Page 1

MF90 Series Portable Filters

Installation & Operation Manual

MF90-65, -80, -110, -126, -160 & -172

"U" & "AU" CONFIGURATIONS

Dean Industries, a member of the Commercial Food Equipment Service Association,

recommends using CFESA Certified Technicians.

24-Hour Service Hotline 1-800-551-8633

Price: $6.00

819-5808

10-00

Page 2

Please read all sections of this manual and retain for future reference.

Installation, maintenance, and repairs should be performed by your Dean

Factory Authorized Service Center.

CAUTION

DO NOT STORE OR USE GASOLINE OR OTHER FLAMMABLE VAPORS AND LIQUIDS IN

THE VICINITY OF THIS OR ANY OTHER COOKING APPLIANCE.

WARNING

IMPROPER INSTALLATION, ADJUSTMENT, ALTERATION, SERVICE, OR

MAINTENANCE CAN CAUSE PROPERTY DAMAGE, INJURY OR DEATH. READ THE

INSTALLATION, OPERATING AND MAINTENANCE INSTRUCTIONS THROUGHLY

BEFORE INSTALLING OR SERVICING THIS EQUIPMENT.

WARNING

SAFE AND SATISFACTORY OPERATION OF YOUR EQUIPMENT DEPENDS ON ITS

PROPER INSTALLATION. INSTALLATION MUST CONFORM TO LOCAL CODES, OR IN

THE ABSENCE OF LOCAL CODES, WITH THE LATEST EDITION OF THE NATIONAL

ELECTRIC CODE, N.F.P.A. 70.

i

Page 3

MF90 Series Portable Filters

TABLE OF CONTENTS

Page #

1. INTRODUCTION 1-1

2. IMPORTANT INFORMA TION 2-1

3. INSTALLATION INSTRUCTIONS 3-1

4. FILTER OPERATION 4-1

5. CLEANING AND MAINTENANCE 5-1

6. TROUBLESHOOTING 6-1

7. PARTS LIST 7-1

ii

Page 4

DEAN PORTABLE MICRO-FLO OIL FILTRATION SYSTEMS

CHAPTER 1: INTRODUCTION

1.1 Ordering Parts

Customers may order parts directly from their local Factory Authorized Service Center (FASC). See

the numbers listed in section 1.2 for information of your nearest FASC.

To speed up your order, the following information is required:

Model Number Type

Serial Number

Optional Features

Item Part Number Quantity Needed

1.2 Service Information

Call the 1-800-551-8633 or (318) 865-1711 Service Hotline number for the location of your nearest

Factory Authorized Service Center. Always give the model and serial numbers of your filter unit.

Also, identify if your unit is supplied with or without a heater.

To assist you more efficiently, the following information will be needed:

Model Number Type

Serial Number

With/Without

Heater

Optional Features

With/Without

Heater

Nature of Problem:

Additional information (i.e. oil temperature at filter time, time of day and other pertinent

information) may be helpful in solving your service problem. Communicate with your service

technician.

1-1

Page 5

1.3 After Purchase

In order to improve service, have the following chart filled in by the Dean Authorized Service

Technician who installed this equipment.

Authorized Service

Technician/FASC

Address

Telephone/Fax

Model Number

Serial Number

1.4 Safety Information

Before attempting to operate your unit, read the instructions in this manual thoroughly.

Throughout this manual, you will find notations enclosed in double-bordered boxes similar to the

ones below.

CAUTION boxes contain information about actions or conditions that may cause or result in a

malfunction of your system.

CAUTION

Example of a CAUTION box.

WARNING boxes contain information about actions or conditions that may cause or result in

damage to your system, and which may cause your system to malfunction.

WARNING

Example of a WARNING box.

DANGER boxes contain information about actions or conditions that may cause or result in injury

to personnel, and which may cause damage to your system and/or cause your system to malfunction.

DANGER

Example of a DANGER box.

