Page 1

Page 2

Omperator's anual

www.fubag.ru

WARNING! BEFORE USING THE WELDING MACHINE READ THE INSTRUCTION

MANUAL CAREFULLY! FOR QUALIFIED AND SPECIALLY TRAINED PERSONS

ONLY AFTER PROPER READING OF THIS MANUAL IS ALLOWED TO USE AND TO

MAINTAINTHIS WELDING MACHINE.

The detailed description, safety rules and all required information necessary for proper operation

and maintenance of FUBAG welding machine are provided below. Keep this instruction manual by

machine and refer to it by any doubts concerning safety operation, maintenance storage and

handling ofFUBAG weldingmachine.

1. Safety perationo

It is highly recommended always to follow the safety rules. Wear protective clothes and

special means to avoid injuries to eyes and skins.

Use the welding mask or special protective glasses while working with the welding

machine. Only by viewing through the filter lens on the welding mask your eyes are

secured by your operation.

Prevent the sparks and spatter from harming your body.

-

Under no circumstance allow any part of your body to touch the welder's output bipolarity

(torch and work piece).

Do not operate under water or more humid place.

-

Fumes and gases produced when welding are hazardous to health. Make sure to work in

places where there are exhaust or ventilation facilities to keep fumes or emissions away

from the breathing zone.

Please remember to keep arc rays away from the other nearby people when welding. This

is only due to the interference from arc rays.

There will be high temperature when welding work piece, so please don't directly touch on it

-

No touching on the output connection or any other electrification parts while welding.

-

No touching on the electrification parts after turning on the power. Cut off the power supply

after operation or before leaving the welding site.

No welding in the dangerous site where easily get an electrical shock.

-

No welding for the container loaded inflammable or explosive materials.

-

Safe measures should be adoptted while operating in high place to avoid accident.

-

No entering the welding site for persons not concerned.

-

Welders possible have electromagnetism and frequency interference, so keep away people

with heart pace or the articles which can be interfered by electromagnetism and frequency.

WARNING. The welder voltage is always higher, so the safety precaution should be taken

before repair to avoid accidental shock. Switch off the power supply before each type of

maintenance work. The untrained people are not allowed to make maintenance of the

machine.

- 1 -

Page 3

Omperator's anual

www.fubag.ru

Check the connection of input and output cables and the earth (ground) connection, etc.

Maintenance should be conducted by the trained personnel.

The newly installed machine or the welder not in use for some time needs to be checked by

-

multimeter have the right insulation resistance between each winding and the case.

When the welder is used outdoors, it should be kept from rain or long exposure to the sun.

Check is needed from time to time to make sure the welding cable is in good condition if the

-

welding machine is in frequent use. Check at least once each month if the welder is in

regular use. It is necessary to check when the welder is in mobile use.

If the welder is not in use either for a long time or temporarily, it should be kept dry and have

-

good ventilation to free it from moisture, erodible or toxic gas.

- The welder must be installed in the place where it can not be exposed to sun and rain. Also it

must be stored in less humid place with the temperature range at -10 +40 .

Dust removal is needed every year. Check the machine's fasteners, moving-iron, current

-

regulation screws, etc to make sure there are no loose connection problems.

The dust, acid and erodible dirt in the air at the job site can not exceed the amount required

-

by the norm (excluding the emission from the welder).

The welder must be installed in the place where it can not be exposed to sun and rain. Also it

-

must be stored in less humid place with the temperature.

There should be 50 cm space about for the welding machine to have good ventilation.

Make sure that there is no metal-like foreign body to enter the welding machine.

Electrode must be taken down from holder when no welding.

No violent vibration in the welder's surrounding area.

Make sure that there is no interference with the surrounding area at the installation site.

The welder should be installed on the horizontal surface and if it over 15°, there should be

-

added some anti-dump set.

Take measures to prevent wind while operating in the strong wind since the welder is gas

-

shielded. The wind speed is limited below 1 0 m/s, or the wind shield device must be loaded.

,

O

C

Safety Check:

Each item listedbelow mustbe carefullychecked beforeoperation:

Make sure thatthere isno short circuitconnection withwelder's bothoutputs.

Make sure that there is always sound output and input wire connection instead of exposing it

outside.

Regular check needs to be conducted by the qualified personnel after the welding machine has

been installed overa longperiod or re-operation, whichinvolves as follows:

Check the weldingcable tosee ifit cancontinue to be usedbefore it is wornout.

-

Replace thewelder's inputcable as soon asit is found tobe broken or damaged.

-

Make sure whether there is enough power supply to make the welding machine work properly.

Any power source required to access the welding machine must be installed with some

protective equipments.

Please do not hesitate to contact us for technical assistance whenever you come across the

problems youcan notwork out or youmay deem difficult to fix.

--2

Page 4

Omperator's anual

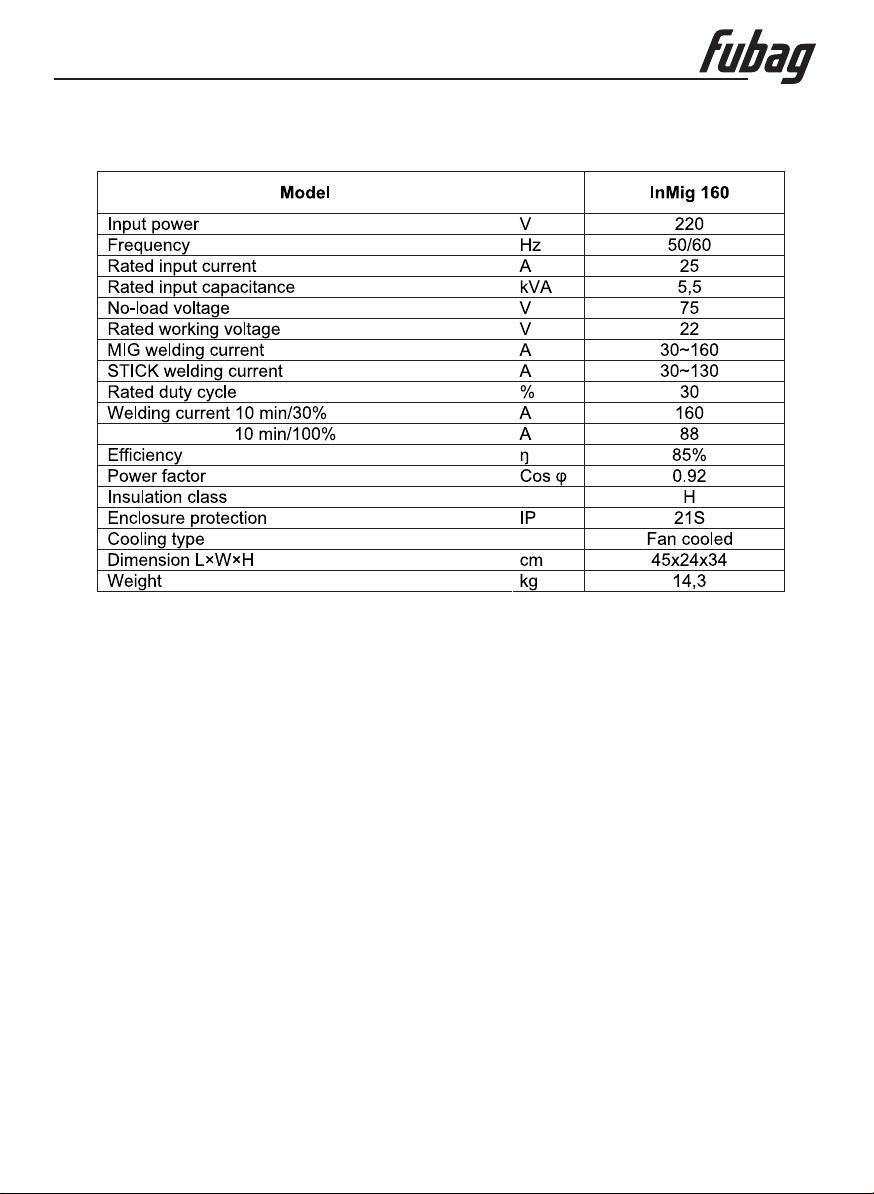

2. Technical Specification

The manufacturer reserves himself the right to make the manual's content or welder's function

change without anypreliminary notification ofthe users.

www.fubag.ru

3. Description

MIG Series Inverter is designed to be used with the advanced IGBT (Insulated Gate Bipolar Tube)

and rapid recovery diode as its main control and transfer components and assisted with the

specially developed control circuit. It is available to MIG ( both CO gas-shielded welding and fluxcored welding) and stickwelding. The continuous wirecan form welding seam metalafter melting so

as to connect the wok pieces each other. The melting electrode gas protects the welding district

easily, so it is easy to operate & observe the whole working process. Its characteristics are high

produce efficiencyand easy to carryout all-position welding.

The highlighted characteristicsof MIGSeries Inverter:

-

Featured with smallvolume andlight weight, itwidely usedin upholstering field, repairingfield and

fieldwork.

-

High working efficiency.Automatic Wire Feedingcan realize high speedwelding.

-

No special requirementsfor thewelding wire. Both solidand flux-cored wires areavailable. The

diameter of thewire isbetween 0 6 1 0

-O

Convenient connection mode. uter connectionmake it quick, safe,simple and reliable.

-U

ndercutfunction makearc-piloting moresuccessful.

-.

Stick function isalso available.And italso can weld cellulosicelectrode

,-,mm.

