Page 1

*8195794*

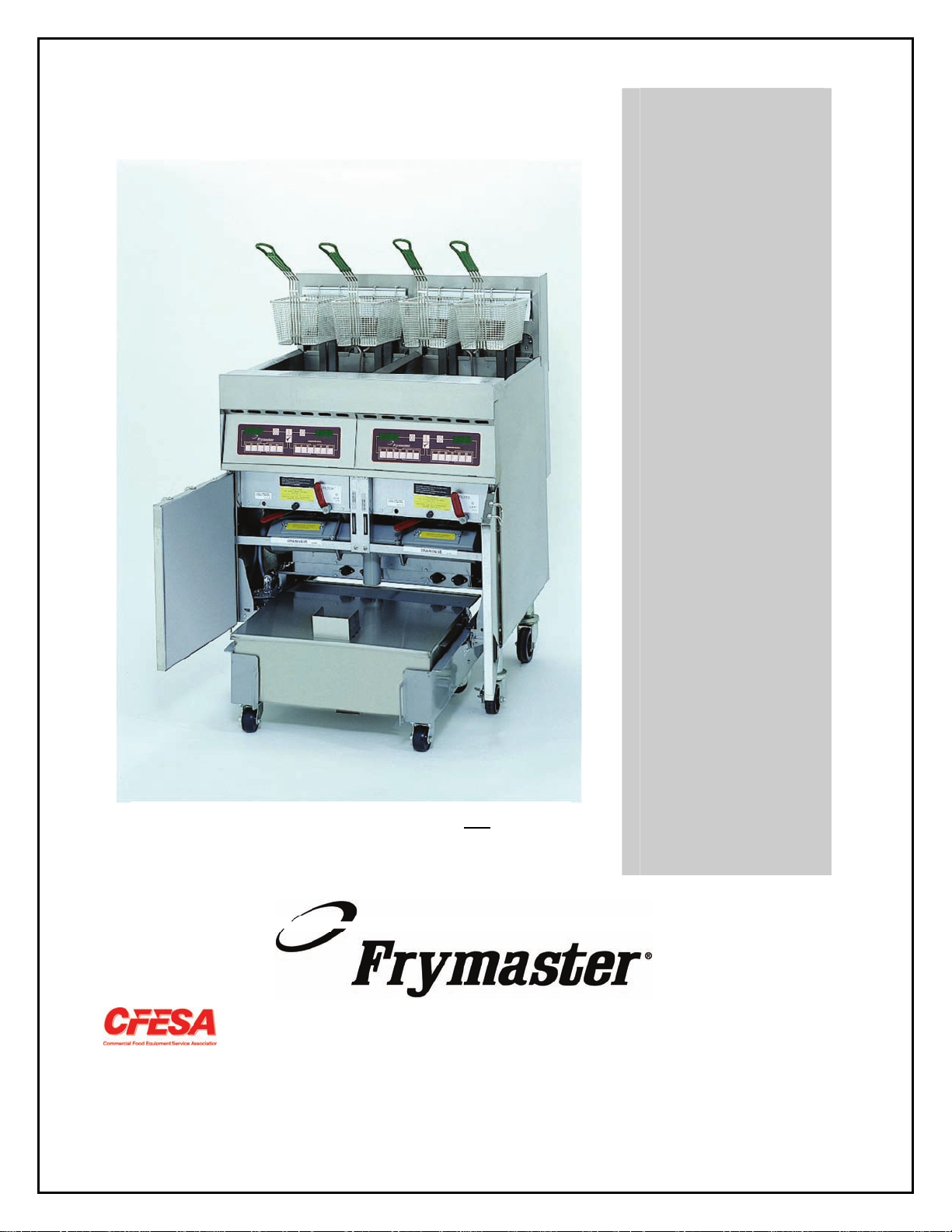

H14/H17/H22 SERIES

ELECTRIC FRYERS

Service & Parts Manual

Beginning with Series Code AN

Frymaster, a member of the Commercial Food Equipment Service Association, recommends

using CFESA Certified Technicians.

24-Hour Service Hotline 1-800-551-8633

AUG 2005

Page 2

NOTICE

IF, DURING THE WARRANTY PERIOD, THE CUSTOMER USES A PART FOR THIS

ENODIS EQUIPMENT OTHER THAN AN UNMODIFIED NEW OR RECYCLED PART

PURCHASED DIRECTLY FROM FRYMASTER/DEAN, OR ANY OF ITS AUTHORIZED

SERVICE CENTERS, AND/OR THE PART BEING USED IS MODIFIED FROM ITS

ORIGINAL CONFIGURATION, THIS WARRANTY WILL BE VOID. FURTHER,

FRYMASTER/DEAN AND ITS AFFILIATES WILL NOT BE LIABLE FOR ANY

CLAIMS, DAMAGES OR EXPENSES INCURRED BY THE CUSTOMER WHICH

ARISE DIRECTLY OR INDIRECTLY, IN WHOLE OR IN PART, DUE TO THE

INSTALLATION OF ANY MODIFIED PART AND/OR PART RECEIVED FROM AN

UNAUTHORIZED SERVICE CENTER.

DANGER

Copper wire suitable for at least 167°F (75°C) MUST be used for power

connections.

DANGER

The electrical power supply for this appliance MUST be the same as

indicated on the rating and serial number plate located on the inside of the

fryer door.

DANGER

This appliance MUST be connected to the voltage and phase as specified

on the rating and serial number plate located on the inside of the fryer

door.

DANGER

All wiring connections for this appliance MUST be made in accordance

with the wiring diagrams furnished with the equipment. Wiring diagrams

are located on the inside of the fryer door.

DANGER

Do not store or use gasoline or other flammable vapors and liquids in the

vicinity of this or any other appliance.

WARNING

Do not attach accessories to this fryer unless fryer is secured from tipping.

Personal injury may result.

WARNING

Frymaster fryers equipped with legs are for permanent installations. Fryers

fitted with legs must be lifted during movement to avoid damage and

possible bodily injury. For a moveable or portable installation, Frymaster

optional equipment casters must be used.

Questions? Call 1-800-551-8633

Page 3

WARNING

Do not use water jets to clean this equipment.

DANGER

All wiring connections for this appliance MUST be made in accordance

with the wiring diagrams furnished with the equipment. Wiring diagrams

are located on the inside of the fryer door.

WARNING

This equipment is intended for indoor use only. Do not install or operate

this equipment in outdoor areas.

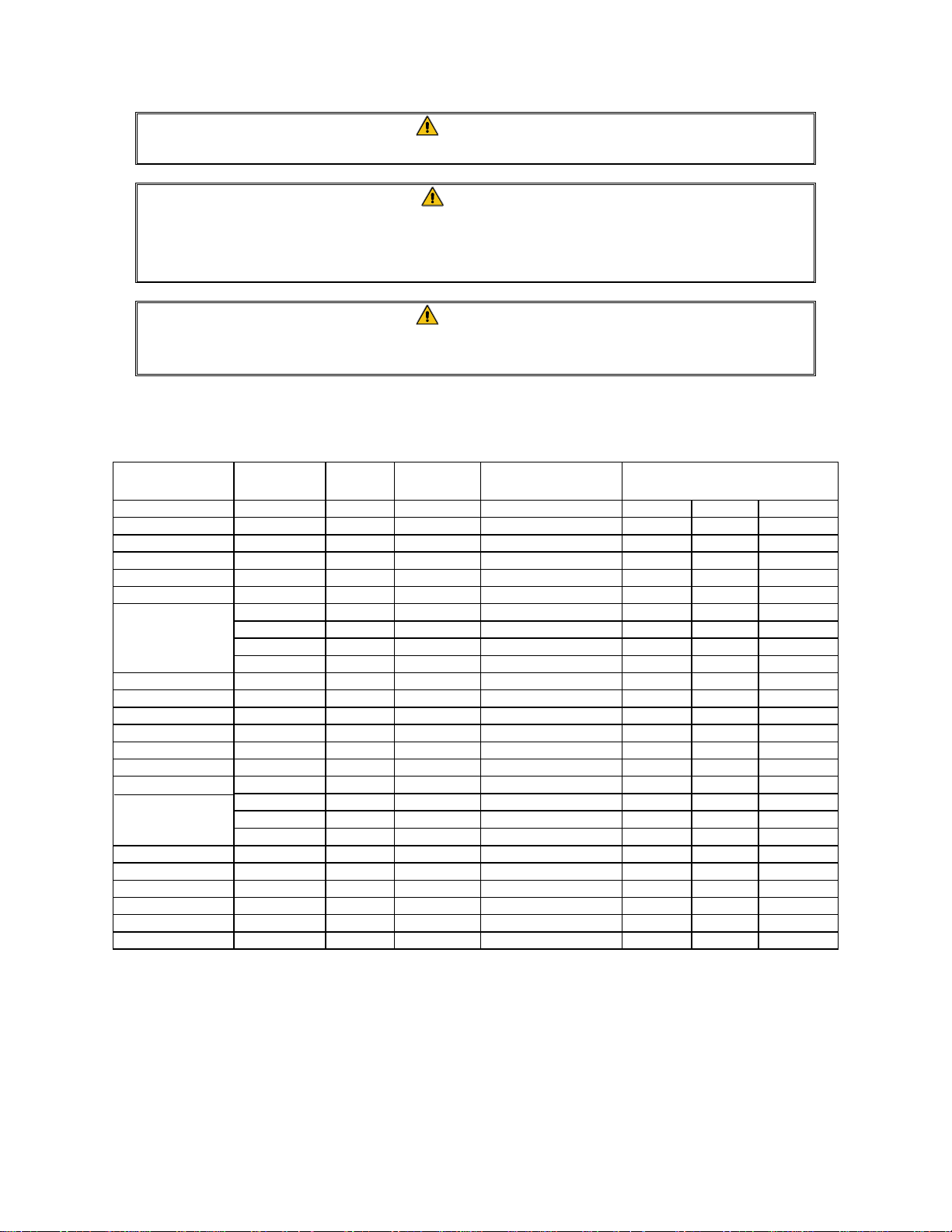

Electrical Requirements

MODEL VOLTAGE PHASE WIRE

SERVICE

H14 208 3 3 6 (16) 39 39 39

H14 240 3 3 6 (16) 34 34 34

H14 480 3 3 8 (10) 17 17 17

H14 220/380 3 4 6 (16) 21 21 21

H14 240/415 3 4 6 (16) 20 20 21

H14 230/400 3 4 6 (16) 21 21 21

ALL

EPH14

SERIES

(SOLID STATE)

H17 208 3 3 6 (16) 48 48 48

H17 240 3 3 6 (16) 41 41 41

H17 480 3 3 6 (16) 21 21 21

H17 220/380 3 4 6 (16) 26 26 26

H17 240/415 3 4 6 (16) 24 24 24

` 230/400 3 4 6 (16) 25 25 25

ALL 208 3 3 6 (16) 48 48 48

EPH17

SERIES

(SOLID STATE)

H22 208 3 3 4 (25) 61 61 61

H22 240 3 3 4 (25) 53 53 53

H22 480 3 3 6 (16) 27 27 27

H22 220/380 3 4 6 (16) 34 34 34

H22 240/415 3 4 6 (16) 31 31 31

H22 230/400 3 4 6 (16) 32 32 32

208 3 3 6 (16) 39 39 39

240 3 3 6 (16) 34 34 34

220/380 3 4 6 (16) 21 21 21

240/415 3 4 6 (16) 20 20 20

240 3 3 6 (16) 41 41 41

220/380 3 4 6 (16) 26 26 26

240/415 3 4 6 (16) 24 24 24

MIN.

SIZE

AWG

(mm2)

AMPS PER LEG

L1 L2 L3

Page 4

TABLE OF CONTENTS

Page #

CHAPTER 1 – SERVICE PROCEDURES

1.1 General

1.2 Replace Computer Controller 1-1

1.3 Replace Interface Board 1-2

1.4 Replace Transformer 1-3

1.5 Replace Temperature Probe 1-3

1.6 Replace Heating Element 1-6

1.7 Replace High-Limit 1-9

1.8 Replace Frypot 1-10

1.9 Replace Contactor 1-10

1.10 Built-in Filter System Service Procedures 1-12

1.11 Basket Lift Service Procedures 1-17

1.12 Electric Interface Board Diagnostic Chart 1-20

1.13 Simplified Wiring Diagrams, Common Electric 1-21

1.14 Wiring Diagrams, Main 1-26

1.15 Wiring Diagrams, Basket Lifts 1-32

1.16 Wiring Diagrams, Filtration Systems 1-34

CHAPTER 2 – PARTS LIST 2-1

2.1 Accessories 2-1

2.2 Basket Lift Assemblies and Component Parts 2-2

2.3 Cabinet Assemblies and Component Parts 2-4

2.4 Casters, Legs and Associated Hardware 2-12

2.5 Component Box Assemblies and Associated Hardware

2.6 Control Panels Assemblies, Doors, and Related Components

2.7 Controller Assemblies

2.8 Electrical Components 2-18

2.9 Filter Base/Pan Assemblies

2.10 Filter Pump and Motor Assemblies and Associated Hardware 2-33

2.11 Drain System Components

2.12 Filtration System Components 2-39

2.13 Frypot Assemblies and Drain Valve Components 2-42

2.14 High-Limit Thermostat and Related Components

1-1

1-1

2-14

2-15

2-17

2-25

2-38

2-44

i

Page 5

H14/H17/H22 SERIES ELECTRIC FRYERS

CHAPTER 1: SERVICE PROCEDURES

1.1 General

Before performing any maintenance on your Frymaster fryer, you must disconnect the electrical

power supply.

When electrical wires are disconnected, it is recommended that they be marked in such a way as to

facilitate re-assembly.

1.2 Replace Computer/Controller

1. Unscrew and remove two control panel

screws.

2. Control panel is hinged at the bottom and will

swing open from the top.

3. Unplug wiring harness at plug on back of

controller.

4. Control panel including controller can be

removed by lifting the assembly from the

hinged slots in the control panel frame.

5. Reverse procedures to install new controller.

1-1

Page 6

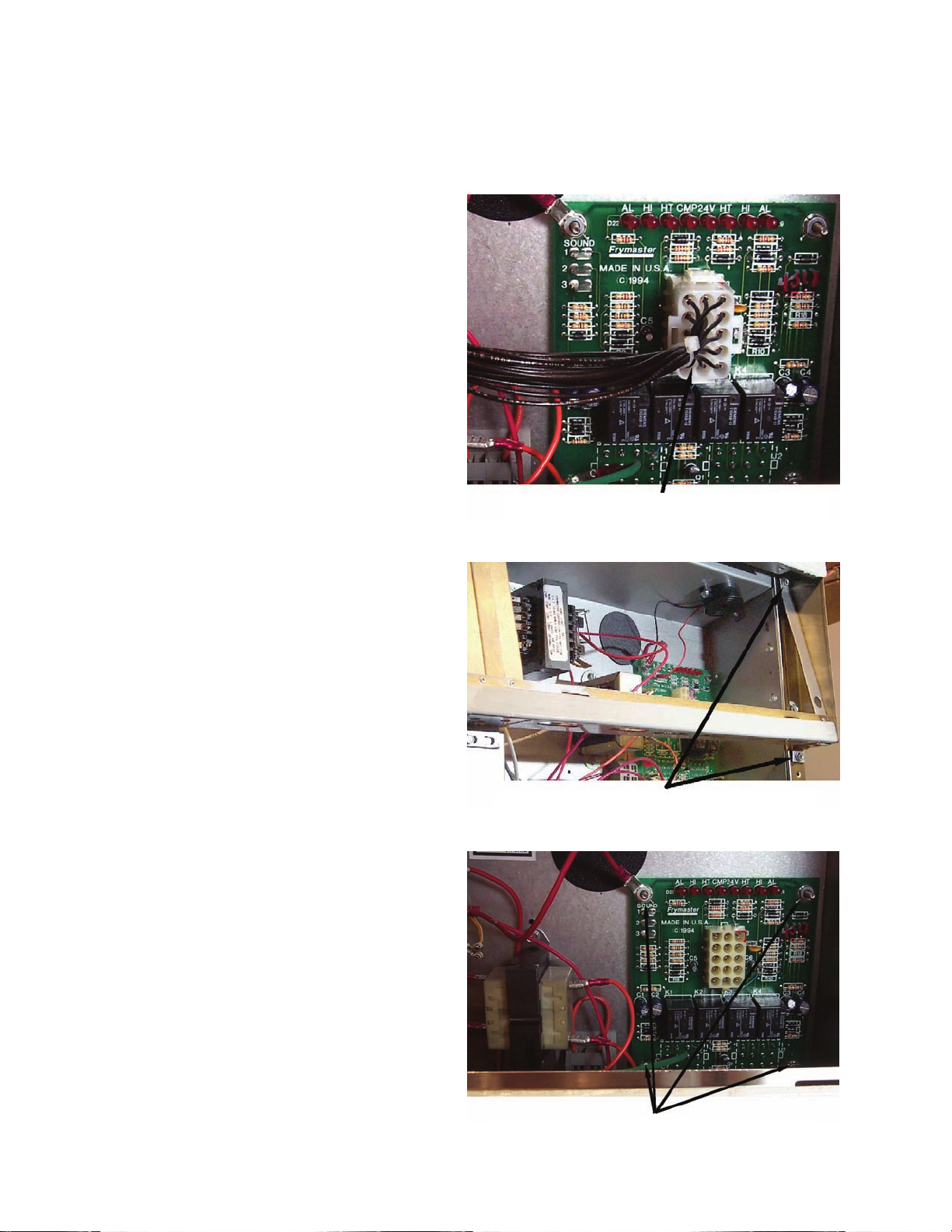

1.3 Replace Interface Board

1. Unplug all power cords. Perform Procedure 1.2, Steps 1-4, Replace Computer/Controller.

2. Unplug wire harness from the interface

board. Remove all wiring from the terminals

of the interface board, ensuring that each wire

is marked for reattachment.

3. Remove the screws securing the control panel

frame. Set the control panel frame/screws

aside.

4. Remove the screws securing the top cap. Set

the top cap/screws aside.

5. Remove the screws securing the component

box. Set the component box drop down

enough so that the wire harness can be

unplugged from the back of the assembly.

6. Remove the nuts from each corner of the

interface board and slide the board from the

studs. Ensure that standoffs remain in place

on studs, prior to installing new interface

board. Install the new interface board by

reversing the previous procedures. Ensure

that wire harnesses are connected to back of

interface board prior to securing component

box. Also ensure that wiring and wire

harnesses are connected to the proper

terminals.

