Page 1

TS-TPI Turbine Pump Interface

Installation and Wiring Guide

Part Number: 000-0042 Rev. A

Copyright

©

December 2003

Page 2

NOTICE

INCON/EBW has strived to produce the finest possible manual for you, and to

ensure that the information contained in it is complete and accurate. However,

INCON/EBW makes no expressed or implied warranty with regard to its contents.

INCON/EBW assumes no liability for errors or omissions, or for any damages,

direct or consequential, that result from the use of this document or the equipment

which it describes.

This document contains proprietary information and is protected by copyright. All

rights are reserved. No part of this document may be reproduced in any form

without the prior written consent of INCON/EBW.

INCON/EBW reserves the right to change this document at any time without notice.

NOTE

Use the Table of Contents to find topics within this manual. Separate installation

instructions are provided for: the Needle Valve (PN 000-0045), the Calibration Kit

(PN 000-0043), and the LSU Transducer (PN 000-0058).

Need Help ? Mail Address (no packages):

INTELLIGENT CONTROLS INC

PO BOX 638

SACO ME 04072

Office Hours: 8 am to 5 pm EST, Monday through Friday

Sales – Orders 24 hour Technical Service

Delivery Schedules: RMA, Application Help:

Fax: (207) 283-0158 Fax: (207) 282-9002

Phone: (800) 872-3455 Phone: (800) 984-6266

email: sales@incon.com email: tech@incon.com

INCON/EBW is a wholly owned subsidiary of Franklin Electric and is member of the:

Franklin Fueling Systems Group. Visit our web site at:

T ank Sentinel®BriteSensors® and INCON®are registered trademarks of Intelligent Controls, Inc.

System Sentinel™ and System Sentinel ™ are trademarks of Intelligent Controls, Inc.

LS300 Auto-Learn® is a registered trademark of FE Petro®.

Copyright© 2003 – all rights reserved.

INSIDE FRONT COVER

TS-TPI Installation and Wiring

www.franklinfueling.com

Page 3

Table of Contents

1 Safety........................................................................................................... 1-1

2 TS-TPI Installation & Wiring.......................................................................... 2-1

3 Tank Sentinel / TS-TPI Interface................................................................... 3-1

4 TS-TPI Setup programming .......................................................................... 4-1

5 TS-TPI and Line Leak Testing....................................................................... 5-1

6 TS-TPI Data and reports............................................................................... 6-1

7 LINE Reports Setup...................................................................................... 7-1

8 Troubleshooting ............................................................................................ 8-1

TABLE OF CONTENTS Page TOC-1

TPI User’s Guide

TOC

Page 4

1 SAFETY

Graphic Symbol Conventions

Through out this User Guide these symbols will highlight information for your safety and the

proper functioning of this equipment. Read carefully the steps in this guide and pay special

attention to the steps where you see these symbols.

NOTE

Important information, tips, and hints are highlighted by the note graphic.

CAUTION messages are highlighted by the CAUTION graphic and contain instructions

that should be followed to avoid faulty equipment operation, or environmental hazards, or

personnel injury!

WARNING

that must be followed to avoid faulty equipment operation, or explosion or shock hazards. If

ignored, severe injury or death may result!

DANGER

must be followed to avoid an explosion or electrical shock hazard. If ignored, severe injury or

death will result!

ELECTRICAL DANGER

and contain instructions that must be followed to avoid an electrical shock. If ignored, severe

injury or death may result and even severe damage to electronic equipment.

messages are highlighted by the WARNING graphic and contain instructions

messages are highlighted by the DANGER graphic and contain instructions that

messages are highlighted by the ELECTRICAL DANGER graphic

SafetyFir st – Befor e Working on this Equipment

CAUTION

hydrocarbon liquids such as gasoline and diesel fuel. Installing or working on this equipment

means working in an environment in which these highly flammable liquids or vapors are

present. This presents a real risk of severe injury or death if these instructions and standard

industry practices are not followed.

Lock out and Tag circuit breakers before installation or service of this and associated equipment

Restrict access to the work area to only certified and trained installers or service personnel

Identify and mark the perimeter of the work area with signs, safety-cones and colored safety tape

Prevent unauthorized vehicle access (block access) into the work areas by using barriers,

barricades, and service trucks

Use only non-sparking tools when working in these Hazardous Areas

Check for presence of hydrocarbon vapors in containment sumps before entering and periodically

there after.

This equipment is designed to be installed in association with volatile

SAFETY Page 1-1

TS-TPI Installation and Wiring Guide

1

Page 5

ELECTRICAL DANGER

installing or servicing this equipment, pumps and related equipment. A potentially lethal

electrical shock hazard and the possibility of an explosion or fire from a spark can result if

the electrical circuit breakers are accidentally turned on during installation or servicing.

ALWAYS lock out and tag electrical circuit breakers while

ELECTRICAL DANGER

described in this manual, otherwise lethal electrical-shock-hazards could exist, which may cause

injury or death. Note: circuit breaker contact(s) can fail to open even when the circuit breaker lever

indicates off.

ELECTRICAL DANGER

automatically to run leak-tests at full line pressure. Automatic pump starts occur between

periods of product dispensing when there is no product being dispensed. BEFORE performing

any installation or service (such as replacing fuel-filters) – tag and lock-out all electrical power

sources to the submersible pump(s), pump controllers, and dispensers and relieve fuel-line pressure.

Failure to turn off power and relieve fuel-line pressure before work is started can result in: Electrical

shock, fuel spills, and fire or explosion hazard that may result in injury or death.

WARNING

may be present in the environment where this equipment is installed or serviced. Failure to follow

this instruction could result in a serious fire or explosion.

WARNING

the entire system. When no other regulations apply, follow NFPA 30, 30A, and 70 from the National

Fire Protection Association. Failure to do so could result in serious property damage, environmentalcontamination, and severe injury or death.

DO NOT smoke while working on or near this equipment. Highly flammable vapors

Follow all federal, state, and local laws governing the installation of this product and

Verify that no voltage exists before working-on, or wiring-to circuits

Electronic line leak detectors start submersible pumps

WARNING

pump manufacturer’s directions about how to do this). The pipeline from the submersible

pump to the dispenser, may be under pressure. If the line leak detector/plug (or any other

part of the submersible pump and fuel line) is removed without first relieving pressure, then a

product spill will occur. This can cause an environmental, fire, or explosion hazard, and may

result in injury or death.

WARNING

unauthorized personnel out of the hazardous work area. Use Safety Cones, Barricades,

Warning Signs, and Safety Tape, and block access with Barricades / service trucks to the

work area to avoid injury or property damage.

1

Page 1-2 SAFETY

Turn off all pump power and relieve pipeline pressure (reference and follow the

Avoid personnel injury or property damage: keep moving vehicles and

TS-TPI Installation and Wiring Guide

Page 6

WARNING

sparks when working on fuel dispensing equipment. Failure to follow these directions may

cause an explosion hazard, which could result in property damage and death.

Allow no source of combustion near the work area. Be careful not to cause

WARNING

If these vapors are inhaled they could cause dizziness or unconsciousness. If the vapors

were ignited they could explode causing serious injury or death.

CAUTION

Electric Code (NEC), and the Automotive and Marine Service Station Code (NFPA 30A in the

USA) before installation or maintenance. This installation is designed for submersible pumps

which have a Pump Control box in the station. If a pump control box does not exist, then the

system must be retrofitted to add a pump control box in the facility to comply with Codes.

CAUTION

vapors, if vapor levels are unsafe ventilate the sump with fresh air. While working in the sump

periodically check the atmosphere in the sump, if vapors reach unsafe levels exit the sump

and ventilate it.

CAUTION

or around a containment sump. Electronic and electrical petroleum monitoring equipment is

often housed in containment sumps designed to trap hazardous liquid spills and prevent

contamination of the environment.

These containment sumps can trap dangerous amounts of hydrocarbon vapors.

Refer to all applicable Federal, State, City and local codes, your National

Before entering a containment sump check for the presence of hydrocarbon

ALWAYS have a second person standing by for assistance when working in

CAUTION

ALWAYS cleanup and dispose of used absorbent/rags and petroleum resistant gloves in

approved waste containers. Cleanup refuse and dispose of these immediately to avoid

personnel injury from vapors or direct skin contact to also avoid possible fire or

environmental safety hazards.

Petroleum is carcinogenic – use adequate protection to avoid health hazards.

SAFETY Page 1-3

TS-TPI Installation and Wiring Guide

1

Page 7

2 TS-TPI INSTALLATION & WIRING

Overview

The TS-TPI Turbine Pump Interface is a communication device that allows the INCON TS-1001,

TS-2001 Automatic Tank Gauge (A TG) or other devices to communicate with the turbine pump

controllers (TPC). The TS-TPI is available as a stand alone unit, which requires it s own input

power, and as an integrated factory inst alled option in the TS-LS300 AutoLearn Line Leak Detector. The TS-TPI allows the ATG or other device to receive pump status information and, depending on the type of TPC, controls the pump.

In this chapter a brief description of each application is presented as well as the wiring of each

component for the particular application. Please contact Franklin Fueling System Technical

Support, (800)984-6266 if the TS-TPI is to be used in any other application.

Specific details of inst allation and the general programming instructions for the ATG is found in

the Tank Sentinel Installation Guide (part number 000-1050). Specific programming instructions

concerning the TS-TPI with the ATG will be covered in this Guide.

Look for your specific application on the following pages. Wire the components according to the

wire diagram and then go to the next chapter “Tank Sentinel/TS-TPI Interface” for information on

the features of the TS-TPI. The rest of the chapters provide instruction for programming the ATG

to take full advantage of the TS-TPI.

Here are the application options covered in this guide:

● TS-ATG with TS-TPI and TS-LS300 AutoLearn Console

● TS-ATG with TS-TPI, TS-LS300 AutoLearn Console and TPCs

● TS-ATG with TS-TPI and two TS-LS300 AutoLearn Consoles

● TS-ATG with TS-TPI, two TS-LS300 AutoLearn Consoles and TPCs

● TS-ATG with Stand alone TS-TPI and TPCs

● Stand alone TS-TPI with TPCs

ELECTRICAL DANGER

circuits described in this manual, otherwise lethal electrical-shock-hazards could exist, which

may cause injury or death. Note: circuit breaker contact(s) can fail to open even when the

circuit breaker lever indicates off.

ELECTRICAL DANGER

all electrical power sources to the submersible pump(s), pump controllers, and dispensers

and relieve fuel-line pressure. Electronic line leak detectors start submersible pumps automatically

to run leak-tests. Automatic pump starts occur between periods of product dispensing when there is

no product being dispensed.

Verify that no voltage exists before working-on, or wiring-to

BEFORE performing any installation or service lock-out and tag

Installation and Wiring Page 2-1

TS-TPI Installation and Wiring Guide

2

Page 8

TS-TPI specifications:

Input power: 120 - 240 Vac 50/60 hz (note: stand alone TS-TPI only. the integrated TS-TPI/TSLS300 does not require any additional power connection to the TS-TPI)

For indoor installation only, operating temperature 40 - 105° F (4 - 41° C)

Use Belden Cable #9365 - 18 AWG or equivalent

TS-TPI revision 2.3 or higher for use with MagVFC, STP-SCI, STP-SCIII, STP-SC, and IST-VFC

controllers. Limited functions available with STP-SCIII, STP-SC and IST-VFC controllers. See

Troubleshooting section for details.

Integrated TS-TPI/TS-LS300 uses PORT 1 exclusively for TS-LS300 communication and is not

available for TPC connections. The stand alone TS-TPI can use PORT1 for TPC connections.

