Frymaster UHC-MCDONALDS Installation Manual

OPERATOR’S MANUAL

UNIVERSAL HOLDING CABINET (UHC)

2 and 4-Slot Models

MANUFACTURED BY

P.O. BOX 51000

SHREVEPORT, LOUISIANA

71135-1000

PHONE 1-318-865-1711

1-800-24 FRYER

Universal Holding Cabinet 1-1

Power Up 2-1

Operational Overview 3-1

Operator Mode 4-1

Timer Operation 5-1

Cook More Prompts 6-1

Switching Between Breakfast. Lunch, Clean Mode and Slot Off 7-1

Slot Temperature Display 8-1

Temperature Alarms 9-1

Product Selection 10-1

Program Mode 10-1

Page Selection 10-2

Meal Selection 10-3

Exiting Program Mode 10-5

Example of Production Selection Change 10-6

Entering and Editing Product Information 11-1

Entering Password 11-1

Entering Product Name 11-1

Entering Product Holding Time 11-3

Enter Meal Usage 11-4

Display Adjustments 12-1

Change Display Time 12-1

Change Display Intensity 12-1

Change F° to C°

Troubleshooting Guide 13-1

Appendices 14-1

Appendix A: Food Item Default Settings 14-1

Appendix B: Cleaning and Preventive Maintenance 14-2

Appendix C: SOC for Universal Holding Cabinet 14-5

Appendix D: Production Charts 14-5

Appendix E: Quick Reference Guide 14-6

Appendix F: Typical Setups/Stacked Arrangements 14-7

12-1

Frymaster L.L.C., 8700 Line Avenue 71106, 5489 Campus Drive 71129

P.O. Box 51000, Shreveport, Louisiana 71135-1000

PHONE 318-865-1711 FAX 318-219-7135

PRINTED IN THE UNITED STATES SERVICE HOTLINE 1-800-24-FRYER 819-5537 10/00

*8195537*

1 Universal Holding Cabinet

The Frymaster Universal Holding Cabinet (UHC) developed and manufactured exclusively for

McDonald’s, is a short-term holding device to extend the freshness of a wide variety of cooked

products. The UHC meets all McDonald’s standards for safety, efficiency, and cleanliness.

1.1 Warranty Statement

A. Frymaster L.L.C. makes the following limited warranties to the original purchaser only for

this equipment and replacement parts:

1.1.1 Warranty Provisions – Universal Holding Cabinet

A. Frymaster L.L.C. warrants all components against defects in material and workmanship for a

period of two years.

B. All parts, with the exception of fuses, are warranted for two years after installation date of

cabinet

C. If any parts, except fuses, become defective during the first year after installation date,

Welbilt will also pay straight-time labor costs to replace the part, plus up to 100 miles/160

km of travel (50 miles/80 km each way).

1.1.2 Parts Return

A. All defective in-warranty parts must be returned to a Frymaster Authorized Factory Service

Center within 60 days for credit. After 60 days, no credit will be allowed.

1.2.3 Warranty Exclusions

• This warranty does not cover equipment which has been damaged due to misuse, abuse,

alteration, or accident such as:

• Improper or unauthorized repair;

• Failure to follow proper installation instructions and/or scheduled maintenance

procedures as prescribed in your MRC cards;

• Improper maintenance;

• Damage in shipment;

• Abnormal use;

• Removal, alteration, or obliteration of the rating plate;

This warranty also does not cover:

• Transportation or travel over 100 miles/160 km (50 miles/80 km each way), or travel

time over two hours;

• Overtime or holiday charges;

• Consequential damages (the cost of repairing or replacing other property that is

damaged), loss of time, profits, use or any other incidental damages of any kind.

1-1

There are no implied warranties or merchantability or fitness for any particular use of purpose.

For international warranty, the above procedures apply, except that the customer is responsible for

freight and duty charges.

PARTS ORDERING AND SERVICE INFORMATION

Parts orders may be placed directly with your local Frymaster Factory Authorized Service Center

(FASC)/Distributor. A list of Frymaster FASC/Distributors was included with the cabinet when

shipped from the factory. If you do not have access to this list, please contact the Frymaster Service

Department at 1-800-24-FRYER or 1-318-865-1711.

