Page 1

Omperator's anual

www.fubag.ru

WARNING! BEFORE USING THE WELDING MACHINE READ THE INSTRUCTION

MANUAL CAREFULLY! FOR QUALIFIED AND SPECIALLY TRAINED PERSONS

ONLY AFTER PROPER READING OF THIS MANUAL IS ALLOWED TO USE AND TO

MAINTAIN THIS WELDINGMACHINE.

The detailed description, safety rules and all required information necessary for proper operation

and maintenance of FUBAG welding machine are provided below. Keep this instruction manual by

machine and refer to it by any doubts concerning safety operation, maintenance storage and

handling of FUBAGwelding machine.

1. Safety perationo

-

It is highly recommended always to follow the safety rules. Wear protective clothes and

special means to avoid injuries to eyes and skins.

-

Use the welding mask or special protective glasses while working with the welding

machine. Only by viewing through the filter lens on the welding mask your eyes are

secured by your operation.

-

Prevent the sparks and spatter from harming your body.

-

Under no circumstance allow any part of your body to touch the welder's output bipolarity

(torch and work piece).

-

Do not operate under water or more humid place.

-

Fumes and gases produced when welding are hazardous to health. Make sure to work in

places where there are exhaust or ventilation facilities to keep fumes or emissions away

from the breathing zone.

-

Please remember to keep arc rays away from the other nearby people when welding. This

is only due to the interference from arc rays.

-

There will be high temperature when welding work piece, so please don't directly touch on it

-

No touching on the output connection or any other electrification parts while welding.

-

No touching on the electrification parts after turning on the power. Cut off the power supply

after operation or before leaving the welding site.

-

No welding in the dangerous site where easily get an electrical shock.

-

No welding for the container loaded inflammable or explosive materials.

-

Safe measures should be adoptted while operating in high place to avoid accident.

-

No entering the welding site for persons not concerned.

-

Welders possible have electromagnetism and frequency interference, so keep away people

with heart pace or the articles which can be interfered by electromagnetism and frequency.

WARNING. The welder voltage is always higher, so the safety precaution should be taken

before repair to avoid accidental shock. Switch off the power supply before each type of

maintenance work. The untrained people are not allowed to make maintenance of the

machine.

- 1 -

Page 2

Omperator's anual

www.fubag.ru

-

Check the connection of input and output cables and the earth (ground) connection, etc.

-

Maintenance should be conducted by the trained personnel.

-

The newly installed machine or the welder not in use for some time needs to be checked by

multimeter have the right insulation resistance between each winding and the case.

-

When the welder is used outdoors, it should be kept from rain or long exposure to the sun.

-

Check is needed from time to time to make sure the welding cable is in good condition if the

welding machine is in frequent use. Check at least once each month if the welder is in

regular use. It is necessary to check when the welder is in mobile use.

-

If the welder is not in use either for a long time or temporarily, it should be kept dry and have

good ventilation to free it from moisture, erodible or toxic gas.

-

Dust removal is needed every year. Check the machine's fasteners, moving-iron, current

regulation screws, etc to make sure there are no loose connection problems.

-

The dust, acid and erodible dirt in the air at the job site can not exceed the amount required

by the norm (excluding the emission from the welder).

-

The welder must be installed in the place where it can not be exposed to sun and rain. Also it

must be stored in less humid place with the temperature.

- +°

When the machine is operating, the temperature must not be higher than 40 C or lower

-°

than 10 C.

-

There should be 50 cm space about for the welding machine to have good ventilation.

-

Make sure that there is no metal-like foreign body to enter the welding machine.

-

Electrode must be taken down from holder when no welding.

-

No violent vibration in the welder's surrounding area.

-

Make sure that there is no interference with the surrounding area at the installation site.

Safety Check:

Each item listedbelow must be carefully checkedbefore operation:

-

Make sure thatthere is no short circuitconnection with welder's both outputs.

-

Make sure that there is always sound output and input wire connection instead of exposing it

outside.

Regular check needs to be conducted by the qualified personnel after the welding machine has

been installed overa long period or re-operation,which involves as follows:

-

Check the weldingcable to see if itcan continue to be usedbefore it is worn out.

-

Replace the welder'sinput cable as soon asit is found to bebroken or damaged.

-

Make sure whether there is enough power supply to make the welding machine work properly.

Any power source required to access the welding machine must be installed with some

protective equipments.

Please do not hesitate to contact us for technical assistance whenever you come across the

problems you cannot work out or youmay deem difficult to fix.

