Fuji Electric FRN0025C2S-2U, FRN0033C2S-2U, FRN0060C2S-2U, FRN0013C2S-4U, FRN0024C2S-4U Instruction Manual

...Page 1

Instruction Manual

Supplement for FRN-C2S-2U/4U (7.5 to 20 HP)

Compact Inverter

Three-phase 200 V series: FRN0025 to 0060C2S-2U

Three-phase 400 V series: FRN0013 to 0030C2S-4U

Thank you for purchasing our FRENIC-Mini series of inverters.

• This manual is a supplement to the FRENIC-Mini Instruction Manual (INR-SI47-1729-E,

INR-SI47-1745-E). It describes the FRENIC-C2S (Inverter types FRN0025 to 0060C2S-2U

and FRN0013 to 0030C2S-4U). For other descriptions, refer to the original manu

al.

• Improper handling might result in incorrect operation, a short life, or even a failure of this

product as well as the motor.

• Deliver this manual to the end user of this product. Keep this manual in a safe place until this

product is discarded..

Fuji Electric Co., Ltd. INR-SI47-1833-E

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 2

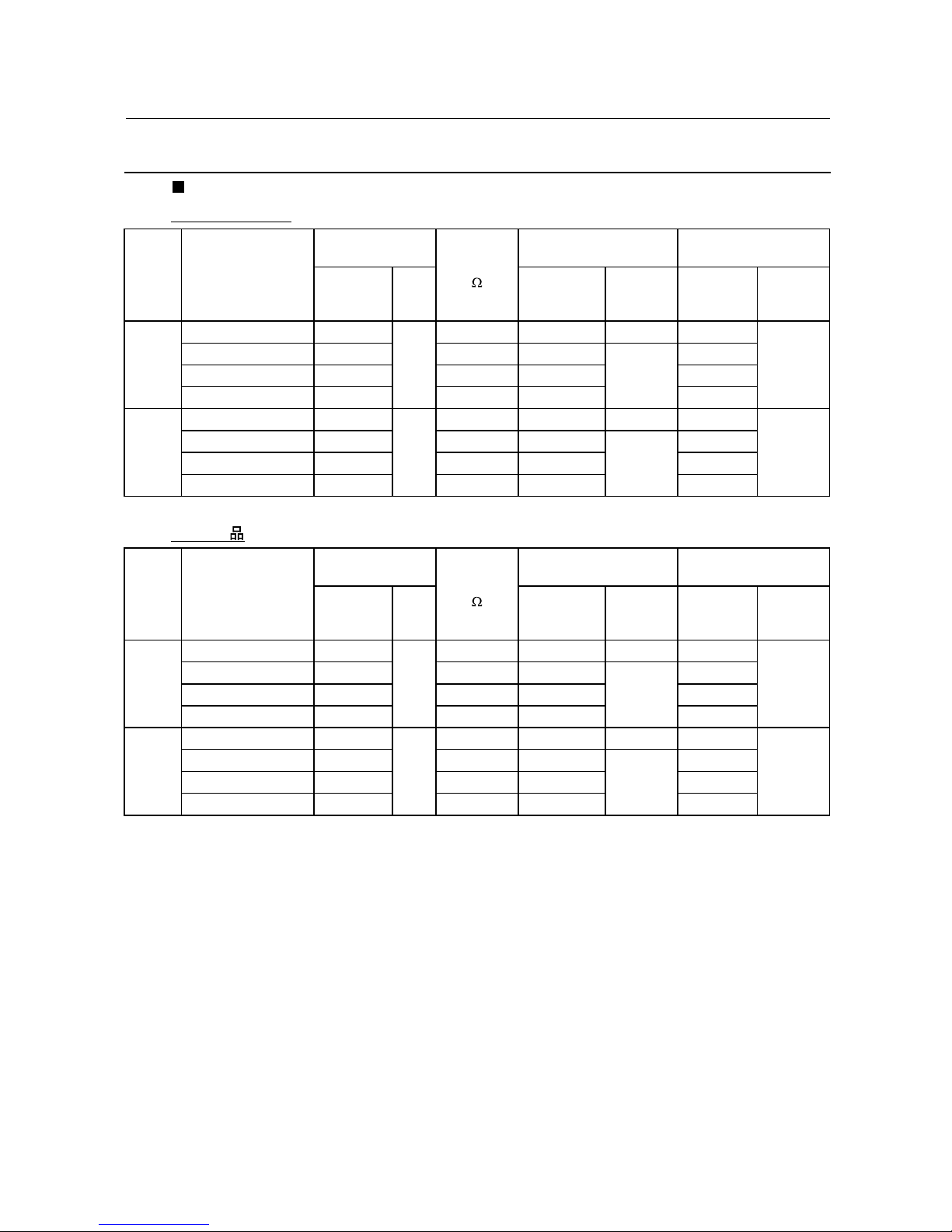

