Page 1

C150-E049-02EN

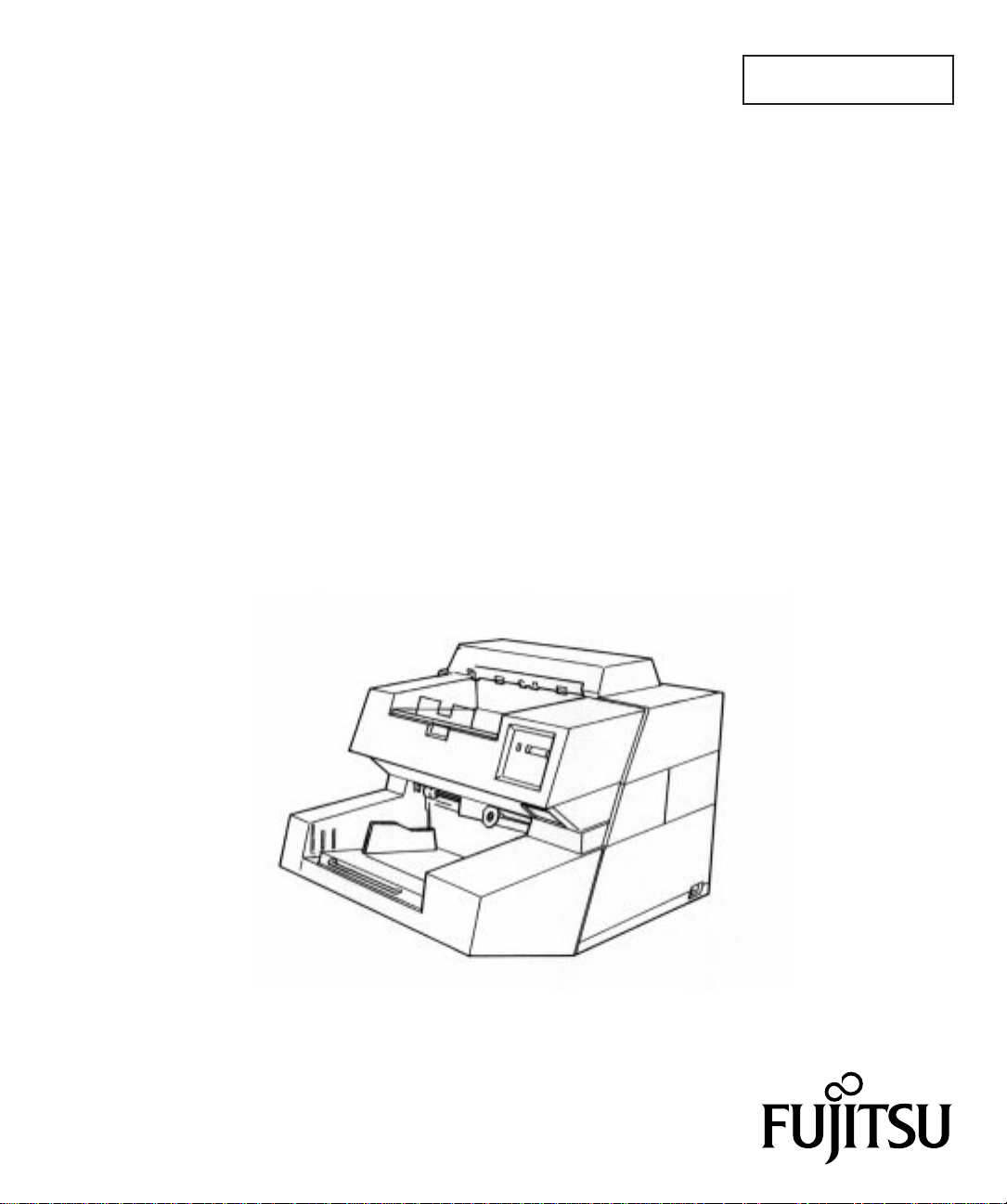

M3099GX/GH IMAGE SCANNER

OEM MANUAL

Page 2

M3099GX/GH IMAGE SCANNER

OEM MANUAL

Page 3

Page 4

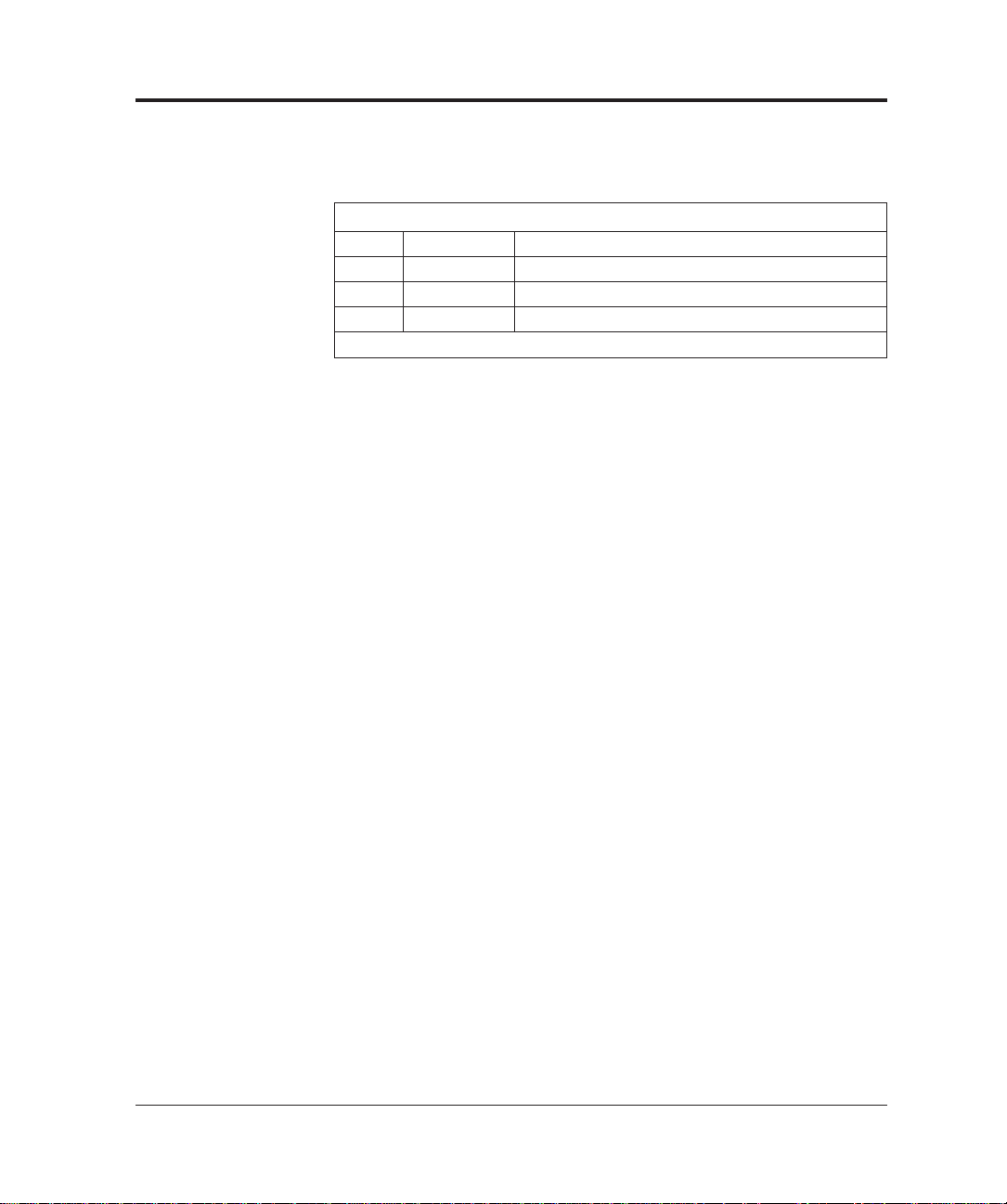

REVISION RECORD

Edition Date published Revised contents

01 Feburary, 1996 First edition

02 April, 1996 Setup mode etc. revised

Specification No. C150-E049-02EN

The contents of this manual may be revised without prior notice.

All Rights Reserved, Copyright © 1996 FUJITSU LIMITED.

Printed in Japan.

No part of this manual may be reproduced in any form without permission.

Address your comments and inquiries on this manual to:

FUJITSU COMPUTER PRODUCTS OF

AMERICA, INC.

2904 Orchard Parkway, San Jose.

California 95134-2022, U.S.A.

TEL: 1-408-432-6333

FAX: 1-408-432-3908

FUJITSU AUSTRALIA LIMITED

475 Victoria Avenue Chatswood.

N.S.W 2067, AUSTRALIA

TEL: 61-2-410-4555

FAX: 61-2-411-8603

FUJITSU CANADA, INC.

2800 Matheson Blvd. East, Mississauga.

Ontario 4X5, CANADA

TEL: 1-905-602-5454

FAX: 1-905-602-5457

FUJITSU DEUTSCHLAND GmbH.

Frankfurter Ring 211,

8000 Munchen 40, F.R, GERMANY

TEL: 49-89-32378-0

FAX: 49-89-32378-100

FUJITSU ESPANA, S.A

Edificio torre Europa

Paseo de la Castellana 95 Madrid 28046, SPAIN

TEL: 34-1-581-8400

FAX: 34-1-581-8125

FUJITSU EUROPE LTD.

2, Longwalk Road, Stockley Park, Uxbridge

Middlesex, UB11 1AB, U.K

TEL: 44-81-573-4444

FAX: 44-81-573-2643

TLX: 263871

FUJITSU FRANCE S.A.

Batiment Aristote, 17 rue Olof palme

94006 Creteil cedex, FRANCE

TEL: 33-14-513-1616

FAX: 33-14-399-0700

FUJITSU HONG KONG Limited

Room 2521, Sum Hung Kai Centre

30 Harbour Road Wanchal, Hong Kong

TEL: 852-827-5780

FAX: 852-827-4724

TLX: 62667

FUJITSU ITALIA S.p.A.

Via Melchiorre Gioia, No. 8-20124 Milano, ITALY

TEL: 39-2-63651

FAX: 39-2-6572257

FUJITSU NORDIC AB

Kung Hans vag, S-191 76 Sollentuna, SWEDEN

TEL: 46-8-626-6000

FAX: 46-8-626-6711

FUJITSU LIMITED

International Operations

Marunouchi 1-6-1, Chiyoda-ku, Tokyo 100, JAPAN

TEL: (81-3) 3216-3211

FAX: (81-3) 3213-7174

TLX: J22833

Cable: “FUJITSU LIMITED TOKYO”

M3099GX/GH OEM Manual

Page 5

Preface

This manual provides technical information required to use the

original equipment manufacturing (OEM) M3099G image scanner.

The manual is organized as shown below.

Chapter 1 Overview

Chapter 1 provides the scanner features, configuration, and

operation.

Chapter 2 Specifications

Chapter 2 provides general, electrical, environmental, physical, and

option specifications.

Chapter 3 Interface Specifications

Chapter 3 provides SCSI interface specifications.

Chapter 4 Basic Operation

Chapter 4 provides power switch operation, opening/closing the

upper transport unit, operator panel arrangement and functions,

messages, loading document, and replacement of parts.

Chapter 5 Error Processing and Recovery

Chapter 5 provides how to handles temporary errors and equipment

errors and what the operator should do to recovery.

M3099GX/GH OEM Manual i

Page 6

Chapter 6 Document Specification

Chapter 6 provides document specifications (size, type, limitations,

grounding color area, drop-out color, and job separation sheet) for

the scanner.

Chapter 7 Consumables and Accessories

Chapter 7 provides consumables and accessories.

Chapter 8 Cleaning

Chapter 8 provides cleaning locations and frequencies, cleaning

tools, and procedures.

It is recommended that you thoroughly familiarize yourself with the

contents of this manual before attempting to use the scanner.

Operators in particular must have read Chapter 4, “Basic

Operation.”

Conventions

ii M3099GX/GH OEM Manual

Special information, such as warnings, cautions are indicated as

follows:

WARNING

A WARNING indicattes that personal injury may result if you do

not follow a procedure correctly.

CAUTION

A CAUTION indicates that damage to the scanner may result if you

do not follow a procedure correctly.

NOTICE

A NOTICE provides “how-to” tips or suggestions to help you

perform a procedure correctly. NOTEs are particularly useful for

first-time users.

