Page 1

Instruction Manual

CC-Link Interface Card

” OPC-F1-CCL”

Thank you for purchasing our CC-Link Interface Card OPC-F1-CCL.

• This product is designed to connect the FRENIC-Eco series of inverters to CC-Link. Read through this

instruction manual and be familiar with the handling procedure for correct use.

• Improper handling blocks correct operation or causes a short life or failure.

• Deliver this manual to the end user of the product. The end user should keep t his manual in a safe place

until the CC-Link Interface Card is discarded.

• For the usage of inverters, refer to the instruction manual prepared for the FRENIC-Eco series of

inverters.

Fuji Electric FA Components & Systems Co., Ltd. INR-HF52237-E

Page 2

Copyright © 2006 Fuji Electric FA Components & Systems Co., Ltd.

All rights reserved.

No part of this publication may be reproduced or copied without prior written permission from Fuji Electric FA

Components & Systems Co., Ltd.

All other product and company names mentioned in this manual are trademarks or registered trademarks of their

respective holders.

The information contained herein is subject to change without prior notice for improvement.

Page 3

Preface

Thank you very much for purchasing CC-Link interface option “OPC-F1-CCL”.

Use this instruction manual to connect CC-Link master (a sequencer manufactured by Mitsubishi Electric

Co., Ltd., etc.) and the FRENIC-Eco through the CC-Link. Please, read through this manual carefully prior to

use of the product to familiarize yourself with correct use. Improper handling may result in malfunction,

shorter service life or failure.

This manual is designed to serve as a quick guide to the installation and operation of the CC-Link

Attestation logo mark

Interface Card. For the FRENIC-Eco and other optional functions, refer to the FRENIC-Eco User’s

Manual (MEH456□), RS-485 User’s Manual (MEH448□).

If you have any questions about the product or this instruction manual, please contact the store or our

nearest sales office.

How this manu al is organ ized

This manual is made up of chapters 1 through 14.

Chapter 1 Features

Gives an overview of the main features of the CC-Link Interface Card.

Chapter 2 Acceptanc e Insp ecti on

Lists points to be checked upon delivery of the Card and precautions for transportation and storage of the Card. Also

presents the appearance of the Card and provides information on how to obtain an EDS file.

Chapter 3 Installation

Provides instructions and precautions for installing the Card.

Chapter 4 Wiri ng and Cab ling

Provides wiring and cabling instructions around the pluggable connector for the Card. Also gives the specifications

for the cables.

Chapter 5 Procedur e for Inst ruction of the Option

The procedure for introducing CC-Link option is described here.

Chapter 6 Function Cod e

Lists the inverter's function codes which are specific to CC-Link.

Chapter 7 Protectiv e Operation

Operation when an abnorm al telecommunication line is generated while operation command and the speed

command given by way of CC-Link.

Chapter 8 Link Fu nction s

Set content when the driving operation of the inverter is done by way of CC-Link.

Chapter 9 Comm un ication bitween Sequen cer

The buffer memory use address of the CC-Link master unit used by the inverter communication.

Chapter 10 Com mu nication Specific ation

I/O signal and a remote register.

Chapter 11 L ink Num ber / Data Form at

Lists the CC-Link comm unication No and the communication data format.

Chapter 12 Ap rication Prog ram examples

The program example of controlling the inverter by the sequence program.

Chapter 13 Troubleshootin g

Provides troubleshooting instructions for certain problems, e.g., when the inverter does not operate as ordered or

when an alarm condition has been recognized.

Chapter 14 Specifications

Lists the general specifications and communications specifications.

1

Page 4

Icons

not operating to full

efficiency, as well as information concerning incorrect operations and settings which can result in

The following icons are used throughout this manual.

This icon indicates information which, if not heeded, can result in the pro duct

accidents.

This icon indicates information that can prove handy when performing certain settings or operations.

This icon indicates a reference to more detailed information.

Table of Contents

Chapter1 Features ..........................3

Chapter2 Acceptance Inspection ..............4

Chapter3 Installation ........................5

Chapter4 Wiring and Cabling .................6

Chapter5 Procedure for Introduction of the Option8

Chapter6 Function Codes ....................9

6.1 Standard function codes...............9

6.2

Function codes exclusive to communication

6.3 Function codes exclusive to the option... 9

Chapter7 Protective Operation ...............10

7.1 Protective Operation function codes .... 10

Chapter8 Link Functions ....................15

8.1 Enabling link operation ...............15

8.2 Confirmation and writing of function code15

Chapter9 Communication between Sequencer .16

9.1 Outline of the communication .........16

9.2 Reliability of data exchanged through link17

9.3 Using area of buffer memory ..........18

9.4 Using addresses of buffer memory .....19

...9

Chapter10 Communication specification ...... 21

10.1 Input/output signal list ............... 21

10.2 Assigning remote registers ........... 23

10.3 Description of remote registers........ 25

Chapter11 Link Number / Data Format........ 27

Chapter12 Application program examples ..... 37

12.1 System configuration ................ 37

12.2 Outline of master unit ................ 37

12.3 CC-Link startup program ............. 39

12.4 Procedure for reading operation status . 40

12.5 Procedure for setting the operation mode41

12.6 Procedure for operation command setting42

12.7 Monitoring procedure ................ 43

12.8 Procedure for reading function codes .. 44

12.9 Procedure for writing function codes ... 45

12.10

Procedure for setting the command frequency

12.11 Procedure for reading alarm difinition .. 47

12.12 Procedure for resetting the inverter .... 48

Chapter13 Troubleshooting ................. 49

Chapter14 Specification .................... 51

46

2

Page 5

Chapter1 Features

CC-Link is FA opening field network system that means Control&Communication Link. It is transmission speed

156kbps~10Mbps the CC-Link master unit is connected with the FRENIC-Eco CC-Link option card with a special

cable. And the total extension are 100m~1,200m. Because the system from which the distance is demanded by the

system from which the speed are demanded can use it in a wide area, a flexible system configuration becomes

possible. This option card corresponds to Ver2.00 (enactment in January, 2003) that can send and recei ve not only

profile Ver1.10 (communications protocol) that the CC-Link society is enacting so far but also more data.(The master

bureau should also be doing for Ver2.00 when using it with Ver2.00.)

Installing this option card in FRENIC-Eco can do the following from the CC-Link master unit:

・

Inputting operation and stop signals

・The frequency instruction can be set.

・

State of driving

can be monitored.

Forward operation, reverse operation,

completion,

・Various states of inverter driving can be monitored.

Frequency instruction,

operation time, etc.

・

Each function code can be referred and be changed.

command code execution completed, alarm state, remote station ready, etc.

output frequency,

can be monitored.

Y1~Y5 State of terminal,

torque operation value,

batch alarm, monitoring,

Frequenc y setting

output current, output voltage, integrated

3

Page 6

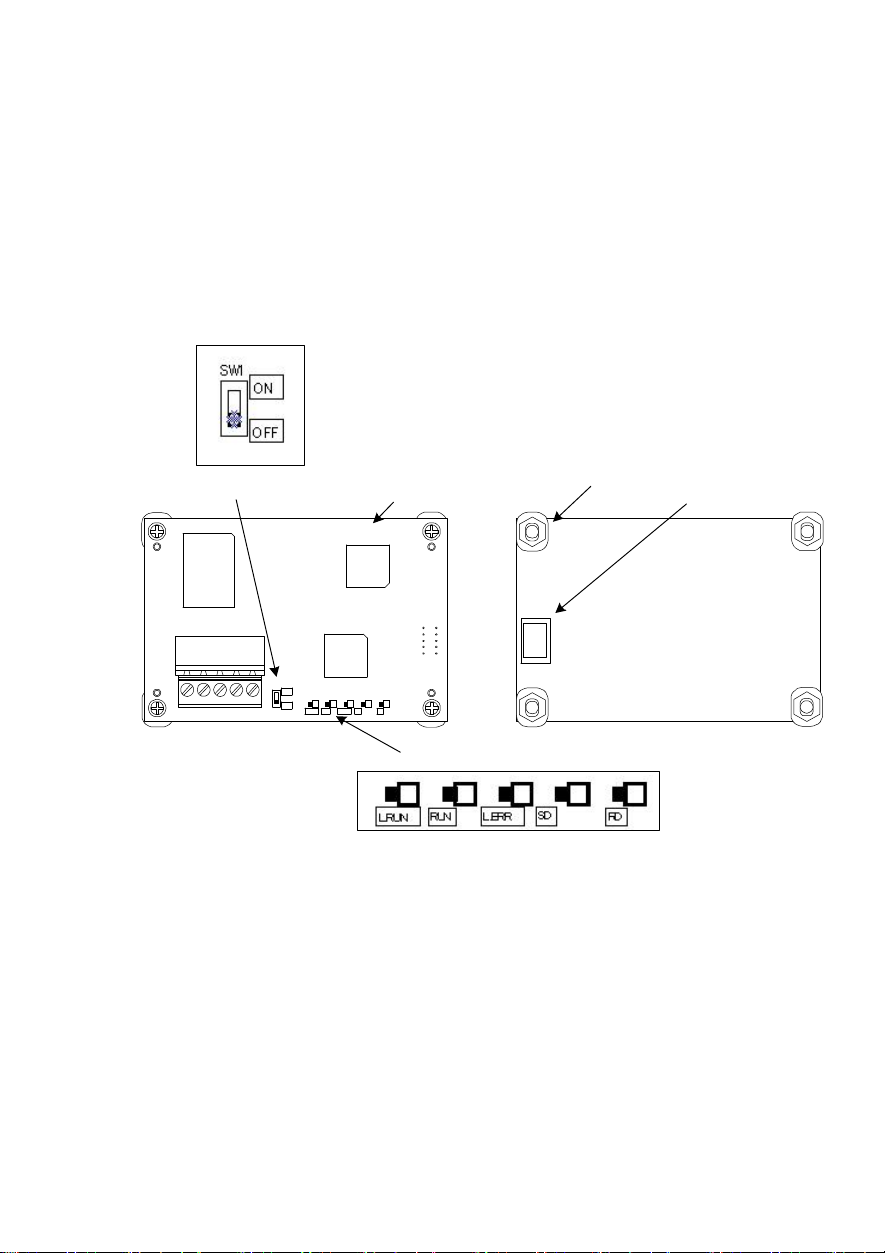

Chapter2 Acceptance Ins pecti on

Unpack the package and check that:

(1) A CC-Link Card is contained in the package.

(2) The DeviceNet Card has not been damaged during transportation--no defective electronic devices, dents, or

warp.

(3) The model name "OPC-F1-CCL" is printed on the DeviceNet Card. (See Figure 1.)

If you suspect the product is not working properly or if you ha ve any questions about your product, contact your Fuji

Electric representative.

This card corresponds to a soft version since 1300 of the FRENIC-Eco series inverters.

SW1(Terminating resistor selection swith)

Model number

Space(4)

CN1

OPC-F1-CCL

TB

1

SW

1

O

N

OF

F

L.RUNRUNL.ER

S

D

R

CN1

R

D

LED(Operation status indicator)

Figure1 Front of the Card Figure2 Back of the Card

4

Page 7

Control PCB

Chapter3 Installat ion

Turn the power off and wait for at least fi ve minutes for models of 30 kW or below, or ten minutes for models

of 37 kW or above, before starting installation. Further, check that the LED monitor is unlit, and check the DC

link circuit voltage between the P (+) and N (-) terminals to be lower than 25 VDC.

Otherwi se, elec tri c shoc k co uld oc cur.

Do not touch any metallic part of the connector for the main unit (CN1) or any electronic component.

Otherwise, electronic components may be damaged by static electricity. Also, the stain or adhesion of sweat

or dust may adversely affect the contact reliability of the connector in the long run.

An accid ent cou ld occ ur.

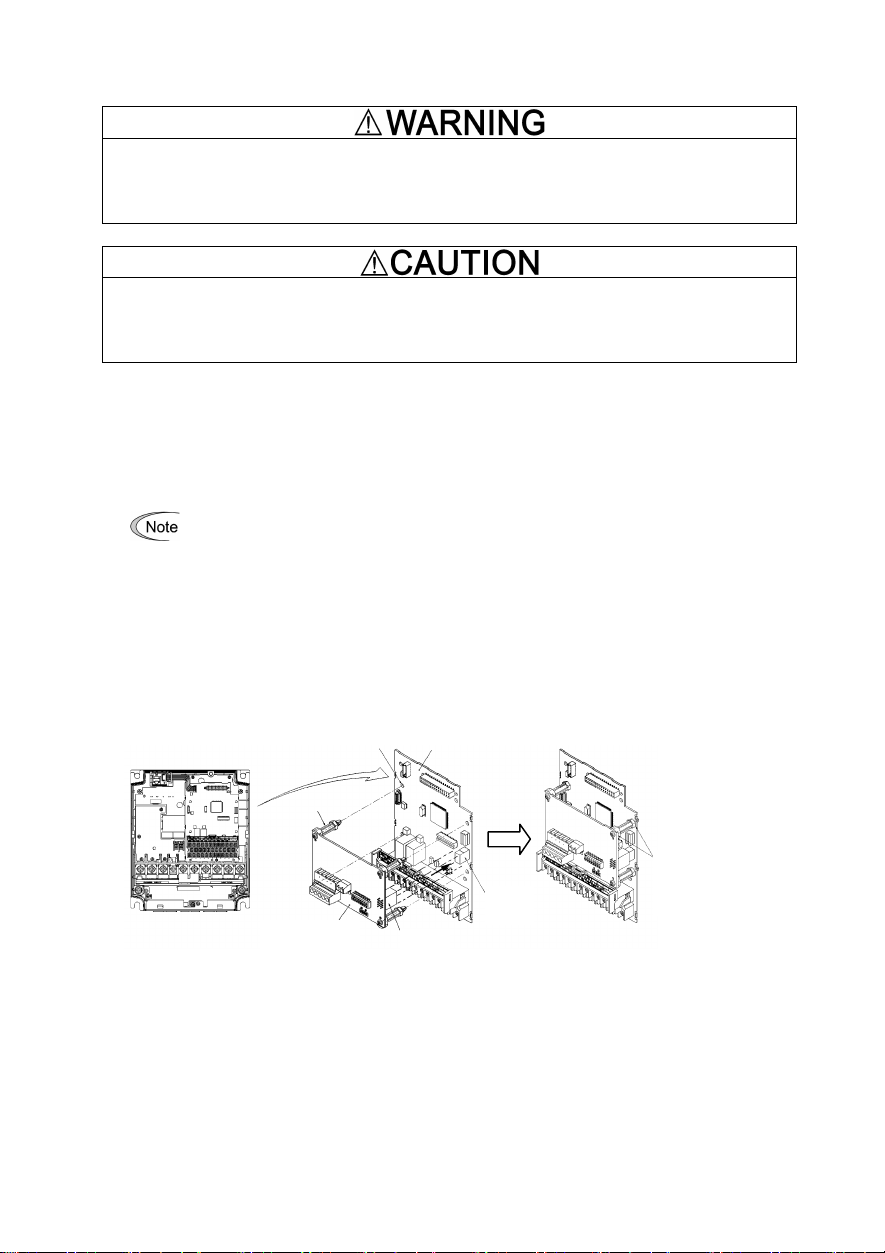

(1) Remove the covers from the inverter to expose the control printed circuit (Figure 3).