1-2

Page 6

DEAN PORTABLE MICRO-FLO OIL FILTRATION SYSTEMS

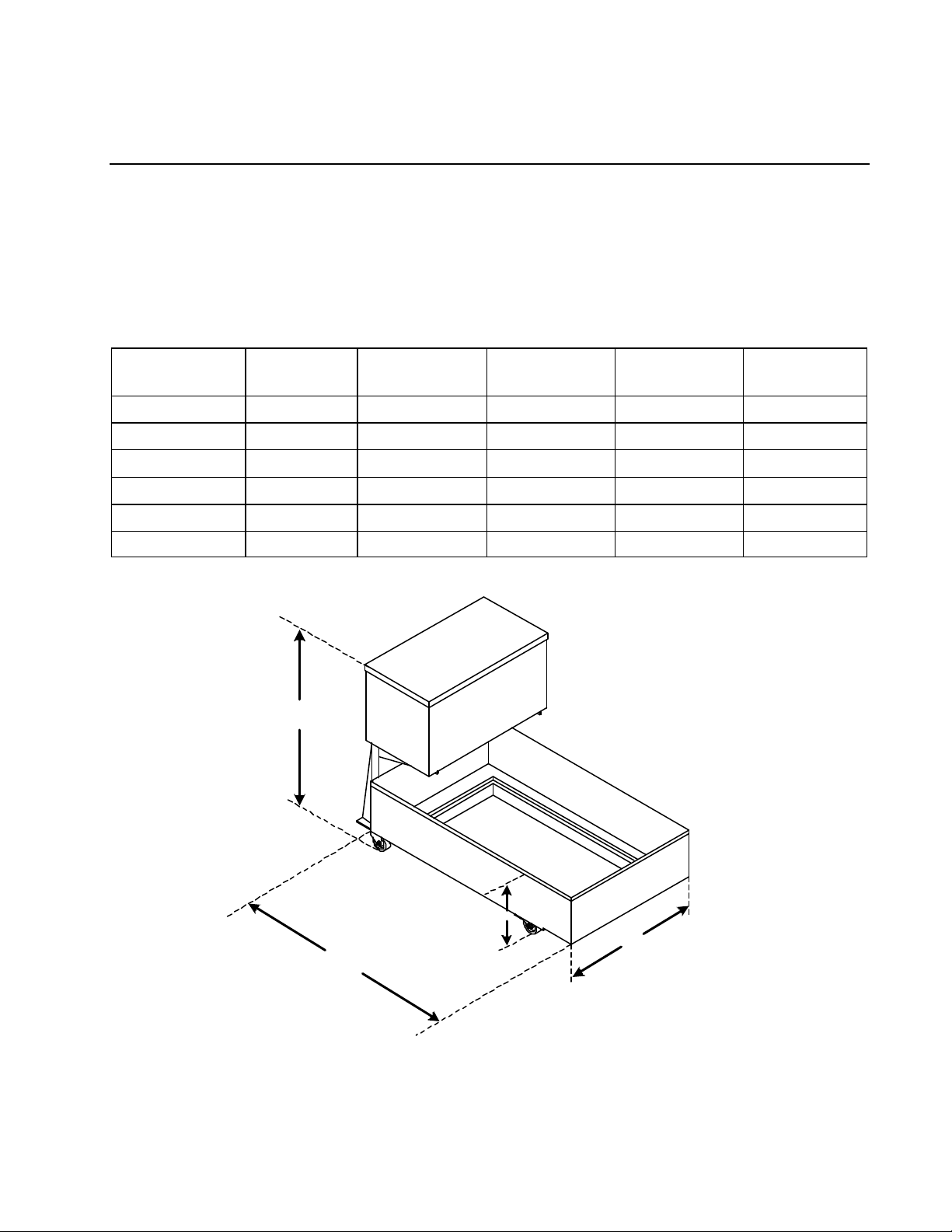

MF90 Series filter unit dimensions (unit and tank heights are measured from bottom

CHAPTER 2: IMPORTANT INFORMATION

2.1 General

The MF-90 portable oil filters may be used with a variety of Dean fryers, as well as other

manufacturers’ equipment. Oil capacity ranges from 65 to 172 pounds of oil, depending on the

model. Length, width, height and tank depth dimensions for all units are listed in the table below.

Model Unit Height

(inches)

MF-90/65 26.87 14 29.5 14 65

MF-90/80 24.12 18.25 24.75 11.25 80

MF-90/80 LP 24 18 34.75 9.63 105

MF-90/110 26.37 18.25 24.75 13.25 110

MF-90/160 25.25 18.25 37 11.5 160

MF-90/172 31 18 29 15 172

Tank Width

(inches)

Tank Length

(inches)

Tank Height

(inches)

Oil Capacity

(pounds)

Unit Height

Tank Height

Tank Length

of casters to top of unit and tank, res pectively).

Tank Width

2-1

Page 7

2.1 General (cont.)

The used oil may be drained by gravity from the fryer into the filter pan, or removed from the fryer

by use of a suction/return hose, according to model. The oil is pumped back into the fryer vessel

using the same suction/return hose.

Oil or shortening is filtered through replaceable filter paper. Filter powder, which enhances the

filtering process, is distributed over the paper prior to filtering.

All units are shipped completely assembled with accessories packed inside the frypots. All units are

adjusted, tested and inspected at the factory before shipment.

CAUTION

The on-site supervisor is responsible for ensuring that operators are made aware of

the inherent dangers of operating a hot oil filter system, particularly the aspects of

oil filtration, and draining/cleaning procedures.

A 7-amp (115V-domestic), or 5-amp (230V-international) circuit breaker installed on the filter unit

switches the power OFF if an overload occurs.

NOTE: If the circuit breaker is triggered, depress the reset button to activate the circuit after the

failure has been detected and repaired.

2.2 Rating Plate

Information on the rating plate includes model and serial numbers, as well as electrical requirements.

Have the rating plate information handy when communicating with the factory about a unit or

requesting special parts or information. Without this information, proper identification of the unit

cannot be confirmed.

2.3 Pre-Installation

NOTE: Failure to use qualified service personnel will void the Dean warranty.

A. Standards: Use of this filter unit must be in accordance with all applicable state and local

codes.

B. Electrical Connections: Domestic MF90 filter units require a 115V 60 Hz., 15 amp electrical

supply. Units are equipped with a grounded male receptacle for use with a flexible six-foot,

16-3 SJT power cord set. If an extension cord is required, it must be a three-conductor,

grounded power cord of at least 16 gauge.

2-2

Page 8

2.4 Unpacking the Filter System

Ensure the container is upright. Unpack the filter carefully a nd remove all accessories from the

carton. Do not discard or misplace parts and/or accessories; they will be needed. Any

accessories or starter kits included with the unit will be packaged inside the filter tank strapped

to the shipping frame.

After unpacking, immediately check the equipment for visible signs of shipping damage. If

such damage has occurred, contact the carrier and file the appropriate freight claims. Do not

contact the factory, as the responsibility of shipping damage is between the carrier and dealer

or end-user.

If your equipment arrives damaged:

a. File claim for damages immediately – Regardless of extent of damage.

b. Visible loss or damage – Be sure this is noted on the freight bill or express receipt and is

signed by the person making the delivery.

c. Concealed loss or damage – If damage is unnoticed until equipment is unpacked, notify

freight company or carrier immediately, and file a concealed damage claim. This should be

done within 15 days of date of delivery. Retain the shipping container for inspection.

