C1 C2 AL1 AL2 AL3

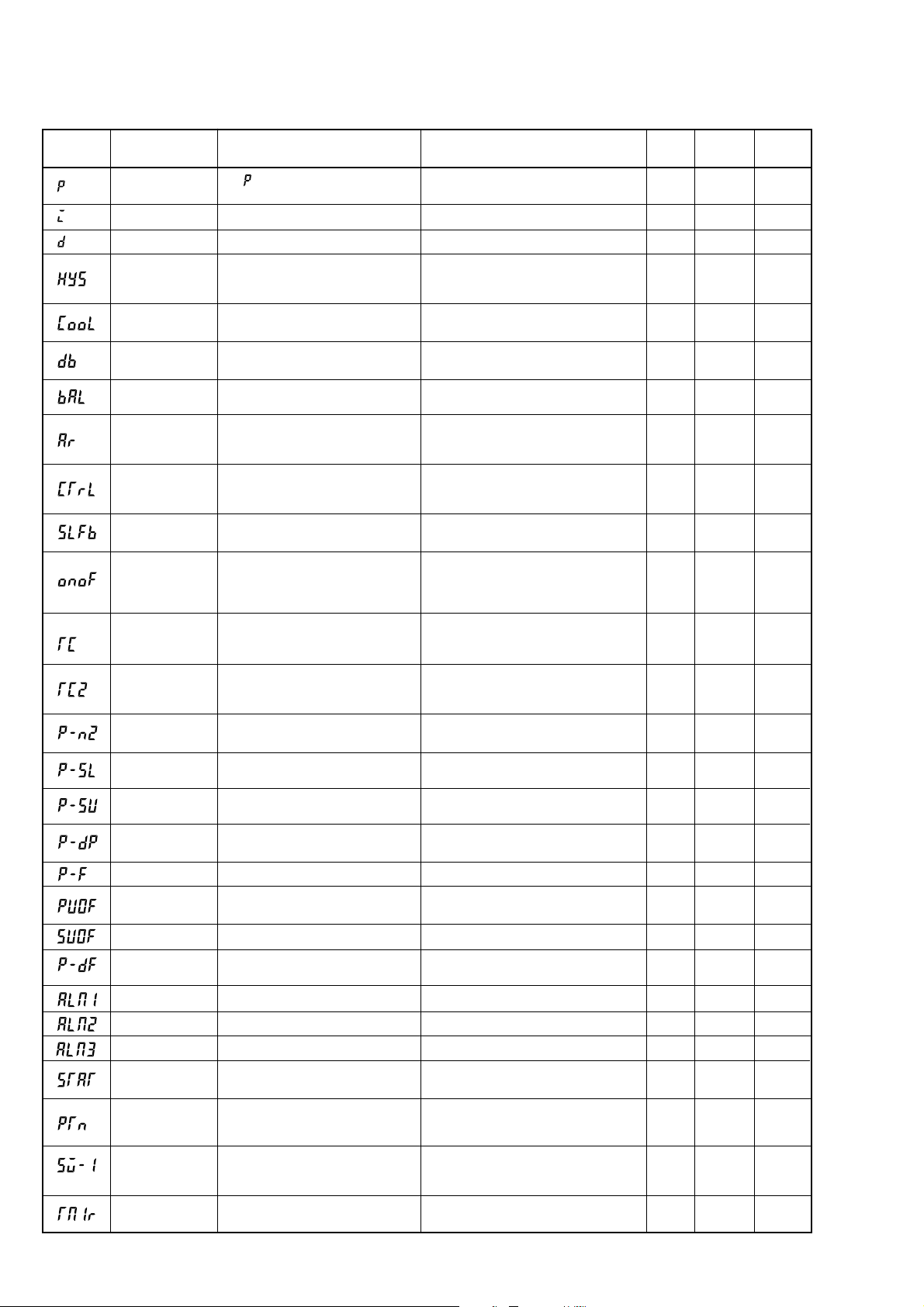

PV

°C

Micro-contr oller X

PXR

SV

SEL

Model: PXR4/5/9

Operation Manual

ECNO:406e

Table of Contents

1. Part Names and Functions ........................................................ 6

2. Operations ................................................................................. 7

2-1 Parameter list ..................................................................................... 7

2-2 Basic operations............................................................................... 12

2-3 Parameter functions and method of settings....................................14

Manual mode setting ................................................................................................. 15

Standby setting .......................................................................................................... 16

Local/remote operation setting .................................................................................. 17

Ramp-soak control..................................................................................................... 18

Canceling the alarm latch .......................................................................................... 19

Auto-tuning function................................................................................................... 20

Displaying ON-delay alarm or the remaining time of timers ...................................... 21

Setting alarm 1, 2 and 3 ............................................................................................ 22

Upper limit of alarm 1, 2 and 3 .................................................................................. 22

Lower limit of alarm 1, 2 and 3................................................................................... 22

Key lock ..................................................................................................................... 23

Proportional band ...................................................................................................... 24

Integral time ............................................................................................................... 25

Derivative time ........................................................................................................... 26

Hysteresis range for ON/OFF control ........................................................................ 27

Cooling-side proportional band coefficient ................................................................ 28

Cooling-side proportional band shift (Dead band/Overlap band) .............................. 29

Output offset value..................................................................................................... 30

Anti-reset windup ....................................................................................................... 30

Control algorithm ....................................................................................................... 31

PV (Measured value) stable range ............................................................................ 35

HYS (Hysteresis) mode at ON/OFF control............................................................... 36

Cycle time of control output 1 .................................................................................... 37

Cycle time of control output 2 (Cooling-side)............................................................. 38

Input signal code........................................................................................................ 39

Setting the measuring range (Input range) ................................................................ 40

Selection °C / °F ........................................................................................................ 40

Decimal point position................................................................................................ 42

PV (Measured value) offset ....................................................................................... 43

SV (Setting value) offset ............................................................................................ 44

Time constant of input filter........................................................................................ 45

Alarm types................................................................................................................ 46

Selecting ramp-soak patterns .................................................................................... 49

Ramp-soak status display.......................................................................................... 50

1st to 8th target SV.................................................................................................... 50

1st to 8th ramp segment time .................................................................................... 50

1st to 8th soak segment time..................................................................................... 50

Ramp-soak modes..................................................................................................... 50

2

Specifying control action and output direction at input burn-out ................................ 53

SV (Setting value) lower limiter.................................................................................. 54

SV (Setting value) upper limiter ................................................................................. 54

The time of ON-delay alarm or timer function............................................................ 55

Displaying current detector input ............................................................................... 57

HB (Set value of heater break alarm) ........................................................................ 57

Hysteresis alarm 1, 2 and 3....................................................................................... 59

Options of alarm 1, 2 and 3 ....................................................................................... 60

Upper and lower limits for control output 1 ................................................................ 62

Upper and lower limits for control output 2 ................................................................ 62

Output limit types ....................................................................................................... 63

Output value display .................................................................................................. 64

RCJ (Cold junction compensation) ............................................................................ 65

Adjusting the PV (Measured value) display (0%)....................................................... 66

Adjusting the PV (Measured value) display (100%)................................................... 66

DI1/2 (Digital input 1/2) operation .............................................................................. 67

Station No. for communication ................................................................................... 70

Parity for communication ........................................................................................... 71

Communication protocol setting ................................................................................ 72

Re-transmission output type setting .......................................................................... 73

Re-transmission base and span scale....................................................................... 74

Remote SV input (0%) adjustment ............................................................................ 75

Remote SV input (100%) adjustment ........................................................................ 75

Remote SV input filter constant ................................................................................. 76

Remote SV input value display.................................................................................. 77

Parameter display mask ............................................................................................ 78

3. Troubleshooting ....................................................................... 79

Index ............................................................................................ 81

3

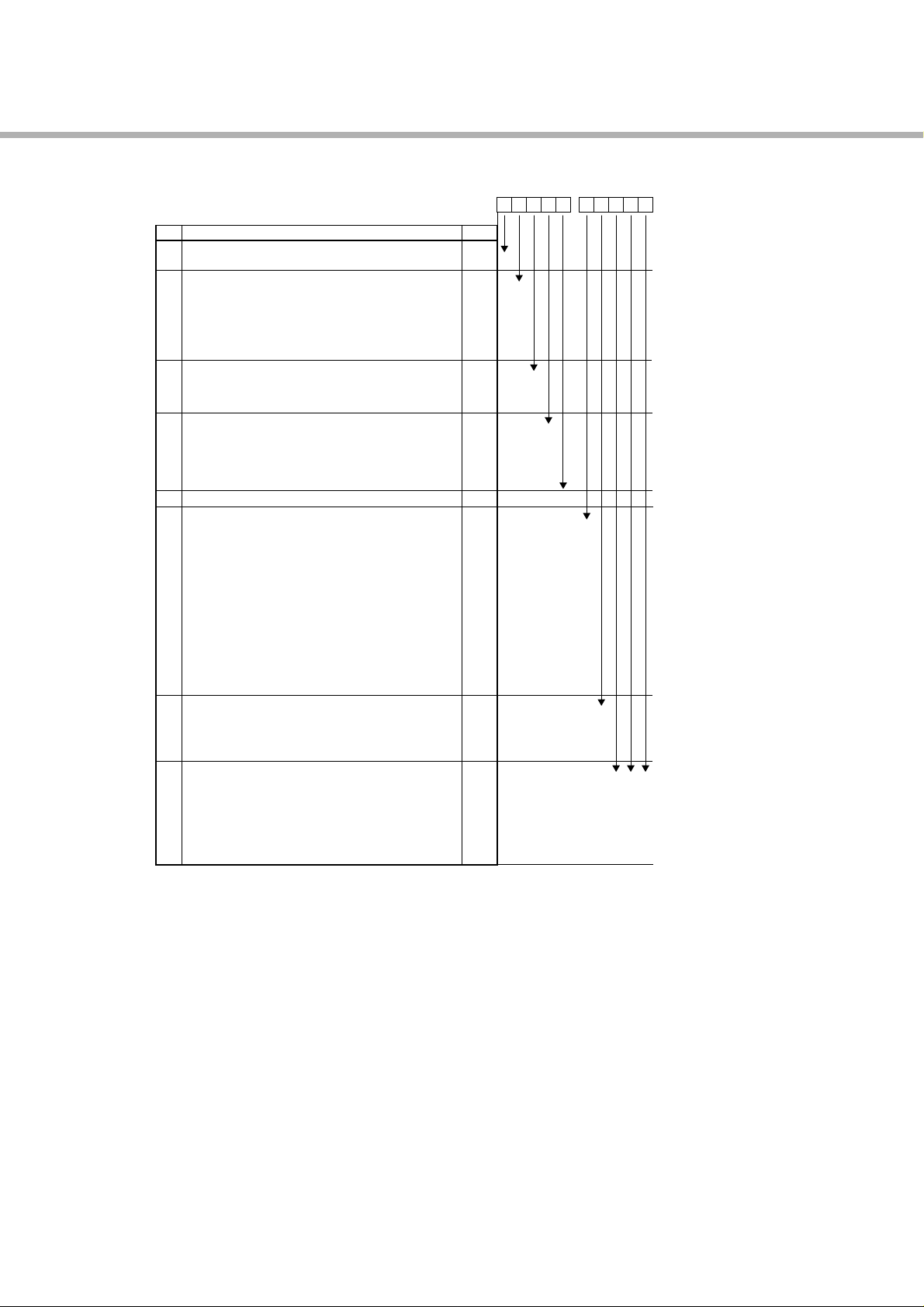

PXR4

45678

PXR

910111213

-

1

Digit

<Front dimensions>

4

48 X 48mm

<Input signal>

5

Thermocouple °C

Thermocouple °F

Resistance bulb Pt100 3-wire type °C

Resistance bulb Pt100 3-wire type °F

1 to 5V DC

4 to 20mA DC

<Control output 1>

6

Relay contact output

Voltage pulse output (24V DC)

4 to 20mA DC output

<Control output 2>

7

None

Relay contact output

Voltage pulse output (24V DC)

4 to 20mA DC output

Re-transmission output (4 to 20mA DC)

<Revision code>

8

<Optional specifications 1>

9

None

Alarm (1 pc.)

Alarm for heater break

Alarm (1 pc.) + Alarm for heater break

Ramp-soak

Alarm (1 pc.) + Ramp-soak

Alarm for heater break + Ramp-soak

Alarm (1 pc.) + Alarm for heater break + Ramp-soak

Alarm (2 pcs.)

Alarm (2 pcs.) + Ramp-soak

Alarm (2 pcs.) + Alarm for heater break + Ramp-soak

Alarm (3 pcs.)

Remote SV

Remote SV + Alarm (2 pcs.)

<Instruction manual> <Power supply voltage>

10

None 100 to 240V AC

English 100 to 240V AC

None 24V DC

English 24V DC

<Optional specifications 2>

11

None

12

RS485 (Modbus) communication

13

RS485 (ASCII) communication

Digital input 1 point

Digital input 2 points

RS485 (Modbus) communication + Digital input 1 point

RS485 (ASCII) communication + Digital input 1 point

Note 1: Cannot be combined with heater break alarm.

( 2, 3, 6, 7, H cannot be specified on 9th digit.)

Note 2: Cannot be combined with alarm (1 pc.) + heater break alarm, alarm (2 pcs.), or alarm (3pcs.).

( 3, 7, F, G, H, M, P cannot be specified on 9th digit.)

Note 3: Cannot be combined with RS485 + 1-point digital input.

(V and W cannot be specified on 11th digit.)

Note 4: In the case of control output 2, either of heater break alarm or remote SV input can be selected.

(A, C, E and R on the 7th digit, and 2,3,6,7,H, D and P on the 9th digit cannot be specified.)

Input signal, measurement range, and set value at the time of deliver are as follows.

When thermocouple is specified: Thermocouple K, Measurement range; 0 to 400°C, Set value; 0°C

When resistance bulb is specified: Pt, Measurement range; 0 to 150°C, Set value; 0°C

When voltage/current is specified: Scaling; 0 to 100%, Set value; 0%

For the cases other than the above, specify input signal and measurement range.

Input signal of the thermocouple and the resistance bulb can be switched by key operation on the front panel.

The actuating method of the control output has been set to reverse for control output 1, and to direct for control

output 2 at the time of delivery. Note that reverse and direct actuation can be switched by key operation on the

front panel.

