Page 1

C150-E100-01EN

M3097DE/DG Image Scanner

Operator's Guide

Page 2

M3097DE/DG

Image Scanner

Operator's Guide

Page 3

01

Date publishedEdition

December, 1997 First edition

Revised contents

Specification No. C150-E101-01EN

This equipment has been tested and found to comply with the limits for a Class A

digital device, pursuant to Part 15 of the FCC Rules. These limits are designed to

provide reasonable protection against harmful interference when the equipment is

operated in a commercial environment. This equipment generates, uses, and can

radiate radio frequency energy and, if not installed and used in accordance with the

instruction manual, may cause harmful interference to radio communications.

Operation of this equipment in a residential area is likely to cause harmful

interference in which case the user will be required to correct the interference at his

own expense.

This digital apparatus does not exceed the Class A limit for radio noise emissions

from digital apparatus set out in the Radio interference Regulations of the Canadian

Department of Communications.

Le pésent appareil numérique n’ément pas de bruits radioélectriques dépassant les

limites applicables aux appareils numériques de la classe A prescridtes dans le

Réglesment sur le brouillage radioélectrique dicté par le ministere des Communications du Canada.

MaschinenlärmInformationsverordnung 3. GSGV, 18.01.1991:Der arbeisplatzbezogene Schalldruckpegel beträgt 70dB(A)oder weniger gemäß ISO 7779.

The contents of this manual may be revised without prior notice.

All Rights Reserved, Copyright © 1997 FUJITSU LIMITED.

Printed in Japan.

No part of this manual may be reproduced in any form without permission.

i

Page 4

Please send your comments on this manual or on Fujitsu products

to the following addresses:

FUJITSU COMPUTER PRODUCTS OF

AMERICA,INC.

2904 Orchard Parkway,San Jose.

California 95134-2022,U.S.A.

TEL:1-408-432-6333

FAX:1-408-432-3908

Home page:http://www.fcpa.com/

FUJITSU AUSTRALIA LIMITED

475 Victoria Avenue Chatswood.

N.S.W2067,AUSTRALIA

TEL:61-2-410-4555

FAX:61-2-411-8603

FUJITSU CANADA,INC.

2800 Matheson Blvd.East,Mississauga.

Ontario 4X5,CANADA

TEL:1-905-602-5454

FAX:1-905-602-5457

FUJITSU DEUTSCHLAND GmbH.

Frankfurter Ring 211,

8000 München 40,F.R,GERMANY

TEL:49-89-32378-0

FAX:49-89-32378-100

FUJITSU ESPAÑA,S.A

Edificio torre Europa 5

Paseo de la Castellana 95 Madrid 28046,SPAIN

TEL:34-1-581-8400

FAX:34-1-581-8125

FUJITSU EUROPE LTD.

2,Longwalk Road,Stockey Park,Uxbridge

Middlesex,UB11 1AB,U.K

TEL:44-81-573-4444

FAX:44-81-573-2643

Home page:http://www.fujitsu-europe.com/

a

FUJITSU FRANCE S.A.

Bâtiment Aristote,17 rue Olof palme

94006 Créteil cedex,FRANCE

TEL:33-14-513-1616

FAX:33-14-399-0700

FUJITSU HONG KONG Limited

Room 2521,Sum Hung Kai Centre

30 Harbour Road Wanchal,Hong Kong

TEL:852-827-5780

FAX:852-827-4724

TLX:62667

FUJITSU ITALIA S.p.A.

Via Melchiorre Gioia,No.8-20124

Milano,ITALY

TEL:39-2-6351

FAX:39-2-6572257

FUJITSU NORDIC AB

Kung Hans vag,S-19176

Sollentuna,SWEDEN

TEL:46-8-626-6000

FAX:46-8-626-6711

FUJITSU LIMITED

International Operations

Marunouchi 1-6-1, Chiyoda-ku,Tokyo 100

JAPAN

TEL:(81-3)3216-3211

FAX:(81-3)3213-7174

TLX:J2283

Cable:”FUJITSU LIMITED TOKYO”

Home page:http://www.fujitsu.co.jp/

ii

Page 5

IMPORTANT NOTE TO USERS

READ CAREFULLY ALL OF THIS MANUAL BEFORE USING THIS PRODUCT.

IF NOT USED CORRECTLY, UNEXPECTED DAMAGES MAY BE CAUSED TO

THE USERS OR THE BYSTANDERS.

While all efforts have been made to ensure the accuracy of all information in this

manual, FUJITSU assumes no liability to any party for any damage caused by

errors or omissions or by statements of any kind in this manual, its updates or

supplements, whether such errors are omissions or statements resulting from

negligence, accidents, or any other cause. FUJITSU further assumes no liability

arising from the application or use of any product or system described herein; nor

any liability for incidental or consequential damages arising from the use of this

manual. FUJITSU disclaims all warranties regarding the information contained

herein, whether expressed, implied, or statutory.

FUJITSU reserves the right to make changes to any products herein, to improve

reliability, function, or design, without further notice and without obligation.

iii

Page 6

Preface

This manual explains how to use the M3097DE/DG image scanner.

This manual contains COMPONENTS, INSTALLATION AND CONNEC-

TION, OPERATING INSTRUCTION,DOCUMENT SPECIFICATION,

SPECFICATIONS and SETUP MODE.

Refer to “Cleaning and Maintenance” for the information about the routine

operation of the M3097DE/DG.

Reference Guide contains OPERATING INSTRUCTION, CLEANING,

REPLACEMENT OF PARTS, ADJUSTMENT and TROUBLESHOOTING.

The M3097DE/DG is very fast and highly functional image scanner developed for volume filing, using charge-coupled device (CCD) image sensors.

This scanner features duplex scanning and high quality image, processing

with an automatic document feeder (ADF).

iv

Page 7

Conventions

Special information, such as warnings, cautions are indicated as follows:

WARNING

WARNING indicates that personal injury may result if you do not follow a

procedure correctly.

CAUTION

CAUTION indicates that damage to the scanner may result if you do not follow a

procedure correctly.

The following symbols are used in this manual.

Used for general WARNING and CAUTION.

Be careful not to pinch your fingers or hands.

v

Page 8

vi

Page 9

CONTENTS

❑ CHAPTER 1 COMPONENTS

❑ CHAPTER 2 INSTALLATION AND CONNECTIONS

❑ CHAPTER 3 OPERATING INSTRUCTION

Checking the Components ........................................................1-1

Units and Assemblies ................................................................1-2

Operator Panel ..........................................................................1-5

Precautions................................................................................2-1

Inspection ..................................................................................2-2

Removing the Carrier Fixing Bracket.........................................2-4

Cable Connection ......................................................................2-5

Mounting the Stacker.................................................................2-7

SCSI-ID setting (M3097DG) ......................................................2-8

Turning the Power On ...............................................................3-1

Reading Mode Setting (M3097DE)............................................3-2

Manual Feed Mode Setting .......................................................3-8

❑ CHAPTER 4 ADF DOCUMENT SPECIFICATION

Document Size ..........................................................................4-1

Document Quality ......................................................................4-2

❑ CHAPTER 5 SPECIFICATIONS

Installation Specifications ..........................................................5-1

Dimensions................................................................................5-2

Consumables.............................................................................5-3

Option ........................................................................................5-4

❑ CHAPTER 6 SETUP MODE

Activating the Setup Mode.........................................................6-1

Contents of the Setup Mode......................................................6-2

❑ GLOSSARY OF TEAMS................................................................................GL-1

❑ INDEX ............................................................................................................. IN-1

vii

vii

Page 10

viii

Page 11

COMPONENTS

INSTALLATION AND CONNECTIONS

OPERATING INSTRUCTION

DOCUMENT SPECIFICATION

SPECIFICATIONS

SETUP MODE

COMPONENTS

INSTALLATION AND

CONNECTIONS

OPERATING

INSTRUCTION

DOCUMENT

SPECIFICATION

SPECIFICATIONS

SETUP MODE

GLOSSARY OF TERMS

INDEX

GLOSSARY

OF TERMS

INDEX

ix

ix

Page 12

CHAPTER

1

COMPONENTS

After unpacking the scanner,confirm that all the components have

been received. This chapter describes the components of the

scanner, part names, and operator panel arrangement and their

function.

Checking the Components

Units and Assemblies

Operator Panel

Page 13

1

Cheking the Components

These high precision components must be handled with care.

Confirm that all the components shown in the following figure have been received.

If any component is missing, please contact your sales agent.

Terminator

(for M3097DG)

Operator's Guide

(this manual)

and Cleaning and Maintenance

Scanner

Power cable

for North America

Power cable

for Europe

or

Pad ASY

1-1

Page 14

Units and Assemblies

This section shows the exterior view and assemblies of the scanner. This section also provides

names of each part and describes their functions.

Units

qDocument cover

rAutomatic document

feeder(ADF)

tStacker

yPower switch

iADF paper chute

!0Power inlet

eDocument

holding pad

wDocument bed

uOperator panel

oADF lever

!2Third party slot

!1Interface connectors

!3Memory cover

1-2

M3097DE

Page 15

oADF lever

iADF paper chute

yPower switch

!1Interface connectors

!0Power inlet

No. Function

q Document cover: Closed over and holds a document to be read.

w Document bed: A document to be read is placed on the bed also called

e Document holding pad: Presses a document to the document bed.

r Automatic document feeder (ADF): Automatically feeds documents to the reading position.

t Stacker: Stacks the read documents.

y Power switch: Turns the power on or off.

u Operator panel: The indication panel indicates the status of the scanner.

i ADF paper chute: Holds the documents to be fed by the automatic

o ADF lever: Opens or closes the automatic document feeder to

!0 Power inlet: To be connected to an AC power outlet with the power

!1 Interface connectors: To be connected to the host system with interface cables.

!2 Third party slot: Reserved. (M3097DE)

!3 Memory cover: Reserved.

!3Memory cover

M3097DG

Flatbed (FB).

document feeder.

remove documents jammed in the feeder.

cable.

