Page 1

Instruction Manual

LONWORKS® Interface Card "OPC-F1-LNW"

Thank you for purchasing our LONWORKS Interface Card OPC-F1-LNW.

• This product is designed to connect the FRENIC-Eco series of inverters to LONWORKS.

Read through this instruction manual and be familiar with the handling procedure for correct

use.

• Improper handling blocks correct operation or causes a short life or failure.

• Deliver this manual to the end user of the product. The end user should keep this manual in a

safe place until the LONWORKS Interface Card is discarded.

• For the usage of inverters, refer to the instruction manual prepared for the FRENIC-Eco series

of inverters.

Fuji Electric Systems Co., Ltd. INR-SI47-1071a-EU REV 052010

Page 2

Copyright © 2005 Fuji Electric FA Components & Systems Co., Ltd.

All rights reserved.

No part of this publication may be reproduced or copied without prior written permission from Fuji Electric FA Components & Systems Co.,

Ltd.

LONWORKS, LonTalk, and LonMaker are registered trademarks of Echelon Corporation in the United States.

All other product and company names mentioned in this manual are trademarks or registered trademarks of their respective holders.

The information contained herein is subject to change without prior notice for improvement.

Page 3

Preface

Thank you for purchasing our LONWORKS Interface Card OPC-F1-LNW.

Installing this card on your FRENIC-Eco makes it possible from other LONWORKS devices in the network to issue run and speed

commands and monitor the inverter running status, using LONWORKS parameters. It also enables modification and monitoring of the

inverter configuration as well as writing to and reading from the inverter's function codes.

How this manual is organized

This manual is made up of chapters 1 through 10.

Chapter 1 Features

Gives an overview of the main features of the LONWORKS interface card.

Chapter 2 Acceptance Inspection

Lists points to be checked upon delivery of the card and precautions for transportation and storage of the card. Also this chapter

presents the appearance of the card and provides information on how to obtain an XIF file and LNS plug-in.

Chapter 3 Basic Functions

Provides instructions on how to use the service button and status indicator LEDs.

Chapter 4 Installation

Provides instructions and precautions for installing the card.

Chapter 5 Wiring

Provides wiring instructions around the terminal blocks on the card and the cable specifications.

Chapter 6 Function Code Settings Required f or LONW ORKS Com muni cation

Describes the inverter's function codes to be set for receiving run and frequency commands via LONWORKS network. It also lists the

related function codes.

Chapter 7 Objects

Describes the objects supported by the card and their network variables (NV) and configuration properties (CP).

Chapter 8 Inverter Reaction to LONWORKS Communications Errors

Describes on how the inverter operates if a LONWORKS communications error occurs.

Chapter 9 Troubleshooting

Provides troubleshooting instructions for certain problems, e.g., when the inverter does not operate as ordered or when an alarm

condition has been recognized.

Chapter 10 Specifications

Lists the general specifications and communications specifications.

1

Page 4

Icons

The following icons are used throughout this manual.

This icon indicates information which, if not heeded, can result in the product not operating to full efficiency, as well as

information concerning incorrect operations and settings which can result in accidents.

This icon indicates information that can prove handy when performing certain settings or operations.

This icon indicates a reference to more detailed information.

Table of Contents

Preface. 1

How this manual is organized .................................................1

Chapter 1 ........................................................... 3 Features

Chapter 2 ..................................... 3 Acceptance Inspection

Chapter 3 ................................................ 4 Basic Functions

3.1 .................................................. 4 Service Button

3.2 ....................................... 4 Status Indicator LEDs

3.3 ................................................ 4 Terminal Blocks

3.4 .................................................. 4 Barcode Label

Chapter 4 ........................................................ 5 Installation

Chapter 5 ............................................................... 6 Wiring

Chapter 6 Function Code Settings

Required for LONWORKS

Communication ................................................................. 7

Chapter 7 ................................................... 9 Object Details

7.1 .......................................................... 9 Overview

7.2 ..................................................... 9 Node Object

7.3 .....................................................11 VSD Object

7.4 VSD Object Input Network

Variables............................................................... 19

7.5 VSD Object Output Network

Variables............................................................... 23

7.6 Reading and Writing from/to

Inverter's Function Codes ..................................... 27

7.7

VSD Object Configuration Properties

)

.............................................................. 29

(CPs

Chapter 8 .......Inverter Reaction to LONWORKS

Communications Errors .................................. 31

8.1 Specifying an Inverter Reaction to

LONWORKS Communications Errors ................... 31

Chapter 9 ............................................. 32 Troubleshooting

Chapter 10 Specifications ............................................... 33

10.1 General Specifications .................................. 33

10.2 Communications

Specifications........................................................ 33

2

Page 5

Chapter 1 Features

k

k

The LONWORKS interface card has the following features:

- Baud rate : 78 kbps

- Profile : Variable Speed Motor Drive Functional Profile Version 1.1 compliant

- Network topology : Free topology (Bus, Star, Loop and Hybrid)

- Network variables (NVs) : 62 in total

- Able to read and write all function codes supported in FRENIC-Eco

- Supports LNS plug-ins available on LonMaker network, enabling easy configuration and monitoring

IMPORTANT

After commissioning of this card, be sure to restart the inverter or reset it with a LONWORKS integration tool (e.g., LonMaker). Until

it is done, the changes made for network variables (NVs) or configuration properties (CPs) will not be validated on the inverter.

Chapter 2 Acceptance Inspection

Unpack the package and check that:

(1) A LONWORKS interface card is contained in the package.

(2) The card has not been damaged during transportation--no defective electronic devices, dents, or warp.

(3) The model name "OPC-F1-LNW" is printed on the card. (See Figure 1.)

(4) A barcode label (representing Neuron ID) is attached to the card. Another barcode label (not attached to the card) comes with the card.

If you suspect the product is not working properly or if you have any questions about your product, contact your Fuji Electric representative.

This card is applicable to all FRENIC-Eco series of inverters and all software versions.

- None of an XIF file, resource file, and LNS plug-in comes with the LONWORKS interface card.

These files can be downloaded for free (registration required) from our website at:

http://web1.fujielectric.co.jp/Kiki-Info-EN/User/index.html

(Fuji Electric FA Components & Systems Co., Ltd. Technical Information)

- A LONWORKS integration tool does not come with the card. Get the one separately. The recommended tool is Echelon LonMaker.

- The Neuron ID is printed on the barcode label. The barcode symbology is Code 39.

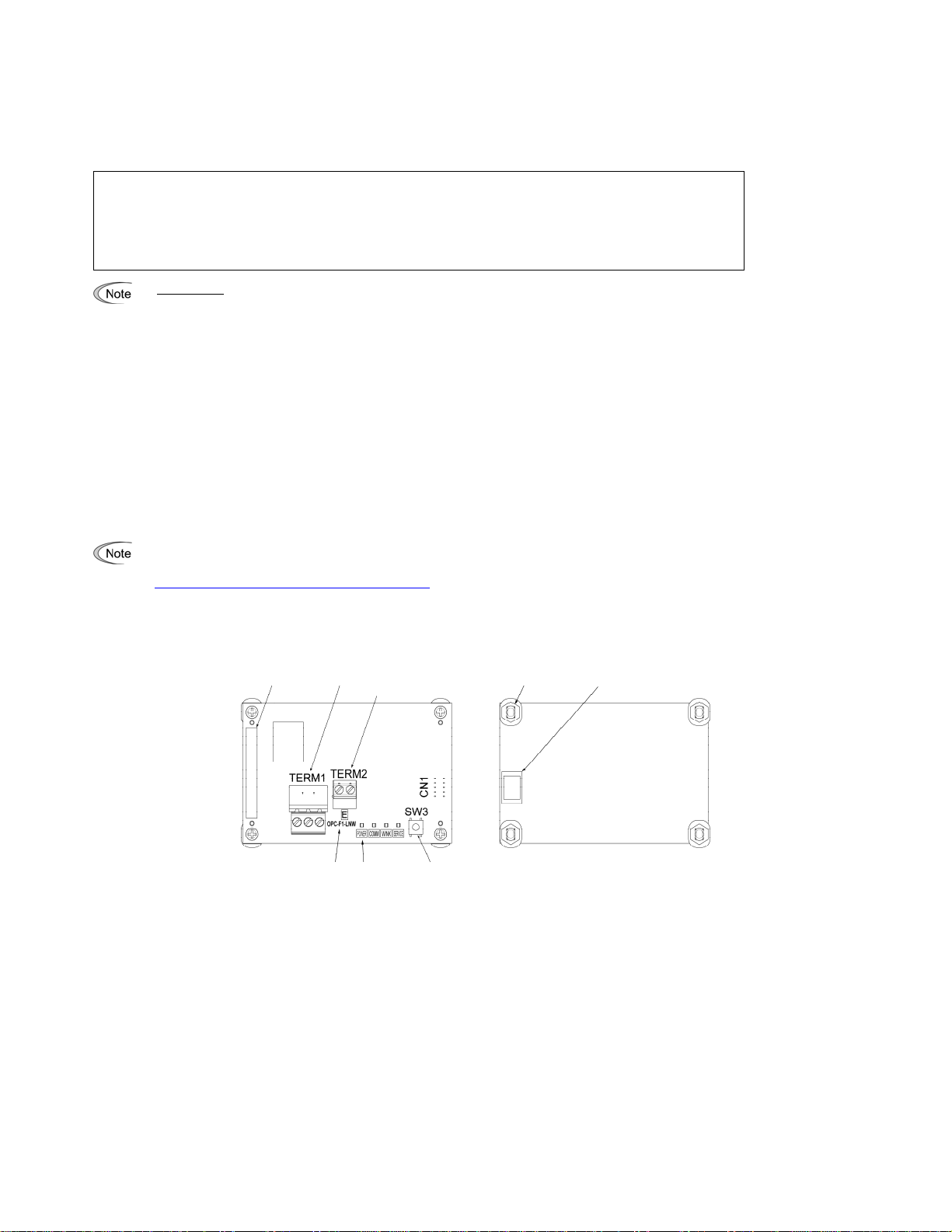

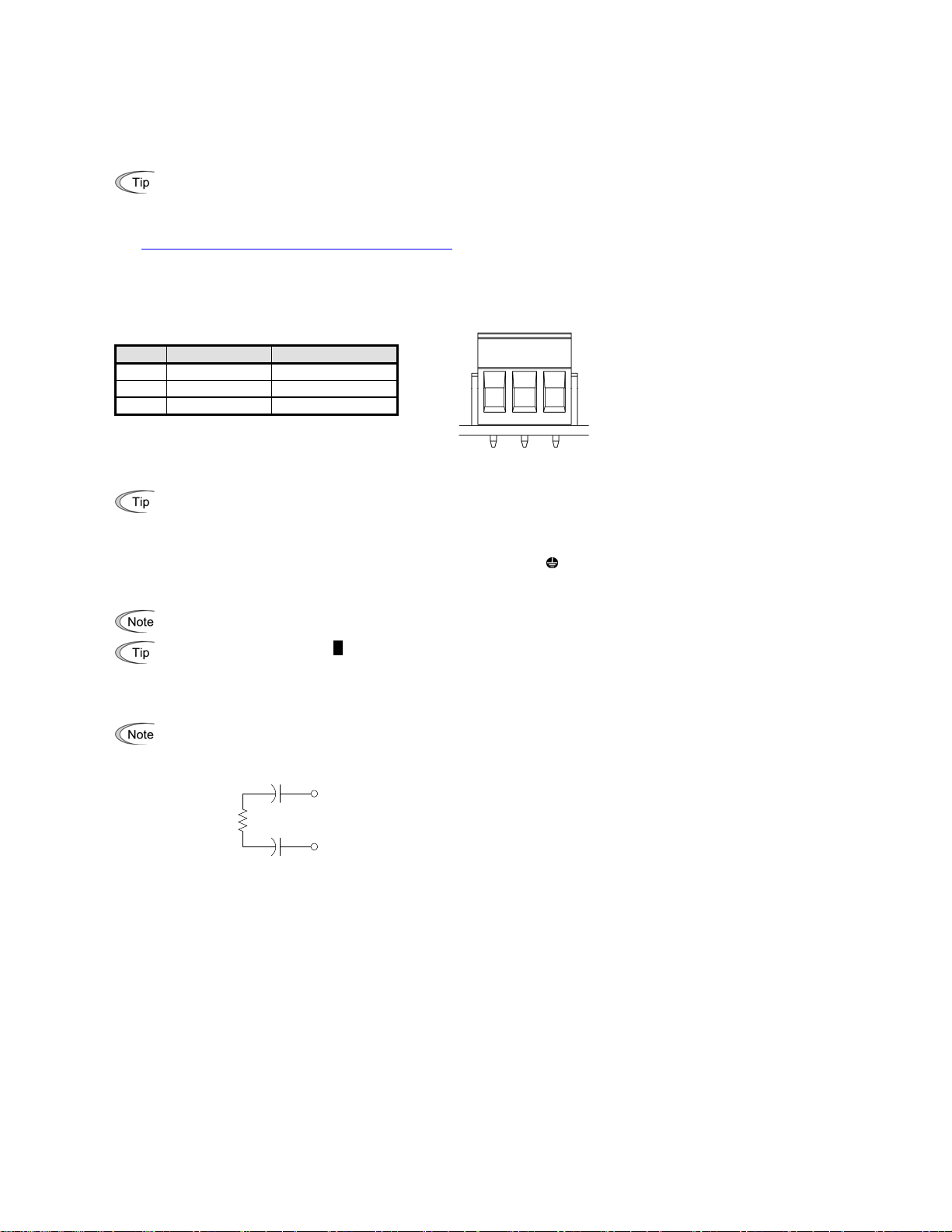

Barcode label

(Neuron ID)

LON

WORKS terminal bloc

Ground terminal bloc

4 sp

acers

CN1

Model name

Status indicator

LEDs

Serv

ice button

Figure

1 Front of the Card Figure 2 Back of the Card

3

Page 6

Chapter 3 Basic Functions

3.1 Service Button

The service button is used to commission the LONWORKS interface card to the network. Pressing the button outputs the Neuron ID to the network.