--2

Page 3

Omperator's anual

IN 190

220 25 10-160 (MMA); 10-190 (TIG) 60/120 (MMA); 60/135 (TIG) 1,6-4,0 7,9

IN 200 LV

220 29,2 10-200 (MMA); 10-200 (TIG) 60/120 (MMA); 60/135 (TIG) 1,6-5,0 7,9

Welding current

of duty cycle

EN 609741, %/A

Weight,

kg

Model

Rated intput

voltage, V

Welding current, А

Electrode

diameter, mm

Max. input

current, А

www.fubag.ru

2. Technical pecificationss

The manufacturer reserves himself the right to make the manual's content or welder's function

change without anypreliminary notification of the users.

3. еD

escription

This is a single phase, Inverter, portable welder, for covered electrode and Lift Arc TIG in DC. It

allows welding with rutiles, basic, stainless steel and cast iron electrodes. In TIG, it allows to weld

most of metals except aluminium and alloys..They are over-voltage protected when used on power

180-265 V forIN 190 (85-265 V forIN 200 LV)

1

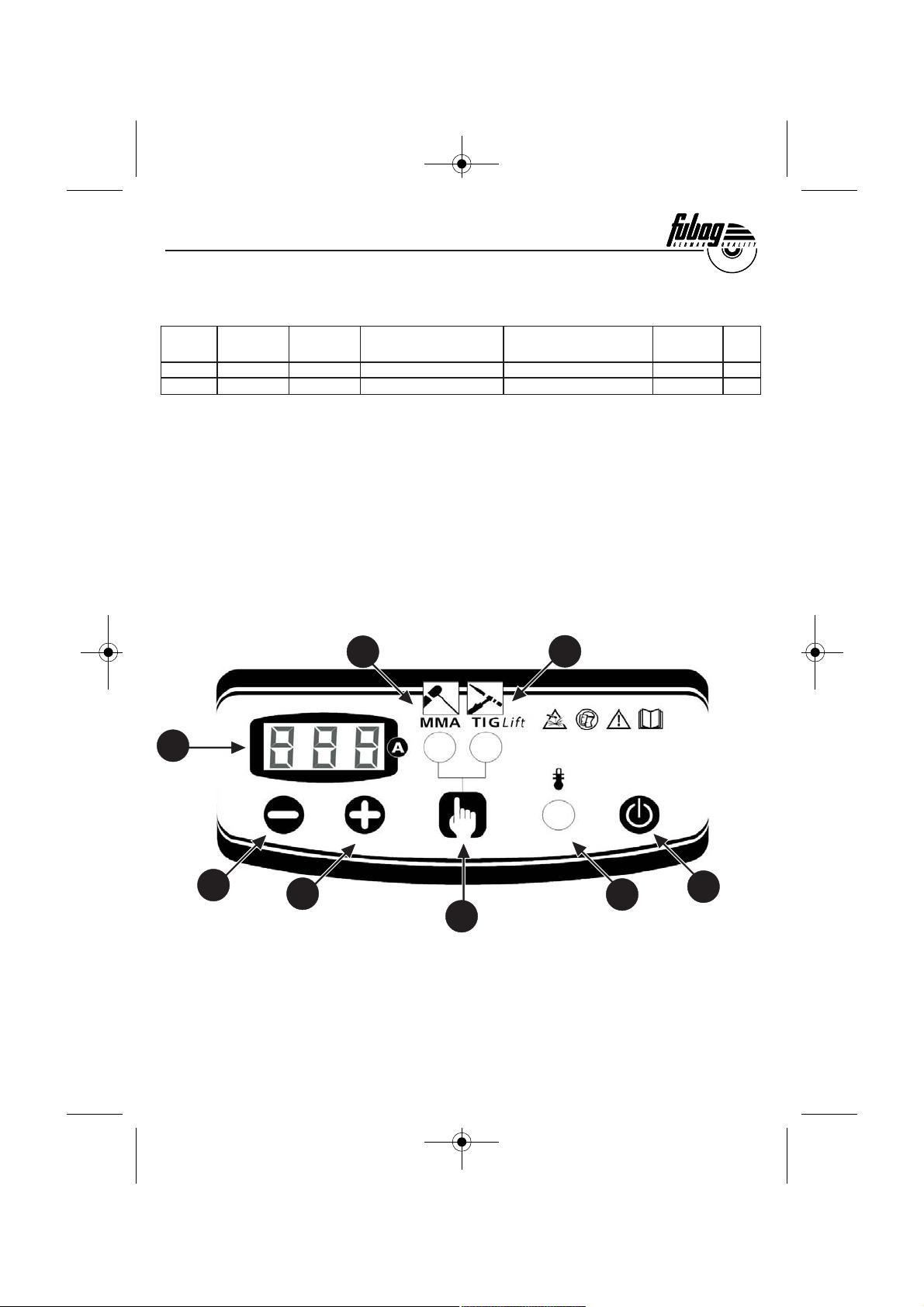

4

1. isplay

D

2. MMA position indicator

3. TIG position indicator

4. Adjust keys

5. Adjust keys

6. elector

S

Thermal protection indicator

7.

