Page 1

/ Instruction Manual

CC-Link Communications Card

"OPC-G1-CCL"

Fuji Electric Co., Ltd. INR-SI47-1328d-JE

Page 2

English Version

Page 3

Page 4

Preface

Thank you very much for purchasing our CC-Link Communications Card "OPC-G1-CCL."

This manual has been prepared to help you connect your FRENIC-MEGA to a CC-Link master (Mitsubishi

Electric PLC, etc.) via CC-Link.

Mounting this communications card on your FRENIC-MEGA allows you to connect the FRENIC-MEGA to a

CC-Link master and control it as a slave using run commands, speed commands, and access to inverter's

function codes.

The communications card can be connected to the A-port only, out of three option connection ports (A-, B-, and

C-ports) provided on the FRENIC-MEGA.

The communications card has the following features:

• CC-Link Version: Complies with CC-Link versions 1.10 and 2.00

• Applicable Profile: Inverter (1 station occupied)

• Monitoring the status of the FRENIC-MEGA (running status, frequency, output torque, output current,

output voltage, etc.)

• Reading and writing from/to function codes applicable to the FRENIC-MEGA

Logo mark:

The communications card is a CC-Link version 2.00 compliant remote device unit and supports the following:

- Extended cyclic transmission

- Easing restrictions on inter-station cable length

This instruction manual does not contain inverter handling instructions. Read through this instruction manual in

conjunction with the FRENIC-MEGA Instruction Manual and be familiar with proper handling and operation of

this product. Improper handling might result in incorrect operation, a short life, or even a failure of this product.

Keep this manual in a safe place.

Related Publications

Listed below are the other materials related to the use of the CC-Link Communications Card "OPC-G1-CCL."

Read them in conjunction with this manual as necessary.

• RS-485 Communication User's Manual

• FRENIC-MEGA Instruction Manual

The materials are subject to change without notice. Be sure to obtain the latest editions for use.

• Read through this instruction manual and be familiar with the CC-Link communications card before

proceeding with installation, connections (wiring), operation, or maintenance and inspection.

• Improper handling might result in incorrect operation, a short life, or even a failure of this product as

well as the motor.

• Deliver this manual to the end user of this product. Keep this manual in a safe place until this product

is discarded.

1

Page 5

Safety precautions

Read this manual thoroughly before proceeding with installation, connections (wiring), operation, or

maintenance and inspection. Ensure you have sound knowledge of the device and familiarize yourself with all

safety information and precautions before proceeding to operate the inverter.

Safety precautions are classified into the following two categories in this manual.

Failure to heed the information indicated by this symbol may lead to

dangerous conditions, possibly resulting in death or serious bodily

injuries.

Failure to heed the information indicated by this symbol may lead to

dangerous conditions, possibly resulting in minor or light bodily injuries

and/or substantial property damage.

Failure to heed the information contained under the CAUTION title can also result in serious consequences.

These safety precautions are of utmost importance and must be observed at all times.

Installation and wiring

• Before starting installation and wiring, turn OFF the power and wait at least five minutes for inverters

with a capacity of 22 kW or below, or at least ten minutes for inverters with a capacity of 30 kW or

above. Make sure that the LED monitor and charging lamp are turned OFF. Further, make sure,

using a multimeter or a similar instrument, that the DC link bus voltage between the terminals P(+)

and N(-) has dropped to the safe level (+25 VDC or below).

• Qualified electricians should carry out wiring.

Otherwise, electric shock could occur.

• Do not use the products that are damaged or lacking parts.

Doing so could cause a fire, accident, or injury.

• Prevent lint, paper fibers, sawdust, dust, metallic chips, or other foreign materials from getting into

the inverter and the communications card.

Otherwise, a fire or an accident might result.

• Incorrect handling in installation/removal jobs could cause a failure.

A failure might result.

• Noise may be emitted from the inverter, motor and wires. Implement appropriate measure to prevent

the nearby sensors and devices from malfunctioning due to such noise.

Otherwise, an accident could occur.

2

Page 6

Operation

• Be sure to install the front cover before turning the inverter's power ON. Do not remove the cover

when the inverter power is ON.

Otherwise electric shock could occur.

• Do not operate switches with wet hands.

Doing so could cause electric shock.

• If you configure the function codes wrongly or without completely understanding FRENIC-MEGA

Instruction Manual and the FRENIC-MEGA User's Manual, the motor may rotate with a torque or at a

speed not permitted for the machine. Confirm and adjust the setting of the function codes before

running the inverter.

Otherwise, an accident could occur.

Maintenance and inspection, and parts replacement

• Before proceeding to the maintenance/inspection jobs, turn OFF the power and wait at least five

minutes for inverters with a capacity of 22 kW or below, or at least ten minutes for inverters with a

capacity of 30 kW or above. Make sure that the LED monitor and charging lamp are turned OFF.

Further, make sure, using a multimeter or a similar instrument, that the DC link bus voltage between

the terminals P(+) and N(-) has dropped to the safe level (+25 VDC or below).

Otherwise, electric shock could occur.

• Maintenance, inspection, and parts replacement should be made only by qualified persons.

• Take off the watch, rings and other metallic objects before starting work.

• Use insulated tools.

Otherwise, electric shock or injuries could occur.

Disposal

• Treat the communications card as an industrial waste when disposing of it.

Otherwise injuries could occur.

Others

• Never modify the communications card.

Doing so could cause electric shock or injuries.

Icons

The following icons are used throughout this manual.

This icon indicates information which, if not heeded, can result in the product not operating to full

efficiency, as well as information concerning incorrect operations and settings which can result in

accidents.

This icon indicates information that can prove handy when performing certain settings or operations.

This icon indicates a reference to more detailed information.

3

Page 7

Table of Contents

Preface ..................................................................... 1

Safety precautions ............................................................ 2

Chapter 1 BEFORE USE ................................................... 5

1.1 Acceptance Inspection .......................................... 5

1.2 Applicable Inverters ............................................... 5

Chapter 2 NAMES AND FUNCTIONS ............................... 6

2.1 External Appearance ............................................. 6

2.2 Terminating Resistor Switch (SW1) ....................... 6

2.3 LED Status Indicators ............................................ 7

Chapter 3 INSTALLATION AND REMOVAL OF THE

CC-Link COMMUNICATIONS CARD ................ 8

3.1 Installing the Communications Card ...................... 8

3.2 Removing the Communications Card .................... 9

Chapter 4 WIRING AND CABLING .................................. 10

4.1 Basic Connection Diagram .................................. 10

4.2 Wiring for CC-Link Terminal Block ........................ 11

4.3 Wiring to Inverter ................................................. 12

Chapter 5 CONFIGURING INVERTER'S FUNCTION

CODES FOR CC-Link COMMUNICATION ..... 13

Chapter 6 SETTING-UP PROCEDURE ........................... 14

Chapter 7 LIST OF I/O SIGNALS ..................................... 15

7.1 Remote I/O Signals ............................................. 15

7.2 Remote Registers ................................................ 17

7.3 List of Monitor Item Codes ................................... 21

7.4 Command Codes and Response Codes ............. 23

Chapter 8 ERROR PROCESSING FOR CC-Link

NETWORK BREAKS ....................................... 25

Chapter 9 LIST OF INVERTER ALARM CODES ............. 26

Chapter 10 APPLICATION PROGRAM EXAMPLES ........ 27

10.1 System Configuration ........................................... 27

10.2 Network Parameter Settings ................................ 27

10.3 Relationship between Master Station Device

and Remote I/O and Remote Register ................. 28

10.4 CC-Link Startup Program ..................................... 29

10.5 Program Example Using the Inverter Running

Status Read ......................................................... 29

10.6 Program Example for Changing the Operation

Mode .................................................................... 30

10.7 Program Example for Specifying Run Command . 30

10.8 Program Example for Monitoring the Output

Frequency ............................................................ 31

10.9 Program Example for Reading from the

Inverter's Function Code Data ............................. 31

10.10 Program Example for Writing to Inverter's

Function Code Data ............................................. 32

10.11 Program Example for Setting up the Reference

Frequency ............................................................ 33

10.12 Program Example for Reading out Alarm Codes . 34

10.13 Program Example for Resetting a Inverter Trip .... 34

Chapter 11 TROUBLESHOOTING ................................... 35

Chapter 12 SPECIFICATIONS ......................................... 36

12.1 General Specifications ......................................... 36

12.2 CC-Link Specifications ......................................... 36

4

Page 8

Chapter 1 BEFORE USE

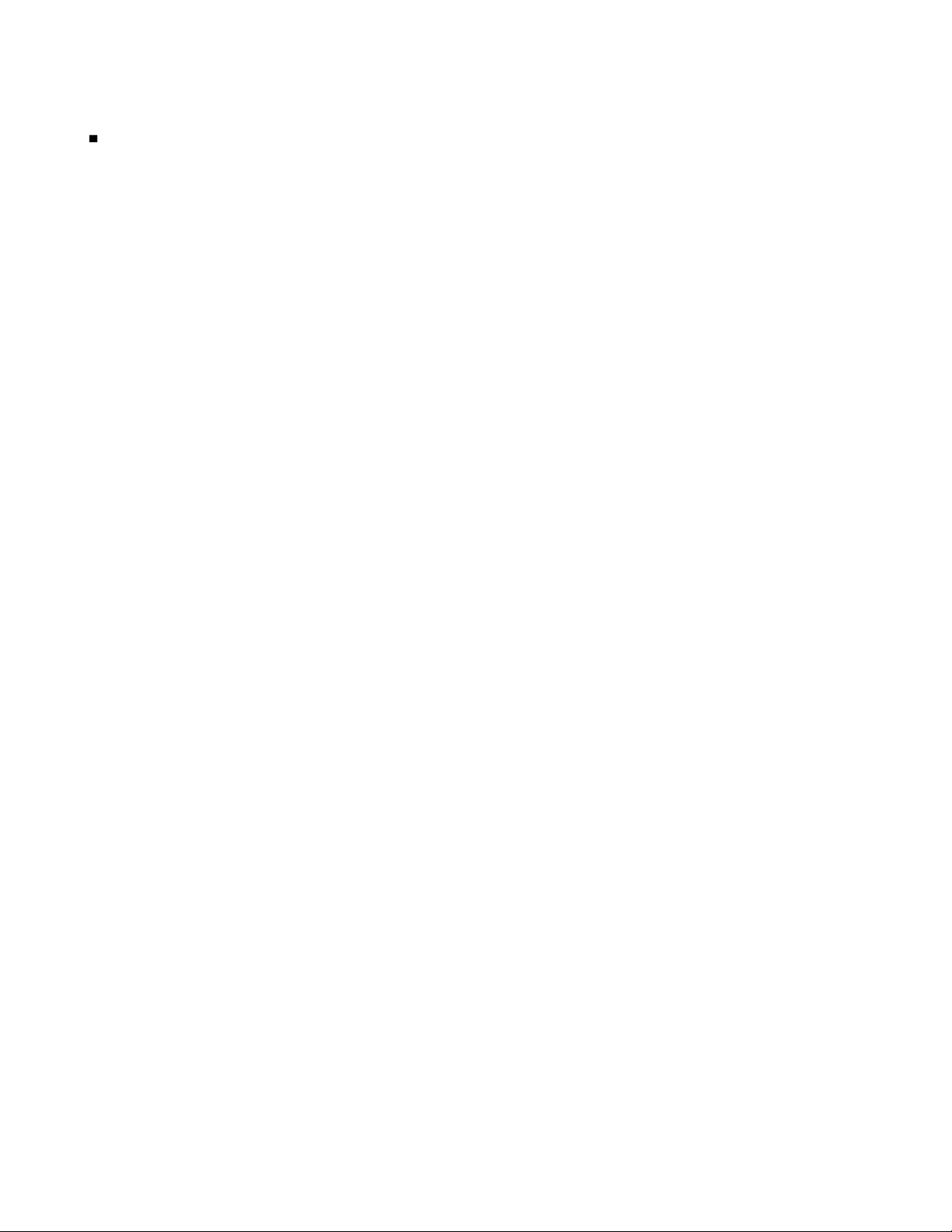

1.1 Acceptance Inspection

Unpack the package and check the following:

(1) A communications card, two screws (M3 8), and the CC-Link Communications Card Instruction Manual

(this manual) are contained in the package.

