Page 1

MJ45 Gas Fryers with

Filtration -- CE

Models

FPP245

FPP245-2

FPP245-4

Model FPP245EC

Shown with optional CM3.5 controller

FPP345

FPP345-2

FPP345-4

FPP345-6

FPP445

FPP445-2

Fryer Standard Features

• Open-pot design (split or full) is easy to

clean

• 50-lb (25-liter) oil capacity per full frypot;

25-lb. (12 L) per split frypot

• 97,271 Btu/hr. input (24,502 kcal) (28.5 kw)

per full frypot; 48,636 Btu/hr. input (12,251

kcal) (14.3 kw) per split frypot

• Frying area 14” x 15” x 5” (35.6 x 38.1 x

12.7 cm) per full frypot; 7” x 15” x 4-3/4”

(17.8 x 38.1 x 12.1 cm) per split frypot

• Master Jet burner system distributes heat

evenly for efficient heat exchange and

quick recovery

• Millivolt controller, no electric connection

required

• Stainless steel frypot, door and cabinet

• Reliable, centerline, fast-action tempera-

ture probe

• Deep cold zone, 1-1/4 in. (3.2 cm) IPS ball-

type drain valve

• Two twin baskets

• Casters

• Gas connection -- see chart

FPP445-4

FPP445-6

FPP445-8

Project

Item

Quantity

CSI Section 11400

Approval

Date

Filter Standard Features

• 50-lb (25 liter) oil capacity

• Space-saving filter which fits inside fryer

cabinet housing two full or qualifying

split frypots in two left most cabinets of

the battery

• Filter pan designed on rails to clear

floormats for easy cleaning

• Sloped drain pan leaves minimal residue

oil behind after filtering

• Large 3” (8.0 cm) round drain line allows

oil to drain freely

• Filter cycle is complete from start to

finish in less than 5 minutes, while other

frypots in the system are in use

• Filters up to 4 fryers in one battery

• 1/3 H.P. filter motor

• 4 GPM (15 LPM) pump

• Stainless steel crumb catcher

• Filter starter kit

• Drain safety switch

• Front oil flush

MJ45 Gas Fryers with Filtration -- CE

Specifications

Designed for versatililty, proven performance

and trouble-free filtering of fryer batteries

without wasting valuable space

The MJ45 gas fryers are unsurpassed in their versatility,

controlled performance and low maintenance needs.

The MJ45 fryers offer options that accommodate a wide

range of frying needs -- everything from French fries,

pre-breaded products to specialty foods.

The Master Jet burner system distributes heat evenly

around the frypot, generating a large heat-transfer

area for efficient exchange and quick recovery. They

have earned a legendary reputation for durability and

reliability. The MJ burners require no burner cleaning

or air shutter adjustment. The reliable centerline

fast-action temperature probe assures accurate

temperatures for efficient heat-up, cooking and

recovery.

8700 Line Avenue

Shreveport, LA 71106-6814

USA

Tel: 318-865-1711

Tel: 1-800-221-4583

Fax: 318-868-5987

E-mail: info@frymaster.com

The filtering process is fast and easy, encouraging

frequent filtering -- a critical part of maximizing oil life,

especially with trans-fat free oils. It is also sequential,

so one fryer may be filtered while the others are still

in use. It is engineered with features that allow added

convenience, easier serviceability and allows for using

three different filter mediums with one pan.

This system is enhanced with a gravity draining

system that allows residual oil to drain into the filter

pan so that drain lines are always open. The filter,

housed beneath two Frymaster fryers or one fryer

and a spreader, is capable of filtering up to six fryers,

individually, without having to be moved from fryer to

fryer, saving valuable labor. One fifty-pound fryer can

be filtered in about four minutes, while other fryers in

the battery keep on cooking.

Large sump with secure hold-down ring ensures proper

vacuum and superior oil filtration. The stainless steel

filter pan slides out easily over floor mats and uneven

floor tiles.

www.frymaster.com

Bulletin No. 818-0831

Revised 11/2/15

Meets CE

food contact

requirements

.

Page 2

MJ45 Gas Fryers with Filtration -- CE

OPTIONS & ACCESSORIES

External oil discharge -- available on built-in filter batteries with 2 or

more frypots -- must specify front or rear connection

Basket lifts* (only available with CM3.5)

CM3.5 or Digital controllers

Electronic ignition (full vats and above controllers)

Spreader cabinet(s) -- must fit within a 4-cabinet fryer battery

Piezo ignitor

Frypot cover(s)

Melt cycle (above controllers only)

Boil out (CM3.5 controller only)

Triplet basket

Full basket

Chicken/Fish tray

Sediment tray(s)

Fish plate

Splash shields

*Not available for split frypots.

