查询MB90427GCPF供应商

FUJITSU SEMICONDUCTOR

DATA SHEET

DS07-13711-4E

16-Bit Original Microcontroller

CMOS

F2MC-16LX MB90420G/425G Series

MB90423GA/423GC/F423GA/F423GC/427GA/427GC/428GA/428GC/

MB90F428GA/F428GC/V420G

DESCRIPTIONS

■

The FUJITSU MB90420G/425G Series is a 16-bit general purpose high-capacity microcontroller designed for

vehicle meter control applications etc.

The instruction set retains the same A T architecture as the FUJITSU original F

further refinements including high-level language instructions, expanded addressing mode, enhanced (signed)

multipler-divider computation and bit processing.

2

MC-8L and F2MC-16L series, with

In addition, a 32-bit accumulator is built in to enable long word processing.

FEATURES

■

• 16-bit input capture (4 channels)

Detects rising, falling, or both edges.

16-bit capture register × 4

Pin input edge detection latches the 16-bit free-run timer counter value, and generates an interrupt request.

• 16-bit reload timer (2 channels)

16-bit reload timer operation (select toggle output or one-shot output)

Event count function selection provided

PACKAGES

■

Plastic QFP, 100-pin Plastic LQFP, 100-pin

(Continued)

(FPT-100P-M06) (FPT-100P-M05)

MB90420G/425G Series

• Watch timer (main clock)

Operates directly from oscillator clock.

Compensates for oscillator deviation

Read/write enabled second/minute/hour register

Signal interrupt

• 16-bit PPG (3 channels)

Output pins (3) , external trigger input pin (1)

Output clock frequencies : f

CP, fCP/2

2

, fCP/24, fCP/2

• Delay interrupt

Generates interrupt for task switching.

Interruptions to CPU can be generated/deleted by software setting.

• External interrupts (8 channels)

8-channel independent operation

Interrupt source setting available : “L” to “H” edge/ “H” to “L” edge/ “L” level/ “H” level.

• A/D converter

10-bit or 8-bit resolution × 8 channels (input multiplexed)

Conversion time : 6.13 µs or less (at f

CP = 16 MHz)

External trigger startup available (P50/INT0/ADTG)

Internal timer startup available (16-bit reload timer 1)

• UART (2 channels)

Full duplex double buffer type

Supports asynchronous/synchronous transfer (with start/stop bits)

Internal timer can be selected as clock (16-bit reload timer 0)

Asynchronous : 4808 bps, 5208 bps, 9615 bps, 10417 bps, 19230 bps, 38460 bps, 62500 bps, 500000 bps

Synchronous : 500 Kbps, 1Mbps, 2Mbps (at f

• CAN interface *

1

Conforms to CAN specifications version 2.0 Part A and B.

Automatic resend in case of error.

Automatic transfer in response to remote frame.

16 prioritized message buffers for data and messages for data and ID

Multiple message support

Receiving filter has flexible configuration : All bit compare/all bit mask/two partial bit masks

Supports up to 1 Mbps

CAN WAKEUP function (connects RX internally to INT0)

• LCD controller/driver (1 channel)

Segment driver and command driver with direct LCD panel (display) drive capability

• Low voltage/Program Looping detect reset *

Automatic reset when low voltage is detected

Program Looping detection function

• Stepping motor controller (4 channels)

High current output for all channels × 4

Synchronized 8/10-bit PWM for all channels × 2

• Sound generator

8-bit PWM signal mixed with tone frequency from 8-bit reload counter.

PWM frequencies : 62.5 kHz, 31.2 kHz, 15.6 kHz, 7.8 kHz (at f

Tone frequencies : 1/2 PWM frequency, divided by (reload frequency +1)

6

CP = 16 MHz)

2

CP = 16MHz)

(Continued)

2

MB90420G/425G Series

(Continued)

• Input/output ports

Push-pull output and Schmitt trigger input

Programmable in bit units for input/output or peripheral signals.

•Flash memory

Supports automatic programming, Embeded Algorithm

Flag indicates algorithm completion

Minato Electronics flash writer

Boot block configuration

Erasable by blocks

Block protection by external programming voltage

*1 : MB90420G series has 2 channels built-in, MB90425G series has 1 channel built-in

*2 : Built-in to MB90420GA/425GA series only. Not built-in to MB90420GC/425GC series.

Embeded Algorithm is a registered trademark of Advanced Micro Devices Inc.

TM

, write/erase/erase pause/erase resume instructions

3

MB90420G/425G Series

PRODUCT LINEUP

■

••••

MB90420G Series

Part

number

Parameter

Configuration

CPU

Clock

System clock

ROM

RAM

CAN interface

Low voltage/

CPU operation

detection reset

Packages

Emulator

dedicated

power supply*

* : When used with emulation pod MB2145-507, use DIP switch S2 setting. For details see the MB2145-50

Hardware Manual (2.7 “Emulator Dedicated Power Supply Pin”) .

MB90F423GA MB90F423GC MB90423GA MB90423GC MB90V420G

Flash ROM model Mask ROM model Evaluation model

F2MC-16LX CPU

1 system 2 systems 1 system 2 systems 2 systems

On-chip PLL clock multiplier type ( × 1, × 2, × 3, × 4, 1/2 when PLL stopped)

Minimum instruction execution time 62.5 ns (with 4 MHz oscillator × 4)

Flash ROM 128 KB Mask ROM 128 KB External

6 KB 6 KB 6 KB

2 channels

Yes No Yes No No

QFP100, LQFP100 PGA-256

No

••••

MB90425G Series

Part number

MB90F428GA MB90F428GC MB90427GA MB90427GC MB90428GA MB90428GC

Parameter

Configuration Flash ROM model Mask ROM model

CPU

2

F

MC-16LX CPU

Clock 1 system 2 systems 1 system 2 systems 1 system 2 systems

System clock

On-chip PLL clock multiplier type ( × 1, × 2, × 3, × 4, 1/2 when PLL stopped)

Minimum instruction execution time 62.5 ns (with 4 MHz oscillator × 4)

ROM Flash ROM 128 KB Mask ROM 64 KB Mask ROM 128 KB

RAM 6 KB 4 KB 6 KB

CAN interface 1 channel

Low voltage/CPU

operation

Yes No Yes No Yes

No

detection reset

Packages QFP100, LQFP100

Emulator

dedicated

power supply

Note : MB90V420G can be used as evaluation model for MB90420G/425G series.

4

PIN ASSIGNMENTS

■

••••

QFP 100

SEG0

SEG1

SEG2

SEG3

SEG4

SEG5

SEG6

SEG7

V

SS

SEG8

SEG9

SEG10

SEG11

P36/SEG12

P37/SEG13

P40/SEG14

P41/SEG15

P42/SEG16

P43/SEG17

P44/SEG18

V

P45/SEG19

P46/SEG20

P47/SEG21

CC

C

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

MB90420G/425G Series

(TOP VIEW)

P06/PPG0/TOT1

P11/TOT0/WOT

P07/PPG1/TIN1

P12/TIN0/IN3

P13/IN2

P14/IN1

P15/IN0

COM0

COM1

COM2

COM3

100

1

2

3

4

5

6

7

8

9

99

98

97

96

95

94

93

92

P05/SCK1/TRG

P10/PPG2

88

89

90

91

P01/SOT0/INT5

P02/SCK0/INT6

P03/SIN1/INT7

P04/SOT1

84

85

86

87

P00/SIN0/INT4

X1

81

X0

80

V

SS

79

X0A

78

83

V

CC

82

P57/SGA

X1A

76

77

RST

75

P56/SGO/FRCK

74

P55/RX0

73

P54/TX0

72

DV

71

P87/PWM2M3

70

P86/PWM2P3

69

P85/PWM1M3

68

P84/PWM1P3

67

DV

66

P83/PWM2M2

65

P82/PWM2P2

64

P81/PWM1M2

63

P80/PWM1P2

62

DV

61

60

P77/PWM2M1

59

P76/PWM2P1

58

P75/PWM1M1

57

P74/PWM1P1

56

DV

55

P73/PWM2M0

54

P72/PWM2P0

53

P71/PWM1M0

52

P70/PWM1P0

51

DV

SS

CC

SS

CC

SS

29

28

27

26

V1

V0

P91/SEG23

P90/SEG22

30

V2

31

37

36

35

34

33

32

P61/AN1

P60/AN0

AVSSP50/INT0/ADTG

AVRH

AVCCV3

(FPT-100P-M06)

40

39

38

V

P63/AN3

P62/AN2

SS

43

42

41

P66/AN6

P65/AN5

P64/AN4

48

47

46

45

44

MD1

MD0

P52/INT2 (/TX1)

P51/INT1 (/RX1)

P67/AN7

50

49

P53/INT3

MD2

5

MB90420G/425G Series

••••

LQFP 100

(TOP VIEW)

P11/TOT0/WOT

P07/PPG1/TIN1

P12/TIN0/IN3

P10/PPG2

P13/IN2

P14/IN1

P15/IN0

COM0

COM1

COM2

COM3

SEG0

SEG1

SEG2

SEG3

SEG4

SEG5

SEG6

SEG7

V

SS

SEG8

SEG9

SEG10

SEG11

P36/SEG12

P37/SEG13

P40/SEG14

P41/SEG15

P42/SEG16

P43/SEG17

P44/SEG18

V

P45/SEG19

P46/SEG20

P47/SEG21

CC

100

98

99

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

C

97

96

95

94

93

92

91

90

P06/PPG0/TOT1

P05/SCK1/TRG

88

89

P01/SOT0/INT5

P02/SCK0/INT6

P03/SIN1/INT7

P04/SOT1

84

85

86

87

P00/SIN0/INT4

X1

81

X0

80

V

SS

79

X0A

78

83

V

CC

82

P57/SGA

X1A

76

77

RST

75

P56/SGO/FRCK

74

P55/RX0

73

P54/TX0

72

DV

71

P87/PWM2M3

70

P86/PWM2P3

69

P85/PWM1M3

68

P84/PWM1P3

67

DV

66

65

P83/PWM2M2

64

P82/PWM2P2

63

P81/PWM1M2

62

P80/PWM1P2

61

DV

60

P77/PWM2M1

59

P76/PWM2P1

58

P75/PWM1M1

57

P74/PWM1P1

56

DV

55

P73/PWM2M0

54

P72/PWM2P0

53

P71/PWM1M0

52

P70/PWM1P0

51

DV

SS

CC

SS

CC

SS

50

49

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

32

31

30

29

28

27

26

P53/INT3

MD2

MD1

MD0

P52/INT2 (/TX1)

P51/INT1 (/RX1)

P67/AN7

P66/AN6

P65/AN5

P64/AN4

V

P63/AN3

P62/AN2

P61/AN1

P60/AN0

AVSSP50/INT0/ADTG

AVRH

AVCCV3

V2

V1

V0

P91/SEG23

P90/SEG22

SS

(FPT-100P-M05)

6

PIN DESCRIPTIONS

■

MB90420G/425G Series

Pin no.