Screws securing control panel frame

Wire harness/connector

Nuts securing interface board

1-2

Page 7

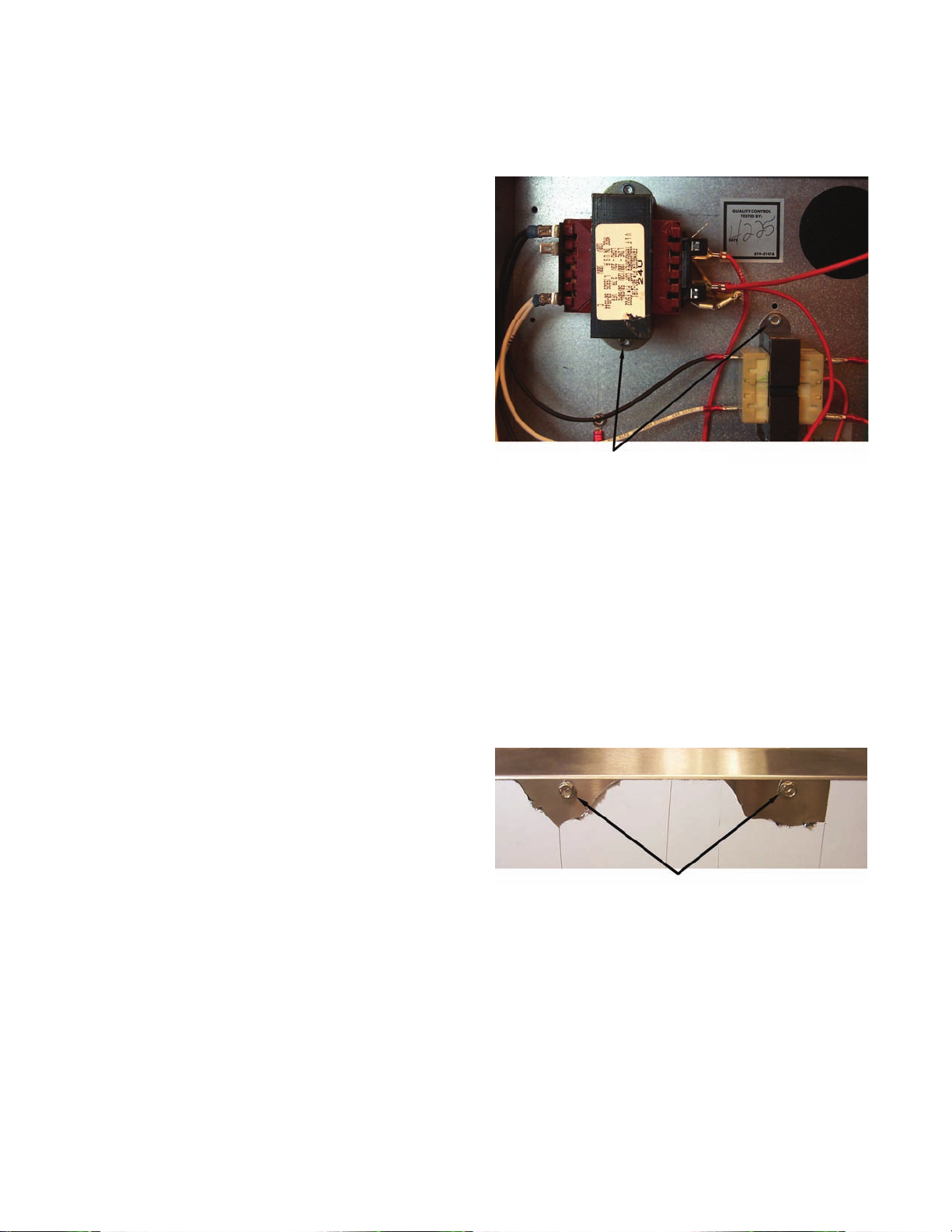

1.4 Replace Transformer

1. Unplug all power cords. Perform Procedure 1.2, Steps 1-4, Replace Computer/Controller.

2. Remove all wiring from the terminals of the

transformer to be replaced.

3. Remove the screws that secure the

transformer to the component box.

4. Install the new transformer by reversing the

preceding procedures. Make sure you

reconnect the wiring to the proper terminals

and the harnesses to the correct connectors.

Screws securing transformers

1.5 Replace Temperature Probe

1. Unplug fryer from the electrical source.

2. Drain the cooking oil from the frypot.

3. Remove the fryer from the exhaust hood to gain access to the rear of the fryer.

4. Remove the screws from the top, center and

bottom back covers. Set the covers and

screws aside.

5. Remove the screws securing the tilt housing

cover. Set the tilt housing cover aside.

Screws securing back covers and tilt housing

1-3

Page 8

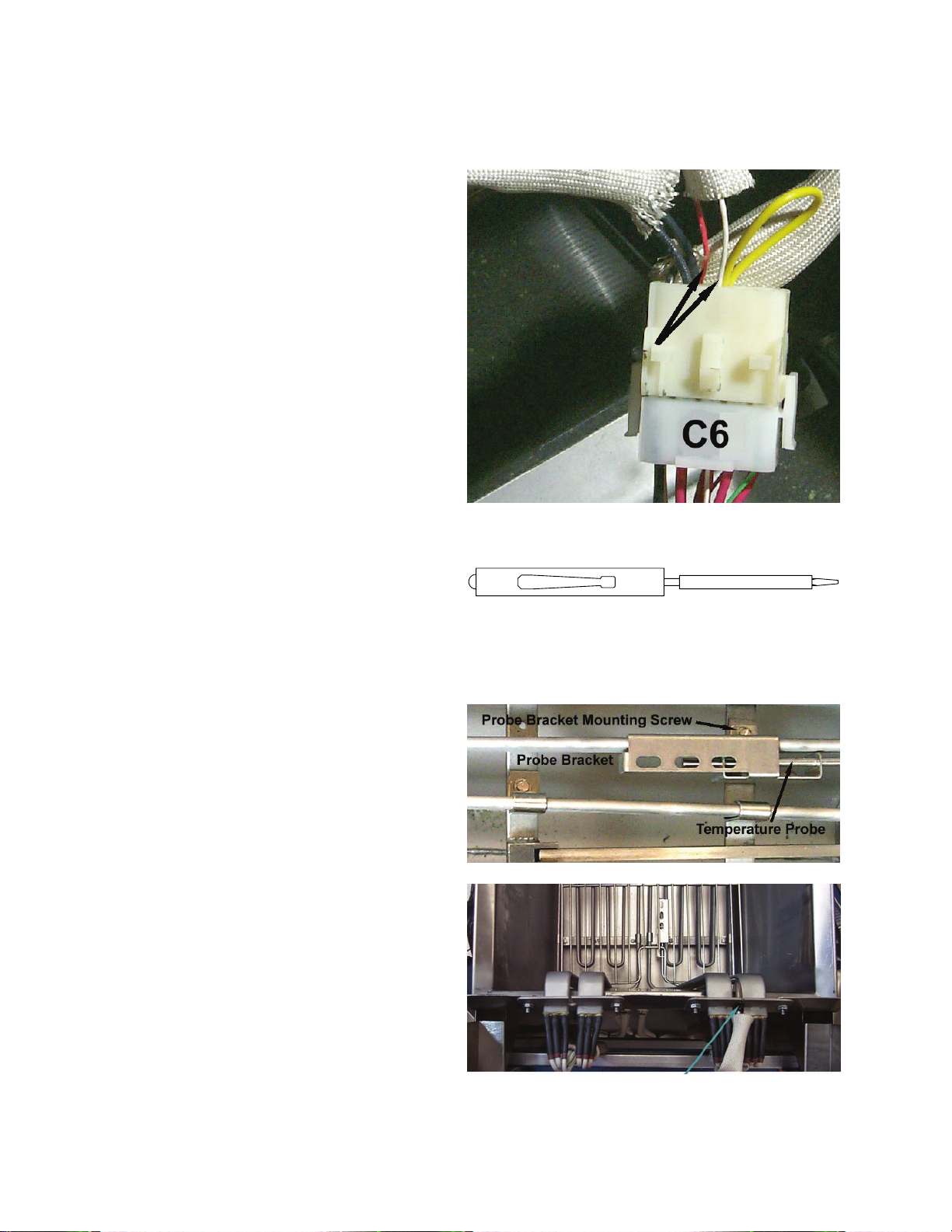

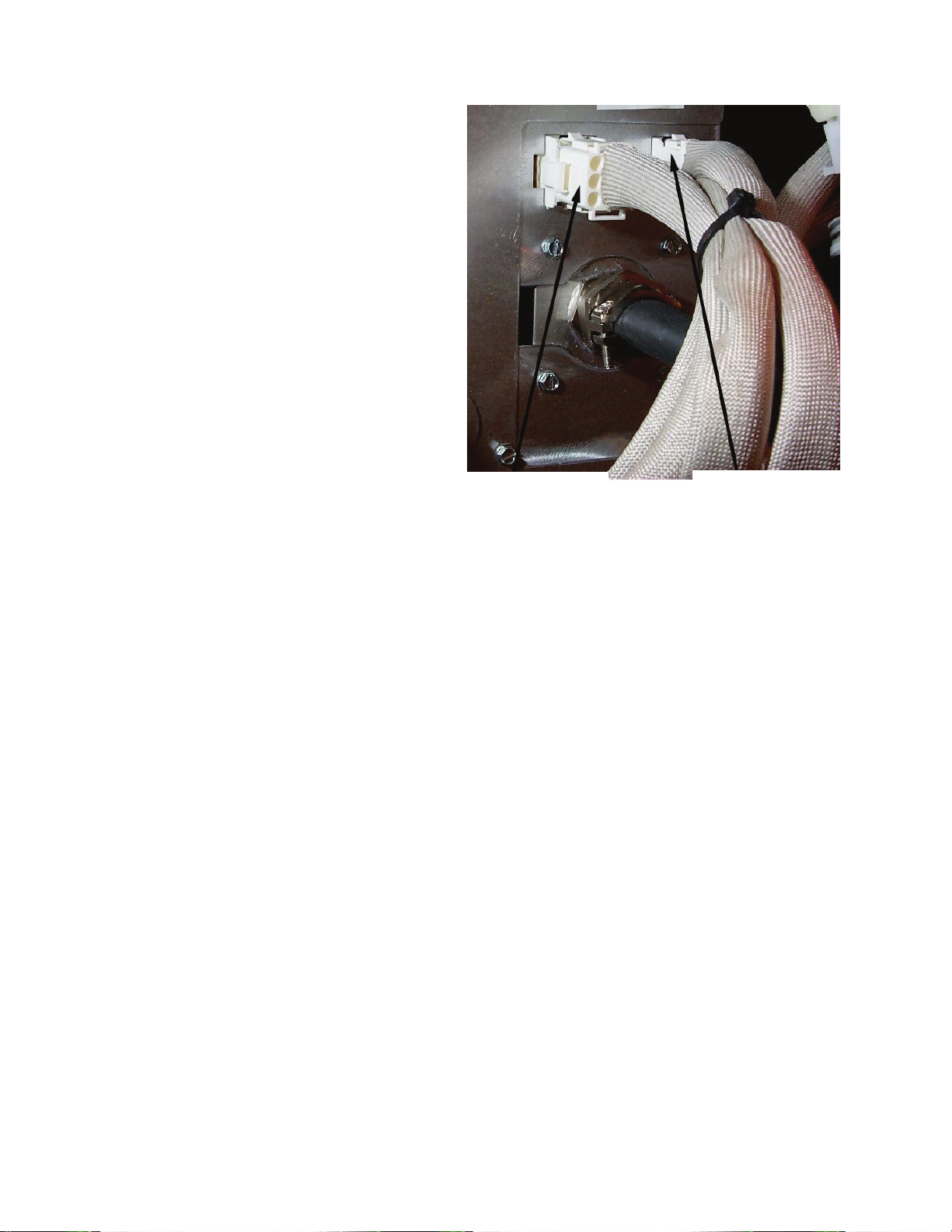

6. Disconnect the wire harness containing the

probe wiring. It may be necessary to remove

the wire ties.

7. Use a pin-pusher (P/N 806-4855 or P/N 807-

0928—see Section 1.7) to remove the probe

wires from the connector. Mark each wire

for re-assembly.

8. Remove the screw(s) securing the probe

bracket to the element.

9. Thread the probe wire through the hole in the

tilt plate assembly and remove the probe and

the securing components from the element.

10. Remove the probe from the probe bracket.

Place the new probe into the bracket.

Use a pin-pusher to remove probe wires from

connector

Pin-pusher (Frymaster P/N 806-4855)

Thread probe wire through hole in tilt plate assembly,

then remove probe and components from element.

1-4

Page 9

11. Place the new temperature probe assembly

onto the element and secure with the screws

removed earlier. Clip the probe onto the rear

of the element. The temperature probe

assembly should be oriented in the same

manner as the probe being replaced.

12. Thread the probe wires into the harness

connector as removed in Step 7.

13. Lower the element into the frypot.

14. Place the tilt housing cover over the tilt

housing assembly and secure with screws

15. Install the top, center and bottom back covers

and secure with screws.

Secure probe to

element with metal

wire-wrap

Tilt housing cover in place

New probe assembly

properly installed in

tilt plate

1-5

Page 10

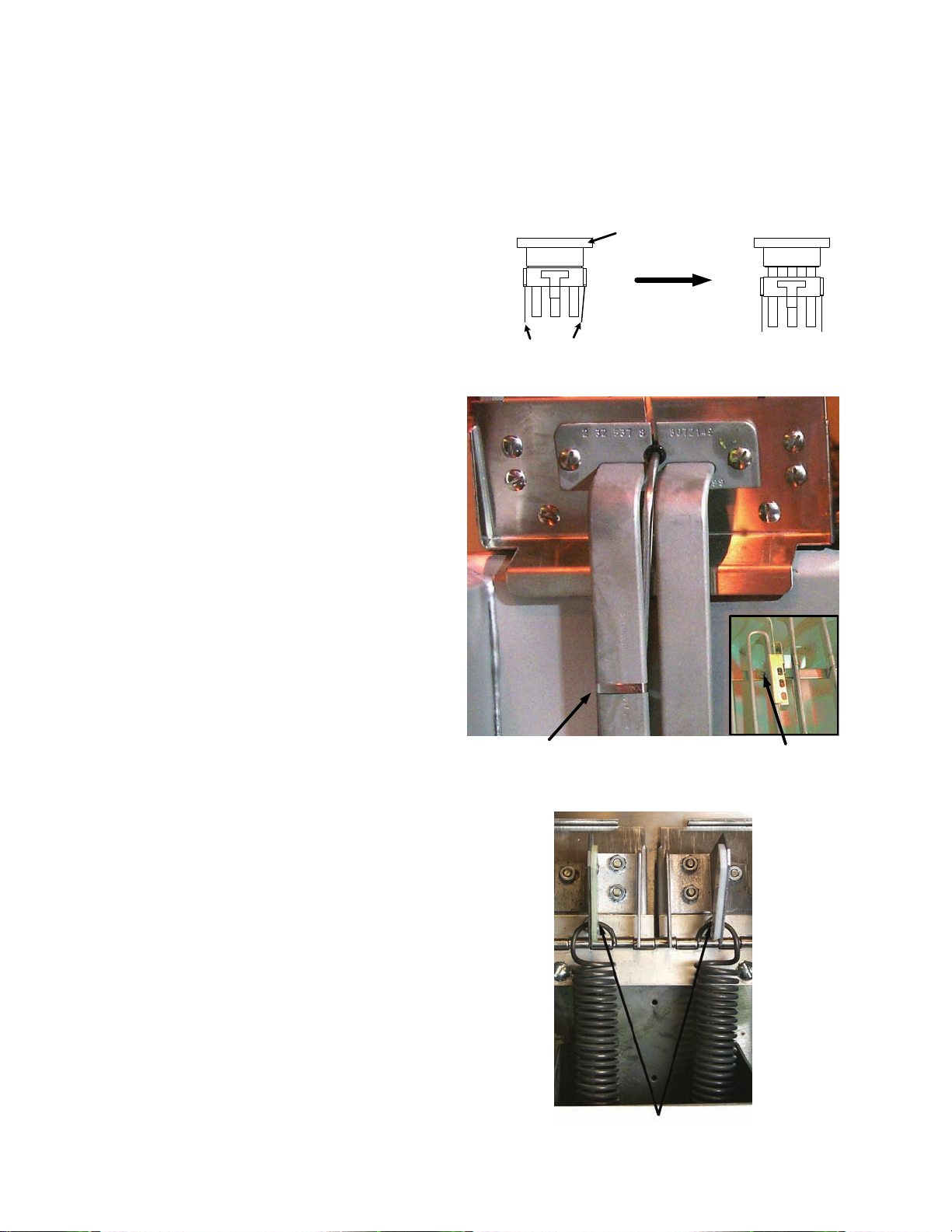

1.6 Replace Heating Element

1. Perform Procedure 1.5, Replace Temperature Probe, Steps 1-7.

2. Remove the element wires from the

connector. Press down on either side of the

connector while pulling up on the top portion.

The connector will open from the top. Pull

all wires from the connector.

3. Remove the screws securing the temperature

probe bracket from the element. Remove the

probe clamp (metal wire-wrap). Set the

temperature probe and probe-securing

components aside.

4. Disconnect the element springs.

Push in on tabs to release

Remove probe clamp (metal wire-wrap), and screws

securing probe bracket to element.

