Frymaster 714E Service Manual

Cool Zone Series Electric Fryers

Models 714E, 1414E, 1818E & 2020E

Installation & Operation Manual

Dean, a member of the Commercial Food Equipment Service Association, recommends using

CFESA Certified Technicians.

24-Hour Service Hotline 1-800-551-8633

Price: $6.00

819-5867

PLEASE READ ALL SECTIONS OF THIS MANUAL AND RETAIN FOR FUTURE

REFERENCE.

This product has been certified as commercial cooking equipment and must be

installed by professional personnel as specified.

We suggest installation, maintenance and repairs should be performed by your

local Factory Authorized Service Center.

INSTRUCTIONS TO BE FOLLOWED IN CASE THE USER SMELLS GAS ARE TO BE POSTED

IN A PROMINENT LOCATION. THIS INFORMATION SHALL BE OBTAINED BY CONTACTING

THE LOCAL GAS COMPANY OR GAS SUPPLIER.

FOR YOUR SAFETY, DO NOT STORE OR USE GASOLINE OR

OTHER FLAMMABLE VAPORS AND LIQUIDS IN THE VICINITY

OF THIS OR ANY OTHER GAS APPLIANCE.

IMPORTANT

SAFE AND SATISFACTORY OPERATION OF YOUR EQUIPMENT DEPENDS

ON IT’S PROPER INSTALLATION. INSTALLATION MUST BE

PLANNED IN ACCORDANCE WITH ALL APPLICABLE STATE

AND LOCAL CODES.

WARNING

Safety labels are a required component of this unit. If missing, or not legible, they must be

replaced. Inspect periodically and replace if necessary. Replacement labels are available

free of charge from the factory.

TABLE OF CONTENTS

1. DESCRIPTION AND SPECIFICATIONS.....................................................1

2. PRE-INSTALLATION......................................................................................2

3. RECEIVING AND INSTALLING THE FRYER............................................2

4. INITIAL START-UP.........................................................................................3

5. DAILY OPERATION........................................................................................4

6. CLEANING & MAINTENANCE.....................................................................5

7. TROUBLESHOOTING.....................................................................................6

8. RECOMMENDED SPARE PARTS/PARTS LIST .........................................7

9. FACTORY SERVICE & PARTS ORDERING..............................................11

10. SPECIFICATIONS......................................................................................12

11. WIRING DIAGRAMS..................................................................................13

LIMITED WARRANTY.......................................................................................17

1. DESCRIPTION AND

SPECIFICATIONS

The Dean Industries Electric Deep Fat Fryers

are energy-efficient, electrically heated units,

listed by the Underwriter's Laboratory, and

manufactured to the following basic

performance and application specifications. All

units are shipped complete assembled, with any

accessories packed inside the fryer tank. All

units are adjusted, tested and inspected at the

factory prior to crating for shipment.