LQFP QFP

80 82 X0

81 83 X1 High speed oscillator output pin.

78 80 X0A

77 79 X1A

75 77 RST

83 85

84 86

85 87

Symbol

P00

SIN0 UART ch.0 serial data input pin.

INT4 INT4 external interrupt input pin.

P01

SOT0 UART ch.0 serial data output pin.

INT5 INT5 external interrupt input pin.

P02

SCK0 UART ch.0 serial clock input/output pin.

INT6 INT6 external interrupt input pin.

Circuit

type

High speed oscillator input pin.

A

Low speed oscillator input pin. If no oscillator is connected, apply

pull-down processing.

A

Low speed oscillator output pin. If no oscillator is connected, leave

open.

B Reset input pin.

General purpose input/output port.

G

General purpose input/output port.

G

General purpose input/output port.

G

Description

86 88

87 89

88 90

89 91

90 92

91 93

P03

SIN1 UART ch.1 serial data input pin.

INT7 INT7 external interrupt input pin.

P04

SOT1 UART ch.1 serial data output pin.

P05

SCK1 UART ch.1 serial clock input/output pin.

TRG 16-bit PPG ch.0-2 external trigger input pin.

P06

PPG0 16-bit PPG ch.0 output pin.

TOT1 16-bit reload timer ch.1 TOT output pin.

P07

PPG1 16-bit PPG ch.1 output pin.

TIN1 16-bit reload timer ch.1 TIN output pin.

P10

PPG2 16-bit PPG ch.2 output pin.

General purpose input/output port.

G

General purpose input/output port.

G

General purpose input/output port.

G

General purpose input/output port.

G

General purpose input/output port.

G

General purpose input/output port.

G

(Continued)

7

MB90420G/425G Series

Pin no.

LQFP QFP

92 94

93 95

94 to 96 96 to 98

97 to 100

1 to 8,

10 to 13

14 to 15 16 to 17

16 to 20,

22 to 24

99 to 100,

1 to 2

3 to 10,

12 to 15

18 to 22,

24 to 26

Symbol

P11

TOT0 16-bit reload timer ch.0 TOT output pin.

WOT Real-time watch timer WOT output pin.

P12

TIN0 16-bit reload timer ch.0 TIN output pin.

IN3 Input capture ch.3 trigger input pin.

P13 to P15

IN2 to IN0 Input capture ch.0-2 trigger input pins.

COM0 to

COM3

SEG0 to

SEG11

P36 to P37

SEG12 to

SEG13

P40 to P47

SEG14 to

SEG21

Circuit

type

General purpose input/output port.

G

General purpose input/output port.

G

General purpose input/output ports.

G

I LCD controller/driver common output pins.

I LCD controller/driver segment output pins.

General purpose output ports.

E

LCD controller/driver segment output pins.

General purpose input output ports.

E

LCD controller/driver segment output pins.

Description

26 to 27 28 to 29

34 36

36 to 39,

41 to 44

45 47

46 48

50 52

38 to 41,

43 to 46

P90 to P91

SEG22 to

SEG23

P50

INT0 INT0 external interrupt input pin.

ADTG A/D converter external trigger input pin.

P60 to P67

AN0 to

AN7

P51

INT1 INT1 external interrupt input pin.

(RX1 *

(TX1 *

1

) CAN interface 1 RX intput pin.

P52

INT2 INT2 external interrupt input pin.

1

) CAN interface 1 TX output pin.

P53

INT3 INT3 external interrupt input pin.

General purpose input output ports.

E

LCD controller/driver segment output pins.

General purpose input output ports.

G

General purpose input output ports.

F

A/D converter input pins.

General purpose input output port.

G

General purpose input output port.

G

General purpose input output port.

G

(Continued)

8

MB90420G/425G Series

Pin no.

LQFP QFP

52 to 55 54 to 57

57 to 60 59 to 62

62 to 65 64 to 67

67 to 70 69 to 72

Symbol

P70 to P73

PWM1P0

PWM1M0

PWM2P0

PWM2M0

P74 to P77

PWM1P1

PWM1M1

PWM2P1

PWM2M1

P80 to P83

PWM1P2

PWM1M2

PWM2P2

PWM2M2

P84 to P87

PWM1P3

PWM1M3

PWM2P3

PWM2M3

Circuit

type

H

H

H

H

Description

General purpose input output ports.

Stepping motor controller ch.0 output pins.

General purpose input output ports.

Stepping motor controller ch.1 output pins.

General purpose input output ports.

Stepping motor controller ch.2 output pins.

General purpose input output ports.

Stepping motor controller ch.3 output pins.

72 74

P54

General purpose input output port.

G

TX0 CAN interface 0 TX output pin.

73 75

P55

General purpose output port.

G

RX0 CAN interface 0 RX input pin.

74 76

P56

SGO Sound generator SG0 output pin.

General purpose input output port.

G

FRCK Free-run timer clock input pin.

76 78

P57

General purpose input output port.

G

SGA Sound generator SGA output pin.

28 to 31 30 to 33 V0 to V3 LCD controller /driver reference power supply pins.

56, 66 58, 68 DV

51, 61, 71 53, 63, 73 DV

CC

SS

High current output buffer with dedicated power supply input pins

(pin numbers 54-57, 59-62, 64-67, 69-72) .

High current output buffer with dedicated power supply GND pins

(pin numbers 54-57, 59-62, 64-67, 69-72) .

32 34 AVCC A/D converter dedicated power supply input pin.

35 37 AV

SS A/D converter dedicated GND supply pin.

33 35 AVRH A/D converter Vref + input pin. Vref − AVss.

(Continued)

9

MB90420G/425G Series

(Continued)

Pin no.

Symbol

LQFP QFP

47

48

49

50

MD0

MD1

49 51 MD2 C/D *

Circuit

type

C Test mode input pins. Connect to V

2

Text mode input pin. Connect to VSS.

Description

CC.

25 27 C

21, 82 23, 84 V

CC Power supply input pins.

External capacitor pin. Connect an 0.1 µF capacitor between this

pin and V

SS.

9, 40, 79 11, 42, 81 VSS GND power supply pins.

*1 : MB90420G series only.

*2 : Type C in the flash ROM models, type D in the mask ROM models.

10

MB90420G/425G Series

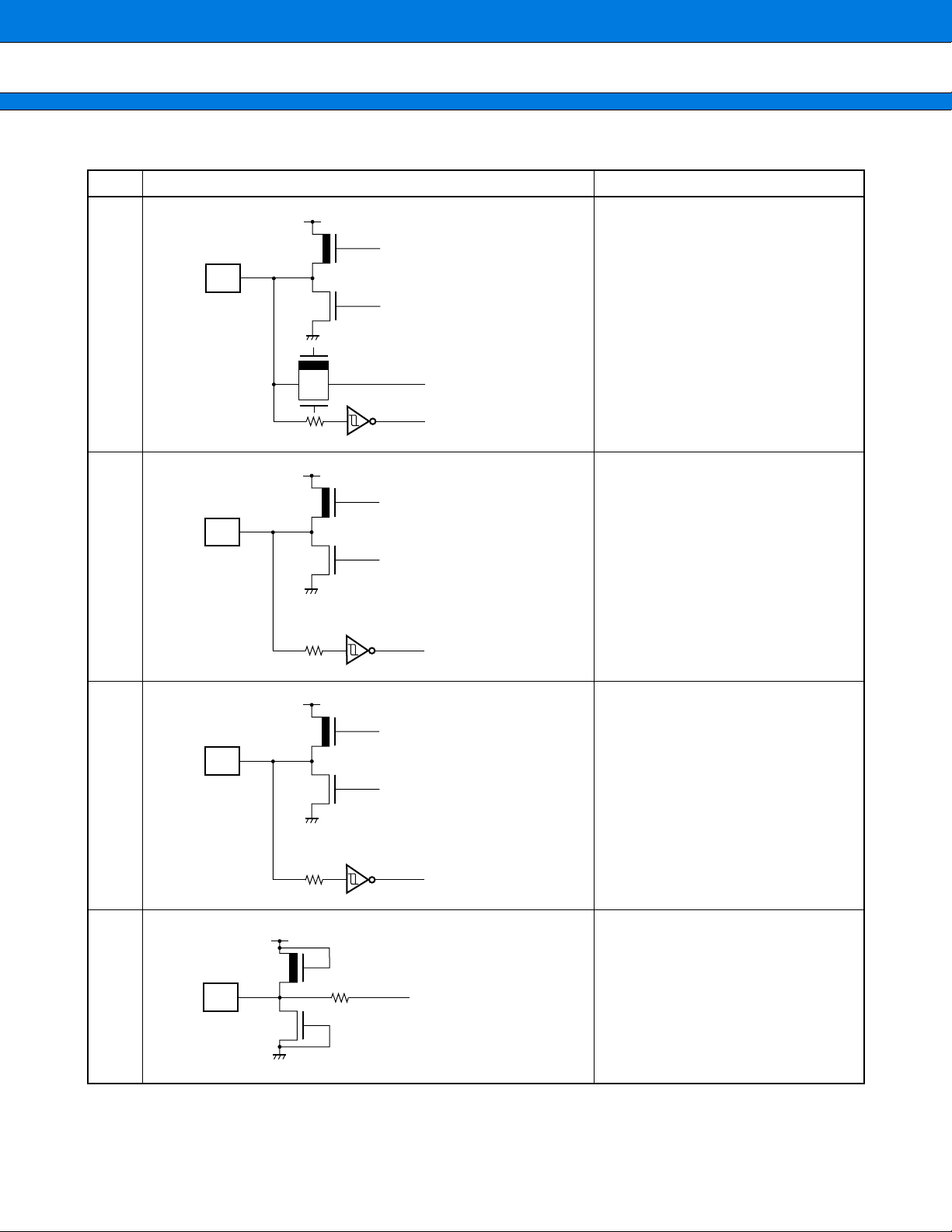

I/O CIRCUIT TYPE

■

Type Circuit Remarks

X1/X1A

• Oscillation feedback resistance :

approx. 1 MΩ (X0, X1 : MAIN)

