FUJIFILM FinePix E900 Service Manual

DIGITAL CAMERA

FinePix E900

SERVICE MANUAL

US/CA/EU/EG/EE/AS/CH/KR-Model

CAUTION

BECAUSE THIS PRODUCTIS RoHS LEAD-FREE COMPLIANT, USE THE DESIG-

NATED AFTER-SELES PARTS AND THE DESIGNATED LEAD-FREE SOLDER WHEN

PERFORMING REPAIRS. (Refer to page 3 to page 5)

WARNING

THE COMPONENTS IDENTIFIED WITH THE MARK “ ” ON THE SCHEMATIC

DIAGRAM AND IN THE PARTS LIST ARE CRITICAL FOR SAFETY.

PLEASE REPLACE ONLY WITH THE COMPONENTS SPECIFIED ON THE SCHEMATIC

DIAGRAM AND IN THE PARTS LIST.

IF YOU USE PARTS NOT SPECIFIED, IT MAY RESULT IN A FIRE AND AN

ELECTRICAL SHOCK.

FUJI PHOTO FILM CO., LTD.

Ref.No.:ZM00609-101

Printed in Japan 2005.10

FinePix E900 Service Manual

SAFETY CHECK-OUT

After correcting the original problem, perform the following

safety check before return the product to the customer.

1. Check the area of your repair for unsoldered or poorly

soldered connections. Check the entire board surface

for solder splasher and bridges.

2. Check the interboard wiring to ensure that no wires are

“pinched” or contact high-wattage resistors.

3. Look for unauthorized replacement parts, particularly

transistors, that were installed during a previous repair.

Point them out to the customer and recommend their

replacement.

4. Look for parts which, though functioning, show obvious

signs of deterioration. Point them out to the customer

and recommend their replacement.

5. Check the B + voltage to see it is at the values

specified.

6. Make leakage - current measurements to determine

that exposed parts are acceptably insulated from the

supply circuit before returning the product to the

customer.

7. CAUTION: FOR CONTINUED

PROTECTION AGAINST FIRE

HAZARD, REPLACE ONLY WITH

SAME TYPE 2.5 AMPERES 125V

FUSE.

2.5A 125V

2.5A 125V

8. WARNING:

RISK OF FIREREPLACE FUSE

AS MARKED

ATTENTION: AFIN D'ASSURER

UNE PROTECTION

PERMANENTE CONTRE LES

RISQUES D'INCENDIE,

REMPLACER UNIQUEMENT

PAR UN FUSIBLE DE MEME,

TYPE 2.5 AMPERES, 125 VOLTS.

TO REDUCE THE ELECTRIC

SHOCK, BE CAREFUL TO

TOUCH THE PARTS.

WARNING!

HIGH VOLTAGE

2

FinePix E900 Service Manual

RoHS lead-free compliance

Because this product is RoHS lead-free compliant, use the designated after-sales parts and the designated lead-free solder

when performing repairs.

<Background & Overview>

With the exception of parts and materials expressly excluded from the RoHS directive (*1), all the internal connections and

component parts and materials used in this product are lead-free compliant (*2) under the European RoHS directive.

*1: Excluded items (list of the main lead-related items)

• Lead included in glass used in fluorescent tubes, electronic components and cathode-ray tubes

• Lead in high-melting-point solder (i.e. tin-lead solder alloys that contain 85% lead or more)

• Lead in ceramic electronic parts (piezo-electronic devices)

• Mercury contained in fluorescent tubes is also excluded.

*2: Definition of lead-free

A lead content ratio of 0.1 wt% or less in the applicable locations (solder, terminals, electronic components, etc.)

<Reference>

RoHS: The name of a directive issued by the European Parliament aimed at restricting the use of

certain designated hazardous substances included in electrical and electronic equipment.

Designated substances (6): Lead, mercury, cadmium, hexavalent chromium, polybrominated biphenyls (PBBs) and

polybrominated diphenyl ether (PBDE)

<Lead-free soldering>

When carrying out repairs, use a designated lead-free solder, bearing in mind the differing work practices for conventional

solder (eutectic) and lead-free solder.

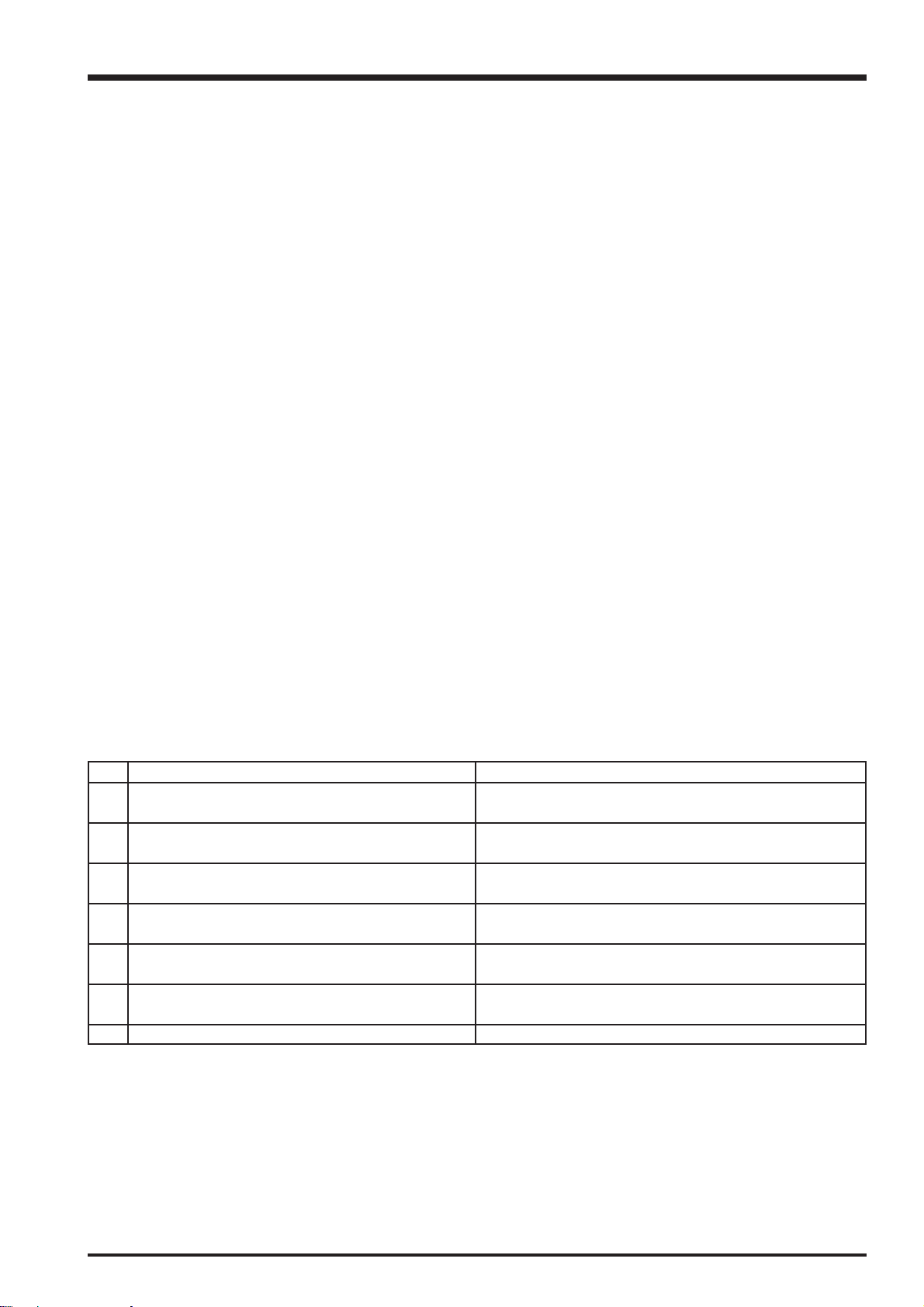

Differences in the soldering work for lead-free and eutectic solder

When the soldering work practices for eutectic solder and lead-free solder are compared, the main differences are as shown

below. In particular, when lead-free solder is used, the solder tends to be less workable than when eutectic solder is used.

Accordingly, the soldering techniques used must take that into account.

Difference

The solder starts melting later.

1

Poor wetting

2

Solder feed rate is difficult to control.

3

Wetting the insides of through holes is especially

4

difficult.

5

During repairs (or modifications) removing solder

from inside through holes is difficult.

6

There is serious carbonization of the soldering iron.

The surface is not glossy.

7

The initial melting point of lead-free solder is high, so you

have to get used to it.

Move the tip of the soldering iron around to heat the entire

connection to the melting temperature and assist wetting.

Use the solder (wire) diameter and soldering iron that are

best suited to connection being soldered.

First apply solder to the area immediately around the

through hold and then feed the solder into the hole.

Use a suitable wicking wire (with a suitable method and

heating) and a suction tool.

Either put solder onto the soldering iron tip after completing

the work, or turn the iron off frequently.

Learn to recognize the appearance of the surface.

Countermeasure

3

FinePix E900 Service Manual

Setting temperature during lead-free soldering

• Lead-free solder melting temperature

The melting point of eutectic (Sn-Pb) solder is 183°C, while the melting point of lead-free solder (Sn-Ag-Cu) is 30°C higher

at 220°C.

• Soldering iron tip temperature

The temperature setting for the soldering iron used should be such that the tip of the soldering iron is at the correct

bonding temperature for the connection. This temperature is normally set at around 100°C higher than the melting point of

the solder.

However, the actual temperature should take into account the shape and size of the soldering iron tip, the heat tolerance

of the connection and the workability of that temperature.

• Correct bonding temperature

The correct bonding temperature refers not to the temperature of the heat source, but to the bonding temperature that will

give the best bond strength.

Precautions when soldering with lead-free solder

• Soldering iron maintenance

Because of the high soldering iron temperature in lead-free soldering, there is rapid carbonization of the flux adhering to

the tip of the soldering iron.

(1) Always cover the tip of the soldering iron with solder when it is not being used.

(2) If the tip is black from carbonization, wipe it gently with a paper towel soaked in alcohol until the solder will wet.

• Uniform heating of the board and components

To ensure that the lead-free solder wets the entire surface of the pattern and the lands despite its poor wetting

characteristics, you must move the tip of the soldering iron over a wide area to raise the temperature of the entire

connection.

Soldering iron

A soldering iron with a temperature control is best.

4

FinePix E900 Service Manual

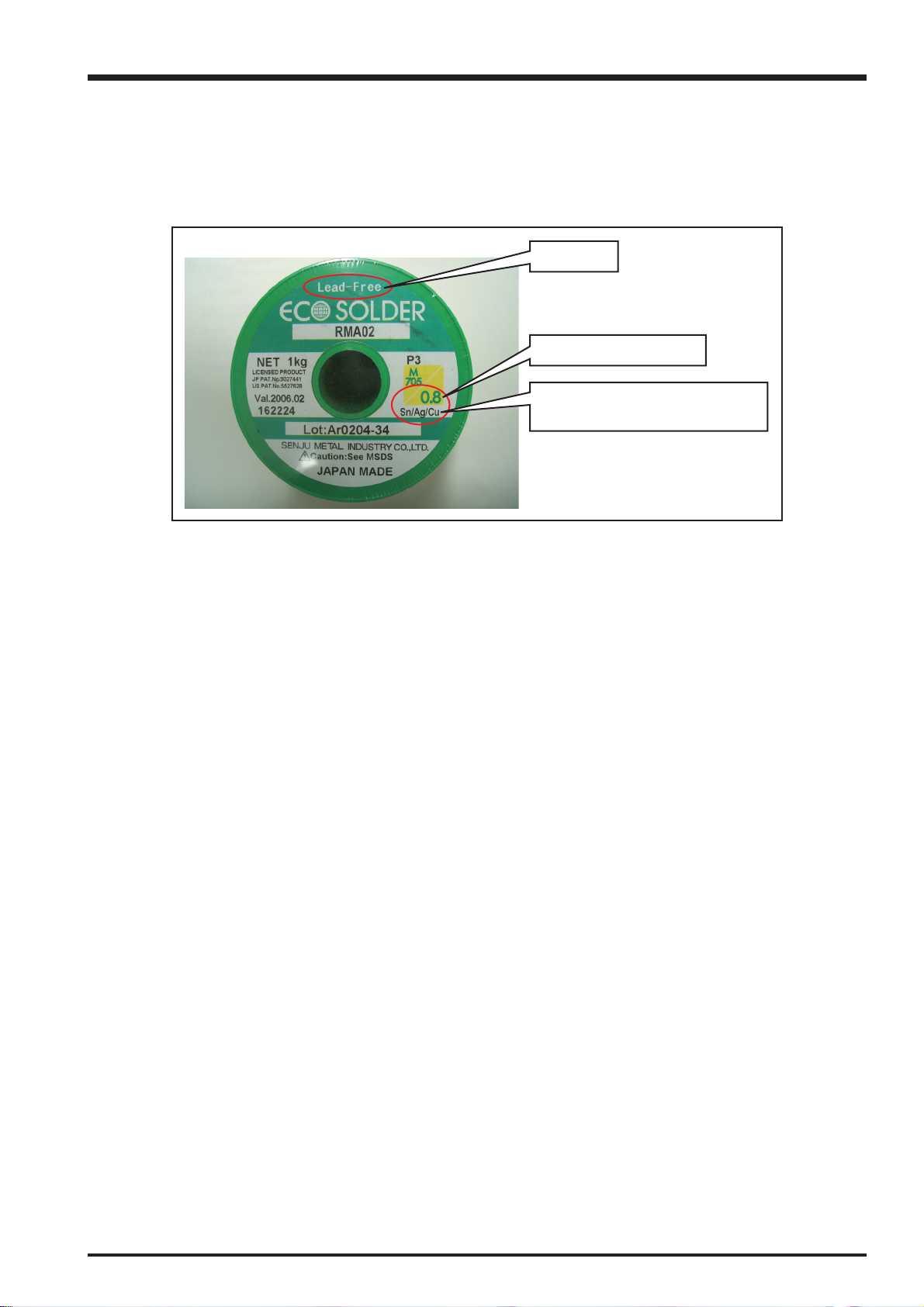

Solder wire (thread)

Use the lead-free solders specified below.

