Page 1

H55 High-Eciency Gas Fryers with

Filtration -- CE

Models

FPH155

FPPH255

FPPH255-2

FPPH255-4

FPPH255CSC

Shown with optional CM3.5 controllers

FPPH355

FPPH355-2

FPPH355-4

FPPH355-6

FPPH455

FPPH455-2

FPPH455-4

FPPH455-6

FPPH455-8

FPPH555

FPPH555-2

FPPH555-4

FPPH555-6

FPPH555-8

FPPH555-10

FPPH655

Fryer Standard Features

• Open-pot design(split or full) is easy to clean

• 50-lb (25 L) oil capacity per full frypot; 25-lb.

(12L) per split frypot

• 71,700 Btu/hr. input (18,060 kcal) (21 kw) per full

frypot; 34,150 Btu/hr. input (8,602 kcal) (10 kw)

per split frypot

• Frying area: 14” x 15” x 4-1/2” (35.6 x 38.1 x 11.4

cm) per full frypot; 6-1/2” x 15” x 4-3/4 (16.5 x

38.1 x 12.1 cm) per split frypot

• Digital controllers

• Stainless steel frypot, door and cabinet

• Center-mounted, RTD, 1° compensating tempera-

ture probe

• Deep cold zone with forward-sloping bottom

and IPS full-port, ball-type drain valve -- 1-1/4”

(full frypot; 1” (split frypot)

• Infrared burners ensure state-of-the-art heat

transfer

• Electronic ignition

• Automatic melt cycle and boil-out temperature

control

• Two twin baskets per frypot

• Casters

• Built-in filtration

• Drain safety switch

• Rear oil flush

• Gas connection -- see chart on back

Project

Item

Quantity

CSI Section 11400

Approval

Date

FPPH655-2

FPPH655-4

FPPH655-6

FPPH655-8

FPPH655-10

FPPH655-12

Filter Standard Features

• 50-lb (25 liter) oil capacity

• Space-saving filter which fits inside fryer

cabinet housing two full or qualifying split

frypots in two left most cabinets of the

battery

• Filter pan designed on rails to clear floormats

for easy cleaning

• Sloped drain pan leaves minimal residue oil

behind after filtering

• Large 3” (8.0 cm) round drain line allows oil to

drain freely

• Filter cycle is complete from start to finish in

less than 5 minutes, while other frypots in the

system are in use

• Filters up to 6 fryers in one battery

• 1/3 H.P. filter motor

• 4 GPM (15 LPM) pump

• Stainless steel crumb catcher

• Filter starter kit

Options and Accessories listed on back.

H55 Fryers with Filtration -- CE

Specifications

Designed for high capacity frying, efficiency

and trouble-free filtering of fryer batteries

without wasting valuable space

Frymaster’s H55 is a premium open-pot fryer that

combines state-of-the-art technology with decades

of frying experience and customer satisfaction to set

the standard for high-efficiency frying. The H55 fryer

saves thousands of dollars annually on energy costs.

H55 fryers have long been the trusted choice of chains

and independent operators worldwide because their

efficient, state-of-the-art heat transfer system, precise

controls and durability have stood the test of time.

Infrared burners and blower system delivers an ultrarefined air-gas mixture so the fryer operates well

in any gas application such as at high altitudes, in

environments where air circulation is sub-optimal or

when the heating value of the gas is diminished.

Frymaster’s renowned, built-in filtration system puts

filtration where it’s most convenient to use -- right

within the fryer battery -- eliminating the need for

additional floor and storage space.

8700 Line Avenue

Shreveport, LA 71106-6800

USA

Tel: 318-865-1711

Tel: 1-800-221-4583

Fax: 318-868-5987

E-mail: info@frymaster.com

The filtering process is fast and easy, encouraging

frequent filtering -- a critical part of maximizing oil life,

especially with trans-fat free oils. It is also sequential,

so one fryer may be filtered while the others are still

in use. It is engineered with features that allow added

convenience, easier serviceability and allows for using

three different filter mediums with one pan.

This system is enhanced with a gravity draining

system that allows residual oil to drain into the filter

pan so that drain lines are always open. The filter,

housed beneath two Frymaster fryers or one fryer

and a spreader, is capable of filtering up to six fryers,

individually, without having to be moved from fryer to

fryer, saving valuable labor. One fifty-pound fryer can

be filtered in about four minutes, while other fryers in

the battery keep on cooking.

Large sump with secure hold-down ring ensures

proper vacuum and superior oil filtration. The stainless

steel filter pan slides out easily over floor mats and

uneven floor tiles.

www.frymaster.com

Bulletin No. 818-0830

Revised 11/2/15

Meets CE

food contact

requirements

.

