Page 1

FUJITSU Server

PRIMEQUEST

Hardware Installation Manual

2000 Series

C122-H007-01EN

Page 2

Preface

C122-H007-01EN

This manual describes the functions and features of the PRIMEQUEST 2000 series. The manual is intended for system

administrators.

For details on the regulatory compliance statements and safety precautions, see the PRIMEQUEST 2 000 Series Safety

and Regulatory Information (C122-E171XA).

Errata and add enda fo r the manu al

The PRIMEQUEST 2000 Series Errata and Addenda (C122-E182EN) provides errata and addenda for the manual.

Read the PRIMEQUE ST 2000 Series Errata and Addenda (C122-E182EN) thoroughly in reference to the manual.

Organization of this manual

This manual is organized as follows.

CHAPTER 1 Installation Data

Chapter 1 provides various useful information on PRIMEQUEST 2000 series installation. The information includes device

configuration details, device outline drawings, installation specifications, and various layout diagrams.

CHAPTER 2 Connected Information

Chapter 2 describes the cables used with the PRIMEQUEST 2000 series and provides an overview of cable connections.

CHAPTER 3 Notes on Carrying In and Installing the Product

Chapter 3 provides notes on carrying in and installing the PRIMEQUEST 2000 series server.

Appendix A Racks

Appendix A provides various information on the mounting racks for the PRIMEQUE ST 2000 series and PCI_Box.

Preface

i

Page 3

Preface

C122-H007-01EN

Revision History

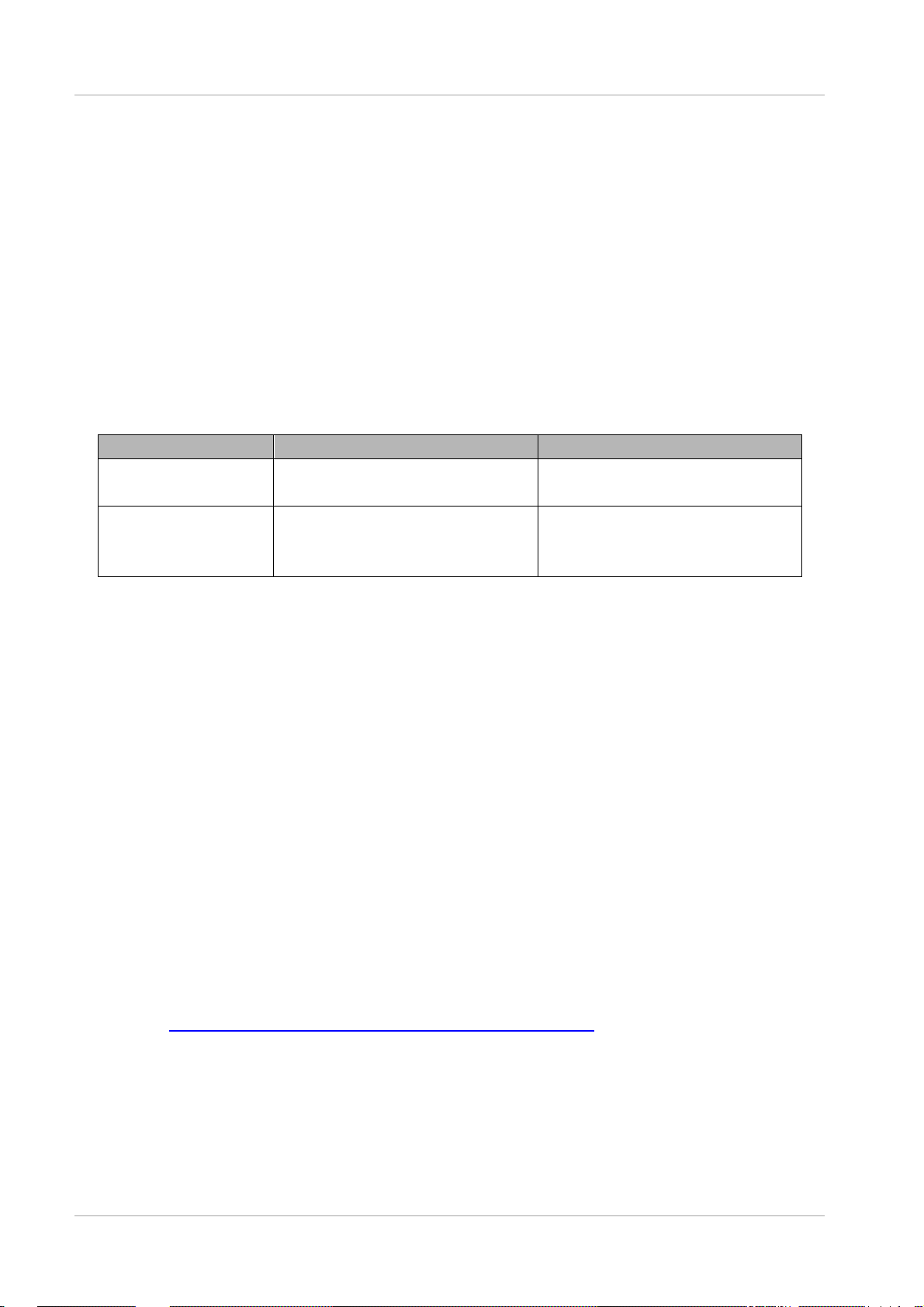

Edition Date Revised location (type) (*1) Description

1 2014-02-18 - -

*1: Chapter, section, and item numbers in the "Revised location" column refer to those in the latest edition of the

document. However, a number marked with an asterisk (*) denotes a chapter, section, or item in a previous

edition of the document.

ii

Page 4

Preface

C122-H007-01EN

Product operating environment

This product is a computer intended for use in a computer room environment. For details on the product operating

environment, see the following manual:

PRIMEQUEST 2000 Series Hardware Installation Manual (C122-H007EN)

Safety Precautions

Alert messages

This manual uses the following alert messages to prevent users and bystanders from being injured and to prevent

property damage.

This indicates a hazardous (potentially dangerous) situation that is likely to result in death or serious

personal injury if the user does not perform the procedure correctly.

This indicates a hazardous situation that could result in minor or moderate personal injury if the user

does not perform the procedure correctly. This also indicates that damage to the product or other

property may occur if the user does not perform the procedure correctly.

This indicates information that could help the user use the product more efficiently.

Alert messages in the text

An alert statement follows an alert symbol. An alert statement is indented on both ends to distinguish it from regular text.

Similarly, one space line is inserted before and after the alert statement.

Only Fujitsu certified service engineers should perform the following tasks on this product and the

options provided by Fujitsu. Customers must not perform these tasks under any circumstances.

Otherwise, electric shock, injury, or fire may result.

- Newly installing or moving equipment

- Removing the front, rear, and side covers

- Installing and removing built-in options

- Connecting and disconnecting external interface cables

- Maintenance (repair and periodic diagnosis and maintenance)

The List of important alert items table lists important alert items.

iii

Page 5

Preface

C122-H007-01EN

List of important alert items

This manual does not contain important alert items.

