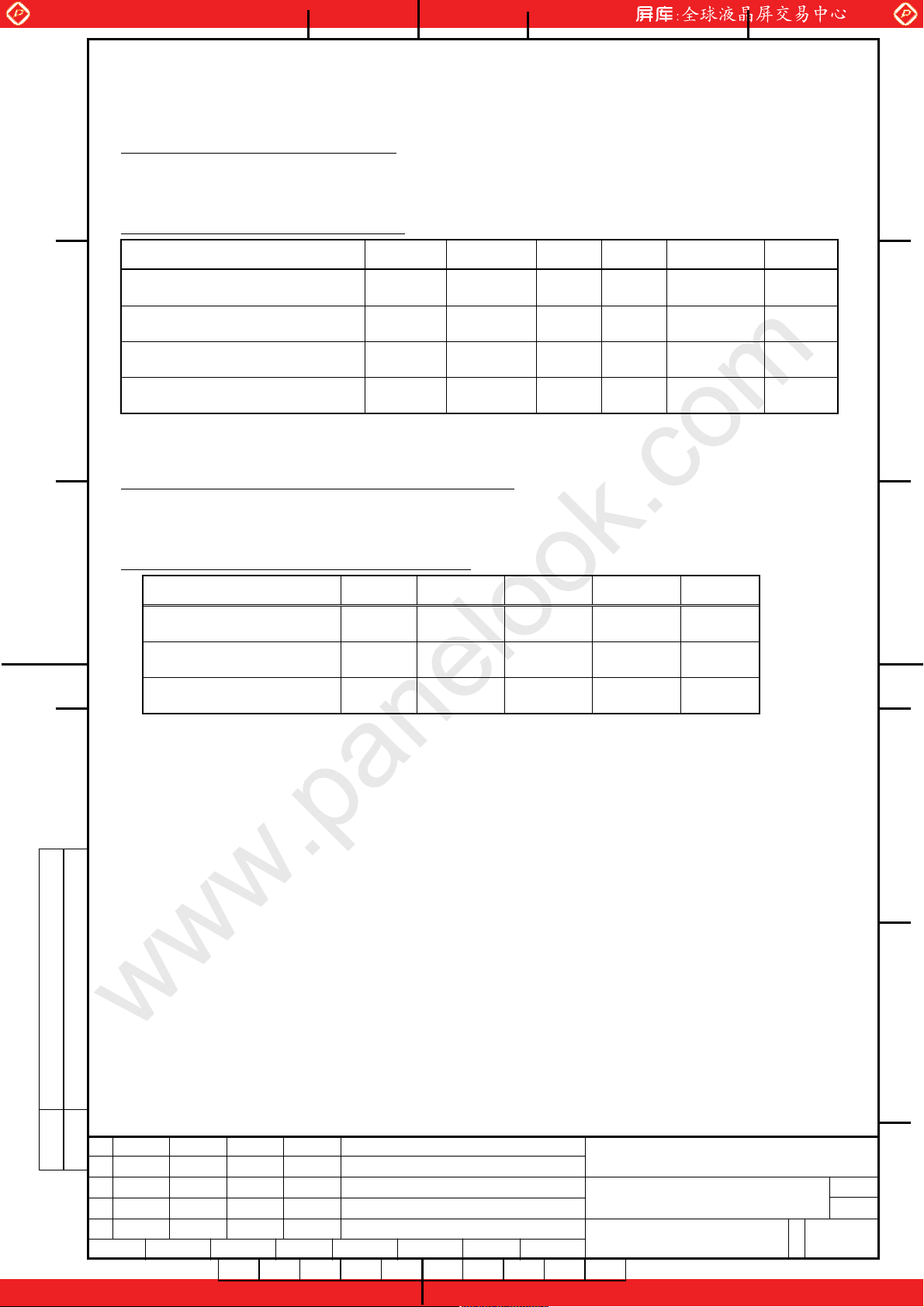

4. CONFIGURATION

This LCD module consists of a color TFT LCD panel and a bezel where the panel driver IC

is mounted into the printed substrate, a cold-cathode florescent tube backlight, and a LVDS

interface PBC. These ar e all combined into one str ucture.

The inverter that supplies electric power to the backlight is configured separately from the

D

LCD module.

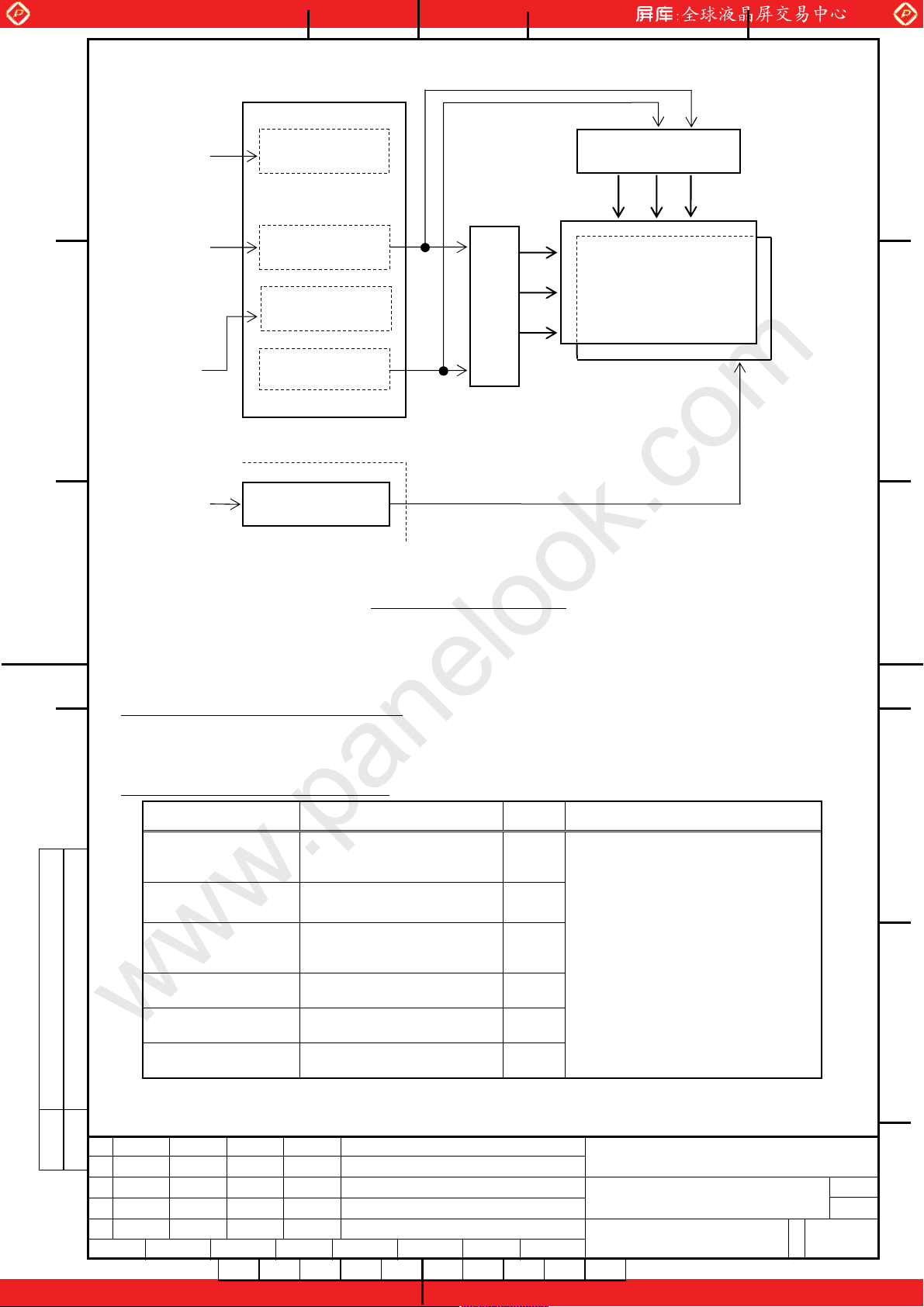

Figure 4-1 shows a block diagram of this LCD module.

D

E

ATE DOCUMENT CONTROL SECTION

D

TITLE

NA19026----C661

NA19026

NA19026

NA19026

DRAW. NO.

T

ech Bes LCD

Tech Bes LCD----00288

Tech Bes LCD Tech Bes LCD

C661

C661C661

00288

0028800288

CUST.

IT

ED

DES

DATE

IG.

DESIG. DESCRIPTION

CHECK

APPR.

CHECK

APPR.

UJITSU DISPLAY TECHNOLOGIES

F

CORPORATION

1

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

䕣

䕘

2

䕕

䕕

/

䕤

www.panelook.com

Page 4

Global LCD Panel Exchange Center

CLKEDID

DATAEDID

A

EDID Power

Supply

RX0+

RX0-

RX1+

RX1RX2+

RX2RXC+

RXC-

EE

nterface Circuit

I

DC/

DC converter

PROM

www.panelook.com

Ga

te Driver

Da

ta Driver

TFT Color

LCD panel

1024x3(RGB)x768

B

Power

Supply

Re

ference Supply

Circuit

+3.3V DC

Separate)

(

DC

C C

.MECHANICAL SPECIFICATIONS

5

T

able 5-1 shows the mechanical specificat ions of this LCD module.

D

Ta ble 5-1 Mechanical Sp ecifications

Invert

er Circuit

ure 4-1 Block Diagram

Fig

Back

-light

(1CCFL)

em Specifications Unit Remark

It

mensions

Di

Di

splay

Resolution

Di

splay Dot Area

(Drive range)

Dot P

itch

317.3×241.8×7.0 (max)

(1024×3)×768 㵪

304.128×228.096 mm

0.297×0.297

mm

mm

Edge type back-light is used

Inverter excluded

For details on dimension,

see dimensional outline

drawing

(on page 35,36)

P

ixel Aspect Ratio 1 : 1

㵪

Weight 670 max g

ATE DOCUMENT CONTROL SECTION

D

IT

ED

DES

DATE

IG.

DESIG. DESCRIPTION

CHECK

APPR.

CHECK

APPR.

TITLE

NA19026----C661

NA19026

NA19026

NA19026

DRAW. NO.

T

ech Bes LCD

Tech Bes LCD----00288

Tech Bes LCD Tech Bes LCD

UJITSU DISPLAY TECHNOLOGIES

F

CORPORATION

1

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

D

E

C661

C661C661

00288

0028800288

䕣

䕘

䕕

䕕

䕤

CUST.

3

/

www.panelook.com

Page 5

Global LCD Panel Exchange Center

ABS OLUTE MAXIMUM R ATING

A

6.

T

able 6-1 shows the absolute maximum rating of this LCD module.

Table 6-1 Absolute Maximum Rating

em Symbol Condition MIN. TYP. MAX. UNIT

It

S

upply Voltage (3.3V)

www.panelook.com

CC Ta

V

=25℃

-0.3

―

4.0

V

B

Supply Voltage (EDID) V

Input Signal Voltage (L VDS)

In

put Signal Voltage (EDID) V

RECOMMEND ED OPERATIONG CONDITIONS

7.

T

able 7-1 shows the reco mmended operating con d itions

EDID

V

IN

IN

-0.3 ―Vcc+0.3

ED

-0.3

―

-0.3 V

6.25

EDID

+0

.3

V

V

V

Ta ble 7-1 Recommended Operat ing Conditions

C C

Item Symbol

Supply Voltage (3.3V)

upply Voltage (EDID) V

S

pple Voltage (V

Ri

CC

) V

V

CC

EDID

RP

MIN. TYP. MAX. UNIT

3.0 3.3 3.6

7

2.

――

―

5.5

100

V

V

䌭䌖p-

p

D

ATE DOCUMENT CONTROL SECTION

D

IT

ED

DES

DATE

IG.

DESIG. DESCRIPTION

CHECK

APPR.

CHECK

APPR.

TITLE

NA19026----C661

NA19026

NA19026

NA19026

DRAW. NO.

T

ech Bes LCD

Tech Bes LCD----00288

Tech Bes LCD Tech Bes LCD

UJITSU DISPLAY TECHNOLOGIES

F

CORPORATION

1

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

D

E

C661

C661C661

00288

0028800288

䕣

䕘

䕕

䕕

䕤

CUST.