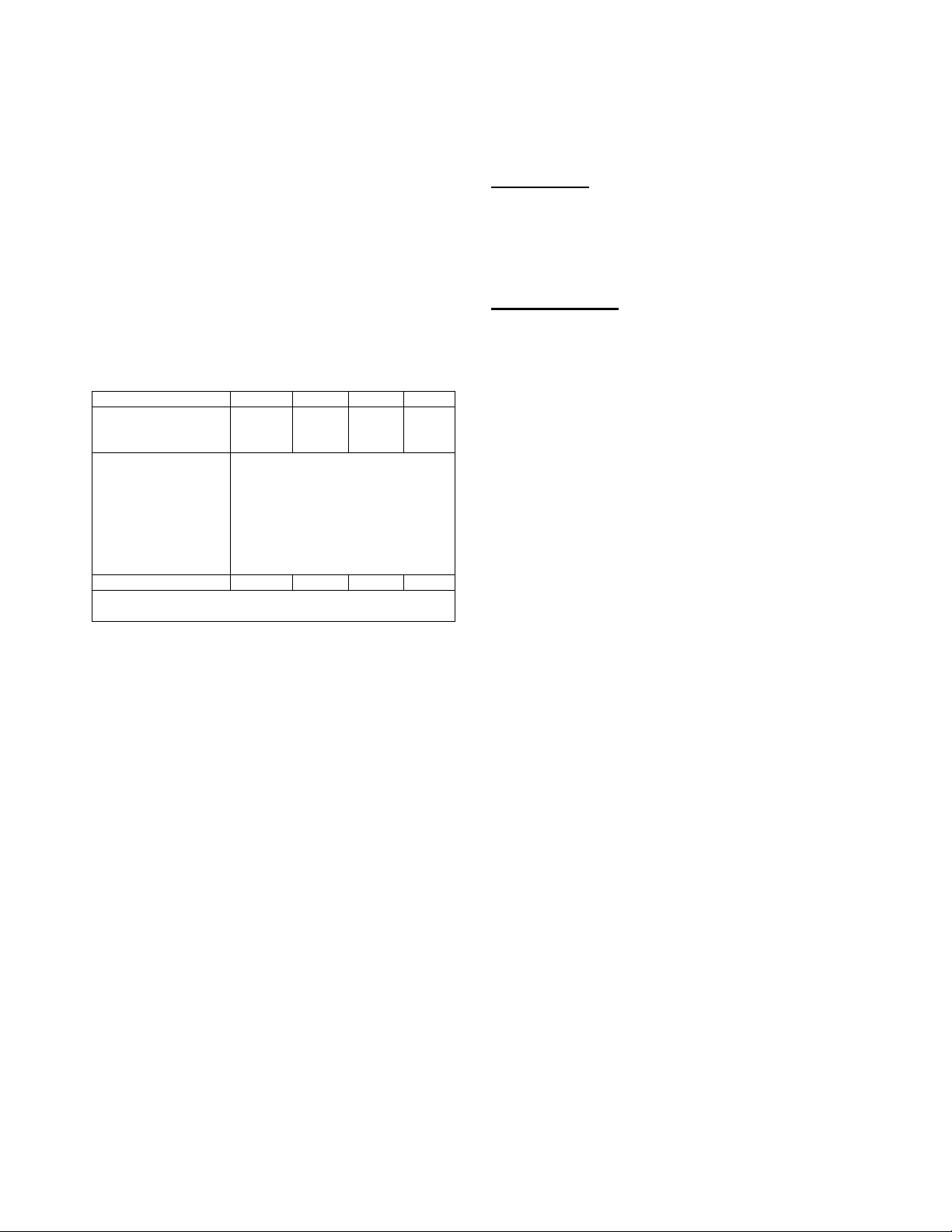

MODEL 714E 1414E 1818E 2020E

FRYING VESSEL

Frying Area:

Oil Capacity

ELECTRICAL

REQUIREMENTS:

Wattage:

Amperage:

APPROX. SHIPPING 115# 153# 190# 200#

Note: 1818E and 2020E are also available in 13.5 KW

models.

6-3/4x14

25#

18KW

208V, 3hp, 49.9 ALL

MODELS

208V, 1hp, 86.5

240V, 3hp, 45.7

240V, 1hp, 75.0

14x 14"

40#

18x18"

70#

20x20

80#

front door on or near the cabinet floor. Optional

panel-mounted main power switch, rocker-type

reset switch, melt cycle switch, and instant

power switch are mounted on control panel.

Melt Cycle:

This feature pulses the heating elements on and

off at a controlled rate. This should be used

when the fryer is being used with solid

shortening.

Instant power:

Except on bulb and capillary type thermostats,

this feature by-passes the temperature

controller for a pre-set period of time to provide

maximum heating power into frying compound

and to allow the operator to anticipate heavy

use.

AUTOMATIC SAFETY FEATURES:

a) High temperature detection to shut off

power to the heating elements should the

controlling thermostat fail.

b) Optional safety switch built into the drain

valve prohibits element operation with the

drain valve even partially open.

VESSEL CONSTRUCTION:

Welded, heavy gauge stainless steel; three

heater elements fixed inside the vessel with an

inner chromed wire mesh protective crumb

screen over the elements. Drain tapped into

center of vessel with front-controlled manual

ball valve.

BODY CONSTRUCTION:

Welded steel base, with visible surfaces of

brushed Series 300 stainless steel or painted

steel. Frame supported by 6" adjustable legs or

5" casters on line-ups of multiple units.

OPERATING CONTROLS:

Unit is shipped standard with a liquid bulb filled

thermostat or an optional solid state

temperature controller. Either temperature

control is mounted in the cabinet behind the

RATING PLATE:

This is riveted to the inside right-hand corner of

the fryer door.