• Oscillation feedback resistance :

approx. 10 MΩ (X0A, X1A : SUB)

A

X0/X0A

Standby control signal

• Pull-up resistance attached :

approx. 50 kΩ, hysteresis input

B

Hysteresis input

• Hysteresis input

C

Hysteresis input

• Pull-down resistance attached :

approx. 50 kΩ, hysteresis input

Hyteresis input

D

• CMOS output

• LCDC output

• Hysteresis input

E

LCDC output

Hysteresis input

(Continued)

11

MB90420G/425G Series

(Continued)

Type Circuit Remarks

• CMOS output

• Hysteresis input

• Analog input

F

Analog input

Hysteresis input

• CMOS output

• Hysteresis input

G

Hysteresis input

• CMOS high current output

• Hysteresis input

High current

H

Hysteresis input

• LCDC output

I

LCDC output

12

HANDLING DEVICES

■

Precautions for Handling Semiconductor Devices

• Strictly observe maximum rated voltages (prevent latchup)

MB90420G/425G Series

When CMOS integrated circuit devices are subjected to applied voltages higher than V

pins other than medium- and high-withstand voltage pins, or to voltages lower than V

excess of rated le vels are applied between V

CC and VSS, a phenomenon known as latchup can occur . In a latchup

CC at input and output

SS, or when voltages in

condition, supply current can increase dramatically and may destroy semiconductor elements. In using semiconductor devices, always take sufficient care to avoid exceeding maximum ratings.

Also care must be taken when power to analog systems is switched on or off, to ensure that the analog power

supply (AV

do not exceed the digital power supply (V

CC, AVRH) , analog input and dedicated power supply for the high current output buffer pins (DVCC)

CC) .

Once the digital power supply (VCC) is switched on, the analog po wer (AVCC,AVRH) and dedicated power supply

for the high current output buffer pins (DV

CC) may be turned on in any sequence.

• Stable supply voltage

Even within the warranted operating range of V

CC supply voltage, sudden fluctuations in supply voltage can

cause abnormal operation. The recommended stability for ripple fluctuations (P-P values) at commercial frequencies (50 Hz to 60 Hz) should be within 10% of the standard V

CC value, and voltage fluctuations that occur

during switching of power supplies etc. should be limited to transient fluctuation rates of 0.1 V/ms or less.

• Power-on procedures

In order to prevent abnormal operation of the internal built-in step-down circuits, v oltage rise time during poweron should be attained within 50 µs (0.2 V to 2.7 V) .

• Treatment of unused pins

If unused input pins are left open, they ma y cause abnormal operation or latchup which may lead to permanent

damage to the semiconductor. An y such pins should be pulled up or pulled do wn through resistance of at least

2 kΩ.

Any unused input/output pins should be left open in output status, or if found set to input status , they should be

treated in the same way as input pins.

Any unused output pins should be left open.

• Treatment of A/D converter power supply pins

Even if the A/D converter is not used, pins should be connected so that AV

CC = VCC, and AVSS = AVRH = VSS.

• Use of external clock signals

Even when an external clock is used, a stabilization period is required following a power-on reset or release

from sub clock mode or stop mode. Also, when an e xternal clock is used it should drive only the X0 pin and the

X1 pin should be left open, as shown in Figure 3.

X0

OPEN

X1

MB90420G/425G Series

Sample external clock connection

13

MB90420G/425G Series

• Power supply pins

Devices are designed to pre vent problems such as latchup when multiple V

CC and VSS supply pins are used, by

providing internal connections between pins having the same potential. However, in order to reduce unwanted

radiation, and to prevent abnormal operation of strobe signals due to rise in ground level, and to maintain total

output current ratings, all such pins should always be connected externally to power supplies and ground.

As shown in figure below, all V

should be handled in the same way. If there are multiple V

CC power supply pins must have the same potential. All VSS power supply pins

CC or VSS systems, the device will not operate properly

even within the warranted operating range.

VCC

VSS

VCC

VSS

VCC

VSS

VSS

VCC

VSS

VCC

Power supply input pins (VCC/VSS)

In addition, care must be given to connecting the V

impedance as possible. It is recommended that a bypass capacitor of 1.0 µF be connected between V

V

SS as close to the pins as possible.

CC and VSS pins of this device to a current source with as little

CC and

• Proper sequence of A/D converter power supply analog input

A/D converter power (AV

(V

CC) is switched on. When power is shut off, the A/D converter power supply and analog input must be cut off

before the digital power supply is switched on (V

AVRH does not exceed AV

sure that the input voltage does not exceed AV

CC, AVRH) and analog input (AN0-AN7) must be applied after the digital power supply

CC) . In both power-on and shut-off, care should be taken that

CC. Even when pins which double as analog input pins are used as input por ts, be

CC. (There is no problem if analog power supplies and digital

power supplies are turned off and on at the same time.)

CC

• Handling the power supply for high-current output buffer pins (DV

Always apply pow er to high-current output b uffer pins (DV

CC, D VSS) after the digital po w er supply (VCC) is turned

on. Also when switching power off, alw a ys shut off the power supply to the high-current output b uffer pins (DV

DV

SS) before s witching off the digital po w er supply (VCC) . (There will be no problem if high-current output buffer

, DVSS)

CC,

pins and digital power supplies are turned off and on at the same time.)

Even when high-current output buff er pins are used as gener al purpose ports, the power for high current output

buffer pins (DV

CC, DVSS) should be applied to these pins.

• Pull-up/pull-down resistance

The MB90420G/425G series does not support internal pull-up/pull-down resistance. If necessary, use external

components.

14

MB90420G/425G Series

• Precautions for when not using a sub clock signal.

If the X0A and X1A pins are not connected to an oscillator, apply pull-down treatment to the X0A pin and leav e

the X1A pin open.

• Notes on during operation of PLL clock mode

If the PLL clock mode is selected, the microcontroller attempt to be working with the self-oscillating circuit ev en

when there is no external oscillator or external clock input is stopped. Performance of this operation, however,

cannot be guaranteed.

15

MB90420G/425G Series

BLOCK DIAGRAM

■

X0, X1

X0A, X1A

RST

P57/SGA

P56/SGO/FRCK

P55/RX0

P54/TX0

P53/INT3

P52/INT2 (/TX1)

P51/INT1 (/RX1)

P50/INT0/ADTG

P00/SIN0/INT4

P01/SOT0/INT5

P02/SCK0/INT6

P03/SIN1/INT7

P04/SOT1

P05/SCK1/TRG

P06/PPG0/TOT1

P07/PPG1/TIN1

P10/PPG2

P11/TOT0/WOT

P12/TIN0/IN3

P13/IN2

P14/IN1

P15/IN0

Clock control

circuit

RAM

ROM

Sound generator

CAN controller

Port 5

External interrupt

(8 ch)

UART0/1

Prescaler

Port 0

PPG0/1/2

Port 1

Reload timer

Real-time

Watch timer

ICU0/1/2/3

0/1

0/1

CPU

F2MC-16LX core

MC-16LX BUS

2

F

Interrupt

controller

Low voltage/

CPU operation

detection reset

Port 8

Stepping

motor

Controller

0/1/2/3

Port 7

Port 6

A/D converter

(8 ch)

Port 9

Port 4

Port 3

P87/PWM2M3

P86/PWM2P3

P85/PWM1M3

P84/PWM1P3

P83/PWM2M2

P82/PWM2P2

P81/PWM1M2

P80/PWM1P2

P77/PWM2M1

P76/PWM2P1

P75/PWM1M1

P74/PWM1P1

P73/PWM2M0

P72/PWM2P0

P71/PWM1M0

P70/PWM1P0

P67 to P60/

AN7 to AN0

AV

CC/AVSS

AVRH

P91, P90/

SEG23, SEG22

P47 to P40/

SEG21 to SEG14

P37, P36/

SEG13 to SEG12

Free-run timer

Evaluation device (MB90V420G)

No built-in ROM

Built-in RAM is 6 KB.

LCD controller/

driver

SEG11 to SEG0

COM3 to COM0

V3 to V0

Note: MB90420G series is equipped with 2-channel CAN interface and MB90425G series is equipped with 1-channel

CAN interface. MB90F423GA, MB90423GA, MB90F428GA, MB90427GA and MB90428GA have low voltage/CPU operation detection reset. MB90F423GC, MB90423GC , MB90F428GC, MB90427GC, MB90428GC

and MB90V420G do not have low voltage/CPU operation detection reset.

See “■ Product Lineup” for detail.