witch

8. S button

5

1

2

2

6

- 3 -

3

7

8

Page 4

Omperator's anual

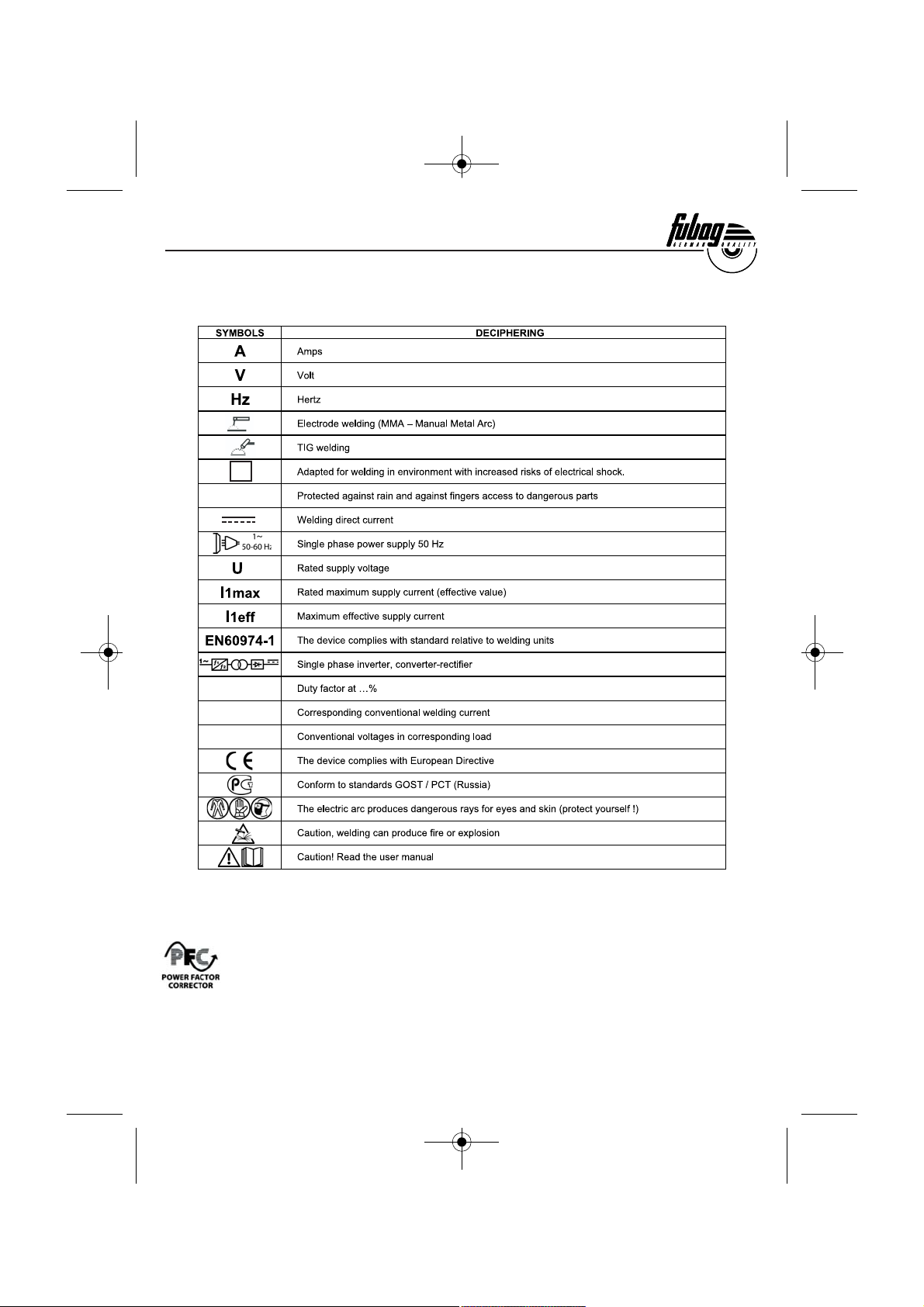

4. Illustration of signs

S

IP23

0

X: 45%; 60%; 100%

I : 160A; 140A; 110A

2

U: V; ;

26,4 25,6 24,4VV

2

www.fubag.ru

5 ower supply.P

- The welding machine is supplied with the in-built power factor correction (PFC) block

to regulate the efficiency of using the current output. Due to this block the machine

could be connected via the 16А-220 plug even in the conditions of intensive

operation. For the same power machines without PFC, the plug 32A-220 is required.

is

Th machine is ideal for construction works with the lengthened cable, where the

V

V

voltage drops are frequent. Also, the exclusive quality of welding is provided by this

machine through the output control circuit, which is controlled by a microprocessor.