Harness

Connector

Closed

top portion

Harness

Connector

Open

Top Portion

1-6

Disconnect element springs here

Page 11

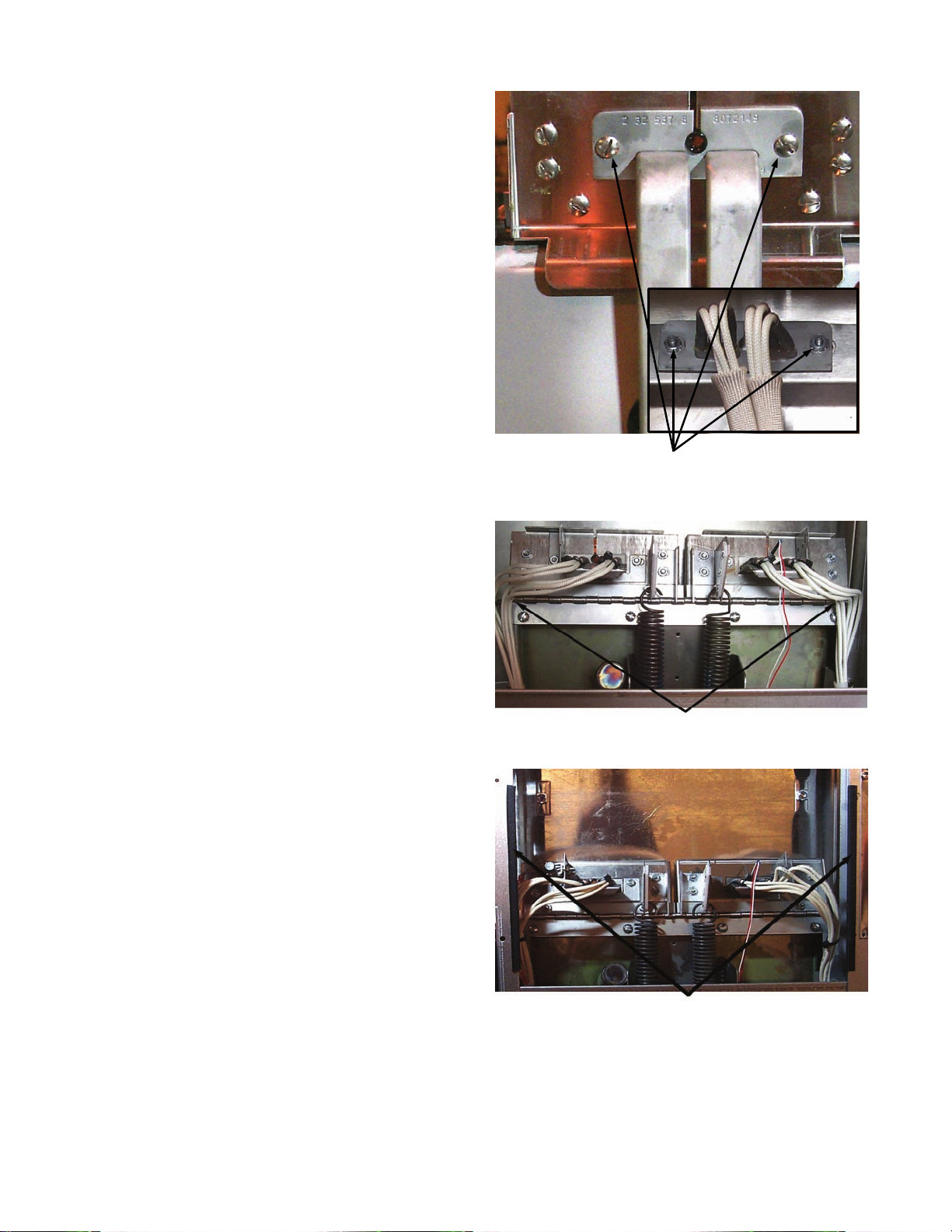

5. Remove the element mounting-screws and

pull the element out of the frypot (split-vats).

On full-vat elements, remove the element

clamps and hardware before removing

mounting-screws and nuts on the defective

element.

6. Install the replacement element in the frypot

and secure with the mounting screws

removed in Step 5.

7. Re-install the temperature probe and probe-

securing components onto the replacement

element.

8. Route the element leads (terminals) to the

rear of the fryer. Ensure that chafing guards

are in place to prevent wire chafing while

raising and lowering elements.

Front

Back

Element mounting-screws and nuts. (Inset Photoback of tilt plate)

Proper element-wire routing is essential to prevent

wire chafing while raising and lowering elements.

Chafing guards on cabinet edges also help prevent

wire chafing while raising and lowering elements.

1-7

Page 12

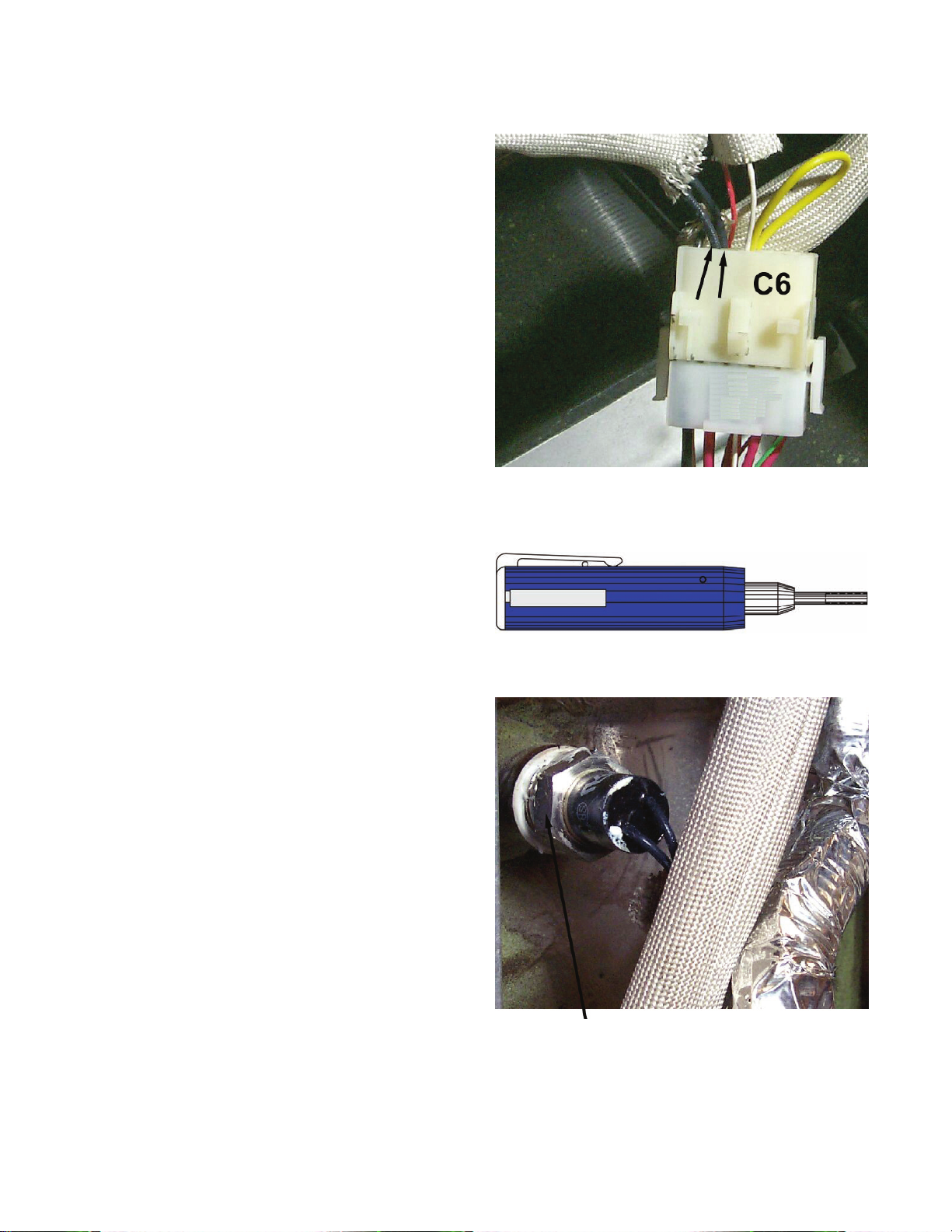

9. When replacing the right element (as viewed

from the rear of the fryer), insert pin

terminals into the corresponding pin-holes in

the 6-pin connector. When all pin terminals

have been fully inserted, close the connector

by sliding the halves together until the tabs

snap back into place (reverse procedure in

Step 2).

10. When replacing the left element (as viewed

from the rear of the fryer), use the 9-pin

connector, inserting the leads from the

replacement element and closing the

connector, see previous step.

11. Insert the connector(s) into the receptacle(s)

on the rear of the contactor box, ensuring that

the latches lock the connectors in place (see

Step 9).

12. Install the temperature probe wires (marked

for re-assembly) in the corresponding pin

locations.

13. Reconnect the element spring.

14. Place the tilt housing cover over the tilt

housing assembly and secure with screws.

15. Install covers and secure with screws.

16. Position fryer under exhaust hood.

Left Element—

9-Pin Connector

Right Element—

6-Pin Connector

1-8

Page 13

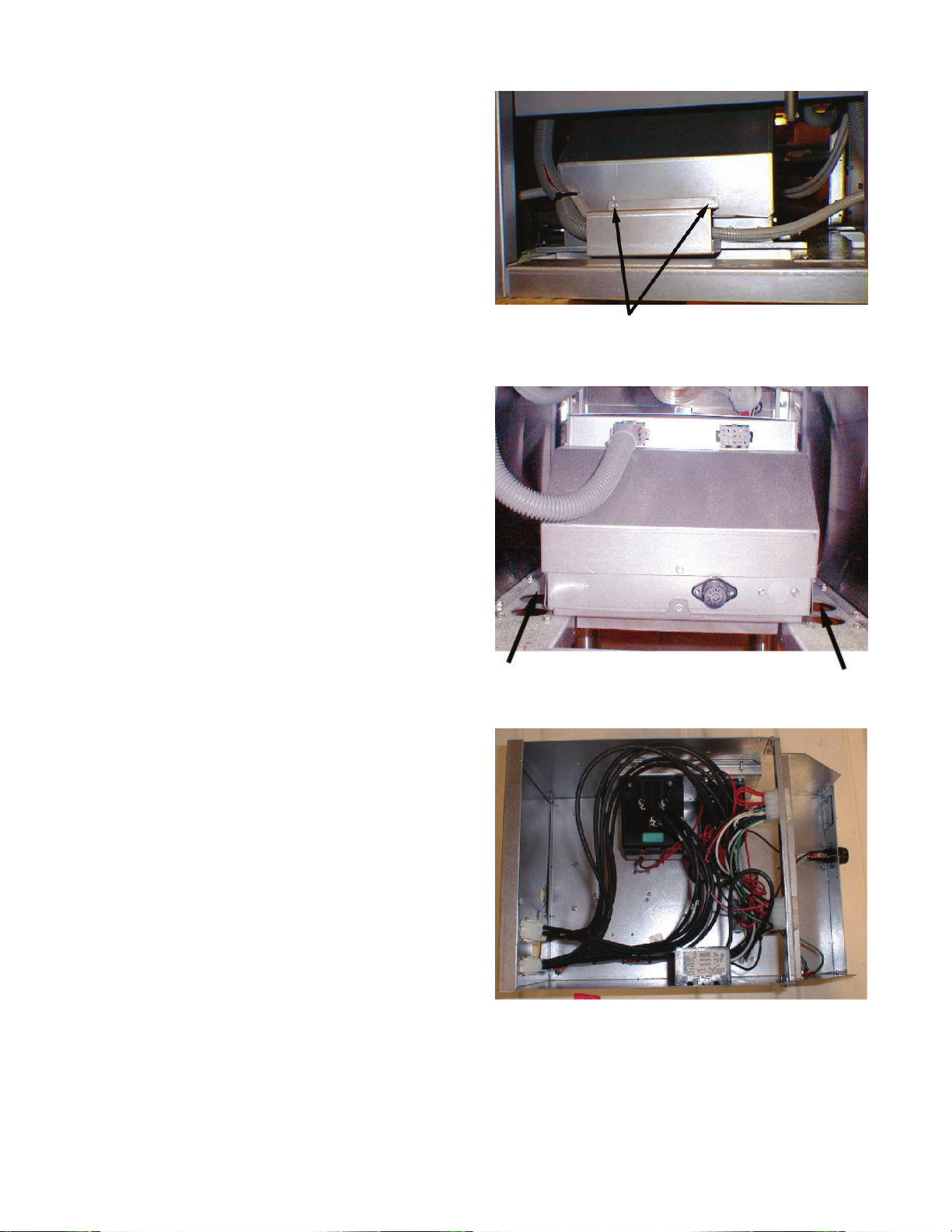

1.7 Replace High-Limit

1. Perform Procedure 1.5, Replace Temperature

Probe, Steps 1-4.

2. Disconnect the wire harness containing the

high-limit wires.

3. Use a pin-pusher (P/N 806-4855 or P/N 807-

0928) to remove the two high-limit wires

from the wire harness connector. For splitpot fryers, remove only the wires for the

high-limit to be replaced. Mark each wire for

re-assembly.

4. Remove the high-limit from the frypot using

an open-end wrench or other suitable tool.

5. Apply Loc-Tite PST 567 sealant to the

replacement high-limit threads.

6. Screw the replacement high-limit into the

frypot and tighten securely. DO NOT

OVERTIGHTEN.

7. Insert the replacement high-limit wires into

the proper pin-holes in the connector. The

same two pin-holes from which the defective

high-limit wires were removed.

8. Reconnect the wire harness connector.

9. Install and secure the back covers.

10. Position the fryer under the exhaust hood.

Proper element-wire routing is essential to prevent

wire chafing while raising and lowering elements.

Pin Pusher— P/N 807-0928

Place wrench here when removing and installing

high-limit.

1-9

Page 14

1.8 Replace Frypot

1. Perform Procedure 1.5, Replace Temperature Probe, Steps 1-7.

2. Perform Procedure 1.2, Replace Computer/Controller, Steps 1-6.

3. Disconnect the wire harness containing the high-limit wires.

4. Use a pin-pusher to remove the high-limit wires from the wire harness connector.

5. Remove the high-limit from the frypot.

6. Disconnect the wire-harnesses connected to the contactor box.

7. Remove the screws securing the capping piece from the fryer. Remove the capping piece and set

aside. It may be necessary to remove the wiring covers from the front of the contactor box.

8. If the fryer has a built-in filtration system, remove all the plumbing from the frypot, including

rear-flush and square-drain plumbing.

9. Remove the screws securing the frypot to the front frame of the fryer.

10. Carefully lift the frypot from the cabinet.

11. Remove the drain valve from the old frypot and install on the new frypot.

12. Apply Loc-Tite Sealant PST 567 to the high-limit threads. Install the high-limit into the new

frypot.

13. Disconnect the tilt plate springs from the old frypot.

14. Remove the securing screws from the tilt plate. Lift the tilt plate/heating element assembly from

the old frypot and install on the new frypot.

15. Follow the preceding steps in reverse to install the new frypot into the fryer.

16. NOTE: Apply Loc-Tite Sealant PST 567 to all pipefittings prior to installation.

1.9 Replace Contactor

1. Perform Procedure 1.4, Replace Temperature Probe, Steps 1-3.

2. Remove the screws securing the bottom and center rear access covers. Set the screws and covers

aside.

1-10

Page 15

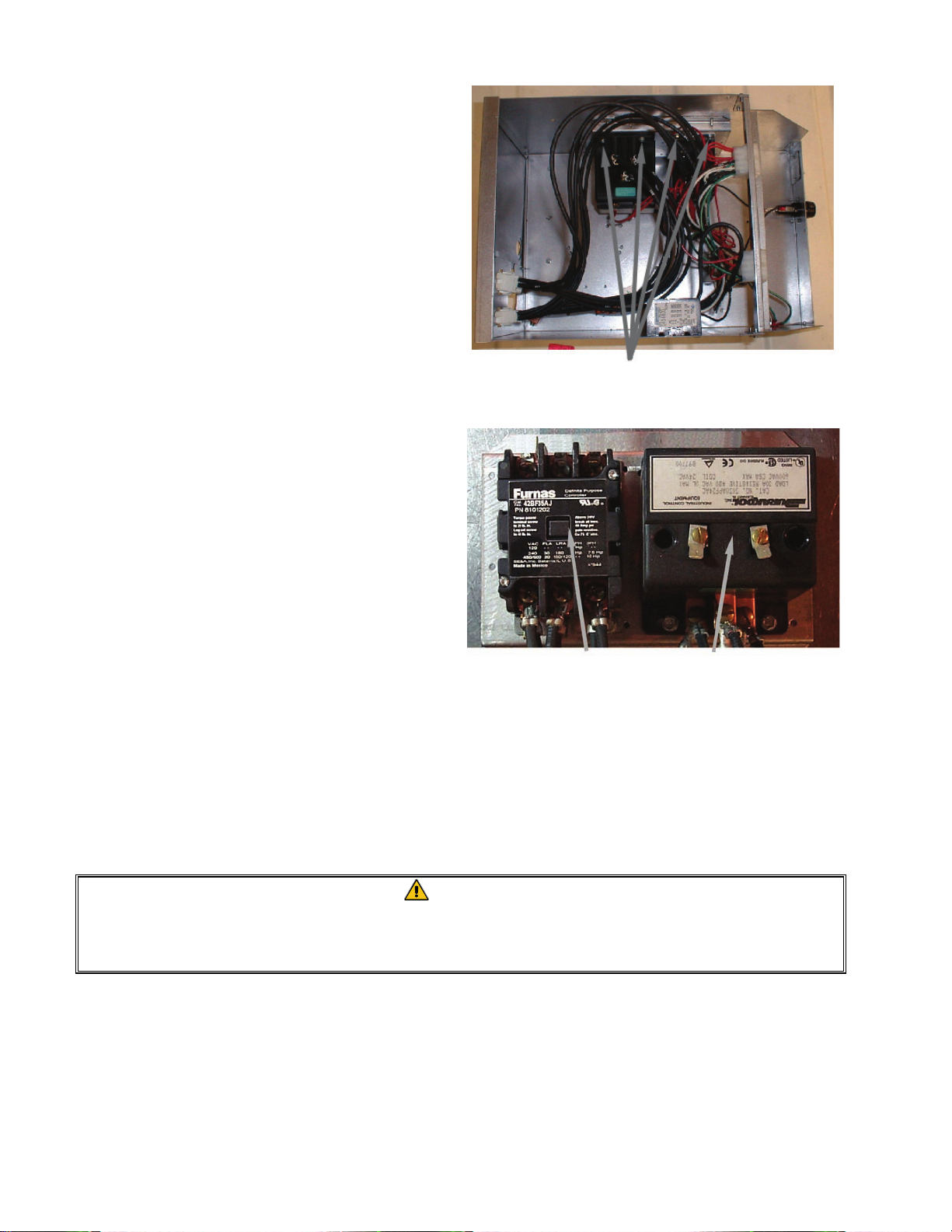

3. If present, remove the screws securing the

wiring covers to the front of the contactor box

(optional on old-style contactor boxes). Set

the screws and covers aside.

4. Disconnect the wire harnesses from the front

and rear of the contactor box.

5. Remove the screws securing the contactor

box to the bottom frame of the fryer.