Solder type: Sn96.5Ag3Cu0.5 (Displayed symbol: SnAgCu)

Wire diameter: 0.6, 0.8 or 1.0 mm

Sample:

lead-free

Wire diameter 0.8mm

Solder type (Displayed symbol)

SnAgCu

Flux

Conventional flux can be used.

Solder application wires (mesh, wicking wire, etc.)

Conventional application wires can be used.

5

CONTENTS

FinePix E900 Service Manual

CONTENTS

1. General ........................................................... 7

1-1. Product specification ..............................................7

1-2. Explanation of Terms ............................................ 11

1-3. Names of External Components .......................... 12

2. Disassembly ................................................. 13

2-1. Names of internal Components ............................13

2-2. Removing the CONST CASE R ...........................14

2-3. Disassembling the CONST CASE R .................... 15

2-4. Removing the internal block ................................. 16

2-5. Removing the ASSY HOLDER BATTERY and

LEAD E.CAP ........................................................ 17

2-6. Removing the LENS ASSY ..................................17

2-7. Removing the ASSY PANEL F internal

components .......................................................... 18

3. Schematics ................................................... 19

3-1. Cautions ...............................................................19

3-2. Basic Block Names and Functions .......................19

3-3. Description of Main Block Functions ....................20

3-3-1. Technical Overview ................................. 20

3-4. Block Diagram ...................................................... 21

3-5. Overall connection Diagram ................................. 22

3-6. Circuit Diagrams ...................................................23

3-6-1. CAMERA BLOCK ................................... 23

3-6-2. DCDC BLOCK ........................................ 24

3-6-3. KSW BLOCK .......................................... 25

3-6-4. LCD BLOCK ........................................... 26

3-6-5. MOTOR BLOCK ..................................... 27

3-6-6. PMAN BLOCK ........................................ 28

3-6-7. PROCESS BLOCK .................................29

3-6-8. AUDIO BLOCK ....................................... 31

3-6-9. CARD BLOCK ........................................ 32

3-6-10. VIDEO BLOCK ....................................... 32

3-6-11. FLASH BLOCK ....................................... 33

3-6-12. MIC FPC BLOCK ....................................33

3-6-13. CCD FPC BLOCK ................................... 34

3-6-14. KEY FPC BLOCK ................................... 35

3-6-15. MODE FPC BLOCK ................................ 35

3-7. Mounted Parts Diagrams ...................................... 36

3-7-1. MAIN PWB ASSY ...................................36

3-7-2. CCD FPC ASSY ..................................... 38

3-7-3. MIC FPC ASSY....................................... 39

3-7-4. MODE FPC ASSY .................................. 40

4. Adjustments .................................................. 41

4-1. Important point Adjustment when

Replacing Major Parts ..........................................41

4-2. Measuring Instruments Used ............................... 41

4-3. Use Jig list ............................................................ 41

4-4. Calibration method of pattern box ........................ 42

4-5. Adjusment software installation ............................ 42

4-5-1. Various downloading software

decompressions, preservation methods,

and notes ................................................42

4-5-2. Installation of DSC jig driver ................... 43

4-5-3. Adjustment software initiation method .... 43

4-6. Initial Settings of the Adjustment Software ........... 44

4-7. Starting the Adjustment Software ......................... 47

4-8. [R] : Flash Memory Reset ..................................... 50

4-9. [F4] : CCD Data Input ...........................................52

4-10. [F5] : CAMERA Adjustment ..................................54

4-11. [ C ] : CCD Line Defect Adjustment ......................59

4-12. [F6] : AF Adjustment .............................................63

4-13. [F7] : Flash Adjustment ......................................... 66

4-14. [F1] : Battery Voltage Adjustment ......................... 68

4-15. [F11] : Video Adjustment ...................................... 72

4-16. [F8] : Firmware Download .................................... 74

4-17. [F12] : End Setting................................................ 76

5. Inspection ..................................................... 80

5-1. Required Measuring Equipment ...........................80

5-2. Connection of Measuring Equipment ................... 80

5-3. Inspection and Factory Settings ........................... 81

6. Parts List....................................................... 85

6-1. Packing and Accessories ..................................... 85

6-1-1. US-model ................................................ 85

6-1-2. CA-model ................................................ 86

6-1-3. EU-model ................................................ 87

6-1-4. EG-model ................................................ 88

6-1-5. EE-model ................................................89

6-1-6. AS-model ................................................90

6-1-7. CH-model ................................................ 91

6-1-8. KR-model ................................................ 92

6-2. Cabi Front Block ...................................................93

6-3. Cabi Rear Block ................................................... 94

6-4. Electrical parts ......................................................95

7. Appendix....................................................... 96

7-1. List of Related Technical Updates Issued ............ 96

6

FinePix E900 Service Manual

1. General

1. General

1-1. Product specification

System

Model Digital camera FinePix E900

Effective pixels 9.0 million pixels

CCD 1/1.6-inch Super CCD HR

Storage media xD-Picture Card (16/32/64/128/256/512 MB/1 GB)

File format Still image: DCF-compliant

Compressed: Exif ver.2.2 JPEG, DPOF-compatible

Uncompressed: CCD-RAW (RAF)

* Design rule for Camera File System compliant DPOF compatible

Movie: AVI format, Motion JPEG

Audio: WAVE format, Monaural sound

Number of recorded pixels Still image: 3488

×

Lens Fujinon 4

F2.8-F5.6

Focal length f=7.2 mm-28.8 mm

(Equivalent to approx. 32 mm-128 mm on a 35 mm camera)

Digital zoom Approx. 7.6

Aperture (Wide-angle) F2.8 to F8 10 steps in 1/3 EV increments Manual/Auto selectable

Focal range Normal: approx. 60 cm (2.0ft.) to infinity

Macro: approx. 7.5 cm (3.0 in.) to 80 cm (2.6 ft.) (wide-angle)

Sensitivity AUTO/Equivalent to ISO 80/100/200/400/800

Photometry TTL 256-zones metering Multi, Spot, Average

Exposure control Program AE (

Manual exposure

Scene position

Exposure compensation -2 EV to +2 EV in 1/3 EV-step increments (P, S, A)

Shutter speed

Continuous shooting Top 4-frame: Number of recorded frames: up to 4 frames

Auto bracketing ± 1/3 EV, ± 2/3 EV, ± 1 EV

Focus Mode: Single AF, Continuous AF, Manual focus

White balance Automatic scene recognition/Preset (Fine, Shade, Fluorescent (Daylight), Fluorescent

Self-timer Approx. 10 sec./2 sec.

Flash type Auto flash

(Natural light), (Portrait), (Sport), (Night)

, S: 3 sec. to 1/1000 sec.

A: 1/4 sec. to 1/1000 sec. M: 15 sec. to 1/2000 sec.

Final 4-frame: Number of recorded frames:

Long-period continuous shooting mode:

AF system: TTL contrast-type

AF frame selection: AF (CENTER), AF (MULTI), AF (AREA)

(Warm White), Fluorescent (Cool White), Incandescent, Custom)

Effective range (

optical zoom lens

, , , , P: 1/4 sec. to 1/2000 sec.

×

2616 pixels/3696 × 2464 pixels/2592 × 1944 pixels/

2048

×

1536 pixels/1600 × 1200 pixels/640 × 480pixels ( / / / / / )

×

(4× optical zoom lens is used together: Max. zoom scale: 30.4× )

, , , , , P), Shutter-priority AE, Aperture-priority AE,

(Max. 1.5 frames/sec.)

last 4 frames before releasing the shutter button

(Max. 1.5 frames/sec.)

Number of recorded frames: up to 40 frames

(Max. 0.6 frames/sec.)

: AUTO): Wide-angle: approx. 30 cm-3.7 m (1.0 ft.-12.1 ft.)

Telephoto: approx. 60 cm-1.9 m (2.0 ft.-6.2 ft.)

7

1. General

FinePix E900 Service Manual

System

Flash mode Auto, Red-Eye Reduction, Forced Flash, Suppressed Flash, Slow Synchro,

Red-Eye Reduction + Slow Synchro

Viewfinder Real image optical Approx. 77% coverage

LCD monitor 2.0 inches, Aspect ratio: 4:3; approx. 115,000 pixels Amorphous silicon TFT,

Approx. 100% coverage

Movie 640

Photography functions Best framing, Post shot assist window, Frame No. memory

Playback functions Trimming, Image rotate, Automatic playback, Multi-frame playback, Sorting by date,

Other functions PictBridge, Exif print, Language (English, Francais, Deutsch,

×

480 pixels/320 × 240 pixels ( / )

(30 frames per second with monaural sound)

A series of continuous image can be recorded up to available recording time per xD-

Picture Card. Zoom cannot be used during movie recording.

Voice memo, Highlight warning

, Italiano, , ),

World time (Time difference), FinePix photo mode (

batteries

-mode), Discharging rechargeable

Input/Output Terminals

A/V OUT NTSC/PAL-type (with monaural sound)

(Audio/Visual output)

Digital input/output USB2.0 High-Speed

DC input socket AC Power Adapter AC-3VX (sold separately)

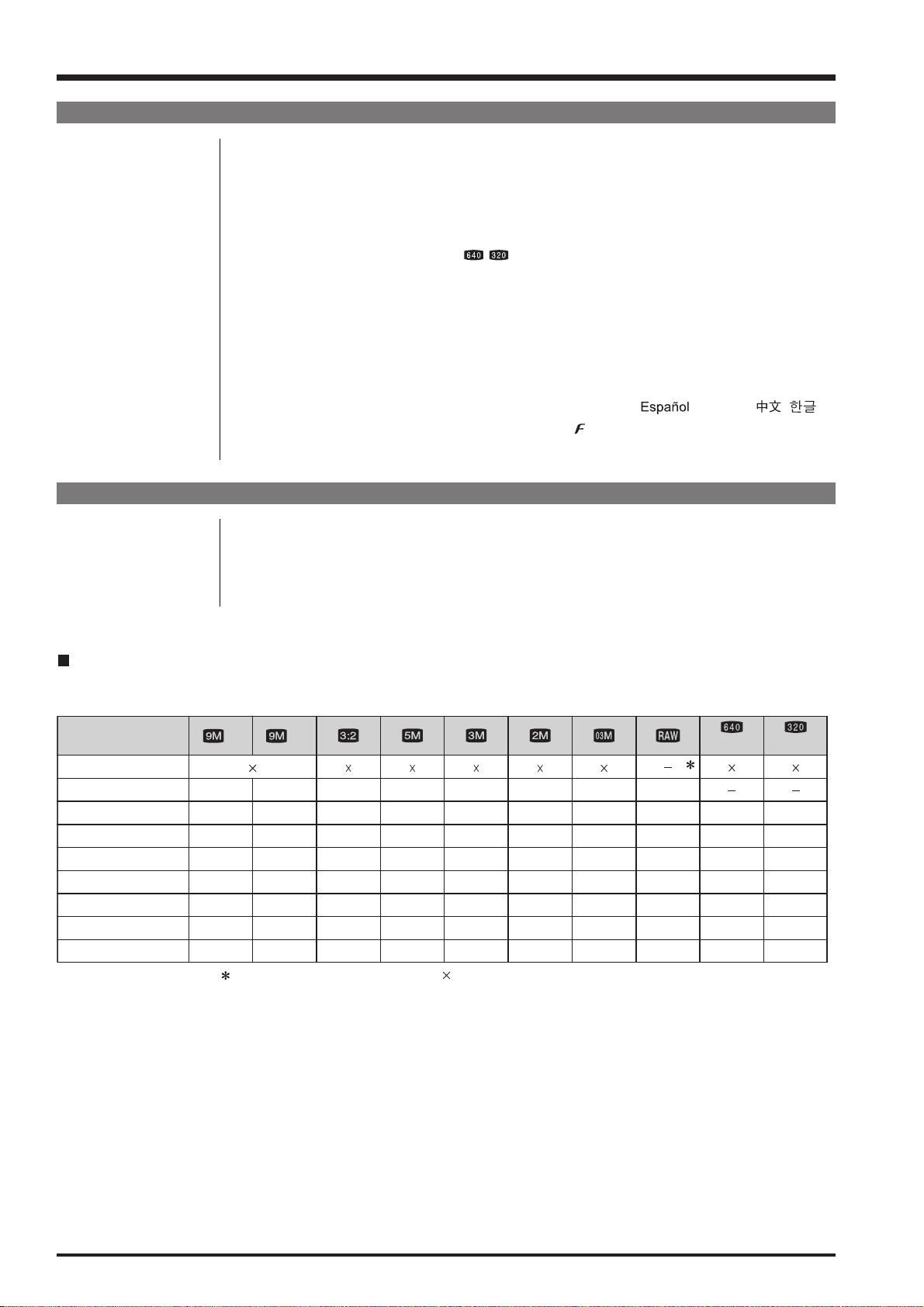

Standard number of available frames/recording time per xD-Picture Card

The number of available

that the divergence between standard number of

xD-Picture Cards with higher capacities.