--3

2

Page 5

Omperator's anual

www.fubag.ru

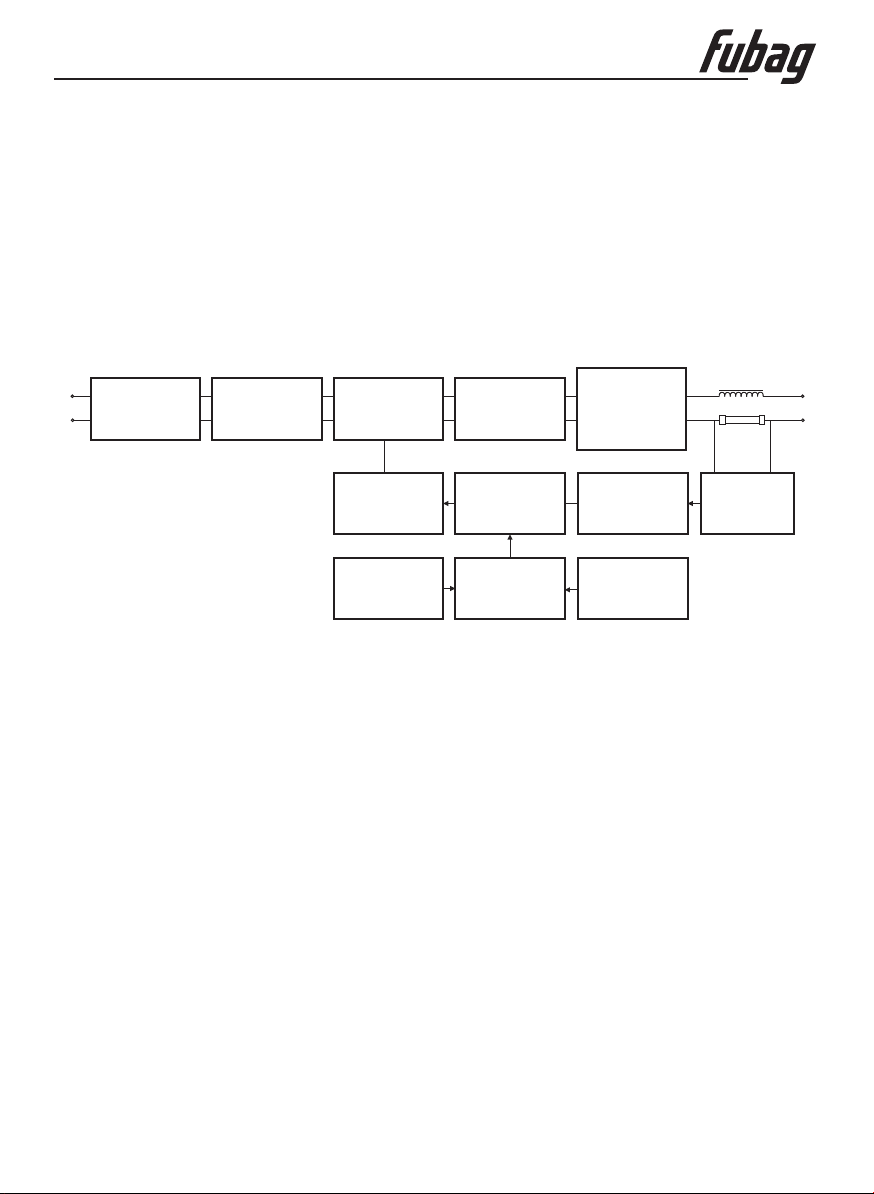

4. Welder’s Principle

The welder acquires 220V single phase industrial frequency DC power source through the power

switch SW101 and rectify through single phase rectifier bridge B1 and then filtered through

capacitor C1, C2, C3, C4 to get the DC current. The 20 KHzAC current is got through the IGBT (Q1,

Q2, Q3, and Q4) all-bridge inverter. Then this alternating current, transformed by the intermediate

frequency transformer and rectified by quick recovery diode ( D4, D5, D6, D7), outputs the stable

direct current for the welder immediately after it has been filtered by the reactor L2. The wire feed

speed can be stepless adjusted through the speed adjust knob. The welding current is easily

influenced from the wire feed speed, usually the faster the wire feed speed thebigger theAmp value

under the samevoltage.

Rectifier

Filter

Inverter

Function

Drive

Protection

Inspect

Transformation

Modulate

Process

Control

High

Frequency

Rectifier

Trait

Control

Current

Adjustment

Sampling

MIG series use the movable carton like structures: The upper part in the front is equipped with a

welding current regulation knob, power indicator light (green), abnormal indicator light (yellow),

working indicator (red) while the lower part is furnished with the torch quick connector and “-” quick

connector. The back side is installed with power switch, gas valve connection , cooling fan, power

source lead-in wire, breaker. On the topthere is a handle forthe convenient of easytransport. When

you openthe cover, there is one primary transformer, one piece of printed circuit board. The bottom

part is supplied with output reactor, primary transformer and etc. Installed in the middle part is a

radiator with powerelements.

Environment to Which the Product Is Subject:

- The surroundingtemperature range: when welding: -10 + 40 С;

During transportor instorage: -25 +55 С

- Relative humidity:when at40 С: ≤50%, 20 С: ≤90%

ОО

О

when at

О

- The dust, acid and erodible materials in the air can not exceed the amount required by the norm

(apart from theemissions fromthe welding process). Noviolent vibration at thejob site.

- Keep fromraining whenit isused outdoor.

-Altitude no more than1,000m.

Requirement for Main Supply:

- The oscillationof the supplied voltageshould not exceed ±10%of the rated value.