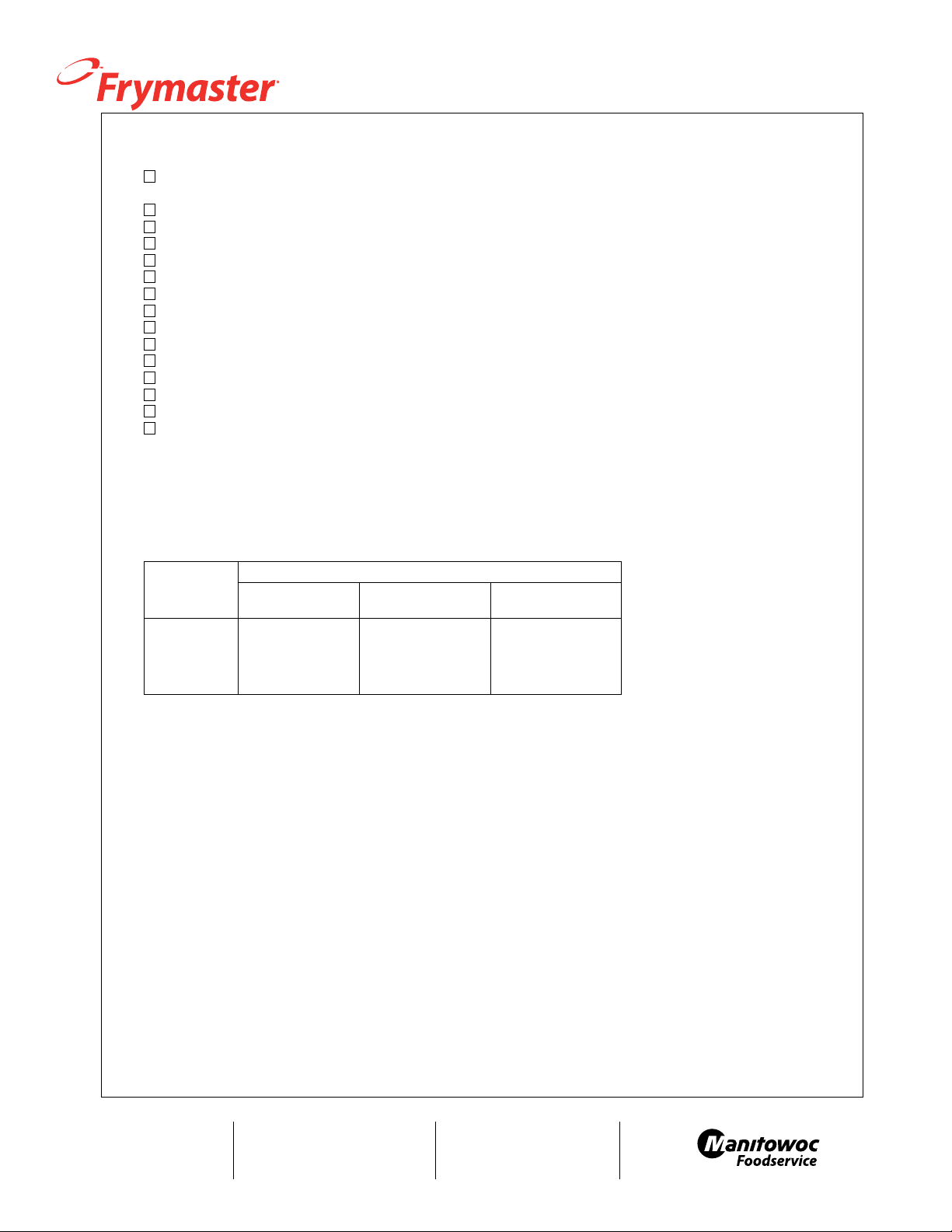

POWER REQUIREMENTS

MODEL NO.

CONTROLS/

FRYPOT

BASIC CE OPTIONS

FILTER

BASKET LIFTS*/

FRYPOT

FPP245**

FPP345**

FPP445**

*Not available for split frypots.

**Includes split pot models.

CLEARANCE INFORMATION

A minimum of 24” (61 cm) should be provided at the front of the unit for

servicing and proper operation, and 6” (15.2 cm) between the sides and

Model #_______________

CSI Section 11400

rear of the fryer to any combustible material.

NOTES:

• 120 V 5 ft. (1.5 m) grounded cord set provided.