- Connect the earth clamp and electrode-holder cables in the quick-plugs. Respect the

polarities indicated on the electrode packaging.

- Starting: switch .

button

- 4 -

Page 5

Omperator's anual

www.fubag.ru

6. Electrode welding

MMAmode

-

Select the MMA position

Apply the usual welding rules

-

-

Adjust the wished current (display ) using the keys and

T

- he cooling takes about 2 minutes

-T

Thermal protection: the indicator lamp .

external temperature

-

Your machine is equipped with 3 specific functions to Inverters

Hot start

Аrc force

melted metal.

Аnti-sticking

sticking.

increases the current at the beginning of the welding.

increases the current in order to avoid the sticking when electrode enters in

Adjustable function.

allows you to easily withdraw your electrode without damaging it in case of

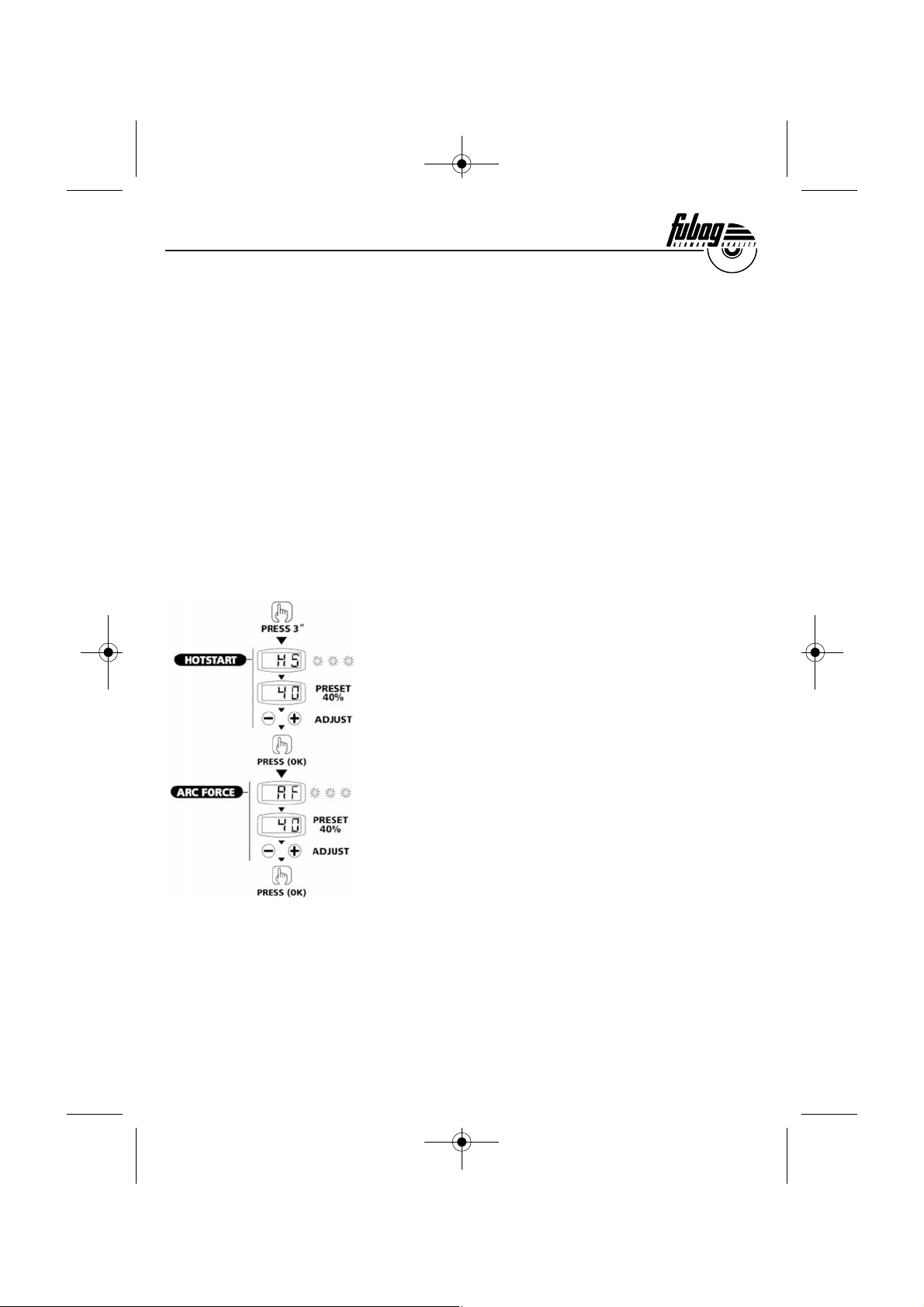

Adjustable Hot StartandArc Force

The Hot Start isadjustable from 0 to 0%.

welding machine 10

with the selector

26

145

he cooling time is about 2 to 5 min according to

7

To adjust the Hot Start, follow the following steps:

:

1. Press the selector during 3 seconds.

2. The “HS” (Hot Start) display flickers and a number

pears.

ap

3. Adjust the wished percentage (display ) using the keys

and .

45

4. Validate the wished value pressing the selector .

5. " "

The inscription AF (Arc Force) starts blinking then one

.

figure

6. ( )

Set the required percentage Arc Force display using

45

keys and

7. Valid the required figure by pressing the selector button

.

6

6

1

6

1

.

- 5 -

Page 6

Omperator's anual

www.fubag.ru

TIG m with functionode Lift Arc

The DC TIG welding requiresa protective gas (argon).

Follow the stepsas below :

- Connect theearth clamp on the positive(+) pole.

- Connect aTIG torch with valveon the negative(-) pole.

- Connect thepipe of the gas bottleand adjust the flow.

- Select theTIG position with theselector .

-Adjust the wishedcurrent (display ) using thekeys and .

- To boot: touch the electrode on the welding part; raise the electrode 2 to 5 mm of the part to be

welded.

- At end of welding: lever 2 times the arc (up-down-up-down) to trigger the automatic fade. This

movement must be performed in less than 4 sec, at a height of 5 to 10 mm. Then close the valve

to stop thetorch gas after cooling ofthe electrode.

AutomaticArc slope with time adjustable

Functjon

activation

6

145