Chapter 2 MOUNTING AND WIRING OF THE INVERTER

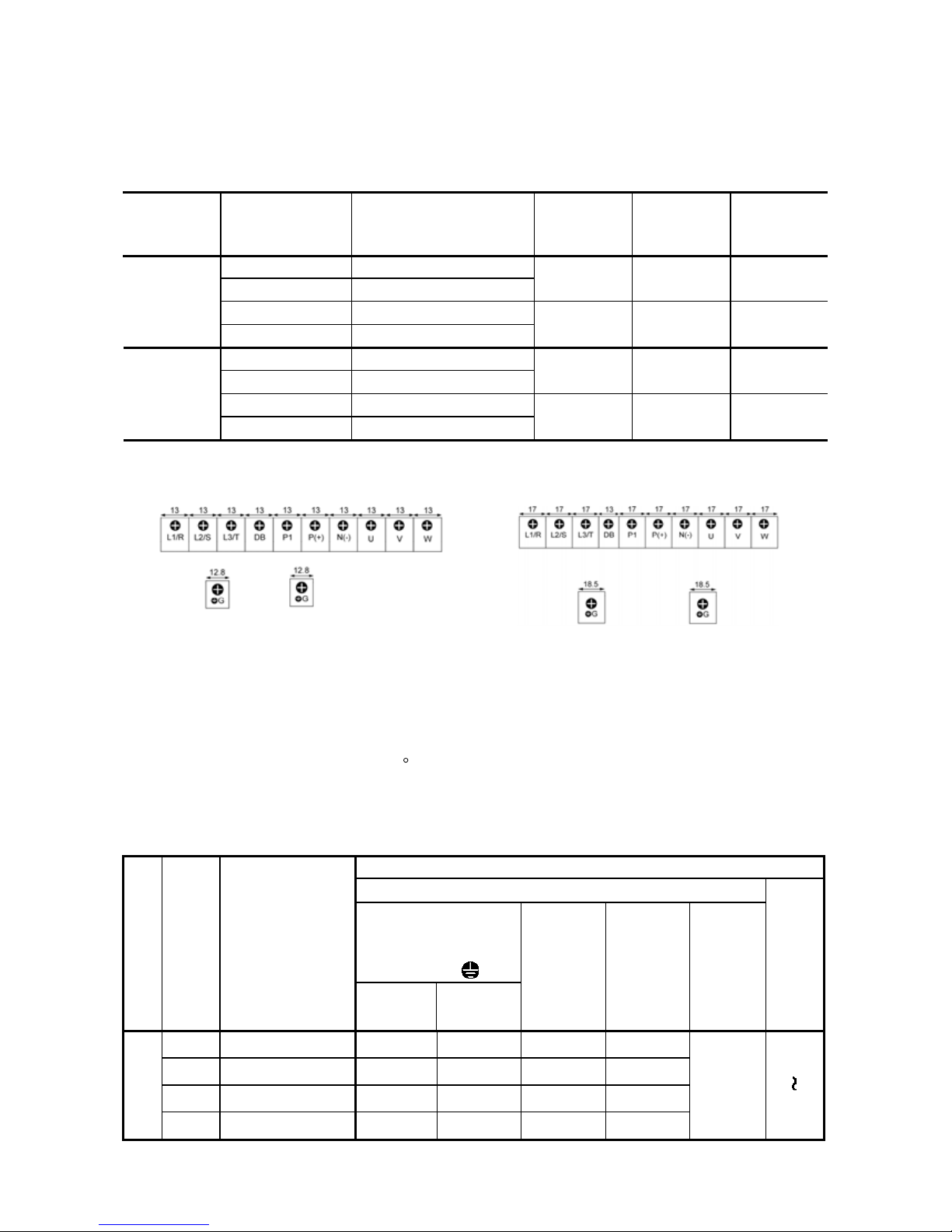

2.3.2 Terminal arrangement and screw specifications

(1) Arrangement of the main circuit terminals

Table 2.3 Main Circuit Terminals

Power

supply

voltage

Nominal ap-

plied motor

(HP)

Inverter type

Terminal

screw size

Tightening

torque

(lb-in)

Refer to:

7.5 FRN0025C2S-2U

10 FRN0033C2S-2U

M5 26.6 Figure E

15 FRN0047C2S-2U

Three-

phase

200 V

20 FRN0060C2S-2U

M6

51.3

Figure

F

7.5 FRN0013C2S-4U

10 FRN0018C2S-4U

M5 26.6 Figure E

15 FRN0024C2S-4U

Three-

phase

400 V

20 FRN0030C2S-4U

M6

51.3 Figure F

Figure E

Figure F

2.3.3 Recommended wire sizes

Table 2.6 lists the recommended wire sizes. The recommended wire sizes for the main circuit terminals for an ambient temperature of 50

C are indicated for two types of wire: HIV single wire (for the

maximum allowable temperature 75°C) (before a sla sh (/)) and IV single wire (for 6 0°C) (after a slash

(/))