For the removal instructions, refer to the FRENIC-Eco Instruction Manual (INR-SI47-0852□), Chapter 2,

Section 2.3 "Wiring." (For ratings of 37 kW or above, also open the keypad enclosure.)

(2) Insert four spacers and connector CN1 on the back of the OPC-F1-CCL (Figure 2) into the four spacer holes and

Port A (CN4) on the inverter's control printed circuit board (PCB) (Figure 4), respectively.

Make sure, visually, that the spacers and CN1 are firmly inserted (Figure 5).

(3) Install the wires for the OPC-F1-CCL.

For wiring instructions, see Chapter 4.

(4) Put the covers back to its original position.

For the installation instructions, refer to the FRENIC-Eco Instruction Manual (INR-SI47-1059-E), Chapter 2,

Section 2.3 "Wiring." (For ratings of 37 kW or above, also close the keypad enclosure.)

4 Spacer Holes

Figure 3 FRN7.5F1S-2J -

FRN15F1S-2J

(example)

4 Spacers

Port A

CC-Link Card

OPC-F1-CCL

Figure 4 Mounting the Card Figure 5 Mounting Completed

CN1

(CN4)

5

Make sure that there

is no space between

control PCB and

spacers.

Page 8

DADBDG

SLD

FG

Motor

Power

DB

DB

DB

Chapter4 Wiring and Cabling

The

wiring and cabling diagram is shown on the page that follows. Observe the following precautions

when connecting the product.

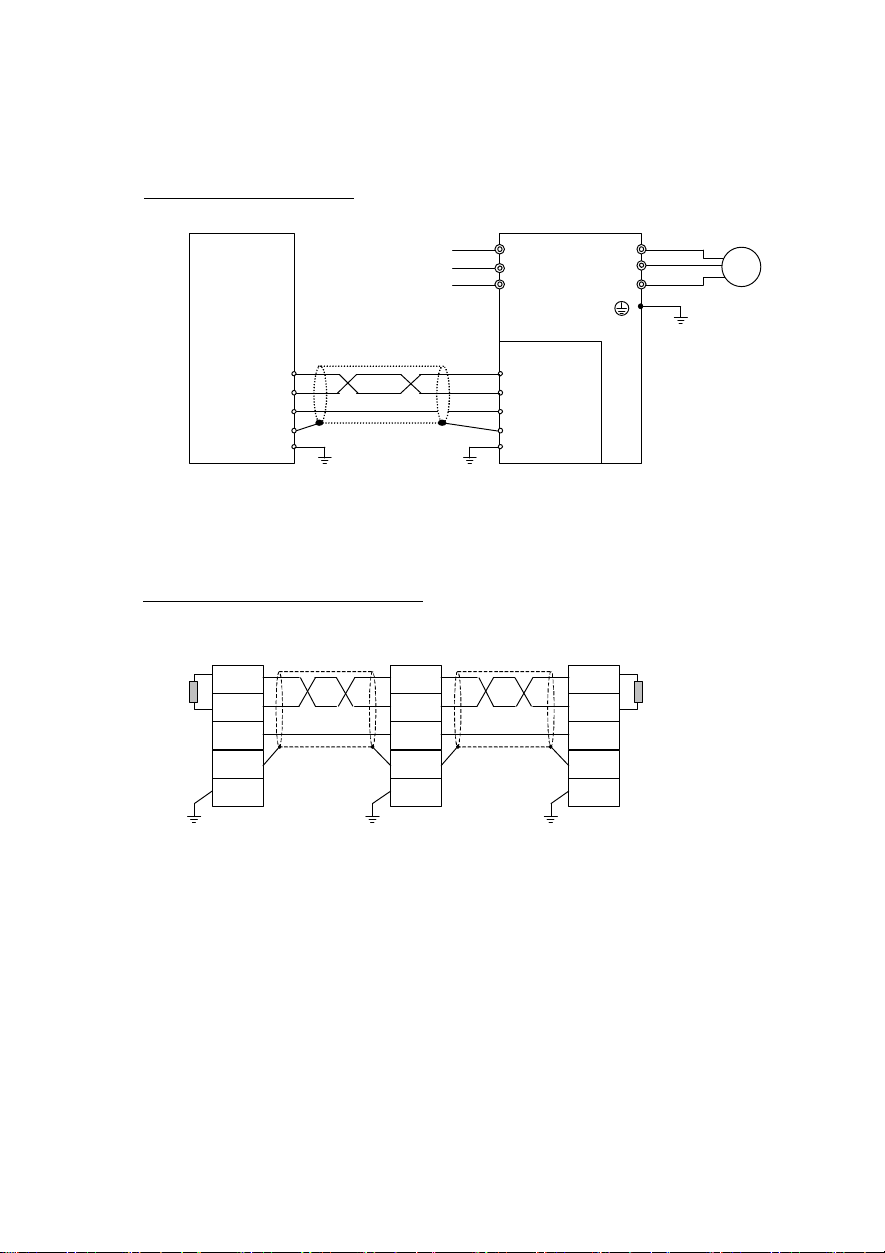

When one inverter is connected:

CC-Link Master

Shielded twist

pair cable

Eco inverter

R U

S V

T W

OPC-F1-CCL

DA

DB

DG

SLD

FG

Figure 6 Inverter connection diagram (One unit)

Set SW1 to ON(With terminating resistor).

When two or more inverters are connected:....... For the number of connected units, refer to chapter 14.

Master

DA

Terminal Terminal resistor

DG

SLD

FG

Shielded twist

pair cable

Eco

OPC-F1-CCL

inverter

DA

DG

SLD

FG

*1

Shielded twist

pair cable

Eco

OPC-F1-CCL

inverter

DA

DG

SLD

FG

(SW1=ON)

Figure 7 Inverter connection diagram (Two or more units)

*1) For the unit in the middle, set SW 1 to OFF(W ithout terminating resistor).

6

Page 9

g

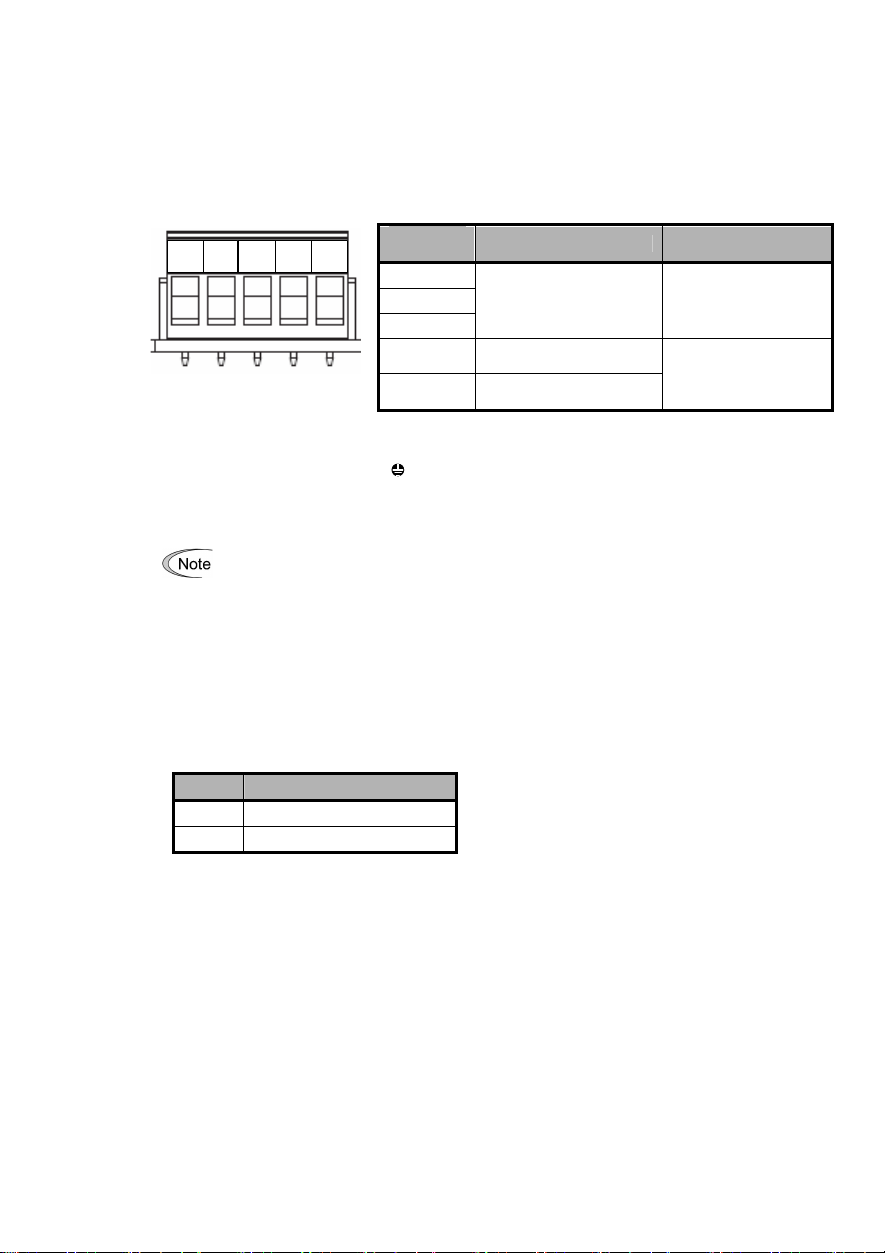

Figure 8

Terminal block TB1

[Precautions about connection]

(1) Use a special cable for the product. (Refer to chapter 14.)

Never use a soldered cable because it may cause disconnection or wire break.

(2)

Wiring around the

FG SLD DG DB DA

[Wiring around the grounding terminal (FG)]

Connecting the grounding terminal( G ) on the inverter.

Applicable wire size: AWG24~12(0.2mm2~2.5mm2)

Tightening torque : 0.5~0.6 [Nm]

For protection against external noise and prevention of failures, be sure to connect a groundin

wire.

A typical pluggable connector meeting the specifications is MSTB 2.5/5-ST-5.08-AU made by Phoeni x

Contacts.

CC-Link

pluggable connector

Table 1

Terminal

designation

DA

DB

DG

SLD

FG

Terminal board specifications

Description Remark

Used for comm unication

data

Used for connecting the

shield wire of the cable

Used for connecting the

earthing wire

The SLD and FG are

connected each other

in the unit.

(3)

Terminating resistor switch

By ON or OFF of SW1, internal terminating resistor can be set.

SW1 Description

OFF Without terminating resistor

ON 110Ω

(4) Use the terminating resistors supplied with the PLC.

(5) Please refer to connected number in Chapter 14 for the maximum, connected number.

(SW1)