NOTE: Dean does not assume responsibility for damage or loss incurred in transit.

2-3

Page 9

DEAN PORTABLE MICRO-FLO OIL FILTRATION SYSTEMS

CHAPTER 3: INSTALLATION INSTRUCTIONS

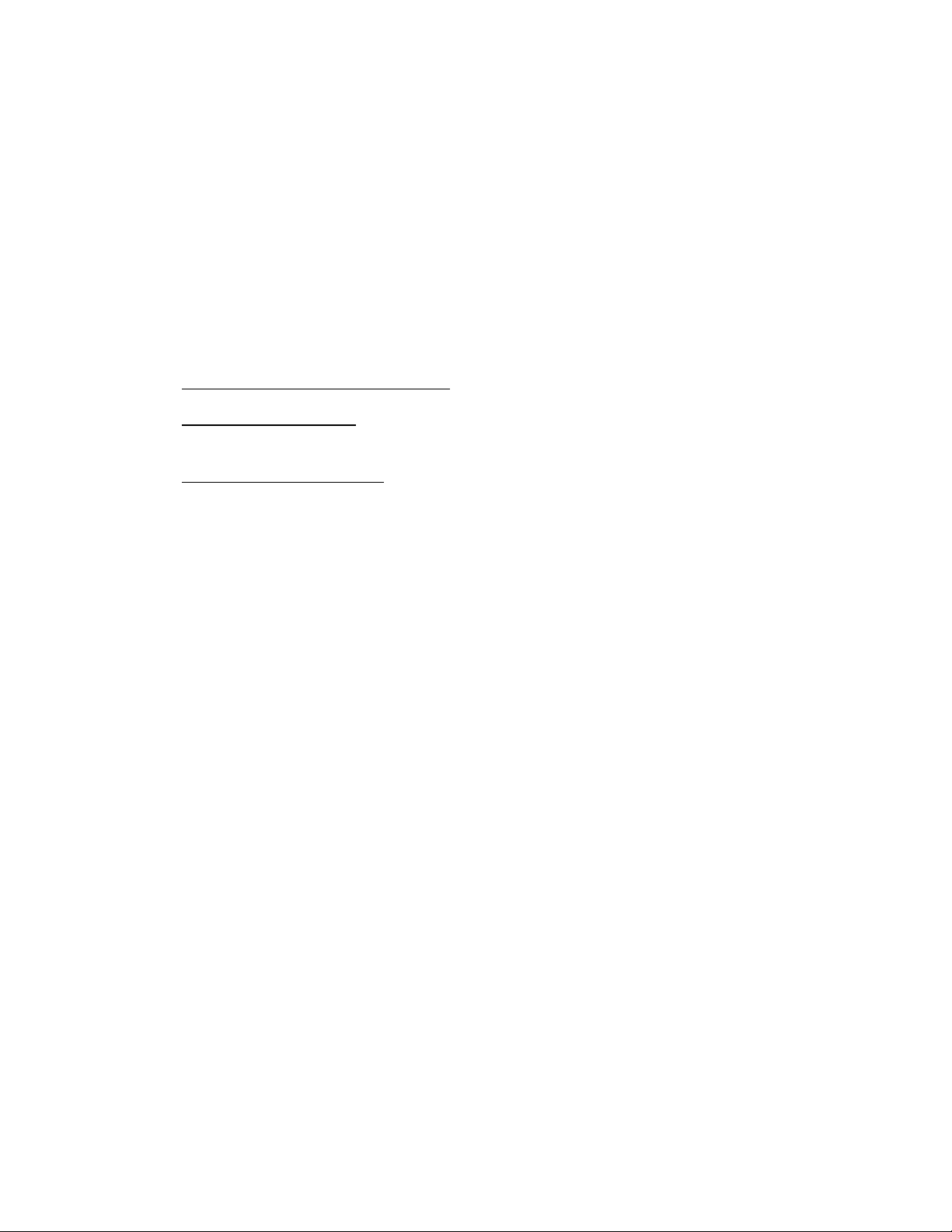

3.1 Assembling The Filter System

On initial installation and before each use, remove all loose parts from the filter, wash the

filter pan and all accessories in hot, soapy water and dry thoroughly.

WARNING!

Water or boil -out solution MUST not be allowed to drain into the filter pan or

filter system. Irreversible damage will result if water is allowed into the

system, and the warranty will be voided.

The MF90 filt ration system uses a filter support grid, two sheets of filter paper and a holddown ring to secure the filter paper in place.

3.1.1 Filter Paper Configuration

See illustration for proper

assembly.

1. Filter Pan Cover

2. Hold-Down Ring

12345

3. Filter Paper (2 sheets)

4. Screen/Support Grid

5. Filter Pan Assembly

A. First, place the support grid in the bottom of filter pan.

B. Put two filter paper sheets on top of the support grid. Be sure the paper covers the whole

filter pan bottom.

C. Position the hold-down ring on top of the filter papers and latch the hold-down ring and

filter papers securely against the filter pan bottom, forming a tight seal.

3-1

Page 10

3.1.1 Filter Paper Configuration (cont.)

MF-90 portable filter positioned correctly next to fryer drain valve, with rear casters

D. Sprinkle 16 ounces of filter powder on the top filter sheet. Distribute the powder over the

filter paper as evenly as possible. If filtering a second frypot immediately after the first,

add only 8 ounces of filter powder for the second filtering.

E. Place the crumb catcher screen (if used) in the filter pan. Allow the crumb catcher to rest

on the top edges of the hold-down ring.