Page 7

Contents

CHAPTER 1 OVERVIEW␣ .................................................................................. 1-1

Scanner Types .............................................................................. 1-1

Features␣ ....................................................................................... 1-4

Configuration ............................................................................... 1-5

Configuration of the scanner .................................................. 1-5

Arrangement of units ............................................................. 1-6

Operation Overview ..................................................................... 1-7

Operation of the mechanism unit .......................................... 1-7

Operation of the control unit ................................................. 1-8

Resolution.............................................................................. 1-9

CHAPTER 2 SPECIFICATIONS␣ ........................................................................ 2-1

General ......................................................................................... 2-1

Electrical Specifications ................................................................ 2-2

Environmental Specifications ....................................................... 2-2

Physical specifications ................................................................... 2-3

Option specifications .................................................................... 2-6

CHAPTER 3 INTERFACE␣ ................................................................................. 3-1

Physical Specifications .................................................................. 3-3

SCSI Bus (See ANSI SCSI-2 4.5)........................................... 3-7

SCSI Bus Signals (See ANSI SCSI-2 4.6) ............................... 3-8

Signal Values.......................................................................... 3-9

Signal Source ......................................................................... 3-9

SCSI Bus Timing ................................................................. 3-11

Arbitration Delay .......................................................... 3-12

Assertion period............................................................. 3-12

Bus Clear Delay ............................................................. 3-12

Bus Free Delay .............................................................. 3-12

Bus Set Delay ................................................................ 3-12

Bus Settle Delay ............................................................ 3-13

Cable Skew Delay .......................................................... 3-13

M3099GX/GH OEM Manual iii

Page 8

Data Release Delay ........................................................ 3-13

Deskew Delay................................................................ 3-13

Disconnection Delay ..................................................... 3-13

Hold Time .................................................................... 3-13

Negation Period ............................................................ 3-13

Power-On to Selection Time ......................................... 3-14

Reset to Selection Time ................................................. 3-14

Reset Hold Time ........................................................... 3-14

Selection Abort Time .................................................... 3-14

Selection Time-out Delay .............................................. 3-14

Transfer Period .............................................................. 3-15

SCSI Bus Phases ......................................................................... 3-15

BUS FREE Phase (See ANSI SCSI-2 6.1.1 for details) ......... 3-15

ARBITRATION Phase ........................................................ 3-16

SELECTION Phase ............................................................. 3-17

RESELECTION Phase ........................................................ 3-18

RESELECTION ........................................................... 3-18

Information Transfer Phases ................................................ 3-19

Asynchronous Information Transfer .............................. 3-20

Synchronous Data Transfer ........................................... 3-21

COMMAND Phase............................................................. 3-22

Data Phase ........................................................................... 3-22

DATA IN Phase ............................................................ 3-23

DATA OUT Phase ....................................................... 3-23

STATUS Phase .................................................................... 3-23

Message Phase ...................................................................... 3-23

MESSAGE IN Phase ..................................................... 3-23

MESSAGE OUT Phase (See ANSI SCSI-2 6.1.9.2 for

details) ........................................................................... 3-24

SCSI Bus Conditions.................................................................. 3-24

Attention Condition ............................................................ 3-24

Reset Condition ................................................................... 3-25

SCSI Bus Phases Sequences ........................................................ 3-26

Commands (See ANSI SCSI-2 7) ............................................... 3-27

RESERVE UNIT Command............................................... 3-30

Superseding Reservations ............................................... 3-31

RELEASE UNIT Command ............................................... 3-31

TEST UNIT READY Command ........................................ 3-32

INQUIRY Command (See ANSI SCSI-2 7.2.5) .................. 3-32

Standard INQUIRY Data (See ANSI SCSI-2 7.2.5.1) .. 3-34

iv M3099GX/GH OEM Manual

Page 9

Vital Product Data ........................................................ 3-37

REQUEST SENSE Command (See ANSI SCSI-2 8.2.14) .. 3-49

SEND DIAGNOSTIC Command ...................................... 3-55

SET WINDOW Command ................................................ 3-56

Vendor Unique Parameters ........................................... 3-65

OBJECT POSITION .......................................................... 3-73

SEND Command ................................................................ 3-74

SCAN Command ................................................................ 3-79

READ Command ................................................................ 3-80

MODE SELECT(6) Command .......................................... 3-86

MODE SENSE(6) Command ............................................. 3-87

Mode Parameter ............................................................ 3-88

ENDORSER Command (ENDORSER option is required) 3-92

Status (See ANSI SCSI-2 7.3)..................................................... 3-97

Message(See ANSI SCSI-2 6.5) .................................................. 3-99

ABORT (Init → Targ) ...................................................... 3-102

BUS DEVICE RESET (Init → Targ) ................................ 3-103

COMMAND COMPLETE (Init ← Targ) ....................... 3-103

DISCONNECT (Init ← Targ) ......................................... 3-103

IDENTIFY (Init → Targ) ................................................. 3-104

INITIATOR DETECTED ERROR (Init → Targ) .......... 3-105

MESSAGE PARITY ERROR (Init → Targ) ..................... 3-105

MESSAGE REJECT (Init ↔ Targ) ................................... 3-106

NO OPERATION (Init → Targ) ..................................... 3-106

RESTORE POINTERS (Init ← Targ) .............................. 3-107

SAVE DATA POINTER (Init ← Targ) ............................ 3-107

SYNCHRONOUS DATA TRANSFER REQUEST ........ 3-107

Command Sequence ................................................................. 3-110

System Initialization........................................................... 3-110

General Procedure for Initializing Devices ......................... 3-111

Verify State Test ................................................................ 3-112

Scanning Sequence............................................................. 3-115

Basic Scanning Sequence (Simplex Mode) : ................. 3-115

Duplex Scanning ......................................................... 3-116

Endorser Control......................................................... 3-117

READ command sequences and phase progression ............ 3-118

Multiple READ (disconnect disabled) ......................... 3-119

Multiple READ (disconnect enabled) .......................... 3-120

M3099GX/GH OEM Manual v

Page 10

CHAPTER 4 BASIC OPERATION␣ ..................................................................... 4-1

Power Switch Operation............................................................... 4-1

Opening the Upper Transport Unit ............................................. 4-2

Closing the Upper Transport Unit ............................................... 4-2

Operator Panel ............................................................................. 4-3

Operator panel function......................................................... 4-3

LCD display .......................................................................... 4-5

Buttons .................................................................................. 4-7

Message List ........................................................................... 4-8

Loading Document ...................................................................... 4-9

Lamp Replacement ..................................................................... 4-10

Roller ASY Replacement ............................................................. 4-16

Pick Roller Replacement ............................................................. 4-18

Belt Replacement........................................................................ 4-19

Pad Replacement ........................................................................ 4-21

CHAPTER 5 ERROR PROCESSING AND RECOVERY␣ ....................................... 5-1

Device and Operator Actions for Temporary Errors ..................... 5-1

Device and Operator Actions for Equipment Errors ..................... 5-4

CHAPTER 6 DOCUMENT SPECIFICATION␣ ...................................................... 6-1

Document Size ............................................................................. 6-1

Document Quality ....................................................................... 6-2

Document type ...................................................................... 6-2

Ream weight .......................................................................... 6-2

Precautions ............................................................................ 6-2

Document Limitations ................................................................. 6-4

Areas that must not be perforated .......................................... 6-4

Print prohibit areas on the front and back surfaces ................. 6-5

Grounding Color Area.................................................................. 6-6

Drop-out Color ............................................................................ 6-7

Print density measurement ..................................................... 6-7

Drop-out color standards ....................................................... 6-7

Job Separation Sheet ..................................................................... 6-8

Shape ..................................................................................... 6-8

Document type ...................................................................... 6-8

vi M3099GX/GH OEM Manual

Page 11

CHAPTER 7 CONSUMABLES AND ACCESSORIES␣ ......................................... 7-1

Consumables ................................................................................ 7-1

Accessories .................................................................................... 7-2

CHAPTER 8 CLEANING␣ ................................................................................... 8-1

Cleaning Locations and Frequencies ............................................. 8-1

Cleaning Tools ............................................................................. 8-2

Procedure ..................................................................................... 8-2

Cleaning the front-side lamp .................................................. 8-2

Cleaning the rollers ................................................................ 8-5

Cleaning the transport paths .................................................. 8-6

Cleaning the glass surface ....................................................... 8-7

Cleaning the sensors ............................................................... 8-7

APPENDIX A ENDORSER␣ .................................................................................. A-1

A1. Specification .......................................................................... A-1

A2. Panel operation ......................................................................A-2

A2.1 How to set the endorser ON (or OFF) ..........................A-2

A2.2 How to set the initial number ........................................A-2

A2.3 How to set the print number reset condition .................A-3

A2.4 How to reset the print number manually ....................... A-3

A2.5 How to reset the print head life counter ........................A-4

A2.6 How to test the printing by the operator

panel operation ............................................................. A-4

A3. Print head handling................................................................A-5

A3.1 Replacing the print head ................................................A-5

A3.2 Print head position adjustment ......................................A-6

APPENDIX B SETUP MODE␣ .............................................................................. B-1

B1. Activating the setup mode ......................................................B-1

B2. Operational transition in the setup mode ............................... B-1

B3. Contents of the setup mode ................................................... B-2

B3.1 Setting double-feed detection ........................................ B-3

B3.2 Setting IPC-2 pre-set mode ........................................... B-4

B3.3 Reset of abrasion counter ............................................... B-6

B3.4 Setting buzzer ................................................................ B-7

B3.5 Setting pre-pick ............................................................. B-7

M3099GX/GH OEM Manual vii

Page 12

B3.6 Adjusting LCD contrast ................................................ B-8

B3.7 Setting pick speed ..........................................................B-8

B3.8 Setting initial value of endorser ...................................... B-9

B3.9 Setting reset method of endorser .................................... B-9

B3.10 Reset of endorser ....................................................... B-10

B3.11 Reset of ink counter ................................................... B-10

B3.12 Setting SCSI-ID ........................................................ B-10

B3.13 Setting Product-ID ....................................................B-10

B3.14 Setting picking start time ........................................... B-11

B3.15 Setting picking time................................................... B-12

B3.16 Setting time-out limit ................................................ B-12

B3.17 Setting hopper time ................................................... B-13

B3.18 Setting heater control ................................................ B-13

APPENDIX C SEPARATION PRESSURE ADJUSTMENT ................................... C-1

GLOSSARY OF TERMS .................................................................................................. GL-1

INDEX ...................................................................................................IN-1

viii M3099GX/GH OEM Manual

Page 13

Figures

1.1 500 sheets hopper type ......................................................... 1-2

1.2 1000 sheets hopper type ....................................................... 1-3

1.3 Scanner block diagram ......................................................... 1-5

1.4 Arrangement of units ............................................................ 1-6

1.5 Control block diagram ......................................................... 1-8

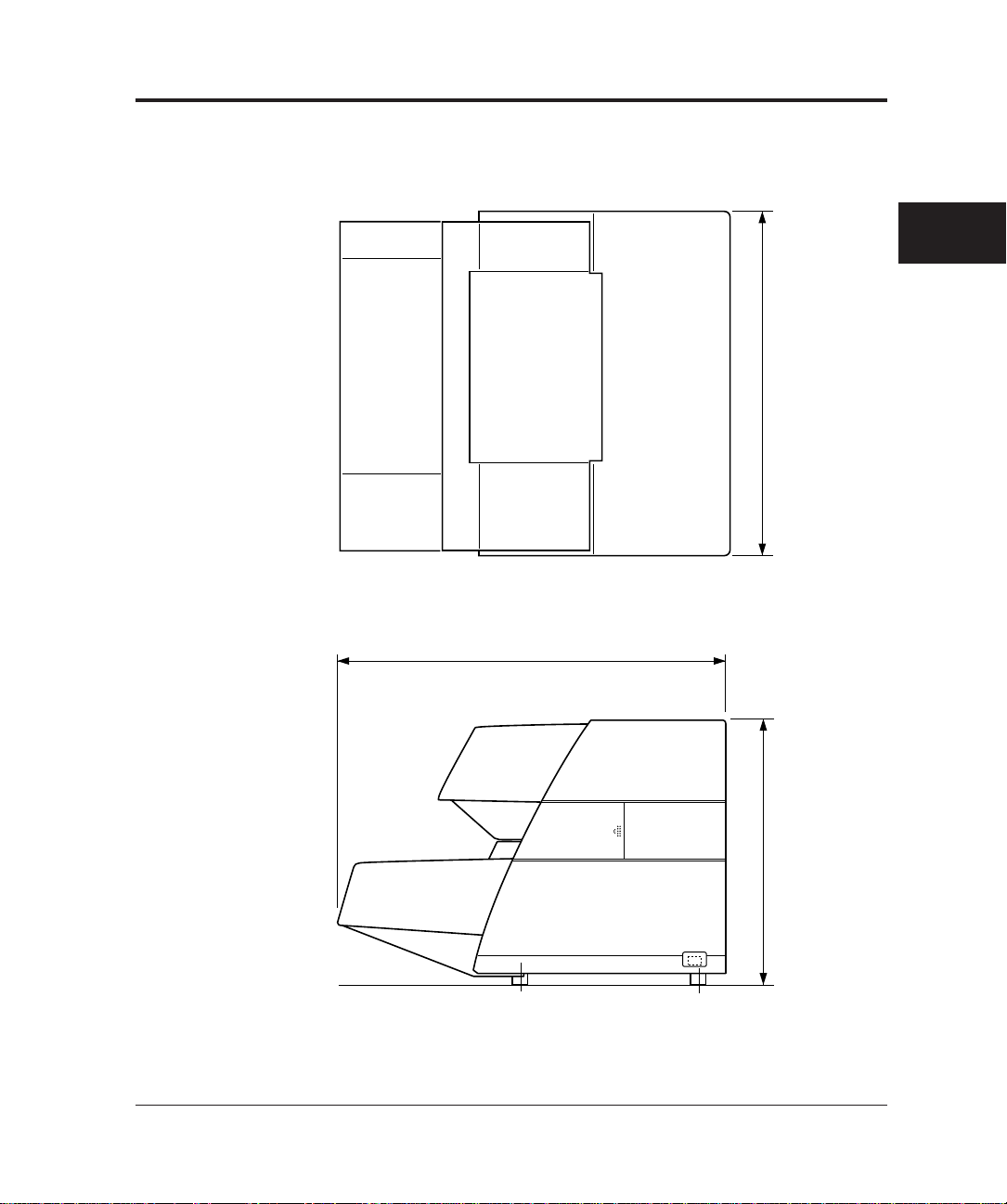

2.1 Dimensions of 500 sheets hopper type ................................. 2-3

2.2 Dimensions of 1000 sheets hopper type ............................... 2-4

2.3 Service areas ......................................................................... 2-5

3.1 SCSI device connection ........................................................ 3-3

3.2 Alternative 1 termination for Single Ended Devices .............. 3-5

3.3 Alternative 2 termination for Single Ended Devices .............. 3-5

3.4 DATA BUS.......................................................................... 3-7

3.5 Phase Sequence................................................................... 3-26

3.6 Verify State Test ............................................................... 3-113

4.1 Power switch location ........................................................... 4-1

4.2 Operator panel layout........................................................... 4-3

6.1 Document size...................................................................... 6-1

6.2 Areas that must not be perforated ......................................... 6-4

6.3 Print prohibit areas on the front and back surfaces ............... 6-5

6.4 Grounding color area ........................................................... 6-6

6.5 Spectrum band ..................................................................... 6-7

6.6 Shape of document ............................................................... 6-8

A.1 Print area.............................................................................. A-1

M3099GX/GH OEM Manual ix

Page 14

Tables

1.1 Types of M3099GH ............................................................ 1-1

1.2 Types of M3099GX ............................................................. 1-2

2.1 General scanner specifications .............................................. 2-1

2.2 Electrical specifications ......................................................... 2-2

2.3 Environmental specifications ................................................ 2-2

2.4 Physical specifications........................................................... 2-5

2.5 Option specifications ............................................................ 2-6

3.1 SCSI physical specification ................................................... 3-4

3.2 Single Ended Contact Assignment - ‘A’ Cable ...................... 3-6

3.3 SCSI Bus Signals .................................................................. 3-8

3.4 Signal Source ...................................................................... 3-10

3.5 SCSI Bus Timing Values .................................................... 3-11

3.6 Information Transfer Phases ............................................... 3-20

3.7 Operation Code Types ....................................................... 3-29

3.8 RESERVE UNIT Command ............................................. 3-30

3.9 RELEASE UNIT Command .............................................. 3-31

3.10 TEST UNIT READY Command ...................................... 3-32

3.11 INQUIRY Command ........................................................ 3-33

3.12 Standard INQUIRY Data Format ...................................... 3-35

3.13 Standard VPD Page Format ............................................... 3-38

3.14 Standard Resolution (unit:Pixel/Inch) ................................ 3-39

3.15 Function ............................................................................ 3-40

3.16 Standard VPD Page Extended Format ................................ 3-41

3.17 Physical Function ............................................................... 3-42

3.18 Implemented Standard Command ..................................... 3-43

3.19 2 bytes structure ................................................................. 3-44

3.20 Implemented Vendor Specific Command .......................... 3-44

3.21 Implemented Vendor Specific Command .......................... 3-44

3.22 Vendor Unique Parameter .................................................. 3-45

3.23 Image Control Function ..................................................... 3-47

3.24 Image Processing Function ................................................. 3-47

3.25 Compression Function ....................................................... 3-48

3.26 Endorser Function .............................................................. 3-48

3.27 REQUEST SENSE Command .......................................... 3-49

3.28 Sense Data Format ............................................................. 3-50

x M3099GX/GH OEM Manual

Page 15

3.29 Sense Key Descriptions ....................................................... 3-52

3.30 Implementation of SK(Sense Key), ASC(Additional Sense

Code), ASCQ(Additional Sense Code Qualifier) Hierachy. 3-54

3.31 SEND DIAGNOSTIC Command .................................... 3-55

3.32 SET WINDOW Command ............................................... 3-56

3.33 Set Window Data Header .................................................. 3-57

3.34 Window descriptor Bytes ................................................... 3-58

3.35 Brightness ........................................................................... 3-61

3.36 Threshold ........................................................................... 3-61

3.37 Contrast ............................................................................. 3-62

3.38 Image Composition Codes ................................................. 3-62

3.39 Halftone Type .................................................................... 3-63

3.40 Halftone Pattern ................................................................. 3-63

3.41 Compression Types and Arguments ................................... 3-64

3.42 Image Processing Parameter ............................................... 3-65

3.43 Gamma Correction Table .................................................. 3-66

3.44 Outline Extract .................................................................. 3-66

3.45 Image Emphasis ................................................................. 3-67

3.46 Automatic Separation ......................................................... 3-67

3.47 Mirroring ........................................................................... 3-67

3.48 SDTC parameter ................................................................ 3-68

3.49 DTC Mode - Byte 47 ......................................................... 3-69

3.50 DTC Mode - Byte 48 ......................................................... 3-69

3.51 White Level Follower ......................................................... 3-70

3.52 Paper Size ........................................................................... 3-71

3.53 DTC Selection ................................................................... 3-72

3.54 OBJECT POSITION Command ...................................... 3-73

3.55 Position Function ............................................................... 3-73

3.56 SEND Command .............................................................. 3-74

3.57 Halftone Mask ................................................................... 3-76

3.58 Gamma Function Data Format .......................................... 3-78

3.59 SCAN Command ............................................................... 3-79

3.60 READ Command .............................................................. 3-80

3.61 Data Type Codes ............................................................... 3-81

3.62 Pixel Size Data.................................................................... 3-83

3.63 Detected Paper Information ............................................... 3-84

3.64 Job Separation Sheet ........................................................... 3-84

3.65 Paper Size ........................................................................... 3-85

3.66 MODE SELECT(6) Command ......................................... 3-86

3.67 MODE SENSE(6) Command ........................................... 3-87

M3099GX/GH OEM Manual xi

Page 16

3.68 Supported Mode Page Code ............................................... 3-88

3.69 Mode Parameter List .......................................................... 3-88

3.70 Mode Parameter Header(6) ................................................ 3-89

3.71 Mode Page Format ............................................................. 3-89

3.72 Lamp Timer page ............................................................... 3-90

3.73 Job Separation Sheet page ................................................... 3-91

3.74 Job Separation Sheet Parameter .......................................... 3-91

3.75 ENDORSER Command .................................................... 3-92

3.76 Endorser Descriptors .......................................................... 3-93

3.77 Endorser Data .................................................................... 3-94

3.78 Font ................................................................................... 3-95

3.79 DIRS .................................................................................. 3-96

3.80 Status Byte ......................................................................... 3-97

3.81 Status Byte Code ................................................................ 3-97

3.82 Message Format ................................................................. 3-99

3.83 Message Codes ................................................................. 3-100

3.84 Extended Message Format ................................................ 3-101

3.85 Extended Message Codes .................................................. 3-101

3.86 IDENTIFY message ......................................................... 3-104

3.87 SYNCHRONOUS DATA TRANSFER REQUEST ....... 3-107

4.1 Button functions .................................................................. 4-4

4.2 LEDs function...................................................................... 4-4

4.3 Messages............................................................................... 4-8

5.1 Device and operator actions for temporary errors ................. 5-1

5.2 Device and operator actions for equipment errors ................. 5-4

7.1 Consumables ........................................................................ 7-1

7.2 Accessories............................................................................ 7-2

8.1 Cleaning locations and frequencies ....................................... 8-1

A.1 Endorser specifications ......................................................... A-1

xii M3099GX/GH OEM Manual

Page 17

Chapter 1: Overview

OVERVIEW

Chapter 2: Specifications

6

Chapter 3: Interface

Chapter 4: Basic Operation

Chapter 5: Error Processing and Recovery

Chapter 6: Document Specification

Chapter 7: Consumables and Accessories

Chapter 8: Cleaning

Appendix A:Endorser

Appendix B:Setup Mode

SPECIFICATIONS

INTERFACE

BASIC

OPERATION

ERROR

PROCESSING

AND RECOVERY

DOCUMENT

SPECIFICATION

CONSUMABLES

AND

ACCESSORIES

CLEANING

ENDORSER

SETUP MODE

Appendix C:Separation Pressure Adjustment

Glossary of Terms

Index

SEPARATION

PRESSURE

ADJUSTMENT

GLOSSARY OF

TERMS

INDEX

Page 18

CHAPTER

OVERVIEW

1

Scanner Types

OVERVIEW

This chapter provides scanner features, configuration, and operation.

The M3099GX/GH is a very fast and highly functional image

scanner developed for volume filing, using charge-coupled device

(CCD) image sensors. This scanner, featuring duplex reading and

high-quality image processing, read documents fed by an automatic

document feeder (ADF).

Scanner types of M3099GH and M3099GX are shown in Table 1.1

and 1.2. Those types of the scanner is hereinafter referred to as “this

scanner”.

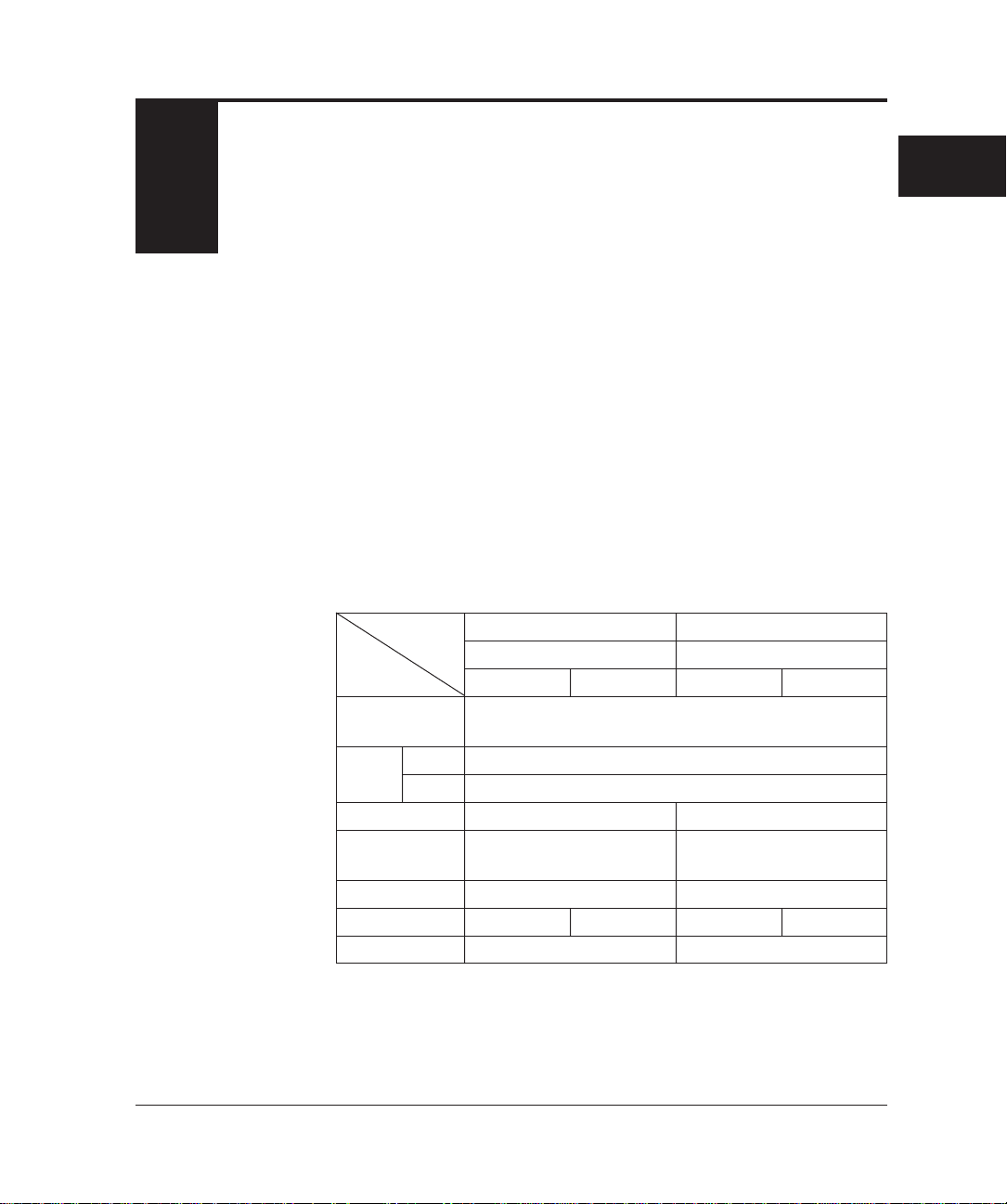

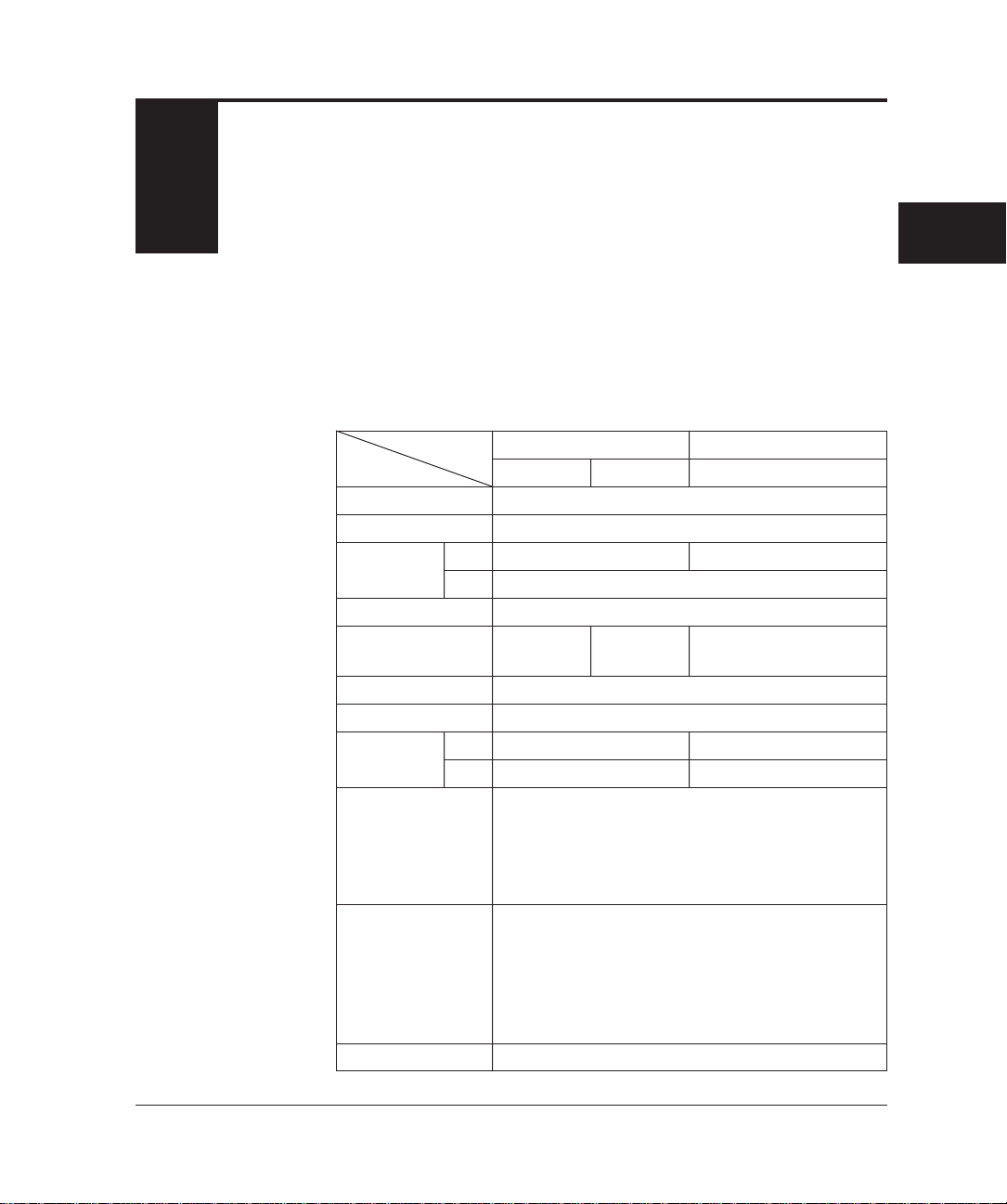

Table 1.1 Types of M3099GH

Type 500 sheets hopper 1000 sheets hopper

with IPC2 with IPC2

Item 100V 200V 100V 200V

Maximum

document size

Scanning Simplex

Duplex

Hopper capacity 500 sheets 1000 sheets

Hight of

the Scanner

IPC2 (option) Installed Installed

Input voltage 100V 200V 100V 200V

Appearance Figure 1.1 Figure 1.2

60 PPM (A4, 200dpi, portrate)

470 mm 530 mm

A4/Letter/Legal

80 PPM (A4, 200dpi, portate)

M3099GX/GH OEM Manual 1-1

Page 19

Table 1.2 Types of M3099GX

Type 1000 sheets hopper

with IPC2

Item 100V 200V

Maximum

document size

Scanning Simplex

Duplex

Hopper capacity 1000 sheets

Hight of

the Scanner

IPC2 (option) Installed

Input voltage 100V 200V

Appearance Figure 1.2

A3/Double letter

60 PPM (A4, 200dpi, portate)

50 PPM (A4, 200dpi, portrate)

530 mm

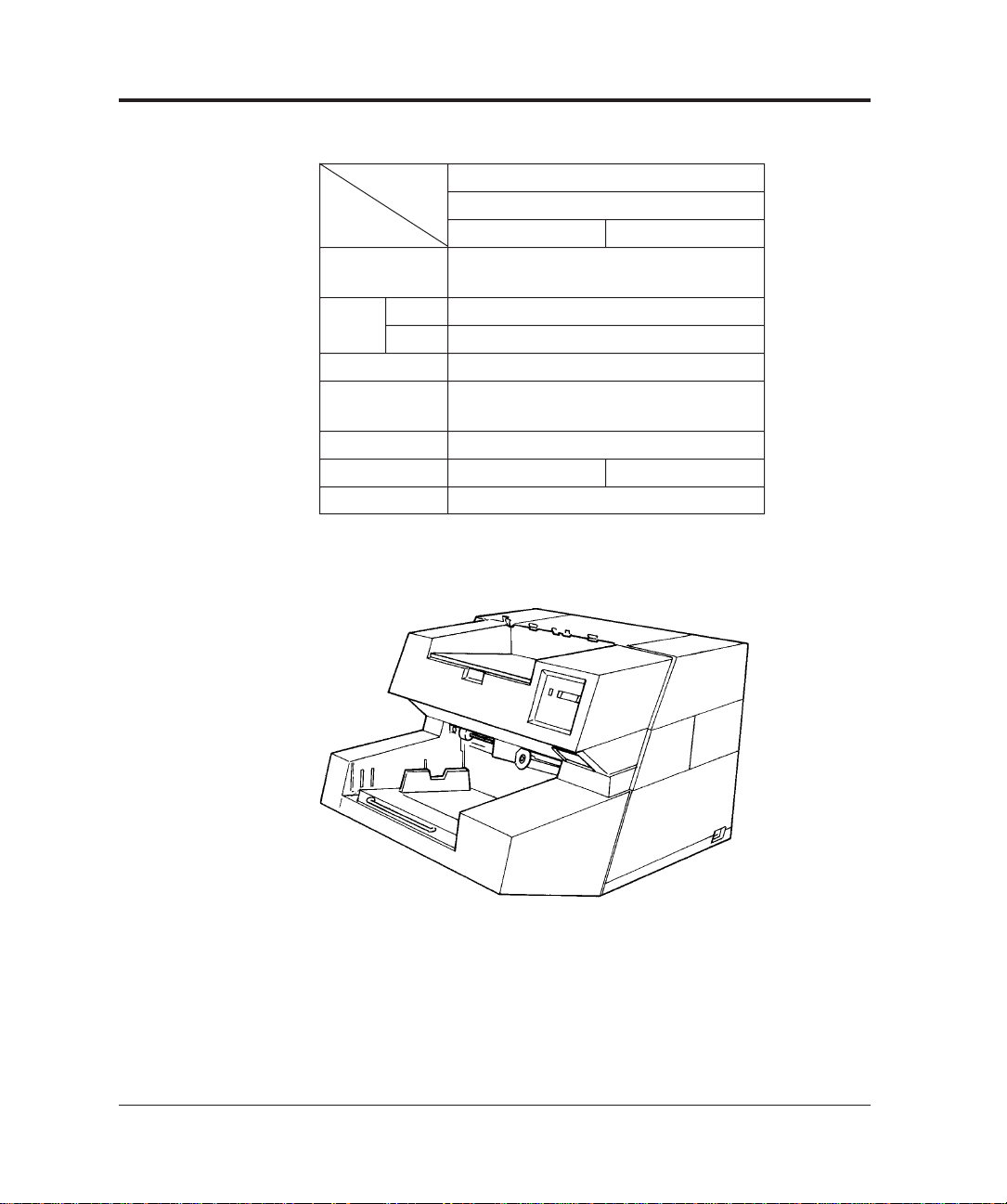

Figure 1.1 500 sheets hopper type

1-2 M3099GX/GH OEM Manual

Page 20

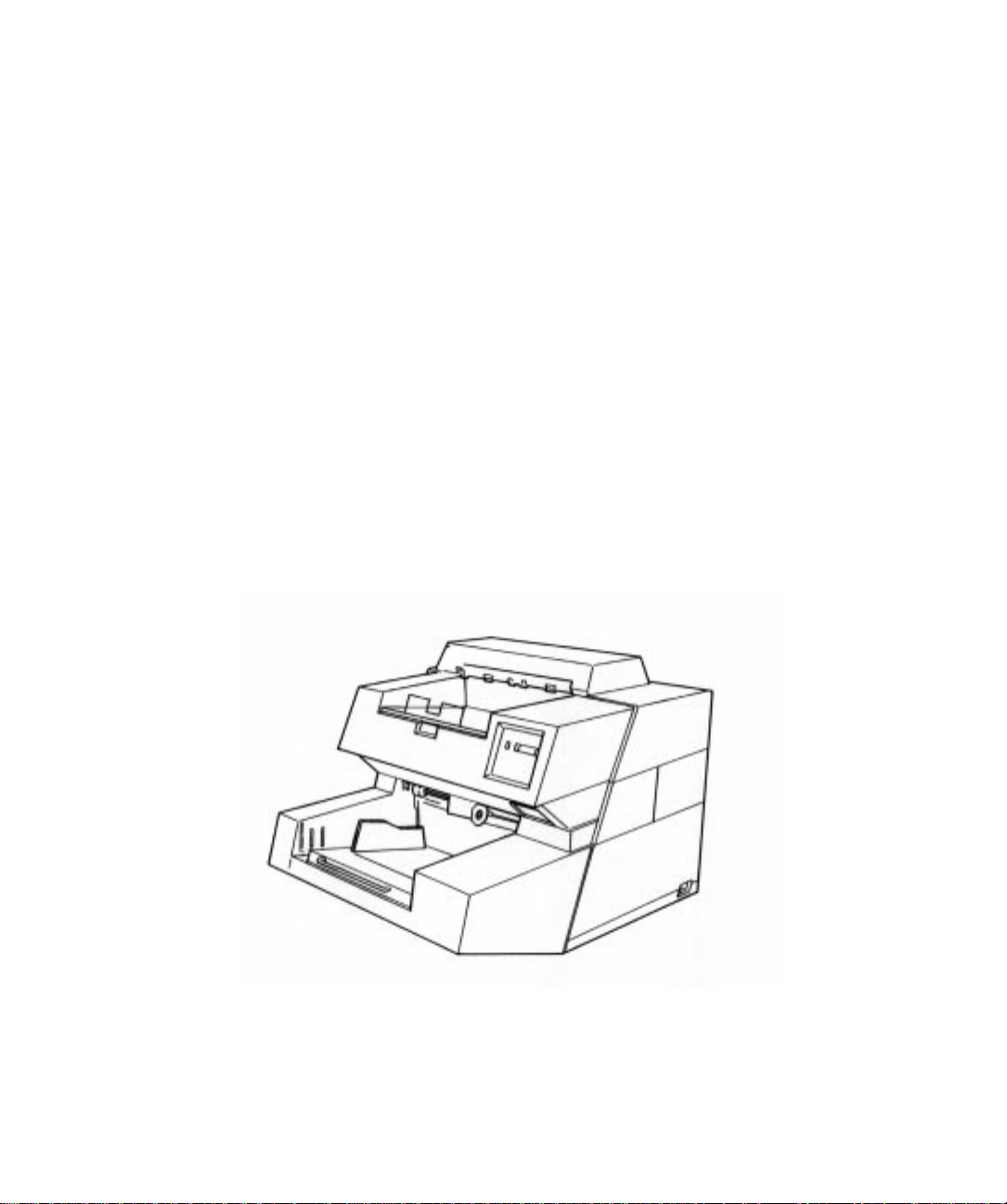

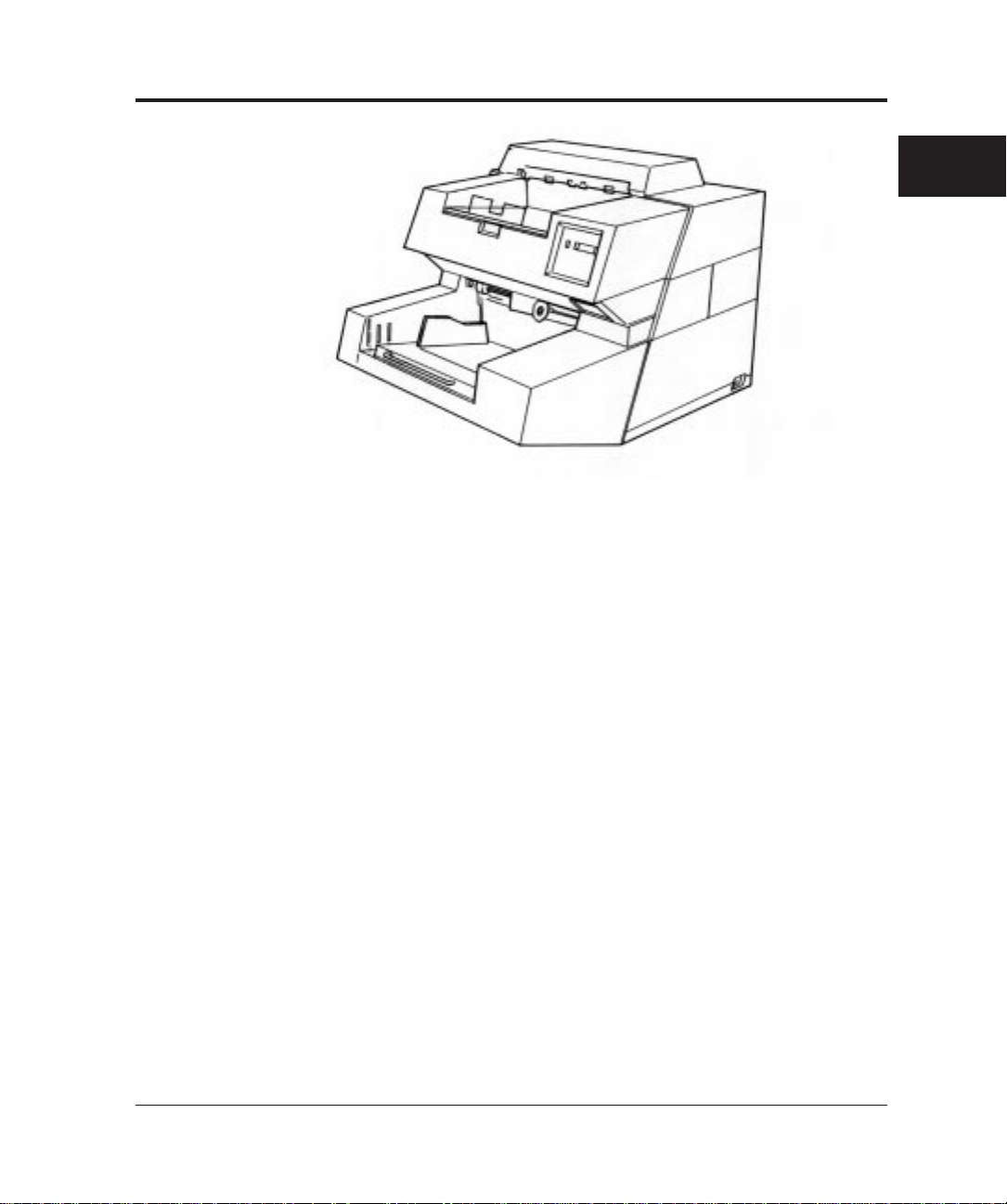

Figure 1.2 1000 sheets hopper type

OVERVIEW

M3099GX/GH OEM Manual 1-3

Page 21

Features

This scanner has the following features:

Duplex reading

Both sides of a document are read at the same time and their data

transferred serially.

Fast reading

This scanner can read documents at high speed: 80 sheets/min (A4,

200dpi) in the simplex reading mode and 60 sheets/min (A4,

200dpi) in the duplex reading mode by M3099GH.

Large-capacity hopper

Up to 1000 sheets (A4, 55 kg) can be loaded on the hopper by the

1000 sheets hopper type.

High-quality image

This scanner uses a compact optical system that provides sharper

focus. Furthermore, the use of new LSI chips produces finer images.

New image processing function

The error diffusion feature is provided as standard. Dithering or

error diffusion can be applied to those areas judged to be

photographs by automatic separation (image processing II option).

1-4 M3099GX/GH OEM Manual

Page 22

Configuration

This section provides configuration and components of the scanner.

Configuration of the scanner

This scanner can be divided into two major sections, mechanism and

control unit.

The mechanism unit consists of a hopper to load documents,

automatic document feeder, upper and lower transport units to

transport documents, a motor drive system, and an optical unit.

The control unit consists of an operator panel, a power supply, a

mechanism driver to drive and control the mechanism unit, an image

processing control, and an interface control.

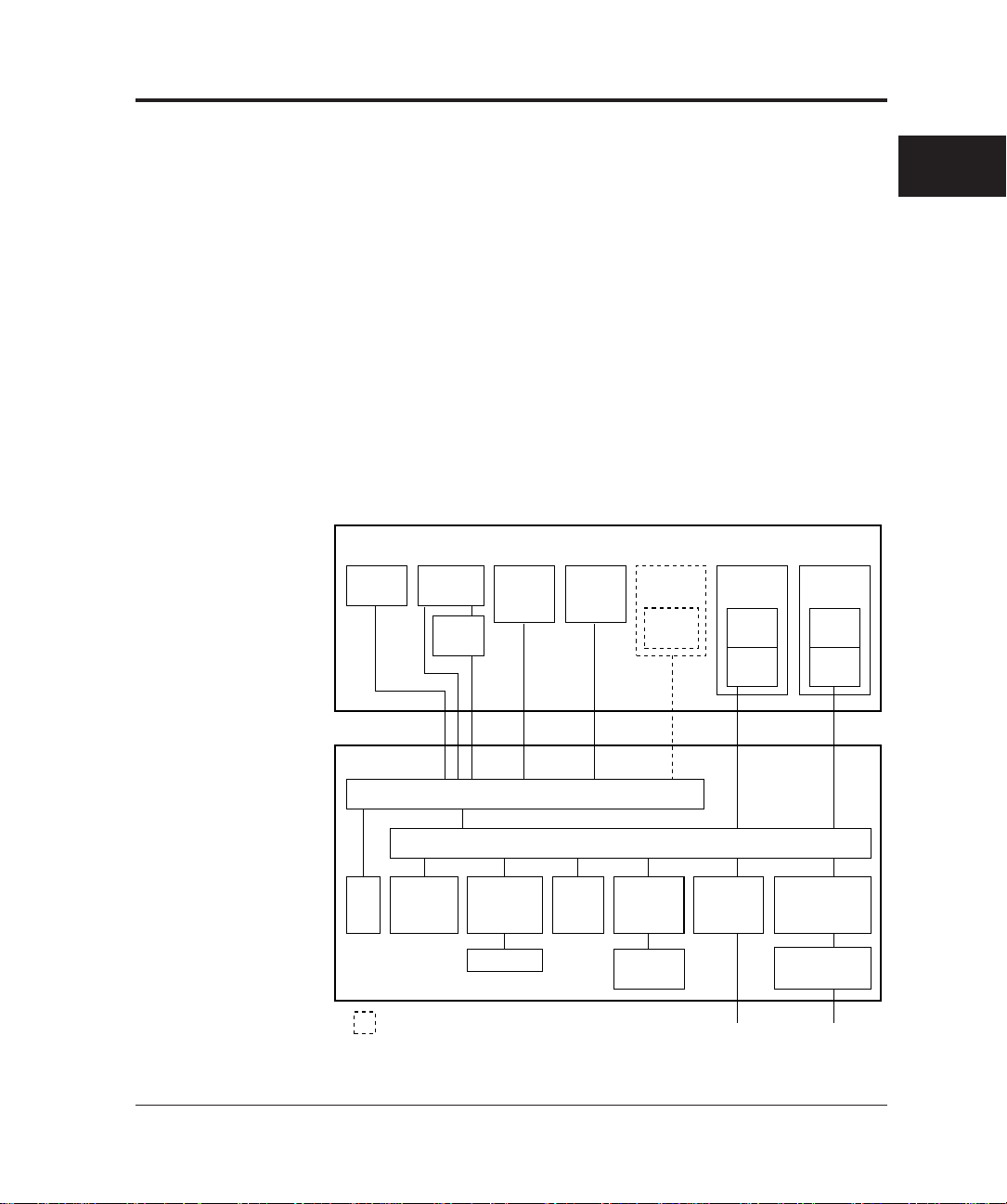

Figure 1.3 shows scanner configuration.

OVERVIEW

Mechanism unit

Transfer

system

Sensor Lamp,

(Front-side) (Back-side) (Back-side)

heater,

inverter

Sensor

board

Lamp,

heater,

inverter

Control unit

Mechanism driver

Motherboard

Fan Operator

panel

: Option

Back-side

reading

board

IPC-2 Extend

(Back-side)

IPC-2 Extend

(Front-side)

Figure 1.3 Scanner block diagram

Printer

Printer

driver

memory

board

memory

(Front-side)

Optical

system

CCD

driver

Video

circuit

Interface

board

SCSI-2 100/200VAC

Optical

system

CCD

driver

Video

circuit

Power supply

(5V, 12V)

Power supply

(24V)

M3099GX/GH OEM Manual 1-5

Page 23

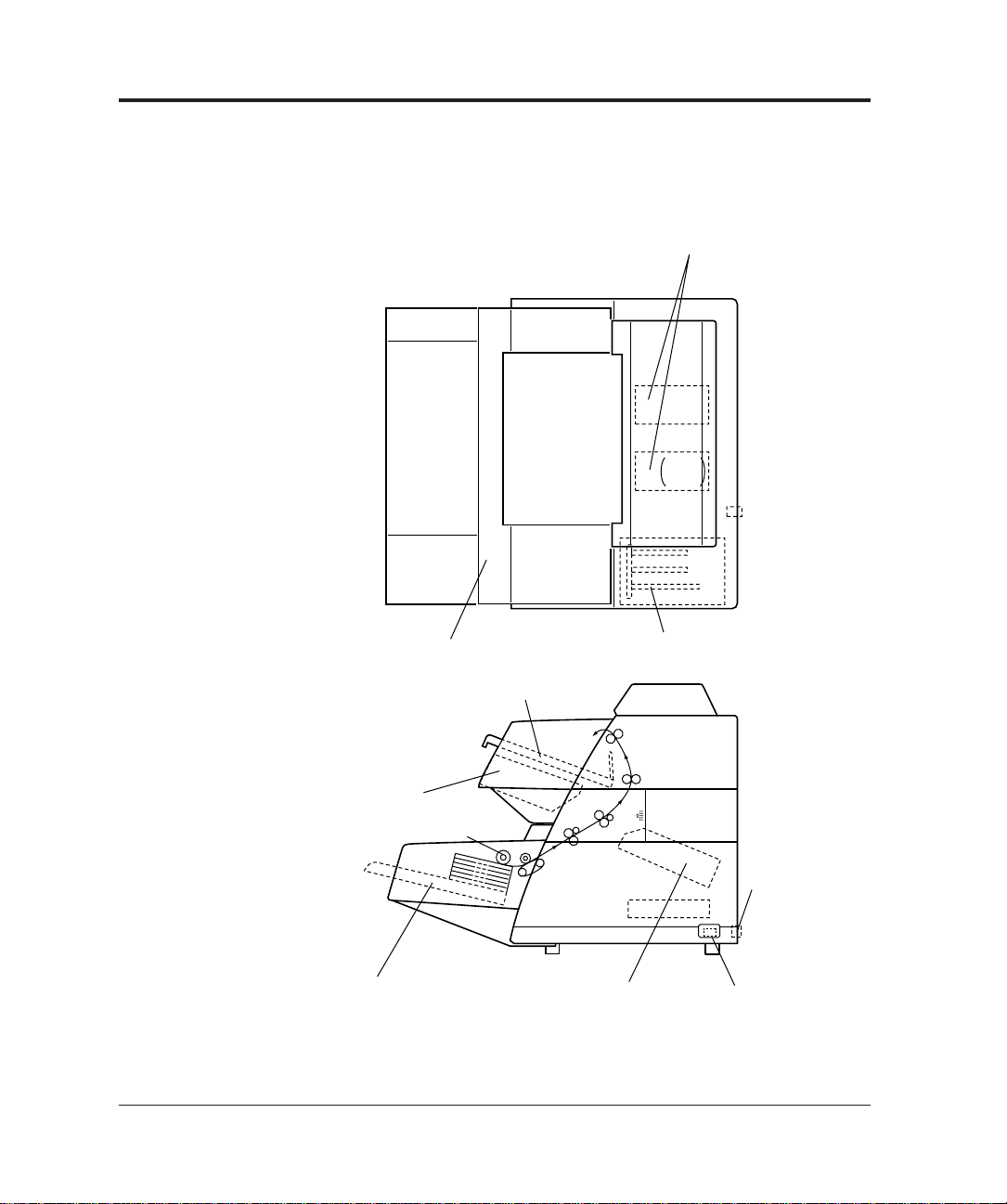

Arrangement of units

Power supply units

(+24V)

+5V

±12V

Control unitOperator panel

Stacker

Optical unit

(front-side)

Automatic document

feeder (ADF)

Hopper

Optical unit

(back-side)

Power switch

Power inlet

Figure 1.4 shows arrangement of these units.

1-6 M3099GX/GH OEM Manual

Figure 1.4 Arrangement of units

Page 24

Operation Overview

This section outlines the operations of the mechanism and control

units of the scanner.

Operation of the mechanism unit

The mechanism unit consists of two optical units (front and back

sides), a hopper and ADF, upper and lower transport units, a motor

drive system, and a stacker. Each optical unit consists of a CCD

image sensor, a lens, and mirrors. The hopper and ADF feeds

stacked documents and the upper and lower transport units transport

the documents. The motor drive system drives these units. The

stacker stores documents.

When the power is turned on, the lamps are lit and the scanner

waits until the light intensities of the lamps become stable. Once the

light intensities have become stable, the scanner is ready for a

command from the host machine.

A document is picked from the hopper and then ADF feeds a

document one by one. The document width is checked and

document top is detected.

The documents are counted, fed, and stacked on the stacker.

OVERVIEW

The lamps illuminate the document, and a lens focuses the images

on CCD for photoelectric conversion processing.

M3099GX/GH OEM Manual 1-7

Page 25

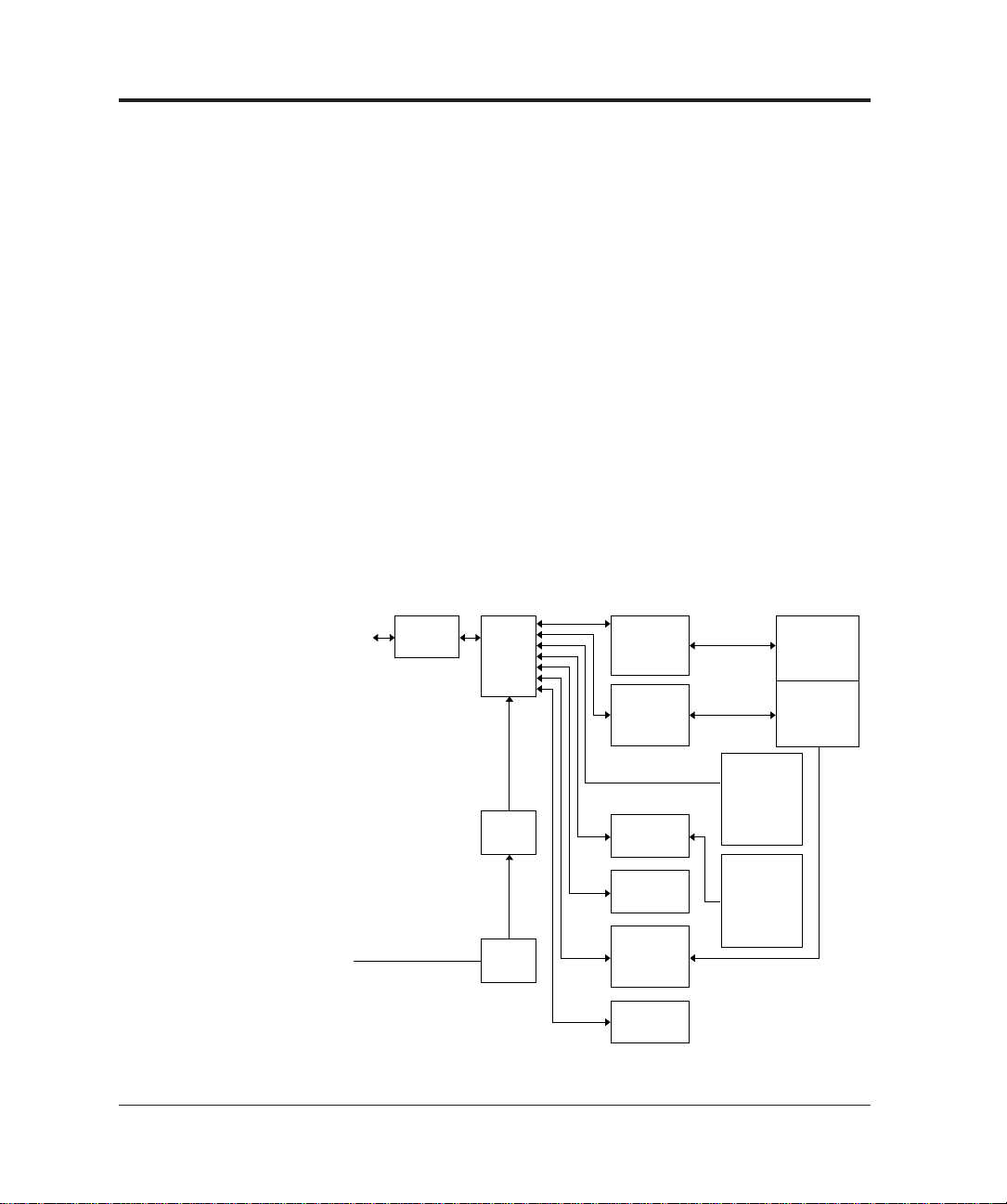

Operation of the control unit

The control unit consists of an operator panel, a power supply unit,

mechanism driver, an image processing control, and an interface

control.

This scanner has the following circuit configuration:

• Operator panel

• Control circuit (MPU)

• Video circuit (front-side/back-side)

• Interface circuit

• Duplex circuit (back-side)

• Motor driver circuit (including a stepper motor, a clutch driver)

• Power supply unit

• Image processing circuit (IPC II option)

• Memory board

Figure 1.5 shows control block diagram.

Host

machine

100 to 120 VAC

220 to 240 VAC

Interface

circuit

Control

circuit

(MPU )

Power

supply

Power

switch

Video

circuit

(front-side)

Video

circuit

(back-side)

Duplex

circuit

Memory

board

Motor

driver

circuit

Operator

panel

Mechanism

unit

ADF

MF

Image

processing

circuit II

(option)

(front-side)

Image

processing

circuit II

(option)

(back-side)

Figure 1.5 Control block diagram

1-8 M3099GX/GH OEM Manual

Page 26

Main control unit

This scanner is controlled by a 80C186 MPU. This scanner consists

of a ROM as a program area, internal registers, an external RAM as a

work area, gate arrays for the MPU peripheral and video circuits,

dither processing and γ conversion RAMs, and error diffusion.

Interface control

SCSI-2 interface

SCSI (small computer system interface) circuit consists of SPC

(MB86601A), VCEP (OTI95C71/20) and a glue ASIC. The scanned

image data are transferred to interface circuit as video interface. The

interface circuit converts internal video interface to SCSI interface via

compression, if required. SCSI interface transferes data 1.5MB/s in

Asynchronous transfer, 4.0MB/s in Synchronous transfer following to

SCSI-2 standard. The VCEP compresses the binary image data in

MH, MR, MMR algorithm defined by CCITT G3, G4. See Chapter

3 for details of SCSI interface.

Resolution

OVERVIEW

The basic resolution of this scanner is 200dpi. The resolution can be

changed to 240, 300, or 400dpi from the host computer or the

operator panel.

The resolution in the subscanning direction is achieved by changing

the document transport speed.

When the image processing circuit II (IPC II) option is installed, the

linear density is changed by setting the parameter to its internal circuit.

Video amplifier and driver section

This section consists of a CCD drive circuit, a video amplifier circuit,

a white-black level correction circuit, sensors, and also control circuits

for the stepping motor, heater, and lamps.

M3099GX/GH OEM Manual 1-9

Page 27

Image processing section

The IPC II option enables the following image processing functions:

• Automatic separation function (to read documents containing

characters and photographs)

• Inversion function

• Mirror image output function

• Outline extraction function

• Overlay function

• Smoothing, filtering, and noise removing

Power supplies

This scanner has two power supplies. Their output voltages are as

follows:

Power supply 1

• +5V: For logic circuits

• ±12V: For video amplifiers

Power supply 2

• 24V: For lamp, heater, and stepping motor drive

1-10 M3099GX/GH OEM Manual

Page 28

CHAPTER

2

General

SPECIFICATIONS

This chapter provides general, electrical, environmental, physical,

and option specifications.

Table 2.1 list general scanner specifications.

Table 2.1 General scanner specifications

Type

Item

Sensor

Scanning method

Document

size

Light source

Hopper/stacker

capacity

Gray scale (internal)

Output video

Scanning speed (A4,

200dpi, portrait)

Output density

Binarization and

halftone function

Interface

MAX.

MIN.

(64 g/m2)

Simplex

Duplex

ADF

216 × 356 mm (A4/Letter/Legal) 297 × 432 mm (A3/Double letter)

Standard: 400, 300, 240, 200dpi (Horizontal

scanning and vertical scanning are independent.)

If the image processing II (IPC2) is installed: 50 to

400 dpi (Horizontal scanning and vertical scanning

are independent.)

Standard: Fixed binarization, dither, error diffusion

method. If the image processing II (IPC2) is

installed: Automatic separation, image emphasis,

outline extraction, mirror image, inversion,

simplified DTC. Dynamic threshold, smoothing,

filtering, nois removing.

SCSI-2

M3099GH M3099GX

500 sheets hopper 1000 sheets hopper

CCD image sensor

(automatic document feeder)

76 × 63 mm (3" × 2.5")

Green fluorescent lamp

MAX. 500 MAX. 1000 MAX. 1000

sheets sheets sheets

Binary/Halftone (64 levels)

80 PPM 60 PPM

60 PPM 50 PPM

1000 sheets hopper

& MF

256 steps

(manual feeder)

SPECIFICATIONS

M3099GX/GH OEM Manual 2-1

Page 29

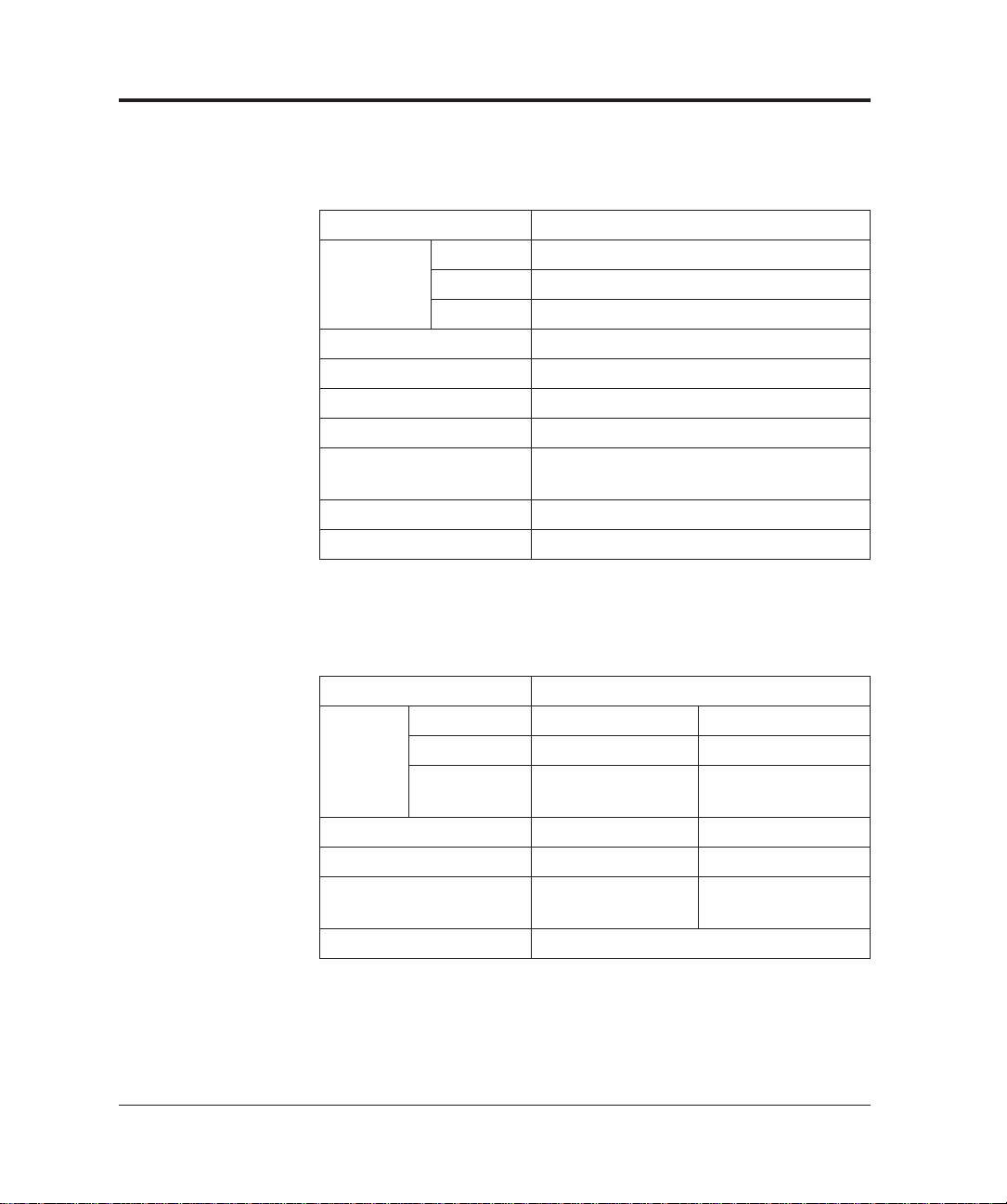

Electrical Specifications

Table 2.2 lists electrical specifications.

Table 2.2 Electrical specifications

Environmental Specifications

Item

Input power

Power consumption

Rush current

Momentary power failure

Leakage current

Dielectric strength

AC line noise

Heat capacity

Voltage

Phase

Frequency

Specification

100 to 120 VAC/220 to 240 VAC ±10%

Single-phase

50/60 Hz +2%, –4%

0.25 kVA or less

30 A or less

100%, 0.5 Hz

3.5 mA or less

DC 1.8 KV for one minute or more

(between FG and AC lines)

Voltage 1.2 KV pulse duration 5 µs

110 Kcal/H (440 BTU/H)

Table 2.3 lists environmental specifications.

Table 2.3 Environmental specifications

Item

Ambient

conditions

Shock

Stability

Acoustic noise

ESD

Device status

Temperature

Humidity

Specification

Operating

5 to 35°C

20 to 80%

(no condensation)

0.2 G less

5° or less

59 dBA or less

(ISO 7779)

8 KV or more

Not operating

–20 to 60°C

8 to 95%

(no condensation)

0.4 G or less

10° or less

50 dBA or less

(ISO 7779)

2-2 M3099GX/GH OEM Manual

Page 30

Physical Specifications

Figure 2.1 to Figure 2.2 show the scanner dimensions, Figure 2.3

shows scanner service areas. Table 2.4 lists physical specifications.

SPECIFICATIONS

610

680

470

(Unit: mm)

Figure 2.1 Dimensions of 500 sheets hopper type

M3099GX/GH OEM Manual 2-3

Page 31

680

610

530

(Unit: mm)

Figure 2.2 Dimensions of 1000 sheets hopper type

2-4 M3099GX/GH OEM Manual

Page 32

Table 2.4 Physical specifications

Type

Item

Dimensions

Weight

500 sheets hopper type 1000 sheets hopper type

Width

Depth

Height

610 mm 610 mm

680 mm 680 mm

470 mm 530 mm

55kg 65kg

SPECIFICATIONS

600680600

Scanner

F

200 610 600

1,390

1,860

F: Front

(Unit: mm)

Figure 2.3 Service areas

M3099GX/GH OEM Manual 2-5

Page 33

Option Specifications

Table 2.5 lists the scanner option specifications.

Table 2.5 Option specifications

Item

Endorser

Specification

CA01023-D004

Detail

Ink-jet

back-side print

max. 20 characters

Remark

2-6 M3099GX/GH OEM Manual

Page 34

CHAPTER

3

INTERFACE

INTERFACE

The M3099G image scanner provides SCSI-2(Small Computer

System Interface-2) interface. The SCSI-2 is a 8 bit-parallel interface

standardized by ANSI(American National Standard Institute).

This chapter provides an overview of the SCSI and interface

specification of this scanner. For detail information, refer to ANSI

SCSI standard document.

Definitions

• SCSI device: A host adapter or a target controller that can be

attached to the SCSI bus.

• Initiator: An SCSI device that requests an I/O process to be

performed by another SCSI device(a target).

• Target: An SCSI device that performes an operation

requested by an initiator.

• Logical unit: A physical or virtual peripheral device addressable

through a target.

Scope

This interface specification is following X3T9.2 draft proposal

revision 10c. refering JBMS(Japan Business Machine Standard).

System configuration

This scanner operates under the multi-initiator, multi-target

environment. An initiator function is not provided. This scanner

incorporates an integrated target and logical unit (image scanner).

SCSI ID: 0 to 7(changeable), default 5.

Logical Unit Number (LUN): 000b(fixed).

M3099GX/GH OEM Manual 3-1

Page 35

Bus phases

All phases are supported

Commands

• INQUIRY

• OBJECT POSITION

• MODE SELECT(6)

• MODE SENSE(6)

• READ

• RELEASE UNIT

• REQUEST SENSE

• RESERVE UNIT

• SCAN

• SEND

• SEND DIAGNOSTIC

• SET WINDOW

• TEST UNIT READY

• ENDORSER (ENDORSER option is required)

Statuses

• BUSY

• CHECK CONDITION

• GOOD

• RESERVEATION CONFLICT

Messages

• ABORT

• BUS DEVICE RESET

• COMMAND COMPLETE

• DISCONNECT

• IDENTIFY

• INITIATOR DETECTED ERROR

• MESSAGE PARITY ERROR

• MESSAGE REJECT

3-2 M3099GX/GH OEM Manual

Page 36

• NO OPERATION

• RESTORE POINTERS

• SAVE DATA POINTER

• SYNCHRONOUS DATA TRANSFER REQUEST

Physical Specifications

Connection

SCSI devices are daisy-chaned together using a common 50conductor ‘A’ cable and, optionally, a 68-conductor ‘B’ cable. Both

ends of each cable are terminated. All signals are common between

all SCSI devices on the ‘A’ cable. In systems that employ the wide

SCSI option, wide SCSI devices additionally connect to the ‘B’ cable.

Various width SCSI devices may be mixed. This scanner supports ‘A’

cable.

Note: Use of ‘B’ cable is not recommended because of ANSI draft

proposal indicates this definition is removed in a future

version of the SCSI.

SCSI device SCSI device SCSI device SCSI device

TERMINATOR

Figure 3.1 SCSI device connection

TERMINATOR

INTERFACE

M3099GX/GH OEM Manual 3-3

Page 37

Physical specification

Table 3.1 SCSI physical specification

Item

Driver/receiver

Connector

Cable

Signal

level

Connector pin assignments for

signal lines

Max. cable length

Characteristic impedance

Cable type

Stub length

Terminator

Driver/receiver

Output characteristics:

Low-level output voltage

High-level output voltage

Input characteristics :

Low level input voltage

High level input voltage

Low level input current

High level input current

Minimum input hysteresis

Specification

Single Ended

50 Contact Shielded Low Density

6 m

90␣ Ω to 140 Ω

25 signal twisted pair

≤ 0.1 m (from mainline)

See Figure. 3.2

Open collector or three states driver

0.0 to 0.5 volts dc at 48mA sinking

(signal assertion)

2.5 to 5.25 volts dc (signal

negation)

0.0 to 0.8 volts dc

2.0 to 5.25 volts dc

–0.4 to 0.0mA at Vi=0.5 volts dc

0.0 to 0.1mA at Vi=2.7 volts dc

0.2 volts dc

See Table 3.2

3-4 M3099GX/GH OEM Manual

Page 38

Termination

Low dropout voltage regulater

Imax ≥ 600mA

Vout = 2.85V

(See Note 1)

Vin Vout

Vadj

R1

R2

C2 C3

+

R3

Component Description

R1

R2

R3-R20

C1

C2

C3

121 Ω, 1%, 0.25W

154 Ω, 1%, 0.25W

110 Ω, 1%

10 µF Alum.15V or 4.7 µF Tant. 15V

150 µF Alum.10V or 22 µF Tant. 10V (ESR at 120 Hz < 4)

0.1 µF Ceramic 25V

+

R20

NOTES

1 The voltage regulator shown is an adjustable type with Vref=1.25V.

R1 and R2 were selected to provide approximately 10mA Iquiescent.

The voltage regulator Vdropout shall be 1.25V or less at Imax.

2 Alternative values that provide lower performance at somewhat

lower cost use Vout 1%; R3−R20=100 Ω,2%

All signals not defined as RESERVED, GROUND, or TERMPWR

shall be terminated at both ends of the cable. The Implementor may

choose one of the following two methods to terminate each end (see

ANSI SCSI-2 ANSI SCSI-2 5.4 Electrical description):

Single-ended alternative (a) [Passive terminator]

TERMINATOR POWER

INTERFACE

M3099GX/GH OEM Manual 3-5

–SIGNAL

220 Ω

330 Ω

GROUND

Figure 3.2 Alternative 1 termination for Single Ended Devices

Single-ended alternative (b) [Active terminator]

Figure 3.3 Alternative 2 termination for Single Ended Devices

The first termination method above is the same as in SCSI-1. The

second termination method is recommended for better signal quality.

Page 39

Connector pin assignments

Table 3.2 Single Ended Contact Assignment - ‘A’ Cable

Signal

Name

GROUND

GROUND

GROUND

GROUND

GROUND

GROUND

GROUND

GROUND

GROUND

GROUND

GROUND

GROUND

OPEN

GROUND

GROUND

GROUND

GROUND

GROUND

GROUND

GROUND

GROUND

GROUND

GROUND

GROUND

GROUND

Connector

Contact

Number Set 2

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

Cable

Connector

Number

1

3

5

7

9

11

13

15

17

19

21

23

25

27

29

31

33

35

37

39

41

43

45

47

49

Connector

Contact

Number Set 2

2

4

6

8

10

12

14

16

18

20

22

24

26

28

30

32

34

36

38

40

42

44

46

48

50

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

Signal Name

-DB(0)

-DB(1)

-DB(2)

-DB(3)

-DB(4)

-DB(5)

-DB(6)

-DB(7)

-DB(P)

GROUND

GROUND

RESERVED

TERMPWR

RESERVED

GROUND

-ATN

GROUND

-BSY

-ACK

-RST

-MSG

-SEL

-C/D

-REQ

-I/O

3-6 M3099GX/GH OEM Manual

Page 40

Note: The minus sign next to a signal indicates active low.

The lines labeled RESERVED in the ‘A’ cable contact

assignment tables shall be connected to ground in the bus

terminator assemblies or in the end devices on the SCSI cable.

The RESERVED lines should be open in the other SCSI

devices, but may be connected to ground. The RESERVED

lines in this scanner are opened.

SCSI Bus (See ANSI SCSI-2 4.5)

Communication on the SCSI bus is allowed between only two SCSI

devices at any given time. There is a maximum of eight SCSI devices.

Each SCSI device has an SCSI ID bit assigned as shown in Figure

3.4.

DB(0)

DB(1)

DB(7)

SCSI ID

Figure 3.4 DATA BUS

ID=7

DB(6)

ID=6

DB(5)

ID=5

DB(4)

ID=4

DB(3)

ID=3

DB(2)

ID=2

ID=1

ID=0

INTERFACE

M3099GX/GH OEM Manual 3-7

Page 41

SCSI Bus Signals (See ANSI SCSI-2 4.6)

Table 3.3 SCSI Bus Signals

Signal

BSY(BUSY)

SEL(SELECT)

C/D

(CONTROL/DATA)

MSG(MESSAGE)

REQ(REQUEST)

ACK

(ACKNOWLEDGE)

ATN(ATTENTION)

RST(RESET)

DB(7-0,P)

(DATA BUS)

Description

An "OR tied" signal that indicates that the bus is

being used.

An "OR tied" signal used by an initiator to select

a target or by a target to reselect an initiator.

A signal driven by a target that controls the

direction of data movement on the DATA BUS

with respect to an initiator. True indicates input

to the initiator. This signal is also used to

distiguish between SELECTION and

RESELECTION phase.

A signal driven by a target during the MESSAGE

phase.

A signal driven by a target on the A cable to

indicate a request for an ACK information

transfer handshake.

A signal driven by an initiator on the A cable to

indicate an acknowledgement for a REQ

information transfer handshake.

A signal driven by an initiator to indicate the

ATTENTION condition.

An "OR tied" signal that indicates the RESET

condition.

Eight data bit signals, plus a parity bit signal that

from a DATA BUS. DB(7) is most significant bit

and has the highest priority during the

ATTENTION phase. Bit number, significance

and priority decrese downward to DB(0). A data

bit is defined as one when the signal value is true

and is defined as zero when the signal value is

false. Data parity DB(P) shall be odd. Parity is

undefined during the ARBITRATION phase.

3-8 M3099GX/GH OEM Manual

Page 42

Signal Values

Signals may assure true or false values. These are two methods of

driving these signals. In both cases, the signal shall be actively driven

true, or asserted. In the case of OR tied drivers, the driver does not

drive the signal to the false state, rather the bias circuitry of the bus

terminators pulls the signal false whenever it is released by the drivers

at every SCSI device. If any driver is asserted, then the signal is true.

In the case of non OR tied drivers, the signal may be actively driven

false. In this standard, whenever the term negated is used, it means

that the signal may be actively driven false, or may be simply released

(in which case the bias circuitry pulls it false), at the option of the

implementor.

Signal Source

Table 3.4. indicates which type of SCSI device is allowed to source

each signal. No attempt is made to show if the source is driving

asserted driving negated, or is passive. All SCSI device drivers that are

not active sources be in the passive state. The RST signal may be

asserted by any SCSI device at any time.

INTERFACE

M3099GX/GH OEM Manual 3-9

Page 43

Table 3.4 Signal Source

C/D, I/O,

MSG,

Bus Phase

BUS FREE

ARBITRATION

SELECTION

RESELCTION

COMMAND

DATA IN

DATA OUT

STATUS

MESSAGE IN

MESSAGE OUT

All: The signal shall be driven by all SCSI devices that are actively

arbitrating.

S ID: A unique data bit (the SCSI ID) shall be driven by each SCSI

device that is actively arbitrating; the other seven data bits shall be

released (i.e., not driven) by this SCSI device. The parity bit

(DB(P)) may be released or driven to the true state, but shall never

be driven to the false state during this phase.

The signal shall be driven by the initiator, target or both, as

specified in the SELECTION phase and RESELECTION phase.

Init: If driven, this signal shall be driven only by the active initiator.

None: The signal shall be released; that is, not be driven by any SCSI

device. The bias circuitry of the bus terminators pulls the signal to

the false state.

Win: The signal shall be driven by the one SCSI device that wins

arbitration.

Targ: If the signal is driven, it shall be driven only by the active target.

BSY

None

All

I&T

I&T

Targ

Targ

Targ

Targ

Targ

Targ

SEL

None

Win

Init

Targ

None

None

None

None

None

None

REQ

None

None

None

Targ

Targ

Targ

Targ

Targ

Targ

Targ

ACK,

ATN

None

None

Init

Init

Init

Init

Init

Init

Init

Init

DB(7,0)

DB(P)

None

S ID

Init

Targ

Init

Targ

Init

Targ

Targ

Init

3-10 M3099GX/GH OEM Manual

Page 44

SCSI Bus Timing

Unless otherwise indicated, the delay time measurements for each

SCSI device, shown in Table 3.5., shall be calculated from signal

conditions existing at that SCSI device’s own SCSI bus connection.

Thus, these measurements (except cable skew delay) can be made

without considering delays in the cable. The timing characteristics of

each signal are described in the following paragraphs.

Table 3.5 SCSI Bus Timing Values

INTERFACE

Timing Description

Arbitration Delay

Assertion Period

Bus Clear Delay

Bus Free Delay

Bus Set Delay

Bus Settle Delay

Cable Skew Delay

Data Release Delay

Deskew Delay

Disconnection Delay

Hold Time

Negation Period

Power-On to Selection Time

Reset to Selection Time

Reset Hold Time

Selection Abort Time

Selection Time-out Delay

Transfer Period

Timing Values

2.4 µs

90 ns

800 ns

800 ns

1.8 µs

400 ns

10 ns

400 ns

45 ns

200 µs

45 ns

90 ns

10 s recommended

25 µs

200 µs

200 µs

250 ms recommended

set during an SDTR message

M3099GX/GH OEM Manual 3-11

Page 45

Arbitration Delay

The minimum time an SCSI device shall wait from asserting BSY for

arbitration until the DATA BUS can be examined to see if

arbitration has been won. There is no maximum time.

Assertion period

The minimum time that a target shall assert REQ (or REQB) while

using synchronous data transfers. Also, the minimum time that an

initiator shall assert ACK (or ACKB) while using synchronous data

transfers. REQB and ACKB timings only apply to optional wide data

transfers.

Bus Clear Delay

The maximum time for an SCSI device to stop driving all bus signals

after:

• The BUS FREE phase is detected.

• SEL is received from another SCSI device during the

ARBITRATION phase.

• The transition of RST to true.

For the first condition above, the maximum time for an SCSI device

to clear the bus is 1200 nanoseconds from BSY and SEL first

becoming both false. If an SCSI device requires more than a bus

settle delay to detect BUS FREE phase, it shall clear the bus within a

bus clear delay minus the excess time.

Bus Free Delay

The minimum time that an SCSI device shall wait from its detection

of the BUS FREE phase until its assertion of BSY when going to the

ARBITRATION phase.

Bus Set Delay

The maximum time for an SCSI device to assert BSY and its SCSI

ID bit the DATA BUS after it detects BUS FREE phase for the

purpose of entering the ARBITRATION phase.

3-12 M3099GX/GH OEM Manual

Page 46

Bus Settle Delay

The minimum time for wait for the bus to settle after changing

certain control signals as called out in the protocol definitions.

Cable Skew Delay

The maximum difference in propergation time allowed between any

two SCSI bus signals measured between any two SCSI devices.

Data Release Delay

The maximum time for an initiator to release the DATA BUS signals

following the transition of the I/O signals from false to true.

Deskew Delay

The minimum time required for deskew of certain signals.

Disconnection Delay

The minimum time that a target shall wait after releasing BSY before

participating in an ARBITRATION phase when honoring a

DISCONNECT message from the initiator.

Hold Time

The minimum time added between the assertion of REQ(or REQB)

or ACK(or ACKB) and the changing of the data lines to provide

hold time in the initiator or target while using synchronous data

transfers. REQB and ACKB timings only apply to optional wide data

transfers.

INTERFACE

Negation Period

The minimum time that a target shall negate REQ (or REQB) while

using synchronous data transfers. Also, the minimum time that an

initiator shall negate ACK (or ACKB) while using synchronous data

transfers. REQB and ACKB timings only apply to optional wide data

transfers.

M3099GX/GH OEM Manual 3-13

Page 47

Power-On to Selection Time

The recommended maximum time from power application until an

SCSI target is able to respond with appropriate status and sense data

to the TEST UNIT READY, INQUIRY, and REQUEST SENSE

commands.

Reset to Selection Time

The recommended maximum time after a hard RESET condition

until an SCSI target is able to respond with appropriate status and

sense data to the TEST UNIT READY, INQUIRY, and REQUEST

SENSE commands.

Reset Hold Time

The minimum time for which RST is asserted. There is no

maximum time.

Selection Abort Time

The maximum time that a target (or initiator) shall take from its

most recent detection of being selected (or reselected) until asserting

a BSY response. This time-out is required to ensure that a target (or

initiator) does not assert BSY after a SELECTION (or

RESELECTION) phase has been aborted. This is not the selection

time-out period; see ANSI SCSI-2 6.1.3.1. and ANSI SCSI-2

6.1.4.2. for a complete description.

Selection Time-out Delay

The minimum time that a SCSI device should wait for a BSY

response during the SELECTION or RESELECTION phase before

starting the time-out procedure. Note that this is only a

recommended time period.

3-14 M3099GX/GH OEM Manual

Page 48

Transfer Period

The Transfer Period specifies the minimum time allowed between

the leading edges of successive REQ pulses and of successive ACK

pulses while using synchronous data transfers. (See ANSI SCSI-2

6.1.5.2 and ANSI SCSI-2 6.6.21.)

INTERFACE

SCSI Bus Phases

The SCSI architecture includes eight distinct phases:

a) BUS FREE phase

b) ARBITRATION phase

c) SELECTION phase

d) RESELECTION phase

e) COMMAND phase

f) DATA phase

g) STATUS phase

h) MESSAGE phase

The SCSI bus can never be in more than one phase at any given

time. In the following descriptions signals that are not mentioned

shall not be asserted.

These phases are collectively termed

the information transfer phase.

BUS FREE Phase (See ANSI SCSI-2 6.1.1 for details)

The BUS FREE phase indicates that there is no current I/O process

and that the SCSI bus is available for a connection.

SCSI devices shall detect the BUS FREE phase after the SEL and

BSY signals are both false for at least a bus settle delay.

SCSI devices shall release all SCSI bus signals within a bus clear delay

after the BSY and SEL signals become continuously false for a bus

settle delay. If an SCSI device requires more than a bus settle delay to

detect the BUS FREE phase then it shall release all SCSI bus signals

within a bus clear delay minus the excess time to detect the BUS

FREE phase. The total time to clear the SCSI bus shall not exceed a

bus settle delay plus a bus clear delay.

M3099GX/GH OEM Manual 3-15

Page 49

If an initiator detects the release of the BSY signal by the target at

any other time, the target is indicating an error condition to the

initiator. The target may perform this transition to the BUS FREE

phase independent of the state of the ATN signal. The initiator shall

manage this condition as an unsuccessful I/O process termination.

The target terminates the I/O process by clearing all pending data

and status information for the affected nexus. The target may

optionally prepare sense data that may be retrieved by a REQUEST

SENSE command.

ARBITRATION Phase

The ARBITRATION phase allows one SCSI device to gain control

of the SCSI so that it can initiate or resume an I/O process.

The procedure for an SCSI device to obtain control of the SCSI bus

is as follows:

a) The SCSI device shall first wait for the BUS FREE phase to

occur. The BUS FREE phase detected whenever both the BSY

and SEL signals are simultaneously and continuously false for a

minimum of a bus settle delay.

b) The SCSI device shall wait a minimum of a bus free after

detection of the BUS FREE phase (i.e. after the BSY and SEL

signals are both false for a bus settle delay) before driving any

signal

c) 3)Following the bus free delay in Step(b), the SCSI device may

arbitrate for the SCSI bus by asserting both the BSY signal and its

own SCSI ID, however the SCSI device shall not arbitrate (i.e.

assert the BSY signal and its SCSI ID) if more than a bus settle

delay has passed since the BUS FREE phase was last observed.

3-16 M3099GX/GH OEM Manual

Page 50

d) After waiting at least an arbitration delay (measured from its

assertion of the BSY signal) the SCSI device shall examine the

DATA BUS. If a higher priority SCSI ID bit is true on the

DATA BUS (DB(7) is the highest), then the SCSI devices has

lost the arbitration and the SCSI device may release its signals

and return to Step(a). If no higher priority SCSI ID bit is true on

the DATA BUS, then the SCSI device has won the arbitration

and it shall assert the SEL signal. Any SCSI device other than the

winner has lost the arbitration and shall release the BSY signal

and its SCSI ID bit within a bus clear delay after the SEL signal

becomes true. An SCSI device that loses arbitration may return to

Step(a).

e) The SCSI device that wins arbitration shall wait at least a bus

clear delay plus a bus settle delay after asserting the SEL signal

before changing any signals.

SELECTION Phase

The SELECTION phase allows an initiator to select a target for the

purpose of initiating some target function (e.g., READ or WRITE

command). During the SELECTION phase the I/O signal is

negated so that this phase can be distinguished from the

RESELECTION phase.

INTERFACE

The SCSI device that won the arbitration has both the BSY and SEL

signals asserted and has delayed at least a bus clear delay plus a bus

settle delay before ending the ARBITRATION phase. The SCSI

device that won the arbitration becomes an initator by not asserting

the I/O signal.

The initiator shall set the DATA BUS to a value which is the OR of

its SCSI ID bit and the target’s SCSI ID bit and it shall assert the

ATN signal (indicating that a MESSAGE OUT phase is to follow

the SELECTION phase). The initiator shall the wait at least two

deskew delays and release the BSY signal. The initiator shall then

wait at least a bus settle delay before looking for a response from the

target.

The target shall not respond to selection if bad parity is detected.

Also, if more than two SCSI ID bits are on the DATA BUS, the

target shall not respond to selection.

M3099GX/GH OEM Manual 3-17

Page 51

No less than two deskew delays after the initiator detects the BSY

signal is true, it shall release the SEL signal and may change the

DATA BUS. The target shall wait unitl the SEL signal is false before

asserting the REQ signal to enter an information transfer phase. (See

ANSI SCSI-2 6.1.3.1 SELECTION Time-out Procedure)

RESELECTION Phase

RESELCTION is an optional phase that allows a target to reconnect

to an initiator for the purpose of continuing some operation that was

previously started by the initiator but was suspended by the

target(i.e., the target disconnected by allowing a BUS FREE phase to

occur before the operation was completed).

RESELECTION

Upon completing the ARBITRATION phase, the winning SCSI

device has both the BSY and SEL signals asserted and has delayed at

least a bus clear delay plus a bus settle delay. The winning SCSI

device becomes a target by asserting the I/O signal. The winning

SCSI device shall also set the DATA BUS to a value that is the

logical OR of its SCSI ID bit and the initiator’s SCSI ID bit. The

target shall wait at least two deskew delays and release the BSY signal.

The target shall wait at least a bus settledelay before looking for a

response from the initiator.

The initiator shall determine that it is reselected when the SEL and

I/O signals and its SCSI ID bit are true and the BSY signal is false

for at least a bus settle delay. The reselected initiator may examine

the DATA BUS in order to determine the SCSI ID of the reselecting

target. The reselected initiator shall then assert the BSY signal within

a selection abort time of its most recent detection of being reselected;

this is required for correct operation of the time-out procedure. The

initiator shall not respond to a RESELECTION phase if bad parity

is detected.

Also, the initiator shall not respond to a RESELECTION phase if

other than two SCSI ID bits are on the DATA BUS.

3-18 M3099GX/GH OEM Manual

Page 52

After the target detects the BSY signal is true, it shall also assert the

BSY signal and wait at least two deskew delays and then release the

SEL signal. The target may then change the I/O signal and the

DATA BUS. After the reselected initiator detects the SEL signal is

false, it shall release the BSY signal. The target shall continue

asserting the BSY signal until it relinquished the SCSI bus. (See

ANSI SCSI-2 6.1.4.2. RESELECTION Time-out Procedure)

Information Transfer Phases

NOTE: The COMMAND, DATA, STATUS, and MESSAGE

phases are all grouped together as the information transfer phases

because they are all used to transfer data or control information via

the DATA BUS. The actual content of the information is beyond

the scope of this section.

The C/D, I/O, and MSG signals are used to distinguish between the

different information transfer phases(see Table 3.6). The target

drives these three signals and therefore controls all changes from one

phase to another. The initiator can request a MESSAGE OUT phase

by asserting the ATN signal, while the target can cause the BUS

FREE phase by releasing the MSG, C/D, I/O, and BSY signals.

The information transfer phases use one or more REQ/ACK

handshakes to control the information transfer. Each REQ/ACK

handshake allows the transfer of one byte of information. During the

information transfer phases the BSY signal shall remain true and the

SEL signal shall remain false. Additionally, during the inforamtion

transfer phases, the target shall continuously envelope the REQ/ACK

handshake(s) with the C/D, I/O, and MSG signals in such a manner

that these control signals are valid for a bus settle delay before the

assertion of the REQ signal of the first handshake and remain valid

until after the negation of the ACK signal at the end of the

handshake of the last transfer of the phase.

INTERFACE

M3099GX/GH OEM Manual 3-19

Page 53

Table 3.6 Information Transfer Phases

Signal

MSG

C/D

0

0

0

0

0

1

0

1

1

0

1

0

1

1

1

1

Key: 0 = False, 1 = True, * = Reserved for future standardization

Phase Name

I/O

DATA OUT

0

DATA IN

1

COMMAND

0

STATUS

1

*

0

*

1

MESSAGE OUT

0

MESSAGE IN

1

Direction of Transfer

Initiator to target

Initiator from target

Initiator to target

Initiator from target

Initiator to target

Initiator to target

Comment

Data

Phase

Message

Phase

Asynchronous Information Transfer

The target shall control the direction of information transfer by

means of the I/O signal. When the I/O signal is true, information

shall be transferred from the target to the initiator. When the I/O