1-3

Page 16

Assemblies

Stacker

Thumb screw

Guide A ASY

Bearing

Pick roller 2

Pad ASY

1-4

Bearing

Pick roller 1

Page 17

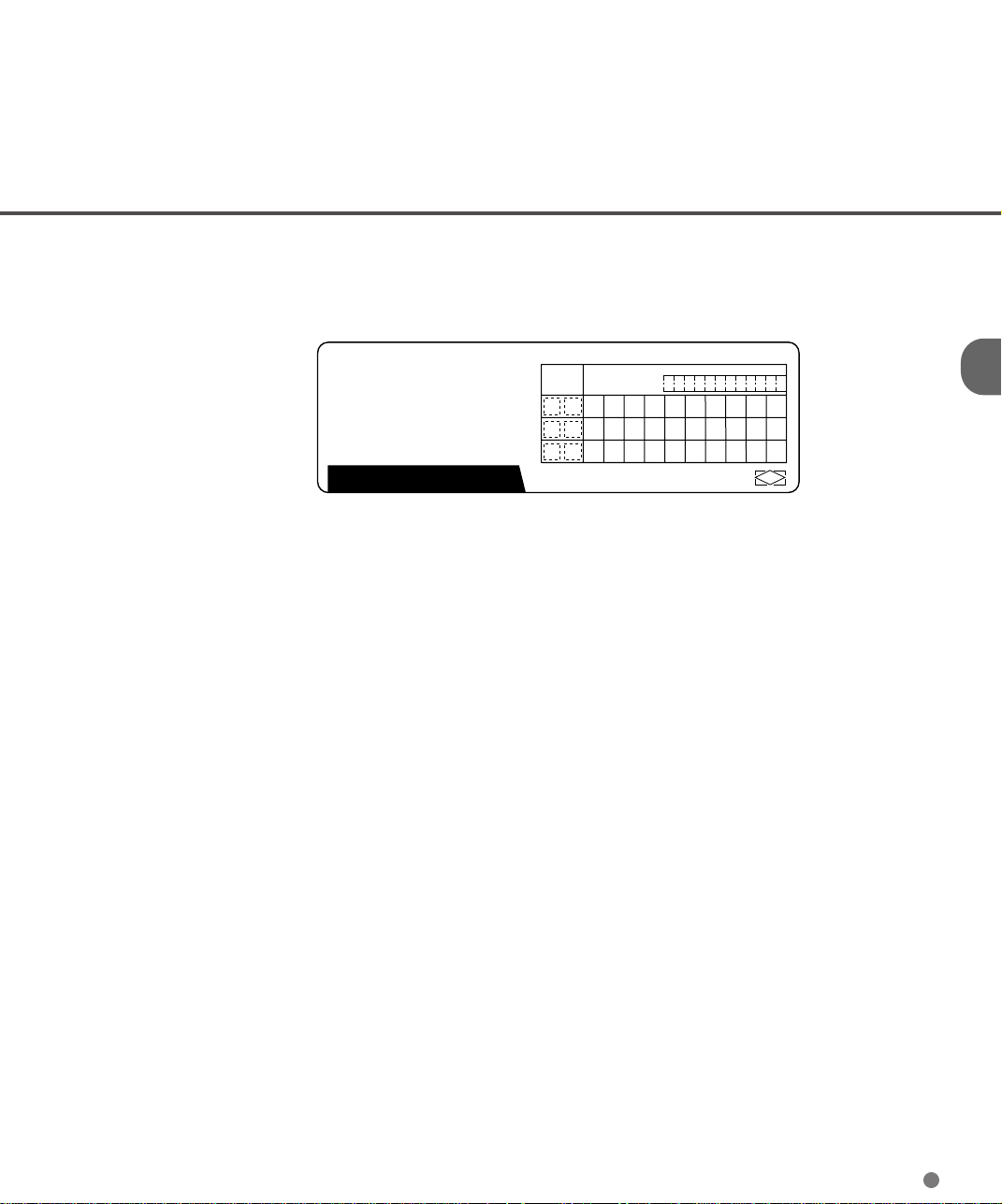

Operator Panel

The operator panel is located at the upper right hand side of the scanner. The panel consists of an

LCD (24 character x 2 line), LEDs and buttons.

Arrangement

Operator panel

( )

Previous

( )

Next

(STOP)

Exit

(START)

ENTER

READ

CHECK

1-5

Page 18

Button/LED Function

Name of the button Function

and LED

Button Next LCD displays the next screen.

Previous LCD displays the Previous screen.

← Moves the cursor to the left

→ Moves the cursor to the right

Exit • When “CHECK” LED lights, pressing this button releases error status (turn

off “CHECK” and returns to “Scanner Readry” screen).

• When you are setting on the operator panel, pressing this button returns to

“Scanner Ready” screen immediately.

ENTER The parameter selected by cursor becomes effective.

(START) When Manual start mode is set or “READ” lamp lights, this button is effective

and starts the reading.

(STOP) This button is effective during reading operation and stops the reading.

LED Indicates that the scanner is ON.

READ Indicates that the scanner is reading or ready to read.

CHECK • If it lights, it means that some alarm occurred. Pressing “Exit” button turns

off “CHECK” lamp.

• If it blinks at one second cycle, it means that jam or double feed is

detected. Removing the jammed paper turns off “CHECK” lamp. At double

feed, pressing “Exit” button turns off “CHECK” lamp.

• If it blinks at four seconds cycle, it means that ADF cleaning is necessary.

1-6

Page 19

Counter Display

The scanner is provided with the counter display.

Paper counter

Abrasion counter

Counter Function

Paper counter Paper counter counts the scanned sheet from the start of reading to Paper

Empty or an error detection. So this counter is automatically reset at the start

of reading.

Abrasion counter Abrasion counter counts the accumulated number of the scanned sheet. This

counter increments at every 10 sheets. This counter is useful to check the

cleaning cycle or parts replacement cycle. How to reset is described in Chapter 6.

1-7

Page 20

Operation status

Operation status is indicated by the following message:

<Power-on>

<Reading>

<Waiting for Start> Scanner displays followig screen when waiting Start button pressed.

(Only M3097DE)

<Cleanig request> When the Pick roller cleaning is necessary, the scanner displays as

follows on the upper line.

When the ADF glass cleaning is necessary, the scanner displays as

follows on the LCD.

1-8

Clean the Pick roller or ADF glass in accordance with the manual,

“Cleaning and Maintenance”.

Page 21

Temporary error

<Hopper empty>

<Jam>

<ADF cover open>

<Double feed error>

This message is displayed if there is no more paper on the ADF paper

chute during a read operation in ADF mode. Fill the ADF paper chute

with paper. To enable the read operation, press the stop button.

This message is displayed if a ducument is jammed in the ADF. See

“Cleaning and Maintenance” for removing jammed ducuments.

This message is displayed if the ADF is not closed completely. Close

the ADF completely, and enable the read operation.

This message is displayed when the ADF detects the Double feed

error. Check the document and re-scan the ducument.

1-9

Page 22

Alarm

One of the following message is displayed if an error occurs in the scanner. If one of the following

error message is displayed, turn the power off and then on again. If the same message is displayed,

contact your service representative.

<Optical alarm front>

<Optical alarm back>

<FB mechanism alarm>

<Motor fuse alarm>

<Lamp fuse alarm>

<Image transfer alarm>

(M3097DG)

<Memory alarm>

<EEPROM alarm>

1-10

Page 23

CHAPTER

2

INSTALLATION AND CONNECTIONS

The chapter describes how to install and connect the scanner.

Precautions

Inspection

Removing the Carrier Fixing Bracket

Cable Connection

Mounting the Stacker

SCSI-ID Setting (M3097DG)

Page 24

Precautions

This section describes precautions when installing the scanner.

Do not install the scanner in the following places and environments.

• Place the scanner away from electrical noise sources, strong magnetic fields and air flow. If the scanner

is used near an air conditioner, copying machine, or TV set, the scanner may operate incorrectly.

• Keep the scanner out of the sun and away from heaters. These environments may shorten the scanner

life or cause hardware failures.

• Do not install the scanner in a place where vibrations may occur. This environment may cause hardware

failures or may cause the scanner to operate incorrectly.

• Do not install the scanner in a humid, dusty, or damp places. These environments may shorten the

scanner life or cause hardware failures. Do not place the scanner where liquid spills may occur.

• Be aware of the static electricity. Be sure that the flooring and the desk are made of materials that do

not generate the static electricity.

See Chapter 5 SPECIFICATIONS for the informantion such as the size of the installation space.

2-1

Page 25

Inspection

This section describes how to check the labels.

Label A (An example)

Label A

Label B

2-2

This device complies with Part 15 of the FCC Rules. Operation is subject to the following two conditions:

(1) This device may not cause harmful interferenca and (2) This device must accept any Interference

received, including interference that may cause undesired operations:

This Class A digital apparatus meets all taquiraents of the Canadian Interferance Causing Equipment Regulations.

Cat appareil auncrique de la classe A respecte loutes les exigences du Reglesent sur le nateriel

bronillesr du Canada.

LR 65408

NRTL/C

N

1 2 4

XXXXXXXX

XXXXX

XXXXXX

VCCI-A

FCC-A

CSA-EMI

ANS

100 - 240 V, 1 - 0.6A. 50/60 Hz, 1φ

Page 26

Label B (An example)

IMAGE SCANNER

MODEL

M3097DE

PART NO.

CAO

**** - ****

SER. NO.

*****

DATE

1997-

2 .

** * *

Kgf

FUJITSU LIMITED

MODEL NAME

Rev.

Label

0123456789

0123456789

0123456789

ANS

2-3

Page 27

Removing the Carrier Fixing Bracket

(

)

To keep the scanner from being damaged during shipping, the carrier unit is fixed with a bracket. After

placing the carrier unit at the installation place, remove this bracket as explained below.

q Place the image scanner on the edge of the desk top so that the left side (where ADF is placed)

of the scanner extends from the desk top. Do not set the image scanner upside down or on its side.

CAUTION

Do not extend the scanner more than 20cm (8 in.) from the desk.

Good

less than 20cm

8 in.

Bad Bad

w Remove the carrier fixing bracket from position A. Then install the carrier fixing bracket at position

B.

Front side

Enlarged

Carier fixing bracket

(Position for operation)

Bottom view

Carier bracket (Position for

storage, position for shipment)

Enlarged section A enlarged

ADF side

B

2-4

A

Carier bracket

(Position for shipment)

Page 28

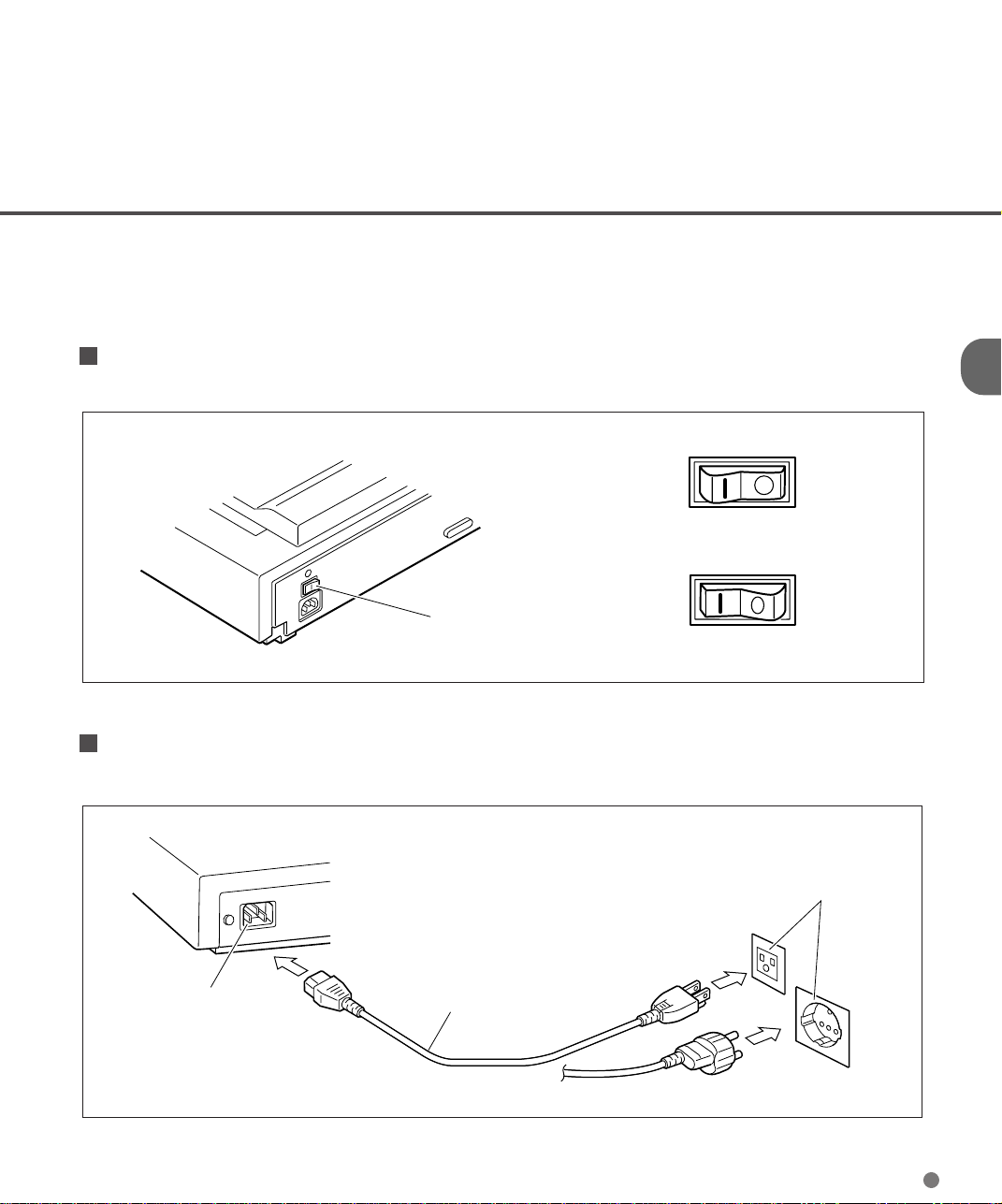

Cable Connection

This section describes how to connect the cables.