F. Place filter pan cover onto the filter pan assembly.

G. Position filter under the fryer drainpipe for gravity drain operations, or nearby for suction

operations. Lock rear casters to prevent filter from moving out of position during the

filtering process.

locked in place.

3-2

Page 11

DEAN PORTABLE MICRO-FLO OIL FILTRATION SYSTEMS

CHAPTER 4: FILTER OPERATION

4.1 General

The Dean Portable Filters are designed to operate primarily as an independent filter unit.

Operations always start by ensuring the unit is properly plugged in, then rolling the filter to

the fryer to be filtered. The filter will work directly under the fryers’ drain valves. The

general layout of a generic MF90 Series Portable Filter System with major components

identified is illustrated below.

WAND

FRY VESSEL

OIL-RETURN HOSE

QUICK-DISCONNECT

COUPLING

PUMP

DRAIN VALVE WITH

EXTENSION

LOCKING

REAR

FILTER PAN

Arrows indicate direction of oil flow during the filtration process.

CASTERS

4-1

Page 12

4.2 Filtering Tools

Scrape exc

ess sediment from top filter

These tools are not required, but are recommended to make the filtering task easier.

A. Measuring Cup: Used to measure eight ounces by volume of filter powder.

B. Scrub Brush: To clean sediment and residue from the filter pan and fry vessel.

C. Appropriate Clothing.

4.3 Filter Preparation

1. Position the MF-90 filter next to the fryer. Remove filter pan lid and position filter

unit under frypot drain-valve extension

2. Ensure the filter power switch is in “OFF” position prior to connecting to power

supply.

3. Plug power cord into electrical outlet. The filter unit is ready for filtering. If

equipped, turn on heater switch to allow pan to preheat. After filtering, follow

instructions in Section 4.4, Changing Filter Paper.

CAUTION

The crumb tray (if equipped) in portable filter systems must be emptied into a

fireproof container at the end of frying operations each day. Some food

particles can spontaneously combust if left soaking in certain shortening

material.

4.4 Changing Fi lter Paper

The top sheet of filter paper should be replaced

after each filter session, and most certainly at the

beginning of each workday. If filter paper is

replaced once per day, excess sediment should

be scraped from the top filter paper after each

frypot is filtered (see photo). Filter at closing if

possible. This ensures the oil/shortening is at

proper filtering temperature.

paper sheet after filtering.

4-2

Page 13

4.4 Changing Filter Paper (cont.)

Remove and replace the paper as follows:

1. Remove filter cover.

2. Open the locking clips of the holddown ring and lift the ring out of the

filter tank.

3. Roll both ends of the top filter paper

into the center, making sure no

sediment falls out, and discard.

Remove the second sheet of filter

paper and retain for re-use.

4-3

Page 14

4.4 Changing Filter Paper (cont.)

Solidified shortening build

-

up around and in

4. Remove and check the support screen

for cleanliness and scrub if

necessary. Ensure there is no buildup of shortening around the nipple

assembly.

5. Check the filter-pan for cleanliness

and scrub if necessary; check the

drain ports at the bottom rear of the

filter pan also.

6. Replace the filter support screen and

place a new sheet of filter paper on

top of the screen. Place the

previously used sheet of filter paper

over the new sheet.

nipple-pipe assembly.

4-4

Page 15

4.4 Changing Filter Paper (cont.)

7. Replace the hold-down ring and

secure.

8. Replace filter pan cover.

4.5 Unit Operation

1. When filtering, follow these steps:

2. Follow the appropriate Sections 4.3 and 4.4 to prepare your filter for operation.

3. Then position filter under fryer drain valve extension for gravity drain, or near the fryer if

the unit is an “AU” unit.

4. Turn the fryer main power switch to the “OFF” position.

WARNING

Do not leave filter unit unattended during the filtering operation. Pressurized

oil moving through the lines can cause the flexible return hose and wand

assembly to pop loose and leak hot oil.

Avoid spilling hot oil onto floor surfaces. Never drain more than the maximum

amount of oil listed on the filter pan.

5. If filter is equipped with an optional heater, turn the filter switch to the heater position for

20 minutes before filtering in order to melt any solid shortening in the pump lines.

4-5

Page 16

4.5 Unit Operation (cont.)

6. Open the fryer door and ensure the filter is in the proper position under the fryer drain

valve extension. Lock rear casters to prevent filter movement during the filtering

process.

WARNING

The oil temperature of the fryer to be filtered should be approximately 350°F

(175°C). Position drain handles properly prior to operating the filter unit.

Failure to do this can result in burn injury to the user.

7. Open the drain-valve and allow the fry

vessel oil to drain into the filter pan.

4-6

Page 17

4.5 Unit Operation (cont.)

8. With oil return nozzle in the vessel, turn

filter switch “ON” to begin pumping

clean oil into the fryer. Allow the oil to

recycle through the fryer for a few

seconds to wash out sediment on the

bottom of the cooking vessel before

closing the drain valve.

9. Close the drain valve handle. It takes

approximately 5 to 7 minutes for the filter

to pump all the oil back into the fryer.

10. Allow the pump to run for 10-15 seconds

after air starts to flow through the wand,

before shutting off the filter. Clearing

residual shortening/oil from the return

lines reduces the likelihood of clogged

lines.

CAUTION

Operating the fryer without oil in the fryer vessel will cause damage to the

fryer and the warranty will be voided.

4-7

Page 18

4.5 Unit Operation (cont.)

NOTE: After filtering, scrape off debris and sediment accumulated on the filter paper and

discard.

CAUTION

If using solid shortening, the return hose must be completely drained after

filtering, or the shortening will solidify and plug the hose or oil return lines as

it cools.

NOTE: If filtration operations problems are encountered during use, please refer to

Chapter 6 in this manual.

