Fuji Electric PXR7 Installation Guide

– 10 –

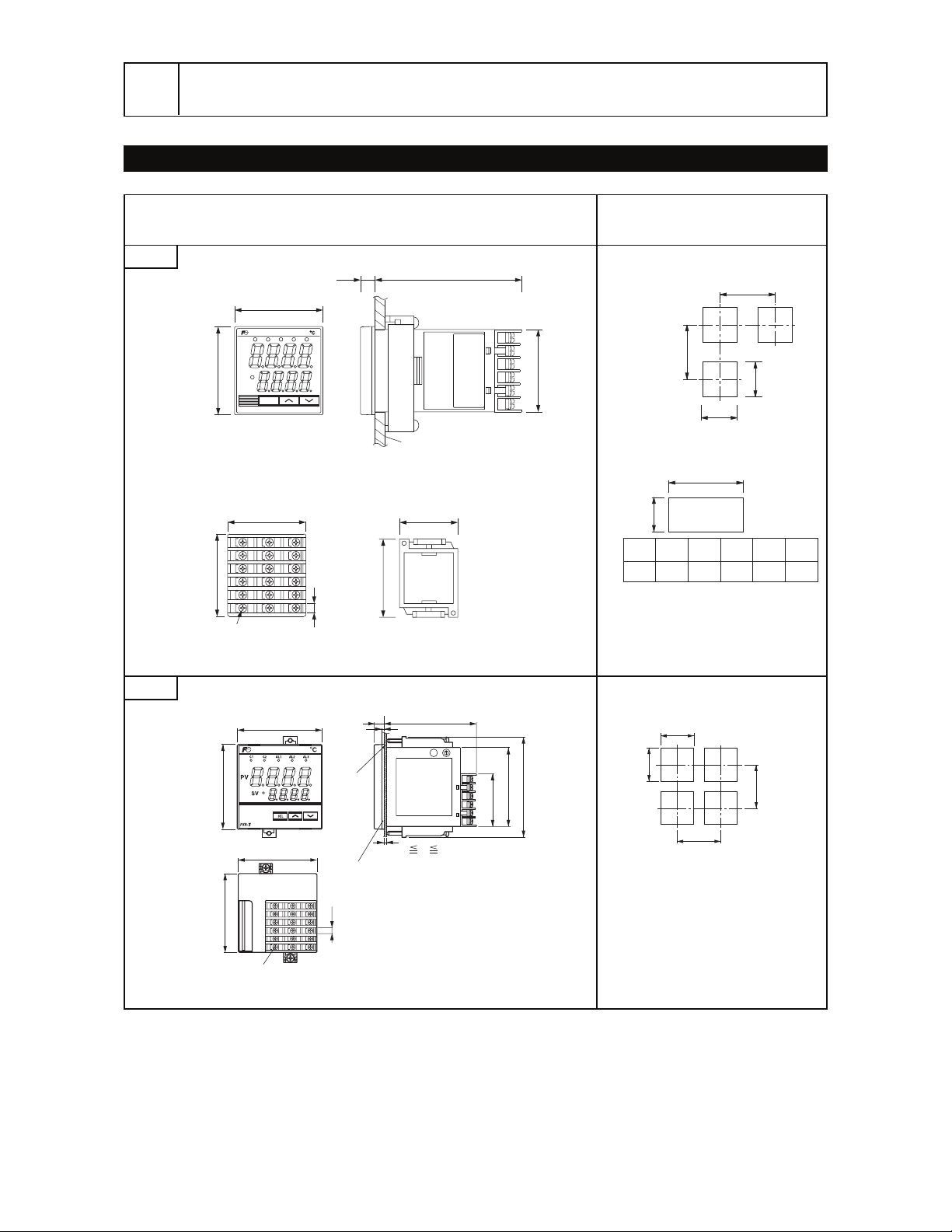

1 Installation/mounting

Outline and Panel Cutout Dimensions

63 or more

73 or more

+0.5

a

-

0

Number

of units

2 3 4 5 6

a 93 141 189 237 285

45

+0.5

0

45

+0.5

0

45

+0.5

0

For side by side installation,

see the Note1.

No. 000001T

PXR4TAA1-1YM00-D

MFD 2000-04

AL2AL1C1 C2 AL3

SEL

PXR-4

SV

PV

48

44.8

44.8

79.88

48

Mounting bracket

Panel

Panel thickness 1 to 8mm

48

44.8

57

6.2

Terminal screw M3×6

13

16

17

18

14

15

7

8

10

11

12

9

1

2

4

5

6

3

Outline dimensions (unit:mm)

Panel cutout dimensions

(unit:mm)

6.2

72

67

67

72

t

2

8.2

79.7

1 t 8

44.8

67

80.8

Panel

Packing

Terminal screw M3×6

92MIN.

0

+0.7

82MIN.

68

0

+0.7

68

PXR4

PXR7

– 11 –

30 min.

70 or more

Note) Panel coating procedure must be taken into account, for the panel cutout dimension should still

conform with the dimensions listed in the left hand column.

Caution on side-by-side installation:

• Maximum ambient temperature is at 45 ˚C when the power supply is at 200VAC or more. When

the PXR4 controller is tightly fixed in vertical and upright direction, the use of 100V AC power

supply is recommended .

(Installation of fan is recommended as a heat release measure)

• Make sure the controller is installed more than 30mm away, when there is an instrument of

more than 70mm depth or a wall on the right side of the controller.

• Side-by-side installation may sacrifice the controller’s waterproof property.

Caution on wiring:

• Terminals at the left hand side (from No.1 to 6) should be used first.

• Crimp terminals with matching screw size should be used. Tightening torque value should be

approx. 0.8N · m.

• Do not connect anything to the terminals that are not used. (Do not use as relay terminal)

Remarks

Loading...

Loading...