--4

Page 6

Omperator's anual

www.fubag.ru

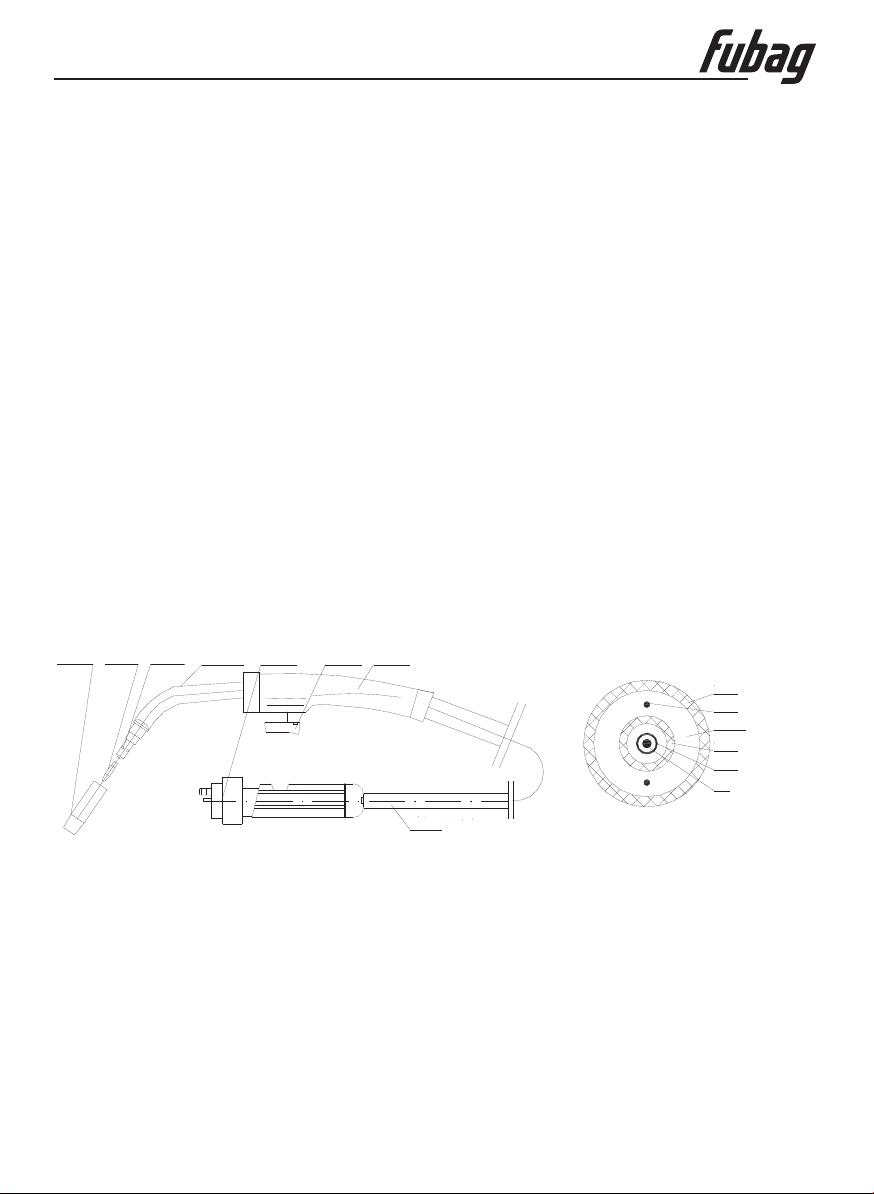

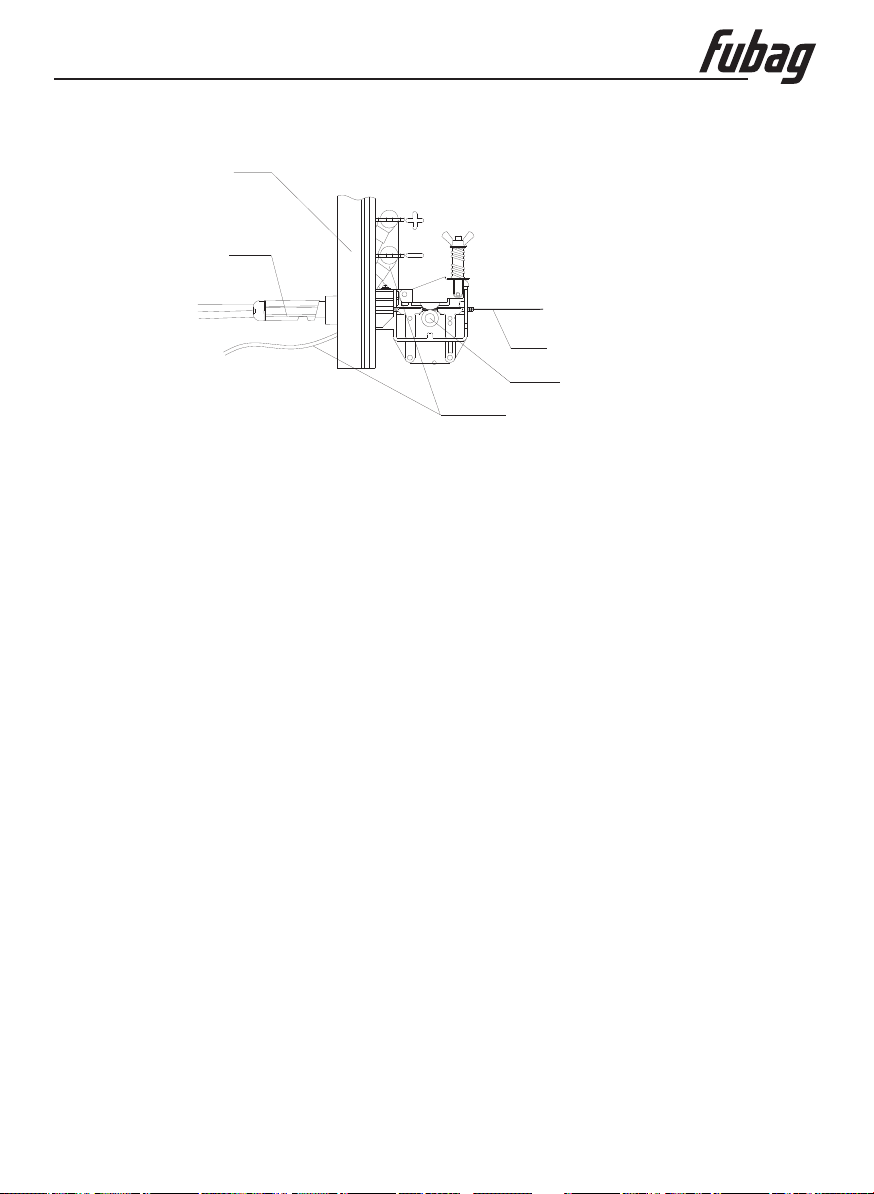

5. orchT

The torch iscomposed bytorch stand,connecting cableand handle.

Torch stand isthe interface of torchand wire feeding device.

Connecting cable: covered bynylon pipethe liner is loaded in thecenter of coreless cable. Theinner

part of liner is the passage for wire feeding. The space between liner and coreless cable is the

passage forshielded gas.Coreless cable is thepassage for current.

There is a gooseneck installed in the handle of the torch. In the back part of the torch there is a

connecting with the coreless cable and in the front part is a shunt. The shielded gas distributes via

the shunt and forms well-proportioned air current in the nozzle, and then spurt out in a form of air

hanging. Setwith asensitive switch on thehandle to control thewelding current.

Notice:

-

Must cut offthe power before assemble/disassembletorch or replace thecomponents.

-

The nozzle must be replaced in time on the condition that welding quality was influenced when it

burned tosome extent.The distributor oftorch must be replacedwhen it ruined.

-

The cable oftorch mustbe replaced whenit wornout.

NOZZLE

CONTACT

TIP

SHUNT

GOOSENECK

STAND

SWITCH

HANDLE

RUBBER LAYER

CONTROL CABLE

CORELESS CABLE

NYLON PIPE

SPRING PIPE

WIRE

CABLE

--5

Page 7

Omperator's anual

6. Sign & Pictures Illustration

www.fubag.ru

SIGN

H

IP21

0

X

I

1

I

2

U

1

U

2

7. Installation

NAME

Current

Power

Frequency

Arc welder

Ground

Insulation grade

Protection class

DC current

Power source

Rated pen ircuit oltageoc v

Duty cycle

Rated nput urrentic

Rated elding urrentwc

Welder’s tructures

Rated nput oltageiv

Rated oadl voltage

Welder’s Placement

- The dust, acid and erosible dirt in the air at the job site can not exceed the amount required by

the norm.

The welder must be installed in the place where it can not be exposed to sun and rain. Also it

must be stored in less humid place with the temperature range at -10 до 40 С.

О

- There should be 50 cm space about for the welding machine to have good ventilation.

Apparatus to exclude wind and smoke should be equipped if the inside aeration is not sound.

-

--6

Page 8

Omperator's anual

www.fubag.ru

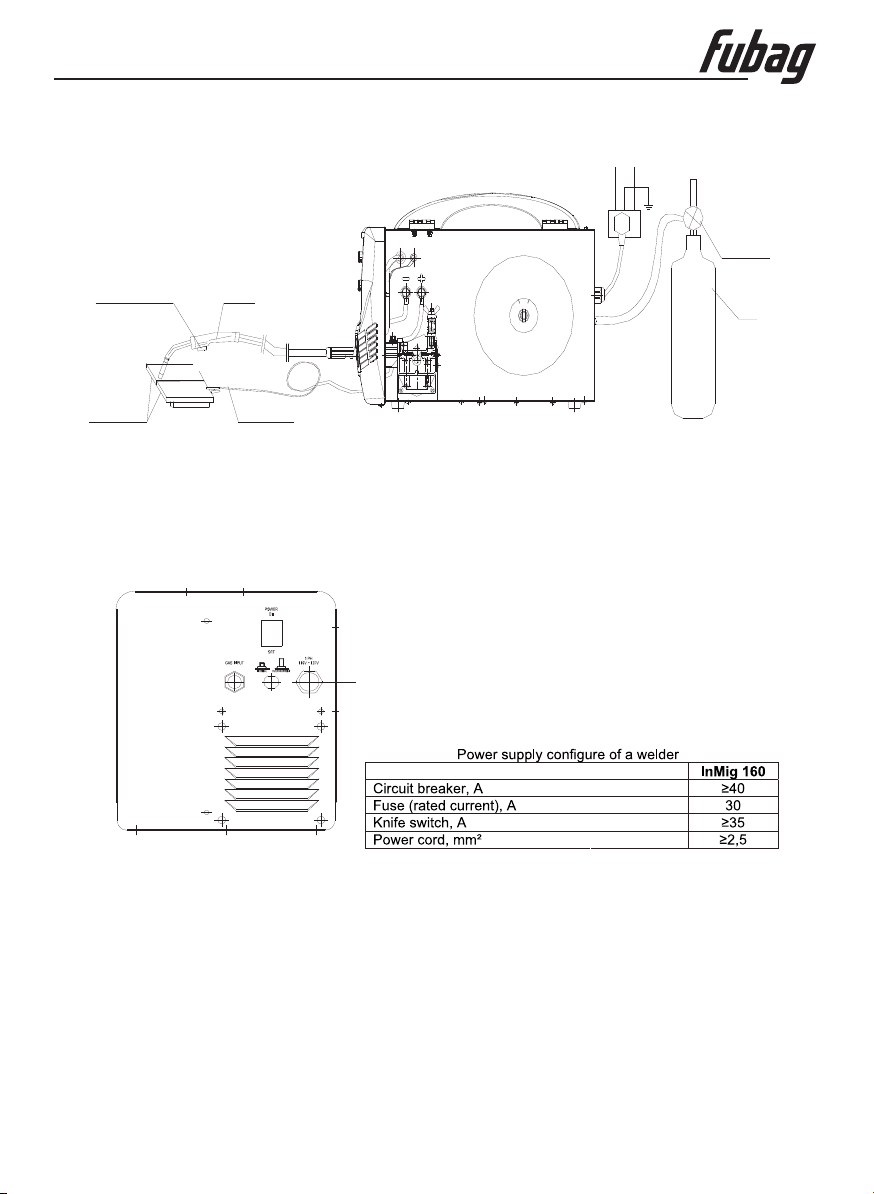

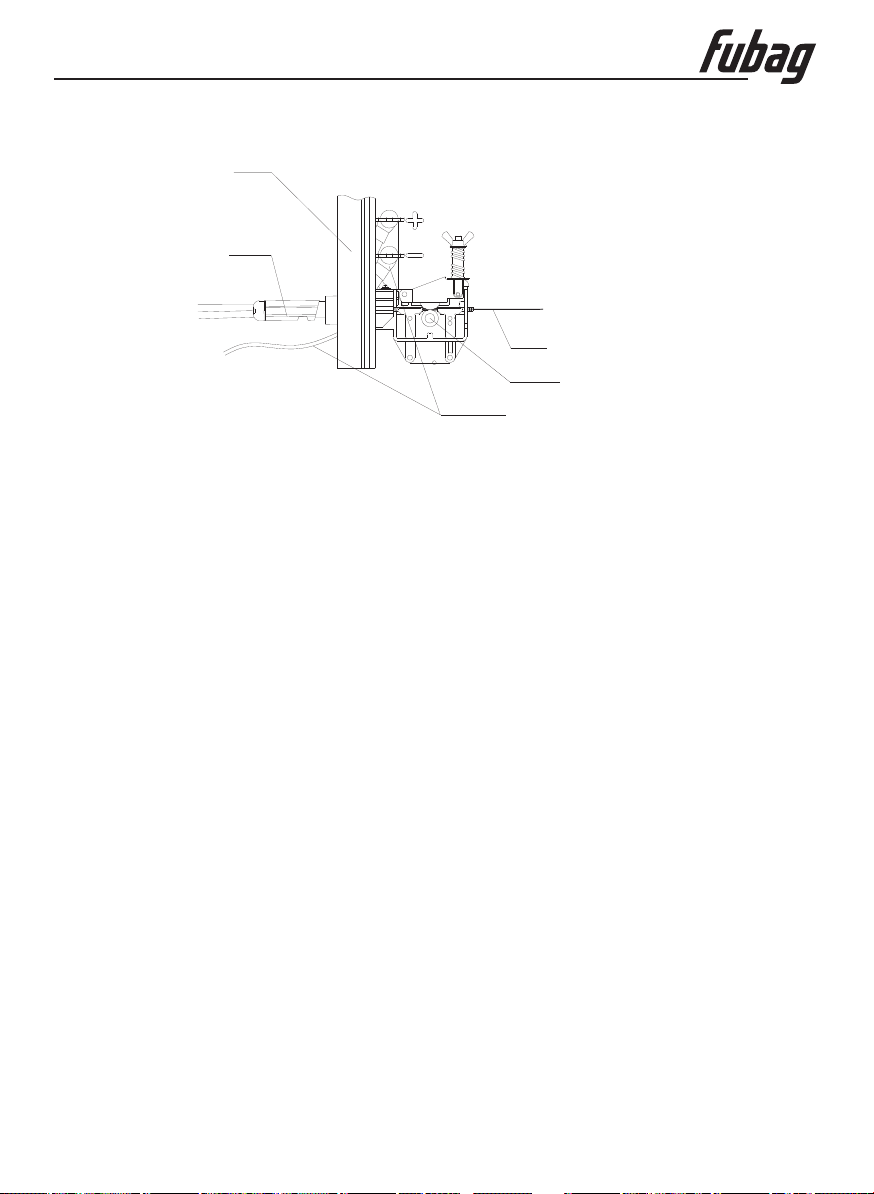

POWER INPUT CABLE

GAS

FLOWMETER

TORCH SWITCH

WORK

PIECE

TORCH

GROUNDING

CABLE

GAS PIPE

СО

2

Connection between Welderand Power Source

Connect the power source cable at the back board of the welder into the single phase 220 voltage

power network with breaker;380 voltage power sources is strictlyprohibited to the welderwhich will

severely damage thewelder, otherwise theuser should take theconsequences for it.