4-8

Page 19

DEAN PORTABLE MICRO-FLO OIL FILTRATION SYSTEMS

CHAPTER 5: CLEANING AND MAINTENANCE

5.1 General

Cleaning operations fall into three general categories:

?? Wiping unit clean after each filter session;

?? Cleaning, changing filter paper and preparing the unit for the next day’s business.

?? Weekly cleaning to remove oil deposits and other particles that were previously

missed.

WARNING

Do not use water jets to clean this equipment.

CAUTION

Never operate the filter unit unless cooking oil is at operating temperature.

5.2 Each Filter Use

Every time your Portable Filter System is used:

?? Wash down the insides of the filter pan with hot oil.

?? Change the top filter paper sheet after each filter session or at the end of the day.

Scrape sediment from the top sheet after each frypot is filtered within a filter session.

?? Wipe up any oil which may have splashed or spilled.

?? Wipe all exterior surfaces of the filter unit.

CAUTION

Do not run water or boil -out solution through the filtration system. Doing so

will cause irreparable damage to the pump, and the warranty will be voided.

5-1

Page 20

5.3 Daily- Close Of Business

At the close of a working day, the last order of business should be to filter the oil in all fryers.

When the last fryer is finished, follow these steps:

1. Ensure the flexible hose and pump lines are clear by running the filter pump for an

additional 10–15 seconds after air bubbles start coming from the oil return line. Then

drain the flexible hose.

2. Remove the filter pan cover and hold-down ring assembly, then remove the filter

paper and filter support screen.

3. Discard the top filter paper sheet and retain bottom filter paper sheet for re-use.

4. Wash all filter components with soapy water and rinse.

5. Dry all filter parts and filter pan thoroughly before reassembling.

6. Check all fittings at the rear of the filter unit; ensure that all fittings are properly

tightened.

CAUTION

The crumb tray in portable filter systems must be emptied into a fireproof

container at the end of frying operations each day. Some food particles can

spontaneously combust if left soaking in certain shortening material.

5.4 Weekly

Follow the same procedure as for “Daily”, with these additional steps:

?? Wash the filter pan with hot, soapy water and a brush. Dry and reassemble with new

filter paper.

?? Clean thoroughly under, around, and behind the fryers and filtering area.

?? Do not operate motor/pump until all traces of water have been removed from the

pan. Under no circumstances should water or boil-out solution be allowed to enter

the pump housing.

?? Check the connections of the inlet lines and tighten if lines become loose or start to

leak oil.

5-2

Page 21

DEAN PORTABLE MICRO-FLO OIL FILTRATION SYSTEMS

CHAPTER 6: TROUBLESHOOTING

6.1 Operating Problems

Plugged lines and plugged filter paper account for over 90% of filtration system

malfunctions. Troubleshooting flowcharts included in this chapter, provide step-by-step

instructions to assist the operator in diagnosing common malfunctions.

A. Plugged Lines

1. If solid shortening is used, and the portable filter is operated improperly, the motor

may deactivate before hot shortening is completely pumped back into the fryer.

Solidification of shortening in the lines will occur as the shortening cools. It is very

important to pump all hot shortening out of the lines to prevent plugging.

2. Hot oil/shortening drains from the frypot into the filter pan, then is drawn through

the filter paper, exits the pan through the ports on the filter pan bottom, then flows

through a rigid tube to the filter pump. From the pump, oil returns to the fryer

through the flexible oil return hose.

3. A solid-shortening plug can exist anywhere in this path; locate the plug using the

procedures found in the flowcharts at the end of this chapter

4. To guard against plugged lines when using solid shortening, follow these guidelines:

a. At the end of the filtering cycle, let the filter bubble into the fryer through the

flexible hose for about 10-15 seconds. If it is blowing bubbles, air is moving

through the lines and the filter is less likely to be plugged.

b. If your filter is equipped with a pan heater, use it each time before you filter.

c. When pumping hot shortening back into the fryer, tilt the filter machine to the

rear for about ten seconds at the end of the filtering cycle. This will remove

about three cups of hot shortening remaining in the bottom port area.

d. When filtering is completed, disconnect the flexible line and drain any

remaining shortening from the line.

B. Plugged Paper

Improper use of the filter pre-coat powder will cause a slow oil flow return rate. The first

indication of paper plugging is a surging, jerking movement of the hose. To correct this,

review the instructions for the correct use of filter powders, and change the filter paper more

frequently. When filtering several fryers prior to changing paper, ensure that excess

sediment is scraped off the filter paper after filtering each frypot. If plugged paper remains a

problem, review the following flowcharts for proper diagnosis.

6-1

Page 22

6.2 Troubleshooting Flowcharts

The following flowcharts contain information to assist the user in diagnosing the most

common malfunctions with portable filtration systems. Possible solutions and/or corrective

actions are given for each scenario.

When utilizing these flowcharts, begin at the top of the diagram, then follow each step in

sequence. Follow the arrows directing you through the sequence of steps, until you find the

cause of the problem. If the malfunction cannot be diagnosed using the flowcharts, contact

your Factory Authorized Service Agent for repairs.

DANGER

Use extreme care when working with or during electrical circuit tests. Live

circuits will be exposed.

DANGER

Inspection, testing and repair of gas or electrical equipment should be

performed by qualified personnel.

6-2

Page 23

Filter Pump Fails To Pump Oil

Filter

pump

fails to

pump

oil.

If filter unit has a

heater, turn heater

ON and allow to

heat for 20

minutes.

Disconnect flexible oil return

hose. Make sure it is cool before

handling. Try blowing air through

the hose.

Can you blow

air through it?

No

Submerge hose in very hot water,

keeping the water out of the hose.