Page 2

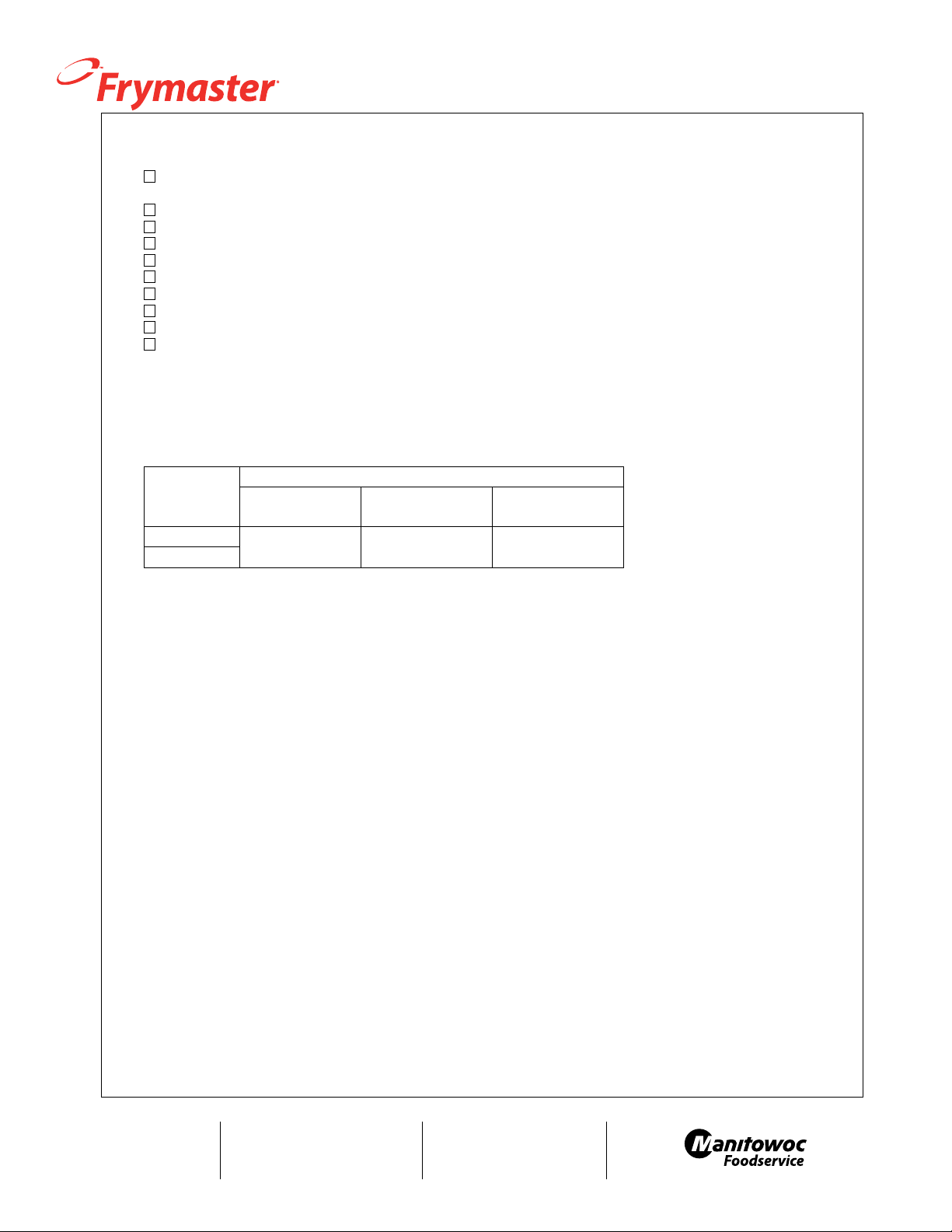

H55 Fryers with Filtration -- CE

OPTIONS & ACCESSORIES

External oil discharge -- available on built-in filter batteries with 2 or

more frypots -- must specify front or rear connection

Basket lifts

CM3.5 or SMART4U® 3000 controllers

Spreader cabinet(s) -- must fit within a 6-cabinet fryer battery

Frypot cover(s)

Foam deck basket banger

Triplet basket

Full basket

Chicken/Fish tray

Sediment tray(s)

POWER REQUIREMENTS

MODEL

NO.

PH155

PH155-2

CONTROLS/

FRYPOT

230V 1 A 230V 5 A 230V 2 A

BASIC CE OPTIONS

FILTER

BASKET LIFTS/

FRYPOT

CLEARANCE INFORMATION

A minimum of 24” (61 cm) should be provided at the front of the unit for

servicing and proper operation, and 6” (15.2 cm) between the sides and

rear of the fryer to any combustible material.

NOTES:

• 120 V 5 ft. (1.5 m) grounded cord set provided.

• 1-1/2” (3.8 cm) kitchen main manifold gas supply line required. Should

exible gas line be used, it must be CSA approved, commercial type and

sized per the gas line size in above drawing. See service manual and/or

plumbing codes for proper pipe sizing. Recommended minimum store

supply pressure to be 6” W.C. for NAT Gas, and 11” W.C. for L.P. Check

plumbing codes for proper supply line sizing to attain burner manifold

pressure of 3.0” W.C. natural or 8.25” W.C. L.P.