This corresponds to the end of welding time required for the

gradual decline in the welding current until the stop of the arc.

This function helps to avoid cracks and craters at end of

welding.

This function is not activated (timer at 0 sec). To activate it,

proceed as follow:

- Press 3seconds on the selector button .

- The inscription "dS" (Downslope) starts blinking then one

figure appears.

- Set the automatic arc slope you wish from 0 to 10 sec (display

) using key and .

145

6

--6

Page 7

Omperator's anual

www.fubag.ru

7 aintenance.M

-

Refer all servicingto qualified personnel.

-

Disconnect the generator and wait until the ventilator stopped before working on the unit.

Inside the device, voltages and current are dangerous.

- Regularly blow the welding machine with the pressed air through the ventilation inlets

8. Troubleshooting

.

9. Transport& torage

When the welder is in storage and transportation, please try to keep it from being exposed to the

rain. When loading, attach ATTENTION to the welder packing. It is recommended to free it from

moisture, erodible gas and dust in storage where it must be kept dry and have good ventilation. The

tolerable temperature, andthe relative humidity.

After the package has been opened, it is suggested to repack the product as per requirement for

future storage andtransport.

s

10. Warranty

Warranty refer to defects of materials and components and do not refer to components subject to

natural wear andmaintenance work.

Only machines cleaned from dust and dirt in original factory packing fully completed, provided with

instruction manual, warranty card with fixed sales date with a shop stamp factory serial number and

originals of sales and warereceipt issued by salesman are subjects of warranty. Within the warranty

period the service center eliminate free of charge all detected production defects.The manufacturer

disclaims warranty and legal responsibilities if nonobservance of the instruction manual by user,

unqualified disassembling repairor maintenance ofthe machine as well does not bearresponsibility

for caused injuryto persons or damages.

--7

Page 8

Инструкция по эксплуатации

www.fubag.ru

ВНИМАНИЕ! ПЕРЕД ИСПОЛЬЗОВАНИЕМ СВАРОЧНОГО АППАРАТА

ВНИМАТЕЛЬНООЗНАКОМЬТЕСЬ СДАННОЙ ИНСТРУКЦИЕЙ.

К использованию и обслуживанию сварочного аппарата допускается только

квалифицированный и специально обученный персонал, ознакомленный с данной

инструкцией.