Setting inverter's function code o30 to "1" is functionally equivalent to the depression of the service button. The function code enables commission from

e keypad so as not to require removing the inverter cover, making it safe and convenient. th

When pressing the service button, take extra care not to touch the inverter high-voltage section. Setting inverter's function code o30 to "1" is functionally

equivalent to the depression of the service button, so using the function code is recommended for safety.

Electric shock could occur.

3.2 Status Indicator LEDs

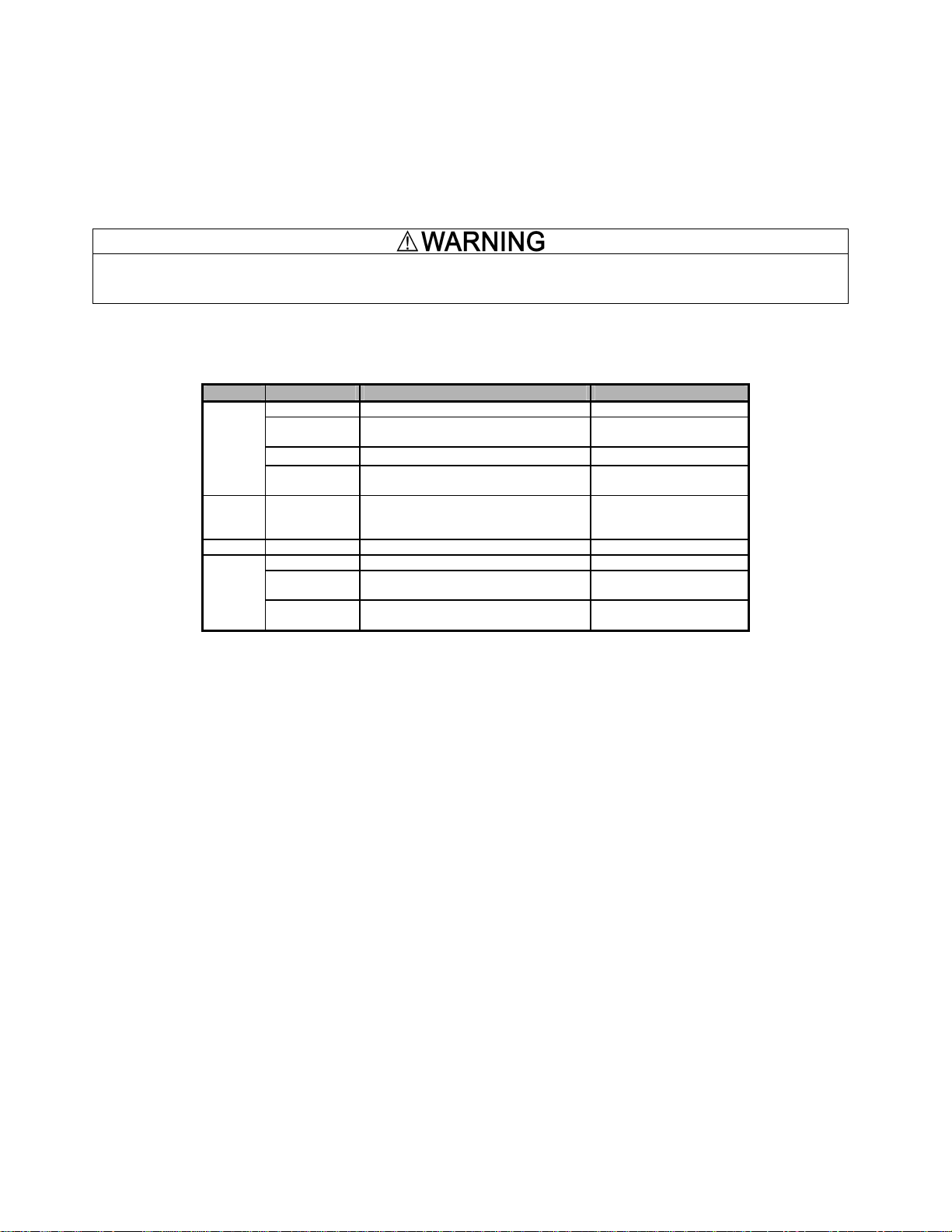

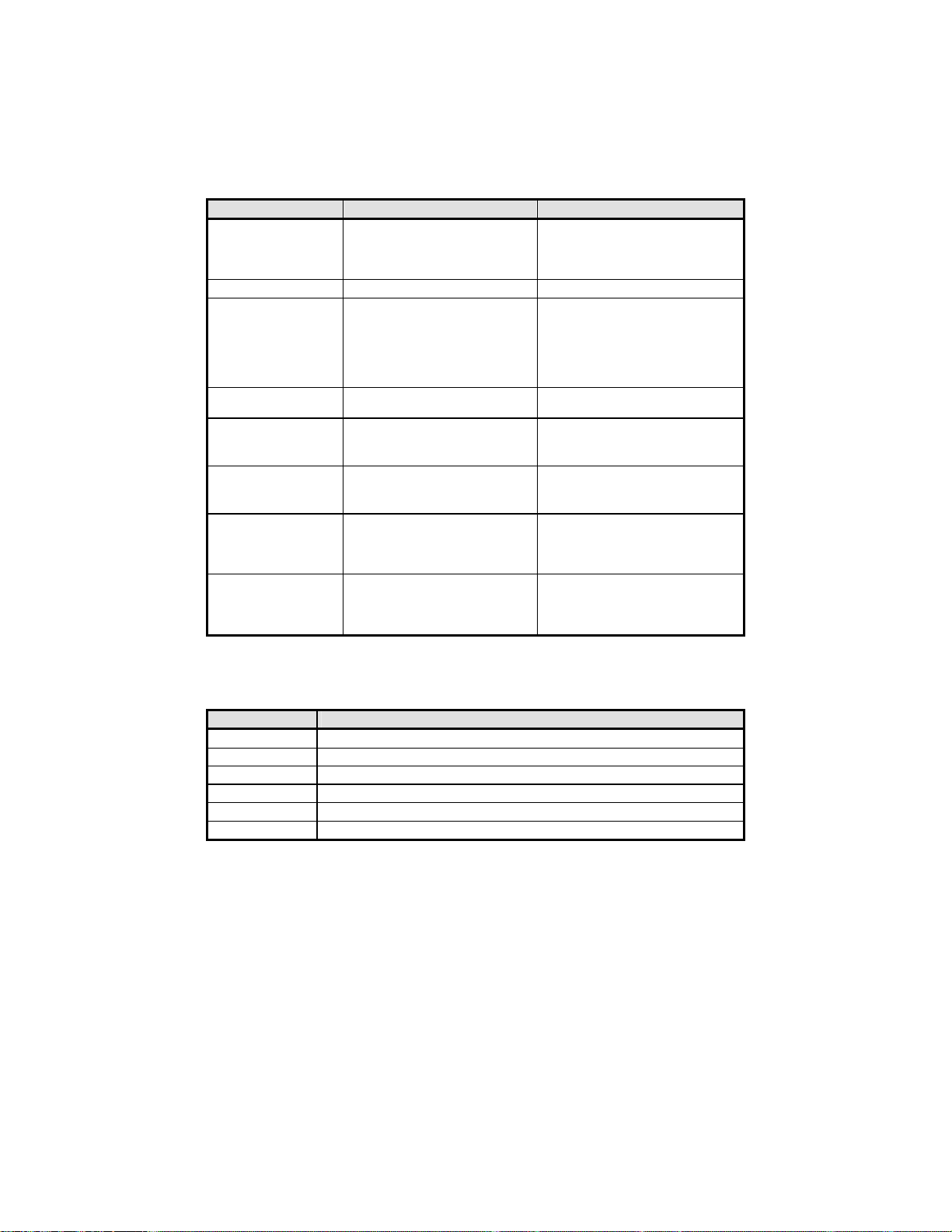

The four status indicator LEDs show the status of the card as listed below.

Table 1 LED Status

Name Color Meaning Note

Lights in green Normal --

POWER

COMM Lights in green

WINK Blinks in green WINK message received Blinking 6 times.

SERVICE

1

*

Configuration for ignoring er5 is possible. For details, refer to Chapter 8, Section 8.1 "Specifying an Inverter Reaction to LONWORKS Communications

Errors."

Blinks in green

Blinks in red LONWORKS communications error

Lights in red

Lights in green Service button being pressed --

Blinks in green Unconfigured

Off Configured

Self-diagnostic test running or initialization in

progress during powering on sequence

Hardware error

(Card not properly installed or card faulty)

Occurrence of LONWORKS

communications event*2

This test takes approx. 0.5

second.

The inverter shows er5. *

The inverter shows er4.

The change of an output NV

value lights this LED even if

the cable is not connected.

Including uncommissioned

state

Including commissioned

state.

1

*2 Upon completion of initialization of the card after the power is turned on, an event that outputs all output network variables supported by this card

occurs in order to tell the latest inverter information to the network. Since this event occurs independent of the cable connection/disconnection,

binding/unbinding, and commissioned/not commissioned, it lights the COMM LED. The delay time from the occurrence of the event to the output of the

output network variables can be adjusted with the VSD object, UCPT_SendDelayAfterDevRdy.

For details about UCPT_SendDelayAfterDevRdy, refer to Section 7.3.3 "List of VSD object configuration properties (CPs)."

3.3 Terminal Blocks

The card ha

For wirings, refer to Chapter 5 "Wiring."

3.4 Barcode Label

The Neuron ID a

string and barcode. The barcode symbology is Code 39. One more barcode label comes with the card for application to a network drawing, etc.

s two terminal blocks: LONWORKS and ground.

ssigned to the Neuron chip mounted on the card is printed on the barcode label pasted on the card in both human-readable character

4

Page 7

Chapter 4 Installation

Turn the power off and wait for at least five minutes for inverters of 40 HP or below, or ten minutes for inverters of 50 HP or above, before starting

installation. Further, check that the LED monitor and charge lamp are unlit, and check the DC link circuit voltage between the P (+) and N (-) terminals to

be lower than 25 VDC.

Otherwise, electric shock could occur.

Do not touch any metallic part of the connector for the main unit (CN1) or any electronic component. Otherwise, electronic components may be

damaged by static electricity charged in your body. Also, the stain or adhesion of sweat or dust may adversely affect the contact reliability of the

connector in the long run.

An accident could occur.