Connect the cables as follows:

Turning the power switch off

Press “O” side of the power switch to turn the power off.

Power switch

Power OFF

Power ON

Connecting the power cable

Connect the power cable to the power inlet of the device and a power outlet.

for North America

Power inlet

Power cable

Power outlet

for Europe

2-5

Page 29

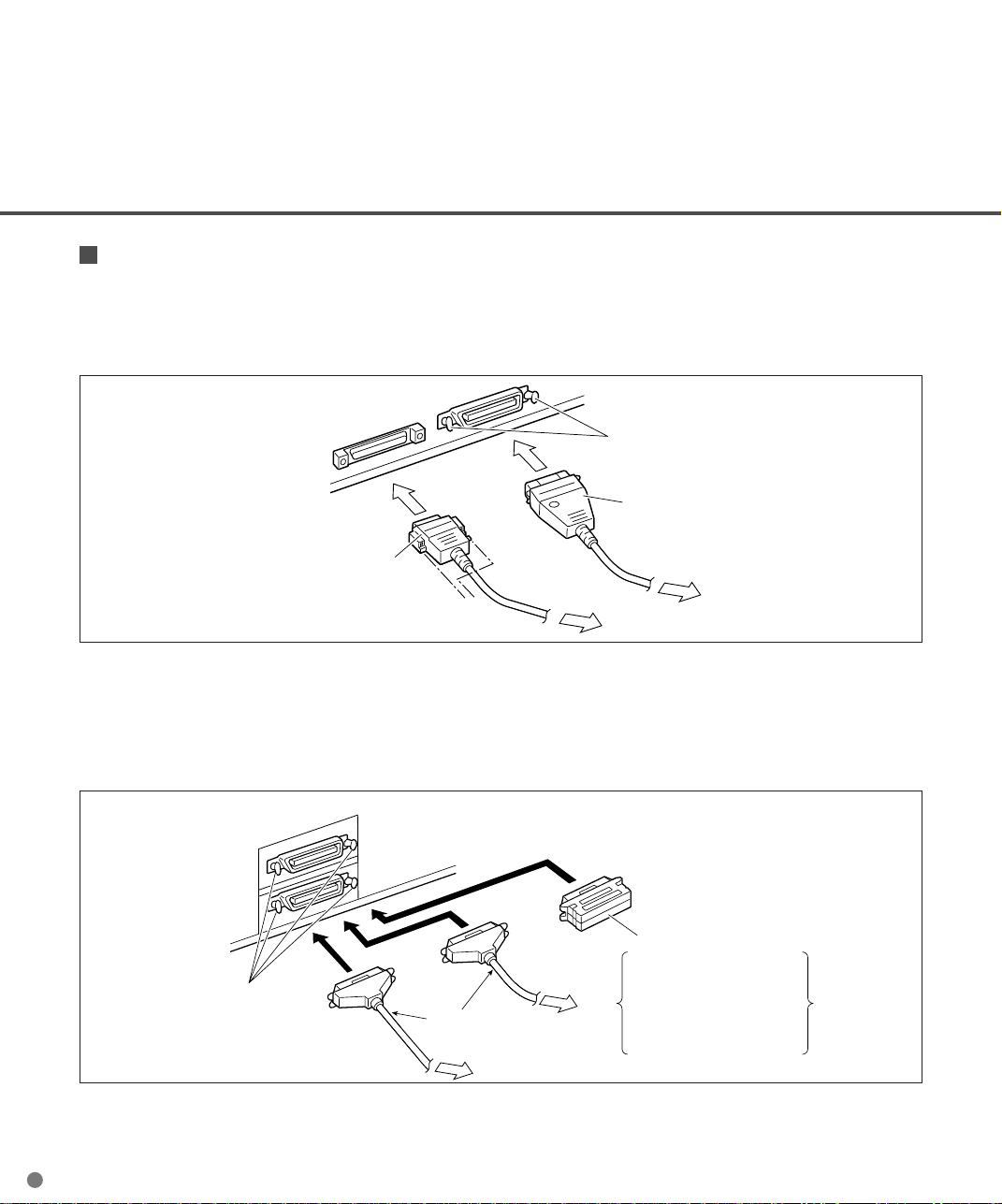

Connecting the interface cable

(M3097DE)

Connect the video interface and RS-232C interface cables and secure them with hooks and screws.

Connect the other ends to the host machine.

Back of the image scanner

Catches

Interface cable for video

Interface cable for RS232C

Screws

To the host system

(M3097DG)

Connect the SCSI interface cables and secure them with hooks and connect the other ends to the host

machine. When the scanner is at the terminal side, connect the terminator to the connector to which an

interface cable is not connected.

Back of the image scanner

Terminator

If the image scanner is at

Catches

Interface cables

To

the host

system

the terminal side, connect

the terminator to the

connector to which an

interface cable is not

connected.

2-6

Page 30

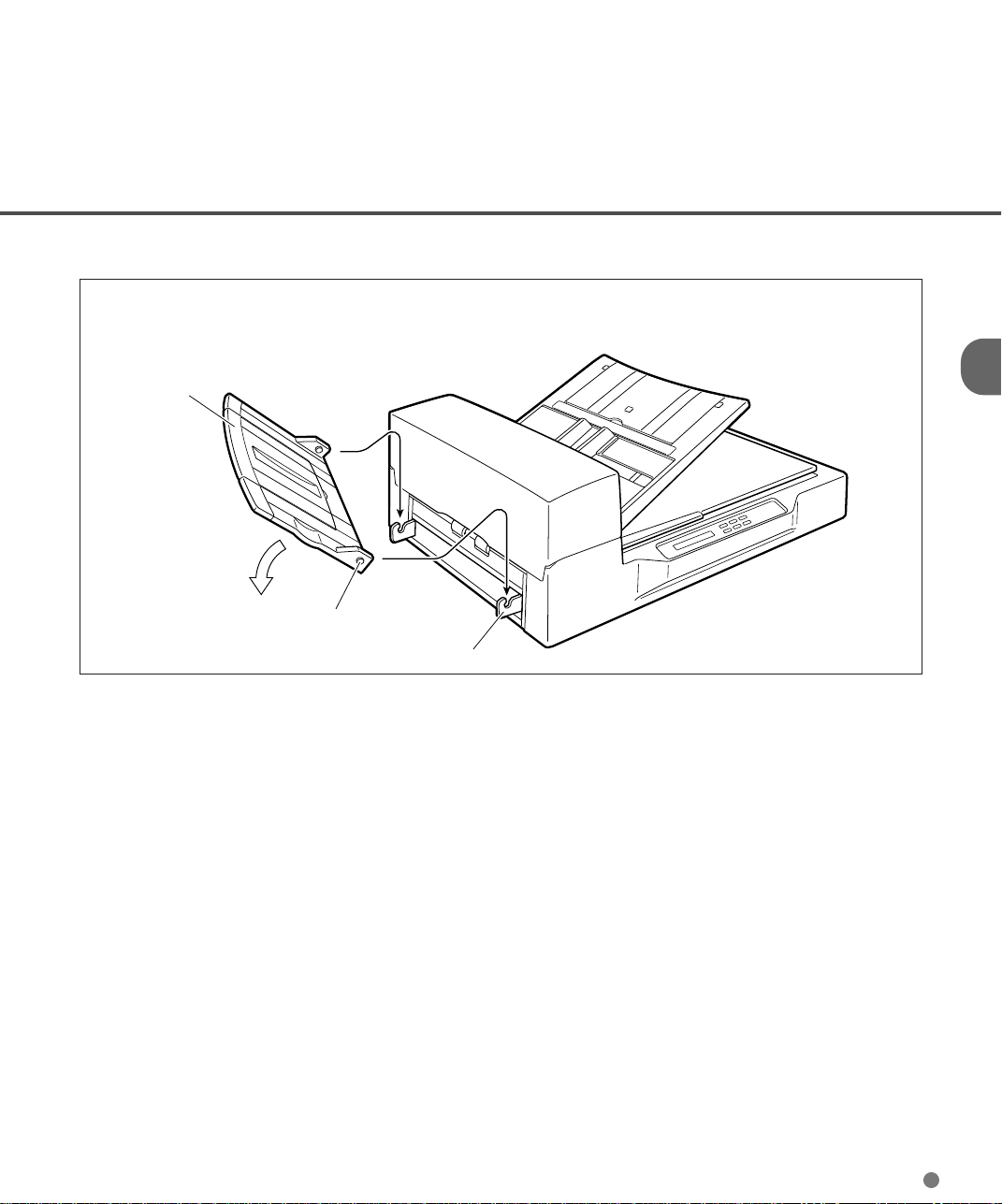

Mounting the Stacker

Mount the stacker using the following procedure.

q Mount the stacker.

Hook the pins on the stacker to the claws on the image scanner.