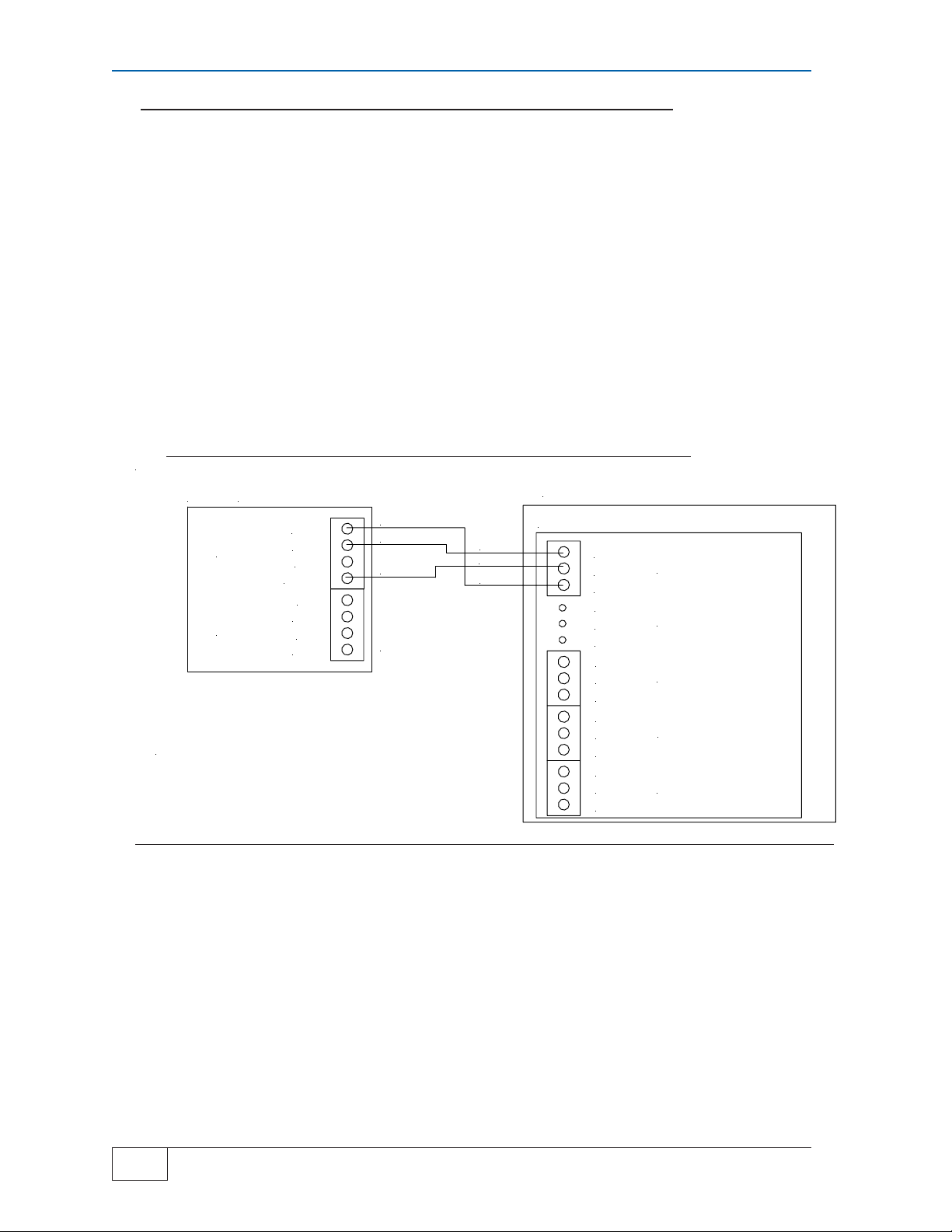

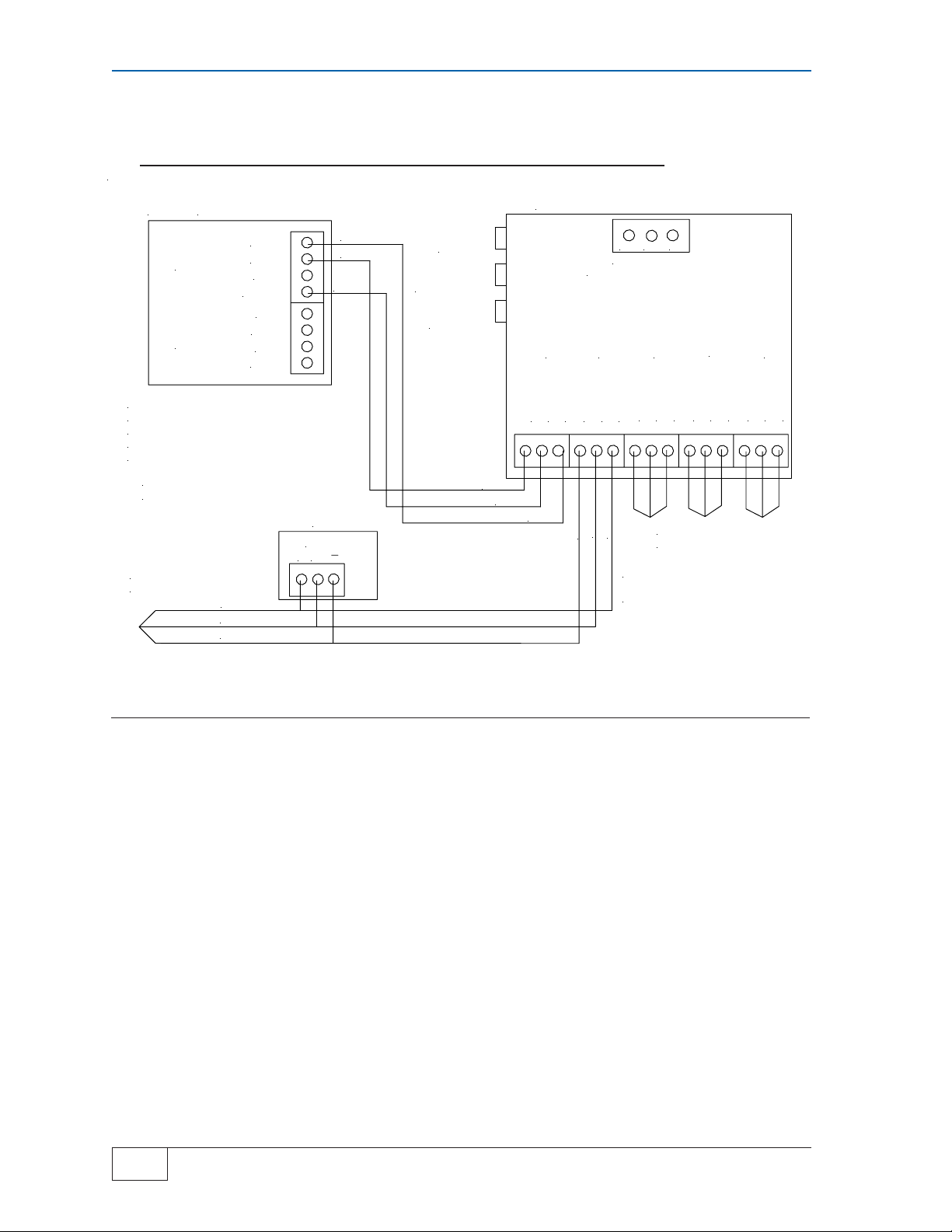

Integrated TS-TPI / TS-LS300 with Automatic Tank Gauge

TS-1001, TS2001

ATG

SEE TA N K SE N T INE L INS T AL LA T ION GUIDE

(PART # 000-1050) AND LS300 USER 'S GUIDE

(PART # 000-0040) FOR COMP LETE ATG AN D

LS300 WIRING INFORM AT ION

TS1001 OR TS2001 ON LY

485A

TS-LLD

INP UTS

485B

DSY

S,RTN

IN 1

GND

IN 2

GND

RED

BLACK

WHITE

CABLE-BELDEN

CONDUCTOR

#9365-18AWG

OR EQUIVALENT

BLACK

WHITE

RED

LS300

TPI BOARD

TXD 485GND

RXD 485+

TXD 485GND

RXD 485+

TXD 485GND

RXD 485+

TXD 485GND

RXD 485+

TXD 485GND

RXD 485+

HOST PORT

PORT 1

PORT 2

PORT 3

PORT 4

Figure 2-1

● This application provides communication between ATG and TS-LS300 only. The

Line Leak detector option is required on the ATG for operation.

● See Tank Sentinel Installation Guide and TS-L300 AutoLearn Installation Guide for

