Page 1

OCF30ATOE

Models

FPEL214CA

FPEL214-2LCA

FPEL214-2RCA

FPEL214-4CA

FPEL314CA

FPEL314-2LCA

Ultimate Oil-Conserving

Electric Fryers With ATO

FPEL314-2RCA

FPEL314-4LCA

FPEL314-4RCA

FPEL314-6CA

FPEL414CA

FPEL414-2LCA

FPEL414-2RCA

FPEL414-4LCA

FPEL414-4RCA

Project

Item

Quantity

CSI Section 11400

Approval

Date

OCF30ATOE Ultimate Oil-Conserving Electric Fryers

FPEL414-6LCA

FPEL414-6RCA

FPEL414-8CA

- 40% less oil; 10% less energy

- SMART4U® 3000 Controller

• Maintains food quality

• Extends oil life

• Monitors equipment performance

• Supports frystation management best

practices

Specifications

Frymaster’s OCF30ATOE electric fryers are the

ultimate oil-conserving, high-performance fryers.

As operators are pressured to do more with less,

the OCF30ATOE electric fryers help improve profit

margins with labor and energy-saving features,

contribute to green and sustainability initiatives,

safeguard workers, and move toward healthier

eating.

The open stainless steel frypot is easy to clean.

These fryers reduce operating costs by using less oil,

30-lbs versus 50-lbs. Oil life is maximized because

the smaller frypot maintains a favorable ratio of

fresh to used oil. This higher ratio of fresh oil slows

down the accumulation of breakdown products that

shortens oil life so the oil lasts longer. Less oil to fill

and longer times between fills saves operators well

over 40% on their oil costs.

This savings helps meet consumer demand for

healthier food choices and regulatory mandates to

use trans fat-free oils by offsetting the higher cost

of these oils. With ASTM ratings that exceed ENERGY

STAR® standards for efficiency, OCF30ATOE electric

fryers qualify for energy-saving rebates. A new COOL

Mode feature reduces the temperature when the

fryer is not in use and saves energy.

Standard Features

• 30-lb. (15 liter*) frypot with open-pot design

requires 40% less oil to cook as much food as

frypots almost twice its size, while using 10%

less energy and producing less waste.

• Frying area 13” x 14” x 3-3/4” (33 x 36 x 9.5 cm)

per full frypot; 6” x 14” x 3-3/4” (15 x 36 x 9.5

cm) per split frypot

• SMART4U® Technology

-- Oil Attendant® – automatically

replenishes oil from Jug-in-box (JIB)

conveniently located inside the fryer cabinet.

-- 3000 controller has operation management

features that monitor and help control food

and oil quality, oil life, and equipment performance. Has 20 programmable cook buttons and auto adjusts cook time to load size.

• Innovative safety features offer proprietary

advantages over other fryers--automatic highlimit reset and audible alarm if 2nd drain is

opened.

• Independent frypot construction of batteries

makes it easy to repair or replace a frypot while

maintaining continuous operation.

• Durable, self-standing, swing-up, flat-bar heat-

ing elements ensure industry-leading energy

efficiency that exceeds ENERGY STAR® standards

and protects against oil migration.

The built-in filtration system encourages more

frequent filtering, which preserves oil life and

ensures consistent, great-tasting food. The simple,

proven 2-lever process has recessed handles tucked

safely inside the cabinet to prevent unplanned

filtration and dangerous extension into busy work

spaces.

The independent frypot construction of the

OCF30ATOE electric fryers makes it easy to repair

or replace a frypot while maintaining continuous

operation and protects operators against nonmanufacturing defect, full-battery replacement

costs. Reliable operation is backed globally by

Manitowoc’s STAR Service.

The OCF30ATOE electric fryer line-up offers 2-4

frypot (full and/or split) batteries and all voltages

worldwide.

• 14 kw full frypots

• 7 kw split frypots

*Liter conversions are for liquid shortening @ 70° F.

• Center-mounted RTD, 1° action thermostat

ensures precise temperature control, which

maximizes oil life and produces uniformlycooked products.

• Built-in filtration puts filtration where it’s

most convenient to use, right in the fryer

battery.

• Stainless steel frypot, door, and

cabinet sides

• Adjustable casters

Options & Accessories

Baskets lifts

Spreader cabinet -- must fit within a

4-cabinet fryer battery

Bulk oil: dispose and/or fresh (rear

only)

Frypot covers

Fish plate (full frypot only)

Semi-solid/solid shortening

Side splash shield

Full basket

Triplet basket

Jug in Box (JIB) Holder -- stainless steel

Chicken/fish tray (full frypot only)

OCF30E fryers meet ENERGY

STAR® guidelines for high

efficiency, and all OCF30E

fryers are part of the Manitowoc

®

program.