Stacker

Pin (inside)

Claw

2-7

Page 31

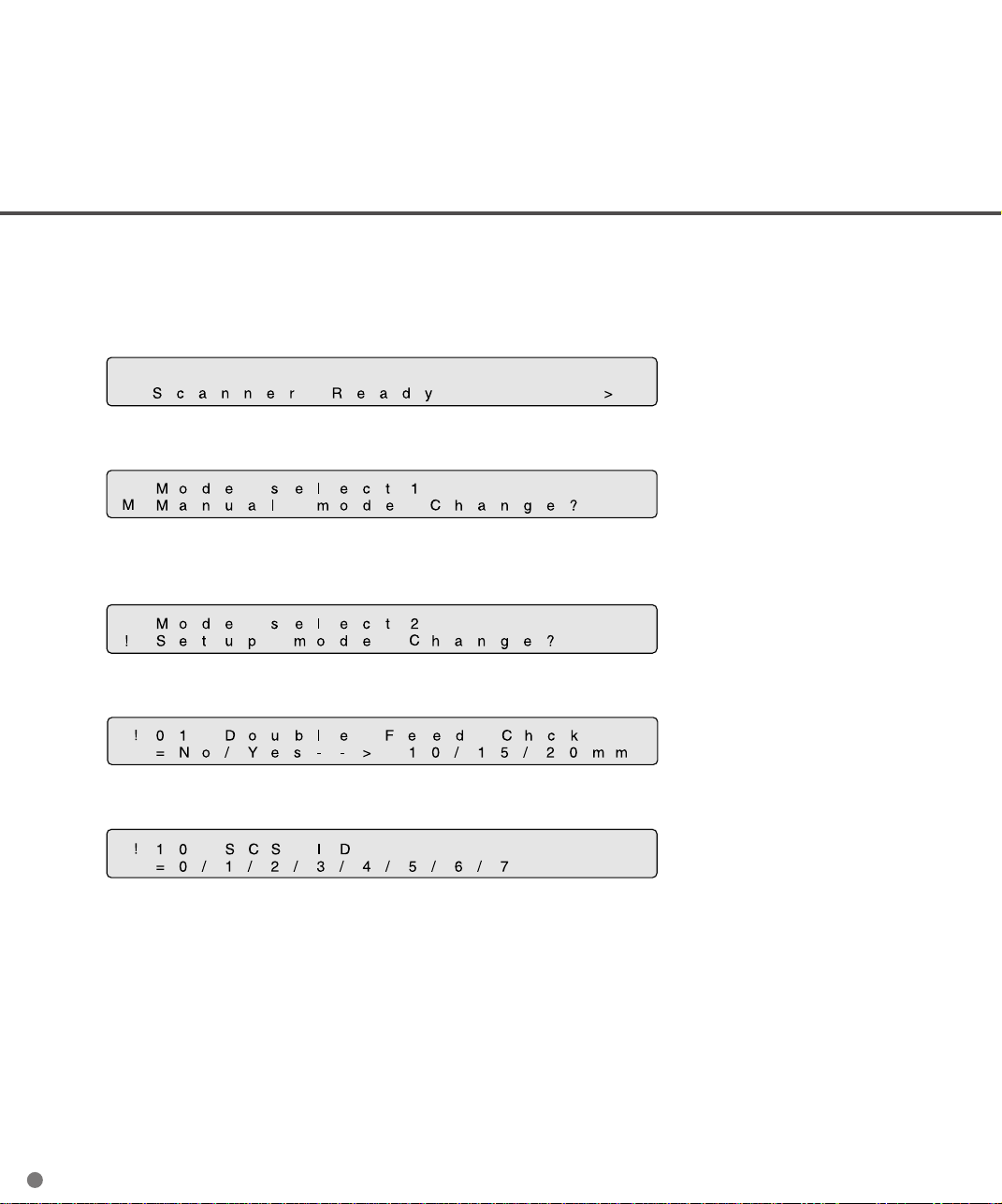

SCSI-ID setting (M3097DG)

The default of SCSI-ID is 5. SCSI-ID is set by Setup mode of the operator panel. The procedure to set SCSI

ID is;

1 Turn the power ON by pressing “I” side of the power switch. The scanner displays “Scanner Ready”

on the lower line of LCD.

2 Then press “Next” button. The scanner displays “Mode select 1”.

3 Then press “Next” button. The scanner displays “Mode select 2” meaning that setup mode is ready.

Then press “ENTER” button.

4 Then press “ENTER” button. The scanner displays as follows.

5 Press “Previous” once, then the scanner displays “SCSI ID” on the upper line of the LCD.

6 Select SCSI ID by pressing “→” or “←” button, and press “ENTER”. (SCSI ID is set.)

7 Press “Exit” to return to “Scanner Ready” screen.

2-8

Page 32

CHAPTER

3

OPERATING INSTRUCTION

This chapter describes how to turn the power on, and also describes button specification and reading mode setting.

Refer to Cleaning and Maintenance about information on loading

document and maintenance.

Turning the Power On

Reading Mode Setting (M3097DE)

Manual Feed Mode Setting

Page 33

3

Turning the Power On

This section describes how to turn the power on.

Press “I” side of the power switch. The power goes on and the green Power lamp at the operator

panel lights.

Power OFF

Power switch

Power ON

3-1

Page 34

Reading Mode Setting (M3097DE)

This section describes the button specifications and setup details for each of the simplex (front-side),

duplex (front-side) and duplex (back-side) reading modes.

When reading mode is set by the command from the host computer, the following button operation is

not required.

At any time you press , scanner returns to screen M1

1 Turn the power ON and verifty that

“Scanner Ready” is displayed on LCD.

2 Press then the scanner displays

Screen M2.

3 Press then the scanner displays

Screen 1.

4 Select ADF or FB by pressing or

then press . The scanner displays

Screen 2.

5 Select “Simplex” or “Duplex” by pressing

or . Then press Enter. The scan-

ner displays Screen 3.

<Screen M1>

<Screen M2>

<Screen 1>

<Screen 2>

6 Select “Portrait” or “Landscape” by

pressing or . Then press .

The scanner displays Screen 4.

3-2

<Screen 3>

Page 35

7 Select Size by pressing or . Then

press . The scanner displays

Screen 5.

<Screen 4>

8 Select Resolution by pressing or .

As the cursor moves to left 100/150 may

appear. Then press . The scanner

displays Screen 6.

9 Select Front Density by pressing or

. As the cursor moves to right,

/ may appear. Then press Enter.

Scanner displays Screen 7.

Density display

Without IPC With IPC-2D Descreption

option or IPC-3D option

Very dark

Dark

AT1 * Dynamic Threshold (DTC mode)

AT2 * Simplified Dynamic Threshold (IPC mode)

Normal

Light

Very light

* This parameter appears only when IPC-2D or IPC-3D is installed.

<Screen 5>

<Screen 6>

3-3

Page 36

10 Select Back Density (when “Duplex” was

Selected) by pressing or . As the

cursor moves to right, /

may appear. Then press . Scanner

displays Screen 8.

<Screen 7>

11 Select Front Halftone by pressing or

.

Parameter Description

No Halftone is OFF. Therefore binary reading is specified.

HT1 Halftone with dither is specified.

HT2 Halftone with error diffusion is specified.

LP1 * Automatic separation with dither is specified.

LP2 * Automatic separation with error diffusion is specified.

* This parameter appears only when the IPC-2D or IPC-3D is installed.

Press to admit. Scanner displays

Screen 9.

12 Select Back Halftone (when “Duplex” was

specified) by pressing or . The

parameters are same as 11. Press

to admit. Then scanner displays Screen

10.

<Screen 8>

<Screen 9>

13 Select Front Document Type by pressing

or .

3-4

<Screen 10>

Page 37

Parameter Description

L.(Line) White level following is ON. Top 3mm part of the document must be left blank

(grounding color is dropout color). It is useful to read line art or text.

P.(Photo) White level following is OFF.

It is useful to read photograph.

Press to admit. The scanner displays

Screen 11.

14 Select Back Document Type (when

“Duplex” was specified) by pressing

or . The parameters are same as (13).

Press to admit. Then scanner

displays Screen 12.

15 Confirm what you have specified.

If some parameter needs to change,

press or to select screen

and re-select the parameter by pressing

or and finally press .

If all parameter is acceptable, press

to return to “Scanner Ready” screen.

<Screen 12>

<Screen 12 (Example)>

Density

Halftone

Line Art or Photo

Resolution

Portrait or Landscape

Paper size

Front side (F) or Back side (B)

Simplex (S) or Duplex (D)

3-5

Page 38

Manual Feed Mode Setting

In this mode, the scanner waits for some predetermined time without issuing “Paper Empty” after all

documents are read. This predetermined time (time-out limit) is specified by Setup mode. Therefore

you can set next documents on ADF chute without interrupting reading operation. The procedures for

setting manual feed mode are as follows.

1 Turn the power ON and verify that

“Scanner Ready” is displayed on LCD.

2 Press then the scanner displays

Screen M2.

3 Press then the scanner displays

Screen M3.

4 Press then the scanner displays

Screen M4.

5 Select “Yes” by pressing . Then press

.

<Screen M1>

<Screen M2>

<Screen M3>

<Screen M4>

6 Press to return to “Scanner Ready”

screen. Note that “Manual Feed” is

shown on LCD. This means that the

scanner is in Manual Feed mode.

3-6

<Screen M1>

Page 39

CHAPTER

4

ADF DOCUMENT SPECIFICATION

This chapter describes the document size and document guality

of the ADF.

Document Size

Document Quality

Page 40

Document Size

The following figure shows document sizes that the scanner can read.

Scanner

M3097DE/DG

Maximum

A

297 (11.7 in)

B

432 (17 in)

Minimum

A

148 (5.8 in)

105 (4.1 in)

B

105 (4.1 in)

148 (5.8 in)

(Unit : mm)

4-1

Page 41

Document Quality

This section describes document types and weights available for the scanner, and precautions.

Document type

The recommended paper type for document is as follows:

• Woodfree paper

• Plain paper (for example, the paper specified for XEROX 4024)

When using all other type paper, check that it is successfully fed by ADF before performing a reading

operation.

Paper weight

The paper weight is as follows :

• 52 to 104 g/m2 (3.9 to 27.8 lb)

Precautions

The following documents may be hard to read by ADF. Preliminary document feed test may be necessary

to avoid the unexpected errors. If the document slips in ADF (JAM error) or double feed occurs frequently,

read them by flatbed.

• Paper with clips or staple

• Paper with wet ink

• Paper of which thickness is not constantly equal. (like envelope)

• Paper with large rumples or curl. (See NOTE on the next page.)