Please note that orders for wire/plastic trays, stacking kits, carts and casters should be placed

with your local Kitchen Equipment Supplier (KES). Frymaster does not supply these

accessory items.

To speed up your order, the following information is required:

Model Number_____________________________________

Serial Number_____________________________________

Voltage___________________________________________

Item Part Number___________________________________

Quantity Needed____________________________________

Service may be obtained by contacting your local Frymaster Authorized Service Center/Distributor.

Service information may be obtained by calling the Frymaster Service Department. The following

information will be needed in order to assist you quickly and efficiently:

Model Number_____________________________________

Serial Number______________________________________

Nature of the

Problem___________________________________________________________________

Also any other information which may be helpful in solving your service problem.

RETAIN AND STORE THIS MANUAL IN A SAFE PLACE FOR FUTURE USE.

1-2

1.2 Product Trays

There are 3 product tray sizes. See Appendices A and C for specific product volumes and

recommended holding sizes and times. Use the tray that is designed for the specific product

described below:

A. 1/3-size plastic tray – Holds meat and egg products that are grilled (hamburger patties,

bacon, eggs, sausage, etc.) There are two important procedures to remember when storing

grilled products:

• The product should not be drained when picked up from the grill.

• The product is stacked when placed in the proper tray. 10-1 and sausage patties can be

stacked up to six high. Eggs (except scrambled), grilled chicken and 4-1 patties can be

stacked up to three high.

B. 1/2-size wire tray – holds fried products (McNuggets, McChicken, Filet-O-Fish, etc.)

Remember this important procedure when storing fried products:

• Fried products are to be placed on the wire rack. The rack should be placed on a crumb

tray. No tray liners are required for these trays.

C. Full-size plastic tray – holds baked products (biscuits, muffins, etc.) Follow these

procedures for baked products:

• After the biscuits have been removed from the biscuit oven, remove the wrapper and

open the cardboard box.

• Put a tray liner in the tray and slide the biscuits onto the liner. The biscuit trays can hold

up to 30 frozen biscuits, 20 scratch biscuits or 20 muffins.

Important Operational Tips

When placing a tray into the cabinet, make sure the slot line on the tray handle lines up with the edge

of the slot.

Discard cracked or damaged trays.

When removing portions from a tray, slide the tray only as far as needed, then quickly return the tray

to the slot line.

1-3

1.3 Install Grill Clip

The grill clip is shipped in the accessory package and is

designed to hold the 1/3-size grill tray. It attaches to the

grill to make transfer from the grill to the UHC faster and

safer.

• Position the front of the grill clip under the lip

of the grill.

• Lower the back of the clip until the grooves rest

over the grill bar. The grill clip should firmly

seat on the front of the grill. If the clip doesn’t

fit snuggly, simply loosen the four nuts under

the clip and slide it in or out as needed to tighten

against the bar. Tighten the nuts after the clip is

properly adjusted.

The grill clip attaches to the grill and holds

grilled product in a UHC tray, making

transfer to the holding cabinet easier.

1.4 Installation of 4” Legs

CAUTION

Use caution when handling the cabinet or tilting the unit to/from the floor to install

the legs. Maneuvering the cabinet should be accomplished by at least two people.

A. Carefully place the Universal Holding Cabinet on its right side (direction is determined with

you facing the front of the unit), exposing the base of the cabinet.

B. Mount the leg pads to the bottom of the base using the 16-¼"-20 x ½" long screws and

lockwashers provided.

C. Screw the leg into the mounted leg pad until fully tight.

D. Carefully turn the UHC upright until the unit stands on its legs. Perform Step 2, Power Up.

IF THE UHC IS INSTALLED WITH THE COUNTERTOP OPTION, ENSURE THE

AREA WHERE THE UHC BASE AND COUNTERTOP MEET IS PROPERLY SEALED

WITH A FOOD GRADE TYPE SEALANT.

1-4

2 Power Up

ALL ELECTRICALLY OPERATED APPLIANCES MUST BE ELECTRICALLY

GROUNDED IN ACCORDANCE WITH LOCAL CODES, OR IN THE ABSENCE OF

LOCAL CODES, WITH NATIONAL ELECTRIC CODE, ANSI/NFPA NO. 70-1990.