Quality setting

Number of recorded pixels

Image data size 4.5 MB 2.2 MB 2.2 MB 1.2 MB 780 KB 630 KB 130 KB

DPC-16 (16 MB) 3

DPC-32 (32 MB)

DPC-128 (128 MB)

DPC-256 (256 MB)

DPC-512/M512 (512 MB)

DPC-M1GB (1 GB)

, recording time or file size varies slightly depending on the subjects photographed. Note also

frames

frames

and the actual number of

F N

3488 2616

6

13 28DPC-64 (64 MB) 28 50 81 101 497 3 55 sec.

28

56

113 227

228 456

113

Number of recorded pixel is 4864 3648 when displaying images on PC by using FinePixViewer.

3696 2464 2592 1944 2048 1536

6

13

56

13

56

113

227

456

6

12

25

102

204

409

819

19

40

162

325

651

1305

1600

204

409

818

1639

1200

25

50

640 480

122

247

997

1997

3993

7995

frames

(30 fps)

640 480

18.8 MB

0 13 sec.

1 27 sec.

6 111 sec.

13 223 sec.

27 7.4 min.

54 14.9 min.

is greater for

(30 fps)

320 240

26 sec.

54 sec.

109 sec.

219 sec.

7.3 min.

14.6 min.

29.3 min.

8

FinePix E900 Service Manual

Power Supply and Others

Power supply Use one of the following:

×

AA-size Ni-MH (nickel-metal hydride) batteries

• 2

• 2

×

AA-size alkaline batteries (sold separately)

• AC Power Adapter AC-3VX (sold separately)

Guide to the number of

available frames for battery

operation

According to the CIPA (Camera & Imaging Products Association) standard procedure for

measuring digital still camera battery consumption (extract):

When using Ni-MH batteries, use the batteries supplied with the camera. The storage

media should be xD-Picture Card.

Pictures should be taken at a temperature of +23

on, the optical zoom moved from full wide-angle to full telephoto (or vice-versa) and back

again to its original position every 30 seconds, the flash used at full power every second

shot and the camera turned off and then on again once every 10 shots.

• Note: Because the number of available shots varies depending on the level of charge in

Ni-MH batteries, the figures shown here for the number of available shots using

batteries are not guaranteed.

The number of available shots will also decline at low temperatures.

Camera dimensions 102.0 mm

(W/H/D) (not including accessories and attachments)

Camera mass (weight) Approx. 200 g/7.1 oz.

(not including accessories, batteries and xD-Picture Card)

Weight for photography Approx. 260 g/9.2 oz. (including batteries and xD-Picture Card)

Operating conditions Temperature: 0

80% humidity or less (no condensation)

Accessories included z AA-size Ni-MH Rechargeable Batteries (2)

z 16 MB, xD-Picture Card (1) Anti-static case (1) included

z Strap (1)

z A/V cable (1) Approx. 1.2 m (3.9 ft.), plug (2.5 mm dia.) to pin-plug

z USB cable (mini-B) (1)

z Battery Charger BC-NH02 (1)

z CD-ROM (1) Software for FinePix CX

z Owner’s Manual (1)

Battery Type With LCD monitor ON

Ni-MH batteries 2500 mAh Approx. 270 frames

o

C (+73oF), with the LCD monitor turned

×

63.0 mm × 34.4 mm/4.0 in. × 2.5 in. × 1.4 in.

o

C to +40oC (+32oF to +104oF)

1. General

×

2

9

1. General

Power Supply and Others

Optional accessories z xD-Picture Card

DPC-16 (16 MB)/DPC-32 (32 MB)/DPC-64 (64 MB)/DPC-128 (128 MB)/

DPC-256 (256 MB)/DPC-512 (512 MB)/DPC-M512 (512 MB)/DPC-M1GB (1 GB)

z AC Power Adapter AC-3VX

z Fujifilm Rechargeable Battery 2HR-3UF

z Fujifilm Battery Charger with Battery BK-NH2 (With Euro type or UK type plug)

z Soft Case SC-FXE01

z Wide Conversion Lens WL-FXE01

z Tele Conversion Lens TL-FXE01

z Adapter Ring AR-FXE 02

z Image Memory Card Reader DPC-R1

• Compatible with Windows 98/98 SE, Windows Me, Windows 2000 Professional,

Windows XP or iMac, Mac OS 8.6 to 9.2.2, Mac OS X (10.1.2 to 10.2.2) and

models that support USB as standard.

• Compatible with xD-Picture Card of 16 MB to 512 MB, and SmartMedia of 3.3 V, 4

MB to 128 MB.

z PC Card Adapter DPC-AD

• Compatible with xD-Picture Card of 16 MB to 512 MB, and SmartMedia of 3.3 V, 2

MB to 128 MB.

z CompactFlash Card Adapter DPC-CF

• Windows 95/98/98 SE/Me/2000 Professional/XP

• Mac OS 8.6 to 9.2/X (10.1.2 to 10.1.5)

z xD-Picture Card USB Drive DPC-UD1

• Compatible with xD-Picture Card of 16 MB to 512 MB

• Windows 98/98 SE/Me/2000 Professional/XP

• Mac OS 9.0 to 9.2.2/X (10.0.4 to 10.2.6)

FinePix E900 Service Manual

10

FinePix E900 Service Manual

1. General

1-2. Explanation of Terms

Deactivated batteries: Leaving an Ni-MH battery unused in storage for a long period may cause a rise in the level

of substances that inhibit current flow inside the battery and result in a dormant battery. A

battery in this state is referred to as deactivated.

Because current flow is inhibited in a deactivated Ni-MH battery, the battery’s original

level of performance cannot be achieved.

EV: A number denotes Exposure Value. The EV is determined by the brightness of the subject

and sensitivity (speed) of the film or CCD. The number is larger for bright subjects and

smaller for dark subjects. As the brightness of the subject changes, a digital camera

maintains the amount of light hitting the CCD at a constant level by adjusting the aperture

and shutter speed.

When the amount of light striking the CCD doubles, the EV increases by 1. Likewise, when

the light is halved, the EV decreases by 1.

Frame rate (fps): The frame rate refers to the number of images (frames) that are photographed or played

back per second. For example, when 10 frames are continuously photographed in a 1-

second interval, the frame rate is expressed as 10 fps.

For reference, TV images are displayed at 30 fps (NTSC).

JPEG: Joint Photographic Experts Group

A file format used for compressing and saving color images. The higher the compression

rate, the greater the loss of quality in the decompressed (restored) image.

Memory effect: If an Ni-MH battery is repeatedly charged without first being fully discharged, its perfor-

mance may drop below its original level. This is referred to as the “memory effect”.

Motion JPEG: A type of AVI (Audio Video Interleave) file format that handles images and sound as a

single file. Images in the file are recorded in JPEG format. Motion JPEG can be played

back by QuickTime 3.0 or later.

Smear: A phenomenon specific to CCDs whereby white streaks appear on the image when there

is a very strong light source, such as the sun or reflected sunlight, in the photography

screen.

WAVE: A standard format used on Windows systems for saving audio data. WAVE files have the

“.WAV” file extension and the data can be saved in either compressed or uncompressed

format. Uncompressed recording is used on this camera.

WAVE files can be played back on a personal computer using the following software:

Windows: MediaPlayer

Macintosh: QuickTime Player

* QuickTime 3.0 or later

White Balance: Whatever the kind of the light, the human eye adapts to it so that a white object still looks

white. On the other hand, devices such as digital cameras see a white subject as white by

first adjusting the color balance to suit the color of the ambient light around the subject.

This adjustment is called matching the white balance.

Exif Print: Exif Print Format is a newly revised digital camera file format that contains a variety of

shooting information for optimal printing.

11

1. General

r

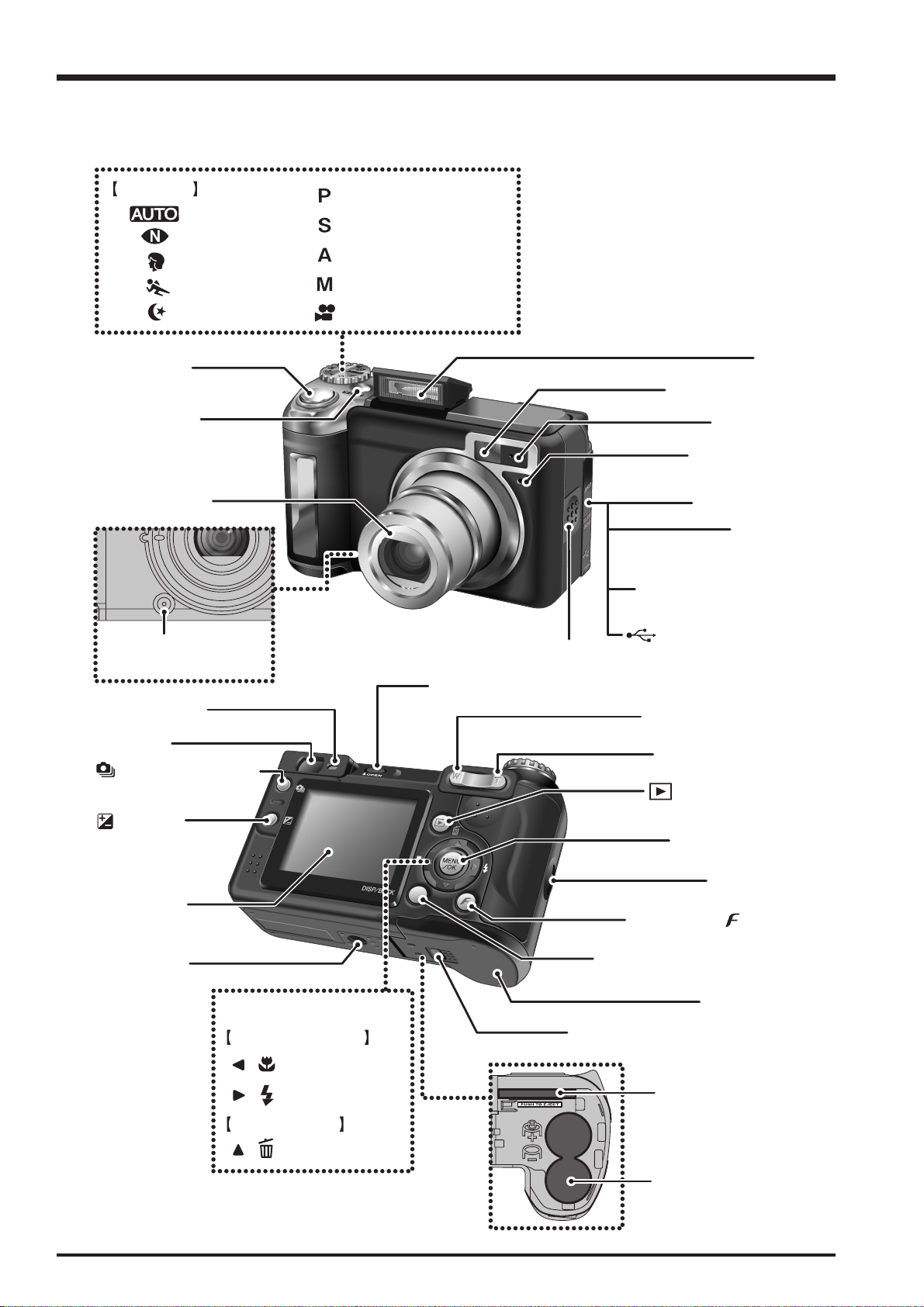

1-3. Names of External Components

FinePix E900 Service Manual

Mode dial

Auto

Natural light

Portrait

Sports

Night

Shutter button

POWER button

Lens (lens cover)