6. Pull the contactor box through the access

opening in the rear of the fryer.

7. Remove the screws securing the contactor

box cover. Set the screws and covers aside.

8. Remove all wiring connected to the contactor

terminals inside the contactor box. Mark

each wire for re-assembly.

Screws securing wire cover to contactor box

(optional on old-style contactor boxes)

Screw location securing contactor box to bottom

frame

Mark each wire for re-assembly, then remove all

wiring connected to the contactor(s) to be replaced.

1-11

Page 16

9. Remove the contactor mounting screws and

remove the contactor.

10. Install the new contactor and connect the

wiring removed in Step 8.

11. Install the contactor box by following the

previous steps in reverse order.

Contactor mounting screws

Latching Contactor

Mercury Contactor

1.10 Built-in Filter System Service Procedures

Filtration Problem Resolution

One of the most common errors is placing the filter paper on the bottom of the filter pan rather than

over the filter screen.

CAUTION

Ensure that filter screen is in place prior to filter paper placement and filter pump

operation. Improper screen placement is the major cause of filter system

malfunction.

Whenever the complaint is “the pump is running, but no oil is being filtered,” check the installation

of the filter paper, and ensure that the correct size is being used. While you are checking the filter

paper, verify that the O-ring on the bottom of the filter pan is present and in good condition. A

missing or worn O-ring allows the pump to take in air and decreases its efficiency. Also, oil leaks

on the floor each time a vat is drained.

1-12

Page 17

If the pump motor overheats, the thermal overload will trip and the motor will not start until it is

reset. If the pump motor does not start, press the red reset switch (button) located on the rear of the

motor.

If the pump starts after resetting the thermal

overload switch, then something is causing the

motor to overheat. A major cause of overheating

is when several frypots are filtered sequentially,

thus overheating the pump and motor. Allow the

pump motor to cool at least 30 minutes before

resuming operation.

Pump overheating can be caused by:

• Solidified shortening in the pan or filter

lines,

or

• Attempting to filter unheated oil or

shortening.

Cold oil and shortening are more viscous,

causing the pump motor to load up and overheat.

If the motor runs but the pump does not, there is

a blockage in the pump. Incorrectly sized or

installed paper/pads will allow food particles and

sediment to pass through the filter pan and into

the pump. When sediment enters the pump, the

gears bind, causing the motor to overload, again

tripping the thermal overload. Shortening that

has solidified in the pump will also cause it to

seize, with the same result.

A pump seized by debris or hard shortening can

usually be freed by manually moving the gears

with a screwdriver or other instrument.

Disconnect power to the filter system.

Remove the input plumbing from the pump.

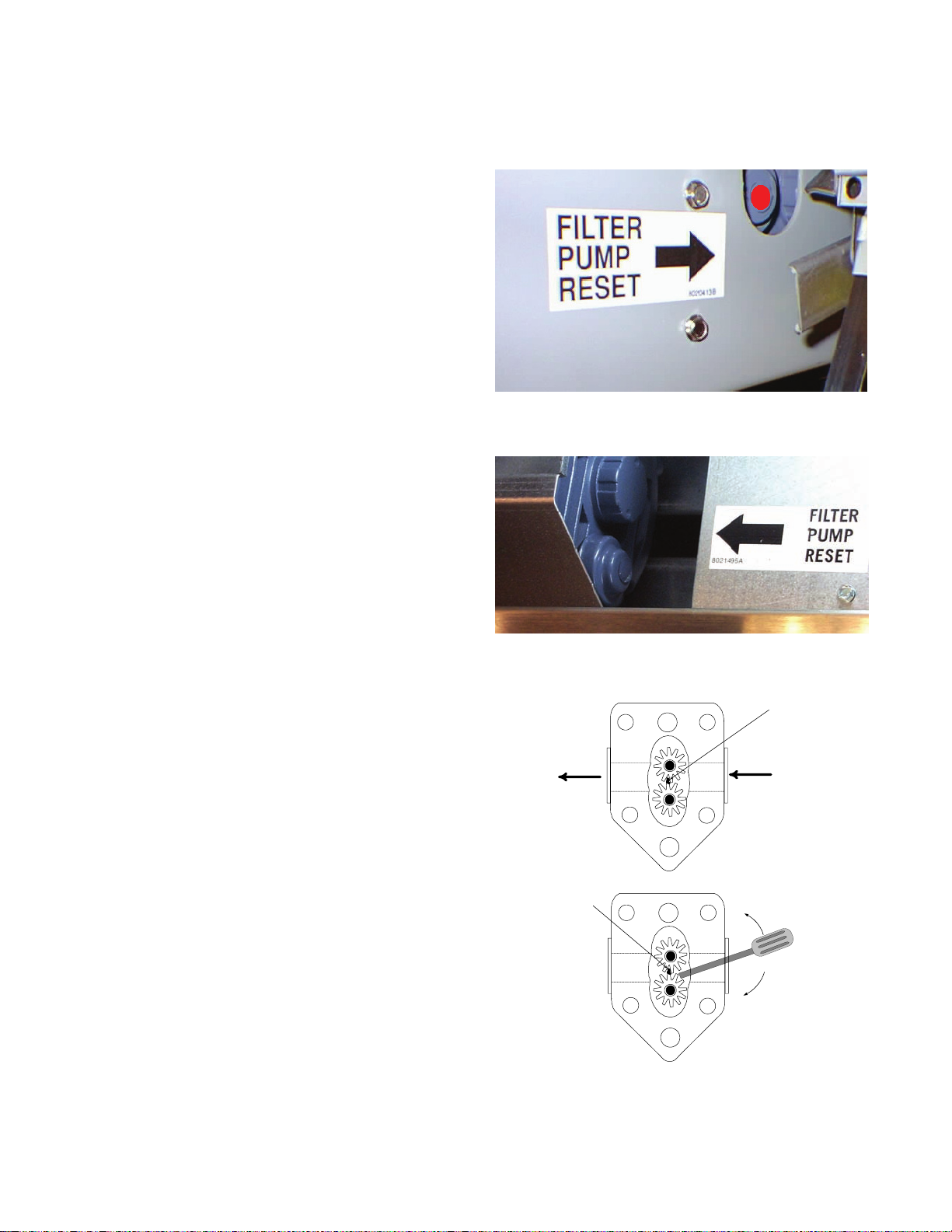

Reset switch location: Old-style FPIII

Reset switch location: New-style FPIII

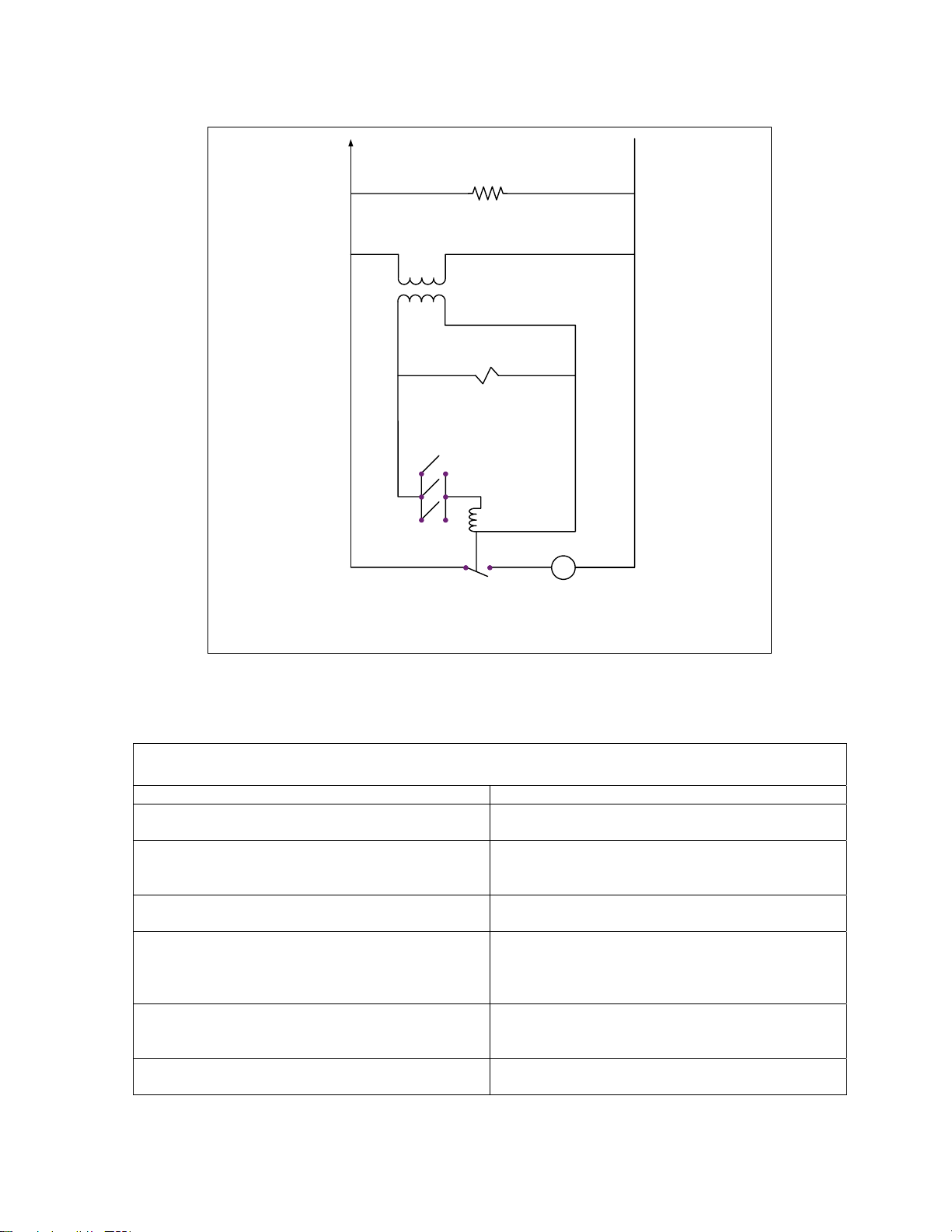

Sediment Particle

Sediment Particle

Oil Flow

Up for reverse

Down for forward

1-13

Freeing a seized pump.

Page 18

Use a screwdriver to manually turn the gears, in which:

● Turning the pump gears in reverse will release a hard particle.

● Turning the pump gears forward will push softer objects and solid shortening through the

pump and allow free movement of the gears.

Incorrectly sized or installed paper/pads will also allow food particles and sediment to pass through

and clog the suction tube on the bottom of the filter carriage. Particles large enough to block the

suction tube may indicate that the crumb tray is not being used.

Pan blockage can also occur if shortening is left in the pan and allowed to solidify. The heater strip

on the suction tube is designed to prevent residual shortening from solidifying in the tube. Heater

strips do not prevent residual shortening from solidifying in the pan.

Blockage removal can be accomplished by forcing the item out with an auger or drain snake.

Compressed air or other pressurized gases should not be used to force out the blockage.

For FootPrint III systems built before October, 1999, all heater tapes are wired directly into the line

VAC source (see wiring diagram, page 1-15). They remain energized as long as the unit is plugged

in. In systems built in October, 1999 and later, oil return line heater tapes have been eliminated. In

these units, the only heater tape used is on the suction tube and pump. This tape is still wired

directly into the line voltage. A pair of vacuum-breaking solenoids is wired into the 24 VAC circuit.

The redesigned FPIII is distinguished from the original design by the absence of casters on the filter

base assembly. The redesign incorporated an improved oil return system that allows oil/shortening

to drain back to the filter pan when the filter system is turned off, eliminating the need for most

heated oil return components.

1-14

Page 19

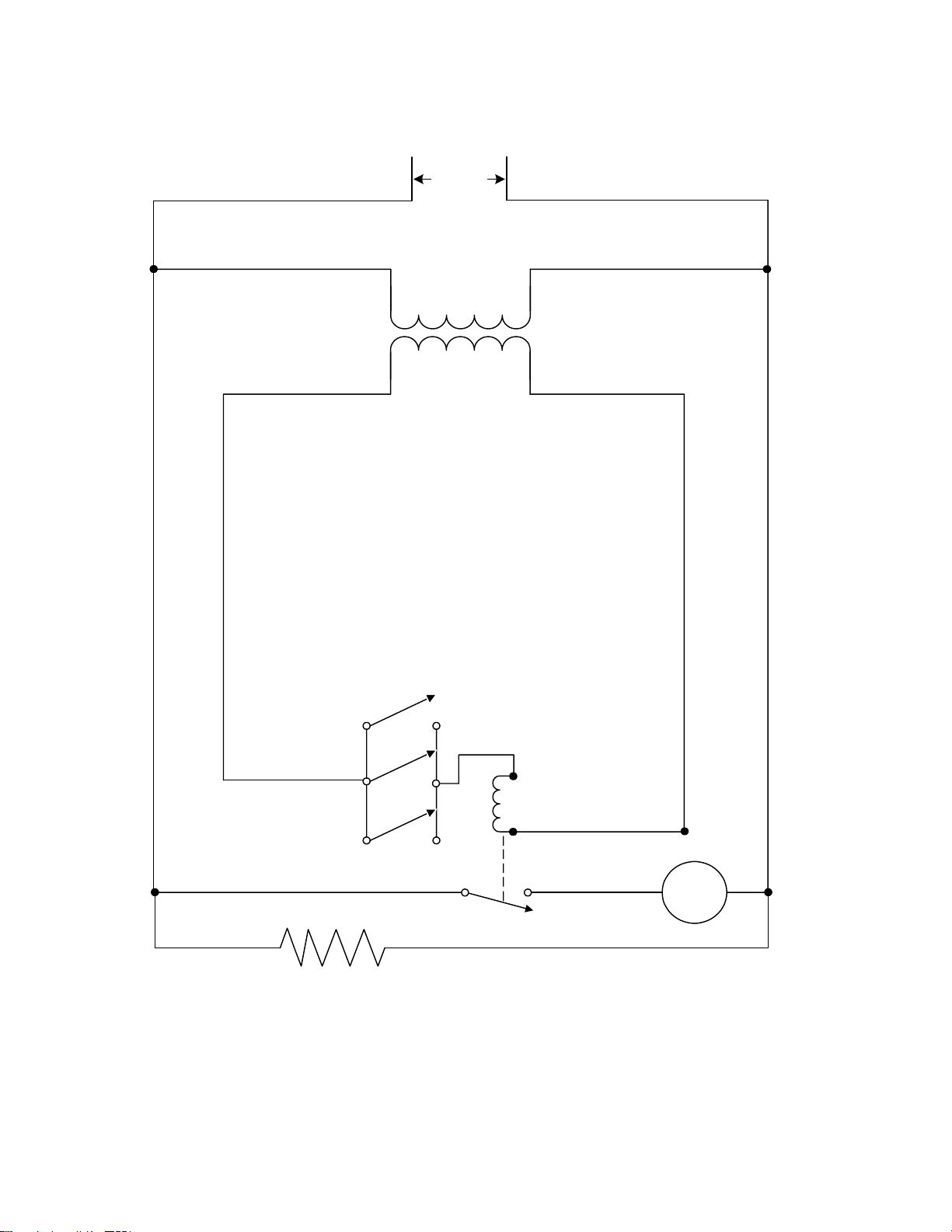

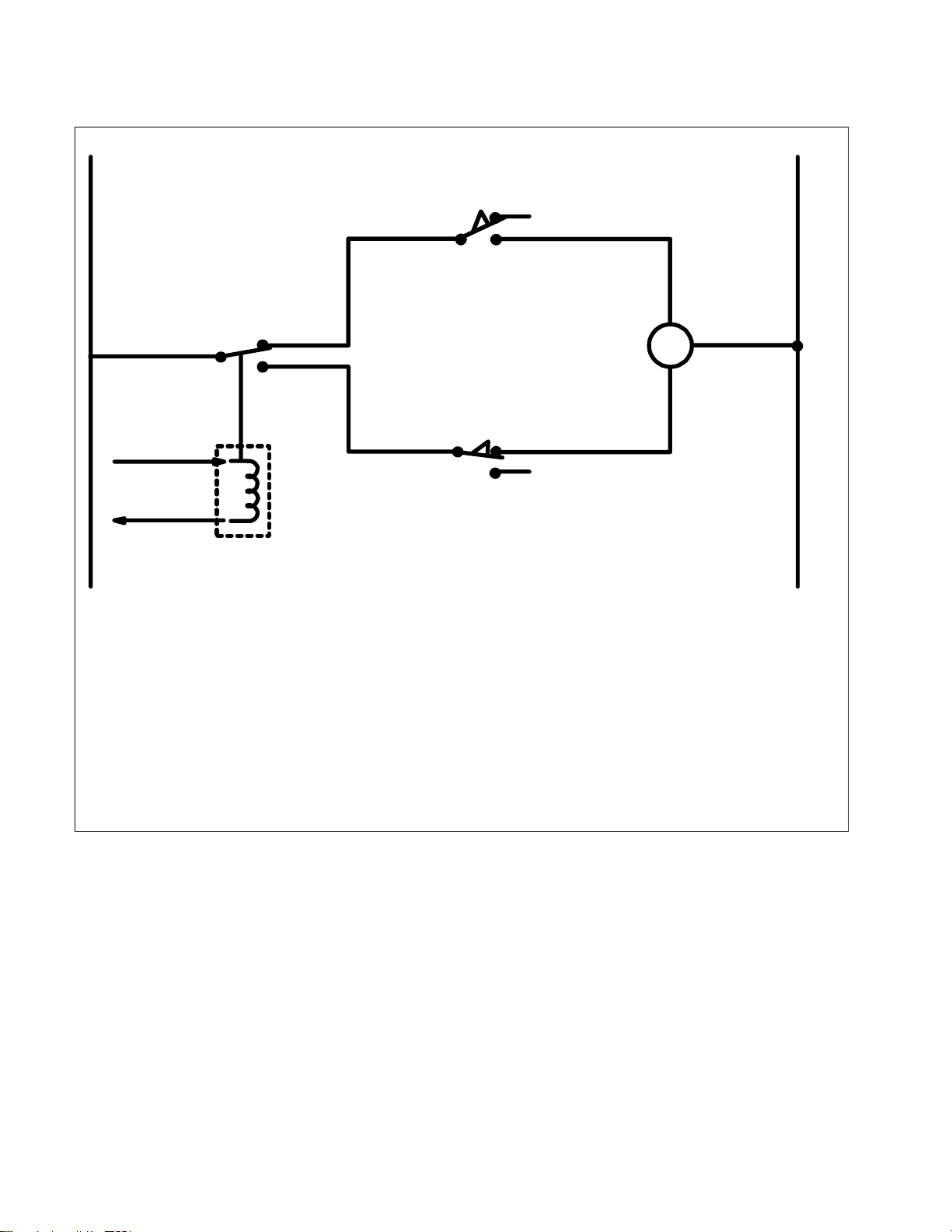

Line

VAC

All Heater Tapes (Original and

Redesigned Models)

(Heater Tapes have been removed from

return lines in Redesigned Models)

24

VAC

Solenoids

(Redesigned Models Only)

Micro-switches

Pump Relay

Coil

Pump Motor

M

Pump Motor Switch

FootPrint III Wiring Diagram

Operation of the redesigned FP-III system is the same as for the original design.

