Page 1

MCJ3230SS

OPTICAL DISK DRIVE

PRODUCT MANUAL

C156-E224-01EN

Page 2

FOR SAFE OPERATION

Handling of This Manual

This manual contains important information for using this product. Read thoroughly before using

the product. Use this product only after thoroughly reading and understanding especially the

section "Important Alert Items" in this manual. Keep this manual handy, and keep it carefully.

FUJITSU makes every effort to prevent users and bystanders from being injured or from suffering

damage to their property. Use the product according to this manual.

This product is designed and manufactured for use in standard applications such as office work,

personal devices and household appliances. This product is not intended for special uses (atomic

controls, aeronautic or space systems, mass transport vehicle operating controls, medical devices for

life support, or weapons firing controls) where particularly high reliability requirements exist,

where the pertinent levels of safety are not guaranteed, or where a failure or operational error could

threaten a life or cause a physical injury (hereafter referred to as "mission-critical" use). Customers

considering the use of these products for mission-critical applications must have safety-assurance

measures in place beforehand. Moreover, they are requested to consult our sales representative

before embarking on such specialized use.

First Edition November 2001

The contents of this manual may be revised without prior notice.

The contents of this manual shall not be disclosed in any way or reproduced in any media without

the express written permission of Fujitsu Limited.

All Rights Reserved, Copyright FUJITSU LIMITED 2001

C156-E224-01EN

Page 3

Revision History

(1/1)

Edition Date

01 November,

2001

Revised section (*1)

(Added/Deleted/Altered)

——

Details

*1 Section(s) with asterisk (*) refer to the previous edition when those were deleted.

C156-E224-01EN

Page 4

This page is intentionally left blank.

Page 5

This manual describes the MCJ3230SS 90 mm (3.5-inch) optical disk drive.

This manual provides an overview of the above optical disk drives, and explains

their specifications, the requirements and procedures for installing them in a

system, and how to clean them.

The manual is intended for users who have a basic understanding of optical disk

drives and their use in computer systems.

See "Manual Organization" for details of the organization of manuals related to

optical disk drives and the scope of this manual. Use the other manuals shown in

"Manual Organization" together with this manual when necessary.

The organization of this manual, related reference manual and conventions for

alert messages follow.

Overview of Manual

This manual consists of the following six chapters, glossary, and abbreviation:

Preface

Chapter 1 General Description

This chapter introduces the MCJ3230SS optical disk drive and describes its

features, drive configuration, and system configuration.

Chapter 2 Specifications

This chapter describes the specifications of the MCJ3230SS optical disk drive and

the specifications of optical disk cartridges.

Chapter 3 Installation Requirements

This chapter describes the basic environmental, mounting, power supply, and

connection requirements for installing the MCJ3230SS optical disk drive in a user

system.

Chapter 4 Host Interface

This chapter describes the host interface of the MCJ3230SS optical disk drive.

Chapter 5 Diagnostics and Maintenance

This chapter describes how to operate and clean the MCJ3230SS optical disk

drive. This chapter also describes how to operate and clean optical disk cartridges.

Chapter 6 Diagnostics and Maintenance

This chapter describes the self-diagnostics functions and maintenance of the

MCJ3230SS optical disk drive.

C156-E224-01EN i

Page 6

Preface

Glossary

The glossary describes the technical terms that need to be understood to read this

manual.

Acronyms and Abbreviations

This manual contains a list of the abbreviations used in this manual and their

meanings.

CONVENTIONS USED IN THIS MANUAL

Throughout this manual, the MCJ3230SS optical disk drive are described as an

"ODD," "drive," "unit," "target (TARG)," or "device."

Decimal values are indicated without any modifiers added.

Hexadecimal values are indicated as X'17B9', 17B9h, 17B9H, and 17B9H.

Binary values are indicated as "010" and 010b.

Conventions for Alert Messages

This manual uses the following conventions to show the alert messages. An alert

message consists of an alert signal and alert statements. The alert signal consists

of an alert symbol and a signal word or just a signal word.

The following are the alert signals and their meanings:

This indicates a hazardous situation likely to result in

serious personal injury if the user does not perform

the procedure correctly.

This indicates a hazardous situation could result in

serious personal injury if the user does not perform

the procedure correctly.

This indicates a hazardous situation could result in

minor or moderate personal injury if the user does

not perform the procedure correctly. This alert signal

also indicates that damages to the product or other

property, may occur if the user does not perform the

product correctly.

This indicates information that could help the user

use the product more efficiently.

In the text, the alert signal is centered, followed below by the indented message.

A wider line space precedes and follows the alert message to show where the alert

message begins and ends. The following is an example:

ii C156-E224-01EN

Page 7

Attention

Preface

(Example)

Low temperature burns: The surface temperatures of some ICs

on the printed circuit board unit in the optical disk drive exceed

55°C while operating. Be careful of low tenperature burns.

The main alert messages in the text are also listed in the “Important Alert Items.”

Please forward any comments you may have regarding this manual.

To make this manual easier for users to understand, opinions from readers are

needed. Please write your opinions or requests on the Comment at the back of this

manual and forward it to the address described in the sheet.

C156-E224-01EN iii

Page 8

DISCLAIMER

Failure of the MCJ3230SS optical disk drive is defined as a failure requiring

adjustment, repair, or replacement. Fujitsu is not responsible for failure due to

misuse, operation outside the specified environment conditions, power line

trouble, controller problems, cable failure, or other failure not caused by the

optical disk drive itself.

iv C156-E224-01EN

Page 9

Important Alert Items

Important Alert Messages

The important alert messages in this manual are as follows:

A hazardous situation could result in minor or moderate personal

injury if the user does not perform the procedure correctly. Also,

damage to the product or other property, may occur if the user does not

perform the procedure correctly.

Task Alert message Page

Low temperature burns:

The surface temperatures of some ICs on the printed circuit

board unit in the optical disk drive exceed 55°C while

operating. Be careful of low tenperature burns.

Device damage:

1) Shock or vibration applied to the drive that exceeds the

values defined in the standard damage the drive. Use care

when unpacking.

2) Do not leave the drive in dirty or contaminated

environments.

3) Since static discharge may destroy the CMOS devices in

the drive, pay attention to the following points after

unpacking:

- Use an antistatic mat and wrist strap when handling

the drive.

- Hold the mounting frame when handling the drive.

Do not touch the Printed circuit board except when

setting the switches.

4) When handling the drive, hold both sides of the mounting

frame. When touching other than both sides of the

mounting frame, avoid putting force.

5) Do not forcibly push up the end of the header pin of the

printed circuit board unit when handling or setting the

drive.

3-1

3-21

C156-E224-01EN v

Page 10

Important Alert Items

Task Alert message Page

Device damage:

Be sure to turn on the power supply before inserting your

cartridge for the first time. It releases the device from

transport protection and enables you to insert the cartridge.

The device may be damaged if you insert the cartridge

without releasing the protection. From the next time, you

don't need to turn on the power supply beforehand.

Before moving the drive, remove the optical disk cartridge. If

the drive is moved with the optical disk cartridge loaded in it,

the head may move back and forth in the drive to damage the

head or disk and reading the data may fail.

• Make sure that the system power is off.

• Do not connect or disconnect any cable when the power is

on.

Device damage:

Before demounting the optical disk drive, turn off the system

power. Do not remove screws securing the cables and drive

when the power is on.

Device Damage:

Be sure to use the dedicated head cleaner described above.

Damage for data medium:

Do not use this cleaning kit for the floppy disk or the optical

disk cartridge used for other optical disk drive.

3-22

3-25

3-27

5-6

5-12

Damage for disk medium:

Clean the cartridge at clean place. Put a disposable groves at

cleaning so that the fingerprint does not put on the disk media

(recommendation).

Damage for disk medium:

At setting the cartridge to the setting case, do not apply the

heavy shock and push hardly.

Eye inflammation:

In case of contact with eyes, immediately flush eyes with

water.

Data loss:

In case of regular repair, the optical disk cartridge should not

be attached except where the cartridge causes the error. And

before having the drive repaired, save the data in the

cartridge. Fujitsu is not responsible for data lost during

maintenance or repair.

5-12

5-13

5-14

6-3

vi C156-E224-01EN

Page 11

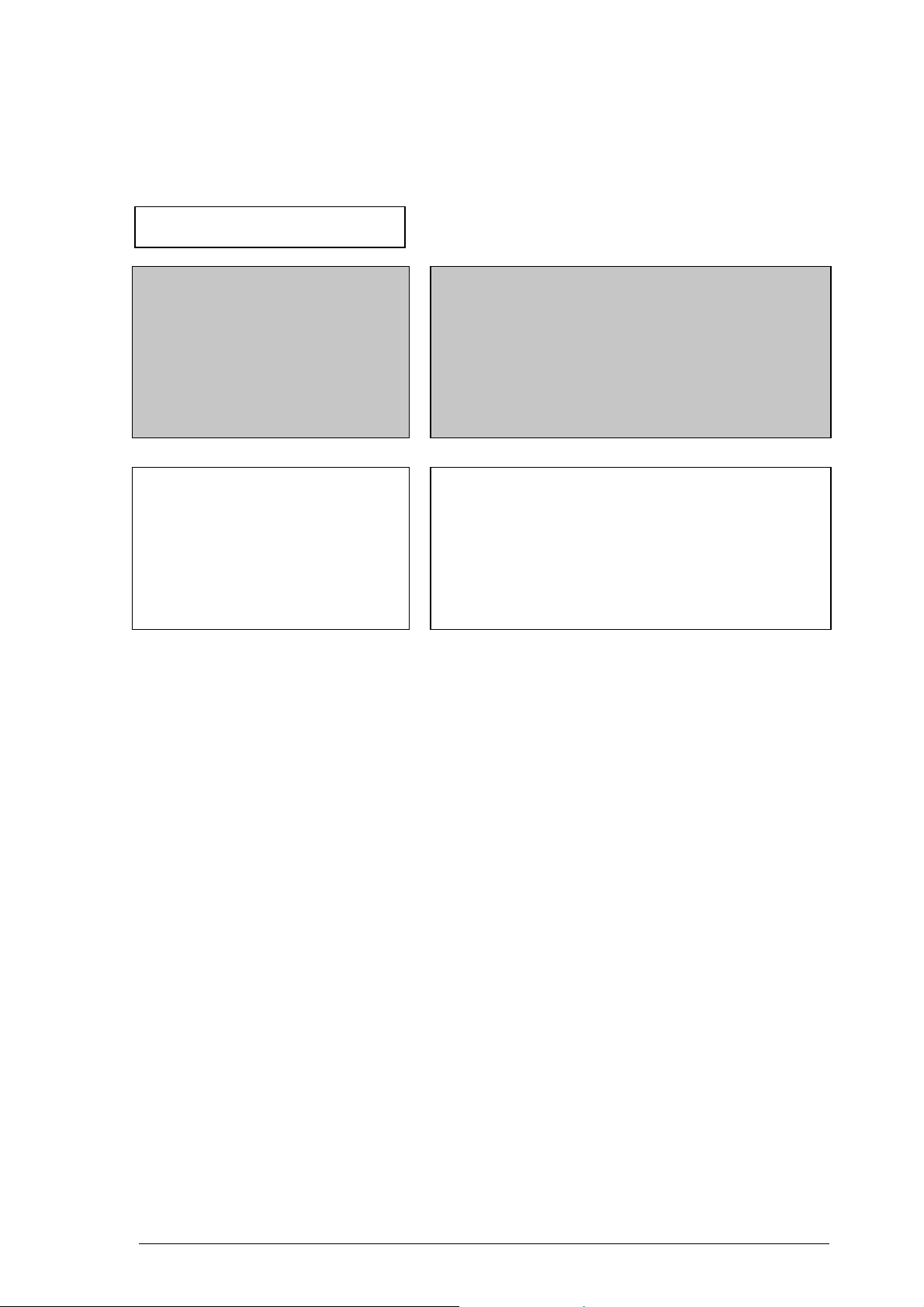

MANUAL ORGANIZATION

OPTICAL DISK DRIVE

PRODUCT MANUAL

(C156-E224)

<This manual>

OPTICAL DISK DRIVES

MAINTENANCE MANUAL

(C156-F043)

1. GENERAL DESCRIPTION

2. SPECIFICATIONS

3. INSTALLATION REQUIREMENTS

4. HOST INTERFACE

5. OPERATION AND CLEANING

6. DIAGNOSTICS AND MAINTENANCE

1. MAINTENANCE AND DIAGNOSIS

2. FAULT ANALYSIS

3. REMOVAL AND REPLACEMENT

PROCEDURES

4. PRINCIPLES OF OPERATION

5. CLEANING

C156-E224-01EN vii

Page 12

REFERENCED STANDARDS

The product specifications and functions described in this manual conform to the

following standards:

Specification

(document) number

ANSI X3. 131-1986 American National Standard for Information

Systems-Small Computer System Interface.