Adapter ring release

button

Viewfinder lamp

Viewfinder

Continuous shooting

button

Programmed Auto

Shutter-priority Auto

Aperture-priority Auto

Manual

Movie

Flash pop-up button

Speaker

Flash

Viewfinder window

Microphone

Self-timer lamp

Terminal cover

A/V OUT

(Audio / Visual output)

socket

DC IN 3V (power input)

socket

USB socket (mini-B)

W (Wide zoom) button

T (Tele zoom) button

(Playback) button

12

Exposure

compensation

button

LCD monitor

Tripod mount

4-direction (abdc) button

Photography mode

/ Macro button

/ Flash button

Playback mode

/ Erase button

MENU/OK button

Strap mount

Photo mode ( ) button

DISP (Display) / BACK button

Battery cove

Battery cover lock release button

xD-Picture Card slot

Battery compartment

FinePix E900 Service Manual

2. Disassembly

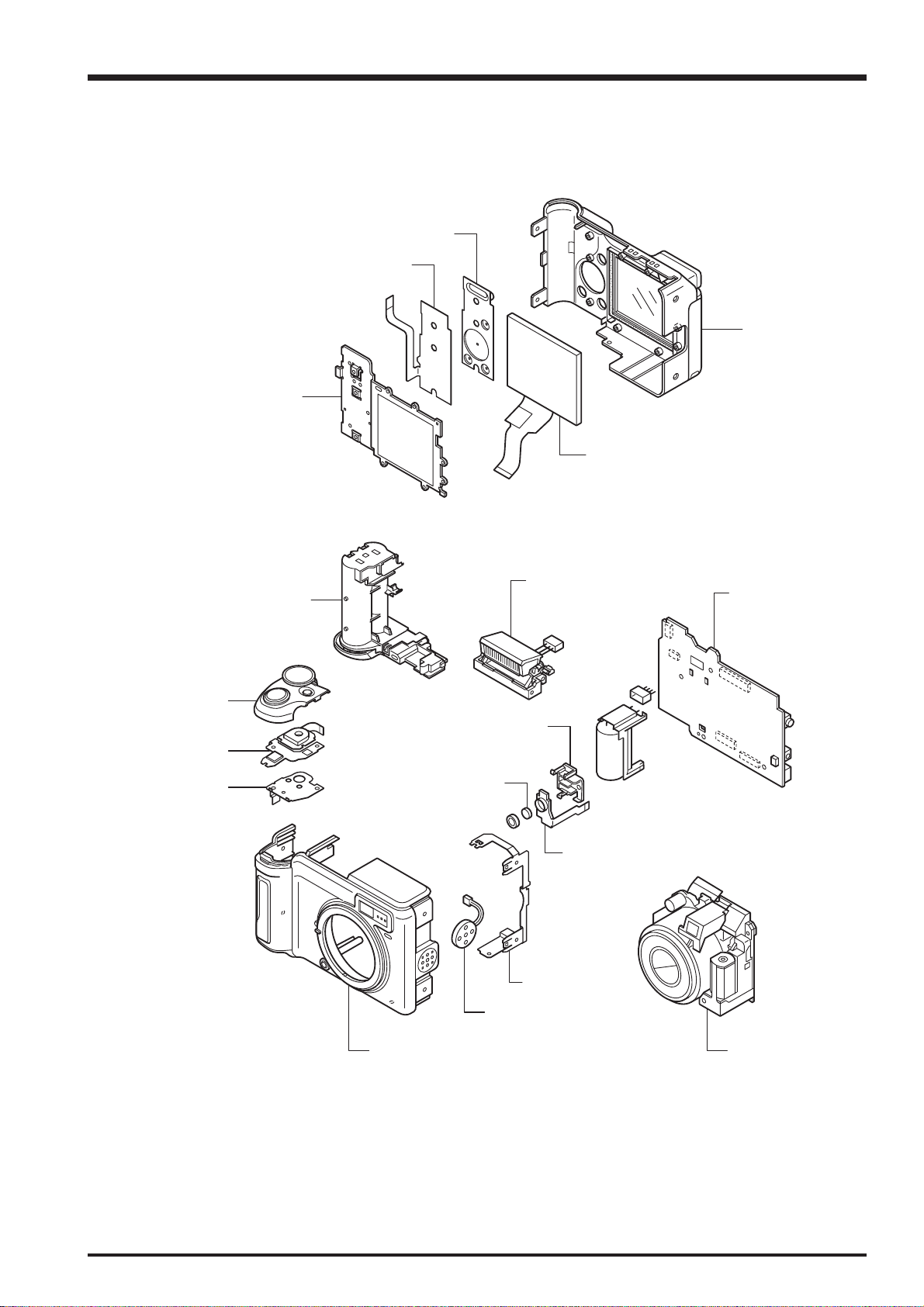

2-1. Names of internal Components

OPE GUM KEY

OPE UNIT

PLATE LCD

2. Disassembly

ASSY CASE R

LCD CONST

ASSY HOLDER BATTRY

ASSY CASE TOP

MODE FPC ASSY

PLATE TOP

UNIT FLASH

MAIN PWB ASSY

HOLDER MIC

MICROPHONE

MIC FPC PWB ASSY

PLATE SIDE

SPEAKER ASSY

ASSY PANEL F

LENS ASSY

13

2. Disassembly

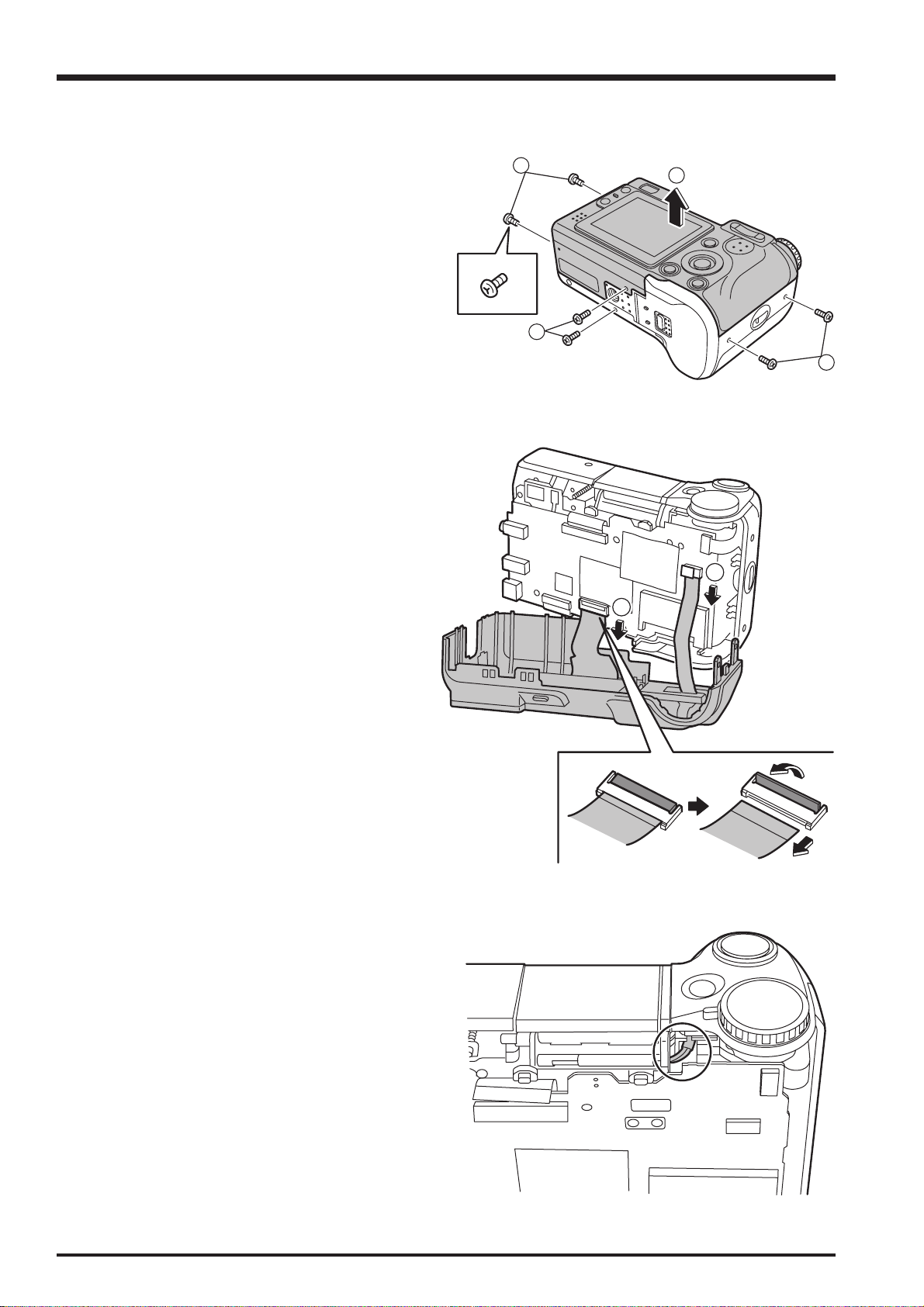

2-2. Removing the CONST CASE R

FinePix E900 Service Manual

(1) Remove the 2 special screws (3-MSN M1.7 x 3.5BN)

using the special screwdriver (ZJ00583-100).

(2) Remove the 4 screws (M1.7 x 5.0).

(3) Remove the CONST CASE R in the direction of the

arrow.

(4) Remove the FPC on CN201 in the direction of the

arrow.

(5) Unlock CN501 and remove the FPC in the direction of

the arrow.

1

2

5

3

2

4

[Assembly]

Assemble by performing the disassembly procedure in

reverse.

[Notes on assembly]

Take care not to pinch the WIRE HARNESS for the UNIT

FLASH.

14

FinePix E900 Service Manual

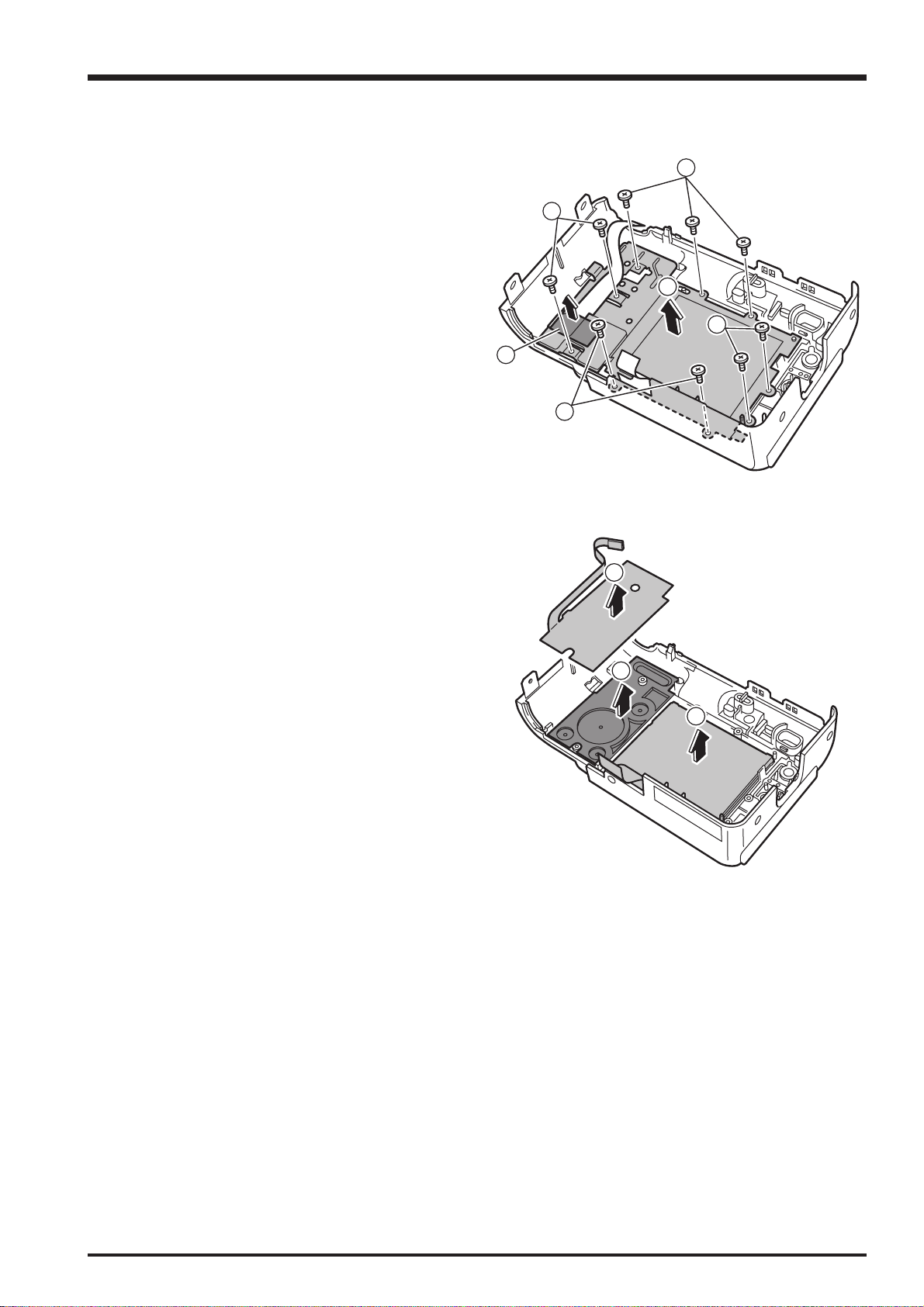

2-3. Disassembling the CONST CASE R

2. Disassembly

(1) Remove the 9 screws (M1.7 x 2.5).