Specification

Note

Note 1

Note 2

Note 2

Note 2

Note 2

Note 3

Note 3

Note 3

Note 3

Note 3

Note 3

Note 3

Note 4

4

T

R

N

S

A

B

A

C

E

Y

A

C

E

R

1

0

1

2

3

4

5

6

7

F

G

H

M

D

P

N

V

C

B

0

0

M

0

N

0

S

0

T

0

V

0

W

0

0

0

0

0

0

0

0

4

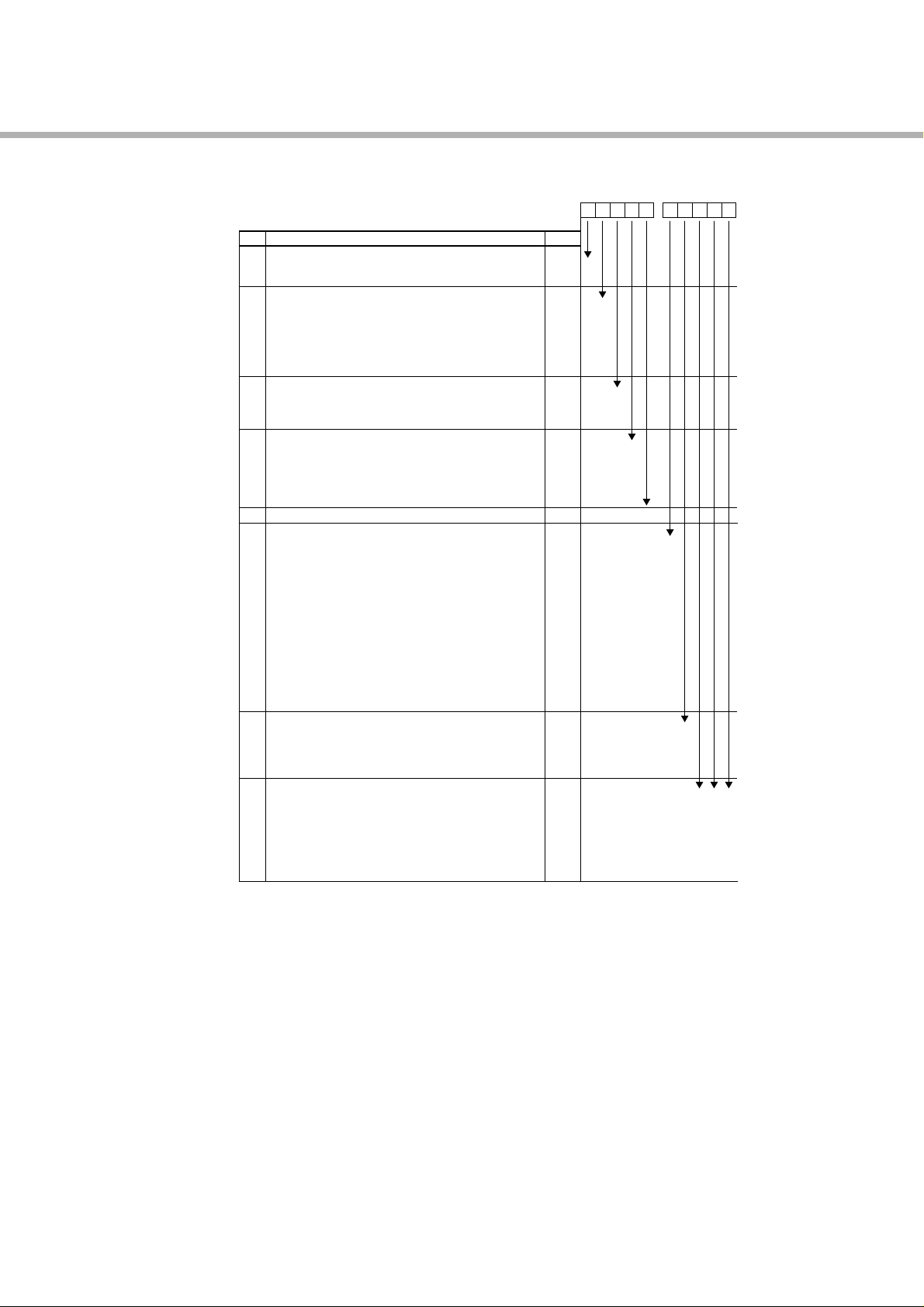

PXR5/9

45678

PXR

910111213

-

1

Digit

<Front dimensions>

4

48 X 96mm

96 X 96mm

<Input signal>

5

Thermocouple °C

Thermocouple °F

Resistance bulb Pt100 3-wire type °C

Resistance bulb Pt100 3-wire type °F

1 to 5V DC

4 to 20mA DC

<Control output 1>

6

Relay contact output

Voltage pulse output (24V DC)

4 to 20mA DC output

<Control output 2>

7

None

Relay contact output

Voltage pulse output (24V DC)

4 to 20mA DC output

Re-transmission output (4 to 20mA DC)

<Revision code>

8

<Optional specifications 1>

9

None

Alarm (1 pc.)

Alarm for heater break

Alarm (1 pc.) + Alarm for heater break

Ramp-soak

Alarm (1 pc.) + Ramp-soak

Alarm for heater break + Ramp-soak

Alarm (1 pc.) + Alarm for heater break + Ramp-soak

Alarm (2 pcs.)

Alarm (2 pcs.) + Ramp-soak

Alarm (2 pcs.) + Alarm for heater break + Ramp-soak

Alarm (3 pcs.)

Remote SV

Remote SV + Alarm (2 pcs.)

<Instruction manual> <Power supply voltage>

10

None 100 to 240V AC

English 100 to 240V AC

None 24V DC

English 24V DC

<Optional specifications 2>

11

None

12

RS485 (Modbus) communication

13

RS485 (ASCII) communication

Digital input 1 point

Digital input 2 points

RS485 (Modbus) communication + Digital input 1 point

RS485 (ASCII) communication + Digital input 1 point

Note 1: Cannot be combined with heater break alarm.

( 2, 3, 6, 7, H cannot be specified on 9th digit.)

Note 2: Cannot be combined with RS485 + 1-point digital input.

(V and W cannot be specified on 11th digit.)

Note 3: In the case of control output 2, either of heater break alarm or remote SV input can be selected.

(A, C, E and R on the 7th digit, and 2,3,6,7,H, D and P on the 9th digit cannot be specified.)

Input signal, measurement range, and set value at the time of deliver are as follows.

When thermocouple is specified: Thermocouple K, Measurement range; 0 to 400°C, Set value; 0°C

When resistance bulb is specified: Pt, Measurement range; 0 to 150°C, Set value; 0°C

When voltage/current is specified: Scaling; 0 to 100%, Set value; 0%

For the cases other than the above, specify input signal and measurement range.

Input signal of the thermocouple and the resistance bulb can be switched by key operation on the front panel.

The actuating method of the control output has been set to reverse for control output 1, and to direct for control

output 2 at the time of delivery. Note that reverse and direct actuation can be switched by key operation on the

front panel.

Specification

Note

Note 1

Note 2

Note 2

Note 2

Note 2

Note 2

Note 2

Note 2

Note 3

5

9

T

R

N

S

A

B

A

C

E

Y

A

C

E

R

1

0

1

2

3

4

5

6

7

F

G

H

M

D

P

N

V

C

B

0

0

M

0

N

0

S

0

T

0

V

0

W

0

0

0

0

0

0

0

0

5

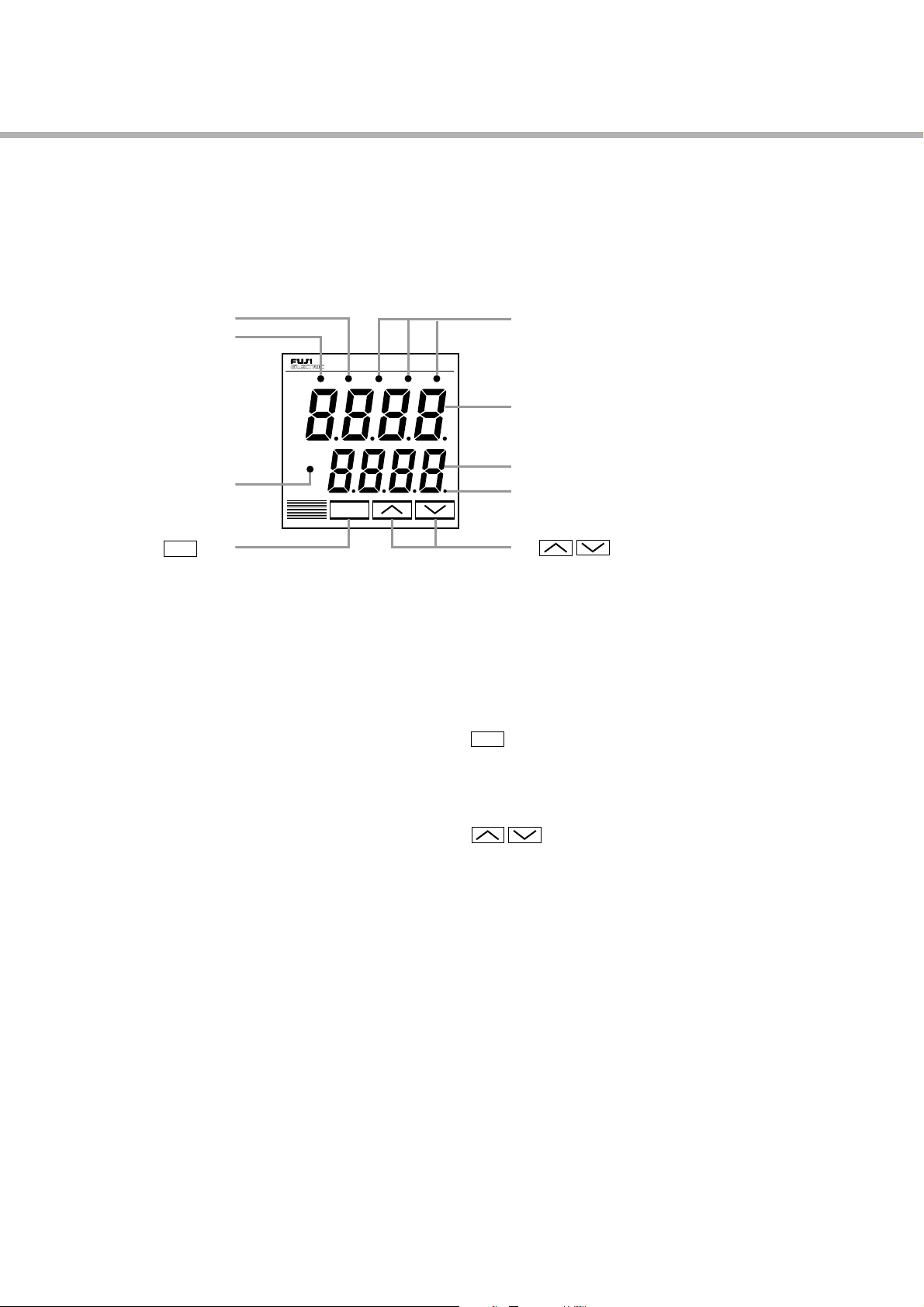

1

This chapter explains the part names and functions on the face panel. The face panel has the PV and SV displays, the sta tus

indicating lamp, and the setting keys, etc. Those functions are explained below. Please read and understand them before

using the PXR. For details about the setting of parameters, see Chapter 2.

w

Lamp for control output 2

q

Lamp for control output 1

Part Names and Functions

e Alarm lamp

°C

C1 C2 AL1 AL2 AL3

PV

SV

i SV lamp

PXR

SEL

y

q Lamp for control output 1

Lights up while control output 1 stays ON.

w Lamp for control output 2

Lights up while control output 2 stays ON.

e Alarm lamp

Lights up on detecting an alarm. The alarm output is

turned ON at the same time.

If the optional heater break alarm is provided, the AL3

lamp lights up on detecting a heater break.

key

SEL

r PV (Measured value) display

t SV (Setting value) display

o Auto-tuning/self-tuning/manual mode

lamp

u

t SV (Setting value) display

Displays the SV. When setting a parameter, its value

appears.

SEL

y

u keys

key

Used to select a parameter block and a parameter, and

register a set value.

Used to change the SV, call parameters, and change parameter values.

keys

r PV (Measured value) display

Displays the PV. When setting a parameter, its name

appears.

6

i SV lamp

Lights up while the SV is displayed in the SV display.

When parameters and data are displayed, the SV lamp

goes out.

o Auto-tuning/self-tuning/manual mode lamp

Flashes under an auto-tuning or self-tuning operation.

The lamp is kept on in manual mode.

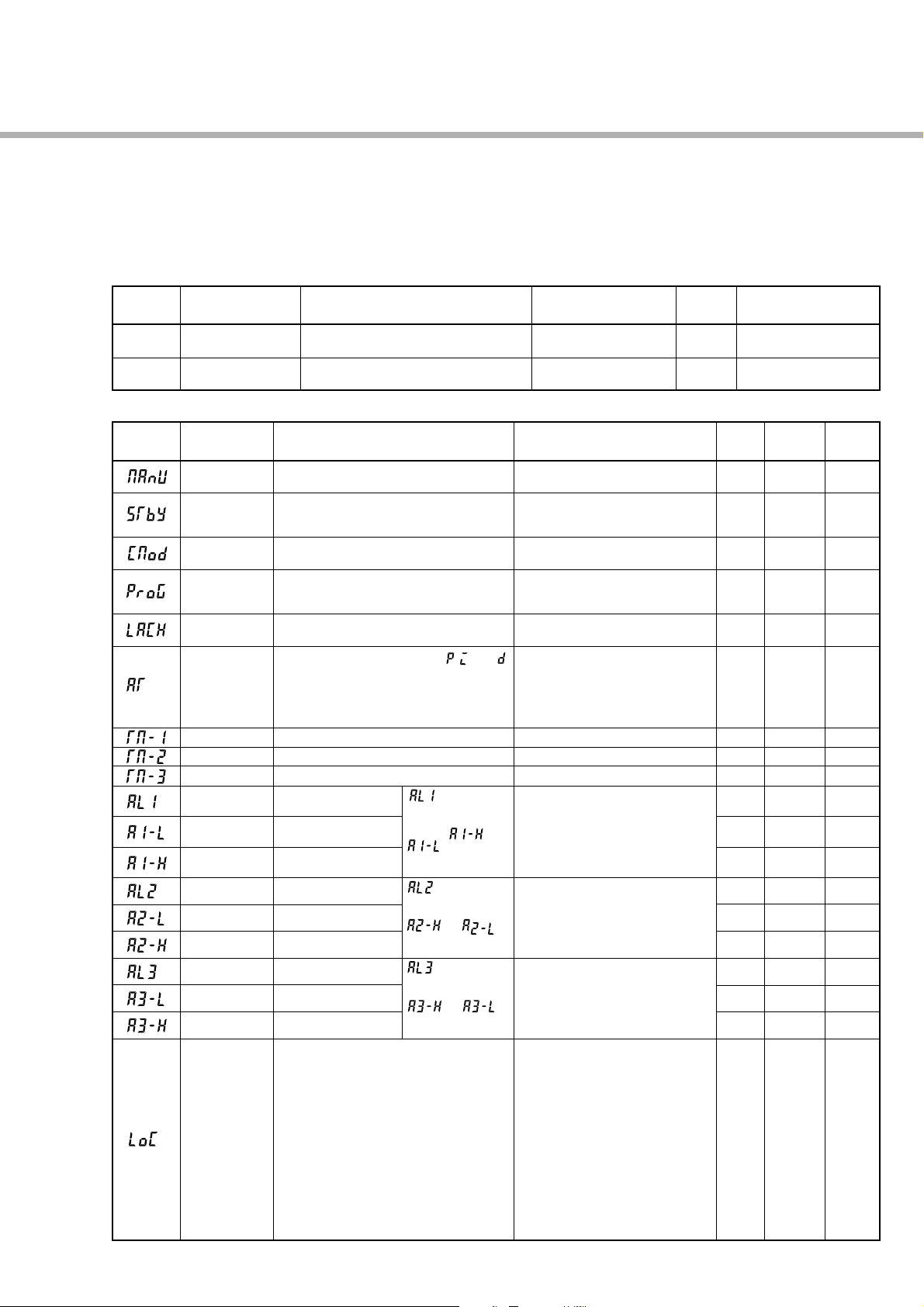

2

Parameter

display symbol

User’s

set value

Reference

page

Parameter name

Description

Setting range and

factory default setting (*)