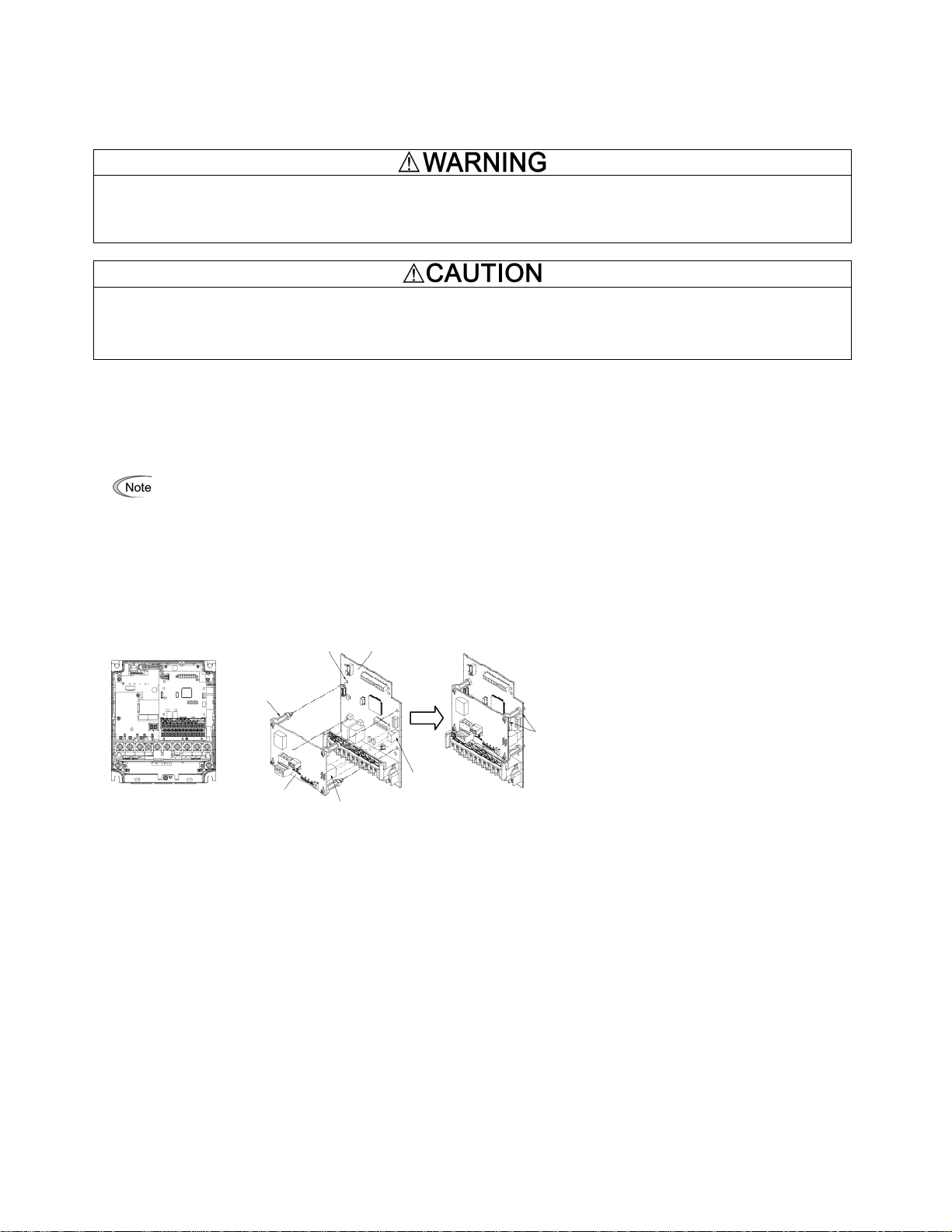

(1) Remove the covers from the inverter to expose the control printed circuit (Figure 3).

For the removal instructions, refer to the FRENIC-Eco Instruction Manual (INR-SI47-1225-E), Chapter 2, Section 2.3 "Wiring." (For inverters of

50 HP or above, also open the keypad enclosure.)

(2) Insert four spacers and connector CN1 on the back of the OPC-F1-LNW (Figure 2) into the four spacer holes and Port A (CN4) on the inverter's

control printed circuit board (PCB) (Figure 4), respectively.

Make sure, visually, that the spacers and CN1 are firmly inserted (Figure 5).

(3) Install the wires for the OPC-F1-LNW.

(4) Put the covers back to their original positions.

For wiring instructions, see Chapter 5.

For the installation instructions, refer to the FRENIC-Eco Instruction Manual (INR-SI47-1225-E), Chapter 2, Section 2.3 "Wiring." (For inverters

of 50 HP or above, also close the keypad enclosure.)

4 spacer holes

Control PCB

LONWORKS interface

card, OPC-F1-LNW

Figure 3 FRN7.5F1S-2J

to

FRN15F1S-2J

(example)

4 spacers

Make sure that there is

no space between

control PCB and

spacers.

CN1

Port A

(CN4)

Figure 4 Mounting the Card Figure 5 Mounting Completed

5

Page 8

Chapter 5 Wiring

s

(1) Use a shielded twist pair cable recommended by LONMARK for network connection.

The recommended cable is LW161S manufactured by Showa Electric Wire & Cable Co., Ltd.

For details about wiring, refer to the "FT3120/FT3150 Smart Transceiver Data Book" published by Echelon. It can be downloaded for free from

our website at:

http://www.echelon.com/support/documentation/manuals/OEM

(2) Wiring to the LONWORKS' terminal block (TERM1)

The terminal block uses a pluggable 3-pin connector shown in Figure 6. Table 2 shows the pin assignment.

The applicable pluggable connector is "MSTB2.5/3-ST-5.08" manufactured by Phoenix Contact Corporation.

1

Table 2 Pin Assignment on TERM1

Pin # Pin Assignment Description

1 SD Shield

2 NET B Signal line

3 NET A Signal line

Figure 6 Pluggable Connector

on LONWORKS Terminal Block

The network wiring is polarity insensitive. Connecting the two wires of the network cable to NET A and NET B enables communication,

without regard to polarity. Wire crossing between the card and other nodes causes no problem.

(3) Wiring to the ground terminal block (TERM2)

Using an electric cable, connect one of the two wires to the grounding terminal (

short-circuited, either one can be connected.

Applicable wire size: AWG17 to 16 (1.0 to 1.3 mm

To keep noise immunity high, be sure to connect a grounding wire to the terminal block. Otherwise, excessively poor communication

performance may result, in the worse case, communication is impossible.

This terminal block is marked with E by its side. "E" signifies earth (ground).

2

)

(4) Network termination

Free topology wiring requires a single terminating resistor per segment.

No terminating resistor comes with the card. Prepare resistors separately. The recommended terminating resistor is "TP/FT-10 Channel

Terminator Model No.44100" manufactured by Echelon.

C1

+

NET A

R: 52.3Ω 1 %, 1/8W

C1, C2: 100 µF, 50 VDC min. voltage rating

2 3

G) on the inverter. Since these two wires are internally

R

C2

+

NET B

Figure 7 LONWORKS Network Termination

6

Page 9

Chapter 6 Function Code Settings Required for LONWORKS Communication

r

t

To enable run, frequency, and nviXcmd_1 to 5 commands via the LONWORKS network, the inverter requires setting function codes listed in Table 3.

To enable particular NVs, modify the function codes listed in Table 4. To enable other functions, modify them listed in Table 5.

For details about function codes, refer to the FRENIC-Eco Instruction Manual (INR-SI47-1225-E), Chapter 5 "FUNCTION CODES" and RS-485

Communication User's Manual (MEH448), Chapter 5, Section 5.2 "Data Formats."

Function code settings in Tables 3 through 5 are not essential for LONWORKS communication. Those settings can be made either before or afte

commissioning of the card.

IMPORTANT

After commissioning of the card, be sure to restart the inverter or reset it w

operate normally just by turning it online.) Until it is done, the changes made for network variables (NVs) or configuration properties (CPs) will no

be validated on the inverter.

To enable particular NVs listed below, modify the following function codes in addition to the ones listed in Table 3.

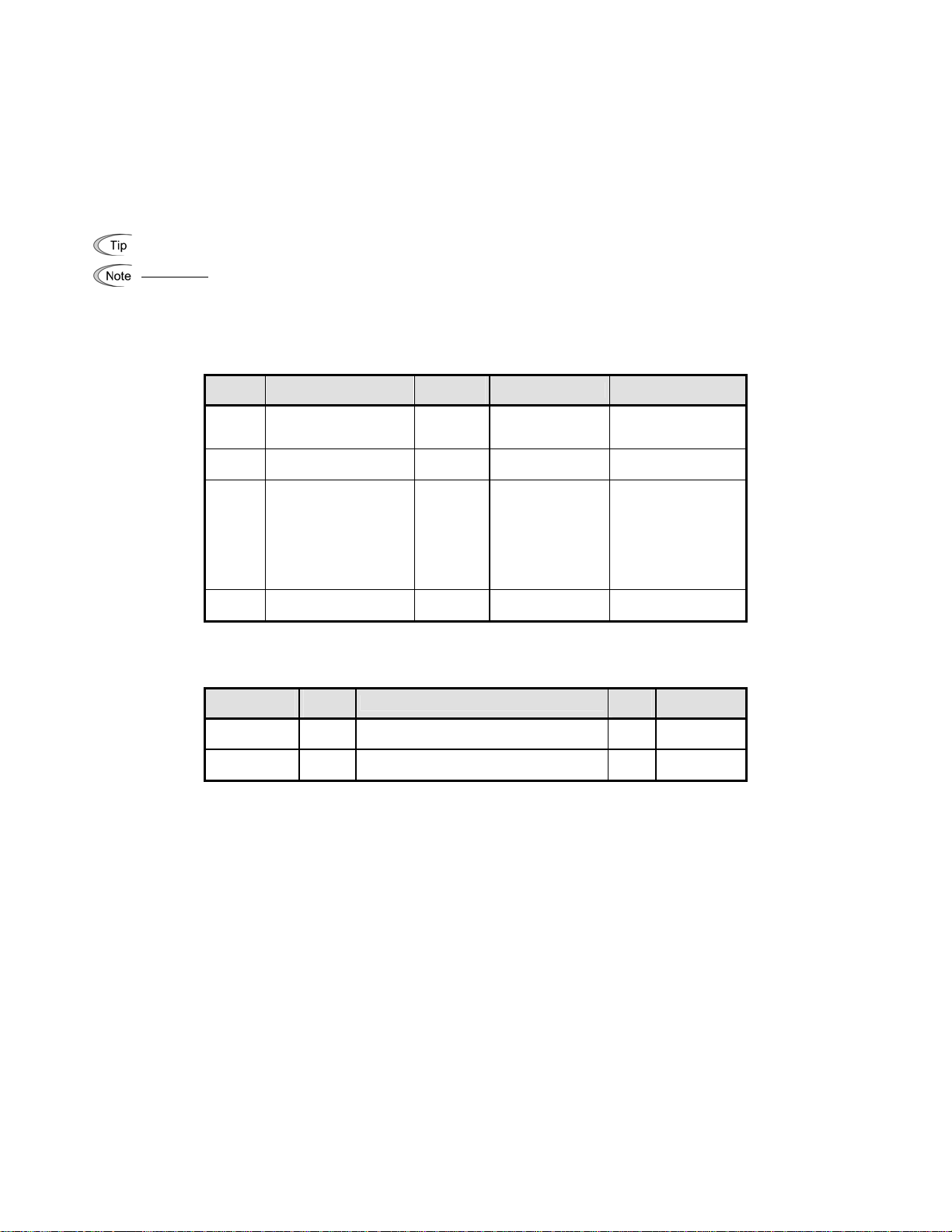

Table 3 Function Code Settings for Enabling Run, Frequency and nviXcmd1 to 5 Commands via LONWORKS Network

Function

code

y98 Run and frequency

y99 Run and frequency

E01 to

E05

E98 Command assignment to

Table 4 Function Codes Required for Enabling nviAOcmd and nviDOcmd_Y1 and Y2

NV to be

Enabled

nviAOcmd F31, F35 Analog output to terminals [FMA] and [FMP] (or

nviDOcmd_Y1,

Y2

Description

commands via

LONWORKS network

commands via Loader

Command assignment to

terminals [X1] to [X5]

terminal [FWD]

Function

code

[FMI])

E20, E21 Signal assignment to terminals [Y1] and [Y2] 0, 1 27 (Universal

Factory

default

0 3 Setting UCPT_LinkFunc

0 0 No change is required

6, 7, 8, 11,

35

98 98 No change is required

Description

ith a LONWORKS integration tool (e.g., LonMaker). (The card does not

Setting Required Remarks

is equivalent to setting

y98.

from the factory default.

Except the following.

24, 1024 (LE selected)

35, 1035 (LOC

selected)

- Even if LE is selected,

turning the physical

terminal ON causes no

problem.