ANSI X3. 131-1994

ISO/IEC 10090 90mm Optical Disk Cartridges, rewritable and

ISO/IEC 13963 Data Interchange on 90mm Optical Disk

ISO/IEC 15041 Data Interchange on 90mm Optical Disk

Cherry Book GIGAMO 1.3GB 90mm Magneto-Optical Disk

Cherry Book 2 GIGAMO 2.3GB 90mm Magneto-Optical Disk

American National Standard for Information

Systems-Small Computer System Interface-2.

read only, for data interchange.

cartridges Capacity: 230 megabytes per

cartridges.

Cartridges Capacity: 640 megabytes per

cartridges.

System.

System.

Name Concerned organization

(SCSI)

(SCSI-2)

American National

Standards Institute

(ANSI)

American National

Standards Institute

(ANSI)

ISO/IEC *1

ISO/IEC *1

ISO/IEC JTC1 *1

FUJITSU LIMITED

SONY CORPORATION

FUJITSU LIMITED

SONY CORPORATION

*1 ISO= International Organization for Standardization

IEC= International Electrical for Commission

JTC1= Joint Technical Committee 1

viii C156-E224-01EN

Page 13

Contents

Preface .........................................................................................................i

DISCLAIMER .......................................................................................................iv

MANUAL ORGANIZATION ...................................................................................vii

CHAPTER 1 General Description.................................................................. 1-1

1.1 Features ........................................................................................................1-2

1.1.1 Performance ..........................................................................................1-2

1.1.2 Reliability..............................................................................................1-3

1.1.3 Maintainability/operability....................................................................1-4

1.1.4 Adaptability........................................................................................... 1-4

1.1.5 Interface.................................................................................................1-5

1.2 Drive Configuration......................................................................................1-7

1.2.1 Drive model...........................................................................................1-7

1.2.2 Configuration ........................................................................................1-8

1.2.3 Mechanical sections ..............................................................................1-9

1.2.4 Control circuit section .........................................................................1-10

CHAPTER 2 Specifications............................................................................ 2-1

2.1 Optical Disk Drive Specifications................................................................2-1

2.1.1 Model and product number ...................................................................2-1

2.1.2 Drive specifications...............................................................................2-2

2.1.3 Environmental and power requirements................................................2-4

2.1.4 Error rate ...............................................................................................2-6

2.1.5 Reliability..............................................................................................2-6

2.2 Optical Disk Cartridge Specifications ..........................................................2-7

2.2.1 Recommended optical disk cartridge specifications .............................2-7

2.2.2 Optical disk cartridge ............................................................................2-8

2.2.3 Disk specifications ................................................................................2-9

C156-E224-01EN ix

Page 14

Contents

2.3 Defect Management ....................................................................................2-11

2.3.1 Defect management schematic diagram ..............................................2-11

CHAPTER 3 Installation Requirements.........................................................3-1

3.1 Environmental Requirements .......................................................................3-1

3.1.1 Temperature measurement point ...........................................................3-1

3.1.2 Temperature requirements and measuring method................................3-3

3.1.3 Air flow .................................................................................................3-3

3.1.4 Temperature rise under several conditions............................................3-4

3.1.5 Air purity ...............................................................................................3-4

3.2 Mounting Requirements ...............................................................................3-5

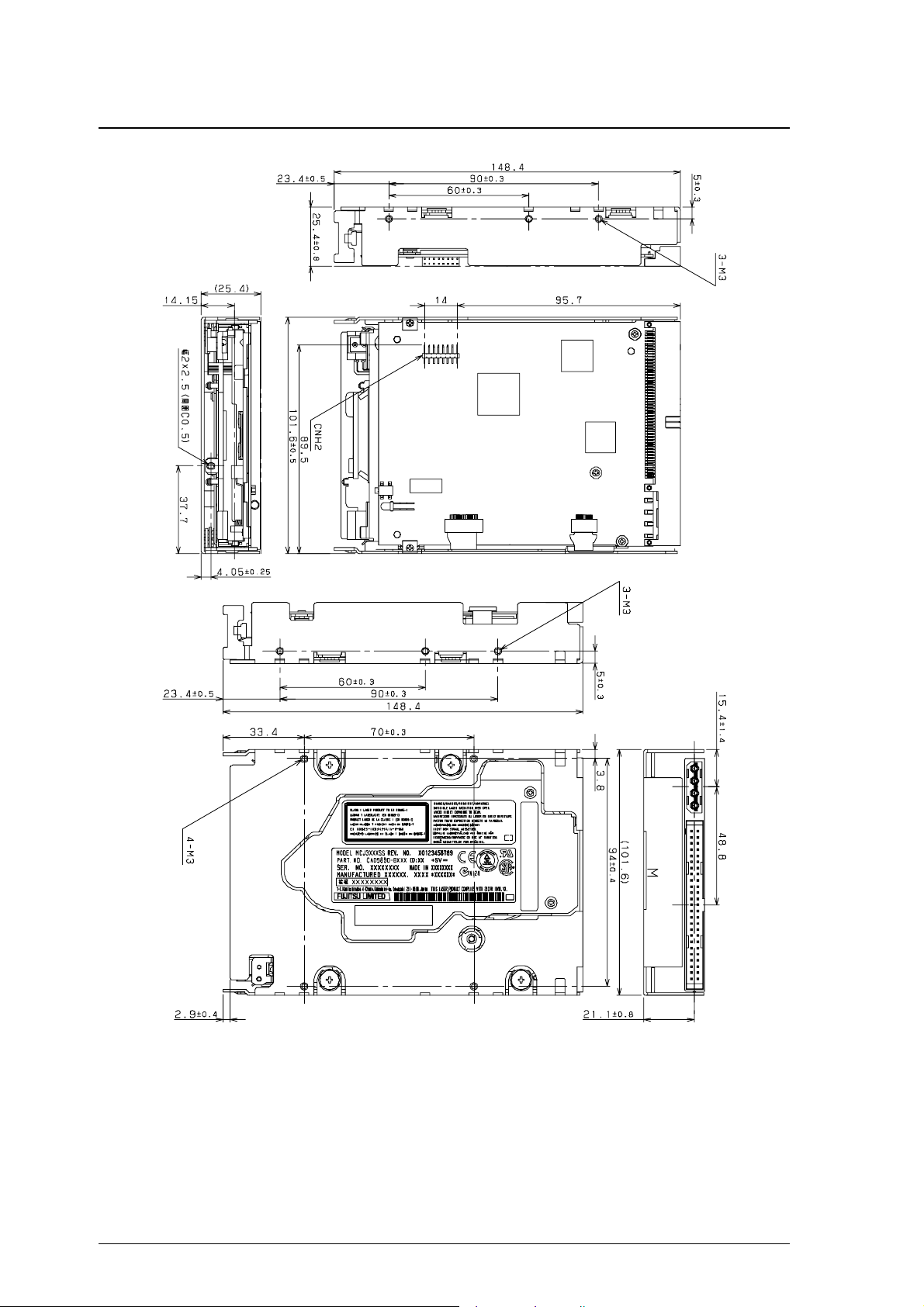

3.2.1 External dimensions ..............................................................................3-5

3.2.2 Installation direction..............................................................................3-7

3.2.3 Centers of gravity ..................................................................................3-8

3.2.4 Notes on mounting.................................................................................3-9

3.3 Power Supply Requirements.......................................................................3-11

3.4 Cable Connections ......................................................................................3-12

3.4.1 Drive connectors..................................................................................3-12

3.4.2 Cable connector specifications ............................................................3-15

3.4.3 Connection Modes...............................................................................3-16

3.5 Settings .......................................................................................................3-18

3.5.1 Default jumper settings........................................................................3-18

3.5.2 Setting terminal....................................................................................3-18

3.6 Notes on Drive Handling ............................................................................3-21

3.7 Mounting.....................................................................................................3-24

3.7.1 Checks before mounting the drive .......................................................3-24

3.7.2 Mounting procedure ............................................................................3-24

3.8 Cable Connections ......................................................................................3-25

3.9 Operation Confirmation and Preparation for Use after Installation............3-26

3.9.1 Confirming initial operations...............................................................3-26

3.9.2 Connection check ................................................................................3-27

3.10 Dismounting Drive .....................................................................................3-27

x C156-E224-01EN

Page 15

CHAPTER 4 Host Interface............................................................................ 4-1

4.1 Interface Connector ......................................................................................4-1

4.2 Various Processes.........................................................................................4-4

4.2.1 Reset response.......................................................................................4-4

4.2.2 Defective sector management ...............................................................4-4

4.2.3 Automatic alternate sector assignment function....................................4-4

4.2.4 Cache function.......................................................................................4-5

4.2.4.1 Data buffer ....................................................................................4-5

4.2.4.2 Read cache ....................................................................................4-5

4.2.4.3 MO write cache ............................................................................. 4-6

4.2.5 Power management function .................................................................4-6

4.2.6 Power mode...........................................................................................4-6

4.2.6.1 Active mode ..................................................................................4-7

4.2.6.2 Pre-idle mode ................................................................................4-7

4.2.6.3 Idle mode.......................................................................................4-7

4.2.6.4 Standby mode................................................................................ 4-7

4.2.6.5 Standby timer ................................................................................4-7

4.2.6.6 Power mode transition...................................................................4-8

4.2.7 LED indications.....................................................................................4-9

4.3 SCSI Commands ........................................................................................4-10

4.3.1 TEST UNIT READY command .........................................................4-11

4.3.2 INQUIRY............................................................................................4-11

4.3.3 READ CAPACITY command ............................................................4-13

4.3.4 MODE SELECT command.................................................................4-13

4.3.5 MODE SENSE command ...................................................................4-22

4.3.6 START/STOP UNIT command..........................................................4-24

4.3.7 RESERVE command ..........................................................................4-25

4.3.8 RELEASE command...........................................................................4-26

4.3.9 REQUEST SENSE command.............................................................4-26

4.3.10 PREVENT/ALLOW MEDIUM REMOVAL command ....................4-31

4.3.11 READ (6) command............................................................................4-32

4.3.12 READ (10) command..........................................................................4-32

4.3.13 VERIFY command..............................................................................4-33

4.3.14 WRITE (6) command.......................................................................... 4-33

4.3.15 WRITE (10) command........................................................................ 4-34

4.3.16 WRITE AND VERIFY .......................................................................4-34

4.3.17 SEEK (6) command.............................................................................4-35

4.3.18 SEEK (10) command...........................................................................4-35

4.3.19 ERASE command ...............................................................................4-36

4.3.20 SYNCHRONIZE CACHE command .................................................4-36

C156-E224-01EN xi

Page 16

Contents

4.3.21 FORMAT UNIT command .................................................................4-37

4.3.22 READ DEFECT DATA command .....................................................4-38

4.3.23 SEND DIAGNOSTIC command.........................................................4-39

4.3.24 RECEIVE DIAGNOSTIC RESULTS command................................4-39

4.3.25 WRITE BUFFER command................................................................4-40

4.3.26 READ LONG command .....................................................................4-41

4.3.27 WRITE LONG command....................................................................4-41

4.4 SCSI Messages ...........................................................................................4-42

4.4.1 Message formats..................................................................................4-42

4.4.2 Message types......................................................................................4-42

4.4.3 Message functions ...............................................................................4-43

4.5 Timing Rule................................................................................................4-46

CHAPTER 5 Operation and Cleaning............................................................5-1