Notice:

The melting currentof thefuse is 1.2~1.5times ofits rated current.

1-

phaze

power supply

220

V

The installation and connection of MIG Welding

Connection and installation of the wire feeder

- Select suitable wire according to welding technology. The wire diameter must be matched with

drive roll, wireguide pipeliner andcontact tip.

-

Open the lid of wire reel on the wire feeder put “Wire Coil” into “Wire Reel” on the wire feeder.

Attention:

-

There is damping screw device inthe “WireReel” (hexhead screw will be seen when openthe lid).

Wire end underthe “WireReel”, opposite wirefeeder.

Pull the wire reel with hand when adjust. If resistance is over large, may adjust damping bolt: screw

clockwise willenlarge thevalue and vice versa.

--7

Page 9

Omperator's anual

www.fubag.ru

FRONT

PANEL

TORCH

WIRE

FEED ROLLER

EARTH CABLE

- Lead wire into “Wire Guide Pipe” of wire feeder, align wire with roll groove through “Drive Roll”, relead “Socket Tip” and press “Drive Roll”. (If more welding wire is needed, it will be done after

switching onthe power.)

Connection between Welderand Torch

- Insert the connector of torch into “Torch Access Hole” on the front panel of the welder and rotate

the screw capfirmly.

Connection of the Connection Cable

-

Connect the copper tip of the earth clampwhich thread through the wire access hole on the panel

with “-“ of the “connecting tip”. The connecting cable must be reliable, or the connecting tip will burn

out.

-

In order to reach sound performance when welding with flux-cord wire, it’s available that connect

the “+”, “-”in an opposite way, that’s the wire feedmotor with “-“andthe connectingcable with “+”.

Notice:

welder andwork piece.

Do not use steel plate or the materials alike which are ill conductor to connect between

The Connection and installation of stick welding

a) Connection ofwelder andwelding cable

Connect the quick connector of welding cable to the output on front panel, and deasil turn down.

The electrode holderis usedfor clamp the electrode

.

b) Connection ofwelder andgrounding cable

Connect the quick connector of grounding cable to the output on the front panel, and deasil turn

down. The earthclamp is used forclamp the work piece

Notice:

Do not use steel plate or the materials alike which are ill conductor to connect between

.

welder andwork piece.

--8

Page 10

Omperator's anual

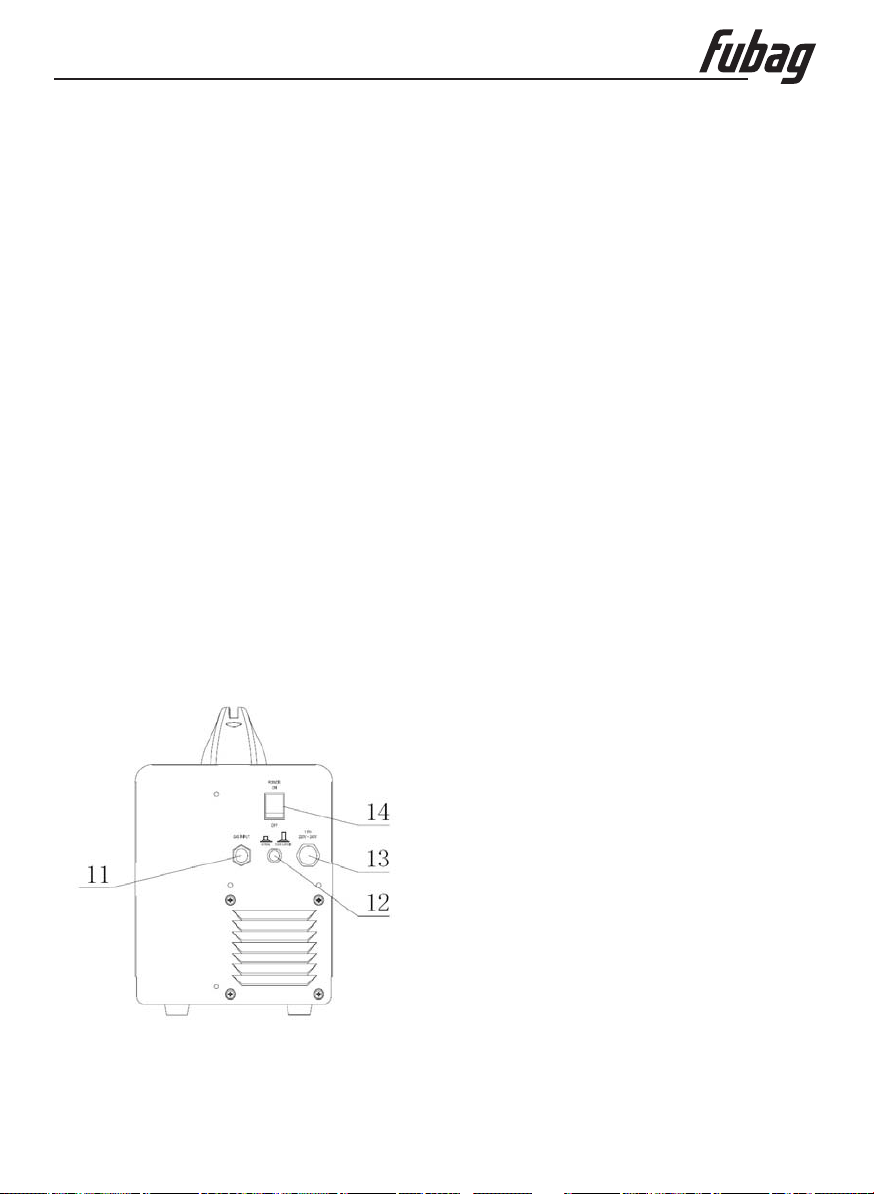

8. Operation

www.fubag.ru

ATTENTION: The protection class of MIG Series is IP21S. It is forbidden to put in a finger or

insert a roundbar less than 12.5 mm (metal bar inparticular) into the welder. No heavy force can be

employed onthe welder.

IN

Welding current adjustor

1.

2 Power Indicator

.

3 Protection indicator

.

4 Working indicator

.

5. Welding Mode Selector

6 Welding current adjustor

.

7 Grounding cable connector

.

8 MIG gun torch switch control

.

9. Welding cable connector

10 Mig torch connector

.

11 Gas input connector

.

12 Circuit breaker

.

13 Power Cord

.

14 Power Switch

.

--9

Page 11

Omperator's anual

www.fubag.ru

Attention:

- The ‘protection indicator light’ will be on after a long time operation, it shows that the inner

temperature is over the permitted data, then the machine should be stopped using for some time to

let it cooldown. Itcan continue usingafter the‘protection indicator light’is off.

-

The power sourceshould beswitched offafter the operation orwhile temporarily leaving jobsite.

-

Welders should dress canvas work cloth and wear welding mask to prevent the hurt from arc and

thermal radiation.

-

Light separating screenshould beput in the jobsite to prevent thearc will hurt otherpeople.

-

Inflammable orexplosive materialsare prohibited to accessthe job site.

-

Each connection ofthe weldershould be connected correctlyand creditably.

Work Piece cleaningBefore Welding

Wire, groove and surrounding 10-20 mm site must be cleaned, no existing rust, greasy dirt, water

and paint etc.

MIG welding steps

a) Debugging beforewelding

-

Install the torch, gas and weldingwire, andthen turnon the power switch. Thepower indicatoris on

and fan works.

- .

Turnon thegas regulator ofgas tank,the gaspressure isshown on the meter

-

Turn the gas regulator anticlockwise, loose the wire roller, press down the torch switch, and then

adjust the gasflow tomeet the technicsrequirement, andthen repressthe wireroller

-.

Press the torchswitch tillthe wire extendsto thenozzle

-

When wire feeding,make thecable straight.

-

When wirefeeding, make sure the wireis located on the wireroller groove reliably and thefeeding

speed should be smooth. If the wire feeding speed is not smooth, please adjust the tension of the

wire roller.

-

When using MIGwire, the V groove wireroller should be used.

b) Welding

-

When welding, please adjust the welding current and welding voltage matchable according to the

.

set-up

-

Aim at the weldingline, press down the torchswitch, the wire feeds automatically. The arc is started

once the wireis touchedthe work piece.When welding,the “working indicator” ison

.

.

Flux welding steps

a) Debugging beforewelding

-

Change the polarityon the vertical board, it is, connect MIG torchlead to “-”, the ground cable lead

to “+”.

-

Install the torch, gas and weldingwire, andthen turnon the power switch. Thepower indicatoris on

and fan works.

-.

Press the torchswitch tillthe wire extendsto thenozzle

-

When wire feeding,make thecable straight.

-

When wirefeeding, make sure the wireis located on the wireroller groove reliably and thefeeding

speed should be smooth. If the wire feeding speed is not smooth, please adjust the tension of the

wire roller.

-

When using fluxwire, thegear type groovewire rollershould beused.

b) Welding

-

When welding, please adjust the welding current and welding voltage matchable according to the

.

set-up

-

Aim at the weldingline, press down the torchswitch, the wire feeds automatically. The arc is started

once the wireis touchedthe work piece.When welding,the “working indicator” ison

.

--10

Page 12

Omperator's anual

www.fubag.ru

Aluminium welding steps

a) Debugging beforewelding

-

Change theliner inMIG torch for telfonliner.