7

Page 10

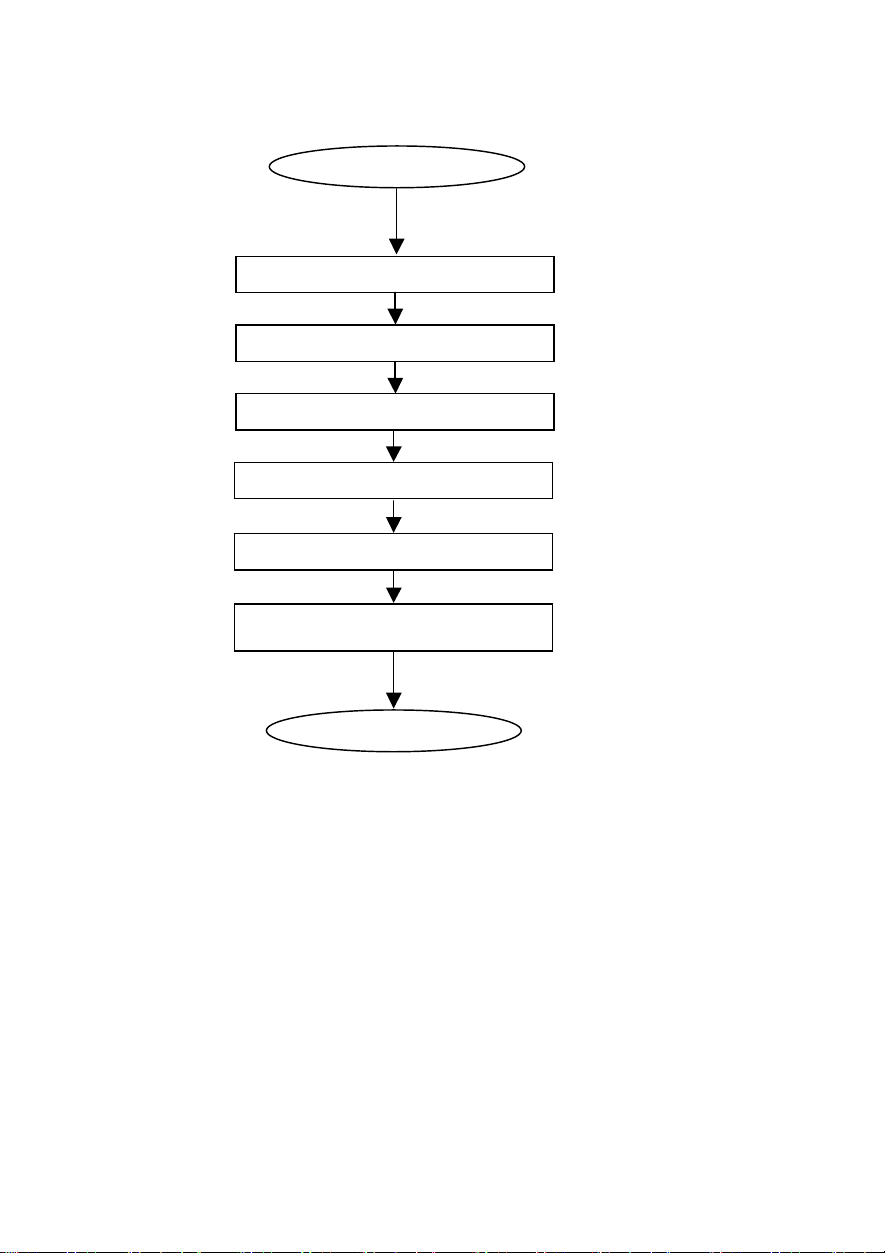

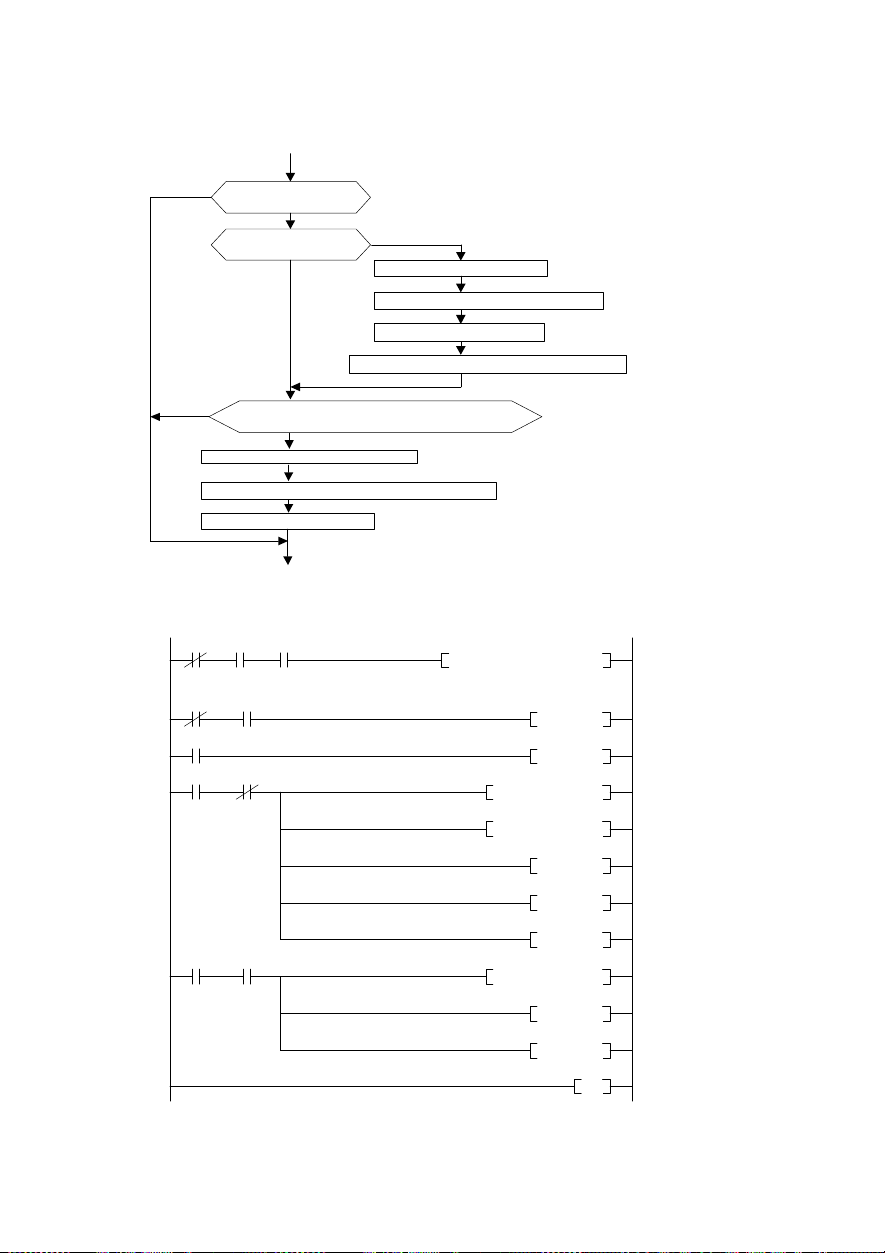

Chapter5 Procedure for In tr oducti on of the Option

The procedure for introducing CC-Link option is described here. Please prepare in the following steps:

Set the switches (SW1).

Turn ON the power to the inverters.

After the above steps have been done, the preparation for operating the inverters is complete.

Confirm the communication is normal after confirming the master side set with LED lit.

Refer to operation status indicate LED in Chapter 14 for lighting LED.

After the master side has been prepared, the inverters can be operated via CC-Link by setting RUN.

Start

Acceptance inspection

Install the option.

Connect the cables.

Set the function codes

(H30,y98,o27~o32).

Preparation finish

See “2. Acceptance Inspection”.

See “3. Installation”.

See “4. Wiring and Cabling”.

See “14 Specifications”.

See “6. Function Codes”, “7.

Protective Operation”,and “8.

Link Functions”.

8

Page 11

Chapter6 Function Codes

·If the data of a function code is incorrect, the system may fall into a dangerous status. Recheck data

whenever you have finished setting or writing data.An acciden t m ay oc cur.

6.1 Standard func tion codes

There are restrictions on the standard function codes that can be accessed from CC-Link. For further

information, refer to the Link No. in chapter 8

6.2 Functi on codes excl usive to communi cati on

A common data format (S-code, M-code, W -code, X-code and Z-code) can be used as the specifications

exclusive to communication. The data relating to the command / monitoring are difined other than the

standard function codes. For the details of the communication-exclusive function codes, refer to Chapter 5 of

FRENIC-Eco RS485 User’s Manual (MEH448). However, the following communication-exclusive function

codes prohibit writing via CC-Link (allows reading).

Table2 Communication-exclusive function codes that prohibit writing

No.

S01

S05 Frequency command

S06 Operation command

Function code name

Frequency command

(p.u.)

Because the same data can be written from the remote

output and the remote register. (Refer to “10.

Communication Specifications”.)

Reason

6.3 Functi on codes excl usive to the optio n

In the software exclusive to CC-Link option, the operations o27,o28 and o30 in addition to the standard

function codes, are available as the function codes exclusive to the option.

Table3 Function codes exclusive to the option

No. Function code name Setting range

Operation when a failure has

o27

occurred

Communication failure when

o28

a failure has occurred

Extended setting

o30

(Multiple setting)

CC-Link option

o31

station number setting

CC-Link option

Transmission Baud rate

o32

setting

For the details of the function code o27 and o28, refer to “7. Protective Operation”.

0~15 The operation when the error is detected is selected.

0.0~60.0sec

0,5~255

1 Occupying one station (CC-Link Ver.1.1)

2 Occupying one station double(CC-Link Ver.2)

3 Occupying one station quadrople(CC-Link Ver.2)

4 Occupying one station octuple(CC-Link Ver.2)

0~64

65~255 Invalidity

0 156kbps

1 625kbps

2 2.5Mbps

3 5Mbps

4 10Mbps

5~255 Invalidity

Time set by the timer for continuing operation if a

communication failure has occurred.

non operation

Sets station number (address)

(Setting value “0”is station number “1”.)

Setting if a failure has occurred

The underlined part is a factory setting value.

9

Page 12

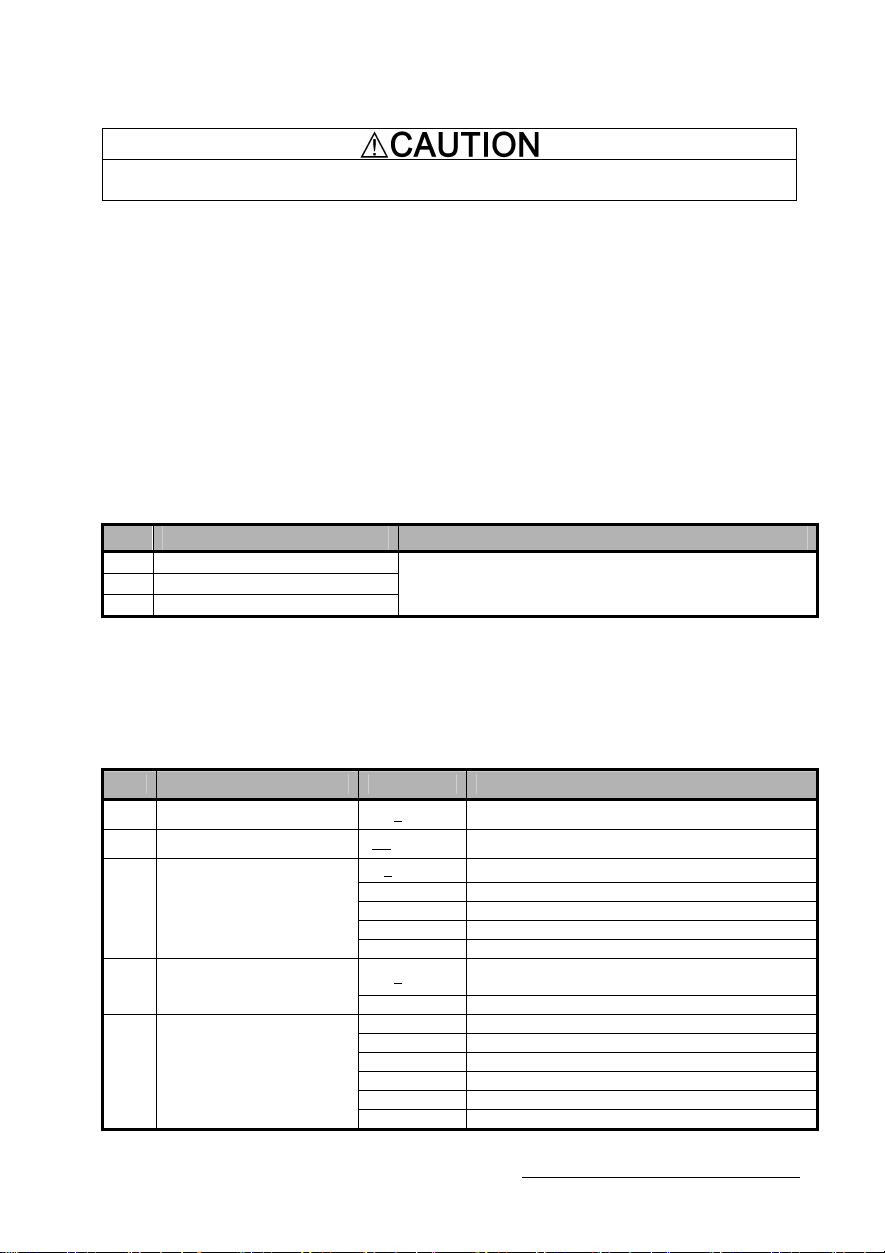

Chapter7 Protecti ve Operation

7.1 Prot ective Operati on function codes

This section describes how to operate if a failure of communication line occurs when the system is being

operated by operation command and speed command given through the CC-Link.

(1)

The inverter operation to be performed if a CC-Link communication error occurs

o27

4~9

13-15 Operating is continued to the return of the

*1

Communication line failure factor:Tim e over error

*2

Setting value of transmission Baud rate setting (o32) is reflected at the reset input (RST) or next power

*3

The factory values are all "0".

Inverter Operation in the Event of an Error Note

0 Put the motor immediately in trip.

1

Immediately trip the inverter by force, when the

time set by o28 (Timer) has expired.

2 Operating is continued to the return of the

communication according to the last command. If

the communication doesn't return to the end at

the time of the tim er of o28, the compulsion trip

mode.

3 Operating is continued to the return of the

communication, and after it returns,

it follows the instruction in the communication.

Same as for [o27=0]

10 Immediately decelerate the motor by force. When

the motor has stopped, turn on er5.

11 When the time set by o28 (Timer) has expired,

immediately decelerate the motor by force, when

the motor has stopped, turn on er5 .

12 Operating is continued to the return of the

communication according to the last command.

After decelerate the motor by force, turn on er5,

if the communication doesn't return to the end at

the time of the timer of o28.

communication, and after it returns,

it follows the instruction in the communication.

Option failure:W hen the MFP3 access error or the main body of the inverter and the communication error

occurs, Er4 is generated. It doesn't relate to the setting value of o27.

supply ON.

Automatic

return after

communication

returns

Automatic

return after

communication

returns

(o27).

The forced deceleration

period is specified by

F08.

10

Page 13

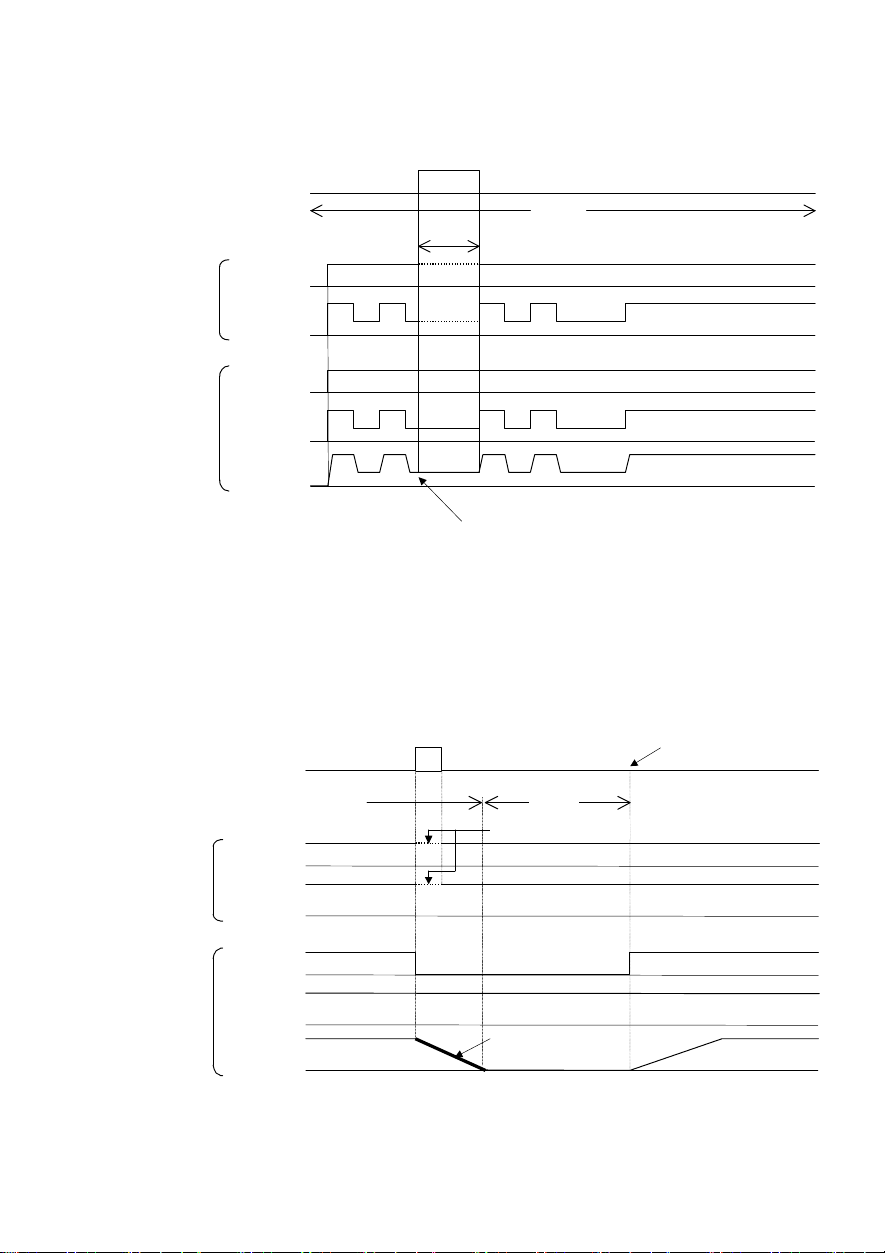

operation of

If transmission error occurs during acceleration, the speed

operation of

(2) Communication failure when a failure has occurred (o28)

0.0~60.0 sec

●

When the function code

o27=0 (

Mode in which the inverter is forced to immediately in trip in case of

communication failure

Command

from master

Communication

status

Indication

FWD

Setting up

frequency

Normal

Normal

ON

Error

Communic ation error

)