4

/

www.panelook.com

Page 6

Global LCD Panel Exchange Center

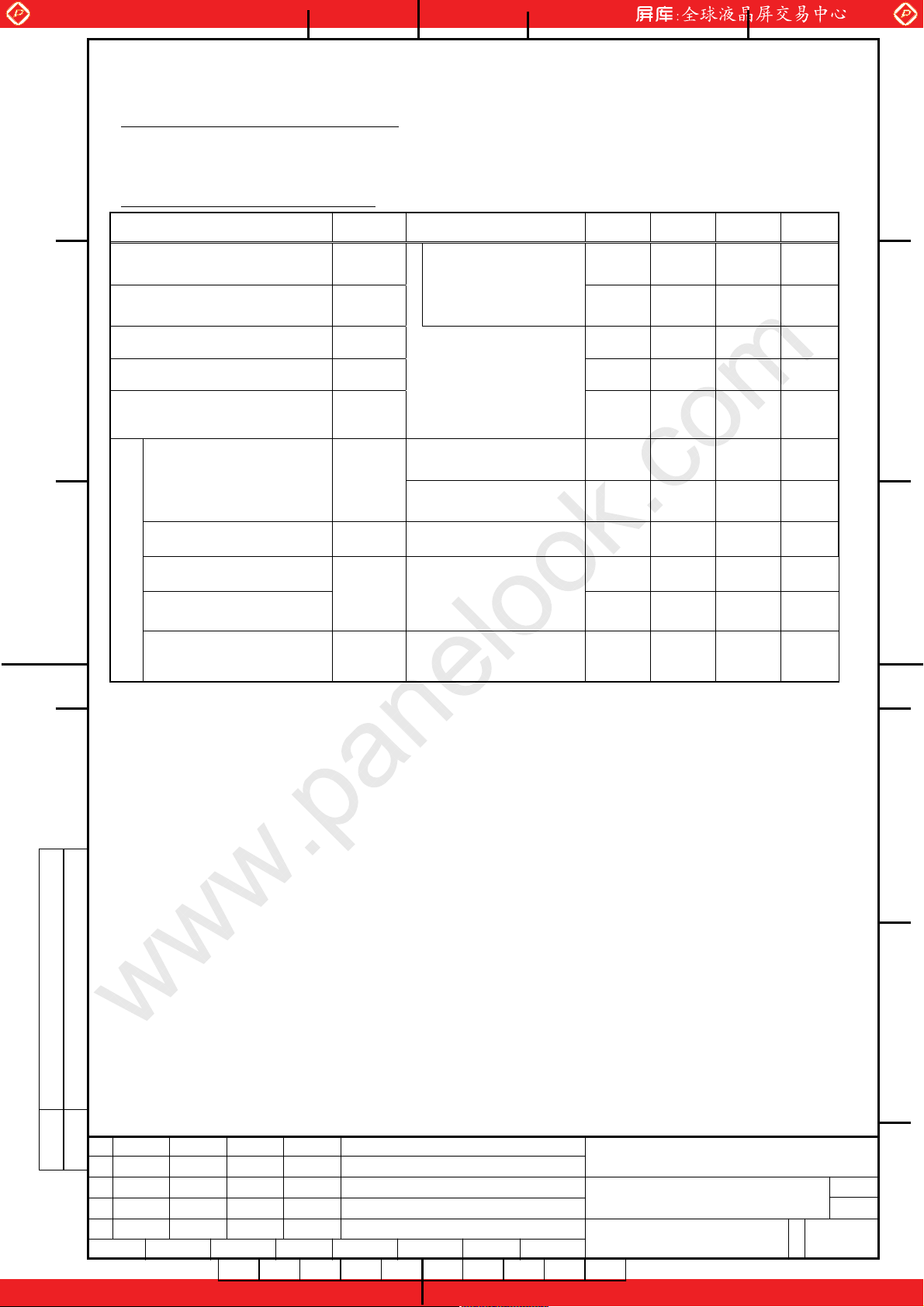

ELECTRICAL SPECIFICATIONS

8.

able 8-1 shows the electrical specifications of this LCD module. Figure 8-1 shows the

A

T

measurement circuit. Figure 8-2 s hows the equivalent circuit of the logic signal input area.

Ta ble 8-1 Electrical Specificat ions

It

em Symbol Condition MIN. TYP. MAX. Unit

D

ifferential input Voltage

(+)

ifferential input Voltage

D

(−)

ply Current

Sup

B

Supply Rush Current

pply Rush Current

Su

Duration (excess 1.2A)

FL Turn on Voltage

CC

(Note)

B

ACK LIGHT

www.panelook.com

IH ――

V

V

V

-100

――

560 850

――

――

――

Vcm=+1.2

V

IL

CC=+3.3

I

Is

V

CC ―

V

SS=0

V

Ta=25℃

CC ――

CK=54.0MHz

Ts

Frame frequency

CC

=60Hz

f

=50kHz,Ta=25℃,

V

L

S

=2

C

L

f

L=50kHz,T a=0℃,

=2

C

L

2pF

2pF

100 mV

mV

mA

2.5 A

2 ms

1650 Vrms

1700 Vrms

V

f

L

L

=50kHz,IL=6mA

L

f

L

=

V

730Vrms,I

L

=6

mA

Lighting Voltage

Lig

C C

hting Frequency 40 60 80 kHz

Recommended

Lighting Frequency

FL tube Current

(Note2)

I

L

=730Vrms

L

V

f

L=50kHz

―

50

730

―

2 6

―

Vrms

60 kHz

6.5 mA

Note)The CCFL turn on voltage is set under the appointed criteria and shall exceed the

maximum range of the specificatio n.

D

●Measurement circuit is based on Figure 8-1

D

ATE DOCUMENT CONTROL SECTION

D

IT

ED

DES

DATE

IG.

DESIG. DESCRIPTION

CHECK

APPR.

CHECK

APPR.

TITLE

NA19026----C661

NA19026

NA19026

NA19026

DRAW. NO.

T

ech Bes LCD

Tech Bes LCD----00288

Tech Bes LCD Tech Bes LCD

UJITSU DISPLAY TECHNOLOGIES

F

CORPORATION

1

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

E

C661

C661C661

00288

0028800288

䕣

䕘

䕕

䕕

䕤

CUST.

5

/

www.panelook.com

Page 7

Global LCD Panel Exchange Center

p

Figure 8-1 Measurement Circuit

A

RX0+

RX0-

RX1+

RX1RX2+

RX2RXC+

RXC-

+

−

www.panelook.com

The

ifferential In

D

LVDS receiver is i ntegrated in the timing cont roller.

L

VDS Receiver

ut

100Ω

Inter

nal

Circuit

B

䌖

DA

TA

CLK

NC(5

EDID

EDID

EDID

pin)

10kΩ

10kΩ

0.1㱘F

EEPROM

WP

01-WDW6

M24C

(ST Micro) or equivalent

Internal

Vcc

C C

GN

D

Fuse

rite beads

Fer

100pF

10μF

Circuit

FG

䋨Frame Ground䋩

Fig

ure 8-2 Equivalent cir cuit of logic signal input

D

ATE DOCUMENT CONTROL SECTION

D

IT

ED

DES

DATE

IG.

DESIG. DESCRIPTION

CHECK

APPR.

CHECK

APPR.

TITLE

NA19026----C661

NA19026

NA19026

NA19026

DRAW. NO.

T

ech Bes LCD

Tech Bes LCD----00288

Tech Bes LCD Tech Bes LCD

UJITSU DISPLAY TECHNOLOGIES

F

CORPORATION

1

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

D

E

C661

C661C661

00288

0028800288

䕣

䕘

䕕

䕕

䕤

CUST.

6

/

www.panelook.com

Page 8

Global LCD Panel Exchange Center

.. OPTICAL SPECIFICATIONS

9

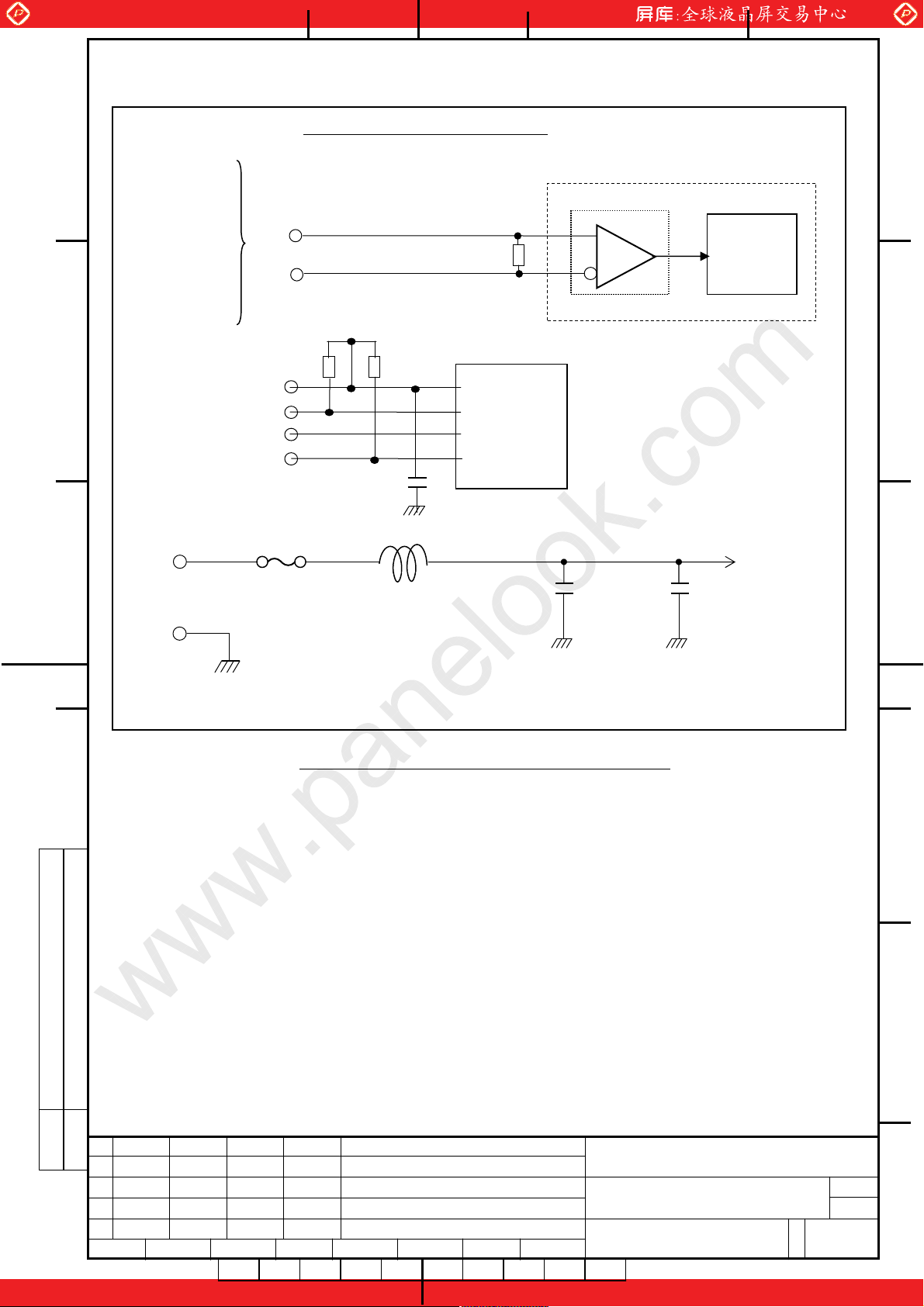

able 9-1 shows the optical specifications of this LCD module.

T

A

Ta ble 9-1 Optical Specificatio ns

www.panelook.com

Item Symbol

Condition

Unit Remark Note

MIN. TYP. MAX.