-

Connect the torch, gas hose, grounding cable, argon gas tank, work piece and then turn on the

power switch, thepower indicatoris on,at thistime, the fan isworking

- .

Turnon thegas regulator ofgas tank,the gaspressure isshown on the meter

-

Turn the gas regulator anticlockwise, loose the wire roller, press down the torch switch, and then

adjust the gasflow tomeet the technicsrequirement, andthen repressthe wireroller

-.

Press the torchswitch tillthe wire extendsto thenozzle

-

When wire feeding,make thecable straight.

-

When wirefeeding, make sure the wireis located on the wireroller groove reliably and thefeeding

speed should be smooth. If the wire feeding speed is not smooth, please adjust the tension of the

wire roller.

-

When using aluminiumwire, the“U” typegroove wireroller should be used.

b) Welding

-

When welding, please adjust the welding current and welding voltage matchable according to the

.

set-up

-

Aim at the weldingline, press down the torchswitch, the wire feeds automatically. The arc is started

once the wireis touchedthe work piece.When welding,the “working indicator” ison

Sticking welding steps

a) Debugging beforewelding

-

Set the “weldingmode switch”on “stick”,it meansthe Stick welding canbe used.

-.

Set the weldingcurrent viawelding current adjustor

b) Welding

-

Take up the electrode holder, install the electrode, aim at the weldingline, scratchthe workpiece to

start the arc.

-.

The “working” indicatoris on

.

.

.

--11

Page 13

Omperator's anual

6InMig 1 0

www.fubag.ru

Initial setting,input voltage,travel speed,cleanliness,and personal preference will affect your actual settings

DCEP - Direct current,electrode positive; DCEN - Direct current,electrode negative

MIG gun replacement parts are Trafimet style

Dual groove drive roll: Small groove is for 0.6 mm wires; Larger groove is for 0.8 mm and 0.9 mm wire.

Use set screw to remove and reverse the drive roll.

Do not overtighten the spool hub tension;adjust so the spool stops when gun trigger is released but no tighter. Do not overtighten the drive roll tension; tighten until the wire does not

slip.

Too-small contact tip,dirty liner,too-tight drive roll tension,and too-tight spool hub tension all affect wire feeding. Aluminum welding can be difficult and should only be attempted bu

experienced welders.

Aluminum welding: Loosen drive roll tension; Keep MIG gun straight; Use separate liner and keep it clean.

-2 -1

Page 14

Omperator's anual

www.fubag.ru

9. Maintenance

Unlike the traditional welder, the reversible welderbelongs tothe scientifically sophisticated product

which uses the modern electronic component parts combined with high technology. Therefore the

trained personnels are required for its maintenance. However, due to the fact that there are very few

components to be easily worn out, it doesn’t need regular service apart from usual cleaning work.

Only the qualified people are allowed to be in charge of the repair job. It is strongly recommended

that customers contact our company for the technical back-up or service when they feel unable to

work out thetechnical hitchor problems.

-

The newly installed welder or which haven’t been in use for some time need s to be surveyed the

insulation resistances between each winding and every winding to case with millimeter, which can

not be lessthan 2 5MΩ.

-

Keep from therain, snowand long termexposing tosunlight when welder isused outdoor.

- C

If the welder is not in use either for a long time or temperature ranges from -25 ~ +55 , and the

relative humidity cannot bemore than 90%.

-

The professional maintenance personnel should use dry compressed air (use air compressor or

bellows) to remove the dust inside the machine. The part adhering to grease must be cleaned with

cloth while make sure there are no loosing parts existed in the tightened places and connected

cable. Usually the machine should be cleaned once a year if the dust accumulation problem is not

very serious, while it needs cleaning once or even twice every quarter if the dust accumulation

problem isserious.

-

Regularly check the input & output cables of welder to guarantee them right and firmly connected

and avoid them being exposed. Check should be taken once every month when fixed using and

every check takenwhen removing.

-

Regularly check the seal performance of gas system, whether the fan and feeder motor having

abnormal soundand whetherevery joint being loose.

-

Keep torch cabledirect whenwelding.

-

Regularly clean the splash of nozzle (cannot use the way similar to knocking the torch head) and

stick to usingsplash ointment.Don’t remove thefeeder device by means ofpulling he torch cable.

-

Use qualified wire,no usinginferior orrusty wire.

-

Clean the dust of liner with compressed air after the welder using some time (the dust is

accumulated by friction between wire and liner roll if find it wear and tear to prevent wire uneven

feeding.

-

The pressed roll can not be pressed too firm to guarantee smooth wire feeding. (It will lead to wire

deformation, adding the feeding resistance and accelerating the friction of gear if pressed over

firmly.)

WARNING:

- The main loop voltage happens to be a bit higher, so safety precaution should be taken before

repair to avoidaccidental shock.The untrained peopleare forbidden to openthe case.

,

O

-.

Power source needsto becut off beforedust removal

-

Never tamper withwire ordamage thecomponent partswhen cleaning.

-3 -1

Page 15

Omperator's anual

10. Troubleshooting

www.fubag.ru

-4 -1

Page 16

Omperator's anual

11.List of Spare Parts

www.fubag.ru

1. Gemel

2. Enclosure

3. Wire holder

4. Control transformer

5. Main PCB

6. Door

7. Door lock

8. Spool holder

9. Vertical Middle board

10. Connection pole (red)

11. Connection pole(Black)

12. Main Transformer

13. Rectifier Radiator

14. Reactor assembly

15. Plastic panel

16. Front panel support

17. Indicator

18. Welding current

potentiometer

19. Potentiometer

20. Potentiometer Knob

21. "-" output cable

22. MIG Torch

23. American Connetor

24. MIG torch Socket

25. Wire feeder

26. Welding mode selector

27. Quick Connector

28. Connection Socket

29. Feet

30. Bottom

31. Loaded PCB

32. Capacitance PCB

33. Heat Sink

34. Rectifier

35. Fan

36. Middle board

37. Back Panel

38. Power Cord Holder

39. Power Cord

-5 -1

40. Circuit Breaker

41. Main Switch

42. Copper Nut

43. Gas Valve connetor

44. Gas Valve

45. Handle

Remarks: The list above is for

reference only, please subject to the

real piece.

Page 17

Omperator's anual

12. Circuit Chart

L2

R7

D5

D4

YR1

C9

T+

www.fubag.ru

C14

C13

C11

C12

RP201

WELDING CURRENT

LED203

LED202

LED201

GREEN

R8

D6

D7

YR2

C10

T3

1

2

21

CN201

RED

YELLOW

STICK

MIG

1

2

1

1

1

2

2

2

3

3

RG5

ZD5

RG6

Q3

Q1

RG2

ZD1

RG1

RG7

ZD8

ZD6

ZD2

+

AC

1

SW101

ZD7

RG8

Q4

C6

C5

Q2

RG4

ZD3

RG3

C4

C3

R1

C2

C1

4-3

AC

B1

2

R101

16A/250Vac

T-

CT1

TH1

ZD4

C15

RLY101

4321

21

CT1

21

MMA-180-PWR

4321

F

FAN1

CN1

1

2

3

4

5

CN101

T101

Handy MIG-S

CN202

220:23+23|19/15VA

L

AC220V 50/60Hz

N

PE

-6 -1

Page 18

Omperator's anual

www.fubag.ru

13. Complete Set Specification

Inverter MIG Welder............................................1

Product Certificate..............................................1

Operator’s Manual..............................................1

Earth Cable (clamp)........................................... 1

14. Transport & Storage

- The machines should be free from rain and snow during transportation and storage. Keep notice of

the warning sign on the packing box when load and unload. The warehouse should keep dry &

ventilation andfree from corrosive gas or dust. The tolerable temperature ranges from -25 + 55 and

the relative humidity can not be more than 90%.

- After the package has been opened, it is suggested to repack the product as per prior requirement

for future storage and transport. (Cleaning job is required before storage and you must seal the plastic

bag in the box for storage.)

- Users should keep the packing materials with the machine to keep well storage during the long

transportation. If the machine need transfer, the wooden case is required. The sign such as ‘Lift’ and

‘Free of rain’ shouldbe labeledon thecase.

O

C

15. Warranty

Warranty refer to defects of materials and components and do not refer to components subject to

natural wear andmaintenance work.

Only machines cleaned from dust and dirt in original factory packing fully completed, provided with

instruction manual, warranty card with fixed sales date with a shop stamp factory serial number and

originals of sales and ware receipt issued bysalesman aresubjects ofwarranty.Within thewarranty

period the service center eliminate freeof chargeall detected production defects. Themanufacturer

disclaims warranty and legal responsibilities if nonobservance of the instruction manual by user,

unqualified disassembling repair ormaintenance of the machineas well does notbear responsibility

for caused injuryto personsor damages.

-7 -1

Page 19

Инструкция по эксплуатации

www.fubag.ru

ВНИМАНИЕ! ПЕРЕД ИСПОЛЬЗОВАНИЕМ СВАРОЧНОГО АППАРАТА

ВНИМАТЕЛЬНООЗНАКОМЬТЕСЬ С ДАННОЙ ИНСТРУКЦИЕЙ.

К использованию и обслуживанию сварочного аппарата допускается только

квалифицированный и специально обученный персонал, ознакомленный с данной

инструкцией.

В этой инструкции содержится описание, правила безопасности и вся необходимая

информация для правильной эксплуатации сварочного аппарата FUBAG. Сохраняйте

данную инструкцию и обращайтесь к ней при возникновении вопросов по безопасной

эксплуатации,обслуживанию, хранению и транспортировкесварочногоаппарата FUBAG.

1. Правила безопасности

- Всегда соблюдайте правила безопасности. Носите защитную одежду и специальные

средства защиты, чтобы избежать повреждения глаз и кожных покровов.

- Всегда надевайте защитную маску во время работы сварочным аппаратом или

используйте очки с защитным затемненным стеклом.

- Старайтесь, чтобы искры и брызги не попали на тело.

- Избегайте контактов с открытыми токоведущими кабелями сварочного аппарата, не

прикасайтесь к электрододержателю/горелке и свариваемой поверхности.