- Even if LOC is selected,

the physical terminal

OFF causes no

problem.

from the factory default.

Factory

default

0, 0 10 (Universal

AO)

DO)

Setting

Required

7

Page 10

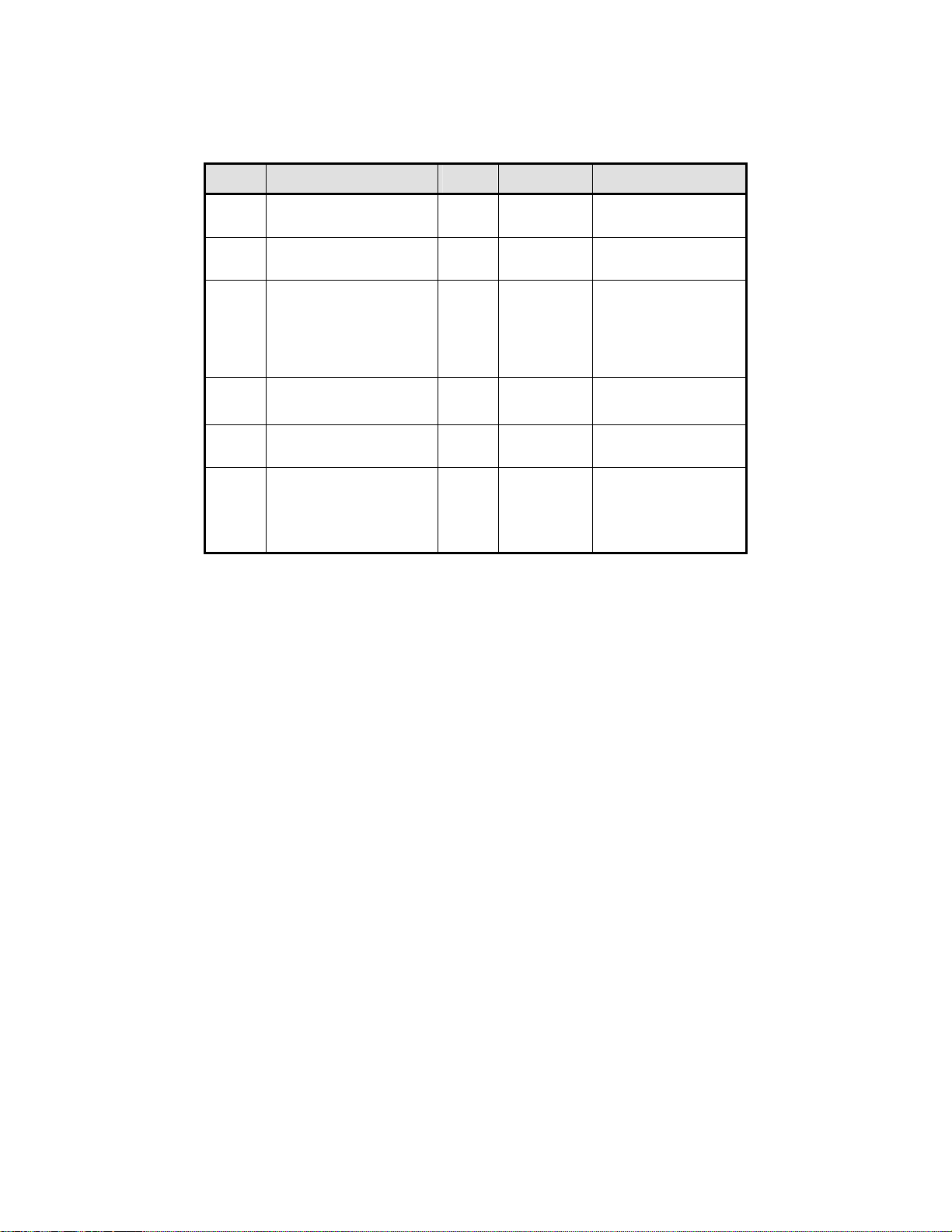

To enable other functions, modify function codes listed in Table 5.

Table 5 Function Codes Required for Enabling Other Functions

Function

code

o27*1 Operation selection at

occurrence of LONWORKS

Description

Factory

default

0 0 to 15 Can be specified by

Setting range Remarks

UCPT_CblLossMode.

communications error

o28*1 Timer at occurrence of

LONWORKS communications

0.0 s 0.0s to 60.0 s Can be specified by

UCPT_CblLossTimer.

error

o30 Service button equivalent 0 0 to 255 Setting o30 to "1" or above is

functionally equivalent to the

depression of the service

button.

Once o30 data is changed, it

will automatically revert to

"0."

W90 LONWORKS card software

version

W95 Count of communications errors

between card and inverter

W96 Contents of communications

errors between card and inverter

(Transmission errors only *2)

Depends

on cards

-(Only for

monitor)

0 --

(Only for

monitor)

0 --

(Only for

monitor)

4-digit in decimal notation.

(Ex.) Ver. 1.42 is shown as

0142.

Contents of the most recent

communications error.

The error codes are identical

with the ones used in the Fuji

general-purpose inverter

*3

protocol.

*1 For details about o27 and o28, refer to Chapter 8, Section 8.1 "Specifying an Inverter Reaction to LONWORKS Communications Errors."

*2 Application errors except transmission errors will be written into the VSD object, nv34 nvoAccessErrCode. For details about error code contents, refer

to Chapter 7, Section 7.6.2 "Writing to inverter's function codes."

*3 For error code details, refer to the RS-485 Communication User's Manual (MEH448), Chapter 4, Section 4.3 "Communications Errors."

8

Page 11

Chapter 7 Object Details

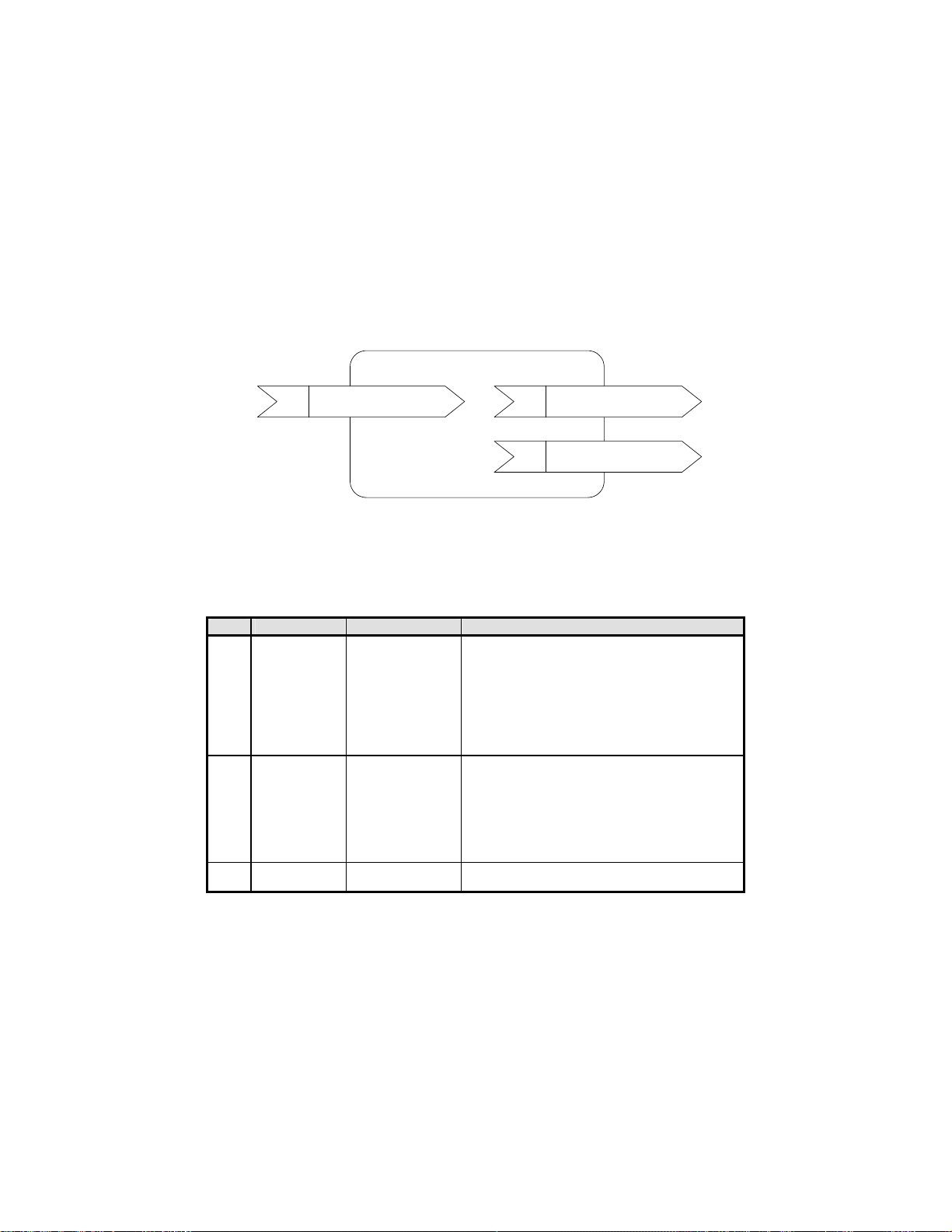

7.1 Overview

This card supports two objects--a node object and Variable Speed Motor Drive object (VSD object). This chapter provides detailed information on these

objects.

7.2 Node Object

7.2.1 Node object overview

The node object processes the system events in LONWORKS network communication for this card. (Usually any intervention of users or integrators

is not required.)

Figure 8 illustrates the relationship between a node object and network variables (NVs).

Node Object #0

nviRequest

nv1

SNVT_obj_request

Figure 8 Overview Structure of Node Object

7.2.2 List of node object network variables (NVs)

Table 6 lists node object network variables supported on this card.

Table 6 Node Object Network Variables

Index Variable name Variable type Description

nv1 nviRequest SNVT_obj_request

nv2 nvoStatus SNVT_obj_status This variable is used to report the status of an object.

nv8 nvoFileDirectory SNVT_address

nvoStatus

nv2

nv8

SNVT_obj_status

nvoFileDirectory

SNVT_adress

This variable is used to request a particular mode for an

object.

Requests supported:

- RQ_NORMAL(0)

- RQ_ENABLED(7)

- RQ_DISABLED(1)

- RQ_UPDATE_STATUS(2)

- RQ_REPORT_MASK(5)

- RQ_CLEAR_ALARM(10)

Statuses supported:

- object_id

- invalid_id

- invalid_request

- disabled

- in_alarm

- report_mask

This variable is used to provide the starting address of

the directory that contains the configuration file.

9

Page 12

7.2.3 NV details

(1) nviRequest

Table 7 lists responses to the request modes of nviRequest.

Table 7 Responses to nviRequest

Request Node object response VSD object response

RQ_NORMAL(0) - Enables the node object and NVs

RQ_ENABLE(7) Same as above. Same as above.

RQ_DISABLE(1) - Stops the motor if running.

RQ_UPDATE_STATUS(2) - Updates nvoStatus and outputs the

RQ_REPORT_MASK(5) - Reports supported requests as "1."

RQ_CLEAR_ALARM(10) - Resets alarm.

All other requests - Returns an invalid request

All other objectIDs - Returns an invalid request

(2) nvoStatus

Table 8 lists the status network variables supported and their descriptions.

Stat us Description

object_id Returns the object ID designated by the Request.

invalid_id Turns "1" when Request is issued to an object with invalid ID.

invalid_request Turns "1" for an invalid request response.

disabled Turns "1" when the VSD object is disabled.

in_alarm Turns "1" when the inverter is in an alarm state or has not solved an alarm.

report_mask Turns the value of the supported status to "1."

to the normal mode.

- Updates nvoStatus and outputs the

new object status.

- Keeps the node object enabled.

- Updates nvoStatus and outputs the

new object status.

new object status.

- Updates nvoStatus and outputs the

new object status.

- Updates nvoStatus and outputs the

new object status.

response.

- Updates nvoStatus and outputs the

new object status.

response.

- Updates nvoStatus and outputs the

new object status.

Table 8 Status Network Variables Supported

7.2.4 Configuration properties (CPs)

Configuration properties are not supported for the node object.

- Enables the VSD object and NVs to

the normal mode.

- Updates nvoStatus and outputs the

new object status.

- Stops the motor if running.

- Disables the VSD object, ignores NV

input, and forbids its output to

transmit.

- Updates nvoStatus and outputs the

new object status.