Parameter

mask DSP

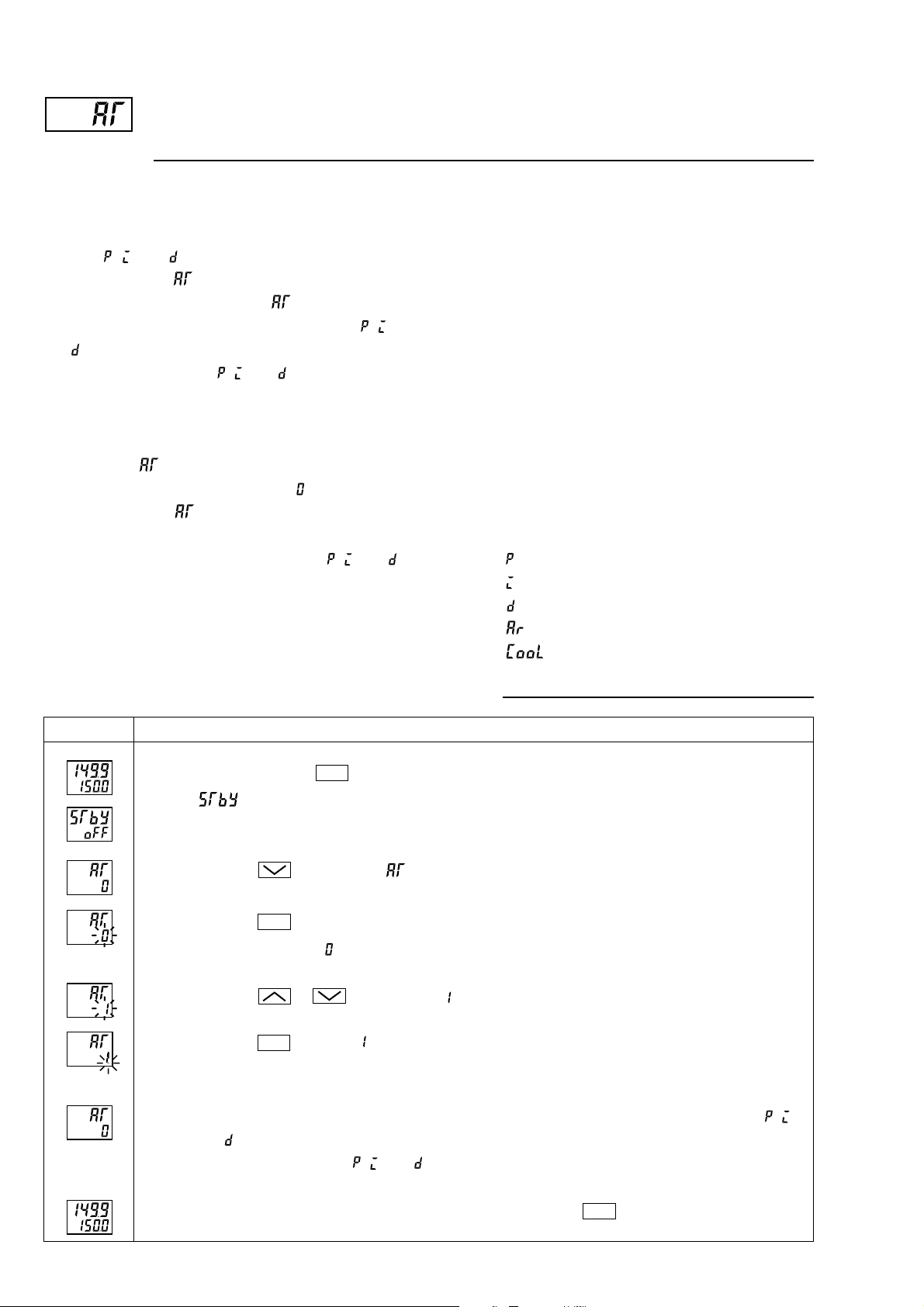

Manual mode

selection

Switches between Auto and Manual operation

modes.

oN: Manual mode

oFF: Auto mode*

0: All settings are changeable both from

the face panel and via communication.*

1: All settings are unchangeable from the

face panel, but changeable via

communication.

2: Only the SV is changeable from the

face panel, and all settings are

changeable via communication.

3: All settings are changeable from the

face panel, but unchangeable via

communication.

4:

All settings are unchangeable from the

face

panel or

via

communication.

5:

Only the SV is changeable from the

face

panel, but all settings are unchangeable

via

communication.

When the alarm type is absolute value:

0 to 100%FS (*:10)

When the alarm type is deviation:

-100 to 100%FS (*:10)

When the alarm type is absolute value:

0 to 100%FS (*:10)

When the alarm type is deviation:

-100 to 100%FS (*:10)

When the alarm type is absolute value:

0 to 100%FS (*:10)

When the alarm type is deviation:

-100 to 100%FS (*:10)

- (Unit: seconds)

- (Unit: seconds)

- (Unit: seconds)

0: OFF (Resets the auto-tuning or does

not use it.)*

1: ON (Performs the auto-tuning in the

SV standard type.)

2: ON (Performs the auto-tuning in

low PV type (SV value-10%FS).)

0: Keeps the alarm latch.*

1: Opens up the alarm latch.

oFF: Stop*

rUn: Start

HLd: Hold

rEM: Remote

LoCL: Local

oN: Control standby

(Output: OFF, Alarm: OFF)

oFF: Control RUN*

Upper limit value

of alarm 3

Ramp-soak

control

Sets the upper limit value at

which alarm 3 is detected.

Specifies whether or not to allow the change of

parameters.

Lower limit value

of alarm 3

Sets the lower limit value at

which alarm 3 is detected.

Set value of

alarm 3

Sets the value at which

alarm 3 is detected.

Upper limit value

of alarm 2

Sets the upper limit value at

which alarm 2 is detected.

Lower limit value

of alarm 2

Sets the lower limit value at

which alarm 2 is detected.

Set value of

alarm 2

Sets the value during which

alarm 2 is detected.

Upper limit

value of alarm 1

Sets the upper limit value at

which alarm 1 is detected.

Lower limit

value of alarm 1

Sets the lower limit value at

which alarm 1 is detected.

Set value of

alarm 1

Sets the value at which

alarm 1 is detected.

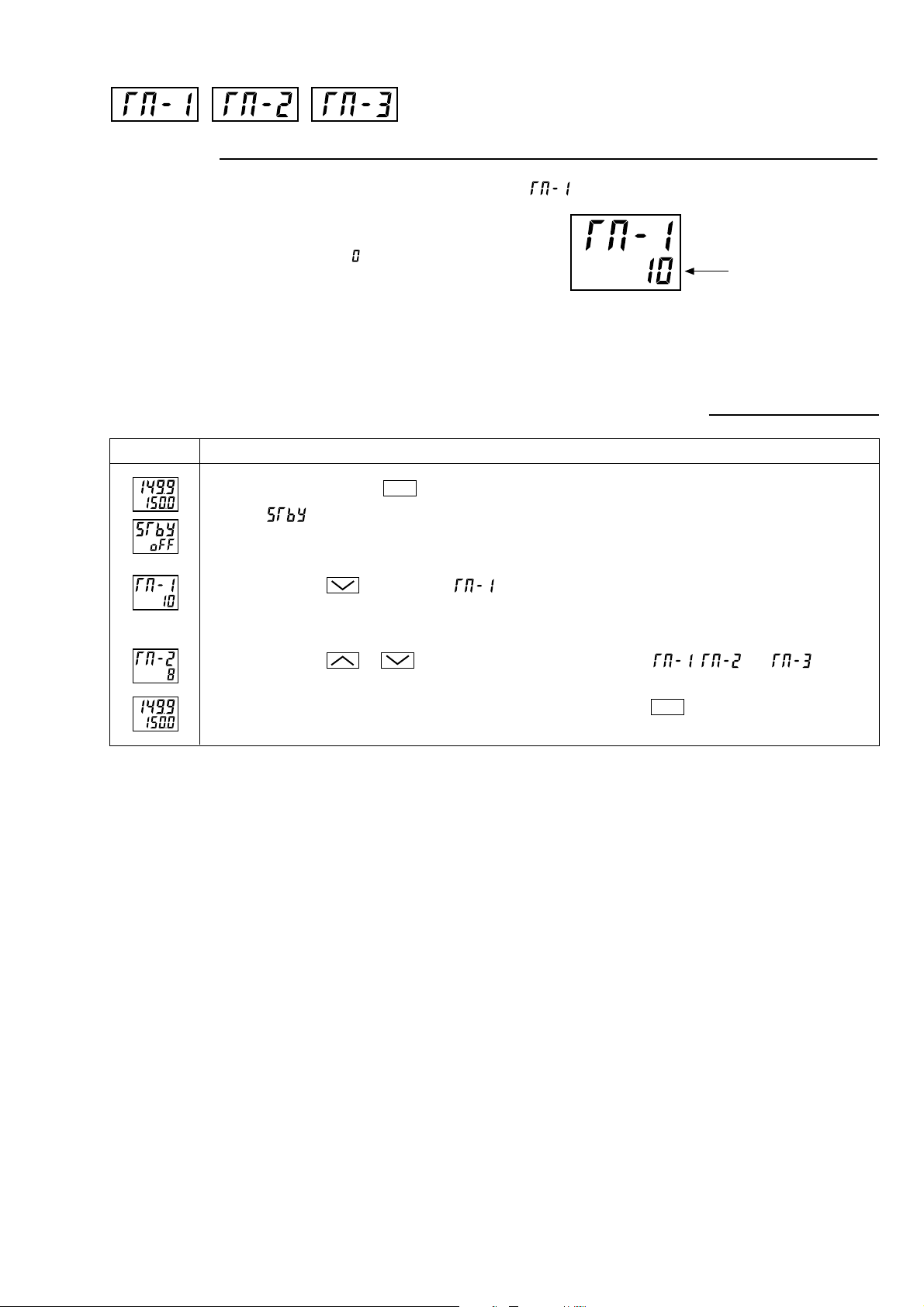

Timer 3 display Displays the remaining time of timer 3.

Timer 2 display Displays the remaining time of timer 2.

Timer 1 display Displays the remaining time of timer 1.

Auto-tuning Used for setting the constants for , , and

by auto-tuning.

Alarm latch

cancel

Cancels the alarm latch.

Remote/local

setting

Switches between remote and local operations.

Standby setting Switches between RUN and Standby for

control.

is displayed

when alarm type 1

is 0 to 15, or 32 to

34, and or

is displayed

when alarm type 1

is 16 to 31.

is displayed

when alarm type 3 is 0

to 15 or 32 to 34, and

or is

displayed when alarm

type 3 is 16 to 31.

is displayed

when alarm type 2 is 0

to 15 or 32 to 34, and

or is

displayed when alarm

type 2 is 16 to 31.

dP13-32

dSP3-1

dSP2-128

dSP2-64

dSP2-32

dSP2-16

dSP2-8

dSP2-4

dSP2-2

dSP2-1

dSP1-128

dSP1-64

dSP1-32

dSP1-16

dSP1-8

dSP1-4

dSP1-2

dp13-8

dSP1-1

15

Parameter

display symbol

Reference

page

Parameter name

Description

Setting range and

factory default setting (*)

Parameter

mask DSP

23

22

*

22

*

22

*

22

*

22

*

22

*

22

*

22

*

22

*

21

21

21

20

19

18

17

16

Set temperature

(Set value)

Displays the set temperature (Set value).

0 to 100%FS (*: 0%FS)

Mask not

allowed.

Measured temperature

(Measurement value)

Displays the currently measured temperature

(Measurement value).

Setting not allowed.

See page 78 for the method

of turning on/off PV.

14

dP13-64

(SV)

(PV)

Operations

This chapter explains how to set the SV (Setting value) and the parameters for the PXR.

2-1 Parameter list

Parameters for the PXR are classified into operation parameters, and the first block, the second block and the third block

parameters according to the frequency of use. The second and the third block parameters are used at initialization or when

they are absolutely necessary.

Operation parameter

Parameters of the first block

Note: The parameters for which * is marked with the page number in Reference page are related to Remedies of “4” on page 79.

7

Parameters of the second block

Note: The parameters for which * is marked with the page number in

Reference page are related to Remedies of “4” on page 79.

Parameter

display symbol

Parameter name

Proportional band

Integral time

Derivative time

Hysteresis range for

ON/OFF control

Cooling-side proportional

band coefficient

Cooling-side

proportional band shift

Output convergence

value

Anti-reset windup

Control algorithm

PV (Measured

value) stable range

Setting HYS

(Hysteresis) mode

Cycle time of

control output 1

Cycle time of

control output 2

(cooling-side)

Input signal code

Lower limit of

measuring range

Upper limit of

measuring range

Setting the decimal

point position

°C / °F selection

PV (Measured

value) offset

SV (Setting value) offset

Time constant of

input filter

Alarm type 1

Alarm type 2

Alarm type 3

Status display of

ramp-soak

Selecting ramp-

soak execute type

1st target value

/Switching-SV

value

First ramp segment

time

Set to 0.0 to select the ON/OFF

control (Two-position control).

Sets the hysteresis for ON/OFF

control.

Selects the control algorithm.

Sets the PV stable range for the selftuning operation.

Selects the hysteresis operation at

ON/OFF control.

Not shown at 4-20mA DC output

Set this parameter when changing

the types of temperature sensors.

Sets the types of alarm operations.

Sets the types of alarm operations.

Sets the types of alarm operations.

Selects ramp-soak patterns.

Sets the 1st target SV of ramp-soak

operation. / Selected at switchingSV function for DI1

Sets the first ramp segment time.

Description

Setting range and factory

default setting (*)

0.0 to 999.9% (*: 5.0)

0 to 3200 seconds (*: 240)

0.0 to 999.9 seconds (*: 60.0)

0 to 50%FS (*: equivalent of 1.0°C)

0.0 to 100.0 (*: 1.0)

-50.0 to +50.0 (*: 0.0)

-100 to 100%

(*: single 0.0, dual 50.0)

0 to 100%FS (*: 100%FS)

PID: Runs normal PID control.*

FUZY: Runs PID control with fuzzy logic.

SELF: Runs PID control with self-running.

0 to 100%FS (*: 2%FS)

oFF: Starts the two-position control at the

values of SV+HYS/2 and SV-HYS/2.

on:

Starts the two-position control at the values

of SV and SV+HYS, or SV and SV-HYS.

RLY, SSR: 1 to 150 seconds

(*: Contact output = 30,

SSR/SSC-driven output = 2)

1 to 150 seconds (*: 30)

1 to 16 (*: specified by customer while

ordering)

-1999 to 9999 (*: specified by customer

while ordering)

-1999 to 9999 (*: specified by customer

while ordering)

0 to 2 (*: specified by customer while

ordering)

°C / °F

-10 to 10%FS (*: 0)

-50 to 50%FS (*: 0)

0.0 to 900.0 seconds (*: 5.0)

0 to 34 (*: 0/5)

0 to 34 (*: 0/9)

0 to 34 (*: 0)

- (*: OFF)

1: Performs 1st to 4th segments.*

2: Performs 5th to 8th segments.

3: Performs 1st to 8th segments.

Within the SV limit. (*: 0%FS)

0 to 99h59m (*: 0.00)

Note 1

Note 1

Note 1

Note 1

*

User’s

set value

Parameter

mask DSP

dSP3-2

dSP3-4

dSP3-8

dSP3-16

dSP3-32

dSP3-64

dSP3-128

dSP4-1

dSP4-2

dSP4-4

dSP4-8

dSP4-16

dSP4-32

dSP4-64

dSP4-128

dSP5-1

dSP5-2

dSP5-4

dSP5-8

dSP5-16

dSP5-32

dSP5-64

dSP5-128

dSP6-1

dSP6-2

dSP6-4

dSP6-8

dSP6-16

Reference

page

24

25

26

*

27

28

29

30

30

*

31

*

35

36

37

38

39

40

40

42

40

43

*

44

*

45

46

46

46

50

49

*

50

50

8

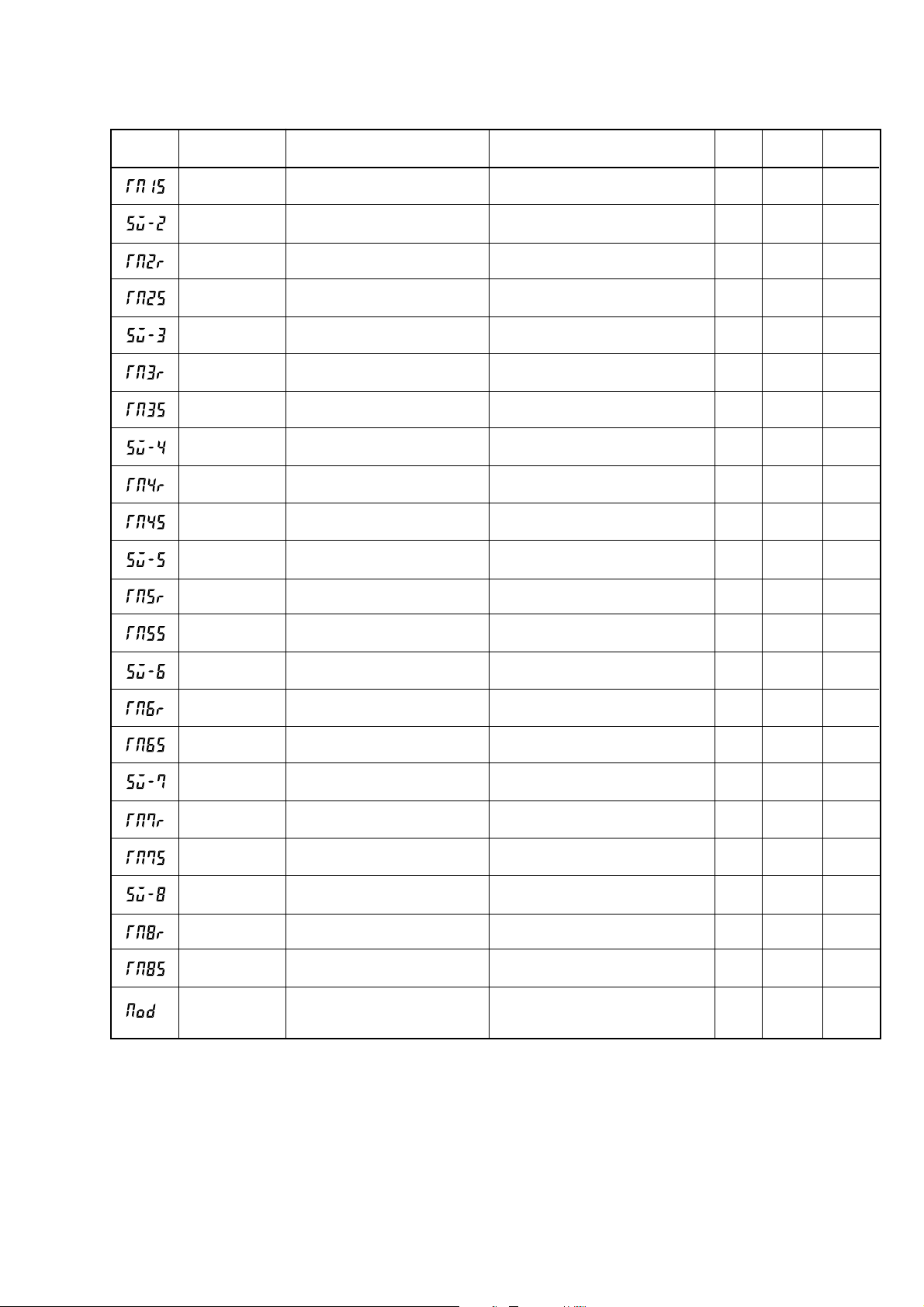

Note: The parameters for which * is marked with the page number in

Reference page are related to Remedies of “4” on page 79.