ORIGINAL VS REDESIGNED FP-III FILTRATION SYSTEM

Original System Redesigned System

Return lines and manifolds wrapped with silicone

strip heaters and aluminum tape.

Filter base assembly connected to unit with a

black, heated return hose beneath the filter.

Filter base assembly equipped with swivel

casters.

Operator-removable filter base assembly. (Filter

base assembly stop-locks in cabinet can be

rotated to remove tray.)

Oil/shortening remains in return lines when filter

system is turned off.

Return drain-manifolds are constructed with pipe

nipples, elbows and other plumbing components.

No heater strips or aluminum tape on return

lines.

Non-heated Teflon hose with a swivel joint

connects the filter base assembly to the unit

above the filter.

Filter base assembly has no casters.

Filter base assembly is not removable except by

a qualified service technician. (Filter base

assembly stop-locks fitted with a screw and nut

to prevent filter removal.)

Oil/shortening drains back to the filter pan when

filter system is turned off, leaving no oil or

shortening in return lines.

Return drain manifolds are one-piece with an inline solenoid valve to facilitate drain to filter pan.

1-15

Page 20

Line VAC

Transformer

24VAC

Microswitches

Pump Relay Coil

Pump Motor

M

Relay Contacts

Pump Heater

Filter Magic Simplified Wiring Diagram

1-16

Page 21

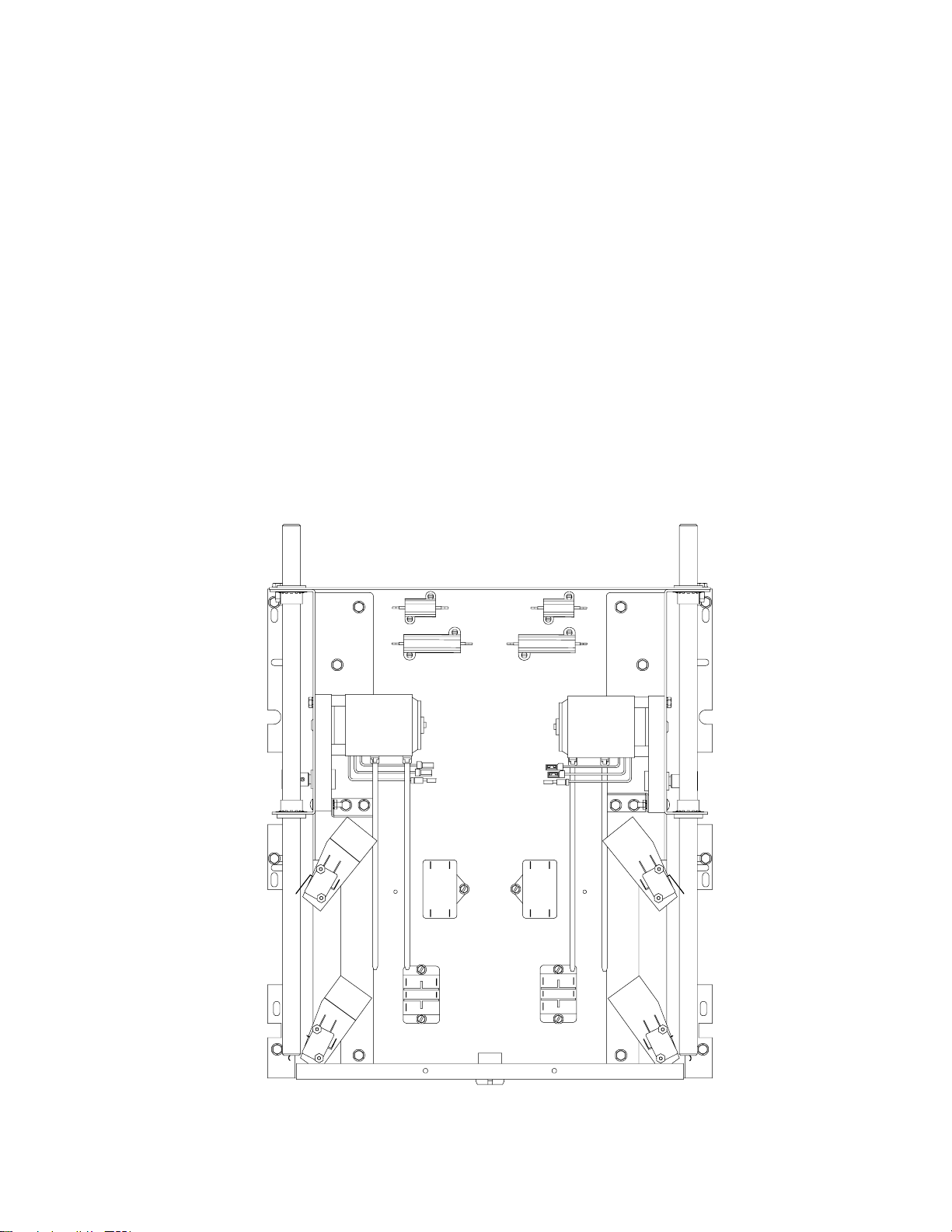

1.11 Basket Lift Service Procedures

H14/H17/H22 Series fryers may optionally be equipped with automatic basket lifts to ensure

uniform cooking times. Basket lifts will always come in pairs, although each operates

independently.

All electric fryers are equipped with “modular” basket lifts.

A modular basket lift (illustrated below) consists of a toothed rod to which the basket lift arm is

attached, a reversible-drive gear motor, and a pair of roller-activated microswitches. The gear motor

engages the teeth in the rod, moving it up or down, depending upon the direction of rotation of the

motor. Microswitches at the upper and lower limits of movement stop the motor when the basket is

in the full up or full down position.

Timing circuitry in the controller initiates and stops basket lift operation depending upon the

variables programmed by the operator. When the product button is pressed, the timing circuitry

activates a coil in the basket lift relay to supply power to the lower microswitch. The microswitches

stop the motor at the lift’s upper and lower travel limits and reverse the direction of current flow thus

reversing the motor direction.

Modular Basket LIft Assembly (Typical)

1-17

Page 22

Simplified Schematic

H

5

1 or 4

3

To computer/controller via

interface board

Basket Lift

Relay

Normally Open Upper-limit

Microswitch

M

Normally Closed Lower-limit

Microswitch

N

6

When the product button is pushed on the computer/controller, current flows through a coil

in the basket lift relay, causing the lower circuit to be activated. The basket lift lowers,

closing the normally open upper-micro-switch. When the lower normally closed microswitch is opened by the downward moving lift rod, power to the motor ceases to flow.

When the computer/controller times-out, the current to the relay coil is cut, allowing the

upper circuit to be activated. The basket lift then raises and re-closes the lower microswitch. When the basket lift rod clears the upper micro-switch, the micro-switch reopens

and power to the circuit is cut and the motor stops. Pushing the product button restarts the

cycle.

Problems with the modular basket lift design can be grouped into three categories:

●

Binding/jamming problems

● Motor and gear problems

Electronics problems

●

1-18

Page 23

BINDING/JAMMING PROBLEMS

Noisy, jerky or erratic movement of the lifts is usually due to lack of lubrication of the rods and their

bushings. Apply a light coat of Lubriplate® or similar lightweight white grease to the rod and

bushings to correct the problem.

With the modular basket lift, another possible cause of binding is improper positioning of the motor,

which prevents the gear from correctly engaging the teeth in the rod. To correct the problem, loosen

the screws that hold the motor in place and move it forward or backward until the rod has just

enough slack to be rotated slightly.

MOTOR AND GEAR PROBLEMS

With the modular basket lift, the most likely problem to be encountered in this category is erratic

motion of the lift due to a worn drive gear. Failure to keep the lift rod and bushings properly

lubricated will cause unnecessary wear of the gear. The problem is corrected by replacing the worn

gear.

If the lift cycles correctly but fails to remain in the up position (i.e., goes up, but then slowly settles

back down into the frypot), the problem is a failed motor brake. A failed motor brake cannot be

repaired and requires replacement of the motor itself.

If power is reaching the motor but the motor fails to run, the motor is burned out and must be

replaced.

ELECTRONICS PROBLEMS

Within this category are problems associated with the relays, microswitches, capacitors, resistors,

interface board, wiring, and controls. The most common problem in this category is a lift that

continuously travels up and down. This is usually caused by a microswitch that is out of adjustment.

Troubleshooting the electronics of a modular-type basket lift is simply a process of verifying current

flow through the individual components up to and including the motor. Using a multimeter set to the

250 VAC range, check the connections on both sides of the component for the presence of the

applied line voltage. The accompanying simplified wiring diagrams identify the components and

wiring connection points.

1-19

Page 24

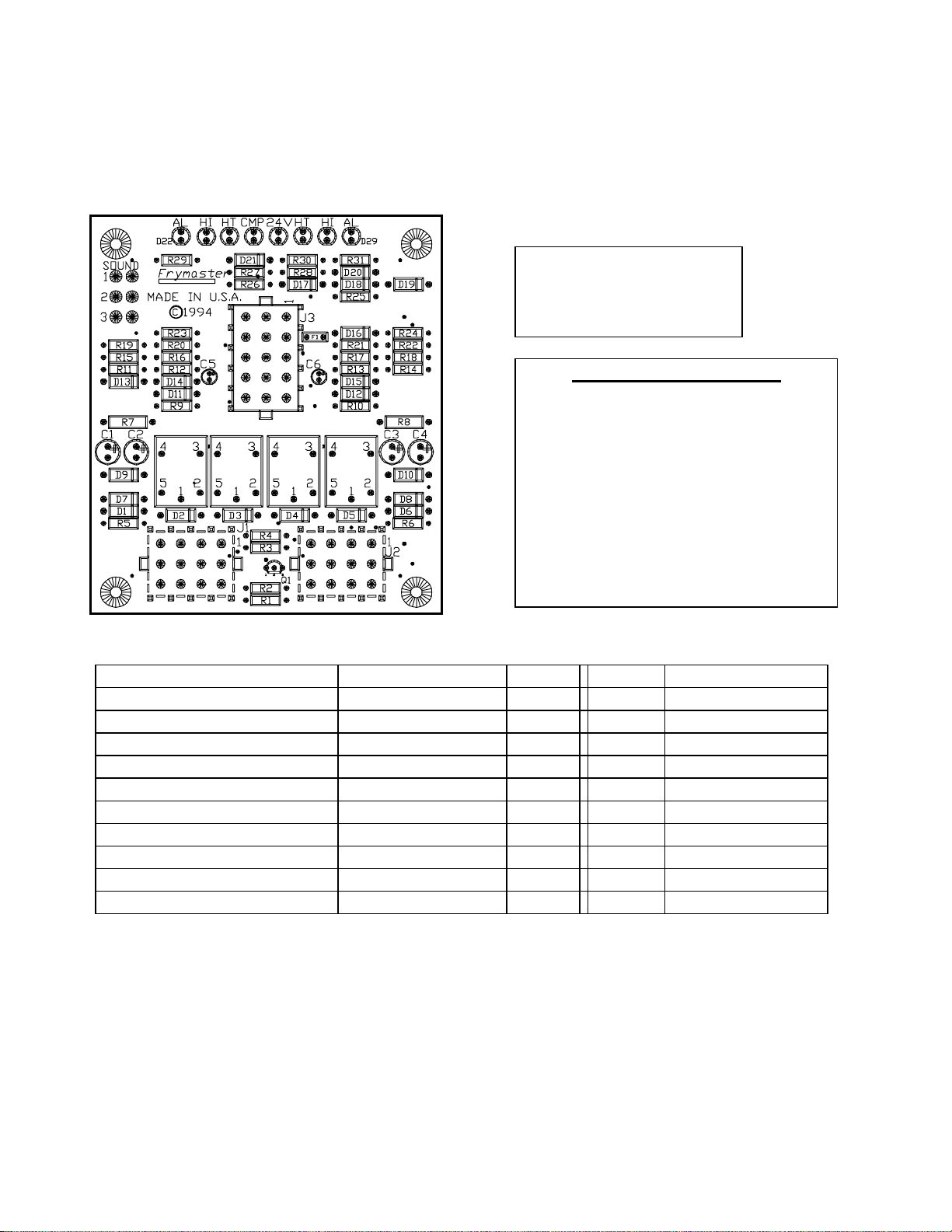

1.12 Electric Interface Board Diagnostic Chart

The following diagram and charts provide ten quick system checks that can be performed using

only a multimeter.

Note: The sealed relays

are not replaceable. If a

relay fails the interface

1

K1

11

12

23

6

5

4

8

7

9

12

11

10

13

15

14

K2

4

7

10

5

8

6

9

1

2

3

K3 K4

10

11

12

4

1

7

5

2

8

6

3

9

board must be replaced.

Diagnostic LED Legend

CMP indicates power from 12V transformer

24 indicates power from 24V transformer

HI (RH) indicates output (closed) from right latch

relay

HI (LH) indicates output (closed) from left latch

relay

HT (RH) indicates output from right heat relay

HT (LH) indicates output from left heat relay

AL (RH) indicates output (open) from right latch

relay

AL (LH) indicates output (open) from left latch

relay

Meter Setting Test Pin Pin Results

12 VAC Power 50 VAC Scale 1 of J2 3 of J2 12-16 VAC

24 VAC Power 50 VAC Scale 2 of J2 Chassis 24-30 VAC

*Probe Resistance (RH) R X 1000 OHMS 11 of J2 12 of J2 See Chart

*Probe Resistance (LH) R X 1000 OHMS 3 of J1 2 of J1 See Chart

Hi-Limit Continuity (RH) R X 1 OHMS 7 of J2 4 of J2 0 - OHMS

Hi-Limit Continuity (LH) R X 1 OHMS 4 of J1 7 of J1 0 - OHMS

Latch Contactor Coil (RH) R X 1 OHMS 8 of J2 Chassis 3-10 OHMS

Latch Contactor Coil (LH) R X 1 OHMS 5 of J1 Chassis 3-10 OHMS

Heat Contactor Coil (RH) R X 1 OHMS 9 of J2 Chassis 18-25 OHMS

Heat Contactor Coil (LH) R X 1 OHMS 6 of J1 Chassis 18-25 OHMS

*Disconnect 15-Pin harness from the computer/controller before testing the probe circuit.

1-20

Page 25

1.13 Simplified Wiring Diagrams, Common Electric

CONTROL CIRCUIT

COMMON ELECTRIC H14/H17/H22 SERIES— FULL-VAT

FUSES

312

GND

3 PHASE POWER TERMINALS

1C

LATCHING

CONTACTOR

2

3

2C

1

HEATING

CONTACTOR

L3

L2

HT

C6-8

J2-9

SD

COMPUTER/CONTROLLER

J3

11

11

HEAT

4

4

T

M

L1

J2

C1-8

J2-8

HI

K3

HEAT

RELAY

C6

TEMP

PROBE

HIGH

LIMIT

24V

12V

7

6

24V

DRAIN

SAFETY

FIRE

CUT-OFF

11 122147

FUSE

SWITCH

3

10

J2

24V

AL

K4

LATCH

RELAY

COMP

13

14

14

10

10 13

5

3

3

1

1

2

25

TROUBLE

ON/OFF

POWER ON

J3

1-21

INTERFACE

BOARD

Page 26

L3

L2

GND

312

1C

LATCHING

CONTACTOR

3

2

2C

1

HEATING

CONTACTOR

C6-8

SD

3 PHASE POWER TERMINALS

L1

J2-8

C6

TEMP

PROBE

67

11 121

24V

HIGH

LIMIT

12V

HIGH

LIMIT

DRAIN

DRAIN

2

SAFETY

SWITCH

47

3

SAFETY

SWITCH

7

HI

24V

COMP

J2-5

K3

HEAT

RELAY

AL

K4

LATCH

RELAY

J2-9

HT

J3

11

11

4

14 1310

5

3

1

HEAT

T

M

14 4

10 13

5

3

1

TROUBLE

ON

POWER

ON

POWER

TEMP

COMMON ELECTRIC H14/H17/H22 SERIES— DUAL-VAT

4

J1 J2

PROBE

1213

C6

32

J1

J2-10

HI

J1-5

K1

LATCH

RELAY

AL

K3

HEAT

RELAY

HT

J1-6

2

2614

12

14

15

15 12

6

J3

TROUBLE

T

M

HEAT

C6-14

HEATING

2

3

3C

LATCHING

CONTACTOR

1

2

3

1

CONTACTOR

4C

COMPUTER/

CONTROLLER

1-22

Page 27

COMMON ELECTRIC H14/H17/H22 SERIES- TRIAC— FULL-VAT

FUSES

CONTROL CIRCUIT

3 PHASE POWER TERMINALS

L3

L2

L1

GND

TEMP

HIGH

2C

C1-11

HT

HEATING TRIACS

C1-9

C6-9

SD

C6-8

COMPUTER/

CONTROLLER

J3

J2-9

11

11

HEAT

4

4

T

M

312

J2

1C

C1-8

HI

LATCHING

CONTACTOR

J2-8

hi relay

J2-5

C6

PROBE

7

6

11 122147

24V

24V

FUSE

24V

LIMIT

12V

DRAIN

SAFETY

SWITCH

3

10

FIRE

CUT-OFF

COMP

K4

AL

LATCH

RELAY

J2

13

13

14

14

10

10

5

5

3

3

1

1

2

2

TROUBLE

ON/OFF

POWER ON

J3

1-23

INTERFACE

BOARD

Page 28

Burn-off Relay option was

discontinued on all Common

Electric fryers manufactured after

mid-98, and is no longer required

for use.