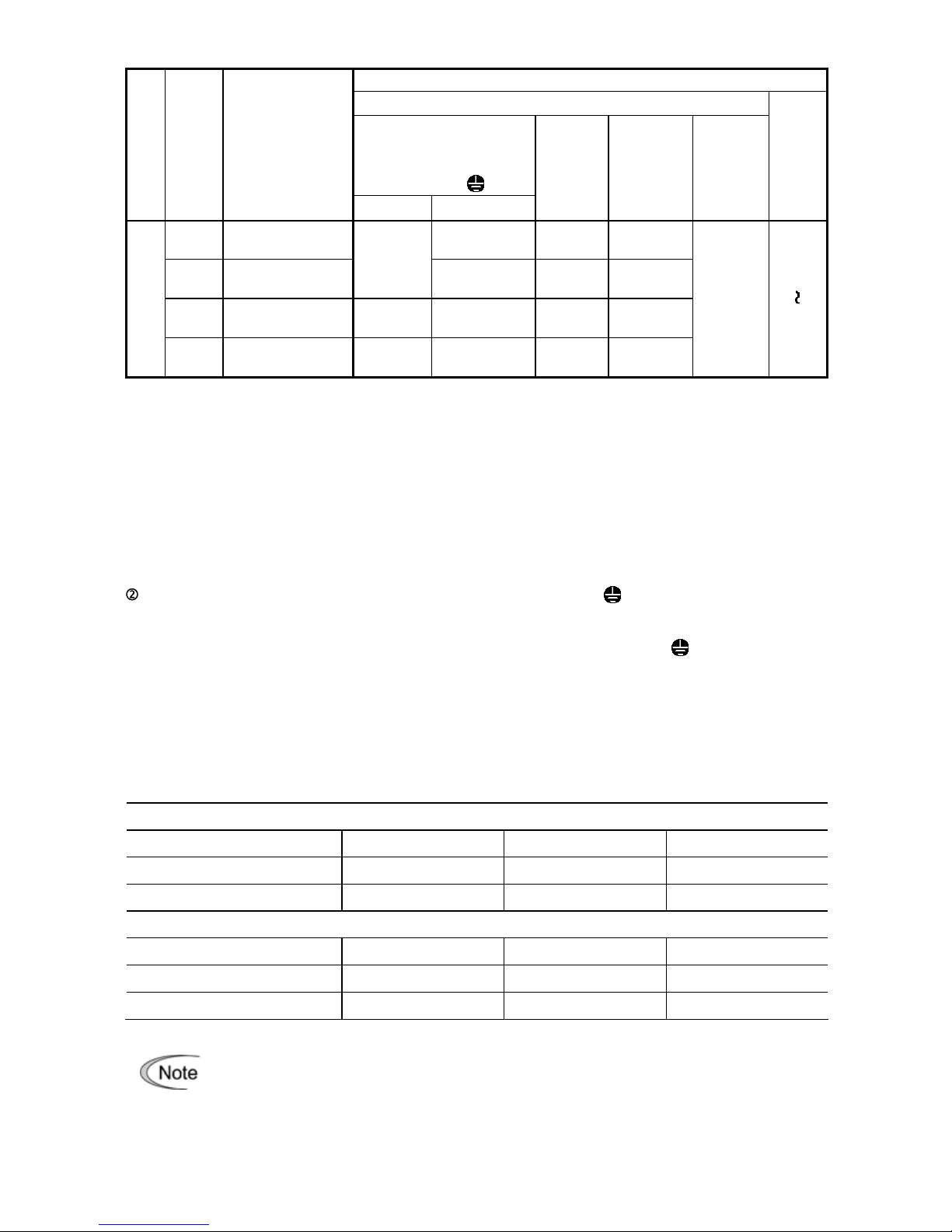

Table 2.6 Recommended Wire Sizes

Recommended wire size (AWG) *1

Main circuit

Main circuit power input

[L1/R, L2/S, L3/T]

[L1/L, L2/N]

Grounding [

G]

Power supply voltage

Nomi-

nal

applied

motor

(HP)

Inverter type

w/ DCR*2w/o DCR

Inverter

output

[U, V, W]

DCR

[P1, P (+)]

Braking

resistor

[P (+), DB]

Control

circuit

7.5

FRN0025C2S-2U

14/10 12/ 8 12/10 12/10

10

FRN0033C2S-2U

12/ 8 10/ 6 12 /8 10/ 6

15

FRN0047C2S-2U

10/ 6 6/ 4 8/ 6 8/ 4

Three-phase

200 V

20

FRN0060C2S-2U

6/ 4 4/ 2 6/ 4 6/ 2

14/14

20

16

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 3

Table 2.6 Recommended Wire Sizes (Continued)

Recommended wire size (AWG) *1

Main circuit

Main circuit power input

[L1/R, L2/S, L3/T]

[L1/L, L2/N]

Grounding [

G]

Power supply voltage

Nomi-

nal

applied

motor

(HP)

Inverter type

w/ DCR w/o DCR *2

Inverter

output

[U, V, W]

DCR

[P1, P (+)]

Braking

resistor

[P (+), DB]

Control

circuit

7.5

FRN0013C2S-4U

14/12

(13)

14/14

(13)

14/14

(13)

10

FRN0018C2S-4U

14/14

(13)

14/10

(11)

14/12

(13)

14/12

(13)

15

FRN0024C2S-4U

14/10

(11)

12 /8

(9)

14/10

(11)

12/10

(11)

Three-phase

400 V

20

FRN0030C2S-4U

12 /8

(9)

10/ 6

(7)

12/ 8

(9)

10 /6

(9)

14/14

(13)

20

16

DCR: DC reactor

*1 Use crimp termina ls covered with an insulated shea th or insulating tube. Recom mended wire sizes are

for HIV

/IV (PVC in the EU).

*2 Wire sizes are calcul ated on the basis of inp ut RMS current under the c ondition that the po wer suppl

y

capacity and impedance are 500 kVA and 5%, respectively.

*3 Insert the DC reactor (DCR) in either of the primary power input lines. Refer to C hapter 10 for more

details.