• Paper with folds or tears

• Tracing paper

• Coating paper

• Carbon paper

• Paper smaller than 148 mm x 105 mm size, or larger than A3 or Double Letter

• Other than paper ; clothes, metal foil, or OHP film

• Photographic paper

• Paper with notches on its side

• Other than rectangle paper

• Paper that is very thin

4-2

Page 42

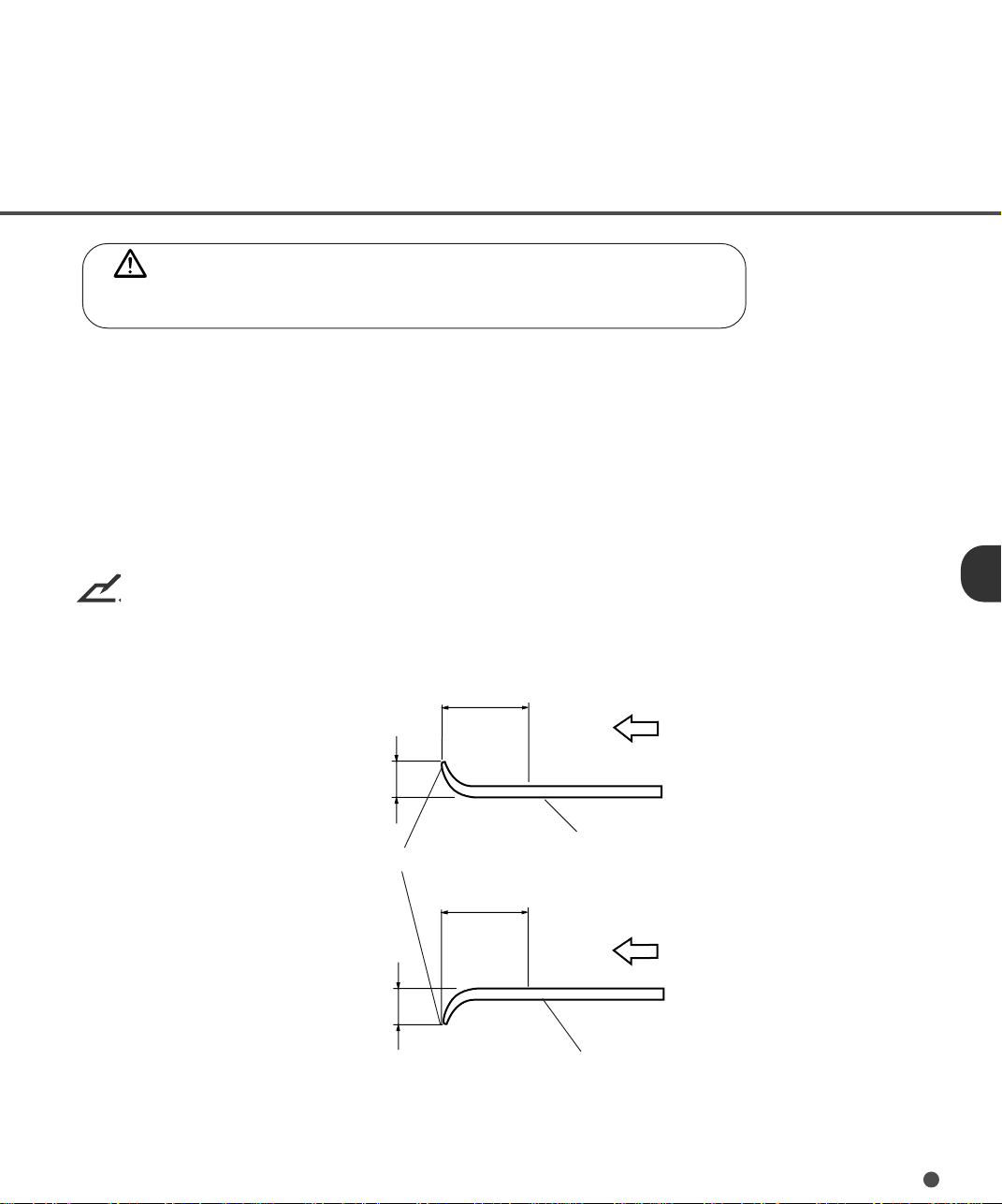

CAUTION

Do not feed an important original document to prevent damage to it on the

off chance.

When scanning a translucent document, set the density to light mode.

Carbon-less papers have the chemical composition which damages the pad and pick roller. Therefore,

note the following remarks

Cleaning: If the miss pick occurs frequently, clean the pad and pick roller in accordance with

the “Cleaning and Maintenance”.

Replacement of parts: The life of the pad and the pick roller may be shorter than the case that PPC

document is fed.

NOTE

• Paper should be straightened to fit the condition below.

More than

30 mm

Less than

3 mm

Top of the paper

Less than

5 mm

Feed direction

Read surface

More than

30 mm

Feed direction

Read surface

4-3

Page 43

4-4

Page 44

CHAPTER

5

SPECIFICATIONS

This chapter describes the installation specifications, dimensions, consumables, option.

Installation Specifications

Dimensions

Consumables

Option

Page 45

Installation Specifications

The following table lists the installation specifications of the scanner.

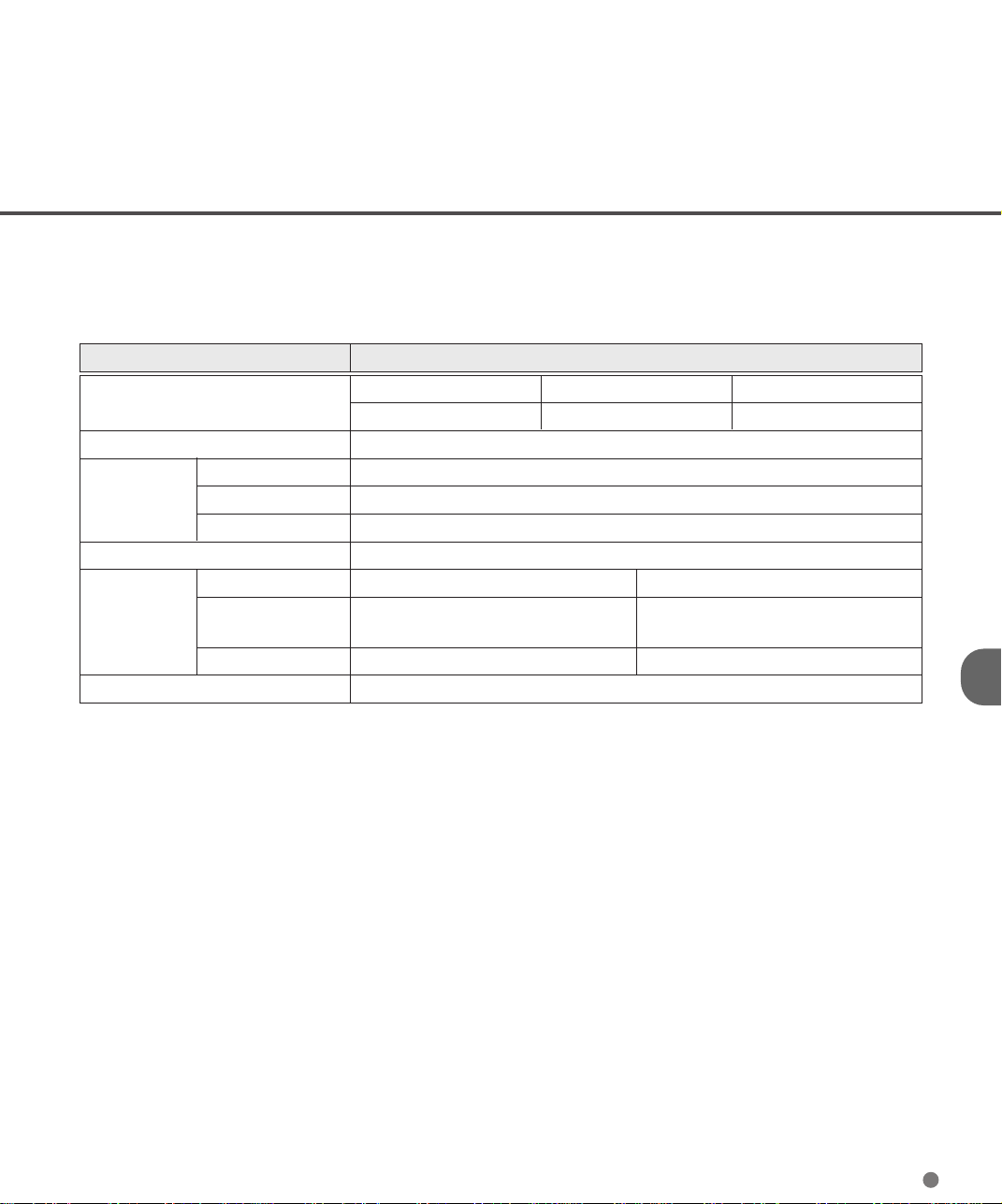

Item Specification

Dimensions (mm)

Weight (kg) 20 (44.2 lb.)

Voltage 100 to 120 VAC, 220 to 240 VAC ±10 %

Input power Phases Single-phase

Frequency 50/60 + 2% -4% Hz

Power consumption 120 VA or less

Device status Operating Not operating

Ambient Temperature 5 to 35°C -20 to 60°C

condition (41 to 95°F) (-4 to 140°F)

Humidity 20 to 80 % 8 to 95 %

Heat capacity 78 kcal/H (312 BTU/H)

Width Depth Height

696 (27.4 in) 497 (19.6 in) 234 (9.2 in)

5-1

Page 46

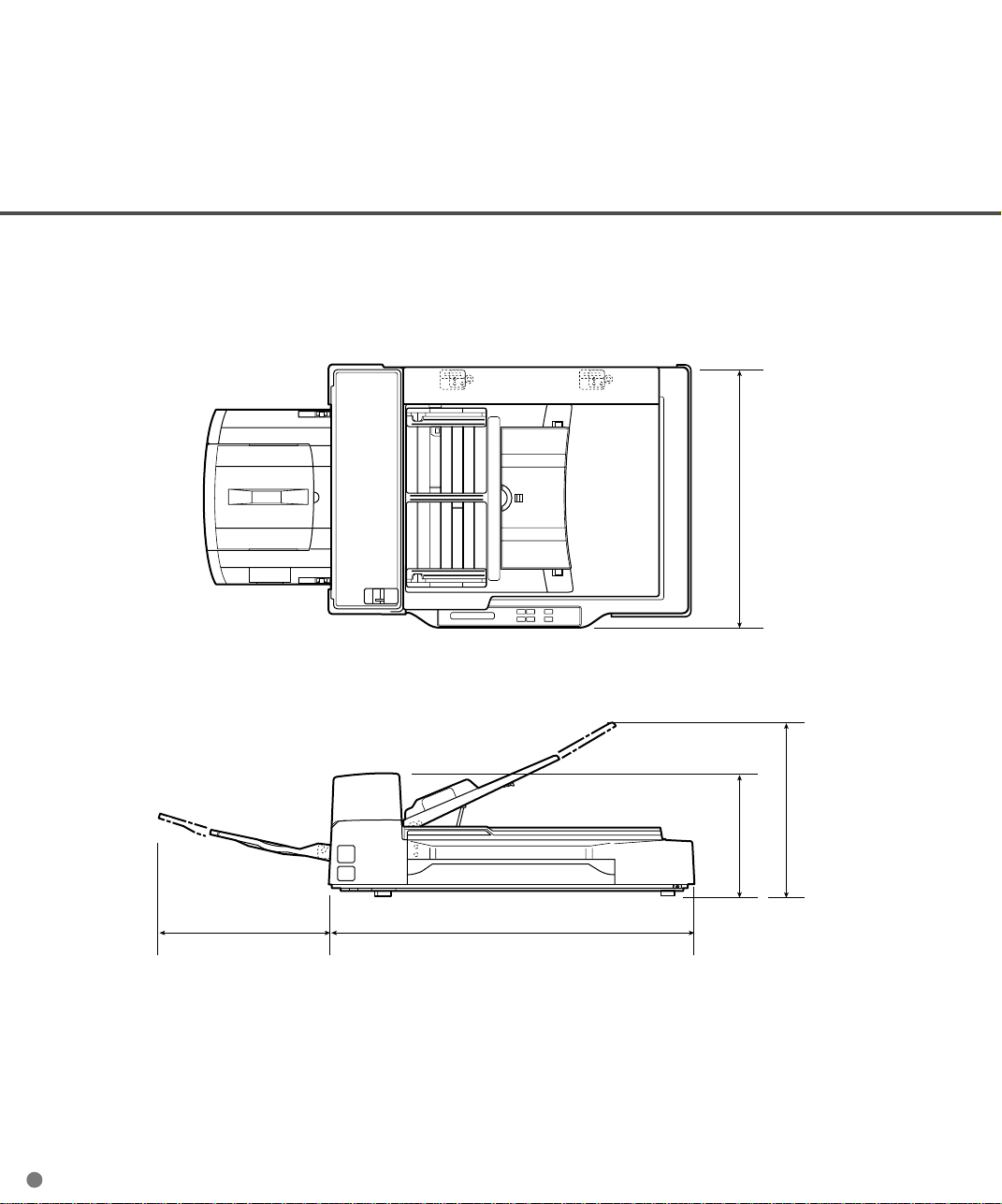

Dimensions

497

5-2

335

234

285 696

(unit: mm)