C

GND

312

N

1C

LATCHING

CONTACTOR

2

3

L3

2C

1

HEATING

CONTACTOR

TILT SWITCH

L2L1

NO

BURN-OFF RELAY

NC

COMMON ELECTRIC H14/H17/H22 SERIES— FULL-VAT— EXPORT WYE

3 PHASE POWER

TERMINALS

TEMP

HIGH

C1-8

J2

HI

24V

HI RELAY

J2-8

COMP

K3

HEAT

RELAY

AL

K4

LATCH

RELAY

12 VDC

Control Circuit

Fuses

C6

12

7

PROBE

6

11

24V

LIMIT

12V

21

DRAIN

SAFETY

SWITCH

7

4

3

FIRE

10

CUT-OFF

J2

HT RELAY

SD

J3

11

11

J2-6

J2-9

J2-5

HT

HEAT

4

4

13

13

14

14

1/50

1K

47K

A

4.7K

10

10

5

5

7

7

3

3

1

1

2

2

T

M

TROUBLE

BURN

OFF

POWER ON

COMPUTER/CONTROLLER

ON/OFF

J3

1-24

INTERFACE

BOARD

Page 29

C

NO

RELAY

BURN-OFF

NC

M

Burn-off Relay option was discontinued on all Common Electric fryer s

manufactured after mid-98, and is no longer required for use.

COMPUTER/CONTROLLER

T

M

L3

GND

312

1C

LATCHING

CONTACTOR

3

2

2C

1

HEATING

CONTACTOR

TILT

SWITCH

L2

L1

TERMINALS

TEMP

HIGH

HIGH

N

J2-8

HT

K3

HEAT

RELAY

C6

PROBE

67

11 121

24V

FUSE

24V

LIMIT

12V

2

DRAIN

SAFETY

SWITCH

47

3

J2

LIMIT

DRAIN

SAFETY

SWITCH

7

4

HI

24V

COMP

AL

K4

LATCH

RELAY

K1

LATCH

RELAY

1/50

10K

3 PHASE POWER

J1

1/50

TEMP

PROBE

1213

C6

J1 32

HI

AL

SD

J2-6

J3

J2-9

J2-5

1K

47K

A

A

1K

47K

11

11

4

4

1310

14

14

10 13

5

5

3

3

1

1

9

9

2

2614

12

14

15

15 12

6

HEAT

T

TROUBLE

BURN

OFF

POWER

ON

BURN

OFF

POWER

ON

TROUBLE

COMMON ELECTRIC McDONALD'S H14 SERIES— DUAL-VAT— EXPORT WYE

K2

HEAT

J2-10

2

3

J1-5

1

3C

LATCHING

CONTACTOR

3

RELAY

HT

J1-6

2

1

J3

HEAT

J1-9

C

NO

TILT

RELAY

4C

HEATING

CONTACTOR

SWITCH

BURN-OFF

NC

1-25

Page 30

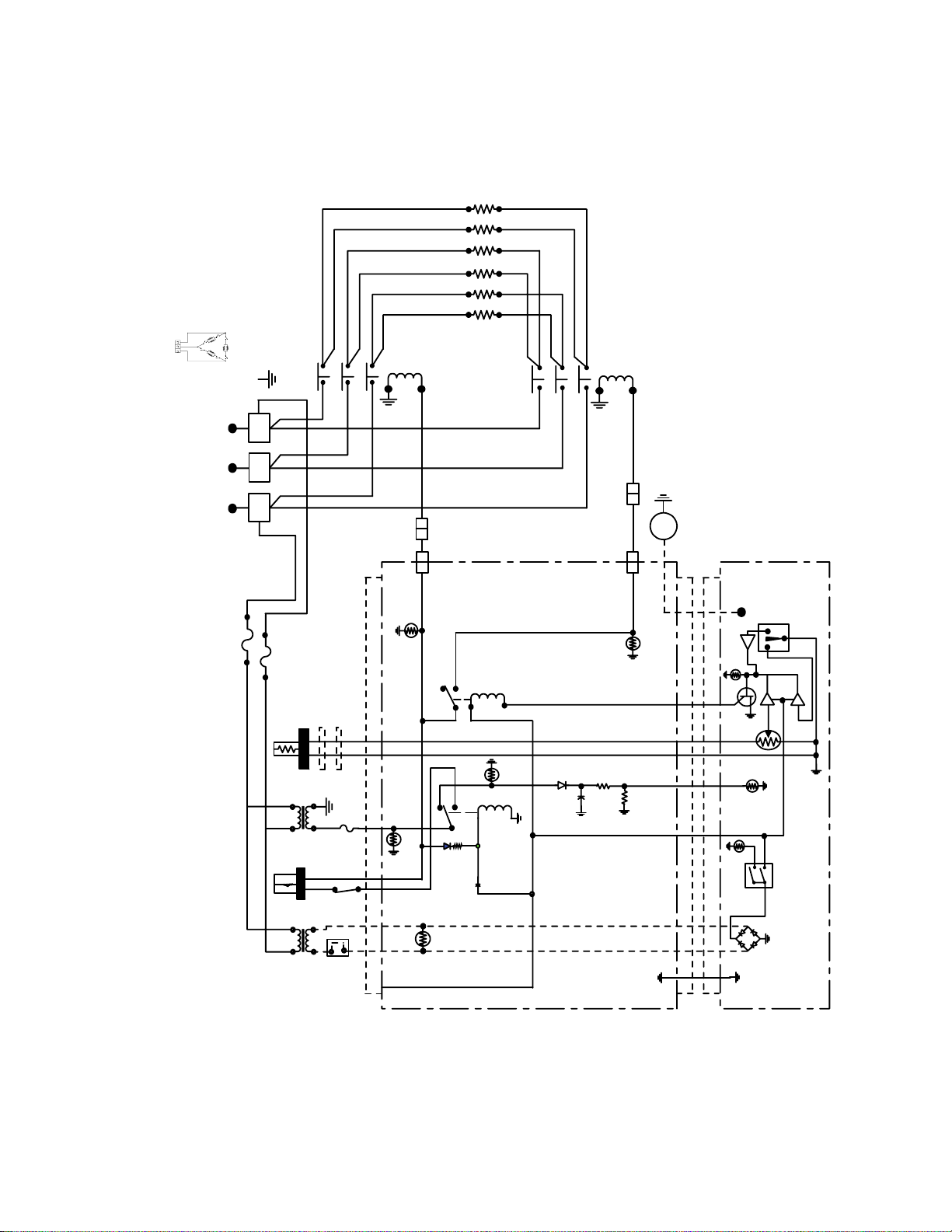

1.14 Wiring Diagrams, Main

Domestic Wiring Diagram

1-26

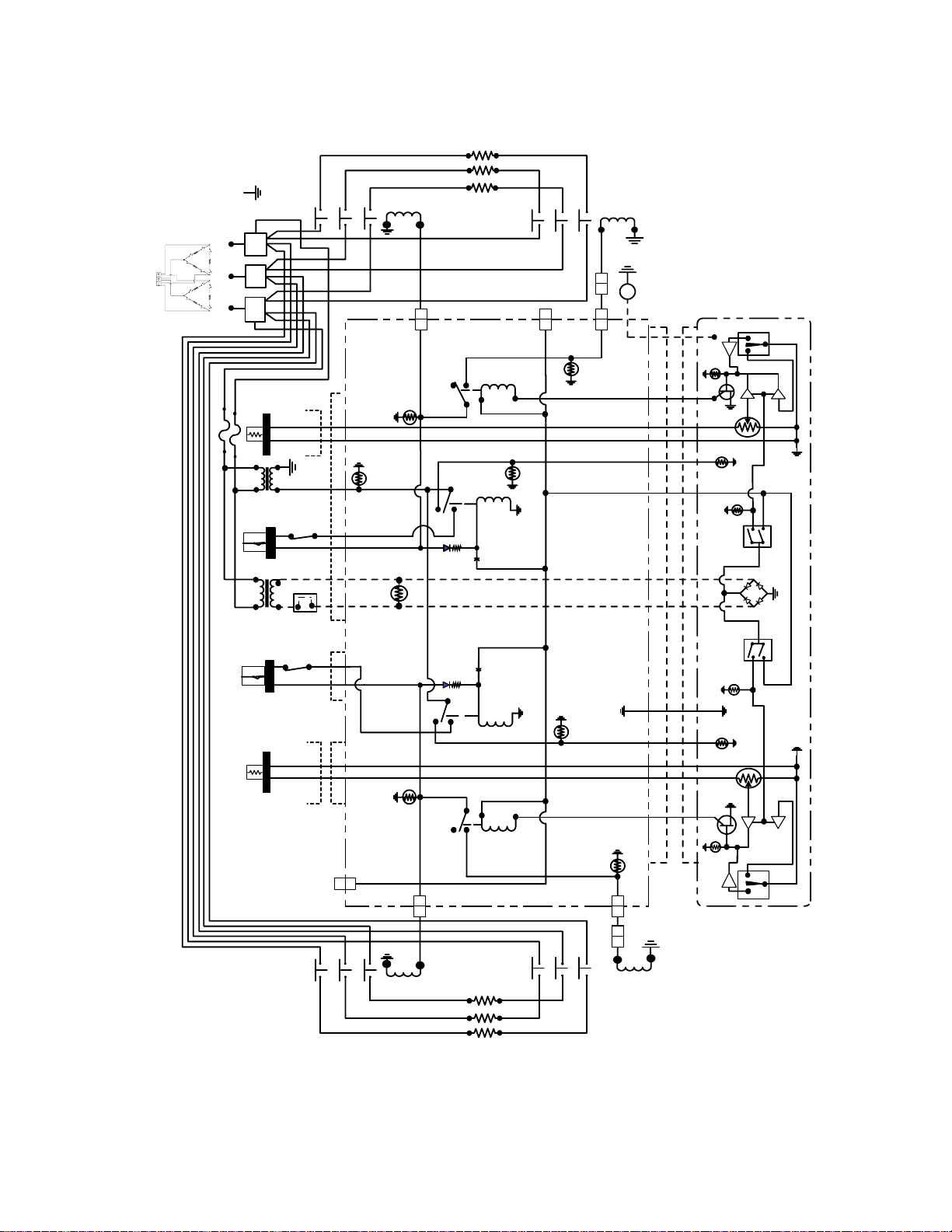

Page 31

FPH114/117/122 CE Wiring Diagram

1-27

Page 32

Delta Wiring Diagram

1-28

Page 33

WYE Wiring Diagram

1-29

Page 34

Delta 480V Non-filter Wiring Diagram

1-30

Page 35

Delta 480V With FootPrint/Filter Magic II Wiring Diagram

1-31

Page 36

1.15 Wiring Diagrams, Basket Lifts

Modular Basket Lift, 100—120V w-Relay Wiring Diagram

1-32

Page 37

1.15 Wiring Diagrams, Basket Lifts (cont.)

Modular Basket Lift, 208—250V w-Relay Wiring Diagram

NOTE: Some units will have four 50ohm resistors rather than two 100ohm resistors.

1-33

8050888C

Page 38

1.16 Wiring Diagrams, Filtration Systems

Filter Magic II (Prior to October 98)

Eliminated on Filter Magic

II systems manufactured

after 10/98

1-34

Page 39

Filter Magic II (October 98 and later)

1-35

Page 40

Footprint III, Early Configuration.

3C

NOTE: REFER TO ABOVE CHART

FOR LINE VOLTAGE CONNECTIONS

24

56

3

1

32C

12C

RED

1 2 4 5 6

78

LINE

LOAD

12 1011 9

9

6

852

74

RED

8C

41C

30C

3

1

45C

52C

RED

NOTE: USE TERMINALS 7 AND 8 FOR 24V OUTPUT.

USE TERMINALS 11 AND 12 FOR 12V OUTPUT.

92C

TO PIN 7

TO PIN 9

VOLTS LINE

100

9

7

8

4

6

5

3

2

1

TO PIN 4

TO PIN 6

TO PIN 1

TO PIN 3

12011

208

220

230

BLACK

WHITE

BLACK

WHITE

10C

11C

9C

62C

T2T1

COM

1

1

1

1240

HOSE

HEATER

4

6

2

4

5

6

PUMP

HEATER

LINE

HEATER

(OPTIONAL)

FILTER WIRING DIAGRAM

NON-REVERSING PUMP

Footprint III, Late Configuration

13

24

108C

11C

RED

RED

12C

LINE

9C

26C

13C

TO PUMP

MOTOR

8050538H

TO PIN 1

TO PIN 3

TO PIN 7

TO PIN 9

32C

45C

52C

T-4

24V/50VA

PUMP

HEATER

PUMP

SOLENOID

T2T1

14C

92C

62C

10C

3

6

2

5

147

4

7

8

5

9

6

9

8

27C

51C

1

2

3

8C

41C

30C

13C

FILTER BOX WIRING DIAGRAM

1-36

26C

9C

TO PUMP

MOTOR

8050902C

Page 41

H14/H17/H22 SERIES ELECTRIC FRYERS

2.1 Accessories

CHAPTER 2: PARTS LIST

1

3

4 5

2

6 7

ITEM PART # COMPONENT

1 803-0209 Brush, FV/DV Frypot

2 803-0046 Cup, Measuring, Plastic, #1040

3 803-0197 Fryer Friend 27-inch (Clean-out Rod)

4 803-0099 Basket, Full-vat

* 803-0271 Basket, Dual-vat

5 803-0113 Sediment Tray, Full-vat

* 803-0122 Sediment Tray, Dual-vat, Left

* 803-0123 Sediment Tray, Dual-vat, Right

6 803-0106 Rack, Electric Dual-Vat Basket Support

7 803-0132 Rack, H50 Full-Vat With Probe Guard Basket

* 803-0002 Carton, Filter Powder

* 803-0170 Filter Pack– 100 Sheets

* 806-3068 Cover, Full Vat Frypot

* 806-3071 Cover, Dual Vat Frypot

* Not illustrated.

2-1

Page 42

2.2 Basket Lift Assemblies and Component Parts

15

16

2

14

1

8

5

6

12

7

3

10

11

13

9

4

2-2

Page 43

ITEM PART # COMPONENT

Common Components

1 813-0035 Bushing, Bronze, .640-inch ID

2 901-8499 Chassis, Modular Basket Lift, Left

3 902-8499 Chassis, Modular Basket Lift, Right

4 807-0158 Connector, 6-Pin Female, Panel Mount

5 900-5529 Gusset, Modular Basket Lift Motor

6 812-0442 Insulation, Microswitch

7 807-2572 Microswitch

8 806-5964SP Motor Assembly, Modular Basket Lift

9 200-2942 Mount, MBL (for old mount w/6-pin plug use 900-7655)

10 809-0082 Ring, Retaining – Truarc

11 810-1012 Rod, Modular Basket Lift

* 823-2704 Left Basket Lift Arm

* 823-2705 Right Basket Lift Arm

12 807-2133

Capacitor, 12.5 μFarad, 250VAC Motor

Resistors

13 807-1683 Relay, 12V (All Basket Lifts w/Relays)

14 806-9185 Resistor Assembly, Modular Basket Lift (used in 806-8532SP)

15 806-8530 Resistor Assembly, Modular Basket Lift (used in 806-8531SP)

16

Resistor Assembly, Modular Basket Lift (see NOTE below)

106-2770 200-220V (used in 806-8086SP and 806-8685SP)

106-2771 230-250V (used in 806-8087SP and 806-8686SP)

Wire Assemblies

WIR00482 For 106-1807SP (for 6-pin MBL assembly 806-8531SP, use WIR0073SP)

WIR0292 For 806-8532SP

WIR0166 For 806-8086SP & 806-8087SP

806-8555SP For 6-pin assemblies 806-8685SP & 806-8686SP

106-1804SP For 12-pin assemblies 106-1809SP & 106-1810SP

Complete Assemblies

106-1807SP 100/120V w/o Relay (for 6-pin assembly, use 806-8531SP)

106-1808SP 100/120V w/Relay (for 6-pin assembly, use 806-8532SP

106-1809SP 200/208/220V w/o Relay (for 6-pin assembly, use 806-8685SP

106-1805SP 200/208/220V w/Relay (for 6-pin assembly, use 806-8086SP

106-1810SP 230/240/250V w/o Relay (for 6-pin assembly, use 806-8686SP

106-1806SP 230/240/250V w/Relay (for 6-pin assembly, use 806-8087SP

* Not illustrated.

NOTE: Item 16 replaces all previous resistors and resistor assemblies used in 200-250V modular

basket lifts.

2-3

Page 44

2.3 Cabinet Assemblies and Component Parts

2.3.1 H114/117/122 Cabinet Assembly, Single FootPrint and Non-Filter

8

6

3

4

7

1

2

5

2-4

Page 45

ITEM PART # COMPONENT

1 806-4910SP Rail Assembly, Single FootPrint

* 200-0129 Rail, Top Front Single Common Electric N/F

2 806-4897SP Base, Single FootPrint

* 806-7003SP Base Assembly, Single Common Electric, N/F

3 900-4393SP Brace, Top, Single FootPrint

4 900-4391SP Brace, Cabinet Front

* 900-2733 Brace, Contactor Box, Front, N/F

* 900-2734 Brace, Support Contactor Box, Common Electric, N/F

* 200-0130 Brace, Rear Horizontal, Common Electric, N/F

* 201-0137 Upright- rear enclosure, Common Electric, N/F

* 202-0137 Upright- rear enclosure, Common Electric, N/F

5 Side, Cabinet – Left Side

911-9314 Stainless Steel

901-9314 Enameled Steel

6 Side, Cabinet – Right Side

912-9314 Stainless Steel

902-9314 Enameled Steel

* 910-2456SP Cabinet Side, Common Electric N/F

7 900-1621 Plate, Rail Mount

8 910-2912 Back, Upper Cabinet, Single FootPrint

* 900-5204 Back, Cabinet, 22kW Single FP

* 900-4412 Bracket, Component, 22kW Single FP

* 900-2717SP Back, Upper Cabinet, Common Electric, N/F

* 900-5141 Back, Center Cabinet, MH114

* 900-8449 Back, Lower Cabinet with U-shaped Cutout

* 200-4581 Back, Lower Cabinet without U-shaped Cutout

* 910-7925 Leg, Cabinet, Front Filter

* 900-9585 Heat Shield, Wire, Common Electric

* 826-1374 Screw, #10-1/2 Hex Head (Pkg. of 25)

* 826-1389 Screw, ¼-20 x ¾ Hex Head (Pkg. of 10)

* 826-1334 Bolt, ¼-20 X 1 ¼ Hex Head (Pkg. of 5)

* 826-1368 Nut, Flange ¼-20 Serrated (Pkg. of 10)

* 809-0070 Nut, Hex ¼ x 20 SS

* 809-0191 Washer, Lock, ¼-inch

* Not illustrated.