- Updates nvoStatus and outputs the

new object status.

- Reports supported requests as "1."

- Resets alarm.

- Updates nvoStatus and outputs the

new object status.

- Returns an invalid request response.

- Updates nvoStatus and outputs the

new object status.

- Returns an invalid request response.

- Updates nvoStatus and outputs the

new object status.

10

Page 13

7.3 VSD Object

7.3.1 VSD object overview

The Variable Speed Motor Drive (VSD) object allows you to control the inverter and monitor its running status. Figure 9 illustrates an overview

structure of a VSD object. Letters in parenthesis at the tail of the NV name strings show the names of the inverter's function codes that are involved

by the related NVs.

For details about the function codes in parenthesis, refer to the RS485 Communication User's Manual (MEH448), Chapter 5, "FUNCTION CODES

AND DATA FORMATS."

VSD Object #1

nviDrvSpeedStptnv1

nviDrvSpeedScalenv2

nvoDrvSpeednv4

nvoDrvCurnt (M11)nv3

nvoDrvVolt (M12)nv5

nvoDrvPwr (M10)nv6

nvoDrvRunHours (W79)nv7

nviOpecmd (S06)nv8

nviFreqcmd (S05)nv9

nviReadParamCodenv10

nviWriteParaCodenv11

nviWriteParamValnv12

nviAOcmd (S12)nv13 nvoAIVal_1 (M49)nv35

nviDOcmd_Y1 (S07)nv14

nviDOcmd_Y2 (S07)nv15

nviFWDcmd (S06)nv16

nviXcmd_1 (S06)nv17

・・・

nviXcmd_5 (S06)nv21

nviAlarmReset (S14)nv22

nvoDrvStatus (M14)nv23

nvoOutputFreq (M09)nv24

nvoDrvTorque (M07)nv25

nvoDrvEnergy (W81)nv26

nvoDrvOpeHours(W70)nv27

nvoReadParamValnv33

nvoAccessErrCodenv34

nvoAIVal_2 (M50)nv36

nvoYstatus_1 (M15)nv39

・・・

nvoYstatus_5 (M15)nv43

nvoInAlarm (M14)nv49

nvoAlarm (M16)nv50

nvoAlarmLog (M17~19)nv51

nvoAlarmOpCmd (M39)nv52

nvoAlarmFreq_1 (M31)nv53

nvoAlarmFreq_2 (M35)nv54

nvoOpeTm_1 (W76)nv28

nvoOpeTm_2 (W77)nv29

nvoDCbusCapacity (W75)nv30

nvoDrvTemp_1 (M61)nv31

nvoDrvTemp_2 (M62)nv32

nvoAiVal_3 (M54)nv37

nvoPIDFb (M72)nv38

nvoXstatus_1 (M13)nv44

・・・

nvoXstatus_5 (M13)nv48

nvoAlarmCurrent (X21)nv55

nvoAlarmVolt (M38)nv56

nvoAlarmOpTime (M42)nv57

nvoAlarmPower (X35)nv58

nvoAlarmTorque (M33)nv59

24 Configuration Properties

Figure 9 Overview Structure of VSD Object

11

Page 14

7.3.2 List of VSD object network variables (NVs)

Table 9 lists the summary of VSD object network variables (NVs). The function code column in the table shows their associated inverter's function

codes.

Some of the VSD object input and output NVs are detailed in Sections 7.4 and 7.5, respectively.

Table 9 VSD Object Network Variables

Index Variable name Variable type Descriptions

nv1 nviDrvSpeedStpt SNVT_switch

nv2 nviDrvSpeedScale

SNVT_lev_perce

nt

This input provides start/stop

commands and a low-resolution

speed setpoint.

(as a percentage of

SCPT_nomFreq)

This input provides scaling for a

low-resolution speed setpoint.

(Negative values indicate reverse

motor direction.)

nv3 nvoDrvCurnt SNVT_amp

nv4 nvoDrvSpeed

SNVT_lev_perce

nt

nv5 nvoDrvVolt SNVT_volt

nv6 nvoDrvPwr

SNVT_power_kilo This output reports the output power

nv7 nvoDrvRunHours SNVT_time_hour

nv8 nviOpeCmd SNVT_state

nv9 nviFreqCmd SNVT_freq_hz

nv10

nviReadParamCo

de

SNVT_count

This output reports the output current

(RMS) with 0.1 A resolution.

This output reports the output speed.

(as a percentage of

SCPT_nomFreq)

This output reports the output voltage

(RMS) with 0.1 V resolution.

with 0.1 kW resolution.

This output reports the cumulative

motor run time.

(Diagnostic reference of the

mechanical component service life)

This input provides run commands

including run forward command, run

reverse command, and terminal

commands assigned to

general-purpose, digital input

terminals.

Functionally equivalent to function

code S06 (dedicated to inverter

communication).

This input provides frequency

command with 0.1 Hz resolution.

This input specifies a target inverter's

function code to read out its data with

nv33 nvoReadParamVal.

nv11 nviWriteParaCode SNVT_count

This input specifies a target inverter's

function code to write data with nv12

nviWriteParamVal.

nv12 nviWriteParamVal SNVT_count

nv13 nviAOcmd

SNVT_lev_perce

nt

This input contains data to write into

the inverter's function code specified

by nv11 nviWriteParaCode.

This input specifies any output level

for the inverter's analog output

terminal.

Functionally equivalent to function

code S12 (dedicated to inverter

communication).

nv14 nviDOcmd_Y1 SNVT_switch

nv15 nviDOcmd_Y2 SNVT_switch

This input turns the inverter's digital

output terminal [Y1] ON/OFF.

If the value is "1," [Y1] is ON. (Setting

E20 to "27" (Universal DO) is

needed.)

This input turns the inverter's digital

output terminal [Y2] ON/OFF.

If the value is "1," [Y2] is ON. (Setting

E21 to "27" (Universal DO) is

needed.)

Functio

n code

Refer to:

- p. 19

- p. 19

M11 -

- p. 23

M12 -

M10 -

W79 -

S06

S05 p. 20

-

-

-

S12

S07

S07

pp. 20

and 27

pp. 21

and 28

pp. 21

and 28

pp. 21

and 7

pp. 21

and 7

pp. 21

and 7

12

Page 15

Index Variable name Variable type

nv16 nviFWDcmd SNVT_switch

nv17 nviXcmd_1 SNVT_switch

nv18 nviXcmd_2 SNVT_switch

nv19 nviXcmd_3 SNVT_switch

nv20 nviXcmd_4 SNVT_switch

nv21 nviXcmd_5 SNVT_switch

nv22 nviAlarmReset SNVT_switch

nv23 nvoDrvStatus SNVT_state

nv24 nvoOutputFreq SNVT_freq_hz

nv25 nvoDrvTorque

SNVT_lev_perce

nt

nv26 nvoDrvEnergy SNVT_elec _kwh

nv27 nvoDrvOpeHours SNVT_time_hour

nv28 nvoOpeTm_1 SNVT_time_hour

nv29 nvoOpeTm_2 SNVT_time_hour

nv30

nvoDCbusCapacty SNVT_lev_perce

nt

nv31 nvoDrvTemp_1 SNVT_temp

nv32 nvoDrvTemp_2 SNVT_temp

nv33

nvoReadParamV

al

SNVT_count

Descriptions Refer to:

This input turns terminal command

FWD (bit XF of S06) ON/OFF, which

is assigned to the inverter's digital

input terminal [FWD] with function

code E98.

FWD runs a motor forward by factory

default.

This input turns a terminal command

(bit X1 of S06) ON/OFF, which is

assigned to the inverter's digital input

terminal [X1] with function code E01.

This input turns a terminal command

(bit X2 of S06) ON/OFF, which is

assigned to the inverter's digital input

terminal [X2] with function code E02.

This input turns a terminal command

(bit X3 of S06) ON/OFF, which is

assigned to the inverter's digital input

terminal [X3] with function code E03.

This input turns a terminal command

(bit X4 of S06) ON/OFF, which is

assigned to the inverter's digital input

terminal [X4] with function code E04.

This input turns a terminal command

(bit X5 of S06) ON/OFF, which is

assigned to the inverter's digital input

terminal [X5] with function code E05.

Turning this variable ON clears alarm

in the inverter.

Once it turns ON, it automatically

returns to OFF.

This output reports the running

status.

Functionally equivalent to function

code M14 (dedicated to inverter

communication).

This output reports the output

frequency with 0.1 Hz resolution.

This output reports the output torque

as a percentage of the rated torque

with 0.005% resolution.

This output reports the inverter's

cumulative power consumption in

watt-hours.

This output reports the cumulative

inverter run time.

(Diagnostic reference data for

inverter lifetime)

This output reports the cumulative

run time of electrolytic capacitors on

printed circuit boards.

(Diagnostic reference data for service

lifetime of the control circuit)

This output reports the cumulative

run time of the cooling fan.

This output reports the current

capacitance of the DC link bus

capacitor in %, based on the

capacitance when shipped as 100%.

This output reports the inverter

internal temperature with 1C

resolution.

This output reports the heat sink

temperature with 1C resolution.

This output reports the data of the

function code read.

Functio

n code

S06

S06

S06

S06

S06

S06

pp. 22

and 7

pp. 22

and 7

pp. 22

and 7

pp. 22

and 7

pp. 22

and 7

pp. 22

and 7

S14 p. 22

M14 p. 23

M09 -

M07 -

W81 -

W70 -

W76 -

W77 -

W75 -

M61 -

M62 -

-

pp. 23

and 27

13

Page 16

Index Variable name Variable type

nv34

nvoAccessErrCode UNVT_ErrCode

(1byteHex x 3)

Descriptions Refer to:

This output reports the code of an

error caused after writing to a

function code, together with the

function code accessed.

Only when nv11 and nv12 access a

function code, this output updates its

data and then outputs it onto the

Functio

n code

-

pp. 24

and 28

network.

nv35 nvoAIval_1

nv36 nvoAIval_2

nv37 nvoAIval_3

SNVT_lev_perce

nt

SNVT_lev_perce

nt

SNVT_lev_perce

nt

This output reports the input voltage

at terminal [12].

(100% at 10 V, 0% at 0 V)

This output reports the input current

at terminal [C1].

(100% at 20 mA, 0% at 4 mA)

This output reports the input voltage

at terminal [V2].

M49 p. 24

M50 p. 24

M54 p. 24

(100% at 10 V, 0% at 0 V)

nv38 nvoPIDFb

SNVT_lev_perce

nt

nv39 nvoYstatus_1 SNVT_switch

nv40 nvoYstatus_2 SNVT_switch

nv41 nvoYstatus_3 SNVT_switch

This output reports the PID feedback

value (%).

This output reports the status of

digital output terminal [Y1] whose

function is assigned by E20.

This output reports the status of

digital output terminal [Y2] whose

function is assigned by E21.

This output reports the status of

digital output terminal [Y3] whose

M72 p. 25

M15 p. 25

M15 p. 25

M15 p. 25

function is assigned by E22.

nv42 nvoYstatus_4 SNVT_switch Reserved. - nv43 nvoYstatus_5 SNVT_switch

This output reports the status of

digital output terminal [Y5A/C] whose

M15 p. 25

function is specified by E24.

nv44 nvoXstatus_1 SNVT_switch

This output reports the status of a

terminal command assigned to digital

M13 p. 25

input terminal [X1].

When E01 data is "25" (Universal

DI), this output reports the ON/OFF

state of the physical terminal [X1].

nv45 nvoXstatus_2 SNVT_switch

This output reports the status of a

terminal command assigned to digital

M13 p. 25

input terminal [X2].

When E02 data is "25" (Universal

DI), this output reports the ON/OFF

state of the physical terminal [X2].

nv46 nvoXstatus_3 SNVT_switch

nv47 nvoXstatus_4 SNVT_switch

nv48 nvoXstatus_5 SNVT_switch

This output reports the status of a

terminal command assigned to digital

input terminal [X3].

When E03 data is "25" (Universal

DI), this output reports the ON/OFF

state of the physical terminal [X3].

This output reports the status of a

terminal command assigned to digital

input terminal [X4].

When E04 data is "25" (Universal

DI), this output reports the ON/OFF

state of the physical terminal [X4].

This output reports the status of a

terminal command assigned to digital

input terminal [X5].

When E05 data is "25" (Universal

DI), this output reports the ON/OFF

M13 p. 25

M13 p. 25

M13 p. 25

state of the physical terminal [X5].

nv49 nvoInAlarm SNVT_switch

nv50 nvoAlarm

UNVT_alarm_co

d

(1byte decimal)

This output remains ON when the

inverter is in an alarm state or has not

canceled the recent alarm.