specific instructions for each component

2

Page 2-2 Installation and Wiring

TS-TPI Installation and Wiring Guide

Page 9

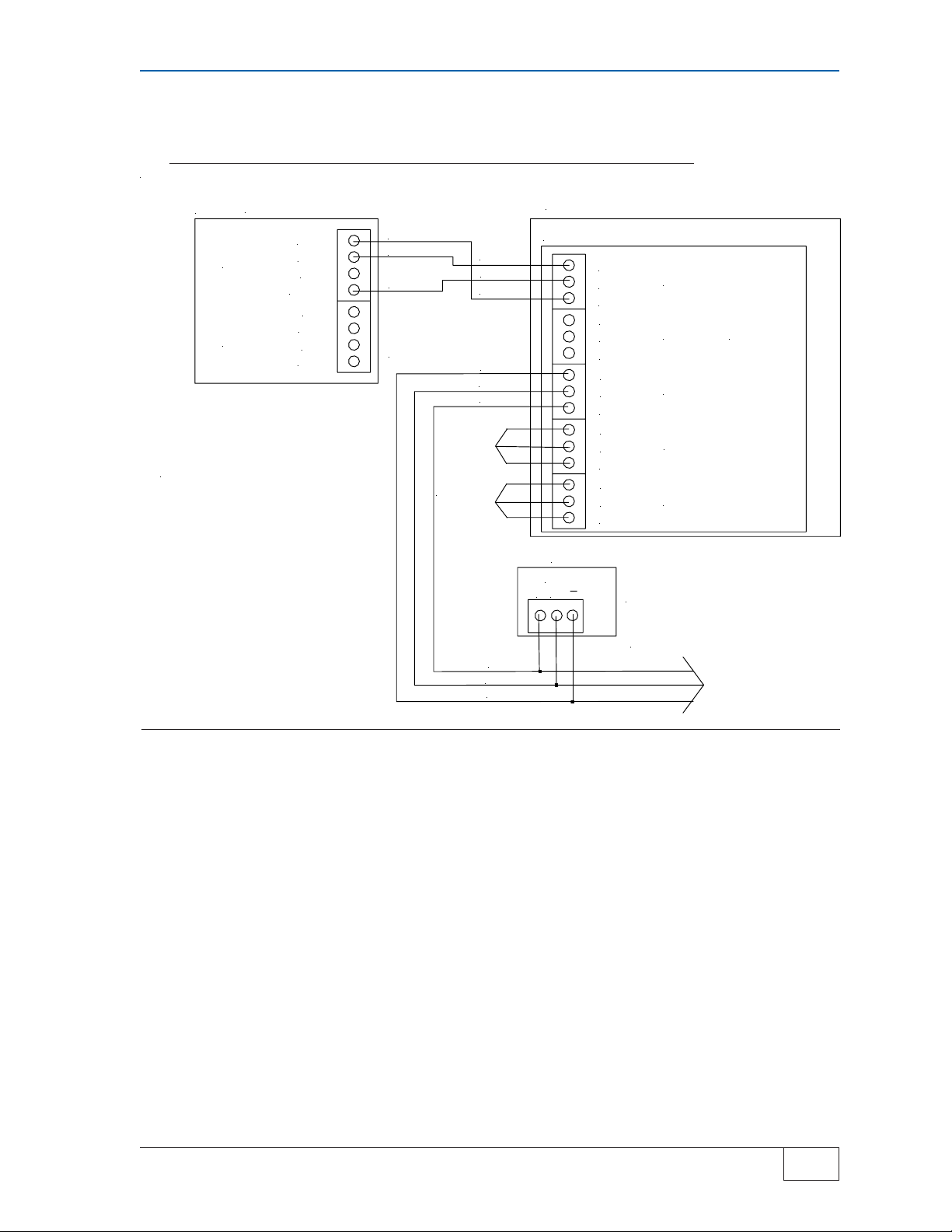

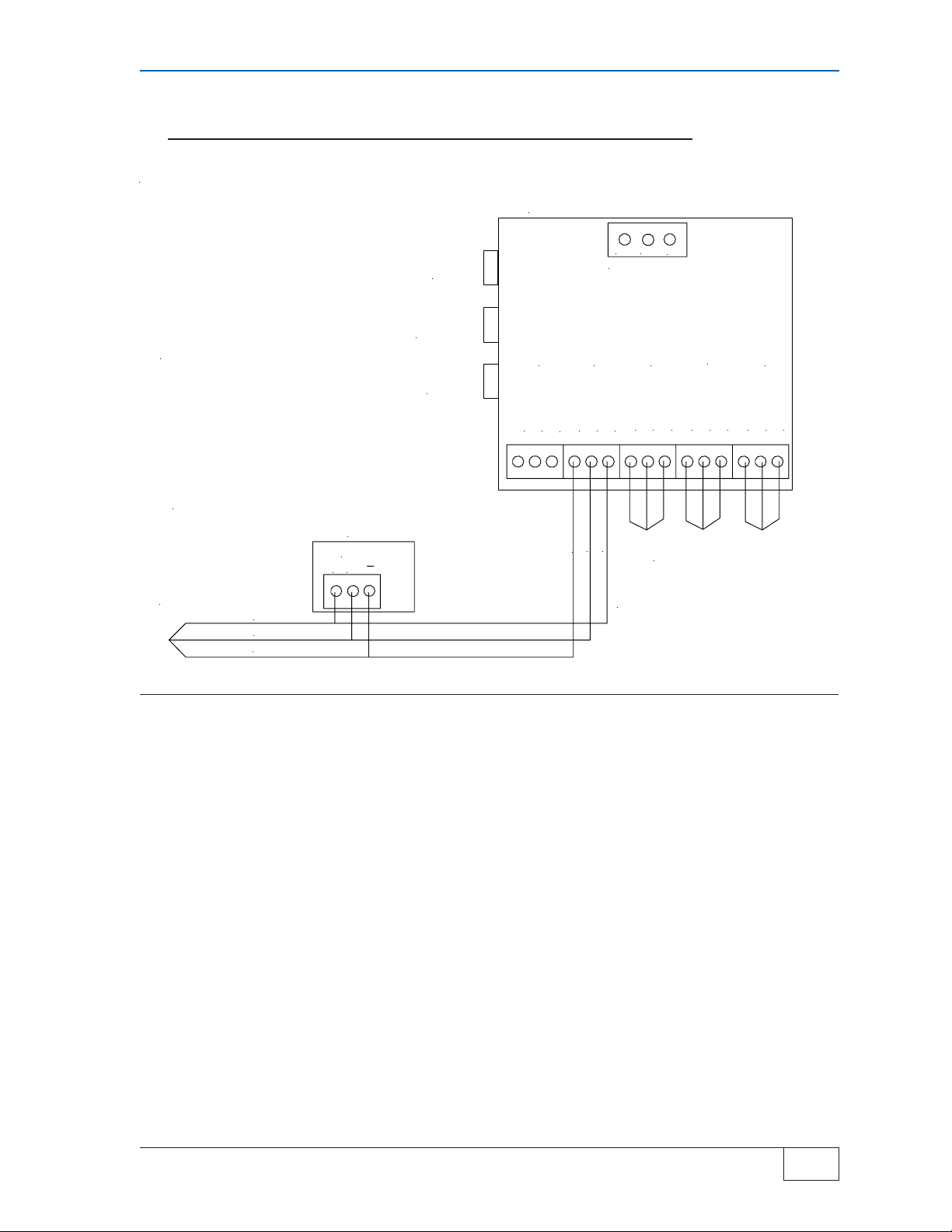

Integrated TS-TPI / TS-LS300 to Automatic Tank Gauge

TS-1001, TS2001 and TPCs

ATG

SEE TANK SENTINEL INSTALLATION GUIDE

(PART # 000-150), LS300 USER'S GUIDE

(PART # 000-0040), AND APPROPRIATE

TPC INSTALLATION AND OWNER'S MANUAL

FOR COMPLETE WIRING INFORMATION

TS1001 OR TS2001 O NL Y

485A

TS-LLD

INPU T S

485B

DSY

S,RTN

IN 1

GND

IN 2

GND

RED

BLACK

WHITE

CABLE-BELDEN

CONDUCTOR

#9365-18AWG

OR EQUIVALENT

ADDITIONAL

TPC

GROUPS

BLACK

WHITE

RED

BLACK

WHITE

RED

RED

WHITE

BLACK

LS300

TPI BOARD

TXD 485GND

RXD 485+

TXD 485GND

RXD 485+

TXD 485GND

RXD 485+

TXD 485GND

RXD 485+

TXD 485GND

RXD 485+

TPC

RS485

+ G

HOST PORT

PORT 1

NOT USED

PORT 2

PORT 3

PORT 4

CONTROLLERS MAY INCLUDE THE

MagVFC, STP-SCI, STP-SCIII,

IST-VFC, AND STP-SC

ADDITIONAL TPC CONNECTIONS

Figure 2-2

● This application provides communication between ATG, TS-LS300, and TPCs. The

Line Leak detector option is required on the ATG for full communication with TSLS300.

● See Tank Sentinel Installation Guide and TS-L300 AutoLearn Installation Guide for

specific instructions for each component

● Connect TPCs so all Stand alone TPCs are on the same port and Master/Slave

configured units are on their own port. Address TPCs so controllers on same port

have unique addresses. If similar type stand alone TPCs are installed on the same

port as Master/Slave TPCs the stand alone TPCs will be seen as Slave units.

Installation and Wiring Page 2-3

TS-TPI Installation and Wiring Guide

2

Page 10

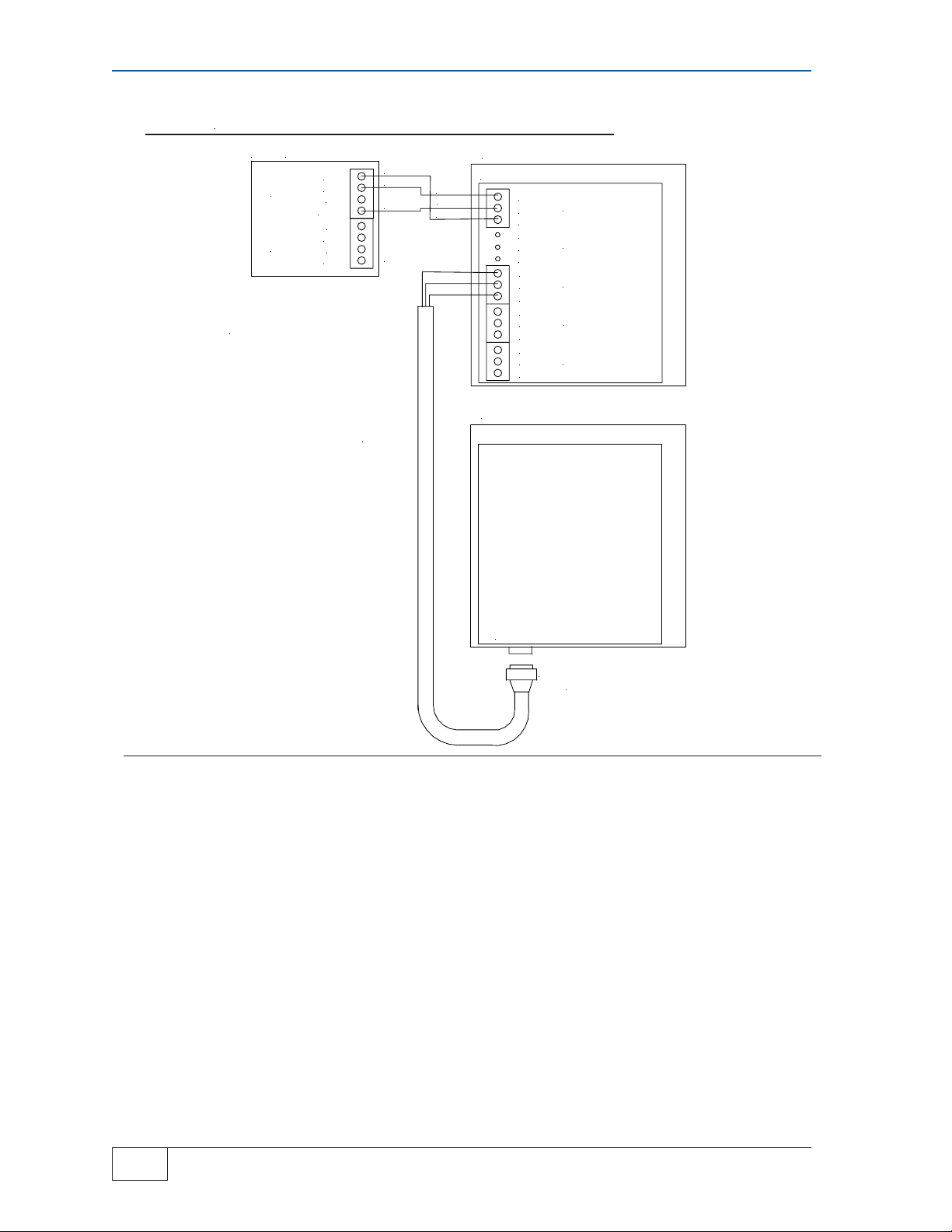

TS-TPI / two TS-LS300 with Automatic Tank Gauge

TS-1001, TS2001

TS1001 OR TS2001 ONLY

ATG

485A

TS-LLD

INPUTS

SEE TANK SENTINEL INSTALLATION GUIDE

(PART # 000-1050) AND LS3 00 US ER 'S GU ID E

(PART # 000-0040) FOR CO M P LET E AT G A ND

LS300 WIRING INFORMATION

485B

DSY

S,RTN

IN 1

GND

IN 2

GND

PURCHASE

RS232 CABLE

LOCALLY

RED

BLACK

WHITE

CABLE-BELDEN

3 CONDUCTOR

#9365-18AWG

OR EQUIVALENT

BLACK

WHITE

RED

LS300

TPI BOARD

TXD 485GND

RXD 485+

TXD 485GND

RXD 485+

TXD 485GND

RXD 485+

TXD 485GND

RXD 485+

TXD 485GND

RXD 485+

LS300

HOST PORT

PORT 1

PORT 2

PORT 3

PORT 4

EXTERNAL

RS232 PORT

NO TS-TPI BOARD IN THIS LS300

IF TS-TPI IS PRESENT, REMOVE IT BEFORE

MAKING THE RS232 CONNECTION

Figure 2-3

● Provides communication between ATG and both TS-LS300 consoles. ATG

requires the Line Leak detection option for full operation of TS-LS300 and ATG

communication.

● Only one TS-LS300 has TS-TPI installed, if both have a TPI board remove the TPI

from one of the TS-LS300

● The RS232 cable is supplied by the customer

● TS-TPI configuration switch SW1 pole 3 is ON. See Figure 2-7 for more details and