- Не работайте под водой или в месте с повышенной влажностью.

- Дым и газ, которые попадают в воздух при сварке, опасны для здоровья. Перед

началом работ убедитесь, что вытяжка и вентиляция исправно работают.

- Убедитесь, что излучение дуги не попадет на других людей, находящихся поблизости

от места сварки.

- Помните, что при сварке температура обрабатываемой поверхности повышается,

поэтому старайтесь не прикасаться к обрабатываемым деталям во избежание ожогов.

- Не прикасайтесь к месту подключения питания или к другим частям сварочного

аппарата, которые находятся под током. Отключайте питание сразу после окончания

работы или перед тем, как оставить место работы.

- Никогда не работайте там, где существует опасность получения электрошока.

- Никогда не производите сварку емкостей, в которых могут содержаться

легковоспламеняющиеся или взрывоопасные материалы.

- При высотных работах во избежание несчастного случая соблюдайте правила техники

безопасности работы на высоте.

- Следите за тем, чтобы на рабочей площадке не было посторонних людей.

- Сварочные аппараты излучают электромагнитные волны и создают помехи для

радиочастот, поэтому следите за тем, чтобы в непосредственной близости от

аппарата не было людей, которые используют стимулятор сердца или другие

принадлежности, для которых электромагнитные волны и радиочастоты создают

помехи.

ВНИМАНИЕ. Сварочный аппарат находится под напряжением, поэтому прежде,чем

приступить кего обслуживанию, следует обесточить его во избежание электрошока.

Перед проведением любыхработ всегда необходимо отключатьисточник питания. К

работамсо сварочным аппаратом допускаются только специалисты.

- 8 -1

Page 20

Инструкция по эксплуатации

www.fubag.ru

- Проверьте подключение входных и выходных кабелей, заземление и т.д.

- Техническое обслуживание должны выполнять только квалифицированные

специалисты.

- Если ваш сварочный аппарат был только что установлен или к работе приступает

новый оператор, следует проверить сопротивление изоляции между обмотками и

кожухом.

- Время от времени следует проверять состояние сварочного кабеля. Если аппарат

используется регулярно, его следует проверять не менее одного раза в месяц.

Состояние сварочного кабеля также следует проверять, если сварочный аппарат

используется как переносной.

- Если сварочный аппарат не используется

продолжительное время, его следует хранить в сухом, хорошо проветриваемом

помещении, не допуская попадания на него влаги, коррозионно-опасных или

токсичных газов.

- Раз в год следует очищать сварочный аппарат от пыли. Проверьте, не ослаблены ли

детали крепления аппарата, электромагнитную систему, ручки настройки тока и т.д.

- Наличие в воздухе пыли, а также едких и коррозионных веществ не должно

превышать допустимых норм.

- Сварочный аппарат должен быть установлен в таком месте, где на него не будет

попадать дождь и солнечные лучи. Его можно хранить в наименее влажном месте с

температурой от -10 до 40 С.

- Необходимо обеспечить доступ воздуха к сварочному аппарату, для этого вокруг него

должно быть свободное пространство не менее 50 см.

- Убедитесь, что на месте работы сварочного аппарата нет металлических или

инородных предметов во избежание их попадания в аппарат.

- Не устанавливайте сварочный аппарат на вибрирующую поверхность.

- Сварочный аппарат должен быть установлен на горизонтальной поверхности, и если

угол наклона составляет более 15°, следует создать условия для предотвращения его

опрокидывания. Примите меры по защите от ветра, так как сварочный аппарат

работает с защитным газом. Скорость ветра должна быть не больше 1,0 м/сек в

противном случае необходимо использовать устройство для защиты от ветра.

- Убедитесь, что в месте установки сварочного аппарата отсутствуют посторонние

помехи.

- Нельзя зажимать кабель сварочной горелки Угол сгиба кабеля не должен быть

слишком маленьким. Радиус канала направляющей не может быть меньше 300 мм

иначе он может повредить внутренний кабель и привести к несчастному случаю.

временно не используется или

О

.

Перед началом работы следует тщательно проверить:

- чтобы не было короткого замыкания между кабелями сварочного аппарата;

- прочность соединения разъемов и кабелей.

Квалифицированный персонал должен регулярно проводить проверку сварочного аппарата

в том случае, если он используется после длительного хранения или ремонта. Эти проверки

включаютследующие процедуры:

- проверку сварочного кабеля. Кабель должен быть заменен прежде, чем будет

полностью изношен. Входной кабель должен быть заменен в случае повреждения;

- проверку мощности источника питания. Любой источник питания, использующийся

для сварочного аппарата, должен быть оснащен защитными системами.

Если вы столкнулись с проблемами, с которыми не можете справиться, обращайтесь в

Сервисный центр.

- 19 -

Page 21

Инструкция по эксплуатации

www.fubag.ru

2. Технические характеристики

Производительимеет право вноситьизменения как в содержание данной инструкции, так ив конструкцию

сварочногоаппаратабез предварительногоуведомления пользователей.

3. Описание

Инверторный аппарат для MIG сварки создан с использованием усовершенствованной

технологии IGBT. Данным аппаратом возможно проводить MIG сварку (с СО в качестве

защитного газа и сварку флюсовым электродом) и точечную сварку. Аппарат использует дугу

между проволокой и свариваемым материалом в качестве источника тепла для плавления

проволоки и обработки металла, и затем подает в зону сварки защитный газ, который

образуетсварочную ванну.

Основными характеристиками данного инверторногоаппарата являются:

- Небольшой объем и легкий вес, из-за чего аппарат широко используется для выполнения

обивочных,ремонтных работ и вполевых условиях.

- Великолепное зажигание дуги иперенос металла.

- Наличие различных средств защиты предохраняет аппарат от перегрева, перенапряжения,

падения напряжения, чрезмерного тока и т.д.

- Высокая производительность. Благодаря автоматической подачи проволоки можно

осуществлятьсварку вбыстром скоростном режиме.

- Нет никаких особых требований к применяемой сварочной проволоке. Подходят и твердые

и флюсовые проволоки. Диаметрпроволоки от0,6 до 1,0 мм.

- Удобное соединение. Внешние разъемы делают соединения безопасными, быстрыми и

надежными.

- Функция точечной сварки.Выполняетсялюбыми целлюлозными электродами.

- 0 -2

2

Page 22

Инструкция по эксплуатации

www.fubag.ru

4. Устройство, принцип и условия работы

Сварочный аппарат потребляет однофазный ток 220 В промышленной частоты через

сетевойвыключательSW 101и выпрямляетего через однофазный выпрямительныймост B1

и затем фильтрует через конденсатор С7, С8, С9, С10 для получения постоянного тока.

Через IGBT (TR1) инвертор получатся переменный ток с частотой 20кГц. Затем этот

переменный ток, преобразованный основным трансформатором и выпрямленный диодом с

быстрым восстановлением, (D4, D5, D6, D7) обеспечивает стабильный постоянный ток для

сварочного аппарата сразу же после его фильтрации индуктивностью L2. Скорость подачи

проволоки можно постепенно регулировать с помощью рычага для регулировки скорости.

Скорость подачи проволоки влияет на сварочный ток, чем выше скорость подачи проволоки,

тем больше силатока при одинаковом напряжении.

Верхняя передняячасть сварочного аппарата оборудованарычагом регулировки сварочного

тока, индикатором включения питания (зеленый), индикатором неполадок (желтый),

рабочим индикатором (красный). На нижней части находятся разъем для подключения

горелки и разъем «-». На задней панели расположен сетевой кабель, разъем для газового

клапана, вентилятор охлаждения, контакт подачи тока, выключатель. На верхней части

аппарата имеется ручка для удобной транспортировки. Когда вы открываете корпус, вы

видите один первичный трансформатор и одну печатную плату. На нижней части установлен

выходной резистор, первичный трансформатор и т.д. В середине установлен радиатор с

электрическими элементами.

Необходимыеусловияокружающей среды:

- температура окружающей среды:при сварке -10 +40 С;

при транспортировке/хранении: -25 +55 С

- относительная влажность:при 40 С: ≤50%,при 20 С: ≤90%

О

ОО

О

- количество пыли, кислоты и грязи в воздухе в рабочей зоне не может превышать значение,

указанное в нормативах (за исключением выбросовот сварочного аппарата).

- отсутствие сильной вибрации нарабочем месте

- высотанад уровнем моря небольше 1000 м

Требованияк электропитанию:

- отклонение напряженияэлектропитания от нормыне должнопревышать ±10%

- 1 -2

Page 23

Инструкция по эксплуатации

www.fubag.ru

5. Горелка

Горелка состоит из крепления горелки, соединительного кабеля и ручки. Крепление горелки

представляет собой устройство сопряжения горелки и устройства для подачи проволоки.

Соединительныйкабель: покрытый нейлоном направляющий канал помещен в центр полого

кабеля. Внутренняя часть канала предназначена для подачи проволоки. Свободное

пространство между каналом и полым кабелем предназначено для подачи защитного газа.

Сам полныйкабель предназначен для подачи тока.

На ручке горелки установлено S-образное колено. На задней части горелки имеется

соединение с полым кабелем, а с передней стороны шунт. Защитный газ проходит через

шунт и образует в сопле хорошо сбалансированный поток воздуха, и затем выбрасывается

струей наружу. Управление током осуществляется с помощью быстродействующего

выключателя на ручке.

Внимание:

- Передсборкой иразборкой горелкиили перед заменой компонентовнеобходимо отключить

подачуэлектропитания

- Следует вовремя заменять сопло, так как его изношенность влияет на качество сварки.