(2) The communications card is not damaged during transportation--no defective parts, dents or warps.

(3) The model name "OPC-G1-CCL" is printed on the communications card. (See Figure 1.1.)

If you suspect the product is not working properly or if you have any questions about your product, contact the

shop where you bought the product or your local Fuji branch office.

Screw hole (left)

Model name

Release knob

Connector CN1

(Front) (Back)

Positioning cutout

Figure 1.1 Names of Parts on CC-Link Communications Card

Screw hole (right)

1.2 Applicable Inverters

The CC-Link communications card is applicable to the following inverters and ROM version.

Table 1.1 Applicable Inverters and ROM Version

Series Inverter type Applicable motor rating ROM version

FRENIC-MEGA FRN G1 - All capacities 0500 or later

* The boxes replace alphanumeric letters depending on the nominal applied motor, enclosure, power supply voltage, etc.

To check the inverter's ROM version, use Menu #5 "Maintenance Information" on the keypad. (Refer to the

FRENIC-MEGA Instruction Manual, Chapter 3, Section 3.4.6 "Reading maintenance information.")

Table 1.2 Checking the Inverter ROM Version

Display on LED Monitor Item Description

Inverter's ROM version Shows the inverter's ROM version as a 4-digit code.

5

Page 9

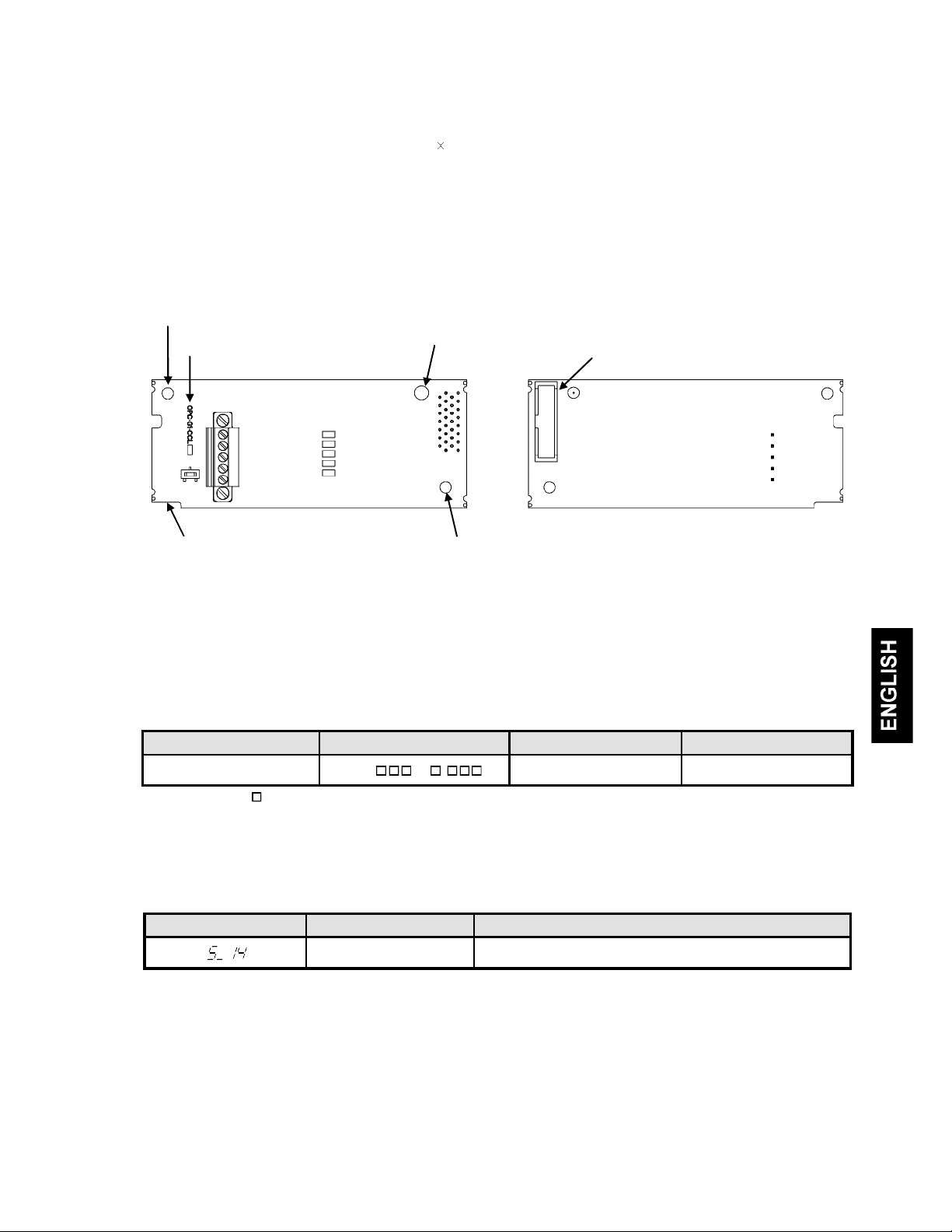

Chapter 2 NAMES AND FUNCTIONS

2.1 External Appearance

The external appearance and the components of the CC-Link communications card are shown in Figure 2.1 and

Table 2.1, respectively.

TERM1

CN1

(on the back)

SW1

Figure 2.1 External View and Component Names

Table 2.1 Components on the CC-Link Communications Card

LED status indicators

Component Description

TERM1 CC-Link terminal block (3.5 mm pitch)

CN1 Connector for joint with inverter

SW1

Terminating resistor switch (For details, see Section 2.2.)

(ON: Insertion of terminating resistor, OFF: No insertion)

LED status indicators RD, SD, L.ERR, RUN, and L.RUN (For details, see Section 2.3.)

2.2 Terminating Resistor Switch (SW1)

The CC-Link communications network requires insertion of line terminating resistors at its both ends. When this

communications card is mounted on the inverter at either end of the network, turn this switch ON to insert the

terminating resistor.