Specification

sual Angle

Vi

θ

L,

R

CR≧10

Ta=25

℃

θ

U,D

Co

B

ntrast

Ratio

Response

Time (ON)

(BݲW)

CR

t

ON

θ

Ta

θ

θ

R,U,D

L,

=25℃

H

=0°

=0°

V

Response

time

(OFF)

t

OFF

θ

θ

H

=0°

=0°

V

(WݲB)

Brightness

C C

Br

ightness

Uniformity

Chromaticity

(White)

L

ΔL

x

y

θ

=0°

H

θ

V

=0°

=25℃

Ta

fL=50kHz

If=6mA

θ

U,D

θ

L,R

=0°

Ta=25

℃

=0°

=0°

80

80

250 400 ― 㵪

― 15 30 ms

――

――

de

de

Ta=0℃― 50 100 ms

Ta=25

℃

― 10 25 ms

Ta=0℃― 50 100 ms

190 300

60

――䋦

―

cd/m

0.283 0.313 0.343

299 0.329 0.359

0.

―

―

g

g

2

Top

Bottom

Left

Right

White

/

Black*1

All

white

display

*2,3,4

(1)(5)

(1)(2)

(3)(5)

(6)

(1)(3)

(5)

(1)(4)

(5)

(1)(5)

(1)(7)

Color Purity

(NTSC ratio)

LCD

Panel Type TFT Color

55 63 ―

䋦

(1)(5)

D

D

isplay Mode Normally Black

D

W

ide Viewing Angle Technology MVA

timum Viewing Angle Symmetry

Op

Display Color 262,144 (6 bit color)

Co

lor of non-display area Black

rface Treatme nt

Su

Glare

Low reflection 䋲H

E

ATE DOCUMENT CONTROL SECTION

D

TITLE

NA19026----C661

NA19026

NA19026

NA19026

DRAW. NO.

T

ech Bes LCD

Tech Bes LCD----00288

Tech Bes LCD Tech Bes LCD

C661

C661C661

00288

0028800288

CUST.

IT

ED

DES

DATE

IG.

DESIG. DESCRIPTION

CHECK

APPR.

CHECK

APPR.

UJITSU DISPLAY TECHNOLOGIES

F

CORPORATION

1

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

䕣

䕘

7

䕕

䕕

/

䕤

www.panelook.com

Page 9

Global LCD Panel Exchange Center

Note

*1) Brightness, Chromaticity, Contrast is measured at a spot diameter ofφ2 and a distance=500mm.

A

*2) The value is measured 15-20 minutes after the light on.

*3) The power supply condition is VCC=3.3V,fL=50kHz,If=6mA when the optical

specification is mea sured.

*4) The operation life of the C CFL is limited. The brightness will deteriorate over time.

B

www.panelook.com

C C

D

D

E

ATE DOCUMENT CONTROL SECTION

D

IT

ED

DES

DATE

IG.

DESIG. DESCRIPTION

CHECK

APPR.

CHECK

APPR.

TITLE

NA19026----C661

NA19026

NA19026

NA19026

DRAW. NO.

T

ech Bes LCD

Tech Bes LCD----00288

Tech Bes LCD Tech Bes LCD

UJITSU DISPLAY TECHNOLOGIES

F

CORPORATION

1

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

C661

C661C661

00288

0028800288

䕣

䕘

䕕

䕕

䕤

CUST.

8

/

www.panelook.com

Page 10

Global LCD Panel Exchange Center

play

www.panelook.com

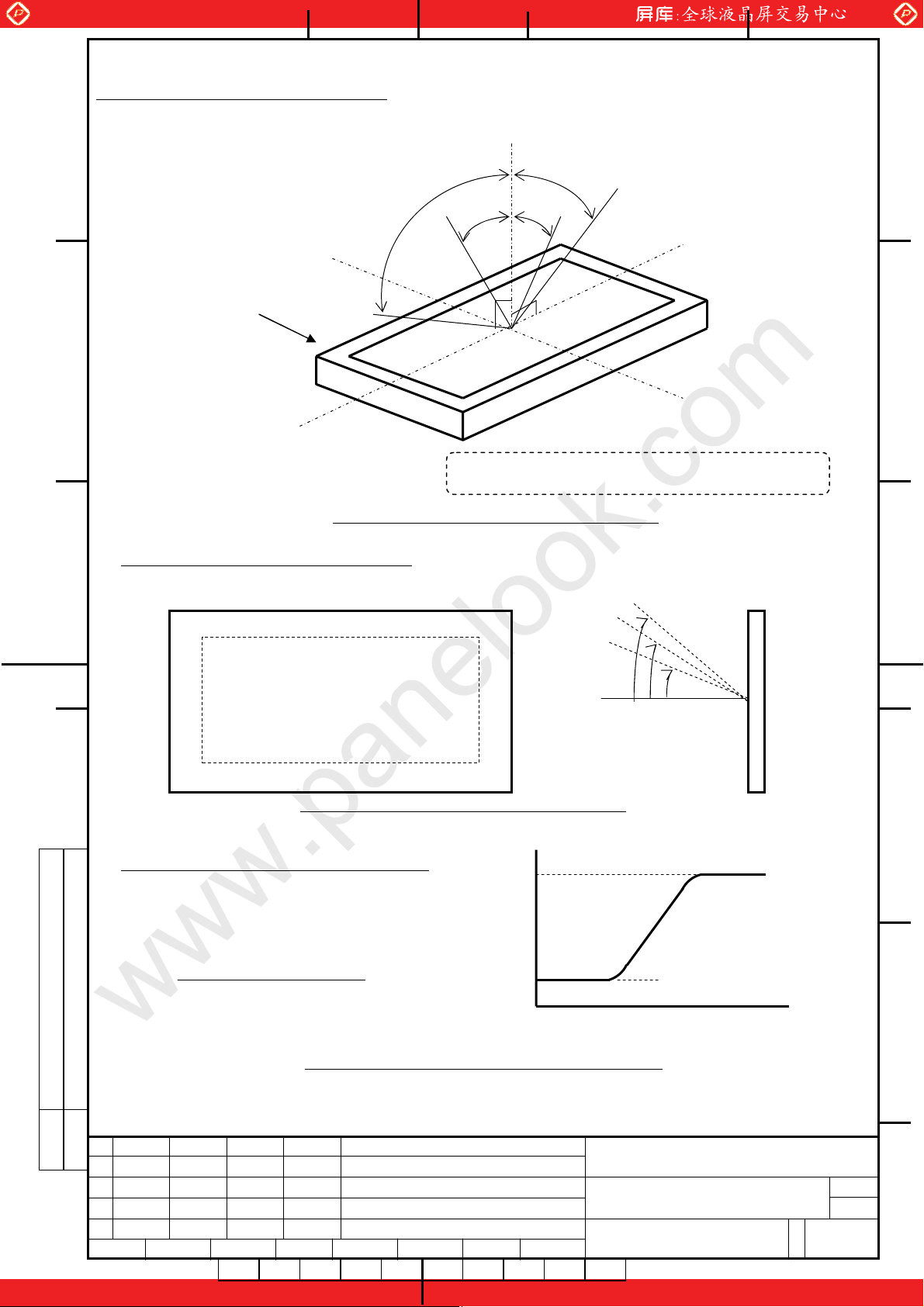

Note 1) D

A

B

efinition of Viewing Angle (1)

sed on Figure 9-1.

Ba

T

Le

Y+

op (12 o’clock Direction)

LCD module

X-

ft (9 o’clock Direction)

Figure 9-1 Definition of Viewing Angle (1)

㱔

䌌

㱔

U

䋪㸢 㱔

*0㫦(Fro

U

nt)

㱔

䌒

㱔

䌄

䋽䋰㫦䋬㱔D䋽䋰

X+

Ri

ght (3 o’clock Direction)

Y-

Bottom (6 o’clock Direction)

㫦䋬㱔

䋽䋰

L

㫦䋬㱔

R

䋽䋰

㫦

Note 2) D

C C

efinition of Viewing Angle (2)

Based on Figure 9-2.

Di

splay Surface

㱔

㱔

L,R,U,D

=0㫦

㱔

MIN

TYP

㱔

MAX

s

Di

Surfa

ce

D

Figure 9-2 Definition of Viewing Angle (2)

Note 3) Definition of Contrast Ratio (CR)

L

W

White

Determined by Formula (1) based on

Figure 9-3 Voltage-Brightness

ightness

characteristics.

Br

䌛L䌝

ack

0

Bl

anel Drive Voltage 䌛䌖䌝

P

䌌

Brightness at white)

(

W

=

䌌

(Brightness at black) 㵺㵺(1)

䌂

L

B

0

D

E

Figure 9-3 Voltage-Brightness Characteristics

ATE DOCUMENT CONTROL SECTION

D

IT

ED

DES

DATE

IG.

DESIG. DESCRIPTION

CHECK

APPR.

CHECK

APPR.

TITLE

NA19026----C661

NA19026

NA19026

NA19026

DRAW. NO.

T

ech Bes LCD

Tech Bes LCD----00288

Tech Bes LCD Tech Bes LCD

UJITSU DISPLAY TECHNOLOGIES

F

CORPORATION

1

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

C661

C661C661

00288

0028800288

䕣

䕘

䕕

䕕

䕤

CUST.

9

/

www.panelook.com

Page 11

Global LCD Panel Exchange Center

p

p

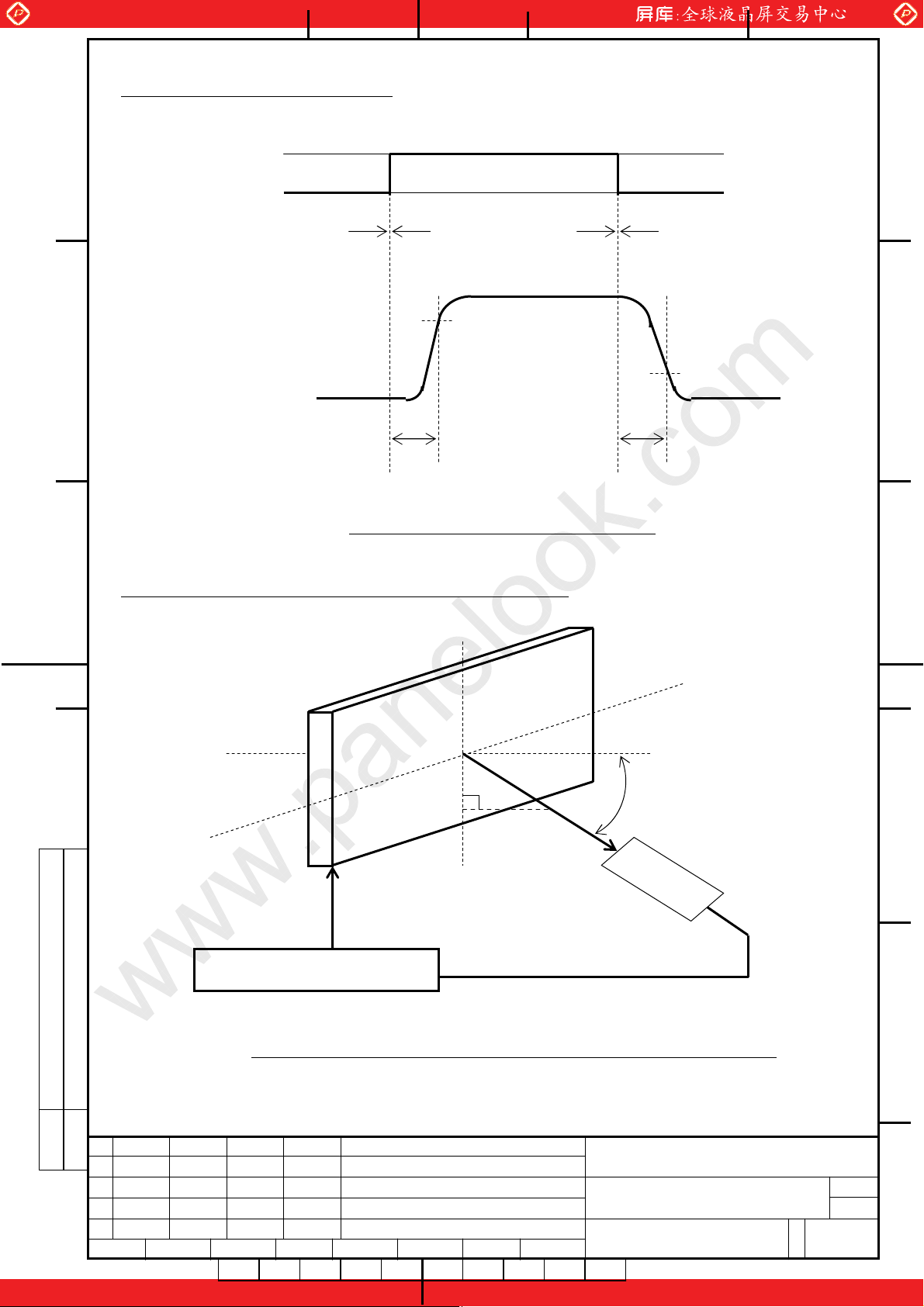

Note 4) Definition of Response Time

Based on Figure 9-4.

www.panelook.com

A

D

rive signal of

LCD panel

ON

OFF

Non-select status Select status Non-select status

100%

lative

Re

Brightnes

B

90%

White

10%

0%

Bl

ack

ON

Res

䌴

on

on

se Time O FF Res

䌴

f

of

on

se Time

Bl

ack

Figure 9-4 Definition of Response Time

C C

e 5) Contrast Ratio and Response Measurement System

Not

D

Ba

sed on Figure 9-5.

