Page 1

USER'S GUIDE

imageRAID® Series

STORAGE SYSTEMS

Page 2

Page 3

USER'S GUIDE

imageRAID® Series

STORAGE SYSTEMS

Page 4

Fujitsu Europe Limited

Restricted Rights and Liability

No part of this manual may be reproduced, stored in a retrieval system, or transmitted, in any form or by any

means, electronic, mechanical, recording, or otherwise, in whole or part, without prior written permission from

Fujitsu Europe Limited.

Fujitsu Europe Limited shall not be liable for any damages or for the loss of any information resulting from the

performance or use of the information contained herein. Your rights to the software are governed by the license

agreement included with any accompanying software. Fujitsu Europe Limited reserves the right to periodically

revise this manual without notice. Product features and specifications described are subject to change without

notice.

Copyright

Fujitsu Europe Limited

Hayes Park Central

Hayes End Road

Hayes, Middlesex, England UB4 8FE

Copyright © 2003 Fujitsu Europe Limited. All rights reserved.

imageRAID and the imageRAID logo are registered trademarks of Fujitsu Europe Limited, Fujitsu is a registered

trademark of Fujitsu Limited.

Other company and product names herein may be trademarks or registered trademarks of their respective

companies.

Agency Notes

WARNING: Drives and controller/adapter cards described in this manual should only be installed in UL-listed and CSA

certified computers that give specific instructions on the installation and removal of accessory cards (refer to your

computer installation manual for proper instructions).

ATTENTION: Les lecteurs et cartes contrôleurs décrits ici ne doivent être montés que sur des ordinateurs homologués (UL et

CSA) et livrés avec des manuels contenant les instructions d’installation et de retrait des accessoires. Reportezvous au manuel d’installation de votre ordinateur.

SERVICE NOTE: Remove the power cables prior to servicing this equipment.

!

Page 5

Contents

About this Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . v

Welcome . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . v

Typographical Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . vi

Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vii

1 Getting Started . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

At a Glance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Front Bezel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

AC Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Cooling Fan Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

SES Controller Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Disk I/O Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Host I/O Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

RAID Controllers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Control and Monitoring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Status Indicator LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Drive LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Audible Alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

2 Topologies and Operating Modes . . . . . . . . . . . . . . . . . . . . . . . . . 21

Operating Mode Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Simplex Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Duplex Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Daisy-Chain JBOD Enclosures . . . . . . . . . . . . . . . . . . . . . . . . . . 34

LUN Mapping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Alternate Path Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Fibre Channel Media Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

A Word about Clustering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Minimizing Downtime for Maximum Data Availability . . . . . . . . . 37

How Available are Clusters? . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Application of Availability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

i

Page 6

Table of Contents

3 Setup and Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Storage System Detailed Installation . . . . . . . . . . . . . . . . . . . . . . 42

Installing the Storage System Enclosure into the Rack Cabinet . . 42

Installing the Storage System into the Tower Stand . . . . . . . . . . 45

Completing the Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Special Note for Microsoft Windows 2000 Installations . . . . . . . . 51

Operating Mode Configuration and Cabling . . . . . . . . . . . . . . . . 52

Upgrades . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

Powering On the Storage System . . . . . . . . . . . . . . . . . . . . . . . . 107

Powering Off the Storage System . . . . . . . . . . . . . . . . . . . . . . . . 107

4 Managing and Monitoring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Enclosure Component Monitoring . . . . . . . . . . . . . . . . . . . . . . . 109

Status Indicator LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

Drive LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

Audible Alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

One-Touch Annunciation Configuration Display . . . . . . . . . . . . 115

VT-100 Interface Enclosure Monitoring . . . . . . . . . . . . . . . . . . . 116

SES Commands Debug . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

Uploading SES Controller Card Firmware . . . . . . . . . . . . . . . . . . 119

Enclosure Fan Speed Control . . . . . . . . . . . . . . . . . . . . . . . . . . 122

Updating the Controller Firmware . . . . . . . . . . . . . . . . . . . . . . . 124

5 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

General Enclosure Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

Common Fibre Loop/Bus Problems . . . . . . . . . . . . . . . . . . . . . . 128

Common Problems and Interpreting the LEDs . . . . . . . . . . . . . . 130

Terminal and COM Port Problems . . . . . . . . . . . . . . . . . . . . . . . 131

Problems During Bootup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

6 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

Removing the Front Bezel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

Replacing the Cooling Fans . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

Replacing a Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

Replacing a Disk Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

Replacing the Disk I/O Card . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

Replacing the Host I/O Card . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

Replacing the SES Controller Card . . . . . . . . . . . . . . . . . . . . . . . 147

Replacing a RAID Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

ii

Page 7

Table of Contents

Replacing the Enclosure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

A Technical Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

B Port Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

Optical SFP Transceiver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

SES Controller Card RS-232 Service Port . . . . . . . . . . . . . . . . . . . 158

Null-Modem Cable Specifications . . . . . . . . . . . . . . . . . . . . . . . . 159

C Regulatory Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

Compliance Information Statement . . . . . . . . . . . . . . . . . . . . . . . 161

FCC Class A Radio Frequency Interference Statement . . . . . . . . . 162

Class A Taiwanese Statement . . . . . . . . . . . . . . . . . . . . . . . . . . . 163

Class A Japanese Statement . . . . . . . . . . . . . . . . . . . . . . . . . . . . 163

CE Notice . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 163

Power Cord Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 164

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 165

iii

Page 8

Table of Contents

iv

Page 9

Preface

About this Manual

Welcome

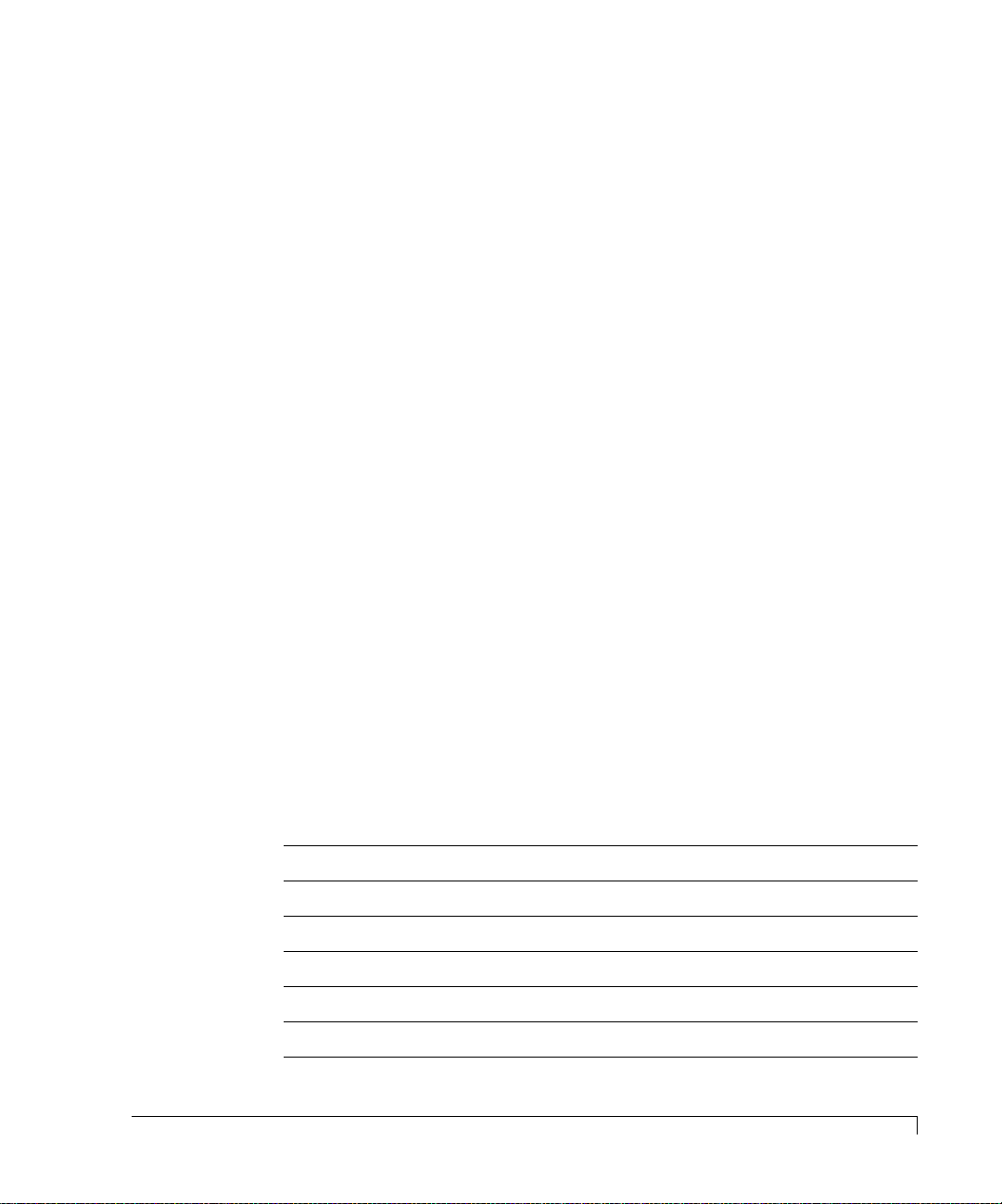

Congratulations on the purchase of your new imageRAID® Storage System from

Fujitsu Europe Limited. This imageRAID series is a very high-performance, fully

fault-tolerant 2 Gb Fibre Channel-to-Fibre Channel RAID storage system. It’s

unique 2U design is optimized to fit in the compact space of today’s data centers

rack environments and as a deskside tower system.

At its core is a Fibre Channel IRF-JBOD storage enclosure which supports up to

twelve hot pluggable 1-inch high Fibre Channel disk drives all in a 2U (3.47-inch)

form factor enclosure. Full component redundancy is provided through hot

pluggable Disk I/O cards, Host I/O cards, cooling fan module, and independent

power supplies. RAID functionality is provided through one or two embedded

imageRAID

for Stand-Alone topologies or dual Controllers for Active-Active topologies.

Controller(s). Available as a single Controller configuration designed

Product Identification

Storage Enclosure Number of Controllers Model of Controller

IRF-JBOD

IRF-1Sxx-xx

IRF-2Sxx-xx

IRF-1Dxx-xx

IRF-2Dxx-xx

0 JBOD

1 imageRAID

2 imageRAID

1 imageRAIDXP

2 imageRAIDXP

v

Page 10

About this Manual

The imageRAID IRF-1Sxx-xx/2Sxx-xx is a 12-Bay 3.5" (2U) rackmount storage

solution with one or two 2 Gbit imageRAID FC-to-FC RAID Controllers. Each

controller has 512 MB of cache memory and a battery-backup unit. The storage

enclosure includes dual Host I/O cards, dual Disk I/O cards, eight optical

transceivers, dual power supplies, dual AC power cords, SES card, and a

removable cooling fan module. It also includes configuration software, DB-9 null

modem cable, and a rackmount rail kit. It is upgradeable to either a imageRAID

IRF-1Dxx-xx or 2Dxx-xx model.

The imageRAID IRF-1Dxx-xx/2Dxx-xx is a 12-Bay 3.5" (2U) rackmount storage

solution with one or two 2 Gbit imageRAIDXP FC-to-FC RAID Controllers. Each

controller has 512 MB of cache memory for each processor providing a total of

1 GB of cache memory and a battery-backup unit. The storage enclosure includes

dual Host I/O cards, dual Disk I/O cards, eight optical transceivers, dual power

supplies, dual AC power cords, SES card, and a removable cooling fan module. It

also includes configuration software, DB-9 null modem cable, and a rackmount

rail kit.

This user’s guide is your complete documentation to set up the storage system

hardware, add components, cable the storage system components, replace parts,

and diagnose/repair your system.

vi

Typographical Conventions

For information on software configuration and management, refer to the software

guide included with your system. Your system includes two VT-100 interfaces

(text-based and menu-based), and one GUI interface, StorView.

Typographical Conventions

The following typographical conventions are used in the user’s guide:

■

Menu items are displayed in the format: “Array Configuration menu,

choose

■

Code font

■

Italic code font

■

Italic

■

Key strokes are enclosed in brackets, e.g., <Esc>, <K>, or <Enter>.

View Unused Drives.”

will indicate literal text used in examples.

indicates a replaceable or variable item in code.

text indicates the item that is selected or chosen.

Page 11

About this Manual

Features

The

imageRAID

requiring the highest performance with uncompromised data reliability, such as

mid-range and enterprise server storage, while maintaining exceptionally high

throughput. The storage system is ideally suited for high bandwidth data intensive

applications, such as electronic commerce, digital video, CAD, seismic research,

digital pre-press, 3-D imaging, and SAN environments.

The following are major features of the imageRAID Series Storage Systems:

■

2 Gb Fibre Channel-to-Fibre Channel storage system enclosure.

■

Hot pluggable disk drives, 12 per enclosure.

■

Hot pluggable cooling fan module and power supplies.

■

SES Enclosure management includes onboard environmental monitoring.

■

Designed to fit standard 19-inch rack enclosures and a deskside tower.

■

Front panel LEDs provide notifications of system component status, and

logical and physical drive status.

■

Support for 16 drives per array and 64 arrays.

Series Storage Systems are designed for mission critical applications

■

RAID Controller uses an Intel XScale 600MHz RISC processor.

■

Transparent failover/failback RAID Controllers in duplex operations.

■

On-board controller-to-host LUN mapping.

■

Mirrored Cache for write-through and write-back operations with a “Save

to Disk” feature for unlimited backup protection.

Operating system independence – no special software or drivers required.

■

Dual 2 Gb/sec (gigabit per second) Fibre Channel ports. Fabric ports are

■

optimized with full duplex operations and auto-negotiate features.

■

Dual 2 Gb/sec disk side ports for high performance, failure resilient paths

to the drives. Full duplex operations optimize disk channels.

■

Capable of sustaining 350 MB/sec sequential RAID 5 reads and up to

100,000 IOPs in active-active configurations.

The base controller installed in the imageRAID has 512 MB cache memory

■

and a total of 1 GB cache memory for the coprocessor models. The

memory is standard PC-100 compatible SDRAM.