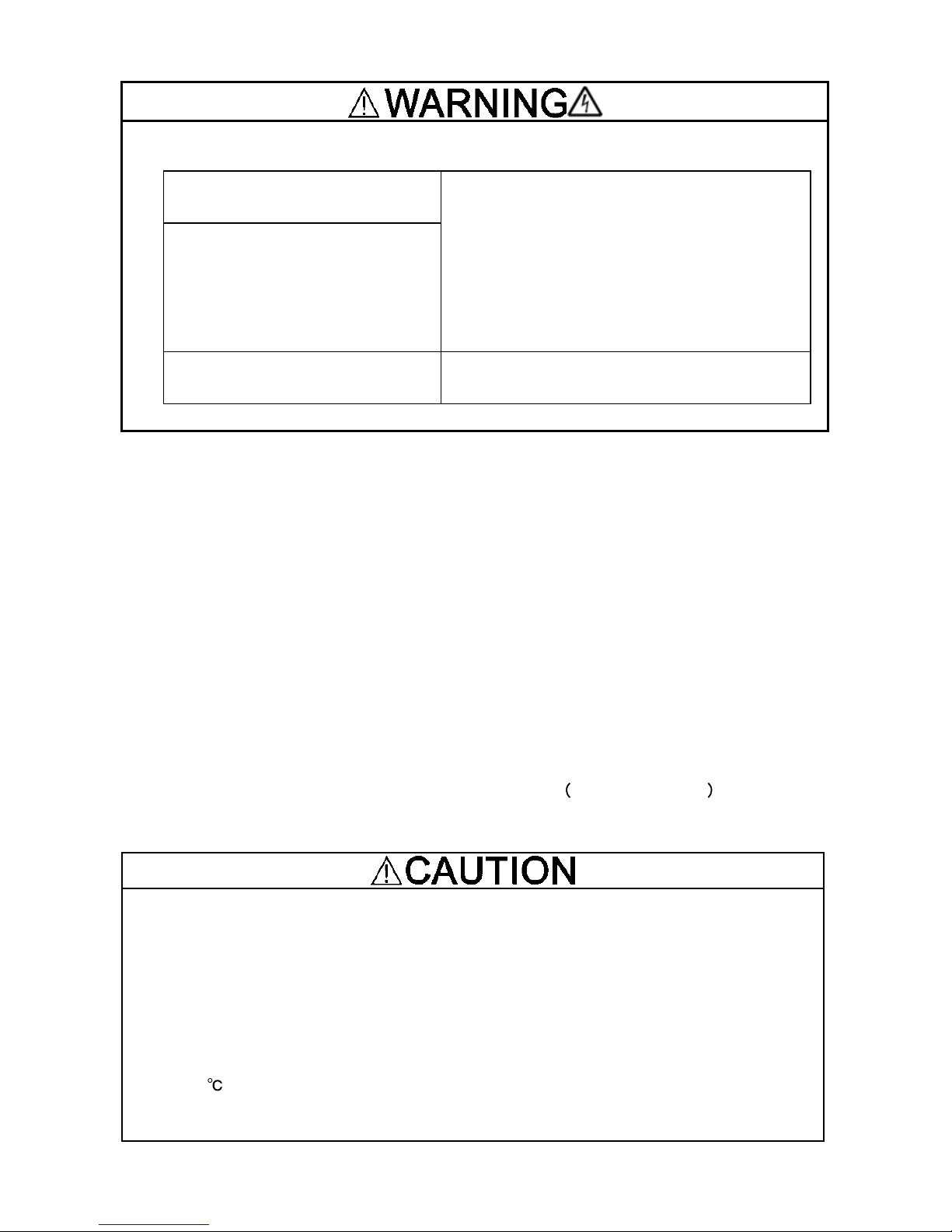

2.3.5 Wiring for main circuit terminals and grounding terminals

Inverter output terminals, U, V, W and grounding terminal ( G)

1) Connect the three wires of the three-phase motor to terminals U, V, and W, aligning phases each other.

2) Connect the grounding wire of terminals U, V, and W to the grounding terminal (

G).

3) If the cable from the inverter to the motor is very long, a high-frequency current may be generated by stray

capacitance between the cables and resul t in an over current trip o f the inverter, an increase in leakage

current, or a reduction in current indication precision.

When a motor is driven b y a PWM-type inverter, the motor terminals may be subject to surge voltage gen erated by inverter element switching. If the motor cable (with 460 V series motors, in particular) is particularly

long, surge voltage will deteriorate motor insulation. To prevent this, use the following guidelines:

Inverters of 7.5 HP or above

Motor Insulation Level 1000 V 1300 V 1600 V

460 VAC Input Voltage 66 ft (20 m) 328 ft (100 m) 1312 ft (400 m)*

230 VAC Input Voltage 1312 ft (400 m)* 1312 ft (400 m)* 1312 ft (400 m)*

Inverters of 5 HP or below

Motor Insulation Level 1000 V 1300 V 1600 V

460 VAC Input Voltage 66 ft (20 m) 165 ft (50 m) 165 ft (50 m)*

230 VAC Input Voltage 328 ft (400 m)* 328 ft (100 m)* 328 ft (100 m)*

* For this case the cable length is determined by secondary effects and not voltage spiking.

When a motor protective thermal O/L relay is inserted between the inverter and the motor, the

thermal O/L relay may malfunction (particularly in the 460 V series), even when the cabl e

length is 165 ft (50 m) or less. T o correc t, insert a fil ter or red uce the carri er frequenc y. (Use

function code F26 (Motor sound).)

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 4

Chapter 5 FUNCTION CODES

5.1 Function Code Tables

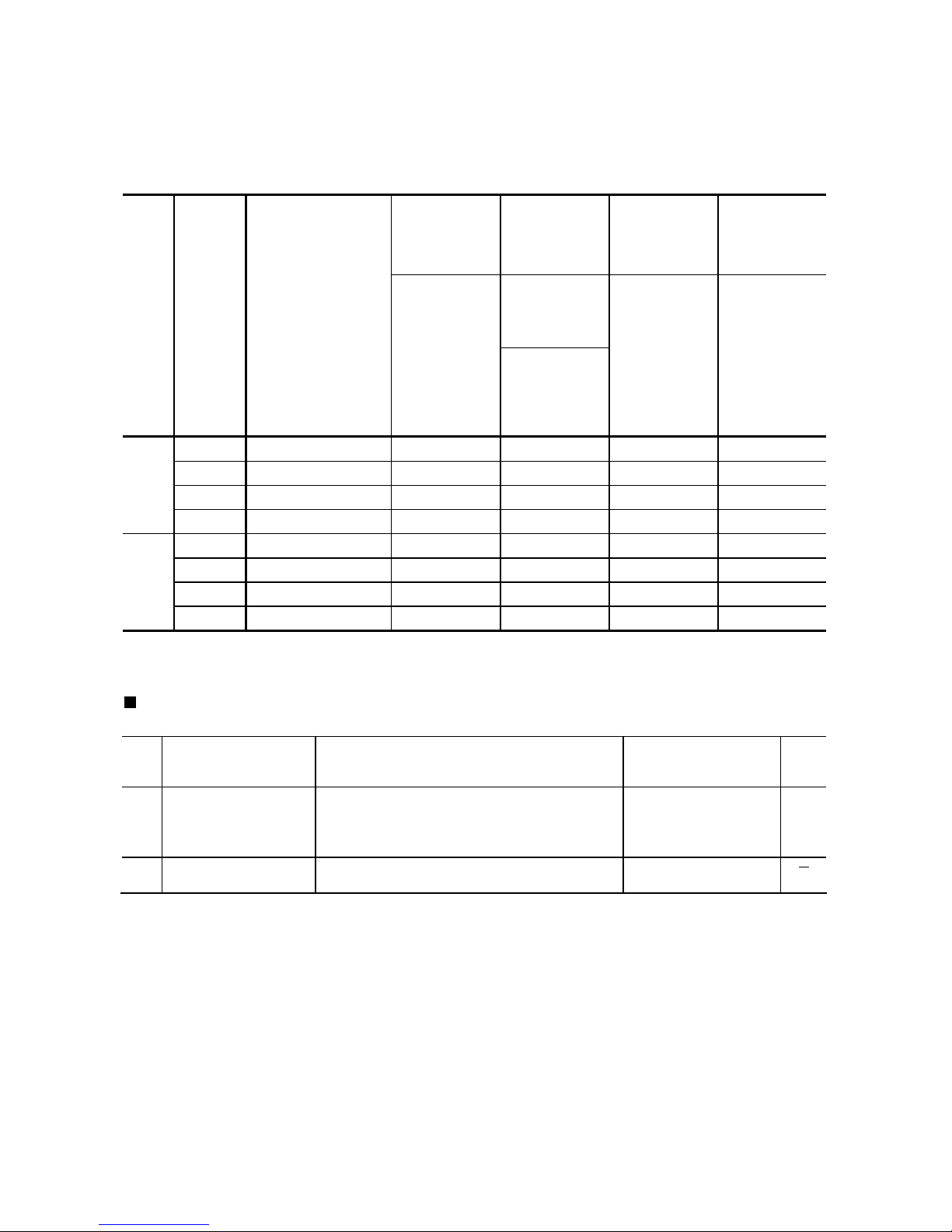

Table A Fuji Standard Motor Parameters

Fuji's standard

torque

boost (%)