This output reports the code of an

alarm that is occurring or has

occurred most recently.

M14 -

M16 p. 26

14

Page 17

Index Variable name Variable type

y

nv51 nvoAlarmLog

UNVT_alarm_log

(1byte dec x 3)

nv52 nvoAlarmOpCmd SNVT_state

Descriptions Refer to:

This output reports three recent

alarm codes in the order of 1st, 2nd,

and 3rd recent ones.

This output reports the status of a run

command being executed when the

most recent alarm occurred.

Functio

n code

M17

M18

p. 26

M19

M39 -

Same format as nv8 nviOpeCmd.

nv53 nvoAlarmFreq_1 SNVT_freq_hz

nv54 nvoAlarmFreq_2 SNVT_freq_hz

nv55 nvoAlarmCurrent SNVT_amp

nv56 nvoAlarmVolt SNVT_volt

This output reports the status of a

frequency command being executed

when the most recent alarm

occurred, with 0.1 Hz resolution.

This output reports the output

frequency being applied when the

most recent alarm occurred, with 0.1

Hz resolution.

This output reports the output current

being applied when the most recent

alarm occurred, with 0.1 A resolution.

This output reports the output voltage

being applied when the most recent

M31 -

M35 -

X21 -

M38 -

alarm occurred, with 0.1 V resolution.

nv57 nvoAlarmOpTime SNVT_time_hour

This output reports the inverter's run

time being accumulated until the

M42 -

most recent alarm occurred.

nv58 nvoAlarmPower

SNVT_power_kilo This output reports the inverter's

power consumption detected when

the most recent alarm occurred, with

X35 -

0.1 kW resolution.

nv59 nvoAlarmTorque

SNVT_lev_perce

nt

This output reports the inverter's

output torque detected when the

most recent alarm occurred, as a

percentage of the rated torque with

0.005% resolution.

M33 -

Fan-out connection using aliases (branching a single output NV to two or more input NVs on this card) should be avoided because the card ma

miss-fetch any input NV depending upon the fetch timing. If it cannot be avoided, use the repeated mode for the connection messaging service to

prevent miss-fetch of the branched NV aliases.

15

Page 18

7.3.3 List of VSD object configuration properties (CPs)

Table 10 lists the summary of VSD object configuration properties (CPs). The function code column in the table shows their associated inverter's

function codes. Modifying function code data can change the associated CP value.

Some of these CPs have detailed descriptions in Section 7.7 (see the page given in the table below).

Refer to the FRENIC-Eco Instruction Manual (INR-SI47-1225-E), Chapter 5 "FUNCTION CODES" for supplementary information on the CPs.

Table 10 VSD Object CPs

CP name Unit Description Default

SCPT_maxSetpoint 0.005%

Defines the maximum frequency as a

percentage of SCPT_nomFreq.

100.000

%

Functio

n code

F03 -

(60 Hz)

SCPT_minSetpoint 0.005%

SCPT_maxSendTim

e

0.1 s Sets the heartbeat send interval.

Defines the lower limit of the output

frequency as a percentage of

SCPT_nomFreq.

The concerned NV continues

transmitting data at this time intervals,

0.000% F16 -

0.0 s - p. 29

regardless the data changing.

Specifying 0.0 s disables this CP.

SCPT_nomRPM 1 r/min

SCPT_nomFreq 0.1 Hz

SCPT_rampUpTm 0.1 s

SCPT_rampDownTm 0.1 s

Used to enter the nominal speed, 100%

of the percent speed command, in

r/min.

Modifying this CP automatically

replaces the value of SCPT_nomFreq.

Used to enter the nominal frequency,

100% of the percent speed command,

in Hz.

All percent speed commands refer to

this value.

Used to enter the ramp-up time from

the zero to maximum speed.

Used to enter the ramp-down time from

the maximum to zero speed.

1800

r/min

60.0 Hz - p. 19

20.0 s F07 -

20.0 s F08 -

- -

(UCPT_rampUpTm2) - Reserved. - - (UCPT_rampDownT

m2)

SCPT_defScale 0.005%

SCPT_maxRcvTime 0.1 s Sets the heartbeat receive interval.

- Reserved. - - -

Contains the default value for

nviDrvSpeedScale.

If the concerned NV receives no data

within this interval, it interprets the

100.000

%

0.0 s

- -

p. 29

transmission as being broken.

Specifying 0.0 s disables this CP.

SCPT_minDeltaLevel 0.5%

Sets the minimum data change rate for

an output NV to start data transmission.

If the data change rate exceeds this

value, the concerned NV interprets the

data as being changed, starting data

transmission.

0.0% p. 30

Specifying 0.0% disables this CP.

SCPT_minSendTime 0.1 s

Sets the minimum pause time for an

output NV to start data transmission.

Once the concerned NV finishes data

transmission, it does not start data

transmission until this time has elapsed

even if the data change rate exceeds

0.5 s p. 30

SCPT_minDeltaLevel.

Setting 0.0 s disables this CP.

UCPT_BaseFreq 0.1 Hz

Sets the base frequency of the inverter

for motor 1.

50.0 Hz F04 -

(UCPT_JogFreq) - Reserved. - - UCPT_JumpFreq 0.1 Hz x 4

Contains an ensemble of four inverter's

function codes specified in the array

order shown below.

"Jump frequency 1, 2, 3 and jump

frequency band"

0.0 Hz,

0.0 Hz,

0.0 Hz,

3.0 Hz

C01,

C02,

C03,

C04

Refe

r to:

-

16

Page 19

CP name Unit Description Default

UCPT_LinkFunc 1

Switches run and speed commands

between "enable" and "disable" via the

0

Functio Refe

n code r to:

y98 p. 7

LONWORKS network.

Functionally equivalent to function code

y98.

Setting y98 data to "3" enables run and

speed commands.

UCPT_multStepFreq

1

UCPT_PIDsettings

0.01 Hz

0.001,

0.1 s,

0.01 s,

0.1 s

Sets the frequency to be applied when

multistep frequency 1 is selected.

Multistep frequency: Assigning terminal

commands to digital input terminals [X1]

to [X5] and [FWD] with E01 to E05 and

E98 and turning those terminals

ON/OFF can select the multistep

frequency.

Contains an ensemble of four PID

parameters specified in the array order

shown below.

"P gain, I time, D time and feedback

0.00 Hz C05 -

0.100,

0.0 s,

0.00 s,

0.5 s

J03,

J04,

J05,

J06

-

filter time constant"

UCPT_StartFreq 0.1 Hz Sets the starting frequency. 0.5 Hz F23 UCPT_StopFreq 0.1 Hz Sets the stop frequency. 0.2 Hz F25 (UCPT_TorqLimit) - Reserved. - - UCPT_CblLossMode 1

Specifies an action to follow when a

communications line break error occurs

0 o27 p. 31

on the LONWORKS network.

Functionally equivalent to function code

o27.

UCPT_CblLossTimer 0.1 s

UCPT_FlyingStart

Mode

UCPT_momentaryP

wr

LossMode

1

1

UCPT_AutoRestart 1

Sets the timer to determine the issuing

timing of er5 alarm triggered by a

communications line break on the

LONWORKS network.

Functionally equivalent to function code

o28.

Specifies the auto search for idling

motor's speed.

In the auto search mode, the frequency

can be specified by function code H17.

Specifies the restart mode after a

momentary power failure.

Functionally equivalent to function code

F14.

Specifies the number of auto-resetting

times for automatically escaping the

0.0 s o28 p. 31

0

(Disable)

H09 -

1 F14 -

0 H04 -

tripped state.

Functionally equivalent to function code

H04.

H05 specifies the reset interval.

UCPT_SendDelay

AfterDevRdy

0.1 s

Specifies the data transmission start

delay time for the LONWORKS

interface card.

The output NV starts data transmission

after this delay time has elapsed from

when the card is powered up or

receives a reset command from the

LONWORKS integration tool.

This CP should be used to strictly

manage the starting time of data

0.0 s ― -

transmission on the whole network.

Specifying 0.0 s makes the NV start

data transmission upon completion of

initialization of the card. *1

*1 This LONWORKS interface card needs approx. 0.5 second for initialization. Therefore, specifying less than 0.5 second cannot start data transmission

from the output NV until approx. 0.5 second elapses.

When the card is powered up, it transmits all output NVs to validate the latest inverter settings on the LONWORKS network.

17

Page 20

Immediately after commissioning, the LONWORKS integration tool temporarily monitors CP default values, so those CP values do no

t

P

e

necessarily match the inverter's function code settings. This is, however, only apparent and the inverter runs with its function code settings.

To make the monitored CP values match the inverter's settings, use the LONWORKS integration tool to execute the "Synchronize CP" command

(e.g., ReSync CPs in LonMaker) and upload the CP values of this card. Or, use any LonMaker proprietary plug-in for easy uploading of C

values. For instructions on how to get the plug-ins, refer to Chapter 2 "Acceptance Inspection."

Modifying CP-associated function codes from the keypad does not automatically update the CP values being monitored by the LONWORKS

integration tool. This is, however, only apparent and the modification is validated on the associated CPs without any problems.

To update the monitored CP values, use the LONWORKS integration tool to execute the "Synchronize CP" command (e.g., ReSync CPs in

LonMaker) and upload the CP values of this card. Or, use any LonMaker proprietary plug-in for easy uploading of CP values in the same way as

the above note.

The moment the LONWORKS integration tool sets CP values (new or unchanged values), all output NVs implemented on this card output th

latest data at that time. Use this feature to update the NVs on the network with the latest data.

In addition, switching the inverter from offline to online also outputs all output NVs as well.

18

Page 21

7.4 VSD Object Input Network V ariables

t

(1) nv1 nviDrvSpeedStpt

This NV controls the inverter's run/stop and frequency commands via the LONWORKS network.

- Variable type: SNVT_switch

Table 11 Operation of nviDrvSpeedStpt

state value Operation

0 NA Run command OFF

1 0.0 (%) Zero speed command (No torque generated)

1 0.5 to 100.0 (%) Run at 0.5 to 100.0% frequency

-1 (0xFF) NA Invalid

- Default setting: state = -1, value = 0

The card calculates the frequency command value with nviDrvSpeedStpt.value, nviDrvSpeedScale and SCPT_nomFreq.

Frequency command (Hz) = nviDrvSpeedStpt.value (%) x nviDrvSpeedScale (%) x SCPT_nomFreq (Hz)

Each time any one of the three terms in the above equation is entered, the card calculates the frequency command again and overwrites the

previous value with new one, regardless of whether the inverter is running or on halt. If state = 0xFF, however, no recalculation takes place even with

any input.

The frequency command can be specified with this NV and nv9 nviFrecmd. If both of these NVs are specified, the last one takes effec

on the inverter (Last command has priority).

To enable the inverter's run/stop and frequency commands via the LONWORKS network, either of the following settings is required.

UCPT_LinkFunc = 3 or inverter's function code y98 = 3

- CPs for control of the affected network bandwidth: SCPT_maxRcvTime

(2) nv2 nviDrvSpeedScale

This NV specifies the motor rotational direction and frequency command.

- Variable type: SNVT_lev_percent

- Data setting range: -163.840 to 163.830% (0.005% resolution)

If entering 163.835% (invalid), for example, the card ignores the entry and the inverter runs with the previous value.

- Default setting: Value specified by SCPT_defScale

- CPs for control of the affected network bandwidth: SCPT_maxRcvTime

19

Page 22

(3) nv8 nviOpecmd

t

This NV specifies the inverter data of run forward/reverse, digital input terminals [X1] to [X5], [FWD] and [REV]. The command format of this NT is the

same as that of function code S06.

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

ALM

RST

[REV]

[FWD

- - - - - - X5 X4 X3 X2 X1 REV FWD

]

FWD, REV: Run forward/reverse commands to the inverter

X1 to X5: Terminal command assignment fields for inverter's digital inputs [X1] to [X5]

[FWD], [REV]: Run forward/reverse terminal command assignment fields for inverter's digital inputs [FWD] and [REV]

ALMRST: Switching from ON to OFF clears inverter alarms.

- Variable type: SNVT_state

- Default setting: 0000000000000000 (16 bit binary)

- CPs for control of the affected network bandwidth: SCPT_maxRcvTime

To validate this NV entry on the inverter, any of the following settings is required.