■

Support for up to 512 Host LUNs.

Features

vii

Page 12

About this Manual

Support for RAID levels 0, 1, 5, 10, and 50.

■

Online capacity expansion allowing reconfiguration without interruptions.

■

Dynamic Drive Addressing where the drives do not require hard

■

addressing, allowing for increased flexibility in configurations.

■

Built-in support for drive firmware updates, allowing one or several disk

drives to be updated in parallel.

■

VT-100 interface for configuration and monitoring.

■

StorView module support for a GUI-based interface providing a robust and

easy-to-use configuration and monitoring tool.

Controller firmware updates can be accomplished through a VT-100

■

terminal or StorView Storage Management Software.

■

Host clustering support for maximum data availability.

■

Intel XScale 600MHz RISC co-processor.

■

Dual XOR engines for increased throughput processing (imageRAIDXP).

■

Additional 512 MB cache memory for the coprocessor (imageRAIDXP).

viii

Features

Page 13

Chapter 1

Getting Started

This chapter provides a description of the enclosure components and its onboard

monitoring systems.

The Components section identifies and gives a complete description of each

major component. The Monitoring section describes the enclosure’s LEDs, and

the manner in which the normal and abnormal conditions are presented.

M

R

A

L

A

T

E

S

E

R

Tower Model

Rack-Mount Model

imageRAID® Series Storage System

R

E

S

E

T

A

L

A

R

M

1

Page 14

Chapter 1 - Getting Started

At a Glance

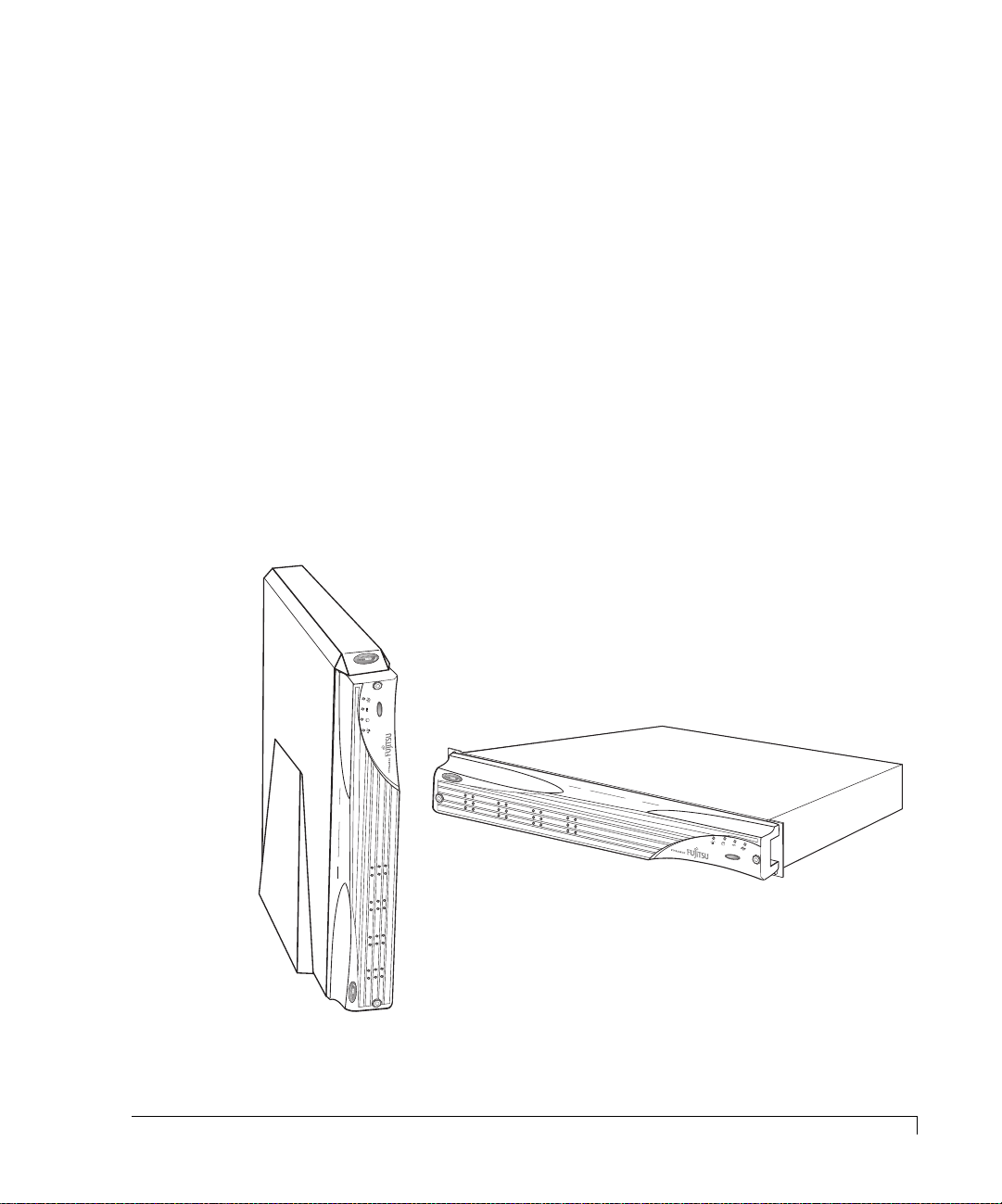

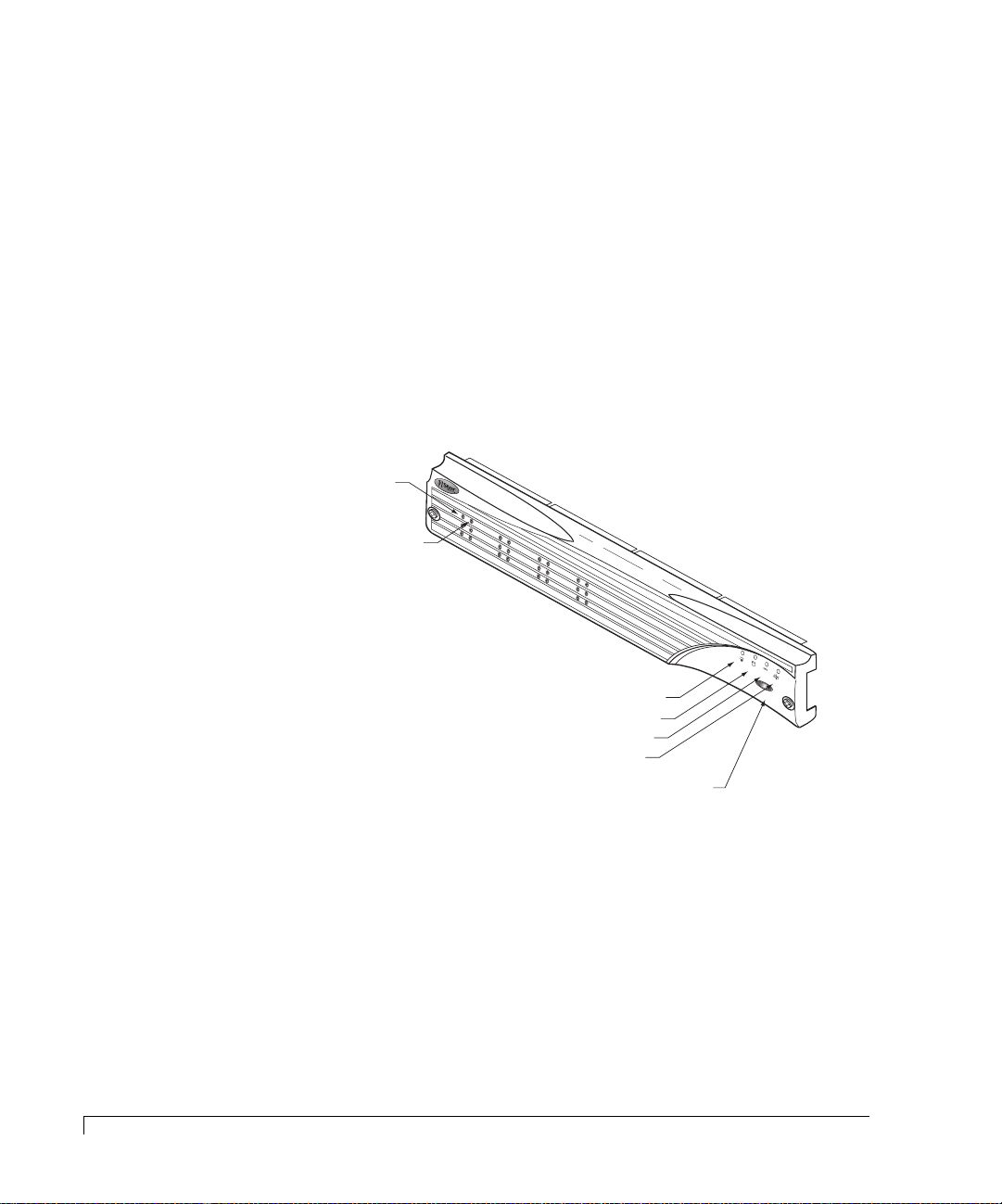

The following illustrations show the featured components of the imageRAID

Series Storage System. Familiarize yourself with its components prior to installing

and using the storage system.

Drive Status LEDs

(left column of LEDs)

Drive Activity LEDs

(right column of LEDs)

Power On LED

Channel Status LED

Power Supply Status LED

Fan Status LED

Alarm Reset Button

R

E

SE

T A

LAR

M

2

At a Glance

350-watt hot-pluggable

independent power supplies

Dual in-line 80-CFM hot

swappable cooling fans

Disk I/O Cards

SES Controller Card

Host I/O Cards

imageRAID Controllers

DISK I/O

D

1

T

x

T

x

T

x

D

I

D

S

D

K

1

T

I

x

/

O

T

x

R

S

-

2

T

3

x

2

D

S

E

S

A

A

A

D

D

D

0

1

Component Views

A

/W

P

R

/N

ev-1

08-9-96318001

Fibre D

FA

I

LU

FO

R

R

IN

E

H

D

S

A

TA

E

R

TE

DW

LL JU

CT

A

R

M

E

P

ER

S

1 &

2

JP

1

F

A

I

L

F

U

O

R

R

E

IN

H

D

S

A

E

T

R

T

A

E

D

L

C

W

L

T

J

A

U

R

M

E

JP

P

E

2

R

S

1

&

2

J

P

1

A

R

T

P

W

A

RT

O

S

R

E

N

K

S

R

U

C

M

E

O

B

V

N

E

IS

T

R

IO

R

0

O

N

8

L

-1

-9

L

E

-9

R

6

J

P

3

2

2

2

0

0

1

2

H

1

OK

2

2G

H

O

S

S

S

T

B

I/O

P

D

1K

P

R

2

D

1

L

2

M

R

Y

T

10/100

1K

10/100

SP

isk IO

LIT BU

A

D

D

LR

JU

S

C

M

M

PE

O

JP

D

R F

E

O

R

1G

O

A

D

PER

D

JU

ATIO

M

P

N

ER FO

R

A

/W

R

P

/N

e

v

J

0

-

F

P

1

8

ib

1

-

re

9

-9

D

6

is

3

S

1

k

P

IO

8

L

0

IT

0

A

L

1

D

B

R

D

C

U

JP

J

S

U

M

2

M

O

P

D

E

E

R

J

P

F

3

O

R

1

G

O

A

P

D

E

D

R

J

A

U

T

M

IO

P

N

E

R

F

O

R

J

P

2

OK

H

0

H

1

1K

O

K

O

H

K

2

H

0

G

O

O

VR

S

10/100

T

CUR

I/O

1K

PR

D

TNR

R

H

T

1

H

A

RS-232 DTE

0

A

O

VR

10/100

CUR

P

W

H

R

1

H

L

0

D

L

1

L

PR

D

TNR

R

H

T

1

H

A

RS-232 DTE

0

A

P

W

H

R

1

H

L

0

D

L

1

L

A/W REV-1

3

D

1

D

A

0

A

D

0

L

D

1

D

A

0

A

D

0

L

P/N 08-9-96319001

FIBRE HOST IO

PIN 8 - VCC

PIN 7 - VCC

PIN 6 - VCC

PIN 5 - C0CH0CH1_ENB

PIN 4 - C0C1_ENB

J

PIN 3 - HUB F

P

2

PIN 2 W

PIN 1 - 1G/2G

AHOO

SWITCH CONNECTIOONS

AILO

VER

A

/W

P

R

/N

E

F

0

V

IB

8

-1

-9

R

E

-9

H

6

3

O

1

S

9

T

0

0

IO

1

P

I

N

8

P

I

-

N

V

7

C

P

I

C

-

N

V

6

C

P

I

C

-

N

V

5

C

P

I

C

-

N

C

4

P

0

C

I

-

N

H

C

3

P

0

0

C

C

I

-

N

H

1

H

_

2

P

1

U

E

_

I

B

N

W

N

E

F

N

B

A

1

S

A

B

H

W

-

I

L

O

1

I

O

T

G

O

V

C

/

2

E

H

G

R

C

O

N

N

E

C

T

I

O

O

N

S

Page 15

Chapter 1 - Getting Started

Components

This section provides a description of each of the major components that

comprise the imageRAID Series Storage System.