Распределительгорелки также следует менять в случаеего поломки

- Необходимо заменять изношенный кабель горелки

СОПЛО

КОНТАКТОР

ШУНТ

ВЫКЛ-ЛЬ

РАЗЪЕМКОЛЕНО

РУЧКА

ОБОЛОЧКА

КАБЕЛЬ УПРАВЛЕНИЯ

ПОЛЫЙ КАБЕЛЬ

ИЗОЛЯЦИЯ

ШЛАНГ

ПРОВОЛОКА

КАБЕЛЬ

- 2 -2

Page 24

Инструкция по эксплуатации

6. Расшифровка пиктограмм

Ток (А)

Напряжение (В)

Частота (Гц)

Заземление

H

IP21

Изоляция

www.fubag.ru

0

X

I

1

I

2

U

1

U

2

Номинальное напряжение в холостом режиме

Цикл

Номинальный входной ток

Номинальный сварочный ток

Номинальный входное напряжение

Номинальный с нагрузкой

7. Установка

Размещение сварочного аппарата

- Количество пыли, кислоты и грязи в воздухе в рабочей зоне не должно превышать

значение, указанное в нормативах (за исключением выбросов от сварочного аппарата)

- Сварочный аппарат должен быть установлен в таком месте, где он не подвергается

воздействию солнечного света и дождя. Также его следует хранить в наименее влажном

месте при температуре от -10 до 40 С.

- Для обеспечения достаточной вентиляции расстояние над сварочным аппаратом

должно быть 50 см

- Если внутренней вентиляции не достаточно, следует установить оборудование для

устранения дыма и предохранения от ветра.

О

- 3 -2

Page 25

Инструкция по эксплуатации

www.fubag.ru

ЭЛЕКТРОПИТАНИЕ

МАНОМЕТР

ВЫКЛЮЧАТЕЛЬ

ГОРЕЛКИ

РАБОЧАЯ

ПОВЕРХНОСТЬ

ГОРЕЛКА

КАБЕЛЬ

ЗАЗЕМЛЕНИЯ

ГАЗОВЫЙ

ШЛАНГ

СО

2

Подсоединение источника питания

Подсоедините электрокабель к клемам на задней панели к однофазной сети

электропитания 220В с выключателем.Напряжение в 380В запрещено использовать,так как

оно может серьезно повредить аппарат и иметь серьезныепоследствия для оператора.

Внимание:

Ток предохранителя в1,2 ~1,5 разапревышает его номинальныйток.

1-фазное

напряжение

220 В

Установкии соединения для проведения сваркив режиме MIG

Подсоединение и установка устройства для подачипроволоки

- Подберите необходимую проволоку в соответствии с технологией сварки. Диаметр

проволоки должен соответствовать приводному ролику, направляющему каналу и

контактному наконечнику.

- Откройте крышку барабана на устройстве для подачи проволоки. Поместите моток

проволоки в барабан на подающем устройстве. Конец проволоки должен

Внимание:

находитьсяпод барабаном,напротив подающего устройства.

- На барабане имеется блокировочный винт (при открытой крышке будет виден винт с

шестигранной головкой). Потяните барабан рукой для регулировки. Если сопротивление

слишком большое, возможно необходимо отрегулировать блокировочный винт: натяжение

увеличивается при вращениипо часовой стрелке, и наоборот.

- 4 -2

Page 26

Инструкция по эксплуатации

www.fubag.ru

ПЕРЕДНЯЯ

ПАНЕЛЬ

ГОРЕЛКА

ПРОВОЛОКА

РОЛИКИ

КАБЕЛЬ

ЗАЗЕМЛЕНИЯ

- Поместите проволоку в направляющий канал подающего устройства, выровняйте

проволоку в канале приводногоролика, перенаправьте Socket tip и нажмите на приводной

ролик. (Если необходимо больше сварочной проволоки, ее можно получить после

включения электропитания.)

Подсоединение горелки

- Поместите соединительную втулку горелки в отверстие для крепежа горелки на передней

панелисварочного аппарата и плотнозакрутите винт

Подсоединение соединительного кабеля

- Соединитемедный наконечникзажима заземления, которыйпроходит черезотверстие для

подачи проволоки на панели с контактом «-» соединительного наконечника.

Соединительный кабель должен быть надежным в противном случае соединительный

наконечник сгорит.

- Для достижения хорошей производительности при сварке флюсовой проволокой есть

возможность подсоединить «+», «-» противоположно, чтобы двигатель подающего

устройства был с«-», а соединительный кабельс «+».

Внимание:

являютсяплохими проводникамидля заземления свариваемого материала.

Не используйте стальную пластину или другие подобные материалы, которые

Соединения и установкидля проведенияточечнойсварки

а) Подсоединение сварочногокабеля

Подсоедините быстросменный соединитель сварочного кабеля к выходному соединению на

передней панели и поверните по часовой стрелке. Электрододержатель используется для

зажима электрода.

b) Подсоединение кабеля заземления

Подсоедините быстросменный соединитель кабеля заземления к выходному разъему на

передней панели и поверните по часовой стрелке. Зажим заземления используется для

зажима свариваемого материала.

Внимание:

Не используйте стальную пластину или другие подобные материалы, которые

являютсяплохими проводникамидля заземления свариваемого материала.

- 5 -2

Page 27

Инструкция по эксплуатации

www.fubag.ru

8. Сварочные работы

ВНИМАНИЕ: Класс защиты данного инверторного аппарата IP21S. Запрещено засовывать

в сварочный аппарат руки или круглые стержни размером меньше 12,5 мм (в особенности

металлические).Нельзя применять силупри обращении со сварочным аппаратом.

1. Регулятор сварочного тока

2. Индикатор включения

3. Индикатор защиты

4. Индикатор работы

5. Селектор переключения режимов сварки

6. Регулятор сварочного тока

7. Разъем кабеля заземления

8. Управление горелкой

9. Разъем подключения сварочного кабеля

10. Разъем подключения сварочной горелки

11. Разъем подсоединения подачи газа

12. Выключатель

13. Кабель электропитания

14. Переключатель

- 6 -2

Page 28

Инструкция по эксплуатации

www.fubag.ru

Внимание:

- Индикатор защиты загорится после долгого периода работы, что означает, что внутренняя

температура превышает допустимое значение, в таком случае следует остановить аппарат

на некоторое время и дать ему остыть. Работу можно продолжить после того, как индикатор

защиты погаснет.

- После завершения работы или при временной остановке работы следует отключать

электропитание.

- Сварщикам следует надевать холщевую защитную одежду и маски для защиты от

повреждений, вызванных дугой и защиты от тепловогоизлучения.

- В рабочей зоне следует установить светозащитныйэкран для защиты других людей.

- Запрещается хранить в рабочейзоне взрывчатые или легковоспламеняющиесявещества.

- Все подсоединенияк сварочномуаппарату должныбыть выполнены правильно инадежно.

Зачистка свариваемого материала передвыполнениемсварки

Проволока, направляющий канал и окружающая зона на расстоянии 10-20 мм должны быть

очищеныот ржавчины,маслянистой пыли, воды и краски ит.д.

Описание основногопроцесса сварки в режимеMIG

а) Регулировка перед проведением сварки

- Установите горелку, газ и сварочную проволоку и затем включите электропитание.

Индикатор включения горит и вентилятор работает.

- Включитегазовый регулятор на газовой емкости, на счетчике будет показано давление газа

- Поверните газовый регулятор против часовой стрелки, ослабьте ролик, нажмите на

выключатель горелки и затем отрегулируйте подачу газа в соответствии с техническими

требованиями и затем снова нажмитена роликдля подачипроволоки.

- Держите выключательгорелки нажатым до тех пор,пока из сопла не появитсяпроволока.

- При подаче проволоки,выпрямите кабель.

- При подаче проволоки убедитесь, что она надежно расположена в канале подающего

ролика и скорость подачи равномерная.Если скорость подачинеравномерна, отрегулируйте

натяжение подающего ролика.

- При использовании проволоки необходимо использовать подающее устройство с Vобразный каналом.

b) Сварка

- При выполнении сварки, пожалуйста, отрегулируйте сварочный ток и сварочное

напряжение в соответствии сустановками.

- Нацелившись на линию сварки, нажмите выключатель горелки, подача проволоки будут

осуществляться автоматически. Дуга возбуждается, как только проволока касается

свариваемогоматериала. При сваркерабочий индикаторгорит.

Описание процесса сварки флюсовой проволокой

а) Регулировка перед проведением сварки

- Измените полярность на вертикальной панели, т.е. подсоединитепровод горелки к контакту

«-», кабельзаземления к контакту «+».

- Установите горелку, газ и сварочную проволоку и затем включите электропитание.

Индикатор включения горит и вентилятор работает.

- Держите выключательгорелки нажатым до тех пор,пока из сопла не появитсяпроволока.

- При подаче проволоки,выпрямите кабель.

- При подаче проволоки убедитесь, что проволока надежно расположена в канале

подающего ролика и скорость подачи равномерная. Если скорость подачи неравномерна,

отрегулируйтенатяжение подающего ролика.

- 7 -2

Page 29

Инструкция по эксплуатации

www.fubag.ru

- При использовании флюсовой проволоки необходимо использовать подающее устройство

с каналом шестеренноготипа.

b) Сварка

- При выполнении сварки, пожалуйста, отрегулируйте сварочный ток и сварочное

напряжение в соответствии сустановками.

- Нацелившись на линию сварки, нажмите выключатель горелки, подача проволоки будет

осуществляться автоматически. Дуга возбуждается, как только проволока касается

свариваемогоматериала. При сваркерабочий индикаторгорит.

Описание процесса сварки алюминием

а) Регулировка перед проведением сварки

- Смените канал в горелке на тефлоновый.

- Подсоедините горелку, газовый шланг, кабель заземления, емкость с газом аргон,

свариваемый материал и затем включите электропитание. Индикатор включения горит и

вентилятор работает.

- Включитегазовый регулятор на газовой емкости, на счетчике будет показано давление газа

- Поверните газовый регулятор против часовой стрелки, ослабьте ролик, нажмите на

выключатель горелки и затем отрегулируйте подачу газа в соответствии с техническими

требованиями и затем снова нажмитена роликдля подачипроволоки.

- Держите выключательгорелки нажатым до тех пор,пока из сопла не появитсяпроволока.

- При подаче проволоки,выпрямите кабель.

- При подаче проволоки убедитесь, что проволока надежно расположена в канале

подающего ролика и скорость подачи равномерная. Если скорость подачи неравномерна,

отрегулируйтенатяжение подающего ролика.