Parameter

display symbol

Parameter name

1st soak segment

time

2nd target SV

2nd ramp segment

time

2nd soak segment

time

3rd target SV

3rd ramp segment

time

3rd soak segment

time

4th target SV

4th ramp segment

time

4th soak segment

time

5th target SV

5th ramp segment

time

5th soak segment

time

6th target SV

6th ramp segment

time

6th soak segment

time

7th target SV

7th ramp segment

time

7th soak segment

time

8th target SV

8th ramp segment

time

8th soak segment

time

Ramp-soak mode

Description

Sets the 1st soak segment time.

Sets the 2nd target SV of ramp-soak

operation.

Sets the 2nd ramp segment time.

Sets the 2nd soak segment time.

Sets the 3rd target SV of ramp-soak

operation.

Sets the 3rd ramp segment time.

Sets the 3rd soak segment time.

Sets the 4th target SV of ramp-soak

operation.

Sets the 4th ramp segment time.

Sets the 4th soak segment time.

Sets the 5th target SV of ramp-soak

operation.

Sets the 5th ramp segment time.

Sets the 5th soak segment time.

Sets the 6th target SV of ramp-soak

operation.

Sets the 6th ramp segment time.

Sets the 6th soak segment time.

Sets the 7th target SV of ramp-soak

operation.

Sets the 7th ramp segment time.

Sets the 7th soak segment time.

Sets the 8th target SV of ramp-soak

operation.

Sets the 8th ramp segment time.

Sets the 8th soak segment time.

Selects the power-on start, repeat, and

standby functions for ramp-soak

operations.

Setting range and factory

default setting (*)

0 to 99h59m (*: 0.00)

Within the SV limit. (*: 0%FS)

0 to 99h59m (*: 0.00)

0 to 99h59m (*: 0.00)

Within the SV limit. (*: 0%FS)

0 to 99h59m (*: 0.00)

0 to 99h59m (*: 0.00)

Within the SV limit. (*: 0%FS)

0 to 99h59m (*: 0.00)

0 to 99h59m (*: 0.00)

Within the SV limit. (*: 0%FS)

0 to 99h59m (*: 0.00)

0 to 99h59m (*: 0.00)

Within the SV limit. (*: 0%FS)

0 to 99h59m (*: 0.00)

0 to 99h59m (*: 0.00)

Within the SV limit. (*: 0%FS)

0 to 99h59m (*: 0.00)

0 to 99h59m (*: 0.00)

Within the SV limit. (*: 0%FS)

0 to 99h59m (*: 0.00)

0 to 99h59m (*: 0.00)

0 to 15 (*: 0)

User’s

set value

Parameter

mask DSP

dSP6-32

dSP6-64

dSP6-128

dSP7-1

dSP7-2

dSP7-4

dSP7-8

dSP7-16

dSP7-32

dSP7-64

dSP7-128

dSP8-1

dSP8-2

dSP8-4

dSP8-8

dSP8-16

dSP8-32

dSP8-64

dSP8-128

dSP9-1

dSP9-2

dSP9-4

dSP9-8

Reference

page

50

*

50

50

50

*

50

50

50

*

50

50

50

*

50

50

50

*

50

50

50

*

50

50

50

*

50

50

50

50

Note 1:When a customer does not specify the settings while ordering, the following settings are selected as factory defaults.

Thermocouple input: Thermocouple K Measured range: 0 to 400°C

Resistance bulb input: Measured range: 0 to 150°C

Voltage/Current input: Scaling: 0 to 100%

9

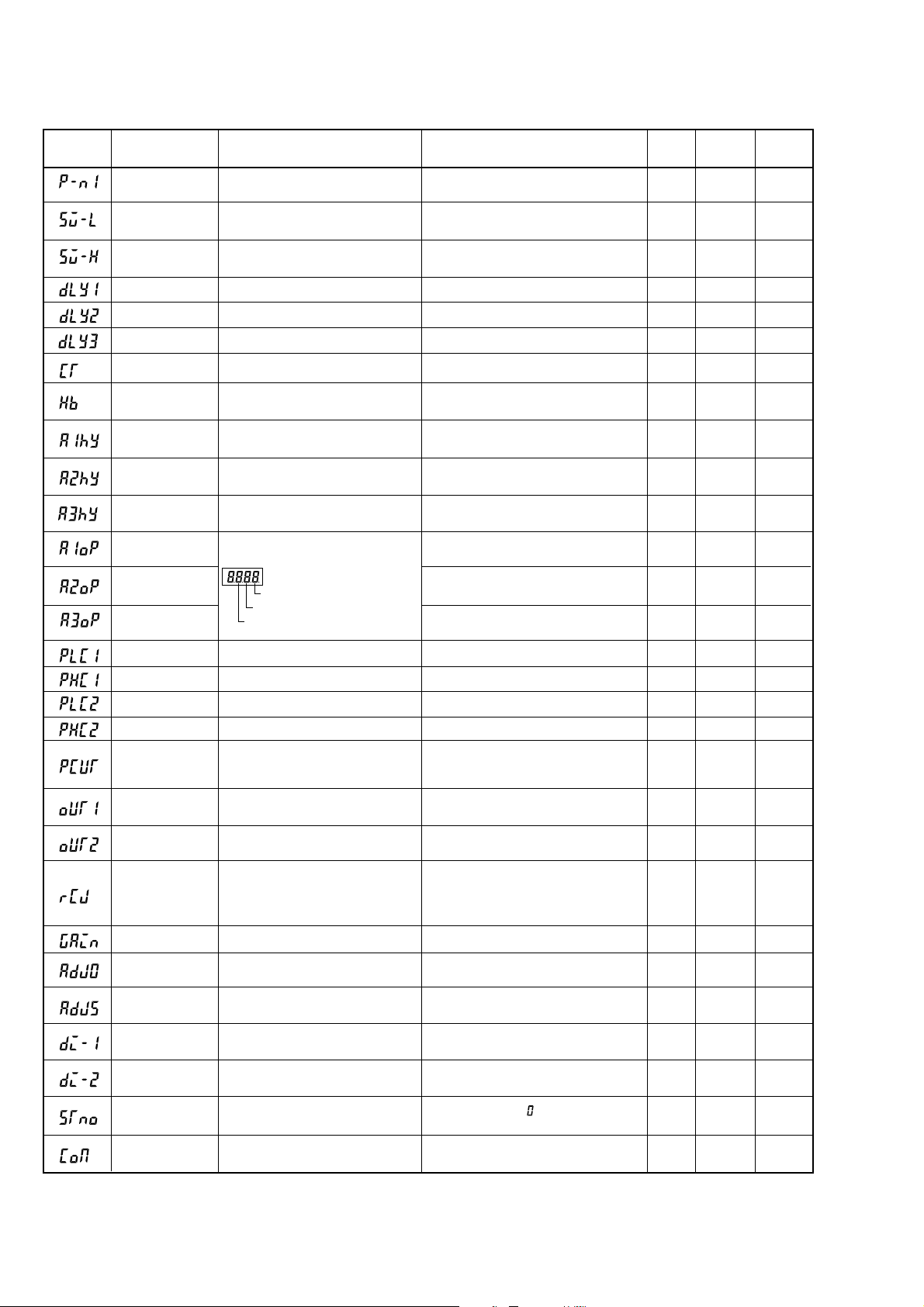

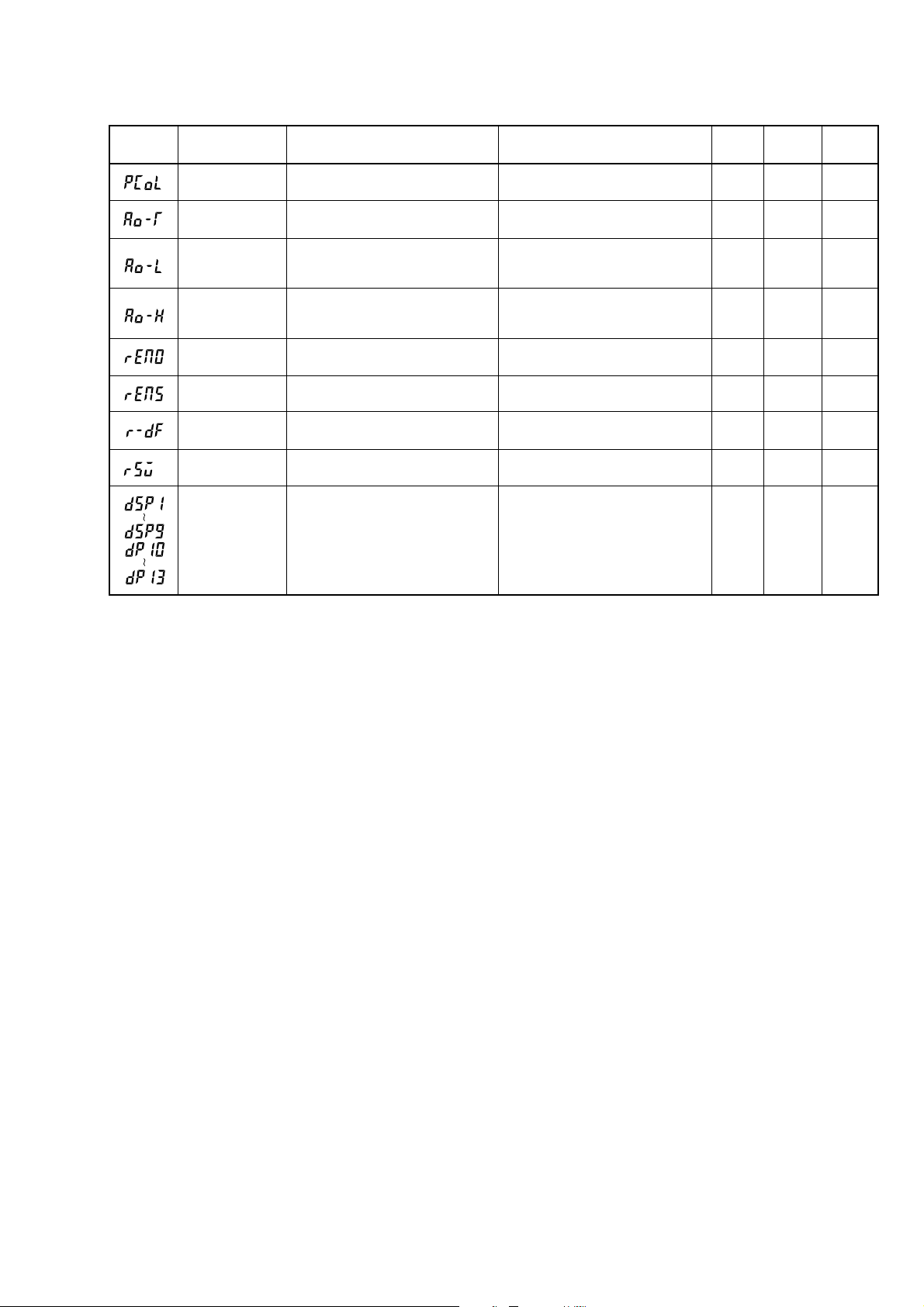

Parameters of the third block

Note: The parameters for which * is marked with the page number in

Reference page are related to Remedies of “4” on page 79

Parameter

display symbol

Parameter name

Control action

SV (Setting value)

lower limiter

SV (Setting value)

upper limiter

Delay time 1

Delay time 2

Delay time 3

Current transe display

HB (Set value of heater

break alarm) setting

Alarm 1 hysteresis

Alarm 2 hysteresis

Alarm 3 hysteresis

Alarm 1 options

Alarm 2 options

Alarm 3 options

Description

Specifies control action and output at

the input burn-out.

Sets the lower limit of the SV.

Sets the upper limit of the SV.

Delay time or timer value for alarm 1 relay.

Delay time or timer value for alarm 2 relay.

Delay time or timer value for alarm 3 relay.

Displays the current detector input value for HB alarm.

Sets the operation value that detects the

heater break.

Sets the hysteresis range of ON and

OFF of alarm 1.

Sets the hysteresis range of ON and

OFF of alarm 2.

Sets the hysteresis range of ON and

OFF of alarm 3.

Sets the optional functions of alarms 1, 2 and

3.

Alarm latch (1: use, 0: not use)

Alarm of error status (1: use, 0: not use)

De-energized output (1: use, 0: not use)

0 to 19 (*: specified by customer while

ordering)

0 to 100%FS (*: 0%FS)

0 to 100%FS (*: 100%FS)

0 to 9999 seconds (*: 0)

0 to 9999 seconds (*: 0)

0 to 9999 seconds (*: 0)

0 to 50.0A (Setting to 0.0A turns off the

HB alarm.) (*: 0.0)

0 to 50%FS (*: 1)

0 to 50%FS (*: 1)

0 to 50%FS (*: 1)

000 to 111 (*: 000)

000 to 111 (*: 000)

000 to 111 (*: 000)

Setting range and factory

default setting (*)

Note 2

User’s

set value

Parameter

mask DSP

dSP9-16

dSP9-32

dSP9-64

dSP9-128

dP10-1

dP10-2

dP10-4

dP10-8

dP10-16

dP10-32

dP10-64

dP10-128

dP11-1

dP11-2

Reference

page

53

*

54

*

54

55

55

55

57

57

*

59

*

59

*

59

60

60

60

Lower limit for output 1

Upper limit for output 1

Lower limit for output 2

Upper limit for output 2

Output limit types

Output value (MV)

display

Output value (MV)

display

RCJ (Cold junction

compensation)

setting

PV gradient

User-definable zero

adjustment

User-definable span

adjustment

DI1 (Digital input 1)

operation

DI2 (Digital input 2)

operation

Station No.

Parity setting

Sets the DI2 operations.

Sets the station No. for

communication.

Sets the parity for communication.

(The baud rate is fixed at 9600bps.

Sets the lower limit for output 1.