Water in the hose will cause severe

splattering when hot oil is circulated

through the hose.

Yes

Insert flexible oil

return hose into

filter pan and turn

pump motor ON.

Does oil flow through oil

return hose?

Yes

Proceed with normal

operations.

Once shortening has had time

to soften, reconnect hose to

filter pump.

Blockage is between bottom of the filter

No

pan and the flexible hose quick

disconnect. Go to "Blockage Between

Filter Pan and Flex Hose Valve.

6-3

Page 24

Rate Of Oil Return Slowing

Rate of oil return to fryer is slowing.

Is this the first fryer being filtered

during this filtering session?

Yes

Check the condition

of the filter paper in

filter pan

Is filter paper properly

secured in filter pan

Yes

Replace filter paper, and reinstall

hold-down ring.

Add the correct amount

of filter powder and

reassemble filter.

Check for excess

sediment build-up

No

No

on filter paper

If paper is incorrectly

installed under hold-down

ring, air may be getting into

the system.

Disassemble unit and wipe

excess sediment out of the

bottom of filter pan "sump", and

remove any sediment from

drain ports in pick-up tube.

Install new filter paper.

Turn motor ON. Has the oil rate

improved?

Yes

Proceed with

filtration

Blockage may be between

the bottom of the filter pan

No

Go to "Blockage Between Filter Pan and

and the flexible hose

quick-connect

Flex Hose Valve".

6-4

Page 25

Blockage Between Filter Pan and Flex-Hose Valve

Possible blockage

between filter pan

bottom and flex-hose

disconnect.

Disconnect oil line from

filter pan to pump at the

pump end.

Turn pump ON and allow it to

operate for a few seconds to ensure

it does not run backwards.

Put your finger over the

pump inlet. Is suction

present?

Yes

Pump is clear; plug is

in the bottom of the

filter pan or in the line

from the pan to pump.

Disconnect line at filter pan.

Can you blow air through line

from pump to pan?

Yes

No

Line is blocked. Remove

No

line, soften and clear

solidified shortening.

Blockage is in pump or in

the discharge line.

Reconnect line and

operate pump. If still

no oil flow, blockage

is in bottom of pan.

Remedy problem and continue

filtration process.

6-5

Page 26

6.3 Wiring Diagrams

MF90 Filter Wiring (AU)

PUMP REVERSING

SWITCH HOUSING

SWITCH

OFF/ON HEATER SWITCH

BLK

CB

7 AMP

T5

T8

T1

T4

MOTOR

TERMINAL BOX

(OPTIONAL)

OPTIONAL

RED

BLK 1

BLK 4

BLK 8

BLK 5

BLK 5

BLK 8

BLK 4

BLK 1

WHT

2 AMP

FUSE

TIMER

SWITCH

INDICATOR

REDRED

RED

Junction

LIGHT

Box

BLK

GRN

WHT

OPTIONAL

OPTIONAL

WHT

Suction Sump

Heater One Way Valve

Heater

MF90 Filter Wiring (U)

POWER CORD

AWG 16-3 SJT

BLK

GRN

WHT

PUMP

SWITCH

BLK

CB

7 AMP

BLK

TIMER

SWITCH

P1

P2

BLK

T3

T5

T2

T4

T8

WHT

6-6

Page 27

DEAN PORTABLE MICRO-FLO OIL FILTRATION SYSTEMS

CHAPTER 7: PARTS LIST

7.1 MF-90/65, U and AU Configuration

7-1

Page 28

7.1 MF-90/65, U and AU Configuration (cont.)

ITEM PART # COMPONENT

1 44272-1 Frame Assembly

2 44-0409 Caster Channel

3 1004 Bolt, ¼ - 20 x ½-inch Hex

4 1008 Washer, Flat ¼-inch

5 1005 Nut, Nylock ¼-20

6 2376 Caster, 3-inch, w/o Brake

7 2736 Caster, 3-inch w/Brake

8 1832 Washer, Flat, ½-inch

9 1709 Nut, ½-13 Hex

10 44267 Electric Box Assembly (U65 w/o Heater)

* 44267-2 Electric Box Assembly (AU/65 w/Heater)

* 44267-1 Electric Box Assembly (U/65 w/Heater)

11 1025 Screw, #8 x ½ Type B

12 1892-2 Motor, 1/3HP 230/120V/50/60Hz

* 1726-1 Pump, 5 GPM (18 LPM)

13 1059 Nipple, Black Pipe ½ x 1-½-inch

14 1013 Elbow, ½ x 3/8-inch 90° Black Pipe

15 2083 Nipple, 3/8 x 3-½ -inch

16 1989 Elbow, 3/8 x 45°

17 1014 Nipple, Black Pipe, 3/8" x Close

18 55016 Couple Assembly (Snap-Tight)

19 1350 Seal, Viton Quick-Disconnect

20 44287 Nozzle and Hose Assembly, Complete

* 55220 Nozzle and Hose Assembly

21 1687 Elbow, Street, Black Pipe, ½-inch x 90°

22 1061 Union, Black Pipe, ½-inch

23 1765 Tee, Black Pipe, ½ x 3/8 x ½-inch

24 1012 Nipple, Black Pipe [ ½ NPT x 6-inch]

25 1057-SC Check Valve, Swing ½-(Plated)

26 1011 Elbow, Black Pipe, ½-inch x 90°

27 1076 Nipple, Black Pipe ½NPT x 3-½-inch

28 44291 Hose Assembly w/Fitting (L= 11.75-inch)

29 1644 Quick-Disconnect Male ½-inch

30 1798 Nipple, Black Pipe, [3/8NPT x 2-inch]