5.1 Operating Optical Disk Drive .......................................................................5-1

5.1.1 Optical disk drive...................................................................................5-2

5.1.2 Note .......................................................................................................5-3

5.1.3 Inserting cartridge ..................................................................................5-3

5.1.4 Ejecting (removing) cartridge................................................................5-5

5.2 Cleaning Drive..............................................................................................5-6

5.3 Optical Disk Cartridge Operation.................................................................5-7

5.3.1 Optical disk cartridge.............................................................................5-7

5.3.2 Write protect tab....................................................................................5-8

5.3.3 How to affix an index label on the MO cartridge..................................5-9

5.3.4 Notes......................................................................................................5-9

5.4 Cleaning Optical Disk Cartridge.................................................................5-11

5.4.1 Cleaning tool .......................................................................................5-11

5.4.2 Cleaning procedure..............................................................................5-12

CHAPTER 6 Diagnosis and Maintenance .....................................................6-1

6.1 Diagnosis ......................................................................................................6-1

6.1.1 Initial self-diagnosis ..............................................................................6-1

6.1.2 Diagnostic command.............................................................................6-2

6.1.3 Test program..........................................................................................6-2

xii C156-E224-01EN

Page 17

6.2 Maintenance Information .............................................................................6-3

6.2.1 Maintenance requirements ....................................................................6-3

6.2.2 Revision number ...................................................................................6-4

Glossary ……………………………………………………………………….GL-1

Abbreviations …….…………………………………………………………………AB-1

Index ………………………………………………………………………...IN-1

C156-E224-01EN xiii

Page 18

Illustrations

Figures

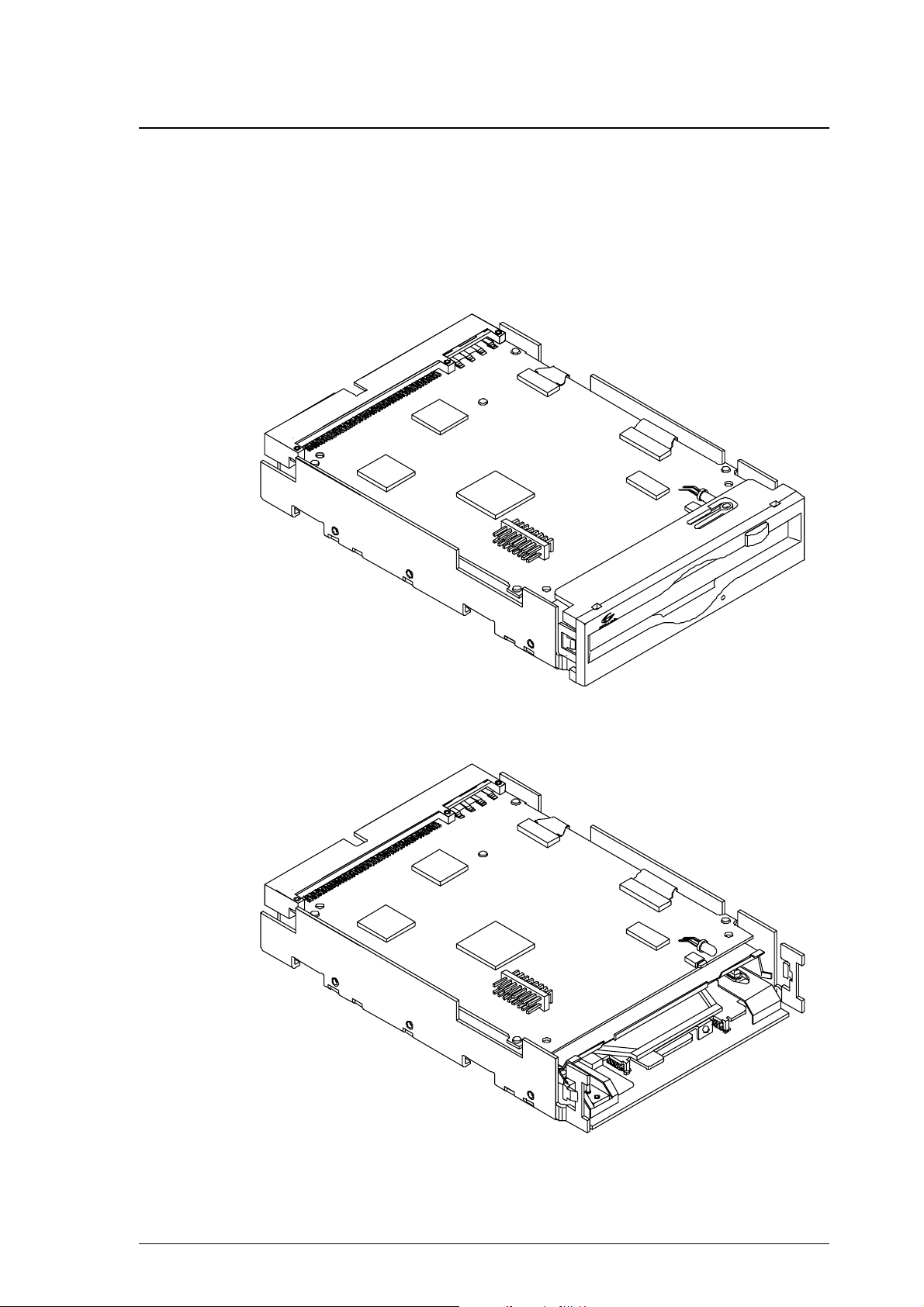

Figure 1.1 Outer view (with panel) .....................................................................................1-7

Figure 1.2 Outer view (without panel)................................................................................1-7

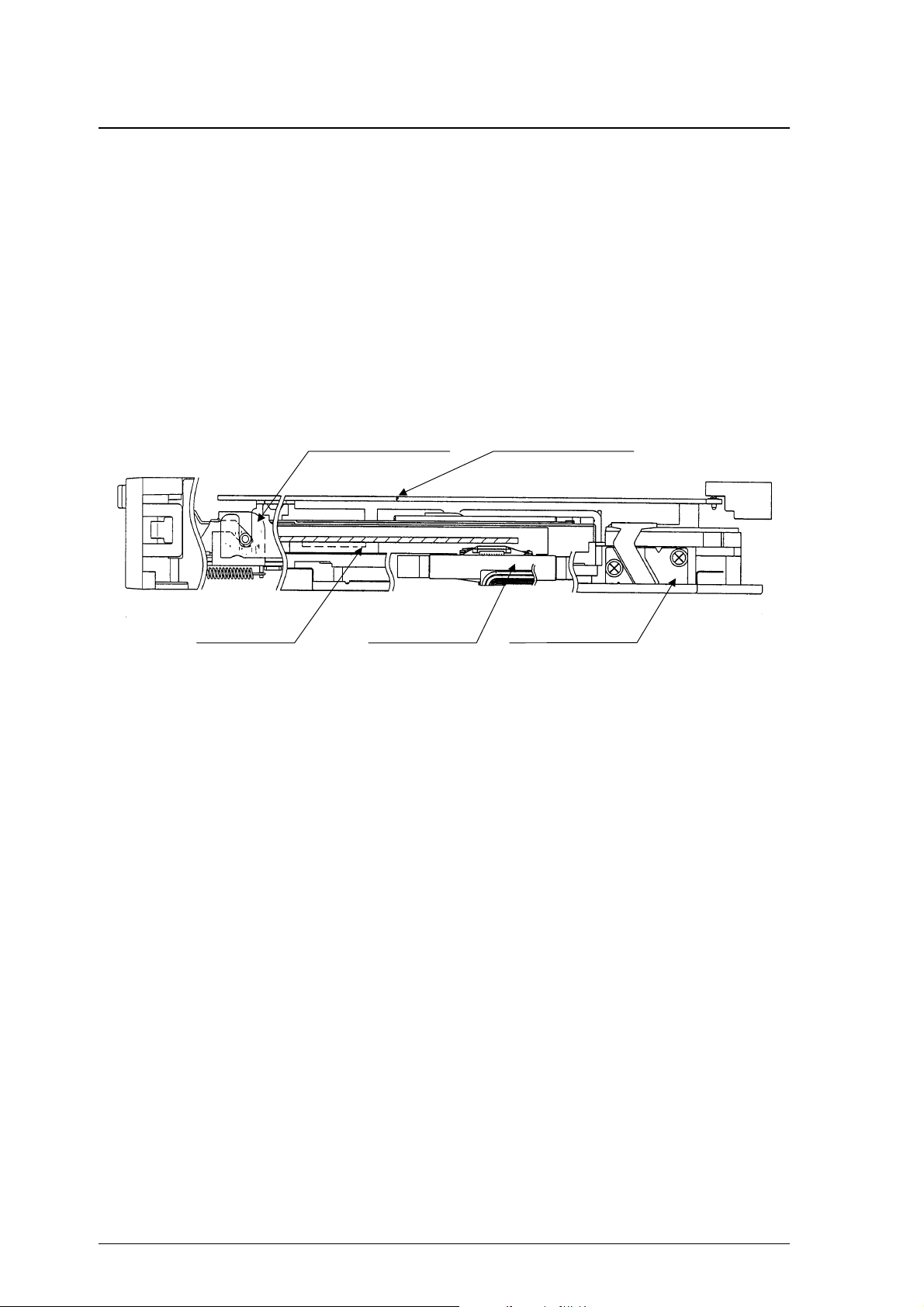

Figure 1.3 Optical disk drive configuration ........................................................................1-8