-

Z

-

X

rive and Measurement System

D

Figure 9-5 Contrast Ratio and Response T ime Measurement System

+

Y

+

X

+

Z

ightness Meter or

Br

㱔

-

Y

Luminance colorimeter

(with luminosity

correction function)

D

E

ATE DOCUMENT CONTROL SECTION

D

IT

ED

DES

DATE

IG.

DESIG. DESCRIPTION

CHECK

APPR.

CHECK

APPR.

TITLE

NA19026----C661

NA19026

NA19026

NA19026

DRAW. NO.

T

ech Bes LCD

Tech Bes LCD----00288

Tech Bes LCD Tech Bes LCD

UJITSU DISPLAY TECHNOLOGIES

F

CORPORATION

1

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

C661

C661C661

00288

0028800288

䕣

䕘

䕕

䕕

䕤

CUST.

10

/

www.panelook.com

Page 12

Global LCD Panel Exchange Center

Note 6) Definition of Optimum Viewing Angle

www.panelook.com

Co

MAX

ntrast

A

Ratio

10

B

䋨-䋩

V

6 o’cloc

e 7) Definition of Brightness Uniformity

Not

Brightness Uniformi ty is defined by the following formula using 9 points 䋨㽲䌾㽺䋩

The

k㸠

Fig

ure 9-6 Definition of Viewing Angle

0

iewing Angle㱔

䋨+䋩

㸢12 o’clock

of the brightness measur ing value shown bellow.

C C

D

Definitional Equat ion:

䌻䋨Minimum Brightness of 㽲䌾㽺䋩䋯䋨Maximum Brightness of 㽲䌾㽺䋩䌽㬍䋱䋰䋰䌛䋦䌝

154 512

①

②

③

④

⑤

⑥

870

⑦

⑧

⑨

Do

t

115

384

653

Note) The center of each position is defined by th e center spot position of the

brightness meter in which the tolerance of the measurement position is ±3mm.

D

E

Figure 9-7 Measuring Points

ATE DOCUMENT CONTROL SECTION

D

IT

ED

DES

DATE

IG.

DESIG. DESCRIPTION

CHECK

APPR.

CHECK

APPR.

TITLE

NA19026----C661

NA19026

NA19026

NA19026

DRAW. NO.

T

ech Bes LCD

Tech Bes LCD----00288

Tech Bes LCD Tech Bes LCD

UJITSU DISPLAY TECHNOLOGIES

F

CORPORATION

1

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

C661

C661C661

00288

0028800288

䕣

䕘

䕕

䕕

䕤

CUST.

11

/

www.panelook.com

Page 13

Global LCD Panel Exchange Center

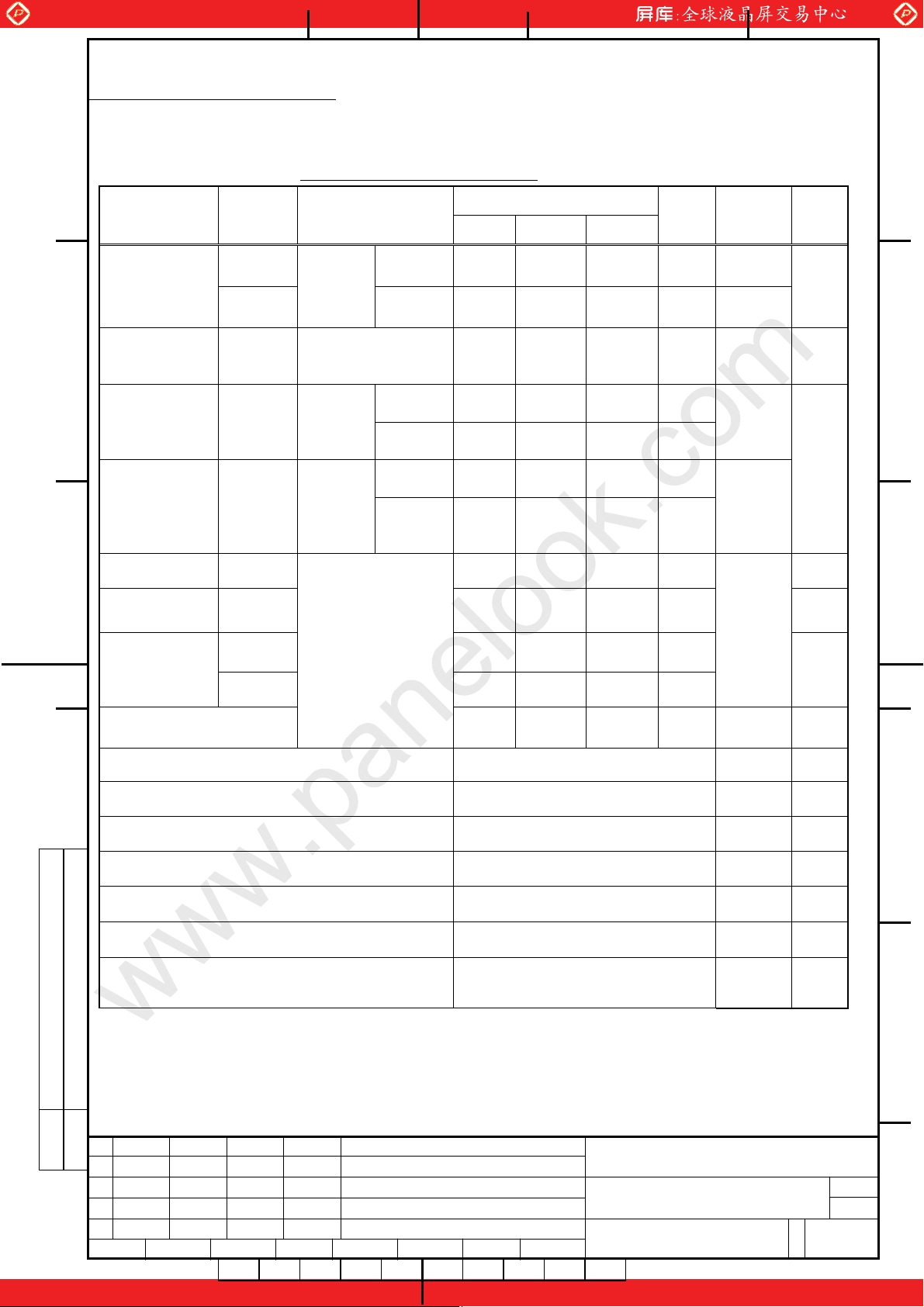

0. INTERFACE SPECIFICATIONS

1

1 Interface Signal Alignme nt

A

10.

T

able 10-1 shows the descri ption and configuration of the interface signals (CN1)

Pi

www.panelook.com

Ta ble 10-1 Interface signals

n No. Symbol Function

+3.3V power supply

+3.3V power supply

B

1 V

2 V

VSS Ground

3

VSS Ground

4

5

CC

CC

RX0- LVDS signal 0-

6 RX0+ LVDS signal 0+

VSS Ground

7

8 RX1- LVDS signal 19

C C

10 VSS Ground

RX1+ LVDS signal 1+

11 RX2- LVDS signal 212

RX2+ LVDS signal 2+

13 VSS Ground

14 RX

15 RX

C- LVDS signal CLK-

C+ LVDS signal CLK+

D

16 VS

17 VEDID

8 NC NC

1

S Ground

19 CLKEDID DDC

20 D

Co

nnector used :FI-SEB20P-HF13

ATA

EDID DDC

Adapted Connector:FI-SE20M

Name of Maker:Japan A viation Electronics Ltd.

Note) Terminal 18 should be open.

ATE DOCUMENT CONTROL SECTION

D

DDC+3.

clock

data

3Vpower supply

TITLE

NA19026----C661

NA19026

NA19026

DRAW. NO.

T

Tech Bes LCD----00288

Tech Bes LCD Tech Bes LCD

NA19026

ech Bes LCD

D

E

C661

C661C661

00288

0028800288

CUST.

IT

ED

DES

DATE

IG.

DESIG. DESCRIPTION

CHECK

APPR.

CHECK

APPR.

UJITSU DISPLAY TECHNOLOGIES

F

CORPORATION

1

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

䕣

䕘

12

䕕

䕕

/

䕤

www.panelook.com

Page 14

Global LCD Panel Exchange Center

T

ransmitter

DS90C365

pin INPUT System side

44

45

47

48

1

3

4

A

B

ut

Inp

Signal

*1

R0

R1

R2

R3

R4

R5

G0

T

TxIN0

TxIN1

TxIN2

TxIN3

TxIN4

TxIN5

TxIN6

www.panelook.com

able 10-2 LVDS Data A ssignment

Interface connector

LCD module

pin

UT0+

Tx O

Tx OUT0-

6

5

Rx0+

Rx0-

LCD

Control

input

R0

R1

R2

R3

R4

R5

G0

G1

G2

G3

G4

G5

B0

B1

6

7

9

10

12

13

15

TxIN7

TxIN8

TxIN9

TxIN10

TxIN11

TxIN12

TxIN13

Tx O

UT1+

Tx OUT1-

9

8

Rx1+

Rx1-

G1

G2

G3

G4

G5

B0

B1

C C

B2

B3

B4

B5

RSVD

RSVD

ENAB

16

18

19

20

22

23

25

TxIN14

TxIN15

TxIN16

TxIN17

TxIN18

TxIN19

TxIN20

Tx OUT2+

Tx OUT2-

12

11

Rx2+

Rx2-

B2

B3

B4

B5

Not use

Not use

ENAB

D

D

CLK 26 TxCLK IN

TxCLK OUT+

15

RxC+

DCLK

D

TxCLK OUT-

*1 Th

e RSVD (reserved) pin on the tran smitter should be connected to the Ground

ATE DOCUMENT CONTROL SECTION

D

IT

ED

DES

DATE

IG.

DESIG. DESCRIPTION

CHECK

APPR.

CHECK

APPR.

14

RxC-

TITLE

NA19026----C661

NA19026

NA19026

NA19026

DRAW. NO.

T

ech Bes LCD

Tech Bes LCD----00288

Tech Bes LCD Tech Bes LCD

UJITSU DISPLAY TECHNOLOGIES

F

CORPORATION

1

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

E

C661

C661C661

00288

0028800288

䕣

䕘

䕕

䕕

䕤

CUST.