(2) Peel off the K TAPE.

(3) Remove the PLATE LCD in the direction of the arrow.

(4) Remove the LCD CONST in the direction of the arrow.

(5) Remove the OPE UNIT in the direction of the arrow.

(6) Remove the OPE GUM KEY in the direction of the

arrow.

1

1

3

1

2

1

5

[Assembly]

Assemble by performing the disassembly procedure in

reverse.

6

4

15

2. Disassembly

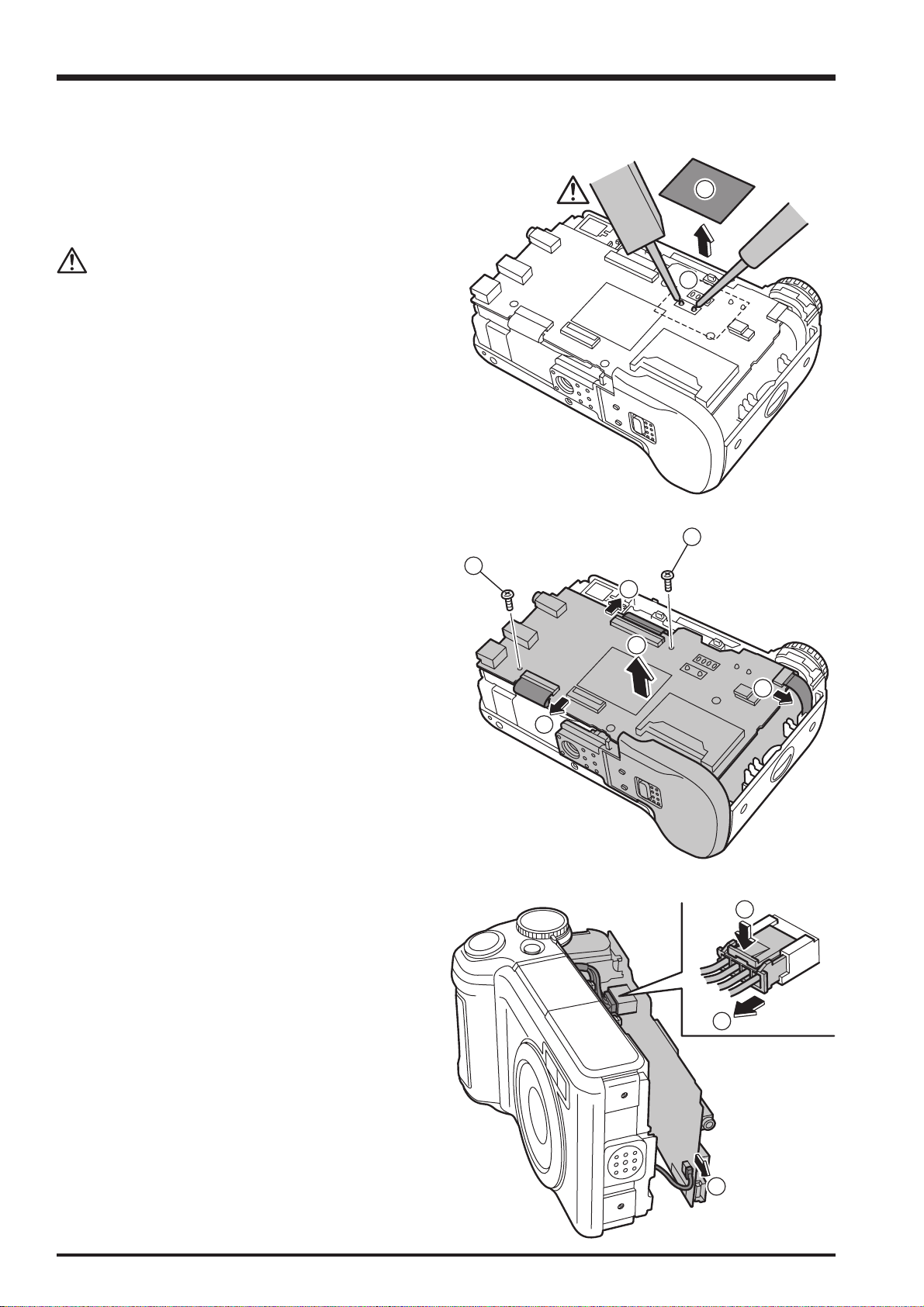

2-4. Removing the internal block

(1) Peel the protective tape off the main capacitor

terminals.

(2) Discharge the main capacitor.

Take care to avoid touching the terminals as this could

cause an electric shock.

FinePix E900 Service Manual

1

2

(3) Remove the FPC on CN802.

(4) Unlock CN151 and disconnect the flexible cable.

(5) Unlock CN101 and disconnect the flexible cable.

(6) Remove the 2 screws (M1.7 x 9.0).

(7) Remove the MAIN PWB ASSY in the direction of the

arrow.

(8) Remove the connector from CN601 in the direction of

the arrow.

(9) While pushing the CN451 locking catch in the direction

of the arrow, remove the connector in the direction of

the arrow.

6

6

4

7

3

5

9

[Assembly]

Assemble by performing the disassembly procedure in

reverse.

16

9

8

FinePix E900 Service Manual

2. Disassembly

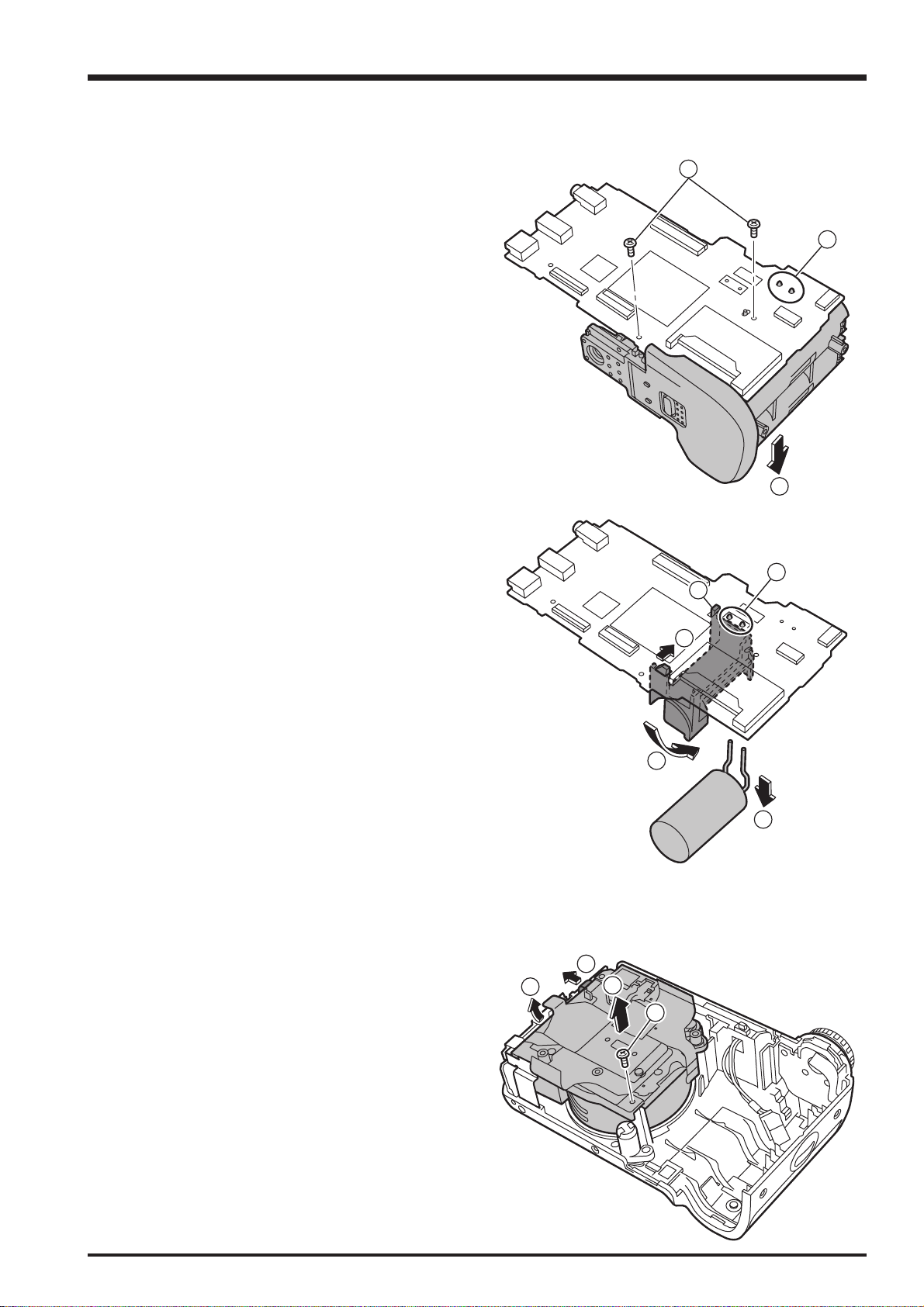

2-5. Removing the ASSY HOLDER BATTERY and LEAD E.CAP

(1) Remove the 2 screws (M1.7 x 3.5).

(2) Remove the solder on the MAIN PWB ASSY (2

locations).

(3) Remove the HOLDER BATTERY in the direction of the

arrow.

(4) Remove the solder on the MAIN PWB ASSY (2

locations).

(5) Remove the LEAD E.CAP (main capacitor) in the

direction of the arrow.

(6) Push the CONDENSER HOLDER catch over in the

direction of the arrow.

(7) With the catch disengaged, remove the CONDENSER

HOLDER in the direction of the arrow.

1

2

3

4

7

6

[Assembly]

Assemble by performing the disassembly procedure in

reverse.

2-6. Removing the LENS ASSY

(1) Peel the edge of the SHEET EMI CCD off in the

direction of the arrow.

(2) Remove the MIC FPC.

(3) Remove the screw (M1.7 x 3.5).

(4) Remove the LENS ASSY in the direction of the arrow.

[Assembly]

Assemble by performing the disassembly procedure in

reverse.

7

5

2

1

4

3

17

2. Disassembly

FinePix E900 Service Manual

2-7. Removing the ASSY PANEL F internal components

(1) Remove the UNIT FLASH in the direction of the arrow.

(There are hooks in 2 locations on PANEL F.)

(2) Spread the side of the ASSY CASE TOP in the

direction of the arrow.

(3) Remove the ASSY CASE TOP in the direction of the

arrow.

(4) Remove the screw (M1.7 x 3.5).

(5) Remove the MIC in the direction of the arrow.

(6) Remove the 2 screws (M1.7 x 3.0).

(7) Remove the HOLDER BAYONET in the direction of

the arrow.

(8) Remove the screw (M1.7 x 3.5).

(9) Disengage the 3 hooks and remove the PLATE SIDE.

(10) Remove the SPEAKER ASSY in the direction of the

arrow. (Take care not to pull on the wire harness.)

10

4

9

5

1

2

6

7

Hook

3

2

[Assembly]

Assemble by performing the disassembly procedure in

reverse.

Hook

8

18

FinePix E900 Service Manual

3. Schematics

3. Schematics

3-1. Cautions

<Cautions when replacing parts>

• Do not reuse removed parts. Always use new parts.

• Note that the negative side of tantalum condensers is readily damaged by heat.

• Except for chemical condensers and tantalum condensers, voltage is not displayed on condensers with a voltage

resistance of 50V or less.

• Resistors not marked are 1/16W chip resistors.

•KΩ = 1000Ω, MΩ = 1000KΩ

• B characteristics of variable resistors and semi-fixed resistors are not displayed.