Information on this plate includes the model and

serial numbers; when communicating with the

factory about a unit or requesting special parts

or information, this data is essential for proper

identification. Other information on this plate is

the kW output of the heaters and electrical

requirements.

ALL DEAN INDUSTRIES DEEP FAT

FRYERS MUST BE CONNECTED ONLY TO

THE TYPE OF ELECTRICAL SERVICE

IDENTIFIED ON THIS RATING PLATE!

1

2. PRE-INSTALLATION

3. RECEIVING &

GENERAL:

Installation of any heavy-duty electrical

appliance should be made by a licensed

electrician.

STANDARDS:

Installation must be planned in accordance with

all applicable state and local codes, taking into

account the following standards:

a) Nat'l Electrical Code ANSI/NFPA

#70-1984:

American National Standards Institute

1430 Broadway

New York, NY 10018

b) NFPA Standards #96 and #211:

National Fire Protection Association

470 Atlantic Avenue

Boston, MA 02110

CAUTION

Local building codes will usually not permit a

deep fat fryer with its open tank of hot oil to be

installed beside an open flame of any type,

whether a broiler or the open burner of a range.

Check local codes before beginning installation.

AIR SUPPLY & VENTILATION:

The area around the appliance must be kept

clear to avoid obstruction to the flow of

ventilation air as well as for ease of

maintenance and service. Under no conditions

is the interior of the fryer's cabinet to be used

for storage.

INSTALLING THE FRYER

UNPACKING:

Check that the container is upright. Use

outward prying - no hammering - to remove the

carton. Check the fryer(s) for visible damage; if

such damage has occurred, do not refuse

shipment, but contact the carrier and file the

appropriate freight claims. Do not contact the

factory, as the responsibility for shipping

damage is between the shipper and the dealer

or end-user.

Remove, unwrap, wash, and temporarily set

aside any accessories shipped in the fryer

vessel. These may include:

Basket hanger with baskets

Wire crumb screen

Goofer rod (clean-out rod)

Drain pipe extension

Lifters, scoops

Vessel cover

Teflon cleaning brush

Legs

LEGS:

Legs should be installed near where the

appliance is to be used. After unpacking, raise

the unit about a foot to permit the legs to be

screwed into their couplings, and lower it gently

to keep any undue strain from the legs and

internal mounting hardware. It is strongly

recommended that a pallet or lift jack be used

rather than tilting.

POSITIONING:

a) Means must be provided for any

commercial heavy-duty cooking

appliance to exhaust cooking vapors to

the outside of the building.

b) Filters and drip-throughs should be part

of any industrial hood, but consult local

codes before constructing and installing

any hood.

Do not push against any of the edges of the unit

in an attempt to adjust its position. Lift it slightly

and place it where it is to be installed. Although

all metal parts are deburred during

manufacture, accidents could occur if the fryer

(or a line-up) should move suddenly while being

pushed into position by hand. Pushing a unit

(rather than using a lift jack) also increases the

probability of bending the leg spindles or the

internal coupling connectors.

2

LEVELING:

a) A carpenter's spirit level should be

placed across the top of the fryer and

the unit leveled both front-to-back and

side-to-side. If it is not level, the unit

may not function efficiently, the oil may

not drain properly for filtering, and in a

line-up it may not match adjacent units.

b) If the floor is smooth and level, level the

unit with the screw thread of the legs;

adjust to the high corner and measure

with the spirit level. If the floor is uneven

or has a decided slope, level the unit

with metal shims; the adjustment

required may exceed the threat available

in the leg.

ELECTRICAL CONNECTIONS:

Close the drain-valve completely and remove

the crumb screen.

Make sure the screws holding the thermostat

and limit control sensing bulbs into the vessel

are tight.

HEATING THE VESSEL:

Fill the fryer vessel with hot or cold water to the

"oil level" line scribed into the back of the tank.

This step will check the heating element

operation, initial thermostat calibration, and

cleans the vessel for initial production.

a) Set the operating thermostat dial to

225°F, just above that of boiling water.

b) Turn on the power switch on the left side

of the control panel.

Standards:

The information in this manual is for reference

only. Installation must be planned and carried

out in accordance with local codes.

Connections to the terminal block and

grounding lug should be made through the hole

provided for this purpose in the junction box.