Sets the upper limit for output 1.

Sets the lower limit for output 2.

Sets the upper limit for output 2.

Sets the limit types of outputs 1 and 2

(breaking the limit, or maintained

within the limit).

Displays the value of output 1.

Displays the value of output 2.

Sets the cold junction compensation

function to ON/OFF.

Shifts the zero point of input value.

Shifts the span of input value.

Sets the DI1 operations.

-3.0 to 103.0% (*: -3.0)

-3.0 to 103.0% (*: 103.0)

-3.0 to 103.0% (*: -3.0)

-3.0 to 103.0% (*: 103.0)

0 to 15 (*: 0)

-

-

ON: Performs the RCJ (Cold junction

compensation).*

OFF: Does not perform the RCJ (Cold

junction compensation).

0.001 to 2.000 (*: 1.000)

-50 to 50%FS (*: 0)

-50 to 50%FS (*: 0)

0 to 12 (*: 0=OFF)

0 to 12 (*: 0=OFF)

0 to 255 (Setting to does not start the

communications function.) (*: 1)

0: Odd parity* 1: Even parity

2: No parity

dP11-4

dP11-8

dP11-16

dP11-32

dP11-64

dP11-128

dP12-1

dP12-2

dP12-4

dP12-8

dP12-16

dP12-32

dP12-64

dP12-128

dP13-1

62

62

62

62

63

64

64

65

66

66

67

67

70

71

*

*

Note 2:The following settings are selected as factory defaults depending on the model you order.

Seventh digit = Y model: 0 Seventh digit = A model: 4

10

Communication

protocol setting

Re-transmission

output type setting

Re-transmission

output scaling base

side setting

Re-transmission

output scaling span

side setting

Remote SV input

zero adjustment

Remote SV input

span adjustment

Remote SV input

filter constant

Remote SV input

value display

Parameter mask

Switches communication protocols

between Modbus and ASCII

Sets the type of signals to be outputted

from

re-transmission

output.

Re-transmission

output scaling setting

on the base side

Re-transmission

output scaling on the

span side

Shifts the zero point of input value.

Shifts the span point of input value.

Sets the filter constant of remote SV

input value.

Displays remote SV input value.

Sets whether or not to display each

parameter.

0 : Z-ASCII

1 : Modbus (RTU)

Setting range

0 : PV / 1 : SV / 2 : MV/ 3 : DV (

*

: 0)

Setting range

-

100.0 to 100.0%

(*

: 0.0)

Setting range

-

100.0 to 100.0%

(*

: 100.0)

-

50 to 50%FS (*: 0)

-

50 to 50%FS (*: 0)

0.0 to 900.0 seconds (*: 0.0)

-

0 to 255 (*: specified by customer

while ordering)

dP13-2

dP13-4

dP13-4

dP13-4

dP13-16

dP13-16

dP13-16

dP13-16

–

78

72

73

74

74

75

75

76

77

Parameter

display symbol

User’s

set value

Reference

page

Parameter name

Description

Setting range and factory

default setting (*)

Parameter

mask DSP

Note: The parameters for which * is marked with the page number in

Reference page are related to Remedies of “4” on page 79.

11

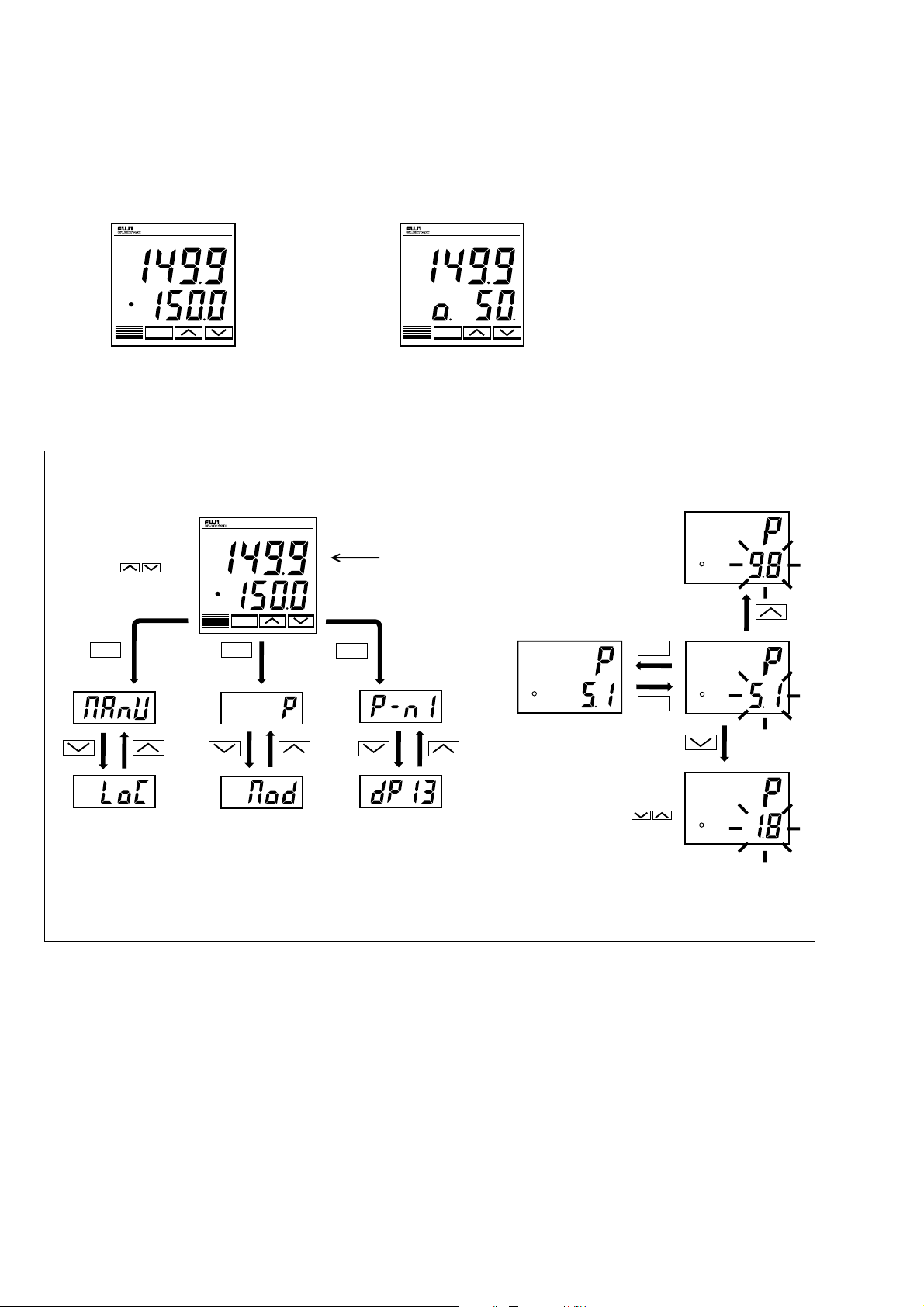

2-2 Basic operations

Just after power-on:

The display below appears just after power-on.

C1 C2 AL1 AL2 AL3

PV

SV

SEL

PXR

°C

Status at delivery

<In Auto mode> <In Manual mode>

How to switch parameters:

The figure below shows the basic operations for the PXR.

Just after power-on

(PV/SV displayed)

°C

SEL

(approx.

5 seconds)

Changes SV.

SEL SEL

(approx.

1 second)

(approx.

3 seconds)

C1 C2 AL1 AL2 AL3

PV

SV

SEL

PXR

C1 C2 AL1 AL2 AL3

PV

SV

SEL

PXR

Not operated

for 30 seconds.

°C

Setting parameters

PV

SV

SEL

SEL

PV

SV

PV

SV

Parameters of the

first block

Parameters of the

second block

Pressing and holding the

Parameters of the

third block

keys makes the value increase or

decrease fast.

Basic operations for the PXR (In Auto mode)

PV

SV

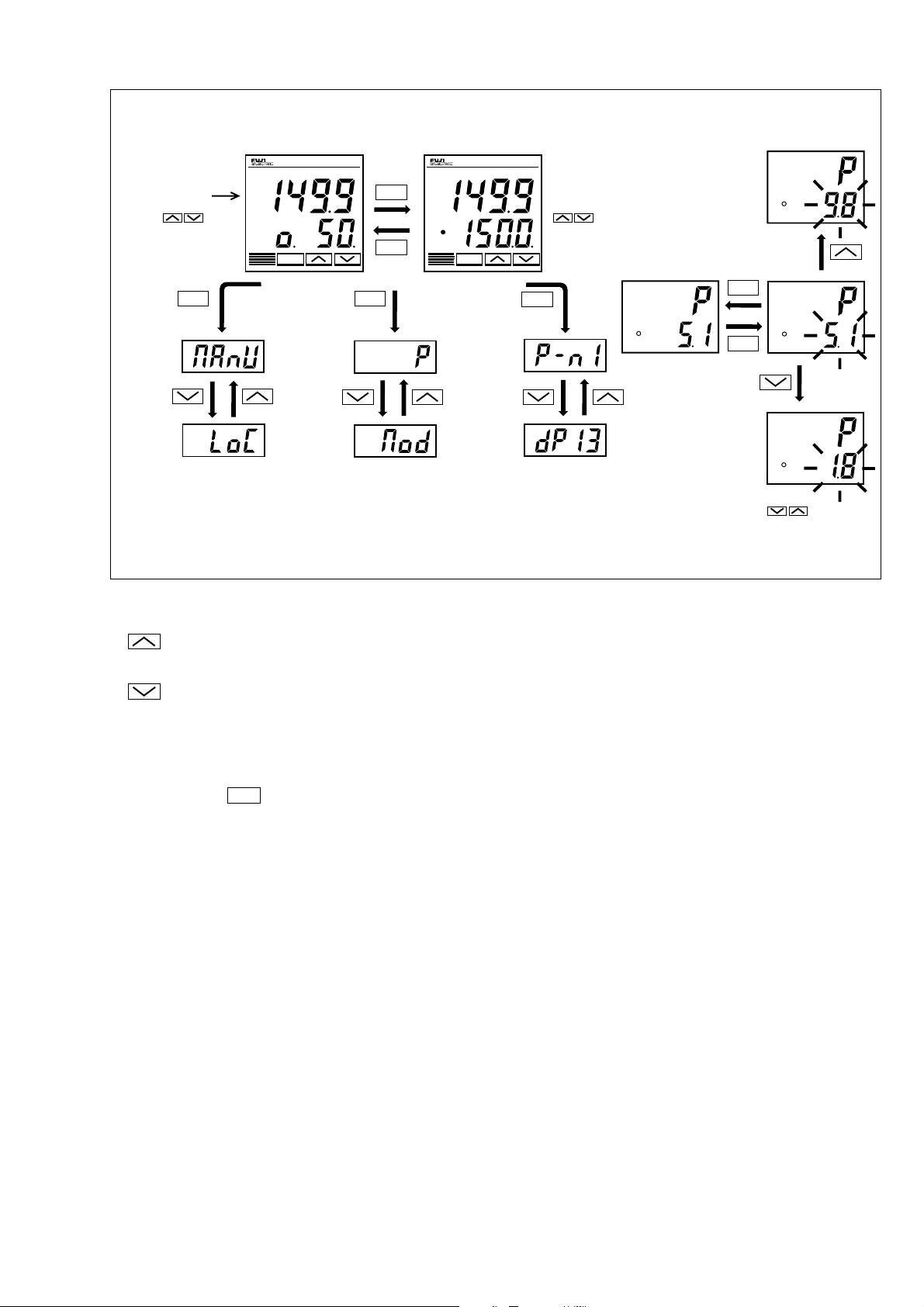

12

Not operated

for 30 seconds.

Just after power-on

(PV/MV displayed)

C1 C2 AL1 AL2 AL3

PV

°C

SEL

(PV/SV displayed)

C1 C2 AL1 AL2 AL3

PV

Setting parameters

°C

PV

SV

Changes MV.

PXR

SEL SEL

(approx.

1 second)

Parameters of the

first block

Basic operations for the PXR (In Manual mode)

How to set values:

key: One press increases the value by 1.

Press and hold this key to increase the value fast.

key: One press decreases the value by 1.

Press and hold this key to decrease the value fast.

SV

SEL

SEL

(approx.

3 seconds)

SV

SEL

PXR

Changes SV.

SEL

PV

SEL

PV

(approx.

5 seconds)

SV

SV

SEL

PV

SV

Parameters of the

second block

Parameters of the

third block

Pressing and holding the

keys makes the value increase or

decrease fast.

How to register the set data:

By pressing the

Note that the SV (SV0) will be registered in 3 seconds without any operation.

key, the displayed values are registered.

SEL

13

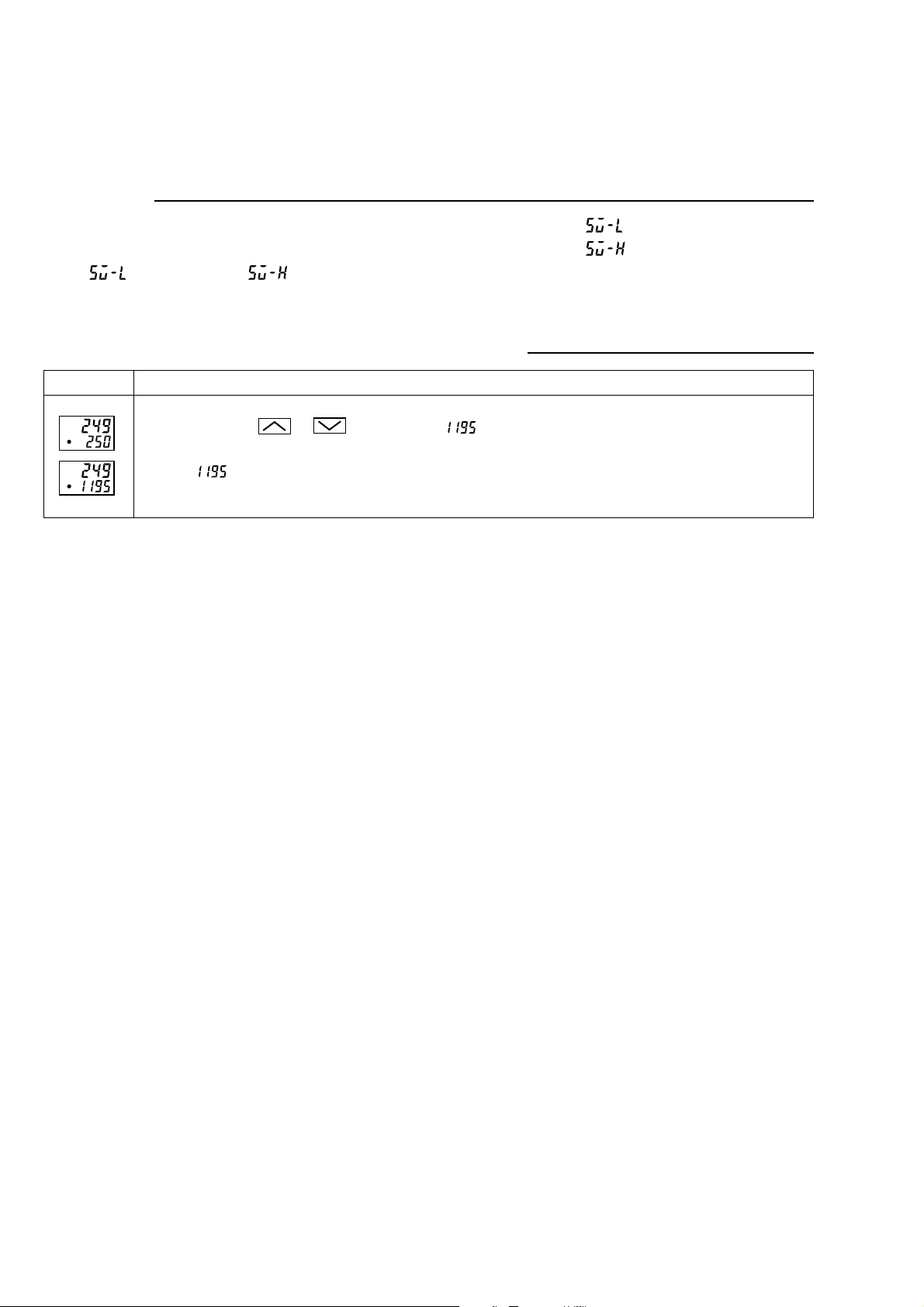

2-3 Parameter functions and method of settings

Method of setting the SV (Setting value)

[Description]

•The SV is a target value for control.