ON OFF

ON OFF

OFF: No insertion of terminating resistor ON: Insertion of terminating resistor

Figure 2.2 Terminating Resistor Switch Settings

6

Page 10

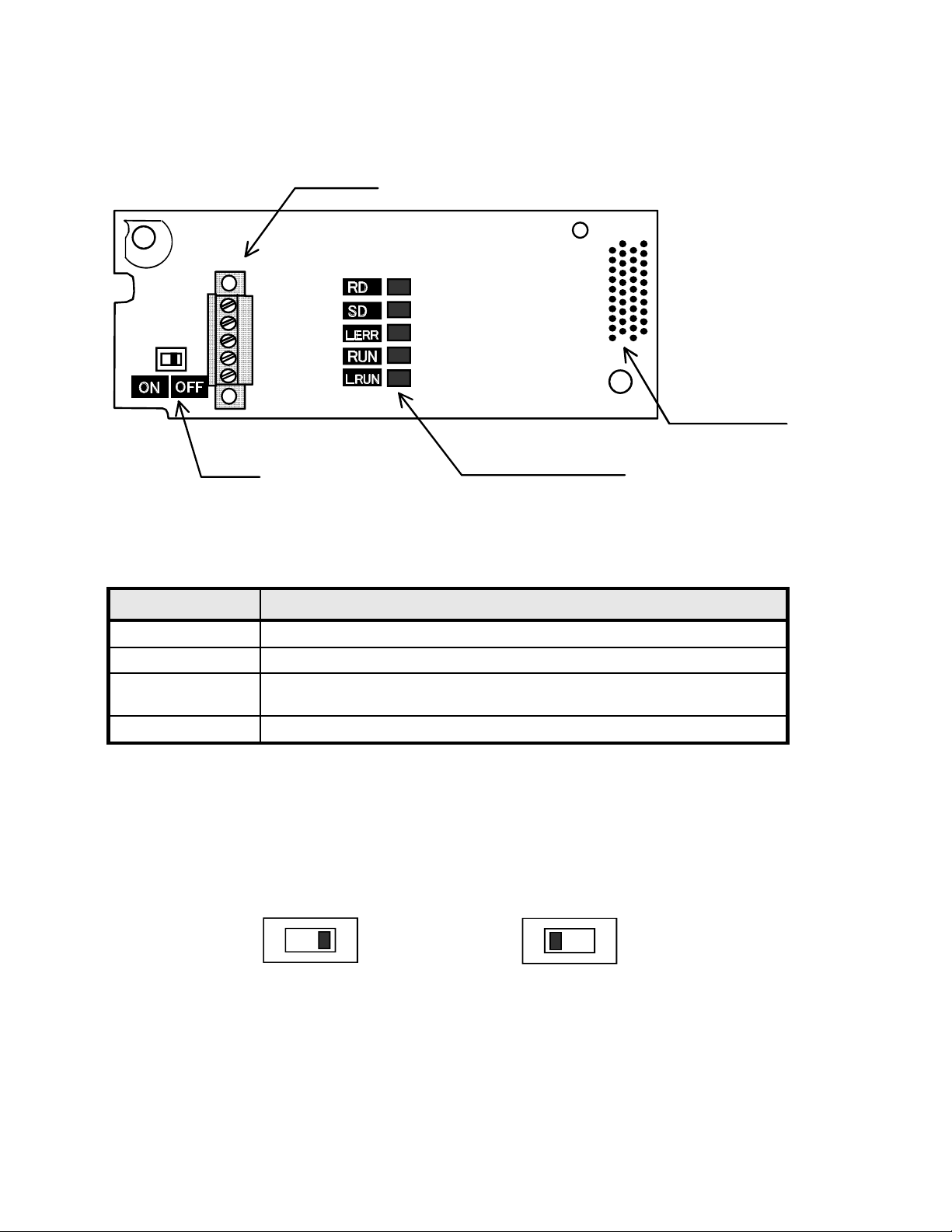

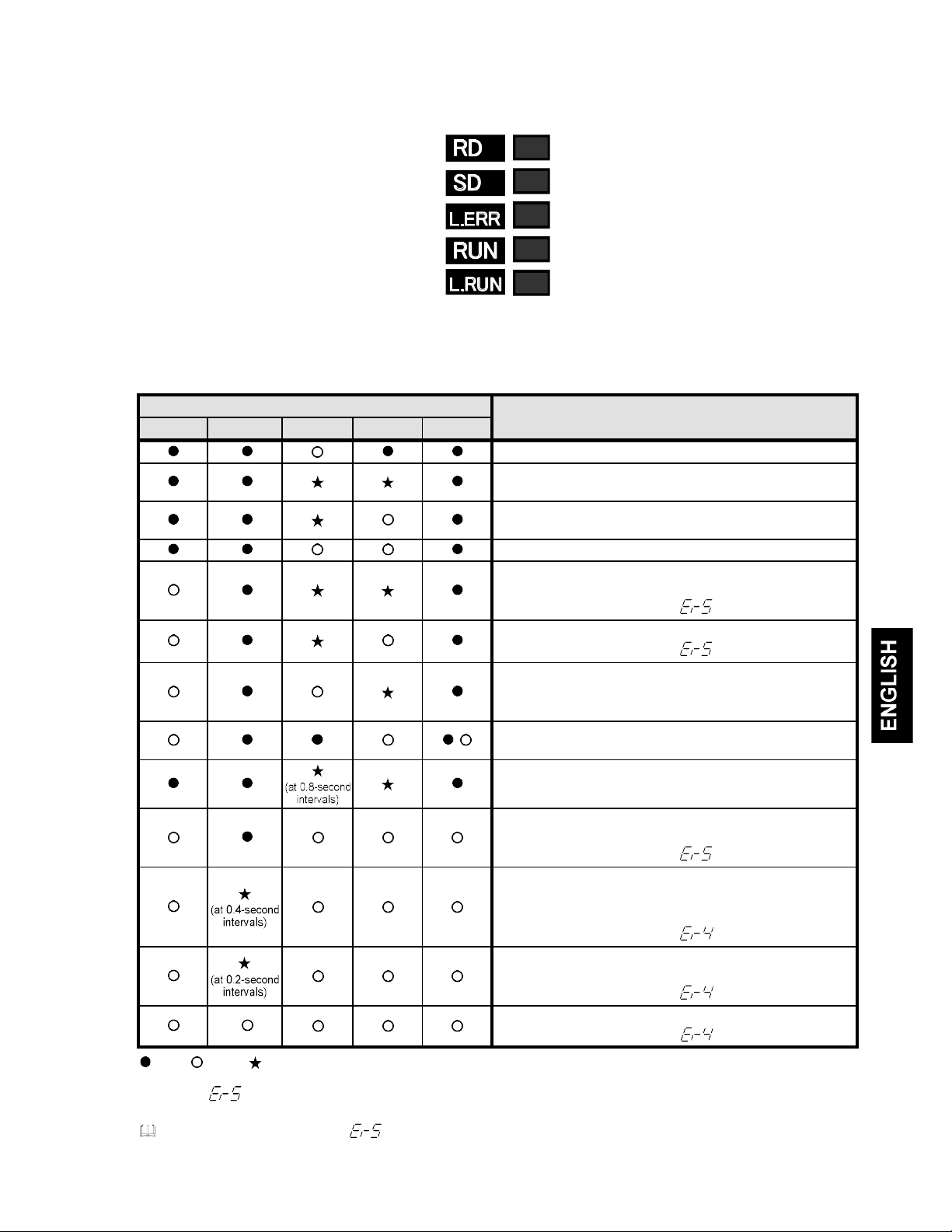

2.3 LED Status Indicators

This communications card has five LED status indicators shown below. They indicate the operation status of the

communications card as listed in Table 2.2.

Figure 2.3 LED Status Indicators

Table 2.2 LED Status Indicators and Operation Status

LED States

L.RUN RUN L.ERR SD RD

/

Normally communicating.

Normally communicating. But sometimes a CRC error

occurs due to electrical noise.

Received data contains a CRC error, so the

communications card cannot respond.

Data destined for this station does not come.

Responding to polling. But refresh data received

contains a CRC error.

The inverter trips with alarm displayed. *1

Data destined for this station contains a CRC error.

The inverter trips with alarm displayed. *1

Station address incorrectly specified.

Data destined for this station cannot be received due

to electrical noise.

Transmission speed (Baud rate) and/or station

address out of the allowable range.

Operation Status

Transmission speed (Baud rate) or station address

changed during CC-Link communication.

The communications card cannot receive data due to

: ON, : OFF, : Blinking (It may seem to be ON depending on the current transmission speed.)

*1 Alarm occurs when a communications error is detected after a normal communications link has been

established once.

It is possible to change the occurrence conditions with inverter's function codes. For details, refer to

Chapter 8 "ERROR PROCESSING FOR CC-Link NETWORK BREAKS."

a network break, etc.

The inverter trips with alarm displayed. *1

The master station is compliant with CC-Link version

1.xx and this slave station, with CC-Link version 2.xx.

Or the inverter's function code o30 is set to "5 to 255."

The inverter trips with alarm displayed.

Communications error between the communications

card and the inverter.

The inverter trips with alarm displayed.

Communications card error.

The inverter trips with alarm displayed.

7

Page 11

Chapter 3 INSTALLATION AND REMOVAL OF THE CC-Link COMMUNICATIONS

CARD

Before starting installation and wiring, turn OFF the power and wait at least five minutes for inverters with a

capacity of 22 kW or below, or at least ten minutes for inverters with a capacity of 30 kW or above. Make

sure that the LED monitor and charging lamp are turned OFF. Further, make sure, using a multimeter or a

similar instrument, that the DC link bus voltage between the terminals P(+) and N(-) has dropped to the

safe level (+25 VDC or below).

Otherwise, electric shock could occur.

• Do not use the products that are damaged or lacking parts.

Doing so could cause a fire, accident, or injury.

• Prevent lint, paper fibers, sawdust, dust, metallic chips, or other foreign materials from getting into the

inverter and the communications card.

Otherwise, a fire or an accident might result.

• Incorrect handling in installation/removal jobs could cause a failure.

A failure might result.

Before mounting the communications card, perform the wiring for the main circuit terminals and control

circuit terminals.

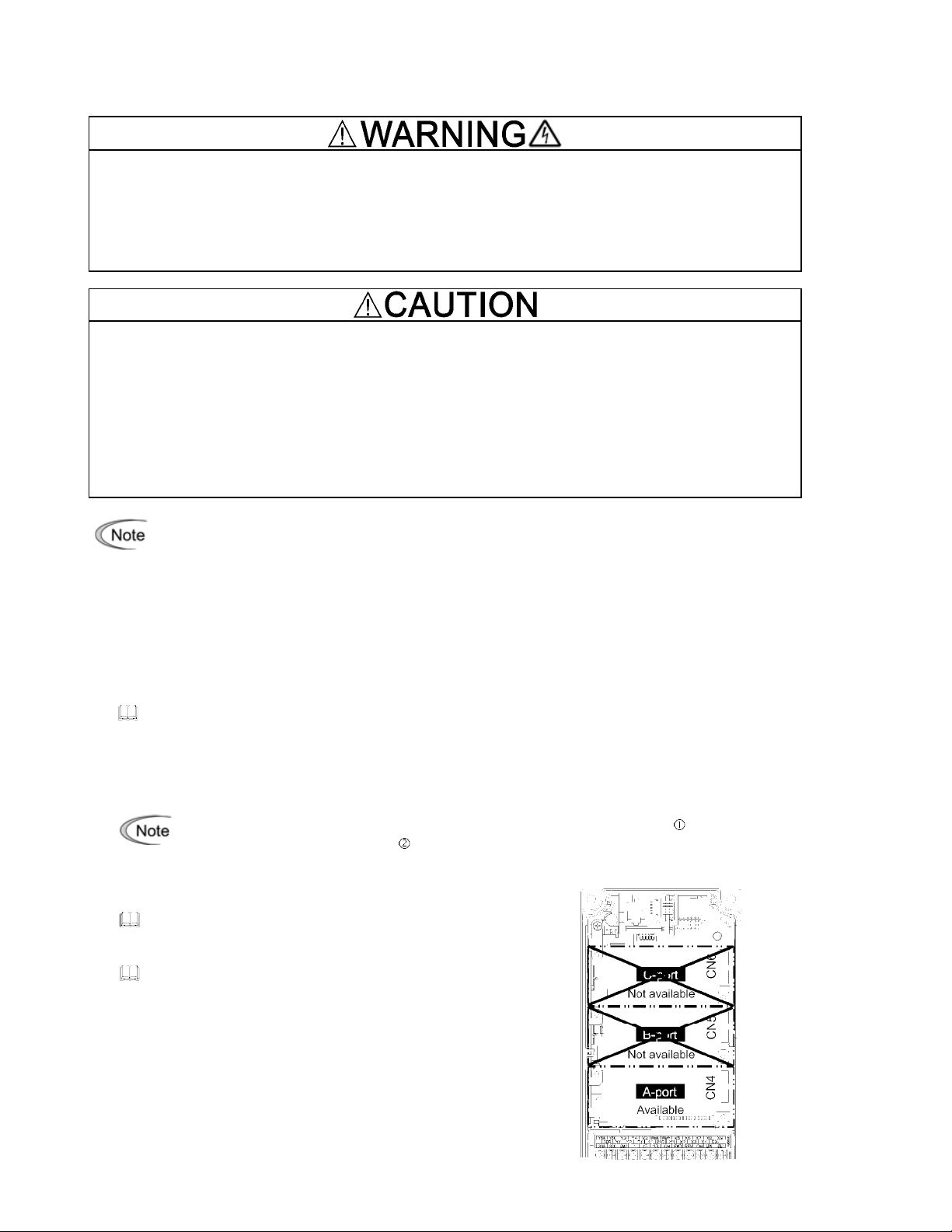

3.1 Installing the Communications Card

(1) Remove the front cover from the inverter and expose the control printed circuit board (control PCB). As

shown in Figure 3.1, the communications card can be connected to the A-port only, out of three option

connection ports (A-, B-, and C-ports) on the control PCB.

To remove the front cover, refer to the FRENIC-MEGA Instruction Manual, Chapter 2, Section 2.3. For

inverters with a capacity of 30 kW or above, open also the keypad enclosure.

(2) Insert connector CN1 on the back of the communications card (Figure 1.1) into the A-port (CN4) on the

inverter's control PCB. Then secure the communications card with the two screws that come with the

communications card. (Figure 3.3)

Check that the positioning cutout (shown in Figure 1.1) is fitted on the tab ( in Figure 3.2) and

connector CN1 is fully inserted ( in Figure 3.2). Figure 3.3 shows the communications card

correctly mounted.

(3) Perform wiring on the communications card.

Refer to Chapter 4 "WIRING AND CABLING."

(4) Put the front cover back into place.

To put back the front cover, refer to the

FRENIC-MEGA Instruction Manual, Chapter 2,

Section 2.3. For inverters with a capacity of 30 kW or

above, close also the keypad enclosure.

