Frymaster FPH55 General Manual

FootPrint Filtration for

Frymaster

™

®

Single H55 Gas Fryers

Models

F PH55 F PH55- 2

Project

Item

Quantity

CSI Sec tion 11400

Approval

Date

FootPrint Filtration for Single H55 Gas Fryers

Standard Features

• Self-contained FootPrint® filter -- extends oil

life, saves money

• Fits conveniently under one fryer requir-

ing no additional floor space

• Filter cycle is complete from start to finish

in under 5 minutes

• Filter pan designed on rails to clear floor-

mats for easy cleaning

• Filter pan with gravity drain design leaves

minimal residue oil behind after filtering

• Filter pan is lightweight and easy to

remove for cleaning

• Oil circulates and returns through rear

frypot oil flush

• 1/3 H.P. filter motor

• 4 GPM pump

Shown with optional computer

Specifications

Designed for high capacity,

reliability, versatility and efficiency

Frymaster’s renowned, patented built-in

FootPrint Filtration System puts filtration

where it’s most convenient to use -- right

within the fryer -- eliminating the need for

additional floor and storage space.

The built-in filtration system is:

Easy to operate utilizing just two handles. The red handle opens and closes the

drain valve, and the yellow handle turns

the filter pump on and off. Rear flush feature helps remove sediment and return filtered oil to the frypot. Elevated filter pan

ensures no problem with uneven floors.

• Stainless steel crumb catcher

• 1 box of 25 prepackaged applications of Filter Magic® powder

• 1 box of 25 sheets of Filter

Magic paper

Options &

Accessories

See H55 specification sheet for

fryer options

Quick. The entire filtering process occurs

within a matter of minutes. Large sump

with a secure hold-down ring ensures

proper vacuum and superior filtration.

Convenient. Everything needed for filtration is built-in for easy operator access.

There is no need to attach a drain spout

or handle a hot hose.

This system is enhanced with a gravity

draining system that aids in the draining

of residual oil into the filter pan so that

drain lines are always open.

FootPrint filter carries a one-year warranty

-- parts and labor.

8700 Line Avenue

Shreveport, LA 71106-6814

USA

Tel: 318-865-17 11

Tel: 1-800-221- 4583

Fax: 318-86 8-5987

E-mail: in fo@frymaster.com

*Liter con versions are for solid shorte ning @ 70°F.