3-2. Basic Block Names and Functions

Part name Block name Function

LENS CONST CCD FPC BLOCK CCD Output (IC1001)

MAIN PWB ASSY CAMERA BLOCK CCD Output A/D Conversion (IC104)

MOTOR BLOCK Shutter/iris/AF/zoom Drive (IC151)

AUDIO BLOCK Audio IN/OUT(IC651)

JACK BLOCK DC Input Terminal, VBS Output

LCD BLOCK LCD Output CN, Back Light Control

DCDC BLOCK Power Supply Generation (IC301), Power Control

PMAN BLOCK Power Control, LED Driver, Strobe Charge Control (IC401)

VIDEO BLOCK Video Output (IC651)

FLASH BLOCK Flash Charge

CARD BLOCK Connection with the xD-Picture Card

KSW BLOCK Key SW

PROCESS BLOCK Image Signal Processing, USB Communications,

System Control (IC205)

MODE FPC ASSY MODE FPC BLOCK Mode SW, Power Switch, Battery Detect SW, Shutter SW

KEY FPC ASSY KEY FPC BLOCK Key SW

MIC FPC ASSY MIC FPC BLOCK Connection with the Mic Assy

19

3. Schematics

FinePix E900 Service Manual

3-3. Description of Main Block Functions

3-3-1. Technical Overview

The FinePix E900 features the newly developed 5th-Generation Super CCD HR image sensor combines higher sensitivity

with the advanced noise suppression capabilities of the new RP Processor to fully exploit the image quality and resolution of

9.0 effective megapixels. Even photos taken in typically noisy situations such as twilight and under other low-light conditions

retain the subtle tonality you saw your own eyes.

CCD signal processing/Camera circuit section

Analog signals output from the 1/1.6 type Super-CCD Honeycom V HR (IC1001), with an effective pixel count of 9.0

mega-pixels, undergo false color compensation processing, adaptive interpolation processing, amplification (AGC) and

signal mixing inside the CCD signal processing IC “BCS (IC104)” before being converted to 14-bit digital signals (A/D)

and sent to the signal processing LSI “YCS (IC205)”.

The vertical drive IC (IC103) for driving the CCD and the OFD voltage control IC (IC102) are in this block.

Motor Circuit Section

The signal processing LSI “YCS (IC205)” that has received various operating switch commands manages the motor drive

IC (IC151) and controls the AF, ZOOM, SHUTTER and IRIS motors.

Imaging and Signal Processing Section

Input data from the CCD

14-bit digital image data (corresponding to 1H) that has been output from the imaging section (CCD/Camera Block) is

sent to the signal processing LSI “YCS (IC205)”, converted to 32-bit (16-bit x 2) data by the [internal buffer] inside this

LSI, and the image data for one frame (3696 x 2464 pix) is stored temporarily in [SD-RAM]. It is also integrated in the

[AUTO operation section] using the 32-bit the signal processing LSI “YCS (IC204)” image data and sent to the BCS_IC

(IC104) to obtain the appropriate AE/AF/AWB.

Record processing to xD Card

Image data stored in SD-DRAM is sent one frame at a time to the internal [signal processing section] in the signal

processing LSI “YCS (IC205)”. In a process called unpacking, “32-bit to 12-bit conversion” and “pre-processing including

digital clamp, white balance and noise reduction processing, linear matrix processing, gamma correction and R/G/B 14-bit

to R/G/B 8-bit conversion” to “8-bit digital R/G/B signals to Y:Cb:Cr = 4:2:2 YC processing•Eare implemented in this

[signal processing section] and 8-bit Y/Cb/Cr image data are sent to the [internal buffer].

The “rearrangement of data in a format in which 8-bit Y/Cb/Cr signals are easily compressed” is done in the [internal

buffer] and after passing through the [JPEG operation block] to the [media controller], they are recorded on the xD card.

Reproduction of images from xD card

Compressed image data from the xD card is sent as 8-bit image data to the signal processing LSI “YCS (IC205)” then it is

sent to the [media control section], the [DMA unit] and the SD-DRAM and then it is sent to the [media controller], to the

[JPEG operation section] and to the [signal processing section].

In the [signal processing section], 8-bit Y/Cb/Cr signals are converted to 8-bit R/G/B signals and at the same time,

lettering display signals are weighted and passed through the [LCD controller] to the LCD unit and displayed.

Image capture system adjustment data are stored in the Flash ROM.

LCD Unit

Digital signals sent from the signal processing LSI “YCS (IC205)” are passed through the [LCD controller] to the LCD unit.

Power Supply Section

Power supply circuits constructed in the core of the DC IC (IC301) create the following power supplies, which are

supplied to each block.

3.3V [IC202 (PROCESS BLOCK)]

D_3.3V [IC205 (YCS), IC401 (IPS2), IC151 (MOTOR BLOCK)]

AD_3.3V [IC205 (YCS), IC651 (VIDEO Drv)]

AU_3.3V [IC601 (AUDIO)]

CAM3.3V [IC103 (V_Drv), IC104 (BCS)]

xD_3.3V [CN251 (xD CARD CONNECTOR)]

D_5V [IC103 (V_Drv), IC401 (IPS2), LCD/EVF BLOCK]

BL_5V [LCD BLOCK]

5V [IC302, IC303 (MOTOR BLOCK)]

CCD_-8V [IC1001 (CCD), IC103 (V_Drv)]

CCD_15V [IC1001 (CCD), IC103 (V_Drv), IC102 (OFD_Drv)]

1.0V [IC205 (YCS), IC401 (IPS2)]

2.5V [IC205 (YCS)]

D_2.5V [IC205 (YCS)]

LCD_8.5V [LCD BLOCK]

20

FinePix E900 Service Manual

A

A

A

A

A

A

A

3. Schematics

3-4. Block Diagram

FINDER

IW

LENS Barrier

Zoom position

Zoom HP

EX-BRTS

RT-P

R

L

_DE

TS_DE

L

TTAB

B

pukca

KCAJ NI CD

V

3

.TTAB

6R AA

2

LET/ED

Focus HP

BRTS PUPOP

G_DEL

F

T

TORP

spetS01 SIRI

SNEL MOOZx4

aV E

6M

ESU

ESUF

O

TCE

elbair

.t

oC

n

sesluP

IC151

hc

6

LTC

SI0_2

IC401

LAMREH

R

N

WE

5

V

)RH(DCC-AH

cni7.1/

h

1

m0.9

O.LPF

slexip nolli

CCDIN

C

IC1001

V

V5 V51

IC102

GR/DFO

DCC

eleS

SAIB

rewoP

MJN

tc

12

IC103

.vrD rotoM

H9603

P

C

SHT PULSE*2

Focus Pulse *3, Zoom Pulse *3

MTR_CS

,LESV

_DC

AC

H

F52

V

.vrD V

4712DM

N

O_M

H

rD

esluP

IC104

STB_SY

seireS

GER

.

5

3

V

SCB

.3

SD

CDA

3R LRZCBB6999DA

noitarepO V3

tib41

latigiD

niaG

.revi

yarG

edoC

T

G

)elbamargorP(

)BV-A40203NA(2SPI

CCDCLK(36MHz)

C

CC

D

LES KL

FLASH CTRL

EL

D

REVIRD

3

C

TR

PWCTL

Hk867.23

Z

L

TC

no rewoP

R

tese

3.3V_ON

DCDC Block

CD/CD

hc6

81203NA

V0.1

V3.3

V5

51DC

V

C

V8-DCC

DCL

V2

1

_0I

3

S

3.3D

V

ABW

.CI

V5.2

r

S

sei

e

GER

5.2

V

A,V3.3_D

eir

S

s

e

GER

3.3

V

IC201

IC202

IC203

V_T

VFH3703UB

VFH2703UB

,DV

1_0IS

A

roniM

egnahC

H

rotareneG kcolC

rotareneG kcolC

htiw reffuB SHU cigoL yniT

CDA,D

SCB,SC_SCB

.42

/545.42

P/TN

CV

HM42

X

48.00MHz

RTS,TCA_SPI,SC_SPI

S_RWP

tnerruC

IC205

GATJ

PIS++

SCY

pO V3.3 eroiF

noitare

RVE_DFO

CFBI

TU

O

A

TU

O

]0:31[TAD_DCC

K

TESER_

T

ESER_RDV

metsys tceteD

z

HM573

LES LA

NO_KL

zHM8

4

O_KLCDCC

N

z

LAT’

832-AF

CC_B

TE

SE

R

CCER

O

RPCY

NEGC

GEPJ

GEPJ

A

FIDCC

FIDCC

AIDEM

AIDEM

CDFT

CDFT

DCNE

DCNE

eroC UPC 94XT

eroC UPC 94XT

F/I GUB

ED

F/I GUB

ED

eroC UPC

eroC UPC

ehca

c-I

k

8

DS

2

ehcac-D

k8

Peripheral BUS 120MHz

.tnoC SUB

.tnoC

SUB

CMARDS

CMARDS

CAMD

CAMD

reffuB O/I

reffuB O/I

M

AR

46x bM65

L

F

3

TRAU

RVE

TDW

OISC

0.2BSU

TF

M

TF

M

UCI

UCI

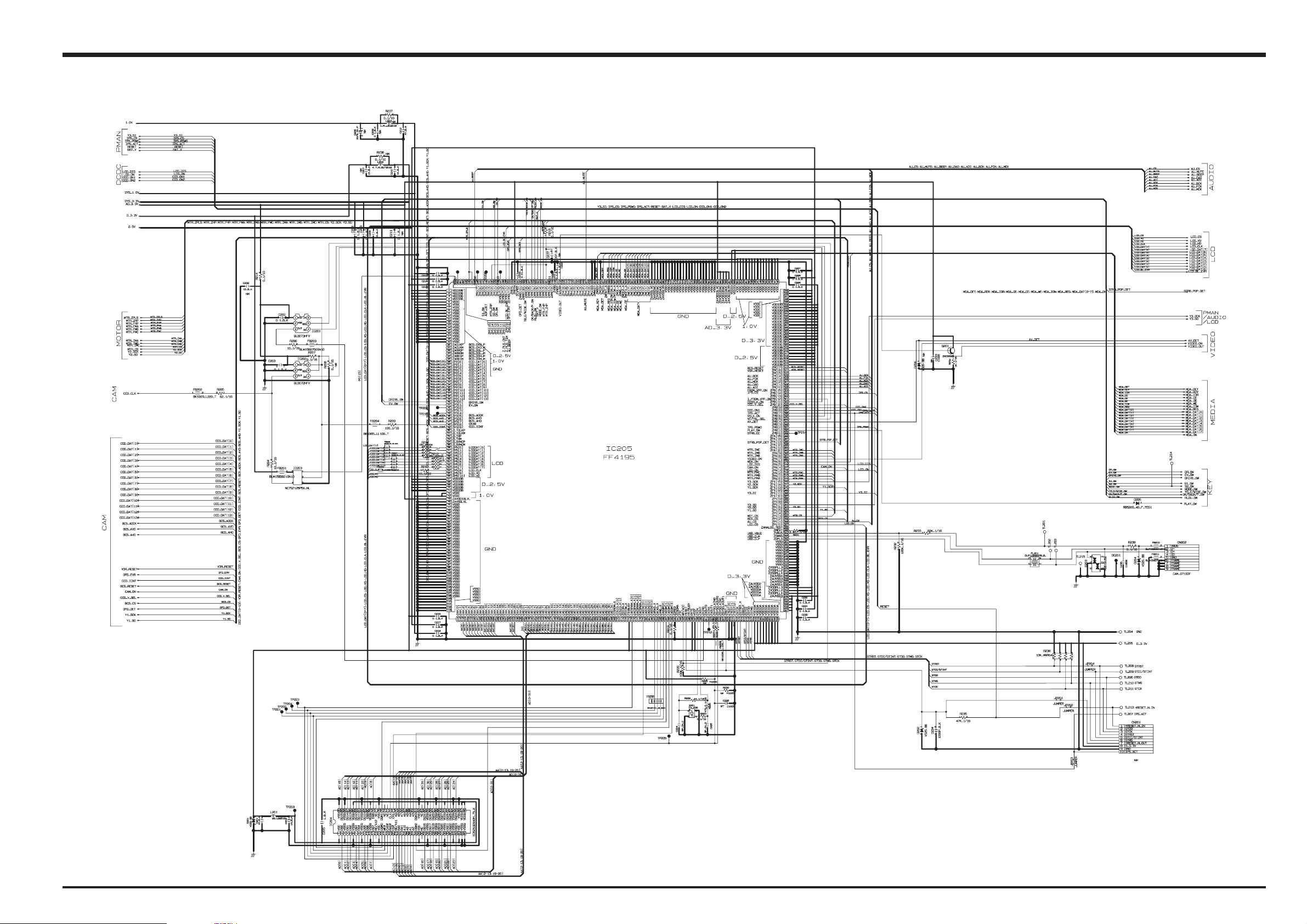

CAD

TROP

TROP

CK

LC

CK

LC

I2S

23x SUB 46x SUB B

HSA

61x tibM2

PLAY_SW

MARDS

6

52

23x b

M

IC204

PEEB

DIV

OE

V_DET

N

DA

I

3.3D

V

W

S

NO_ADM

UB DRAC

S

WS_RD

TADDCL

RVE_LB_DCL

draC Dx

tolS

)NIP02(

DR_SW

,KLC_DCL,]0:7[

DV_DCL,DH_DCL

draC Dx

DCL

lenaP

OISAC

hcni0.2

3_OIS

DEL LB

IC501

_

NO

oediV

V

revirD

IC651

KLCM

B

A,KLCF

KL

C

TUOAD

revirD

TUO_SB

AU_OUT

L

TC

OEDIV

KCAJ

9p

USB_MINI_B

DC IN 3V

3x DEL LB

Cradle

Not

Supported

CI OIDUA

2

E-NK2187U

REKAEPS

PMA_PS

PMA_CIM

LTC

IC601

CIM

ASC_U

A

B

2

I

S

AD

D

A

ETUM_U

3_O

IS

YEK

NO_DCC

EDO

M

)2S/1S(WS ESAELER

EDIW/ELET

WS U/D/L/R

WS F/KCAB/KO

)sop01(WS

WS esneS

WS VE

MAIN PWB ASSY

WS REWOP

IC301

WS YALP

21

3. Schematics

3-5. Overall connection Diagram

FinePix E900 Service Manual

ST_UNIT

MODE_FPC

XE

MIC

ST_LED

LCD

LENS

4 X Zoom

(32.5 ~ 130mm)

CCD

9M-HA

1/1.7

30

41

MAIN_PWB

MOTOR

MOTOR drv

M63069HP

CAM

BCS

AD9996BBCZRL R3

LCD

XE PWB

STRB

IGBT

PROCESS

PW

WIRE

4

POP_

DET

KEY

R_LED

G_LED

MODE_

DIAL

10

RLSE

KEY_FPC

MAIN

CAD.