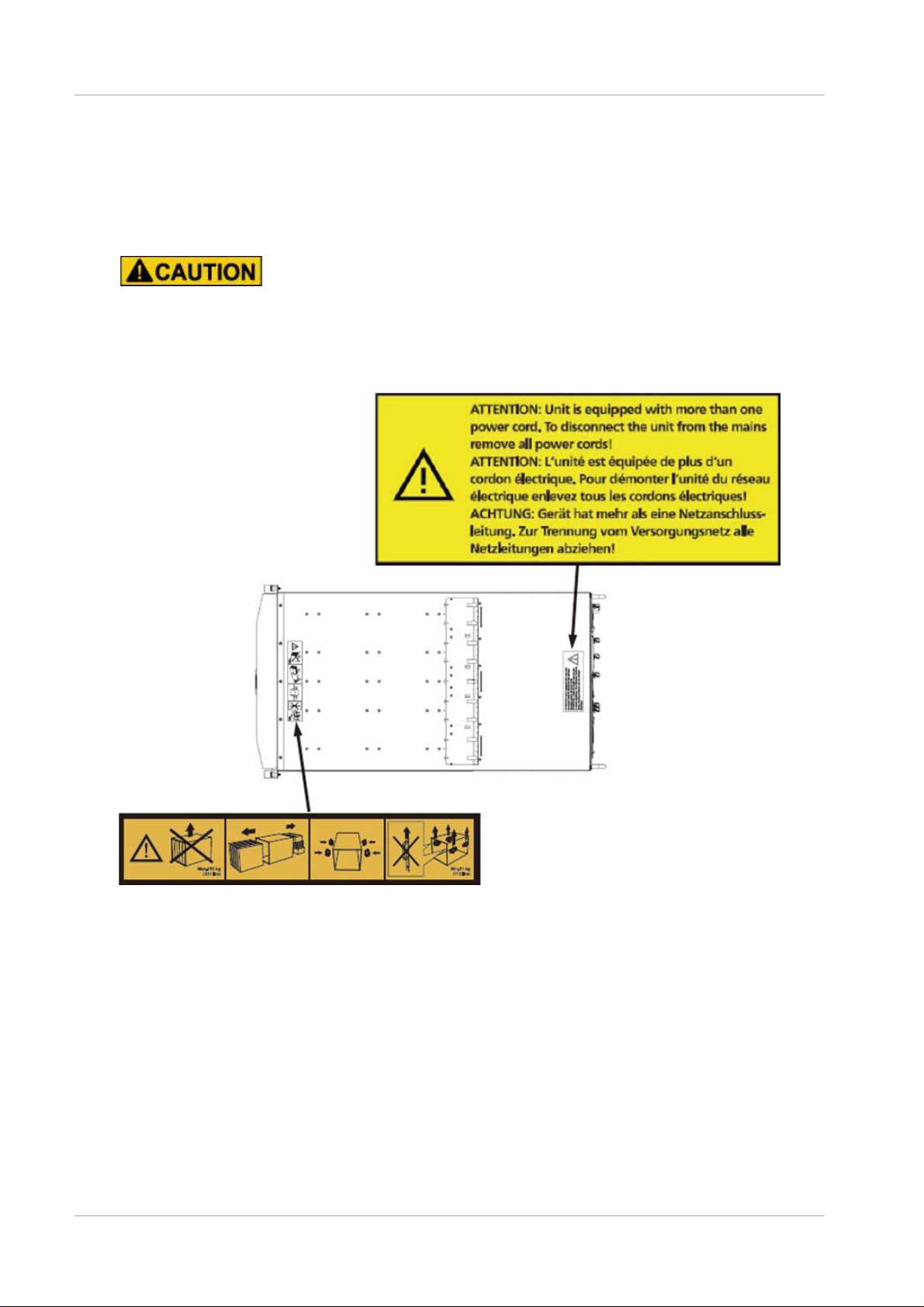

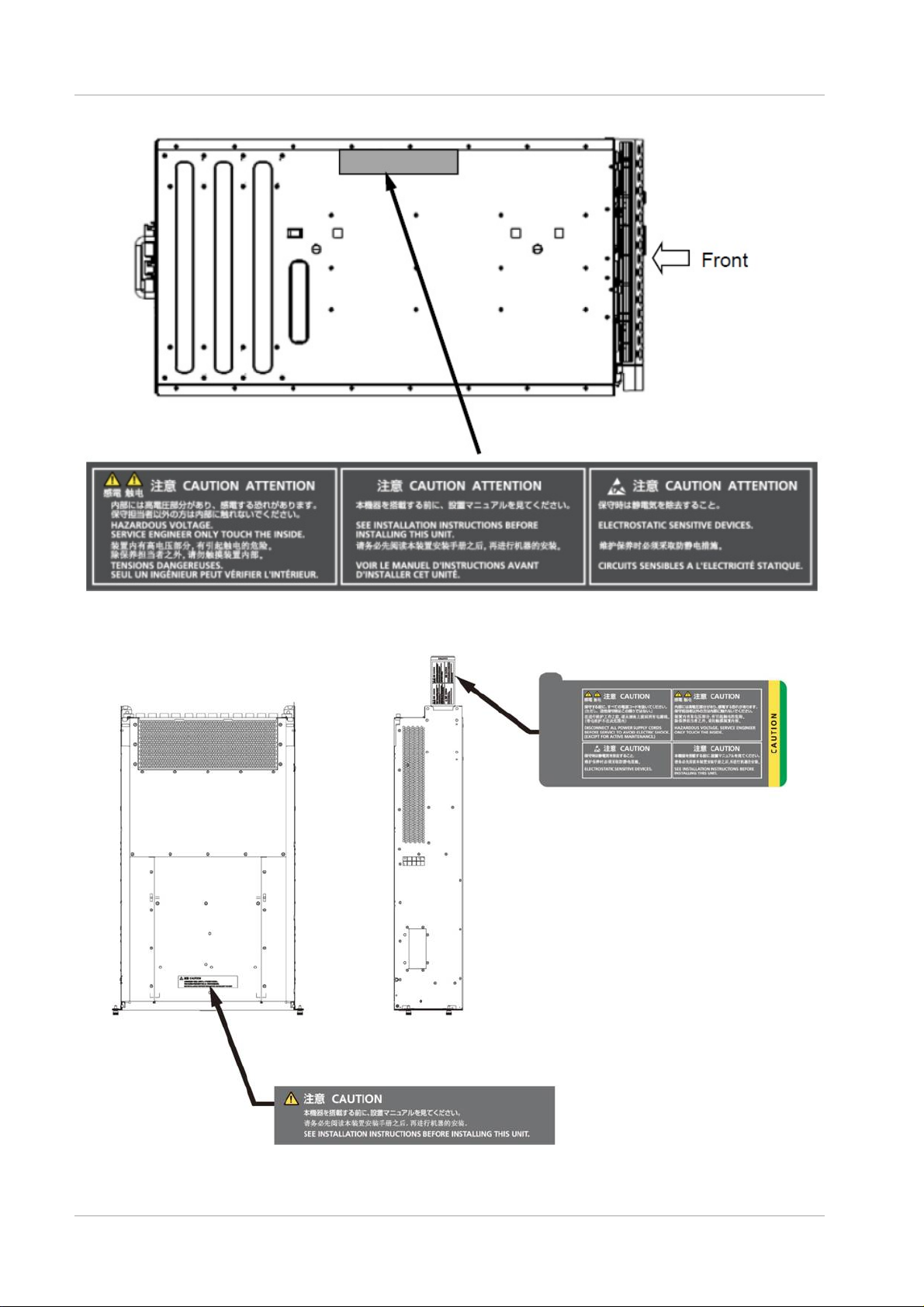

Warning labels

Never remove the warning labels.

Warning label location (the main cabinet top)

Warning label location (the main cabinet left)

iv

Page 6

Preface

C122-H007-01EN

Warning label location (PCI_B ox)

v

Page 7

Preface

C122-H007-01EN

Notes on Handling the Product

About this product

This product is designed and manufactured for standard applications. Such applications include, but are not limited to,

general office work, personal and home use, and general industrial use. The product is not intended for applications that

require extremely high levels of safety to be guaranteed (referred to below as "safety-critical" applications). Use of the

product for a safety-critical application may present a significant risk of personal injury and/or death. Such applications

include, but are not limited to, nuclear reactor control, aircraft flight control, air traffic control, mass transit control, medical

life support, and missile launch control. Customers shall not use the product for a safety-critical application without

guaranteeing the required level of safety. Customers who plan to use the product in a safety-critical system are requested

to consult the Fujitsu sales representatives in charge.

Storage of accessories

Keep the accessories in a safe place because they are required for server operation.

Adding optional products

For stable operation of the PRIMEQUEST 2000 series server, use only a Fujitsu-certified optional product as an added

option.

Note that the PRIMEQUEST 2000 series server is not guaranteed to operate with any optional product not certified by

Fujitsu.

Maintenance

Only Fujitsu certified service engineers should perform the following tasks on this product and the

options provided by Fujitsu. Customers must not perform these tasks under any circumstances.

Otherwise, electric shock, injury, or fire may result.

- Newly installing or moving equipment

- Removing the front, rear, and side covers

- Installing and removing built-in options

- Connecting and disconnecting external interface cables

- Maintenance (repair and periodic diagnosis and maintenance)

Only Fujitsu certified service engineers should perform the following tasks on this product and the

options provided by Fujitsu. Customers must not perform these tasks under any circumstances.

Otherwise, product failure may result. PRIMEQUE ST 2000 Series General Description

- Unpacking an optional Fujitsu product, such as an optional adapter, delivered to the customer

Modifying or recycling the product

Modifying this product or recycling a secondhand product by overhauling it without prior approval

may result in personal injury to users and/or bystanders or damage to the product a nd/or ot her

property.

vi

Page 8

Preface

C122-H007-01EN

Note on erasing data from hard disks when disposing of the product or transferring it

Disposing of this product or transferring it as is may enable third parties to access the data on the hard disk and use it for

unforeseen purposes. To prevent the leakage of confidential information and important data, all of the data on the hard

disk must be erased before disposal or transfer of the product.

However, it can be difficult to completely erase all of the data from the hard disk. Simply initializing (reformatting) the hard

disk or deleting files on the operating system is insufficient to erase the data, even though the data appears at a glance to

have been erased. This type of operation only makes it impossible to access the data from the operating system.

Malicious third parties can restore this data.

If you save your confidential information or other important data on the hard disk, you should completely erase the data,

instead of simply carrying out the aforementioned operation, to prevent the data from being restored. To prevent important

data on the hard disk from being leaked when the product is disposed of or transferred, you will need to take care to erase

all the data recorded on the hard disk on your own responsibility.

Furthermore, if a software license agreement restricts the transfer of the software (operating system and application

software) on the hard disk in the server or other product to a third party, transferring the product without deleting the

software from the hard disk may violate the agreement. Adequate verification from this point of view is also necessary.

Product and service inquiries

For all product use and technical inquiries, contact the distributor where you purchased your product, or a Fujitsu sales

representative or systems engineer (SE). If you do not know the appropriate contact address for inquiries about the

PRIMEQUEST 20 00 series, use the Fujitsu contact line.

Fujitsu contact line

We accept Web inquiries. For details, visit our website:

https://www-s.fujitsu.com/global/contact/computing/PRMQST_feedback.html

Warranty

If a component failure occurs during the warranty period, we will repair it free of charge in accordance with the terms of the

warranty agreement. For details, see the warranty.

Before requesting a repair

If a problem occurs with the product, confirm the problem by referring to 11.2 Troubleshooting in the PRIMEQUEST 2000

Series Administration Manual (C122-E175ENEN). If the error recurs, contact your sales representative or a field engineer.

Confirm the model name and serial number shown on the label affixed to the right front of the device and report it. Also

check any other required items beforehand according to 11.2 Troubleshooting in the PRIMEQUEST 2000 Series

Administration Manual (C122-E175ENEN).

The system settings saved by the customer will be used during maintenance.

vii

Page 9

Preface

C122-H007-01EN

including

Manual

How to use this manual

This manual contains important information about the safe use of this product. Read the manual thoroughly to understand

the information in it before using this product. Be sure to keep this manual in a safe and convenient location for quick

reference.

Fujitsu makes every effort to prevent users and bystanders from being injured and to prevent property damage. Be sure to

use the product according to the instructions in this manual.