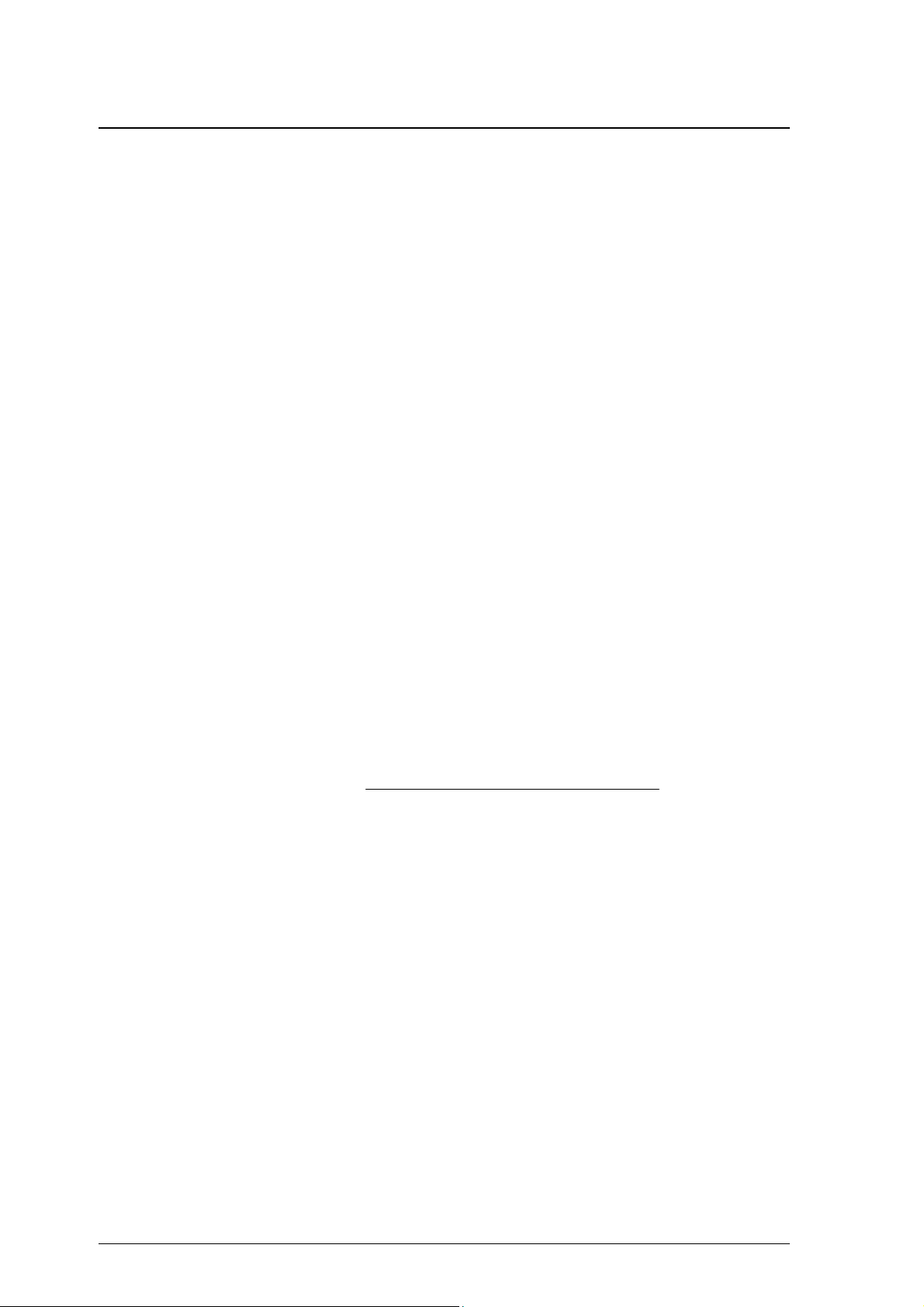

Figure 1.4 Control circuit section block diagram..............................................................1-10

Figure 2.1 Optical disk cartridge.........................................................................................2-8

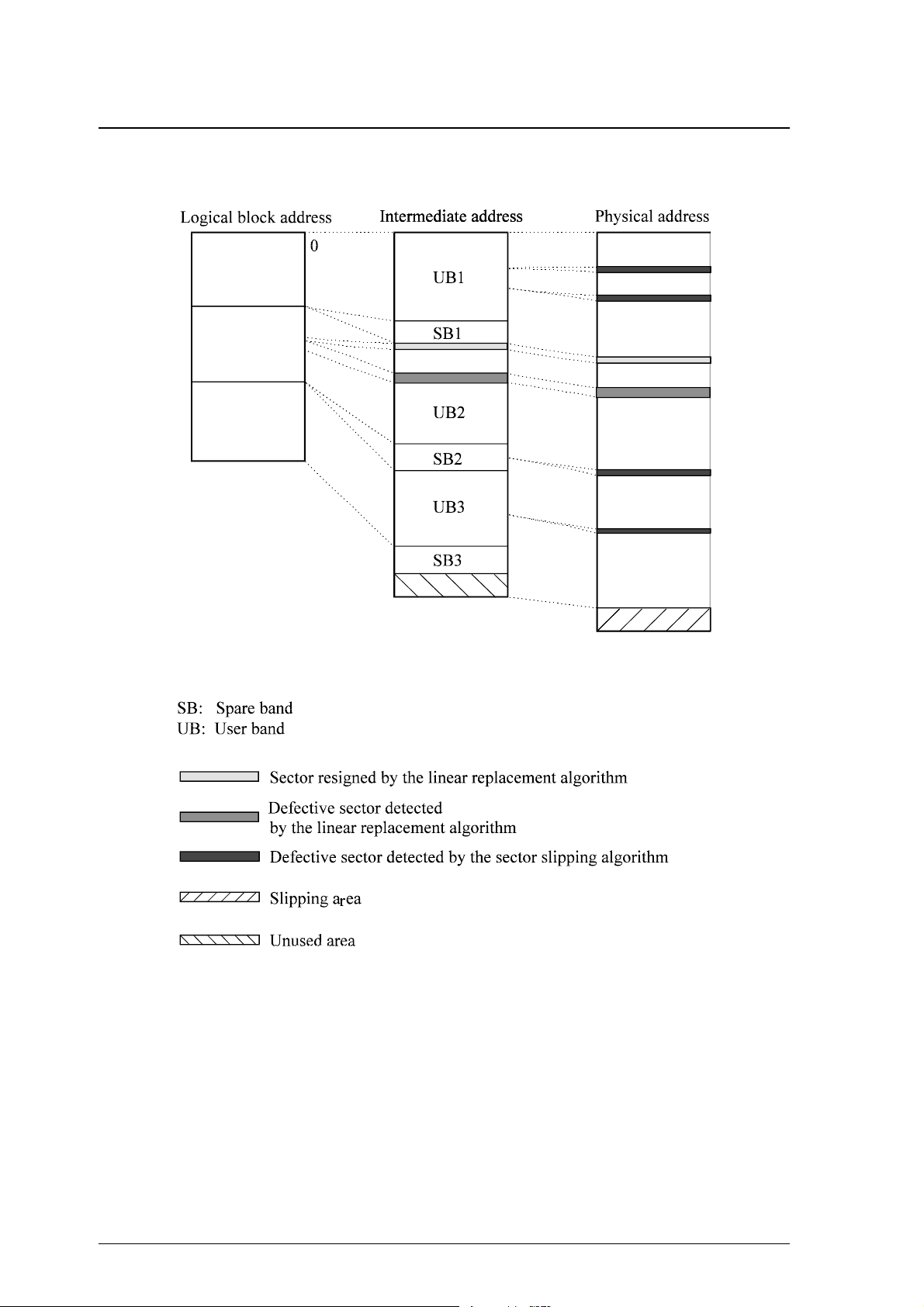

Figure 2.2 Algorithms for alternate processing.................................................................2-11

Figure 2.3 Example of alternate processing ......................................................................2-12

Figure 3.1 Surface temperature measurement points ..........................................................3-2

Figure 3.2 Dimensions ........................................................................................................3-5

Figure 3.3 Dimensions (without panel)...............................................................................3-6

Figure 3.4 Installation directions.........................................................................................3-7

Figure 3.5 Centers of gravity...............................................................................................3-8

Figure 3.6 Mounting frame structure ..................................................................................3-9

Figure 3.7 Service clearance .............................................................................................3-10

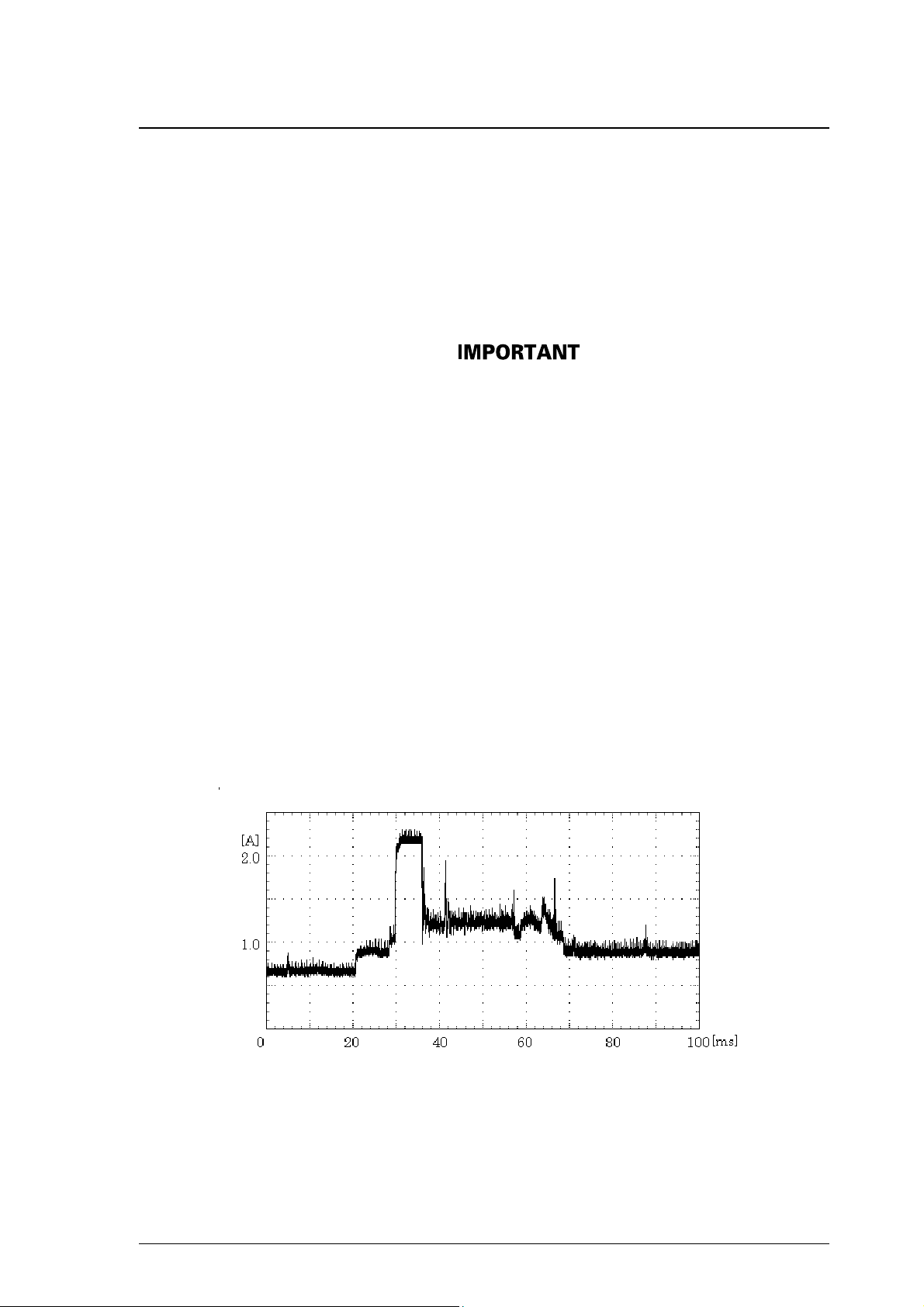

Figure 3.8 Current waveform (+5 VDC)...........................................................................3-11