Normal

Er 5

ON

Alarm reset

Internal

Inverter

●

When the function code

Communication

Indication

FWD

Setting up

frequency

Operation

command

Setting up

frequency

Output

frequency

Command

from master

Internal

Inverter

Operation

command

Setting up

frequency

Output

frequency

o27=1 and o28=5.0 (

status

Normal

Operation

Normal

※11

ON

Operation

Stop

Free-run

Operation

Mode in which the inverter is forced to stop five seconds after a

communication failure occurred

Error

Normal

Er 5

5.0s

OFF

Stop

Free-run

)

Alarm reset

ON

Operation

accelerates up to the setting up f requency

11

Page 14

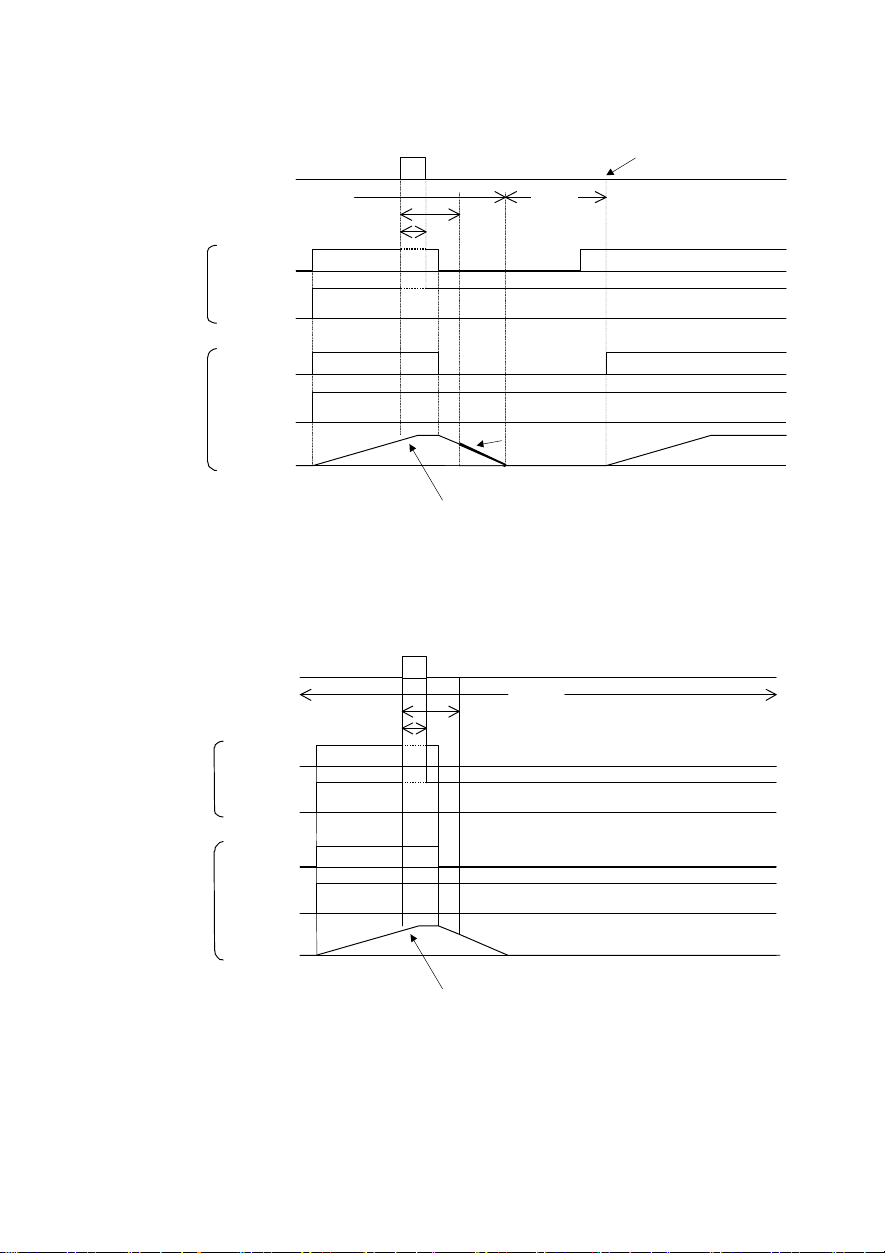

operation of

Indication

operation of

sion error occurs during acceleration, the

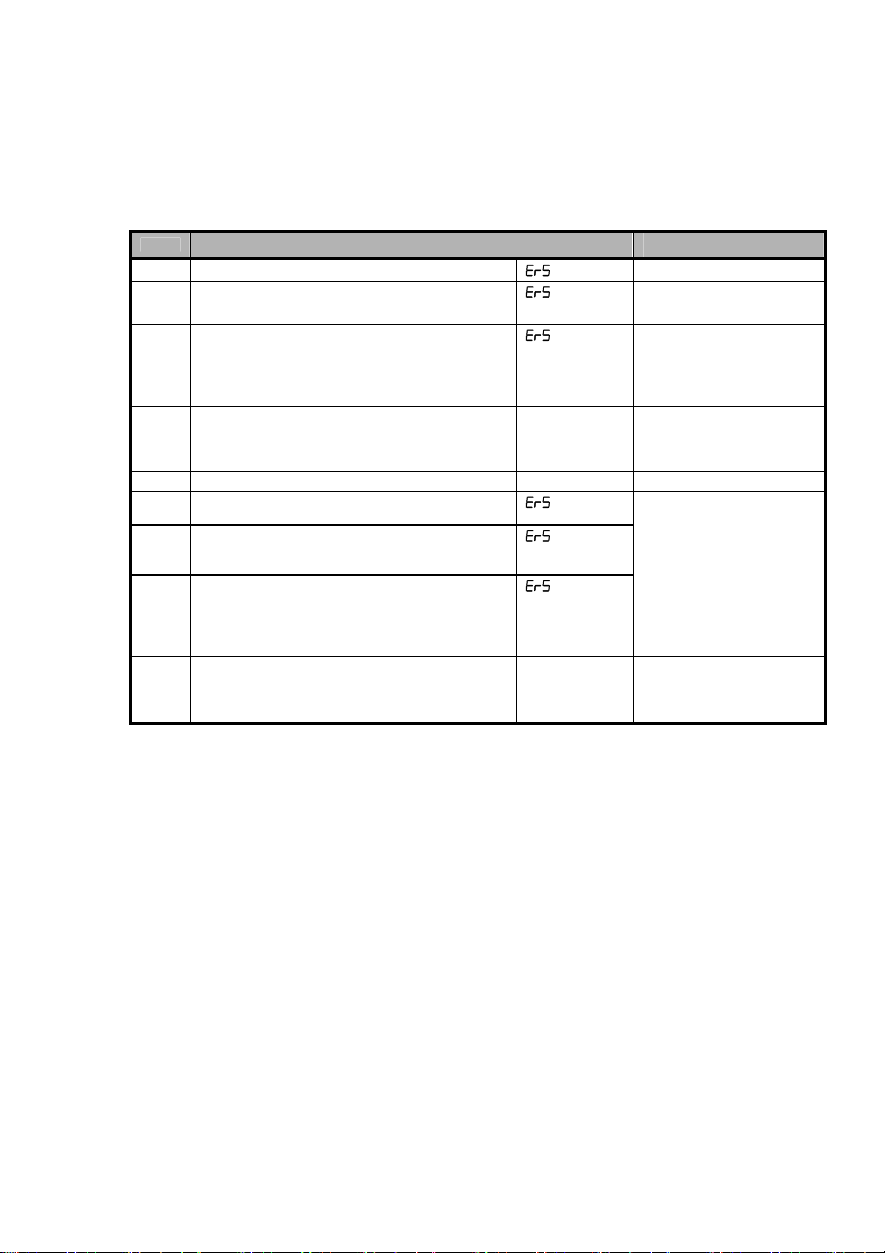

●

When the function code

Command

from master

Communication

FWD

Setting up

frequency

o27=2 and o28=5.0 (

When c ommunications is not recovered although five seconds

elapsed from the occurrence of a communications failure , and an er8 trip

occurs

)

status

Normal

Normal

ON

5.0 s

Error

Normal

※11

Alarm reset

Er 5

ON

Operatio n

command

Internal

Inverter

Setting up

frequency

frequency

※11

For the period until communications is recovered, the command (command data, operation

data) executed just before the communications failure had occurred is retained.

●

When the function code

Command

from master

Internal

Inverter

Communication

FWD

Operation

command

Setting up

frequency

frequency

Output

o27=2 and o28=5.0 (

status

Indication

Setting up

frequency

Output

Operation

Normal

※11

ON

Operation

Stop

Free-run

If transmission error occurs during acceleration, the

speed accelerates up to the setting up frequency

Operation

When a communications failure occurred but communications

was recovered within five seconds

Error

Normal

Normal

5.0s

OFF

Stop

If transmis

speed accelerates up to the set ting up frequency

12

)

Page 15

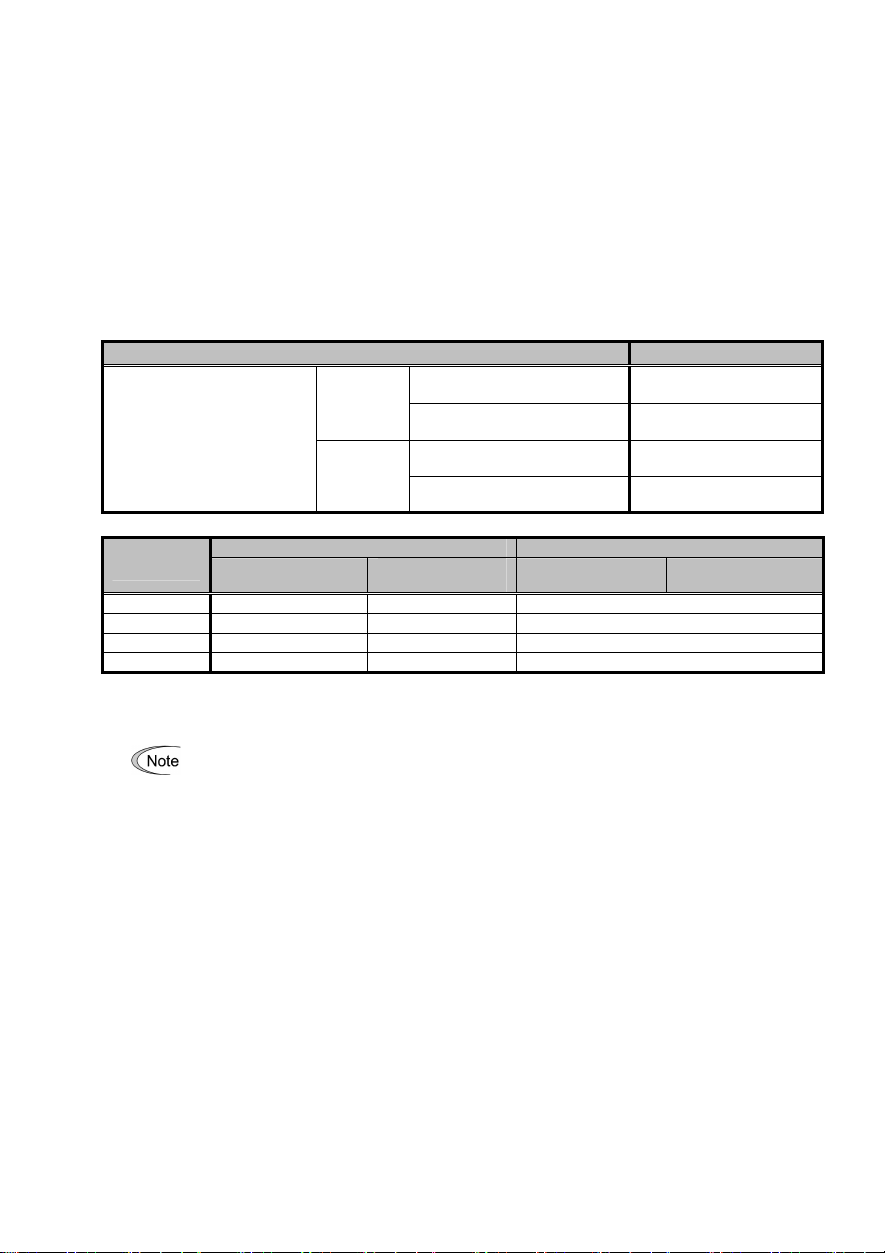

ON

operation of

Communication

of transm ission error is held

operation of

Setting up

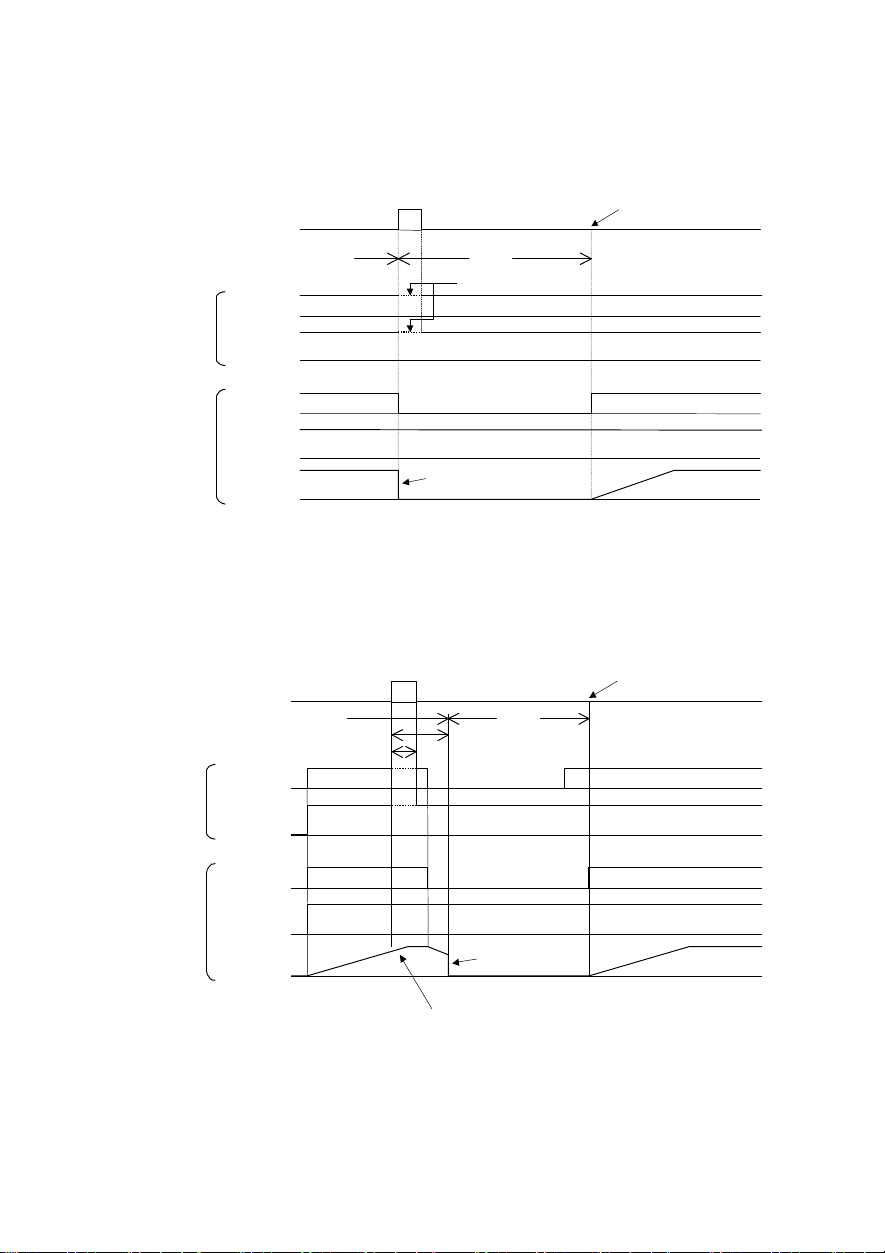

●

When the function code

Indication

Command

from master

FWD

Setting up

frequency

o27=3,13 ~ 15 (

status

Mode in which the inverter continues operating when a

communication failure occurs

Error

Normal

ON

)

Normal

Normal

※11

Operation

command

Internal

Inverter

Setting up

frequency

Output

frequency

※11

For the period until communications is recovered, the command (command data, operation

data) executed just before the communications failure had occurred is retained.