16

■■■■ MEMORY MAP

000000H

0000C0H

MB90420G/425G Series

Single chip mode

(with ROM mirror function)

Peripheral area

000100H

Address #2

003900

004000H

010000H

Address #1

FFFFFFH

Register

RAM area

H

Peripheral area

ROM area

(FF bank image)

ROM area

: Internal access memory

: Access prohibited

Parts No. Address #1 Address #2

MB90423GA/GC FE0000

H 001900H

MB90427GA/GC FF0000H 001100H

MB90428GA/GC FE0000H 001900H

MB90F423GA/GC FE0000H 001900H

MB90F428GA/GC FE0000H 001900H

MB90V420G FE0000H 001900H

Note : To select models without the ROM mirror function, see the “ROM Mirror Function Selection Module.” The

image of the ROM data in the FF bank appears at the top of the 00 bank, in order to enable efficient use of

small C compiler models. The lower 16-bit address for the FF bank will be assigned to the same address,

so that tables in ROM can be referenced without declaring a “far” indication with the pointer. For example

when accessing the address 00C000

H, the actual access is to address FFC000H in ROM. Here the FF bank

ROM area exceeds 48 KB, so that it is not possible to see the entire area in the 00 bank image. Therefore

because the ROM data from FF4000

recommended that the ROM data table be stored in the area from FF4000

H to FFFFFFH will appear in the image from 004000H to 00FFFFH, it is

H to FFFFFFH.

17

MB90420G/425G Series

I/O MAP

■

• Other than CAN Interface

Address Register name Symbol Read/write Peripheral function Initial value

00

H Port 0 data register PDR0 R/W Port 0 XXXXXXXX

01

H Port 1 data register PDR1 R/W Port 1 - - XXXXXX

02H (Disabled)

03

H Port 3 data register PDR3 R/W Port 3 XX - - - - - -

04

H Port 4 data register PDR4 R/W Port 4 XXXXXXXX

05H Port 5 data register PDR5 R/W Port 5 XXXXXXXX

06

H Port 6 data register PDR6 R/W Port 6 XXXXXXXX

07

H Port 7 data register PDR7 R/W Port 7 XXXXXXXX

08H Port 8 data register PDR8 R/W Port 8 XXXXXXXX

09

H Port 9 data register PDR9 R/W Port 9 - - - - - -XX

0A

H to

0F

H

10H Port 0 direction register DDR0 R/W Port 0 0 0 0 0 0 0 0 0

(Disabled)

11

H Port 1 direction register DDR1 R/W Port 1 - - 0 0 0 0 0 0

12

H (Disabled)

13H Port 3 direction register DDR3 R/W Port 3 0 0 - - - - - -

14

H Port 4 direction register DDR4 R/W Port 4 0 0 0 0 0 0 0 0

15

H Port 5 direction register DDR5 R/W Port 5 0 0 0 0 0 0 0 0

16

H Port 6 direction register DDR6 R/W Port 6 0 0 0 0 0 0 0 0

17H Port 7 direction register DDR7 R/W Port 7 0 0 0 0 0 0 0 0

18

H Port 8 direction register DDR8 R/W Port 8 0 0 0 0 0 0 0 0

19

H Port 9 direction register DDR9 R/W Port 9 - - - - - - 0 0

1AH Analog input enable ADER R/W Port 6, A/D 1 1 1 1 1 1 1 1

1B

H to

1F

H

20

H A/D control status register lower ADCSL R/W

(Disabled)

0 0 0 0 0 0 0 0

21H A/D control status register higher ADCSH R/W 0 0 0 0 0 0 0 0

A/D converter

22

H A/D data register lower ADCRL R XXXXXXXX

23

H A/D data register higher ADCRH R/W 0 0 1 0 1 XXX

24H

R/W

XXXXXXXX

Compare clear register CPCLR

25

H R/W XXXXXXXX

18

26

H

Timer data register TCDT

H R/W 0 0 0 0 0 0 0 0

27

R/W 0 0 0 0 0 0 0 0

16-bit free-run timer

28H Timer control status register lower TCCSL R/W 0 0 0 0 0 0 0 0

29

H Timer control status register higher TCCSH R/W 0 - - 0 0 0 0 0

(Continued)

MB90420G/425G Series

Address Register name Symbol Read/write Peripheral function Initial value

2A

H PPG0 control status register lower PCNTL0 R/W

16-bit PPG0

2BH PPG0 control status register higher PCNTH0 R/W 0 0 0 0 0 0 0 -

2C

H PPG1 control status register lower PCNTL1 R/W

16-bit PPG1

2D

H PPG1 control status register higher PCNTH1 R/W 0 0 0 0 0 0 0 -

2E

H PPG2 control status register lower PCNTL2 R/W

16-bit PPG2

2FH PPG2 control status register higher PCNTH2 R/W 0 0 0 0 0 0 0 -

30

H External interrupt enable ENIR R/W

31

H External interrupt request EIRR R/W 0 0 0 0 0 0 0 0

External interrupt

32H External interrupt level lower ELVRL R/W 0 0 0 0 0 0 0 0

33

H External interrupt level higher ELVRH R/W 0 0 0 0 0 0 0 0

34

H Serial mode register 0 SMR0 R/W

35H Serial control register 0 SCR0 R/W 0 0 0 0 0 1 0 0

36

Input data register 0/

H

Output data register 0

SIDR0/

SODR0

R/W XXXXXXXX

UART 0

0 0 0 0 0 0 0 0

0 0 0 0 0 0 0 0

0 0 0 0 0 0 0 0

0 0 0 0 0 0 0 0

0 0 0 0 0 - 0 0

37

H Serial status register 0 SSR0 R/W 0 0 0 0 1 0 0 0

38H Serial mode register 1 SMR1 R/W

39

H Serial control register 1 SCR1 R/W 0 0 0 0 0 1 0 0

3A

3B

Input data register 1/

H

Output data register 1

H Serial status register 1 SSR1 R/W 0 0 0 0 1 0 0 0

SIDR1/

SODR1

R/W XXXXXXXX

UART1

0 0 0 0 0 − 0 0

3CH (Disabled)

3D

H Clock division control register 0 CDCR0 R/W Prescaler 0 - - - 0 0 0 0

3E

H CAN wake-up control register CWUCR R/W CAN - - - - - - - 0

3FH Clock division control register 1 CDCR1 R/W Prescaler 0 - - - 0 0 0 0

40

H to 4FH Area reserved for CAN interface 0

50

H Timer control status register 0 lower TMCSR0L R/W

51H

52

53

Timer control status register 0 higher

H

Timer register 0/

Reload register 0

H XXXXXXXX

TMCSR0H R/W - - - 0 0 0 0 0

16-bit reload timer 0

TMR0/

TMRLR0

R/W

54H Timer control status register 1 lower TMCSR1L R/W

55

56

57

58H Watch timer control register lower WTCRL R/W

59

Timer control status register 1 high-

H

er

H

Timer register 1/

Reload register 1

H XXXXXXXX

TMCSR1H R/W - - - 0 0 0 0 0

16-bit reload timer 1

TMR1/

TMRLR1

R/W

Real-time

H Watch timer control register higher WTCRH R/W 0 0 0 0 0 0 0 0

watch timer

0 0 0 0 0 0 0 0

XXXXXXXX

0 0 0 0 0 0 0 0

XXXXXXXX

0 0 0 - - 0 0 0

(Continued)

19

MB90420G/425G Series

Address Register name Symbol Read/write Peripheral function Initial value

5A

H Sound control register lower SGCRL R/W

5BH Sound control register higher SGCRH R/W 0 - - - - - 0 0

5C

H Frequency data register SGFR R/W XXXXXXXX

Sound generator

5D

H Amplitude data register SGAR R/W 0 0 0 0 0 0 0 0

5E

H Decrement grade register SGDR R/W XXXXXXXX

5FH Tone count register SGTR R/W XXXXXXXX

0 0 0 0 0 0 0 0

60

H

XXXXXXXX

Input capture register 0 IPCP0 R

61

H XXXXXXXX

Input capture 0/1

62H

XXXXXXXX

Input capture register 1 IPCP1 R

63

H XXXXXXXX

64

H

XXXXXXXX

Input capture register 2 IPCP2 R

65

H XXXXXXXX

Input capture 2/3

66

H

XXXXXXXX

Input capture register 3 IPCP3 R

H XXXXXXXX

67

68H Input capture control status 0/1 ICS01 R/W Input capture 0/1 0 0 0 0 0 0 0 0

69

H (Disabled)

6A

H Input capture control status 2/3 ICS23 R/W Input capture 2/3 0 0 0 0 0 0 0 0

6B

H (Disabled)

6CH LCD control register lower LCRL R/W

6D

H LCD control register higher LCRH R/W 0 0 0 0 0 0 0 0

6E

Low voltage/CPU operation

H

detection reset control register

LVRC R/W

LCD controller/

driver

Low voltage/CPU opera-

tion detection reset

0 0 0 1 0 0 0 0

1 0 1 1 1 0 0 0

6FH ROM mirror ROMM W ROM mirror XXXXXXX1

70

H to 7FH Area reserved for CAN interface 1

20

80

H PWM control register 0 PWC0 R/W

Stepping motor

controller0

0 0 0 0 0 - - 0

81H (Disabled)

82

H PWM control register 1 PWC1 R/W

83

H (Disabled)

Stepping motor

controller1

0 0 0 0 0 - - 0

84H PWM control register 2 PWC2 R/W Stepping motor controller2 0 0 0 0 0 - - 0

85

H (Disabled)

86

H PWM control register 3 PWC3 R/W Stepping motor controller3 0 0 0 0 0 - - 0

87

9D

H to

H

(Disabled)

(Continued)

MB90420G/425G Series

Address Register name Symbol Read/write Peripheral function Initial value

9E

H ROM correction control register PACSR R/W

9F

H Delay interrupt/release DIRR R/W Delayed interrupt - - - - - - - 0

A0H Power saving mode LPMCR R/W

A1

H Clock select CKSCR R/W 1 1 1 1 1 1 0 0

A2

A7

H to

H

(Disabled)

Address match

detection function

Power saving

control circuit

- - - - - 0 - 0

0 0 0 1 1 0 0 0

A8H Watchdog control WDTC R/W Watchdog timer XXXXX 1 1 1

A9

H Time base timer control register TBTC R/W Time base timer 1 - - 0 0 1 0 0

AA

H Watch timer control register WTC R/W

ABH to

AD

H

AE

H Flash control register FMCS R/W Flash interface 0 0 0 X 0 XX 0

AF

H (Disabled)