switch settings on TS-TPI

2

Page 2-4 Installation and Wiring

TS-TPI Installation and Wiring Guide

Page 11

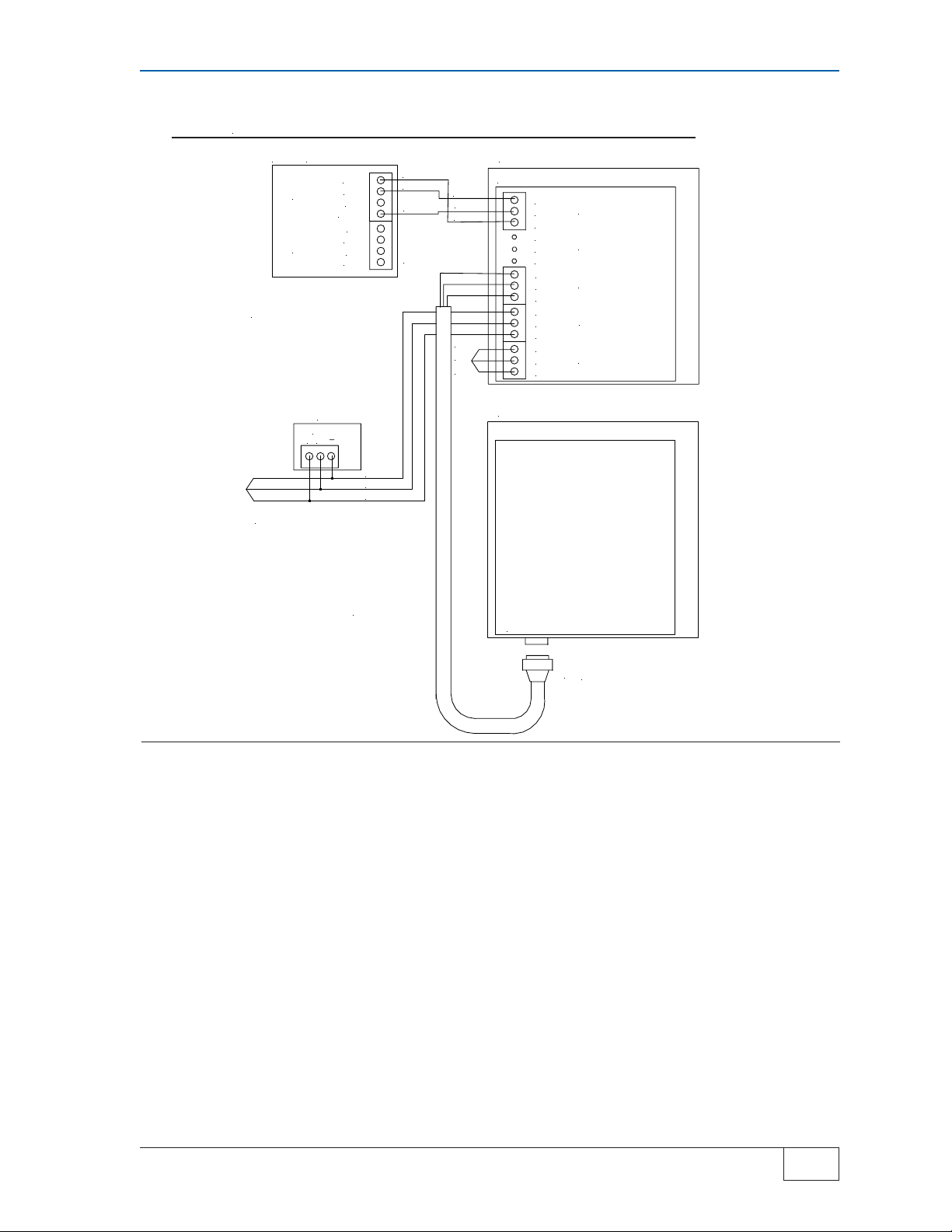

Wire diagram for TS-TPI with two TS-300 AutoLearn to

Automatic Tank Gauge TS-1001, TS2001 and TPCs

TS1001 OR TS2001 ONLY

ATG

485A

TS-LLD

INPUTS

SEE TANK SENTINEL INSTALLATION GUIDE

(PART # 000-1050) AND LS300 USER'S GUIDE

(PART # 000-0040) FOR COMPLETE ATG AND

LS300 WIRING INFORMATION

485B

DSY

S,RTN

IN 1

GND

IN 2

GND

RED

BLACK

WHITE

CABLE-BELDEN

3 CONDUCTOR

#9365-18AWG

OR EQUIVALENT

BLACK

WHITE

RED

ADDITIONAL

TPC

GROUPS

LS300

TPI BOARD

TXD 485GND

RXD 485+

TXD 485GND

RXD 485+

TXD 485GND

RXD 485+

TXD 485GND

RXD 485+

TXD 485GND

RXD 485+

HOST PORT

PORT 1

PORT 2

PORT 3

PORT 4

TPC

RS485

+ G

BLACK

WHITE

CONTROLLERS MAY INCLUDE THE

MagVFC, STP-SCI, STP-SCIII, VFC AND STP-SC

RED

LS300

PURCHASE

RS232 CA BL E

LOCALLY

EXTERNAL

RS232 PORT

NO TS-TPI BOARD IN THIS

TS-LS300 CONSOLE. IF TS-TPI

IS PRESENT REMOVE IT BEFORE

MAKING RS232 CONNECTIONS

Figure 2-4

● Provides communication between ATG, TPCs, and both TS-LS300 consoles. ATG

requires the Line Leak detection option for full operation of TS-LS300 and ATG

communication.

● Only one TS-LS300 has TS-TPI installed, if both have a TPI board remove the TPI

from one of the TS-LS300

● The RS232 cable is supplied by the customer

● Connect TPCs so all Stand alone TPCs are on the same port and Master/Slave

configured units are on their own port. Address TPCs so controllers on same port

have unique addresses. If similar type stand alone TPCs are installed on the same

port as Master/Slave TPCs the stand alone TPCs will be seen as Slave units.

● TS-TPI configuration switch SW1 pole 3 is ON. See Figure 2-7 for more details and

switch settings on TS-TPI

Installation and Wiring Page 2-5

TS-TPI Installation and Wiring Guide

2

Page 12

Stand AloneTS-TPI with Automatic Tank Gauge TS-1001 or

TS2001 and TPCs

ATG

SEE TANK SENTINEL INSTALLATION GUIDE

(PART # 000-1050), THIS TPI USER 'S GUIDE

AND APPROPRIATE

TPC INSTALLATION AND OWNER'S MANUAL

FOR COMPLETE WIRING INFORMATION

CABLE-BELDEN CONDUCTOR

#9365-18AWG OR EQUIVALENT

TS1001 OR TS2001 ONLY

485A

TS-LLD

INPU T S

485B

DSY

S,RTN

IN 1

GND

IN 2

GND

RED

BLACK

WHITE

TPC

RS485

+ G

ADDITIONAL

TPC CONNECTIONS

RED

WHITE

BLACK

TS-TPI

RESET

TPC FAULT

RESET

ALARM

SILENCE

BLACK

WHITE

STAND ALONE TPI

GND L2/N L1

INP U T POW ER

120 -240 Vac 50/60 hz

TXD 485-

RED

HOST PORT

GND

PORT 1

TXD 485-

GND

RXD 485+

WHITE

BLACK

PORT 2

TXD 485-

GND

RXD 485+

RED

CONTROLLERS MAY INCLUDE THE

MagV F C , ST P -SCI, STP-SC III, VFC

AND STP-SC

RXD 485+

ADDITIONAL TPC

GROUPS

PORT 3

TXD 485-

GND

PORT 4

TXD 485-

GND

RXD 485+

RXD 485+

Figure 2-5

● Communication between ATG and TPCs, no additional ATG options required for full

operation

● Stand Alone TS-TPI requires separate 120 - 240 vac, 50/60 hz, power

● See Tank Sentinel Installation Guide for specific ATG instructions

● TPCs that can be installed are MagVFC, IST-VFC, STP-SCI, STP-SC and STP-

SCIII. Available functions are limited on the IST-VFC, STP-SC and the STP-SCIII

controllers, see troubleshooting section for details

● Connect TPCs so all Stand alone TPCs are on the same port and Master/Slave

configured units are on their own port. Address TPCs so controllers on same port

have unique addresses. If similar type stand alone TPCs are installed on the same

port as Master/Slave TPCs the stand alone TPCs will be seen as Slave units.

2

Page 2-6 Installation and Wiring

TS-TPI Installation and Wiring Guide

Page 13

Stand AloneTS-TPI with TPCs

SPECIFICATIONS

Input power:

120 - 240 Vac 50/60 hz

TS-TPI

RESET

STAND ALONE TS-TPI

GND L2/N

INPUT POWER

L1

Indoor installation only.

Operating temperature:

40 - 105° F (4 - 41° C)

CABLE-BELDEN CONDUCTOR

#9365-18AW G O R E Q UIVA LE NT

ADDITIONAL

TPC CONNECTIONS

RED

WHITE

BLACK

● Communication between TS-TPI and TPCs. Use this application for remote

controller fault indication and controller fault reset.

TPC

RS485

+ G

TPC FAULT

RESET

ALARM

SILENCE

Figure 2-6

TXD 485-

RXD 485+

TXD 485-

PORT 3

GND

RXD 485+

TXD 485-

PORT 4

GND

RXD 485+

HOST PORT

GND

RXD 485+

BLACK

PORT 1

TXD 485-

GND

WHITE

RED

PORT 2

TXD 485-

GND

RXD 485+

ADDITIONAL TPC

GROUPS

CONTROLLERS MAY INCLUDE THE

MagVFC, STP-SCI, STP-SCIII, IST-VFC

AND STP-SC

● Stand Alone TS-TPI requires separate 120 - 240 vac, 50/60 hz, power

● TS-TPI reset switch will reset the TS-TPI in the event of a communication conflict.

● The TPC fault reset will reset a pump controller that is in a fault conditon. It will

only reset controllers that are indicating a fault alarm. If none of the controllers are

in alarm no reset will take place.

● Alarm Silence button will silence the audible alarm but not clear the fault.

● Connect TPCs so all Stand alone TPCs are on the same port and Master/Slave

configured units are on their own port. Address TPCs so controllers on same port

have unique addresses.

Installation and Wiring Page 2-7

TS-TPI Installation and Wiring Guide

2

Page 14

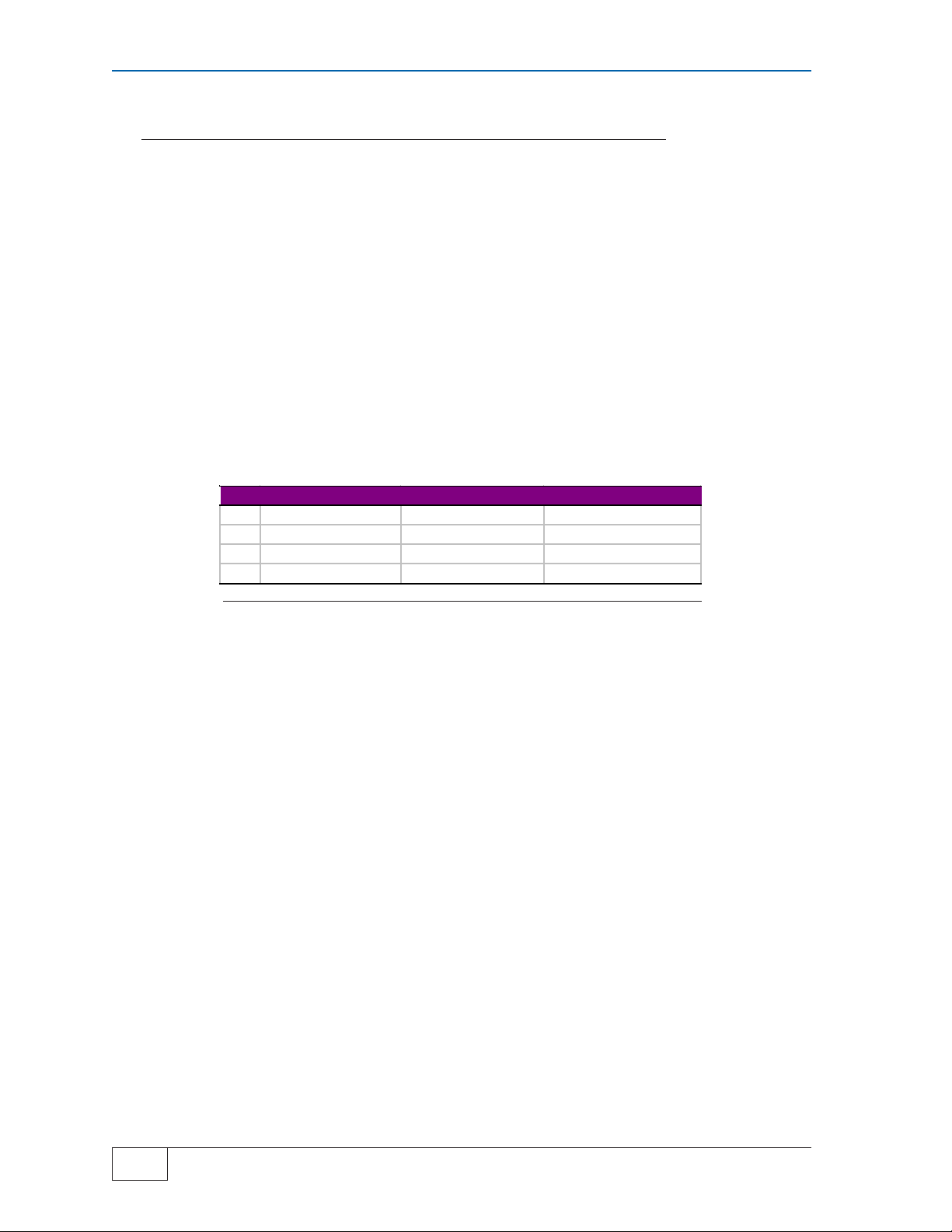

TPI Configuration Switch

Locate the single dip switch on the TS-TPI board labeled SW1.

This set of switches sets how the various ports communicate. The host (ATG) and Pump

Controllers all communicate using RS-485 connections. The TS-LS300 communicates using RS-

232.

