Page 1

Protector® Gas Fryers

Frymaster

™

®

Models

F PGL230 F PGL330 F PGL430

Project

Item

Quantity

CSI Sec tion 11400

Approval

Date

Protector Gas Fryers

-40% less oil

-Extended oil life

-ASTM rating of 56%

-Qualifies for energy saving rebates

Specifications

Frymaster’s innovative Smart4U Technology is

built into the Protector gas fryers. They have a 30lb. (15 liter*) oil capacity. The frying area is 13 x

14 in. (330 x 356 mm). This 75,000 Btu/hr. (18,892

kCal) (21.97 kW ) model is designed for highvolume frying and maximum fuel economy.

The Oil Attendant automatically replenishes oil

from the Jug-In-Box (JIB) conveniently located

inside the fryer cabinet. This auto-fill feature

senses the need for fresh oil and replaces it automatically. The in-cabinet oil supply eliminates the

need to retrieve oil containers from storage and

manually refill the fryer, saving labor and protecting staff safely. The Oil Attendant monitors the

JIB’s oil level so you don’t have to. A flashing light

indicates when the JIB needs replacement.

The built-in FootPrint PRO filtration system

encourages more frequent filtering, which

preserves oil life and ensures consistent, great

tasting food. The computer counts the number

of cooks and a “Filter Now,” “Yes/No” message

feature prompts staff to activate the filter cycle.

The large -capacity filter pan design has easy-toclean corners and is lightweight for easy removal

for cleaning. The filter pan is designed on rails to

clear floormats.

Standard Features

• 30-lb. frypot with open-pot design, --

uses 40% less oil to cook as much food

as frypots almost twice its size

• Smart4U® Technology

- Oil AttendantTM -- automatic frypot oil

replenishment and flashing alert to

change in-cabinet oil supply

- FootPrint PRO® -- built-in filtration

• Computer Magic® controller counts the

number of cooks and displays “Filter

Now” and “Yes/No” messages

• High-efficiency infrared burner ensures

efficiency that exceeds ENERGY STAR®

standards

• Centerline, solid-state, 1° action ther-

mostat ensures precise temperature

The open stainless-steel fr ypot has a large heat

transfer area to fry more product per load and is

available in full-frypot configuration.

Frymaster’s state-of-the-art infrared burner system, ensures precise air/gas mixing for consistent

combustion and efficient heat transfer at any

elevation. The reliability of the burner system has

been tested by time and is trusted by operators

worldwide.

The Protector gas fryer is the ultimate in oilconserving, high-performance, energy-efficient

frying extending Frymaster’s industry leading line

of gas equipment. It has an ENERGY STAR® rating

of 56%, meeting requirements for energy-saving

rebates. It uses less oil to cook the same volume

as fryers with almost twice its oil capacity and

maximizes oil life with the continual replacement

of fresh oil to the frypot. Reliable operation is

backed globally by Frymaster and Enodis STAR

Service.

*Liter conver sions are for sol id shortening @ 70°F.

control, which maximizes oil life

and produces uniformly-cooked

products

• Electronic ignition effortless start-

up

• Boil-out mode

• Stainless-steel frypot, door and

cabinet

• 8-1/2” (216 mm) adjustable casters

(adjusts to 10” (254 mm)