Figure 3.9 Connector and terminal locations ....................................................................3-12

Figure 3.10 Location of setting terminal.............................................................................3-12

Figure 3.11 Shape of setting terminal .................................................................................3-13

Figure 3.12 SCSI bus connection modes ............................................................................3-16

Figure 3.13 SCSI bus connecti on modes ...........................................................................3-17

Figure 3.14 Setting terminal (CNH2) .................................................................................3-18

Figure 3.15 Packing style....................................................................................................3-23

Contents

Figure 4.1 SCSI interface connector (ODD side)................................................................4-1

Figure 4.2 SCSI interface connector (cable side)................................................................4-2

Figure 4.3 Power mode .......................................................................................................4-8

Figure 4.4 BUS FREE phase.............................................................................................4-49

Figure 4.5 ARBITRATION phase ....................................................................................4-50

Figure 4.6 SELECTION phase..........................................................................................4-51

Figure 4.7 RESELECTION phase.....................................................................................4-51

Figure 4.8 Transfer in asynchronous mode .......................................................................4-52

Figure 4.9 Transfer in FAST SCSI mode..........................................................................4-53

Figure 4.10 ATTENTION condition...................................................................................4-54

Figure 5.1 Optical disk drive front view (with panel) .........................................................5-2

Figure 5.2 Inserting cartridge..............................................................................................5-4

Figure 5.3 Removing cartridge............................................................................................5-5

Figure 5.4 Optial disk cartridge...........................................................................................5-7

Figure 5.5 Write protect tab ................................................................................................5-8

Figure 5.6 How to stick an index label on the MO cartridge ..............................................5-9

Figure 5.7 Cleaning procedure (1) ....................................................................................5-12

Figure 5.8 Cleaning procedure (2) ....................................................................................5-13

Figure 5.9 Cleaning procedure (3) ....................................................................................5-13

Figure 5.10 Cleaning procedure (4) ....................................................................................5-14

xiv C156-E224-01EN

Page 19

Figure 6.1 Revision label ....................................................................................................6-4

Figure 6.2 Revision number indication...............................................................................6-4

C156-E224-01EN xv

Page 20

Tables

Table 2.1 Model and order number....................................................................................2-1

Table 2.2 Specifications (1 of 2)........................................................................................2-2

Table 2.2 Specifications (2 of 2)........................................................................................2-3

Table 2.3 Environmental and power requirements (1 of 2) ...............................................2-4

Table 2.3 Environmental and power requirements (2 of 2) ...............................................2-5

Table 2.4 Power consumption in power save mode

when the temperature inside the drive is 20°C or lower ....................................2-5

Table 2.5 Recommended optical disk cartridge specifications..........................................2-7

Table 2.6 Disk specifications...........................................................................................2-10

Table 3.1 Temperature requirements at measurement points ............................................3-3

Table 3.2 Temperature at each measuring point (Reference) ............................................3-4

Table 3.3 Pin assignments................................................................................................3-14

Table 3.4 Recommended components for connection .....................................................3-15

Table 3.5 SCSI ID setting (CNH2) ..................................................................................3-18

Table 3.6 SCSI terminating resistor mode.......................................................................3-19

Table 3.7 Write cache mode setting.................................................................................3-19

Table 3.8 Spindle motor automatic stop mode setting.....................................................3-20

Contents

Table 4.1 SCSI interface connector pin assignments (single-ended type) .........................4-3

Table 4.2 LED indications .................................................................................................4-9

Table 4.3 SCSI commands...............................................................................................4-10

Table 4.4 TEST UNIT READY command......................................................................4-11

Table 4.5 INQUIRY command........................................................................................4-11

Table 4.6 INQUIRY command response data .................................................................4-12

Table 4.7 READ CAPACITY command.........................................................................4-13

Table 4.8 READ CAPACITY data..................................................................................4-13

Table 4.9 MODE SELECT command .............................................................................4-13

Table 4.10 Mode page codes .............................................................................................4-14

Table 4.1 Mode parameter list .........................................................................................4-14

Table 4.12 Mode parameter header....................................................................................4-14

Table 4.13 Block descriptor...............................................................................................4-15

Table 4.14 Mode page........................................................................................................4-15

Table 4.15 Read/write error recovery page........................................................................4-15

Table 4.16 Variable values in the read-write error recovery page.....................................4-16

Table 4.17 Default values in the read-write error recovery page.......................................4-16

Table 4.18 Flexible disk page ............................................................................................4-17

Table 4.19 Variable values in the flexible disk page .........................................................4-18

Table 4.20 Default values in the flexible disk page...........................................................4-18

Table 4.21 Caching page....................................................................................................4-19

Table 4.22 Variable values in the Caching Page ...............................................................4-19

Table 4.23 Default values in the Caching Page .................................................................4-19

Table 4.24 Power condition page.......................................................................................4-19

Table 4.25 Variable values in the Power condition page...................................................4-20

Table 4.26 Default values in the Power condition page.....................................................4-20

Table 4.27 Verify control page ..........................................................................................4-20

Table 4.28 Verify mode .....................................................................................................4-21

Table 4.29 Variable values in the Verify control page ......................................................4-21

Table 4.30 Default values in the Verify control page ........................................................4-21

xvi C156-E224-01EN

Page 21

Table 4.31 MODE SENSE command................................................................................4-22

Table 4.32 Page control field.............................................................................................4-22

Table 4.33 Mode parameters .............................................................................................4-23

Table 4.34 Mode Parameter Header.................................................................................. 4-23

Table 4.35 Block Descriptor..............................................................................................4-23

Table 4.36 Mode Page .......................................................................................................4-24

Table 4.37 START/STOP UNIT command ......................................................................4-24

Table 4.38 Start, stop, and eject processing.......................................................................4-24

Table 4.39 RESERVE command.......................................................................................4-25

Table 4.40 RELEASE command.......................................................................................4-26

Table 4.41 REQUEST SENSE command .........................................................................4-26

Table 4.42 Request Sense Data .........................................................................................4-27

Table 4.43 Error Code .......................................................................................................4-27

Table 4.44 Sense Key ........................................................................................................4-28

Table 4.45 Logical track address format ...........................................................................4-28

Table 4.46 ASC and ASCQ definitions.............................................................................4-29

Table 4.47 Format progress indication bytes ..................................................................... 4-30

Table 4.48 PREVENT/ALLOW MEDIUM REMOVAL command................................. 4-31

Table 4.49 Responses to Prevent, Allow, and Eject ..........................................................4-31

Table 4.50 CDB of READ (6) command ..........................................................................4-32

Table 4.51 READ (10) command......................................................................................4-32

Table 4.52 VERIFY command .......................................................................................... 4-33

Table 4.53 CDB of WRITE (10) command.......................................................................4-33

Table 4.54 WRITE (10) command ....................................................................................4-34

Table 4.55 WRITE AND VERIFY command...................................................................4-34

Table 4.56 SEEK (6) command......................................................................................... 4-35

Table 4.57 SEEK (10) command....................................................................................... 4-35

Table 4.58 ERASE command............................................................................................ 4-36

Table 4.59 SYNCHRONIZE CACHE command..............................................................4-36

Table 4.60 FORMAT UNIT command .............................................................................4-37

Table 4.61 FORMAT UNIT parameter list .......................................................................4-37

Table 4.62 Defect List Header........................................................................................... 4-37

Table 4.63 READ DEFECT DATA command .................................................................4-38

Table 4.64 Defect List Format of READ DEFECT DATA (10) command ......................4-38

Table 4.65 Defect list header of READ DEFECT DATA (10) command ........................4-38

Table 4.66 Defect descriptor..............................................................................................4-39

Table 4.67 Sector address format ......................................................................................4-39

Table 4.68 SEND DIAGNOSTIC command..................................................................... 4-39

Table 4.69 RECEIVE DIAGNOSTIC RESULTS command ............................................ 4-39

Table 4.70 WRITE BUFFER command............................................................................4-40

Table 4.71 READ LONG command .................................................................................4-41

Table 4.72 WRITE LONG command................................................................................4-41

Table 4.73 Types of messages provided by ODD .............................................................4-42

Table 4.74 Transfer mode settings requested by INIT to ODD.........................................4-45

Table 4.75 Timing specifications (1 of 3)..........................................................................4-46

Table 4.75 Timing specifications (2 of 3)..........................................................................4-47

Table 4.75 Timing specifications (3 of 3)..........................................................................4-48

Table 4.76 FAST SCSI Timing specifications ..................................................................4-49

Table 5.1 Head cleaner ......................................................................................................5-6

Table 5.2 Cleaning kit......................................................................................................5-11

Table 5.3 Packed items (cleaning kit)..............................................................................5-11

Table 6.1 Self-diagnostic function.....................................................................................6-1

C156-E224-01EN xvii

Page 22

This page is intentionally left blank.

Page 23

CHAPTER 1 General Description

1.1 Features

1.2 Drive Configuration

This chapter describes the features and configuration of the optical disk drives.

The MCJ3230SS (hereafter, the optical disk drive) is the successor model to the

MCE3130SS. This optical disk drive, which maintains compatibility with the

MCE3130SS, offers high performance and high capacity. Supporting 2.3 GB of

storage capacity, this device delivers superior performance with a 5,455-rpm

rotational speed, and supports security functions.

The optical disk drive is high-performance, 90 mm (3.5-inch) commutative

rewritable optical disk drive which incorporates an SCSI controller.

The interface connecting the optical disk drive to the host system complies with

the SCSI-2.

The flexibility and expandability through SCSI I/F, the high performance of the

optical disk drive, and the drive's commands set enable the user to construct highreliability, high-performance disk subsystems with advanced functions and largescale storage.

C156-E224-01EN 1-1

Page 24

General Description

1.1 Features

This section describes the following drive features:

•

Performance

•

Reliability

•

Maintainability/operability

•

Adaptability

•

Interface

1.1.1 Performance

(1) Half-height standard 90 mm (3.5-inch) size (25.4 mm height)

The SCSI controller can be connected to the system SCSI bus. The controller

meets the specifications of the standard 25.4 mm height 90 mm

(3.5-inch) fixed disk drive form factor.

(2) 2.3 GB capacity

The optical disk drive conforms to the 2.3 GB GIGAMO standard. It also

supports read and write accesses to 128 MB, 230 MB, 540 MB, 640 MB, and 1.3

GB disks.

(3) High-speed data transfer

The optical disk drive supports a disk media rotational speed of 3,637 rpm when

using 2.3 GB disks. The device supports a rotational speed of 5,455 rpm (ZCAV)

when using a 128 MB, 230 MB, 540 MB, or 640 MB disks. When using 1.3 GB

disks, the optical disk drive supports ZCAV mode with a rotational speed of 3,637

rpm, and ZCLV mode that controls the speed at three levels: 3,637/4, 138/4,801

rpm, in accordance with the position of the optical head.

In ZCLV mode, the optical disk drive speeds up by detecting continuous accessing

of inner disk tracks to prevent a reduction of inner disk rotation.