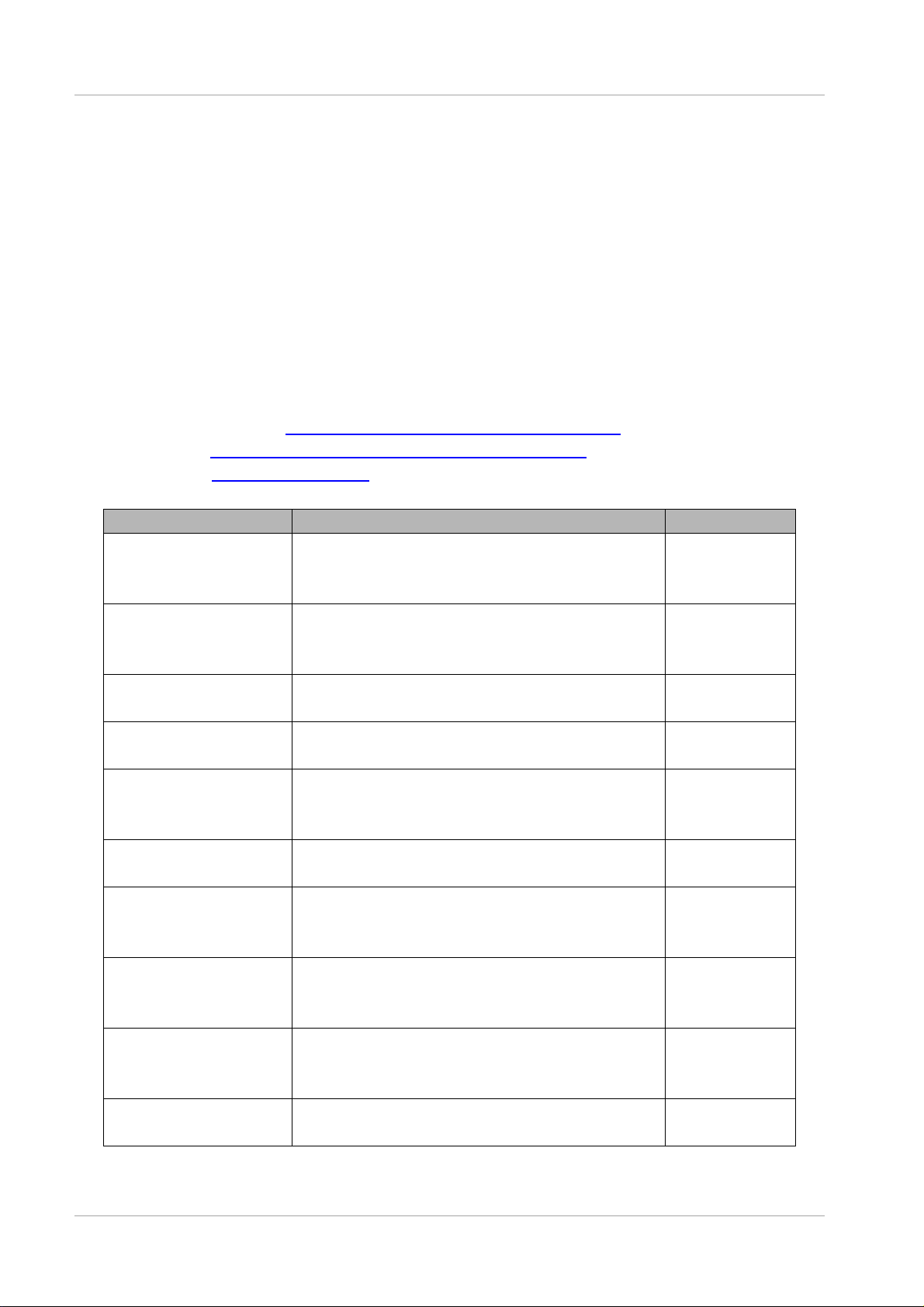

Manuals for the PRIMEQUEST 2000 series

The following manuals have been prepared to provide you with the information necessary to use the PRIMEQUEST 2000

series.

You can access HTML versions of these manuals at the following sites:

Japanese-language site: http://jp.fujitsu.com/platform/server/primequest/manual/2000/

Global site: http://www.fujitsu.com/global/services/computing/server/primequest/

http://manuals.ts.fujitsu.com/

Title

PRIMEQUEST 2000 Series

Getting Started Guide

PRIMEQUEST 2000 Series

Safety and Regulatory

Information

PRIMEQUEST 2000 Series

Errata and Addenda

PRIMEQUEST 2000 Series

General Description

SPARC Enterprise/

PRIMEQUEST C ommon

Installation Planning Manual

PRIMEQUEST 2000 Series

Hardware Installation Manual

PRIMEQUEST 2000 Series

Installation Manual

PRIMEQUEST 2000 Series

User Interface Operating

Instructions

PRIMEQUEST 2000 Series

Administration Manual

PRIMEQUEST 2000 Series

Tool Reference

Describes what manuals you should read and how to access

important information after unpacking the PRIMEQUEST 2000

series server. (This manual comes with the product.)

Contains important information required for using the

PRIMEQUEST 20 00 series safely.

Provides errata and addenda for the PRIMEQUEST 2000 series

manuals. This manual will be updated as needed.

Describes the functions and features of the PRIMEQU EST 2000

series.

Provides the necessary information and concepts you should

understand for installation and facility planning for SPARC

Enterprise and PRIMEQUEST installations.

Includes the specifications of and the installation location

requirements for the PRIMEQUEST 2000 series.

Describes how to set up the PRIMEQUEST 20 00 series server,

including the steps for installation preparation, initialization, and

software installation.

Describes how to use the Web-UI and UEFI to assure proper

operation of the PRIMEQUEST 2000 series server.

Describes how to use tools and software for system

administration and how to maintain the system (component

replacement and error notification).

Provides information on operation methods and settings,

details on the MMB, PSA, and UEFI functions.

Description

Manual code

C122-E170XA

C122-E171XA

C122-E182EN

C122-B025EN

C120-H007EN

C122-H007EN

C122-E174EN

C122-E176EN

C122-E175EN

C122-E177EN

viii

Page 10

Preface

C122-H007-01EN

problem occurs

Title

PRIMEQUEST 2000 Series

Message Reference

PRIMEQUEST 2000 Series

REMCS Installation Manual

PRIMEQUEST 2000 Series

Glossary

Lists the messages that may be displayed when a

during operation and describes how to respond to them.

Describes REMCS service installation and operation C122-E180EN

Defines the PRIMEQUEST 2000 series related terms and

abbreviations.

Description

Manual code

C122-E178EN

C122-E179EN

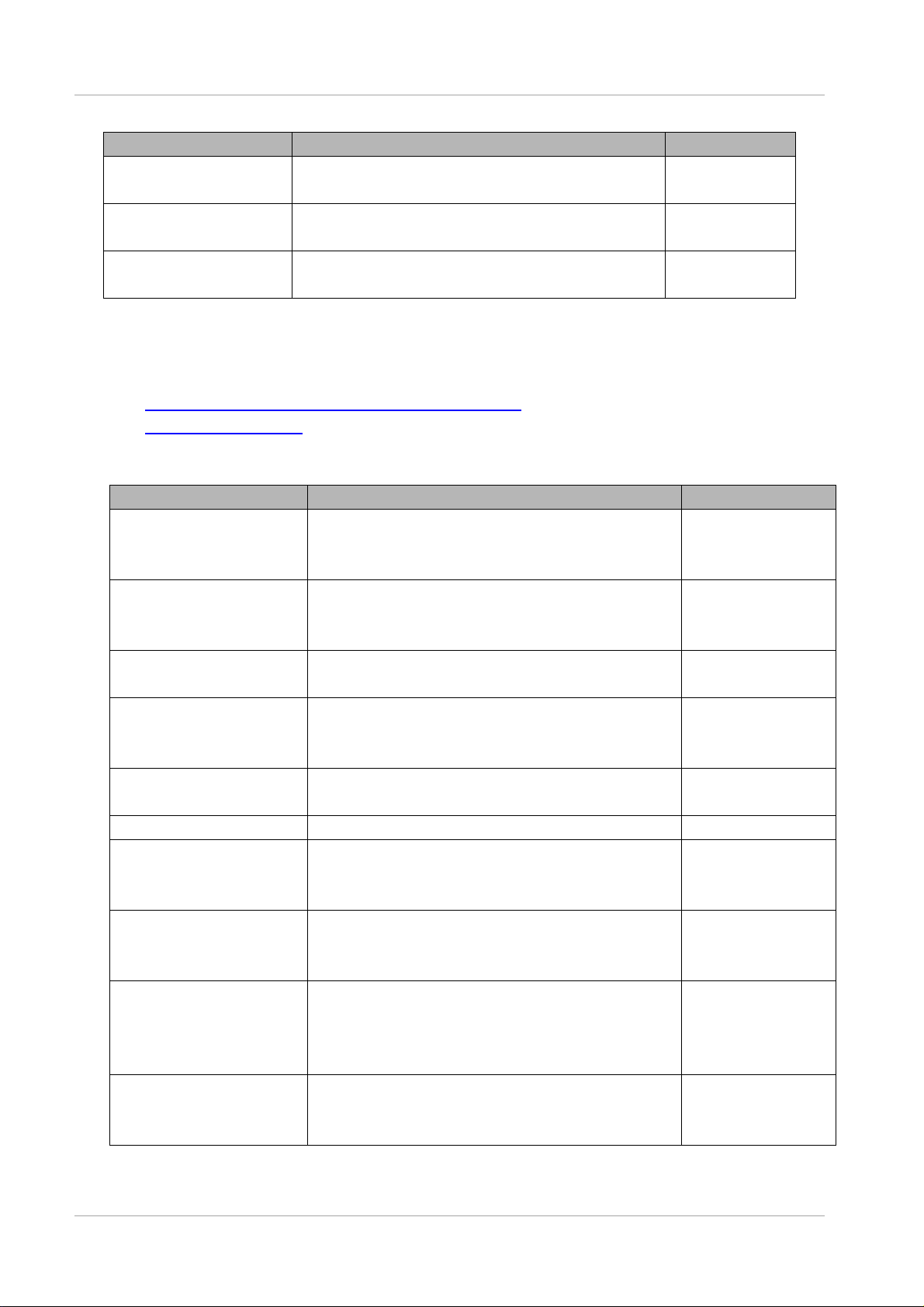

Related manuals

The following manuals relate to the PRIMEQUEST 2000 series.

You can access these manuals at the following site:

http://www.fujitsu.com/global/services/computing/server/primequest/

http://manuals.ts.fujitsu.com/

Contact your sales representative for inquiries about the ServerView manuals

Title

ServerView Suite ServerView

Operations Manager Quick

Installation (Windows)

ServerView Suite ServerView

Operations Manager Quick

Installation (Linux)

ServerView Suite ServerView

Installation Manager

ServerView Suite ServerView

Operations Manager Server

Management

ServerView Suite ServerView

RAID Management User Manual

ServerView Suite Basic Concepts Describes basic concepts about ServerView Suite. None

ServerView Operations Manager

Installation ServerView Agents for

Linux

ServerView Operations Manager

Installation ServerView Agents for

Windows

ServerView Mission Critical

Option User Manual

ServerView RAID Manager

VMware vSphere ESXi 5

Installation Guide

Describes how to install and start ServerView Operations

Manager in a Windows environment.

Describes how to install and start ServerView Operations

Manager in a Linux environment.

Describes the installation procedure using ServerView Installation

Manager.

Provides an overv iew of serv er moni tori ng usin g Serv erView

Operations Manager, and describes the user interface of

ServerView Operations Manager.

Describes RAID management using ServerView RAID Manager. None

Describes installation and update installation of ServerView Linux

Agent.

Describes installation and update installation of ServerView

Windows Agent.

Describes the necessary functions unique to PRIMEQUEST

(notification via the MMB, hot replacement command) and

ServerView Mission Critical Option (SVmco), which is required for

supporting these functions..

Describes the installation and settings required to use ServerView

RAID Manager on the VMware vSphere ESXi 5 server.