13

/

www.panelook.com

Page 15

Global LCD Panel Exchange Center

0.2 CORRESPONDENCE BETWEEN COLOR AND INPUT SIGNAL

1

able 10-3 shows the cor respondence between input signal and color

T

lor and

Co

A

Brightness

Gradation

Black

Blue

Green

Cyan

Re

d

䌣 䌃䌯䌬䌯䌲

enta

Mag

B

䌂䌡䌳䌩

Y

ellow

White

Black 0

×

1

Darker 2

×

:

Ø

䌤 Gradation

䌒䌥

C C

hter 61

Brig

Ø

d 63

Re

Black 0

×

rker

Da

::

:

:

:

::

62

1

2

×

:

Ø

䌥䌥䌮 Gradation

Brighte

䌇䌲

Ø

Green

:

::

::::

r 61

62

63

Black 0

D

×

Da

rker 2

1

×

:

Ø

䌥 Gradation

::

:

:

::

:

Brighter 61

䌂䌬䌵

Ø

Blu

e 63

62

R4 R3 R2 R1 R0

R5

0

0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

0 0 0 0 0 0 0 0 0 0 0 1 1 1 1 1 1

0

0

0 0 0 0 0

0 0 0 0 0

0

1 1 1 1 1 0 0 0 0 0 0 0 0 0 0 0 0

1

1

1 1 1 1 1

1 1 1 1 1

1

1 1 1 1 1

1

0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

0

0 0 0 0 1 0 0 0 0 0 0 0 0 0 0 0 0

0

0 0 0 0 1 0 0 0 0 0 0 0 0 0 0 0 0 0

:

: : : : : : :

: : : : : : : : : : : : : : : :

: : : : : : : : : : : : : : : :

: : : : : : : :

: : : : : : : : : : : : : : : :

: : : : : : : : : : : : : : : :

: : : : : : : :

: : : : : : : : : : : : : : : :

: : : : : : : : : : : : : : : :

1 1 1 0 1

1

1

1 1 1 1 0

1 1 1 1 1

1

0

0 0 0 0 0

0 0 0 0 0

0

0 0 0 0 0

0

:

: : : : : : :

: : : : : : : : : : : : : : : :

: : : : : : : : : : : : : : : :

: : : : : : : :

: : : : : : : : : : : : : : : :

: : : : : : : : : : : : : : : :

: : : : : : : :

: : : : : : : : : : : : : : : :

: : : : : : : : : : : : : : : :

0

0 0 0 0 0

0 0 0 0 0

0

0

0 0 0 0 0

0 0 0 0 0

0

0

0 0 0 0 0

0

0 0 0 0 0

: : : : : : :

: : : : : : : : : : : : : : : :

:

: : : : : : : :: : : : : : : :

:

: : : : : : :

: : : : : : : : : : : : : : : :

: : : : : : : : : : : : : : : :

: : : : : : :

: : : : : : : : : : : : : : : :

:

: : : : : : : : : : : : : : : :

0 0 0 0 0

0

0 0 0 0 0

0

0

0 0 0 0 0

www.panelook.com

Data Signal (0:Low Level, 1:High Level)

G5 G4 G3

1 1 1 1 1 1

1 1 1 1 1 1

0

1

1

: : : : : : : : : : : : :

: : : : : : : : : : : : : : : :

: : : : : : : : : : : : : : : :

: : : : : : : : : : : : : : : :

: : : : : : : : : : : : : : : :

: : : : : : : : : : : : : : : :

0

0

0

0

0

0

: : : : : : : : : : : : : : : :

: : : : : : : : : : : : : : : :

: : : : : : : : : : : : : : : :

: : : : : : : : : : : : : : : :

: : : : : : : : : : : : :

: : : : : : : : : : : : : : : :

1

1

1

0

0

0

: : : : : : : : : : : : : : : :

: : : : : : : :: : : : : : : :

: : : : : : : : : : : : :

: : : : : : : : : : : : : : : :

: : : : : : : : : : : : : : : :

: : : : : : : : : : : : : : : :

0

0

0

G2 G1 G0 B5 B4 B3 B2 B1 B0

0

1

0 0 0 0 0 1 1 1 1 1 1

1 1 1 1 1

1 1 1 1 1

0 0 0 0 0

0 0 0 0 0

0 0 0 0 0

0 0 0 0 0

0 0 0 0 1

0 0 0 1 0

1 1 1 0 1

1 1 1 1 0

1 1 1 1 1

0 0 0 0 0

0 0 0 0 0

0 0 0 0 0

0 0 0 0 0

0 0 0 0 0

0 0 0 0 0

0

1

: : : : : : : :

: : : : : : : : : :

: : : : : : : :

: : : : : : : : : : : : : : : :

: : : : : : : :

: : : : : : : : : : : : : : : :

0

0

0

0 0 0 0 0 0

0 0 0 0 0 0

0

: : : : : : : :

: : : : : : : : : : : : : : : :

: : : : : : : :

: : : : : : : : : : : : : : : :

: : : : : : : :

: : : : : : : : : :

0

0

0

0

0

0

: : : : : : : :

: : : : : : : :: : : : : : : :

: : : : : : : :

: : : : : : : : : :

: : : : : : : :

: : : : : : : : : : : : : : : :

1

1

1

0 0 0 0 0

1 1 1 1 1

0 0 0 0 0

1 1 1 1 1

: : :

: : : : : :

0 0 0 0 0

0 0 0 0 0

0 0 0 0 0

0 0 0 0 0

: : :

: : : : : :

0 0 0 0 0

0 0 0 0 0

0 0 0 0 0

0 0 0 0 0

0 0 0 0 1

0 0 0 1 0

: : :

: : : : : :

1 1 1 0 1

1 1 1 1 0

1 1 1 1 1

D

Note 1) D

efinition of gray scale: Color (n)…”n” indicates the gray scale level.

The larger number means brighter level.

Note 2) Data: 1:High level, 0:Low level

Note 3) There are 18 color data which consists of 6 bit of red, green and blue where they

individually display 64 signals. By combining these colors, 262,144 colors can be

displayed.

ATE DOCUMENT CONTROL SECTION

D

IT

ED

DES

DATE

IG.

DESIG. DESCRIPTION

CHECK

APPR.

CHECK

APPR.

TITLE

NA19026----C661

NA19026

NA19026

NA19026

DRAW. NO.

T

ech Bes LCD

Tech Bes LCD----00288

Tech Bes LCD Tech Bes LCD

UJITSU DISPLAY TECHNOLOGIES

F

CORPORATION

1

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

E

C661

C661C661

00288

0028800288

䕣

䕘

䕕

䕕

䕤

CUST.

14

/

www.panelook.com

Page 16

Global LCD Panel Exchange Center

3 INPUT SIGNAL TIMING

10.

input signal timing is show n i n table 10-3 and figure 10-1.

A

The

www.panelook.com

Ta ble 10-3 T im ing Chara cterist ics

(Ta=0〜50℃,Vcc=3.3±0.3V)

Item Symbol MIN. TYP. MAX. Unit Remark

Period

DC

LK

Signal

(Clock)

B

CLK-Data

D

Timing

zontal

Hori

Signal

rtical

Ve

Signal

C C

AB signal Data ENAB timing

EN

Frequency

Duty

High time

Low time

Setup time

Hold time

Horizontal period

Hor. Period (1)

Hor. Display period

Vertical Period

Ver. Frequency

Ver. Display period

Tc

1/Tc

Tch/Tc

TclkH

TclkL

Ts

et

Thold

Th

Th

Thd

Tv

1/Tv

Tvd

Td

n

15

15.

60

45

6.0

6.0

3

5

1320

0

18.

1024

780

55

768

─

15.38

65

50

─

─

─

─

1344

20.68

1024

806

60

768

0

16.67

66

55

─

─

─

─

2046

─

1024

1023

65

768

─

ns

MHz

%

ns

ns

ns

ns

DCL

K

μs

DCL

K

Th

Hz

Th

DCL

K

*4

*1,4

*4

*2

*1

16.67ms

*2

*3

*1) ・The horizontal direction of the dis pl ay p os ition is defined by the rise of the ENA B s ign al.

Right after the signal rises, the latched data is displayed from the left edge of the screen.

The vertical direction of the display position is when th e E N AB signal changes from “H”

to “L” and “L” is over 2048 DCLK, then the next risen ENAB signal data is displayed from

the top line of the screen.

D

*2) ・If the “H” period of the ENAB signal is less then 1024 DCLK, then black is displayed on the

remaining area.

・If the ENAB signal is les s than 768 Th within a frame, then the d is pl ayed data is

continuously displaye d from the top line of the screen co ntinuously.

*3) ・If the valid data period an d the “H” p eriod of the ENAB signal do not synchronize, then

the display position is displayed as out of place.

*

4) When the horizontal period is less than 1320 DCLK or 18μs, the display quality such as

unevenness and light line defect can occur.

If the DCLK frequency exceeds 66MHz, garbled data may ca use flickering.

In addition, if the DCLK frequency is le ss than 60MHz, then unevenness may occur.

D

E

ATE DOCUMENT CONTROL SECTION

D

IT

ED

DES

DATE

IG.

DESIG. DESCRIPTION

CHECK

APPR.

CHECK

APPR.

TITLE

NA19026----C661

NA19026

NA19026

NA19026

DRAW. NO.

T

ech Bes LCD

Tech Bes LCD----00288

Tech Bes LCD Tech Bes LCD

UJITSU DISPLAY TECHNOLOGIES

F

CORPORATION

1

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

C661

C661C661

00288

0028800288

䕣

䕘

䕕

䕕

䕤

CUST.

15

/

www.panelook.com

Page 17

Global LCD Panel Exchange Center

A

DCLK

ENAB

R5-0

G5-0

B5-0

B

R5-0

G5-0

B5-0

ENAB

www.panelook.com

Tc

lk

TclkL

0.9V

1Tset

Tc

Tc

2.3V

Tc

1.

65

h

Th

Thd

old

2.3V

0.9V

Th

R5-0

C0

01 C768

G5-0

B5-0

C C

ENAB

Tvd

Tv

Tc

DCLK

D

R5-0

0001

0002

0003

0004

0005

0006 1018

1019

1021 1023

1020

1022

1024

G5-0

B5-0

Tdn Tdn

ENAB

D

Figure 10-1 Input Signal Timing Chart

ATE DOCUMENT CONTROL SECTION

D

IT

ED

DES

DATE

IG.

DESIG. DESCRIPTION

CHECK

APPR.

CHECK

APPR.

TITLE

NA19026----C661

NA19026

NA19026

NA19026

DRAW. NO.

T

ech Bes LCD

Tech Bes LCD----00288

Tech Bes LCD Tech Bes LCD

UJITSU DISPLAY TECHNOLOGIES

F

CORPORATION

1

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

E

C661

C661C661

00288

0028800288

䕣

䕘

䕕

䕕

䕤

CUST.