• DO NOT CURB MOUNT

8700 Line Avenue

Shreveport, LA 71106-6800

USA

Tel: 318-865-1711

Tel: 1-800-221-4583

Fax: 318-868-5987

E-mail: info@frymaster.com

www.frymaster.com

Bulletin No. 818-0830

Revised 11/2/15

Page 3

-C-

* 6 BATTERY FRYER CONSISTS OF TWO 3 BATTERY FRYERS

6BATT = 1" NPT (2 PLACES)

H55 Fryers with Filtration -- CE

-B-

29.6

[752]

W/O BASKET

LIFT

32.7

[831]

W/BASKET

LIFT

17.5

[444]

18.7

[475]

TOP VIEW

-A-

FRONT VIEW

8.0

[203]

36.6

[930]

12.0

[304]

DRAIN

HEIGHT

SIDE VIEW

BACK VIEW

17.9

[455]

10.7

[271]

-E-

OPTIONAL BASKET LIFT

IN RAISED POSITION

49.2

[1250]

45.6

[1159]

54.9

[1395]

-D-

FRYER DIMENSION CHART

BATTERY

2

3

4

5

6 *

-A- Width

IN

31.3

47.1

62.5

78.2

93.8

GERMANY FRYERS - 1/2" NPT CONNECTION PER POT

MM

795

1195

1587

1986

2381

-B- Gas #1

IN MM

749

29.5

1146

45.1

749

29.5

749

29.5

45.1 1146

-C- Gas #2

IN MM

N/A

N/A

49.5

1257

65.0

1651

92.0 2337

-D- Cord #1

IN MM

823

32.4

-E- Cord #2

IN MM

N/A N/A

63.6 1615

2BATT = 1" NPT (1 PLACE)

3BATT = 1" NPT (1 PLACE)

4BATT = 1" NPT (2 PLACES)

5BATT = 1" NPT (2 PLACES)

GAS CONNECTIONS:

DIMENSIONS FP FILTER ONLY IS 251/2” W X 16” D X 121/2” H

FP FILTER WITH FRYERS

MODEL

NO.

FPH155

FPPH255

FPPH355

FPPH455

FPPH555

FPPH655

OIL

CAPACITY/

FRYPOT

50 lbs. (25 L)

25 lbs. (12 L)

each side

OVERALL SIZE (cm)

FULL OR SPLIT FRYPOTS

WIDTH DEPTH HEIGHT

15-5/8”

(39.7)

31-3/8

(79.8)

47”

(119.4)

62-5/8”

29-5/8”*

(75.3)

45-5/8”*

(115.8)

(159)

78-1/8”

(198.4)

93-3/4”

(238)

DRAIN

HEIGHT

10-1/4”

(26.1 cm)

*Six or more fryers/cabinets ship in two cartons.

8700 Line Avenue

Shreveport, LA 71106-6800

USA

Tel: 318-865-1711

Tel: 1-800-221-4583

Fax: 318-868-5987

E-mail: info@frymaster.com

SHIPPING INFORMATION

WEIGHT CLASS CUBE DIMENSIONS (cm)

306

(139 kg)

492

(223 kg)

671 lbs.

(304 kg)

881 lbs.

(400 kg)

1,076 lbs.

(488 kg)

1,236 lbs.

(561 kg)

www.frymaster.com

Bulletin No. 818-0830

Revised 11/2/15

85 52.84

77.5 52.84

77.5 74.39

77.5 100.12

77.5 120.98

77.5

*2 @

74.39 ea.

W

38”

(96.5)

38”

(96.5)

53”

(135.9)

72”

(189.2)

87”

(22.1)

*2 @ 53”

ea.

(135.9)

44-1/2”

(113.0)

44-1/2”

(113.0)

44-1/2”

(113.0)

44-1/2”

(113.0)

44-1/2”

(113.0)

*2 @ 44-1/2”

(113.0)

ea.

D

H

54”

(137.2)

54”

(137.2)

54”

(137.2)

54”

(137.2)

54”

(137.2)

*2 @ 54”

ea.

(137.2)

Page 4

H55 Fryers with Filtration -- CE

BUILT-IN FILTRATION COMBINATIONS

FPPH255

FPPH555

FPPH355FPPH455

FPPH655

HOW TO SPECIFY EXAMPLE

The following description will assist with ordering the features desired for this equipment:

FPPH355 Three 50-lb. (25 L) high-eciency, open full frypot gas fryer with, digital controllers,

electronic ignition, melt cycle, boil-out temperature control and center-mounted (RTD) 1°

compensating temperature probe, built-in ltration

FPPH355-2 Two 50-lb. (25 L) high-eciency, open full frypot gas fryers and one split frypot gas fryer

with digital controllers, electronic ignition, melt cycle, boil-out temperature control and

center-mounted (RTD) 1° compensating temperature probe, built-in ltration

C CM3.5 controller

BL Basket Lifts

Model #_______________

CSI Section 11400

8700 Line Avenue

Shreveport, LA 71106 -6800

USA

We reserve the right to change specications appearing in this bulletin without incurring any obligation for equipment previously or subsequently sold.

Check www.frymaster.com for updates.

Tel: 318-865-1711

Tel: 1-800-221-4583

Fax: 318-868-5987

E-mail: info@frymaster.com

www.frymaster.com

Bulletin No. 818-0830

Revised 11/2/15

Litho in U.S.A. ©Frymaster

Loading...

Loading...