144 μF

EV

10

DRIVE

WIDE TELE

ZOOM

CAM/

PB

U

LR

OK/

MENU

sp

AV_JACK

USB

35

YCS

T8K29BAMBG-

0302(B)

CARD

AUDIO

AUDIO IC

2

VIDEO

4

9

BU7812KN

DC

VIDEO IC

BH76809FVM

SDRAM (256Mb X 32)

EDS2532AABH-75-E

DC IC

AN30218

3

PMAN

IPS2

AN30204A-VB

20

DR_SW

DISP/

BACK

D

F

22

DC_JACK

- + BATT X2

FinePix E900 Service Manual

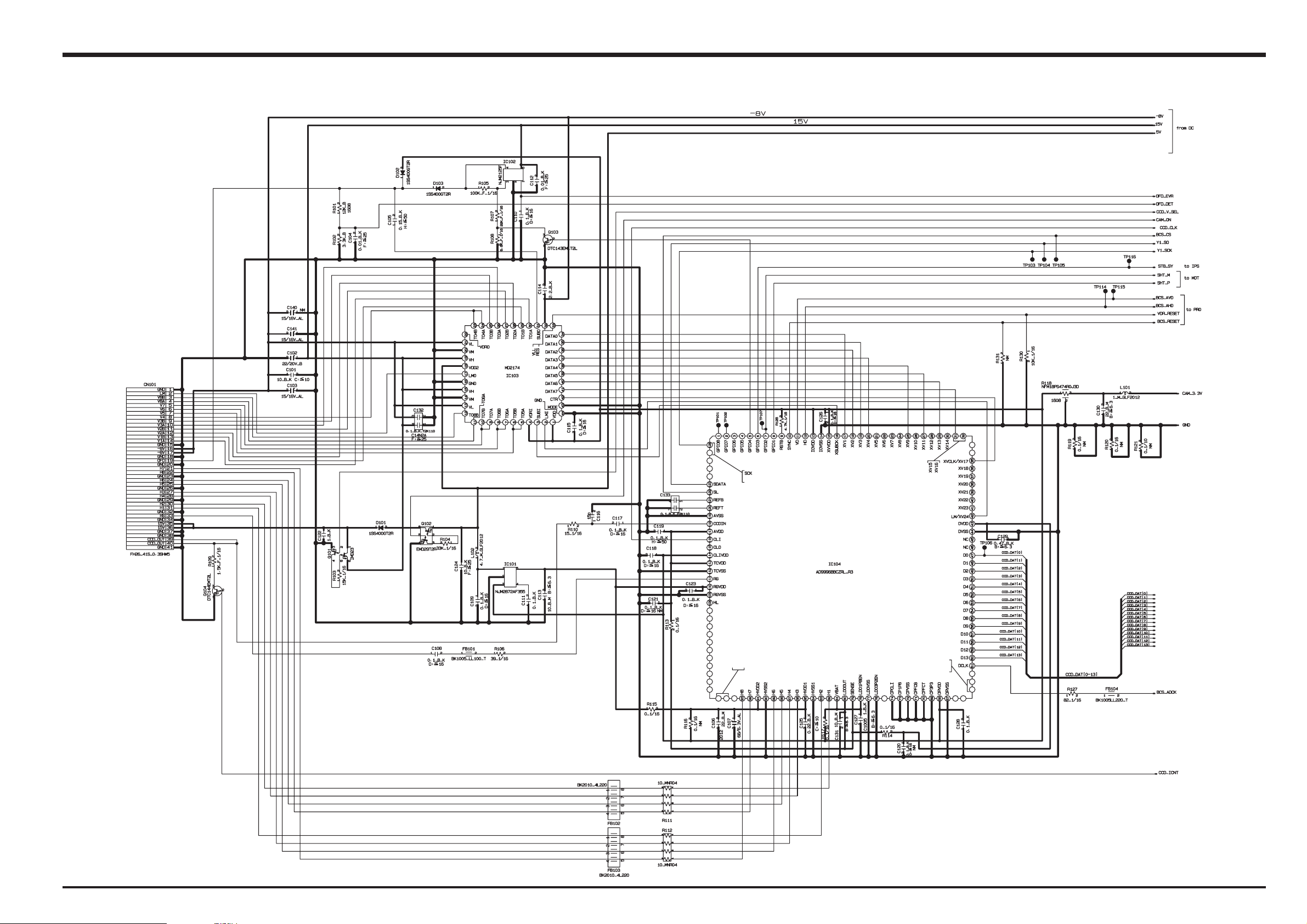

3. Schematics

3-6. Circuit Diagrams

3-6-1. CAMERA BLOCK

23

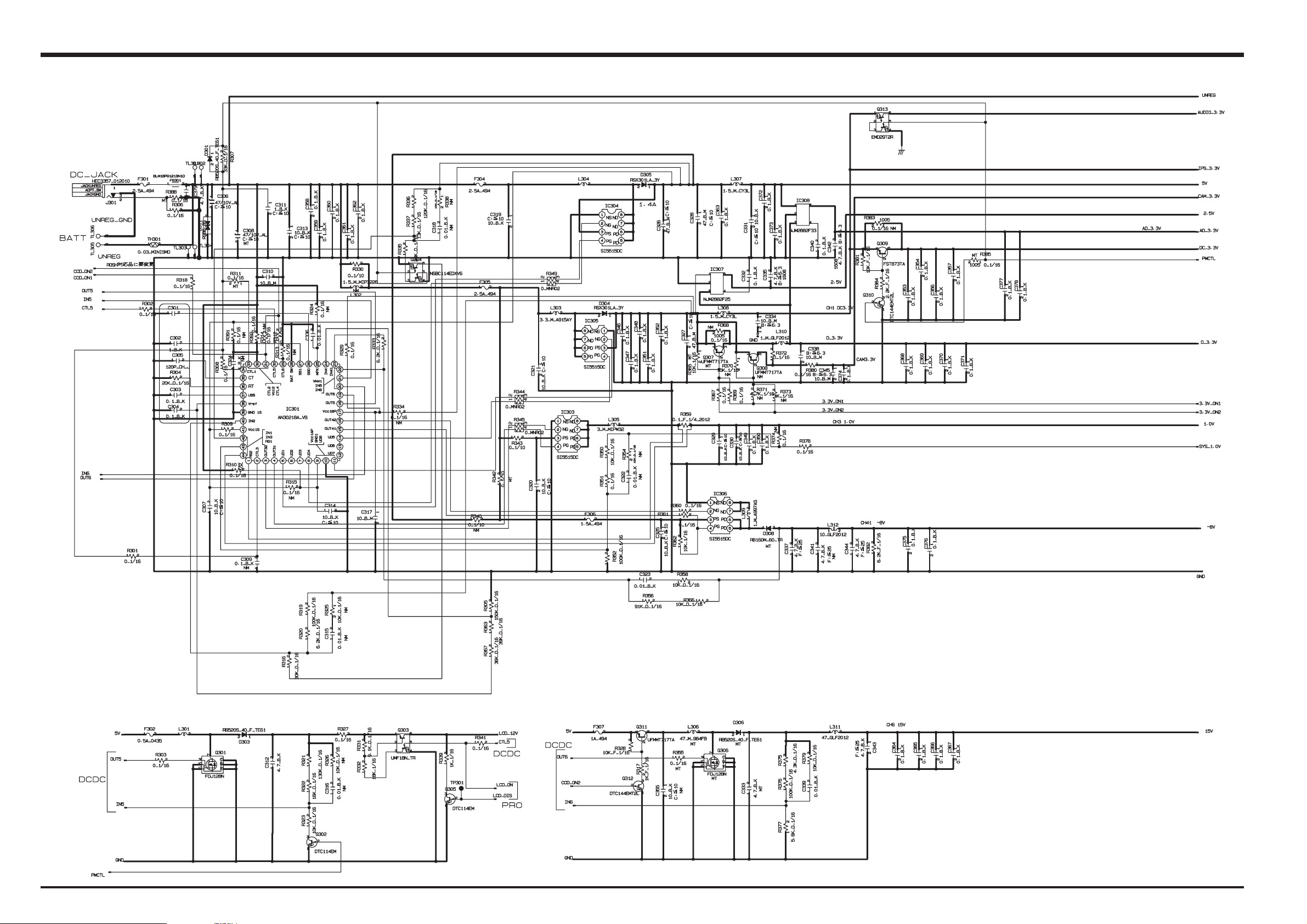

3. Schematics

3-6-2. DCDC BLOCK

FinePix E900 Service Manual

24