Figure 3.1 In the case of 0.4 kW

8

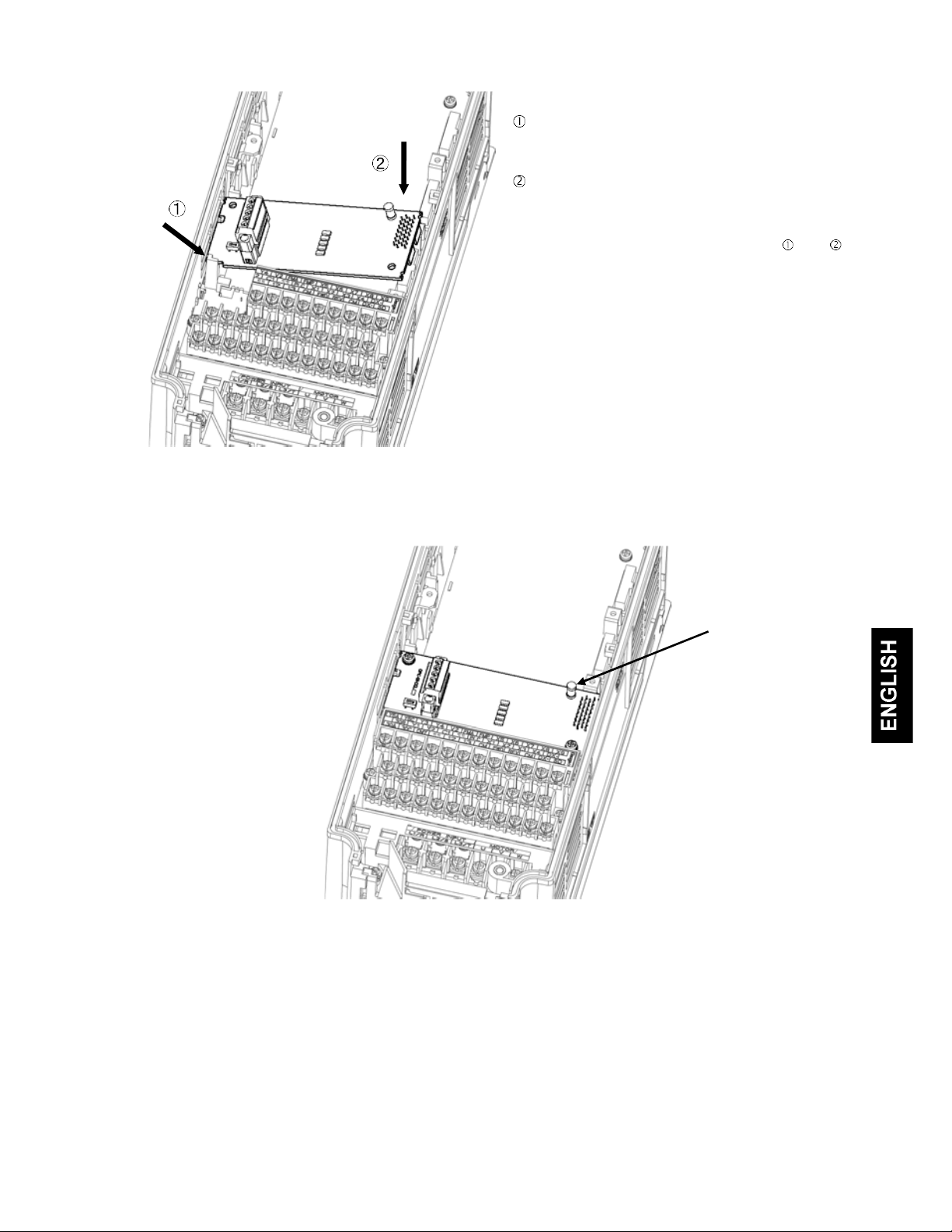

Page 12

Fit the positioning cutout of the communications

card over the tab on the inverter to determine

the mounting position.

Insert connector CN1 on the communications

card into the A-port on the inverter's control

PCB.

Note: Be sure to follow the order of and .

Inserting CN1 first may lead to insufficient

insertion, resulting in a contact failure.

Figure 3.2 Mounting the Communications Card

(Release knob)

Figure 3.3 Mounting Completed

3.2 Removing the Communications Card

Remove the two screws that secure the communications card and pull the release knob (shown above) to take

the communications card out of the inverter.

9

Page 13

Chapter 4 WIRING AND CABLING

• Before starting installation and wiring, turn OFF the power and wait at least five minutes for inverters with

a capacity of 22 kW or below, or at least ten minutes for inverters with a capacity of 30 kW or above.

Make sure that the LED monitor and charging lamp are turned OFF. Further, make sure, using a

multimeter or a similar instrument, that the DC link bus voltage between the terminals P(+) and N(-) has

dropped to the safe level (+25 VDC or below).

• Qualified electricians should carry out wiring.

Otherwise, an electric shock could occur.

• In general, the covers of the control signal wires are not specifically designed to withstand a high voltage

(i.e., reinforced insulation is not applied). Therefore, if a control signal wire comes into direct contact with

a live conductor of the main circuit, the insulation of the cover might break down, which would expose the

signal wire to a high voltage of the main circuit. Make sure that the control signal wires will not come into

contact with live conductors of the main circuit.

Failure to observe this precaution could cause an electric shock or fire.

Noise may be emitted from the inverter, motor and wires. Take appropriate measures to prevent the nearby

sensors and devices from malfunctioning due to such noise.

An accident could occur.

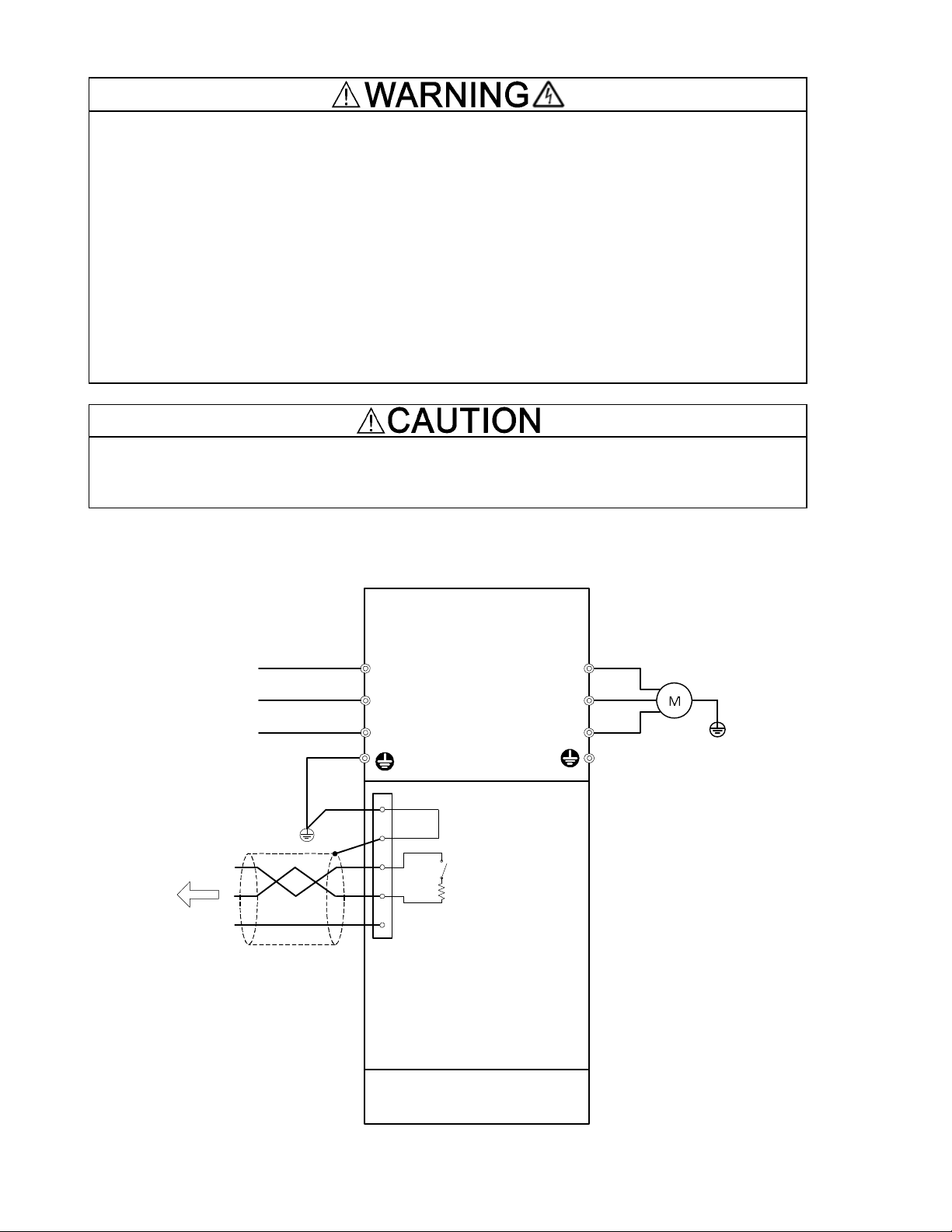

4.1 Basic Connection Diagram

To CC-Link

network

CC-Link cable

L1/R

L2/S

L3/T

Blue

White

Yellow

CC-Link

terminal block

FRENIC-MEGA

G

FG

SLD

Terminating

DA

resistor switch

DB

DG

U

V

W

G

Motor

G

OPC-G1-CCL

Figure 4.1 Basic Connection Diagram

10

Page 14

4.2 Wiring for CC-Link Terminal Block

(1) To connect this communications card to a CC-Link network, use a CC-Link dedicated cable complying with

the CC-Link specifications. Using a cable other than a CC-Link dedicated cable does not assure the

CC-Link system performance. Also observe the wiring lengths specified in the CC-Link version 1.10

specifications.

The recommended CC-Link cable is FANC-110SBH made by Kuramo Electric Co., Ltd.

For details about wiring for CC-Link, refer to the CC-Link Master Use's Manual or CC-Link Cable Wiring

Manual published by the CC-Link Partner Association. The CC-Link Cable Wiring Manual is available as a

free download from the CC-Link Partner Association's website at:

http://www.cc-link.org/eng/t_html/siryo.html

(2) Wiring around the CC-Link terminal block

The terminal block uses a pluggable 5-pin connector as shown in Figure 4.2. Table 4.1 shows the

correspondence between the pin numbers and the ID colors.

A typical connector that matches this terminal block is Phoenix Contact MCVW 1.5/5-STF-3.5.

Table 4.1 Layout of Terminal Pins

Pin # Name

ID Color of

Wire Sheath

Description

1 DA Blue

2 DB White For communication data

3 DG Yellow

4 SLD Metallic For shielded wire

5 FG For grounding

Figure 4.2 Connectors on the

CC-Link Terminal Block

Table 4.2 lists the recommended terminal screw size and its tightening torque, and Figure 4.3 shows the

recommended strip length of the cable wire end.

Table 4.2 Recommended Tightening Torque of the

Terminal Screws on the CC-Link Terminal Block

Terminal screw size

Tightening torque

Cable wire

Approx.

6.0 mm

M2 0.22 to 0.25 N·m

Figure 4.3 Recommended Strip Length of the

Cable Wire End for Terminal

Connection

(3) When two or more inverters are connected

Master

DA

Terminating

resistor

DB

DG

SLD

CC-Link cable

FG

* On CC-Link communications cards connected in the middle of the network, set their terminating

resistor switches (SW1) to OFF (No insertion of terminating resistor).

Figure 4.4 Connection Diagram of Two or More Inverters

OPC-G1-CCL

DA

DB

DG

SLD

FG

11

CC-Link cable

OPC-G1-CCL

DA

DB

DG

SLD

FG

Terminating resistor

(SW1 ON)

Page 15

4.3 Wiring to Inverter

Route the wiring of the CC-Link cable as far from the wiring of the main circuit as possible.

Otherwise electric noise may cause malfunctions.

Pass the wires from the communications card between the control circuit terminal block and the

front cover.

• For inverters with a capacity of 22 kW or below

In the case of 0.4 kW

• For inverters with a capacity of 30 kW or above

In the case of 75 kW

Figure 4.5 Examples of Wiring

12

Page 16

Chapter 5 CONFIGURING INVERTER'S FUNCTION CODES FOR CC-Link

COMMUNICATION

Before starting CC-Link communication between the inverter equipped with this communications card and the

CC-Link master device, configure the inverter's function codes listed in Table 5.1.