Nominal rated

current of

Fuji standard

motor (A)

Nominal rated

capacity of

Fuji standard

motor (kW)

Restart Mode

after Momentary

Power Failure

(s)

Function codes

F11/A07/

E34/E37

Power

supply

voltage

Applicable

motor rat-

ing

(HP)

Inverter type

Function code

F09/A05

Shipping destina-

tion (version)

Function code

P02/A16

Function

code

H13

7.5 FRN0025C2S-2U

4.9

20.06

5.50 0.5

10 FRN0033C2S-2U

4.4

25.72

7.50 0.5

15 FRN0047C2S-2U

3.5

37.21

11.00 1.0

Threephase

200 V

20 FRN0060C2S-2U

2.8

48.50

15.00

1.0

7.5 FRN0013C2S-4U

4.9

10.24

5.50 0.5

10 FRN0018C2S-4U

4.4

12.86

7.50 0.5

15 FRN0024C2S-4U

3.5

18.60

11.00 1.0

Threephase

400 V

20 FRN0030C2S-4U

2.8

24.25

15.00 1.0

The following function code , in the ROM version 0800 or later, the data setting range and the

factory default is change.

Code Name Data setting range Default setting

Refer

to

page:

F44 Current Limiter (Level)

20 to 180 : 3.7kW or below

20 to 200 : 5.5kW or above

(The data is interpreted as the rated output current of the inverter for 100%.)

3.7kW or below : 160

5.5kW or above : 180

5-42

H27

Thermistor for Motor

(Level)

0.00 to 5.00 1.6

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 5

5.2 Details of Function Codes

F50, F51

Electronic Thermal Overload Protection for Braking Resistor

(Discharging capability and Allowable average loss)

External Braking Resistors

Standard models

Braking resistor

Continuous braking

(100% braking torque)

Intermittent braking

(Period: 100 s or less)

Power

supply

voltage

Inverter type

Type Qty.

Resistance

(

)

Discharging

capability

(kWs)

Braking

time

(s)

Allowable

average loss

(kW)

Duty

(%ED)

FRN0025C2S-2U

DB5.5-2 20 55

20

0.138

FRN0033C2S-2U

DB7.5-2 15 37 0.188

FRN0047C2S-2U

DB11-2 10 55 0.275

Threephase

200 V

FRN0060C2S-2U

DB15-2

1

8.6 75

10

0.375

5

FRN0013C2S-4U

DB5.5-4 80 55

20

0.138

FRN0018C2S-4U

DB7.5-4 60 38 0.188

FRN0024C2S-4U

DB11-4 40 55 0.275

Threephase

400 V

FRN0030C2S-4U

DB15-4

1

34.4 75

10

0.375

5

10%ED

Braking resistor

Continuous braking

(100% braking torque)

Intermittent braking

(Period: 100 s or less)

Power

supply

voltage

Inverter type

Type Qty.

Resistance

(

)

Discharging

capability

(kWs)

Braking

time

(s)

Allowable

average loss

(kW)

Duty

(%ED)

FRN0025C2S-2U

DB5.5-2C 20 55

20

0.275

FRN0033C2S-2U

DB7.5-2C 15 37 0.375

FRN0047C2S-2U

DB11-2C 10 55 0.55

Threephase

200 V

FRN0060C2S-2U

DB15-2C

1

8.6 75

10

0.75

10

FRN0013C2S-4U

DB5.5-4C 80 55

20

0.275

FRN0018C2S-4U

DB7.5-4C 60 38 0.375

FRN0024C2S-4U

DB11-4C 40 55 0.55

Threephase

400 V

FRN0030C2S-4U

DB15-4C

1

34.4 75

10

0.75

10

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 6

Chapter 8 SPECIFICATIONS

8.1 Standard Models

8.1.1 Three-phase 200 V class series

Item Specifications

Type (FRN_ _ _ _ C2S-2U) 0025 0033 0047 0060

Applicable motor rating (HP) *1

7.5 10 15 20

Rated capacity (kVA) *2 9.5 12 17 22

Rated voltage (V) *3 Three-phase, 200 to 240 V (with AVR function)

Rated current (A)

25

(23.5) *10

33.0

(31.0) *10

47.0

(44.0) *10

60.0

(57.0) *10

Overload capability

150% of rated output current for 1 min or 200% of rated output

current for 0.5 min

Output Ratings

Rated frequency (Hz) 50 60 Hz

Phases, voltage, fre-

quency

Three-phase, 200 to 240 V, 50/60 Hz

Voltage and frequency

variations

Voltage: +10 to -15% (Interphase voltage unbalance: 2% or less)

*5, Frequency: +5 to -5%

(w/ DCR) 21.1 28.8 42.2 57.6

Rated current (A) *6

(w/o DCR) 31.5 42.7 60.7 80.0

Input Ratings

Required power supply

capacity (kVA) *7

7.4 10 15 20

Torque (%) *8 20

DC braking

Braking starting frequency*9: 0.0 to 60.0 Hz,

Braking time: 0.0 to 30.0 s, Braking level: 0 to 100%

Braking

Braking transistor Built-in

Applicable safety standards UL508C, IEC 61800-5-1: 2007 (under application)

Enclosure IP20 (IEC 60529:1989), UL open type (UL50)

Cooling method Fan cooling

Mass (lbs)

6.8 6.8 9.8 9.8

*1 Fuji 4-pole standard motors

*2 Refers to the rated capacity assuming the rated output voltage as 220 V for three-phase 200V series.

*3

Output voltages cannot exceed the power supply voltag

e.