16

/

www.panelook.com

Page 18

Global LCD Panel Exchange Center

㻡

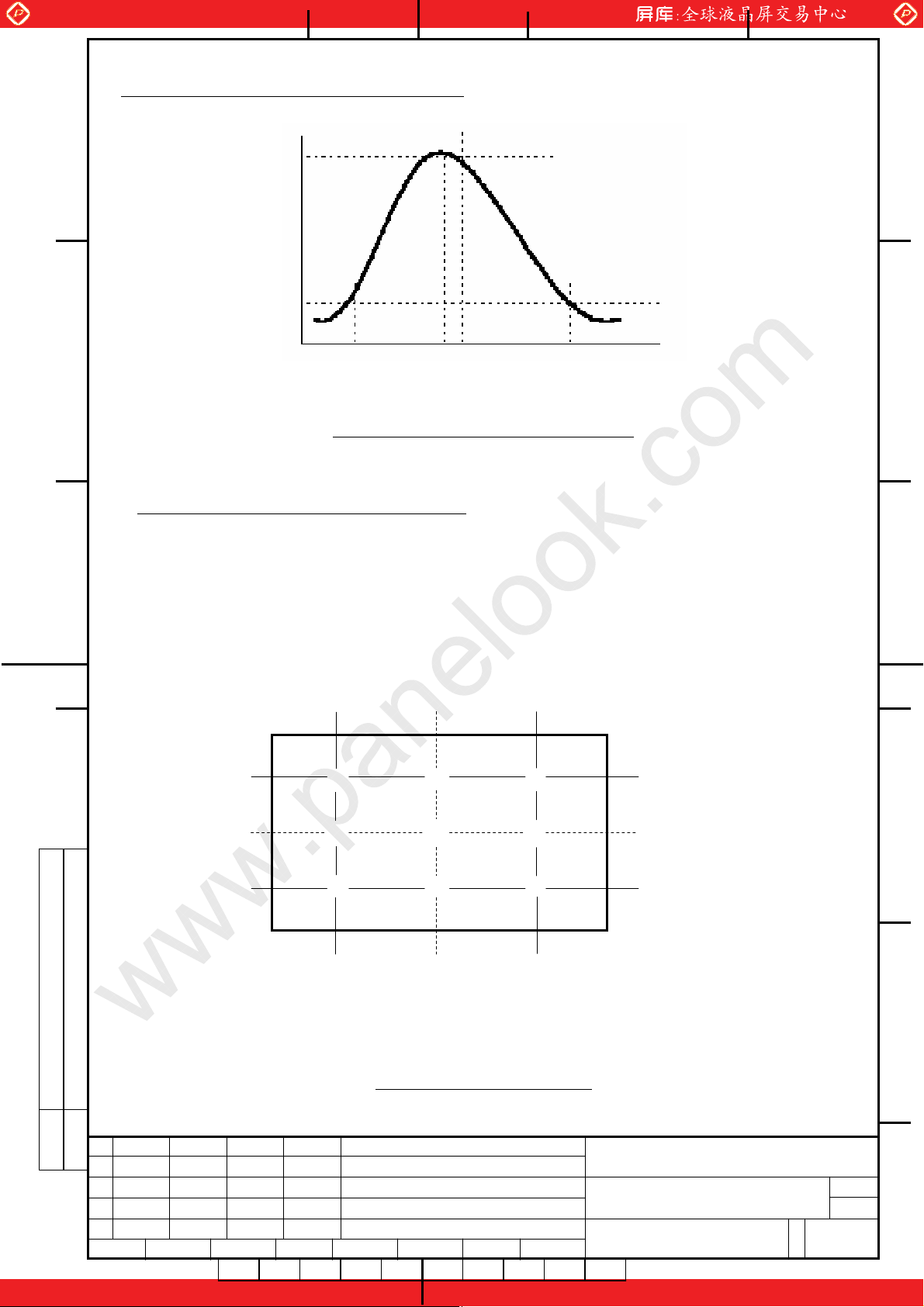

4 Correspondence bet ween Data and Display Position

10.

ure 10-2 shows the Correspondence between D ata and Display Positio n.

A

Fig

S0001 S0002 S0003 S0004 S0005 S0006 S0007 S0008 S3071 S3072

www.panelook.com

C001

R

0001G0001B0001R0002G0002B0002R0003G0003

G

1024B1024

B

G

C7

68R0001G0001B0001R0002G0002B0002R0003G0003

igure 10-2 Correspondence Data and Display Position

F

1024B1024

C C

10-5 Pow

er Supply Sequence

ure 10-3 defines the rise tim e of the power supply, voltage descent and the

Fig

power supply sequence. Especially the sequence of power supply and the input

signal is necessary to latch up of the driver IC and DC driving.

D

Power Supply Voltage

Vcc

O

ON

FF

(0V)

LVDS

Input Signal

ATE DOCUMENT CONTROL SECTION

D

H

L

3.0V

T4㻡20ms

90%

10%

T1

T2

10ms㻡T1㻡40m

10ms㻡T2㻡40ms

Figure 10-3 Power Supply Sequence

T5㻡20m

亖

3.0V

2.5V

s

s(Voltage Descent)

亖

亖

亖

TITLE

DRAW. NO.

3.

0V

3.0V

0.5V

ms

C661

C661C661

00288

0028800288

T6

0.1s

0ms㻡T3㻡40

NA19026----C661

NA19026

NA19026

NA19026

T

ech Bes LCD

Tech Bes LCD----00288

Tech Bes LCD Tech Bes LCD

D

E

CUST.

IT

ED

DES

DATE

IG.

DESIG. DESCRIPTION

CHECK

APPR.

CHECK

APPR.

UJITSU DISPLAY TECHNOLOGIES

F

CORPORATION

1

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

䕣

䕘

17

䕕

䕕

/

䕤

www.panelook.com

Page 19

Global LCD Panel Exchange Center

6 EDID Signal Timing

10.

able 10-4 shows DC characteristics of EDID signals. Figure 10-4 shows in put ti ming.

T

www.panelook.com

㪘

SC

Ta ble 10-5 shows AC characteristics and Table 10-6 shows the contents of EDID data.

L,SDA

Ta ble 10-4 EDID DC Characteristics

Item Symbol MIN. MAX.

Hi

gh voltage

VIH

0.

7V

EDID

─

䋨䌔a䋽䋰䌾䋵䋰㷄䋬䌖cc䋽3.3㫧䋰䋮3䌖䋩

Uni

t

Re

marks

V

Terminal

input

voltage

Low voltage

VIL

─

0.

3V

EDID

V

㪙

Hysteresis voltage

Ou

tput voltage

ll

Input

leak

current

A

input-and-output

pins

WP pin

Output leak current

VHY

VOL1

VOL2

Tv

1/Tv

n

Td

S

0.05V

─

─

-10

-10

-10

EDID

─

4

0.

0.6

10

50

10

V

V

V

μA

μA

μA

I0L

=3mA, V

I0L=6mA, V

EDID

EDID

VIN=0.1V to V

WP= V

VOUT=0

D

EDI

.1V to V

=2.5V

=2.5

EDI

D

EDID

V

,W

P=VSS

㪚 㪚

Terminal capacity

(Input and output)

erating current

Op

tillness current

S

Cin,Co

ICC W

ICC Re

ICCS

ut

r

─

─

─

─

─

10

3

1

30

100

pF

mA

mA

μA

μA

VCC=5

Ta=25㷄, Fclk=1MHz

V

V

V

VCC=5.5V,SDA=SCL=VCC

WP=VSS,A0,A㪈,A2=VSS

.0V

=

5.5V,SCL=400KHz

EDID

=

5.5V,SCL=400KHz

EDID

CC=3.0V,SDA=SCL=VCC

㪛

ATE DOCUMENT CONTROL SECTION

D

IT

ED

DES

DATE

IG.

DESIG. DESCRIPTION

CHECK

APPR.

CHECK

APPR.

TITLE

NA19026----C661

NA19026

NA19026

NA19026

DRAW. NO.

T

ech Bes LCD

Tech Bes LCD----00288

Tech Bes LCD Tech Bes LCD

UJITSU DISPLAY TECHNOLOGIES

F

CORPORATION

㪈

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

㪛

㪜

C661

C661C661

00288

0028800288

䕣

䕘

䕕

䕕

䕤

CUST.

18

/

www.panelook.com

Page 20

Global LCD Panel Exchange Center

able 10-5 EDID AC Characteristics

T

www.panelook.com

㪘

Item Symbol

Standard

operation mode

Vcc=2.5V-5.5V

Vcc=4.5V-5.5V

High-speed

operation mode

Unit Remarks

MIN. MAX. MIN. MAX.

lock frequency Fclk

C

THI

lock high time

C

ock low time TLOW

Cl

SDA

, SCL rising time TR

, SCL falling time TF

SDA

㪙

ST

ART hold time

ART setup time

ST

DATA input hold time

DATA input setup time

OP setup time

ST

Output decision time

from a clock

B

us free time TBUF

Min

㪚 㪚

imum VIH, VIL

Rising time

Spike oppression

(SDA, SCL pins)

write-in cycle time TWR

A

The

number of times of

data rewriting

GH

D:SDA

TH

TSU:ST

THD:

DAT

DAT

STU:

TSU:STO

TAA 100

TOF

TSP

─

─

4000

4700

─

─

4000

A

4700

0

250

4700

4700

─

─

─

1M

100

─

─

1000

300

─

─

─

─

─

3500

─

250

50

10

─

20+

─

600

1300

─

─

600

600

0

100

600

100

1300

0.1CB

─

─

1M

400

─

─

300

300

─

─

─

─

─

900

─

250

50

10

─

kHz

ns

ns

ns

ns

ns

ns

ns

ns

ns

ns

ns

ns

ns

ms

cycle

CB≦10

Byt

25℃,

0pF

e and page mode

Vcc=5.0V

block mode

ATE DOCUMENT CONTROL SECTION

D

㪛

CLKedid

TSU:STA

TAedid

DA

SOA

OUT

TAA

TF

TH

IGH

TLOW

THD:

STA THD:DAT

TH

D:STA

Fig

ure 10-4 EDID signal timi ng

TSU:DA

T

AA

TR

㪛

T

TSU:STA

TBUF

㪜

TITLE

NA19026----C661

NA19026

NA19026

DRAW. NO.

T

Tech Bes LCD----00288

Tech Bes LCD Tech Bes LCD

NA19026

ech Bes LCD

C661

C661C661

00288

0028800288

CUST.

IT

ED

DES

DATE

IG.

DESIG. DESCRIPTION

CHECK

APPR.

CHECK

APPR.

UJITSU DISPLAY TECHNOLOGIES

F

CORPORATION

㪈

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

䕣

䕘

19

䕕

䕕

/

䕤

www.panelook.com

Page 21

Global LCD Panel Exchange Center

.

Ad

ress

㪘

Byte

s

Header (8bytes) Color Characteristics (10bytes)

No

d

scription Data Addr

De

www.panelook.com

able 10-6 The Content s of EDID data

T

No

ess

Byte

s

.

scription Data

De

00h 1

01h

1 FFh 1Ah 1 Blue/White Low Bits **h

02h 1

00h 19h 1 Red/Green Low Bits **h

FFh 1Bh 1 Red-x **h

03h 1 FFh 1Ch 1 Red-y **h

04h 1

FFh 1Dh 1 Green-x **h

05h 1 FFh 1Eh 1 Green-y **h

㪙

06h 1 FFh 1Fh 1 Blue-x **h

07h 1

V

endor/Product identification (10 bytes) 21h 1 White-x **h

08h

2 ID Manufacturer name 1894h 22h 1 White-y **h

00h 20h 1 Blue-y **h

0Ah 2 ID product code ****h Established timing (3 bytes)

0C

h 1 ID serial number **h 23h 1 Established Timings1 00h

h 1 ID serial number **h 24h 1 Established Timings2 00h

0D

M

h 1 ID serial number **h 25h 1

㪚 㪚

0E

h 1 ID serial number **h Standard timing identification

0F

anufactures reserved

timing

00h

(16 bytes)

10h

1

12h 1

1 Week of man ufacture

**䌨

1h 1 Y ear of manufacture **h

ID (2bytes)

ED

Version # 01h

26h 2 Standard timing

Identification #1

28h 2 Standard timing

Identification #2

61h

40h

01h

01h

13h 1 Revision # 03h

asic display parameter/features (5 bytes)

㪛

B

14h 1

15h

16h

1 Max. horizontal image size 1Eh

1 Max. vertical image size 17h

17h 1

Video input definition 80h

Display transfer

B4h

2Ah 2 Standard timing

Identification #3

2Ch 2 Standard timing

Identification #4

2Eh 2 Standard timing

Identification #5

01h

01h

01h

01h

01h

01h

㪛

Characteristics (Gamma)

18h 1

ATE DOCUMENT CONTROL SECTION

D

Feature support 08h

30h 2

Standard timing

Identification #6

32h 2 Standard timing

Identification #7

34h 2 Standard timing

Identification #8

TITLE

NA19026----C661

NA19026

NA19026

DRAW. NO.

T

Tech Bes LCD----00288

Tech Bes LCD Tech Bes LCD

NA19026

ech Bes LCD

C661

C661C661

00288

0028800288

01h

01h

01h

01h

01h

01h

㪜

CUST.

IT

ED

DES

DATE

IG.

DESIG. DESCRIPTION

CHECK

APPR.

CHECK

APPR.