www.frymast er.com

Bulletin N o. 818-0184 12/08

Frymaster

™

®

FootPrint Filtration for Single H55 Gas Fryers

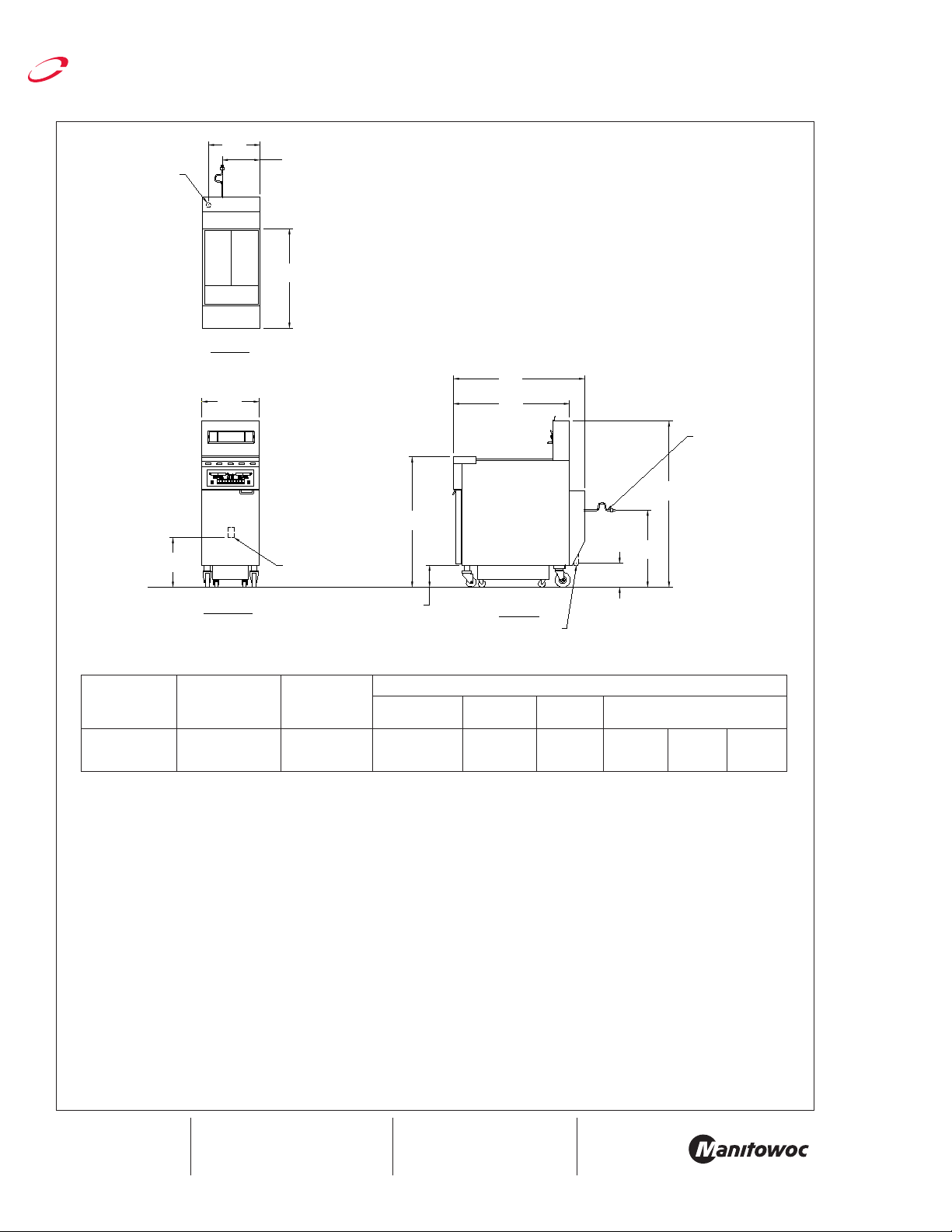

13.50

[343]

DRAIN

HEIGHT

FILTER DRAIN

FRONT VIEW

TOP VIEW

SIDE VIEW

6.50

[165]

6 ft. (1.8m)

CORD SET 120V

PROVIDED

GAS LINE

6.00

[152]

15.63

[397]

GAS LINE

14.00

[356]

21.00

[533]

10.25

[260]

45.30

[1151]

35.50

[902]

35.69

[907]

31.58

[802]

27.09

[688]

DIMENSIONS

MODEL NO. DR AIN HE IGH T NE T W EIG HT SH IPP ING IN FOR MATI ON

WE IGH T CL ASS CU. FT. DI MEN SIO NS

265 l bs.

(121 kg)

85 31.95 H

(1194 mm)

47”

W

25”

(635 mm)

NOTES

FPH55

FPH55 -2

13-1/ 2”

(343 mm)

235 l bs.

(107 kg)

Supply Voltage 120V 60Hz -- Control Voltage 24V 60 Hz.

120 VAC 5 ft. (1.5 m) grounded cord set provided.

Recommended minimum store manifold pressure to be 6” W.C. for NAT

Gas, and 11” W.C. for L.P. Check plumbing codes for proper supply line

sizing to attain burner manifold pressure of 3.0” W.C. natural or 8.25”

W.C.

L.P. Incoming supply line should be 1-1/2”.

All units require a 3/4” connection. Should flexible gas line be used, it

must be AGA approved, commercial type and at least 1” I.D.

CLEARANCE INFORMATION

A minimum of 24” (610 mm) should be provided at the front of the unit

for servicing and proper operation, and 6” (152 mm) between the sides

and rear of the fryer to any combustible material.

8700 Line Avenue

Shreveport, LA 71106-6814

USA

We reserve the right to change specifications appearing in this bulletin without incurring any obligation for equipment previously or subsequently sold.

Check www.frymaster.com for updates

Tel: 318-865-17 11

Tel: 1-800-221- 4583

Fax: 318-86 8-5987

E-mail: in fo@frymaster.com

www.frymast er.com

Bulletin N o. 818-0184 12/08

Litho in U.S.A. ©Frymaster, LLC

L

47”

(1194 mm)

Mode l #_______________

CSI Section 11400