Table 5.2 lists other related function codes to be configured if necessary.

Table 5.1 Inverter's Function Codes for CC-Link Communication

(The underlined values are factory defaults.)

Function

code

1

*

o27

1

*

o28

2

*

o30

3

*

o31

3

*

o32

Function Setting range Description

Select error processing for

CC-Link network breaks.

Set the operation timer to be

used in error processing for

network breaks.

CC-Link extension

Station address

Transmission speed

0 to 15

0.0 to 60.0 sec.

0, 1

2

3

4

5 to 255

1 to 64

0, 65 to 255

0

1

2

3

4

5 to 255

Error processing to perform when a

communications link error or a communications

card failure is detected.

Specify the timer period during which the

inverter keeps running even if a network break

is detected.

1 station occupied (CC-Link version 1.10)

1 station occupied, 2X setting

(CC-Link version 2.00)

1 station occupied, 4X setting

(CC-Link version 2.00)

1 station occupied, 8X setting

(CC-Link version 2.00)

No operation

Set a station address.

Invalid

156 kbps

625 kbps

2.5 Mbps

5 Mbps

10 Mbps

Invalid

*1 For details about the function codes o27 and o28, refer to Chapter 8 "ERROR PROCESSING FOR CC-Link

NETWORK BREAKS."

*2 After changing the o30 data, resetting the communications card (by turning the terminal signal RST ON or by

pressing the key on the keypad) validates the new setting. However, resetting the communications card causes

an inverter trip with an alarm if Version 1.xx is specified on the master station and Version 2.xx on the o30

setting.

*3 Changing the o31 or o32 data causes the L.ERR LED to start blinking. Resetting the communications card validates

the new setting and turns the L.ERR LED OFF.

Table 5.2 Other Related Function Codes

Function

code

y98 * Select

run/frequency

command sources

Function

Factory

default

0

Function code data Remarks

Select from the following choices:

y98

command source

Frequency

Run command

0 Inverter Inverter

1 CC-Link Inverter

source

If there is no

special problem

with your system,

setting y98 = 3 is

recommended.

2 Inverter CC-Link

3 CC-Link CC-Link

* In addition to y98, there are some function codes that specify run/frequency command sources. Using those function

codes enables more flexible settings of run/frequency command sources. For details, refer to the description for the

function codes H30 and y98 in the FRENIC-MEGA Instruction Manual, Chapter 5 "FUNCTION CODES."

13

Page 17

Chapter 6 SETTING-UP PROCEDURE

The following flow shows the initial setting-up procedure for the CC-Link communications card.

Start

Acceptance inspection

Mount the communications card

Connect the CC-Link cable

Configure the terminating resistor switch (SW1)

Turn ON the inverter power

Configure function codes y98 and o27 to o32

to match the settings in the master

See Chapter 1 "BEFORE USING THE

CC-Link COMMUNICATIONS CARD."

See Chapter 3 "INSTALLATION AND

REMOVAL OF THE COMMUNICATIONS

CARD."

See Chapter 4 "WIRING AND

CABLING."

See Chapter 2, Section 2.2

"Terminating Resistor Switch."

See Chapter 5 "CONFIGURING

INVERTER'S FUNCTION CODES

FOR CC-Link COMMUNICATION."

Preparation completed

Now the inverter is ready to run via CC-Link.

After confirming that the CC-Link master has been set up, check that the communications link is established

according to the ON/OFF states of the LED status indicators (see Chapter 2, Section 2.3 "LED Status

Indicators").

After the CC-Link master becomes ready, run the master to operate the inverter via CC-Link.

14

Page 18

Chapter 7 LIST OF I/O SIGNALS

7.1 Remote I/O Signals

(1) Remote outputs (Master Inverter)

Device No. Signal name Description Remarks

RY0 Run forward command OFF: Stop command

ON: Run forward command

RY1 Run reverse command OFF: Stop command

ON: Run reverse command

RY2 Terminal X1 function Terminal command assigned by inverter's

function code E01 *

RY3 Terminal X2 function Terminal command assigned by inverter's

function code E02 *

RY4 Terminal X3 function Terminal command assigned by inverter's

function code E03 *

RY5 Terminal X4 function Terminal command assigned by inverter's

function code E04 *

RY6 Terminal X5 function Terminal command assigned by inverter's

function code E05 *

RY7 Terminal X6 function Terminal command assigned by inverter's

function code E06 *

RY8 Terminal X7 function Terminal command assigned by inverter's

function code E07 *

RY9 Secondary side output

ON: Coast to a stop Effective only when

cut off (BX)

RYA

Terminal X8 function *

2

Terminal command assigned by inverter's

function code E08 *

RYB

Terminal X9 function *

2

Terminal command assigned by inverter's

function code E09 *

3

RYC *

Monitor command Turning this signal ON causes the inverter to store monitored values

into remote registers RWr0, 1, 4 to 7 and then turns the "Monitoring"

signal (RXC) ON.

RYD *

Frequency command /

Torque command

(RAM)

Turning this signal ON writes the reference frequency (RWw1) /

torque command (RWwC) to the inverter's RAM. Upon completion of

writing, the "Frequency setting / Torque setting completed" signal

4

(RXD) is turned ON.

RYE Not used. -RYF *

Command code

execution request

Turning this signal ON executes processing corresponding to

command codes specified in RWw2, 10, 12, 14, 16, and 18. After

5

execution of those command codes, the "Command code execution

completed" signal (RXF) is turned ON.

If a command code execution error occurs, the error factor will be set

to the response code (RWr2, 10, 12, 14, 16, and 18).

6

RY1A *

Alarm reset request flag Turning this signal ON and then OFF when a trip has occurred

resets the trip state and turns this flag (RX1A) OFF.

*1For details about inverter's function codes E01 to E09, refer to the FRENIC-MEGA Instruction Manual,

Chapter 5 "FUNCTION CODES." Depending upon terminal commands assigned to terminals X1 through X9,

these signals may not be operated via CC-Link. For details, refer to the RS-485 Communication User's

Manual, Chapter 5, Section 5.1.2 [ 3 ] "Operation command data."

*2These terminals are not provided in some types of the FRENIC-MEGA. For details, refer to the

FRENIC-MEGA Instruction Manual, Chapter 5 "FUNCTION CODES."

*3While the "Monitor command" (RYC) is ON, the monitored values are constantly updated.

*4While the "Frequency command / Torque command" (RYD) is ON, the current reference frequency (RWw1)

/ torque command (RWwC) is constantly reflected on the speed.

*5Each time the "Command code execution request" (RYF) is turned ON, the command specified by the

command code executes once. To execute it again, it is necessary to turn the "Command code execution

request" (RYF) ON again.

*6Turning the "Alarm reset request flag" signal (RY1A) from ON to OFF resets the alarm. Normally, this signal

should be set to OFF.

Simultaneously

turning RY0 and RY1

ON is functionally

equivalent to a stop

command.

1

1

1

1

1

1

1

the run command

source is CC-Link.

1

1

15

Page 19

(2) Remote inputs (Inverter Master)

Device No. Signal name Description

RX0 Running forward OFF: Except running in forward direction (Stopped or Rotating in

reverse direction)

ON: Rotating in forward direction

RX1 Running reverse OFF: Except running in reverse direction (Stopped or Rotating in

forward direction)

ON: Rotating in reverse direction

RX2 Terminal Y1 function

RX3 Terminal Y2 function

RX4 Terminal Y3 function

RX5 Terminal Y4 function

RX6 Terminal Y5 function

RX7 Terminal 30A/B/C

Terminal state assigned by inverter's function code E20 *

Terminal state us assigned by inverter's function code E21 *

Terminal state assigned by inverter's function code E22 *

Terminal state assigned by inverter's function code E23 *

Terminal state assigned by inverter's function code E24 *

Terminal command assigned by inverter's function code E27 *

function

RXC Monitoring This signal is turned ON when turning the "Monitor command" (RYC)

ON has caused the inverter to store monitored values into remote

registers RWr0, 1, 4 to 7.

1

1

1

1

1

1

Turning the "Monitor command" (RYC) OFF turns this signal OFF.

RXD Frequency setting /

Torque setting

completed

This signal is turned ON when turning the "Frequency command /

Torque command" (RYD) ON has written the reference frequency /

torque command into the inverter.

Turning the "Frequency command / Torque command" (RYD) OFF

turns this signal OFF.

RXE Not used. -RXF Command code

execution completed

This signal is turned ON when turning the "Command code execution

request" (RYF) ON has completed the execution of processing

corresponding to command codes (specified in RWw2, 10, 12, 14, 16,

and 18).

Turning the "Command execution request" (RYF) OFF turns this signal

OFF.

RX1A Alarm state flag This signal is turned ON when the inverter has tripped.

RX1B Remote station

ready

This signal is turned ON when powering on the inverter or resetting the

hardware has readied the inverter. (This signal is used for interlocking

with reading or writing from/to the master unit.)

This signal is turned OFF concurrently when the "Alarm state flag"

(RX1A) is turned ON if the inverter trips.

*1For details about inverter's function codes E20 to E24 and E27, refer to the FRENIC-MEGA Instruction

Manual, Chapter 5 "FUNCTION CODES."

16

Page 20

7.2 Remote Registers

(1) Remote registers RWw (Master Inverter)

Device No. Signal name Description Remarks

RWw0 Monitor code 2/

Monitor code 1

RWw1 Reference

frequency /

Torque command

RWw2 Command code

Write the codes (listed in Table 7.1) of monitor

items to be referred to, into RWw0. After that,

turning the RYC ON stores the value of those

monitor items into RWr0 and RWr1.

Write the reference frequency into RWw1. After

that, turning the RYD ON sets up that frequency

to the inverter. After completion of frequency

setting, the RXD is turned ON.

If torque command is activated by the function

code H18, torque command is written instead of

reference frequency.

In detail, refer to the remarks of “RWwC”.

Write one of command codes (listed in Table 7.2)

into RWw2, which are required for execution of

the following: writing/reading of operation

methods (run command sources) and inverter's

function codes, referring to the alarm history,

alarm resetting, etc.

The lower and upper

bytes correspond to

monitor codes 1 and

2, respectively.

Unit: 0.01 Hz

Unit: 0.01%

Effective only the

case y98=1, 3.

In case o30=3, 4 (4X

/ 8X setting of

CC-Link extension),

only frequency can

be set with RWw1.

The command code

format for specifying

inverter's function

codes is shown in

Table 7.4.

After writing of a command code, turning the RYF

ON executes that command.

Upon completion of the execution, the RXF is

turned ON.

RWw3 Write data

RWw4 Monitor code 3

RWw5 Monitor code 4

RWw6 Monitor code 5

RWw7 Monitor code 6

RWw8 Alarm history Write 0000, 0100, 0200, or 0300 into RWw8 to

RWw9

RWwA Not used. --

PID set value

(SV)

Write object data specified in RWw2, into

RWw3, if necessary.

After writing into RWw2 and RWw3, turn the

RYF ON.

If no write data is required, zero (0) should be

written into RWw3.

Write the code (listed in Table 7.1) of monitor

item to be referred to, into the corresponding

register (RWwn). After that, turning the RYC ON

stores the data of the monitor item into the

RWrn.

("n" denotes any of the corresponding register

numbers 4 to 7.)

specify which alarm code--latest, last, 2nd last, or

3rd last--should be read out, respectively.

(The lower 8 bits are fixed to 00H.)

The content of the specified alarm code and its

related information are stored in RWr8, 9, A, B,

and C.