- При использовании алюминиевой проволоки необходимо использовать подающее

устройство с U-образныйканалом.

b) Сварка

- При выполнении сварки, отрегулируйте сварочный ток и сварочное напряжение в

соответствиис установками.

- Нацелившись на линию сварки, нажмите выключатель горелки, подача проволоки будет

осуществляться автоматически. Дуга возбуждается, как только проволока касается

свариваемогоматериала. При сваркерабочий индикаторгорит.

Описание процесса точечной сварки

а) Регулировка перед проведением сварки

- Установите режим сварки «точечный», этозначит, чтоможно применять точечную сварку.

- Отрегулируйте сварочныйток.

b) Сварка

- Возьмите электрододержатель, установите электрод, нацелившись на линию сварки,

царапните свариваемый материал для возбуждения дуги. Рабочий индикаторгорит.

- 8 -2

Page 30

Инструкция по эксплуатации

www.fubag.ru

будут влиять на ваши текущие установки 6InMig 1 0

Начальная установка, напряжение на входе, скорость подачи электрода, чистота и личные предпочтения

- 29 -

DCEP - Постоянный ток, положительная полярность; DCEN - Постоянный ток, отрицательная полярность

Сменные детали пистолета MIG тип Trafimet

Приводной ролик с двойной канавкой: - маленькая канавка для проволоки 0.6 мм; - большая канавка для проволоки 0,8 и 0,9 мм

- используйте установочный винт для удаления и поворота приводного ролика.

Не натягивайте слишком сильно катушку, отрегулируйте ее таким образом, чтобы при ослабленном курке пистолета катушка останавливалась, но не сильнее.

Не натягивайте слишком сильно приводной ролик; натяните его таким образом, чтобы проволока не соскальзывала.

Слишком маленький контактный наконечник, загрязненный направляющий канал, слишком сильное натяжение приводного ролика и слишком сильное натяжение катушки

будет влиять на подачу проволоки.

Проводить алюминиевую сварку может быть сложно и ее следует производить только опытным сварщикам.

Алюминиевая сварка: Ослабьте натяжение приводного ролика; Держите пистолет MIG прямо; Используйте отдельный направляющий канал и содержите его в чистоте.

Page 31

Инструкция по эксплуатации

www.fubag.ru

9. Техническое обслуживание

В отличие от стандартного сварочного аппарата, данный сварочный аппарат является

усовершенствованным, в котором используются современные электронные компоненты и

совершенная технология. Поэтому проведение технического обслуживания такого аппарата

следует проводить только квалифицированному персоналу. Однако, в силу того, что в

данном аппарате присутствует очень малое количество быстро изнашиваемых деталей, он

не требует проведения регулярного сервисного обслуживания, за исключением очистки.

Отвечать за выполнение данной работы могут только квалифицированные работники. Мы

настоятельно рекомендуем покупателям в случае возникновения проблем, которые они

неспособны решить собственными силами обращаться к нам для получения технической

поддержки.

- У нового сварочного аппарата или аппарата, который не использовался в течение

некоторого времени, необходимо проверить сопротивление изоляции между каждой

обмоткой,которое не должно бытьменее 2,5МОм.

- Защищайте аппарат от дождя, снега и длительного воздействия солнечного света при

использованиина улице.

- Если сварочный аппарат не используется долгое время, его следует хранить при

температуреот -25 С до+55 С и относительная влажность не может быть более 90%.

- Профессиональный работник сервисной службы должен регулярно очищать сварочный

аппарат от пыли сжатым сухим воздухом (воздушный компрессор или другое подобное

устройство). Детали склонные к замасливанию должны очищаться тряпкой и одновременно

можно также проводить осмотр на наличие неплотно закрепленных деталей внутри

аппарата. В случае обнаружения скопления пыли необходима немедленная очистка. В

нормальных условиях очистку необходимо проводить только один раз в год. В случае

чрезмерногопылеобразования очистку следуетпроводить разв квартал.

- Необходимо регулярно проверять входные и выходные кабели сварочного аппарата, для

того, чтобы гарантировать их правильное и прочное соединение. Проверку необходимо

проводитьодин раз в месяци каждый раз перед тем как убиратьаппарат на хранение.

- Регулярно проводите проверку герметичности системы газа, не наблюдается ли у

вентилятора или двигателя подающего устройства ненормальных шумов и нетли неплотных

соединений.

- Регулярно очищайте сопло и пруток при помощи специальной мази для удаления

расплавленногометалла. Не снимайтеподающее устройство потянув за кабель горелки.

- Используйте только качественную проволоку. Никогда не используйте ржавую проволоку

или проволоку плохого качества.

- Счищайте пыль с роликового канала сжатым воздухом после длительного использования

сварочного аппарата. (Накапливание пыли происходит из-за трения между проволокой и

роликом и удалять ее необходимо для того, чтобы обеспечить ровную подачу проволоки.

- Для ровной подачи проволоки не рекомендуется слишком плотно прижимать ролик.

(Слишком плотное прижатие приведет к деформации проволоки, увеличению

сопротивленияпри подаче иувеличениятрения механизма).

ВНИМАНИЕ:

- Если напряжение основного контура немного повышается, следует принять все меры

предосторожности перед выполнением ремонта, чтобы избежать случайного удара

электрическим током. Неквалифицированным работникам запрещено открывать корпус

аппарата!

ОО

- Перед проведением очистки от пыли необходимо отключить источник питания.

- Никогда не манипулируйте проводами и не повреждайте детали при проведении очистки.

- 0 -3

Page 32

Инструкция по эксплуатации

10. Неисправности и их устранение

www.fubag.ru

- 1 -3

Page 33

Инструкция по эксплуатации

11.Запчасти

www.fubag.ru

1. Парные элементы

2. Корпус

3. Держатель проволоки

4. Изолирующий транс-ор

5. Основная панель

управления

6. Дверца

7. Дверной замок

8. Держатель катушки

9. Вертикальная средняя

панель

10. Соединительный полюс

(красный)

11. Соединительный полюс

(черный)

12. Основой трансформатор

13. Радиатор выпрямителя

14. Реактор

15. Пластиковая панель

16. Опора передней панели

17. Индикатор

18. Сварочный потенциометр

19. Потенциометр

20. Рычаг потенциометра

21. Выходной кабель «-»

22. Горелка для сварки MIG

23. Штекер

24. Гнездо для подключения

горелки MIG

25. Устройство для подачи

проволоки

26. Селектор переключения

режимов подачи проволоки

27. Быстросменное соединение

28. Разъем

29. Ножки

30. Днище

31. Плата

32. Плата конденсаторов

33. Теплоотвод

- 2 -3

34. Выпрямитель

35. Вентилятор

36. Средняя плата

37. Задняя панель

38. Держатель сетевого кабеля

39. Сетевой кабель

40. Прерыватель цепи

41. Выключатель электропитания

42. Соединение газового клапана

43. Газовый клапан

44. Ручка

Внимание: Данный список

представлен только для примера

Page 34

Инструкция по эксплуатации

12. Схемаэлектрическая принципиальная

C14

C13

C11

L2

R7

D5

D4

YR1

C9

T+

C12

LED203

LED201

GREEN

R8

D6

D7

YR2

C10

T3

21

1

1

2

CN201

www.fubag.ru

RP201

WELDING CURRENT

LED202

RED

YELLOW

STICK

MIG

2

1

1

1

2

2

2

3

3

RG5

ZD5

RG6

Q3

Q1

RG2

ZD1

RG1

RG7

ZD8

ZD6

ZD2

+

AC

1

SW101

ZD7

RG8

Q4

C6

C5

Q2

RG4

ZD3

RG3

C4

C3

R1

C2

C1

4-3

AC

B1

2

R101

16A/250Vac

T-

CT1

TH1

ZD4

C15

RLY101

4321

21

CT1

21

MMA-180-PWR

4321

F

FAN1

CN1

1

2

3

4

5

CN101

T101

Handy MIG-S

CN202

220:23+23|19/15VA

L

AC220V 50/60Hz

N

PE

- 3 -3

Page 35

Инструкция по эксплуатации

www.fubag.ru

13. Комплектация

Инверторныйаппарат............................................1 шт

Сертификат............................................................1 шт

Руководство по эксплуатации..............................1шт

Кабельзаземления (сзажимом заземления).... 1 шт

14. Хранение и транспортировка

- Аппарат следует беречь от попадания воды и снега. Обратите внимание на обозначения на

упаковке. Тара для хранения должна быть сухой и со свободной циркуляцией воздуха и без

наличия коррозийного газа или пыли. Диапазон допускаемых температур от -25 до +55 , и

относительнаявлажность не более 90%.

- После того, как упаковка была открыта, рекомендуется для дальнейшего хранения и

транспортировки переупаковать аппарат. (Перед хранением рекомендуется провести очистку

и запечатать пластиковый пакет, вкоторый необходимо поместить аппарат передпомещением

в коробку).

- У пользователей должны быть всегда в наличии упаковочные материалы для хранения

аппарата. Если машина будет перемещаться во время транспортировки, тогда необходим

деревянный ящик. На ящик необходимо поместить надпись «LIFT» или «Предохранять от

дождя».

OO

CC

5. Гарантийные обязательства1

Гарантийныйсрок наоборудование указывается в прилагаемом сервисномталоне

Гарантия относится к дефектам в материалах и узлах и не распространяется на компоненты,

подверженные естественному износуи работыпо техническому обслуживанию.

Гарантийному ремонту подлежат только очищенные от пыли и грязи аппараты в заводской

упаковке, полностью укомплектованные, имеющие инструкцию по эксплуатации, гарантийный

талон с указанием даты продажи, при наличии штампа магазина, заводского номера и

оригиналов товарногои кассовогочеков, выданныхпродавцом.

В течение гарантийного срока Сервисный центр устраняет за свой счёт выявленные

производственные дефекты. Производитель снимает свои гарантийные обязательства и

юридическую ответственность при несоблюдении потребителем инструкций по эксплуатации,

самостоятельной разборки, ремонта и технического обслуживания аппарата, а также не несет

никакой ответственностиза причиненныетравмы инанесенный ущерб.

.

- 4 -3

Page 36

Loading...

Loading...