•Any SV that is outside of the range set in the parameters

of (lower limit) and (upper limit) of the

third block cannot be set. (See page 54.)

[Setting example] Changing the SV from 250°C to 1195°C

Operating procedureDisplay

Press the or keys to display .

SV

1.

Related parameters: (page 54)

(page 54)

SV

2.

will be registered in the SV (SV0) in three seconds. After that, the controller will operate

with the SV being 1195.

14

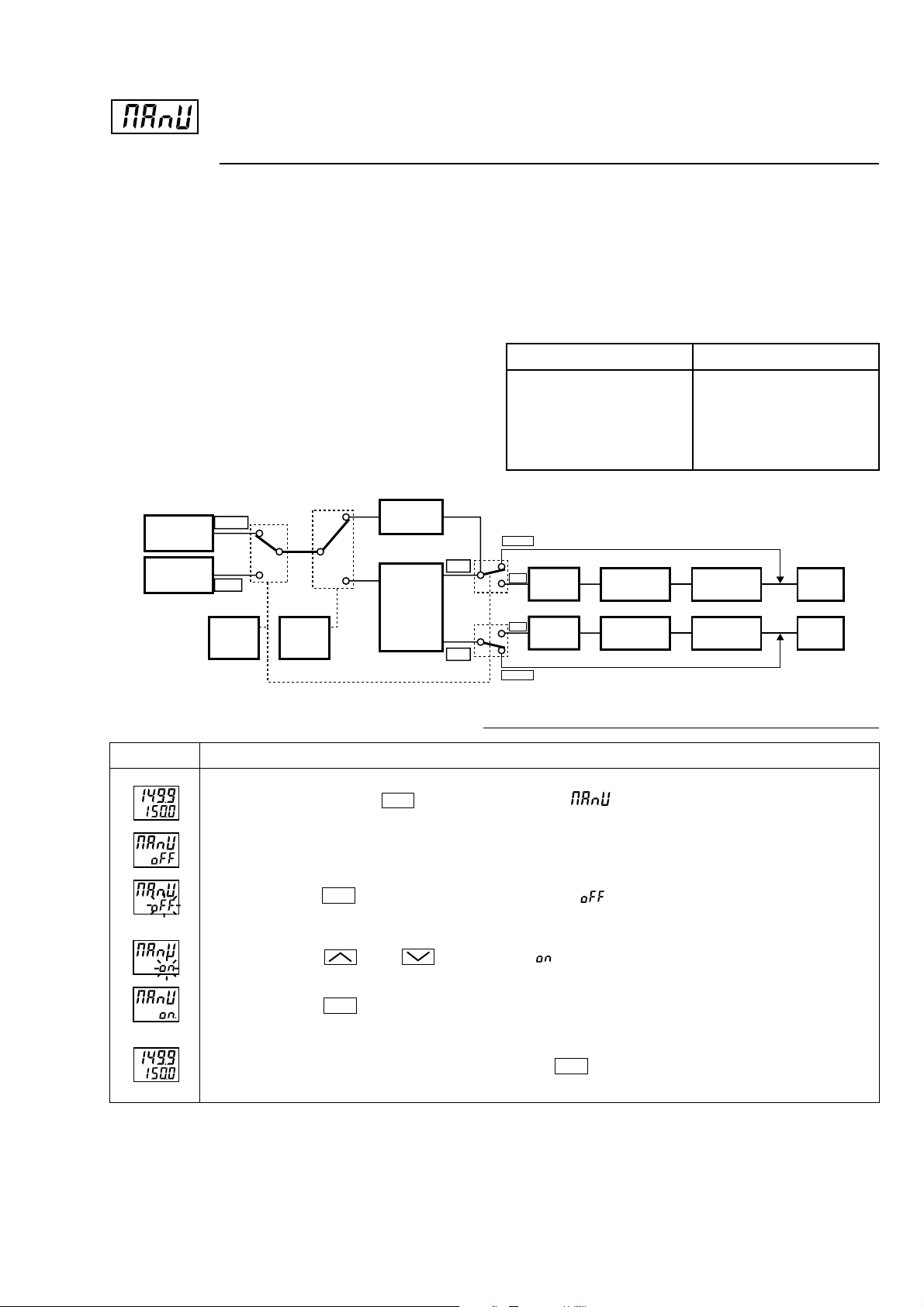

Manual mode setting (Settings: oFF/on)

[Description]

•This parameter switches the control mode between Auto

and Manual.

• During Manual operation, the decimal point is kept on at

the far right in the SV display section.

• During Manual operation, auto tuning or self tuning is

not done. If the mode is switched to Manual while auto

or self tuning is being done, the tuning is forcibly

terminated. The PID parameter remains the same in such

cases.

• Manual operation output is not limited by MV limit.

•Manual operation can be carried out during standby

operation.

•The operation output set value during Auto/Manual

operation mode and manual mode is stored in non-volatile

memory. It is kept stored even if a power interruption

occurs. When the power is turned on again, the state

before the power interruption is resumed.

•The following table lists the operation output at the time

of switching between Auto and Manual..

Auto → Manual Manual → Auto

Balanceless bumpless

(Switches to manual mode,

holding the MV value just

before the switching.)

MV output according to

PID operation

(Sudden change may occur

to the MV value.)

Single

output

MV1

Dual

output

MV2

Manual

MV

PID

calculation

Manual

AUTO

MAnU

=

ON

P-n1

=

Single

[Setting example] Switching to manual mode

1.

Press and hold the

2.

Press the

Press the or the keys to display .

3.

key once, and the current set value (

SEL

key for one second, and is displayed.

SEL

Manual

Auto

Auto

Manual

Limit

Standby

StandbyLimit

Error

output

Error

output

OUT1

OUT2

Operating procedureDisplay

) on the SV display section starts flickering.

4.

Press the

key once, and the manual lamp at the lower right corner comes on, indicating that

SEL

the mode has been switched to Manual.

5.

To display operation status, press and hold the

SEL

key for two seconds.

15

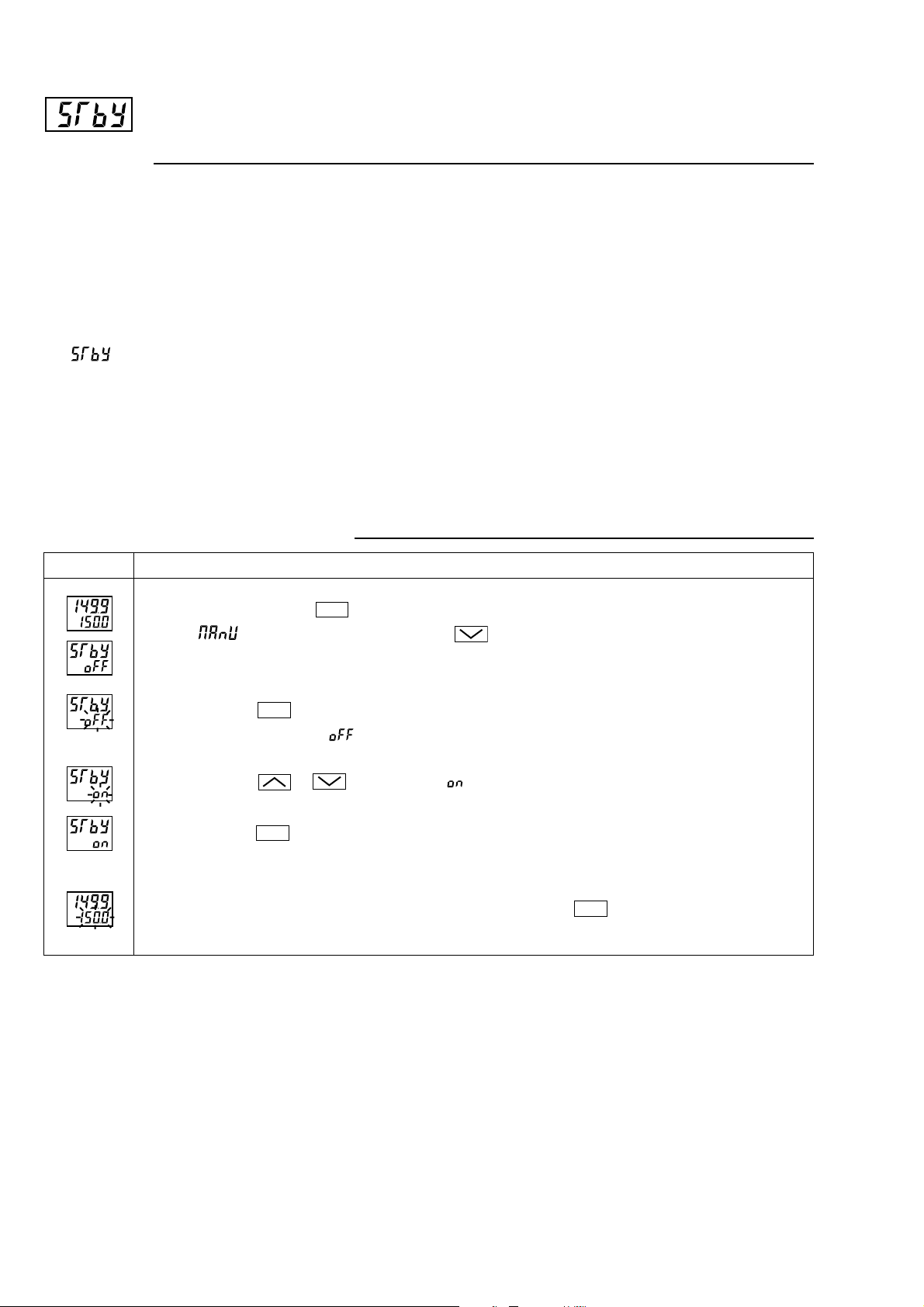

Standby setting (Settings: oFF/on)

[Description]

•This parameter switches the control between RUN and

Standby.

• During standby, the control output and the alarm output

stay OFF, like the standby for ramp-soak operation.

• While the alarm with a hold is selected, the hold function

takes effect after changing the Standby setting from ON

to OFF.

• is displayed during the standby for ramp-soak

operations or the controller changes to the standby state

in case of the occurrence of errors.

• The other operations are the same as those of the rampsoak standby.

•The setting of ON/OFF for standby is saved after poweroff.

[Setting example] Starting the control

•When the standby is set to ON during the auto-tuning,

self-tuning, and ramp-soak operations, those operations

will stop. (The PID constant will not be renewed.) Even

through it is set to OFF later, the auto-tuning, self-tuning,

and ramp-soak operations will not be re-started.

• During standby, the ON-delay timer is reset. When

returning to RUN from the standby state, the timer will

start from the beginning.

Operating procedureDisplay

Press and hold the

1.

will be displayed. Then press the key once.

2.

Press the

The current setting (

3.

Press the or keys to display .

4.

Press the

outputs: OFF)

5.

If you want to display the operation status, press and hold the

on the SV display will flash, indicating the standby status.

SEL

key once.

key once. The standby state for control is selected . (control output and all the alarm

SEL

key for one second.

SEL

) flashes on the SV display.

key for two seconds. The v alue

SEL

16

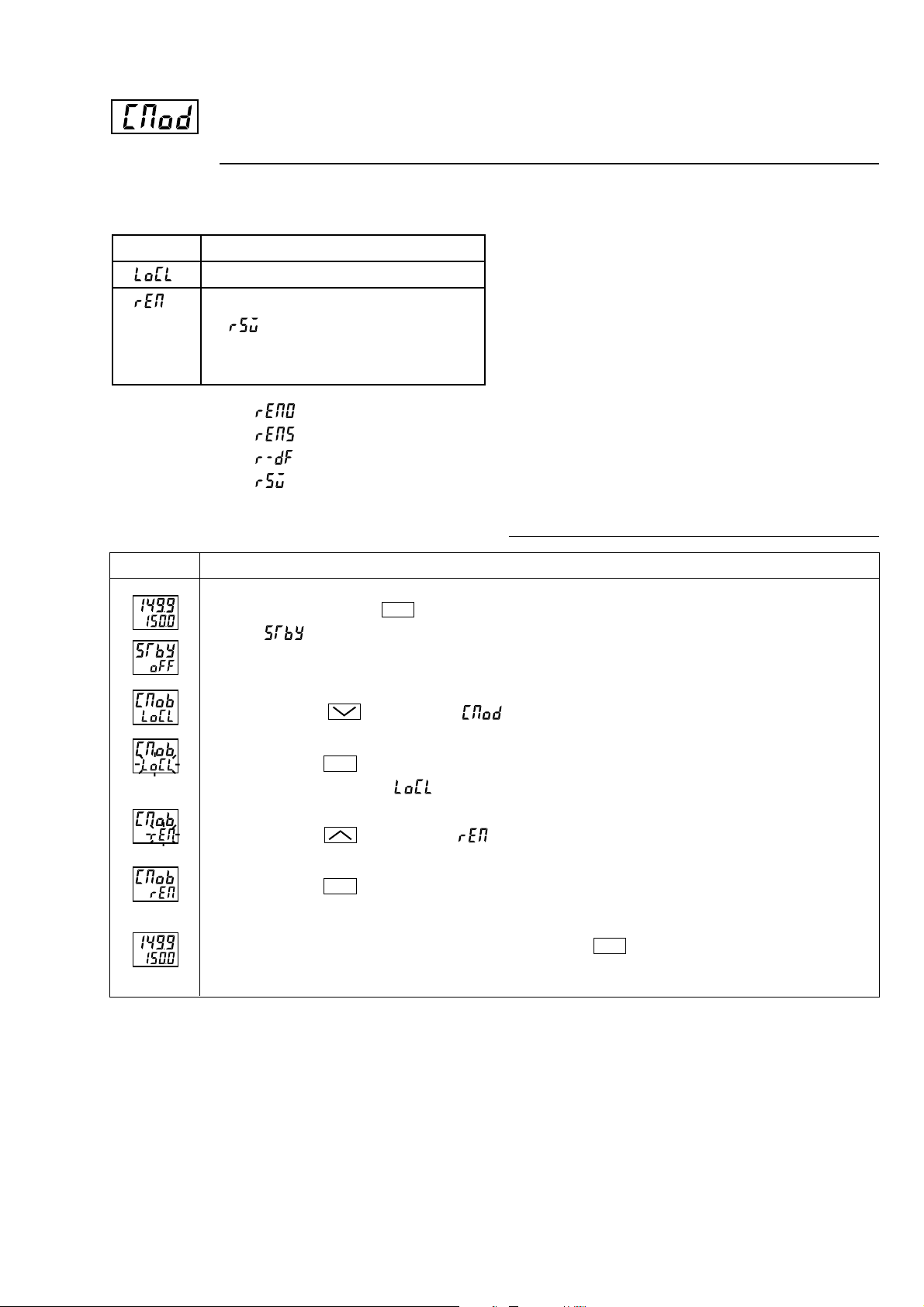

Local/remote operation setting (Setting range: LoCL/rEM) (Option)

[Description]

•This parameter is used to switch between local and remote operations.

Set value Operation

Performs local operation.

Performs remote operation.

(“ ” and the set value (SV) are displa yed

alternately in the SV display section on the

front face while in remote operation.)

Related parameters:

(page 75)

(page 75)

(page 76)

(page 77)

[Setting example] Switching to remote operation

Operating procedureDisplay

Press and hold the

1.

will be displayed on the PV display section.

key for one second.

SEL

* Local operation: Control by SV set by the keys on the

front face, ramp-soak operation, SV

selection determined by digital input,

and SV setting via communication

* Remote operation: Control by SV determined by Remote

SV input

2.

Press the keys to display .

Press the

3.

The current setting (

4.

Press the keys to display .

Press the

5.

To display the operation status, press and hold the

6.

key once.