A. Power Requirements:

• Voltage – 208/240 VAC

• 2620 Watts @ 208V – 3420 Watts @ 240V

• Frequency – 50/60 Hertz

• Single Phase

• 20 amp Service

THIS APPLIANCE IS EQUIPPED WITH A THREE-PRONG GROUNDING PLUG FOR

YOUR PROTECTION AGAINST SHOCK HAZARD AND MUST BE PPLUGGED INTO A

PROPERLY GROUNDED THREE-PRONG RECEPTACLE. DO NOT CUT OR REMOVE

THE GROUNDING PRONG FROM THIS PLUG.

B. Plug the Universal Holding Cabinet into the power source.

C. Place the power switch in the ON position. All control displays will illuminate green

approximately 2 seconds after the power switch is activated.

D. Monitor the temperature of the slots. The time it takes the slot(s) to heat from ambient (room)

temperature to a 155°F (68°C) setpoint should be approximately 15 minutes. It should take

approximately 25 minutes to reach a 200°F (93°C) setpoint. If setpoint is not consistently

achieved within these limits, call your local Factory Authorized Service Center for repair.

2-1

3 Operational Overview

The Universal Holding Cabinet (UHC) has either four slots that can hold up to three trays of product per slot

or two slots, which hold up to three trays. Each slot has a controller that indicates the holding time and

product selection for each tray position.