Description

None

None

None

None

None

None

None

None

Manual code

ix

Page 11

Preface

C122-H007-01EN

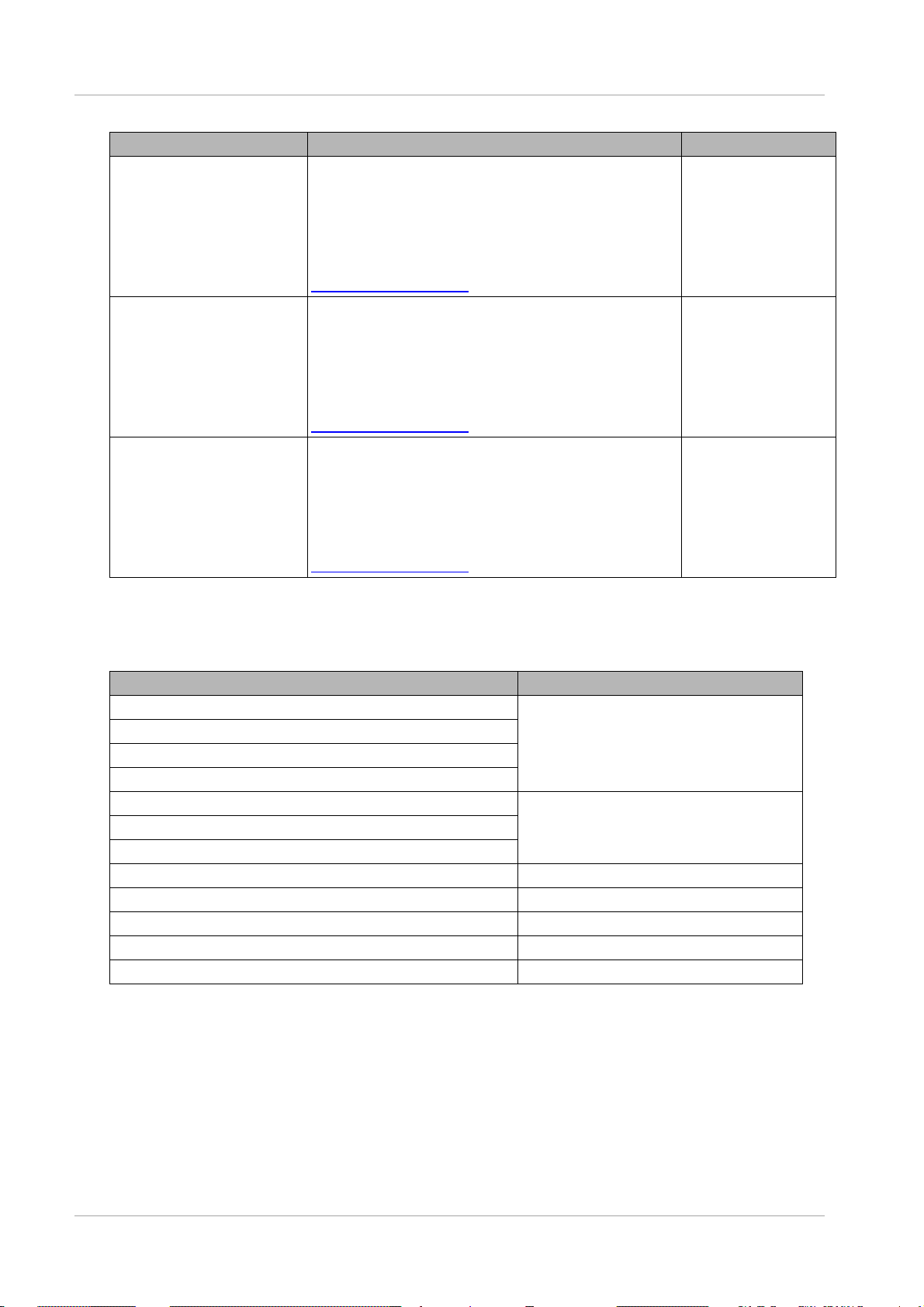

Title

MegaRAID SAS Software Provides technical information on using RAID controllers.

Refer to the manual from the SVS-ServerView Suite ServerBooks

DVD(Manual)2 supplied with the product or from the following

URL:

The Fujitsu Technology Solutions manuals server

http://manuals.ts.fujitsu.com/

MegaRAID SAS Device Driver

Installation

Modular RAID Controller

Installation Guide

Provides technical information on using RAID controllers.

Refer to the manual from the SVS-ServerView Suite ServerBooks

DVD(Manual)2 supplied with the product or from the following

URL:

The Fujitsu Technology Solutions manuals server

http://manuals.ts.fujitsu.com/

Provides technical information on using RAID controllers.

Refer to the manual from the SVS-ServerView Suite ServerBooks

DVD(Manual)2 supplied with the product or from the following

URL:

The Fujitsu Technology Solutions manuals server

http://manuals.ts.fujitsu.com/

Description

Manual code

None

None

None

Abbreviations

This manual uses the following product name abbreviations.

Formal product name Abbreviation

Microsoft ® Windows Server ® 2012 R2 Datacenter Windows, Windows Server 2012

Microsoft ® Windows Server ® 2012 R2 Standard

Microsoft ® Windows Server ® 2012 Datacenter

Microsoft ® Windows Server ® 2012 Standard

Microsoft ® Windows Server ® 2008 R2 Standard Windows, Windows Server 2008

Microsoft ® Windows Server ® 2008 R2 Enterprise

Microsoft ® Windows Server ® 2008 R2 Datacenter

Red Hat ® Enterprise Linux ® 6 (for Intel64) Linux, RHEL6, RHEL

Novell (R) SUSE(R) LINUX Enterprise Server 11 Service Pack 3 SLES11 SP3

Oracle Linux 6 (x86_64) Oracle Linux, Oracle Linux 6

VMware vSphere (R) 5 VMware, vSphere 5.x, VMware 5, VMwar e 5.x

VMware (R) ESXi (TM) 5 ESXi, ESX i 5, ESXi 5.x

Trademarks

- Microsoft, Windows, and Windows Server are trademarks or registered trademarks of Microsoft Corporation in the

United States and/or other countries.

- Linux is a registered trademark of Linus Torvalds.

- Red Hat, the Shadowman logo and JBoss are registered trademarks of Red Hat, Inc. in the U.S. and other countries.

- Oracle and Java are registered trademark of Oracle Corporation and its related company.

- Intel, Intel logo, Intel Inside, Intel Inside logo, Intel Atom, Intel Atom Inside, Intel Core, Core Inside, Intel vPro, vPro

x

Page 12

Preface

C122-H007-01EN

Inside, Celeron, Celeron Inside, Itanium, Itanium Inside, Pentium, Pentium Inside, Xeon, Xeon Phi, Xeon Inside,

Ultrabook are trademarks or registered trademarks of Intel Corporation.

- Ethernet is a registered trademark of Fuji Xerox Co., Ltd. in Japan and is a registered trademark of Xerox Corp. in the

United States and other countries.

- VMware is a trademark or registered trademark of VMware, Inc. in the United States and other countries.

- Novell and SUSE Linux Enterprise Server are trademarks of Novell, Inc.

- Xen is a trademark or registered trademark of Citrix Systems, Inc. or its subsidiaries in the United States and other

countries.

- Other company names and product names are the trademarks or registered trademarks of their respective owners.

- Trademark indications are omitted for some system and product names in this manual.

Notation

This manual uses the following fonts and symbols to express specific types of information.

Font or symbols Meaning Example

italics Title of a manual that you should refer to See the PRIMEQUEST 2000 Series

Installation Manual (C122-E174EN).

[ ]

Window names as well as the names of

buttons, tabs, and drop-down menus in

windows are enclosed in brackets.

Click the [OK] button.

Notation for the CLI (command line interface)

The following notation is used for commands.

Command syntax

Command syntax is represented as follows.

- Variables requiring the entry of a value are enclosed in angle brackets < >.

- Optional elements are enclosed in brackets [ ].

- Options for optional keywords are grouped in | (stroke) separated lists enclosed in brackets [ ].

- Options for required keywords are grouped in | (stroke) separated lists enclosed in braces { }.

Command syntax is written in a box.

Remarks

The command output shown in the PDF manuals may include line feeds at places where there is no line feed symbol

(\ at the end of the line)

Notes on notations

- If you have a comment or request regarding this manual, or if you find any part of this manual unclear, please take a

moment to share it with us by filling in the form at the following webpage, stating your points specifically, and sending

the form to us:

https://www-s.fujitsu.com/global/contact/computing/PRMQST_feedback.html

- The contents of this manual may be revised without prior notice.

- In this manual, the Management Board and MMB firmware are abbreviated as "MMB."

- In this manual, IOU_10GbE and IOU_1GbE are collectively referred to as IO Units.

- Screenshots contained in this manual may differ from the actual product screen displays.

- The IP addresses, configuration information, and other such information contained in this manual are display

examples and differ from that for actual operation.

xi

Page 13

Preface

C122-H007-01EN

- The PDF file of this manual is intended for display using Adobe® Reader® in single page viewing mode at 100%

zoom.

This manual shall not be reproduced or copied without the permission of Fujitsu Limited.

Copyright 2014 FU JITSU LIM ITED

xii

Page 14

Preface

C122-H007-01EN

Contents

Preface ................................................................................................................................................................................................................ i

Installation Data .................................................................................................................................................................... 1 CHAPTER 1

Configuration Contents of Device ................................................................................................................................................. 1

1.1

1.2 External Overview of Device ......................................................................................................................................................... 1

1.2.1 External Overview of Device (Main equipment) ...................................................................................................................... 1

1.2.2 External Overview of Device (PCI_Box) .................................................................................................................................. 5

1.3 Installation Specifications ............................................................................................................................................................... 6

1.3.1 Installation specifications (PRIMEQUEST 2400E) ................................................................................................................. 6

1.3.2 Installation Specifications (PRIMEQUEST 2800E) ................................................................................................................. 8

1.3.3 Installation Specifications (PRIMEQUEST 2800B) .............................................................................................................. 10

1.3.4 Installation Specifications (PCI_Box) .................................................................................................................................... 12

1.4 Installation Area ........................................................................................................................................................................... 13

1.5 Flow of Cooling Air and Exhaust Air of Installation .................................................................................................................... 14

1.5.1 Flow of Cooling Air and Exhaust Air (Main Cabinet) ............................................................................................................ 14

1.5.2 Flow of Cooling Air and Exhaust (PCI_Box)......................................................................................................................... 14

1.6 Installation Environment ............................................................................................................................................................. 15

1.6.1 Dust ........................................................................................................................................................................................ 15

1.6.2 Corrosive Gas ........................................................................................................................................................................ 15

1.6.3 Sea Water (Salt Damage) ..................................................................................................................................................... 15

1.7 Safety Measures ......................................................................................................................................................................... 15

Connected Information ..................................................................................................................................................... 16 CHAPTER 2

Connection summary ................................................................................................................................................................. 16