The Factory default setting is switches 1, 2 and 3 are OFF and switch 4 is ON. When a second TS-

LS300 is used (more than 4 pipelines at a site) switch 3 is set to the ON positon, see Figure 2-7

SW1 Stand Alone TS- TPI TS-TPI in TS-LS300 Two TS- LS300 in use

1 OFF OFF OFF

2 OFF OFF OFF

3OFF OFF ON

4ON ON ON

Figure 2-7

2

Page 2-8 Installation and Wiring

TS-TPI Installation and Wiring Guide

Page 15

3 TANK SENTINEL/TS-TPI

INTERFACE

Overview

The Turbine Pump Interface (TS-TPI) hardware has been developed to facilitate communications of

the Turbine Pump Controllers (TPC) operating conditions with the INCON Tank Sentinel Automatic

Tank Gauge (ATG) consoles via the RS-485 port.

The integration of ATG , TS-TPI and TPC allows the ATG to intervene when pumps experience

certain fault conditions by resolving the fault and enabling the pump to continue dispensing fuel. In

addition to this, the ATG keeps an alarm history to aid in troubleshooting. A technician can review an

alarm history report at the site or remotely via System Sentinel® and System Sentinel Anyware® .

The TS-TPI requests status and fault conditions of the TPCs. This information is transmitted to the

ATG on demand. The ATG can then make this status available for purposes of:

● Displaying, Printing and Faxing Pump Controller Status

● Resetting Pump Controllers

● Making Pump Controller Status available to System Sentinel

Sentinel Anyware

®

®

and System

● Basic Operation Features

There are several basic operation features listed below and detailed further in separate chapters of

this manual.

Monitor, Record and Reset Pump Controller Faults

The primary feature is that the ATG maintains the state of the Pump controller such that it continues

to run and function without user intervention. The Pump Controller will stop a pump when a fault

condition exists. The A TG monitors pump controllers through the RS-485 port for fault conditions.

When fault conditions are received, the ATG will manage them by reporting alarms, silencing the

audible alarms on the controllers, and resetting the controller when appropriate.

Fault Diagnostic Capabilities

The secondary feature provides fault detection diagnostics. The ATG will take control of the pumps

when certain fault conditions are active in the ATG . For example, if a site has multiple t anks of the

same product and one of the tanks gets overfilled, the A TG will make the over filled tank the priority

tank, even if it is not programmed as the priority tank, until the over fill conditon is corrected. Pump

Controller alarms have been added to the alarm processing code of the tank gauge.

Level Management

The third feature allows a customer to utilize the ATG to control the “mode” the pumps use to draw

down product in two or more tanks with the same product. The “Leveling Mode” alternates the

pumps so that the tank levels are equal as the tanks are being drawn down. The “Priority Mode”

gives one pump priority over the others while it draws product down. A pump remains in “Priority

Mode” until an user specified reserve percentage level is reached. The tank gauge then gives

priority to another pump and it then draws down the product from another tank.

TANK SENTINEL/ TS-TPI INTERFACE Page 3-1

TS-TPI Installation and Wiring Guide

3

Page 16

In “Leveling Mode”, the ATG keeps the levels on multiple tanks the same and in the

“Priority Mode”, a specified tank will draw down to its reserve percentage before other

tanks are called upon.

The ATG also performs tank level management by generating alarms to warn the

operator of High and High High product limits, Low and Low Low product limits, water

levels limits and even an obstruction on the pump motor. The ATG can shut down

pumps, turn on pumps and change priority based on the active alarm at the ATG . For

example, if the water level in the tank is within two inches of the user defined pump

height the ATG will indicate the “Pump in Water” alarm and shut down the pump. The

A TG will prevent the pump from operating until the water level is reduced.

For Overfill Management the ATG will generate an alarm to warn the operator when

the product level in the tank exceeds the High or High High limits. If these conditions

occur, the ATG will change the tank priority in the group and make it the primary tank

so it will be the first tank to draw down product until the product level drops below the

High level limit.

TS-LS300 report, Leak Test Initiating Capabilities

The TS-TPI allows the TS-LS300 AutoLearn Line leak detection to communicate

product pipeline status. The A TG can respond to TS-LS300 alarms and print report s

of pipeline status. Reports can be scheduled by the end user . The user can schedule

precision line tests at any time in the ATG. Then the ATG , communicating throught

the TS-TPI, will initiate the line test. These tests are in addition to the tests the TSLS300 will do automatically .

TS-TPI Setup Programing Operations

The ATG Setup Programming menus allow for the TS-TPI feature to be enabled. An

Auto-configuration (AUTO CFG) is then performed, which sets up the TS-TPI system

for the first time, adding menus to the setup display . The ATG will detect the number

of pump controllers that are connected and will configure the ATG to monitor them.

The AUT O CFG updates the system configuration with the number of pump controllers connected, what type of controller, how the controllers are grouped and how the

associated pumps are to be managed.

The user Configuration menus control the pump name, tank association, pump

height, pump mode and reserve setting.

Data Display and Reports

On the ATG a pump controller Display menu is available from the console to allow

viewing of live and updated information about the pump controller. The ATG will also

monitor the pump controllers for information such as: status, faults, volts, amps,

watts, frequency, flow, pressure, temperature, dip switch settings, and sof tware

version.

The Pump Controller Status Report provides the same information found in the

Display menu. A separate TPI setup Report shows the various Group, Pump and

Tank associations.

3

Page 3-2 TANK SENTINEL/ TS-TPI INTERFACE

TS-TPI Installation and Wiring Guide

Page 17

Diagnostic Operations

A pump controller Diagnostic menu is available on the console display to allow a user

to reset a pump controller from the ATG . Another diagnostic function that is available

is the ability to enable automatic calibration of the pump controller and its pumps.

Remote Management

The remote management feature allows an interface within System Sentinel or

System Sentinel Anyware to acquire and display pump controller st atus. This feature

allows the user to remotely poll data from the ATG including pump controller status

and alarms. A pump Controller Interface screen in Site Link shows controller status.

TANK SENTINEL/ TS-TPI INTERFACE Page 3-3

TS-TPI Installation and Wiring Guide

3

Page 18

TPI ENABLE (UP/DOWN)

YES

TPI ENABLE (UP/DOWN)

NO

TPI

ENABLE

SETUP MENU (MORE)

TPI

4 TS-TPI SETUP PROGRAMMING

SELECT MENU OPTION

SETUP UPGRADE LANGUAGE DATALOG

TPI

ENABLE PUMP GROUP

TS-TPI Menu

H U

MENU

7

½ Press this key and follow the

highlighted sequence below...

M1 M2 M3 M4

M1 M2 M3 M4

NOTE

Prior to Enabling TPI, the System configuration for

Number of Tanks is required. Refer to the Tank

Sentinel Setup Programming Guide.

TPI ENABLE (user entry)

Description of Step s:

Here are the SELECT MENU OPTION menu

names displayed.

1) Press the M1 key to display the SETUP menu.

Here is the main SETUP MENU display

2) Press the DOWN key several times until the TPI

menu name is displayed.

“TPI” may be aligned with any of the menu keys

(M1--M4), depending on what other features are

programmed on enabled. for this example TPI is

aligned with M1

3) Press the M1 key to display the TPI menu

M1 M2 M3 M4

Here is the TPI ENABLE menu.

4) Press the M1 key to display the TPI ENABLE

user entry field. The default selction is NO. Choose

YES to enable TPI programming and subsequent

menus.

5) Use the UP/DOWN keys to change the selection

to YES.

6) Press the ENTER key to accept the entry .

The display returns to the TPI menu, which now

shows the Pump and GROUP menus.

TS-TPI SETUP PROGRAMMING Page 4-1

TS-TPI Installation and Wiring Guide

4

Page 19

TPI PUMP

AUTOCFG

TS-TPI PUMP Menu(s)

SETUP MENU (MORE)

COM PORTS CVS

TPI

TPI

ENABLE PUMP

GROUP

TPI PUMP

AUTOCFG PUMP1 PUMP2

• AUTO CFG (user entry)

• NO PUMPS “READ ONLY”

• PUMP N Menus (both)

AUTO CFG (user entry)

Description of Step s:

1) Press the MENU key to display the SELECT

MENU OPTION menu.

NOTE

H U

MENU

7

Before preforming AUTO CFG verify all

TPCs dip switches are set correctly. If

TPC switches are changed after AUTO

CFG the ATG will need to be Cold

Booted and the AUTO CFG procedure

repeated.

2) Press the M1 key under the word SETUP to

display the SETUP MENU menu.

3) Press the DOWN key until the TPI menu is

displayed (TPI appears as the last menu item).

TPI may be aligned with any of the menu keys

(M1 -- M4), depending on what other features are

programmed or enabled.

4) Press the M3 key to display the TPI menu.

Here is the main TPI menu, which shows ENABLE, PUMP and GROUP...

5) Press the M2 key to display the PUMP menu.

M1

K X

DOWN

SP ACE

M1 M2 M3 M4

M1 M2 M3 M4

Here is the TPI PUMP menu, which only shows

AUTO CFG

6) Press the M1 key to start the AUTO CFG

process.

Here is the TPI PUMP menu, which now shows

AUTO CFG, PUMP1, PUMP2, ...

Please read the following note about Auto-Configuration for your better understanding of this feature.

4

Page 4-2 TS-TPI SETUP PROGRAMMING

M1 M2 M3 M4

TS-TPI Installation and Wiring Guide

Page 20

AUTO-CONFIGURATION NOTE

SETUP MENU (MORE)

EXIT SYSTEM TANKS PROBES

SETUP INFO (MORE)

NO.LINES NO.SENS NO.PUMPS

NUMBER OF PUMPS READ ONLY

2

The AUT O CFG function is used to invoke the routines which query the TPI for the number of pump

controllers attached to the TS-TPI and other controller and pump related information.

When AUT O CFG is started, the tank gauge scans the TS-TPI for all the pump controllers attached

to the TS-TPI. For each controller found, a corresponding pump number will be displayed (e.g. if the

TS-TPI finds two controllers, there will be a Pump 1 and a Pump 2). Their types will be stored in the

TYPE Menu configuration and the number of controllers will be stored in the NO. PUMPS configuration.

The Auto-Configuration process will automatically update the following READ ONLY configuration

settings:

• NO. PUMPS (in System Menu)

• PUMP ADDRESS

• PUMP TYPE

• GROUP TYPE

• PUMP GROUP

See the Tank Sentinel Setup Programming Guide for more information on programming the ATG to

include Lines for TS-LS300 PROGRAMMING.

Number of Pumps Menu

NO.PUMPS “READ ONL Y”

Description of Step s:

The number of pumps information is displayed

under the SYSTEM menu. Return to the main

SETUP MENU display , which shows...

1) Press the M2 key to display the SYSTEM

menu.

2) Press the DOWN key until NO.PUMPS is

displayed...

READ ONL Y NOTE

Fields that display the words “READ ONL Y” in the

upper right corner have been automatically filled in

by the Auto-Configuration process. These fields are

not editable. The next Auto-Configuration process

will over-write these fields and values.

M1 M2 M3 M4

K X

DOWN

SP ACE

3)Press the M3 key to display the number of

pumps information...

The number represents the number of pump

controllers that the TPI device has detected.

The data on display “2” was generated from

Auto-Configuration.

4) Press the CANCEL key twice, to return to the

SETUP MENU menu.

M1 M2 M3 M4

NOTE

TS-TPI SETUP PROGRAMMING Page 4-3

TS-TPI Installation and Wiring Guide

NO.PUMPS may be aligned with

any of the menu keys (M1--M4),

depending on what other features

are programmed or enabled. For

this example, the menu is aligned

with the M3 key .

4

Page 21

PUMP N Menu(s)

PUMP N (MORE)

NAME TYPE GROUP ADDRESS

NAME PUMP N A ... M

PUMP1 BACKSPACE

• NAME (user entry)

• TYPE “READ ONLY”

• GROUP “READ ONLY”

• ADDRESS “READ ONLY”

• TANK (user entry)

• HEIGHT (user entry)

NAME (user entry)

Description of Step s:

The PUMP N menu displays six subsequent

fields, including TANK and HEIGHT (scroll

down)...

1) Press the M1 key to display the NAME

PUMP N user entry field...

The default name of “PUMP 1 is displayed...

2) Press the M4 key to backspace and

erase the “PUMP 1” default name.

3) Use the keypad to enter a unique name

for each pump, up to 8 characters long (See

NOTE below).