For random accesses, the optical disk drive switches to ZCAV mode that is fixed

to 3,637 rpm to prevent access performance degradation.

In the disk unit, high-speed data transfers at rates of 4.62 to 8.26 MB/s (2.3 GB)

are realized. The maximum data transfer rate on the SCSI bus is 20 MB/s in

synchronous transfer mode.

The SCSI bus high-speed data transfer capacity can be used effectively through

the optical disk unit's large capacity data buffer.

1-2 C156-E224-01EN

Page 25

(4) High-speed mean seek time

This drive features a linear voice-coil motor for high-speed head positioning. The

average seek time is the average of 1,000 random seeks and is 19 ms. (However,

this does not include command overhead or address check.)

(5) Compatible with international standards (media interchangeability)

90 mm (3.5 inch) type optical disks as well as ISO standards compatible 128 MB,

230 MB, 540 MB and 640 MB format optical disk media can be used in the optical

disk unit.

(6) Direct-overwrite medium support

The drive can use an optic modulation direct-overwrite disk that does not perform

an erase operation; 230-MB disk, 540-MB disk with the ISO standard.

(7) Dust resistance

The optical disk unit provides low-power consumption, eliminating the need for a

cooling fan. The top of the cartridge is sealed with film, and the bottom of the

optical disk unit is sealed with sheet metal, providing protection that is not

complicated.

1.1 Features

The optical disk drive needs class 5 millions or less of the dust particles.

(8) Lower power consumption

The power consumption of the optical disk drive is 6.5 W (These power

consumption values are typical values during read and write operation.) These

drives do not use a fan.

The minimum power consumption is 1.0 W (typical value) during power save.

(9) Automatic spindle stop function

If access is not made within a certain time, this function stops disk rotation to

minimize dust accumulation on the disk. This function can be set that time by the

MODE SELECT command.

1.1.2 Reliability

(1) Mean time between failures (MTBF)

This drive features a 120,000 hour MTBF.

(2) Error recovery

For the error depending on the optical disk drive, recovery process is made by a

suitable retry. This drive features Reed-Solomon error correction (ECC) to assure

error-free operation.

C156-E224-01EN 1-3

Page 26

General Description

(3) Automatic allocation of alternate data blocks

This drive features a function which automatically allocates alternate data blocks

to defective data blocks detected while data is being read from or written to an

optical disk.

1.1.3 Maintainability/operability

(1) Diagnostic function

This drive has a diagnostic function to check optical disk drive operations. The

diagnostic function facilitates test and restoration.

(2) Five-year service life (no overhaul)

This drive will not require overhaul within the first five years of installation if

appropriately handled, maintained, and cleaned as recommended.

1.1.4 Adaptability

(1) Wide operating environment

An LSI circuits reduce power consumption. This drive features a wide operating

environment (5 to 45°C, general office environment). Dust particles are class 5

millions or less.

(2) Vibration resistance (shock resistance)

Rubber vibration isolators protect the drive against external shock or vibration.

(3) Safety standards

•

UL1950 (U.S.A., safety)

•

CDRH class 1 (U.S.A., laser)

•

CSA C22.2 No. 950 (Canada, safety)

•

EN60950 (Europe, safety)

•

EN60825 Class 1 (Europe, laser)

(4) Various radio wave standards

This optical disk device is installed in a host system, and meets the following

standards:

•

EN55022 class B, EN55024 (European wave standards)

•

AS/NZS3548 class B (Australian wave standards)

•

CNS13438 (Taiwanese radio interference standard)

1-4 C156-E224-01EN

Page 27

1.1.5 Interface

(1) Conformance to SCSI-2

(2) Continuous block processing

(3) Data buffer

1.1 Features

This optical disk device supports the basic functions of SCSI-2.

SCSI commands enable data manipulation using logical block addresses that are

independent of the physical attributes of the optical disk device, enabling software

flexibility in terms of system expansion in the future.

Logical block addresses are used for data block addressing. Without consideration

of the physical attributes of track boundaries, the host can access data by

specifying a block number in logically continuous data space.

7,600 KB buffer is used to transfer data between the SCSI bus and disk. Since

data is stored in this buffer, the host can execute input-output processing

effectively by using the high-speed data transfer capability of the SCSI bus

without regard to the data transfer rate of the optical disk drive.

(4) Read-ahead cache feature

The read-ahead cache feature enables high-speed sequential data access as

follows:

After executing a command to read data from the disk, the drive automatically

reads the next data block and stores it in the data buffer (pre-reading). If the next

command requests this data, the data is transferred from the buffer without another

disk access.

(5) Write cache feature

When the host system issues the write command to the optical disk drive, a

command complete is usually responded after completion of the write and verify

operations. By using the write cache feature, a command complete is responded

after completion of the data transfer to the data buffer without waiting the

completion of the write and verify operations then the write and verify operations

are made asynchronously with the interface operation. Therefore, the apparent

write command processing time measured at the host system is reduced and the

I/O performance of the host system is improved.

The write cache feature is enabled or disabled by MODE SELECT command.

C156-E224-01EN 1-5

Page 28

General Description

(6) Defective block slipping

When a disk is initialized, logical data blocks are reallocated in a physical

sequence by slipping defective data blocks. This enables high-speed continuous

data block processing without rotational delay due to defective data blocks.

(7) Device driver software

The optical disk drive requires more extended processing time than conventional

optical device drives because of higher density. Consequently, a processing time

timeout when using the OS can occur and this requires special device driver

software.

When the write cache feature is enabled, a write error is reported at

the completion status of next command. At a system so that the host

retries the command, a retry process may be failed.

1-6 C156-E224-01EN

Page 29

1.2 Drive Configuration

1.2.1 Drive model

Figures 1.1 and 1.2 show the outer view.

1.2 Drive Configuration

Figure 1.1 Outer view (with panel)

Figure 1.2 Outer view (without panel)

C156-E224-01EN 1-7

Page 30

General Description

1.2.2 Configuration

Figure 1.3 shows the drive configuration.

The drive consists of mechanical sections, a fixed optics section, actuator, and a

control circuit section. The mechanical sections include the spindle motor,

actuator section, bias magnet, and the cartridge folder vertical motion mechanism.

The fixed optics section consists of the optical components, position detector, and

LD controller.

The control circuit sections include the drive control circuit section and SCSI

controller section.

Spindle motor

Optical disk cartridge

Figure 1.3 Optical disk drive configuration

Control circuit section

Fixed optics sectionActuator section

1-8 C156-E224-01EN

Page 31

1.2.3 Mechanical sections

(1) Optical disk cartridge load/eject

The system includes a cartridge mechanism which lowers the optical disk cartridge

and mounts (loads) it on the spindle motor automatically when the optical disk

cartridge is fully inserted in the optical disk drive's disk slot, and a mechanism

which automatically ejects the cartridge when the Eject button on the front panel is

pressed.

(2) Spindle motor

Optical disk cartridge hubs are linked through magnetic clamps to minimize

slippage between the spindle motor shaft and disk. The spindle motor is the direct

drive type which rotates the disk at the same speed as the spindle motor shaft. A

DC brushless spindle motor is used. The spindle motor rotates at 5,455 rpm ±

0.1%.

(3) Actuator section

1.2 Drive Configuration

The positioner moves (seeks) a head actuator radically across the disk surface.

The positioner is driven by a linear voice coil motor. A pulse-width modulation

(PWM) is adopted as a driving system and realizes low power consumption and

high-speed access.

(4) Separate optical sections

The optical head section is separated in such a way that the fixed optics section

is separated from the moving optics section to minimize seek time and positioning

error. (See Subsection 1.2.4 for the fixed optical section.) This reduces the weight

of the moving parts.

The fixed optics section consists of the laser diodes, collimator lens, and optical

detector.

The fixed optics section includes a laser diode for recording and playback, and

transmits one laser beam to the head actuator.

(5) Panel

The central part of the panel is hollowed out deeply to provide pushing finger

space for inserting the cartridge, thereby facilitating the insertion.

The panel is also simply designed by making the eject button and LED light

emitting part integral with each other.

C156-E224-01EN 1-9

Page 32

General Description

1.2.4 Control circuit section

Figure 1.4 is the block diagram of the control circuit section.

Figure 1.4 Control circuit section block diagram

The control circuit section is divided into two parts: a controller section which

deals with control between the SCSI interface and drive interface, and a drive

circuit section which controls the drive.

(1) Controller circuit section

The controller circuit's reliability is improved by large-scale integrated circuit

technology. The high-speed microprocessor (MPU) handles SCSI interface

control and drive control such as drive read-and-write control and single-beam

control.

(2) Drive circuit section

The drive circuit section consists of the following circuits:

•

Laser diode control circuit

•

Signal reproduction circuit

•

Servo/seek control circuit

•

Rotation control circuit

•

Drive miscellaneous control circuit

1-10 C156-E224-01EN

Page 33

1.2 Drive Configuration

The DSP (digital signal processor) is used for the servo/seek control circuit to

reduce the circuit amount, therefore this circuit is a simple configuration.

The drive circuit section executes operations such as seek, erase, record, and

playback while the MPU controls the focus-tracking of the beam.

C156-E224-01EN 1-11

Page 34

This page is intentionally left blank.

Page 35

CHAPTER 2 Specifications

2.1 Optical Disk Drive Specifications

2.2 Optical Disk Cartridge Specifications

2.3 Defect Management

This chapter contains the specifications of the optical disk drive, and the optical

disk cartridge.

2.1 Optical Disk Drive Specifications

2.1.1 Model and product number

Table 2.1 lists the model and order number.