2.1

2.2 Connection of signal cable ......................................................................................................................................................... 17

2.2.1 Basic interface and peripheral ............................................................................................................................................... 17

2.2.2 Details of external interface connection ................................................................................................................................ 17

2.3 Power cable connection ............................................................................................................................................................. 22

2.3.1 Power Supply Cable Connection (PRIMEQUEST 2400E) ................................................................................................. 22

2.3.2 Power Cables Connections (PRIMEQUEST 2800E/2800B) .............................................................................................. 25

2.3.3 Power Cable Connections (PCI_Box) .................................................................................................................................. 27

2.4 Connection Specifications of Input Power ................................................................................................................................. 30

2.4.1 Input Power Connection Specifications (Base Cabinet) ...................................................................................................... 30

2.4.2 Input Power Supply Connection Specifications (PCI_Box) ................................................................................................. 30

2.4.3 Power Distribution Box and Distribution Panel ..................................................................................................................... 31

2.5 Free Access Underfloor Connection of Power Cable ............................................................................................................... 31

2.6 Cutoff Characteristics of Distribution Panel (At the time of connecting power distribution box) .............................................. 32

Notes on Carrying In and Installing the Product .............................................................................................................. 34 CHAPTER 3

Elevator Load Conditions ........................................................................................................................................................... 34

3.1

3.2 Earthquake Preparedness Measures ....................................................................................................................................... 34

Appendix A Racks .......................................................................................................................................................................................... 35

A.1 Rack Mounting ..................................................................................................................................................................................... 35

A.2 Rack Mounting Requirements ............................................................................................................................................................ 35

A.2.1 Requirements for mounting in a Fujitsu 19-inch rack ................................................................................................................. 35

xiii

Page 15

Preface

C122-H007-01EN

A.2.2 Requirements for mounting in a third party's rack ....................................................................................................................... 37

xiv

Page 16

Preface

C122-H007-01EN

Figures

FIGURE 1.1 PRIMEQUEST 2400E/2800E front view ........................................................................................................................... 1

FIGURE 1.2 PRIMEQUEST 2400E/2800E rear view ............................................................................................................................ 2

FIGURE 1.3 PRIMEQUEST 2400E/2800E top view.............................................................................................................................. 2

FIGURE 1.4 PRIMEQUEST 2400E/2800E right side view .................................................................................................................... 2

FIGURE 1.5 PRIMEQUEST 2800B front view ....................................................................................................................................... 3

FIGURE 1.6 PRIMEQUEST 2800B rear view ........................................................................................................................................ 3

FIGURE 1.7 PRIMEQUEST 2800B top view .......................................................................................................................................... 3

FIGURE 1.8 PRIMEQUEST 2800B right side view ................................................................................................................................ 4

FIGURE 1.9 Front View of PCI_Box ........................................................................................................................................................ 5

FIGURE 1.10 Rear View of PCI_Box ...................................................................................................................................................... 5

FIGURE 1.11 Top View of PCI_Box ........................................................................................................................................................ 5

FIGURE 1.12 Right Side View of PCI_Box ............................................................................................................................................. 5

FIGURE 1.13 Service Area at the time of installing 19 inch rack model ............................................................................................. 13

FIGURE 1.14 Flow of Cooling Air and Exhaust Air (Main Cabinet)..................................................................................................... 14

FIGURE 1.15 Flow of Cooling Air and Exhaust (PCI_Box) ................................................................................................................. 14

FIGURE 2.1 Summary of Device Connection ...................................................................................................................................... 16

FIGURE 2.2 External interface connection figure of (PRIMEQUEST 2400E (Front surface)) .......................................................... 18

FIGURE 2.3 External interface connection figure of (PRIMEQUEST 2400E (Back surface)) .......................................................... 18

FIGURE 2.4 External interface connection figure of (PRIMEQUEST 2800E (Front surface)) .......................................................... 19

FIGURE 2.5 External interface connection figure of (PRIMEQUEST 2800E (Back surface)) .......................................................... 19

FIGURE 2.6 External interface connection figure of (PRIMEQUEST 2800B (Front surface)) .......................................................... 20

FIGURE 2.7 External interface connection figure of (PRIMEQUEST 2800B (Back surface)) .......................................................... 20

FIGURE 2.8 Details of external interface (MMB) .................................................................................................................................. 21

FIGURE 2.9 Details of external interface (I OU_1G bE) ........................................................................................................................ 21

FIGURE 2.10 Details of external interface (IOU_10GbE) .................................................................................................................... 21

FIGURE 2.11 Details of external interface (DU) ................................................................................................................................... 21

FIGURE 2.12 Details of external interface (PCI_Box).......................................................................................................................... 22

FIGURE 2.13 100V Standard Power Feed Configuration (Single power feed, no Redundant Power Feed) .................................. 22

FIGURE 2.14 100V Redundant Power Feed Configuration (Single power feed, Redundant Power Feed) .................................... 23

FIGURE 2.15 Standard Configuration of 200 V (single power feed, no redundant power feed) with Power Distribution Box

Connection ...................................................................................................................................................................................... 23

FIGURE 2.16 200 V Redundant Power Feed Configuration (single power feed, redundant power feed) with Power Distribution

Box Connection .............................................................................................................................................................................. 24

FIGURE 2.17 200 V Dual Power Feed Configuration with Power Distribution Box Connection ....................................................... 24

FIGURE 2.18 200V Standard Configuration (single power feed and no redundant power feed) with Power Distribution Box

Connection ...................................................................................................................................................................................... 25

FIGURE 2.19 200 V Redundant Power Feed Configuration (single power feed, redundant power feed) with Power Distribution

Box Connection .............................................................................................................................................................................. 26

FIGURE 2.20 200 V Dual Power Feed Configuration with Power Distribution Box Connection ....................................................... 27

FIGURE 2.21 100 V Configuration (Single power feed, no Redundant power feed) ......................................................................... 27

FIGURE 2.22 100 V Redundant power feed configuration (Single power feed, redundant power feed) ......................................... 28

FIGURE 2.23 200V Standard configuration (single power feed, no redundant power feed) power distribution box connection .... 28

xv

Page 17

Preface

C122-H007-01EN

FIGURE 2.24 200 V Redundant Power Feed Configuration (Single power feed, Redundant Power Feed) Power Distribution Box

Connection ...................................................................................................................................................................................... 29

FIGURE 2.25 200 V Dual Power Feed Configuration with Power Distribution Box Connection ....................................................... 29

FIGURE 2.26 When Underfloor Height is less than 300mm (11.8 in) ................................................................................................ 31

FIGURE 2.27 When the under floor height is 300 mm (11.8 in) or more. ........................................................................................... 31

FIGURE 2.28 Characteristics of Breaker of Distribution Panel ............................................................................................................ 33

FIGURE A.1 Example of rack mounting ............................................................................................................................................... 36

FIGURE A.2 Length of rack ................................................................................................................................................................... 38

FIGURE A.3 Width of rack ..................................................................................................................................................................... 38

FIGURE A.4 Format of rack posts ........................................................................................................................................................ 39

xvi

Page 18

Preface

C122-H007-01EN

Tables

TABLE 1.1 Name and Contents of Configuration of Each device .......................................................................................................... 1

TABLE 1.2 Installation Specifications (PRIMEQUEST 2400E) .............................................................................................................. 6

TABLE 1.3 Installation Specifications (PRIMEQUEST 2800E) .............................................................................................................. 8

TABLE 1.4 Installation Specifications (PRIMEQUEST 2800B) ........................................................................................................... 10

TABLE 1.5 Installation Specifications (PCI_Box) ................................................................................................................................. 12

TABLE 1.6 Permissible Level of Corrosive Gas ................................................................................................................................... 15

TABLE 2.1 Notes for Device connection .............................................................................................................................................. 17

TABLE 2.2 Power Cable Specifications (Base Cabinet)...................................................................................................................... 30

TABLE 2.3 Power Cable Specification (PCI_Box) ............................................................................................................................... 30

TABLE 2.4 Power Supply Cable Specifications of Power Distribution Box and Distribution Panel ................................................... 31

TABLE 2.5 Characteristic Condition of Distribution Panel Breaker ..................................................................................................... 32

TABLE 3.1 Elevator load conditions ...................................................................................................................................................... 34

TABLE A.1 Recommended racks for mounting ................................................................................................................................... 35

TABLE A.2 PRIMEQUEST 2000 series external dimensions............................................................................................................. 35

TABLE A.3 Structural condition of rack ................................................................................................................................................. 37

xvii

Page 19

CHAPTER 1 Installation Data

C122-H007-01EN

Equipment Name

Content Configuration

Size

(Height)

PRIMEQUEST

2400E

Maximum 2 SB (Maximum 4 CPU), Maximum 4 IOU are available.

10 U

PRIMEQUEST

2800E/2800B

Maximum 4 SB (Maximum 8 CPU), Maximum 4 IOU are available.

PCI_Box

Device for extending PCI Express Slot.

One PCI_Box has 12 PCI Express slots.

4U

1.1 Configuration Contents of Device

Installation Data CHAPTER 1

It explains the various data used while installing various drawings for device configuration, device overview,

installation specification and layout.

1.1 Configuration Contents of Device

It shows the name and contents of configuration of each device.

TABLE 1.1 Name and Contents of Configuration of Each device

Maximum 4 units can be connected in PRIMEQUEST 2400E/2800E.

Remarks

Each device shown in “TABLE 1.1 Name and Contents of Configuration of Each device” is installed in 19

inch rack of EIA standard.

For the details on 19 inch rack, contact the distributor where you purchased your product, or your sales

representative.

1.2 External Overview of Device

This section describes the External Overview of each equipment.

1.2.1 External Overview of Devic e (M ai n equi pm e nt )

External Overview of device (Front view, Rear view, Top view, Right side view) of PRIMEQUEST 2000

Series is shown below.

PRIMEQUEST 2400E/2800E

FIGURE 1.1 PRIMEQUEST 2400E/2800E front view

1

Page 20

CHAPTER 1 Installation Data

C122-H007-01EN

1.2 External Overview of Device

FIGURE 1.2 PRIMEQUEST 2400E/2800E rear view

FIGURE 1.3 PRIMEQUEST 2400E/2800E top view

FIGURE 1.4 PRIMEQUEST 2400E/2800E right side view

2

Page 21

CHAPTER 1 Installation Data

C122-H007-01EN

1.2 External Overview of Device

PRIMEQUEST 2800B

FIGURE 1.5 PRIMEQUEST 2800B front view

FIGURE 1.6 PRIMEQUEST 2800B rear view

FIGURE 1.7 PRIMEQUEST 2800B top view

3

Page 22

CHAPTER 1 Installation Data

C122-H007-01EN

1.2 External Overview of Device

FIGURE 1.8 PRIMEQUEST 2800B right side view

4

Page 23

CHAPTER 1 Installation Data

C122-H007-01EN

1.2 External Overview of Device

1.2.2 External Overview of Device (PCI_Box)

Device External Overview (Front view, Rear view, Top view, Right side view) of PCI_Box is shown below.