2-5

Page 46

2.3.2 H114/117/122 Cabinet Assembly, Battered Option—Filter Ready

9

2

8

7

11

13

3

1

5

10

4

6

12

14

ITEM PART # COMPONENT

1 806-4897 Base, Single FP

2 806-5317 Filter Rail Assembly, Single FP

3 809-0361 Screw, 8 x ½ Hex

4 809-0412 Screw, #10-½ Hex

5 900-1786 Motor Mount, Cantilever Bracket

6 900-4391 Brace, Cabinet Front

7 900-4551 Motor Mount, Single FootPrint

8 900-4813 Brace, Cabinet Top Single

9 900-7448 Back, Top, FPH 50

10 901-1405 Gusset, Cabinet FP-TCF Left

11 902-1405 Gusset, Cabinet FP-TCF Right

12 910-8673 Leg, Front Filter w/Swivel Caster

13 Side, Cabinet, Left

911-9324 Side, Stainless Steel

901-9324 Side, Cold Rolled Steel

14 Side, Cabinet, Right

912-9324 Side, Stainless Steel

902-9324 Side, Cold Rolled Steel

* 910-0889 Cover, 4” x 4” S/S (for enameled steel, use 900-0889)

* 910-0890 Cover, 4” x 6” S/S (for enameled steel, use 900-0890)

* 809-0359 Screw, #8 x ¼” Hex Washer Head

* Not illustrated.

2-6

Page 47

2.3.3 Filter Magic Under-Counter Cabinetry (after 8/2000)

3

5

9

15

17

See Detail

2

14

7

12 16

1

10

6

8

Detail

11

ITEM PART # COMPONENT

1 201-0483 Side, Cabinet U/C Enameled – Left

2 202-0483 Side, Cabinet U/C Enameled – Right

* 211-0483 Side, Cabinet U/C Stainless Steel – Left

* 212-0483 Side, Cabinet U/C Stainless Steel – Right

3 806-8059 Leg Pad Assembly

4 806-8062SP Filter Rail Assembly, Common Electric FM

5 806-8935SP Base Assembly, FM 3-Piece

6 826-1362 Nut, ¼ - 20 Hex (Pkg. of 10)

7 826-1389 Screw, Hex Head ¼ -20 x ¾ (Pkg. of 10)

8 809-0191 Washer, ¼ Lock

9 826-1374 Screw, #10- ½ Hex Head (Pkg. of 25)

10 809-0429 Bolt, ¼ -20 x 2

11 810-0665 Nut, Leveling

12 823-2827 Mount (Weld Assembly), Common Electric Single FP

13 900-4391 Brace, Cabinet Front

14 900-4785 Brace, Cabinet – Top and Center

15 900-8582 Mount, Motor Single FP Common Electric

16 900-8591 Bracket, Mount Common Electric Single FP

17 910-8659 Leg, Cabinet Front Common Electric Single FP

* Not illustrated.

13

4

2-7

Page 48

2.3.4 FootPrint III, Filter Magic II and Non-Filter Options

4

27

28

1

23

8

3

30

24

21 7 8 13

22

See Detail A

26

See

Detail B

18

11 142

ITEM PART # COMPONENT

1 200-0076 Divider, Cabinet, Common Electric

2 200-0084 Brace, Rear Horizontal, 2 Battery (Quad and Double)

* 200-0085 Brace, Rear Horizontal, 3 Battery (Triple)

3 200-0091 Rail, Top- Quad Cabinet

* 200-0072 Rail, Top- Triple Cabinet

* 200-0081SP Rail, Top- Double Cabinet

4 200-0092 Support, Rear, Common Electric

5 200-0126 Brace, Rear Support

6 200-0138 Door Post, Common Electric

7 201-0093 Enclosure, Rear Upright with Hole (Quad Only)

8 201-0137 Upright, Rear Enclosure, Common Electric

9 202-0093 Enclosure, Rear Upright with Hole (Quad Only)

10 202-0137 Upright, Rear Enclosure, Common Electric

11 806-7005SP Base, Filter Assembly, Common Electric- Quad

* 806-6513SP Base, Filter Assembly, Common Electric- Triple

* 806-6511SP Base, Filter Assembly, Common Electric- Double

* 806-6997SP Base Assembly, Common Electric N/F- Double

* 806-6999SP Base Assembly, Common Electric N/F- Triple

* 806-7001SP Base Assembly, Common Electric N/F- Quad

12 826-1376 Nut, 10-32 (Pkg. of 10)

13 826-1374 Screw, #10 ½-Inch (Pkg. of 25)

Continued on following page.

5

32

Detail B

25

10

6

29

31

17 16

20

12

Detail A

19

15

2-8

Page 49

ITEM PART # COMPONENT

14 809-0413 Spacer, Door Post (Quad and Triple Only)

15 809-0422 Screw, Shoulder- 10-32 x .40

16 809-0538 Bolt, Shoulder- ¼-20 x 3/8

17 823-2290 Front Bridge Support, Left

18 823-2291 Front Bridge Support, Right

19 900-1957 Lock Filter

20 900-1959 Bracket, Mounting, Filter Lock

21 900-2463 Post, Center Door, Common Electric

22 900-2464SP Brace, Lower, Front Horizontal, Common Electric

23 900-2514 Bridge, Common Electric

24 900-2653 Plate, Swivel, Common Electric

25 900-2718 Brace, Contactor, Front, Common Electric w/Filter-Quad

* 200-0078 Brace, Contactor, Front, Common Electric [(w/Filter-Triple), N/F- Quad)]

* 200-0075 Support, Contactor, Front, Common Electric N/F

26 900-2720 Brace, Contactor, Rear, Common Electric-Quad

* 200-0077 Brace, Contactor, Rear, Common Electric [(w/Filter-Triple), N/F- Quad)]

* 200-0074 Support, Contactor, Rear, Common Electric N/F

27 900-2861SP Support, Bottom, Common Electric

28 900-5988 Support, Rear, Bridge Filter, Common Electric

29 901-1810 Gusset, Cabinet, Left

* 902-1810 Gusset, Cabinet, Right

30 901-1948 Channel, Side Support

31 910-2456SP Side, Cabinet – Stainless Steel, Common Electric

* 900-2456SP Side, Cabinet – Enameled Steel, Common Electric

* 901-2843SP Side, FM Common Electric w/Cut-out Left Cabinet, Enameled Steel

* 902-2843SP Side, FM Common Electric w/Cut-out Right Cabinet, Enameled Steel

* 911-2843SP Side, FM Common Electric w/Cut-out Left Cabinet, Stainless Steel

* 912-2843SP Side, FM Common Electric w/Cut-out Right Cabinet, Stainless Steel

* 900-8451 Back, Lower Triple

* 900-8450 Back, Lower Double

* 900-5145 Back, Center Triple

* 900-5143 Back, Center Double

* 900-9635 Back, Upper Triple

* 900-9637 Back, Upper Double

32 900-9585 Heat Shield, Wire, Common Electric

* Not illustrated.

2-9

Page 50

2.3.5 Common Electric Filter Magic Unitary Cabinetry (after 8/2000)

See Detail "A"

67 8

25

1213 14

11

22

123 4

910

5

24

See Detail "B"

Detail "A"

19

16

17

21

18 20

15

Detail "B"

26

23

28

27

2-10

Page 51

ITEM PART # COMPONENT

1 106-0215 Base Assembly, Quad—FM Common Electric (1F24)

* 106-0217 Base Assembly, Quad—FM Common Electric (31F2)

* 106-0218 Base Assembly, Quad—FM Common Electric (531F)

* 106-0220 Base Assembly, Quad—FM Common Electric (F246)

* 106-0214 Base Assembly, Triple—FM Common Electric (1F2)

* 106-0216 Base Assembly, Triple—FM Common Electric (31F)

* 106-0219 Base Assembly, Triple—FM Common Electric (F24)

* 106-0221 Base Assembly, Double—FM Common Electric (F2)

* 106-0222 Base Assembly, Double—FM Common Electric (1F)

2 200-0020 Shield, Filter Magic Pan CE

3 200-0074 Support, Rear Contactor Box

4 200-0075 Support, Front Contactor Box

5 200-0076 Divider, Cabinet Common Electric

6 200-0077 Brace, Rear Contactor Box

7 200-0078 Brace, Front Contactor Box Common Electric

8 200-0091 Brace (Rail), Top Quad Common Electric

* 200-0072 Brace (Rail), Top Triple Common Electric

* 200-0081SP Brace (Rail), Top Double Common Electric

9 200-0092 Support, Rear Common Electric

10 200-0126 Brace, Rear Support

11 200-0138 Doorpost, Common Electric

12 200-0343 Brace, Rear Horizontal-Quad Common Electric

* 200-0085 Brace, Rear Horizontal-Triple Common Electric

* 200-0084 Brace, Rear Horizontal-Double Common Electric

13 201-0137 Upright, Rear Enclosure, Left, Common Electric

14 202-0137 Upright, Rear Enclosure, Right, Common Electric

15 806-8062SP Filter Rail Assembly, Common Electric FM

16 826-1362 Nut, ¼ - 20 Hex (Pkg. of 10)

17 809-0191 Washer, ¼ Lock

18 826-1374 Screw, #10 - ½ Hex (Pkg. of 25)

19 809-0429 Bolt, ¼ - 20 x 2

20 826-1379 Screw, #10 x ½ Phillips (Pkg. of 10)

21 810-0665 Leveling Nut

22 900-2861SP Support, Bottom Common Electric

23 900-4391SP Brace, Cabinet Front

24 900-8582 Mount, Motor- Single FP Common Electric

25 910-2456SP Side, Cabinet—Stainless Steel Common Electric

* 900-2456SP Side, Cabinet—Cold Rolled Steel Common Electric

26 826-1389 Screw, Hex Head— ¼-20 x ¾ (Pkg. of 10)

27 823-2827 Mount (Weld Assembly) Common Electric Single FP

28 900-8591 Bracket, Mount – Common Electric Single FP

* Not illustrated.

2-11

Page 52

2.4 Casters, Legs and Associated Hardware

1 2 3 4

6 7

8

5

9 10

11 12 13

14

19

15

2016 17 18

2-12

Page 53

ITEM PART # COMPONENT

1 810-0005 Caster, Rigid

2 810-0006 Caster, Swivel-Rokite

3 810-0327 Caster, Adjustable, Without Brake

4 810-1565 Caster, Stud, Single FP 3-inch, With Lock

* 823-2844 Caster, With Brake – Single FP Electric

5 810-0944 Caster, Adjustable 3-inch With Brake

6 810-0356 Caster, 5-inch Wheel Without Brake

7 810-0357 Caster, 5-inch Wheel With Brake

8 810-0651 Caster w/Brake –FootPrint II

9 810-1239 Caster, 8.5-inch Swivel w/Brake (for Cracker Barrel units, use 810-2737)

10 810-1242 Caster, 8.5-inch Rigid

11 810-1367 Caster, Adjustable 3-inch w/o Brake

12 810-1494 Caster, 8.5-inch Swivel w/o Brake (for Cracker Barrel units, use 810-2738)

13 810-1365 Caster, Adjustable 3-inch w/Brake

14 810-0378 Caster, Stationary Rigid, 5-inch Wheel

15 826-0900 Chain Restraint Kit (for use on fryers w/casters)

16 806-3811 Leg, Package (4 per set)

17 810-0007 Leg, Adjustable (For 1 ¼-inch square tubing)

18 826-1234 Leg, Adjustable, 8.5-inch (with hardware)

19 810-1414 Insert, Square Leg, Baby FootPrint

* 910-7925 Leg ,Single FootPrint w/Caster Front Filter

* 910-1601 Leg, Square, Filter Cabinet Front

* 910-8659 Leg, Cabinet Front— Common Electric Single FootPrint

20 900-2941 Strap, Anchor—Common Electric

* 900-1835 Strap, Anchor—Single Fryers with Legs

* Not illustrated.

2-13

Page 54

2.5 Component Box Assemblies and Associated Hardware

8

6

3

123

456

789

10

13

1415

1112

2

4

119

1

5

7

ITEM PART # COMPONENT

1 810-1164 Terminal Block Wire Assembly

2 806-8244 Component Box/Stud Assembly

3 Transformer, 12VAC

807-2191 208-240 V

807-0979 208-240V

807-2192 100-120V

807-0855 120V, 20VA

4 Transformer, 24VAC

807-0680 208-240 V (without fuse)

807-2180 208-240 V (with fuse)

807-2181 100-120V, 62VA (with wires)

807-0800 120V, 50VA (without wires)

* 807-1999 12/24 VAC Transformer, 208/220/230/240, 20/50 VA (Single FootPrint)

5 Interface Board

806-6336 Standard Models

806-3850 HE EF Models w/Rear Probe

806-6347 Solid State (Triac) Models

106-2982 Fast Computer

* 807-3932 Relay, Heat/Latch 12VDC SPDT 12A

6 807-1084 Bushing

7 806-6854SP Wiring Assembly, Transformer

8 806-7179SP Sound Device

9 826-1337 Terminal Tab (Pkg. of 5)

10 806-2071 Cable Assembly, Computer/Interface Board

* Not illustrated.

10

10

9 8 7

6 5 4

3 2 1

15 141312 11

2-14

Page 55

2.6 Control Panel Assemblies, Doors, and Related Components

2.6.1 Control Panel Assemblies, Top Caps, and Associated Components

4

10

1

9

6

8

2

3

5

7

ITEM PART # COMPONENT

1 Control Panel Assembly

806-7171SP Single Fryer

806-7172SP Two-Fryer Battery

806-7173SP Three-Fryer Battery

806-7174SP Four-Fryer Battery

106-2171SP Five-Fryer Battery

106-2324SP Applebee’s Fryer with Dump Station on Left

106-2325SP Applebee’s Fryer with Dump Station on Right

2 823-2307 Control Panel Bezel, with Slot

3 823-0768 Control Panel Bezel, without Slots (for Digital and Analog Controllers)

4 Topcap

106-3034SP Single Non-Filter

824-0409 Single FootPrint (requires Item 9 also)

106-3033SP Double

106-3035SP Triple

106-3036SP Quad Common Electric

824-1037 5-Battery (requires Item 9 also)

824-1047 Applebee’s Fryer with Dump Station on Left (requires Item 9 also)

824-1048 Applebee’s Fryer with Dump Station on Right (requires Item 9 also)

5 Tilt Housing

824-0791 Single

824-0789 Double

824-0798 Triple

824-0799 Quad

824-0852 5-Battery

6 Basket Hanger, Aluminum (No longer available, use Item 7)

7 810-1403 Basket Hanger, Wire

8 809-0171 Screw, Basket Hanger

9 826-1351 Cage Nut (Pkg. of 10) (receives Basket Hanger Screw)

10 823-1885 Top Connecting Strip

2-15

Page 56

2.6.2 Door Assembly Components

5

4

3

2

1

6

7

8

ITEM PART # COMPONENT

806-6545SP Door Assembly, Universal

1 809-0266 Screw, #10- ½-inch

2 824-0137SP Panel, Door

3 806-4487SP Door Pin Assembly

* 809-0193 Washer, Flat ¼-Inch Nylon (Door Pin Bushing)

4 826-1343 Spring, Door Hinge (Pkg. of 10)

5 900-2485 Liner, Door

6 810-1422 Handle, Wireform, Door

7 810-1105 Magnet, Door

8 810-1508 Hinge, Universal Door

* Not illustrated.

2-16

Page 57

2.7 Controller Assemblies

1

3

ITEM PART # COMPONENT

1

Computer Magic III

106-1193 Full-vat (CE)

106-1194 Dual-vat (CE)

806-7158 Full-vat (Domestic)

806-7159 Dual-vat (Domestic)

806-7162 Full-vat (Triac/Solid-State)

806-7163 Dual-vat (Triac/Solid-State)

2

Analog Controller

806-7422 Full-vat

806-7423 Dual-vat

3

Basket Lift Timer

106-2090SP Full-vat (CE)

106-2091SP Dual-vat (CE)

106-2088SP Full-vat (Domestic)

106-2076SP Dual-vat (Domestic)

4

Digital Controller

106-1507 Full-vat (CE)

106-1508 Dual-vat (CE)

106-1503 Full-vat (Domestic)

106-1952 Dual-vat (Domestic)

2

4

2-17

Page 58

2.8 Electrical Components

2.8.1 Contactor Box Components, Mercury Contactor

12

13

14

2

8

7

6

5

4

9

15

16

17

9

111

10

3

1

2-18

Page 59

ITEM PART # COMPONENT

1 900-5445 Front Cover, Contactor Box

2 900-5446 Top Cover, Contactor Box

3 807-0922 Holder, Buss Fuse

* 807-2278 Fuse, 20 Amp

* 807-2279 Fuse, 15 Amp

* 807-0501 Fuse Block 3-Pole Buss (22kW)

* 807-2240 Fuse 60 Amp (22kW)

* 807-2865 Block Support, Fuse (22kW)

4 816-0217 Paper, Insulating Terminal Block (CE)

5 810-1164 Terminal Block

6 807-1973 Terminal Post

7 C1 Wiring Assembly

806-7198SP For Dual-vat Applications

806-7199SP For Full-vat Applications

8 807-2464 Power Block, Delta

* 807-2465 Power Block, WYE

9 810-1202 Contactor, 3-Pole 600V 40 Amp

10 C2 Wiring Assembly

806-7191SP Dual- and Full-vat

11 807-1071 Contactor, Mercury 24 VAC 30 Amp

* 807-0884

Contactor, Mercury 24 VAC 50 Amp (See NOTE)

12 806-7183SP Wire Assembly, Left, Dual-vat

* 806-7186SP Wire Assembly, Left, Full-vat

* 807-2136 Connector, 6-Pin Female

* 807-2135 Connector, 6-Pin Male

13 806-7185SP Wire Assembly, Right (Full- and Dual-vat)

* 807-2138 Connector, 9-Pin Female

* 807-2137 Connector, 9-Pin Male

14 807-0070 Terminal, Ground Lug

15 900-5447 Back Cover, Contactor Box

16 900-5782 Bracket, Connector Common Electric

17 900-5444 Box, Contactor Common Electric

* Not illustrated.

NOTE: For H22 Models using 208-240V, but not 480V.