Write the PID set value into RWw9.

The setting range is from -100.00% to 100.00%.

Latest: 0000

Last: 0100

2nd last: 0200

3rd last: 0300

Unit: 0.01%

RWwB Not used. --

17

Page 21

Device No. Signal name Description Remarks

RWwC Torque command Specify torque command (or torque current

command). By turning RYD ON after setting this

register, torque command (or torque current

command) is written into the inverter.

Completing the writing turns RXD ON.

RWw10 Command code 2 Use these registers in the same way as RWw2.

RWw12 Command code 3

RWw14 Command code 4

RWw16 Command code 5

RWw18 Command code 6

After writing into these registers, turning the RYF

ON executes these command codes in the order

of RWw2, 10, 12, 14, 16, and 18.

Upon completion of execution of RWw18, the RXF

is turned ON.

To nullify the execution of RWw10 to 18, FFFF

H

should be written into these registers.

RWw11 Write data 2 Write object data specified in RWw10, 12, 14, 16,

RWw13 Write data 3

RWw15 Write data 4

RWw17 Write data 5

RWw19 Write data 6

and 18, if necessary, into RWw11, 13, 15, 17, and

19, respectively.

After writing into RWw10, 12, 14, 16, and 18 and

their respective registers RWw11, 13, 15, 17, and

19, the RYF should be turned ON.

If no write data is required, zero (0) should be

written into each of RWw11, 13, 15, 17, and 19.

Unit: 0.01%

In case of torque

command, the

data of RWwC is

written into S02,

and in case of

torque current

command, the

data of RWwC is

written into S03.

(Refer to

Figure.7.1)

Effective only the

case y98=1, 3.

CC-Link extension

In CC-Link version 1.10, RWw0 to RWw3 are available.

In CC-Link version 2.00,

with 2X setting, RWw0 to RWw7 are available

with 4X setting, RWw0 to RWwF (RWw9 for this communications card) are available

with 8X setting, RWw0 to RWw1F (RWw19 for this communications card) are available.

Figure 7.1 T

18

Page 22

(2) Remote registers RWr (Inverter Master)

Device No. Signal name Description Remarks

RWr0 Monitored value 1 Turning the RYC ON stores the value of the monitor

item specified by "Monitor code 1" (RWw0), into

RWr0.

RWr1 Monitored value 2 Turning the RYC ON stores the value of the monitor

item specified by "Monitor code 2" (RWw0), into

RWr1.

RWr2 Response code Turning the RYF ON stores the response code for

the command code specified in RWw2, into RWr2.

If the command code has normally executed, zero

(0) is automatically written into RWr2; if any error

has occurred during processing of the command

code, any value other than zero is written.

RWr3 Read data If the command code has normally executed, the

response data for that command (specified by the

command code) is automatically written into RWr3.

See Table 7.3 for

response codes.

RWr4 Monitored value 3

RWr5 Monitored value 4

RWr6 Monitored value 5

Turning the RYC ON stores the value of the

monitor item specified by RWwn, into the

corresponding RWrn.

("n" denotes any of the register numbers 4 to 7.)

RWr7 Monitored value 6

RWr8 Alarm code The content of the alarm code specified in RWw8

is automatically written into the lower 8 bits of

RWr8. The upper 8 bits of RWw8 will be echoed

back into the upper 8 bits of RWr8.

RWr9 Output frequency

at an alarm

occurrence

RWrA Output current at

an alarm

occurrence

RWrB Output voltage at

an alarm

occurrence

RWrC Cumulative

power-ON time at

an alarm

This register stores the output frequency applied

at the occurrence time of the alarm specified in

RWw8.

This register stores the output current applied at

the occurrence time of the alarm specified in

RWw8.

This register stores the output voltage applied at

the occurrence time of the alarm specified in

RWw8.

This register stores the cumulative power-ON time

elapsed until the occurrence time of the alarm

specified in RWw8.

occurrence

RWr10 Response code 2 Turning the RYF ON stores the response code to

RWr12 Response code 3

RWr14 Response code 4

RWr16 Response code 5

the command code specified in RWw10, 12, 14,

16, and 18, into RWr10, 12, 14, 16, and 18,

respectively.

If the command code has normally executed, zero

(0) is automatically written into the corresponding

RWr18 Response code 6

register (RWr10, 12,14, 16, or 18); if any error has

occurred during processing of the command code,

any value other than zero is written.

RWr11 Read data 2

RWr13 Read data 3

RWr15 Read data 4

If the command code specified in RWw10, 12, 14,

16, or 18 has normally executed, the response

data for that command code is automatically

written into RWr11, 13, 15, 17, or 19, respectively.

RWr17 Read data 5

RWr19 Read data 6

See Chapter 9 for

alarm codes.

Unit: 0.01 Hz

*1

Unit: 0.1 V

Unit: 1h

See Table 7.3 for

response codes.

19

Page 23

CC-Link extension

In CC-Link version 1.10, RWr0 to RWr3 are available.

In CC-Link version 2.00,

with 2X setting, RWr0 to RWr7 are available

with 4X setting, RWr0 to RWrF (RWrC for this communications card) are available

with 8X setting, RWr0 to RWr1F (RWr19 for this communications card) are available.

*1 Unit: 0.01A for 55 kW or below, 0.1 A for 75 kW or above

20

Page 24

7.3 List of Monitor Item Codes

Table 7.1 lists the monitor item codes available in RWw0, 4 to 7.

Table 7.1 Monitor Item Codes

Code Monitor item Unit Remarks

00H No monitoring (Fixed to 0) --

01H Output frequency 0.01 Hz

02H Output current 0.01 A/0.1 A *3

03H Output voltage 0.1 V

04H No monitoring (Fixed to 0) --

05H Reference frequency 0.01 Hz

06H Motor speed 1 r/min

07H Calculated torque 0.1%

08H DC link bus voltage 0.1 V In units of 1 V

09Hto 0CH No monitoring (Fixed to 0) --

0DH Input power 0.01 kW/0.1 kW *3

0EH Motor output 0.01 kW/0.1 kW *3

0FH Input terminal status -- *1

10H Output terminate status -- *2

11H Load factor

0.1%

12H to 13H No monitoring (Fixed to 0) --

14H Cumulative run time 1 hr

15H to 16H No monitoring (Fixed to 0) --

17H Cumulative motor run time 1 hr

18

H

Current output from the inverter in

RMS (based on the inverter rating)

0.1%

19H Input watt-hour 1 kWhr

1AH No monitoring (Fixed to 0) --

20H Torque command 0.1%

21H Torque current command 0.1%

22H to 33H No monitoring (Fixed to 0) --

34H PID command 0.1%

35H PID feedback 0.1%

36H PID deviation 0.1%

37H to 39H No monitoring (Fixed to 0) --

3A

H

Input terminal state of digital input

interface card

--

3BH No monitoring (Fixed to 0) --

3C

H

Output terminal state of digital output

interface card

--

3DHor greater No monitoring (Fixed to 0) --

Assuming the motor rated

load as 100%

Assuming the inverter rated

current as 100%

*1 The format of the input terminal status signal is shown below. Individual bits denote the ON/OFF states of

input terminals on the actual control circuit terminal board. If terminals X1 through X9 are turned ON or OFF

by remote outputs RY2 to RYB, the change of the ON/OFF states cannot be reflected on this monitor.

b15 b8 b7 b0

XR XF - EN X9 X8 X7 X6 X5 X4 X3 X2 X1 REV FWD

- Empty (Fixed to 0)

X8, X9, EN : These terminals are not provided in some types of the FRENIC-MEGA. For

details, refer to the FRENIC-MEGA Instruction Manual, Chapter 5 "FUNCTION

CODES."

Figure 7.1 Input Terminal Status Signal Format

21

Page 25

*2 The format of the output terminal status signal is shown below. Individual bits denote the ON/OFF states of

output terminals on the control circuit terminal block. Their states are changed in synchronization with

remote inputs RX2 to RY7.

b15 b8 b7 b0

- - - - - - - 30 - - - Y5 Y4 Y3 Y2 Y1

- Empty (Fixed to 0)

Figure 7.2 Output Terminal Status Signal Format

*3 In units of 0.01 A or 0.01 kW for inverters with 55 kW or below, 0.1 A or 0.1 kW for ones with 75 kW or

above.

22

Page 26

7.4 Command Codes and Response Codes

Table 7.2 lists the command codes available in remote registers RWw2, 10, 12, 14, 16, and 18. The response

codes (to be stored in RWr2, 10, 12, 14, 16, and 18) to those command codes are listed in Table 7.3.

The format of command codes in reading or writing from/to the inverter's function codes is shown in Table 7.4.

Table 7.2 Command Codes

Item Code number Description Remarks

Read from function

code

Write to function

code

Read from operation

method (run

command source)

Write to operation

method (run

command source)

Read from the latest

and last alarm codes

Read from the 2nd

and 3rd last alarm

codes

Read reference

frequency

Write reference

frequency

Clear alarm history 00F4H 9696H: Clears alarm history.

Reset alarm 00FDH 9696H: Resets tripped state.

0000H to 1163HReads or writes data from/to

inverter's function codes.

0080H to 11E3

H

007BH 0000H: Link operation (CC-Link)

0001H: Terminal command for

external drive

0002H: Keypad operation

0003H: Others

00FBH 0000H: Link operation (CC-Link)

0001H: Terminal command for

external drive

0002H: Keypad operation

0074

Reads the content of the latest

H

and last alarm codes.

0075

Reads the content of the 2nd

H

and 3rd last alarm codes.

006D

Reads out the reference

H

frequency via CC-Link.

00ED

Writes the reference frequency.

H

(This frequency is effective only

when the frequency command

source is CC-Link.)

Inverter's function codes should be

specified in the format shown in

Table 7.4.

Change to y98=3

Change to y98=0 and F02=1

Change to y98=0, F02=0, and

F01=0

Lower byte: Latest alarm code

Higher byte: Last alarm code

(The contents of alarm codes are

detailed in Chapter 9.)

Lower byte: 2nd last alarm code

Higher byte: 3rd last alarm code

(The contents of alarm codes are

detailed in Chapter 9.)

The allowable setting range is from 0

to +/-20000. Specify the ratio of the

frequency relative to the maximum

frequency (defined by F03 in Hz)

being assumed as 20000.

Table 7.3 Response Codes

Code number Item Description

0000H Normal (No error) Execution of command code has been normally completed.

0001H Not allowed to write - Attempted to write to function code whose data cannot be

changed while the inverter is running.

- Attempted to write to function code whose data is being

edited from the keypad.

0002H Invalid command code An invalid command code has been specified.

0003H Out of setting range Write data is out of the allowable setting range.

23

Page 27

Table 7.4 Command Code Format for Specifying Inverter's Function Codes

(bit 15) (bit 0)

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

Empty (Fixed to 0)

Function code group

00H (=0): F codes (F00 to F99)

01H (=1): E codes (E00 to E99)

02H (=2): C codes (C00 to C99)

03H (=3): P codes (P00 to P99)

04H (=4): H codes (H00 to H99)

05H (=5): A codes (A00 to A99)

06H (=6): o codes (o00 to o99)

07H (=7): S codes S00 to S99)

08H (=8): M codes (M00 to M99)

0DH (=13): J codes (J00 to J99)

0EH (=14): y codes (y00 to y99)

0FH (=15): w codes (w00 to w99)

10H (=16): x codes (x00 to x99)

11H (=17): z codes (z00 to z99)

12H (=18): d codes (d00 to d99)

13H (=19): b codes (b00 to b99)

14H (=20): r codes (r00 to r99)

15H (=21): U codes (U00 to U99)

0: Read

1: Write

Function code number

00 to 99 (00H to 63H)

Inverter's communication dedicated function codes S01 to S03, S05, S06, and S19 are read-only.