The wiring diagram is attached to the inside of

the fryer door and all diagrams are included in

the centerfold of these instructions. Amperage

for each unit depends on the type of installation

and accessories supplied with the unit. See

detailed instructions packaged with the line-up.

4. INITIAL START-UP

CLEANING:

New units are wiped clean with solvents at the

factory to remove any visible signs of dirt, oil,

grease, etc., remaining from the manufacturing

process, then given a light coat of oil. They

should be washed thoroughly with hot, soapy

water to remove film residues and any

installation dust or debris before being used for

food preparation, then rinsed out and wiped dry.

Wash also any accessories shipped with the

unit.

c) When the water starts to boil, turn the

dial to below 212°F. The elements will

turn off and the water will stop boiling.

d) When satisfied that the heaters and

thermostat are operating properly, drain

the vessel of water and dry thoroughly.

Refill it with shortening as directed

below.

FINAL PREPARATION:

a) When using a liquid shortening (cooking

oil), fill the fryer to the "oil level" line

scribed into the back of the vessel.

b) When using solid shortening, either melt

it first or cut it into small pieces and pack

it thoroughly around the heating

elements, leaving no air spaces around

the elements and being careful not to

disturb the sensing bulbs. Melt this

shortening either with the "melt cycle"

control or by turning the heaters "ON" for

about five to ten seconds, "OFF" for a

minute, "ON" for five to ten seconds,

"OFF" for a minute, etc., until the

shortening is melted. If you see smoke

coming from the oil while melting this

way, shorten the "ON" cycle and

lengthen the "OFF" cycle, as smoke

indicates that you are scorching the

shortening and reducing its usual life.

3

c) When the fryer vessel is filled and the

WARNING:

shortening melted, replace the crumb

screen.

d) Before starting operation, turn the

operating thermostat to the probable

working temperature, wait for the

temperature to stabilize, then check with

a high-quality immersion thermometer.

the frying compound temperature will

stabilize and be ready for production.

USE OF THE FRYER:

For optimum results, the following general

information is offered.

a) For consistent product quality,

convenience, and long-term savings,

use a high-quality liquid frying

compound.

The fryer must not be operated without

enough cooking compound in the vessel to

cover the heating elements.

Do not move a fryer filled with a hot liquid.

Always wear oil-proof, insulated gloves

when working with the fryer filled with hot

oil

Always drain hot oil into a metal

container...hot oil can melt plastic buckets

and crack glass on containers.

5. DAILY OPERATION

OPENING:

At opening time, always visually check the fryer

for:

a) Power switch "off".

b) Temperature controller dial "OFF".

GENERAL TURN-ON PROCEDURE:

a) If the fryer is empty, pour enough frying

compound into the fryer to at least cover the

heating elements, or fill the vessel to the "oil

level" line scribed on the rear wall. If solid

shortening is to be used, melt enough in a

separate container to cover the heating

elements in the bottom of the vessel, then

melt the rest in the vessel by turning the

power switch off and on.

b) If using solid shortening, never attempt

to melt a block of shortening by setting it

whole in the fryer vessel. This is

inefficient and dangerous.

c) Temperature of frying compound.

Although 350°F is the usual temperature

recommended for most cooking

operations, frying should be carried out

at the lowest temperature which will

produce a high quality and product while

ensuring maximum life of the frying

compound.

When the fryer is not in use, the

temperature controller or operating

thermostat should be set lower than that

used during cooking. Light loads, too,

may be cooked at lower temperatures.

A good operator will experiment to

determine the optimum temperature and

load conditions for the various food

items to be cooked.

d) Salting. Operators sometimes salt the

food over the frying vessel. This

practice should be avoided, as salt

deteriorates the frying compound quickly

and flavors everything being cooked, not

just the batch being salted.

FILTERING:

The frying compound should be filtered at least

daily, or even more frequently if cooking is

heavy. This assures the longest life possible for

the frying compound, gives a better taste to the

food being prepared, and minimizes flavors

being transferred from batch to batch.

b) Turn the power switch on; turn the

temperature controller to 350°F

(recommended). In less than 30 minutes,

When completing a filter cycle, always close the

return valve(s) at the fryer(s) to avoid siphoning

oil out of the fryer into the filter, and open the

4

Loading...

Loading...