2-19

Page 60

2.8.2 Contactor Box Components, Solid State Relays (Triac)

21

22

6

19 15

3

9

11

23

10

8

25

2

7

1614

4

24

5

1

18

12

13

2017

26

27

.312 ± .030

.775

Triac

.130 REF.

Circuit Board

28

Triac board for fryers with serial

numbers of 9809XX0000 and lower

(XX is the series code).

2-20

Page 61

ITEM PART # COMPONENT

1 806-7185SP Wire Assembly, HV Right Contactor

* 806-7184SP Wire Assembly, HV Right FV H22 Contactor

2 806-7186SP Wire Assembly, HV Left FV Contactor

* 806-7188SP Wire Assembly, HV Left FV H22 Contactor

* 806-7183SP Wire Assembly, HV Left DV Contactor

3 806-7191 C2 Wire Assembly, Common Electric

4 806-7198 C1 Wire Assembly, Dual-vat Common Electric

* 806-7199 C1 Wire Assembly, Full-vat Common Electric

5 806-8589 Front Assembly, Fuse Contactor Box Common Electric

6 806-8673 Heat Sink Assembly, Full-vat Solid State Relay

* 806-8674 Heat Sink Assembly, Dual-vat Solid State Relay

* 826-1562 Kit, 40A 280V Relay w/Heat Sink Compound

7 806-0070 Terminal, Ground Lug

8 807-0501 Fuse Block, Buss #2968 3-Pole

9 807-0922 Holder, Buss Fuse HPS

10 807-2240 Fuse, Buss 60 Amp 300 VAC

11 807-2278 Fuse, 20 Amp

12 807-2464 Power Block, Delta Common Electric

* 807-2465 Power Block, WYE Common Electric

* 806-9124 Filter Assembly (WYE Solid-State/Triac Contactor Box Only)

13 810-0743 Button, Plug ¾-inch

14 810-1164 Terminal Block, 1 PLC Screwless

* 807-0064 Transformer-150VA, 480V Applications, w/o Basket Lift

* 807-0331 Transformer-250VA, 480V Applications, w/Basket Lift

15 810-1202 Contactor, 3-Pole 600V 40 Amp

16 816-0217 Paper, Insulating Terminal Block CE

17 900-2519 Hinge, Control Box Common Electric

18 900-2752 Plate, Cordset Common Electric

19 900-5782 Bracket, Connector Common Electric Box

20 900-5784 Box, Contactor Common Electric

21 900-5785 Rear, Triac Contactor Box Common Electric

22 900-5786 Rail, 2-Contactor Common Electric

23 900-5797 Support, Fuse Block Common Electric

24 900-5895 Top, Triac Contactor Box Common Electric

25 900-8239 Rear, Split Triac Contactor Box

26 806-5072 Triac Board Assembly (2 required for Dual-vat Applications)

* 812-1283 Heat Sink, Triac Board

27 807-1276 Triac 600/40A TO-218

* 815-0554 Heat Sink Compound (required for installing Triac Board to Heat Sink)

28 807-1337 Standoff, Triac Board

* Not illustrated.

2-21

Page 62

2.8.3 Elements and Related Components

11

1

2

3

Dual Vat Full Vat

4

5

6 7

11

8

9

10

19

18

16

16

Full Vat

12

13

17 14

15

Dual Vat

2-22

Page 63

ITEM PART # COMPONENT

1 826-1339 Bushing, .375 Split (Pkg. of 10)

2 809-0567 Ty-Wrap, Metal

3 Heating Element

807-2639 208V 7 kW

807-2640 208V 8.5 kW

807-2641 220V 8.5 kW

807-2642 230V 7 kW

807-2643 230V 8.5 kW

807-2644 240V 7 kW

807-2645 240V 8.5 kW/ 220V 7 kW

807-2646 200V 8.5 kW

807-2647 380V 7 kW

807-2648 380V 8.5 kW

807-2649 440V 7 kW

807-2650 440V 8.5 kW

807-2651 480V 7 kW

807-2652 480V 8.5 kW

807-2653 400V 8.5 kW

807-3171 220V 11 kW

807-3172 230V 11 kW

807-3173 240V 11 kW

807-3174 200V 11 kW

807-3175 380V 11 kW

807-3176 440V 11 kW

807-3177 480V 11 kW

807-3178 400V 11 kW

807-3237 208V 11 kW

* Heating Element Assemblies

806-3141SP 208V, 14kW Full-vat

806-3142SP 240V 7kW Dual-vat

806-8474SP 240V 14 kW Full-vat

806-7887SP 230V H22, Dual-vat

806-8497SP 440V H14/17, Full-vat

806-8677SP In-N-Out 208V 22kW

4 807-2478 Temperature Probe

5 816-0480 Dome Plug, .375 OD. (Full-vat Only)

6 809-0518 Screw #8 32 x 3/8-inch

7 910-2042 Clamp, Element

8 910-3681 Element Support, Full-vat

* 910-5214 Element Support, Dual-vat

9 910-5022 Bracket, Temperature Probe

10 910-5213 Clamp, H14/H17 Element

11 106-0003SP Tilt Plate Assembly, Full-vat

* 106-0004SP Tilt Plate Assembly, Dual-vat

12 106-0573SP Spring Slot Bracket Assembly, Right

13 106-0572SP Spring Slot Bracket Assembly, Left

* 810-0297 Spring, Element (14 and 17kW only)

Continued on following page.

2-23

Page 64

ITEM PART # COMPONENT

* 810-1546 Spring, Element (22kW only)

Tilt Plate Assembly, Individual Components

14 826-1330 Screw, 10-32 x 3/8 (Pkg. of 25)

15 826-1376 Nut, 10-32 (Pkg. of 10)

16 810-0035 Hinge, Stainless Steel Split—14-Inch

17 901-8509 Bracket, Element Support, Left

18 902-8509 Bracket, Element Support, Right

19 910-9640 Plate, Tilt, Full-vat (1 Required)

19 910-9641 Plate, Tilt, Dual-vat (2 Required)

* 826-1061 Tilt Switch, Mercury Non-CE (Full-Vat requires one switch and Dual-Vat

requires two.)

* 826-2228 Tilt Switch, CE (Full-Vat requires one switch and Dual-Vat requires two.)

* Not illustrated.

2-24

Page 65

THIS PAGE INTENTIONALLY LEFT BLANK

2-25

Page 66

2.9 Filter Base/Pan Assemblies

2.9.1 Filter Base Assemblies and Components, FootPrint III

6

5

4

1 2

7 8

3

2-26

Page 67

ITEM PART # COMPONENT

806-8648SP Filter Base Assembly, FootPrint III (After 8/97)

806-5985SP Filter Base Assembly, FootPrint III w/Casters (Before 8/97)

1 810-0180 Handle, Filter Base Assembly

* 826-1360 Screw, #10-24 x 5/16 [Pkg. of 25 (to attach P/N 810-0180)]

2 901-8542 Filter Base, Left Side

3 902-8542 Filter Base, Right Side

4 823-2289 Filter Pan Support

5 900-5396 Motor Support

6 826-1374 Screw, #10-1/2 Hex Head (Pkg. of 25)

* 900-5477 Cover, Motor (August 1997 and later)

* 824-0558 Cover, Motor (Prior to August 1997)

* 900-1949 Standoff, Filter Wiring Box

7 810-1423 Hose, Oil Return

8 823-2638 Bracket, Oil Return Hose

* Not illustrated.

NOTE: Item 1 (P/N 810-0180 Handle, Filter Base Assembly) is available as a replacement for

damaged handles on base assemblies manufactured from 8/97 to 8/99. If damaged filter bases need

replacement, they must be replaced with P/N 901-8542 and 902-8542, which include handles.

Filter bases with replaceable handles are no longer available.

2-27

Page 68

2.9.2 Filter Pan Assemblies, Single FootPrint and FootPrint III

2

1

8

3

4

5

7

6

9

20

19

18

17

14

13

12

16

1011

15

21

2-28

Page 69

ITEM PART # COMPONENT

Filter Pan Assembly, Single FootPrint [See Section 2.9.3 Filter Magic II

1 806-9546SP

(Before 2/99)] for filter screen, crumb screen and other inner-pan

components)

* 823-2828 Filter Pan

2 806-9547SP Cover Assembly, Filter Pan

* 809-0045 Nut, 10-32

* 809-0117 Screw, 10-32 x 3/8 SS

* 809-0185 Washer, Flat #10

* 910-1816 Handle, Filter Pan, Single FootPrint

3 826-1360 Screw, 10-24 x 5/16 (Pkg. of 25)

4 810-0005 Caster, Rigid

5 810-0006 Caster, Swivel

6 826-1376 Nut, 10-32 (Pkg. of 10)

7 810-0180 Handle, Door

8 813-0411 Plug, Pipe-1/8 Internal Hex

9 806-5618SP Filter Pan Assembly, FootPrint III

10 810-1388 Tube, Check Valve

11 810-0948 Ball, Check Valve

12 810-0946 Spring, Check Valve

13 809-0422 Screw, Shoulder 10-32 x 7/16

14 900-5448 Strain Plate, Check Valve

15 816-0181 O-Ring, Check Valve

16 823-1979SP Filter Pan

17 810-1387 Retainer, Check Valve

18 900-8819 Screen, Filter

19 810-1405 Hold-down Ring

20 823-2027 Cover, Filter Pan

21 824-0430 Screen, Crumb

* 826-1490 Kit, Filter Pan Check Valve Service (Items 10, 11, 12, 14, 15, and 17)

* Not illustrated.

2-29

Page 70

2.9.3 Filter Pan Assemblies, Filter Magic II (Before 2/99)

20

21 22

1

10

1514131211

19

2

4

18

17

5

3

7

6

8

33

9

12 14 16

Contact Block Assembly

(Not shown to scale.)

40

38

32

34

11

37

27

35

26

36

39

41

Fitting on outside

24 25

302928

bottom of inner pan.

23

31

2-30

Page 71

ITEM PART # COMPONENT

806-7411SP Outer Pan Assembly (Includes Items 1-22)

1 823-1360SP Outer Pan

2 823-2332 Base, Filter Pan Assembly

3 806-9471 Channel, Caster Mounting

4 900-2805 Channel, Caster Lift Base

5 810-0006 Caster, Swivel

6 810-0005 Caster, Rigid

7 826-1376 Nut, 10-32 Hex Keps (Pkg. of 10)

8 824-0291 Cover, Suction Tube

9 810-0695 Contact, Pan

10 807-1270 Washer, Insulated Shoulder

11 809-0053 Nut, 10-32 Hex

12 809-0184 Washer, #10 Lock

13 826-1337 Tab, Terminal (Pkg. of 5)

14 809-0185 Washer, #10 Flat

15 807-1367 Washer, Non-Conductive Flat

16 809-0020 Nut, 10-24 Cap

17 809-0189 Washer, ¼-inch Flat

18 826-1362 Nut, ¼-20 Hex (Pkg. of 10)

19 826-1374 Screw, #10 X ½-inch Hex Washer Head (Pkg. of 25)

20 813-0411 Plug, ⅛-inch Hex Head Pipe

* 806-4373 Heater Strip Assembly, 24V 25W

* 811-0861 Insulation, Foam (Heater Strip)

* 811-0746 Tape, Aluminum (50-yard Roll)

* 810-0441 Clamp, Heater (Aluminum)

21 910-1350 Clamp, Suction Tube

22 826-1371 Screw, #8 X ½-inch Hex Head Drill Point (Pkg. of 25)

806-5282SP Inner Pan Assembly (Includes Items 23-31)

23 823-1731SP Inner Pan

24 810-0180 Handle, Filter Pan

25 809-0024

Screw, 10-24 X

5

⁄16-inch Slotted Round Head

26 900-8827 Screen, Filter (SanaGrid)

27 810-1406 Ring, Hold Down

28 910-1366 Handle, Filter Pan

29 809-0117

Screw, 10-32 X

5

⁄16-inch Slotted Truss Head

30 809-0045 Nut, 10-32 Hex Cap

31 816-0117 O-Ring

32 824-0416 Screen, Crumb

33 823-1390 Cover, Filter Pan

806-4694SP Contact Block Assembly (Includes Items 11 and 34-41)

34 810-0694 Block, Contact

35 810-0693 Pin, Contact

36 810-0696 Spring, Contact Pin

37 809-0185 Washer, #10 Flat

38 816-0126 Insulator, Contact Block

39 900-1521 Bracket, Contact Block

40 809-0291 Screw, ¼-20 X 1.5-inch

41 826-1372 Nut, ¼-20 Hex Grip (Pkg. of 10)

* Not Illustrated.

2-31

Page 72

2.9.4 Filter Pan Assembly, Filter Magic II One-Piece

6

7

1 2

ITEM PART # COMPONENT

Complete Pan Assemblies

106-0361SP After July 2000

806-9449SP Between March 1999 and July 2000

106-0090SP Carl’s Jr. w/Magnasol Filter

1 810-0006 Caster, Swivel

2 810-0005 Caster, Rigid

3 Pan, Filter

823-2828SP Used with Filter Pan Assembly 106-0361SP

823-2751SP Used with Filter Pan Assembly 806-9449SP

823-2951SP Used with Filter Pan Assembly 106-0090SP

4 Screen, Filter (SanaGrid)

900-8933 Used with Filter Pan Assembly 106-0361SP

900-8827 Used with Filter Pan Assembly 806-9449SP

5 Ring, Hold Down

823-2899 Used with Filter Pan Assembly 106-0361SP

810-1406 Used with Filter Pan Assembly 806-9449SP

6 824-0416 Screen, Crumb

7 810-0180 Handle, Filter Pan

* 826-1360 Screw, 10-24 X 5⁄16-inch Slot Head

* Not illustrated.

5

4

3

2-32

Page 73

2.10 Filter Pump and Motor Assemblies and Associated Hardware.

1

13

11

3

2

4

10

9

12

7

8

5

ITEM PART # COMPONENT

1 Pump and Motor Assembly (Illustration Purposes Only)

2 826-1270 Motor and Gasket Kit, 230V-250V 50/60 Hz

* 826-1756 Motor and Gasket Kit, 208V 50/60 Hz

* 826-1712 Motor and Gasket Kit, 100V-115V 60 Hz

3 826-1264 Kit—Pump and Gasket

* 807-1995 Pump, Viking 4 GPM

* 809-0514 Cap Screw, 5/16-18 Hex Head

* 809-0194 Washer, Flat 5/16-inch

* 816-0093 Gasket, Pump/Motor

4 810-0278 Gemini Valve w/o Handle

5 810-1067 Flex Line, Oil Return, 11-inch

6 813-0022 Nipple, ½-inch x Close (Dual-vat Configuration)

7 813-0062 Elbow, ½-inch 90° (Dual-vat Configuration)

8 813-0165 Elbow, ½ x ½-inch 90° Street

9 813-0253 Nipple, ½ x 10-inch (Dual-vat Configuration)

10 813-0331 Elbow, ½-inch, With Side Outlet

11 900-2935 Nut, Retainer; Oil Return Valve

12 901-2772 Handle, Valve, Rear Flush Left (Dual-vat Configuration)

13 902-2772 Handle, Valve, Rear Flush Right

14 813-0098 Nipple, ½ x 6.5-inch

15 813-0469 Cap, Pipe ½-inch

* Not illustrated.

6

14

15

Full-Vat Only

2-33

Page 74

2.10 Filter Pump and Motor Assemblies and Associated Hardware (cont.)

Standard FP III Configuration (Prior

to August 1997)

2

1

3

4

Standard FP III Configuration (August

1997 and Later)

12

11

Filter Magic Oil Return Plumbing

(Typical)

13

5

6

7

910

8

15 11

11

16

14

17 18

Dual-vat Configuration (Typical)

1920

2-34

Page 75

ITEM PART # COMPONENT

1

Hose, Heated Oil Return

810-0945 120VAC

810-1037 208-250VAC

2 810-1159 Flexline, 7½-inch (19cm) Oil Return

3 900-1958 Support, Oil Return

4 810-1404 Flexline, Oil Return (pump to rear manifold)

5 813-0265 Nipple, ½-inch x 2 ½-inch

6 813-0460 Nipple, ½-inch x 3-inch

7 813-0331 Elbow, ½-inch 3-way

8 813-0304 Bushing, ½-inch to ¼-inch Reducer

9 810-1373 Flexline, Pump Bypass

10 807-2484 Valve, Solenoid Vent

11 810-1057 Flexline, 15½-inch (39.4 cm) Oil Return

12 813-0537 Nipple, ¼-inch x 2-inch

13 813-0368 Nipple, ½-inch x 16-inch

14 813-0156 Pipe Plug, ½-inch

15 813-0275 Nipple, ½-inch x 9-inch

16 810-1488 Flexline, 7-inch (17.8 cm) Oil Return

17 810-1668 Adapter, ½-inch, Female to Female (Used with Item #11, #16 and #18)

18 810-1160 Flexline, 5½-inch (14 cm) Oil Return

19 826-1392 O-Ring (2 required) (Pkg. of 5)

20 823-1356 Disconnect Fitting

* 816-0102 Grommet, Disconnect Fitting

* 900-1472 Diverter, Oil

* 910-1627 Bracket, Disconnect Fitting Support

* 826-1668 Kit, 100V-120V Heater Tape Replacement

* 826-1669 Kit, 108V-250V Heater Tape Replacement

* 811-0746 Aluminum Tape

* 811-0861 Foam Tape

* 811-0208 Spaghetti Insulation

* Not illustrated.

2-35

Page 76

2.10.1 Filter Pump Boxes and Components

4 5

3

BOTTOM SLOT

6

TOP SLOT

2

FootPrint III Filter Box

Components

7

10

Filter Magic Filter Box

Components

1

37 8

9

2-36

Page 77

ITEM PART # COMPONENT

1 900-5250 Box, Filter FP III

2 810-0044 Plug Button .875, #SS48155 K1110

3 Relay

807-2434 18A 1/3 HP 24V Coil (before 09/2000)

807-0012 18A 1/3 HP 24V Coil (after 08/2000)

4 810-1164 Terminal Block, 1 PLC Screwless

* 810-1168 Terminal, Block Screwless End (230V, 50 Hz Filter Magic)

* 807-0276 Block, UL Male 12 Pin Terminal

* 816-0217 Paper, Insulating Terminal Block CE

5 806-7494 Plug Assembly, FPIII Non-Reversing

6 806-8021 Plug Assembly, Filter Box

7 Transformer

807-0800 120V/24VAC, 50/60 Hz, 50VA

807-0680 208/240/24VAC, 50/60 Hz, 43VA