UCPT_LinkFunc = 2 or 3, or inverter's function code y98 = 2 or 3

(4) nv9 nviFreqcmd

This NV specifies the frequency command in Hz with 0.1 Hz resolution.

- Variable type: SNVT_freq_hz

- Data setting range: 0.0 to 6553.5 Hz (Valid range for inverter: 0.0 to 400.0 Hz)

- Default setting: 0.0 Hz

- CPs for control of the affected network bandwidth: SCPT_maxRcvTime

The frequency command can be specified with this NV and nv1 nviDrvSpeedStpt. If both of these NVs are specified, the last one takes effec

on the inverter (Last command has priority).

To validate this NV entry on the inverter, any of the following settings is required.

UCPT_LinkFunc = 1 or 3, or inverter's function code y98 = 1 or 3

(5) nv10 nviReadParamCode

This NV specifies a target inverter's function code to read out its data with nv33 nvoReadParamVal.

For details about readout of function code data, refer to Section 7.6.1 "Reading from inverter's function codes."

- Variable type: SNVT_count

- Data setting range: 0000 to FFFF (hexadecimal)

- Default: 0000 (hexadecimal)

- CPs for control of the affected network bandwidth: None

20

Page 23

(6) nv11 nviWriteParaCode, nv12 nviWriteParamVal

e

Data contained in nv12 will be written into a function code specified by nv11.

For details about writing data, refer to Section 7.6.2 "Writing to inverter's function codes."

- Variable type: SNVT_count

- Data setting range: 0000 to FFFF (hexadecimal)

- Default setting: 0000 (hexadecimal)

- CPs for control of the affected network bandwidth: None

(7) nv13 nviAOcmd

This NV outputs its value onto the inverter's analog output terminal [FMA/FMP/FMI] (same as universal AO).

To terminal [FMA], the NV outputs 0 to 10 VDC or 4 to 20 mADC. To terminal [FMP], it outputs a square wave pulse train prescribed by the inverter.

For [FMI], it outputs 4 to 20 mADC.

This allows the inverter to work as an analog output device having a single channel, physical analog output.

For details about terminals [FMA] and [FMP] (or [FMI]), refer to the FRENIC-Eco Instruction Manual (INR-SI47-1225-E), Chapter 2, Section

2.3.7 "Wiring for control circuit terminals" and Chapter 5, Section 5.2 "Overview of Function Codes," F31 and F35.

- Variable type: SNVT_lev_percent

- Data setting range: -163.840 to 163.830% (Valid range for inverter: 0.000 to 105.000%)

Setting 163.835% (invalid), for example, will be ignored so that the inverter runs with the previous value.

- Default setting: 0.000%

- CPs for control of the affected network bandwidth: SCPT_maxRcvTime

To validate this NV entry on the inverter, either of the following settings is required.

For [FMA], inverter's function code F31 = 10

For [FMP] (or [FMI]), F35 = 10

It is possible to enable both [FMA] and [FMP], however, both terminals output the same analog level signals.

(8) nv14 nviDOcmd_Y1, nv15 nviDOcmd_Y2

The nv14 or nv15 outputs its ON/OFF value onto inverter's digital output terminal [Y1] or [Y2], respectively (same as universal DO). This allows the

inverter's physical Y terminals to work as a 2-bit (max.) digital output device.

For details about Y terminals, refer to the FRENIC-Eco Instruction Manual (INR-SI47-1225-E), Chapter 2, Section 2.3.7 "Wiring for control circuit

terminals" and Chapter 5, Section 5.2 "Overview of Function Codes," E20 and E21.

- Variable type: SNVT_switch

- Data setting range: value = 0.0 to 100.0%, state = 1, 0, -1

- Default settings: value = 0.0%, state = 0

- CPs for control of the affected network bandwidth: SCPT_maxRcvTime

Do not use nviDOcmd_Y1 or nviDOcmd_Y2 as a bit array. This is because, in LONWORKS communication, two or more variables ar

never output concurrently, so the card may miss-fetch the bit array at the timing when the data gets validated on the inverter. Accordingly, the

inverter could receive it as unexpected data. To handle them as a bit array, read out S07 by the function code readout feature.

To validate this NV entry on the inverter, either of the following settings is required.

For [Y1], inverter's function code E20 = 27

For [Y2], E21 = 27

21

Page 24

(9) nv16 nviFWDcmd

s

s

r

This NV controls the ON/OFF of inverter's digital input terminal [FWD]. Command assignment to [FWD] is made with function code E98. The factory

default command is "Run forward."

For details about function code E98, refer to the FRENIC-Eco Instruction Manual (INR-SI47-1225-E), Chapter 5 "FUNCTION CODES."

- Variable type: SNVT_switch

- Data setting range: value = 0.0 to 100.0%, state = 1, 0, -1

- Default setting: value = 0.0%, state = 0

- CPs for control of the affected network bandwidth: SCPT_maxRcvTime

To assign the "Run reverse" command to terminal [FWD], it is necessary to assign a terminal command other than "Run reverse" to terminal

[REV] using function code E99.

The run command issued by this NV is independent of the one issued by nviDrvSpeedStpt, so turning ON either one of those run command

runs the motor. To stop it, therefore, concurrently turn OFF both of them issued by the two NVs.

To validate this NV entry on the inverter, any of the following settings is required.

UCPT_LinkFunc = 2 or 3, or inverter's function code y98 = 2 or 3

(10) nv17 to nv21 nviXcmd_1 to nviXcmd_5

These NVs control the ON/OFF of inverter's digital input terminals [X1] to [X5]. Command assignments to [X1] to [X5] are made with function codes

E01 to E05, respectively.

For details about function codes E01 to E05, refer to the FRENIC-Eco Instruction Manual (INR-SI47-1225-E), Chapter 5 "FUNCTION CODES."

- Variable type: SNVT_switch

- Data setting range: value = 0.0 to 100.0%, state = 1, 0, -1

- Default settings: value = 0.0%, state = 0

- CPs for control of the affected network bandwidth: SCPT_maxRcvTime

Do not use any of nviXcmd_1 to nviXcmd_5 as a bit array (e.g., multistep speed command). This is because, in LONWORKS

communication, two or more variables are never input concurrently, so the card may miss-fetch the bit array at the timing when the data get

validated on the inverter. Accordingly, the inverter could transmit it as unexpected data. To handle them as a bit array, use nv8 nviOpecmd,

instead.

Depending on the command assignment to inverter's digital input terminals, some ON/OFF commands via the LONWORKS network using

these NVs may be ignored. On the other hand, some commands entered from the terminal block may be unconditionally validated. Fo

details about these events, refer to the RS485 Communication User's Manual (MEH448), Chapter 5, Section 5.1.2 [2] "Operation command

data."

To validate this NV entry on the inverter, any of the following settings is required

UCPT_LinkFunc = 2 or 3, or inverter's function code y98 = 2 or 3

(11) nv22 nviAlarmReset

Setting the ON value to this NV releases the inverter's trip state. If any alarm factor persists at the entry of the ON value, the trip state cannot be

released. After the entry of the ON value, the NV state automatically reverts to OFF.

- Variable type: SNVT_switch

- Data setting range: value = 0.0 to 100.0%, state = 1, 0, -1

- Default setting: value = 0.0%, state = 0

- CPs for control of the affected network bandwidth: None

22

Page 25

7.5 VSD Object Output Network V ariables

This section describes VSD object output network variables that need supplemental explanations. For variables not found in this section, refer to Section

7.3 "VSD Object."

(1) nv4 nvoDrvSpeed

This NV outputs the inverter's output frequency as a percentage of SCPT_nomFreq (Base frequency).

- Variable type: SNVT_lev_percent

- Data setting range: -163.840 to 163.830% (0.005% resolution)

- CPs for control of the affected network bandwidth: SCPT_maxSendTime, SCPT_minSendTime and SCPT_minDeltaLevel

- Output timing: At the time of data change, at intervals specified by SCPT_maxSendTime (if specified), after the time specified by

(2) nv23 nvoDrvStatus

This NV outputs the current inverter status. The format of this NV is the same as that of the inverter's communication function code M14.

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

BUS

Y

FWD, REV : Run forward, Run reverse IL : During output current limiting

EXT : During DC-braking (or Pre-exciting) ACC : During acceleration

INT : Inverter shutdown DEC : During deceleration

BRK : Braking ALM : Alarm relay output

NUV : DC link bus voltage established (0: Undervoltage) RL : Communication active

VL : Output voltage limiting BUSY : Busy in writing function codes

- Variable type: SNVT_state

- CPs for control of the affected network bandwidth: SCPT_maxSendTime and SCPT_minSendTime

- Output timing: At the time of data change, at intervals specified by SCPT_maxSendTime (if specified), or after the time specified by

(3) nv33 nvoReadParamVal

This NV reads out data from the inverter's function code specified by nv10 nviReadParamCode.

For details about readout of function code data, refer to Section 7.6.1 "Reading from inverter's function codes."

- Variable type: SNVT_count

- Data setting range: 0000 to FFFF (hexadecimal)

- CPs for control of the affected network bandwidth: SCPT_maxSendTime

- Output timing: At the input time of nv10 nviReadParamCode or at intervals specified by SCPT_maxSendTime (if specified)

SCPT_minSendTime (if specified), or when the data change rate exceeds the value specified by SCPT_minDeltaLevel (if

specified)

- - RL ALM DEC ACC IL VL - NUV BRK INT EXT REV FWD

SCPT_minSendTime (if specified)

This NV is issued after input of nviReadParamCode, regardless of whether the data has been changed or not.

23

Page 26

(4) nv34 nvoAccessErrCode

0

After completion of writing of inverter's function code data with nv11 nviWriteParaCode and nv12 nviWriteParamVal, this NV outputs a three-byte

string "Write error code (1 byte) + Function code accessed (2 bytes)." If the data has been successfully written, the error code value is 00h.

For details about error codes, refer to Section 7.6.2 "Writing to inverter's function codes," Table 15.

- Variable type: UNVT_ErrCode (3 bytes)

1 byte 1 byte 1 byte

Error code

Function code

group of error

detection target

Function code

number of the

error detection

LonMaker represents this NV data in the format: "Error code (decimal), Function code group (decimal), Function code number (decimal)."

For details about the NV format and function code writing procedure, refer to Section 7.6.2 "Writing to inverter's function codes."

- Data setting range: 00, 00, 00 to FF, FF, FF (hexadecimal)

- CPs for control of the affected network bandwidth: None

- Output timing: After the input time of nv12 nviWriteParamVal

(5) nv35 to nv37 nvoAIVal_1 to nvoA IVal_3

The nv35 to nv37 output the voltage or current input level applied to inverter's analog input terminals [12], [C1] and [V2] in percentage, respectively.

Table 12 lists the relationship between terminals and NVs.

Table 12 Analog input terminals and NVs

Network variables Analog terminals Analog signal level

nvoAIVal_1 [12] 0 to 100% = 0 to 10 V

nvoAIVal_2 [C1] 0 to 100% = 4 to 20 mA

nvoAIVal_3 [V2] 0 to 100% = 0 to 10 V

For details about terminals [12], [C1] and [V2], refer to the FRENIC-Eco Instruction Manual (INR-SI47-1225-E), Chapter 2, Section 2.3.7 "Wiring

for control circuit terminals."

- Variable type: SNVT_lev_percent

- Data setting range: 0.000 to 100.000% (0.005% resolution)

- CPs for control of the affected network bandwidth: SCPT_maxSendTime, SCPT_minSendTime, SCPT_minDeltaLevel

- Output timing: At the time of data change, at intervals specified by SCPT_maxSendTime (if specified), after the time specified by

SCPT_minSendTime (if specified), or when the data change rate exceeds the value specified by SCPT_minDeltaLevel (if

specified)

The NV ignores bias and gain data for each analog input. On the LONWORKS network, the following relationship is always established

regardless of the bias and gain data: When 0 V (or 4 mA) is applied to an analog input terminal, the NV value is 0%, and when 10 V (or 2

mA), 100%.

24

Page 27

(6) nv38 nvoPIDFb

s

When the PID feedback value is assigned to any of analog input terminals [12], [C1] and [V2], this NV outputs the analog signal level applied to that

terminal as the PID feedback value in percentage.

To use this NV, it is necessary to enable the inverter's PID control. For details about the PID control, refer to the FRENIC-Eco User's Manual

(MEH456), Chapter 4, Section 4.9 "PID Frequency Command Generator" and Chapter 9, Section 9.2.6 "J codes."