SEL

key once. Flickering stops and the operation is switched to remote.

SEL

) in the SV display section flickers.

key for two seconds.

SEL

17

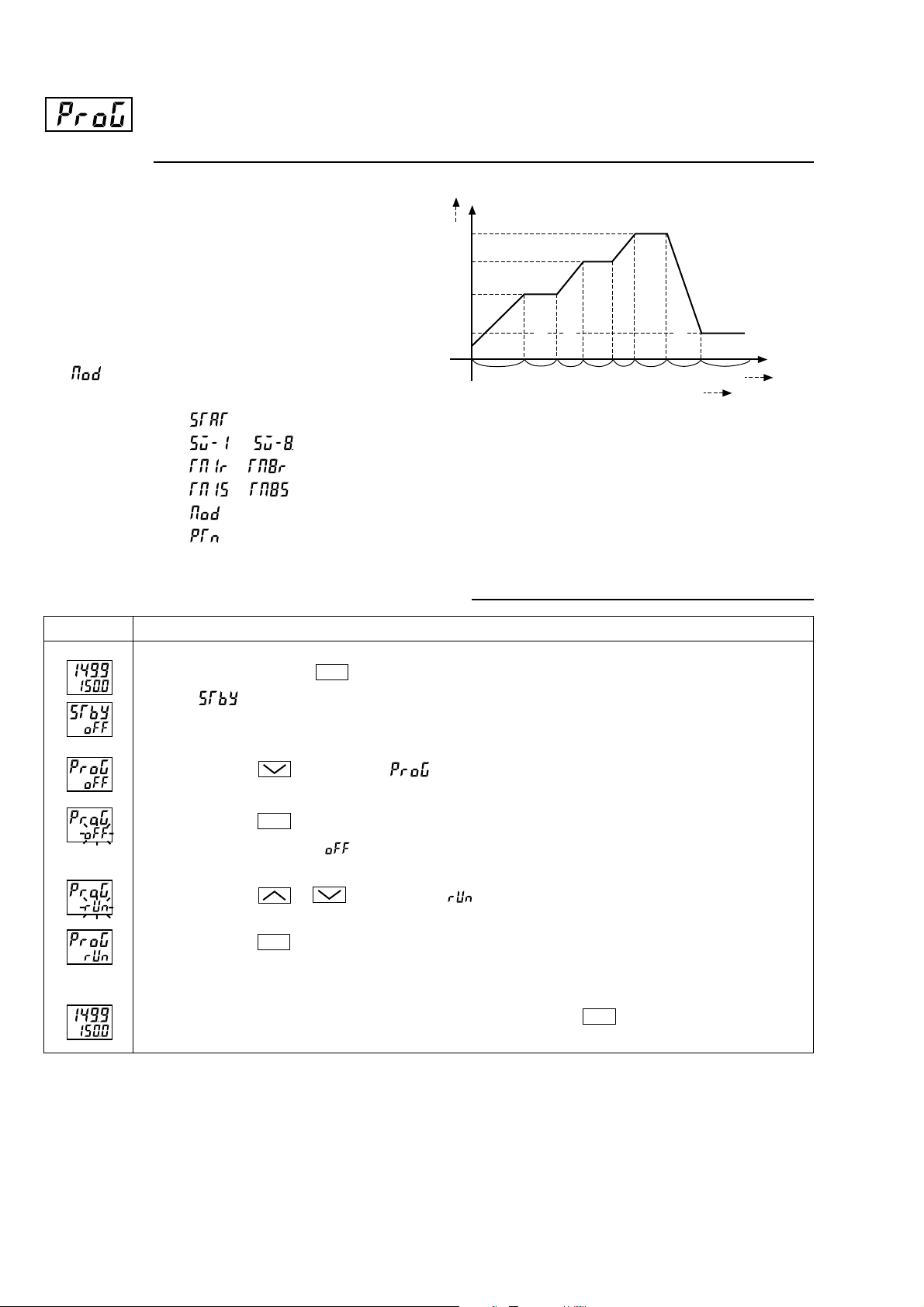

Ramp-soak control (Settings: oFF/rUn/hLd) (Option)

[Description]

• This function automatically changes the SV (Setting

value) according to the program pattern set in advance as

shown in the right line graph. Up to eight pairs of rampsoak operation can be programmed.

•The first ramp starts at the PV (Measured value) that is

the one just before running the program.

•The program can also automatically run at power-on

(Power-on starting function). Refer to the parameter of

(page 47).

Related parameters:

(page 50)

to (page 50)

to (page 50)

to (page 50)

(page 50)

(page 49)

Up to SV-8

SV-3

SV-2

SV-1

SV-4

PV

First ramp

TM1r

Ramp: the section in which the SV changes toward the target value.

Soak: the section in which the SV is the target value, and remains unchanged.

First soak

TM1S

Second soak

Second ramp

TM2S

TM2r

Third soak

Third ramp

Fourth ramp

TM3S

TM3r TM4r

Fourth soak

TM4S

Up to TM8r

Up to TM8s

[Setting example] Starting the ramp-soak operation

Operating procedureDisplay

Press and hold the

1.

will be displayed on the PV display.

Press the

2.

Press the

3.

key to display

key once.

SEL

The current setting ( ) flashes on the SV display.

Press the or keys to display .

4.

Press the

5.

key once. Then, the program will start according to the ramp-soak pattern that is

SEL

set in advance.

If you want to display the operation status, press and hold the

6.

key for one second.

SEL

key for two seconds.

SEL

18

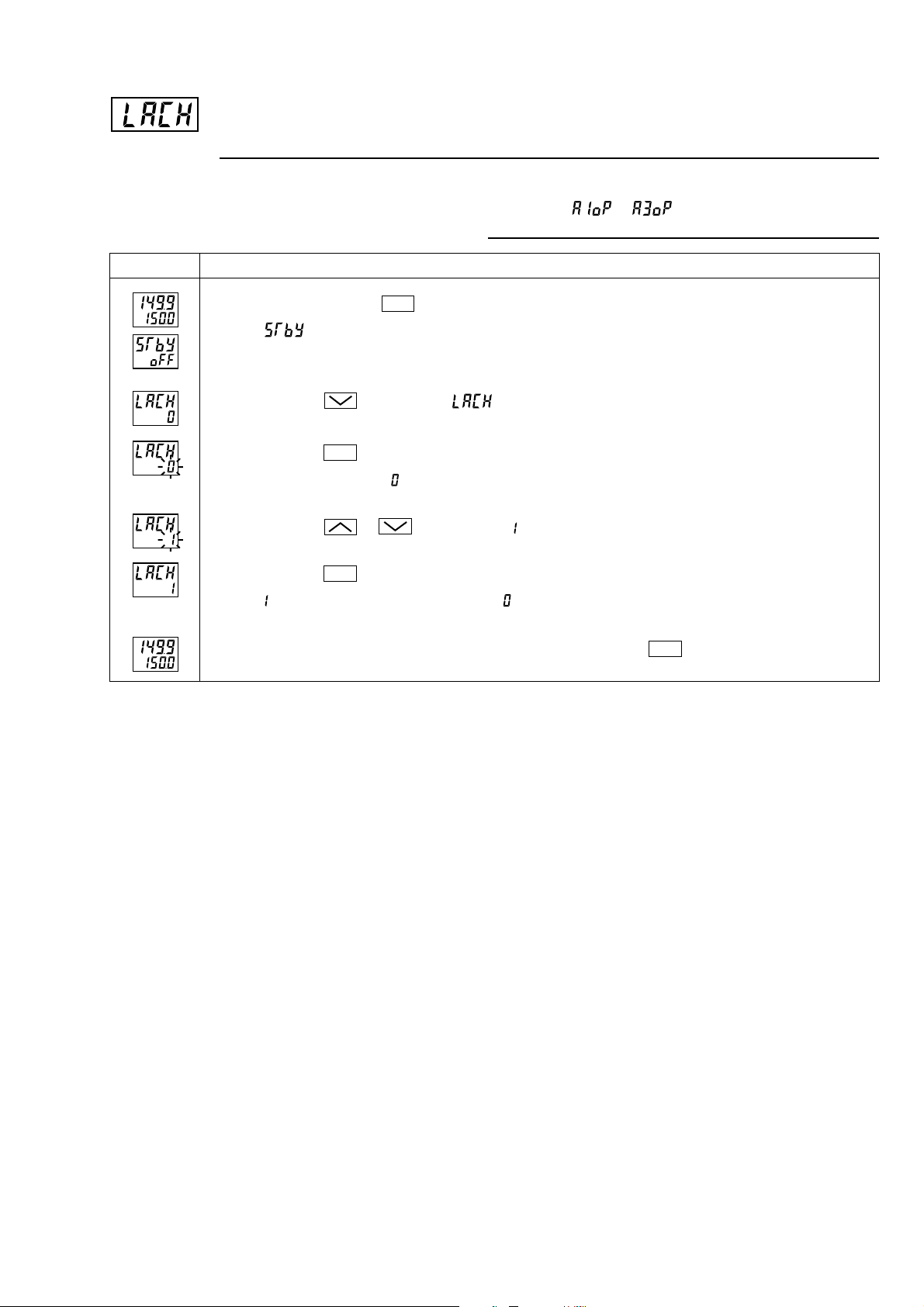

Canceling the alarm latch (Setting range: 0/1) (Option)

[Description]

•This parameter cancels the alarm latch when it is latching.

[Setting example] Opening up the alarm latch

Operating procedureDisplay

Related parameters:

to (page 60)

Press and hold the

1.

will be displayed on the PV display.

Press the key to display .

2.

Press the

3.

The current setting ( ) flashes on the SV display.

Press the or keys to display .

4.

Press the

5.

will stop flashing and will change to in a few seconds.

If you want to display the operation status, press and hold the

6.

SEL

SEL

SEL

key once.

key once.

key for one second.

key for two seconds.

SEL

19

Auto-tuning function (Settings: 0/1/2)

[Description]

[Note]

If the controller is powered off during auto-tuning, this

makes the auto-tuning ineffectiv e with each parameter

of , , and unchanged. To start the auto-tuning

operation, set to “1” or “2” again.

•To suspend the auto-tuning, set to “0”. This makes

the auto-tuning cancel with each parameter of , , and

unchanged.

• Once the parameters of , , and are set automatically

by the auto-tuning, those parameters are stored in the

controller even after it is power ed of f. Therefore, it is not

necessary to execute the auto-tuning again.

• By setting to “1” or “2” , the auto-tuning operation

starts, and at the end of the tuning, will be displayed

automatically to .

• After the auto-tuning operation, the controller starts to

operate at the automatically set values of , , and .

•A decimal point at the right end of the SV display flashes

during auto-tuning.

•There are two codes for AT:

Setting code [1]: SV standard type

Performs the auto-tuning based on the SV.

Setting code [2]: Low PV type

Performs the auto-tuning based on the

SV-10%FS.

[Note]

Since ON/OFF control is performed during auto-tuning, overshoot against the SV may occur. To reduce

the overshoot, execute the auto-tuning operation with

the setting code [2] (Low PV) selected.

•The auto-tuning can be executed both just after power-on

and in a control or stable status.

Related parameters:

(page 24)

(page 25)

(page 26)

(page 30)

(page 28)

[Setting example] Setting the auto-tuning operation to 1

Operating procedureDisplay

Press and hold the

1.

will be displayed on the PV display.

Press the key to display .

2.

Press the

3.

The current setting ( ) flashes on the SV display.

Press the or keys to display .

4.

Press the

5.

a decimal point at the right end of the SV display flashes.

When the auto-tuning finishes properly, a decimal point stops flashing, and the set values of , ,

6.

and parameters change. When the auto-tuning f inishes abnormally, a decimal point stops flashing, but the set values of , , and parameters remain unchanged.

key once.

SEL

key once. will stop flashing and the auto-tuning will start. During auto-tuning,

SEL

key for one second.

SEL

20

If you want to display the operation status, press and hold the

7.

key for two seconds.

SEL

,

,

Displaying ON-delay alarm or the remaining time of timers

[Description]

•These parameters display the remaining time of Timers

1, 2 and 3.

• The remaining time of the ON/OFF-delay timer is counted

down. When the counter shows , the alarm relay is

closed.

• During count-down, if the PV changes to the value of the

temperature at which the alarm is set to OFF, or if “DI”

for the timer is set to OFF, the counter is reset, and the

alarm relay is opened.

• display parameter

PV

SV

[Setting example] Displa ying ON-delay alarm or the remaining time of timers

Operating procedureDisplay

(unit: seconds) (Option)

Remaining time (seconds)

Press and hold the

1.

will be displayed.

Press the key to display

2.

The remaining time of timer 1 will be displayed.

Press the or keys to display the remaining time of , and .

3.

If you want to display the operation status, press and hold the

4.

key for one second.

SEL

.

key for two seconds.

SEL

21

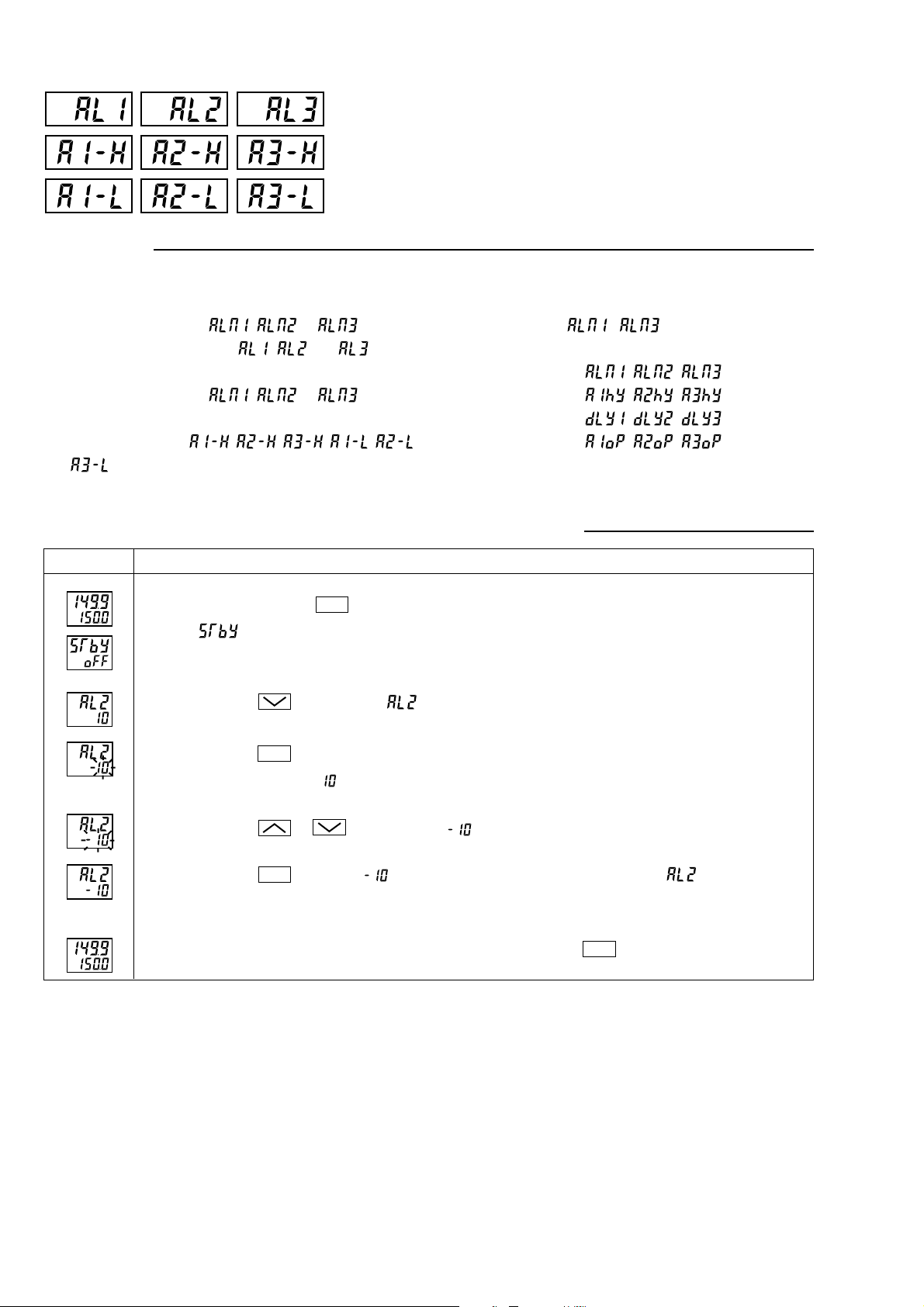

[Description]

Setting alarm

1, 2 and 3

Upper limit of alarm

1, 2 and 3

Lower limit of

alarm 1,2 and 3

(Setting range:

Absolute value alarm: 0 to 100%FS

Deviation value alarm: -100 to 100%FS )

}

(Option)

• These parameters are used to for settings of alarm 1, 2

and 3.