Attempting to write to those function codes results in a "Not allowed to write" error (Response code:

0001H). These function codes are functionally equivalent to certain remote outputs and remote

registers.

(Examples)

(1) Reading from H95

Function code group: 04H, Function code number: 95 (=5FH), bit 7 = 0 (Read)

Set "045FH" to the command code

(2) Writing "10" to E20

Function code group: 01H, Function code number: 20 (=14H), bit 7 = 1 (Write)

Set "0194H" to the command code

Write data: 10 (000AH)

Set "000AH" to the write data

The data of inverter's function codes should be specified in the individual data formats. For details about

the data formats, refer to the RS-485 Communication User's Manual, Chapter 5, Section 5.2, "Data

Formats."

24

Page 28

Chapter 8 ERROR PROCESSING FOR CC-Link NETWORK BREAKS

If the inverter detects a CC-Link network break such as broken wires, it trips with an alarm by factory

default. The inverter's error processing after detection of a network break can be changed with inverter's

function codes o27 and o28 as listed in Table 8.1.

Table 8.1 Error Processing for CC-Link Network Breaks, Defined by Function Codes o27 and o28

o27 o28

0,

4 to 9

1 0.0 to 60.0 s

2 0.0 to 60.0 s

3,

13 to 15

10 Invalid

11 0.0 to 60.0 s

12 0.0 to 60.0 s

Invalid Immediately coast to a stop and trip with .

Invalid

Error Processing

after Detection of CC-Link Network Break

After the time specified by o28, coast to a stop and

trip with .

If the communications link is restored within the

time specified by o28, ignore the communications

error. If a timeout occurs, coast to a stop and trip

with .

Keep the current operation, ignoring the

communications error. (No trip)

Immediately decelerate to a stop.

Issue after stopping.

After the time specified by o28, decelerate to a

stop. Issue after stopping.

If the communications link is restored within the

time specified by o28, ignore the communications

error. If a timeout occurs, decelerate to a stop and

trip with .

Remarks

The inverter's function

code F08 specifies the

deceleration time.

Same as above.

Same as above.

In any of the following cases, the inverter does not perform error processing defined in Table 8.1 if it

detects a CC-Link network break, ignoring the occurrence of the error.

1) The CC-Link communications link has not been established once after the communications card

was turned ON.

2) Both run and frequency command sources specified are not CC-Link (that is, any of the following

three).

- Inverter's function code y98 = 0

- Terminal command LE is assigned to a terminal X and the LE is OFF.

- Inverter's function code y99 = 3, or y99 data = y98 data.

25

Page 29

Chapter 9 LIST OF INVERTER ALARM CODES

Through CC-Link, the master can monitor the information on alarms (in Table 9.1) that have occurred in the

inverter, by using the following procedure.

(1) Specify which alarm code--latest, last, 2nd last, or 3rd last--should be read out, into the remote register

RWw8. (The alarm code will be stored in RWr8.)

(2) Specify command codes 0074H and 0075H (in remote registers RWw2, 10, 12, 14, 16, or 18) to read out

alarm codes.

(3) Use inverter's communication dedicated function codes M16 to M19 to read out the latest, last, 2nd last, and

3rd last alarm codes, respectively.

Table 9.1 List of Inverter Alarm Codes

Alarm

code

0 (00H)

1 (01H)

2 (02H)

No alarm --- 31 (1F

Overcurrent

(during acceleration)

Overcurrent

(during deceleration)

Description

Overcurrent

3 (03H)

(During running at constant

speed)

5 (05H) Grounding fault 35 (23H)

6 (06H)

7 (07H)

Overvoltage

(during acceleration)

Overvoltage

(during deceleration)

Overvoltage

8 (08H)

(during running at constant

speed or stopped)

10 (0AH) Undervoltage 44 (2CH) Overload of motor 3

11 (0BH) Input phase loss 45 (2DH) Overload of motor 4

Alarm

code

) Memory error

H

32 (20H) Keypad communications error

33 (21H) CPU error

Description

Option communications error

34 (22H)

(Communications card

hardware error)

Option error

(CC-Link communications error)

36 (24H) Operation protection

37 (25H) Tuning error

38 (26H)

RS-485 communications error

(COM port 1)

14 (0EH) Fuse blown 46 (2EH) Output phase loss

16 (10H) Charger circuit fault 47 (2FH)

17 (11H) Heat sink overheat 51 (33H)

18 (12H) External alarm 53 (35H)

19 (13H) Inverter internal overheat 54 (36H) Hardware error

20 (14H)

22 (16H) Braking resistor overheat 57 (39

23 (17H) Overload of motor 1 58 (3A

24 (18H) Overload of motor 2 59 (3B

25 (19H) Inverter overload 254 (FE

27 (1BH) Overspeed

28 (1CH) PG wire break

29 (1DH) NTC thermistor wire break

Motor protection

(PTC/NTC thermistor)

56 (38H)

Speed mismatch

(Excessive speed deviation)

Data saving error during

undervoltage

RS-485 communications error

(COM port 2)

Positioning control error

) EN circuit failure

H

) PID feedback wire break

H

) Braking transistor broken

H

) Mock alarm

H

26

Page 30

Chapter 10 APPLICATION PROGRAM EXAMPLES

10.1 System Configuration

Station #1 Station #2

PLC

Power

supply

Q61P -A1

Insert the terminating resistor that comes

with the master unit between DA and DB.

CPU

Q02CPU

CC-Link

master unit

QJ61BT11N

Input

X20

unit

CC-Link o31=1

Figure 10.1 System Configuration

FRENIC-MEGA

OPC-G1-CCL

FRENIC-MEGA

OPC-G1-CCL

( Set the

terminating

resistor switch

to ON)

o31=2

10.2 Network Parameter Settings

In program examples given in this chapter, the network parameters of the master unit are set as listed in Table

10.1.

Table 10.1 Network Parameter Settings of the Master Unit

Parameter Settings

Start I/O No. 0000

For units where a data link

Operation settings

error is detected

At the time of CPU stop Refresh

Type Master unit

Mode Remote Net Ver. 1 mode

Total number of slaves connected 2

Remote input (RX) X1000

Remote output (RY) Y1000

Remote register (RWr) W0

Remote register (RWw) W100

Special relay (SB) SB0

Special register (SW) SW0

Retry count 3

Automatic reconnection station count 1

For CPU down Stop

Scan mode Asynchronous

Clear input

27

Page 31

10.3 Relationship between Master Station Device and Remote I/O and Remote Register

(1) Remote I/Os

Figure 10.2 shows the relationship between the master station devices and remote I/Os (RX and RY) in the

program examples given on the following pages.

Master station Remote station Remote station

(Station #1) (Station #2)

X100F to X1000 RX F to RX 0

X101F to X1010 RX 1F to RX 10

X102F to X1020 RX F to RX 0

X103F to X1030 RX 1F to RX 10

X104F to X1040

X105F to X1050

Y100F to Y1000 RY F to RY 0

Y101F to Y1010 RY 1F to RY 10

Y102F to Y1020 RY F to RY 0

Y103F to Y1030 RY 1F to RY 10

Y104F to Y1040

Y105F to Y1050

Figure 10.2 Relationship between Master Station Devices and Remote I/Os

(2) Remote registers

Figure 10.3 shows the relationship between the master station devices and remote registers (RWw and RWr) in

the program examples given on the following pages.

Master station Rem ote station Rem ote station

(Station # 1) (Station #2)

W 100 RWw0

W 101 RW w1

W 102 RW w2

W 103 RW w3

W 104 RW w0

W 105 RW w1

W 106 RW w2

W 107 RW w3

W 108

W 109

W 10A

W 10B

W 000 RW r0

W 001 RW r1

W 002 RW r2

W 003 RW r3

W 004 RWr0

W 005 RWr1

W 006 RWr2

W 007 RWr3

W 008

W 009

W 00A

W 00B

Figure 10.3 Relationship between Master Station Devices and Remote Registers

28

Page 32

10.4 CC-Link Startup Program

Shown below is a CC-Link startup program example to run for ACPU.

No startup program is required for QCPU which starts up CC-Link communication with the network parameter

settings made in the master unit.

X00

Unit failure

M300

M301

M9038

One scan ON

after RUN

X00

Unit failure

M302

M303

X0F

Unit ready

X0F

Unit ready

PLS M300

SET M301

TO H0 H1 K2 K1

TO H0 H20 H1101 K1

TO H0 H21 H1102 K1

RST M301

SET Y00

PLS M302

SET M303

SET Y06 Link start request

Permission to write settings

Request to write settings

Number of units connected = 2

Station info on inverter (Station #1)

Station info on inverter (Station #2)

Writing of settings completed

Permission to bit output (If OFF, no RY

output yet.)

Permission to write settings

Request to write settings

X06

Link startup

normally

completed

X07

Link startup

abnormally

terminated

RST Y06

RST M303

FROM H0 H668 D315 K1

RST Y06

RST M303

Cancel of link start request

Link startup completed

Read link special device

Cancel of link start request

Link startup completed

Figure 10.4 CC-Link Startup Program Example (for ACPU only)

10.5 Program Example Using the Inverter Running Status Read

The program example shown below turns ON the auxiliary relay M100 when FRENIC-MEGA station #1 starts

running.

X0

X0F X1

Unit

failure

Unit

ready

M0 X1002

Inverter running (RX02)

Host station

being linked

BMOV SW80 K4MO K4

M100

Read out data link status of slave

stations

Turn ON the auxiliary relay M100

Figure 10.5 Program Example

29

Page 33

10.6 Program Example for Changing the Operation Mode

The program example shown below switches the operation mode of FRENIC-MEGA station #1 to network

operation (specifying CC-Link as both run command and frequency command sources).

X0

Unit failure

M0

M300

X0F X1

Unit

Host station

ready

being linked

X20

Writing

ON

BMOV SW80 K4M0 K4

PLS M300

SET M301

Read out data link status of slave

stations

Command code

execution

completed

M302

Command code

execution

completed

MOV H0FB W102

MOV H0 W103

SET Y100F

RST M301

SET M302

X100F

MOV W2 D2

RST Y100F

RST M302

END

Write the “Operation mode”

command code (HFB) into RWw2,

and object data (H0000) into RWw3

Turn command code execution

request (RYF) ON

When the command code execution

completed signal (RXF) is turned ON,

the response code (RWr2) is read

out into D2. (0: Reading out has

normally finished.)

Turn command code execution

request (RYF) OFF

Figure 10.6 Program Example

10.7 Program Example for Specifying Run Command

The program example shown below writes the run forward command (FWD) into FRENIC-MEGA station #1

X0

Unit failure

M0

X0F X01

Unit

Host station

ready

being linked

Run ON

BMOV SW80 K4M0 K4

Figure 10.7 Program Example

30

Y1000

END

Read out data link status of slave

stations

Run forward command (RY0)

Page 34

10.8 Program Example for Monitoring the Output Frequency

The program example shown below reads out the output frequency from FRENIC-MEGA station #1 into data

register D1.