• 1-1/2” (3.8 cm) kitchen main manifold gas supply line required. Should

exible gas line be used, it must be CSA approved, commercial type and

sized per the gas line size in above drawing. See service manual and/or

plumbing codes for proper pipe sizing. Recommended minimum store

supply pressure to be 6” W.C. for NAT Gas, and 11” W.C. for L.P. Check

plumbing codes for proper supply line sizing to attain burner manifold

pressure of 3.0” W.C. natural or 8.25” W.C. L.P.

• DO NOT CURB MOUNT

230V 1 A 230V 5 A 230V 2 A

8700 Line Avenue

Shreveport, LA 71106-6800

USA

We reserve the right to change specications appearing in this bulletin without incurring any obligation for equipment previously or subsequently sold.

Check www.frymaster.com for updates.

Tel: 318-865-1711

Tel: 1-800-221-4583

Fax: 318-868-5987

E-mail: info@frymaster.com

www.frymaster.com

Bulletin No. 818-0831

Revised 11/2/15

Page 3

1" GAS CONNECTION

15.63

(397)

31.24

(793)

46.86

(1190)

6.00

(152)

CORDSET

36.50

(927)

35.75

(908)

INCHES

(MM)

Frymaster Gas Connection Requirements

No. of Fryers Gas Connection Size

(With or Without

2-3 One 1”

4 Two 1”

31.55

(801)

3.00

(76)

1" GAS

CONNECTION

Filtration)

47.67

(1211)

46.00

(1168)

49.12

(1248)

57.82

(1469)

MJ45 Gas Fryers with Filtration -- CE

DIMENSIONS

MODEL

NO.

FPP245*

FPP345*

FPP445*

*Full or split(s).

**without basket lifts

CAPACITY/

FRYPOT

50 lbs. (25 L)

full pot

25 lbs. (12 L)

split pot

(FP FILTER ONLY IS 25-1/2” W x 16” D x 12-1/2” H )

FP FILTER WITH FRYERS

OIL

OVERALL SIZE cm

FULL OR SPLIT FRYPOTS

WIDTH DEPTH HEIGHT

31-3/8”

(79.8)

(119.4)

62-5/8”

(159)

47”

31-1/2”

(80.1)

31-1/2”

(80.1)

31-1/2”

(80.1)

46”**

(116.8)

46”**

(116.8)

46”**

(116.8)

DRAIN

HEIGHT

cm

10-5/8”

(26.9)

10-5/8”

(26.9)

10-5/8”

(26.9)

6.10

(155)

SHIPPING INFORMATION

WEIGHT CLASS CUBE

525 lbs.

(238 kg)

658 lbs.

(298 kg)

896 lbs.

(406 kg)

77.5 52.84

77.5 74.39

77.5 100.12

12.85

(326)

8.40

(213)

DIMENSIONS cm

W D H

38”

(96.5)

53”

(135.9)

72”

(182.9)

44-1/2”

(113.0)

44-1/2”

(113.0)

44-1/2”

(113.0)

CORDSET

54”

(137.2)

54”

(137.2)

54”

(137.2)

Model #_______________

CSI Section 11400

8700 Line Avenue

Shreveport, LA 71106-6800

USA

Tel: 318-865-1711

Tel: 1-800-221-4583

Fax: 318-868-5987

E-mail: info@frymaster.com

www.frymaster.com

Bulletin No. 818-0831

Revised 11/2/15

We reserve the right to change specications appearing in this bulletin without incurring any obligation for equipment previously or subsequently sold.

Check www.frymaster.com for updates.

Page 4

MJ45 Gas Fryers with Filtration -- CE

BUILT-IN FILTRATION COMBINATIONS

FPP245

FPP345 FPP445

HOW TO SPECIFY EXAMPLE

The following description will assist with ordering the features desired for this equipment:

FPP345 Three 50-lb. (25 L), open full frypot gas fryers with millivolt controllers and built-in ltration.

FPP345-2 Two 50-lb. (25 L), open full frypot gas fryers and one split frypot gas fryer with millivolt

controllers and built-in ltration.

C CM3.5 controller

BL Basket Lifts

Model #_______________

CSI Section 11400

8700 Line Avenue

Shreveport, LA 71106 -6800

USA

We reserve the right to change specications appearing in this bulletin without incurring any obligation for equipment previously or subsequently sold.

Check www.frymaster.com for updates.

Tel: 318-865-1711

Tel: 1-800-221-4583

Fax: 318-868-5987

E-mail: info@frymaster.com

www.frymaster.com

Bulletin No. 818-0831

Revised 11/2/15

Litho in U.S.A. ©Frymaster

Loading...

Loading...