* 1799 Nipple, Black Pipe [3/8NPT x2 -½-inch ]

31 1043 Elbow, 3/8-inch x 90°

32 44-0379 Holder, Power Cord

33 1100A Valve, Ball- 3/8-inch

34 55-0004 Bolt, Hold-down Handle

35 1010 Nipple, Black Pipe, ½-inch x Close

36 2124 Nipple, Black Pipe[3/8 NPT x 7-inch]

37 1985 Flare Fitting 3/8-inch NPT

7-2

Page 29

7.1 MF-90/65, U and AU Configuration (cont.)

ITEM PART # COMPONENT

38 1036 Nut, ½-inch Flare 37°

39 1037 Tubing Sleeve ½-inch 37°

40 1034 Tube, SS, [ ½-inch Diameter x Feet]

41 55-0007 Plate, IN-OFF-OUT (AU Only)

* 1081 Plate, PUMP-OFF-HEAT (with Heater Option)

* 1678 Plate, ON-OFF (U Only)

42 1385 Switch, 3PDT 90 Amp Push ON

* 1083 Switch, Toggle SPDT (U Only, With Heater Option)

* 1541 Switch, Toggle (U Only, No Heater Option)

43 44-0443 Handle, Ball Valve, (3/8-inch)

44 1856 Clamp, Pipe ½-inch (Jiffy H-40)

45 44268 Holster, Hose Assembly

46 1032 Screw, 10-32 x ½-inch Round Slotted Head

47 2081 Clamp, Draw (HR-1)

48 1096 Connector, 3/8-inch x 45°

49 1092 Connector, 3/8-inch x 90°

50 1098 Conduit, 3/8-inch Flex

51 2053 Inlet Flanged Base 120V

52 2059 Power Cord,1613 SJTO

53 2036 Circuit Breaker (7 Amp - 120V Applications)

* 2175 Circuit Breaker (5 Amp - 230V Applications)

54 44282 Motor/Pump Cover Assembly (AU-65)

55 44285 Filter Pan Assembly (U/AU-65 /Clamp)

56 1033 Screw, ¼-28 x ½ Round Phillips Head

57 2009 Nipple, Black Pipe [ ½ NPT x 2-½ -inch]

58 1391 Elbow, ½-inch, 45° Black Pipe

59 1075 Nipple, Black Pipe ½NPT x 3-inch

60 55191 Quick Disconnect Assembly ( ½-inch)

61 1645-1 O-Ring

62 55156 Wire Grid and Channel Assembly (#12)

63 1334-PK Filter Paper, 11 x 22-5/8 (20 Sheets/Pack)

* 1334 Filter Paper, 11 x 22-5/8 (100 Sheets/Pack)

64 55127 Hold-Down Ring w/Handle Assembly

65 55-0011 Lever, Hold -Down Ring

66 44262 Pan Assembly, w/o clamps

67 1016 Connector, Male 3/8”

68 55228-SC Handle Assembly

69 55-0121 Nozzle, Threaded (One End)

70 44-0450 Nozzle, Threaded (Both Ends)

71 55-0264 Pipe Screen

72 44286 Pan, Lid Assembly

* 44-0447 Pan Lid Only

73 1039 Handle, Filter Pan Lid (w/Screws)

7-3

Page 30

7.1 MF-90/65, U and AU Configuration (cont.)

ITEM PART # COMPONENT

74 44273 Heater Junction Box

75 44561 8" Strip Heater w/Bracket Weld Assembly**

76 44-0425 Pan Slide, Electric Motor

77 1031 Nut, Nylock (#10-32

* 44274 Rear Heater Guard Assembly

79 44-0828 Pipe Support

* 44-0837 Back , Filter Cover

* 55546 Crumb Basket, MF90/65

* 2174 Glove, Neoprene, (Hot-oil)

* 8030002 Filter Powder

* 1049 Measuring Cup, 16 Oz.

* 55030 Scoop Assembly (Small)

* Not Illustrated

** For probe heater components, see Section 7.2.1.

7.2 MF- 90/80, 80-LP, 110, 126, 160 and 172 Series, U and AU

Configurations

22

15

23

24

20

16

14

11

10

8

9

13

21

17

18

26

19

25

6

12

45

27 28

2 137

7-4

Page 31

7.2 MF- 90/80, 80-LP, 110, 126, 160 and 172 Series, U and AU

Configurations (cont.)

ITEM PART # COMPONENT

1 55084 Lid, Filter Pan Assembly, (80 and 110 Series Only)

* 55086 Lid, Filter Pan Assembly, (126 and 172 Series Only)

* 55135 Lid, Filter Pan Assembly (160 Series Only)

* 55438 Lid, Filter Pan Assembly (80-LP Series Only)

2 1039 Handle, Cover

3 55083 Hold-Down Ring with Handle Assembly Standard (80

and 110 Series Only)

* 55033 Hold-Down Ring with Handle Assembly, Jumbo (126,

160 and 172 Series Only)

* 55308 Hold-Down Ring with Handle Assembly (80-LP Series

Only)

4 55-0011 Locking Lever, Hold Down Ring

5 55-0004 Latch Bolt

6 1038 Filter Paper 16-3/8 x 18-3/8" (80, 80-LP And 110

Only)

* 1054 Filter Paper, 16-3/8 x 24-3/8 (126, 160 And 172 )

* 1053 Filter Powder, 22,7kg (50 lb.) bag

7 55120 Grid and Channel Assembly, Standard [80, 80-LP (UL

AND CE Only) and 110 Series Only]

* 55121 Grid and Channel Assembly, Jumbo (80-LP, 126, 160

and 172 Only)

8 55190 Pan Assembly (80 Series Only)

* 55437 Pan Assembly (80-LP Series Only)

* 55189 Pan Assembly (110 Series Only)

* 55059 Pan Assembly (126 Series Only)

* 55187 Pan Assembly (160 Series Only)

* 55186 Pan Assembly (172 Series Only)

* 55019 Filter Frame Assembly (80 Series Only)

* 55020 Filter Frame Assembly (110 Series Only)

* 55021 Filter Frame Assembly (80-LP and 126 Series Only)

* 55046 Filter Frame Assembly (160 Series Only)

* 55022 Filter Frame Assembly (172 Series Only)

9 1003 Caster, Filter Pan— 2-inch

* 2734 Caster, Filter Pan—2-inch w/Brake

10 2175 Circuit Breaker (5 Amp)

11 1026 Switch, Timer (60 Min.)