EnerLogic

OCF30ATOE

Electric Frypot

Standard

Electric Frypot

8700 Line Avenue

Shreveport, LA 71106-6814

USA

Tel: 318-865-1711

Tel: 1-800-221-4583

Fax: 318-868-5987

E-mail: info@frymaster.com

www.frymaster.com

Bulletin No. 818-0652

Revised 5/8/15

Page 2

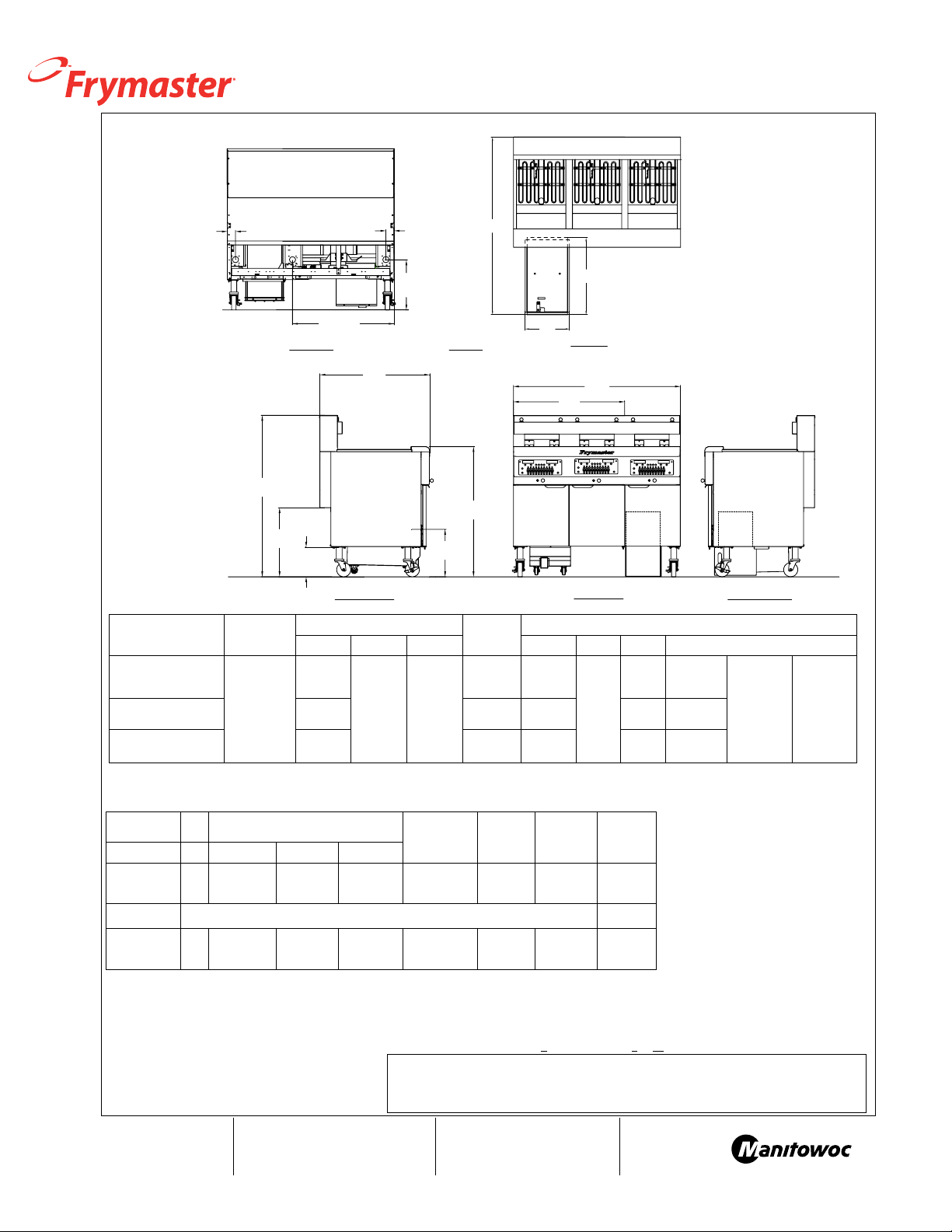

OCF30ATOE Ultimate Oil-Conserving Electric Fryers

2.3

[59]

CORDSET

LOCATION

2.3

[59]

CORDSET

LOCATION

FILTER PAN

REMOVAL

49.9

[1267]

DIMENSIONS

MODEL NO.