●

When the function code

Command

from master

Communication

Indication

FWD

frequency

status

Operation

o27=10 (

Mode in which the inverter is forced to immediately stop when a

communication failure occurs

Normal

Normal

ON

Error

The stting at the time

on and the operation continues.

)

Normal

Er 5

Communication error

ON

Alarm reset

Internal

Inverter

Operation

command

Setting up

frequency

Output

frequency

Operation

Stop

Decelerate the motor by force

(

Deceleration time is by F08.

13

Operation

)

Page 16

If transmission error occurs during acceleration, the

operation of

11

operation of

frequency

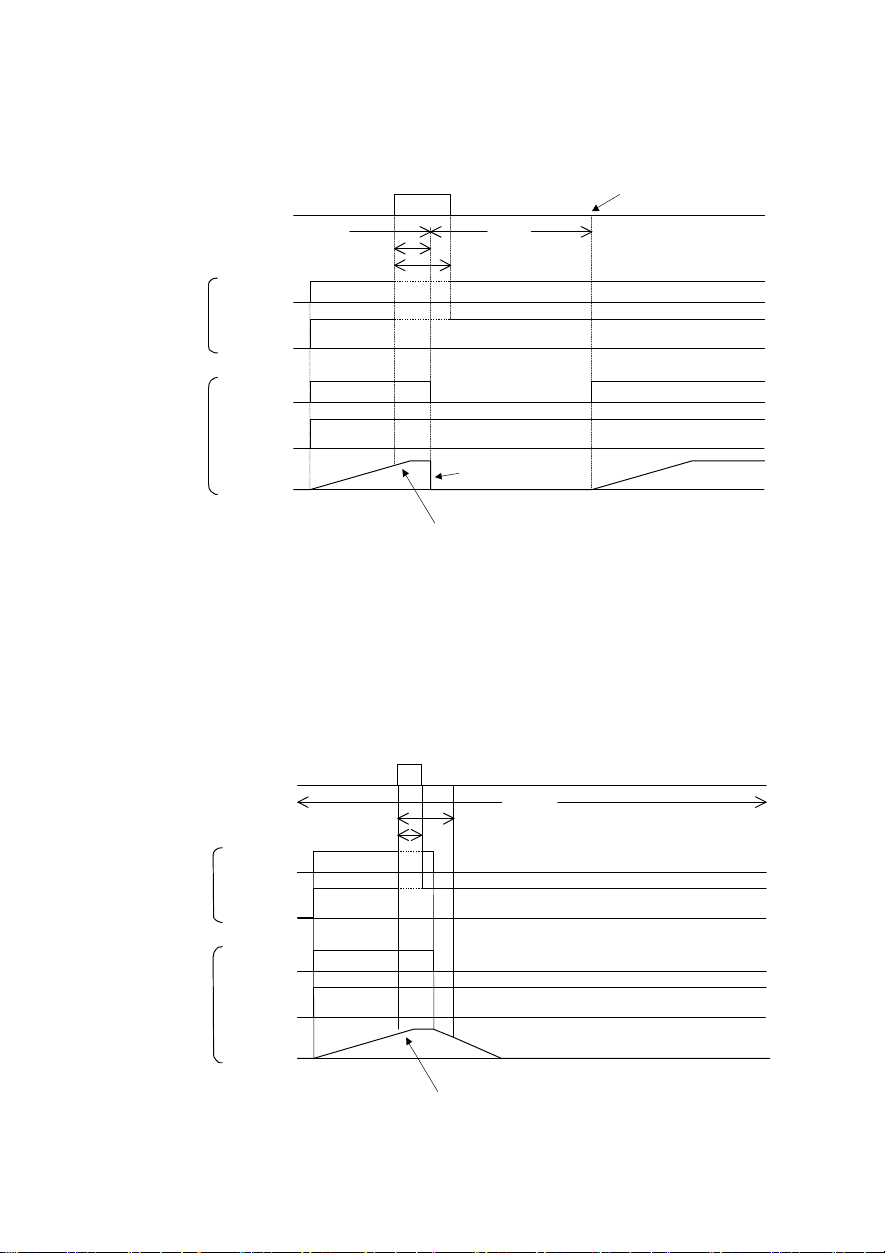

●

When the function code

Command

from master

Communication

Indication

FWD

Setting up

frequency

o27=11 and o2 8=5.0 (

status

Normal

Normal

ON

Mode in which the inverter is forced to stop in 5 sec onds

when a communication failure occurs

Error

Normal

※11

5.0s

Er 5

OFF

)

Alarm reset

ON

Operation

command

Internal

Inverter

Setting up

frequency

frequency

●

When the function code

Command

from master

Internal

Invert er

Communication

FWD

Operation

command

Setting up

frequency

frequency

Output

o27=12 and o28=5.0 (

status

Indication

Setting up

Output

Operation

Normal

※

ON

Operation

Stop

Decelerate the motor by force

(

Deceleration time is by F08.

speed accelerates up to the setting up frequency

Operation

)

Mode in which the communication returned within five seconds,

when a communication failure occurs

Error

Normal

Normal

5.0s

OFF

Stop

If transmission error occurs during acceleration, the

speed accelerates up to the setting up frequency

)

14

Page 17

S codes (command data, operation data) can be

Chapter8 Li nk Functions

The function code y98 “Bus Link function (Mode selection)” and the X function “24: operation selection through link

[LE]” switch the validity (REM · LOC/COM) of command data (S area). Familiarize yourself with it together with the

control block (Chapter 4 in the FRENIC-Eco User’s Manual (MET456)).

8.1 Enabling li nk operatio n

When the inverter is operated through the CC-Link, the operation must be switched to “Operation through link

enable” mode and “command through communication (other than 0)” must be selected by y98 “ Bus Link function

(Mode selection)”. (Such a flexible system configuration as operation command sent from the terminal board and

speed command sent through communication is enabled by selecting the value of y98 “Bus Link function (Mode

selection)”.)

Con ditio n Mod e

Command code FBH

(operation mode) = 0

Command code FBH

(operation mode) = 1

Corresponding X terminal ON “Operation through link

Corresponding X terminal OFF “Operation through link

Assigning “24 : operation

selection through link [LE]” to

E01~E05 “X function selection”

Not

assigned

Assigned

y98 set ti ng

val ue

0

1

2

3

“ Oper atio n t hroug h link enable” mode “ Operat ion thro ugh li nk d isable” mo de

Com mand data

× × ×

○ × ×

× ○ ×

○ ○ ×

Operat io n

comman d

Com mand data

:Command through communication is valid. ×:Command through communication is invalid (Operation is

enabled by the command from the terminal board or the keypad.)

Even in “Operation through link disable” mode,

written.

8.2 Confir mation and writing of funct ion code

The change (writing) and the confirmation (reading) in the function code from CC-Link are always effective.

15

“Operation through link

enable” mode

“Operation through link

disable” mode

enable” mode

disable” mode

Operat io n co mm and

Page 18

read

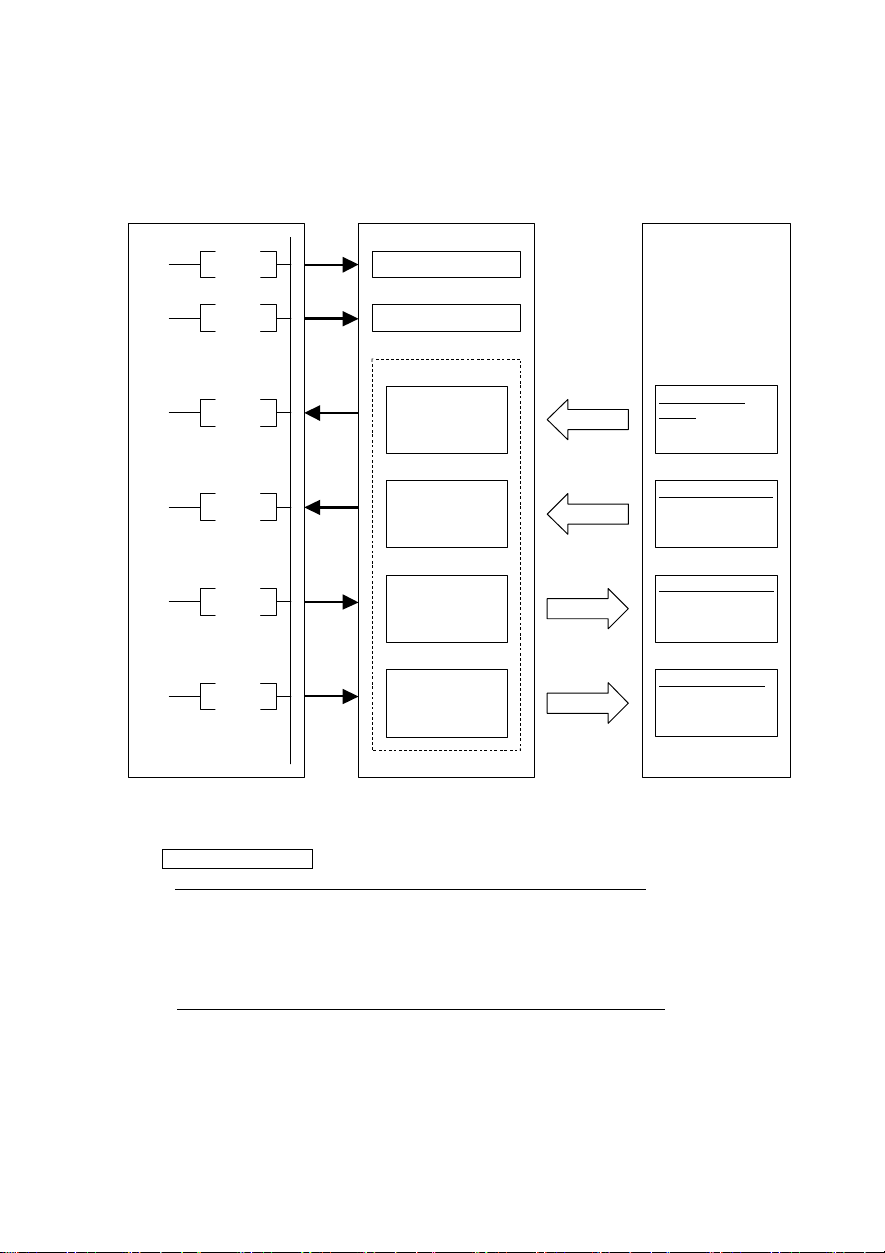

Chapter9 Com munication between Sequencer

9.1 Outline of t he co mmu nication

Sequencer CPU

SET Yn0

CC-Link

master unit

Refresh command

Eco Inverter

SET Yn6

FROM

FROM

TO

TO

Data link start

Buffer memory

Remote input

(RX)

Remote register

(RWr)

Remote output

(RY)

Remote register

(RWw)

Link scan

Control signal

output

· Inverter status

Control data output

· Monitor

· Function code

Control signal input

· Operation

command

Control data i nput

· Speed command

· Function code

write

Figure 9

CC-Link master station

(1) CPU with automatic refresh function installed (Example: QnA-CPU)

Communication between the CC-Link master station and the remote device is performed by

exchanging data through the sequence ladder and by autom atically refreshing the refresh

buffer of the master station with END command.

(2) CPU without automatic refresh function installed (Example: AnA-CPU)

Communication between the CC-Link master station and the remote device is performed by

exchanging data directly with the refresh buffer of the master station through the sequence

ladder.

16

Page 19

9.2 Reliability of data exc hang ed thro ugh link

· Consistency between the bit data and word data exchanged through link is established by the data

configuration in which bit data of different timing from word data can not be included in a word data

when bit data changes.

· The buffer operation commands of master unit (FROM, TO), different from normal inputs/outputs, are

not updated in batch, but processed through interrupt during execution of the program. The

input/output operation through link are executed at the timing of the command. So, note the following

three points:

(1) Execute data acquisition by FROM command at the start of the program.

(2) Execute update of output by TO comm and after all the related internal processing has finished.

(3) Execute update of output buffers of a unit at a same time (in one row).