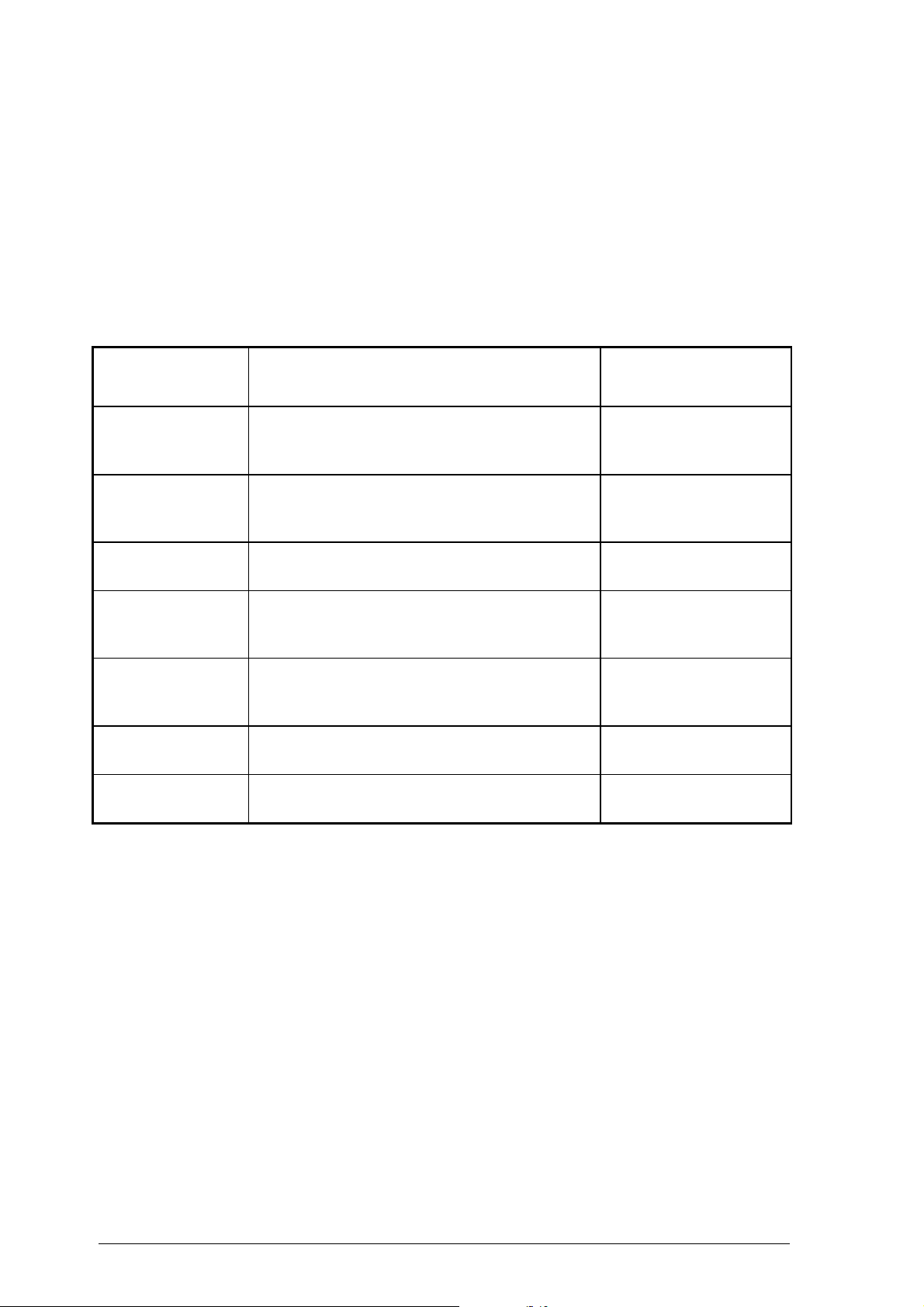

Table 2.1 Model and order number

Model Name Order No. Panel Panel Color Mounting Screws

MCJ3230SS CA05890-B001 with panel Light gray

(2.5Y 7.2/0.4)

CA05890-B201 without panel

CA05890-B101 with panel Light gray

(2.5Y 7.2/0.4)

Note: The panel colors (2.5Y 7.2/0.4) are indicated in Munsell symbols. (JIS

Z8721)

Metric screws (M3)

Metric screws (M3)

Metric screws (M3)

C156-E224-01EN 2-1

Page 36

Specifications

2.1.2 Drive specifications

Table 2.2 lists MCJ3230SS drive specifications

Table 2.2 Specifications (1 of 2)

Item Specifications

Optical disk cartridge 128 MB media 230 MB media 540 MB media 640 MB media 1.3 GB media 2.3 GB media

Total capacity Unformatted

Formatted

Capacity/track Unformatted

Formatted

Capacity/sector Unformatted

Formatted

Number of user tracks/side *1

Number of alternate sectors/side

Number of sectors/track

Data transfer rate

Random seek time *2

Average latency

Rotational speed

Heads

Positioner type

Servo tracking method

181 MB 325 MB 819 MB 818 MB 1.683 GB 2.901 GB

128 MB 230 MB 538 MB 643 MB 1.283 GB 2.261 GB

18,100 bytes 18,100 bytes

12,800 bytes 12,800 bytes

725 bytes 778 bytes 778 bytes 2,584 bytes 2,694 bytes 2,766 bytes

10,000 17,940 42,042 18,480 36,855 64,944

≤ 1,024 ≤ 1,025 ≤ 2,250 ≤ 2,244 ≤ 4,437 ≤ 8,976

1.65 MB/s (max.)

0.39 MB/s

continuous

writing (effective)

1.16 MB/s

continuous

reading (effective)

(logical track

capacity)

(logical track

capacity)

512 bytes 2,048 bytes

25 17

2.00 to 3.16 MB/s

(max.)

0.47 to 0.75 MB/s

continuous

writing (effective)

1.40 to 2.23 MB/s

continuous

reading (effective)

19,450 bytes

(logical track

capacity)

12,800 bytes

(logical track

capacity)

3.45 to 5.94 MB/s

(max.)

0.78 to 1.30 MB/s

continuous

writing (effective)

2.33 to 3.91 MB/s

continuous

reading(effective)

5.5 ms 8.2 ms

5.455 rpm 3,637 rpm

Positioner + Separete Optical Section

Linear voice coil motor

ISO continuous servo method

3.52 to 5.87 MB/s

0.93 to 1.55 MB/s

writing (effective)

2.79 to 4.66 MB/s

reading (effective)

19 ms (typ)

43,928 bytes

(logical track

capacity)

34,816 bytes

(logical track

capacity)

(max.)

continuous

continuous

45,798 bytes

(logical track

capacity)

34,816 bytes

(logical track

capacity)

3.92 to 6.70 MB/s

(max.)

0.99 to 1.70 MB/s

continuous

writing (effective)

2.98 to 5.09 MB/s

continuous

reading (effective)

5.17 to 6.70 MB/s

(ZCLV max.)

continuous

writing

(ZCLV effective)

1.31 to 1.70 MB/s

continuous

reading

(ZCLV effective)

3.93 to 5.09 MB/s

7.2 ms (ZCLV)

6.3 ms (ZCLV)

4,138 rpm

(ZCLV)

4,801 rpm(ZCLV)

47,022 bytes

(logical track

34,816 bytes

(logical track

4.69 to 8.38 MB/s

1.16 to 2.07 MB/s

writing (effective)

3.84 to 6.21 MB/s

reading (effective)

capacity)

capacity)

(max.)

continuous

continuous

8.2 ms

3,637 rpm

2-2 C156-E224-01EN

Page 37

2.1 Optical Disk Drive Specifications

Table 2.2 Specifications (2 of 2)

Item Specifications

Optical disk cartridge 128 MB media 230 MB media 540 MB media 640 MB media 1.3 GB media 2.3 GB media

Density

Loading time *3

Unloading time *4

Load/unload life

Host interface

Data Transfer Model and rates

Data buffer

Error correction *5

24,424 bpi

(1.04µm/bit)

15,875 tpi

29,308 bpi

(0.87µm/bit)

18,275 tpi

52,900 bpi

(0.48µm/bit)

23,090 tpi

8 sec. (typ) 12 sec. (typ) 14 sec. (typ)

4 sec. (typ)

20,000

SCSI (SCSI-2 standard)

Asynchronous transfer 5MB/s

Synchronous transfer 20MB/s

7,600 KB

Correctable up to 8-byte/interleave

Bit error rate: 10

-12

or less

89,100 bpi

(0.285µm/bit)

28,200 tpi

112,474 bpi

(0.228µm/bit)

37,910 tpi

*1 The number of user tracks indicates the maximum user zone which includes

the spare area and slipping area.

*2 Mathematical average of 1,000 times of seek and does not include command

overhead nor track address recognition time. Furthermore, it may depend

on the quality of media and drive installation environment.

*3 Loading time is the time from when the optical disk cartridge is inserted to

when the optical disk drive is ready.

*4 Unloading time is the time from when the eject button is pressed or the eject

command is issued to when the optical disk cartridge is ejected.

-12

*5 Thebiterrorratemustbe10

-4

or less is used.

10

or less when a disk whose raw error rate is

C156-E224-01EN 2-3

Page 38

Specifications

2.1.3 Environmental and power requirements

Table 2.3 lists the environmental and power requirements.

Table 2.3 Environmental and power requirements (1 of 2)

Item Specification

Power

requirements

Power

consumption

(Average)

Average +5 VDC±5%, 1.4 A (2.5 A Max.) *1

Ripple requirement 100mV P-P (DC-1 MHz)

Ready (active mode) 4.8 W (typical) *2

Random seek, read/ write 6.5 W (typical) *2

Physical Format 7.3 W (typical) *2

Power save mode

Dimensions

(W×D×H)

Pre-idle mode

Idle mode

Standby mode

With panel

Without panel

4.0 W (typical) *2

2.0 W (typical) *2

1.0 W (typical) *2

101.6 × 150.0 × 25.4 mm

101.6 × 148.4 × 25.4 mm

Weight 480 g (with panel)

Environmental

requirements

Operating Temperature: 5 to 45°C *3

(gradient 15°C /h or less)

Relative humidity: 10 to 85% (Noncondensing)

Max. wet bulb temperature: 29°C or lower

Non Operating Temperature: 0 to 50°C

Relative humidity: 10 to 85% (Noncondensing)

Max. wet bulb temperature: 36°C or lower

Transport Temperature: -40 to 60°C (24 hours or less)

Temperature: -20 to 60°C (24 hours or more)

Relative humidity: 5 to 90% (Non condensing)

Max. wet bulb temperature: 41°C or lower

Installation Tilt angle -5° to +10° *3

Vibration/

shock

Operating 3.9 m/s2(5 to 500 Hz, sine sweep)

1.96 m/s

2

(5 to 500 Hz, sine sweep AV record/play)

2

(10ms, half-sine pulse)

2

(10 ms, half-sine pulse)

Non Operating

No cartridge, power ON

Shock 19.6 m/s

9.8 m/s2(5 to 500 Hz, sine sweep)

Shock 49 m/s

Transport Shock 490 m/s2(10 ms, half-sine pulse)

Requirement: Packing conditions specified by

Fujitsu

2-4 C156-E224-01EN

Page 39

2.1 Optical Disk Drive Specifications

Table 2.3 Environmental and power requirements (2 of 2)

Item Specification

Altitude Operating 3,000 m (10,000 ft) or less

Non Operating 12,000 m (40,000 ft) or less

Air flow Unused *4Ambient for

purity

Air purity General office environment or better

(dust perticles: Class 5 millions or less)

Note:

*1 At random seek or read/write. Excluding pulse waveform under 500 us or

less.

*2 It demonstrates in an installation environment of a temperature of 25°C,

voltage of 5 V.

See Section 4.4.8 for information on the power management function.

*3 The efficiency is specified in an environment of a temperature of 25°C and

0° horizontal level placement.

*4 For details, refer to section 3.1.3 'Air Flow'

1. Current limiter value for +5 VDC power: 5 A or less

2. Specifications under transporting condition are under the packaging specified

by Fujitsu.

3. A voltage drop may occur depending on the used power supply or power

cable.

4. If power for the terminators in the other SCSI devices is supplied via an

optical disk drive, note that the current of the +5VDC power for the optical

disk drive may increase by a maximum of 200 mA. The method of supplying

power to terminators cannot be changed.

5. Table 2.4 lists power consumption in power save mode when the temperature

inside the drive is 20°C or lower.

Table 2.4 Power consumption in power save mode when the temperature inside the

drive is 20°C or lower

IETM Power consumption at 20°C or lower

Pre-idle mode 4.0W (typ)

Power consumption in

power save mode

Idle mode 2.0W (typ)

Standby mode 1.0W(typ)

6. If the temperature inside the drive is 14°C or lower, disk access might become

longer because the speed of the related mechanisms varies with temperature.

C156-E224-01EN 2-5

Page 40

Specifications

2.1.4 Error rate

Data blocks to be accessed are evenly distributed on the disk. Errors due to disk

defects are not included.

(1) Bit error rate after ECC processing

The error rate after ECC processing must be 10

whose raw error rate is 10

(2) Positioning error rate

The positioning error rate must be 10

2.1.5 Reliability

(1) Mean time between failures (MTBF)

The MTBF is 120,000 hours or more. Failure due to disk errors is not included.

Conditions

-4

or less should be used.

-6

or less. (with retry)

-12

or less. An optical disk cartridge

•

Power-on time: 200 hours/month or less

•

LD-on time: 20% or less of power-on time

•

Environment Temp.: 25°C

Note:

The MTBF is defined as follows:

(2) Service Life

Under appropriate handling and operation, disk cleaning and optical head

cleaning, overhaul of the drive is not required for the first five years.

total operating time in all fields (hours)

MTBF=

number of device failure in all fields

- Operating time is the total time power is applied.

- Device failures indicate that devices require repair, readjustment, or

replacement. Failure due to external factors such as minor defects

during device handling, operation outside environmental

specifications, power failure, host system errors, and interface cable

errors are not included.

(3) Data security at power failure

Except for the data of the block to which write operation is in progress, all data on

the disk is secure from power failure. This does not apply if power failure occurs

during disk initialization (formatting) or defect processing (alternate block

allocation).

2-6 C156-E224-01EN

Page 41

2.2 Optical Disk Cartridge Specifications

2.2 Optical Disk Cartridge Specifications

2.2.1 Recommended optical disk cartridge specifications

The following three disk types comply with the specifications.

Table 2.5 shows the specifications of the optical disk cartridge recommended for

this optical disk drive. The use of another disk cartridge may lower drive

performance.

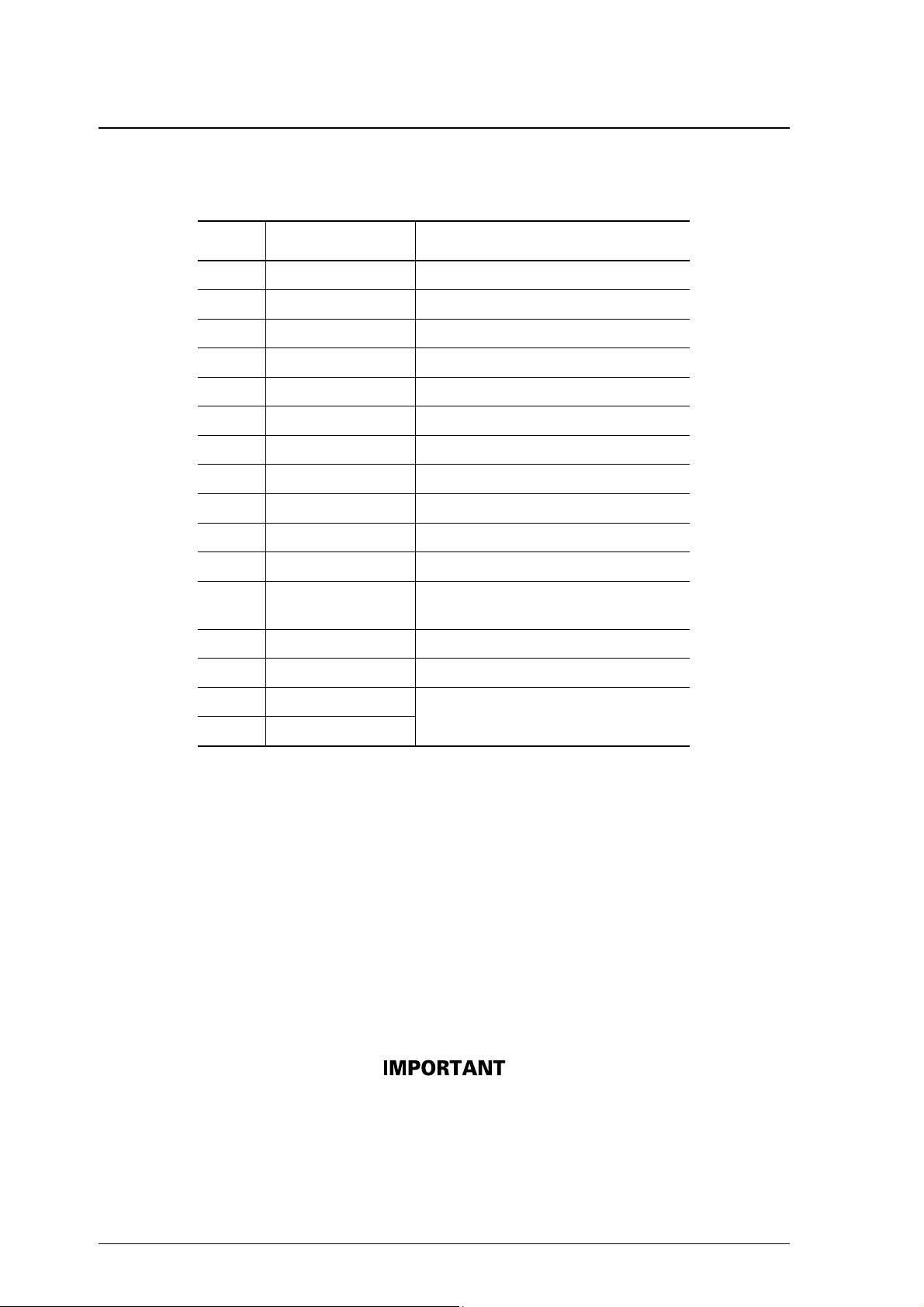

Table 2.5 Recommended optical disk cartridge specifications

Model Order number Figure number

Optical disk cartridge (128 MB) 0242110 CA90002-C010

Optical disk cartridge (230 MB) 0242210 CA90002-C011

Optical disk cartridge (540 MB) 0242410 CA90002-C012

Optical disk cartridge (640 MB) 0242610 CA90002-C013

Optical disk cartridge (1.3 GB) 0242810 CA90002-C015

Optical disk cartridge (2.3 GB) 0242910 CA90002-C030

Overwrite optical disk cartridge (230 MB) 0242310 CA90002-C041

Overwrite optical disk cartridge (540 MB) 0242510 CA90002-C042

Overwrite optical disk cartridge (640 MB) 0242710 CA90002-C043

C156-E224-01EN 2-7

Page 42

Specifications

2.2.2 Optical disk cartridge

Figure 2.1 shows an optical disk cartridge. The figure below shows the cartridge

with its shutter open.

a. Shutter closed

2) Shutter

1) Cartridge case

3) Write protect tab

b. Shutter open

4) Disk

Figure 2.1 Optical disk cartridge

5) Hub

2-8 C156-E224-01EN

Page 43

2.2 Optical Disk Cartridge Specifications

The following explains the components of the optical disk drive shown in Figure

2.1:

1) Cartridge case

Covers the disk to protect it from damage when handled and facilitates disk

replacement. The cartridge case is labeled and has a write protect tab.

2) Shutter

Protects the disk against dust. When the cartridge is inserted into the optical

disk drive, the shutter (metallic door) is opened.

3) Write protect tab

The write protect tab selects whether write is enabled or disabled.

4) Disk

Holds information which can be read by an optical beam.

5) Hub

The hub is placed at the center of the disk and is linked to the spindle of the

drive. The hub is used for radial centering and axial positioning.

2.2.3 Disk specifications

(1) 128 MB disk

The ISO/IEC10090 defines 128 MB disk specification.

(2) 230 MB disk

The ISO/IEC13963 defines 230 MB disk specification.

(3) 540 MB/640 MB disk

The ISO/IEC15041 defines 540 MB/640 MB disk specification.

(4) 1.3 GB disk

The Cherry Book defines 1.3 GB disk specification.

(5) 2.3 GB disk

The Cherry Book 2 defines 2.3 GB disk specification.

Table 2.6 lists disk specifications.

C156-E224-01EN 2-9

Page 44

Specifications

Table 2.6 Disk specifications

Item Specification

Reliability Read cycle >10

Erase/write/read cycle >10

Load/unload cycle 25,000

Archival life (according to acceleration test results) >10 years *1

Shelf life (according to acceleration test results) >10 years *2

Operating temperature 5 to 55°CEnvironmental

requirements

Operating relative humidity 3 to 85%RH *3

Storage temperature -20 to 55°C

Storage humidity 3 to 90% RH *3

*1 Archival life is the period in which recorded information can be read.

*2 Shelf life is the period in which information to be recorded can be written.

*3 Maximum wet bulb temperature = 29°C.

Note:

Non-recommended disks must be checked for compatibility.

8

6

2-10 C156-E224-01EN

Page 45

2.3 Defect Management

2.3.1 Defect management schematic diagram

Defective sectors on the disk shall be replaced by good sectors according to the

defect management scheme as follows: Defective sectors found during surface

certification are handled by a sector slipping algorithm. Defective sectors found

after initialization are handled by a linear replacement algorithm.

Figure 2.2 shows the algorithms for alternate processing.

2.3 Defect Management

(a) Sector slipping algorithm

(b) Linear r eplacement algorithm

Figure 2.2 Algorithms for alternate processing

The user area is divided into several groups during media initialization. Each

group contains data sectors and spare sectors. Spare sectors are used as

replacements for defective data sectors. Media initialization can include a

certification of the user area.

Figure 2.3 shows an example of alternate processing.

C156-E224-01EN 2-11

Page 46

Specifications

Figure 2.3 Example of alternate processing

2-12 C156-E224-01EN

Page 47

CHAPTER 3 Installation Requirements

3.1 Environmental Requirements

3.2 Mounting Requirements

3.3 Power supply Requirements

3.4 Cable Connections

3.5 Settings

3.6 Notes on Drive Handling

3.7 Mounting

3.8 Cable Connections

3.9 Operation Confirmation and Preparation for Use after Installation

3.10 Dismounting Drive

This chapter describes environmental, mounting, power supply, and connection

requirements.

3.1 Environmental Requirements

The environment in which these drives are installed must comply with the ambient

environmental requirements defined in Subsection 2.1.3.

3.1.1 Temperature measurement point

When a drive is operating, the ambient temperature measured 3 cm from the base

surface of the optical disk drive and the PCA unit surface must satisfy the

environmental requirements specified in Subsection 2.1.3. For the temperature of

each surface during operation, the contact temperature at each measurement point

shown in Figure 3.1 must satisfy the requirements specified in Subsection 3.1.2.

Low temperature burns: The surface temperatures of some ICs

on the printed circuit board unit in the optical disk drive exceed

55°C while operating. Be careful of low tenperature burns.

C156-E224-01EN 3-1

Page 48

Installation Requirements

a) Inside optical disk cartridge

Operating of inner

partition wall

Hole for inserting thermocouple

b) IC (controller, read amp)

IC (controller)

Tip of thermocouple

IC (read amp)

IC (power amp)

Figure 3.1 Surface temperature measurement points

3-2 C156-E224-01EN

Page 49

3.1 Environmental Requirements

3.1.2 Temperature requirements and measuring method

Table 3.1 shows the temperature requirement at each measurement point shown in

Figure 3.1.

Table 3.1 Temperature requirements at measurement points

Measurement point Maximum surface temperature

Cartridge inside 55°C *

IC (controller) surface 90 °C

IC (read amp.) surface 95 °C

IC (power amp.) surface 90 °C

* Following procedure is for temperature measurement of inside cartridge.

1) Make a hole for the thermocouple as shown in Figure 3.1.

3.1.3 Air flow

2) Disassemble the cartridge disk.

3) Cut off a part of the partition wall for the optical media as shown in Figure

3.1. (Cut off width: 5 to 10 mm)