*5

2004):3-61800IECto(Refer67

(V)voltageaveragephase-3

(V)eMin.voltag-(V)voltageMax.

(%)unbalancevoltageInterphase

If this value is 2 to 3%, use an optional AC reactor (ACR).

*6 Refers to the estimated value to apply w hen the power supply capacity i s 500 kV A (inv erter capaci ty x 10 when the

inverter capacity exceeds 50 kVA) and the inverter is connected to the %X = 5% power supply.

*7 Refers to the value to apply when a DC reactor (DCR) is used.

*8 Refers to the average br aking torq ue to apply w hen the motor r unning alone decel erates fr om 60 Hz wi th the AVR

control being OFF. (It varies with the efficie ncy of the motor.)

*9 Available only for induction motor drive.

*10The load shall be reduced so that the continuous operating current is the rated current in parentheses or less if the

carrier frequency is set to 4 kHz or above or the ambient temperature exceeds 40°C

104°F .

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 7

8.1.2 Three-phase 400 V class series

Item Specifications

Type (FRN_ _ _ _ C2S-4U) 0013 0018 0024 0030

Applicable motor rating (HP) *1 7.5 10 15 20

Rated capacity (kVA) *2 9.9 13 18 22

Rated voltage (V) *3 Three-phase, 380 to 480 V (with AVR function)

Rated current (A) 13.0 18.0 24.0 30.0

Overload capability

150% of rated output current for 1 min or 200% of rated output

current for 0.5 min

Output Ratings

Rated frequency (Hz) 50 60 Hz

Phases, voltage, fre-

quency

Three-phase, 380 to 480 V, 50/60 Hz

Voltage and frequency

variations

Voltage: +10 to -15% (Interphase voltage unbalance: 2% or less)

*5, Frequency: +5 to -5%

(w/ DCR) 10.6 14.4 21.1 28.8

Rated current (A) *6

(w/o DCR) 17.3 23.2 33.0 43.8

Input Ratings

Required power supply

capacity (kVA) *7

7.4 10 15 20

Torque (%) *8 20

DC braking

Braking starting frequency*9: 0.0 to 60.0 Hz,

Braking time: 0.0 to 30.0 s, Braking level: 0 to 100%

Braking

Braking transistor Built-in

Applicable safety standards UL508C, IEC 61800-5-1: 2007 (under application)

Enclosure IP20 (IEC 60529:1989), UL open type (UL50)

Cooling method Fan cooling

Mass (lbs)

6.8 6.8 9.8 9.8

*1 Fuji 4-pole standard motors

*2 Refers to the rated capacity assuming the rated output voltage as 440 V for three-phase 400V series.

*3 Output voltages cannot exceed the power supply voltage.

*5

2004):3-61800IECto(Refer67

(V)voltageaveragephase-3

(V)eMin.voltag-(V)voltageMax.

(%)unbalancevoltageInterphase

If this value is 2 to 3%, use an optional AC reactor (ACR).

*6 Refers to the estimated value to apply when the power supply capacity i s 500 kV A (inv erter capacity x 10 when the

inverter capacity exceeds 50 kVA) and the inverter is connected to the %X = 5% power supply.

*7 Refers to the value to apply when a DC reactor (DCR) is used

.

*8

Refers to the average braking torque t o apply when the motor runni ng al one decel erates fro m 60 Hz wi th the AV

R

control being OFF. (It varies with the efficiency of the motor.)

*9 Available only for induction motor drive.

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 8

8.4 External Dimensions

8.4.1 Standard models

Unit inch [mm]

Power supply

voltage

Inverter type

FRN0025C2S-2U

Three-phase

200 V

FRN0033C2S-2U

FRN0013C2S-4U

Three-phase

400 V

FRN0018C2S-4U

Power supply

voltage

Inverter type

FRN0047C2S-2U

Three-phase

200 V

FRN0060C2S-2U

FRN0024C2S-4U

Three-phase

400 V

FRN0030C2S-4U

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 9

Chapter 9 LIST OF PERIPHERAL EQUIPMENT AND OPTIONS

Name of peripheral

equipment

Function and application

Main peripheral equipment

Molded case

circuit breaker

(MCCB)

Residual-currentoperated protective device (RCD)

/Earth leakage

circuit breaker

(ELCB)

*

*

with overcu

rrent

protection

MCCBs are designed to protect the power circuits between the power control

board and inverter’s main terminals (L1/R, L2/S and L3/T for three-phase

power, L1/L and L2/N for single-phase power) from overload or sh ort-circuit

which in turn prevents secondary disaste rs caused by the inverter malfunctioning.

RCDs/ELCBs function in the same way as MCCBs. Use the MCCBs and

RCDs/ELCBs that satisfy the recommended rated current listed below.

Recommended rated current (A) of

MCCB and RCD/ELCB

Power

supply

voltage

Applicable

motor

rating

(HP)

Inverter type

w/ DC reactor w/o DC reactor

7.5

FRN0025C2S-2U 30 50

10

FRN0033C2S-2U 40 75

15

FRN0047C2S-2U 50 100

Three-

phase

200 V

20

FRN0060C2S-2U 75 125

7.5

FRN0013C2S-4U

15

30

10

FRN0018C2S-4U

20

40

15

FRN0024C2S-4U

30

50

Three-

phase

400 V

20

FRN0030C2S-4U

40

60

When connecting the inverter to the power supply, add a recommended

molded case circuit breaker (MCCB) or a residual-curre nt-opera ted protective device (RCD)/earth leakage circuit breaker (ELCB)* in the path of power

supply. Do not use the devices with the rated current out of the recommended range. *With overcurrent protection

Fire could occur.

Select the MCCB or RCD/ELCB with appropriate rated current and breaking

capacity according to the power supply capacity.

Chapter 10 APPLICATION OF DC REACTORS (DCRs)

Since the "Japanese Guideline for Suppressing Harmonics in Home and General-purpose Appliances" issued by the Mini stry of Interna tional T rade and Industry (Currently the Ministry of Econom y,

Trade and Industry) was revised in January 2004, the general-purpose inverters have no longer

been subject to the guideline. Individual inverter manufacturers have voluntarily employed harmonics suppression measures. It is recommended that DC reactors (DCRs) specified in Table 10.1

be connected to the FRENIC-Mini series of inverters.