12 1026-1 Knob, Timer Switch

13 1385 Switch, IN/OFF/OUT (MF90-AU)

* 1083 Switch, ON/OFF (MF90-U)

* 55-0007 Plate, Switch IN -OFF-OUT

14 55-0029 Switch Housing

7-5

Page 32

7.2 MF- 90/80, 80-LP, 110, 126, 160 and 172 Series, U and AU

Configurations (cont.)

ITEM PART # COMPONENT

15 55217 Suction Tube, Pan to Filter Pump ("U" Series Only)

* 55246 Suction Tube, Pan to Check Valve ("AU" Series Only)

16 1057-SC Valve, Swing Check 1/2"(Plated) ("AU" Series Only)

17 55-0064 Motor Mount Tray

18 55016 Coupler Assembly (Snap-Tight)

19 1016 Male Coupler

20 1726-1 Pump, 5 GPM (18 LPM)

21 1892-2 Motor, 1/3HP 230/120V/50/60Hz

22 1021 Power Cord 10' 16/3 SJTO Black

* 6136 Power Cord 16/3 SJTO(W)

* 2563 Receptacle, 230V, 3-Prong

23 55-0070 Bracket, Handle Cord

24 55-0065 Housing, Top Cover

* 55-0066 Housing, Back Cover

25 55-0068 Motor Housing

26 55210 Hose Only, with Fittings

27 55228-SC Handle Assembly

28 55115 Nozzle with Handle

* 55220 Nozzle and Hose Assembly, Portable Filter

* 55245 Harness Assembly, "A" Type Filter

* 1004 Bolt, ¼ - 20 x ½-inch Hex

* 1005 Nut, Nylock ¼-20

* 1008 Washer, Flat ¼-inch

* 1009 Washer, Lock ¼-inch

* 1010 Nipple, Black Pipe, ½-inch x Close

* 1011 Elbow, Black Pipe, ½-inch x 90°

* 1013 Elbow, ½ x 3/8-inch 90° Black Pipe

* 1014 Nipple, Black Pipe, 3/8" x Close

* 1019 Ring Terminal #8

* 1020 Connector, Romex— 3/8"

* 1022 Ring Terminal #10

* 1025 Screw, #8 x ½ Type B

* 1027 Screw 8-32 x ½ Round Slotted Head

* 1028 Lock-nut, #8-32 Hex

* 1029 Plug Button ½-inch Nickel-Plated

* 1030 Wire Joint RC -6

* 1031 Nut, Nylock, #10-32

* 1032 Screw, 10-32 x ½-inch Round Slotted Head

* 1035 Fitting, 37°, Flare, ½-inch

* 1058 Tee, Black Pipe ½

* 1059 Nipple, Black Pipe ½ x 1-½-inch

7-6

Page 33

7.2 MF- 90/80, 80-LP, 110, 126, 160 and 172 Series, U and AU

Configurations (cont.)

ITEM PART # COMPONENT

* 1061 Union, Black Pipe, ½-inch

* 1063 Wire 16 AWM/TEW Black

* 1074 Nipple, Black Tube—½ x 5-inch

* 1173 Push-On Terminal, RB 250

* 2165 Kep-Nut #10-32 Hex

* 2174 Glove, Neoprene, Hot-Oil

* 55030 Scoop Assembly, Small

* 55218 Tubing Assembly (80, 80-LP, 126 and 160 Series

Only)

* 8030002 Filter Powder, FM/Dean Filters

* 55-0130 Bracket, Strain Relief

* 55089-1 Housing Assembly, Filter— MF-90

* 55089-2 Housing Assembly, Filter— MF-90A

* Not Illustrated

7.2.1 Probe Heater Components, All MF90 U and AU

ITEM PART # COMPONENT

* 1957 Probe Heater ¼ x 6 x ¼ NPT 120V

* X-424-1 Support, Probe Heater Housing

* X-424-2 Housing, Probe Heater

* X-424-3 Cover, Probe Heater Housing

* 1095 Connector, Lt, 3/8" Straight

* 1098 Conduit, 3/8 Flex Lt

* 1096 Connector, Lt, 3/8" x 45°

* 1678 Plate, ON-OFF

* 1082 Light, Indicator (Red)

* 1541 Switch, Toggle

* 1960 Tee, Black Pipe, ½ x ¼ x ½

* 1081 Plate, PUMP-OFF-HEAT

* Not Illustrated

7-7

Page 34

Dean, 8700 Line Avenue, PO Box 51000, Shreveport, Louisiana 71135 -1000

Shipping Address: 8700 Line Avenue, Shreveport, Louisiana 71106

TEL 1-318-865-1711 FAX (Parts) 1-310-327-3343 FAX (Tech Support) 1-318-219-7135

PRINTED IN THE UNITED STATES

SERVICE HOTLINE

1-800-551-8633

Price: $6.00

819-5808 10-00

Loading...

Loading...