В этой инструкции содержится описание, правила безопасности и вся необходимая

информация для правильной эксплуатации сварочного аппарата FUBAG. Сохраняйте

данную инструкцию и обращайтесь к ней при возникновении вопросов по безопасной

эксплуатации, обслуживанию, хранению итранспортировке сварочного аппарата FUBAG.

1. Правила безопасности

- Всегда соблюдайте правила безопасности. Носите защитную одежду и специальные

средства защиты, чтобы избежать повреждения глаз и кожных покровов.

- Всегда надевайте защитную маску во время работы сварочным аппаратом или

используйте очки с защитным затемненным стеклом.

- Старайтесь, чтобы искры и брызги не попали на тело.

- Избегайте контактов с открытыми токоведущими кабелями сварочного аппарата, не

прикасайтесь к электрододержателю/горелке и свариваемой поверхности.

- Не работайте под водой или в месте с повышенной влажностью.

- Дым и газ, которые попадают в воздух при сварке, опасны для здоровья. Перед

началом работ убедитесь, что вытяжка и вентиляция исправно работают.

- Убедитесь, что излучение дуги не попадет на других людей, находящихся поблизости

от места сварки.

- Помните, что при сварке температура обрабатываемой поверхности повышается,

поэтому старайтесь не прикасаться к обрабатываемым деталям во избежание ожогов.

- Не прикасайтесь к месту подключения питания или к другим частям сварочного

аппарата, которые находятся под током. Отключайте питание сразу после окончания

работы или перед тем, как оставить место работы.

- Никогда не работайте там, где существует опасность получения электрошока.

- Никогда не производите сварку емкостей, в которых могут содержаться

легковоспламеняющиеся или взрывоопасные материалы.

- При высотных работах во избежание несчастного случая соблюдайте правила техники

безопасности работы на высоте.

- Следите за тем, чтобы на рабочей площадке не было посторонних людей.

- Сварочные аппараты излучают электромагнитные волны и создают помехи для

радиочастот, поэтому следите за тем, чтобы в непосредственной близости от

аппарата не было людей, которые используют стимулятор сердца или другие

принадлежности, для которых электромагнитные волны и радиочастоты создают

помехи.

ВНИМАНИЕ. Сварочный аппарат находится под напряжением, поэтому прежде, чем

приступить к его обслуживанию, следует обесточить его во избежание электрошока.

Перед проведением любых работ всегда необходимоотключать источник питания. К

работам со сварочным аппаратом допускаются только специалисты.

--8

Page 9

Инструкция по эксплуатации

www.fubag.ru

- Проверьте подключение входных и выходных кабелей, заземление и т.д.

- Техническое обслуживание должны выполнять только квалифицированные

специалисты.

- Если ваш сварочный аппарат был только что установлен или к работе приступает

новый оператор, следует проверить сопротивление изоляции между обмотками и

кожухом.

- Когда сварочный аппарат используется при работах вне помещений, его следует

беречь от дождя и предохранять от длительного воздействия солнечных лучей.

Температура окружающей среды при эксплуатации аппарата должна быть от -10 C до

- °

+40 C

°.

- Время от времени следует проверять состояние сварочного кабеля. Если аппарат

используется регулярно, его следует проверять не менее одного раза в месяц.

Состояние сварочного кабеля также следует проверять, если сварочный аппарат

используется как переносной.

- Если сварочный аппарат не используется

продолжительное время, его следует хранить в сухом, хорошо проветриваемом

помещении, не допуская попадания на него влаги, коррозионно-опасных или

токсичных газов.

- Регулярно следует очищать сварочный аппарат от пыли. Проверьте, не ослаблены ли

детали крепления аппарата, электромагнитную систему, ручки настройки тока и т.д.

- Наличие в воздухе пыли, а также едких и коррозионных веществ не должно

превышать допустимых норм.

- Сварочный аппарат должен быть установлен в таком месте, где на него не будет

попадать дождь и солнечные лучи.

- Необходимо обеспечить доступ воздуха к сварочному аппарату, для этого вокруг него

должно быть свободное пространство не менее 50 см.

- Убедитесь, что на месте работы сварочного аппарата нет металлических или

инородных предметов во избежание их попадания в аппарат.

- Если аппарат не эксплуатируется, электрод следует вынимать из держателя.

- Не устанавливайте сварочный аппарат на вибрирующую поверхность.

- Убедитесь, что в месте установки сварочного аппарата отсутствуют посторонние

помехи.