X00

Unit

failure

M0

X0F X01

Unit

Host station

ready

being linked

X20

Writing

ON

BMOV SW80 K4M0 K4

MOV H1 W100

Y100C

Read out data link status of slave

stations

Write the monitor item code (H01) of

output frequency into RWw0

Turn monitor command (RYC) ON

X100C

MOV W0 D1

Monitoring

END

Turning RYC ON reads out the output

frequency from the remote register

(RWw0) into D1.

Figure 10.8 Program Example

10.9 Program Example for Reading from the Inverter's Function Code Data

The program example shown below reads out the F07 data (Acceleration time 1) from FRENIC-MEGA station

#1

X0

Unit failure

M300

M301 X100F

ready

M0

Command code

execution

completed

X0F X1

Unit

Host station

being linked

X20

Writing

ON

BMOV SW80 K4M0 K4

PLS M300

SET M301

MOV H7 W102

SET Y100F

RST M301

Read out data link status of slave

stations

Write the “Read F07” command code

(H07) into RWw2

Turn command code execution

request (RYF) ON

M302

Command code

execution

completed

X100F

SET M302

MOV W3 D1

MOV W2 D2

RST Y100F

RST M302

Figure 10.9 Program Example

31

END

When the command code execution

completed signal (RXF) is turned ON,

the acceleration time 1 (RWr3) and

response code (RWr2) are read out

into D1 and D2, respectively

Turn command code execution

request (RYF) OFF

Page 35

10.10 Program Example for Writing to Inverter's Function Code Data

The program example shown below writes 3.0 s to the F07 data (Acceleration time 1) of FRENIC-MEGA station

#1.

X0

X0F X1

Unit failure

M0

M300

M301 X100F

Command code

execution

completed

Unit

ready

X20

Writing

ON

Host station

being linked

BMOV SW80 K4M0 K4

PLS M300

SET M301

MOV H87 W102

MOV H12C W103

Read out data link status of slave

stations

Write the “Write F07” command code

(H87) into RWw2, and the

acceleration time (H12C) into RWw3

M302

Command code

execution

completed

X100F

SET Y100F

RST M301

SET M302

MOV W2 D2

RST Y100F

RST M302

Figure 10.10 Program Example

END

Turn command code execution

request (RYF) ON

When the command code execution

completed signal (RXF) is turned ON,

the response code is read out from

the remote register (RWr2) into D2.

(0: Writing normally completed.)

Turn command code execution

request (RYF) OFF

32

Page 36

10.11 Program Example for Setting up the Reference Frequency

The program example shown below writes the reference frequency 50.00 Hz to FRENIC-MEGA station #1.

X0

X0F X1

Unit failure

M0

M300

M301 X100D

Frequency setting

completed

Unit

ready

X20

Writing

ON

Host station

being linked

BMOV SW80 K4M0 K4

PLS M300

SET M301

MOV K5000 W101

SET Y100D

RST M301

SET M302

Read out data link status of slave

stations

Write reference frequency into RWw1

Turn the frequency command RAM

(RYD) ON

M302

X100D

Frequency setting

completed

MOV W2 D2

RST Y100D

RST M302

Figure 10.11 Program Example

END

When the frequency setting

completed signal (RXD) is turned

ON, read out the response code

(RWr2) into D2

Turn the frequency command RAM

(RYD) OFF

33

Page 37

10.12 Program Example for Reading out Alarm Codes

The program example shown below reads out alarm codes stored in FRENIC-MEGA station #1 into data

register D1.

X0

Unit failure

M0

M300

M301 X100F

Command code

execution

completed

M302

Command code

execution

completed

X0F X1

Unit

Host station

ready

being linked

X20

Writing

ON

X100F

BMOV SW80 K4M0 K4

PLS M300

SET M301

MOV H74 W102

SET Y100F

RST M301

SET M302

MOV W3 D1

MOV W2 D2

Read out data link status of slave

stations

Write the “Read from the latest and

last alarm codes” command code

(H74) into RWw2

Turn command code execution

request (RYF) ON

When the command code execution

completed signal (RXF) is turned ON,

read out alarm code (RWr3) and

response code (RWr2) into D1 and

D2, respectively

RST Y100F

RST M302

END

Turn command code execution

request (RYF) OFF

Figure 10.12 Program Example

10.13 Program Example for Resetting a Inverter Trip

The program example shown below resets a trip that has occurred in FRENIC-MEGA station #1.

X0

Unit failure

M0

X0F X01

Unit

ready

X101A X20

Alarm

status flag

Host station

being linked

Alarm

reset request ON

BMOV SW80 K4M0 K4

Y101A

END

Figure 10.13 Program Example

Read out data link status of slave

stations

Turn X20 from ON to OFF to reset

the trip

34

Page 38

r

r

Chapter 11 TROUBLESHOOTING

(1) Option communications error

(Communications card hardware error) ( )

has occurred.

Do the CC-Link

versions of the slave

and master stations

match with each other?

(master station version

1.xx, slave station

version 2.xx)

Match the versions of

NO

the master station and

the slave station with

each other.

YES

Is the option mounted

on the inverter

correctly?

YES

The option or inverter

unit may be defective.

Contact Fuji Electric.

NO

Mount the option into

place referring to this

manual.

(3) Commands via CC-Link not reflected

Commands received

via CC-Link are not

reflected.

Is the data of function

code y98 set to any

value other than “0” ?

YES

Is [LE] assigned to X

function?

NO

Is the L. ERR LED on

the option lit or

blinking?

NO

Is the setting of the

function code o30

"CC-Link extension"

correct?

NO

Correct y98 data.

YES

Turn ON the

appropriate contact.

Check the CC-Link

YES

wiring and the

sequencer CPU

settings.

NO

Match the setting of

o30 with that of the

master.

(2) Option error (CC-Link communications error)

( )

If this error occurs, analyze the cause of the erro

referring to the RAS information in the master CPU. Fo

the access to the RAS information and its contents, see

the master user’s manual.

has occurred.

Turn ON the power to

Is the power to the

master shut down? Or

is the master unit

detached?

NO

Does the detailed RAS

information in the CPU

module indicate that

an error has occurred?

NO

Is the station address

setting (o31) correct?

YES

Any of the following

wiring problems?

Wire(s) broken

Wrong connection

to the terminal block

Signal lines wired in

parallel with power line

Terminating resistor

setting

CC-Link cable not used

Maximum cable length,

inter-station cable

length, and the number

of units connected, out

of specifications

NO

YES

the master, reset the

CPU, and reset the

inverter. Operation

can be resumed.

YES

Remove the error

factor from the station

concerned and reset

the inverter.

Make the station

NO

address of o31 match

that in the system

configuration

definition.

YES

Correct the wiring.

YES

Is the command code

format for specifying

function code(s)

correct?

NO

Correct the format,

referring to the RS-485

Communication User’s

Manual, Chapter 5.

The option or inverter

unit may be defective.

Contact Fuji Electric.

YES

Is data written into the

buffer memory areas

(RX, RY, RWw, RWr)

as assigned to

addresses?

NO

Check writing to the

I/O memory areas.

YES

The option or inverter

unit may be defective.

Contact Fuji Electric.

35

Page 39

Chapter 12 SPECIFICATIONS

12.1 General Specifications

Table 12.1 lists the environmental requirements for the inverter equipped with the communications card. For the

items not covered in this section, the specifications of the inverter itself apply.

Table 12.1 Environmental Requirements

Item Specifications

Site location Indoors

Surrounding temperature Refer to the FRENIC-MEGA Instruction Manual, Chapter 2.

Relative humidity 5 to 95% (No condensation)

Atmosphere The inverter must not be exposed to dust, direct sunlight, corrosive gases,

flammable gases, oil mist, vapor or water drops.

Pollution degree 2 (IEC60664-1) (Note)

The atmosphere can contain a small amount of salt.

(0.01 mg/cm2 or less per year)

The inverter must not be subjected to sudden changes in temperature that will

cause condensation to form.

Altitude 1,000 m max.

Atmospheric pressure 86 to 106 kPa

Vibration Refer to the FRENIC-MEGA Instruction Manual, Chapter 2.

Applicable inverters FRENIC-MEGA series of inverters, ROM Ver. 0500 or later

(Note) Do not install the inverter in an environment where it may be exposed to lint, cotton waste or moist dust or dirt

which will clog the heat sink of the inverter. If the inverter is to be used in such an environment, install it in a

dustproof panel of your system.

12.2 CC-Link Specifications

Table 12.2 lists the CC-Link specifications for this communications card. For the items not covered in this

section, the specifications of the CC-Link apply.

Table 12.2 CC-Link Specifications

Item Specifications

Name CC-Link communications card

Station type Remote device station

Number of units

connectable

Number of stations

occupied

CC-Link version

Terminal block for

connection

Communications cable

Max. 42 units (one station occupied per unit)

1

The communications card complies with CC-Link versions 1.10 and 2.00. It can

be configured with the function code o30 as follows:

1 station occupied (CC-Link version 1.10): o30 = 0 or 1

1 station occupied with 2X setting (CC-Link version 2.00): o30 = 2

1 station occupied with 4X setting (CC-Link version 2.00): o30 = 3

1 station occupied with 8X setting (CC-Link version 2.00): o30 = 4

Setting invalid: o30 = Other than the above data

5-pin terminal block (M3×5 screws)

CC-Link dedicated cable

- Use the CC-Link dedicated cable in CC-Link system.

- Using a cable other than a CC-Link dedicated cable does not assure the

CC-Link system performance.

- For further information about the CC-Link dedicated cable specifications and

inquiries, visit the CC-Link Partner Association's website at:

http://www.cc-link.org/eng/t_html/top.html

36

Page 40

Table 12.2 CC-Link Specifications (Continued)

Item Specifications

Station address 1 to 64. The station address can be specified with the inverter's function code o31.

Transmission speed

(Baud rate)

LED status indicators

10 Mbps (o32 = 4), 5 Mbps (o32 = 3), 2.5 Mbps (o32 = 2), 625 kbps (o32 = 1),

156 kbps (o32 = 0)

The transmission speed can be specified with the inverter's function code o32.

L.RUN: Lights when the communications card is normally receiving refresh data.

It goes off if data transmission is interrupted for a certain period of time.

L.ERR: Lights when a communications error has occurred. It blinks if the station

address (o31) or the transmission speed (o32) is changed when the

power is on.

RUN: Lights during normal communication. It blinks when mismatch in CC-Link

version settings is found or the connection between the inverter and the

communications card is cut.

SD: Lights during data transmission.

RD: Lights during data reception.

37

Page 41

38

Page 42

CC-Link Communications Card

"OPC-G1-CCL"

Instruction Manual

First Edition, June 2008

Fifth Edition, April 2011

Fuji Electric Co., Ltd.

The purpose of this manual is to provide accurate information in the handling, setting up and operating of the

CC-Link Communications Card for the FRENIC-MEGA series of inverters. Please feel free to send your

comments regarding any errors or omissions you may have found, or any suggestions you may have for

generally improving the manual.

In no event will Fuji Electric Co., Ltd. be liable for any direct or indirect damages resulting from the application of

the information in this manual.

Page 43

URL http://www.fujielectric.co.jp/

Fuji Electric Co., Ltd.

Gate City Ohsaki, East Tower, 11-2, Osaki 1-chome,

Shinagawa-ku, Tokyo, 141-0032, Japan

Phone: +81 3 5435 7283 Fax: +81 3 5435 7425

URL http://www.fujielectric.com/

2011-04 (D11d/F08) 1CM

Loading...

Loading...