FPEL2

FPEL2 SPLITS

FPEL3

FPEL3 SPLITS

FPLEL4

FPEL4 SPLITS

*Without basket lifts.

POWER REQUIREMENTS

BASIC

DOMESTIC

FPELCA 14

BASIC

EXPORT & CE

FPELCA 14

*3 PH/3 Wire/Plus Ground Wire

**1 PH/2 Wire/Plus Ground Wire

Model #_______________

CSI Section 11400

HOW TO SPECIFY

FPELCA High-eciency, oil conserving, 30-lb. open frypot

8700 Line Avenue

Shreveport, LA 71106-6814

USA

(full or split) electric fryer with Auto Top-O, 3000

controller, 14 kw, built-in ltration, casters and

stainless steel frypot, door, and cabinet sides.

28.6 [725]

CORDSET LOCATION

BACK VIEW

45.4

[1152]

19.4

[492]

8.3

[212]

LEFT SIDE VIEW

OIL

CAPACITY

30 lbs.

(15 liters)

Full Frypot

16 lbs.

(8 liters)

Split Frypot

OVERALL SIZE (cm)

WIDTH DEPTH HEIGHT WEIGHT CLASS CU. FT. DIMENSIONS (cm)

31-1/4”

(79.4)

46-7/8”

(119.2)

62-1/2”

(158.8)

kw ELEMENTS/FRYPOT

VOLTAGE 3 PHASE* I PHASE**

208V

240V

480V

220V/380V

230V/400V

240V/415V

39 A

34 A

17 A

22 A

21 A

20 A

Tel: 318-865-1711

Tel: 1-800-221-4583

Fax: 318-868-5987

E-mail: info@frymaster.com

12.5

[316]

31.26

[794]

AUT O

TOPOFF/

FRYPOT

1 A

1 A

1 A

1 A

1 A

1 A

21.6

[549]

TOP VIEW

46.9

[1192]

FRONT VIEW

77.5

120V 3 A

30.9

[784]

30-7/8”*

(78.6)

67 A

58 A

N/A

N/A

14.0 [357]

CORDSET

LOCATION

DIMENSIONS

DRAIN

HEIGHT

45-3/8”*

(115.2)

CONTROLS/

FRYPOT

1 A

1 A

120V 1 A

1 A

1 A

1 A

13.3

[339]

INCHES

[MM]

36.6

[929]

NE T

WEIGHT

305 lbs.

(138 kg)

486 lbs.

(220 kg)

667 lbs.

(303 kg)

FILTER

5 A

4 A

120V 8 A

4 A

4 A

4 A

535 lbs.

(243 kg)

667 lbs.

(303 kg)

978 lbs.

(444 kg)

MODEL NO. EXPLANATION: FPELX14 CA & FPELX14 -YZCA

FP = Built-in lter: FM represents built-in

X = Number of fr ypots (1-4)

14 = kw

C = Controller

lter with spreader

www.frymaster.com

Bulletin No. 818-0652

Revised 5/8/15

Litho in U.S.A. ©Frymaster

RIGHT SIDE VIEW

SHIPPING INFORMATION

52.5W37-1/2”

74.2

98.03

BASKET

LIFTS/

FRYPOT

2 A

2 A

2 A

2 A

2 A

-Y = Split frypot(s) (-2 to -8)

Z = Position of split frypot (L = left,

A = Auto Top O

BL = Basket lifts

(953)

53”

(1346)

70”

(1778)

NOTES

• One Cord is provided per full or dual split

frypot on 3 phase units.

• Single phase units must be eld wired. No

cord or plug provided. Check electrical

codes for proper supply line sizing.

• Plug is optional on units shipping with cord.

Canada is an exception and cords, where

available, must have a plug attached.

• Optional plug -- (Domestic NEMA #15-60P).

• Controller, filter pump and basket lifts are

powered by element voltages except for

480V fryers.

• All 480 volt models are provided with sepa-

rate 120 volt cord and plug for lter pump,

controller, and/or basket lifts.

CLEARANCE INFORMATION

A minimum of 24” (61.0 cm) should be provided at the front of the unit for servicing and

proper operation, and 6” (15.2 cm) between

the sides and rear of the fryer to any combustible material.

Contact Customer Service at 1-800-221-4583 inside

USA; +1-318-865-1711 outside USA.

C = center, R = right)

D

44”

(1118)

H

55”

(1397)

We reserve the right to change specications appearing in this bulletin without incurring any obligation for equipment previously or subsequently sold.

Check www.frymaster.com for updates.

Loading...

Loading...