временно не используется или

Перед началом работы следует тщательно проверить:

- чтобы не было короткого замыкания между кабелями сварочного аппарата;

- прочность соединения разъемов и кабелей.

Квалифицированный персонал должен регулярно проводить проверку сварочного аппарата

в том случае, если он используется после длительного хранения или ремонта. Эти проверки

включают следующие процедуры:

- проверку сварочного кабеля. Кабель должен быть заменен прежде, чем будет

полностью изношен. Входной кабель должен быть заменен в случае повреждения;

- проверку мощности источника питания. Любой источник питания, использующийся

для сварочного аппарата, должен быть оснащен защитными системами.

Если вы столкнулись с проблемами, с которыми не можете справиться, обращайтесь в

Сервисный центр.

--9

Page 10

Инструкция по эксплуатации

IN 190

220 25 10-160 (MMA); 10-190 (TIG) 60/120 (MMA); 60/135 (TIG) 1,6-4,0 7,9

IN 200 LV

220 29,2 10-200 (MMA); 10-200 (TIG) 60/120 (MMA); 60/135 (TIG) 1,6-5,0 7,9

Сварочный ток

при нагрузке в %

от маx по EN 609741, %/A

Вес, кгМодель

Номинальное

напряжение, В

Сварочный ток, А

Диаметр

электродов, мм

Макисмальный

потребляемый

ток, А

2. Технические характеристики

Производительимеетправо вносить изменения как в содержание даннойинструкции, так и вконструкцию

сварочногоаппаратабез предварительного уведомленияпользователей.

3. Описание

www.fubag.ru

Данный сварочный аппарат является однофазным

ручной дуговой и аргонодуговой сварки неплавящимся электродом (с поджигом Lift Arc) на

постоянном токе. Позволяет производить сварку рутиловыми, основными электродами,

электродами для нержавеющих сталей и чугуна. При агонодуговой сварке (TIG), это

позволяет сваривать все металлы кроме алюминия и его сплавов.

Аппарат адаптирован к российским условиям эксплуатации, имеет защиту и предназначен

для работы от сетевого напряжения 180-265 IN 190 (85-265 IN 200 LV).

В для В для

2

инвертором, предназначенным для

3

1

4

5

7

8

6

1. Дисплей

2. Индикатор режима

3. Индикатор режима

4. Кнопка уменьшения сварочного тока

5.

Кнопка увеличения сварочного тока

6. Селектор режимов сварки

7. Индикатор термозащиты

8. Кнопка включения

MMA

TIG

--10

Page 11

Инструкция по эксплуатации

www.fubag.ru

4. Расшифровка пиктограмм и предупредительных знаков

S

IP23

0

X: 45%; 60%; 100%

I : 160A; 140A; 110A

2

U: V; ;

26,4 25,6 24,4VV

2

5. Подключение питания

-

Сварочный аппарат снабжен встроенным блоком коррекции мощности (PFC),

регулирующим эффективность использования в . Благодаря этому

блоку аппарат можно подключать от вилки 16А-220В даже в условиях

интенсивной эксплуатации. Для аппаратов той же мощности без блока

коррекции мощности требуется вилка 32А-220В. Аппарат идеален для

использования на стройк с удлиненным шнуром .

К тому же, исключительное качество сварки этого аппарата обеспечивается

цепью регулирования на выходе, управляемой микропроцессором.

- Подсоедините зажим массы и электрододержатель к сварочному аппарату в

зависимости от полярности, соответствующей используемому типу электрода.

- Включение сварочного аппарата производится нажатием кнопки включения.

тока на ыходе

ах , где часты спады напряжения

- 1 -1

Page 12

Инструкция по эксплуатации

www.fubag.ru

6. Сварочные работы

Режим MMA

-

Выберите MMA позицию селектором

- Соблюдайте общепринятые правила сварки

-

Регулировка тока (показывается на дисплее ) производится кнопками и

- Оставьте аппарат включенным после сварки на 2 минуты, чтобы он достаточно

охладился

-

Если загорелся желтый индикатор значит сработала термозащита. Время

охлаждения сварочного аппарата составляет от 2 до 5 минут в зависимости от

температуры окружающей среды.

-

Данный сварочный аппарат снабжен 3 функциями, свойственными инверторам:

Hot start

начальный момент для улучшения поджига дуги

Аrc force

ванну, во избежании прилипания электрода

Аnti-sticking

случае залипания.

(горячий старт) обеспечивает поревышение (импульс) сварочного тока в

выдаёт серию импульсов в момент погружения электрода в сварочную

позволяет легко оторвать электрод, не вызывая его прокаливания в

РегулировкаHot Start и Arc Force

Данный сварочный аппарат имеет возможность регулировки функции Hot Startот 0 до 100%.