Remember:

Use the SHIFT key to change the keypad for

A...M to N...Z and to (numeric) 1-9, 0, ., =/-,

and SP ACE (a blank space)

NOTE

In the following examples, “N” represents any pump

number - 1, 2, 3 and so on.

M1 M2 M3 M4

M1 M2 M3 M4

4) Press the ENTER key to accept the data

entry .

The display returns to the PUMP N menu.

Repeat the user entry steps for each pump.

NOTE

4

Page 4-4 TS-TPI SETUP PROGRAMMING

The Pump name can be up to 8 alpha/numeric characters. This alias

is used throughout the system in the display and reports. An example

name would be UNLEADED. The name is not automatically updated

or over-written by an AUT O CFG operation.

TS-TPI Installation and Wiring Guide

Page 22

TYPE “READ ONL Y”

TYPE PUMP N READ ONLY

VFC

PUMP N (MORE)

NAME TYPE GROUP ADDRESS

PUMP N (MORE)

NAME TYPE GROUP ADDRESS

GROUP PUMP 1 READ ONLY

2

Description of Steps:

1) Press the M2 key to display the TYPE PUMP

N “READ ONL Y” field...

In this example, the type “VFC” is displayed...

There are five types of controller displays VFC,

SC, SCIII, SCI and VFCIV . The displayed TYPE

PUMP coresponds with the following FE Petro

controllers:

SC STP-SC

SCI STP-SCI

SCIII STP-SCIII

VFC IST-VFC

VFCIV MagVFC

M1 M2 M3 M4

2) Press the CANCEL key to return to the

PUMP N menu.

GROUP “Read Only”

Description of Steps:

1) Press the M3 key to diplay the GROUP

PUMP N “READ ONL Y” field...

In this example, the group “2” is displayed...

2) Press the CANCEL key to return to the

PUMP N menu.

CANCEL

M1 M2 M3 M4

This menu item defines which pump is connected to which TS-TPI port number. A group

number of 1, 2, 3, or 4 will indicate that the pump is on that port number. The TS-LS300

occupies Group 1 in the factory installed TS-TPI/TS-LS300, therefore the first pump group is

Group 2 and is connected on PORT 2. The Stand Alone TS-TPI has all ports and therefore all

groups available to TPCs.

TS-TPI SETUP PROGRAMMING Page 4-5

TS-TPI Installation and Wiring Guide

4

Page 23

ADDRESS PUMP 1 READ ONLY

0

ADDRESS “READ ONL Y”

PUMP N (MORE)

NAME TYPE GROUP ADDRESS

TANK ASSOCIATION PUMP 1 NUMERIC

0BACKSPACE

PUMP N (MORE)

TANK HEIGHT

Description of Step s:

1) Press the M4 key to display the ADDRESS

PUMP N “READ ONL Y” field...

In this example, address “0” is displayed...

The address range is from 0-31.

M1 M2 M3 M4

2) Press the CANCEL key to return to the PUMP

N menu.

Press the DOWN key to display the TANK and

HEIGHT user entry menus...

TANK (user entry)

Description of Step s:

1) Press the M1 key to display the TANK ASSOCIA TION PUMP N user entry field...

The default TANK ASSOCIATION number “0” is

displayed...

The user selects the tank number associated with

PUMP N. The values range from 0-8(0=none, or

the maximum number of tanks available for the

ATG model)

NOTE: This will allow a pump to be associated

with a tank. If the pump is not associated with a

tank (i.e. for level monitoring by the tank gauge),

then NONE may be chosen, but this will disable

some features of the pump controller interface for

that controller. If a t ank has multiple pumps in it,

more than one controller may be associated with

the tank.

CANCEL

K X

DOWN

SP ACE

M1 M2 M3 M4

2) Use the keypad to enter the tank number .

In the event that a number is already entered and

needs to change, press the M4 key to backspace

and erase the entry . The default “0” tank number

will be displayed.

4

Page 4-6 TS-TPI SETUP PROGRAMMING

TS-TPI Installation and Wiring Guide

Page 24

3) Press the ENTER key to accept data entry .

HEIGHT PUMP 1 NUMERIC

+7.000000 BACKSPACE

PUMP N (MORE)

TANK HEIGHT

PUMP N (MORE)

TANK HEIGHT

The display returns to the PUMP N menu. Repeat

the user entry steps for each pump.

HEIGHT (user entry)

1) Press the M2 key to display the HEIGHT PUMP

N user entry field...

ENTER

The default HEIGHT of “+7.0”(inches) is displayed...

2) Press the M4 key to backspace and erase the

“+7.000000” default height number.

NOTE: HEIGHT is the distance (in inches or

millimeters) between the bottom of the pump to

the bottom of the TANK. this allows the pump

height to be set by the user, which af fect s the

handling of the DRY TANK, BLOCKED INTAKE,

and PUMP IN WATER alarms. This variable

defaults to 7 inches and is user-programmable.

3) Use the keypad to enter the height value.

4) Press the ENTER key to accept data entry .

The display returns to the PUMP N menu showing

T ANK and HEIGHT.

To repeat these steps for the next pump:

M1 M2 M3 M4

Press the CANCEL key to display the TPI PUMP

menu, which displays AUT O CFG, PUMP 1,

PUMP2, ...

Repeat each PUMP N Menu step for every pump

number.

When these entries are completed...

Press the CANCEL key to display the main TPI

menu, which displays ENABLE, PUMP and

GROUP.

M1 M2 M3 M4

TS-TPI SETUP PROGRAMMING Page 4-7

TS-TPI Installation and Wiring Guide

4

Page 25

TPI Group Menu

TPI

ENABLE PUMP GROUP

TPI GROUP

GROUP1 GROUP2 GROUP3 GROUP4

GROUP 2

TYPE MODE

TYPE GROUP 2 READ ONLY

MASTER SLAV

• TYPE “READ ONLY”

• MODE (user entry)

• RESERVE (user entry)

TYPE “READ ONL Y”

Description of Step s:

Here is the main TPI menu, displaying

ENABLE, PUMP and GROUP...

1) Press the M3 key to display the TPI

GROUP menu...

Here is the TPI GROUP menu displaying

GROUP numbers 1 to 4 (zero LS-300s)

GROUP MENU NOTES

The Group menu is not available when pump controllers

are not connected/programmed with the TS-TPI device.

The Group menu name appears on the display but it does

not function.

Group 1 is removed from the display if one LS-300 is

connected to the TS-TPI. Groups 1 and 2 are removed

when two LS300s are connected. All Group s are displayed

if zero LS-300s are connected.

M1 M2 M3 M4

2) Press the (M) key of the group number to

be displayed. For this example, press M2 to

display the GROUP 2 menu...

Here is the GROUP 2 menu displaying TYPE

and MODE...

3) Press the M1 key to display the TYPE of

group as detected during Auto-Configuration.

This is a READ ONL Y field.

In this example, the type “MAST SLA V” is

displayed...

4) Press the CANCEL key to return to the

GROUP 2 menu.

To repeat the user entry steps for each

group, press CANCEL again to display the

TPI Group menu.

M1 M2 M3 M4

M1 M2 M3 M4

CANCEL

NOTE

4

NOTE: Please read the MODE Notes to gain a better understanding of the MODE

and RESERVE features.

Page 4-8 TS-TPI SETUP PROGRAMMING

TS-TPI Installation and Wiring Guide

Page 26

MODE “User Entry” Note

MODE GROUP 2 (UP/DN)

NONE

GROUP 2

TYPE MODE RESERVE

MODE GROUP 2 (UP/DN)

PRIORITY

(Mode functions are not available with STP-SC, STP-SCIII or IST-VFC)

MODE allows the operator to select which Level Management mode to use for a particular group. The

choices are NONE, LEVELING, and PRIORITY:

• Selecting NONE means NO level management mode for the Group (no Reserve to enter). This is

used for Groups with TPCs configured as stand alone controllers.

• Selecting the LEVELING mode seeks to maintain an equal level of fuel in each tank by placing

pump controllers associated with the tank containing the most amount of fuel to priority. This will

force the pump with the highest level of fuel to activate when the dispenser switch is activated (no

Reserve to enter).

• Selecting the PRIORITY option enables a mode that seeks to drain one tank before the other

tank(s). Only when the PRIORITY mode is selected the RESERVE menu will appear.

Reserve Configuration Note

RESERVE is set after choosing the PRIORITY MODE. This entry sets the reserve level of fuel remaining in the tank. The programming defines this percentage as an “empty” tank and is programmed in %

full.

For example, setting the Reserve to 20% means, when the tank is 20% full it is considered “empty”.

This will trigger two events; the ATG will change the priority of the pumps so a pump starts pumping

fuel from a different tank and lowers the priority of the pump in the tank that has reached its Reserve.

This helps to prevent the faults Dry Run and PUMP in W ater. If all tanks reach the Reserve level the

pumps will function in leveling mode.

Mode Type and Reserve Note

The STND ALON “type” designated the GROUP as a Stand Alone Group without any Master/Slave

associations. Members of the group consists of only one pump and one controller . The menus

MODE and RESERVE are not enabled for S tand Alone TYPE. This completes Setup Programming

for this type.

The MAST SLA V ‘type’ designates the GROUP as a Master/Slave configuration. The group consists

of more than one pump controller. This “type” is further defined by the kind of Level Management

“mode” either Leveling or Priority . If Priority is selected, the user is required to enter a value for

RESERVE.

MODE (user entry)

Description of Step s:

Here is the MODE GROUP 2 user entry

field display . NONE is the default setting...

K X

DOWN

SP ACE

1) Use the UP/DOWN keys to change the

default mode and scroll through the other

modes - LEVELING and PRIORITY...

2) Press the ENTER key to accept data

entry . This entry returns the display to the

GROUP N menu.

G T

UP

+/-

ENTER

If PRIORITY is selected,

Proceed to the RESERVE

menu, which is described

next...

TS-TPI SETUP PROGRAMMING Page 4-9

TS-TPI Installation and Wiring Guide

4

Page 27

RESERVE (user entry)

GROUP 2

TYPE MODE RESERVE

RESERVE PERCENT GROUP 2 NUMERIC

20 BACKSPACE

Description of Step s:

Here is the GROUP 2 main menu, displaying

TYPE, MODE and RESERVE...

1) Press the M3 key to display the RESERVE

menu...

Here is the RESERVE user entry field displaying the “percent full” value for GROUP 2 (in

Priority mode). The default setting is 20.

2) Press the M4 key to backspace and erase

the default percent value. this will clear the

field.

3) Use the keypad to enter a percent value for

each group.

4) Press the ENTER key to accept data entry .

This entry returns the display to the GROUP N

menu, displaying TYPE, MODE, and RESERVE.

5) Press the CANCEL key to return to the TPI

GROUP menu, displaying GROUP 1 to

GROUP 4.

Proceed to the next group number menu.

Repeat the steps above to set the reserve

percent for each group that is in Priority Mode.

M1 M2 M3 M4

M1 M2 M3 M4

ENTER

When set up programming is completed, follow the Exiting Setup Mode

steps (next section) to return the Tank Sentinel to the Run Mode.

Exiting Setup Mode

EXIT SETUP (user entry)

Description of Step s:

1)Press the CANCEL key to return to the main TPI menu, which displays ENABLE, PUMP and

GROUP.

This completes the Setup Programming for the TPI device.

2) Press the CANCEL key to return to the TPI SETUP MENU menu, which displays TPI.

3) Press the CANCEL key to return to the main SETUP MENU menu, which displays EXIT, SYSTEM,

T ANKS and PROBES.

4) Press the M1 key under the word EXIT to return the A TG to RUN MODE.

4

Page 4-10 TS-TPI SETUP PROGRAMMING

TS-TPI Installation and Wiring Guide

Page 28

5 TPI AND LINE LEAK TESTING

SELECT MENU OPTION

SETUP UPGRADE LANGUAGE DATALOG

SYSTEM INFO (MORE)

NO. LINES NO. SENS LIMITS SENTINEL

SETUP MENU (MORE)

EXIT SYSTEM TANKS LINES

SETUP MENU (MORE)

LK TESTS SCLD TEST LN TESTS CLK/CAL

LINE TESTS

SCHEDULE FAIL OG FAULT OG

LN (Line) Test Menu

H U

MENU ½ Press this key and follow the

7

M1 M2 M3 M4

M1 M2 M3 M4

highlighted sequence below

NOTE

Disregard this Chapter if the LN TESTS menu

does not appear. Note that the position of this

menu can be displaced by other menus.