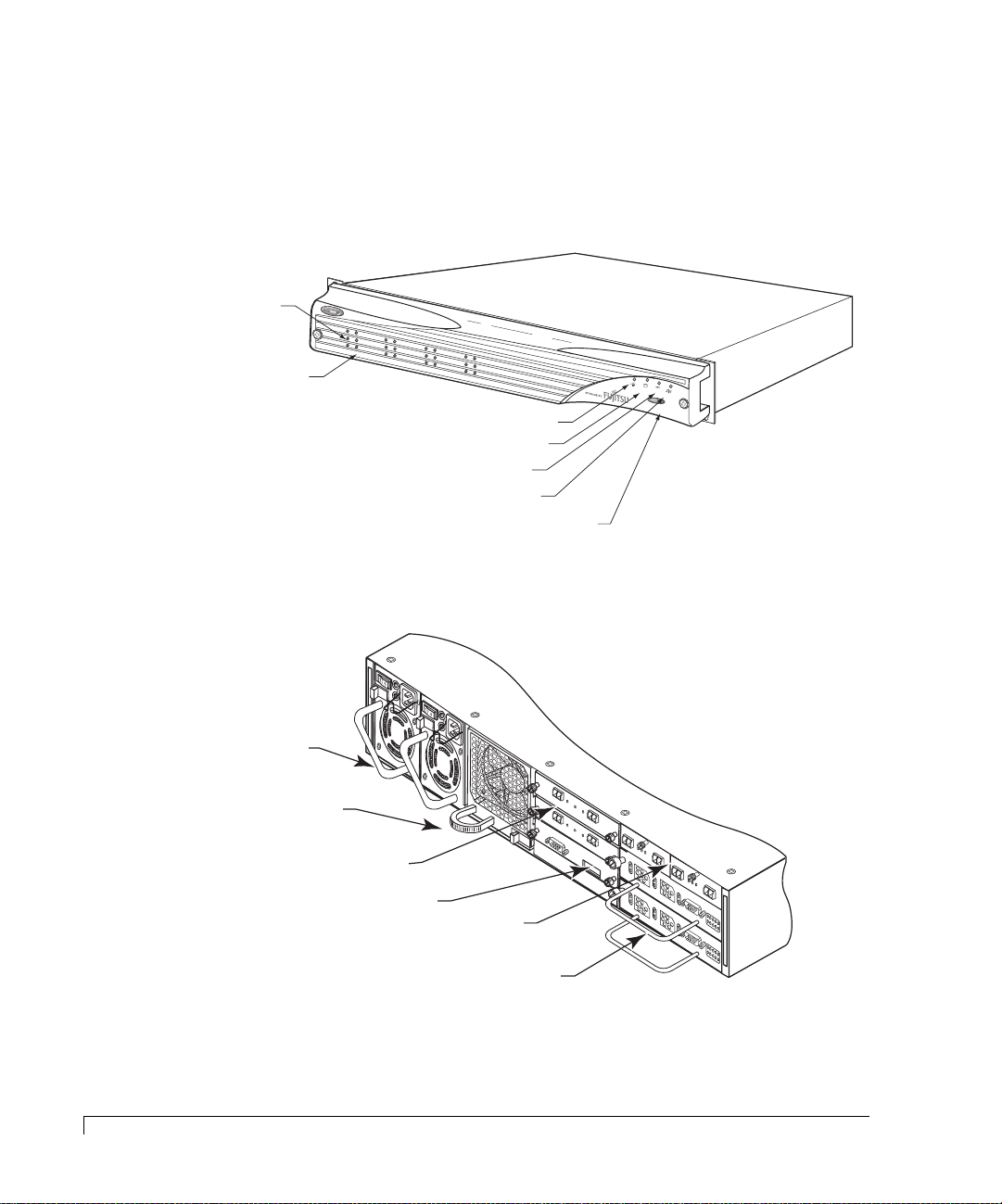

Front Bezel

The front bezel houses the Status LEDs, Drive LEDs, and alarm reset button. When

removed, the user has access to the disk drives. The front bezel can be installed or

removed without interruption to system activities.

Embedded within the front bezel is the electronic package that provides the

communication with the SES controller. The SES controller manages the signals to

the front panel through a smart interface. Power is applied to the front bezel

through the interface edge connector, where a control circuit monitors the bezel

for proper connection. When the bezel is properly installed and power is applied

to the enclosure, the bezel is immediately energized.

Refer to “Control and Monitoring” on page 18 for details on the monitoring

functions.

Drive LEDs

R

e

s

e

t A

la

r

Status LEDs

Alarm Reset Button

m

Removable Front Bezel

To remove the bezel and gain access to the disk drives, use a Phillips screwdriver

to release both bezel fasteners, then grasp and remove the bezel. The fasteners

rotate one-quarter turn clockwise to lock and counter-clockwise to unlock.

Components

3

Page 16

Chapter 1 - Getting Started

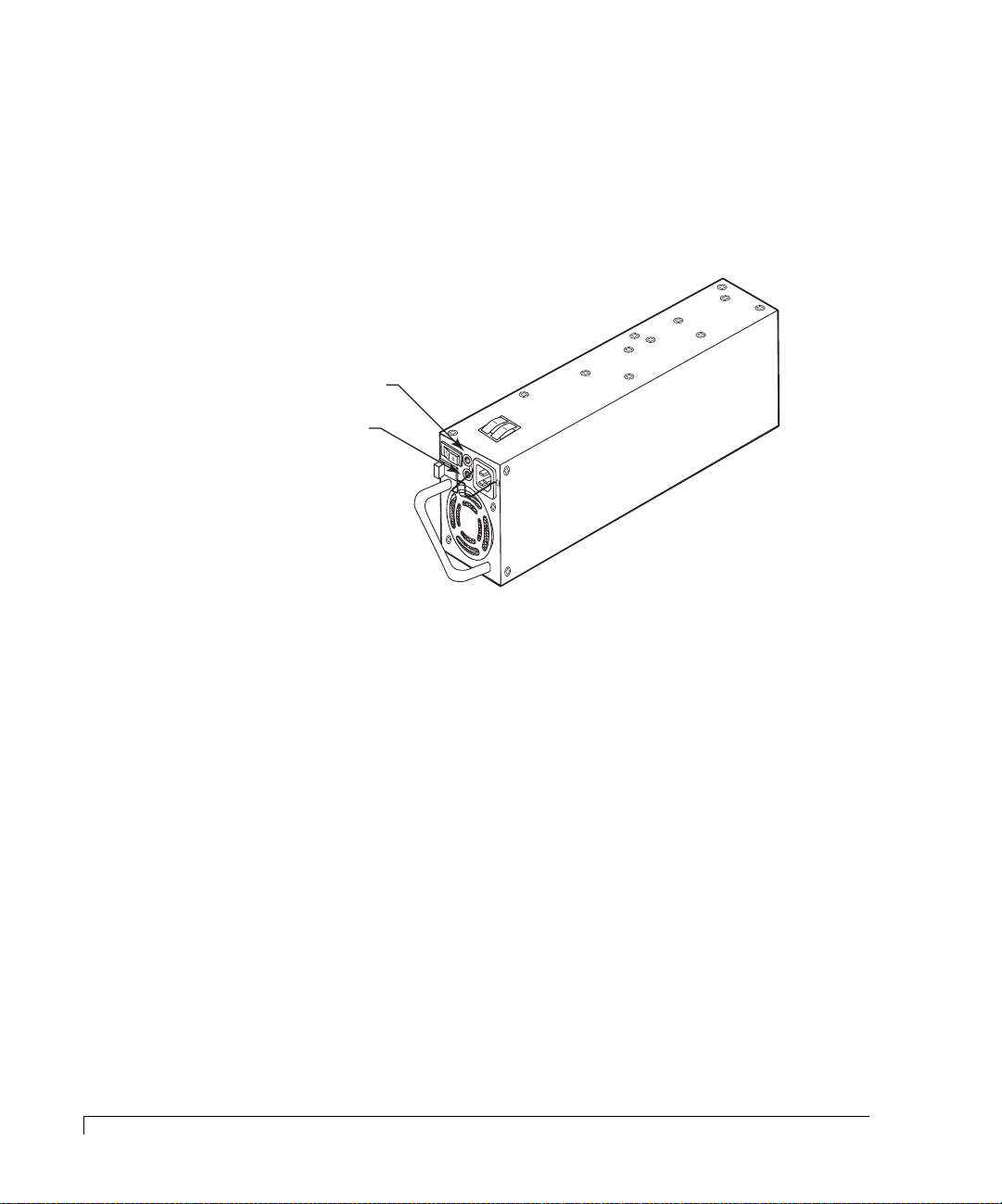

AC Power

The power system consists of two 350-watt hot-pluggable power supplies, each

with independent AC power cords and cooling fans. This power system provides

the enclosure with “N+1” redundant power. Each power supply has auto-switching

circuitry for use with either 100V or 240V AC systems.

Power On LED

(green)

Fault LED

(amber)

Power Supply

Power is applied to the enclosure by pressing each of the two power supply

On/Off switches to their “On” position. A Power On LED located on each power

supply will be illuminated indicating that AC power has been applied. The front

bezels’ Power On LED will also be illuminated indicating that power has been

applied.

Each power supply also incorporates an amber general Fault LED. If the power

supply is installed and power is not applied to the power supply or the power

supply cooling fan fails, the Fault LED will illuminate, along with an audible alarm.

The front bezels’ Power Supply Status LED will illuminate green when both

power supplies are on and operating normally. If only one power supply is

operational, the Power Supply Status LED will be illuminated amber.

Each power supply has an AC Power Cord Module. The module has a power

cord bale incorporated into the design to secure the power cord once it has been

properly inserted. The bale prevents inadvertent disconnects.

4

AC Power

Page 17

Chapter 1 - Getting Started

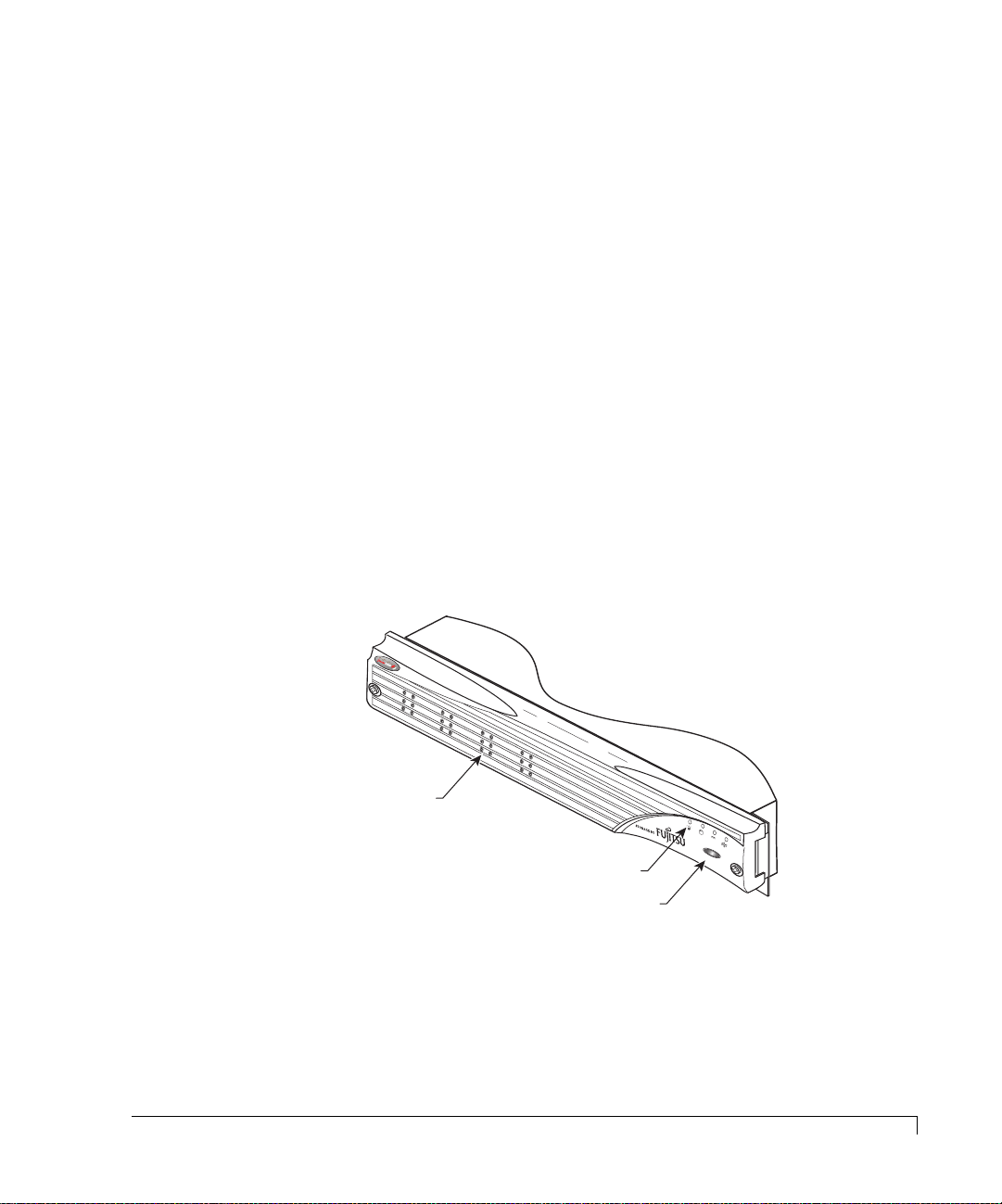

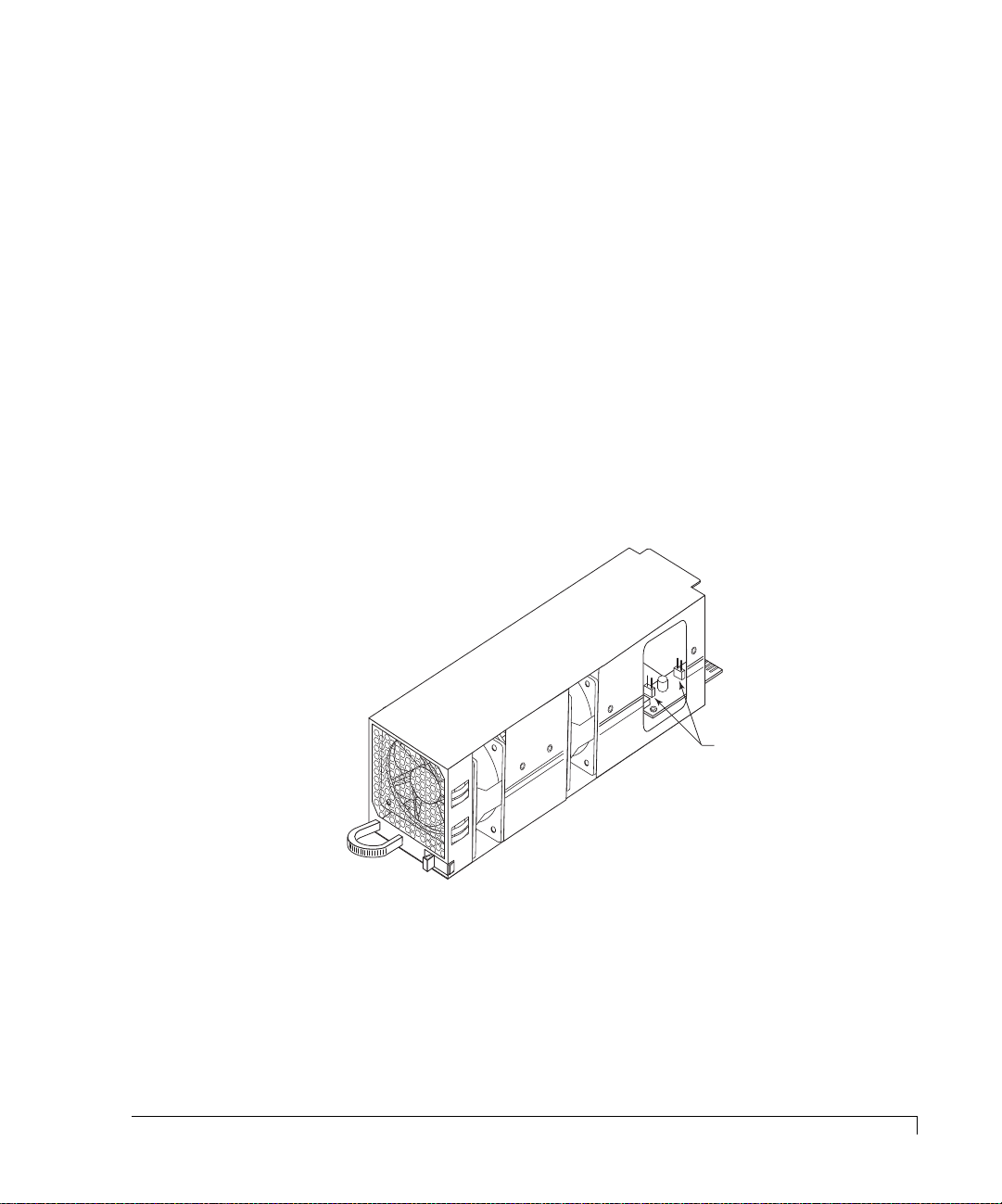

Cooling Fan Module

The cooling system consists of two high-performance (80-CFM) cooling fans

mounted in a single fan module which slides into a bay at the rear of the

enclosure. The design of the fan module provides for an easy-to-install user-

replaceable component in a live environment without interruption of service.

If any one fan should fail, cooling redundancy and efficiency are degraded. The

cooling fans and enclosure temperature are constantly monitored by the SES

processor for fault conditions. In the event of a fault condition the front panel Fan

Status LED will change from a green state to a solid amber state in the case of a fan

failure, or to a blinking amber green state in the case of an over-temperature

condition. In both cases an audible alarm sounds. The SES processor will also

provide notification data to monitoring software, such as StorView.

WARNING:

Do not operate the enclosure for extended periods of time (greater

than 5 minutes) with the cooling fan module removed.

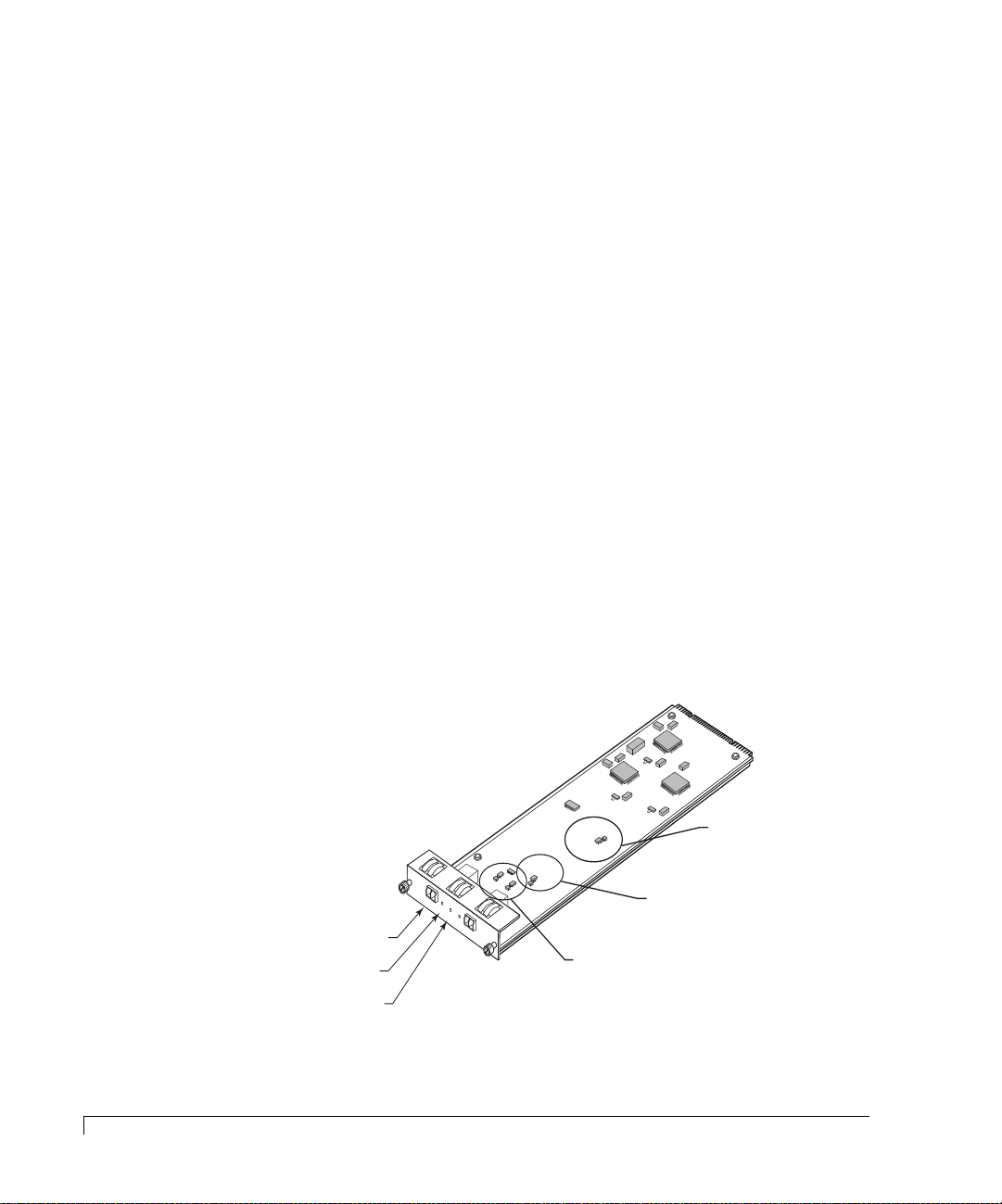

Fan Speed Override Control

Jumpers JP1 (Fan 0)

and JP2 (Fan 1)

Cooling Fan Module

The enclosure has temperature sensors in three different areas, the drive bay, the

imageRAID Controllers, and the power supplies. There are several steps the storage

system performs to prevent component damage due to over temperature

conditions.

Cooling Fan Module

5

Page 18

Chapter 1 - Getting Started

If the drive bay area reaches a temperature of 50°C (122°F) an audible alarm will

sound, the front panel Fan Status LED will toggle amber green, and the monitoring

software will post a warning message. These notifications give the user a warning

that some condition is causing the enclosure temperature to exceed the preset

value, and an action is required by the user to determine the cause and take

corrective measures. It may be due to a blockage of air flow or a low fan speed.

If any controller reaches a temperature of 65°C (149°F) an audible alarm will

sound, the front panel Fan Status LED will alternate amber and green, and the

monitoring software will post a warning message. If the temperature on any

controller continues to rise and reaches 71°C (159°F), the controller will flush its

cache and shutdown. If it is the only controller (Simplex mode) or the only

remaining controller (surviving controller from a failed over operation) then the

controller will also spin down the disk drives at this temperature.

If any power supply reaches 85°C (185°F) the power supply will shut down.

The SES Controller card has a firmware-based VT-100 interface which provides an

option to manage fan speed. This option provides a whisper mode fan operation

for noise sensitive environments. When enabled (default), and based on a set of

conditions, the software will manage the cooling fans RPM speed to maintain the

enclosure temperature while minimizing noise levels. Refer to “Enclosure Fan

Speed Control” on page 122 for more details on using this option.

6

Cooling Fan Module

A manual override of the fan speed control is available for special circumstance

environments. Referring to the illustration on the preceding page, two jumpers are

provided on the fan module printed circuit board to override the software control

of the fan speeds. This hardware setting routes full power voltage to the fans for

maximum operational speed, which is greater than the maximum speed set by the

automatic software control. This configuration is normally used when fan speed

noises are not an issue, and the ambient operating temperature is at or above 30°C

(86°F), thus ensuring that maximum available cooling is being provided.

The jumpers JP1 and JP2 by default are offset, which enables the automatic fan

speed control. The jumper JP1 controls Fan 0 and JP2 controls Fan 1. Placing the

jumper on both pins for each jumper will override the automatic setting and

configure the fans to maximum power.

Page 19

SES Controller Card

Chapter 1 - Getting Started

WARNING:

The SES Controller card is NOT HOT SWAPPABLE. You must POWER

DOWN the enclosure prior to removing or inserting this card.

The

SES Controller

card provides the built-in environmental and system status

monitoring. It also houses the switches for setting the drive spin up options. This

card is installed at the rear of the enclosure in the lowest slot below the two Disk

I/O cards.

The SES processors continuously monitor the enclosure for temperature status,

fan status, power supply status, and FC loop status. The processors are

responsible for reporting environmental and system status to the front bezel

LEDs/audible alarms, SES Monitoring software (VT-100), and external monitoring

software such as StorView.

J

P

2

A

R

T

P

W

A

R

O

S

T

R

E

N

S

K

C

U

R

M

O

E

B

V

N

E

I

T

S

R

R

I

O

08

O

N

L

-

-

L

9

E

1

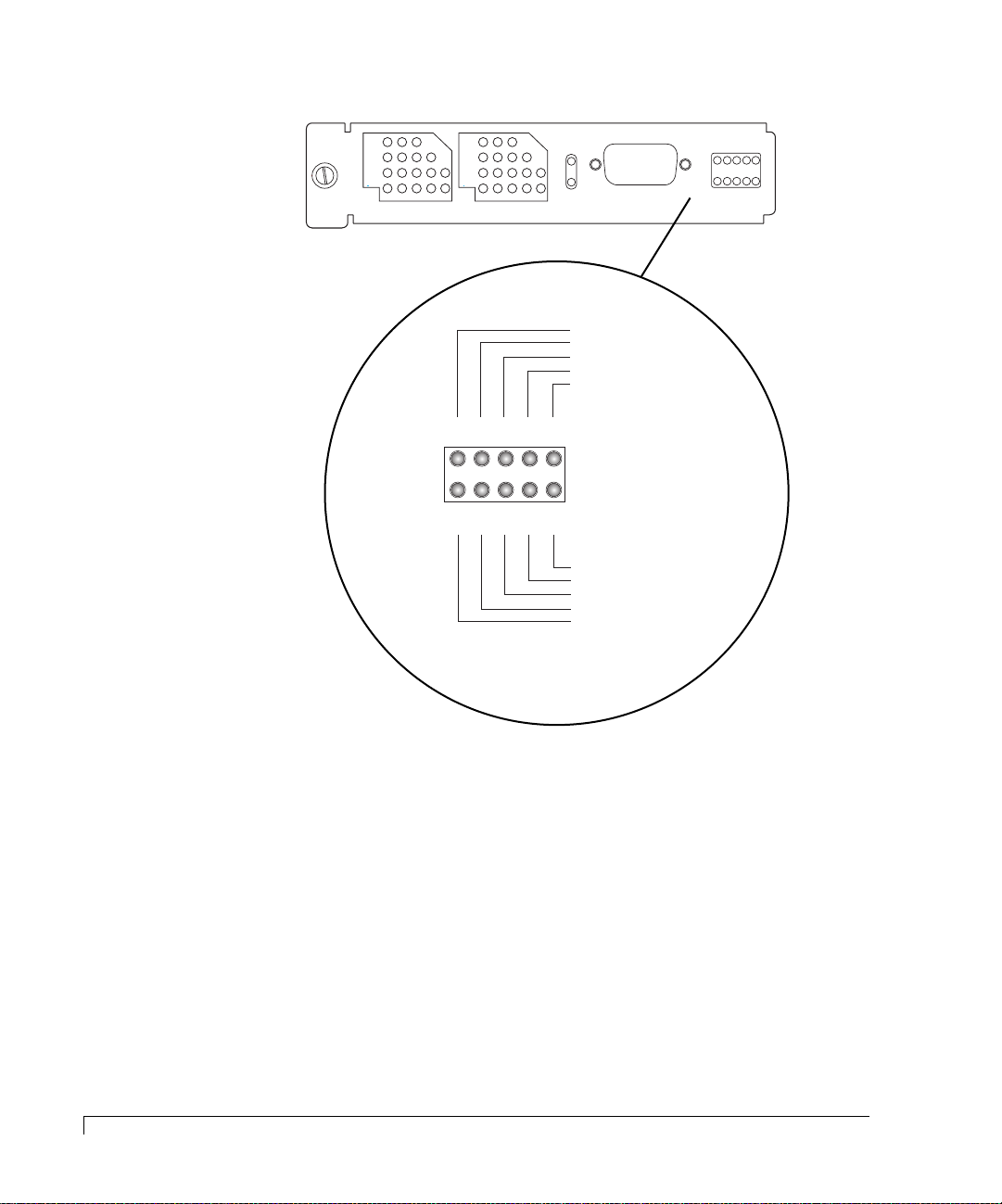

-9

R

6

3

2

2

001

RS-232 Service Port

RS-232

SES

A

A

A

D

S

D

S

B

D

0

P

D

1

P

R

D

2

1

L

2

M

R

Y

T

SES Switches

SES Controller Card

At power up, the SES processors will read the switch settings and execute a

self-test. The cards’ firmware also contains software functions for enclosure

monitoring and management. This firmware is flash upgradeable using the SES

RS-232 Service port located on the card face plate. Refer to “Uploading SES

Controller Card Firmware” on page 119 for more details.