Options &

Accessories

Stainless-steel frypot covers

Automatic basket lifts

Spreader cabinet

Two, three and four frypot models

Protector Frypot

Standard Frypot

8700 Line Avenue 71106

P. O. Box 51000 71135-1000

Shreveport, LA USA

Tel: 318-865-17 11

Tel: 1-800-221- 4583

Fax: 318-86 8-5987

E-mail: in fo@frymaster.com

www.frymast er.com

Bulletin N o. 818-0583 4/08

Page 2

Frymaster

™

®

Protector Gas Fryers

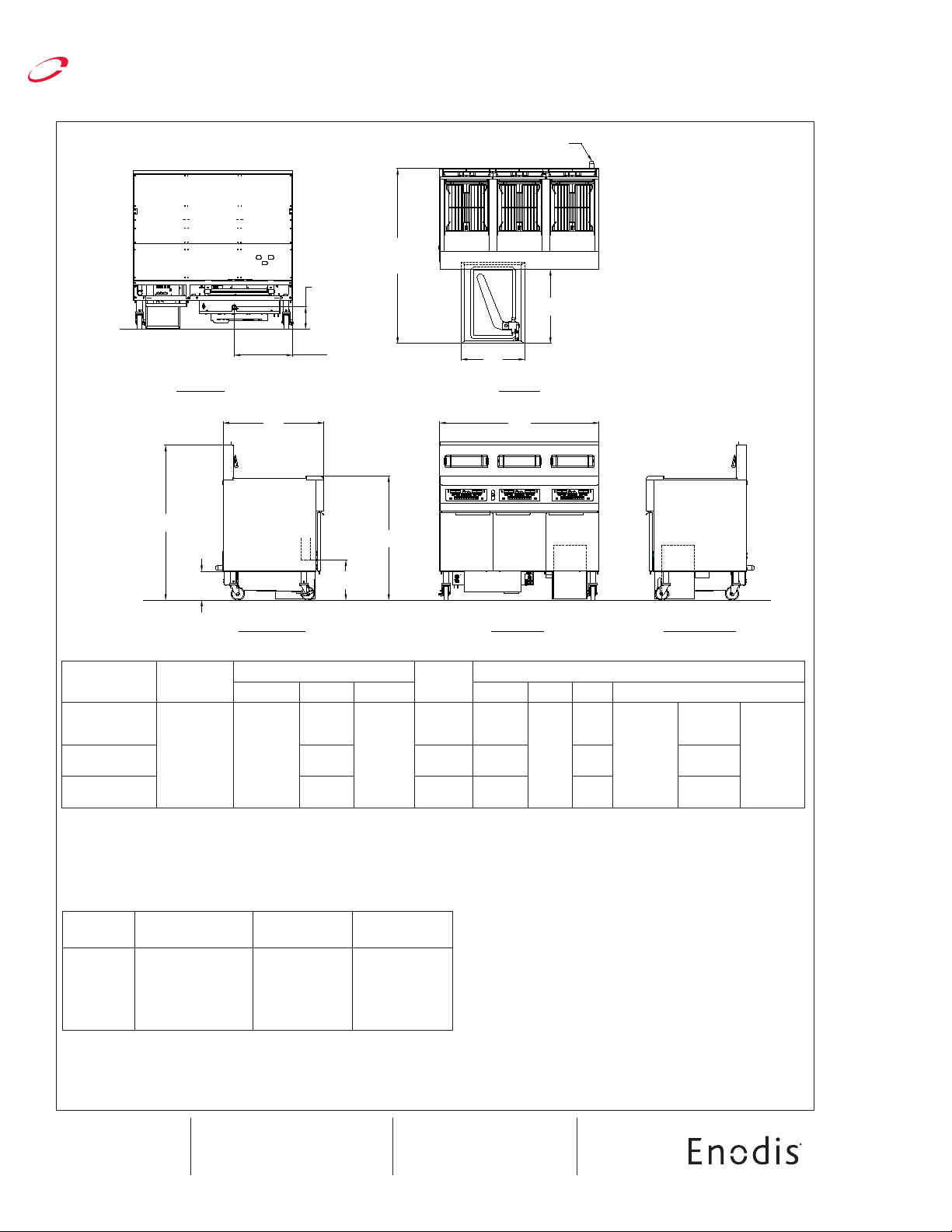

17.19 [437]

CORDSET

LOCATION

6.48 [165]

CORDSET

LOCATION

45.60

[1158]

8.50

[216]

11.83

[300]

36.50

[927]

46.86

[1190]

LEFT SIDE VIEW FRONT VIEW RIGHT SIDE VIEW

BACK VIEW TOP VIEW

1" NPT GAS SUPPLY

DRAIN

HEIGHT

29.64

[753]

21.75

[552]

18.72

[475]

51.48

[1308]

FILTER PAN

PULLED OUT

DIMENSIONS

MODEL NO. OIL

FPGL2 30

FPGL3 30 46.86 ”

FPGL4 30 62.48 ”

C APACIT Y

30 lbs.

(15 liters)

per f rypo t

*without basket lifts

POWER REQUIREMENTS

MO DEL

NO.

FPGL 75,00 0 Bt u/hr. in put

NAT URA L O R L P

GA S I NPU T R ATIN G

(18,892 kCal)

(21.97 kW )

OV ERA LL SIZ E mm NE T

HE IGH T WI DTH LE NGT H WE IGH T CL ASS CU. FT. DIM ENS ION S MM

31.24 ”

45.60 ”*

(1158 )

Non-b aske t lift

120V (1.0 AMP)

220V (0.5 AMP)

120V (7.0 AMP)

220V (3.5 AMP)

(794)

(1190 )

(1587 )

EL ECT RICA L EX POR T

Baske t Li ft

29.64 ”

(753)

200V - 25 0V

50/60 Hz.

3.5 A MP

POWER REQUIREMENTS FOR FILTER ONLY

AMPERAGE FOR FILTER ONLY -- Filter Motor -- Domestic: 120V 60 Hz (7.5 AMP)

Export: 220V-240V 50/60 Hz (4.5 AMP) -- Contact factory for other voltages

8700 Line Avenue 71106

P. O. Box 51000 71135-1000

Shreveport, LA USA

We reserve the right to change specifications appearing in this bulletin without incurring any obligation for equipment previously or subsequently sold.

Tel: 318-865-17 11

Tel: 1-800-221- 4583

Fax: 318-86 8-5987

E-mail: in fo@frymaster.com

WE IGH T

500

(227 kg)

675

(306 kg)

858

(390 kg)

www.frymast er.com

Bulletin N o. 818-0583 4/08

Litho in U.S.A. ©Frymaster, LLC

544

(247 kg) 77 .5

723

(328 kg)

908

(412 kg)

SH IPP ING IN FOR MATI ON

52.84 H

74.39 53.30 ”

100.1 2 72

54”

(1372 )

W

38”

(965)

(1359 )

(1829 )

L

44.50

(1130 )

NOTES

Supply Voltage 120V 60Hz

120 VAC 5 ft. (1.5 m) grounded cord set provided.

Recommended minimum store supply pressure

to be 6” W.C. for NAT Gas, and 11” W.C. for L.P.

Check plumbing codes for proper supply line sizing to attain burner manifold pressure of 3.0” W.C.

natural or 8.25” W.C. L.P. Incoming supply line

should be 1-1/2”. Should flexible gas line be used,

it must be AGA approved, commercial type and

sized per the gas line size in above drawing.

CLEARANCE INFORMATION

A minimum of 24” (610 mm) should be provided

at the front of the unit for servicing and proper

operation, and 6” (152 mm) between the sides

and rear of the fryer to any combustible material.

Model #_______________

CSI Section 11400

Loading...

Loading...