The LN TESTS and LINES menu, only appear if

one or more NO. LINES are entered under the

SYSTEM setup menu.

The TS-LS300 AutoLearn Line Leak Detector

automaticly performs a monthly precision (0.2

gph) test after a 3 hour quiet time.

With this menu you may control the time this

happens or schedule it to happen at a different

time or day than tank leak tests run (to avoid

affecting tank leak test results).

Character input / editing:

• Push UP/DOWN ▲ ▼ keys to show more

menus or menu selections.

M1 M2 M3 M4

NOTE

The TS-LS300 will run the Gross , Monthly and Annual line leak test s

automaticly . Scheduling tests is not required. See the TS-LS300 User Guide

for details of the different Line Leak Tests performed.

• Use menu keys (M1 to M4) to access

menus.

• Press ENTER to accept a selection or input

a value into the setup configuration

memory.

• Press CANCEL to cancel data entry

ÖÖ

Ö

ÖÖ

ÕÕ

Õ

ÕÕ

• Press M1 to move the cursor left

• Use M2 to move the cursor right

• Press M4 to backspace (delete) one

character to the left

ÕÕ

Õ

ÕÕ

TPI AND LINE LEAK TESTING Page 5-1

TS-TPI Installation and Wiring Guide

5

Page 29

Line Leak Test Requirements & Notes:

1) Inform the Site Personnel to: (If the store closes at night - not 24-hour) Leave

the Pump Controllers power on at night with dispenser power off. The

Submerged Turbine Pump (STP) must be able to turn on to run the pressurized

line leak tests.

2) It is recommended that Line Leak Tests and Tank Leak Tests should not be

scheduled to run at the same time.

3) Note: The Monthly (0.2 gph) precision Line Leak Test will begin after 3 hours of

quiet-time between product dispensing. (The line leak detector can start the

pump at any time to run pressurized line leak tests.)

4) The annual (0.1) precision line leak test requires 6 hours of quiet-time

(after the final dispense) before it will begin testing. Make sure to take this

into account when scheduling a Annual precision 0.1 Line Leak Test.

5) Note: See the TS-LS300 AutoLearn User’s Guide or consult INCON Technical

Service for Special Applications (for example: manifolded lines, nonstandard

pumps, etc.).

6) Before programming, reference the State and Local Regulations about line leak

testing, type / precision of the tests, test frequency, and reporting

requirements... adhere to these requirements.

LN Line (leak) LN Line (leak)

LN Line (leak)

LN Line (leak) LN Line (leak)

* Only the No. of lines that are programmed in System menu will be displayed

SCHEDULE Press the M1 key.

SELECT A LINE

LINE 1 Use (M) keys to select a LINE#.

LINE 2 * Use UP/DOWN ▲ ▼ keys to show more choices.

:*

LINE 8 *

LINE TEST SCHEDULE N Program a Schedule and Time for each Line#

SCHED 0.1 0.1 = Precision Annual Line Leak Test

NONE

DAIL Y

MONDAY Use UP/DOWN ▲ ▼ keys to show more choices.

:

TT

ests Menests Men

T

ests Men

TT

ests Menests Men

No schedule / not scheduled

uu

u

uu

5

Page 5-2 TPI AND LINE LEAK TESTING

TS-TPI Installation and Wiring Guide

Page 30

SUNDAY Press ENTER to accept this data.

1 ST DA Y Dispensing during the test will abort the test*

:

30 TH DAY NOTE: February does not have 30 days !

LAST DAY

TIME 0.1 See Test Requirements and Notes !

0.1 GPH LINE TEST TIME N

00:00:00 24 HOUR FORMA T See T ABLE 5-1

Use Keypad to input 24-hour time data.

Press ENTER to accept this data.

T ABLE 5-1 24 Hour Input Format

HH:MM:SS

00:00:00 = midnight 22:00:00 = 10 pm + 12 (hours)

(add 12 hours to pm times starting at 1 pm to 11:59 pm)

02:05:00 = 2:05 am

NOTE

Both the 0.1 & 0.2 gph line leak tests can be programmed for a particular Line or all Lines. But, the

schedule and times must be different ! Also see Test

Requirements and Notes.

SCHED 0.2 0.2 = Monthly Compliance Line Leak Test

NONE

DAIL Y

MONDAY Use UP/DOWN ▲ ▼ keys to show more choices.

:

SUNDAY Press ENTER to accept this data.

1 ST DA Y Dispensing during the test will abort the test*

:

30 TH DAY NOTE: February does not have 30 days !

LAST DAY

TIME 0.2 See Test Requirements and Notes !

0.1 GPH LINE TEST TIME N

00:00:00 24 HOUR FORMA T See T ABLE 5-1

No schedule / not scheduled

Use Keypad to input 24-hour time data.

Press ENTER to accept this data.

TPI AND LINE LEAK TESTING Page 5-3

TS-TPI Installation and Wiring Guide

5

Page 31

LN Line (leak) LN Line (leak)

LN Line (leak)

LN Line (leak) LN Line (leak)

* Only the No. of lines that are programmed in System menu are displayed

FAIL OG Will go Active when any (3 gph, 0.2 gph, and 0.1 gph)

LINE TEST FAIL OUTPUT GROUP Line Leak T est fails

LINE 1

LINE 2 * Press (

:* Use

LINE 8 *

LINE TEST FAIL OUTPUT GROUP N

NONE

GROUP A-FF One OG selected (A=1st OG, FF=32nd OG)

ALL GROUPS All OGs selected

TT

ests Menests Men

T

ests Men

TT

ests Menests Men

(32 Output Groups (OGs) available...

Programming Guide, Worksheet 12-1)

Not assigned to an Output Group (OG).

Use UP/DOWN ▲ ▼ keys to choose an OG.

Press ENTER to accept this data.

uu

u

uu

M) key to select a LINE#.

UP/DOWN ▲ ▼ keys to show more choices.

See T ank Sentinal Setup

FAULT OG Will go active when a fault (TS-LLD flashing alarm

LINE TEST FAIL OUTPUT GROUP error-code) occurs

LINE 1

LINE 2 * Press (M) key to select a LINE#.

:* Use UP/DOWN ▲ ▼ keys to show more choices.

LINE 8 *

LINE TEST FAUL T OUTPUT GROUP N

NONE

GROUP A-FF One OG selected (A=1st OG, FF=32nd OG)

ALL GROUPS All OGs selected

(32 Output Groups (OGs) available...

Programming Guide, Worksheet 12-1)

Not assigned to an Output Group (OG).

Use UP/DOWN ▲ ▼ keys to choose an OG.

Press ENTER to accept this data.

See T ank Sentinal Setup

5

Page 5-4 TPI AND LINE LEAK TESTING

TS-TPI Installation and Wiring Guide

Page 32

6 TS-TPI DATA AND REPORTS

Overview

The INCON Tank Sentinel displays, prints and faxes data and report information for

the user. This chapter describes the DISPLAY and DIAG (Diagnostic) menus, that

feature comprehensive user-interface data and report functions.

TPI Status Display Notes

The Display function allows a user to view current information from pump controllers

on a real time basis. The TPI periodically collects data from each pump controller.

The Tank Sentinel, in turn, periodically collects the data from the TPI and stores it

internally. The Tank Sentinel Display interface allows this data to be viewed at any

time.

To access the Display function, the user first presses the MENU key and then

DISPLAY key. Amongst the option keys displayed, the user must select the PUMPS,

which will cause a list of the attached pump controllers to be presented. Once the

user selects a pump, the console will proceed to display the real time data for that

pump controller.

See Appendix A at the back of this manual for Status Code definitions and Pump

Controller Fault Code definitions.

Tank Sentinel Keypad & Menu Navigation

Character input/editing:

Use UP or DOWN keys to display more menus- (MORE) or selections (UP/DN)

Press the CANCEL key to cancel data entry

Use the ENTER key to accept data entry

Press menu keys (M1 to M4) to access menus.

Press M4 to backspace (delete) one or more characters to the left

Use M2 to move the cursor right

Press M1 to move the cursor left

TS-TPI DATA AND REPORTS Page 6-1

TS-TPI Installation and Wiring Guide

6

Page 33

Display Menu

SELECT MENU OPTION (MORE)

SETUP UPGRADE LANGUAGE DATALOG

SELECT MENU OPTION (MORE)

DISPLAY DIAG

SETUP MENU OPTION

SCALD PUMPS

SELECT PUMP (MORE)

PUMP 1 PUMP 2 PUMP 3 PUMP 4

NOTE

PUMPS (Data Display)

Descriptions of Steps:

1) Press the MENU key and follow the

highlighted sequences...

The SELECT MENU OPTION menu is

shown.

2) Press the DOWN key once...

Here is the second SELECT MENU OPTION

menu.

3) Press the M1 key to show the DISPLA Y

menu.

“(Dat a Display)” means only data will appear in the

display - there are no entries to make.

“(User Interface)” means the user must make

entries to implement the feature.

H U

MENU

7

K X

DOWN

SP ACE

M1 M2 M3 M4

Here is the main DISPLA Y menu.

4) Press the M2 key to display the SELECT

PUMP menu.

The SELECT PUMP menu displays all of the

pump numbers that are communicating with

the Tank Sentinel.

5) Press the (M) key under each pump

number to display the data. In this example,

press the M1 key for PUMP 1.

M1 M2 M3 M4

PUMPS may be aligned with any of the menu

keys (M1 - M4), depending on what other

features are programmed or enabled. For this

example, PUMPS is aligned with the M2 key .

M1 M2 M3 M4

6

Page 6-2 TS-TPI DATA AND REPORTS

TS-TPI Installation and Wiring Guide

Page 34

Pump DISPLA Y examples:

PUMP1 STATUS FAULT VOLTS CVOLT 1

PUMP N 0071 00 204 201

PUMP1 AMPS C AMPS1 WATTS C WATTS

PUMP N 6.5 6.5 1140 1140

PUMP1 DIPSW SREV

PUMP N FFFB 103

Each controller type will vary in the available

data that can be displayed. The example

below is for the SCI controller.

Here is the first display of three possible

(typical) data displays...

Press the DOWN key to scroll through the

data displays.

NOTE

See Appendix A for Status Code

and Fault Code definitions.

6) Press the CANCEL key to return to the

SELECT PUMP menu.

The display returns to the SELECT PUMP

menu.

Repeat the data display steps for each

pump.

Use the CANCEL key to return to the

SELECT MENU OPTION display.

NOTE

Please read the Notes on the following page to gain a better underst anding of the Diagnostic feature.

TS-TPI DATA AND REPORTS Page 6-3

TS-TPI Installation and Wiring Guide

6

Page 35

TPI Diagnostic Function Notes

SELECT MENU OPTION (MORE)

SETUP UPGRADE LANGUAGE DATALOG

SELECT MENU OPTION (MORE)

DISPLAY DIAG

The diagnostic function allows the user to command the pump controllers from the Tank Sentinel

console. The user is able to issue resets to clear faults and enable calibration.

To access this function, the user first presses the MENU key, then DIAG, then PUMPS and then

PUMP #. The tank gauge allows the user to select a pump number and will then display the

diagnostic function keys RESET and CALIBRT.

If the user selects the RESET function, the Tank Sentinel will ask, “ARE YOU SURE?” and if the

user presses the ENTER key, then the reset will be performed. Pressing ENTER in response to the

question will issue the reset to the controller. If the user is not sure about the reset, perhaps due to

a safety concern, then the user should press the CANCEL key to abort this operation.

The CALIBRT function is for STP-SCI TPC only. For details of the calibration process see the STPSCI Installation and Owner’s manual. When a user selects the CALIBRT function, the Tank

Sentinel asks “ARE YOU SURE?” Pressing ENTER enables calibration on the selected pump

controller. Pressing cancel aborts the operation. When calibration is enabled, the STP-SCI

memory is erased. For proper calibration no product flow can go out of the pump. Close a ball

valve at the pump discharge or turn down the pump’s clamp valve before calibrating. During the

calibration process the TPC takes a snap shot of the voltage, current and power of the pump.

These values are displayed as are the Calibrated status values in the Display Menu.

DANGER!

The potential for electric

shock exists! Verify the site

is safe! -- before proceeding

with a Reset operation.

DIAG Menu

PUMPS (User Interface)

Description of Steps:

1) Press the MENU key and follow the highlighted sequences...