It is recommended that all the link buffers are updated in batch.。

17

Page 20

9.3 Usin g area of bu ffer memory

(1)

Remote input signal (Inverter Master)

Mas ter s tation Rem ote dev ice s tatio n Rem ote dev ice sta tion

no. 1

For stati on

no. 2

For stati on

no. 3

For stati on

no. 63

For stati on

no. 64

Ad dress Rem ote in put

00E 0H R X 0 ~ RX F

00E 1H RX 1 0 ~ RX 1F RX 10 ~ RX 1F

00E 2H RX 2 0 ~ RX 2F

00E 3

00E 4H RX 4 0 ~ RX 4F RX 0 ~ RX F

00E 5

015 CH RX 7C0 ~ R X 7CF

015 D

015 EH RX 7E0 ~ R X 7EF

015 F

H

H

~

H

H

RX 30 ~ RX 3F

RX 50 ~ RX 5F

RX 7D0 ~ R X 7DF

RX 7F0 ~ R X 7FF

~

(2)

Remote output signal (Master Inverter)

Mas ter sta tion Rem ote dev ice st ation R emo te de vice s tation

no. 1

For statio n

no. 2

For statio n

no. 3

For statio n

no. 63

For statio n

no. 64

Ad dress Rem ote in put

01 60H R Y 0 ~ R Y F

01 61H RY 1 0 ~ RY 1 F RY 1 0 ~ RY 1F

01 62H RY 2 0 ~ RY 2 F

01 63

01 64H RY 4 0 ~ RY 4 F R Y 0 ~ RY F

01 65

01 DCH RY 7C0 ~ RY 7CF

01 DD

01 DEH RY 7E0 ~ RY 7EF

01 DF

H

H

~

H

H

RY 30 ~ RY 3F

RY 50 ~ RY 5F

RY 7D0 ~ RY 7DF

RY 7F0 ~ RY 7FF

~

(3)

Remote register (Master Inverter)

For station

no. 1

For station

no. 2

For station

no. 3

For station

no. 64

Mas ter sta tion Rem ote dev ic e st ation Rem ote dev ice stat ion

Add ress

01E 0H RWw 0 RWw 0

01E 1H RWw 1 RWw 1

01E 2H RWw 2 RWw 2

01E 3H RWw 3 RWw 3

01E 4H RWw 4 RWw 0

01E 5

01E 6H RWw 6 RWw 2

01E 7H RWw 7 RWw 3

01E 8H RWw 8 RWw 4

01E 9H RWw 9 RWw 5

01E AH RWw A RWw 6

01E BH RWw B RWw 7

02D CH RWw F C

02D DH RWw FD

02D EH RWw F E

02D FH RWw FF

Rem ote inp ut

H

~

RWw 5

~

Stat ion no .1: one statio n occ upied Stati on no .3: one stati on occ upied

RX 10 ~ RX 1F

RX 0 ~ RX F

For stati on

Figure 10

Stati on no .1: one stati on occ upied Stati on no. 3: one statio n occ upied

RY 1 0 ~ RY 1F

RY 0 ~ RY F

For statio n

Figure 11

Statio n no.1: one station oc cupied S tation no .2: one station o ccupied

RWw 1

Figure 12

/ d ouble

18

Page 21

(4)

Remote register (Inverter Master)

Mas ter st ation Re mot e dev ice st ation Remo te de vice stat ion

For statio n

no. 1

For statio n

no. 2

For statio n

no. 3

For statio n

no. 64

Add ress

02 E0H RWr 0

02 E1H RWr 1 RW r 1

02 E2H RWr 2 RW r 2

02 E3

H

02 E4H RWr 4 RW r 0

02 E5H RWr 5 RW r 1

02 E6H RWr 6 RW r 2

02 E7H RWr 7 RW r 3

02 E8H RWr 8 RW r 4

02 E9H RWr 9 RW r 5

02 EAH RWr A RW r 6

02 EBH RWr B RW r 7

~

03 DCH RWr FC

03 DDH RWr FD

03 DEH RWr FE

03 DFH RWr FF

Rem ote in put

RWr 3

~

9.4 Usin g add resses of buffer memo ry

Table 4 Conversion formula of buffer memory address

Master

CPU with automatic refresh

function installed (QnA type)

CPU without automatic refresh

function installed (AnA type)

Register no.

Address Buffer memory top address

Table 5 Buffer m emory address assignment

Station

Input (Inverter Master) Output (Master Inverter)

no.

Register no. Address Register no. Address Register no. Address Register no. Address

1 RX 0~RX 1F 00E0H~00E1

2 RX 20~ RX 3F 00E2H~00E3

3 RX 40~ RX 5F 00E4H~00E5

4 RX 60~ RX 7F 00E6H~00E7

5 RX 80~ RX 9F 00E8H~00E9

6 RX A0~ RX BF 00EAH~00EB

7 RX C0~ RX DF 00ECH~00ED

8 RX E0~ RX FF 00EEH~00EF

9 RX100~ RX11F 00F0H~00F1

10 RX12 0~RX13F 00F2H~00F3

11 RX14 0~RX15F 00F4H~00F5

12 RX16 0~RX17F 00F6H~00F7

13 RX18 0~RX19F 00F8H~00F9

14 RX1A 0~RX1BF 00FAH~00FB

15 RX1C 0~RX1DF 00FCH~00FD

16 RX1E 0~RX1FF 00FEH~00FF

17 RX20 0~RX21F 0100H~0101

18 RX22 0~RX23F 0102H~0103

19 RX24 0~RX25F 0104H~0105

20 RX26 0~RX27F 0106H~0107

21 RX28 0~RX29F 0108H~0109

Remote input/output signal Remote register

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

RY 0~RY 1F 0160H~0161

RY 20~ RY 3F 0162H~0163

RY 40~ RY 5F 0164H~0165

RY 60~ RY 7F 0166H~0167

RY 80~ RY 9F 0168H~0169

RY A0~ RY BF 016AH~016B

RY C0~ RY DF 016CH~016D

RY E0~ RY FF 016EH~016F

RY100~ RY11F 0170H~0171

RY120~ RY13F 0072H~0173

RY140~ RY15F 0074H~0175

RY160~ RY17F 0076H~0177

RY180~ RY19F 0078H~0179

RY1A0~ RY1BF 007AH~017B

RY1C0~ RY1DF 007CH~017D

RY1E0~ RY1FF 007EH~017F

RY200~ RY21F 0180H~0181

RY220~ RY23F 0182H~0183

RY240~ RY25F 0184H~0185

RY260~ RY27F 0186H~0187

RY280~ RY29F 0188H~0189

Statio n no.1: one station occu pied Sta tion n o.2: occ uping one s tation d ouble

RWr 3

RWr 0

Figure 13

Conversion formula

(Derive register number divided by buffer memory address

from station no.)

Remote input/output signal

Remote register

(Station no.-1) 20H (Station no.-1) 4H

Buffer memory top address

+(station no.-1) 2H

Master Inverter Inverter Master

RWw 0~ RWw 3 01E0H~01E3

H

RWw 4~ RWw 7 01E4H~01E7

H

RWw 8~ RWw B 01E8H~01EB

H

RWw C~ RWw F 01ECH~01EF

H

RWw10~ RWw13 01F0H~01F3

H

RWw14~ RWw17 01F4H~01F7

H

RWw18~ RWw1B 01F8H~01FB

H

RWw1C~ RWw1F 01FCH~01FF

H

RWw20~ RWw23 0200H~0203

H

RWw24~ RWw27 0204H~0207

H

RWw28~ RWw2B 0208H~020B

H

RWw2C~ RWw2F 020CH~020F

H

RWw30~ RWw33 0210H~0213

H

RWw34~ RWw37 0214H~0217

H

RWw38~ RWw3B 0218H~021B

H

RWw3C~ RWw3F 021CH~021F

H

RWw40~ RWw43 0220H~0223

H

RWw44~ RWw47 0224H~0227

H

RWw48~ RWw4B 0228H~022B

H

RWw4C~ RWw4F 022CH~022F

H

RWw50~ RWw53 0230H~0233

H

+(station no.-1) 4H

RWr 0~ RWr 3 02E0H~02E3

H

RWr 4~ RWr 7 02E4H~02E7

H

RWr 8~ RWr B 02E8H~02EB

H

RWr C~ RWr F 02ECH~02EF

H

RWr10~ RWr13 02F0H~02F3

H

RWr14~ RWr17 02F4H~02F7

H

RWr18~ RWr1B 02F8H~02FB

H

RWr1C~ RWr1F 02FCH~02FF

H

RWr20~ RWr23 0300H~0303

H

RWr24~ RWr27 0304H~0307

H

RWr28~ RWr2B 0308H~030B

H

RWr2C~ RWr2F 030CH~030F

H

RWr30~ RWr33 0310H~0313

H

RWr34~ RWr37 0314H~0317

H

RWr38~ RWr3B 0318H~031B

H

RWr3C~ RWr3F 031CH~031F

H

RWr40~ RWr43 0320H~0323

H

RWr44~ RWr47 0324H~0327

H

RWr48~ RWr4B 0328H~032B

H

RWr4C~ RWr4F 032CH~032F

H

RWr50~ RWr53 0330H~0333

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

19

Page 22

Station no.

Input (Inverter Master) Output (Master Inverter)

Register no. Address Register no. Address Register no. Address Register no. Address

22 R X2A0~RX2BF 010AH~010B

23 R X2C0~RX2DF 010CH~010D

24 R X2E0~RX2FF 010EH~010F

25 R X300~RX31F 0110H~0111

26 R X320~RX33F 0112H~0113

27 R X340~RX35F 0114H~0115

28 R X360~RX37F 0116H~0117

29 R X380~RX39F 0118H~0119

30 R X3A0~RX3BF 011AH~011B

31 R X3C0~RX3DF 011CH~011D

32 R X3E0~RX3FF 011EH~011F

33 R X400~RX41F 0120H~0121

34 R X420~RX43F 0122H~0123

35 R X440~RX45F 0124H~0125

36 R X460~RX47F 0126H~0127

37 R X480~RX49F 0128H~0129

38 R X4A0~RX4BF 012AH~012B

39 R X4C0~RX4DF 012CH~012D

40 R X4E0~RX4FF 012EH~012F

41 R X500~RX51F 0130H~0131

42 R X520~RX53F 0132H~0133

43 R X540~RX55F 0134H~0135

44 R X560~RX57F 0136H~0137

45 R X580~RX59F 0138H~0139

46 R X5A0~RX5BF 013AH~013B

47 R X5C0~RX5DF 013CH~013D

48 R X5E0~RX5FF 013EH~013F

49 R X600~RX61F 0140H~0141

50 R X620~RX63F 0142H~0143

51 R X640~RX65F 0144H~0145

52 R X660~RX67F 0146H~0147

53 R X680~RX69F 0148H~0149

54 R X6A0~RX6BF 014AH~014B

55 R X6C0~RX6DF 014CH~014D

56 R X6E0~RX6FF 014EH~014F

57 R X700~RX71F 0150H~0151

58 R X720~RX73F 0152H~0153

59 R X740~RX75F 0154H~0155

60 R X760~RX77F 0156H~0157

61 R X780~RX79F 0158H~0159

62 R X7A0~RX7BF 015AH~015B

63 R X7C0~RX7DF 015CH~015D

64 R X7E0~RX7FF 015EH~015F

Remote input/output signal Remote register

Master Inverter Inverter Master

RY2A0~RY2BF 018AH~018B

H

RY2C0~RY2DF 018CH~018D

H

RY2E0~RY2FF 018EH~018F

H

RY300~RY31F 0190H~0191

H

RY320~RY33F 0192H~0193

H

RY340~RY35F 0194H~0195

H

RY360~RY37F 0196H~0197

H

RY380~RY39F 0198H~0199

H

RY3A0~RY3BF 019AH~019B

H

RY3C0~RY3DF 019CH~019D

H

RY3E0~RY3FF 019EH~019F

H

RY400~RY41F 01A0H~01A1

H

RY420~RY43F 01A2H~01A3

H

RY440~RY45F 01A4H~01A5

H

RY460~RY47F 01A6H~01A7

H

RY480~RY49F 01A8H~01A9

H

RY4A0~RY4BF 01AAH~01AB

H

RY4C0~RY4DF 01ACH~01AD

H

RY4E0~RY4FF 01AEH~01AF

H

RY500~RY51F 01B0H~01B1

H

RY520~RY53F 01B2H~01B3

H

RY540~RY55F 01B4H~01B5

H

RY560~RY57F 01B6H~01B7

H

RY580~RY59F 01B8H~01B9

H

RY5A0~RY5BF 01BAH~01BB

H

RY5C0~RY5DF 01BCH~01BD

H

RY5E0~RY5FF 01BEH~01BF

H

RY600~RY61F 01C0H~01C1

H

RY620~RY63F 01C2H~01C3

H

RY640~RY65F 01C4H~01C5

H

RY660~RY67F 01C6H~01C7

H

RY680~RY69F 01C8H~01C9

H

RY6A0~RY6BF 01CAH~01CB

H

RY6C0~RY6DF 01CCH~01CD

H

RY6E0~RY6FF 01CEH~01CF

H

RY700~RY71F 01D0H~01D1

H

RY720~RY73F 01D2H~01D3

H

RY740~RY75F 01D4H~01D5

H

RY760~RY77F 01D6H~01D7

H

RY780~RY79F 01D8H~01D9

H

RY7A0~RY7BF 01DAH~01DB

H

RY7C0~RY7DF 01DCH~01DD

H

RY7E0~RY7FF 01DEH~01DF

H

RWw54~RWw57 0234H~0237

H

RWw58~RWw5B 0238H~023B

H

RWw5C~RWw5F 023CH~023F

H

RWw60~RWw63 0240H~0243

H

RWw64~RWw67 0244H~0247

H

RWw68~RWw6B 0248H~024B

H

RWw6C~RWw6F 024CH~024F

H

RWw70~RWw73 0250H~0253

H

RWw74~RWw77 0254H~0257

H

RWw78~RWw7B 0258H~025B

H

RWw7C~RWw7F 025CH~025F

H

RWw80~RWw83 0260H~0263

H

RWw84~RWw87 0264H~0267

H

RWw88~RWw8B 0268H~026B

H

RWw8C~RWw8F 026CH~026F

H

RWw90~RWw93 0270H~0273

H

RWw94~RWw97 0274H~0277

H

RWw98~RWw9B 0278H~027B

H

RWw9C~RWw9F 027CH~027F

H

RWwA0~RWwA3 0280H~0283

H

RWwA4~RWwA7 0284H~0287

H

RWwA8~RWwAB 0288H~028B

H

RWwAC~RWwAF 028CH~028F

H

RWwB0~RWwB3 0290H~0293

H

RWwB4~RWwB7 0294H~0297

H

RWwB8~RWwBB 0298H~029B

H

RWwBC~RWwBF 029CH~029F

H

RWwC0~RWwC3 02A0H~02A3

H

RWwC4~RWwC7 02A4H~02A7

H

RWwC8~RWwCB 02A8H~02AB

H

RWwCC~RWwCF 02ACH~02AF

H

RWwD0~RWwD3 02B0H~02B3

H

RWwD4~RWwD7 02B4H~02B7

H

RWwD8~RWwDB 02B8H~02BB

H

RWwDC~RWwDF 02BCH~02BF

H

RWwE0~RWwE3 02C0H~02C3

H

RWwE4~RWwE7 02C4H~02C7

H

RWwE8~RWwEB 02C8H~02CB

H

RWwEC~RWwEF 02CCH~02CF

H

RWwF0~RWwF3 02D0H~02D3

H

RWwF4~RWwF7 02D4H~02D7

H

RWwF8~RWwFB 02D8H~02DB

H

RWwFC~RWwFF 02DCH~02DF

H

RWr54~RWr57 0334H~0337

H

RWr58~RWr5B 0338H~033B

H

RWr5C~RWr5F 033CH~033F

H

RWr60~RWr63 0340H~0343

H

RWr64~RWr67 0344H~0347

H

RWr68~RWr6B 0348H~034B

H

RWr6C~RWr6F 034CH~034F

H

RWr70~RWr73 0350H~0353

H

RWr74~RWr77 0354H~0357

H

RWr78~RWr7B 0358H~035B

H

RWr7C~RWr7F 035CH~035F

H

RWr80~RWr83 0360H~0363

H

RWr84~RWr87 0364H~0367

H

RWr88~RWr8B 0368H~036B

H

RWr8C~RWr8F 036CH~036F

H

RWr90~RWr93 0370H~0373

H

RWr94~RWr97 0374H~0377

H

RWr98~RWr9B 0378H~037B

H

RWr9C~RWr9F 037CH~037F

H

RWrA0~RWrA3 0380H~0383

H

RWrA4~RWrA7 0384H~0387

H

RWrA8~RWrAB 0388H~038B

H

RWrAC~RWrAF 038CH~038F

H

RWrB0~RWrB3 0390H~0393

H

RWrB4~RWrB7 0394H~0397

H

RWrB8~RWrBB 0398H~039B

H

RWrBC~RWrBF 039CH~039F

H

RWrC0~RWrC3 03A0H~03A3

H

RWrC4~RWrC7 03A4H~03A7

H

RWrC8~RWrCB 03A8H~03AB

H

RWrCC~RWrCF 03ACH~03AF

H

RWrD0~RWrD3 03B0H~03B3

H

RWrD4~RWrD7 03B4H~03B7

H

RWrD8~RWrDB 03B8H~03BB

H

RWrDC~RWrDF 03BCH~03BF

H

RWrE0~RWrE3 03C0H~03C3

H

RWrE4~RWrE7 03C4H~03C7

H

RWrE8~RWrEB 03C8H~03CB

H

RWrEC~RWrEF 03CCH~03CF

H

RWrF0~RWrF3 03D0H~03D3

H

RWrF4~RWrF7 03D4H~03D7

H

RWrF8~RWrFB 03D8H~03DB

H

RWrFC~RWrFF 03DCH~03DF

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

20

Page 23

Chapter10 Com munication specification

10.1 Input/output sig nal list

Table

6

Output signals (Master Inverter)

Device no.