Page 47

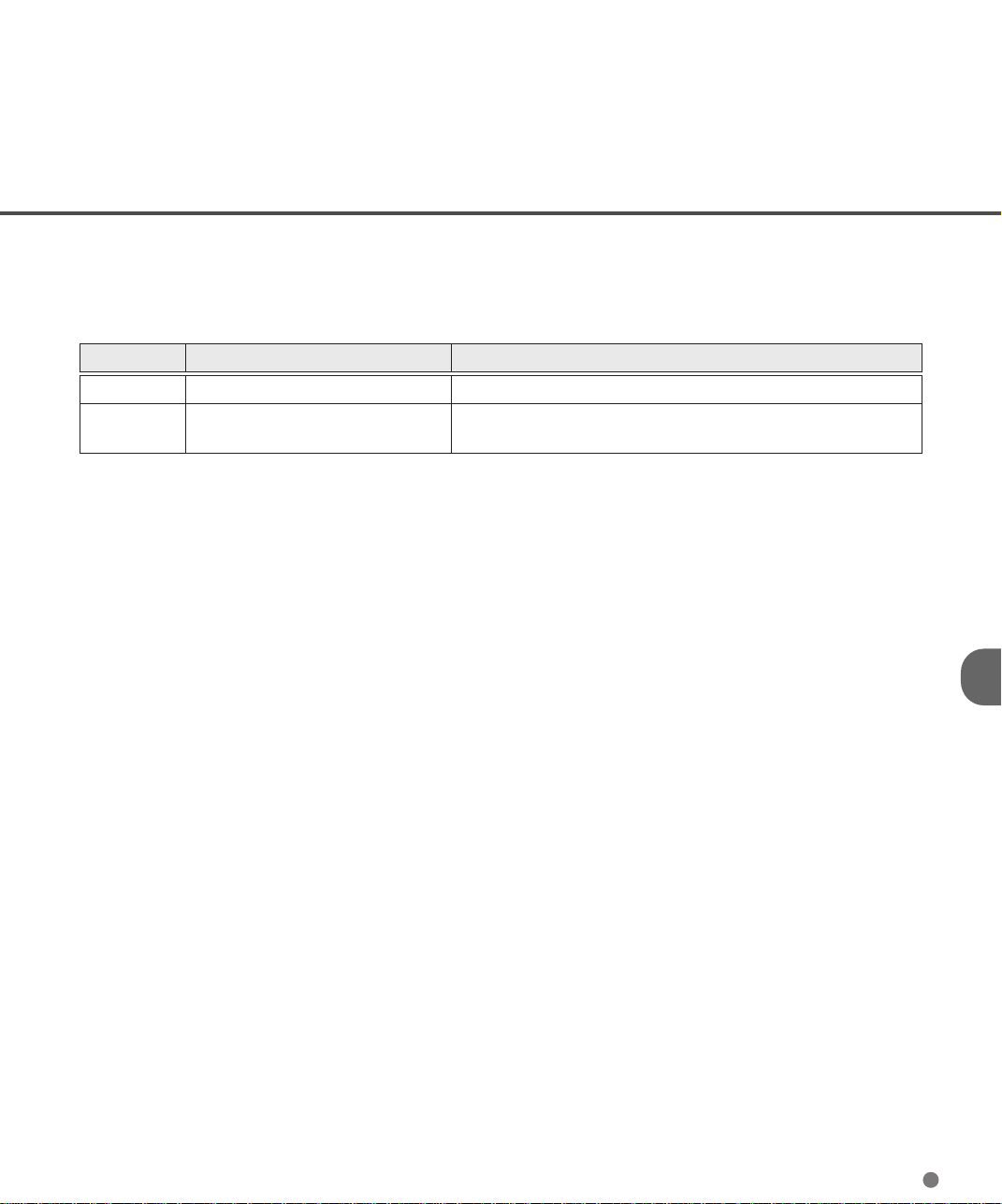

Consumables

The following table lists consumables used for the scanner. Be sure to keep some consumables in stock.

Customer is responsible to change these items periodically. The abrasion counter can be used to check

the number of scanned documents.

Name Specification Remark

Pad ASY PA03951-0021 Up to 100,000 sheets or one year.

Pick roller PA03951-0025 Up to 200,000 sheets or one year.

(Two roller are included.)

5-3

Page 48

Option

The following table lists options of the scanner.

Name Specification Remark

Extended Memory TBD 16MB, EDO SIMM, 72pin, 60ns

IPC-2D* CA01952-0192 Image Processing Circuit

IPC-3D* CA02919-0511 Image Processing Circuit

* One of these option can be installed at a time

Contact your Fujitsu sales agent for more information.

without parity

One per unit

One per unit

One per unit

5-4

Page 49

CHAPTER

6

SETUP MODE

This chapter describes the setup mode of the scanner.

Activating the Setup Mode

Contents of the Setup Mode

Page 50

Activating the Setup Mode

This section describes how to activate the setup mode.

1 Turn the power ON. Then the scanner

displays “Scanner Ready” on LCD.

2 If the scanner is M3097DG, go to the

procedure 3. Press then the scanner (M3097DE) displays Screen M2.

3 Press then the scanner displays

Screen M3.

4 Press then the scanner displays

Screen M4.

5 Press . Now the scanner is at

Screen 41 (page 6-3) in Setup mode.

<Screen M1>

<Screen M2>

<Screen M3>

<Screen M4>

NOTE

Any time you press , you can return to “Scanner Ready” screen.

6-1

Page 51

Contents of the Setup Mode

This section describes the contents of the setup mode.

No Item Description Selectable Default

parameters

1 Double feed check Double feed is detected by checking the

document length one by one.**

2 IPC pre-setting Scanner automatically sets the recom-

mended reading parameters. 5 sets of

recommended parameters are available.

3 Rest of abrasion Abrasion counter can be reset.

counter

4 Pick start time The time from the document Insertion to

setting the start of picking is specified. User can

select most comfortable Pick start time for

the job.

5 Time-out limit setting The time that the scanner waits for next

ducument insertion after last document

scanned can be specified.

6 ADF front offset Horizontal and vertical offset of the front

setting* side image by ADF is specified.

7 ADF back offset Horizontal and vertical offset of the back

setting* side image by ADF is specified.

8 FB offset setting* Horizontal and vertical offset of the FB

image is specified.

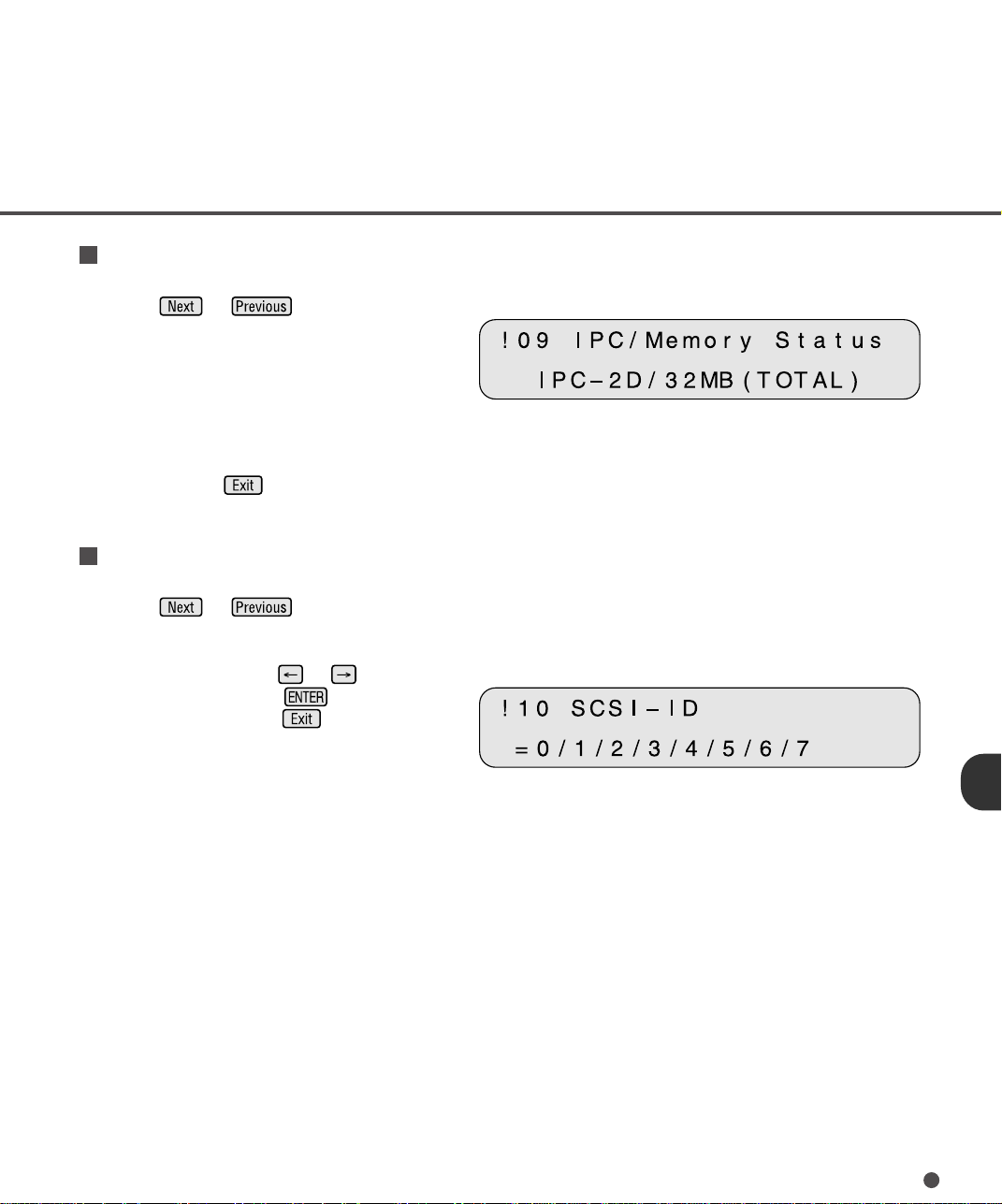

9 IPC/Memory status The type of IPC option (IPC-2D or IPC-3D)

display and total memory installed are displayed.

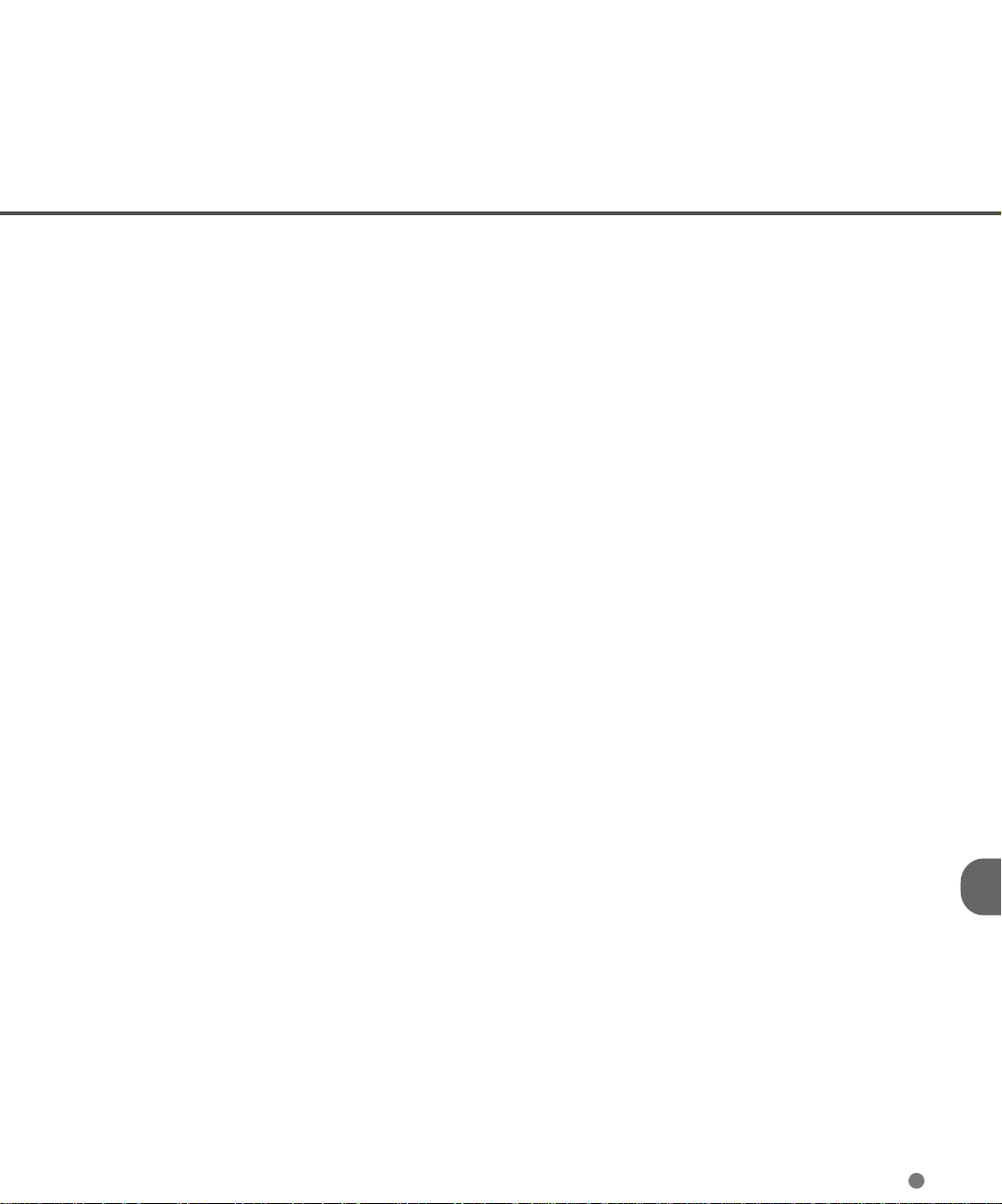

10 SCSI ID setting SCSI ID is selectable.

Tolerance: No

No/10/15/20mm

Document: No

No/1/2/3/4/5

--

Time:

0.2 to 29.8 sec

Time:

27 values from 30 sec

1 to 1999 sec

Offset: Offset:

H:-2 to +3mm H: 0 mm

V:-2 to +3mm V: 0 mm

Offset: Offset:

H:-2 to +3mm H: 0 mm

V:-2 to +3mm V: 0 mm

Offset: Offset:

H:-2 to +3mm H: 0 mm

V:-2 to +3mm V: 0 mm

SCSI ID:

0/1/2/3/4/5/6/7 5

1.0 sec

* This offset means the deference from the value adjusted by automatic offset adjustment.

** The document length on ADF paper chute must be same. If the completely overlapped sheets are

fed, the scanner cannot detects the double feed.

6-2

Page 52

Setting double feed detection

When you set the using of double feed detection, you must set as follows:

1 Press or and let the

scanner display Screen 41.

2 At Screen 41, press or to select

the tolerance (10 or 15 or 20mm) and

press to activate the double feed

detecton. Scanner compares the length

of the scanned document with the length

of the first document. When the length of

the scanned document is longer or

shorter than the length of the first document exceeding the tolerance, double

feed is detected. If you want to disable

the double feed, select “No” then press

. Press to return to “Scanner

Ready” screen.

NOTE

Double Feed detection is effective only when the length of the all document on ADF is same.

<Screen 41>

NOTE

Scanner stops document feeding at the double feed detection. When the document in ADF is not the

double fed document, previous document may be double fed.

NOTE

If the completely overlapped sheets are fed, the scanner can not detect the double feed.

6-3

Page 53

Setting IPC pre-set mode

When you set the using of IPC-2 pre-set mode, you must set as follows:

1 Press or and let the

scanner display Screen 42.

2 At Screen 42, press or to select

<Screen 42>

the document number and press to

activate the IPC pre-setting. Then the

scanner displays Screen 42-1. Go to

procedure 3. If you want to disable the

IPC pre-setting, select “No” then press

. Finally press to return to

“Scanner Ready” screen.

3 At Screen 42-1, select “Yes” to activate

<Screen 42-1>

the IPC pre-setting or select “No” to

disable the IPC pre-setting. Note that

when you activate the IPC pre-setting,

the IPC setting by Host computer is

ignored. Finally press , then the

scanner displays next item, Screen 43.

<Classification of document number>

Document number are classified in line-art scanning as follows:

The horizontal axis shows the background density/color of paper.

The vertical axis shows the density of charcter/ line.

Background density

Normal← →Dark

Red Green Blue

Background color

Normal

Character

density

q - t are the document number set in setup mode.

q:Normal background

↑

↓

Light

and character.

w:Normal background

and light character.

6-4

e:Dark background

and normal-density

character.

r:Light character

on red paper.

t:Light character

on green paper.

Page 54

NOTE

• When IPC pre-set is executed in setup mode

Scanner checks that IPC-2D or IPC-3D are installed when the scanner enters in IPC pre-set.

If IPC-2D or IPC-3D is not installed, the scanner does not enter in IPC pre-set.

• When IPC pre-set mode is executed

When IPC pre-set mode is executed in online mode, the reading parameter is valid or invalid (Host

setting is invalid) as follows:

Reading parameter

Reading

mode

Valid

Invalid

DTC

Valid

Invalid

Conversion

Valid

Invalid

Tranfer

mode

Size

Sharpness

Transfer

rate

Portrait/

Landscape

Reading parameter

Outline

extraction

Resdution

Reading parameter

Picking

Overlay

Document

Start of

reading

selection

Simplified

DTC

Density

r patterns

Zooming

Line-art

/ Photo

Contrast

Halftone

Automatic

separation

6-5

Page 55

Reset of abrasion counter

When you reset the abrasion counter, you must set as follows:

1 Press or and let the

scanner display Screen 43.

2 At Screen 43;

If you want to reset the abrasion counter,

select “Yes” by or button and

press . Go to procedure 3.

If you do not want to reset the abrasion

counter, select “No” and press .

Finally press to return to “Scanner

Ready” screen.

3 At Screen 43-1;

If you want to reset the abrasion counter,

select “Yes” and press . If you do

not want to reset, select “No” and press

.

<Screen 43>

<Screen 43-1>

Setting pick start time

When you set the pick start time, you must set as follows:

1 Press or and let the

scanner display Screen 44.

2 At Screen 44, press to increase the

Pick start time or press to decrease

the Pick start time. Then press to

activate the setting. Finally press to

return to “Scanner Ready” screen.

6-6

<Screen 44>

Page 56

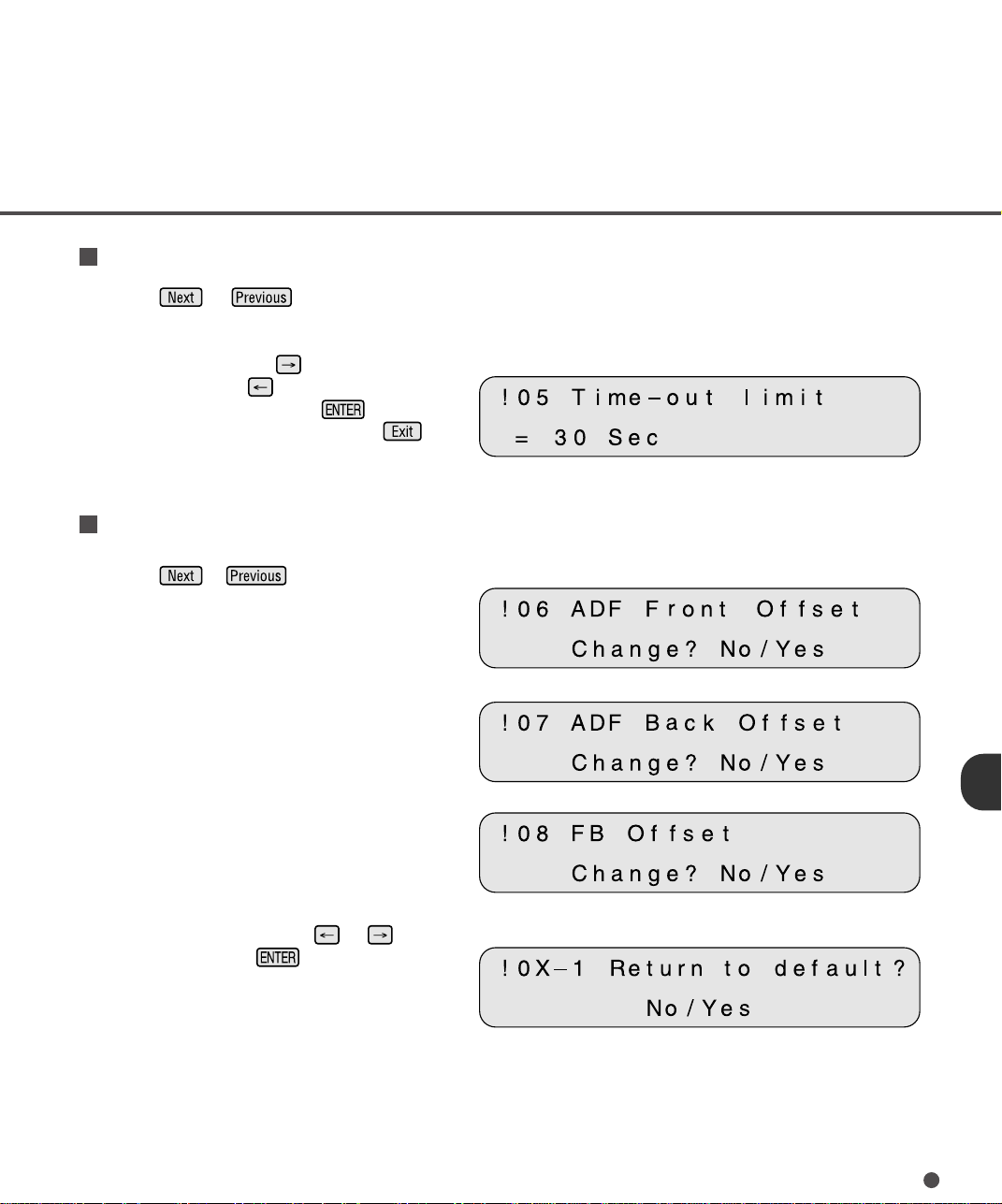

Setting time-out limit

1 Press or and let the

scanner display Screen 45.

2 At Screen 45, press to increase the

number or press to decrease the

time-out limit. Then press to

activate the setting. Finally press to

return to “Scanner Ready” screen.

Setting Offset

1 Press or and let the scan-

ner display as follows;

• Front Offset by ADF : Screen 46.

• Back Offset by ADF : Screen 47.

• Offset of Flatbed : Screen 48.

<Screen 45>

<Screen 46>

<Screen 47>

<Screen 48>

2 Select “Yes” by pressing or

button, and press . Then scanner

displays Screen A.

<Screen A>

6-7

Page 57

3 At Screen A, if you want to let the offset

return to default, select “Yes” otherwise

“No” then press . The scanner

displays Screen B.

<Screen B (Example of ADF Front Offset)>

<Screen B (Example of ADF Back Offset)>

<Screen B (Example of FB Offset)>

4 At Screen B, press to increase the

offset or press to decrease offset.

The increment or decrement is 0.5 mm.

Then press to activate the setting.

The scanner displays Screen C.

5 At Screen C, press to increase the

offset or press to decrease offset.

Then press to activate the setting.

The scanner displays the next item of the

setup mode.

<Screen C (Example of ADF Front Offset)>

<Screen C (Example of ADF Back Offset)>

<Screen C (Example of FB Offset)>

6-8

Page 58

Reviewing the IPC/Memory Status

1 Press or and let the

scanner display Screen 49.

2 Screen 49 displays the IPC option

installed and total image memory installed. Press to return to “Scanner

Ready” screen.

Setting SCSI-ID (M3097DG)

1 Press or ant let the scan-

ner display Screen 4A.

2 At Screen 4A, press or to select

SCSI-ID. Then press to activate the

setting. Finally press to return to

“Scanner Ready” screen.

<Screen 49 (Example of 32MB)>

(An example)

<Screen 50>

6-9

Page 59

6-10

Page 60

GLOSSARY OF TERMS

A4 size

A standard paper size used in Japan and other countries. Paper size is 210 x 297 mm (8.25 x 11.6 inches).

Abrasion counter

Indicates when belts/rollers should be replaced. The number of read document accumulates until an

operator resets the counter. It should be reset when consumables are replaced.

ASCII

The acronym for American Standard Code for Information Interchange.

ASCII is a set of 256 codes (numbered 0 to 255) used to communicate information between a computer

and another device such as scanner.

Automatic separation

The image processing method to detect the difference between text and photos and choose the threshold

accordingly. Automatic separation allows the scanner to switch between line mode and half tone mode

in one pass.

Automatic start mode (<-> manual start mode)

In this mode the reading operation is activated only by START command.

Back-side reading = Back-side scanning

Refers to reading the back-side of the document, specifically in Duplex reading mode.

Bit

The smallest unit of information in computer memory. A bit is a single digit, either a 1 or a 0, in the binary

numbering system.

Eight bits equal one byte.

Density

Refers to a measurement of the depth of the display in this manual.

Dither

Technique for producing halftone images representing the entire grayscale using two pixel levels black

and white.

GL-1

Page 61

Double feed detection

A function which detects the status when multiple sheets are fed in the ADF unit.

dpi

Dots per inch.

Drop-out color

A color which is used to the document but does not appear in the read image.

Duplex reading mode

Both sides of the document are read in this mode.

Equipment Error

An error that is not recoverable by operator. Call CE.

Error diffusion

High-quality halftone (pseudo-grayscale) image production based on black-and-white pixel binarization.

A pixel+s optical density and that of adjacent pixels are summed, with black pixels relocated in their order

of density as they relate to adjacent pixels.

The purpose of this technique is to minimize the average error between read and printed densities.

Density data for adjacent pixels is modified by diffusing errors on the objective pixel into several pixels,

which are then binarized. This maintains high grayscale levels and resolution during reading, while

suppressing more patterns by dotted halftone images such as newspaper photo graphs.

Filtering

The quality of images written in pencil or ball-pointed pen and read depends on the reflective light

characteristics of the ink or lead.

Dropped pixel+s may produce out lines, gaps or thin, barely connected lines due to even optical density.

Filtering detects areas lighter than their surroundings and increases their density to improve image clarity.

Front-side reading = Front-side scanning

Refers to reading the front-side of the document, specifically in Duplex reading mode.

Halftone processing

Used to reproduce a photograph which includes a shade as an image composed of dots, namely a binary

image. Dithering and error diffusion processing are examples of the halftone processing.

GL-2

Page 62

Hexadecimal

A base-16 numbering system(also commonly referred to as hex numbers). Since a base-16 system

requires 16 digits, numbers 0 through 9 and letters A through F are used. It is convenient to express binary

numbers in hexadecimal because fewer digits are required.

Image emphasis

Density is decreased for lighter but not completely white areas adjacent to black areas. Weakening this

emphasis eliminates spot noise or produces softened images.

Image processing

An image is read with specified parameters.

Interface

The connection that allows communication from one part of a system to another. For example, electrical

signals are transferred between the computer and scanner over an interface cable.

Inversion (Reverse-image reading)

In reverse-image reading, data is changed from black to white and vice versa.

IPC pre-set mode

While reading binary images, it is necessary to set the scanner according to the quality of the sheet to be

read. In this mode these settings can be performed in advance by corresponding each setting to a pattern

number.

IPC-2D or IPC-3D

Image processing option of this scanner.

IRAS

Initialization of the hardware.

Landscape

A document is transported and read with the long side vertical to the moving direction.

GL-3

Page 63

Letter size

A standard paper size used in the U.S.A. and other countries. Paper size is 8-1/2 x 11 inches (215.9 x

279.4 mm).

Linedrawing mode

Selecting linedrawing mode makes threshold and contrast settings effective but prevents brightness from

being set. The specified threshold value determines whether black or white pixels are scanned. Linedrawing mode is therefore appropriate for scanning text and line art images.

Manual Feed mode = Manual Mode

Requires the operator to feed each document manually to the ADF paper chute.

Manual start mode (<-> automatic start mode)

The reading operation is activated by pressing the START button in this mode.

Mirror image

The read image is symmetrically flipped to produce a mirror image of the original detected in the main

scanning direction.

Noise removal

Isolated noise from an image appearing as black spots in white areas and voids in black areas is removed

to improve image quality.

Operator panel

A panel containing the scanner indicators and buttons. The operator panel is used to control scanner

operations such as loading document, selecting features, and changing setup options.

Outline extraction

The boundary between black and white areas is traced and the outline extracted for closed areas.

PAPER JAM

A warning informing the user that document is jammed in the transport unit, or that transportation is

disabled because the transport unit is slippery. This warning also appears when a double fed is detected.

GL-4

Page 64

Photograph mode (White level follower OFF)

Selecting photograph mode makes brightness and contrast settings effective but prevents the threshold

from being set. With photograph mode, the darkness of image corresponds to the black-pixel density,

making it suitable in scanning images such as photographs having gradations.

Photo mode = photograph mode

A photograph is read properly in this mode.

Pick start time

The period from the manual insertion of the document until picking starts after the document passes the

hopper empty sensor.

Portrait

A document is transported and read with the long side parallel to the moving direction.

Paper counter

Indicates the total number of read document from reading start until the hopper becomes empty.

Read operation

Refers to the reading operation including Simplex reading and Duplex reading.

RS-232C interface

A type of serial interface. See Serial interface.

SCSI-ID

Used to specify a particular SCSI device when the initiator selects a target or the target re-connects to the

initiator.

Serial interface

A standard computer interface. Information is transferred between devices over a single wire (although

other wires are used for control).

With a serial interface, an interface cable greater than 3 meters (10 feet) can be used. This is often

necessary in networking environments, where the scanner may be shared.

GL-5

Page 65

SETUP mode

In this mode, users can view or set a variety of function in Off-line.

Simplex reading mode

Only the front side of the document is read in this mode. Place the documents face-up at the center of

the hopper table.

Smoothing

Smoothing eliminates jaggies from slanted lines and curves. Irregular convexities are deleted and

irregular concavities filled in. This is useful in OCR applications, for example.

Temporary Error

An error that is recoverable by operator.

Terminator

Devices with SCSI interface are daisy-chained. A resistor that includes terminal circuits needs to be

placed at both ends of a cable when devices are daisy-chained.

Time-out limit

This is the time which the scanner waits for next document insertion after the last document feeding. The

scanner returns Paper Empty when no document is set after time-out limit.

GL-6

Page 66

INDEX

A3 3-3

A

A4 3-3

Abrasion counter 1-7

Activating the Setup Mode 7-1

ADF 1-2, 1-3

ADF

Lever 1-2, 1-3

mode 1-6

paper chute 1-2

Alarm 1-10

Ambient condition 5-1

Arrangement 1-5

Assemblies 1-4

Belt 5-3

B

Button

/LED Function 1-6

Cable Connection 2-5

C

Carrier fixing bracket 2-4

Checking the Components 1-1

Connecting

the interface cable 2-6

the power cable 2-5

Consumables 5-3

Contents of the Setup Mode 6-2

Conventions iii

Double

feed check 6-2

feed detection 6-3

feed error 1-9

Duplex

reading mode 3-2

(back-side) reading mode 3-2

(front-side) reading mode 3-2

ENTER button 1-6

E

Exit button 1-6

Feeding direction 4-1

F

Halftone processing 3-4

H

Heat capacity 5-1

Hopper empty 1-9

Image processing circuit 5-4

I

IMPORTANT NOTE TO USERS i

input power 5-1

Inspection 2-2

Installation Specifications 5-1

Interface connectors 1-2, 1-3

IPC

pre-setting 6-2, 6-4

status 6-2, 6-9

Density 3-3, 3-4

D

Dimentions 5-1, 5-2

DLT (Double letter) 3-3

Document

bed 1-2, 1-3

holding pad 1-2, 1-3

Quality 4-2

Size 4-1

type 3-5, 4-2

IN-1

Page 67

Label

L

M

N

O

P

A 2-2

B 3-3

Landscape 3-2

LCD 1-5

LCD Display 1-6

LED 1-6

LG (Legal) 3-3

LT (Letter) 3-3

Manual

feed mode 3-6

start mode 1-6

Memory

cover 1-2, 1-3

status 6-2, 6-9

Next button 1-6

Offset setting 6-2, 6-7

Operation Status 1-8

Operator’s Guide 1-1

Operator panel 1-2, 1-5

Option 5-4

Pad ASY 5-3

Paper

counter 1-7

direction 3-2

weight 4-2

Perface ii

Pick

roller 1-4, 5-3

start time 6-2, 6-6

Plain paper 4-2

Portrait 3-2

Power

cable 1-1, 2-5

consumption 5-1

inlet 1-2, 1-3

switch 2-5, 3-1

Precautions 2-1, 4-2

Previous button 1-6

Reading

R

S

T

mode 3-2

face 3-2

Reset of abrasion counter 6-6

Resolution 3-3

Reviewing the IPC/Memory Status 6-9

Scanner 1-1

Setting

double feed detection 6-3

IPC pre-set mode 6-4

Offset 6-7

picking start time 6-6

SCSI-ID 6-9

time-out limit 6-7

Setup mode 6-1, 6-2

Simplex 3-2

Size 3-3

Specifications 5-1

Stacker 1-2, 2-7

Start button 1-5, 1-6

Stop button 1-5, 1-6

Terminator 1-1

Temporary error 1-9

Third party slot 1-2, 1-3

Turning

IN-2

Page 68

U

W

the Power On 3-1

the power switch off 2-5

Units 1-2

Units and Assemblies 1-2

Weight 5-1

button 1-6

button 1-6

(START) button 1-6

(STOP) button 1-6

IN-3

Page 69

IN-4

Page 70

Loading...

Loading...