FIGURE 1.9 Front View of PCI_Box

FIGURE 1.10 Rear View of PCI_Box

FIGURE 1.11 Top View of PCI_Box

FIGURE 1.12 Right Side View of PCI_Box

5

Page 24

CHAPTER 1 Installation Data

C122-H007-01EN

Item

Contents

External

[mm(in.)]

Width

445(17.52)

Length(*1)

782(30.79)

Height

438(17.25) 10U

Mass [kg(lb)] (*2)

128(282)

Conditions for

Maximum Calorific value

Input

Interruptible Power

11,887(11,266)

High efficiency Power

11,805(11,189)

Input

100V

Interruptible Power

12,528(11,874)

Displacement

Recommended Environmental

temperature

10(353)

Maximum

24(848)

Temperature and

Operati

Temperature[ºC(ºF)]

(*5)

Humidity[%RH]

20 to 80

Highest Wet bulb

Temperature[ºC(ºF)]

29(84.2)

Down

Temperature[ºC(ºF)]

0 to 50(32 to 122)

Humidity[%RH]

8 to 80

Highest Wet bulb

Temperature[ºC(ºF)]

29(84.2)

Noise[dB](*7,*8)

60

Acoustic power level[B](*8)

7.8

Permissible Vibration

Operating Time(including waiting

time)

4.0(400)( synthetic

seismic wave)

Down time(*9)

10.0(1000)( synthetic

seismic wave)

Permissible dust level[mg/m3]

0.15

Power

Input Voltage and Pulse number

200 to 240VAC±10%

1φ

Frequency and Fluctuation

50/60 Hz+2/-4%

Maximum Power

Operating

Input

Interruptible

Supply(*13)

4.17 kW/4.39 kVA

High efficiency

supply(*13)

4.04 kW/4.25 kVA

Input

100 V

Interruptible

Supply(*13)

4.42 kW/4.65 kVA

Standby time

0.079kW

Power Factor(*10)

0.95 or more

Inrush current[A][Rush time](*11)

20 or less

Leak current[mA](*12)

6.8 or less at 200V

3.5 or less at 100V

1.3 Installation Specifications

1.3 Installation Specifications

This section explains installation specification of each equipment.

1.3.1 Installation specifications (PRIMEQUEST 2400E)

TABLE 1.2 Installation Specifications (PRIMEQUEST 2400E)

Dimensions

Air

Conditioning

Conditions

[kJ/h(BTU/h)]

[m3/min(ft3/min)](*3)

Humidity Conditions(*4)

[m/s2(gal)]

Voltage:

200V

Voltage:

ng Time

Time(*6

)

Supply(*13)

supply(*13)

Supply(*13)

100 to 120VAC±10%

*1: Dimensions without protrusions (Dimensions including the front cover are 832mm(32.76in)).

Consumption

/Apparent Power

time

Voltage :

200 V

Voltage :

6

Power

Power

Power

Page 25

CHAPTER 1 Installation Data

C122-H007-01EN

1.3 Installation Specifications

*2: Numeric value when each optional device is mounted for maximum number of options.

However, rail for mounting rack (5.7kg) and cable type are not inclu ded.

Mass as per the installation configuration can be calculated using formula as shown below.

Device Mass: 78 + (11.1* A) + (2.5* B) + (1.8* C) + (3.3* D) [kg]

A= Number of mounted SB (Minimum 1 to Maximum 2)

B=Number of mounted IOU (Minimum 1 to Maximum 4)

C=Number of mounted extended PSU (Minimum 2 to Maximum 4)

D=Number of mounted DU (Minimum 0 to Maximum 2)

*3: If the device is overloaded or if abnormality is detected even though the recommended environmental

temperature is used, the FAN rotates at high-speed.

*4: Protect from condensation

*5: Temperature conditions changes according to installation location above sea level.

For 0 to 1000 m (0 to 3281 ft) above sea level, temperature range at the time of installation: 5 to 35ºC

(41 to 95.0ºF)

For 1000 to 1500 m (3281 to 4921 ft) above sea level, temperature range at the time of installation: 5 to

33ºC (41 to 91.4ºF)

For 1500 to 2000 m (4921 to 6562 ft) above sea level, temperature range at the time of installation: 5 to

31°C (41 to 87.8°F)

For 2000 to 3000 m (6562 to 9843 ft) above sea level, temperature range at the time of installation: 5 to

29°C (41 to 84.2°F)

Error of + 100m in the sea level settings of the location of installation is permissible.

*6: Downtime is the condition in which the device is packed and maintained.

*7: Level of noise which is actually heard varies as per the mounting condition of the position from where the

noise is heard or the position of rack.

*8: Level of noise and level of acoustic power changes according to the Hardware configuration, the

processing load and the environmental temperature.

*9: Downtime is the condition in which the device is installed. However, the power is switched off.

*10: Value at the time of operations.

*11: Value of 1 input cable

*12: Value of 1 device

*13: Interruptible power supply is the built-in PSU (80 PLUS SILVER supported), high efficiency power

supply is the built-in PSU (80 PLUS PLATINUM supported)

7

Page 26

CHAPTER 1 Installation Data

C122-H007-01EN

Items

Contents

Dimensions

Width

445(17.52)

Depth (*1)

782(30.79)

Length

438(17.25) 10U

Mass [kg (lb)] (*2)

150(331)

Conditions for

Max. calor ific

[kJ/h (BTU/h)]

Interruptible power source

17,712(16,787)

High efficiency power supply (*13)

17,388(16,480)

Displacement

Recommended environmental

temperature

12(424)

Max.

28(989)

Temperature and

At the time

Temperature [°C (°F)]]

(*5)

Humidity [%RH]

20 to 80

Max wet bulb

temperature [°C (°F)]]

29 (84.2)

Downtime

Temperature [°C (°F)]]

0 to 50 (32 to 122)

Humidity [%RH]

8 to 80

Max wet bulb

temperature [°C (°F)]]

29 (84.2)

Noise [dB] (*7, *8)

60

Acoustic power level [B] (*8)

7.8

Permissible

At the time of operation (Including

standby)

4.0 (400) (Composi te seismic

wave)

Downtime (*9)

10.0 (1000) (Composite

seismic wave)

Permissible dust level [mg/m3]

0.15

Power supply

Input voltage and source resultant pulse number

200 to 240 VAC±10 %

1φ

Frequency and fluctuating Range

50/60 Hz + 2/-4%

Max power

At the time

Interruptible power

source (*13)

6.11 kW/6.43 kVA

High efficiency power

supply (*13)

5.92 kW/6.23 kVA

Downtime

0.084 kW

Power factor (*10)

0.95 or more

Inrush current [A] [Rush hours] (*11)

20 or less

Leak current [mA] (*12)

6.9 or less

1.3 Installation Specifications

1.3.2 Installation Specific a ti ons ( P RIMEQUEST 2800E)

TABLE 1.3 Installation Specifications (PRIMEQUEST 2800E)

[mm (in.)]

air conditioner

conditions

value

[m3/min (ft3/min)]

(*3)

Humidity

conditions (*4)

Vibration [m/s2

(gal)]

consumption /

apparent power

of operation

(*6)

of operation

*1: Dimensions without protrusions (832 mm(32.76in) including front cover)

*2: Numeric value when each optional device is mounted for maximum number of options.

However, rail for mounting rack (5.7kg) and cable type are not inclu ded.

Mass as per the installation configuration can be calculated using formula as shown below.

Device mass = 78 + (11.1 * A) + (2.5 * B) + (1.8 * C) + (3.3 * D) [kg]

A = Number of mounted SB (Minimum 1 to Maximum 4)

B= Number of mounted IOU (Minimum 1 to Maximum 4)

C= Number of mounted PSU (Minimum 2 to Maximum 6)

D= Number of mounted DU (Minimum 0 to Maximum 2)*3: There are cases when device is overloaded or

when abnormality is detected, FAN rotates at high-speed even if recommended environmental

temperature is used.

*4: Protect from condensation.

*5: Temperature condition changes accord ing to the inst alla ti on locat ion abov e sea lev el.

For 0 to 1000 m (0 to 3281 ft) above sea level, temperature range at the time of installation: 5 to 35°C

(41 to 95°F)

For 1000 to 1500 m (3281 to 4921 ft) above sea level, temperature range at the time of installation: 5 to

33°C (41 to 91.4°F)

For 1500 to 2000 m (4921 to 6562 ft) above sea level, temperature range at the time of installation: 5 to

31°C (41 to 87.8°F)

8

Page 27

CHAPTER 1 Installation Data

C122-H007-01EN

1.3 Installation Specifications

For 2000 to 3000 m (6562 to 9843 ft) above sea level, temperature range at the time of installation: 5 to

29°C (41 to 84.2°F)

Error of + 100m in the sea level settings of the location of installation is permissible.

*6: Downtime is the condition in which the device is packed and maintained.

*7: Level of noise which is actually heard varies as per the mounting condition of the position from where the

noise is heard or the position of rack.

*8: Level of noise and the level of acoustic power changes according to the Hardware configuration, the

processing load and the environmental temperature.

*9: Downtime is the condition in which the device is installed. However, the power is switched off.

*10: Value at the time of operations.

*11: Value of 1 input cable

*12: Value of 1 device

*13: Interruptible power supply is the built-in PSU (80 PLUS SILVER supported), high efficiency power

supply is the built-in PSU (80 PLUS PLATINUM supported)

9

Page 28

CHAPTER 1 Installation Data

C122-H007-01EN

Items

Contents

Dimensions

Width

445(17.52)

Depth (*1)

782(30.79)

Length

438(17.25) 10U

Mass [kg (lb)] (*2)

143(315)

Conditions for

Max. calor ific

[kJ/h (BTU/h)]

Interruptible power source

16,992(16,105)

High efficiency power supply (*13)

16,740(15,866)

Displacement

Recommended environmental

temperature

12(424)

Max.