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 10

Table 10.1 List of DC Reactors (DCRs)

Power

supply

voltage

Nominal applied

motor (HP)

Applicable inverter type DCR type

7.5 FRN0025C2S-2U

DCR2-5.5

10 FRN0033C2S-2U

DCR

2-7.5

15 FRN0047C2S-2U

DCR2-11

Threephase

200 V

20 FRN0060C2S-2U

DCR

2-15

7.5 FRN0013C2S-4U

DCR4-5

.5

10 FRN0018C2S-4U

DCR4-7

.5

15 FRN0024C2S-4U

DCR

4-1 1

Threephase

400 V

20 FRN0030C2S-4U

DCR

4-15

Chapter 11 COMPLIANCE WITH STANDARDS

11.1 Compliance with European Standards

The CE marking on Fuji products indicates that they comply with the essential requirements of the

Electromagnetic Compatibility (EMC) Directive 2004/108/EC issued by the Council of the European

Communities and Low Volta ge Directive 2006/95/EC.

Inverters that bear a CE marking are compliant with the Low Voltage Directive.

The products comply with the following standards:

Low Voltage Directive EN61800-5-1: 2007

EMC Directives EN61800-3: 2004 +A1: 2012

Immunity: Second environment (Industrial)

Emission: Category C2

(Applicable only when an optional EMC-compliant filter

is attached)

CAUTION

The FRENIC-Mini series of inverters are categorized as a "restricted sales distribution class" of the

EN61800-3. When you use these products with any home appliances or office equipment, you may

need to take appropriate countermeasures to reduce or eliminate any noise emitted from these

products.

11.2 Compliance with EMC Standard

11.2.2 Recommended installation procedure

In case an outboard, EMC-compliant (optional) is used

If noise from the inverter exceeds the permissible level, enclose the inverter and its peripherals

within a metal pane.

For details, refer to the FRENIC-Mini Instruction Manual (INR-SI47-1745-E), Chapter 11

Sec-

tion

11.2 "Comp liance with EMC Standard."

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 11

11.2.3 Leakage current of EMC-complaint filter (optional)

Table 11.1 Leakage Current of EMC-compliant Filter (optional)

Inverter type Leakage current (mA)

*1 to *4

For Japan For other countries

Filter type

Normal Worst

FRN5.5C2S-2J FRN0025C2S-2U

FRN7.5C2S-2J FRN0033C2S-2U

FS5956-53-52

11

*1

11

*1

FRN11C2S-2J FRN0047C2S-2U

FRN15C2S-2J FRN0060C2S-2U

EFL-15SP-2

20

*1

20

*1

FRN5.5C2S-4J

FRN0013C2S-4U

FRN7.5C2S-4J

FRN0018C2S-4U

FS21559-24-07-1 4

*2

59

*2

FRN11C2S-4J

FRN0024C2S-4U

FRN15C2S-4J FRN0030C2S-4U

FS21312-44-07 4

*3

167

*3

*1) The values are calculated assuming the power supplies of three-phase 240 V (50 Hz).

*2) The values are calculated assuming the power supplies of three-phase 400 V (50 Hz).

*3) The values are calculated assuming the power supplies of three-phase 480 V (50 Hz).

*4) The worst condition includes a phase loss in the supply line.

11.4 Compliance with the Low Voltage Directive in the EU

11.4.1 General

General-purpose inverters are regulated by the Low Voltage Directive in the EU. Fuji Electric has

obtained the proper certification for the Low V oltage Directi ve from the offi cial inspection agency. Fuji

Electric states that all our inverters with CE marking are compliant with the Low Voltage Directive.

11.4.2 Points for consideration when using the FRENIC-Mini series in a system to be

certified by the Low Voltage Directive in the EU

If you want to use the FRENIC-Mini series of inverters in systems/equipment in the EU, refer to the

guidelines given below.

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 12

Conformity to the Low Voltage Directive in the EU

If installed according to the guidelines given below, inverters marked with CE are considered as

compliant with the Low Voltage Directive 2006/95/EC.

12. Use wires listed in IEC60364-5-52.

Recommended wire size (mm2 )

*1

Rated current (A)

of

MCCB or RCD/ELCB

*2

Main circuit

power input

[L1/R, L2/S, L3/T]

[L1/L, L2/N]

Grounding [

G]

Power supply voltage

Appli-

cable

motor

rating

(HP)

Inverter type

w/ DCR

*3

w/o DCR

w/ DCR*3w/o DCR

*2

Inverter

output

[U, V,

W]

*2

DCR

[P1,

P (+)]

Braking

resistor

[P (+),

DB]

Control

circuit

(30A,

30B,

30C)

7.5

FRN0025C2S-2U 30 50 4.0 6.0 4.0 4.0

10

FRN0033C2S-2U 40 75 6.0 10 6.0 6.0

15

FRN0047C2S-2U 50 100 10 16 10 16

3-phase 200 V

20

FRN0060C2S-2U 75 125 16 25 16 25

0.5

7.5

FRN0013C2S-4U 15 30 2.5

10

FRN0018C2S-4U 20 40

2.5

4.0

2.5 2.5

15

FRN0024C2S-4U 30 50 4.0 6.0 4.0 4.0

3-phase 400 V

20

FRN0030C2S-4U 40 60 6.0 10 6.0 6.0

0.5

MCCB: Molded case circuit breaker

RCD: Residual-current-operated protective device

ELCB: Earth leakage circuit breaker

*1 The frame size and model of the MCCB or RCD/ELCB (with overcurrent protection) will vary, de-

pending on the power transformer capacity. Refer to the related technical documentation for details.

*2 The recommen ded wire size for main circuits is for the 70

C 600V PVC wires used at an ambient

temperature of 40

C.

*3 In the case of no DC reactor, the wire sizes are determined on the basis of the effective input current

calculated under the condition that the power supply capacit y and impedance are 500 kVA and

5%, respectively.

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 13

Conformity to the Low Voltage Directive in the EU (Continued)

13. To prevent the risk of hazardous accidents that could be caused by damage of the inverter,

install the specified fuses in the supply side (primary side) according to the following tables.