UJITSU DISPLAY TECHNOLOGIES

F

CORPORATION

㪈

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

䕣

䕘

20

䕕

䕕

/

䕤

www.panelook.com

Page 22

Global LCD Panel Exchange Center

dd

A

ress

㪘

D

D

No.

bytes

etailed timing descript ion (72 bytes) 56h 00h

etailed timing descript ion 1 (18 bytes) 57h 00h

Description Data Add

36h

37h

38h

00h Detailed timing description #3 or monitor

39h

h 41h 5Bh 00h

3A

3B

h 00h 5Ch 00h

㪙

h 25h 5Dh 10h

3C

3Dh 30h 5Eh 00h

3Eh 00h 5Fh 00h

h 00h 60h 00h

3F

www.panelook.com

No.

ress

bytes

64h 58h 00h

19h 59h 00h

Descriptor (18 bytes)

40h 5Ah 00h

Description Data

40h

41h

42h

43h

44h 10h 65h 00h

㪚 㪚

45h

46h

47h

Detai

led timing description #2 or monitor

00h 61h 00h

00h 62h 00h

30h 63h 00h

E4h 64h 00h

00h 66h 00h

00h 67h 00h

18h 68h 00h

69h 00h

descriptor

(18 bytes)

48h

00h 6Ah 00h

49h 00h 6Bh 00h

h 00h Detailed timing descr iption #4 or monitor

4A

㪛

descriptor (18 bytes)

4B

h 10h 6Ch 00h

4C

h 00h 6Dh 00h

h 00h 6Eh 00h

4D

4Eh 00h 6Fh 10h

h 00h 70h 00h

4F

㪛

50h

00h 71h 00h

51h 00h 72h 00h

52h

53h

54h

55h

ATE DOCUMENT CONTROL SECTION

D

IT

ED

DES

DATE

IG.

DESIG. DESCRIPTION

CHECK

APPR.

CHECK

00h 73h 00h

00h 74h 00h

00h 75h 00h

00h 76h 00h

TITLE

NA19026----C661

NA19026

NA19026

NA19026

CORPORATION

APPR.

DRAW. NO.

T

ech Bes LCD

Tech Bes LCD----00288

Tech Bes LCD Tech Bes LCD

UJITSU DISPLAY TECHNOLOGIES

F

㪈

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

㪜

C661

C661C661

00288

0028800288

䕣

䕘

䕕

䕕

䕤

CUST.

21

/

www.panelook.com

Page 23

Global LCD Panel Exchange Center

dd

A

ress

㪘

77h

No.

bytes

Description Data

www.panelook.com

00h

78h

00h

79h 00h

7Ah 00h

7B

h 00h

h 00h

7C

h 00h

7D

7Eh 00h

㪙

7F

h Check Sum **h

㪚 㪚

㪛

ATE DOCUMENT CONTROL SECTION

D

IT

ED

DES

DATE

IG.

DESIG. DESCRIPTION

CHECK

APPR.

CHECK

APPR.

TITLE

NA19026----C661

NA19026

NA19026

NA19026

DRAW. NO.

T

ech Bes LCD

Tech Bes LCD----00288

Tech Bes LCD Tech Bes LCD

UJITSU DISPLAY TECHNOLOGIES

F

CORPORATION

㪈

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

㪛

㪜

C661

C661C661

00288

0028800288

䕣

䕘

䕕

䕕

䕤

CUST.

22

/

www.panelook.com

Page 24

Global LCD Panel Exchange Center

1 BACK-LIGHT SPECIFICATION

1

www.panelook.com

A

1-1 Pin configuration for Back-light

1

Ta ble 11-1 shows the description of the pin assignment and the type s of

back-light (CN-2)

Ta ble1 1-1 Pin Assignment of CN-2

n No. Signal Function Remark

Pi

B

1VH

2VL

Power s

(High)

Power s

(Low)

upply for CCFL

upply for CCFL

Cable color: Pink

Cable color: White

Used connector : BHSR−02VS−1

Applied connector : SM02B−BHSS−1

Maker :Japanese Solde rle ss Terminal Tr ad ing Com pa ny LTD. (J. S. T)

C C

11-2 Life

D

The

life duration of the LCD pane l is considered to be over 50,000 hours.

The life duration of the Back Light is considered to be over 10, 000 hours based on th e

criteria bellow.

(1)Operating condition

①Ambient temperature : 25±5℃

②Tube current(I

F) :

6mA or less

(2)Definition of life

① When brightness is bellow 50% of the minimum brightness value shown in section

9, table 9-1.

② When the CCFL turn on voltage stated in section 8 of table 8-1 exceeds

1700Vrms

③ When flickering and blinking occurs based under the condition of life guarantee.

D

E

ATE DOCUMENT CONTROL SECTION

D

IT

ED

DES

DATE

IG.

DESIG. DESCRIPTION

CHECK

APPR.

CHECK

APPR.

TITLE

NA19026----C661

NA19026

NA19026

NA19026

DRAW. NO.

T

ech Bes LCD

Tech Bes LCD----0028

Tech Bes LCD Tech Bes LCD

UJITSU DISPLAY TECHNOLOGIES

F

CORPORATION

1

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

C661

C661C661

00288888

00280028

䕣

䕘

䕕

䕕

䕤

CUST.

23

/

www.panelook.com

Page 25

Global LCD Panel Exchange Center

www.panelook.com

12.E

A

nvironmental Specif ication

T

able 12-1 shows the env ironmental specificatio n.

Ta ble 12-1 Environmental Specification

Item Specification Remark

The temperature of the LCD panel

surface (display area)

temperature.

Maximum wet bulb temperature

Should not exceed 29℃.

No condensation

For single module.

Test criteria is stated in (Note 1 )

B

emperature

T

midity

Hu

bration

Vi

Op

eration

Storage

Operation

Storage

Operation

0〜50℃

−20〜60℃

20〜85%RH

5〜85%RH

10-500Hz, 2G peak, 2 Hrs

each in X,Y,Z direction

Approx. 20 min for 1 cycle.

15G

ock

Sh

Note 1) T

, 6ms,

Non-

opera

ting

1 time each for X,Y,Z

direction

he distance between the vibration table and the back surface of the LCD

For single module.

When packaging refer to (Note 2)

module should be set to 3mm when conducting a vibration test.

Note 2) The shock resisting standard when packing is shown in table 12-2 and

figure 12-1.

C C

D

Table 12-2 Shock resistance standard when packaging module

Dropping

height

No. of times

A,B

ontact point

C

,C,D 55cm

1 time each

E,F,G,H,I,J 60cm

䌇䋨Top face䋩䌊䋨Rear face䋩

䌃䋨Ed

䌅䋨Side face䋩

e face䋩

䌆䋨Sid

䌂(Edge)

䌉䋨Front face䋩

䌄䋨Edge䋩

䌈䋨Bottom face䋩

䌁䋨Corner䋩

ge䋩

D

E

Fig

ure 12-1 The direction of applying shock when packing

ATE DOCUMENT CONTROL SECTION

D

IT

ED

DES

DATE

IG.

DESIG. DESCRIPTION

CHECK

APPR.

CHECK

APPR.

TITLE

NA19026----C661

NA19026

NA19026

NA19026

DRAW. NO.

T

ech Bes LCD

Tech Bes LCD----0028

Tech Bes LCD Tech Bes LCD

UJITSU DISPLAY TECHNOLOGIES

F

CORPORATION

1

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

C661

C661C661

00288888

00280028

䕣

䕘

䕕

䕕

䕤

CUST.

24

/

www.panelook.com

Page 26

Global LCD Panel Exchange Center

www.panelook.com

13.Di

splay

The m

odule has the following i nd ications.

A

(1)Product name : LCD Unit

(2)Model Number: NA19026-C66 1

4 9 0 0 0 0 1

0 0 0 0 1

(3) Manufacturing Number:

4 9

4 9

0 0 0 0 1 0 0 0 0 1

4 9

S

erial number

(To be reset every month on 1st.)

B

Manufacturing month

(Oct. = X, Nov. =Y, Dec. =Z)

Last digit of manufacturing year.

)Manufacturing Country Name: MADE IN JAPAN or MADE IN TAIWAN

(4

(5) Disposal method of cold-cathode tubes.

unit

LCD

C C

NA19026- C661

.

4900001

M

ADE IN TAIWAN

st2

IS

T

LOR

D

䊶TH

TF

CO

FLUORESCENT

OR

RE

GULATIONS

䊶

ᒰᶧ᥏䊂

䈇䉁䈜䈱䈪䇮ᣇ⥄ᴦ䈱᧦䉁䈢䈲ⷙೣ䈮ᓥ䈦䈩

ᑄ䈚䈩䈘䈇䇯

䉞䉴䊒䊧䉟䊡䊆䉾䊃䈮䈲Ⱟశ▤䈏⚵䉂ㄟ䉁䉏䈩

LAM

LC

FO

PS.

R

ONTAINS

C

PL

ITS DIS

EASE

CO

LLOW

FO

POSAL.

LD

CA

THODE

LO

CAL

RDINANCES

O

Figure 13-1 Product Label (Example)

14.P

ACKAGING SPECIFICATION

aging specification is specified separately in the p ackaging specification.

Pack

D

15.WARRENTY

The w

arranty period is one year after shipping. Any products that fail during this period are

repaired or replaced without charge, unless the failure is caused by the user.

Figure 13-2

D

E

ATE DOCUMENT CONTROL SECTION

D

IT

ED

DES

DATE

IG.

DESIG. DESCRIPTION

CHECK

APPR.

CHECK

APPR.

TITLE

NA19026----C661

NA19026

NA19026

NA19026

DRAW. NO.

T

ech Bes LCD

Tech Bes LCD----0028

Tech Bes LCD Tech Bes LCD

UJITSU DISPLAY TECHNOLOGIES

F

CORPORATION

1

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

C661

C661C661

00288888

00280028

䕣

䕘

䕕

䕕

䕤

CUST.

25

/

www.panelook.com

Page 27

Global LCD Panel Exchange Center

www.panelook.com

16.PREC

㪘

㪙

AUTIONS

In or

der to use the LCD module properly, please abide by the following precautions.

(1)Han

dling of LCD panel

①

Do not apply excessive mechanical s hock to the LCD panel

The

panel is made of glass. Exc es sive s hock may cause damage or malfunction to the

LCD panel.

2

② Do not press the panel surface too hard (MAX 20N/cm

The

re are 2 glass plates within the pa nel and they should be kept pe rfectl y even to

)

maintain display properties and reliability. If the panel is pressed hard, then the following

problems may occur;

① Color uniformity ②Disorder of orientation of liquid crysta l

Problem ① will clear as time passes. For problem ②, turn the power off and then on

in order to bring the screen back to normal. However, these operations should be

avoided to insure reliab il ity.

㪚 㪚

③Do n

ot scratch the polarizer film on the LCD panel s urface

o not press or rub the display surface with a hard tool, tweezers, etc.

・ D

・ When handling the panel, use cotton or conductive gloves so that the display surface

is not soiled.

・ If dust or dirt soils the display surface, use a soft cloth (deer skin) to clear the panel

using the following method;

〔Dust〕Dust the panel usi ng a soft cloth. (Do not rub).

〔Dirt〕Saturate clear water to a soft cloth and squeeze hard until there are no water

㪛

drops, then wipe the surface lightly. Make sure water or solvents are not

splashed onto the edge of the panel to prevent fluid from seep ing i nto the panel.

Do not use alcohol, detergent, ketone (acetone, etc.) and aromatics (xylene,

tolune, etc.) as solvents.

・ Adherence of saliva and water drops for a long period may cause partial deformation

and decolorization. Clean the surface prom ptly using the 〔Dirt〕method.

xCleaners that are alkaline will damage the surface of the polarizor and should not be

used

・Adherence of excessive oil is hard to clean and precaution should be taken to avoid oil

adherence.

㪛

㪜

ATE DOCUMENT CONTROL SECTION

D

IT

ED

DES

DATE

IG.

DESIG. DESCRIPTION

CHECK

APPR.

CHECK

APPR.

TITLE

NA19026----C661

NA19026

NA19026

DRAW. NO.

Tech Bes LCD

Tech Bes LCD----00288

Tech Bes LCDTech Bes LCD

UJITSU DISPLAY TECHNOLOGIES

F

NA19026

CORPORATION

㪈

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

C661

C661C661

26

CUST.

/

00288

0028800288

䕣

䕘

䕕

䕕

䕤

www.panelook.com

Page 28

Global LCD Panel Exchange Center

④ Do not place or contact objects onto the LCD pane l for a long per io d of time

www.panelook.com

㪘

There is a possibility that the components may deform an d can cause the quality of

the LCD panel to deteriorate.

(2)Handling of the LCD module

① Do not pull the cold-cathode tube cable with strength

If the cable is pulled in strength with more than 20N

㪙

deterioration of reliability.

, th

en this can cause damage or

② Assemble the equipment in a dust free environme nt

pecially conductive foreign matters can cause the module to fail.