28(989)

Temperature and

At the time

Temperature [°C (°F)]]

(*5)

Humidity [%RH]

20 to 80

Max wet bulb

temperature [°C (°F)]]

29 (84.2)

Downtime

Temperature [°C (°F)]]

0 to 50 (32 to 122)

Humidity [%RH]

8 to 80

Max wet bulb

temperature [°C (°F)]]

29 (84.2)

Noise [dB] (*7, *8)

60

Acoustic power level [B] (*8)

7.8

Permissible

At the time of operation (Including

standby)

4.0 (400) (Composi te seismic

wave)

Downtime (*9)

10.0 (1000) (Composite

seismic wave)

Permissible dust level [mg/m3]

0.15

Power supply

Input voltage and source resultant pulse number

200 to 240 VAC±10 %

1φ

Frequency and fluctuating Range

50/60 Hz + 2/-4%

Max power

At the time

Interruptible power

source (*13)

6.00 kW/6.32 kVA

High efficiency power

supply (*13)

5.81 kW/6.12 kVA

Downtime

0.084 kW

Power factor (*10)

0.95 or more

Inrush current [A] [Rush hours] (*11)

20 or less

Leak current [mA] (*12)

6.9 or less

1.3 Installation Specifications

1.3.3 Installation Specific a ti ons ( P RIMEQUEST 2800B)

TABLE 1.4 Installation Specifications (PRIMEQUEST 2800B)

[mm (in.)]

air conditioner

conditions

value

[m3/min (ft3/min)]

(*3)

Humidity

conditions (*4)

Vibration [m/s2

(gal)]

consumption /

apparent power

of operation

(*6)

of operation

*1: Dimensions without protrusions

*2: Numeric value when each optional device is mounted for maximum number of options.

However, rail for mounting rack (5.7kg) and cable type are not included.

Mass as per the installation configuration can be calculated using formula as shown below.

Device mass = 77 + (9.6 * A) + (2.5 * B) + (1.8 * C) + (3.3 * D) [kg]

A = Number of mounted SB (Minimum 1 to Maximum 4)

B= Number of mounted IOU (Minimum 1 to Maximum 4)

C= Number of mounted PSU (Minimum 2 to Maximum 6)

D= Number of mounted DU (Minimum 0 to Maximum 2)

*3: There are cases when device is overloaded or when abnormality is detected, FAN rotates at high-speed

even if recommended environmental temperature is used.

*4: Protect from condensation.

*5: Temperature condition changes accord ing to the inst alla ti on locat ion abov e sea lev el.

For 0 to 1000 m (0 to 3281 ft) above sea level, temperature range at the time of installation: 5 to 35°C

(41 to 95°F)

10

Page 29

CHAPTER 1 Installation Data

C122-H007-01EN

1.3 Installation Specifications

For 1000 to 1500 m (3281 to 4921 ft) above sea level, temperature range at the time of installation: 5 to

33°C (41 to 91.4°F)

For 1500 to 2000 m (4921 to 6562 ft) above sea level, temperature range at the time of installation: 5 to

31°C (41 to 87.8°F)

For 2000 to 3000 m (6562 to 9843 ft) above sea level, temperature range at the time of installation: 5 to

29°C (41 to 84.2°F)

Error of + 100m in the sea level settings of the location of installation is permissible.

*6: Downtime is the condition in which the device is packed and maintained.

*7: Level of noise which is actually heard varies as per the mounting condition of the position from where the

noise is heard or the position of rack.

*8: Level of noise and the level of acoustic power changes according to the Hardware configuration, the

processing load and the environmental temperature.

*9: Downtime is the condition in which the device is installed. However, the power is switched off.

*10: Value at the time of operations.

*11: Value of 1 input cable

*12: Value of 1 device

*13: Interruptible power supply is the built-in PSU (80 PLUS SILVER supported), high efficiency power

supply is the built-in PSU (80 PLUS PLATINUM supported)

11

Page 30

CHAPTER 1 Installation Data

C122-H007-01EN

Item

Contents

Dimensions

Width

482 (18.98)

Depth

740 (29.13)

Length

175 (6.89) 4U

Mass [kg (lb)] (*2)

35 (77)

Conditions

Max. calorific value [kJ/h (BTU/h)]

1656 (1570)

Displacement [m3/min

FAN low speed (Low)

3 (106)

FAN medium speed (Normal)

4 (141)

FAN high speed (High)

5 (177)

Temperature

At time of

Temperature [°C (°F)]]

(*5)

Humidity [%RH]]

20 to 80

Max wet bulb temperature [°C

(°F)]]

29 (84.2)

Downtime

Temperature [°C (°F)]]

0 to 50 (32 to 122)

Humidity [%RH]]

8 to 80

Max wet bulb temperature [°C

(°F)]]

29 (84.2)

Noise [dB] (*7, *8)

(Included in

installation)

Acoustic power level [B] (*8)

(Included in

installation)

Permissibl

At the time of operation (Including standby)

4.0 (400) (Composite

seismic wave)

Downtime (*9)

10.0 (1000)

wave)

Permissible dust level [mg/m3]

0.15

Power

Input voltage and source resultant pulse number

200 to 240 VAC±10 %

1φ

Frequency and fluctuating Range

50/60 Hz + 2/-4%

Max

power

At the time of

operation

Input voltage: 200 V

450W/475 VA

Input voltage: 100 V

460W/485 VA

Downtime

Input voltage: 200 V

10W/40VA

Input voltage: 100 V

10W/35 VA

Power factor (*10)

More than equal to

0.95

Inrush current [A] [Rush hours] (*11)

Less than or equal to

25

Leak current [mA] (*12)

Less than or equal to

3.5

1.3 Installation Specifications

1.3.4 Installation Specific a ti ons ( P CI_Box)

TABLE 1.5 Installation Specifications (PCI_Box)

[mm (in)]

for air

conditioner

(ft3/min)] (*3)

Supply

conditions

and Humidity

condition (*4)

e Vibration

2

[m/s

(gal)]

power

consumpti

on /

apparent

operation

(*6)

(Composite seismic

100 to 120 VAC±10 %

*1: Dimensions without protrusions.

*2: Numeric value when each optional device is mounted for maximum number of options.

*3: If the device is overloaded or if abnormality is detected even though the recommended environmental

temperature is used, the FAN rotates at high-speed.

*4: Protect from condensation.

*5: Temperature condition changes according to the installation location above sea level.

For 0 to 1000 m (0 to 3281 ft) above sea level, temperature range at the time of installation: 5 to 35°C

(41 to 95°F)

For 1000 to 1500 m (3281 to 4921 ft) above sea level, temperature range at the time of installation: 5 to

33°C (41 to 91.4°F)

For 1500 to 2000 m (4921 to 6562 ft) above sea level, temperature range at the time of installation: 5 to

31°C (41 to 87.8°F)

For 2000 to 3000 m (6562 to 9843 ft) above sea level, temperature range at the time of installation: 5 to

29°C (41 to 84.2°F)

Error of + 100m in the sea level settings of the location of installation is permissible.

*6: Downtime is the condition in which the device is packed and maintained.

12

Page 31

CHAPTER 1 Installation Data

C122-H007-01EN

Number

Description

(1)

Rear side maintenance area

(2)

Rack

(3)

Front side maintenance area

(4)

Rack width

Model 2724/2737/2742, PCRM1 724S/742S/724A/742A

700 mm

Model 2616/2624/2642, PCRM1 616S/624S/642S

600 mm

1.4 Installation Area

*7: Level of noise which is actually heard varies as per the mounting condition of the position from where the

noise is heard or the position of rack.

*8: Level of noise and level of acoustic power changes according to the environmental temperature

*9: Downtime is the condition in which the device is installed. However, the power is switched off.

*10: Value at the time of operations.

*11: Value of 1 input cable

*12: Value of 1 device

1.4 Installation Area

Here, the installation area and the service area when the PRIMEQUEST 2000 series or the PCI_Box is

installed on 19-inch made by Fujitsu rack are ex plained.

The installation area and the service area differ according to the installed 19-inch rack.

For details on the 19-inch racks, contact the distributor where you purchased your product, or your sales

representative.

FIGURE 1.13 Service Area at the time of installing 19 inch rack model

13

Page 32

CHAPTER 1 Installation Data

C122-H007-01EN

Number

Description

(1)

Inspiration

(2)

Exhaust

(3)

Location of exhaust

Number

Description

(1)

Inspiration

(2)

Exhaust

(3)

Location of exhaust

1.5 Flow of Cooling Air and Exhaust Air of Installation

1.5 Flow of Cooling Air and Exhaust Air of Installation

Here, the flow of the cooling air and the exhaust of each device are explained.

Note

Flow of cooling air and exhaust air should be considered while studying the installation of a device. If device

is installed without considering them, it may get affected by inhaling the exhaust air from the other device.

Especially, the device detecting the intake air temperature may raise alarm indicating abnormality.

1.5.1 Flow of Cooling Air and Exhaus t Air (Main Cabinet)

FIGURE 1.14 Flow of Cooling Air and Exhaust Air (Main Cabinet)

1.5.2 Flow of Cooling Air and E x ha us t (PCI_ Box )

FIGURE 1.15 Flow of Cooling Air and Exhaust (PCI_Box)

14

Page 33

CHAPTER 1 Installation Data

C122-H007-01EN

Name of gas

Permissible level

Hydrogen sulfide (H2S)

7.1ppb or less

Sulfur dioxide (Sulfur oxide)(SO2)

37ppb or less

Hydrogen chloride (HCL)

6.6ppb or less

Chlorine (CI2)

3.4ppb or less

Hydrogen fluoride (HF)

3.6ppb or less

Nitrogen dioxide (Nitrogen oxides)(NO2)

52ppb or less

Ammonia(NH3)

420ppb or less

Ozone(O3)

5ppb or less

Fluid vapor

0.2mg/m3 or less

1.6 Installation Environment

1.6 Installation Environment

This section describes the installation environment of the base cabinet and PCI_Box.

1.6.1 Dust

Suspended Particles

Suspended particles in a computer room should not exceed 0.15mg/m3. A computer is designed in such a

way that it withstands the suspended particles. This value is permissible in an ordinary office. However, this

value can be maintained in the ordinary computer room if there is less outdoor air infiltration having

suspended particles like dust and if there is no smoke of cigarettes.

Dust Removal

The suspended particles like dust are collected in the filter of an air conditioner. The dust should be removed

from the computer room by cleaning floor surfaces and underfloor periodically. Cleaning is necessary in the

following cases.

When the computer room is ready, and before bringing in the computers

At the time of repairing the computer room

At the time of shifting the computers and re-arranging the devices

1.6.2 Corrosive Gas

Corrosive gas and salty wind cause corrosion, mal fun cti oning, and damage of the device, and reduce life of

the device remarkably.

Corrosive gas should be removed by providing suitable air cleaning equipment. In addition, positive clear air

pressure in the room prevents an entering of the corrosive gas from the outside. The chemical factory area,

thermal water/ volcanic zone etc. are considered as a source of corrosive gas.