RYn0

RYn1

RYn2

RYn3

RYn4

RYn5

RYn6

RYn7 Unused RYn8 Unused RYn9 Secondary side output is

RYnA Unused -

RYnB Unused -

RYnC

*1

RYnD

*2

RYnE Unused RYnF

*3

RY(n+1)A

*4

Signal name Description

Forward command OFF: Stop command

Reverse command OFF: Stop command

X1 terminal function

X2 terminal function

X3 terminal function

X4 terminal function

X5 terminal function

cut off (BX)

Monitor command

Speed setting command

(RAM)

Command code execution

request

Alarm reset request flag If an inverter alarm occurs, turning ON the alarm reset request flag

n: Value determined by setting station number

*1

During the time when the monitor command (RYnC) is ON, the monitor value is constantly updated.

*2

During the frequency setting command

(RWwn+1) is constantly reflected on the speed.

*3

During the time when “command code execution request” is ON, the command code is constantly

executed. (W ith read request the read value is constantly updated, and with write request the write

value is constantly reflected on the writing.) However, the function codes (except S code) are written

only once.

*4

During the time when the alarm reset request flag (RY(n+1)A) is ON, alarm reset is constantly

executed. So, turn OFF the flag after an alarm has been reset. Alarm reset is always possible

irrespective of operation mode.

ON: Forward rotation

ON: Reverse rotation

Uses it as a self-maintenance signal when the

three-wire is operated.

(HLD) is ON、(FWD) or (REV)signal is self-maintained,

and this maintenance is released by turning off.

Turning this On works as the free-run command (BX).

(Secondary side output is cut off )

Turing this ON works as the abnormal rest (RST).

Turning this On works as selected frequency setting

2(Hz2/Hz1).

Turning this On works as the operation command and

the frequency setting from the touch panel become

effective(LOC).

Turning this On works as the free-run command (BX).

(Secondary side output is cut off )

By turning ON the monitor command (RYnC), the monitor value is set to

RWrn, and the monitoring (RXnC) is turned ON.

By turning ON the frequency setting command (RYnD), the speed

command (RW wn+1) is written in the volatile memory (RAM) of the

Note2

inverter.

(RXnD) is turned ON. If a frequency setting error occurs, a value other

than 0 is set to the response code (RWrn+2).

By turning ON the command code request command (RYnF), the

processing corresponding to the command code set to the command

code (RW wn+2) is executed.

executed, “command code execution complete” (RXnF) is turned ON. If

a command code execution error occurs, a value other than 0 is set to

the response code (RWrn+2).

After the writing has finished, “frequency setting complete”

Note 3

After the command code has been

resets the inverter, and turns OFF the alarm state flag (RX(n+1)A).

(RYnD)

is ON,, the value of the frequency command

Simultaneous

turn-on of

RYn0 and

RYn1 makes

stop

command.

Function of

each X

terminal (E01

~ E05) can

be changed

by setting

X-terminal

function

selection.

21

Page 24

Table 7

Input signals (Inverter Master)

Device no.

RXn0 Rotating in forward

RXn1 Rotating in reverse

RXn2 Y1 terminal function

RXn3 Y2 terminal function

RXn4 Y3 terminal function

RXn5 Unused

RXn6 Y5 terminal function

Signal name Description

direction

direction

OFF: Other than rotating in forward direction (stop or rotating in

reverse direction)

ON: Rotating in forward direction

OFF: Other than rotating in reverse direction (stop or rotating in

forward direction)

ON: Rotating in reverse direction

Turned ON with inverter running (RUN)

Turned ON with frequency arrival signal (FAR)

Turned ON with frequency detected (FDT)

-

Turned ON with select AX terminal function (AX)

Output signal

can be

changed by

setting

Y-terminal

function

selection

21,E22,E24).

RXn7

RXnC Monitoring By turning ON the monitor command (RYnC), the monitor value is set to

RXnD

RXnE Unused

RXnF Command code

RX(n+1)A Alarm status flag Turned ON when an inverter alarm (alarm other than Er3) occurs.

RX(n+1)B Remote station ready After the power has been turned on, or after the hardware has been

n: Value determined by setting station number

*1

If the operation condition setting switch of the master unit, “input data status of station with data link

Failure relay output

(ABC)

Frequency setting

complete

(RAM)

execution complete

Turned ON when inverter protection function works and output

stops.

the remote register RWrn (see 10.2) and the monitoring (RXnC) is

turned ON. When the monitor command (RYnC) is turned OFF, the

monitoring (RXnC) is turned OFF.

By turning ON the frequency setting command (RYnD), the frequency

command is written in the volatile memory (RAM) and this signal is

turned ON. When the frequency setting command (RYnD) is turned OFF,

“frequency setting complete” (RXnD) comes OFF.

-

By turning ON the command code execution request (RYnF), the

processing corresponding to the command code (RWwn+2) is

executed, and when the processing has been finished, this signal is

turned ON. When the command code execution request (RYnF) is

turned OFF, the “command code execution complete” comes OFF.

reset, and when the initial data setting has been finished and the

inverter has become ready, this signal is turned ON. (This signal is

used for interlock with read/write from the master unit.) If an inverter

alarm occurs, this signal is turned OFF simultaneously with the alarm

status flag (RX (n+1)A) ON.

failure (SW4)”, is set to ON, the input data from the station with data link failure holds its value

received just before the failure has occurred. So, note that, even if an inverter alarm has occurred,

the signal “remote station ready” remains ON.

*2

Note that, if the master outputs an operation command when commands through communication are

set invalid (H30 = 0, 1 or [LE] command OFF), the inverter does not operate but the signals “speed

setting complete” and “command code execution complete” are turned ON. Also, if the commands

through communication are set invalid, whether the input signal from the link (COM) is coming in or

not can be checked with “I/O check” on the keypad.

(E20,E

22

Page 25

10.2 Ass igning remote register s

Table 8

Remote registers (Master Inverter)

Address

Signal

name

RWwn Monitor

RWwn+1

code1/2

Frequency

command

RWwn+2 Comm and

RWwn+3 W rite data Sets the data specified by the above command code. Turn

RWwn+4 Monitor

RWwn+5 Monitor

RWwn+6 Monitor

RWwn+7 Monitor

RWwn+8 Alarm

RWwn+9

RWwn+A Unused -

RWwn+B Unused RWwn+10

RWwn+12

RWwn+14

RWwn+16

RWwn+18

RWwn+11

RWwn+13

RWwn+15

RWwn+17

RWwn+19

code

code 3

code 4

code 5

code 6

definition

No

PID set

point

Link

parameter

extension

setting /

Command

codes

Write data Set the specified by the instruction code of RWw10, 12, 14,

Sets the monitor code (see Table 10) to be referred to. After

the setting has been finished, the data of specified monitor

is set to RWrn by turning ON RYnC signal.

Sets Frequency command. After the command has been set

to this register, the frequency is written by turning ON the

RYnD mentioned previously. After the writing the frequency

has been finished, RXnD comes ON.

Sets the command code (see Table 11 or, it accesses each

function code by formatting the data of page 26.) for

rewriting operation mode, reading and writing function code,

referring to alarm record, resetting alarm, etc. After the

register has been set, the set comm and is executed by

turning ON RYnF. After the command has been executed,

RXnF comes ON.

ON RYnF after the above command code and this register

have been set (as required). If writing data is not necessary,

set the data to 0.

Set the monitor code to be monitored. By switching on the

RYC signal after setting, the specified monitored data is

stored to RWrn□.

(□ indicates a register number.(RWrn4~7))

Set how many alarm definitions in past to be read. Back to

eight alarm definitions in past can be read. (lower 8bits is

H00)

Set the PID set point.

Set the instruction code for execution of operation mode

rewrite, Pr.read/write, error clear, etc. The corresponding

instruction is executed in order of RWw2, 10, 12, 14, 16, 18

by switching on RYF after completion of register setting,

then, RXF switches on completion of instruction execution

of RWw18. Set HFFFF to disable an instruction by RWw10

to18.

16, and 18. (when required.) RWw10 and 11, 12 and 13, 14

and 15, 16 and 17, and 18 and 19 correspond each other.

After setting this register corresponding to the instruction

code of RWw10, 12, 14, 16, and 18, switch on RYF. Set

zero when the write code is not required.

n: Value determined by setting station number

CC-Link extension setting is,at CC-Link Ver1.10,[RWwn~RWwn +3] can be used.

at CC-Link Ver2.00 double,[RWwn~RWwn +7] can be used.

at CC-Link Ver2.00 quadrople,[RWwn~RWwn +F] can be used.

at CC-Link Ver2.00 octuple,[RWwn~RW wn +1F] can be used.

Description Remark

Every 0.01Hz

Latest 0000

Once ahead 0100

Twice ahead 0200

Three ahead 0300

23

Page 26

【Reading of function・W riting・Reading of link extended setting・W riting data format】

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

Reserved

Table 9

Remote registers (Inverter Master)

Address

RWrn Monitor value 1 The monitor value specified by the monitor code RWwn is set.

RWrn+1 Monitor value 2 The monitor value specified by the monitor code RWwn is set.

RWrn+2 Response code Set reply code corresponds to the command code of RWwn+2.

RWrn+3 Read data With correct response, the response data for the command

RWrn+4

RWrn+5

RWrn+6

RWrn+7

RWrn+8 Alarm definition

RWrn+9 Alarm definition

RWrn+A Alarm definition

RWrn+B Alarm definition

RWrn+C Alarm definition

RWrn+10

RWrn+19

~

Monitor value

Monitor value

Monitor value

Monitor value

(alarm data)

(output frequency)

(

output current

(

output voltage

(

energization time

Reply code

Read data

Function code group (0~31)

00H(=0) : Fcode(F00~F99)

01H(=1) : Ecode (E00~E99)

02H(=2) : Ccode (C00~C99)

03H(=3) : Pcode (P00~P99)

04H(=4) : Hcode (H00~H99)

06H(=6) : ocode (o00~o99)

07H(=7) : Scode (S00~S99)

08H(=8) : Mcode (M00~M99)

0DH(=13) : Jcode (J00~J99)

0EH(=14) : ycode (y00~y99)

0FH(=15) : Wcode (W00~W99)

10H(=16) : Xcode (X00~X99)

11H(=17) : Zcode (Z00~Z99)

Signal name Description Remark

(see table12)

For correct response “ 0” is set, and for data error other than “0”

is set.

specified by the command code is set in this register.

3

When RYC is on, the monitor value specified to the monitor code

(RWw□) is stored. (□ indicates a register number (RWw 4 to

4

7))

5

6

The alarm data of alarm definition No. specified by RWw8 is

stored in the lower 8bits. Alarm definition No. specified is echo

backed to the upper 8bits.

Output frequency of the alarm definition No. specified in RW w8 is

stored.

Output current of the alarm definition No. specified in RWw8 is

)

stored.

Output voltage of the alarm definition No. specified in RW w8 is

)

stored.

Energization time of the alarm definition No. specified in RWw8

)

is stored.

Turning on RYnF stores the reply code corresponds to the

instruction code of RW w10, 12, 14, 16, and 18. T he value “0” is

set for a normal reply and other than “0” is set for data fault,

mode error, etc.

With correct response, the response data for the command

specified by the command code is set in this register.

n: Value determined by setting station number

CC-Link extension setting is,at CC-Link Ver1.10,[RWrn~RWrn +3] can be used.

at CC-Link Ver2.00 double,[RWrn~RWrn +7] can be used.

at CC-Link Ver2.00 quadrople,[RWrn~RWrn +F] can be used.

at CC-Link Ver2.00 octuple,[RWrn~RWrn +1F] can be used.

0:Read

1:Write

Function code

00~99

24

Page 27

10.3 Description of remote regis ters

Table 10

Monitor codes

Code No.

00H No monitor (monitor value fixed to 0)

01H Output frequency 0.01Hz Output in increments of 0.1 Hz

02H Output current 0.01A/0.1A *1

03H Output voltage 0.1V

04H No monitor (monitor value fixed to 0) -

05H Set frequency 0.01Hz

06H Running speed 1r/min

07H Calculated output torque 0.1%

08H DC intermediate voltage 0.1V Output in increments of 1 V

09

H

|

0CH

0DH Input power 0.01kW/0.1kW *1

0EH Output power 0.01kW/0.1kW *1

0FH Input terminal status -

10H Output terminal status -

11H Load factor 0.1%

12H

|

13H

14H Integrated operation time 1hr

15H

|

16H

17H Actual operation time 1hr

18H Output current effect value 0.1%

19H Cumulative power 1kWhr

1AH

|

33H

34H PID set point 0.1%

35H PID measured value 0.1%

36H PID deviation 0.1%

37H | No monitor (monitor value fixed to 0)

*1 The setting depends on the inverter capacity.(55kWor less/75 kW or m ore)

◆

Detailed explanation of Input terminal status

b15 b8 b7 b0

-

◆

Detailed explanation of output terminal status

b15 b8 b7 b0

- - - - - - - 30 - - - Y5A - Y3 Y2 Y1

“-”: Vacant (fixed to 0)

Second Monitor

Description

(the first 8 bits)

No monitor (monitor value fixed to 0)

First Monitor

Description

(the first 8 bits)

Unit Remark

No monitor (monitor value fixed to 0)

No monitor (monitor value fixed to 0)

No monitor (monitor value fixed to 0)

- - - - - - - - X5 X4 X3 X2 X1 REV FWD

Figure 14

Figure 15

25

Page 28

Table 11

Command codes

Item Code No.

Operation mode read 007BH 0000H: Link operation (CC-Link)

Operation mode write 00FBH 0000H: Link operation (CC-Link)

Alarm record No.1

and No.2 read

Alarm record No.3

and No.4 read

Frequency

command read

Frequency

command write

Function code read 0000H~

Function code write 0080H~

Batch alarm definition

clear

Alarm reset 00FDH 9696H:Resets the alarm Even not link operation, reset can be

Table 12

Response codes

Description of data Remark

0001H: External operation

(Terminal board)

0002H: Keypad operation

0003H: Others

0001H: External operation

(Terminal board)

0002H: Keypad operation

0074H

0075H

006DH

00EDH

0063H

00E3H

00F4H 9696H:Batch-clears the alarm

Record No.1 and No.2 read

Record No.3 and No.4 read

Reading frequency command

Writing frequency command

Function code is read or written

in combination with the link

parameter extension setting.

history

Change to “y98=3”

Change to “y98=0”,”F02=1”

Change to “y98=0”,”F02=0”,”F01=0”

Caution)

・It doesn't return to former setting when

the power supply is turned on again.