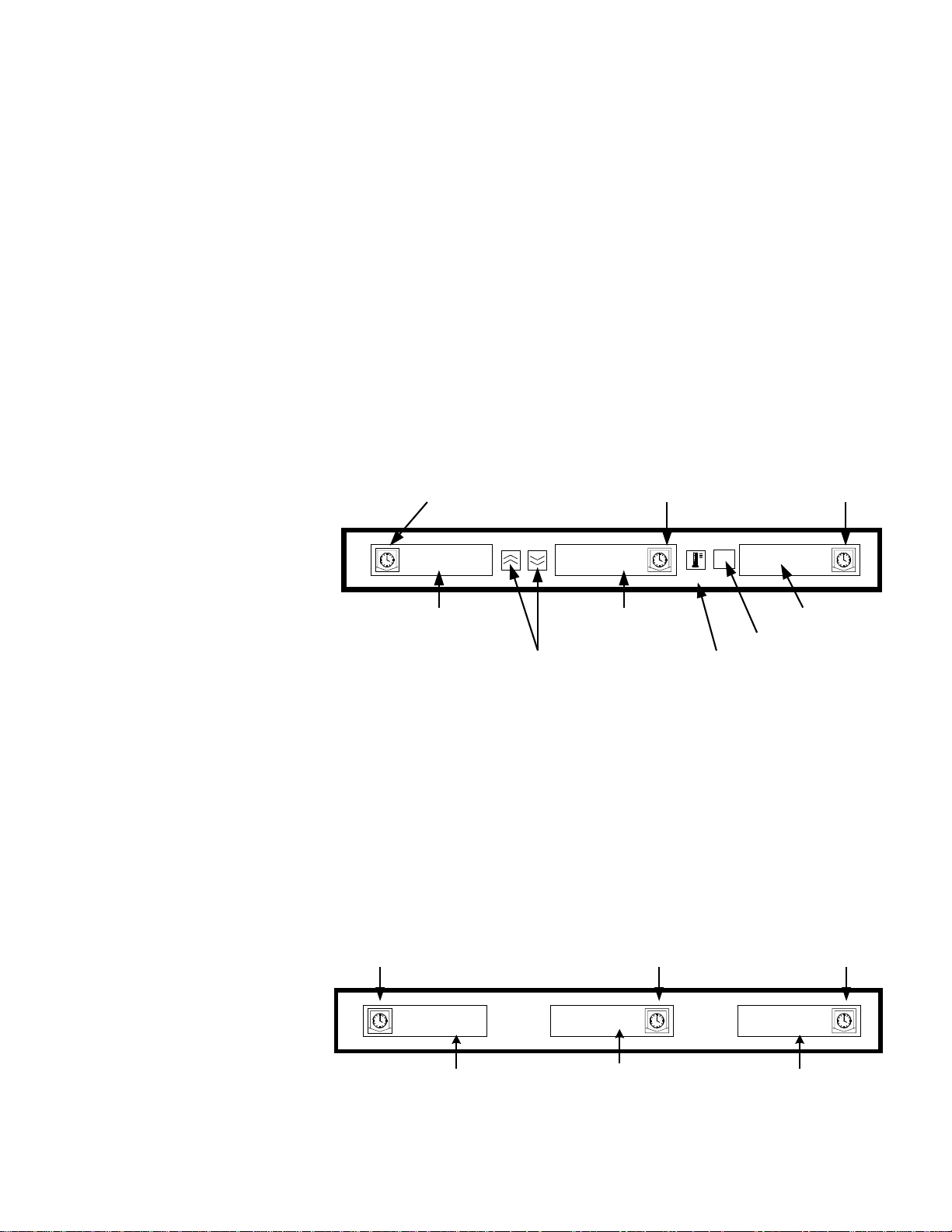

Universal Holding Cabinet (UHC)

The operator enters information into the controller via the display and keypad shown below. Each product

selection has a temperature setpoint and product holding time. All product timers run independently. The

slot temperature is controlled by the temperature setpoint of the leftmost product entry in each slot as

viewed from the front of the cabinet. Product selections that have a holding temperature different that

the leftmost product selection will not be available for entry into that slot’s configuration.

Most UHC’s have a front and rear display for each slot. All operator mode selections can be made from

either display. Program changes can only be made from the front display. A Special Point of Distribution

(SPOD) cabinet has only a front controller for each slot.

UHC Controller (Front Display and Keypad)

Timer keys (Left, Center, and

Left Timer Key

Center Timer Key

Right Timer Key

Right) start and stop the timer

associated with each tray

position. The timer keys also

turn off audible alarms.

Displays (Left, Center, and

Right) show product selection

and holding time for each tray

position. The displays also

provide programming

SAUS SAUS SAUS

Left Display

UP/DOWN Arrow Keys

Center Display

ENTER

MENU

PAGE

Right Display

Menu Key

Temperature/Enter

/Page Key

information in program mode.

MENU key is used to select meal transitions (breakfast to lunch), Clean Mode operation and to turn

individual slots on or off. The MENU key also provides access to program mode.

TEMPERATURE/ENTER/PAGE key has three functions. 1) Display slot temperature information; 2)

Enter operational changes; and 3) Select Page parameters in program mode.

Up and Down ARROW keys are used to increase/decrease variables or change selections.

UHC Controller (Rear

Display and Keypad,

Traditional UHC Only)

Left Timer Key

Center Timer Key

SAUS SAUS SAUS

Left Display

Center Display Right Display

3-1

Right Timer Key

4 Operator Mode

Operator Mode is the normal operating mode of the controller when all slots are at the proper

temperature and no alarm conditions exist. Product information and holding time is displayed.

4.1 Display of Product Information

In Operator Mode the slot display indicates the following:

1. The product selection for a tray location.

2. The holding time remaining (in minutes) for active timers.

An active timer alternately displays the product selection and the time remaining. Inactive timers

display only product selection.