26

145

7

.

. Функция р мая

Для регулировки Hot Start необходимо сделать

следующее:

1. Нажать на кнопку в течении 3 сек.

2. После троекратного моргания на дисплее символа

“HS” (Hot Start) появляется численное значение

функции Hot Start в процентах.

3. Регулировка необходимого процента функции Hot Start

(показывается на дисплее ) производится кнопками

и.

5

4. Сохраните значение, установленной функции Hot

Start, нажав на кнопку .

6

егулируе .

14

6

5. Мигает надпись " " , и появляется число.

6. Регулировка необходимого процента функции

Force

(показывается на дисплее ) производится

кнопками и .

7.

Сохраните значение, установленной функции нажав

на кнопку .

45

6

AF (Arc Force)

Arc

1

- 1 -2

Page 13

Инструкция по эксплуатации

www.fubag.ru

Р аргонодуговой сварки с функцией Lift Arcежим TIG

Сварка TIG DC (при постоянном токе) требует использования инертного защитного газа

(Аргон).

Для сварки в режиме TIG:

Подсоедините кабель массы к положительной клемме (+) сварочного аппарата и к

свариваемой поверхности.

Подсоедините TIG горелку с вентилем к отрицательной клемме (-) сварочного

аппарата.

Подсоедините газовый шланг от горелки к газовому баллону, через редуктор, и

отрегулируйте подачу газа.

Выберите режим TIG селектором .

-

Отрегулируйте сварочный ток (показывается на дисплее ) при помощи кнопок и .

-

Для поджига дуги коснитесь детали электродом, а затем поднимите электрод на 2-5мм

от свариваемой детали

Для окончание сварки нужно увеличить длину дуги в 2 раза чтобы спровоцировать

автоматическое затухание. Это действие должно занять минимум 4 секунды на высоте

от 5 до 10мм. Затем закройте вентиль горелки чтобы прекратить доступ газа после

охлаждения электрода.

Автоматическое затухание дуги с регулируемой длительностью

Активация

6

145

Данное действие соответствует времени необходимому

для постепенного снижения сварочного тока при

окончании сварки для затухания дуги. Эта функция

позволяет избежать образования трещин и кратеров при

окончании сварки.

По умолчанию эта функция неактивна (= 0 сек).

Для активации проделайте следующее:

- Нажмите на кнопку в течении 3 сек

- Замигает надпись "dS" (Downslope) и появится число.

- Отрегулируйте желаемое время затухания от 0 до 10

сек (индикатор ) с помощью кнопок и .

6

145

- 1 -3

Page 14

Инструкция по эксплуатации

www.fubag.ru

7. Техническое обслуживание

- Обслуживание аппарата может производиться только квалифицированным персоналом.

- Всегда отключайте аппарат и дожидайтесь остановки вентилятора. Внутри аппарата

существуют высокие напряжения и токи, опасные для жизни.

- Регулярно продувайте аппарат сжатым воздухом через вентиляционные отверстия.

8. Неисправности и их устранение

910. Хранение и транспортировка

Во время транспортировки и хранения сварочного аппарата старайтесь беречь его от

попадания влаги. Рекомендуется хранить сварочный аппарат в сухом, хорошо

проветриваемом помещении и не подвергать его воздействию повышенной влажности,

коррозионно-опасных газов и пыли. После вскрытия упаковки рекомендуется снова упаковать

сварочный аппарат, если предполагается перевозить его к месту работы или на хранение.

. Гарантийные обязательства

Гарантийный срок на оборудование указывается в прилагаемомсервисном талоне

Гарантия относится к дефектам в материалах и узлах и не распространяется на компоненты,

подверженные естественному износуи работы потехническому обслуживанию.

Гарантийному ремонту подлежат только очищенные от пыли и грязи аппараты в заводской

упаковке, полностью укомплектованные, имеющие инструкцию по эксплуатации, гарантийный

талон с указанием даты продажи, при наличии штампа магазина, заводского номера и

оригиналов товарного икассового чеков, выданных продавцом.

В течение гарантийного срока Сервисный центр устраняет за свой счёт выявленные

производственные дефекты. Производитель снимает свои гарантийные обязательства и

юридическую ответственность при несоблюдении потребителем инструкций по эксплуатации,

самостоятельной разборки, ремонта и технического обслуживания аппарата, а также не несет

никакой ответственности за причиненные травмы и нанесенныйущерб.

- 1 -4

.

Loading...

Loading...