TABLE 1.6 Permissible Level of Corrosive Gas

1.6.3 Sea Water (Salt Damage)

A large number of sea-salt particles are suspended in air by the salty wind near the sea-coast. If the sea-salt

particles remain in the computer, moisture and chemically condensed substances cause insulation failure,

and corrosion degradation of the components. Therefore, the computer should be installed at a place which

is far from the sea-coast.

Installation standards to prevent damage due to sea salt particles are shown below.

Standards: The computer should be installed at a place which is at least 0.5km away from the sea-coast

(Excluding the case having air-conditioner which prevents an entering of air from outside)

1.7 Safety Measures

For details on safety measures, see “Chapter 8 Safety Measures” of “SPARC M10 System/ SPARC

Enterprise/PRIMEQUEST Common Installation Planning Manual” (C120-H007EN).

15

Page 34

CHAPTER 2 Connected Information

C122-H007-01EN

2.1 Connection summary

Connected Information CHAPTER 2

This section describes the connection summary of cable and cable used in PRIMEQUEST 2000 series.

2.1 Connection summary

This section shows the Device connection summary of PRIMEQUEST 2000 series.

FIGURE 2.1 Summary of Device Connection

16

Page 35

CHAPTER 2 Connected Information

C122-H007-01EN

Number

Configured part

Description

*1

SB

PRIMEQUEST 2400E

Maximum 2 units can

be mounted

PRIMEQUEST 2800E/2800B

Maximum 4 units can

be mounted

*2

IOU

PRIMEQUEST 2400E/2800E/2800B

Maximum 4 units of

mounted.

*3

MMB

PRIMEQUEST 2400E/2800E

Maximum 2 units can

be mounted

PRIMEQUEST 2800B

Maximum 1 unit can be

mounted

*4

PCI_Box

PRIMEQUEST 2400E/2800E

Maximum 4 units can

be mounted

PRIMEQUEST 2800B

No PCI_Box can be

mounted.

2.2 Connection of signal cable

TABLE 2.1 Notes for Device connection

2.2 Connection of signal cable

IOU_1GbE or

IOU_10GbE can be

This section describes the notes for connection of signal cable, cable list and cable procure.

2.2.1 Basic interface and peripheral

For details of basic interface of PRIMEQUEST 2000 series and cable connection of peripheral, see

“PRIMEQUEST 2000 series system mounting”

2.2.2 Details of external interface connection

Mounting position of external interface connecting part of PRIMEQUEST 2000 series is shown in the section

below. When calculating the length of the connection cable, you should take account into the mounting

position.

17

Page 36

CHAPTER 2 Connected Information

C122-H007-01EN

2.2 Connection of signal cable

External interface conn ect ion (PRIMEQUEST 2400E in base cab inet)

External interface connection figure of PRIMEQUEST 2400E in base cabinet is shown in the section below.

The figure below is uncovered front surface (face).

The front cover must be attached in normal operation.

FIGURE 2.2 External interface connection figure of (PRIMEQUEST 2400E (Front surface))

FIGURE 2.3 External interface connection figure of (PRIMEQUEST 2400E (Back surface))

18

Page 37

CHAPTER 2 Connected Information

C122-H007-01EN

2.2 Connection of signal cable

External interface conn ect ion (PRIMEQUEST 2800E in base cabinet)

External interface connection figure of PRIMEQUEST 2800E in base cabinet is shown in the section below.

This figure is uncovered front surface (face).

The front cover must be attached in normal operatio n.

FIGURE 2.4 External interface connection figure of (PRIMEQUEST 2800E (Front surface))

FIGURE 2.5 External interface connection figure of (PRIMEQUEST 2800E (Back surface))

19

Page 38

CHAPTER 2 Connected Information

C122-H007-01EN

2.2 Connection of signal cable

External interface conn ect ion (PRIMEQUEST 2800B in base cabinet)

External interface connection figure of PRIMEQUEST 2800B in base cabinet is shown in the section below.

This figure is uncovered front surface (face).

The front cover must be attached in normal operation.

FIGURE 2.6 External interface connection figure of (PRIMEQUEST 2800B (Front surface))

FIGURE 2.7 External interface connection figure of (PRIMEQUEST 2800B (Back surface))

20

Page 39

CHAPTER 2 Connected Information

C122-H007-01EN

2.2 Connection of signal cable

Details of external int erf ace (MMB)

FIGURE 2.8 Details of external interface (MMB)

Details of external int erf ace (IOU_1GbE/IOU_10Gb E )

FIGURE 2.9 Details of external interface (IOU_1GbE)

FIGURE 2.10 Details of external interface (IOU_10GbE)

Details of external int erf ace (DU)

FIGURE 2.11 Details of external interface (DU)

21

Page 40

CHAPTER 2 Connected Information

C122-H007-01EN

Number

Description

(1)

Distribution Panel AC100V AC#0system

2.3 Power cable connection

Details of external int erf ace (PCI_Box)

FIGURE 2.12 Details of external interface (PCI_Box)

PCIC:PCI slot

LNKC:LINK card

2.3 Power cable connection

Input power system of PRIMEQUEST 2000series and PCI_Box is described in this section.

2.3.1 Power Supply Cable Connection (PRIMEQUEST 2400E)

Input power system diagram of PRIMEQUEST 2400E is as shown below.

100 V Standard Power Feed Configuration (Single power feed, no Redundant Power

Feed)

It is necessary to arrange three PSUs, three FANUs and three power supply cables (100 V NEMA 5-15P) for

100V standard power feed configuration (single power feed, no redundant power feed).

FIGURE 2.13 100V Standard Power Feed Configuration (Single power feed, no Redundant Power Feed)

22

Page 41

CHAPTER 2 Connected Information

C122-H007-01EN

Number

Description

(1)

Distribution Panel AC100V AC#0system

Number

Description

(1)

Power distribution box (200V C 19 3 type)

2.3 Power cable connection

100 V Redundant Power Feed Configuration (Single power feed, Redundant Power

Feed)

It is necessary to arrange four PSUs, two FANUs and four power supply cables (100 V NEMA 5-15P) for

100V redundant power feed configuration (single power feed, redundant power feed).

FIGURE 2.14 100V Redundant Power Feed Configuration (Single power feed, Redundant Power Feed)

Standard Configuration of 200 V (single power feed, no redundant power feed) with

Power Distribution Box Connection

It is necessary to arrange two PSUs, four FANUs, two power cables (200 V IEC60320 C20) and two power

distribution boxes (200 V IEC60320 C19×3type) for standard configuration of 200 V (single pow er feed, no

redundant power supply).

When the power distribution box is used, it is necessary to secure the breaker characteristic of distribution

panel. See “2.6 Cutoff Characteristics of Distribution Panel (At the time of connecting power distribution box).”

FIGURE 2.15 Standard Configuration of 200 V (single power feed, no redundant power feed) with Power

Distribution Box Connection

23

Page 42

CHAPTER 2 Connected Information

C122-H007-01EN

Number

Description

(1)

Power distribution box (200V C 19 3 type)

Number

Description

(1)

Power distribution box (200V C 19 3 type)

2.3 Power cable connection

200 V Redundant Power F eed Configuration (with single power feed, redundant power

feed) with Power Distribution Box Connection

It is necessary to arrange three PSUs, three FANUs, three Power cables (200 V IEC60320 C20) and two

power distribution box (200 V IEC60320 C19×3type) for of 200 V Redundant Power Feed Configuration

(single power feed, redundant power feed).

When the power distribution box is used, it is necessary to secure the breaker characteristic of distribution

panel. See “2.6 Cutoff Characteristics of Distribution Panel (At the time of connecting power distribution box).”

FIGURE 2.16 200 V Redundant Power Feed Configuration (single power feed, redundant power feed) with

Power Distribution Box Connec tio n

200V Dual Power Feed Configuration with Power Distribution Box Connection

It is necessary to arrange four PSUs, two FANUs, four power cables (200 V IEC60320 C20) and two power

distribution box (200 V IEC60320 C19×3type) for 200 V dual power feed configuration for Japan and

Overseas.

When the power distribution box is used, it is necessary to secure the breaker characteristic of distribution

panel. See “2.6 Cutoff Characteristics of Distribution Panel (At the time of connecting power distribution box).”

FIGURE 2.17 200 V Dual Power Feed Configuration with Power Distribution Box Connection

24

Page 43

CHAPTER 2 Connected Information

C122-H007-01EN

Number

Description

(1)

Power distribution box (200V C 19 3 type)

2.3 Power cable connection

2.3.2 Power Cables Connections (PRIMEQUEST 2800E/2800B)

This section shows the figure of input power of PRIMEQUEST 2800E/2800B.

Standard Configuration of 200 V (Single power feed and no Redundant Power Feed)

with Power Distributi on B ox Connection

It is necessary to arrange three PSUs, three FANUs, three power cables (200 V IEC60320 C20) and two

power distribution box (200 V IEC60320 C19×3type) for 200 V standard configuration.

When the power distribution box is used, it is necessary to secure the breaker characteristi c of distribution

panel. See “2.6 Cutoff Characteristics of Distribution Panel (At the time of connecting power distribution box).”

FIGURE 2.18 200V Standard Configuration (single power feed and no redundant power feed) with Power

Distribution Box Connection

25

Page 44

CHAPTER 2 Connected Information

C122-H007-01EN

Number

Description

(1)

Power distribution box (200V C 19 3 type)

2.3 Power cable connection

200 V Redundant Power Feed Confi guration (single power feed, redundant power feed)

with Power Distributi on B ox Connection

It is necessary to arrange four PSUs, two FANUs, four Power cables (200 V IEC60320 C20) and two power

distribution boxes (200 V IEC60320 C19×3type) for 200 V Redundant Power Feed configuration (with single

power feed, redundant power feed).

When the power distribution box is used, it is neces sary to secure the brea ker char act er is ti c of distribution

panel. See “2.6 Cutoff Characteristics of Distribution Panel (At the time of connecting power distribution box).”

FIGURE 2.19 200 V Redundant Power Feed Configuration (single power feed, redundant power feed) with

Power Distribution Box Connec tio n

26

Page 45

CHAPTER 2 Connected Information

C122-H007-01EN

Number

Description

(1)

Power distribution box (200V C 19 3 type)

Number

Description

(1)

Customer distribution panel AC 100V AC#0 system

2.3 Power cable connection

200 V Dual Power Feed Conf iguration with Power Distribut ion Box Connection

It is necessary to arrange six PSUs, six power cables (200 V IEC60320 C20) and four power distribution

boxes (200 V IEC60320 C19×3type) for 200 V dual power feed configuration.