・【LE】The terminal becomes top priority.

L byte:Latest alarm

H byte:First alarm in past

L byte: Second alarm in past

H byte: Third alarm in past

0~20000 (Nmax. at 20000)

Accessible from remote register

When “y=1,3” is set, it is possible to

write it.

For the link No. and data format, refer to

Chapter 11.

made,

Code No. Item Description

0000H

0001H

0002H

0003H

Normal (no error) Command code has been normally executed.

Write mode error

・Function code has been written during inverter operation.

・Function code has been written during EEPROM write.

(Prohibition while it changes with keypad)

・Function code has been written with transmission error.

Function code select error An inaccessible link No. has been set.

Setting range error The set data is out of the changeable range.

26

Page 29

Bias(Frequency command1

0012

0092

6

Mode selection

001D

009D

1

Output adjustment

001E

009E

1

Chapter11 Li nk Num ber / Data Format

Link No of each function code is described. Understand together with refer to Chapter 5 of RS-485 user's manual

(MEH448*) for the data format form).

F:Fundamental Functions

Code Name

F00 Data protection 0000 0080 1

F01 Frequency command 1 0001 0081 1

Run Command

F02

F03 Maximum frequency 0003 0083 3

F04 Base frequency 0004 0084 3

F05 Rated Voltage at Base Frequency 0005 0085 1

F07 Acceleration time 0007 0087 12

Deceleration time

F08

F09 Torque boost 0009 0089 3

F10 Electronic thermal (Select motor characteristics) 000A 008A 1

F11 Overload Protection for (Overload detection level) 000B 008B 24

F12 Motor (Thermal time constant) 000C 008C 3

F14 Restart mode after momentary power failure (Mode selection) 000E 008E 1

F15 Frequency limiter (High) 000F 008F 3

F16 (Low) 0010 0090 3

F18

F20 DC Braking (Braking start frequency) 0014 0094 3

F21 (Braking level) 0015 0095 1

F22

F23 Starting frequenc 0017 0097 3

F25 Stop frequency 0019 0099 3

F26 Motor sound (Carrier frequency) 001A 009A 1

F27 ( tone) 001B 009B 1

F29 Analog Output [FMA]

F30

F31

Pulse Output [FMP]

F33

F34 (Duty)) 0022 00A2 1

F35 (Function) 0023 00A3 1

Load Selection/Auto Torque Boost /Auto Energy Saving Operation

F37

F43 Current Limiter (Mode selection) 002B 00AB 1

F44 (Level) 002C 00AC 1

)

(Braking time)

(

(

(

Function)001F 009F 1

(Pulse rate) 0021 00A1 1

READ WRITE

0002 0082 1

0008 0088 12

0016 0096 5

)

)

0025 00A5 1

Attribute

CC Link No

Communication

data format

27

Page 30

Analog Input for (Extension function selection) [12]

E:Extension Terminal Functions

Code Name

Command Assignment to: [X1]

E01

E02 [X2]

E03 [X3]

E04 [X4]

E05

Signal Assignment to: [Y1]

E20

(Transistor signal) [Y2]

E21

E22

(Relay contact signal) [Y5A/C]

E24

E27 [30A/B/C]

Frequency Detection (FDT) (Detection level)

E31

E34 Overload Early Warning (Level)

/Current Detection (Timer)

E35

E40 PID Display coefficient A

E41 PID Display coefficient B

E43 LED Monitor (Item selection)

LCD Monitor (Item selection)

E45

E46 (Language selection)

E47

E48 LED Monitor (Speed monitor item)

Coefficient for Speed Indication

E50

E51 Display Coefficient for Input Watt-hour Data

Keypad

E52

E61

E62

E63 [V2]

E64

Saving Digital Reference Frequency

E65 Command Loss Detection

Detect Low Torque (Detection level)

E80

E81 (Timer)

Command Assignment to: [FWD]

E98

E99 [REV]

(Contrast control)

CC Link No Communication

READ W RITE

0101 0181 1

0102 0182 1

0103 0183 1

0104 0184 1

[X5]

0105 0185 1

0114 0194 1

0115 0195 1

[Y3]

0116 0196 1

0118 0198 1

011B 019B 1

011F 019F 3

0122 01A2 24

0123 01A3 5

0128 01A8 12

0129 01A9 12

012B 01AB 1

012D 01AD 1

012E 01AE 1

012F 01 AF 1

0130 01B0 1

0132 01B2 5

0133 01B3 45

0134 01B4 1

013D 01BD 1

[C1]

013E 01BE 1

013F 01 BF 1

0140 0 1C0 1

0141 0 1C1 1

0150 0 1D0

0151 0 1D1 5

0162 01E2 1

0163 01E3 1

data format

1

28

Page 31

READ

WRITE

Selection of Normal/ Inverse Operation

C:Con trol Functions of Freq uency

Code Name

Jump Frequency 1

C01

C02 2

C03 3

C04

Multistep Frequency 1

C05

C06 2

C07 3

C08 4

C09 5

C10 6

C11 7

Frequency Command 2 021E 029E 1

C30

C32

Analog Input Adjustment for [12] (Gain) 0220 02A0 5

C33

C34

Analog Input Adjustment for [C1] (Gain) 0225 02A5 5

C37

C38

C39

Analog Input Adjustment for [V2] (Gain) 022A 02AA 5

C42

C43

C44

Bias Reference Point (Frequency command 1)

C50

Bias for PID command 1 (Bias value) 0233 02B3 6

C51

C52

C53

CC Link No

0201 0281 3

0202 0282 3

0203 0283 3

(Band)

0204 0284 3

0205 0285 5

0206 0286 5

0907 0987 5

0208 0288 5

0209 0289 5

020A 028A 5

020B 028B 5

Communication

data format

(Filter time constant) 0221 02A1 5

(Gain reference point)

0222 0 2A2 5

(Filter time constant) 0226 02A6 5

(Gain reference point) 0227 02A7 5

(Filter time constant) 022B 02AB 5

(Gain reference point) 022C 02AC 5

0232 0 2B2 5

(Bias reference point) 0234 02B4 5

(Frequency command 1) 0235 02B5 1

P:Motor Parameters

Code Name

Motor (No. of poles)

P01

P02

P03

P04

P06

P07

P08

Motor Selection

P99

CC Link No

READ W RITE

(Rated capacity)

(Rated current)

(Auto-tuning)

0301 0381 1

0302 0382 11

0303 0383 24

0304 0384 21

(No-load current) 0306 0386 24

(%R1)

0307 0387 5

(%X)

0308 0388 5

0363 03E3 1

29

Communication

data format

Page 32

Select Starting Characteristics (Auto search time for idling motor speed)

H:High Performance Function s

Code Name

Data Initialization

H03

Auto-resetting (Times)

H04

H05

Cooling Fan ON/OFF Control

H06

Acceleration/Deceleration Pattern

H07

H09

H11 Deceleration Mode

Instantaneous Overcurrent Limiting (Mode selection)

H12

Restart Mode after (Restart time)

H13

H14

H15

H16

Select Starting Characteristics (Frequency for idling motor speed)

H17

PTC Thermistor (Mode selection)

H26

H27

Communications Link Function (Mode selection)

H30

Capacitance of DC Link Bus Capacitor

H42

Cumulative Run Time of Cooling Fan

H43

Initial Capacitance of DC Link Bus Capacitor

H47

Cumulative Run Time of Capacitors on the Printed Circuit Board

H48

Select Starting Characteristics (Auto search time for idling mot or speed)

H49

Non-linear V/f Pattern (Frequency)

H50

H51

Deceleration Time for Forced Stop

H56

Low Limiter (Mode selection)

H63

(Lower limiting frequency)

H64

Automatic Deceleration

H69

Overload Prevention Control

H70

Deceleration Characteristics

H71

Gain for Suppression of Output Current Fluctuation for Motor

H80

Reserved

H86

Reserved

H87

Reserved

H88

Reserved

H89

Reserved

H90

Reserved

H91

Continue to Run (P-component: gain)

H92

H93

Cumulative Run Time of Motor

H94

DC Braking (Braking response mode)

H95

STOP Key Priority/Start Check Function

H96

Clear Alarm Data

H97

Protection/Maintenance Function

H98

(Allowable momentary power failure time)

(Reset interval)

(Frequency fall rate)

(Continuous running level)

(Level)

(Voltage)

(Mode selection)

(I-component: time)

(Mode selection)

CC Link No

READ W RITE

0403 0483 1

0404 0484 1

0405 0485 3

0406 0486 1

0407 0487 1

0409 0487 1

040B 048B 1

040C 048C 1

040D 048D 3

040E 048E 5

040F 048F 1

0410 0490 3

0411 0491 3

041A 049A 1

041B 049B 5

041E 049E 1

042A 04AA 1

042B 04AB 1

042F 04AF 1

0430 04B0 1

0431 04B1 3

0432 04B2 3

0433 04B3 1

0438 04B8 12

043F 04BF 1

0440 04C0 3

0445 04C5 1

0446 04C6 5

0447 04C7 1

0450 04D0 5

0456 04D6 1

0457 04D7 3

0458 04D8 1

0459 04D9 1

045A 04DA 1

045B 04DB 1

045C 04DC 7

045D 04DD 7

045E 04DE 1

045F 04DF 1

0460 04E0 1

0461 04E1 1

0462 04E2 1

Communication

data format

30

Page 33

J:Application

Code Name

J01 PID Control (Mode selection)

J02

(Remote process comm and)

J03

J04

J05

J06

J10

J11

J12

(Upper limit alarm (AH))

J13

J15

J16

(Stop frequency for slow flowrate)

(Slow flowrate level stop latency)

J17

J18

J19

Dew Condensation Prevention (Duty)

J21

J22

Commercial Power Switching Sequence

(Upper limit of PID process output)

(Lower limit of PID process output)

I (Integral time)

D (Differential time)

(Feedback filter)

(Anti reset windup)

(Select alarm output)

(Lower limit alarm (AL))

(Starting frequency)

y: Link Functions

P (Gain)

CC Link No

READ WRITE

0D01 0D81 1

0D02 0D82 1

0D03 0D83 7

0D04 0D84 3

0D05 0D85 5

0D06 0D86 3

0D0A 0D8A 1

0D0B 0D8B 1

0D0C 0D8C 2

0D0D 0D8D 2

0D0F 0D8F 1

0D10 0D90 1

0D11 0D91 1

0D12 0D92 1

0D13 0D93 1

0D15 0D95 1

0D16 0D96

Communication

data format

1

Code Name

RS485 Communication (Standard)

y01

y02

y03

y04

y05

y06

y07

y08

y09

y10

RS485 Communication (Option) (Station address) 0E0B 0E8B 1

y11

y12

y13

y14

y15

y16

y17

y18

y19

y20

Bus Link Function (Mode selection)

y98

Loader Link Function (Mode selection)

y99

CC Link No

READ WRITE

Communication

data format

(Station address) 0E01 0E81 1

(Communications error processing)

0E02 0 E82 1

(Error processing timer) 0E03 0E83 3

(Transmission speed) 0E04 0E84 1

(Data length) 0E05 0E85 1

(Parity check) 0E06 0E86 1

(Stop bits) 0E07 0 E87 1

(No-response error detection time)

(Response latency time)

0E08 0 E88 1

0E09 0 E89 5

(Protocol selection) 0E0A 0E8A 1

(Communications error processing) 0E0C 0E8C 1

(Error processing timer) 0E0D 0E8D 3

(Transmission speed) 0E0E 0E8E 1

(Data length)

0E0F 0E8F 1

(Parity check) 0E10 0E90 1

(Stop bits) 0E11 0 E91 1

(No-response error detection time) 0E12 0E92 1

(Response latency time) 0E13 0E93 5

(Protocol selection) 0E14 0E94 1

0E62 0EE2 1

0E63 0EE3 1

31

Page 34

o32

CC-Link optionTransmission Baud ratesetting

0620

06A0

1

O:Option Functions

Code Name

o27 Operation when a failure has occurred 061B 069B 1

o28 Communication failure when a failure has occurred 061C 069C 3

Link

o30 CC

extended setting 061E 069E 1

o31 CC-Link option station number setting 061F 069F 1

CC Link No

READ WRITE

Attribute

Communicatio

n data format

32

Page 35

S:Commun ic ations Dedicated Func tion Codes(pub lic)(Command data)

Communication

Display

S07

Universal D0

0000H~FFFFH

0707

0787

15

HEX

S08

Acceleration time

0.0~3600.0

0708

0788

3

0.1

S09

Deceleration time

0.0~3600.0

0709

0789

3

0.1

S12

Universal A0

-32768~32767

070C

078C

29

HEX

Alarm reset command

0~65535

1

HEX

M:Co mmunic ati ons Dedicated Fu nction Cod es(publi c)(Monitor data)

Communication

Display

NO

form

READ WRITE NO fo rm

PID command -32768~32767

S13

S14

M01

Frequency command (p.u.) (final command) -32768~32767

M05

Frequency command 0.00~655.35

M06

Output frequency 1 (p.u.) - 32768~32767

M07

Output torque -327.68~327.67

M09

Output frequency 1 -655.35~655.35

M10

Input power 0 .00~399.99

Output current effective value

M11

Output voltage effective value

M12

M13

Operation command (final command) 0000H~FFFFH

M14

Operation status 0000H~FFFFH

M15

General-purpose output terminal information 0 000H~FFFFH

Latest alarm contents

M16

Last alarm contents

M17

Second last alarm contents

M18

Third last alarm contents

M19

Cumulative operation time

M20

DC link circuit voltage

M21

Model code

M23

Capacity code

M24

ROM version

M25

M26 Transmission error transaction code 0~127 081A - 20 1

M27 Frequency command on alarm (p.u.) (final command) - 32768~32767 081B - 29 HEX

M31 Frequency command on alarm (final command) 0.00~655.35 081F - 22 0.01

M32 Output frequency 1 on alarm (p.u.) -32768~32767 0820 - 29 HEX

Output torque on alarm

M33

Output frequency 1 on alarm

M35

Input power on alarm

M36

Output current effective value on alarm

M37

Output voltage effective value on alarm

M38

Operation command on alarm

M39

Operation status on alarm

M40

General-purpose output terminal information on alarm

M41

Cumulative operation time on alarm

M42

DC link circuit voltage on alarm

M43

Inverter internal air temperature on alarm

M44

Heat sink temperature on alarm

M45

Life of main circuit capacitor

M46

Life of PC board electrolytic capacitor

M47

Life of heat sink

M48

Input terminal voltage ([12])

M49

Input terminal current ([C1])

M50

Input terminal voltage ([V2])

M54