- Breaking capacity: Min. 10 kA

- Rated voltage: Min. 500 V

Power

supply

voltage

Nominal

applied

motor (HP)

Inverter type

Fuse rating

(A)

7.5

FRN0025C2S-2U

125(IEC60269-4)

10

FRN0033C2S-2U

160(IEC60269-4)

15

FRN0047C2S-2U

160(IEC60269-4)

Three-phase

200V

20

FRN0060C2S-2U

200(IEC60269-4)

7.5

FRN0013C2S-4U

80(IEC60269-4)

10

FRN0018C2S-4U

80(IEC60269-4)

15

FRN0024C2S-4U

125(IEC60269-4)

Three-phase

400V

20

FRN0030C2S-4U

160(IEC60269-4)

14. Use this inverter at the following power supply system.

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 14

Conformity to the Low Voltage Directive in the EU (Continued)

*1 Use this inverter at the following IT system.

Non-earthed (isolated from earth) IT

system

IT system which earthed neutral

by an impedance

Can be used.

In this case the insu l ation between the control

interface and the main circuit of the inverter is

basic insulation.

Thus do not connect SELV circuit from external

controller directly (make connection using a

supplementary insulation.).

Use an earth fault detector able to disconnect

the power within 5s after the earth fault occurs.

Corner earthed / Phase-earthed IT

system by an impedance

Can not be used

*2 Cannot apply to Corner earthed / Phase-earthed TT system of 400V type.

11.5 Compliance with UL Standards and Canadian Standards (cUL certification)

11.5.1 General

Originally, the UL standards were established by Underwriters Laboratories, Inc. as private criteria

for inspections/investigations pertainin g to fire/accident insurance in the USA. Later , these standards

were authorized as the official standards to protect operators, service personnel and the general

populace from fires and other accidents in the USA.

cUL certification means that UL has given certification for products to clear CSA Standards. cUL

certified products are equivalent to those compliant with CSA Standards.

11.5.2 Considerations when using FRENIC-Mini in systems to be certified by UL and cUL

To use the FRENIC-Mini series of inverters as a part of UL Standards or CSA Standards (cUL certified) certified product, refer to the guidelines given below.

Conformity to UL standards and Canadian standards cUL certification

If installed according to th e guidelines given below, inverters marked with UL/cUL are con sidered a s

compliant with the UL and CSA (cUL certified) standards.

Integral solid state short circuit protection does not provide branch circuit protection. Branch

circuit protection must be provided in accordance with the National Electrical Code and any

additional local codes.

1. Solid state motor overload prote ction ( m otor protection by electr onic thermal ov erload relay )

is provided in each model.

Adjust function codes F10 to F12 and H89 to set the protection level.

2. Connect the power supply satisfying the characte ristics show n in the table below as an input

power supply of the inverter. (Short circuit rating)

3. Use 75

Cu wire only.

4. Use Class 1 wire only for control circuits.

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 15

Conformity to UL standards and Canadian standards cUL certification

Short circuit rating

When protected by class J fuses, su it able for use on a circui t capable of delivering not more

than B rms symmetrical amperes, A volts maximum.

Power

supply

voltage

Inverter type

Power supply max. voltage

Volts

Power supply current

Amperes

FRN0025C2S-2U

FRN0033C2S-2U

FRN0047C2S-2U

Three-phase

200V

FRN0060C2S-2U

240VAC 100,000 A or less

FRN0013C2S-4U

FRN0018C2S-4U

FRN0024C2S-4U

Three-phase

400V

FRN0030C2S-4U

480VAC 100,000 A or less

5. Install UL certified fuses rated 600Vac between the power supply and the invert er, referrin g to

the table below.

Required torque

Ib-in (N

m)

Wire size

AWG or kcmil(mm2)

Control circuit Control circuit

Power

supply

voltage

Inverter type

Main

terminal

*1

TERM1

*2

TERM2-1

TERM2-2

*3

Main

terminal

*1

TERM1

*2

TERM2-1

TERM2-2

Class J fuse cur-

rent(A)

FRN0025C2S-2U 60

FRN0033C2S-2U

27

(3.0)

8

(8.4)

75

FRN0047C2S2U

6

(13.3)

100

Three-phase

200V

FRN0060C2S-2U

51.3

(5.8)

3.5

(0.4)

1.7

(0.2)

4

(21.2)

6

(13.3)

20

(0.5)

150

FRN0013C2S-4U

12

(3.3)

10

(5.3)

30

FRN0018C2S-4U

27

(3.0)

10

(5.3)

40

FRN0024C2S-4U 60

Three-phase

400V

FRN0030C2S-4U

51.3

(5.8)

3.5

(0.4)

1.7

(0.2)

8

(8.4)

20

(0.5)

70

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 16

Conformity to UL standards and Canadian standards cUL certification (Continued)

*1 Denotes the relay contact terminals for [30A], [30B] and [30C].

*2 Denotes control terminals except for [30A], [30B] and [30C].

*3 Values in [ ] mean the size(AWG) of Grounding wire if exist.

6. To comply with CSA for 400VAC input models, transient surge suppressio n shall be installed

on the line side o f this equipme nt and shall be rated 278V ( phase to gro und), 480V (phase to

phase), suitabl e f or over vol ta g e ca te gor y 3, and s hal l p ro vid e p ro t ecti on for a rat ed im pu ls e

withstand voltage peak of 4k

V.

7. All models rated 380-480 V input voltage ratings shall be connected to TN-C system power

source, i.e. 3-phase, 4-wire, wye (480Y/277V), so that the phase-to-ground rated system

voltage is limited to 300V maxi

mum.

8

. Maximum surrounding air temperature rating of 50 ºC

.

Compact Inverter

Instruction Manual

Supplement for FRN-C2S-2U/4U 7.5 to 20HP

First Edition, March 2014

Fuji Electric Co., Ltd.

The purpose of this instruction manual is to provide accurate information in handling, setting up and

operating of the FRENIC-Mini series of inverters. Please feel free to send your comments regarding

any errors or omissions you may have found, or any suggestions you may have for generally improving the manual.

In no event will Fuji Electric Co., Ltd. be liable for any direct or indirect damages resulting from the

application of the information in this manual.

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Loading...

Loading...