FinePix E900 Service Manual

3. Schematics

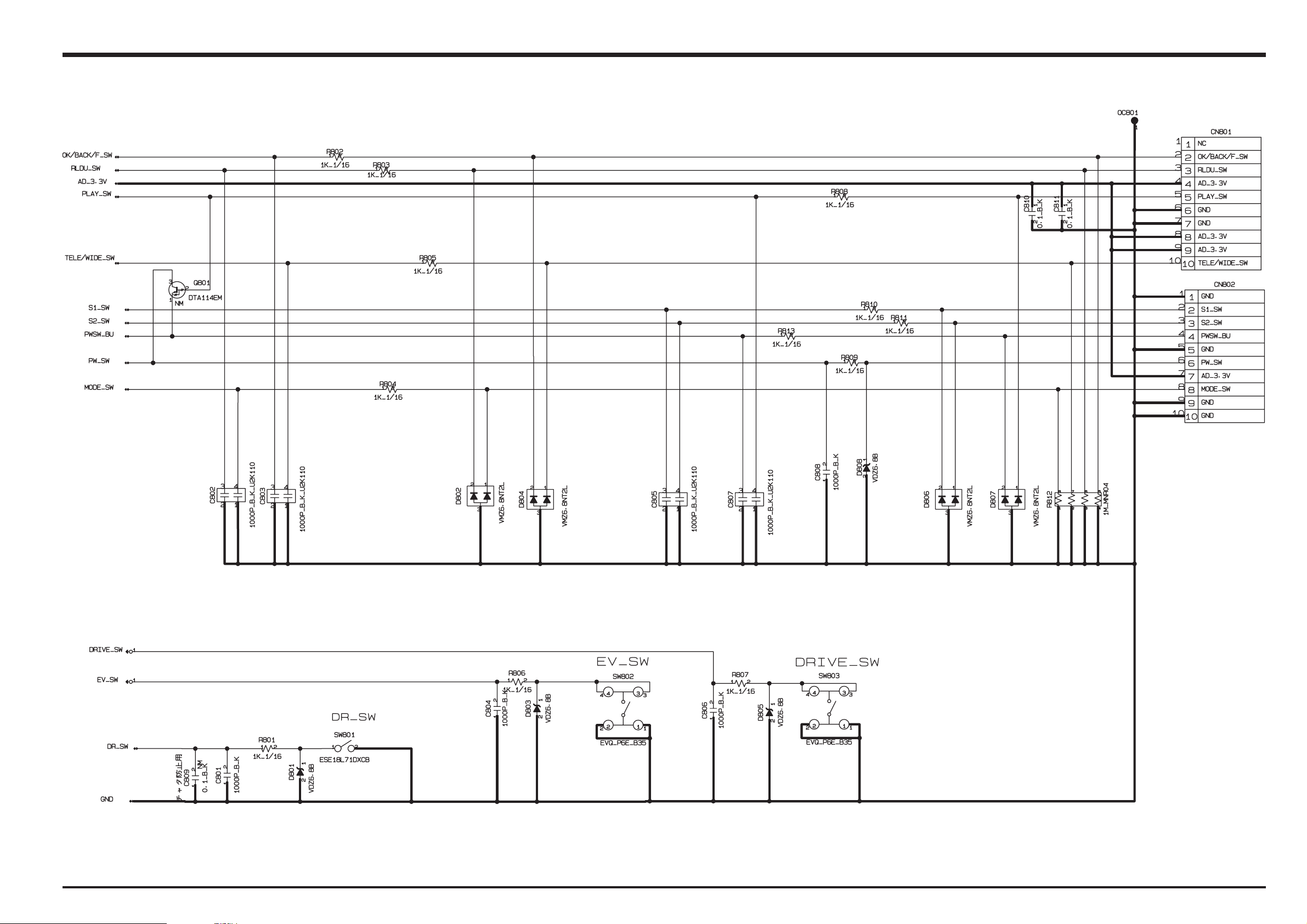

3-6-3. KSW BLOCK

25

3. Schematics

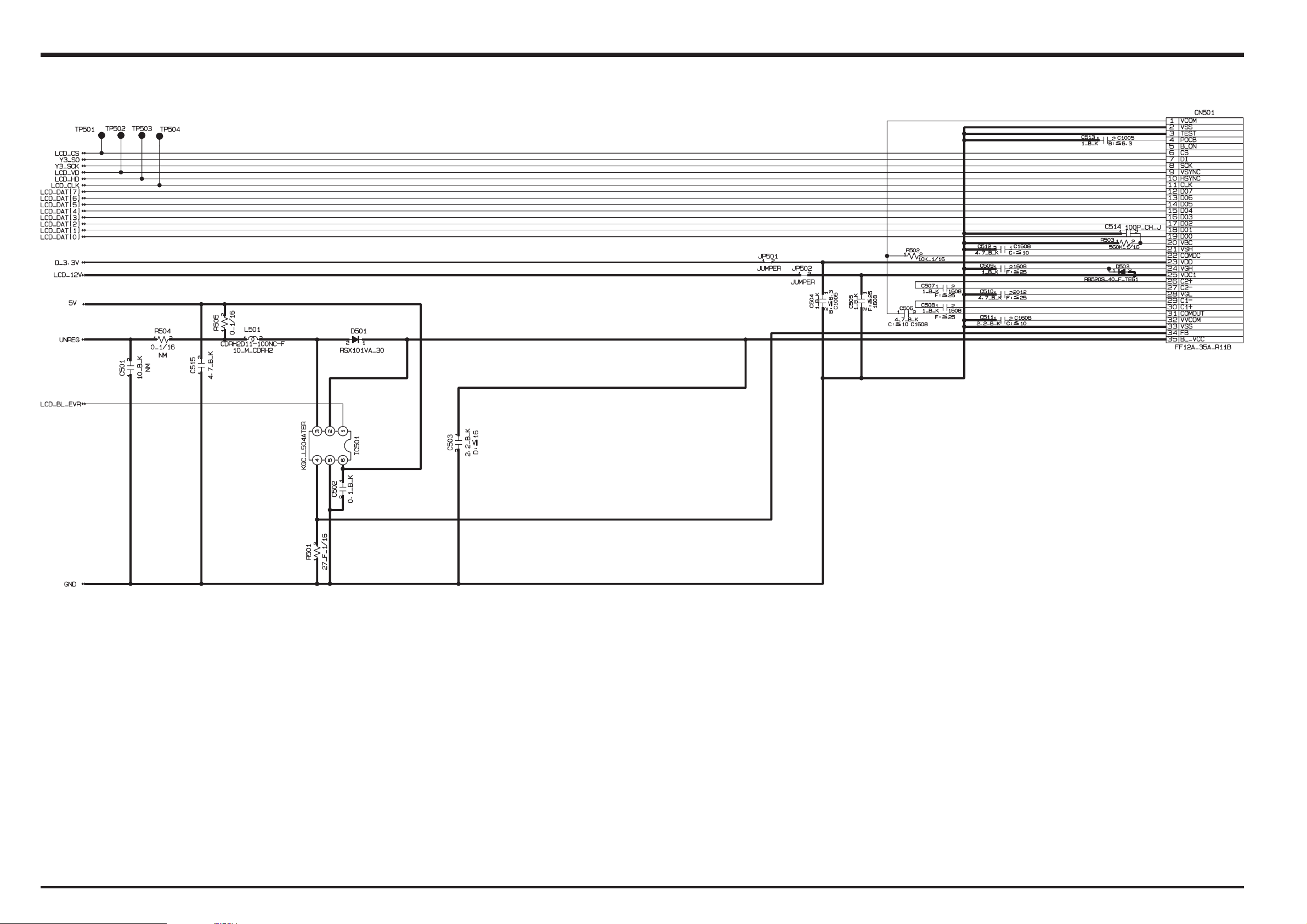

3-6-4. LCD BLOCK

FinePix E900 Service Manual

26

FinePix E900 Service Manual

3. Schematics

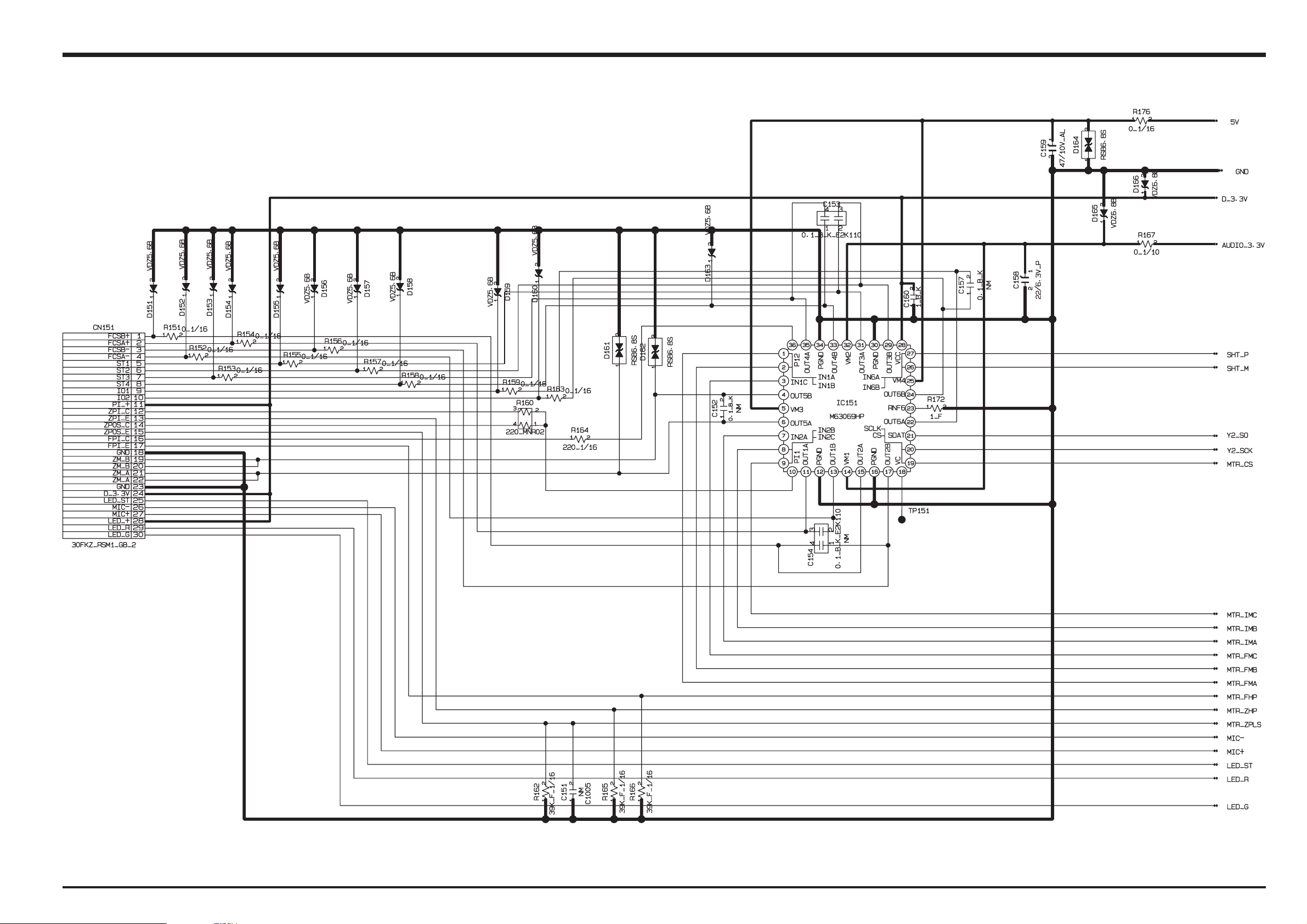

3-6-5. MOTOR BLOCK

27

3. Schematics

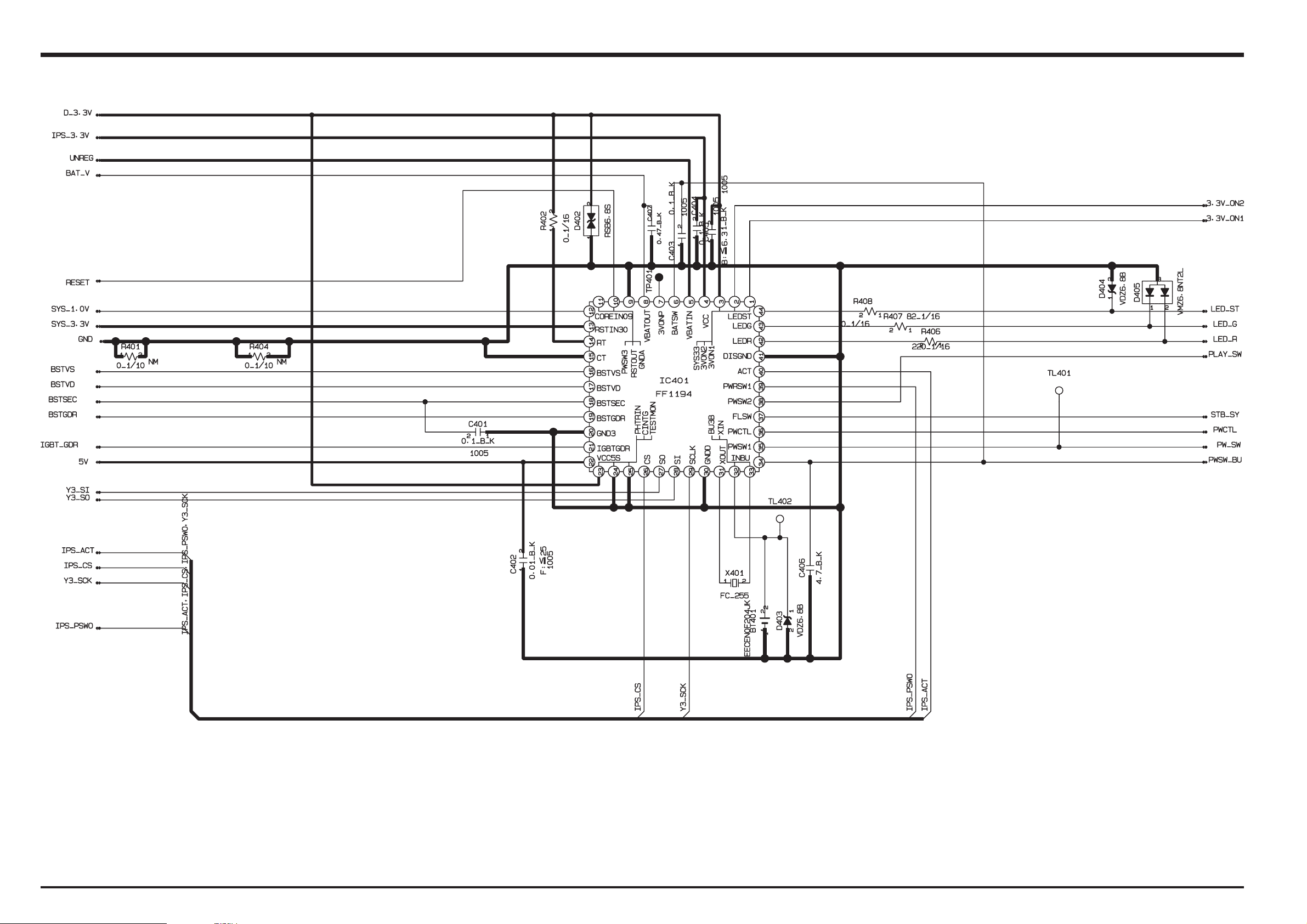

3-6-6. PMAN BLOCK

FinePix E900 Service Manual

28

FinePix E900 Service Manual

3. Schematics

3-6-7. PROCESS BLOCK

29

3. Schematics

MEMO

FinePix E900 Service Manual

30

Loading...

Loading...