- Variable type: SNVT_lev_percent

- Data setting range: 0.0 to 163.830% (0.005% resolution)

- CPs for control of the affected network bandwidth: SCPT_maxSendTime, SCPT_minSendTime, SCPT_minDeltaLevel

- Output timing: At the time of data change, at intervals specified by SCPT_maxSendTime (if specified), after the time specified by

SCPT_minSendTime (if specified), or when the data change rate exceeds the value specified by SCPT_minDeltaLevel (if

specified)

This NV data can be adjusted with analog input gain setting. The related inverter's function codes are C32, C34, C37, C39, C42 and C44.

(7) nv39, nv40, nv41, nv43 nvoYstatus_1, nvoYst atus_2, nvoYst atus_3, nvoYstatus_5

The nv39 to nv41 and nv43 output the ON/OFF status of inverter's digital output terminals [Y1] to [Y3] and relay contact output terminal [5A/C],

respectively. Signal assignments to these terminals are made with function codes E20 to E22 and E24.

For details about function codes E20, E21, E22 and E24, refer to the FRENIC-Eco Instruction Manual (INR-SI47-1225-E), Chapter 5

"FUNCTION CODES."

- Variable type: SNVT_switch

- Data setting range: value = 0.0, 100.0%, state = 1, 0

- CPs for control of the affected network bandwidth: SCPT_maxSendTime, SCPT_minSendTime

- Output timing: At the time of data change, at intervals specified by SCPT_maxSendTime (if specified) or after the time specified by

SCPT_minSendTime (if specified)

Although the nv42 nvoYstatus_4 exists, it does not function since the FRENIC-Eco does not support terminal [Y4].

(8) nv44 to nv48 nvoXstatus_1 to nvoXstatus_5

The nv44 to nv48 check whether terminal commands applied to inverter's digital input terminals [X1] to [X5] are validated or not on the inverter,

respectively, and outputs it in ON/OFF state.

Setting data "0" to inverter's function code y98 or UCPT_LinkFunc makes it possible to monitor the validation status of terminal command

applied to physical terminals [Xn], respectively. In this situation, it is also possible to monitor commands assigned by nviXcmd_1 to

nviXcmd_5 as well.

For details, refer to the RS485 Communication User's Manual (MEH448), Chapter 5, Section 5.1.2 [2] "Operation command data."

- Variable type: SNVT_switch

- Data setting range: value = 0.0, 100.0%, state = 1, 0

- CPs for control of the affected network bandwidth: SCPT_maxSendTime, SCPT_minSendTime

- Output timing: At the time of data change, at intervals specified by SCPT_maxSendTime (if specified) or after the time specified by

SCPT_minSendTime (if specified)

25

Page 28

r

Assigning "Universal DI" to a digital input terminal (E01 to E05 = 25) makes it possible to output the physical ON/OFF status of terminal [Xn]

onto the LONWORKS network. Accordingly, the inverter's physical terminal [Xn] can be used as a digital input device having max. 5 bits.

Depending on the command assignment to inverter's digital input terminals, some ON/OFF commands via the LONWORKS network using

these NVs may be ignored. On the other hand, some commands entered from the terminal block may be unconditionally validated. Fo

details about these events, refer to the RS485 Communication User's Manual (MEH448), Chapter 5, Section 5.1.2 [2] "Operation command

data."

(9) nv50 nvoAlarm

This NV outputs the contents of an alarm that is occurring or has recently occurred.

- Variable type: UNVT_alarm_cod (1 byte, decimal)

- Data setting range: 0 to 255

- CPs for control of the affected network bandwidth: SCPT_minSendTime

- Output timing: At the time of data change or after the time specified by SCPT_minSendTime (if specified)

Table 13 Alarm Code Table

Code Alarm Code Alarm

0 No alarm --- 22 Braking resistor overheated dbh

1 Overcurrent during acceleration 0c1 23 Motor overload 0l1

2 Overcurrent during deceleration 0c2 25 Inverter overload 0lu

3

Overcurrent during running at

constant speed

0c3 31 Memory error er1

5 Grounding fault ef 32 Keypad communication error er2

6 Overvoltage during acceleration 0u1 33 CPU error er3

7 Overvoltage during deceleration 0u2 34 Interface card connection error er4

8

Overvoltage during running at

constant speed

0u3 35 Field bus communications error er5

10 Undervoltage lu 36 Operation action error er6

11 Input phase loss lIn 37 Tuning error er7

14 Blown fuse fus 38 RS-485 communications error er8

16 Charging circuit fault pbf 46 Output phase loss 0pl

17 Overheating of the heat sink 0h1 51

18 External alarm 0h2 53

19 Inverter overheat 0h3

20

Motor protection (PTC

thermistor)

0h4

Data save error due to

undervoltage

RS-485 communication errors

(option)

54

LSI error (Power printed circuit

board)

(10) nv51 nvoAlarmLog

This NV outputs the history of recent 3 alarms.

- Variable type: UNVT_alarm_log (Decimal, 1 byte x 3)

1 byte 1 byte 1 byte

Most recent alarm

2nd recent alarm

code

code

(Decimal)

LonMaker represents this NV data in the format: "Most recent alarm code, 2nd recent alarm code, 3rd recent alarm code."

(Decimal)

3rd recent alarm

code

(Decimal)

- Data setting range: 0, 0, 0 to 255, 255, 255

- CPs for control of the affected network bandwidth: SCPT_minSendTime

- Output timing: At the time of data change or after the time specified by SCPT_minSendTime (if specified)

erf

erp

erh

26

Page 29

7.6 Reading and Writing fr om/to Inv erter's Functi on Codes

s

y

e

7.6.1 Reading from inverter's function codes

Use nv10 nviReadParamCode and nv33 nvoReadParamVal. This section summarizes the reading procedure.

(1) Enter the inverter's target function code into nv10 nviReadParamCode in the 16-bit format shown below. This starts the readout process of the

inverter's function code.

(Example) Reading H30 from the inverter

H: Function code group 08

30:

1E (hexadecimal)

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

Inverter's function code group Function code number

Inverter's function code group: Group of function codes (F, E, C etc.). See Table 14 below.

Function code number: 2-digit number following the function code group. For example, 98 in E98.

(2) nv33 nvoReadParamVal outputs the data of the function code specified by nv10 nviReadParamCode, then the readout process terminates. The

value is subject to the format of individual function codes.

For details about the data format of individual function codes, refer to the RS485 Communication User's Manual (MEH448), Chapter 5, Section

5.2 "Data Formats."

Input of a non-existing function code returns "0" to nv33 nvoReadParamVal.

If a running readout process for a function code is interrupted by another readout request, the interrupting request will be ignored. Thi

interface card does not support any output NV that identifies whether a readout process is already running. To run the read process ver

frequently, therefore, it is recommended that the software be so designed that it monitors the input/output status of nv10 nviReadParamCod

and nv33 nvoReadParamVal, confirms the completion of all the previous processes, and then starts a new readout process.

Group

Group

code

S 2 0x02 Run command data o 10 0x0A Option function

M 3 0x03 Monitor data J 14 0x0E Application functions

F 4 0x04 Fundamental functions y 15 0x0F Link functions

E 5 0x05 Extension terminal functions W 16 0x10 Keypad monitor data

C 6 0x06 Control functions X 17 0x11 Alarm data 1 for keypad

P 7 0x07 Motor parameters Z 18 0x12 Alarm data 2 for keypad

H 8 0x08 High performance functions

Example: Reading the inverter's function code F23 (Starting frequency) whose value is 0.5 Hz

1) nv10 nviReadParamCode: Enter 417 (hex) to this NV.

2) nv33 nvoReadParamVal: This NV outputs 5.

081E (hexadecimal) = 2078 (decimal)

Table 14 Function Code Groups

Function code name Group

Group

code

Function code name

Function code group = F (04h), Function code number = 23 (17h)

(5 means 0.5 Hz because of the format with 0.1 Hz resolution)

27

Page 30

7.6.2 Writing to inverter's function codes

p

o

Use nv11 nviWriteParamCode, nv12 nviWriteParamVal, and nv34 nvoAccessErrCode. This section summarizes the writing procedure.

(1) Enter the inverter's target function code into nv11 nviWriteParamCode. The data entry format is the same as that of the readout on the previous page.

(2) Enter data to be written into the target function code, into nv12 nviWriteParamVal. This starts the writing process of the function code data to the

inverter. The data entry format is the same as that of the readout on the previous page.

For details about the data format of individual function codes, refer to the RS485 Communication User's Manual (MEH448), Chapter 5, Section

5.2 "Data Formats."

(3) nv34 nvoAccessErrCode outputs the result of the writing process, then the writing process terminates. The format of nv34 nvoAccessErrCode is

shown below.

1 byte 1 byte 1 byte

Error code

LonMaker represents this NV data in the format: "Error code (decimal), Function code grou

(decimal), Function code number (decimal)."

Function code

group of error

detection target

Function code groups are the same as those in the readout process. See Table 14 on the previous page.

Error code Description

00h (0) Normal

01h (1) Link priority error

02h (2) Attempted to write data to a non-existing function code

03h (3) Attempted to write data to a write-protected function code

06h (6) Attempted to write data to a function code not allowed to change during running

07h (7)

08h (8) Out of data entry range

09h (9) Attempted to write data to a password-protected function code

0Fh (15) Function code write error

If a writing process for a function code is interrupted by another writing request, error code 0Fh

(Function code write error) is immediately issued to nv34 nvoAccessErrCode as a response t

the interrupting request, then the response to the interrupted process will be issued.

Example: Writing 9.5 s to the inverter's function code H13 (Restart Mode after Momentary Power Failure, Restart time)

1) nv11 nviWriteParaCode: Enter 80Dh to this NV.

2) nv12 nviWriteParamVal: Enter 95 to this NV.

3) nv34 nvoAccessErrCode: The written result is returned to this NV as the following strings.

- For normal writing: 0, 8, 13

- For out of range writing: 8, 8, 13

Function code

number of the

error detection

Table 15 Error Codes

Attempted to write data to a function code not allowed to change when the terminal input

is alive.

Function code group = H (08h), Function code number = 13 (0Dh)

(95 means 9.5 seconds because of the format with 0.1 s resolution)

(0: Error code, H: Function code group, 13: Function code number)

(8: Error code, H: Function code group, 13: Function code number)

28

Page 31

7.7 VSD Object Configuration Properties (CPs)

This section details VSD object configuration properties (CPs) that need supplemental descriptions. For CPs not found in this section, refer to Section 7.3

"VSD Object."

(1) SCPT_maxRcvTime

Receive heartbeat. This CP specifies the heartbeat receive interval for input NVs listed in Table 16 in block. If no data is received within this interval

after the reception of the last data, the interface card interprets the state as a LONWORKS communications error.

Setting the heartbeat time at 0.0 s does not break the connection to the LONWORKS network even if no data is received.

For details about the settings and activities on a LONWORKS connection break, refer to Chapter 8, Section 8.1 "Specifying an Inverter

Reaction to LONWORKS Communications Errors."

- Data setting range: 0.0 to 6553.4 s (0.1 s resolution)

- Default setting: 0.0 s (Ignore connection break)

Table 16 NVs with Receive Heartbeat Time Specified by SCPT_maxRcvTime

Index NV name

nv1 nviDrvSpeedStpt

nv2 nviDrvSpeedScale

nv8 nviOpeCmd

nv9 nviFreqCmd

nv13 nviAOCmd

nv14, nv15 nviDOcmd_Y1, Y2

nv16 nviFWDcmd

nv17 to nv21 nviXcmd_1 to 5

(2) SCPT_maxSendTime

Send heartbeat. This CP specifies the constant updating period for all output NVs listed in Table 17 below in block. Specifying it periodically updates

those NVs that include the internal monitor values.

Setting the send heartbeat at 0.0 s does not cause updating.

- Data setting range: 0.0 to 6553.4 s (0.1 s resolution)

- Default setting: 0.0 s (No periodic updating)

Table 17 NVs with Send Heartbeat Time Specified by SCPT_maxSendTime

Index NV name Index NV name

nv3 nvoDrvCurnt nv32 nvoDrvTemp_2

nv4 nvoDrvSpeed nv33 nvoReadParamVal

nv5 nvoDrvVolt nv35 nvoAiVal_1

nv6 nvoDrvPwr nv36 nvoAiVal_2

nv23 nvoOpeStatus nv37 nvoAiVal_3

nv24 nvoOutputFreq nv38 nvoPIDFb