The SES protocol uses the drives installed in slots 1 and 7 to maintain its

communication link. You must install drives in both of these slots to ensure fault

tolerance for the SES communications link.

SES Controller Card

7

Page 20

Chapter 1 - Getting Started

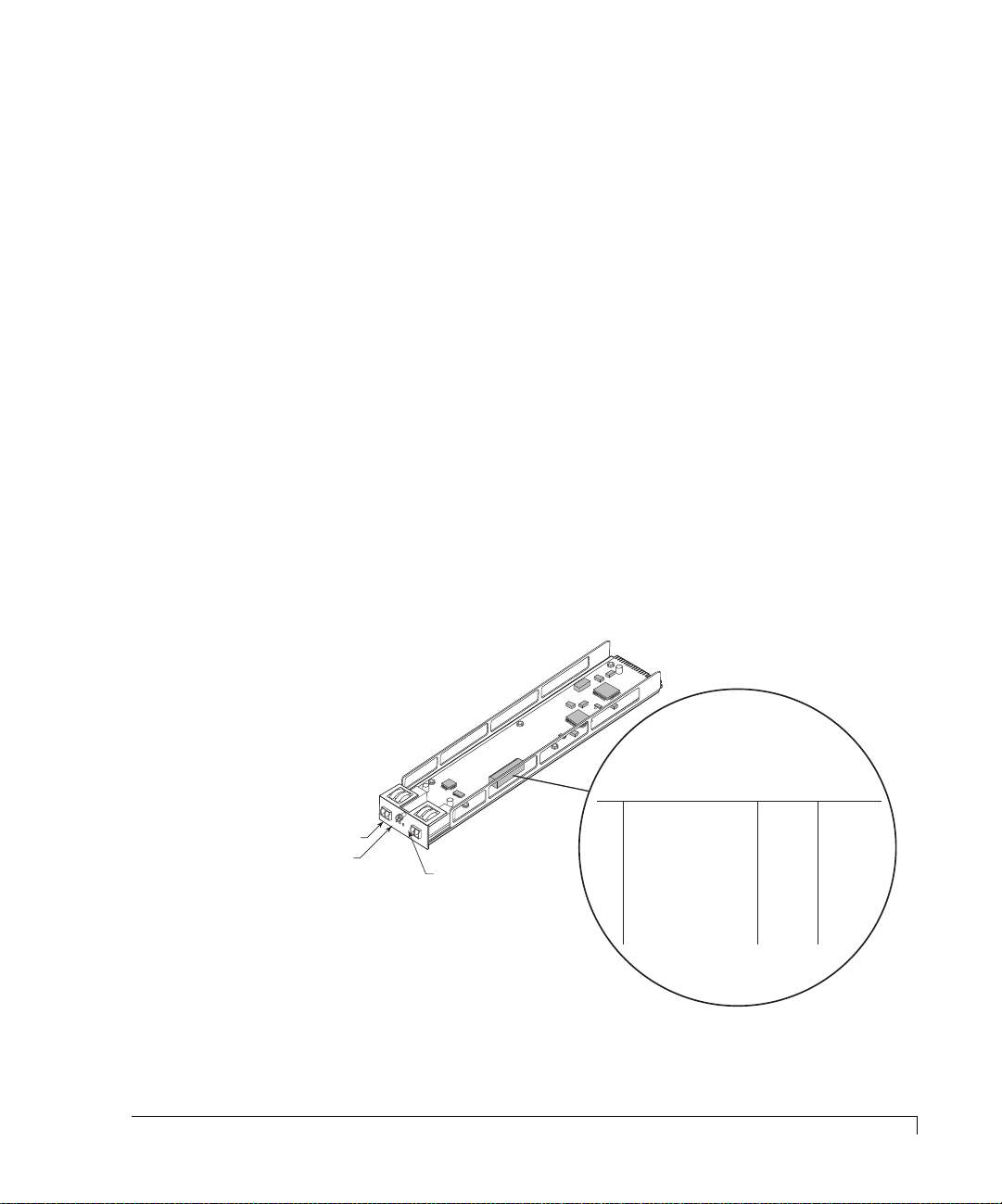

Below is an illustration depicting the drive slot identification. Drive slot numbers

are not the drive device IDs. Drive slots appearing in gray are the SES

communication slots.

Drive Device ID Settings

Located on the SES Controller card face plate are a set of switches. These

switches will configure the enclosure base Fibre address which configures the

disk drives in each drive slot with a device ID, as well as drive delay spin-up and

remote spin-up options. The default settings is all switches are set to their DOWN

position.

Viewed from the front of the enclosure

Slot 1 Slot 4 Slot 7 Slot 10

Slot 2 Slot 5 Slot 8 Slot 11

Slot 3 Slot 6 Slot 9 Slot 12

Drive Slot Location

S

A

A

A

S

B

D

RS-232

SES

D

0

12

D

1

P

D

P

D

L

1

2

2

R

Y

345678

R

M

T

Up position

Down position

8

Drive Device ID Settings

SES Controller Card Switches

The left three switches (AD0, AD1 and AD2) will configure drive slots with a

series of pre-determined device IDs. Refer to the table below:

A

A

D

Switch

Ranges

IDs 0-11

IDs 16-27

IDs 32-43

IDs 48-59

IDs 64-75

IDs 80-91

IDs 96-107

IDs 112-123

0

Down

Down Down

Down

Up Down

Down

Up Up

Down

Down

UpUp Up

Disk Device ID Switch Settings

A

D

D

1

2

DownUp

Down

UpDown

UpUp Down

UpUp

Page 21

Chapter 1 - Getting Started

For example, if the setting for switches 1 through 3 are “Down.” the device ID

addresses for the drive slots 1 - 12 would be 0 - 11 respectively.

NOTE:

If a hard address ID conflict occurs during Fibre Channel loop

initialization, the Fibre Channel protocol will dynamically set the drive

IDs. This could cause problems with some software products.

Switches 4, 5, and 6 are not used.

Spin-Up Settings

Switches 7 and 8 control the drive spin-up functions. The switches are directly

attached to all of the drive slot start signals. Switch 7 controls the “Start_1” signal

(Delay Spin-up) and switch 8 controls the “Start_2” signal (Remote Spin-up).

The table below describes the function of each switch.

“DL” Switch 7 “RM” Switch 8 Drive Spin-up Mode

Down (0)* Down (0)* Drive motor spins up at DC power on.

Down (0) Up (1) Drive motor spins up only on SCSI “start”

commands.

Up (1) Down (0) Drive motor spins up after a delay of 12

(may vary depending on drive type) seconds

times the numeric ID setting of the

associated drive.

Up (1) Up (1) Drive motor will not spin-up.

* Default setting for proper operation.

Spin-Up Settings

9

Page 22

Chapter 1 - Getting Started

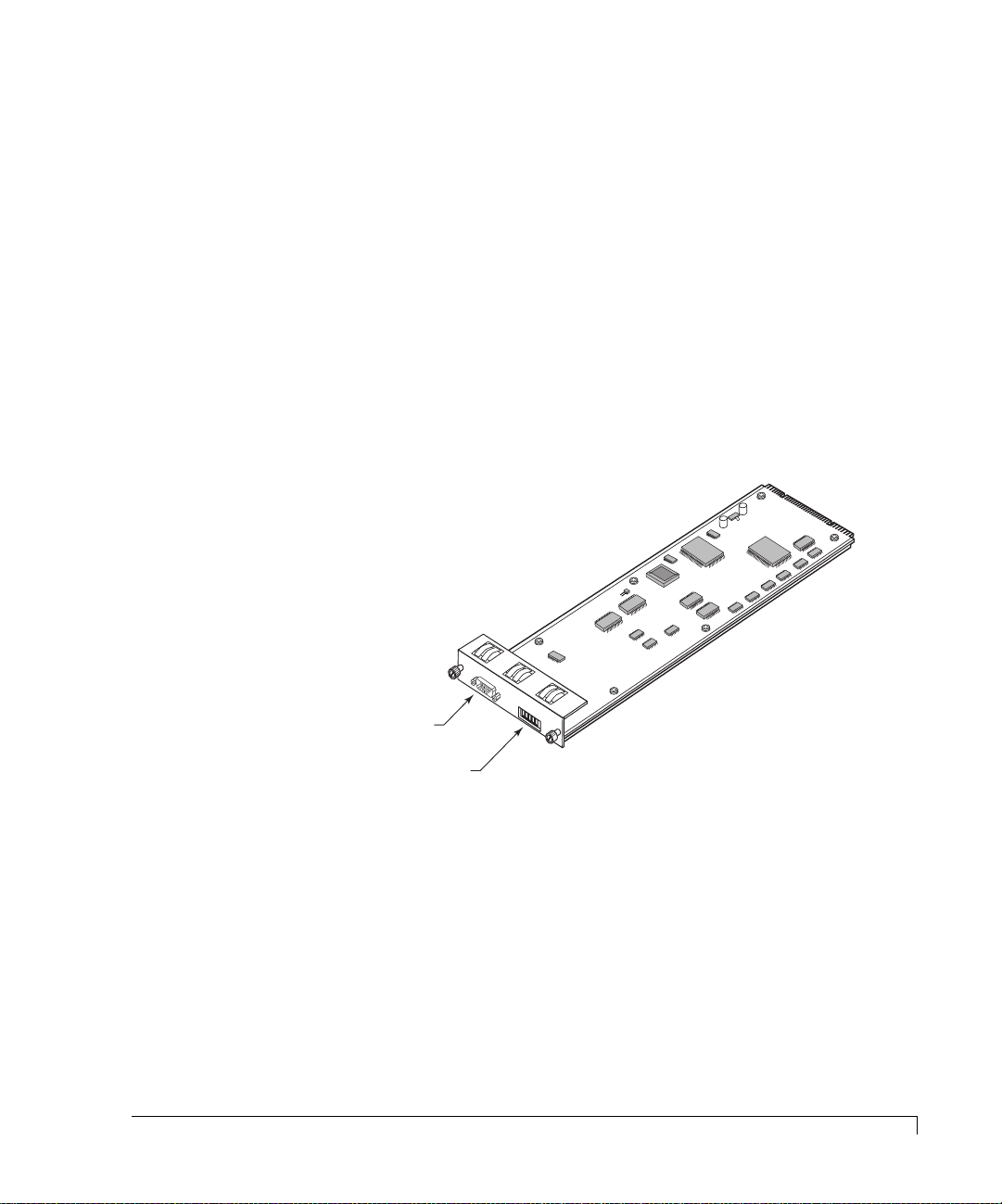

Disk I/O Card

The Disk I/O card is provided for drive channel expansion. By connecting daisy

chained IRF-JBOD enclosures to the Disk I/O cards additional enclosures and

drives can be added to your system. This card’s design incorporates an active

hub, and provides automatic loop regeneration (LRC) and port bypass. The loop

regeneration function will “heal” the FC-AL (Fibre Channel-Arbitrated Loop)

when components become disconnected or faulty.

There are two Disk I/O cards installed at the rear of the enclosure adjacent to the

cooling fan bay. The upper Disk I/O card provides the connection to the “Loop

0” side of the disk drives, and the lower Disk I/O card provides the connection to

the “Loop 1” side of the disk drives.

Each Disk I/O card supports Small Form-Factor Pluggable (SFP) cages to accept

either optical or copper transceivers. They are designed to support NCITS T11

Fibre Channel compliant devices at speeds of 1.0625 Gb per sec or 2.125 Gb per

second. The speed is set through a hardware jumper (JP4) located on the Disk

I/O card. Set the jumper on one pin only or offset for 2Gb mode. If you need to

configure the system for 1Gb mode, position the jumper to both pins. An LED on

the card’s faceplate will illuminate to indicate the 2 Gb mode.

10

Disk I/O Card

FC-AL Loop Port

Loop Status LED

2 Gb/1 Gb Mode LED

P1

DISK I/O

OK

2G

OK

P2

A/W Rev-1

P/N 08-9-96318001

FAILURE DETECT

FOR HARDWARE

INSTALL JUMPERS 1 & 2

1G OPERATION

JP2

ADD JUMPER FOR

JP4

JP1

Disk I/O Card

SPLIT BUS MODE

ADD JUMPER FOR

Fibre Disk IO LRC

JP3

Jumpers JP1 and JP2

must be installed on

both pins .

Jumper JP3 must be offset

or installed on one pin only.

This enables Single Bus mode.

Jumper JP4 must be set

to one pin only for 2Gb mode.

Position it on both pins for

1Gb mode.

Page 23

Chapter 1 - Getting Started

The jumper, (JP3), must be set to one pin only or offset. This configures the bus

to single bus mode.

The jumpers JP1 and JP2 must be installed on both pins. They provide hardware

failure detect signals.

NOTE: The Disk I/O cards are universal and can be interchanged.

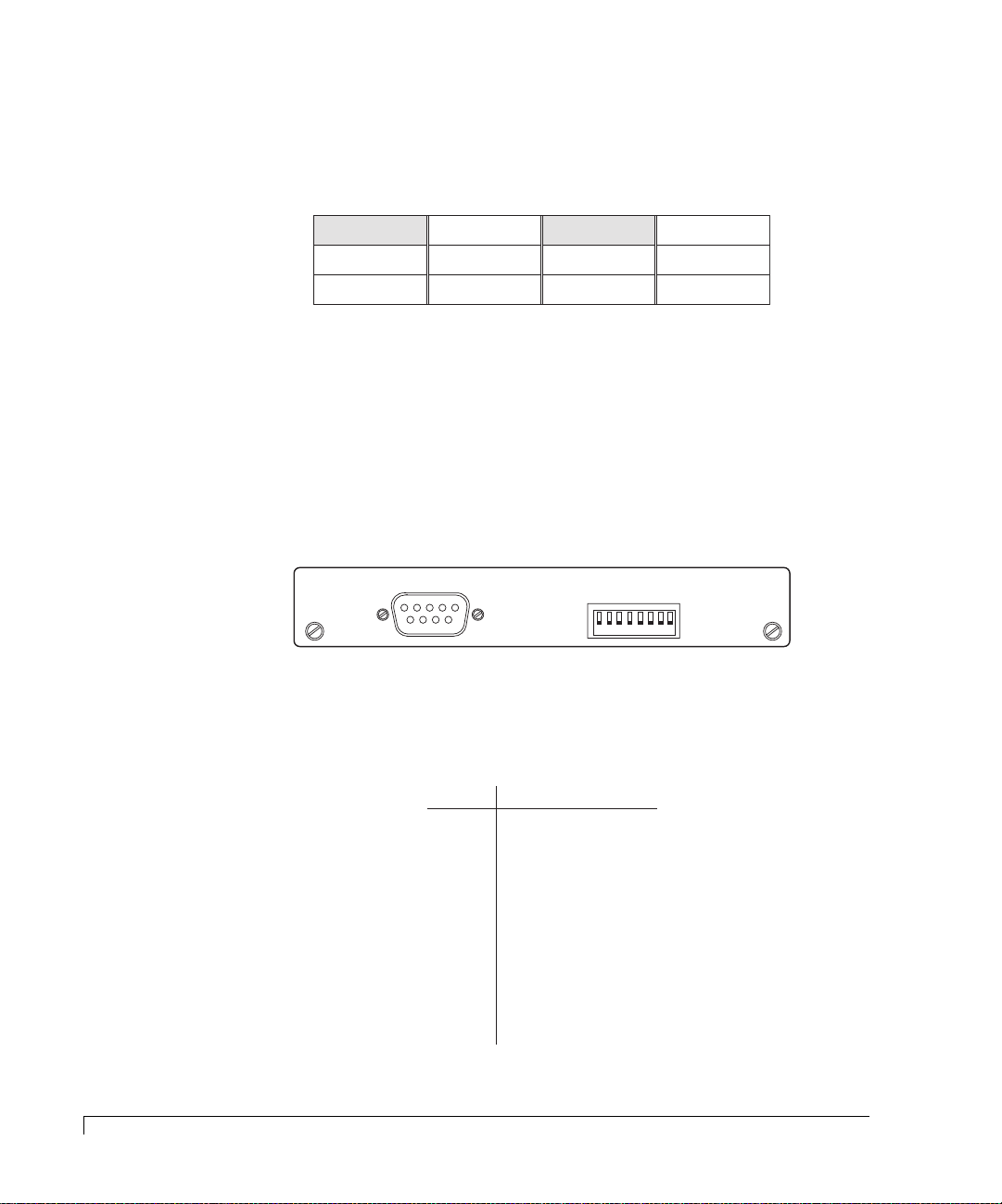

Host I/O Card

The Host I/O card provides the fibre connectivity from the host computer(s) to

the Fibre Channel controller ports. This hot swappable card is designed to

support NCITS T11 Fibre Channel compliant devices at speeds of 1.0625 Gb per

sec or 2.125 Gb per sec. Each card has two SFP cages that house optical or

copper SFP transceivers. They are labeled “H0” and “H1.”

The Host I/O cards are installed at the rear of the enclosure, above the controller

slots. The right Host I/O card provides connectivity to controller’s port 0 (C0P0 and

C1P0) of both controllers, and the left card provides connectivity to controller’s

port 1 (C0P1 and C1P1) of both controllers.

LEDs on the card’s face plate will illuminate to indicate 2 Gb speed mode, host

link status, and activity.

FC Host Ports

Link Status LED

H0

O

K

H1

2

H

G

O

O

S

K

T

I/O

A/W

P/N 08-9-96319003

R

EV-1

E H

OST IO

S

W

I

T

H

C

O

H

S

P

T

C

O

T

S

S

R

P

I

T

L

E

H

I

E

M

O

U

D

N

O

B

D

H

F

E

O

A

O

I

N

S

L

O

/

T

C

O

V

T

H

1

F

E

L

G

0

F

R

R

H

/

D

2

D

0

1

G

U

I

P

L

S

A

0

I

/

L

N

E

P

D

K

N

A

1

I

S

C

A

/

T

E

D

I

N

V

I

S

E

A

/

E

D

N

I

S

A

/

E

D

N

I

S

A

G

/

E

N

N

D

A

G

/

V

N

C

D

C

/

V

C

C

2 Gb/1 Gb Mode LED

FIBR

Host I/O Card

Switch Name

1

HOST SPEED 1G/2G

2

CTRL MODE DIS/ENA

3

HUB FAILOVER DIS/ENA

4

HOST H0H1 LINK DIS/ENA

5

CTRL0 P0P1 LINK DIS/ENA

6

DUAL ACTIVE DIS/ENA

7

GND/VCC

8

GND/VCC

Switch Settings

2 Gb

imageRAID

Enabled

Enabled

Not Used

Enabled

Not Used

Not Used

Function

UP (ON) DOWN (OFF)

1 Gb

Not Used

Disabled

Disabled

Not Used

Disabled

Not Used

Not Used

Host I/O Card

11

Page 24

Chapter 1 - Getting Started

The following table defines the function of each switch:

Switch Name Function

1 HOST SPEED Sets the FC Loop speed to 1 Gb or 2 Gb. An LED on the

card will illuminate to indicate 2 Gb mode. The “up”

position sets 2 Gb mode and the “down” position will set

the loop to 1 Gb mode.

2 CTRL MODE Sets the enclosure for a specific controller model. This

switch must be set to the “up” position for the

“imageRAID” Controller. The “down” position is not

applicable.

3 HUB FAILOVER This switch is not used.

4 HOST H0H1 LINK This switch when enabled, “up” position, provides the

link between the Host I/O card H0 and H1 ports. This

switch should be set to the “down” position when Switch

6 is enabled (‘up’ position).

5 CTRL0 P0P1 LINK This switch is not used.

6 DUAL ACTIVE This switch is enabled (up position) when dual

controllers are installed. It is used to enable automatic

internal hub failover during a controller failure.

7 GND/VCC This switch is not used.

8 GND/VCC This switch is not used.

12

SFP Transceiver

Each card contains Port Bypass Circuits (PBC) that allows for hot swapping,

improved signal quality and valid FC signal detection. An onboard Clock

Recovery Units (CRU) is provided to improve the signal quality, determine

whether the input is a valid FC signal, and amplification and jitter removal for

optimum quality signals.

Cabling diagrams are provided in the Installation chapter for each supported

topology. To ensure proper connectivity, failover and failback operations, and

LUN presentation, follow the cabling diagram for your selected topology.

SFP Transceiver

The Host I/O and Disk I/O cards incorporate SFP cages which support optical

hot-swappable Small Form-Factor Pluggable (SFP) transceivers.

The optical SFP transceiver is Class 1 Laser safety compliant and conforms to

Class 1 eye safety standards.

CAUTION:

Do not look into the laser light beam for any extended period of time.

Page 25

Chapter 1 - Getting Started

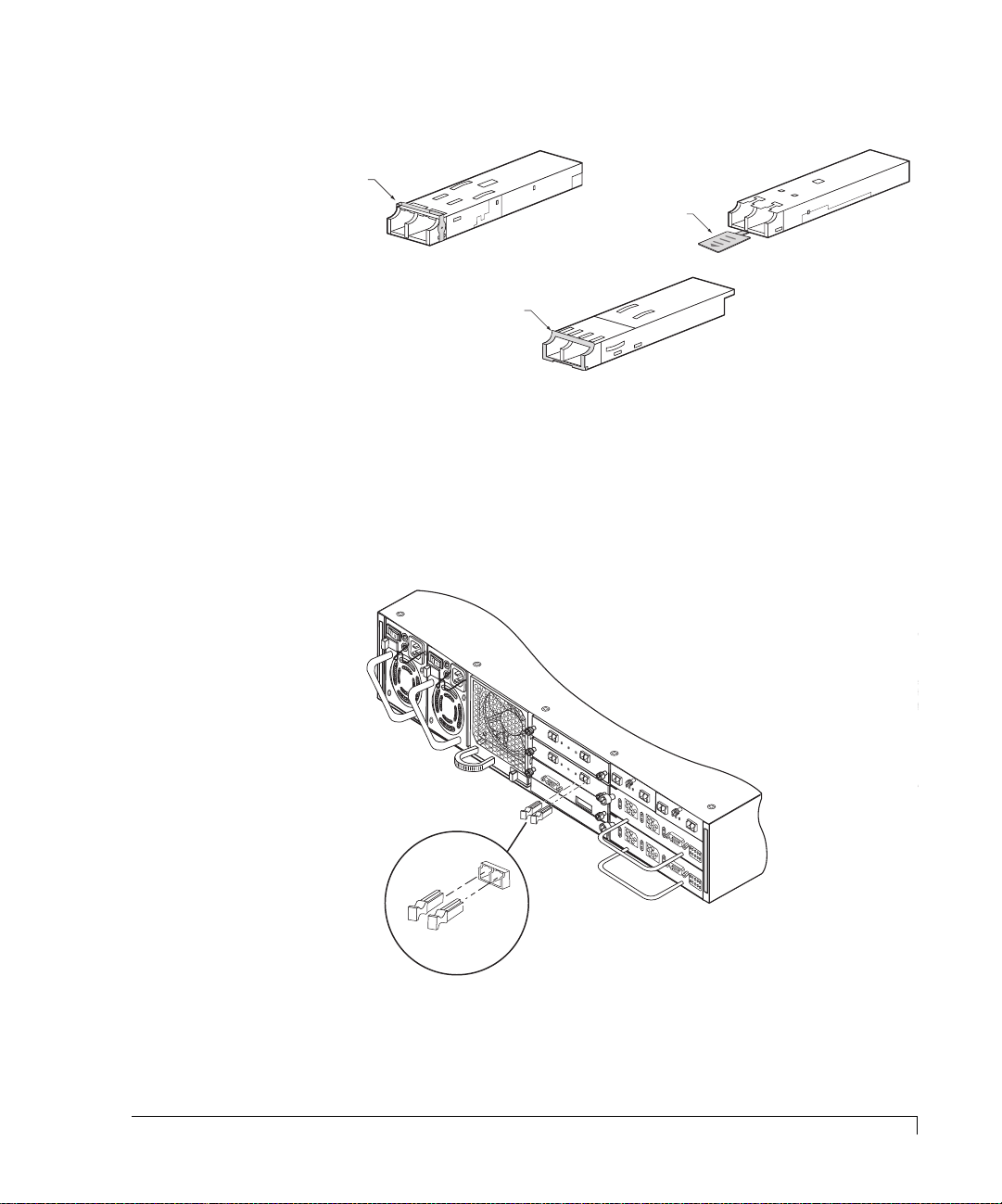

Ejector Release Lever

Ejector Release Tab

Ejector Release Lever

SFP Optical Transceiver Models

NOTE: Refer to the Installation chapter for transceiver installation procedures.

Dust covers are provided to protect the transceivers’ optics. It is highly recommend

that the dust covers be installed when a connector is not in place.

A

/W

P

R

/N

e

08

Fibre D

v-1

-9-9

F

A

I

L

F

U

O

R

R

E

H

D

A

T

E

R

A

TE

D

L

L JU

W

C

A

T

R

M

E

P

E

R

S

1

&

2

JP

1

FA

I

LU

FO

R

R HA

E

IN

D

S

E

TA

R

TE

DW

LL JU

C

T

A

R

M

E

JP

P

E

2

R

S

1 &

D

2

I

S

D

K

1

JP1

T

I

x

T

x

DISK I/O

D1

T

x

T

x

RS-232

S

E

A

/

R

O

T

P

W

A

R

O

T

R

N

K

S

R

U

C

M

E

O

B

V

N

E

IS

T

T

R

IO

RO

x

0

N

8

L

-1

-9

LE

-9

R

6

JP

32

2

2

0

0

D

1

2

H

1

T

x

O

K

D2

S

A

A

H

A

OST

D

S

D

S

D

B

0

P

D

1

1

P

K

R

2

D

1

L

2

M

R

Y

T

1

0

/

1

0

0

1

K

1

0

/1

0

0

S

P

6318

isk IO

L

A

IT

D

B

0

D

IN

L

01

U

JU

R

S

S

C

M

M

P

O

JP

E

D

R

E

F

O

R

1

G

O

A

D

P

E

D

R

JU

A

TIO

M

P

N

E

R

F

O

R

A

/W

R

P

/N

ev-1

J

08-9-9

Fibre

P

1

D

6318001

isk IO

S

P

LIT

AD

LR

BU

D

C

JP

JU

S

M

2

M

O

P

D

E

E

R

F

O

R

1G

O

A

P

D

E

D

R

JU

ATIO

M

PE

N

R

F

O

R

S

E

JP

2

O

H

K

2

0

G

I/O

H

1

1

K

O

K

O

K

2

H

G

O

O

S

V

R

T

1

0

C

/

I/O

1

U

0

0

R

1

K

P

D

R

T

N

R

R

T

RS-232 DTE

O

V

R

1

0

C

/

1

U

0

0

R

P

W

R

P

D

R

T

N

R

R

T

RS-232 DTE

P

W

R

A

3

/W

P

R

/N

E

F

0

V

IB

8

-1

-

R

9

E

-

9

H

6

3

O

1

S

9

T

0

IO

0

1

P

I

N

8

P

I

-

N

V

7

P

C

JP

I

C

-

N

V

3

6

P

C

I

C

-

N

V

5

P

C

I

C

-

N

C

J

4

P

0

P

I

C

-

N

C

2

H

3

P

0

0

I

C

C

-

N

H

1

H

2

P

_

U

1

E

I

_

B

N

W

N

E

F

1

A

S

B

N

A

H

W

B

-

I

L

O

1

I

T

O

G

O

C

V

/

2

H

E

G

R

C

O

N

N

E

C

T

I

O

O

N

S

P

I

N

8

P

I

-

N

V

7

C

I

C

-

N

V

6

C

C

-

V

C

C

-

C

0

C

H

0

C

H

1

_

1

E

_

N

E

N

B

B

I

L

O

V

E

R

H

0

H

1

H

A

0

D

A

1

D

A

0

A

H

1

H

L

0

D

L

1

D

L

0

L

H

1

H

A

0

D

A

1

D

A

0

A

H

1

H

L

0

D

L

1

D

L

0

L

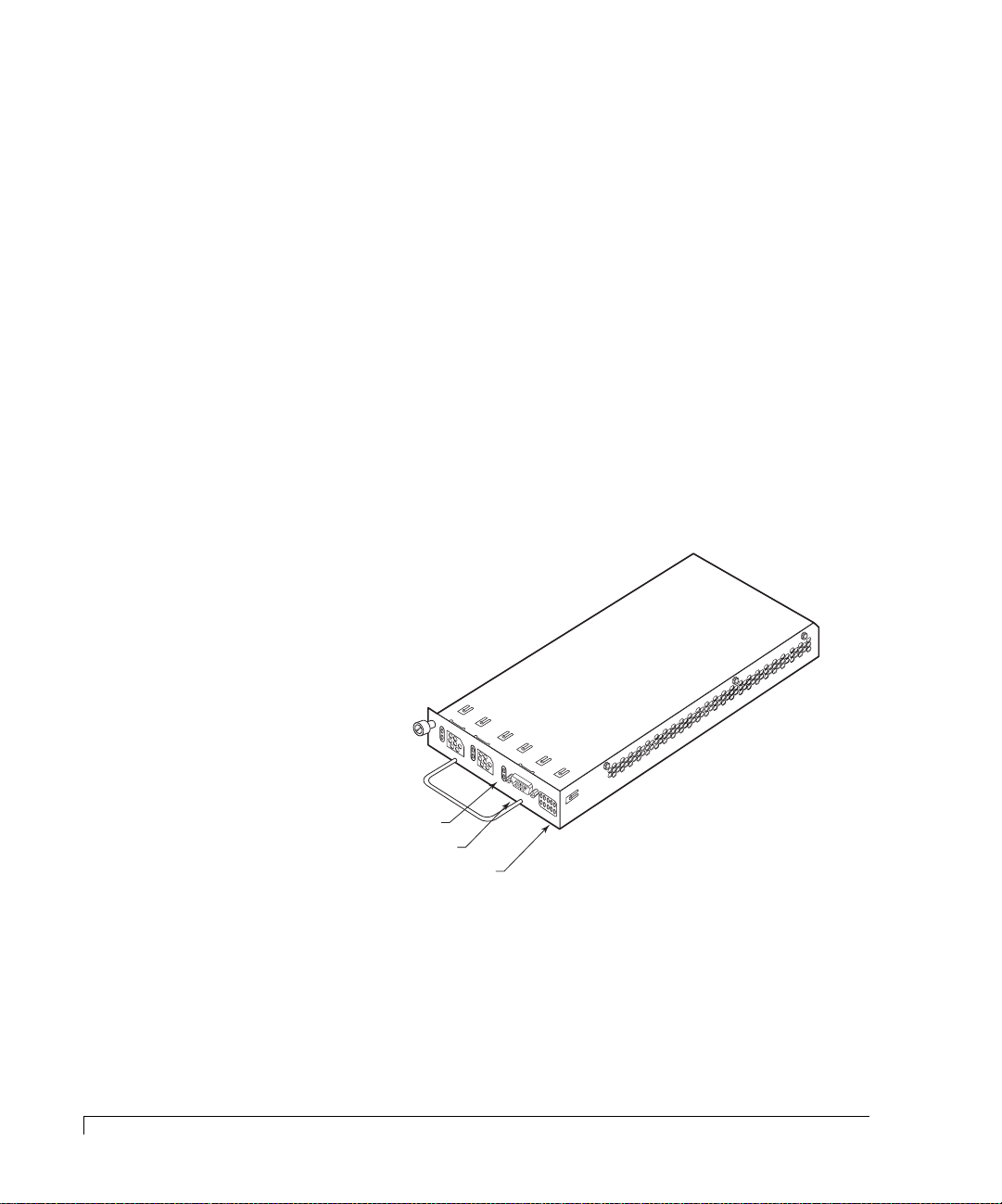

Install the Dust Covers

when the optical transceiver

port is not in use.

Installing and Removing Optical Transceiver Dust Covers

E

V

-1

6

3

1

90

01

P

P

I

N

5

P

I

N

4

P

I

-

N

C

3

P

0

C

I

-

N

H

2

P

U

I

B

N

W

F

A

1

S

A

H

W

-

O

1

I

T

G

O

C

/

2

H

G

C

O

N

N

E

C

T

I

O

O

N

S

A

/W

P

R

/N

FIB

0

8

-9

R

E

-9

H

O

S

T

IO

SFP Transceiver

13

Page 26

Chapter 1 - Getting Started

RAID Controllers

The imageRAID Series Storage System is designed to house one or two hot

pluggable imageRAID Controllers. They are next generation dual port

high-performance 2 Gb/second Fibre Channel-to-Fibre Channel RAID controllers

supporting RAID levels 0, 1, 5, 10, and 50.

There are two models of the

a FC-FC RAID Controller with a single RISC processor. The

imageRAID

Controller. The base

imageRAID

imageRAID

XP model is

model is

the base controller plus a co-processor.

The controllers are

designed for “I/O Intensive” and “Bandwidth Intensive”

applications, providing simplex (stand-alone) and duplex (active-active)

configurations designed for existing and future Fibre Channel topologies.

simplex operations, the controller operates autonomously. In

duplex

In

configurations, the two controllers operate as a pair. In the event one controller

fails, fault tolerance is maintained via hardware failover allowing either controller to

take over the operations of the other controller.

1K

1

10

K

/10

0

Over Current & Partner Controller Status

RS-232 Service Port

Controller Status LEDs

O

V

R

10

C

/100

U

R

P

DRT

R

T

N

R

H1A

H0A

R

D1A

S-232

D0A

DTE

PWR

H1L

H0L

D1L

D0L

14

Fibre Channel-Fibre Channel imageRAID Controller

Each controller has two Fibre Channel ports and two Fibre Channel disk ports for

a “2x2” configuration (dual host-dual drive). In duplex configurations, it can

process up to 80,000 I/O’s per second (IOPS). The active-active pair of RAID

controllers can feed data to SAN nodes at a sustained rate of 320 MB/sec, and

process RAID 5 write operations at 220 MB/sec.

RAID Controllers

Page 27

Chapter 1 - Getting Started

The core processor of the controller is based on an Intel XScale™ RISC processor

running at 600 MHz. The processor has integrated instructions and data caches

that allow for the most frequent instructions to be executed without having to

access external memory. Coupled with the micro kernel, it processes commands

and I/O’s at extremely high rates.

The processor’s companion chip implements dual independent 64-bit 66MHz PCI

busses. Devices on these busses have independent access to the shared 512 MB

of SDRAM. Also, an integrated XOR accelerator is included for RAID 5 or 50

parity generation.

The imageRAID Controller disk drive interface uses QLogic ISP 2312 dual Fibre

Channel controllers which takes full advantage of the dual fibre loops on each

disk drive. The controller’s host interface also uses QLogic ISP 2312 dual Fibre

Channel controllers which provides two independent ports for host connectivity.

Each port can operate at either 1 Gb/sec or 2 Gb/sec, and the controller will

automatically detect the correct rate. The ports are sometimes referred to as “Host

Loops.”

Located on the controller face plate are Activity, Link and Status LEDs. Refer to

the table below and the illustration on the following page for descriptions for

each LED.

NOTE: The “TXRX-LNK” and “1K-10/100” LEDs are provisions for future options.

RAID Controller Face Plate LEDs

PWR

OVR CUR

PRTNR

TXRX - LNK

1K - 10/100

Indicates power is applied.

Indicates controller over current condition exceeds +5V.

If on, it will indicate that the partner controller has failed.

Option for future enhancement.

Option for future enhancement.

RAID Controllers

15

Page 28

Chapter 1 - Getting Started

Amber LEDs

D0A

D1A

H0A

H1A

O

VR

C

UR

RS-232 DTE

P

RTNR

DRT = Cache Dirty

H1A = Host Loop 1 Activity

H0A = Host Loop 0 Activity

D1A = Drive Loop 1 Activity

D0A = Drive Loop 0 Activity

On = Activity Sensed

DRT

H1A

H0A

D1A

D0A

Off = No Activity

DRT

PWR

H1L

H0L

D1L

D0L

Green LEDs

PWR

H1L

H0L

D1L

D0L

D0L = Drive Loop 0 Link Status

D1L = Drive Loop 1 Link Status

H0L = Host Loop 0 Link Status

H1L = Host Loop 1 Link Status

PWR = Power Applied

On = Link Valid

Off = Link Invalid

imageRAID Controller Face Plate LEDs and Descriptions

Battery Backup Unit

The main board of the imageRAID Controller includes battery control circuitry for

a single cell Lithium Ion battery along with a battery pack mating connector. The

main purpose of battery backup is to maintain the cache memory during brief

power interruptions, but is capable of maintaining the memory content for

several hours, depending on the type and size of the memory.

16

Battery Backup Unit

Page 29

Chapter 1 - Getting Started

The battery control circuitry has constant current, constant voltage (CCCV) charger.

The battery charger provides a maximum 250mA charge current. When the charge

current falls below 16mA, the charger determines that the end of charge has been

reached, generates an end of charge indication and shuts itself off. If the battery

voltage drops below 3.0V, a complete battery discharge is indicated.

The battery control circuitry includes a battery safety circuit. The safety circuit

protects the battery by limiting the over-voltage to 4.3V, the maximum discharge

current to 3A for catastrophic events, and the minimum battery voltage to 2.35V. If

any of these conditions exist, the safety circuit disconnects the battery. These

conditions will only exist if there is a hardware fault present, and would never be

seen under normal operating conditions. In addition, the battery pack utilized, part

number 44-9-95611001, includes a resettable polyfuse that trips when the current

exceeds 700mA at room temperature. This protects the 1 amp rated connector

when for example a partial short exists caused by aa component failure.

Lithium Ion batteries have no requirement for conditioning, even after partial

discharges. The current battery pack utilizes a Renata ICP883448A-SC cell, with a

nominal capacity of 1150mAh. For a completely discharged battery, the charge time

is approximately 5 hours. Under lab conditions, current draw was measured for

different configurations of memory. The table below shows the results of those

tests, and the expected backup time is indicated for the specified memory

configuration. The table shows the absolute maximum backup time calculated from

the current draw measurements. The “Expected Safe Backup Time” is the absolute

maximum de-rated by 50% to account for different operating temperatures and

capacity reduction due to battery charge/discharge cycles. This is the time that

should be used when developing a system level power backup plan.

BBU Battery Hold-Up Times

Configuration

Main board

only w/512 MB

Main board

w/512 MB and

Coprocessor

w/512 MB

Memory Vendor and

Part Number

Kingston

KVR100X72C2/512

Kingston

KVR100X72C2/512

Measured

Current Draw

27.9mA 41.2 hours 20.6 hours

48.3mA 23.8 hours 11.9 hours

Absolute Maximum

Backup Time

Expected Safe

Backup Time

Battery Backup Unit

17

Page 30

Chapter 1 - Getting Started

Control and Monitoring

An integral part of the imageRAID Series Storage System is its control and monitor

capabilities.

The SES processors provide monitoring data for the enclosure environmental

conditions such as enclosure temperature, cooling fans, power supplies, and FC

Loop status. This data is reported to the monitoring system to provide LED and

audible alarm notifications. This monitored information is also communicated to

external monitoring software.

Refer to “VT-100 Interface Enclosure Monitoring” on page 116 for complete

details.

Drive Status LEDs

(left column of LEDs)

Drive Activity LEDs

(right column of LEDs)

18

Control and Monitoring

R

e

se

t A

la

Power On LED

Channel Status LED

Power Supply Status LED

Fan Status LED

Alarm Reset Button

rm

Front Bezel LEDs and Reset Button Identification

The imageRAID Controllers provide monitoring data for its environmental

condition and logical arrays. They communicate that data to the front bezel LEDs,

third-party configuration and monitoring software such as StorView, and the

VT-100 firmware-based interface for management and monitoring. (Refer to the

software user’s guide for configuration, management, and monitoring of the

controllers and logical arrays.)

Page 31

Chapter 1 - Getting Started

The

imageRAID

Display” which provides LED readout of the fan control, Host I/O and Disk I/O

speed modes, Disk I/O and Host I/O card presence and controller presence. Refer

to “One-Touch Annunciation Configuration Display” on page 115 for more details.

Series incorporates a “One-Touch Annunciation Configuration

Status Indicator LEDs

The Status Indicator LEDs comprise the Power-On LED, Channel Status LED,

Power Supply Status LED, and Fan Status LED. These series of LEDs are grouped

on the right side of the front bezel directly above the Alarm Reset button. The

following is a description of each of these LEDs.

Power-On LED

The Power-On LED signifies that the enclosure is powered on and will be

illuminated green when power has been applied.

Channel Status LED

The Channel Status LED will illuminate green to indicate a valid status of the FC

loop or a logical array. Should an error occur, the LED will change to amber.

Power Supply Status

The Power Supply Status LED indicates the condition of the power supplies. The

LED will illuminate steady green when both power supplies are functioning

normally and will change to amber if one of the power supply should fail or is

turned off.

Fan Status

The Fan Status LED indicates the condition of the cooling fans. The LED will

illuminate green when both fans are functioning normally and will change to

amber if any of the fans fail.

Status Indicator LEDs

19

Page 32

Chapter 1 - Getting Started

Drive LEDs

The Drive LEDs are located on the left side of the front bezel in between the

ventilation ribs, and comprise the Drive Status LEDs and Drive Activity LEDs. The

Drive LEDs are grouped in pairs and are in the general location of the disk drive

slot. There are 12 Drive Status and 12 Drive Activity LEDs, one group for each

disk drive.

Refer to “Drive LEDs” on page 110 for detailed information.

Audible Alarm

An audible alarm will sound when any of the enclosure’s component status

changes to an abnormal state. To silence the alarm, press the Alarm Reset button

located on the front bezel. The corresponding alarm’s LED will remain

illuminated until the condition returns to a normal state.

20

Drive LEDs

Page 33

Chapter 2

Topologies and Operating Modes

This chapter provides an overview of the supported operating modes and

topologies. This information should provide you with an understanding to make

the best choices for the optimum configuration that compliments your storage

system solution.

Essentially there are two operating modes available: Simplex and Duplex. The

IRF-1Sxx-xx or IRF-1Dxx-xx models with their single RAID controller support the

simplex operating mode, and the IRF-2Sxx-xx or IRF-2Dxx-xx models with their

dual RAID controllers support the duplex operating mode.

Operating Mode Overview

These operating modes allow you to configure the enclosure’s drives and RAID

controller(s) to support a variety of host environments topologies.

■ Simplex – In this operating mode, the enclosure is configured as a RAID

storage system with its single RAID controller operating in a stand-alone

configuration. This operating mode supports dual port topologies.

■ Duplex – In this operating mode, the enclosure is configured as a RAID

storage system with dual RAID controllers operating in an active-active or

redundant fault-tolerant configuration. This operating mode supports

Multiple Port Mirrored topologies.

21

Page 34

Chapter 2 - Topologies and Operating Modes

Simplex Mode

The simplex operating mode uses a single RAID controller solution that provides

a limited level of redundancy. With its dual port topology, the controller also

provides dual active ports that increases the bandwidth capabilities. Essentially,

there are four supported topologies for this operating mode:

■ “Dual Port Single Host Connection” on page 22

■ “Dual Port Single Host Dual Connection” on page 23

■ “Dual Port Multi-Host Single Connection” on page 24

■ “Dual Port Multi-Host Dual Connection” on page 25

Dual Port Single Host Connection

This topology provides an entry-level RAID storage solution for single ported HBA

host system. It offers the following advantages:

deploy

multiple points of failure (host server, host HBA, controller, and data cable), and it

has limited bandwidth capabilities due to its single Fibre loop (200 MB/sec).

and is a simple direct attached solution. It has several disadvantages:

an initially lower cost system to

22

Simplex Mode

Right Host I/O Card

Simplex Mode Logical View - Dual Port Single Host Connection

Host/Server (Node A)

FC HBA 1

H1

SW 4

H0

Port 0 (P0)

Active

Controller 0 (C0)

Port 1 (P1)

Active

H0H1

SW 4

Left Host I/O Card

Page 35

Chapter 2 - Topologies and Operating Modes

In this topology the Host I/O card switches 1, 2, and 4 are set to the “Up”

position.

Switch 1 sets the bus speed mode on the Host I/O card to 2 GB/sec.

Switch 2 configures the enclosure for the imageRAID Controller.

Switch 4 provides the link between the Host I/O card “H0” and “H1” ports to

the same Fibre loop.

Dual Port Single Host Dual Connection

This topology provides an entry-level RAID storage solution for dual ported host

systems with multiple paths to the storage. It offers the following advantages: an

initially lower cost system to deploy, multiple paths from host which can

maximize controller bandwidth, and it provides multiple paths for optional

upstream failover. It has several disadvantages: the RAID Controller is a single

point of failure, it requires two single ported HBAs or a dual ported HBA, and if

upstream path failover is implemented then additional software is required.

Host/Server (Node A)

FC HBA 1

Right Host I/O Card

H1

SW 4

FC HBA 2

H0

Port 0 (P0)

Active

Port 1 (P1)

Controller 0 (C0)

Active

SW 4

H0H1

Left Host I/O Card

Simplex Mode Logical View - Dual Port Single Host Dual Connection

In this topology the Host I/O card switches 1, 2, and 4 are set to the “Up”

position.

Switch 1 sets the bus speed mode on the Host I/O card to 2 GB/sec.

Dual Port Single Host Dual Connection

23

Page 36

Chapter 2 - Topologies and Operating Modes

Switch 2 configures the enclosure for the imageRAID Controller.

Switch 4 provides the link between the Host I/O card “H0” and “H1” ports to

the same Fibre loop.

Dual Port Multi-Host Single Connection

This topology provides a base shared RAID storage solution for up to four host

systems. It offers the following advantage: clustered storage between multiple

host system (no requirement for external hubs or switches). It has a few

disadvantages: the controller and the single fibre loop are single points of failure,

for clustering operations third-party clustering software is required and it also has

limited bandwidth performance due to a singe Fibre loop (200 MB/sec).

Host/Server (Node A) Host/Server (Node B)

FC HBA 1

Right Host I/O Card

H1

SW 4

H0

Port 0 (P0)

Active

Controller 0 (C0)

Port 1 (P1)

Active

H0H1

SW 4

FC HBA 1

Left Host I/O Card

Simplex Operating Mode Logical View - Dual Port Multi-Host Single Connection

In this topology the Host I/O card switches 1, 2, and 4 are set to the “Up”

position.

Switch 1 sets the bus speed mode on the Host I/O card to 2 GB/sec.

Switch 2 configures the enclosure for the imageRAID Controller.

Switch 4 provides the link between the Host I/O card “H0” and “H1” ports to

the same Fibre loop.

24

Dual Port Multi-Host Single Connection

Page 37

Chapter 2 - Topologies and Operating Modes

Dual Port Multi-Host Dual Connection

This topology provides a base shared RAID storage solution for up to four host

systems. It offers the following advantages: clustered storage between multiple

host system (no requirement for external hubs or switches). It has a few

disadvantages: the controller and the single fibre loop are single points of failure,

for clustering operations third-party clustering software is required and it also has

limited bandwidth performance due to a singe Fibre loop (200 MB/sec).

Host/Server (Node A) Host/Server (Node B)

FC HBA 1

Right Host I/O Card

H1

FC HBA 2 FC HBA 1 FC HBA 2

H0

SW 4

Port 0 (P0)

Active

Controller 0 (C0)

Port 1 (P1)

Active

SW 4

H0H1

Left Host I/O Card

Simplex Operating Mode Logical View - Dual Port Multi-Host Dual Connection

In this topology the Host I/O card switches 1, 2, and 4 are set to the “Up”

position.

Switch 1 sets the bus speed mode on the Host I/O card to 2 GB/sec.

Switch 2 configures the enclosure for the imageRAID Controller.

Switch 4 provides the link between the Host I/O card “H0” and “H1” ports to

the same Fibre loop.

Dual Port Multi-Host Dual Connection

25

Page 38

Chapter 2 - Topologies and Operating Modes

Duplex Mode

The duplex operating mode is a dual RAID controller solution providing a

redundant controller or an active-active RAID storage solution. Beginning with a

minimum level redundancy solution it can be configured to provide the most

robust redundant RAID storage solution. This operating mode supports the

Multiple Port Mirrored topology.

In a Multi-Port topology, all ports are active and provide transparent hardware

failover and failback operations. It provides for higher host bandwidth

capabilities with each port connected to an individual fibre loop.

During controller failure, internal HUB circuitry on the Host I/O cards

automatically detect a failure and connects the incoming Fibre loops together so

that the surviving controller immediately starts processing host commands.

There are essentially five supported topologies available for the Duplex mode:

■ “Multi-Port Mirrored Single Host-Single Connection” on page 27.

26

■ “Multi-Port Mirrored Single Host-Dual Connection” on page 28.

■ “Multi-Port Mirrored Dual Host System-Quad Connection” on page 31.

■ “Multi-Port Mirrored SAN Attach Single Switch Connection” on page 32.

■ “Multi-Port Mirrored SAN Attach Dual Switch Connection” on page 33.

NOTE: Some Operating Systems, such as HP-UX, when connected to a fabric

require that you set the Controller Parameter option “Host Different

Node Name” to enabled. This will cause the controller to present a

different Configuration WWN for each controller port. Otherwise if the

same WWN is reported on both ports, one port would be blocked by the

OS. Refer to the VT-100 or StorView Software Guide for specific

information on this option.

Duplex Mode

Page 39

Chapter 2 - Topologies and Operating Modes

Multi-Port Mirrored Single Host-Single Connection

This topology provides an redundant RAID storage solution for single host systems

with one fibre port where a fault-tolerant disk subsystem storage is required. It has

the following advantages: initial lower costs, redundant RAID controllers, and

transparent failover and failback operations. It has several disadvantages:

performance limited bandwidth capabilities due to the single Fibre loop, and the

host system, host HBA and the single fibre loop are single points of failure.

Host/Server (Node A)

FC HBA 1

Right Host I/O Card

Port 0 (P0)

H1

Active

Controller 0 (C0) Controller 1 (C1)

Failover

Circuit

H0

Port 1 (P1)

Active

Port 0 (P0)

Active

H0H1

Failover

Circuit

Port 1 (P1)

Left Host I/O Card

Active

Duplex Mode Logical View - Multi-Port Mirrored Single Host-Single Connection

In this topology the Host I/O card switches 1, 2, and 6 are set to the “Up”

position.

Switch 1 sets the bus speed mode on the Host I/O card to 2 GB/sec.

Switch 2 configures the enclosure for the imageRAID Controller.

Switch 6 enables automatic internal hub failover during a controller failure.

Multi-Port Mirrored Single Host-Single Connection

27

Page 40

Chapter 2 - Topologies and Operating Modes

Multi-Port Mirrored Single Host-Dual Connection

This Multi-Port Mirrored topology provides an active-active RAID storage solution

for single host systems with dual Fibre ports where fault-tolerant RAID disk

subsystem storage is required. It has several advantages: redundant active-active

controllers, and transparent failover and failback operations, LUN isolation (LUNs

appear only once to the host OS), and dual connections for higher performance

independent access to assigned LUNs.

It has two disadvantages which are the host HBA and the single fibre loop which

are single points of failure.

Host/Server (Node A)

FC HBA 1

Right Host I/O Card

Port 0 (P0)

Active

Controller 0 (C0) Controller 1 (C1)

H1

Failover

Circuit

FC HBA 2

H0

Port 1 (P1)

Active

Port 0 (P0)

Active

Failover

Circuit

H0H1

Port 1 (P1)

Active

Left Host I/O Card

Duplex Mode Logical View - Multi-Port Mirrored Single Host-Dual Connection

In this topology the Host I/O card switch 1, 2, and 6 are set to the “Up” position.

Switch 1 sets the bus speed mode on the Host I/O card to 2 GB/sec.

Switch 2 configures the enclosure for the imageRAID Controller.

Switch 6 enables automatic internal hub failover during a controller failure.

28

Multi-Port Mirrored Single Host-Dual Connection

Page 41

Chapter 2 - Topologies and Operating Modes

Example of Multi-Port Mirrored in Fail-Over Mode

The following illustration demonstrates how the ports failover in the Multi-Port

Mirrored topology.

Switch 6 which enables automatic internal hub failover when a controller failure

is detected and also controls the logical function of switch 4. When a controller

failure is detected, the logic circuit will close connecting the “H0” and “H1” ports

on the Host I/O card, regardless of the physical position of switch 4.

As shown below even though switch 4 is disabled (down position) when the

controller failed, switch 6 logically enabled that circuit providing alternate paths

to the surviving controller ports.

Host/Server (Node A)

FC HBA 1

Right Host I/O Card

Port 0 (P0)

Controller 0 (C0) - Failed

Failed

H1

Failover

Circuit

FC HBA 2

H0

Port 1 (P1)

Failed

Port 0 (P0)

Active

Controller 1 (C1)

Failover

Circuit

H0H1

Port 1 (P1)

Active

Left Host I/O Card

Duplex Mode Logical View - Multi-Port Mirrored Single Host-Dual Connection (Failover)

Multi-Port Mirrored Single Host-Dual Connection

29

Page 42

Chapter 2 - Topologies and Operating Modes

Multi-Port Mirrored Dual Host System-Single Connection

This topology provides one of the more robust active-active RAID storage

solution for dual host systems with single Fibre ports. It has the following

advantages: high availability and high-performance where each host requires

access to all LUNs, redundant active-active RAID controllers, transparent failover

and failback, and shared storage between two host systems.

Its disadvantage is the single fibre loop which becomes a single point of failure.

Host/Server (Node A) Host/Server (Node B)

FC HBA 1

Right Host I/O Card

Port 0 (P0)

H1

Failover

Active

Controller 0 (C0) Controller 1 (C1)

Circuit

H0

Port 1 (P1)

Active

FC HBA 1

Port 0 (P0)

Active

Failover

Circuit

H0H1

Port 1 (P1)

Active

Left Host I/O Card

Duplex Mode Logical View - Multi-Port Mirrored Dual Host System-Single Connection

In this topology the Host I/O card switch 1, 2, and 6 are set to the “Up” position.

Switch 1 sets the bus speed mode on the Host I/O card to 2 GB/sec.

Switch 2 configures the enclosure for the imageRAID Controller.

Switch 6 enables automatic internal hub failover during a controller failure.

30

Multi-Port Mirrored Dual Host System-Single Connection

Page 43

Chapter 2 - Topologies and Operating Modes

Multi-Port Mirrored Dual Host System-Quad Connection

This topology provides one of the more robust active-active RAID storage

solution for dual host systems with dual fibre ports. It has the following

advantages: high availability and high-performance where each host requires

access to all LUNs, redundant active-active RAID controllers, transparent failover

and failback, and shared storage between two host systems.

Its disadvantages are the requirement for dual ported HBA’s and multiple cables.

Host/Server (Node A) Host/Server (Node B)

FC HBA 1

Right Host I/O Card

Port 0 (P0)

Active

Controller 0 (C0) Controller 1 (C1)

FC HBA 2 FC HBA 1 FC HBA 2

H1

Failover

Circuit

H0

Port 1 (P1)

Active

Port 0 (P0)

Active

H0H1

Failover

Circuit

Port 1 (P1)

Left Host I/O Card

Active

Duplex Mode Logical View - Multi-Port Mirrored Dual Host System-Quad Connection