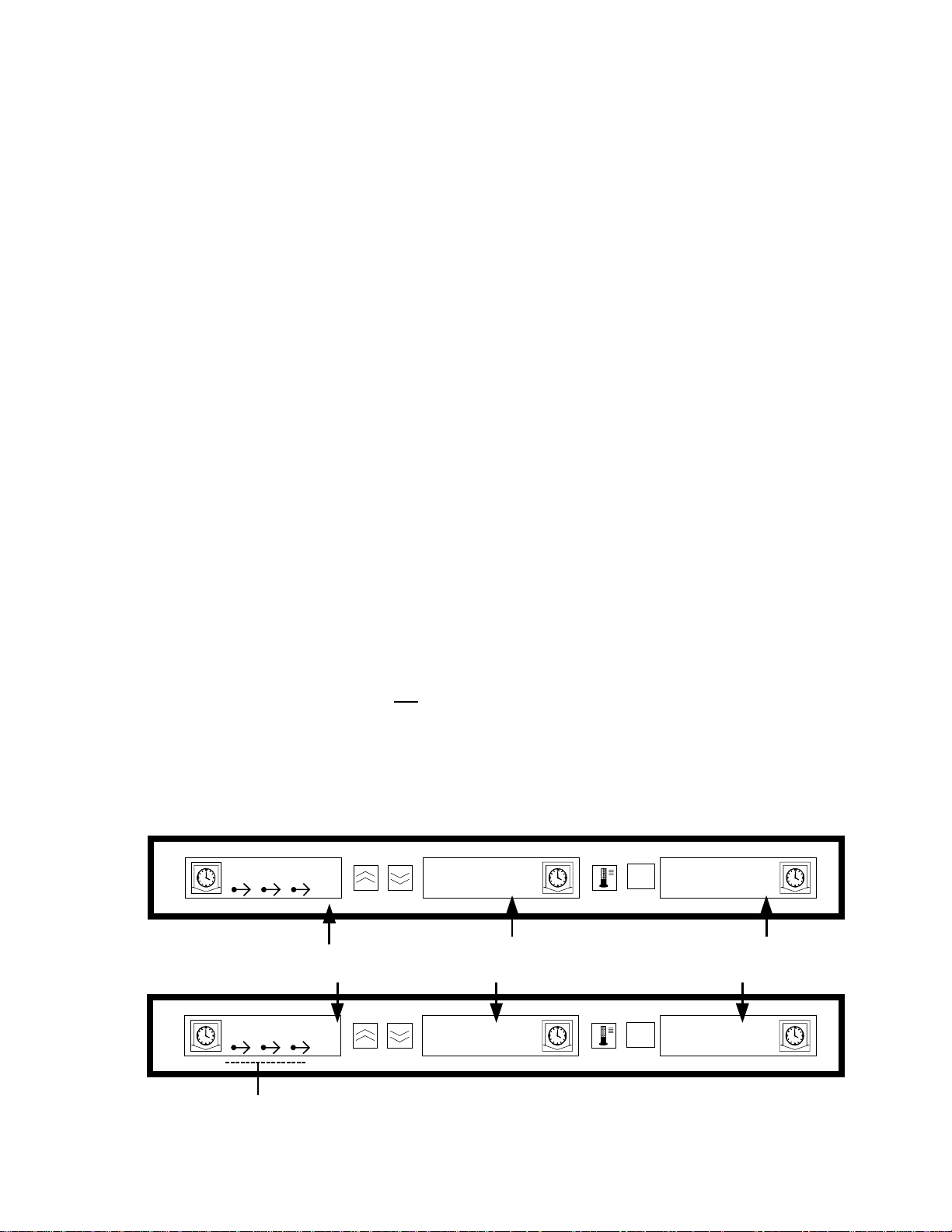

4.2 Product Information and the Use First Display

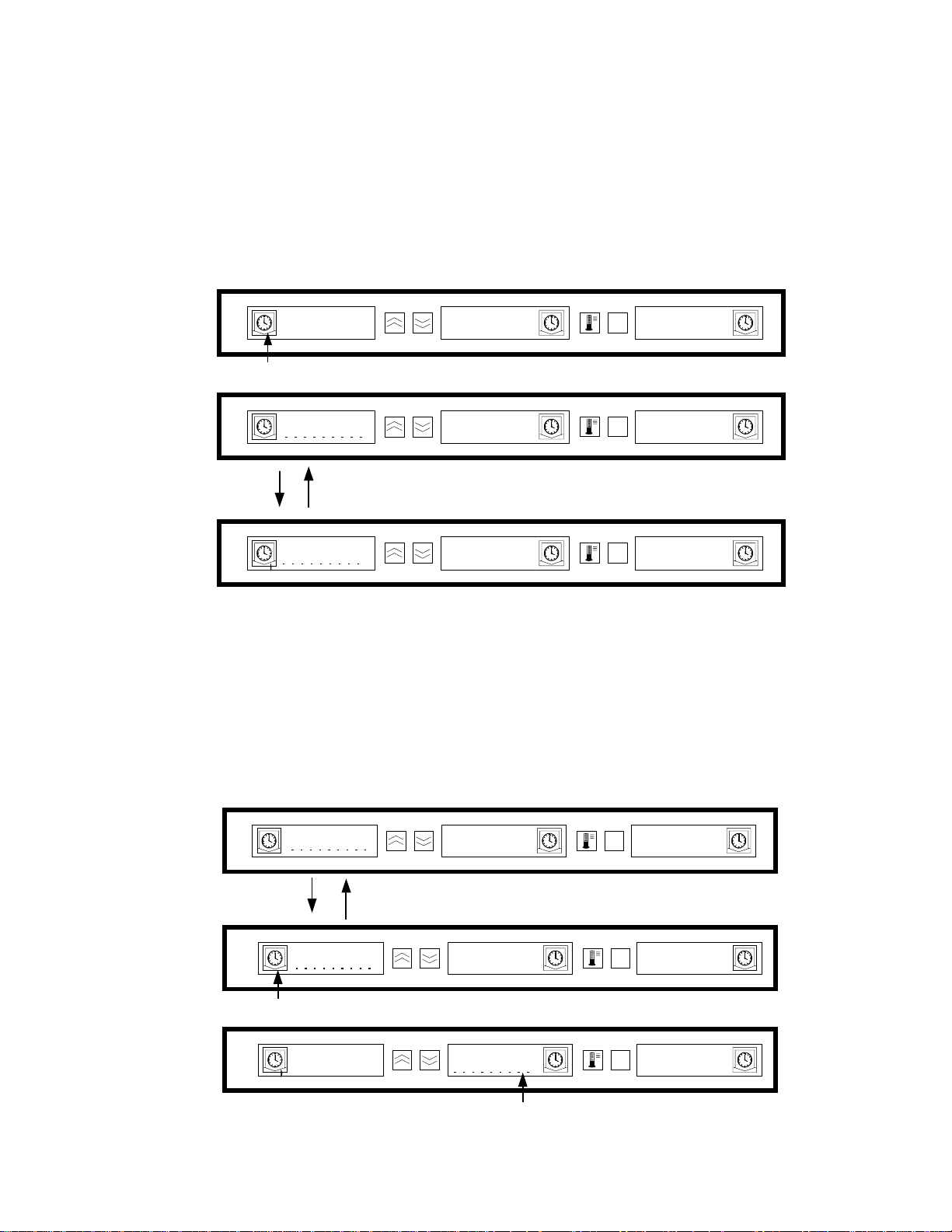

The Operator Mode indicates product selection and holding time status by changing the display

intensity.

The “Use First Display” indicates the product with the least amount of holding time remaining.

There are two levels of display intensity used to indicate product status.

1. Brighter level of display intensity and running dots indicate the “use first” product

selection.

2. Lower level of display intensity indicates:

a. An active timer that is not the product selection with the least holding time remaining.

b. An inactive timer where only the product selection is displayed.

Timer Status Indicators

SAUS

Use-First Timer

Higher Intensity

12

ENTER

SAUS SAUS

Active Timer

Lower Intensity

20 SAUS

MENU

PAGE

Inactive Timer

Lower Intensity

ENTER

MENU

PAGE

Running Dots

4-1

5 Timer Operation

5.1 Starting A Timer

Press the Timer key above the tray position to start a timer. The timer will time down from a

preset value and alternately display product selection and the holding time remaining. If more than

one tray of a product selection is timing, the location of the product with the least remaining holding

time is indicated by the Use First display status.

ENTER

SAUS SAUS SAUS

Press TIMER key to start a timer

60 SAUS SAUS

Active display alternately indicates

holding time and product selection

SAUS SAUS SAUS

MENU

PAGE

ENTER

MENU

PAGE

ENTER

MENU

PAGE

5.2 Stopping A Timer

Press the Timer key above the slot position to turn off an active timer. The timer stops timing

and the display changes to the inactive timer status. If more than one tray of a product selection is

timing, use first indication changes to next active timer.

Timer to Stop

SAUS SAUS SAUS

Active display alternately indicates

holding time and product selection

19 24 SAUS

Press TIMER key to stop timer

SAUS SAUS SAUS

Next Shortest Time

ENTER

PAGE

ENTER

PAGE

ENTER

PAGE

Inactive Timer

MENU

MENU

MENU

Use-First indication changes to next

active timer

5-1

Loading...

Loading...