(Disabled)

B0H Interrupt control register 00 ICR00 R/W

B1

H Interrupt control register 01 ICR01 R/W 0 0 0 0 0 1 1 1

B2

H Interrupt control register 02 ICR02 R/W 0 0 0 0 0 1 1 1

B3

H Interrupt control register 03 ICR03 R/W 0 0 0 0 0 1 1 1

Watch timer

(sub-clock)

1 X 0 0 0 0 0 0

0 0 0 0 0 1 1 1

B4H Interrupt control register 04 ICR04 R/W 0 0 0 0 0 1 1 1

B5

H Interrupt control register 05 ICR05 R/W 0 0 0 0 0 1 1 1

B6

H Interrupt control register 06 ICR06 R/W 0 0 0 0 0 1 1 1

B7H Interrupt control register 07 ICR07 R/W 0 0 0 0 0 1 1 1

Interrupt controller

B8

H Interrupt control register 08 ICR08 R/W 0 0 0 0 0 1 1 1

B9

H Interrupt control register 09 ICR09 R/W 0 0 0 0 0 1 1 1

BAH Interrupt control register 10 ICR10 R/W 0 0 0 0 0 1 1 1

BB

H Interrupt control register 11 ICR11 R/W 0 0 0 0 0 1 1 1

BC

H Interrupt control register 12 ICR12 R/W 0 0 0 0 0 1 1 1

BDH Interrupt control register 13 ICR13 R/W 0 0 0 0 0 1 1 1

BE

H Interrupt control register 14 ICR14 R/W 0 0 0 0 0 1 1 1

BF

H Interrupt control register 15 ICR15 R/W 0 0 0 0 0 1 1 1

C0H to

FF

H

(Disabled)

(Continued)

21

MB90420G/425G Series

Address Register name Symbol Read/write Peripheral function Initial value

1FF0

H ROM correction address 0 PADR0 R/W

1FF1H ROM correction address 1 PADR0 R/W XXXXXXXX

1FF2

H ROM correction address 2 PADR0 R/W XXXXXXXX

1FF3

H ROM correction address 3 PADR1 R/W XXXXXXXX

1FF4

H ROM correction address 4 PADR1 R/W XXXXXXXX

Address match

detection function

1FF5H ROM correction address 5 PADR1 R/W XXXXXXXX

3900

391F

H to

H

(Disabled)

XXXXXXXX

3920

H

PPG0 down counter register PDCR0 R

3921

H 1 1 1 1 1 1 1 1

3922

H

PPG0 cycle setting register PCSR0 W

H XXXXXXXX

3923

16-bit PPG 0

3924H

PPG0 duty setting register PDUT0 W

3925

H XXXXXXXX

3926

3927

H to

H

(Disabled)

3928H

PPG1 down counter register PDCR1 R

3929

H 1 1 1 1 1 1 1 1

392A

H

PPG1 cycle setting register PCSR1 W

H XXXXXXXX

392B

16-bit PPG 1

392CH

PPG1 duty setting register PDUT1 W

392D

H XXXXXXXX

392E

392F

H to

H

(Disabled)

3930H

PPG2 down counter register PDCR2 R

3931

H 1 1 1 1 1 1 1 1

1 1 1 1 1 1 1 1

XXXXXXXX

XXXXXXXX

1 1 1 1 1 1 1 1

XXXXXXXX

XXXXXXXX

1 1 1 1 1 1 1 1

22

3932

H

PPG2 cycle setting register PCSR2 W

H XXXXXXXX

3933

3934

H

16 bit PPG 2

PPG2 duty setting register PDUT2 W

3935

H XXXXXXXX

3936H to

3959

H

(Disabled)

XXXXXXXX

XXXXXXXX

(Continued)

MB90420G/425G Series

Address Register name Symbol Read/write Peripheral function Initial value

395A

H

395B

395C

395D

395E

Sub second data register WTBR R/W

H XXXXXXXX

H - - - XXXXX

H Second data register WTSR R/W - - XXXXXX

H Minute data register WTMR R/W - - XXXXXX

Real time

watch timer

XXXXXXXX

395FH Hour data register WTHR R/W - - - XXXXX

3960

396B

396C

397F

3980H

H to

LCD display RAM VRAM R/W

H

H to

H

(Disabled)

LCD controller/

driver

XXXXXXXX

XXXXXXXX

PWM1 compare register 0 PWC10 R/W

3981

H - - - - - - XX

3982

H

PWM2 compare register 0 PWC20 R/W

H - - - - - - XX

3983

3984

H PWM1 select register 0 PWS10 R/W - - 0 0 0 0 0 0

3985

H PWM2 select register 0 PWS20 R/W - 0 0 0 0 0 0 0

3986H to

3987

H

(Disabled)

Stepping motor

controller 0

XXXXXXXX

3988

H

XXXXXXXX

PWM1 compare register 1 PWC11 R/W

3989

H - - - - - - XX

398A

H

PWM2 compare register 1 PWC21 R/W

H - - - - - - XX

398B

398C

H PWM1 select register 1 PWS11 R/W - - 0 0 0 0 0 0

398D

H PWM2 select register 1 PWS21 R/W - 0 0 0 0 0 0 0

398EH to

398F

H

3990

H

(Disabled)

Stepping motor

controller 1

XXXXXXXX

XXXXXXXX

PWM1 compare register 2 PWC12 R/W

3991

H - - - - - - XX

3992H

PWM2 compare register 2 PWC22 R/W

3993

H - - - - - - XX

3994

H PWM1 select register 2 PWS12 R/W - - 0 0 0 0 0 0

Stepping motor

controller 2

XXXXXXXX

3995H PWM2 select register 2 PWS22 R/W - 0 0 0 0 0 0 0

3996

3997

H to

H

(Disabled)

(Continued)

23

MB90420G/425G Series

(Continued)

Address Register name Symbol Read/write Peripheral function Initial value

3998

H

XXXXXXXX

PWM1 compare register 3 PWC13 R/W

3999

H - - - - - - XX

399A

H

PWM2 compare register 3 PWC23 R/W

399B

H - - - - - - XX

399C

H PWM1 select register 3 PWS13 R/W - - 0 0 0 0 0 0

Stepping motor

controller 3

XXXXXXXX

399DH PWM2 select register 3 PWS23 R/W - 0 0 0 0 0 0 0

399E

H to

39FF

H

3A00

H to

3AFF

H

3B00H to

3BFF

H

3C00

H to

3CFF

H

3D00

H to

3DFF

H

3E00H to

3EFF

H

Area reserved for CAN interface 0

Area reserved for CAN interface 1

Area reserved for CAN interface 0

Area reserved for CAN interface 1

(Disabled)

(Disabled)

• Initial value symbols :

“0” initial value 0.

“1” initial value 1.

“X” initial value undetermined

“-” initial value undetermined (none)

• Write/read symbols :

“R/W” read/write enabled

“R” read only

“W” write only

• Addresses in the area 0000

H to 00FFH are reserved for the principal functions of the MCU. Read access

attempts to reserved areas will result in an “X” value. Also, wr ite access to reserved areas is prohibited.

24

• I/O Map for CAN Interface

Address

CAN0 CAN1

000040

H 000070H

Message buffer valid area BVALR (R/W) 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

000041

H 000071H

MB90420G/425G Series

Register name Symbol

Read/

write

Initial value

000042H 000072H

000043

H 000073H

000044H 000074H

000045

H 000075H

000046H 000076H

000047

H 000077H

000048H 000078H

000049

H 000079H

00004AH 00007AH

00004B

H 00007BH

00004CH 00007CH

00004D

H 00007DH

00004EH 00007EH

00004F

H 00007FH

003C00H 003D00H

003C01

H 003D01H

003C02H 003D02H

003C03

H 003D03H

003C04H 003D04H

003C05

H 003D05H

Transmission request register TREQR (R/W) 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

Transmission cancel register TCANR (W) 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

Transmission completed register TCR (R/W) 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

Receiving completed register RCR (R/W) 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

Remote request receiving register RRTRR (R/W) 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

Receiving overrun register ROVRR (R/W) 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

Receiving interrupt enable register RIER (R/W) 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

Control status register CSR (R/W, R) 0 0 - - - 0 0 0 0 - - - - 0 - 1

Last event indicator register LEIR (R/W) - - - - - - - - 0 0 0 - 0 0 0 0

RX/TX error counter RTEC (R) 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

003C06H 003D06H

003C07

H 003D07H

003C08H 003D08H

003C09

H 003D09H

003C0AH 003D0AH

003C0B

H 003D0BH

003C0CH 003D0CH

003C0D

H 003D0DH

003C0EH 003D0EH

003C0F

H 003D0FH

Bit timing register BTR (R/W) - 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1

IDE register IDER (R/W) XXXXXXXX XXXXXXXX

Transmission RTR register TRTRR (R/W) 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

Remote frame receiving wait register RFWTR (R/W) XXXXXXXX XXXXXXXX

Transmission interrupt enable register TIER (R/W) 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

(Continued)

25

MB90420G/425G Series

Address

CAN0 CAN1

003C10

003C11

H 003D10H

H 003D11H

003C12H 003D12H

003C13

H 003D13H

003C14H 003D14H

003C15

H 003D15H

003C16H 003D16H

003C17

H 003D17H

003C18H 003D18H

003C19

H 003D19H

003C1AH 003D1AH

003C1B

003A00H

003A1F

H 003D1BH

to

H

003B00H

to

003B1F

003A20H 003B20H

003A21

H 003B21H

003A22H 003B22H

003A23

H 003B23H

003A24H 003B24H

003A25

H 003B25H

003A26H 003B26H

003A27

H 003B27H

Register name Symbol

Read/

write

Initial value

XXXXXXXX XXXXXXXX

Acceptance mask select register AMSR (R/W)

XXXXXXXX XXXXXXXX

XXXXXXXX XXXXXXXX

Acceptance mask register 0 AMR0 (R/W)

XXXXX- - - XXXXXXXX

XXXXXXXX XXXXXXXX

Acceptance mask register 1 AMR1 (R/W)

XXXXX- - - XXXXXXXX

General purpose RAM (R/W) XXXXXXXX to XXXXXXXX

H

XXXXXXXX XXXXXXXX

ID register 0 IDR0 (R/W)

XXXXX- - - XXXXXXXX

XXXXXXXX XXXXXXXX

ID register 1 IDR1 (R/W)

XXXXX- - - XXXXXXXX

003A28H 003B28H

003A29

H 003B29H

003A2AH 003B2AH

003A2B

H 003B2BH

003A2CH 003B2CH

003A2D

H 003B2DH

003A2EH 003B2EH

003A2F

H 003B2FH

003A30H 003B30H

003A31

H 003B31H

003A32H 003B32H

003A33

H 003B33H

26

XXXXXXXX XXXXXXXX

ID register 2 IDR2 (R/W)

XXXXX- - - XXXXXXXX

XXXXXXXX XXXXXXXX

ID register 3 IDR3 (R/W)

XXXXX- - - XXXXXXXX

XXXXXXXX XXXXXXXX

ID register 4 IDR4 (R/W)

XXXXX- - - XXXXXXXX

(Continued)

MB90420G/425G Series

Address

CAN0 CAN1

003A34

003A35

H 003B34H

H 003B35H

003A36H 003B36H

003A37

H 003B37H

003A38H 003B38H

003A39

H 003B39H

003A3AH 003B3AH

003A3B

H 003B3BH

003A3CH 003B3CH

003A3D

H 003B3DH

003A3EH 003B3EH

003A3F

H 003B3FH

003A40H 003B40H

003A41

H 003B41H

003A42H 003B42H

003A43

H 003B43H

Register name Symbol

Read/

write

ID register 5 IDR5 (R/W)

ID register 6 IDR6 (R/W)

ID register 7 IDR7 (R/W)

ID register 8 IDR8 (R/W)

Initial value

XXXXXXXX XXXXXXXX

XXXXX- - - XXXXXXXX

XXXXXXXX XXXXXXXX

XXXXX- - - XXXXXXXX

XXXXXXXX XXXXXXXX

XXXXX- - - XXXXXXXX

XXXXXXXX XXXXXXXX

XXXXX- - - XXXXXXXX

003A44H 003B44H

003A45

H 003B45H

003A46H 003B46H

003A47

H 003B47H

003A48H 003B48H

003A49

H 003B49H

003A4AH 003B4AH

003A4B

H 003B4BH

003A4CH 003B4CH

003A4D

H 003B4DH

003A4EH 003B4EH

003A4F

H 003B4FH

003A50H 003B50H

003A51

H 003B51H

003A52H 003B52H

003A53

H 003B53H

XXXXXXXX XXXXXXXX

ID register 9 IDR9 (R/W)

XXXXX- - - XXXXXXXX

XXXXXXXX XXXXXXXX

ID register 10 IDR10 (R/W)

XXXXX- - - XXXXXXXX

XXXXXXXX XXXXXXXX

ID register 11 IDR11 (R/W)

XXXXX- - - XXXXXXXX

XXXXXXXX XXXXXXXX

ID register 12 IDR12 (R/W)

XXXXX- - - XXXXXXXX

(Continued)

27

MB90420G/425G Series

Address

CAN0 CAN1

003A54

003A55

H 003B54H

H 003B55H

003A56H 003B56H

003A57

H 003B57H

003A58H 003B58H

003A59

H 003B59H

003A5AH 003B5AH

003A5B

H 003B5BH

003A5CH 003B5CH

003A5D

H 003B5DH

003A5EH 003B5EH

003A5F

H 003B5FH

003A60H 003B60H

003A61

H 003B61H

003A62H 003B62H

003A63

H 003B63H

Register name Symbol

Read/

write

Initial value

XXXXXXXX XXXXXXXX

ID register 13 IDR13 (R/W)

XXXXX- - - XXXXXXXX

XXXXXXXX XXXXXXXX

ID register 14 IDR14 (R/W)

XXXXX- - - XXXXXXXX

XXXXXXXX XXXXXXXX

ID register 15 IDR15 (R/W)

XXXXX- - - XXXXXXXX

DLC register 0 DLCR0 (R/W) - - - -XXXX - - - -XXXX

DLC register 1 DLCR1 (R/W) - - - -XXXX - - - -XXXX

003A64H 003B64H

003A65

H 003B65H

003A66H 003B66H

003A67

H 003B67H

003A68H 003B68H

003A69

H 003B69H

003A6AH 003B6AH

003A6B

H 003B6BH

003A6CH 003B6CH

003A6D

H 003B6DH

003A6EH 003B6EH

003A6F

H 003B6FH

003A70H 003B70H

003A71

H 003B71H

003A72H 003B72H

003A73

H 003B73H

003A74H 003B74H

003A75

H 003B75H

DLC register 2 DLCR2 (R/W) - - - -XXXX - - - -XXXX

DLC register 3 DLCR3 (R/W) - - - -XXXX - - - -XXXX

DLC register 4 DLCR4 (R/W) - - - -XXXX - - - -XXXX

DLC register 5 DLCR5 (R/W) - - - -XXXX - - - -XXXX

DLC register 6 DLCR6 (R/W) - - - -XXXX - - - -XXXX

DLC register 7 DLCR7 (R/W) - - - -XXXX - - - -XXXX

DLC register 8 DLCR8 (R/W) - - - -XXXX - - - -XXXX

DLC register 9 DLCR9 (R/W) - - - -XXXX - - - -XXXX

DLC register 10 DLCR10 (R/W) - - - -XXXX - - - -XXXX

(Continued)

28

MB90420G/425G Series

Address

CAN0 CAN1

003A76

003A77

H 003B76H

H 003B77H

003A78H 003B78H

003A79

H 003B79H

003A7AH 003B7AH

003A7B

H 003B7BH

003A7CH 003B7CH

003A7D

H 003B7DH

003A7EH 003B7EH

003A7F

003A80H

003A87

003A88

003A8F

003A90

003A87

H 003B7FH

to

H

H

to

H

H

to

H

003B80H

to

003B87

003B88H

to

003B8F

003B90H

to

003B97

Register name Symbol

Read/

write

Initial value

DLC register 11 DLCR11 (R/W) - - - -XXXX - - - -XXXX

DLC register 12 DLCR12 (R/W) - - - -XXXX - - - -XXXX

DLC register 13 DLCR13 (R/W) - - - -XXXX - - - -XXXX

DLC register 14 DLCR14 (R/W) - - - -XXXX - - - -XXXX

DLC register 15 DLCR15 (R/W) - - - -XXXX - - - -XXXX

Data register 0 (8 bytes) DTR0 (R/W) XXXXXXXX to XXXXXXXX

H

Data register 1 (8 bytes) DTR1 (R/W) XXXXXXXX to XXXXXXXX

H

Data register 2 (8 bytes) DTR2 (R/W) XXXXXXXX to XXXXXXXX

H

003A98

H

to

003A9F

003AA0H

to

003AA7

003AA8

to

003AAF

003AB0

to

003AB7

003AB8H

to

003ABF

003AC0

to

003AC7

003AC8

to

003ACF

003B98H

003B9F

H

003BA0H

003BA7

H

H

003BA8H

003BAF

H

H

003BB0H

003BB7

H

003BB8H

003BBF

H

H

003BC0H

003BC7

H

H

003BC8H

003BCF

H

to

to

to

to

to

to

to

Data register 3 (8 bytes) DTR3 (R/W) XXXXXXXX to XXXXXXXX

H

Data register 4 (8 bytes) DTR4 (R/W) XXXXXXXX to XXXXXXXX

H

Data register 5 (8 bytes) DTR5 (R/W) XXXXXXXX to XXXXXXXX

H

Data register 6 (8 bytes) DTR6 (R/W) XXXXXXXX to XXXXXXXX

H

Data register 7 (8 bytes) DTR7 (R/W) XXXXXXXX to XXXXXXXX

H

Data register 8 (8 bytes) DTR8 (R/W) XXXXXXXX to XXXXXXXX

H

Data register 9 (8 bytes) DTR9 (R/W) XXXXXXXX to XXXXXXXX

H

(Continued)

29

MB90420G/425G Series

(Continued)

Address

CAN0 CAN1

003AD0

H

003BD0H

to

003AD7

003AD8H

003BD7

H

003BD8H

to

003ADF

003BDF

H

to

to

Data register 10 (8 bytes) DTR10 (R/W) XXXXXXXX to XXXXXXXX

H

Data register 11 (8 bytes) DTR11 (R/W) XXXXXXXX to XXXXXXXX

H

Register name Symbol

Read/

write

Initial value

003AE0

to

003AE7

003AE8

to

003AEF

003AF0H

to

003AF7

003AF8

to

003AFF

H

003BE0H

003BE7

H

H

003BE8H

003BEF

H

003BF0H

003BF7

H

H

003BF8H

003BFF

H

to

to

to

to

Data register 12 (8 bytes) DTR12 (R/W) XXXXXXXX to XXXXXXXX

H

Data register 13 (8 bytes) DTR13 (R/W) XXXXXXXX to XXXXXXXX

H

Data register 14 (8 bytes) DTR14 (R/W) XXXXXXXX to XXXXXXXX

H

Data register 15 (8 bytes) DTR15 (R/W) XXXXXXXX to XXXXXXXX

H

30

MB90420G/425G Series

■

INTERRUPT SOURCES, INTERRUPT VECTORS, AND INTERRUPT CONTROL REGISTERS

2

OS

Interrupt source

EI

compatible

Reset × #08 08

INT9 instruction × #09 09

Exception processing × #10 0A

Interrupt vector

Number Address ICR Address

H FFFFDCH High

H FFFFD8H

H FFFFD4H

CAN0 RX × #11 0BH FFFFD0H

CAN0 TX/NS × #12 0CH FFFFCCH

CAN1 RX × #13 0DH FFFFC8H

CAN1 TX/NS × #14 0EH FFFFC4H

Input capture 0 #15 0FH FFFFC0H

DTP/external interrupt - ch 0 detected #16 10H FFFFBCH

Reload timer 0 #17 11H FFFFB8H

DTP/external interrupt - ch 1 detected #18 12H FFFFB4H

Input capture 1 #19 13H FFFFB0H

DTP/external interrupt - ch 2 detected #20 14H FFFFACH

Input capture 2 #21 15H FFFFA8H

DTP/external interrupt - ch 3 detected #22 16H FFFFA4H

Input capture 3 #23 17H FFFFA0H

DTP/external interrupt - ch 4/5 detected #24 18H FFFF9CH

Interrupt control register

ICR00 0000B0H *

ICR01 0000B1H *

ICR02 0000B2H *

ICR03 0000B3H *

ICR04 0000B4H *

ICR05 0000B5H *

ICR06 0000B6H *

1

1

1

1

1

1

1

Priority

2

*

PPG timer 0 #25 19H FFFF98H

ICR07 0000B7H *

1

DTP/external interrupt - ch 6/7 detected #26 1AH FFFF94H

PPG timer 1 #27 1BH FFFF90H

ICR08 0000B8H *

1

Reload timer 1 #28 1CH FFFF8CH

PPG timer 2 #29 1DH FFFF88H

ICR09 0000B9H *

1

Real time watch timer × #30 1EH FFFF84H

Free-run timer over flow × #31 1FH FFFF80H

ICR10 0000BAH *

1

A/D converter conversion end #32 20H FFFF7CH

Free-run timer clear × #33 21H FFFF78H

ICR11 0000BBH *

1

Sound generator × #34 22H FFFF74H

Time base timer × #35 23H FFFF70H

ICR12 0000BCH *

1

Watch timer (sub-clock) × #36 24H FFFF6CH

UART 1 RX #37 25H FFFF68H

ICR13 0000BDH *

1

UART 1 TX #38 26H FFFF64H

UART 0 RX #39 27H FFFF60H

ICR14 0000BEH *

1

UART 0 TX #40 28H FFFF5CH

Flash memory status × #41 29H FFFF58H

ICR15 0000BFH *

1

Delayed interrupt generator module × #42 2AH FFFF54H Low

31

MB90420G/425G Series

2

: Compatible, with EI

: Compatible

: Compatible when interrupt sources sharing ICR are not in use

× : Not compatible

*1 : • Peripheral functions sharing the ICR register have the same interrupt level.

• If peripheral functions sharing the ICR register are using expanded intelligent I/O services, one or the other

cannot be used.

• When peripheral functions are sharing the ICR register and one specifies expanded intelligent I/O services,

the interrupt from the other function cannot be used.

*2 : Priority applies when interrupts of the same level are generated.

OS stop function

32

MB90420G/425G Series

PERIPHERAL FUNCTIONS

■

1. I/O Ports

The I/O ports function is to send data from the CPU to be output from I/O pins and load input signals at the I/O

pins into the CPU, according to the port data register (PDR) . Port input/output at I/O pins can be controlled in

bit units by the port direction register (DDR) as required. The following list shows each of the functions as well

as the shared peripheral function for each port.

• Port 0 : General purpose I/O port, shared with peripheral functions (external interrupt/UART/PPG)

• Port 1 : General purpose I/O port, shared with peripheral functions (PPG/reload timer/clock timer/ICU)

• Port 3 : General purpose I/O port, shared with peripheral functions (LCD)

• Port 4 : General purpose I/O port, shared with peripheral functions (LCD)

• Port 5 : General purpose I/O port, shared with peripheral functions (External interrupt/CAN/SG)

• Port 6 : General purpose I/O port, shared with peripheral functions (A/D converter)

• Port 7 : General purpose I/O port, shared with peripheral functions (Stepping motor controller)

• Port 8 : General purpose I/O port, shared with peripheral functions (Stepping motor controller)

• Port 9 : General purpose I/O port, shared with peripheral functions (LCD)

(1) List of Functions

Port Pin name

Port 0

Port 1

Port 3

Port 4

Port 5

Port 6

Port 7

Port 8

Port 9

P00/SIN0/INT4 to

P07/PPG1

P10/PPG2 to

P15/IN0

P36/SEG12 to

P37/SEG13

P40/SEG14 to

P47/SEG21

P50/INT0 to

P57/SGA

P60/AN0 to

P67/AN7

P70/PWM1P0 to

P77/PWM2M1

P80/PWM1P2 to

P87/PWM2M3

P90/SEG22 to

P91/SEG23

Input

format

CMOS

(hysteresis)

(Automotive level*)

Analog

CMOS

(hysteresis)

(Automotive level*)

CMOS

(hysteresis)

(Automotive level*)

Output for-

mat

CMOS

Function

General purpose I/O port

Peripheral function

General purpose I/O port

Peripheral function

General purpose I/O port

Peripheral function

General purpose I/O port

Peripheral function

General purpose I/O port

Peripheral function

General purpose I/O port

Peripheral function

General purpose I/O port

Peripheral function

General purpose I/O port

Peripheral function

General purpose I/O port

Peripheral function

(Continued)

33

MB90420G/425G Series

(Continued)

Port bit7 bit6 bit5 bit4 bit3 bit2 bit1 bit0

P07 P06 P05 P04 P03 P02 P01 P00

Port 0

PPG1 PPG0 SCK1 SOT1 SIN1 SCK0 SOT0 SIN0

TIN1 TOT1 INT7 INT6 INT5 INT4

P15 P14 P13 P12 P11 P10

Port 1

Port 3

Port 4

Port 5

Port 6

Port 7

Port 8

Port 9

IN0 IN1 IN2 IN3 WOT PPG2

TIN0 TOT0

P37 P36

SEG13 SEG12

P47 P46 P45 P44 P43 P42 P41 P40

SEG21 SEG20 SEG19 SEG18 SEG17 SEG16 SEG15 SEG14

P57 P56 P55 P54 P53 P52 P51 P50

SGA SGO RX0 TX0 INT3 INT2 INT1 INT0

FRCK TX1 RX1

P67 P66 P65 P64 P63 P62 P61 P60

AN7 AN6 AN5 AN4 AN3 AN2 AN1 AN0

P77 P76 P75 P74 P73 P72 P71 P70

PWM2M1 PWM2P1 PWM1M1 PWM1P1 PWM2M0 PWM2P0 PWM1M0 PWM1P0

P87 P86 P85 P84 P83 P82 P81 P80

PWM2M3 PWM2P3 PWM1M3 PWM1P3 PWM2M2 PWM2P2 PWM1M2 PWM1P2

P91 P90

SEG23 SEG22

*: Range of input voltage.

For ratings see “3. DC Characteristics” in “■ ELECTRICAL CHARACTERISTICS”

Note : Port 6 also functions as an analog input pin. When using this port as a general purpose port, always write

“0” to the corresponding analog input enable register (ADER) bit. The ADER bit is initialized to “1” at reset.

34

.

(2) Block Diagrams

Ports 0, 1, 3, 4, 5, 7, 8, 9

PDR (Port data register)

MB90420G/425G Series

Peripheral function output

Peripheral function input

Peripheral function output enabled

PDR read

Output latch

Internal data bus

Port 6

PDR write

DDR (Port direction register)

DDR write

DDR read

ADER

PDR (Port data register)

RDR read

Pin

Direction

latch

Standby control (SPL = 1)

or LCD output enabled

Analog input

Output latch

Internal data bus

PDR write

DDR (Port direction register)

DDR write

DDR read

Pin

Direction

latch

Standby control (SPL = 1)

35

MB90420G/425G Series

2. Watchdog Timer/Time Base Timer/Watch Timer

The watchdog timer, timer base timer, and watch timer have the following circuit configuration.

• Watchdog timer : Watchdog counter, control register, watchdog reset circuit

• Time base timer : 18-bit timer, interval interrupt control circuit

• Watch timer : 15-bit timer, interval interrupt control circuit

(1) Watchdog timer function

The watchdog timer is composed of a 2-bit watchdog counter that uses the carry signal from the 18-bit time

base timer or 15-bit watch timer as a clock source, plus a control register and watchdog reset control circuit.

After startup, this function will reset the CPU if not cleared within a given time.

(2) Time base timer function

The time base timer is an 18-bit free-run counter (time base counter) synchronized with the internal count clock

(base oscillator divided by 2) , with an interval timer function providing a selection of four interval times. Other

functions include a timer output for an oscillator stabilization wait time and clock feed to the watchdog timer or

other operating clocks. Note that the time base timer uses the main clock regardless of the setting of the MCS

bit or SCS bit in the CKSCR register.

(3) Watch timer function

The watch timer provides functions including a clock source for the watchdog timer, a sub clock base oscillator

stabilization wait timer, and an interval timer to generate an interrupt at fixed intervals. Note that the w atch timer

uses the sub clock regardless of the setting of the MCS bit or SCS bit in the CKSCR register.

36

•Block Diagram

TBTC

TBC1

TBC0

TBR

TBIE

TBOF

Time base

interrupt

WDTC

WT1

WT0

WTE

AND

Selector

S

QR

Selector

11

2

13

2

16

2

18

2

TBTRES

2-bit

counter

CLR

MB90420G/425G Series

Main base oscillator

divided by 2

Clock input

Time base timer

11213216218

2

OF

Watchdog reset

generator circuit

CLR

T o WDGRST

internal reset

generator circuit

WDCS

MC-16LX bus

2

F

WTOF

Clock interrupt

WDTC

PONR

WRST

WTC

SCE

WTC2

to

WTC0

WTR

WTIE

ERST

SRST

AND

Q

S

R

AND

Selector

Q

SGW

Power-on reset,

sub-clock stop

8

2

9

2

10

2

11

2

12

2

13

S

R

2

14

2

16

2

WTRES

2102132142

Watch timer

16

Clock input

Sub base oscillator divided by 4

From power-on generator

RST pin

From RST bit in STBYC

register

37

MB90420G/425G Series

3. Input Capture

This circuit is composed of a 16-bit free-run timer and four 16-bit input capture circuits.

(1) Input capture (

××××

4)

The input capture circuits consist of four independent exter nal input pins and corresponding capture registers

and control registers. When the specified edge of the external signal input (at the input pin) is detected, the value

of the 16-bit free-run timer is saved in the capture register, and at the same time an interrupt can also be

generated.

• The valid edge (rising edge, falling edge, both edges) of the external signal can be selected.

• The four input capture circuits can operate independently.

• The interrupt can be generated from the valid edge of the external input signal.

(2) 16-bit free-run timer (

××××

1)

The 16-bit free-run timer is composed of a 16-bit up-counter, control register, 16-bit compare register, and

prescaler. The output values from this counter are used as the base time for the input capture circuits.

• The counter clock operation can be selected from 8 options. The eight internal clock settings are φ, φ/2, φ/4,

φ/8, φ/16, φ/32, φ/64, φ/128 where φ represents the machine clock cycle.

• Interrupts can be generated from overflow events, or from compare match events with the compare register.

(Compare match operation requires a mode setting.)

• The counter value can be initialized to “0000

H” by a reset, soft clear, or a compare match with the compare

register.

(3) Block diagram

interrupt

#31 (1F

H)

φ

IVF IVFE STOP MODE SCLR CLK2 CLK1 CLK0

16-bit free-run timer

16-bit compare clear register Compare circuit

MC-16LX bus

2

F

Capture data register 0/2

EG11 EG10 EG01 EG00

Capture data register 1/3

ICP0 ICP1 ICE0 ICE1

Divider

MSI3 to 0

Clock

ICLR

Edge detection

Edge detection

Interrupt

#33 (21H)

ICRE

A/D startup

IN0/2

IN1/3

Interrupt

#19, #23

Interrupt

#15, #21

38

MB90420G/425G Series

4. 16-bit Reload Timer

The 16-bit reload timer can either count down in synchronization with three types of internal clock signals in

internal clock mode, or count down at the detection of the designated edge of an external signal. The user may

select either function. This timer defines a transition from 0000

underflow occurs when counting from the value [Reload register setting + 1].

A selection of two counter operating modes are av ailable. In reload mode, the counter is reset to the count v alue

and continues counting after an underflow, and in one-shot mode the count stops after an underflow . The counter

can generate an interrupt when an underflow occurs, and is compatible with the e xpanded intelligent I/O services

2

(EI

OS) .

(1) 16-bit Reload timer operating modes

Clock mode Counter mode 16-bit reload timer operation

Reload mode Soft trigger operation

Internal clock mode

One-shot mode

H to FFFFH as an underflow event. Thus an

External trigger operation

External gate input operation

Event count mode

(external clock mode)

Reload mode

Soft trigger operation

One-shot mode

(2) Internal clock mode

One of three input clocks is selected as the count clock, and can be used in one of the following operations.

• Soft trigger operation

When “1” is written to the TRG bit in the timer control status register (TMCSR0/1) , the count operation

starts.Trigger input at the TRG bit is nor mally valid with an external trigger input, as well as an external gate

input.

• External trigger operation

Count operation starts when a selected edge (rising, falling, both edges) is input at the TIN0/1 pin.

• External gate input operation

Counting continues as long as the selected signal level (“L” or “H”) is input at the TIN0/1 pin.

(3) Event count mode (External clock mode)

In this mode a down count event occurs when a selected valid edge (rising, falling, both edges) is input at the

TIN0/1 pin. This function can also be used as an interval timer when an external clock with a fixed period is used.

(4) Counter operation

• Reload mode

In down count operation, when an underflow event (transition from “0000

H” to “FFFFH”) occurs, the set count

value is reloaded and count operation continues. The function can be used as an inter val timer by generating

an interrupt request at each underflow event. Also, a toggle waveform that inverts at each underflow can be

output from the TOT0/1 pin.

Counter clock Counter clock period Interval time

1

2

/φ (0.125 µs) 0.125 µs to 8.192 ms

Internal clock

External clock 2

3

/φ (0.5 µs) 0.5 µs to 32.768 ms

2

5

2

/φ (2.0 µs) 2.0 µs to 131.1 ms

3

/φ or greater (0.5 µs) 0.5 µs or greater

φ : Machine clock cycle. Figures in ( ) are values at machine clock frequency 16 MHz.

39

MB90420G/425G Series

(5) One-shot mode

In down count operation, the count stops when an underflow event (transition from “0000

H” to “FFFFH”) occurs.

This function can generate an interrupt at each underflow. While the counter is operating, a rectangular wave

form indicating that the count is in progress can be output form the TOT0 and TOT1 pins.

(6) Block diagram

Internal data bus

1

16-bit reload register

CLK

Gate input

3

Reload signal

UF

Valid clock

decision circuit

CLK

Reload

control circuit

Wait signal

To UART 0,1*

<To A/D converter>

Machine

clock

TMRLR0 *

<TMRLR1>

1

TMR0 *

<TMR1>

16-bit timer register (down counter)

Prescaler

1

Pins

P12/TIN0 *

<P07/TIN1>

CSL1 CSL0 OUTEOUTL RELD INTE UF CNTE TRG

1: Channel 0 and channel 1. Figures in

*

2: Interrupt number

*

Input

control

circuit

1

3 2

Function selection

Timer control status register (TNGSR0)*

External clock

WOD2WOD1 WOD0

<TNGSR1>

are for channel 1.

< >

Clock

selector

Select

signal

Output signal

Inverted

1

generator

circuit

EN

Operation

control

circuit

Pins

P11/TOT0 *

<P06/TOT1>

Interrupt

request signal

#17 (11h)*

<#28 (1CH)>

2

1

40

MB90420G/425G Series

5. Real Time Watch Timer

The real time watch timer is composed of a real time watch timer control register, sub second data register,

second/minute/hour data registers, 1/2 clock divider, 21-bit prescaler and second/minute/hour counters. Because

the MCU oscillation frequency operates on a given real time watch timer operation, a 4 MHz frequency is

assumed. The real time watch timer operates as a real world timer and provides real world time information.

•Block diagram

OE

Main oscillator clock

1/2 clock

divider

prescaler

EN

Sub second

register

21-bit

CO

OE

WOT

STUPDT

INTE0 INT0

Second

CI

counter

EN

LOAD CO CO

6-bit 6-bit 5-bit

Second/minute/hour register

INTE1

INT1 INTE2 INT2 INT3 INT3

Minute

counter

Hour

counter

CO

IRQ#30

41

MB90420G/425G Series

6. PPG Timer

The PPG timer consists of a prescaler, one 16-bit down-counter, 16-bit data register with buff er for period setting,

and 16-bit compare register with buffer for duty setting, plus pin control circuits.

The timer can output pulses synchronized with an externally input soft trigger. The period and duty of the output

pulse can be adjusted by rewriting the values in the two 16-bit registers.

(1) PWM function

Programmable to output a pulse, synchronized with a trigger.

Can also be used as a D/A converter with an external circuit.

(2) One-shot function

Detects the edge of a trigger input, and outputs a single pulse.

(3) Pin control

• Set to “1” at a duty match (priority) .

• Reset to “0” at a counter borrow event

• Has a fixed output mode to output a simple all “L” ( or “H”) signal.

• Polarity can be specified

(4) 16-bit down counter

• Select from four types of counter operation cloc ks. F our internal clocks (φ, φ/4, φ/16, φ/64) φ : Machine clock

cycles.

• The counter value can be initialized to “FFFF

(5) Interrupt requests

• Timer startup

• Counter borrow event (period match)

• Duty match event

• Counter borrow event (period match) or duty match event

(6) Multiple channels can be set to start up at an external trigger, or to restart during operation.

H” at a reset or counter borrow event.

42

(7) Block diagram

Prescaler

1/1

1/4

1/16

1/64

PCSR PDUT

CK

PSCT

16-bit down counter

MB90420G/425G Series

Load

CMP

Machine clock

Trigger input

P05/SCK1/TRG

Enable

Edge detection

Soft trigger

Start

Borrow

PPG mask

SQ

R

Inversion bit

Interrupt

selection

PPG

output

Interrupt IRQ#25, 27, 29

43

MB90420G/425G Series

7. Delayed Interrupt Generator Module

The delayed interrupt generator module is a module that generates interrupts for task switching. This module

makes it possible to use software to generate/cancel interrupt requests to the F

•Block diagram

F2MC-16LX bus

Delayed interrupt source generate/delete decoder

Source latch

2

MC-16LX CPU.

44

8. DTP/External Interrupt Circuit

MB90420G/425G Series

The DTP (Data transfer peripheral) /e xternal interrupt circuit is located between an externally connected peripheral device and the F

2

MC-16LX CPU and sends interrupt requests or data transfer requests generated from the

peripheral device to the CPU, thereby generating e xternal interrupt requests or starting the expanded intelligent

I/O services (EI

2

OS) .

(1) DTP/external interrupt function

The DTP/external interrupt function uses a signal input from the DTP/external interrupt pin as a startup source.

And it is accepted by the CPU by the same procedure as a normal hardware interrupt, and can generate an

external interrupt or start the expanded intelligent I/O service (EI

2

OS) .

When the interrupt is accepted by the CPU, if the corresponding expanded intelligent I/O service (EI

prohibited the interrupt operates as an external interrupt function and branches to an interrupt routine. If the

2

EI

OS is permitted the interrupt functions as a DTP function, using EI2OS for automatic data transfer, then

branching to an interrupt routine after the completion of the specified number of data transfers.

External interrupt DTP function

Input pins 8 pins (P50/INT0/ADTG to P53/INT3, P00/SIN0/INT4 to P03/INT7)

Request level setting register (ELVR) sets the detection level, or selected edge for

each pin

Interrupt sources