Es

③ Take anti-electrostatic meas ures when assembling the modu le

T

he LCD unit contains a CMOS-IC. The following points should be taken into consideration.

㪚 㪚

・ General anti-electrostatic measures should be ta ken when handling instruments.

(cotton or conductive gloves should be worn/grounding worker/disposal of ground on

floor, operating table etc./disposal of operating tools (soldering iron, radio pliers,

tweezers, etc.)etc.)

・Do not take the module out of the conductive bag until the module is assembled.

・ Conduct the assembly of the module under a humid controlled environment

(50%-60%RH).

Do not handle the module under the humid of 50%RH.

㪛

④

Do not disassemble or remodel the LCD module.

Di

sassembly, remodel can cause the model to fail and can cause deterioration of display

㪛

quality and reliability.

(3) P

recautions to be made when operating the LCD module

① Please abide by the spec ified power supply sequence

This is necessary to prevent latch up of CMOS-IC, failure or deterioration of the display

quality and reliability due to the application of DC voltag e to the l iquid crystal.

㪜

ATE DOCUMENT CONTROL SECTION

D

IT

ED

DES

DATE

IG.

DESIG. DESCRIPTION

CHECK

APPR.

CHECK

APPR.

TITLE

NA19026----C661

NA19026

NA19026

DRAW. NO.

Tech Bes LCD

Tech Bes LCD----00288

Tech Bes LCDTech Bes LCD

UJITSU DISPLAY TECHNOLOGIES

F

NA19026

CORPORATION

㪈

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

C661

C661C661

27

CUST.

/

00288

0028800288

䕣

䕘

䕕

䕕

䕤

www.panelook.com

Page 29

Global LCD Panel Exchange Center

② Do not input power supply, signal when condensation occurs

www.panelook.com

㪘

If voltage is a

pplied to the panel when there is condensation on the terminal, the terminal

can cause an electrochemica l reaction and there is a possibility of disconnection.

Condensation occurs right after the unit has been moved from a cold environment to a

warm environment in a short period of time.

Troubles that occur when LCD panel is not used under recommended temperature

③

eration under high temperature(Ta>50℃):The display color shifts to blue.

・Op

・Storage under high temperature(Ta>60℃): The contrast ratio decreases due to

㪙

eration under low temperature(Ta< 0℃):The response speed of the display decreases.

・Op

deterioration of polarizer film.

・ Storage under low temperature(Ta<−20℃):The liquid cryst al may solidify and be damaged.

④ Control signal is to be input within a specified time after the power supply

has been turned on

A

fter turning the power supply on, if control signals (DCLK, ENAB) are not input into the

timing control circuit or if the input timing is not within the specified timing、 this can cause

㪚 㪚

deterioration of image quality such as DC drive of liquid crystal, image s t icking, decrease in

contrast ratio etc.

4) Precautions in regards to mounting and designing the module

①

Do not put excessive pressure onto the screen and rear si de of the L CD module

E

xcessive pressure put on to the surface of the screen under mounting condition can

cause deterioration of display quality and reliability. If excessive pressure has been put

㪛

onto the back light module, brightness uniformity can occur and the reliability of the

CCFL may decrease.

㪛

② Avoid twisting and bending the LCD module

T

wisting and bending of the LCD module can cause damage to the display quality and

reliability.

③ Do not extend the power supply cable that connects the back light and the inverter

Extension of the cable can cause the backlight to not light or flicker.

㪜

ATE DOCUMENT CONTROL SECTION

D

IT

ED

DES

DATE

IG.

DESIG. DESCRIPTION

CHECK

APPR.

CHECK

APPR.

TITLE

NA19026----C661

NA19026

NA19026

DRAW. NO.

Tech Bes LCD

Tech Bes LCD----00288

Tech Bes LCDTech Bes LCD

UJITSU DISPLAY TECHNOLOGIES

F

NA19026

CORPORATION

㪈

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

C661

C661C661

28

CUST.

/

00288

0028800288

䕣

䕘

䕕

䕕

䕤

www.panelook.com

Page 30

Global LCD Panel Exchange Center

④ Keep the power supply cable awa y from metal enclosures of the LCD module

The high voltage currency of the backlight drive may leak onto metal enclosures in which

www.panelook.com

㪘

the desired brightness may not be assured. Therefore, when evaluating take

consideration and a pp ropriate method in wiring.

⑤ When mounting the LCD module, use a M2.0 screw (x8) in which the screw should be

tightened with a torque of 20cN・m or below

⑥Initial defect or problems with long term reliability may occur when other applied

connectors are used.

㪙

(5)STORAGE METHOD

① Do not store the LCD module in an organic solvent or corrosive gas environment

・ The

polarizer film can discolor in an organic solve nt envi ronment.

・ Various parts of the module may corrode or deteriorate in a corrosive ga s environment.

② Store the LCD module in a Fujitsu package

㪚 㪚

・ The

LCD module within the container box is covered in anti-static bag.

・ When stacking the boxes, make sure it is kept bellow 4 boxes.

③ The LCD is recommended to be stored in a humidity controlled, cool and dark place

Recommended storage environment

· Place : Dark (avoid sunlight)

· Temperature: 10〜35℃

㪛

· Humidity : 50〜60%RH

Note) If the module is left in an environment of over 60℃ for a long period of time, optical

characteristics may deteriorate.

㪛

㪜

ATE DOCUMENT CONTROL SECTION

D

IT

ED

DES

DATE

IG.

DESIG. DESCRIPTION

CHECK

APPR.

CHECK

APPR.

TITLE

NA19026----C661

NA19026

NA19026

DRAW. NO.

Tech Bes LCD

Tech Bes LCD----00288

Tech Bes LCDTech Bes LCD

UJITSU DISPLAY TECHNOLOGIES

F

NA19026

CORPORATION

㪈

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

C661

C661C661

29

CUST.

/

00288

0028800288

䕣

䕘

䕕

䕕

䕤

www.panelook.com

Page 31

Global LCD Panel Exchange Center

(6)DISPOSABLE METHOD

㪘

① LCD

· T

Module

he components of this LCD module can be grouped into metal, resi n, gla ss etc.

· Descriptions of material s or abbreviated names are listed on the plastic par ts.

· The inside of the back light source of the CCFL contains mercury and should be

disposed accordi ng to the local ordinance or regul ations.

② Package

㪙

A

ll packages are made of recyclable paper s exce pt for the anti-ESD bag.

(7)Others

① If the panel breaks, d o not inhale or swallow the liquid crystal

www.panelook.com

· If the liquid crystal adheres to the body or clothes, wash the liquid off immediately

with soap.

· Follow regular precautions for other electric compone nts.

㪚 㪚

② Flux residue which may be found on the printe d circuit board is harm less

Fujitsu has adopted a non-wash technolo gy f or the module assembly process.

17 OTHERS

T

here may be changes made to the parts used in FDTC LCD panels. In those situations, a

discussion will be made in advance between both parties regarding the changes that will be

㪛

made to the parts.

In addition, if any doubts arise in regards to descript items in the specification, the problem

shall be resolved through discussion between b oth parties.

FDTC panels are not designed and manufactured for the purpose of aerospace, nuclear

reaction control, medical equipments that require extremely high reliability for life support.

Any customers that intend to use FDTC panels for these purposes should contact and

consult the design department.

㪛

ATE DOCUMENT CONTROL SECTION

D

IT

ED

DES

DATE

IG.

DESIG. DESCRIPTION

CHECK

APPR.

CHECK

APPR.

TITLE

NA19026----C661

NA19026

NA19026

DRAW. NO.

Tech Bes LCD

Tech Bes LCD----00288

Tech Bes LCDTech Bes LCD

UJITSU DISPLAY TECHNOLOGIES

F

NA19026

CORPORATION

㪈

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

C661

C661C661

30

CUST.

/

00288

0028800288

䕣

䕘

䕕

䕕

䕤

www.panelook.com

㪜

Page 32

Global LCD Panel Exchange Center

www.panelook.com

18.R

㪘

eturn method for LCD module when requested for repair or analysis of the problem

When returning the LCD module, follow the procedure accordingly by not damaging

the LCD panel or the backlight cables. (Refer to Figure 18- 1, 2, 3, 4)

It should be noted that FDTC would not take responsibility for damaged LCD modules that are

returned where the reason for damage is due to failure of following the specified packaging

procedure.

18-1 In case of made in Taiwan

㪙

(1)S

tabilize the back light cable using tape.

ar side

Re

If the cables are not stabilize d, the

connectors may scratch the LCD panel

surface or it can cause damage to the cables.

Backligh

t cable

㪚 㪚

(2)Put the LCD module into the anti-electrostatic bag.

(Do not use anti-electrostatic bag that are torn)

Anti-electrostatic bag

㪛

Fro

nt side

Fig

ure 18-1 Packaging Method

B

acklight cable

㪛

㪜

ATE DOCUMENT CONTROL SECTION

D

IT

ED

DES

DATE

IG.

DESIG. DESCRIPTION

CHECK

APPR.

CHECK

APPR.

TITLE

NA19026----C661

NA19026

NA19026

DRAW. NO.

Tech Bes LCD----0028

T

Tech Bes LCD Tech Bes LCD

UJITSU DISPLAY TECHNOLOGIES

F

NA19026

ech Bes LCD

CORPORATION

㪈

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

C661

C661C661

31

CUST.

/

00288888

00280028

䕣

䕘

䕕

䕕

䕤

www.panelook.com

Page 33

Global LCD Panel Exchange Center

www.panelook.com

㪘

㪙

(3)S

toring into a container box

・ When using a carton box manufactured by FDTC

(Carton boxes and arrowheads that are not crushed shou ld be used)

㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷

15"

& 15.2" Panel

Cu

shion

Top

For

15" & 15.2"

us

e

mark

Cushion

side

"H" taping close

Carton

label

positi on

Carton

㪚 㪚

㪛

ce the front side of the LCD module

Pla

in the direction of the arr ow shown on the

holder (top).

****Directions of arrowheads are s hown on holders****

ure 18-2 Packaging Method

Fig

・ When using other methods of packaging other than specified above

Thoughtful consideration should be take n so that damage is not ma de to the LCD module by

wrapping the module individually with an air cap. It should be noted that FDTC would not

㪛

㪜

take responsibility for damages caused by failure of packaging

ATE DOCUMENT CONTROL SECTION

D

IT

ED

DES

DATE

IG.

DESIG. DESCRIPTION

CHECK

APPR.

CHECK

APPR.

TITLE

NA19026----C661

NA19026

NA19026

DRAW. NO.

Tech Bes LCD----0028

T

Tech Bes LCD Tech Bes LCD

UJITSU DISPLAY TECHNOLOGIES

F

NA19026

ech Bes LCD

CORPORATION

㪈

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

C661

C661C661

32

CUST.

/

00288888

00280028

䕣

䕘

䕕

䕕

䕤

www.panelook.com

Page 34

Global LCD Panel Exchange Center

www.panelook.com

ase of made in Japan

Stabilize the back light cable us ing tape.

ar side

Re

㪘

18-2 In c

(1)

㪙

Backlight cable

(2)Put the LCD module into the anti-electrostatic bag.

(Do not use anti-electrostatic bag that are torn)

If the cables are not stabilized, the

connectors may scratch the LCD panel

surface or it can cause damage to the cables.

㪚 㪚

Anti-electrostatic bag

nt side

Fro

㪛

acklight cable

B

ure 18-3 Packaging Method

Fig

㪛

㪜

ATE DOCUMENT CONTROL SECTION

D

IT

ED

DES

DATE

IG.

DESIG. DESCRIPTION

CHECK

APPR.

CHECK

APPR.

TITLE

NA19026----C661

NA19026

NA19026

DRAW. NO.

Tech Bes LCD----0028

T

Tech Bes LCD Tech Bes LCD

UJITSU DISPLAY TECHNOLOGIES

F

NA19026

ech Bes LCD

CORPORATION

㪈

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

C661

C661C661

33

CUST.

/

00288888

00280028

䕣

䕘

䕕

䕕

䕤

www.panelook.com

Page 35

Global LCD Panel Exchange Center

www.panelook.com

㪘

㪙

(3)S

toring into a container box

・ When using a carton box manufactured by FDTC