• When the alarm type ( ,

0 to 15, alarms 1, 2 and 3 ( ,

set.

• When the alarm type ( ,

any value other than 0 to 15, the upper and lower limits

of alarm 1, 2 and 3 ( , ,

) can be set.

[Setting example] Setting the operation value of alarm 2 to -10°C

Press and hold the

1.

will be displayed on the PV display.

Press the key to display .

2.

or

and

or

,

key for one second.

SEL

) is set to

) can be

) is set to

,

,

[Note]

Setting codes (12 to 15) cannot be selected in alarm

type 1 and 3 (

Related parameters: ,

Operating procedureDisplay

/

).

,

,

,

,

,

,

,

(page 46)

(page 59)

(page 55)

(page 60)

Press the

3.

The current setting ( ) flashes on the SV display.

Press the or keys to display .

4.

Press the

5.

controller will operate with the operation value of alarm 2 being -10°C.

If you want to display the operation status, press and hold the

6.

key once.

SEL

key once. will stop flashing and will be registered for . After that, the

SEL

SEL

key for two seconds.

22

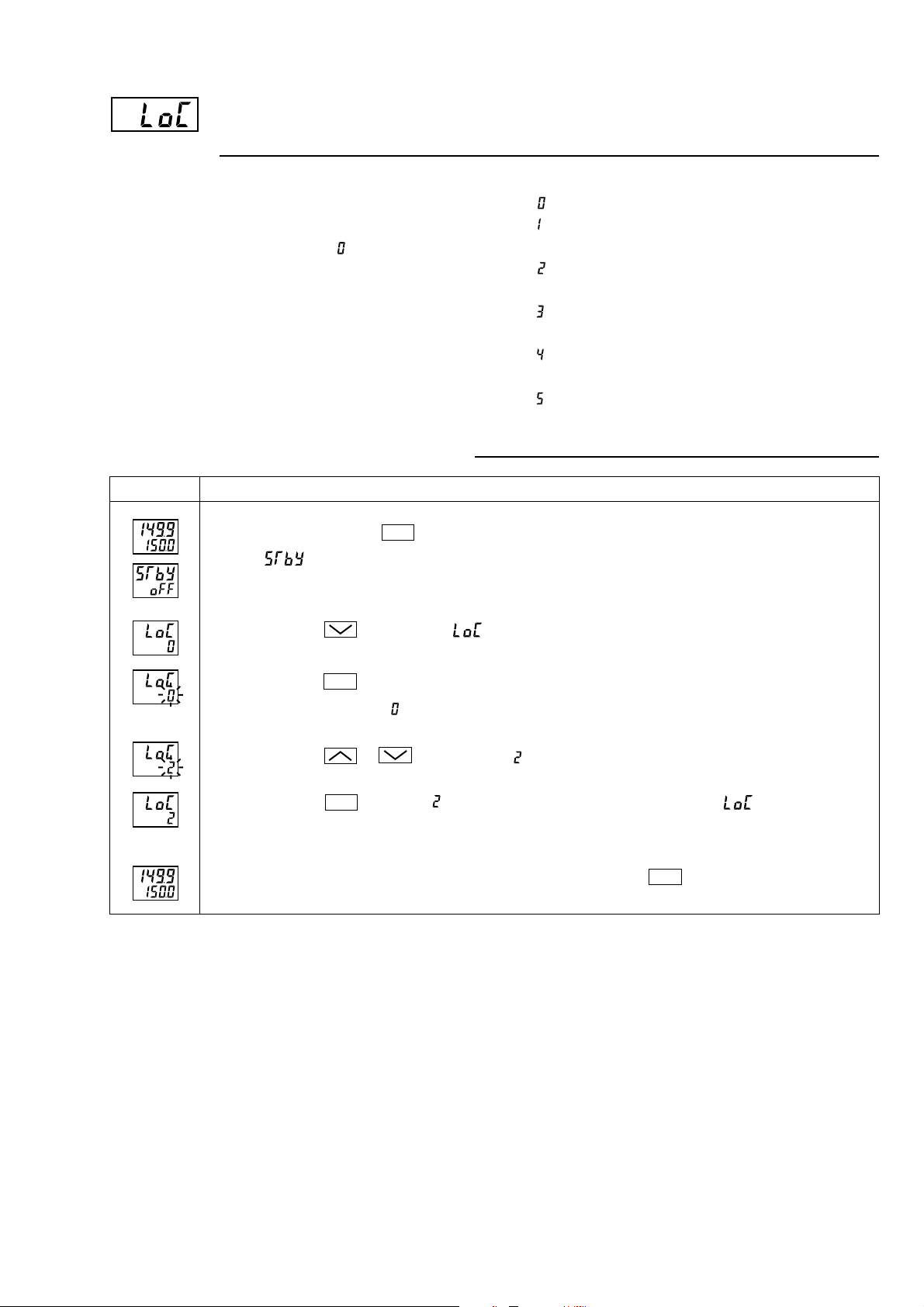

Key lock (Setting range: 0

−

5)

[Description]

•This parameter makes the set values of parameters

unchangeable. However, the parameter name and the set

values can be displayed.

•To reset the key lock, change to .

•Even when the key lock is set, control and alarm functions

can operate properly.

[Setting example] Setting the key lock to “2”

•There are six levels of the key lock:

: Unlocked (reset)

: All settings are unchangeable from the controller, but

changeable via communication.

: Only the SV is changeable from the controller, and all

settings are changeable via communication.

: All settings are changeable from the controller, but

unchangeable via communication.

:

All settings are unchangeable from the controller or

via communication.

: Only the SV is changeable from the controller, but all

settings are unchangeable via communication.

Operating procedureDisplay

Press and hold the

1.

will be displayed on the PV display.

Press the key to display .

2.

Press the

3.

The current setting ( ) flashes on the SV display.

Press the or keys to display .

4.

Press the

5.

setting other than the SV cannot be changed from the front panel.

If you want to display the operation status, press and hold the

6.

key once.

SEL

SEL

key once. will stop flashing and will be registered for

key for one second.

SEL

key for two seconds.

SEL

. After that, any

23

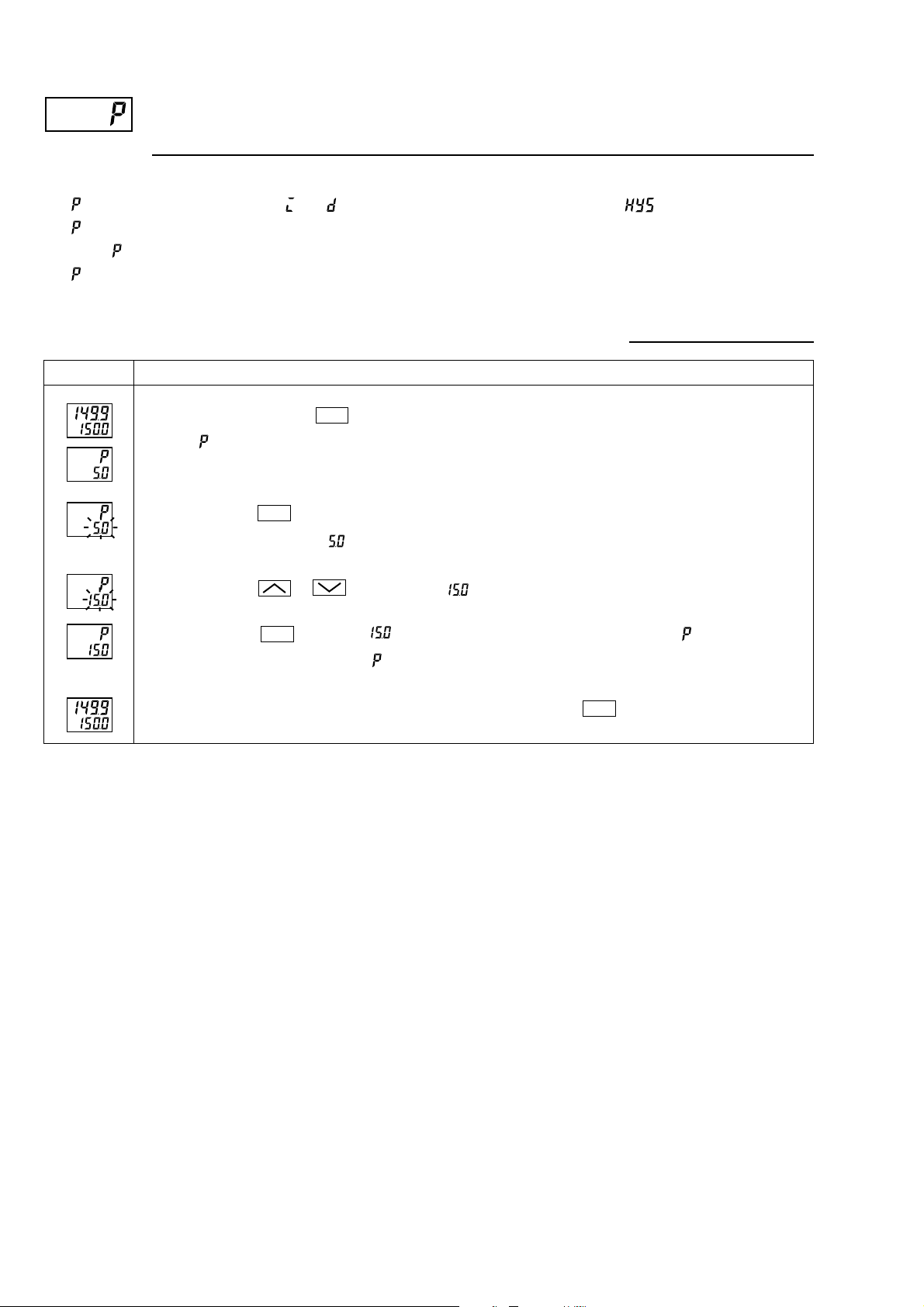

Proportional band (Setting range: 0.0 to 999.9% of the measured range)

[Description]

•To select the ON/OFF control (two-position control), set

to 0.0. It is not necessary to set and .

• can be automatically set by the auto-tuning operation.

• When is too small, control will be unstable, and when

is too large, the response will be delayed.

• Set the hysteresis of the ON/OFF control (two-position

control) in the parameter

• If auto-tuning is run after the ON/OFF control is selected,

the ON/OFF control changes to the PID control. To keep

the ON/OFF control selected, do not execute the autotuning.

[Setting example] Changing the proportional band from 5.0% to 15.0%

Operating procedureDisplay

.

1.

Press and hold the

will be displayed on the PV display.

Press the

2.

The current setting

Press the or keys to display .

3.

Press the

4.

controller will operate with being 15.0%.

If you want to display the operation status, press and hold the

5.

SEL

key once.

key once. will stop flashing and will be registered for . After that, the

SEL

SEL

key for three seconds.

( )

flashes on the SV display.

SEL

key for two seconds.

24

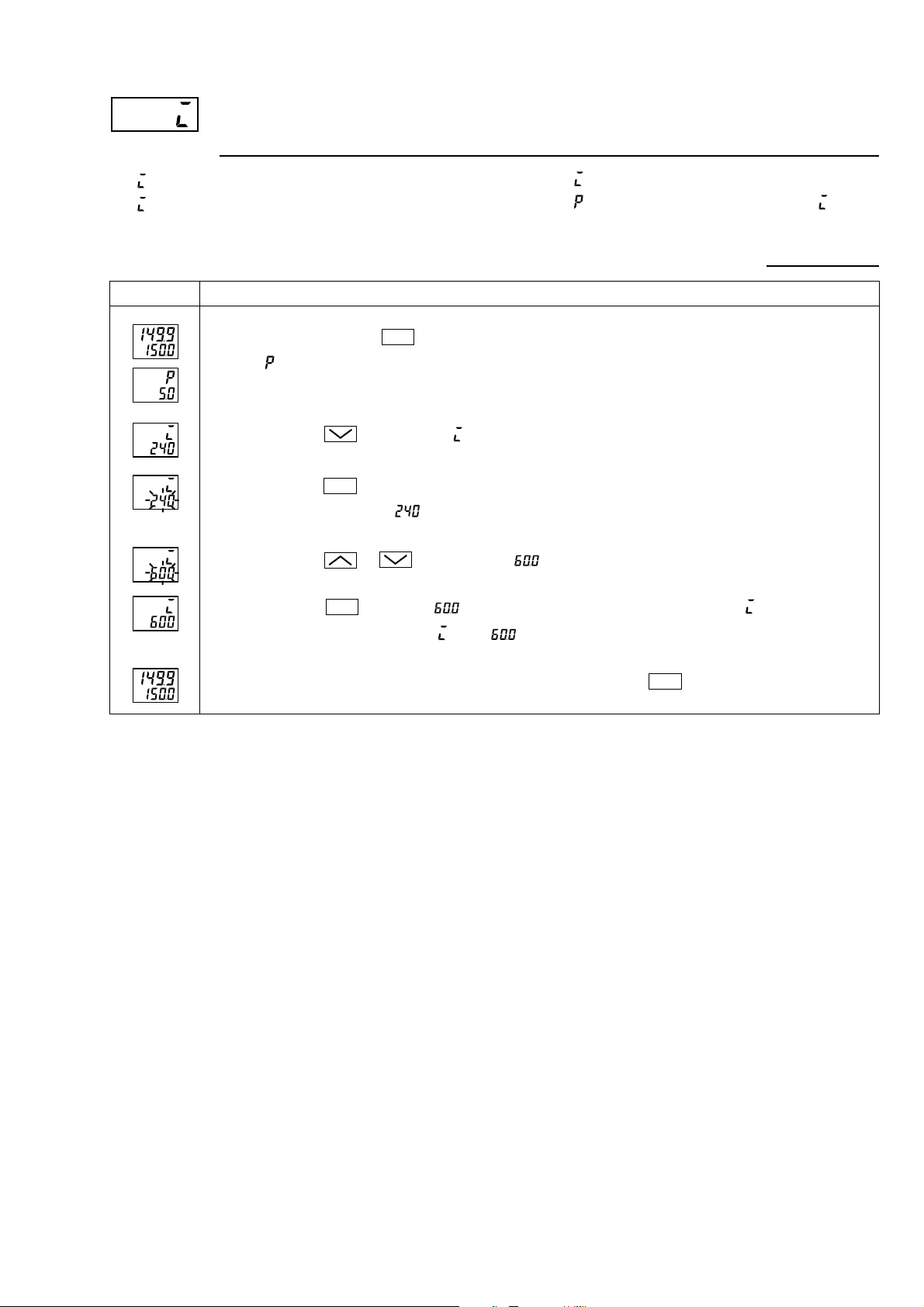

Integral time (Setting range: 0 to 3200 seconds)

[Description]

• can be set automatically by the auto-tuning operation.

• can also be set manually.

•When is set to 0, the integral operation does not start.

•When is set to 0.0, this makes the setting of ineffective.

[Setting example] Changing the integral time from 240 seconds to 600 seconds

Operating procedureDisplay

1.

Press and hold the

will be displayed on the PV display.

2.

Press the key to display .

key for three seconds.

SEL

Press the

3.

The current setting ( ) flashes on the SV display.

4.

Press the or keys to display .

Press the

5.

controller will operate with being seconds.

If you want to display the operation status, press and hold the

6.

key once.

SEL

SEL

key once. will stop flashing and will be registered for . After that, the

key for two seconds.

SEL

25

Loading...

Loading...