The SELECT MENU OPTION menu is shown.

2) Press the DOWN key once...

Here is the second SELECT MENU OPTION

menu.

3) Press the M2 key to show the DIAG menu.

Here is the main DIAG menu.

4) Press the M1 key to display the SELECT

H U

MENU

7

K X

DOWN

SP ACE

M1 M2 M3 M4

6

Page 6-4 TS-TPI DATA AND REPORTS

TS-TPI Installation and Wiring Guide

Page 36

PUMP menu.

SETUP MENU OPTION

PUMPS

SELECT PUMP (MORE)

PUMP 1 PUMP 2 PUMP 3 PUMP 4

SELECT DIAGNOSTIC OPTION

RESET CALIBRT

SELECT DIAGNOSTIC OPTION

RESET CALIBRT

RESET PUMP 1

ARE YOU SURE?

The SELECT PUMP menu displays all of

the pump numbers that are communicating

with the Tank Sentinel.

5) Press the (M) key under each pump

number to display the SELECT DIAGNOSTIC OPTION menu. In this example, Press

the M1 key for the PUMP 1 options.

Here is the DIAGNOSTIC OPTION MENU.

RESET Menu

M1 M2 M3 M4

M1 M2 M3 M4

RESET (User Interface)

Description of Step s:

Here is the SELECT DIAGNOSTIC OPTION

menu displaying RESET and CALIBRT.

1) Press the M1 key under the word RESET.

The RESET PUMP N display asks if the

user is sure before resetting a pump controller; giving the user a chance to press

CANCEL to abort the reset operation.

2) Press the ENTER key to reset the pump

controller.

Press the CANCEL key to abort the reset

operation.

M1 M2 M3 M4

DANGER!

The potential for electric shock exists!

Verify the site is safe! -- before

proceeding with a Reset operation.

M1 M2 M3 M4

DANGER!

The potential for electric shock exists!

Verify the site is safe! -- before

proceeding with a Reset operation.

After entering a reset, the display will flash the word DONE... for a few seconds then it will automatically return to the SELECT DIAGNOSTIC OPTION menu, displaying RESET and CALIBRT.

TS-TPI DATA AND REPORTS Page 6-5

TS-TPI Installation and Wiring Guide

6

Page 37

CALIBRT Menu

SELECT DIAGNOSTIC OPTION

RESET CALIBRT

RESET PUMP 1

ARE YOU SURE?

CALIBRT (User Interface)

Description of Step s:

Here is the SELECT DIAGNOSTIC OPTION

menu displaying RESET and CALIBRT.

NOTE

In the following examples, “N”

represents any pump number 1, 2, 3 and so on.

1) Press the M2 key under CALIBRT.

The CALIBRA TE PUMP N display asks if the

user is sure before enabling automatic

calibration for a particular pump controller;

giving the user a chance to press CANCEL

to abort the calibration process.

2) Press the ENTER key to enable calibration for the pump controller.

M1 M2 M3 M4

ENTER

Press the CANCEL key to

abort the process.

(For STP-SCI controller only) Af ter enabling calibration, the display will flash the word DONE... for a

few seconds and then it will automatically return to the SELECT DIAGNOSTIC OPTION menu,

displaying RESET and CALIBRT.

Follow the Calibration Procedure steps below to complete STP-SCI calibration. For further details on

the calibration process see the STP-SCI Installation and Owner’s manual.

CANCEL

Calibration Procedure

1) Prevent product flow out of the STP by closing a ball valve at the pump discharge.

2) When calibration is enabled, the green, red and yellow LEDs on the pump controller will blink.

3) Turn on the hook signal to begin calibration process. The controller t akes a snap shot of the

voltage, current and power (these are the Calibration status values seen in the Display Menu mentioned earlier).

4) The calibration process is complete when the red LED stops flashing. The green LED will remain

flashing on stand alone TPCs and the green and yellow remain flashing in Master/Slave or Alternating

configured TPCs.

5) Turn of f the hook.

6) Verify that the Tank Sentinel display has returned to the RUN MODE, showing SYSTEM, TANK,

SENSOR, etc. are all OKA Y.

7) Refer to the STP-SCI Installation and Owner’s Manual Troubleshooting Guide if the pump does not

start or an alarm condition is present on the controller .

6

Page 6-6 TS-TPI DATA AND REPORTS

TS-TPI Installation and Wiring Guide

Page 38

Pump Controller Status Report

A Pump Status report indicates the current state of the pumps. This report is designed to facilitate

troubleshooting at the site. This is the same information as found in the pump section of the programming and the DISPLAY pump status real time interface. The information can be polled and stored in

System Sentinel or printed at the site by a technician when required.

The following is a representation of a new pump controller status report. Only values available for a

specific controller would be printed.

INCON

INTELLIGENT CONTROLS

INC

P.O. BOX 638

SACO ME 04072

1-800-984-6266

06/12/2002 6:45 PM

PUMP CONTROLLER STATUS

PUMP 1 REGULAR 1

TYPE SCI

GROUP 1

GROUP TYPE MAST SLAV

STATUS 61

FAULT 00

VOLTS1 204

CVOLTS1 201

AMPS1 0.1

CAMPS1 6.5

: :

::

SOFTWARE VERSION 3.XXX

TS-TPI DATA AND REPORTS Page 6-7

6

TS-TPI Installation and Wiring Guide

Page 39

How to print the report:

SELECT REPORT GROUP (MORE)

PUMP

SYSTEM TANK SENSOR LINE

OKAY OKAY OLAY OKAY

PUMP STATUS REPORT

PRINTER FAX

Description of Step s:

Here is the Tank Sentinel display in RUN

MODE, showing SYSTEM, T ANK,

SENSOR, etc. are all OKA Y...

1) Press the REPORT key to display the

SELECT REPORT GROUP menu...

2) Press the DOWN key twice to show

the PUMP menu selection...

Here is the SELECT REPORT GROUP

menu showing the PUMP menu selection...

3) Press the M1 key to display the PUMP

ST ATUS REPORT selection menu...

Here is the PUMP STA TUS REPOR T

display , showing two choices - PRINTER

or FAX ...

4) Print the report to the console printer

or a fax-modem with the programmed

fax telephone number.

J W

REPORT

9

K W

DOWN

SP ACE

M1 M2 M3 M4

M1 M2 M3 M4

(See the Tank Sentinel Setup Programming Guide 000-1053, for instructions on

how to enter a fax-modem telephone

number into the programming.)

The Tank Sentinel display returns to the

RUN MODE.

6

Page 6-8 TS-TPI DATA AND REPORTS

TS-TPI Installation and Wiring Guide

Page 40

System Setup Report

SELECT REPORT GROUP (MORE)

SENSOR ALARM SETUP

SYSTEM TANK SENSOR LINE

OKAY OKAY OLAY OKAY

Additions -TPI/Pump Controller Setup

Tank Sentinel Setup reports show the entire

configuration of the Tank Sentinel programming.

The TPI/Pump Controller section is located in

the System Setup Report, below the Sensors

section and above (before) the Cathodic

Protection section. Here is a sample of how it

looks:

Please Note:

PUMP HEIGHT will be in inches or

centimeters, depending on what Units

are set in the program.

If TPI is not enabled, then this dat a

will not be displayed or printed.

The SYSTEM Setup report includes the information about TPI and Pump Controllers. Here

is how to access it...

TPI

ENABLED YES

ADDRESS 80

PUMP CONTROLLERS

NUMBER OF PUMPS 5

PUMP 1

NAME PUMP 1

TYPE SCI

GROUP 1

ADDRESS 0

TANK 1

PUMP HEIGHT 7.00 IN

PUMP GROUPS

GROUP 1

PUMPS 1, 2

TYPE MAST SLAV

MODE PRIORITY

RESERVE 20

How to print the report:

Description of Step s:

Here is the Tank Sentinel display in RUN

MODE, showing SYSTEM, TANK, SENSOR,

etc. are all OKA Y...

1) Press the REPORT key to display the

SELECT REPORT GROUP menu...

2) Press the DOWN key to show the SETUP

menu selection...

Here is the SELECT REPORT GROUP menu

showing the SETUP menu selection...

3) Press the M3 key to display the SELECT

SETUP REPORT selection menu...

TANKS 1 , 2

J W

REPORT

9

K W

DOWN

SP ACE

M1 M2 M3 M4

TS-TPI DATA AND REPORTS Page 6-9

TS-TPI Installation and Wiring Guide

6

Page 41

Here is the SELECT SETUP REPORT display,

SELECT SETUP REPORT

SYSTEM TANK

SYSTEM SETUP REPORT

PRINTER FAX

showing SYSTEM, TANK, etc. ...

4) Press the M1 key to display the SYSTEM

SETUP REPORT selection menu...

Here is the SYSTEM SETUP REPORT display,

showing two choices - PRINTER or FAX...

5) Print the report to the console printer or via a

fax-modem to a programmed fax telephone

number.

The Tank Sentinel display returns to the RUN

MODE.

M1 M2 M3 M4

M1 M2 M3 M4

(See the Tank Sentinel Setup Programming Guide

000-1053, for instructions on how to enter a faxmodem telephone number into the programming.)

6

Page 6-10 TS-TPI DATA AND REPORTS

TS-TPI Installation and Wiring Guide

Page 42

7 LINE Reports SETUP

SELECT MENU OPTION

SETUP UPGRADE LANGUAGE DATALOG

SETUP MENU (MORE)

EXIT SYSTEM TANKS PROBES

SETUP MENU (MORE)

PRODUCTS MANIFOLDS*

REPORTS

LK TSTS

REPORT SCHEDULE (MORE)

LINE COMP* LINE DIAG LINE HIST* LINE TEST*

TABLE 7.1 Typical Report Schedule

NONE

(no schedule)

SHIFT 1ST DAY

DAIL Y :

MONDA Y 30TH DA Y

: LAST DAY

SUNDAY (Feb. does not have 30 days)

TABLE 7.2 24 Hour Time Input Format

HH:MM:SS

00:00:00 = midnight

22:00:00 = 10 pm + 12 ( hours )

( add 12 hours to pm times starting at

1 pm to 11:59 pm )

02:05:00 = 2:05 am

Reports Menu

H U

MENU ½

7

M1 M2 M3 M4

M1 M2 M3 M4

Press this key in the highlighted

sequence shown below

Press the DOWN ▼ key...

Use this menu to program reports

to print or FAX automatically on a

schedule (faxing requires an

optional Fax/Modem device).

See Tank Sentinel Setup

Programming Guide Chapters 1,

10, 11 and 12 about Tank and

Line Test Reports & Scheduling.

See TABLE 7.1 – The SHIFT

selection allows 2 or 3 scheduled

reports to print or Fax per day

...

only one report will print if two

report-times are duplicated /

identical.

The asterisked (*) menus are

hardware or software dependent

and may or may not appear.

Press the DOWN ▼ key until the Line Comp, Line

Diag, Line Hist and Line Test menus are shown.

Push UP/DOWN ▲ ▼ keys to show

more menus or menu selections.

To access menus, press the

corrsponding (M) key below each

menu name.

— Continued on next page —

LINE REPORTS SETUP Page 7-1

TS-TPI Installation and Wiring Guide

7

Page 43

Reports Schedule Menu

Line Compliance Report:

The Line Compliance Report will include one year’s worth of 0.2 gph monthly compliance tests for a

selected line, or all lines. The most recent test is shown first and the oldest test last. Af ter a year, the

oldest test will be dropped when a new test passes.

Follow the following steps to schedule the line compliance report. All other line reports follow this

same process. The rest of this section of the manual will only describe the report. To schedule the

diferent line reports follow this same process under each of the report menus.

LINE COMP

LINE COMPLIANCE Use

SCHEDULE

NONE (select schedule – see T ABLE 7.1)

TIME 1

00.00.00 to 23.59.59 (input time – see TABLE 7.2)

TIME 2

00.00.00 to 23.59.59 (input shift # 2 time... N/A if not SHIFT)

TIME 3

00.00.00 to 23.59.59 (input shift # 3 time... N/A if not SHIFT)

FAX

NO or YES (yes requires optional fax / modem)

PRINTER

YES or NO Press ENTER to accept this data.

Only with Line Leak Detector(s)

*

UP/DOWN ▲ ▼ to show choices.

Line Diagnostics Report:

This report is typically used by service technicians to diagnose line test issues. This report is not

typically scheduled.

Line Test Report: